BORGER CRANES’

6 Up Front with Borger Crane Hire and Rigging

Borger Crane Hire and Rigging’s complex bridge lift.

10 CICA CEO report

Brandon Hitch reviews CICA’s 2024 achievements.

12 CICA’s safety award CICA’s Damien Hense recognised with Safety Pioneer Award.

13 CANZ CEO report Sarah Toase looks to the future.

16 Harvey Norman Technology for Business Cyber Attacks a real threat for crane sector.

19 Terex Franna

New capacity Rough Terrains released.

22 TRT trailers TRT launches new trailer.

Between Hook & Load features

26 Lif ting Equipment Engineers Association LEEA’s 2024 highlights.

33 Titan Lifting Technologies Titan’s quality control approach reflected in extensive product range.

36 Queensland Rigging Hire New premises, more products, bigger team.

41 Modulif t’s power lifts Modulift supplies bespoke spreader bars for nuclear lifts.

43 Alliance Engineering Consultants (AEC) AEC looks back on 30 successful years in the industry.

’s plans for Australia Zoomlion’s bold plans for Australian crane sector.

53 Managing Liebherr’s supply chain Alex Coleman provides insights into Liebherr ’s supply chain strategies.

56 Grove upgrades Significant upgrades to Grove heavy lif ters.

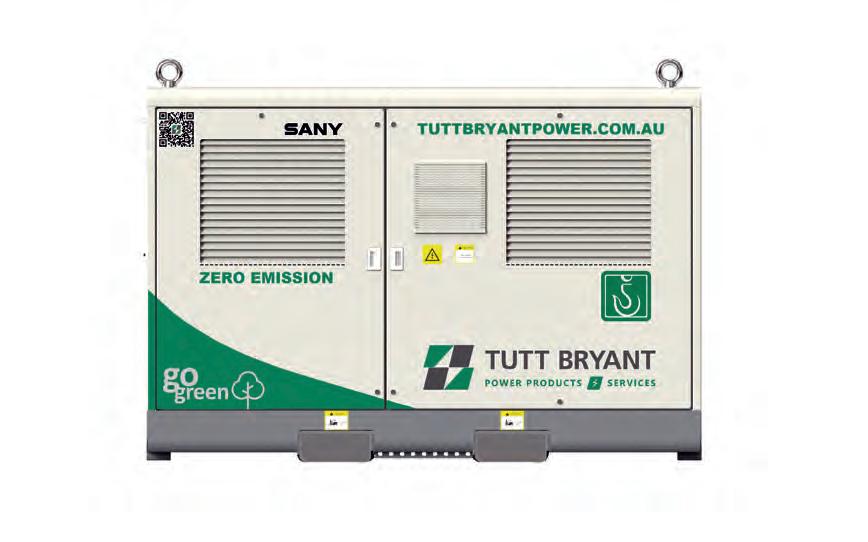

60 Tutt Bryant Tutt Bryant’s Go Green range proves to be a sustainable option for crane sector.

63 The Buddie System Crane sector’s very positive response to Buddie System launch.

66 Sany Crawlers

The Sany SCC3200A-1 crawler duo is playing a pivotal role in major WA infrastructure project.

69 Sino Distribution Milleen Constructions recently bought two Zoomlion machines for a rural NSW infrastructure project.

72 TRT and QUBE QUBE goes large with TRT Trailers.

74 Lif t of the Month What our industry does best.

Published by:

GENERALLY SPEAKING, A GOOD thermometer on how the health of the construction industry, and therefore the crane sector, is the number of tower cranes seen on city sky lines.

The 25th edition of the Rider Levett Bucknall (RLB) Crane Index® reveals there are 863 cranes on sites nationally. The RLB Crane Index® has recorded more than 800 cranes nationally for the past six editions.

The non-residential index has reached 322 points, the highest index value since commencement, primarily due to the many government-funded civil projects across the country. The highest number of fixed cranes on a site was the Amazon Fulfillment Centre in Melbourne, with seven cranes.

With 30 long-term crawler cranes in operation, Melbourne’s $36 billion North East Link project has the largest crane deployment in the country. The Gold Coast increased crane numbers to reach a record 62 cranes across the region.

New South Wales accounted for 49.5%

of all cranes across Australia; Melbourne accounted for 22.8%; and South-East Queensland for 16.5% of all cranes. The gap between Sydney and Melbourne’s crane numbers continues to be significant at 191 cranes, with Sydney hosting 387 cranes and Melbourne 196. So, it does appear that the construction sector will be bouncing back in 2025.

This issue is very much a review of 2024 with many articles taking a quick glimpse at 2025. The team at Cranes and Lifting magazine takes this opportunity to thank the crane sector for the unwavering support you have afforded us over the last 12 months and we wish everyone the very best for the Festive Season and the year ahead.

Simon Gould Editor, Cranes and Lifting

379 Docklands Drive, Docklands VIC 3008

T: 03 9690 8766

www.primecreativemedia.com.au

CEO

John Murphy

E: john.murphy@primecreative.com.au

Chief Operating Officer

Christine Clancy E: christine.clancy@primecreative.com.au

Managing Editor

Andrew Hobbs

E: andrew.hobbs@primecreative.com.au

Editor Simon Gould

E: simon.gould@primecreative.com.au

T: 0404 865 109

Journalist

Jacob Lynch

E: jacob.lynch@primecreative.com.au

Business Development Manager

Emily Schlegel

E: emily.schlegel@primecreative.com.au

T: 0466 317 555

Client Success Manager

Louisa Stocks

E: louisa.stocks@primecreative.com.au

Art Director

Bea Barthelson

Imaging Assistant

Paul Breen

Subscriptions

Frank Rapone

T: 03 9690 8766

E: frank.rapone@primecreative.com.au

The Publisher reserves the right to alter or omit any article or advertisement submitted and requires indemnity from the advertisers and contributors against damages or liabilities that may arise from material published.

© Copyright – No part of this publication may be reproduced, stored in a retrieval system or transmitted in any means electronic, mechanical, photocopying, recording or otherwise without the permission of the publisher.

For five decades, Gamuda has been a global leader in delivering complex infrastructure projects that connect cities and communities.

It’s our people who make the difference. They bring their expertise to help deliver critical projects to our clients in the roads, rail, and energy sectors. With a workforce of over 2,000 people across five states, the Gamuda Group of Companies offers a full end-to-end solution in design, construction, and project management.

To find out more about Gamuda, visit gamuda.com.au

Borger Crane Hire and Rigging, in conjunction with joint venture partners Ferrovial and Gamuda, recently lifted into place the Luke Bowen Bridge, a key element of the Coffs Harbour Bypass project in New South Wales. The new pedestrian bridge spans a total eight lanes over the Pacific Highway and two local roads.

BOTH THE AUSTRALIAN AND NSW

Governments are investing in the 14-kilometre project which is designed to boost the regional economy and improve connectivity, road transport efficiency and safety for local and interstate motorists.

The Gamuda and Ferrovial joint venture is delivering the major package of work through a collaborative Design and Construct contract with Transport for NSW. With a focus on innovation, efficiency and value for money, the project includes three tunnels, about 11 kilometres of new road and about 3.5 kilometres of upgraded highway.

The Luke Bowen Bridge lift was not without its challenges, explains Dean Tauasa - better known as “Dingo” in the

industry - who is the National Lifting and Rigging Manager for Gamuda. Dean has been with Gamuda for two and a half years, having worked with John Holland and Melrose Crane Hire on projects such as the Rozelle Interchange, Waterloo Station, WestConnex (M8) and Northwest Rapid Transit (NRT) just to name a few.

“For this project, we went with Borger Cranes for all of our big lifts, we did look at local providers, but the largest capacity crane available was a 250t and that simply would not cut it when it came to the Super T girders and big lifts. We needed a large capacity crane, mainly due to the size of the bridge, and so we decided on Borger’s 650t capacity LTM 1650-8.1. We’ve had the LTM 1650-8.1 up here quite a few times for majority of our bridges, we even had the LTM 1750-9.1 on the project for the very first bridge girder installation back in May,” said Dean.

“When it comes to craneage, Borger

engaged as a supplier for the Rozelle Interchange project. With branches in Sydney, Newcastle and South East Queensland, and with the location of this project, Borgers have been able to supply us with large capacity cranes, from both sides of the border. Nathan and Shawn Borger as well as Matt Steain, Borger Cranes Heavy Lift Supervisor, have been very supportive and accommodating, working in with the requirements of the project to help meet specific and tight deadlines,” he said.

With the Pacific Highway being the main arterial road between New South Wales and Queensland, disruption to traffic had to kept to a minimum - which required meticulous planning, explains Dean.

“We were given a window from 7pm until midnight for the closure of the

northbound lanes, to allow us to set up the crane. From midnight we closed the entire highway, and we had until 3am (max) to complete the installation. Heavy vehicles were parked up both north and south of the crane setup, with light vehicles and emergency services being diverted via a local road. By 6am we had to have everything packed away and off the road for the highway to open to the full four lanes again,” he said.

The set up for the crane wasn’t ideal as it was on a significant incline, and the dimensions of the bridge were also a complicating factor, said Dean.

“Weight wise, the bridge was quite manageable, coming in at about 80 tonnes, but the bridge was a single span construction 61 metres long, 4.5 metres tall and 5 metres wide. We also had to set the crane up on a hill, which meant

“We needed a large capacity crane mainly due to the size of the bridge, and so we decided on Borger’s 650t capacity LTM 1650-8.1.”

set

packing the underside of the front of the crane with TRT mats and timbers. We used a 100t capacity all terrain and a Franna from Coffs City Cranes to assist in the build of the crane and the preparation for the lift,” said Dean.

The lift was more than 18 months in the planning, says Dean, with Tom Patterson (FGJV Senior Project Engineer) leading the charge alongside Transport for NSW project team members.

“There were all sorts of factors influencing the timing of the lift. Obviously, Tom and his team worked closely with the fabricator of the bridge to understand when it would be ready for transporting and examine the best ways of getting it to site and ready for lifting. We also had to factor in constraints including the NSW and Queensland school holidays so as to minimise the disruption for road users,” he said.

Dean explains how detailed the planning had to be and how closely he and the team at Borger Cranes worked on planning every aspect of the lift.

“A week before the lift we met the Borger Cranes’ team on site, and we went through an hour-by-hour planning session. The bridge was already on site

“A week before the lift we met the Borger Cranes’ team on site, and we went through an hour-by-hour planning session.”

sitting on stands so we were able to get a good look at what we were lifting.

“When the Liebherr LTM 1650-8.1 got to site the following week, we picked up the bridge and loaded it onto the Jinker which would get it into position for lifting. This loading process proved a good option,” said Dean.

“Because the lift wasn’t scheduled for a couple of days, moving it to the Jinker provided a good opportunity for us to work with the rigging and make adjustments if required. There was a Crossfall on the bridge and we needed to ensure that the rigging was in the correct positions to get the Crossfall right. We made some adjustments and got the bridge onto the Jinker. When it came to the actual lift, we hooked down and got the rigging back on the hook and proceeded with the lift,” he said.

“The rigging featured a spreader bar the width of the bridge and that was right at the top of the rigging and then we had

some very long slings which attached to engineered lifting points on top of the bridge. The LTM Liebherr 1650-8.1 proved ideal. Although the bridge only weighed 80t, we needed a lot of ‘boom out’ to allow for the rigging lengths as well as the required head height to get the bridge into position,” said Dean.

Dean paid tribute to all parties involved.

“The success of this lift is the result of the tireless work put in by everyone, including the client (Transport for NSW), subcontractors including Borger Cranes, Goldsprings Heavy Haulage, Coffs City Cranes, Coates Hire and Civmec. We are grateful to the expertise from the Ferrovial Gamuda Joint Venture Project and Site teams including Adrian Hawkins, Tom Patterson, Borja Llanos and Jamie Mason along with their respective teams. With the support of the Project Safety Team and Senior Management, this complex lift was completed and delivered safely and successfully,” said Dean.

At Harvey Norman Technology for Business, we hear it all the time from small business owners —

We don’t need Cyber Security. They won’t target us, we’re too small.

The reality is, cyber threats don’t discriminate. We’ve helped many small businesses who thought they were safe — until they weren’t.

When the big IT companies won’t help because you’re too small, that’s where we come in. We specialise in robust, affordable cyber security for businesses like yours.

24/7/365 Monitoring: Continuous protection through our Security Operations Centre (SOC)

Managed Threat Detection & Response: Non-stop defence against ransomware and malware

Proactive Monitoring & Management: Fixing potential issues before they impact your business

Security Awareness Training: Keep your staff one step ahead of cyber threats

Compliance Management: Stay legally compliant with industry standards

Not sure if your business is Cyber Compliant?

Sign up for a Free Cyber Security Assessment. Protect your business with enterprise-level solutions at unbeatable prices. Contact us today to secure your business’s future.

Scan to arrange your FREE Cyber Security Assessment

Email info@harveynormanbusiness.com.au or call 1300 781 865 for assistance.

installation and setup on all Technology Service and Security Packages during December 2024!

AS WE APPROACH THE END OF 2024, it’s a fitting time to reflect on a transformative year for the crane industry in Australia, marked by significant advancements in safety, regulatory reform and innovation. Throughout the year, CICA has continued to pioneer initiatives that support our members and the industry more broadly nationwide, ensuring safer, more compliant and supportive work environments.

Raising the Bar on Safety: The CICA Lift Supervisor Course

This year saw attendees in the CICA Lift Supervisor Course, reach record numbers. This course has been designed to elevate safety standards and operational oversight by supporting the crucial role of the Crane Lift Supervisor, who oversees all lifting activities to maintain high safety and coordination standards on construction sites. It’s heartening to see this initiative so positively embraced across the industry, emphasising the importance of specialised oversight in complex lift operations. Dates for 2025 are now available on the CCA website.

“CICA continues to lobby for the adoption of HVAMS, so that crane owners and operators can look forward to more efficient access to roads nationwide.”

Supporting Regulatory Reform: A Modernised High-Risk Work Licence Framework

In 2024, CICA has been a key contributor to Safe Work Australia’s review of the High-Risk Work (HRW) licence. This initiative is central to modernising licensing standards, ensuring they meet the needs of today’s equipment and work practices.

forward are essential in enhancing both safety and competence within our industry.

Transforming Access: The Heavy Vehicle Access Management System (HVAMS) CICA continues to lobby for the adoption of HVAMS, so that crane owners and operators can look forward to more efficient access to roads

The introduction of the ROVER (Road Vehicle Certification System) by the Federal Labor Government has brought about new standards for crane compliance with Australian Design Rules (ADRs). CICA has worked closely with manufacturers and government bodies to facilitate smooth transitions under the ROVER system and this work is also ongoing,

As we look to 2025, we remain committed to supporting our members with continuous professional development, advocating for industry-led reforms, and ensuring a safer, more efficient operational framework for crane operators across Australia. This holiday season let’s celebrate the progress we’ve made and look forward to a productive new year ahead.

On a personal level, I hope you’ll have the opportunity to take a step back from your daily routine and take time out to be with the people who matter most. In the midst of work commitments, deadlines, and responsibilities, it’s easy to lose sight of what truly matters. Taking a pause to reconnect with loved ones allow us to reflect on the blessings in our lives and recharge for the year ahead.

To all our members, partners, and stakeholders, thank you for your dedication and shared commitment to advancing our industry. On behalf of the Board and everyone at CICA, I wish you a Merry Christmas and a New Year filled with safety, success, and continued growth.

Brandon Hitch Chief Executive Officer

CICA BOARD

Ben Pieyre – President

Marcus Ferrari – Vice President

Danny Adair – Director

Danny Black – Director

Andrew Esquilant – Director

David Solomon – Director

Karli Sutherland– Director

CICA OFFICE

Brandon Hitch Chief Executive Officer 0428 228 048 ceo@cica.com.au

Alice Edwards Road Technical Engineer 03 8320 0440 alice@cica.com.au

Patrick Cran

CICA Site Operations Advisor 0488 004 274 pat@cranesafe.com.au

Sharon Pearce

Crane Crew Competency Officer, 0491 134 533 sharon@cica.com.au

Damien Hense

CICA Road Policy Advisor 0488 007 575 damien@cica.com.au

Julie Turner CICA Executive Assistant/ Board Secretariat 03 8320 0411 julie@cica.com.au

Kate Galloway Traineeship & Industry Engagement Coordinator 0491 047 118 kate@cica.com.au

Michelle Verkerk Communications and Special Projects Advisor michelle@cica.com.au

Just ina Blackman Member Events and Engagement 0403 717 626 justina@cica.com.au

Ashleigh Gould Office Operations Coordinator, 0490 356 041 ashleigh@cica.com.au

Shane Coupe

CraneSafe & CrewSafe Administrative Assistant Officer 0491 047 134 shane@cica.com.au

Unit 10, 18–22 Lexia Place, Mulgrave Vic 3170

Phone: 03 9501 0078

Email: admin@cica.com.au

Website: www.cica.com.au

For information, please visit our website or call the CICA office.

and Safety Show in Sydney, Damien Hense was awarded the prestigious Safety Pioneer Award for his groundbreaking work on The Crane Industry Council of Australia (CICA) On-Road Articulated Steering Mobile Crane Training Course.

This honour highlights his dedication to workplace health and safety (WHS) and the positive impact of his efforts on keeping mobile cranes safely on the road across the country.

Damien Hense was part of the Australian Road Research Board (ARRB), focusing on research-based applications development, innovation and industry consultation activities, including interaction with Australian governments and municipal bodies across key road transport projects.

Damien has been involved in programs of work related to road infrastructure management, including intermodal solutions, network operations, road safety (including risk assessment technology) and the operation of high productivity freight vehicles.

workplace health and safety (WHS) and the positive impact of his efforts on keeping mobile cranes safely on the road across the country

Damien Hense engaged and worked with numerous stakeholders to find a workable solution to keep articulated mobile cranes on the road. This is the CICA On-Road Articulated Steering Mobile Crane Training Course.

Being part of the team planning the solution, the implementation and the feedback - Damien has worked to make the workplace and Australian roads safer. This will continue as more and more operators complete both elements of the CICA on-road articulated steering crane program.

Training is being provided to an industry that has been overlooked in both the heavy vehicle road licence and high-risk work licence.

By developing this standardised training, it also assists small and medium businesses that would otherwise not have resources to create this training in-house.

The greatest outcomes to date have been: aising awareness on the issue in such a way, without crippling the industry

Damien joined CICA in 2018 and works with CICA’s members and key stakeholders to focus on road safety, access and mutually beneficial network operations outcomes.

In Australia, articulated or “pickand-carry” cranes are widely used —they’re a go-to for many jobs across different industries. But with high usage comes high risk, especially since these cranes are often moving on roads to different sites or moving loads through busy, uneven job sites.

The Mobile Articulated Crane on Road Safety course is a specialised program developed by CICA to

“Damien Hense engaged and worked with numerous stakeholders to find a workable solution to keep articulated mobile cranes on the road.”

address the unique challenges of operating articulated mobile cranes on Australian roads.

Many experienced pick-and-carry crane operators haven’t actually been formally trained or assessed in how to safely operate these articulated cranes.

Because of current licence frameworks, operators with a general slewing crane licence can legally operate pick-and-carry cranes— without needing any specific training to do so.

• Helping operators, employers and companies meet their obligations under the Heavy Vehicle National Law (HVNL) by addressing specific hazards and risks associated with articulated crane operation.

• C ustomising the delivery to the user in a way that is easily accessible and encourages participation.

For more information on the CICA On Road Articulated Steering Mobile Crane Training Course go to: https:// www.cica.com.au/The-CICA-OnRoad-Course

AS I WRITE MY LAST MESSAGE IN Cranes and Lifting Magazine for 2024, my mind is already looking to 2025. Next year holds special significance for the Crane Association of New Zealand (CANZ), as it will mark our 50th anniversary. This milestone not only gives us a chance to honour the Association’s legacy but also propels us toward an exciting future.

Reflecting on the journey we’ve taken together since I joined four years ago, I am reminded daily of the importance of our history and the legacy of those who have laid the foundation for where we stand today.

Our association’s heritage is something I deeply respect. Every time I glance at the name board in my office, I’m reminded of the numerous individuals who’ve contributed to the crane industry in New Zealand. These are people who have invested their heart and soul—not just for personal or professional gain but to uplift and strengthen the entire industry.

I felt this legacy profoundly when we honoured Tony Gibson with a life membership at this year’s conference. Tony was the President of the Association when I first came on board, and his support has been instrumental in my own journey.

I am now beginning to see my own story woven into the fabric of this Association. I am proud of the progress we’ve made together, and I feel a profound responsibility to serve our members with the same passion and commitment as those who came before me.

This shared journey and dedication to our members are what make this

industry such a pleasure to be part of. I know how challenging the last 12 months have been economically for many of our members. We are all still waiting for those first signs of recovery, and that tough reality sharpens my focus on what the Association needs to do to elevate the New Zealand crane industry. We are here to be both a support and an advocate, ensuring that our industry is resilient and forwardthinking.

Our commitment to the future is firmly grounded in our four strategic

priorities, which provide a roadmap for everything we do:

These pillars guide our actions, and I am proud to say that our council lives by them. We have ensured that all our activities are aligned with these priorities to create a strong, thriving industry for our members.

The emphasis on training has been especially important over the past two years. We have invested heavily in training initiatives, setting up our private training enterprise (PTE) to

“CANZ’s vision for the future is one of innovation, resilience, and unwavering commitment to our members.”

provide gold standard training resources for crane operators. When I first joined, one of the most significant concerns from members was the availability and quality of training. Today, we have made enormous strides in addressing that concern, and this will continue to be a vital focus as we move forward.

Looking ahead to the next 12-24 months, we are turning our attention to

another critical area in our strategic vision: regulatory updates and industry guidance. During our recent AGM, this focus resonated with our members, affirming that we are on the right path. They expressed the need for updated regulations and guidance to reflect the realities and challenges of our industry today. It’s clear that our regulatory framework needs to evolve to keep pace with the industry’s growth and the complexity of modern crane operations.

To achieve this, CANZ is already working closely with the government. Recently, we met with both WorkSafe and the Ministry of Business, Innovation and Employment (MBIE) to chart a path forward for crane regulations. Our goal is to create a regulatory environment that enhances safety, supports professionalism and fosters growth within the industry.

Additionally, we’re exploring operator licensing and a crane-specific pre-qualification process to establish a consistent industry standard. Reducing duplication and ensuring high standards across the board will benefit both operators and businesses, making the industry safer and more efficient.

This regulatory and standards initiative aligns closely with CANZ’s founding purpose: to support the success of our members. As we continue this work, I’m excited and motivated because I know it will make a difference where it counts. It’s my hope that the efforts of everyone involved—whether in the President’s chair, in council seats, or as part of our dedicated team—will leave a legacy that our members value and appreciate.

A wireless instant safety alert device designed for crane operators and dogmen enabling rapid alarm activation in emergencies.

The true measure of our success as an Association lies in what we deliver for our members. As our PTE gains traction and we update industry guidance, the value of these initiatives will become apparent in the form of higher standards, better training, and a stronger industry overall. I am confident that these actions will lead to a tangible improvement in the quality of our industry, positioning New Zealand’s crane sector to thrive in the years to come.

Our work is far from over, and as we enter our 50th year, we remain as committed as ever to raising the bar. By focusing on the critical areas of training, regulation, and industry standards, we aim to build a future where New Zealand’s crane industry is recognised for its professionalism, expertise and excellence. As I look back on the progress we’ve made and ahead to the work still to be done, I am filled with both pride and anticipation. CANZ stands on the shoulders of the giants who have shaped this Association, and I am honoured to be part of this legacy.

As we move into 2025, we will continue to serve as the voice of the industry, advocating for the needs of our members and ensuring that they have the resources and support they need to succeed. CANZ’s vision for the future is one of innovation, resilience, and unwavering commitment to our members. Thank you to everyone who has been part of this journey, and here’s to the next 50 years of growth, progress and shared success in the New Zealand crane industry.

The TBS device overcomes the shortfalls of two-way radio failure and often-inaudible backup whistles. The TBS device allows a dogman to instantly transmit an alarm signal to a crane operator to stop.

A quick snap on the TBS the alarm.

Rutland Smith, Director of Harvey Norman Technology For Business (HNTFB) spoke at The Crane Industry Council of Australia’s (CICA) National Conference and Exhibition. From the feedback he received, it is apparent that Cyber Attacks are viewed as a genuine threat to the crane industry.

“I WAS GRATEFUL FOR THE OPPORTUNITY to present during CICA’s National Conference and Exhibition and from the feedback I received, Cyber Attacks do pose a genuine risk to the crane industry. This doesn’t surprise me as the criminals behind these attacks do not discriminate, they carefully plan their deception and implement their attacks with precision with any industry seen as fair game.

CYBER CRIMINALS POSE A VERY REAL RISK TO YOUR BUSINESS

“The subject of Cyber Security was even raised during the Crane Owners panel and the CEO of a national crane hire business shared how his business was only just getting back to normal following an attack five years ago,” said Rutland.

“During the conversations I had with crane businesses, there were many misconceptions about how vulnerable businesses are to Cyber Attacks. A lot of small business owners make the assumption that big businesses are at risk and their business is too small to be a target. The reality is it’s the other way around. Cyber criminals tend to focus on smaller businesses, and that’s because they are more vulnerable and have much lower defenses.

“We know from the Australian Cyber Security Centre (ACSC) statistics that 43 per cent of attacks in Australia actually happen to small businesses. So the first thing I’d say is the assumption that ‘I’m too small to be attacked’ is actually incorrect. The second thing I’d

say is small businesses have the most to lose,” said Rutland.

Every industry is a target but criminals target different industries for different reasons, he added. The crane industry is particularly appealing to cyber criminals for fake invoice scams because of the larger size of the amounts transacted between crane businesses and their customers. The crane industry is also targeted for ransomware attacks because of the enormous costs associated with the business being unable to operate for days or even weeks.

The average cost of an attack on a small business in Australia is a

involved in government work such as Tier One projects.

“The issue to be aware of is that most large government departments, and certainly most large corporations, are now insisting that you have a certain level of cybersecurity before they’ll allow you to tender for their business. If you don’t meet the requirements, you won’t be allowed to tender or quote for the business. You’ll simply be prevented from even participating.”

The Federal Government’s Australian Cyber Security Centre has published a cybersecurity risk mitigation framework called the Essential Eight.

“We know from the Australian Cyber Security Centre (ACSC) statistics that 43 per cent of attacks in Australia actually happen to small businesses.”

little over $46,000, according to the ACSC. These costs can be crippling to a business and may even result in the business closing down.

In addition to the financial risks associated with cyber security, many crane operators will need to make themselves compliant with government guidelines for legal reasons and because larger projects will exclude non compliant businesses from their tenders.

Rutland explains the risks to small and medium sized crane businesses

In many ways, the framework has the same function as Occupational Health and Safety Guidelines, but instead of physical security, this is about cybersecurity. Rutland explains more.

“Under the findings of the courts, all businesses have a duty of care to protect their customer data, and the measurement for whether or not that duty has been discharged is whether or not the business has made the appropriate effort to implement the recommendations of the Essential Eight. The Essential Eight framework is complicated and it’s not something

that you can implement by yourself, you need someone like us help you,” he said.

CAN HARVEY NORMAN HELP Rutland explains how complicated cybersecurity can be for small to medium sized businesses and how HNTFB simplifies the process.

“One of the challenges for all businesses is to meet the standard of the courts. They have to implement the ‘Essential Eight’. That’s an incredibly complicated framework to implement, and almost no small business, that I’m aware of, is capable of implementing that by themselves.

“By getting HNTFB on board as their IT department, we are able to provide a small business with all the support that they need and ensure they are compliant with the government framework” said Rutland.

HNTFB recently partnered with The Crane Industry Council of Australia (CICA) with the aim of offering members solutions to the increasing threat from cyberattacks. Rutland explains how HNTFB can help a crane hire business in practical terms.

“We are fortunate that we’ve entered into this relationship with CICA and

we’ve created a landing page that’s been created specifically for CICA members.

“From this page, members are able to make contact with our team. They’re also able to see the special offers that are available to CICA members only, and they’re also able to learn more about cybersecurity by reading the ‘tips and tricks’ on the page.

“We are asking owners of small to medium sized businesses to imagine how much more you can achieve with Harvey Norman as your IT department? We are just like a really large IT department for a big company. But we don’t just provide IT support and services, we also provide our customers with advice on what they should be doing with their IT moving forward,” he said,

Working with CICA and its members is exciting for Rutland and his team at HNTFB.

“We’re really pleased that CICA has approached us for this partnership, it is great that they’re taking the initiative in trying to protect their members from cyberattacks. We are keen to show CICA and its members what we are capable of and, as a show of goodwill, we are offering to provide an ‘Essential

Eight Business Assessment’ free of charge. This normally retails for $499.

“There is nothing to be lost by having HNTFB conduct this assessment. We will provide members with an independent view that confirms everything is dandy and there is nothing to worry about, or we will provide you with a list of things that are missing and recommendations on how you can fix it. You don’t have to do that with us, you can go and do that with any provider you want,” said Rutland.

“With the various industry sectors we work in, there are always owners of small to medium sized businesses believing they are too small to be the subject of a cyberattack. We are here to tell you these criminals do not discriminate, they are targeting vulnerable businesses no matter the size, and as I’ve said, many businesses simply don’t recover from an attack. So, we are asking CICA members to take the FREE ‘Essential Eight Assessment’ and ask, ‘can you afford not to?’” finished Rutland.

Visit the CICA members page at https://www.harveynormanbusiness. com.au/pages/cica to find out more about what Harvey Norman can offer.

The SCX2800A-3 is designed for versatility across diverse job sites. It includes a sturdy winch that guarantees stable operations, and its ‘Eco winch mode’ boosts operational efficiency while optimising energy consumption. Created with innovative design principles for easy use, it also offers features such as wide shoes and options for reduced counterweight, making its high-performance lifting capacity of 275 tonnes ideally suited for building the future.

The Terex TRT100 has a maximum capacity of 100 tonnes and main boom length of 47 metres, with a 17m jib stowed on the crane’s side that can be easily attached to the main boom to extend reach.

New additions to Terex Rough Terrain range highlight ambitious portfolio expansion

TEREX ROUGH TERRAIN CRANES IS pleased to launch two new models from its expanding TRT Series of userfriendly, flexible, durable cranes—the TRT100 and TRT60.

These new models follow the recently launched TRT 80L, also part of the TRT Series. With advanced features including the intelligent TEOS

operating system, four steering modes, an Eco Mode function, a proportional full power telescoping boom and T-Link telematics platform, and its compact design, the TRT Series has been exceptionally well-received in the marketplace. The cranes also come fitted with LED lights, a comfortable, spacious, tiltable cabin with large glass surfaces and high-quality components throughout. Combined, these advanced features contribute to the strength and ease of operation of the TRT Series and make these cranes ideal for applications including ports, construction, infrastructure, mining, energy, yard

possesses the capacity and flexibility to address daily lifting challenges in the modern working environment,” said Giancarlo Montanari, General Manager, Terex Rough Terrain Cranes. “The marketplace is highly competitive, but I have great confidence in our dedicated team members and the superior Italian craftsmanship behind every crane produced at our Crespellano manufacturing centre of excellence.”

Specifically, the TRT100 has a maximum capacity of 100 tonnes and main boom length of 47 metres, with

counterweight aids operational efficiency, stability and transportability. On the other hand, the TRT 60 has a maximum capacity of 60 tonnes and main boom length of 42.5 metres, with a stowable jib of 8-15 metres.

These machines are the first to feature the new ‘IdeaLift’ from Terex Rough Terrain Cranes, which optimises load lifting with asymmetric outriggers. Whether fully extended or partially retracted, the crane automatically selects the best lifting capacity based on the specific formation of the outriggers.

reintroducing some past product lines that are currently in demand in certain markets,” adds Montanari. “This is an exciting development for our engineering and manufacturing teams, and we eagerly anticipate bringing these innovations to the marketplace in the coming year. I am proud of our team and believe these future advancements will strengthen our value offering and reputation in the lifting industry.”

For more information, please visit https://www.terex.com/roughterrain-cranes

Specifically designed to meet your requirements, providing you with complete control while still allowing remote operation via radio remote control, with a 25,000kg capacity for heavy-duty tasks.

Non-Marking Tyres to Prevent Floor Markings

Multiple Attachment Options Removable Counterweights Counter Rotation on Front Wheels

Evolution is a continuous process at TRT and when they’ve made their best version, they make it better. Every generation of TRT trailers builds on the innovative design engineering that came before it. The team at TRT recently staged a customer event focused on a new trailer design.

TRT’S ENGINEERING AND DESIGN TEAM have spent the last 12 months refining the design of the new 4x8 dedicated ESS Low Loader. The design is a New Zealand specification, new Low Loader build that uses TRT’s patented Electronic Steering System (ESS) technology and follows in the footsteps of its successful ESS Platform and House Trailers. Jeremy Carden, TRT Trailer Sales, explains more.

“For some time now, TRT has seen the need for an all-steering Rows of Eight Low Loader in the NZ market. The design is new but the TRT team has simply tapped into the ESS Platform design and worked out where the tare weight can be removed, while at the same time maintaining the strong chassis shape and construction. This reduction in tare weight enables the new trailer to be highly competitive within the NZ heavy haulage market.

“Over a period of time we’ve undertaken a number of changes and updates to the design and general construction of the trailer. We are now in a position where we can manufacture a four-line platform trailer with the same dimensions that previously weighed 30 tonne. The newly designed trailer comes in at 22.5 tonne, providing customers with a 7.5 tonne payload increase.

The customer benefits are numerous explains Jeremy.

• A competitive tare weight, allowing for increased payloads

• Reduced running costs – rubber stays on the rim.

• Massive advantages in manoeuvrability due to an active, intuitive steering system, along with

an increased suspension stroke.

“Customers with a four-line lead platform trailer require a dolly in the mix to be legal on the road, whereas with the new trailer, for at least 50% to 60% of the time, the customer will be able to remove the dolly from the equation.

“Dollies don’t steer and are generally

TRT’s ESS trailers follow the truck’s arc through a turn and have a pivot point that can be adjusted.

regarded as a difficult piece of equipment to operate, so eliminating the dolly is a significant benefit,” Jeremy said.

“Another benefit in New Zealand, more than in Australia I’d say, is nonsteering trailers in the heavy-haulage market have been the norm for many years. In regards to the maintenance

“Our ESS trailers follow the truck’s arc through a turn and have a pivot point that can be adjusted. Like all-terrains, our trailers can crab sideways behind the truck and can basically mirror the truck’s angle.”

of the running gear, customers are constantly wearing through tyres, breaking them off the bead and generally placing heavy strain on the trailer leading axles and the trucks chassis.”

“Another huge benefit of the ESS system design is the suspension stroke. In comparison to standard rows of eight, the new build features three and a half times a suspension stroke, which means it’s going to be a lot more user friendly on uneven terrain,” said Jeremy.

“The idea of having a trailer that is not ‘fighting’ you as you navigate corners and roundabouts because it’s actively steering behind you, has seen a large number of customers purchase our ESS Platform Trailers which has been a huge step forward in the New Zealand

market,” said Jeremy. “Kiwis are a very progressive bunch, our roads aren’t getting better any time soon, so our trailers need to be constantly evolving as the loads tend to get larger and longer.”

ESS technology is very similar to that seen in modern all-terrain and mobile cranes, enabling the trailer to actively steer behind the truck, says Jeremy. The driver can override the auto-steering as long as the truck is at an offset angle, this can be done right up to 50km/h and is probably the biggest advantage to this ESS system overall.

“Our ESS trailers follow the truck’s arc through a turn and have a pivot point that can be adjusted. Like all-terrains, our trailers can crab sideways behind the truck and can basically mirror the truck’s angle. Having been the Grove distributor since 1972, none of this technology is new to us and we’ve basically developed this technology in our trailers. In terms of software development, our partner is Bosch Rexroth with the ‘brain’ or the ‘beating heart’ of the trailer being the Rexroth controllers or RC controllers, which are mounted in an enclosure on the side of the gooseneck,” said Jeremy.

“As long as the operator has configured the trailer correctly, as the truck moves off at a different angle, it causes a rotation in the slew ring up on the fifth wheel coupling, and that transfer of angle is picked up by mechanical cogs that are mounted to two encoders inside the teeth of the slew ring. That information is then communicated through the controllers with signals being sent via CANBUS to the individual steering rams,” he said.

“For a live demonstration trailer event in New Zealand, the Customer Day was very well attended. The majority of customers in NZ are smaller owneroperators, whereas in Australia our customers tend to be larger companies,” said Jeremy.

“We were really pleased to see between 30 and 40 customers in attendance, and we had 15 of our staff on hand to talk about the development.

The course instructors are seasoned professionals who will mentor course participants through real-life scenarios, preparing them for the challenges and responsibilities of a Crane Lift Supervisor.

Crane Lift Supervisors are in high demand globally. Completing this course enhances employability and opens doors to a wide array of job opportunities and career growth.

The curriculum covers a wide range of topics, including lift planning, load calculations, safety protocols, communication strategies, and legal compliance.

Scan the QR code to book in now

Melbourne 5-6 February 2025

Sydney 19-20 February 2025

Brisbane 5-6 March 2025

Perth 19-20 March 2025

Melbourne 4-5 June 2025

Brisbane 10-11 July 2025

Perth 16-17 July 2025

Sydney 17-18 September 2025

“We were able to demonstrate how the integration between the truck, the operator and the trailer work into one cohesive unit.”

We also had a number of customers attend from the South Island, which was really impressive. The Customer Day included a static display of the trailer and staff were able to highlight the various features and benefits, but customers really wanted to see the steering.

“We were able to demonstrate how the integration between the truck, the operator and the trailer work into one cohesive unit. We demonstrated how the remote control can override the steering and how to use the truck to dictate the crab steering. I think everyone was impressed with what they saw,” said Jeremy.

“We are actively building large modular ESS platform trailer systems for companies that require this type of technology, and at the moment, it seems to be in high demand from crane companies in particular - these include Borger’s, Max Services, Pollocks Cranes and Qube Heavy Lift.

“There are plenty of others that are seeing the advantages of our trailers because of the amount of infrastructure work they are involved in. For many of these projects, the lifts are in tight and confined areas and the ESS technology is ideal for these applications.

“The next step for Australia isn’t going to be a four by eight, it will be a five by eight ESS low loader. On the east coast of Australia especially, it’s going to be a lot more useful and that design will be ready over the next six to 12 months,” said Jeremy.

Justin Boehm takes a look at LEEA’s year, highlighting a number of stand out successes.

2024 HAS TRULY BEEN A MILESTONE year for LEEA in Australia and New Zealand. We’ve continued to set the bar high with our unwavering commitment to improving standards, promoting safety and fostering collaboration within the lifting equipment industry.

A significant highlight of the year was the expansion of LEEA’s training programs into Australia. This year, we teamed up with our Licensed Training Partners (LTP) - ATC Offshore and Tower Crane Training - to deliver LEEA’s highly regarded, globally

recognised training courses. Thanks to these partnerships, LEEA members can now offer comprehensive training to their lifting industry professionals, ensuring they are equipped with the latest knowledge and skills to maintain safety and efficiency during their examinations and inspections through their local LTP.

LEEA’s dedication to enhancing industry standards remains steadfast. In 2024 we’ve made significant progress in our work to raise standards, in particular through the

development of the Australia and New Zealand Technical Committee.

The inaugural LEEA ANZ Technical Committee meeting was a pivotal event for us, symbolising a new chapter for LEEA in the region. We are thrilled to announce Ashlea Johnston from Bunzl Safety and Lifting as the new Chair of the Technical Committee. Ashlea, with her extensive industry background, is a fantastic ambassador for our field. She will lead a committee of technical experts from across our industry,

“With continued focus on training, standards, and industry collaboration, LEEA is poised to lead the lifting industry into a new era.”

whose focus will be on renewing guidance documents for the local market, providing a unified voice in our representations to Standards Australia and offering expert knowledge to our global technical advisory team based in the UK.

This year Australian members were again winners at the LEEA Awards, held at the world-famous Dorchester in London. The LEEA Awards received hundreds of nominations from across the LEEA membership globally and Bunzl Safety and Lifting took out two awards – Sustainability Excellence and the Excellence in Safety awards. This is a significant achievement for our region and we should again commend our industry leaders for their commitment.

However, on top of all that, the crowning glory of the year was undoubtedly LiftEx on the Gold Coast. This two-day exhibition brought together global manufacturers, industry leaders and professionals from across the region. LiftEx Gold Coast was our first full-scale exhibition outside the UK and set a new standard for future events. The event attracted visitors from all corners of the country, as well as international attendees, providing a platform for high-level conversations, significant business deals and valuable networking opportunities. Exhibitors and attendees alike praised the quality and quantity of inquiries received, with many confirming substantial orders during the event. This success has spurred us to plan our next major expo in 2026.

Looking ahead, we’re gearing up for an even bigger year in 2025.

We’ll be introducing new products and revamped training programs for endusers of lifting equipment. Our training courses for lifting industry professionals will receive a fresh update. Additionally, we’ll be honouring our industry legends with a new annual award and ensuring that our industry stalwarts receive the recognition they deserve for dedication to our industry.

As we move forward, LEEA remains committed to its vision of lifting and height safety industries which have eliminated accidents, injuries and fatalities. Our dedication to promoting

enhanced standards and industry best practice, through our achievements of this year, are a testament to the association’s capability and the collaborative efforts of its members. With continued focus on training, standards and industry collaboration, LEEA is poised to lead the lifting industry into a new era.

As we look ahead to 2025, we are excited to continue building on our successes, driving innovation and fostering a culture of safety and excellence in the lifting equipment industry.

Over the past 12 months, Andromeda Industries has continued to make significant inroads in the local lifting and rigging industry. Experiencing significant growth in almost every state Geoff Bower, Andromeda’s Customer Relationship Manager, highlights the reasons for the continued momentum.

“THE LAST 12 MONTHS HAVE BEEN VERY good for the business, and we have definitely experienced a significant upsurge from a number of our resellers whilst others are generating a steady flow

“With all the activity in the resources sector, Western Australia remains very strong for us, and although we have seen a slight dip in demand from Victoria, Queensland has increased in activity to fill this void. Traditionally, Victoria has been our second largest market and although it has quietened down, all signs are it will bounce back early next year,” said Geoff.

Although Andromeda Industries services the market via a network of 100-plus distributors that includes major nationals as well as independent family businesses, all specialising in rigging and lifting equipment, Geoff and the team understand the importance of increasing the profile of the Andromeda brand and product range directly with end user

“This year we exhibited at both LiftEx Gold Coast, organised by the Lifting Equipment Engineers Association (LEEA), and The Crane Industry Council of Australia’s (CICA) National Conference and Exhibition in Adelaide. Both were very successful for Andromeda Industries and our brand. We’ve already received concrete orders from attending the

“LiftEx and the CICA Conference and Exhibition attracted different audiences. At LiftEx we were talking to our distributors who were either exhibiting or

hire businesses and Tier One construction companies.

“The CICA Conference and Exhibition was more focused on end users and again we spoke to most of the large crane hire companies as well as smaller family-owned businesses. We generated all sorts of enquiries, and it was good to reinforce that our products are designed, engineered and manufactured in our facility just north of Tamworth, in the New England region of New South Wales,” said Geoff.

Although the enquiries were right across the Andromeda Industries range

proved to be most popular with the crane sector.

The Dean-O is a sling produced by Andromeda Industries especially designed to provide a single lifting point under Ramshorn Hooks on large cranes. These slings can be made very short and creates a single point load to be attached and still maintain centreline loading. Unbalanced loads can cause the Ramshorn Hooks to skew on the rig centreline, potentially damaging the block assembly and wire rope. Andromeda manufactures the Dean-O Sling in capacities ranging from 11 tonnes up to 165 tonnes.

“The Dean-O Sling has been around for a couple of years, but it’s only recently that we’ve started pushing it. We had it properly displayed at the CICA event and it drew a lot of attention from some of the major national crane companies and also smaller crane hire businesses from all over the country.

“Companies we spoke with are really keen on it and with capacities ranging from 11 tonne to 165 tonne, the Dean-O Sling covers most applications. There are already a number of the Dean-O Slings operating in WA with the large crane hire companies. We also have some large tower crane companies using them on the east coast,” said Geoff.

The demand for the Dean-O Sling is being driven by the dramatic increases in crane capacities and by the construction industry moving down the path of modular construction says Geoff.

“The construction industry is moving to modular construction methods where elements of new buildings like bathroom and kitchens are built in offsite facilities, transported to site and then lifted into place. With infrastructure, the components in bridge construction for example, are getting so much bigger and heavier requiring these large capacity cranes.

“The Dean-O Sling was a concept designed by Raymond McLaren, the founder of Andromeda Industries, many years ago. He saw the benefit of a centralised lifting point utilising the Ramshorn Hook, rather than having multiple slings or Master Shackles with soft slings and a massive rigging configuration. Basically, we were able to utilise our Double-Ended Strops with a specialised Cast Steel Thimble that we designed and developed in-house to create a central lifting point for Ramshorn Hooks,” said Geoff.

“Basically, you can keep the Dean-O Sling on the Ramshorn Hook and interchange the rigging gear. If you are lifting with a 110 tonne capacity Ramshorn, you can fit smaller shackles and rigging gear to lift a one tonne crate, for example.

“The Dean-O Sling concept also originated because there were so many new people coming into the industry.

It was designed to simplify the rigging configurations using the Ramshorn.

“Crane companies have said you don’t have to interchange your hooks, which is time-consuming, labour-intensive and comes with a number of work safety-related associated issues. As with everything we do, safety must be paramount,” said Geoff.

Andromeda Industries has been designing, engineering and manufacturing large steel cables since 1972, providing some of the largest locally manufactured steel cable in Australia, as well wire rope

The construction industry is moving to modular construction methods where elements of new buildings like bathroom and kitchens are built in offsite facilities, transported to site and the lifted into place.

“Obviously we are recognised for our lifting and rigging products, but we also operate a rubber division and it would appear not many people outside of our local area know this.”

roofing slings are extremely popular in Victoria and Queensland, however they are not as well known in NSW, so it was great to be able to showcase the range.

“We had plenty of visitors to the stand saying, ‘So you are the guys that manufacture these products,’ which is great, because they are starting to put pieces of the puzzle together. The market is understanding that Andromeda Industries products are Australian designed and manufactured,” he said.

LiftEx and CICA’s National Conference and Exhibition provided Geoff and the Andromeda team an ideal opportunity to confirm to the market that there are two distinct aspects to the business.

“Obviously we are recognised for our lifting and rigging products, but we also operate a rubber division and it would appear not many people outside of our local area know this,” said Geoff.

Andromeda Industries’ Rubber Belt division is Australia’s leading supplier of re-purposed rubber belt and rubber matting products. Repurposing used belts minimises the environmental impact of ‘hard-to-dispose of’ materials, whereas recycling uses much more energy.

The main product from this Division is SPLITBELT which is created by the process of mechanically splitting the rubber belt using specialised machinery developed through Andromeda’s engineering division. The resulting SPLITBELT rubber matting is very strong and durable, whilst remaining lighter and easier to handle. With over 100 plus different applications, SPLITBELT is available in various lengths, widths and thicknesses.

“Our re-purposed rubber belt and new rubber matting products are not as wellknown as our lifting products, but there are so many applications for them. They

are being used by large crane companies as Friction Coefficients for ‘steel on steel’ contact surfaces which is now an important issue for the National Heavy Vehicle Regulator. Increasingly crane companies are recognising our rubber products are exactly what they need,” said Geoff.

“Our rubber mats are ideal for support trailers transporting counterweights or supporting hook blocks and other heavy lifting equipment. The mats sit between the steel surfaces adding to the stability of the load as it is being transported. Once again, a simple product that is designed with safety in mind for such critical industries.”

“Our rubber products also make a positive contribution to a sustainable future because we are positively repurposing very durable rubber products which are manufactured for tough environments and notoriously difficult to recycle or dispose of. There’s no need for either with our rubber products, they are ready for a new life in these types of Friction Coefficient applications. We are proud of the fact that our overall wastage is down to just 0.4% and we are continually working to reduce this further, ensuring a sustainable future,” he said.

Quality control (QC) is at the heart of Titan Lifting Technologies’ precision hoisting and lifting equipment, with industry knowledge and traceability as its non-negotiables. Titan Chief Operating Officer John Di Michele explains how the Bundoora-based company helps the industry lift with some of the most trusted materials on the market.

that can help the industry lift high capacity loads, the science of what sits between hook and load is a speciality of Titan Lifting Technologies.

The Australian company has designed and developed an extensive product range that spans the lifting, rigging, mining, shipping, construction and transport industries.

Specialising in chain and lever hoists as well as electric chain hoists and trolleys, the company has also designed lashing and loading equipment, load and lifting chains, shackles and ratchet straps, hooks and wire cable products.

John Di Michele said much of this equipment is manufactured overseas, adding that Titan works hard to ensure the product reaches the highest of standards before it enters the market.

“At Titan, we are proud to say we purchase from best manufacturers in China for lifting gear,” he said.

As the Australian agent for Wirop International, Titan not only sells these testers, it fully utilises its own machine to carry out testing.

“The lifting industry is stronglysafety oriented, whether it’s lifting something into a high-rise building, on a construction site, on an offshore petroleum rig, on the ship or restraining something on the back of a semi-trailer, it’s all safety oriented. It’s got to be safe. It’s got to be secure; so the product has to perform how it’s meant to perform, and also in an efficient way.”

Founded in 1998 as Allan Marketing Group but known colloquially as Titan Lifting, Titan’s journey began back in 1974 when founder and current

Managing Director, Ian Allan, moved from tools manufacturing with Bosch to working with an international lifting equipment company, PWB Anchor.

Ian’s investment in high quality, safe, reliable lifting equipment organically grew, resulting in the development of Titan Lifting Technologies.

John’s expertise in hoists and slings is the result of receiving Ian’s tutelage as well as many of his own visits to China, looking for the best products to bring back to Australian shores.

“The lifting solutions we provide customers with via our products is all knowledge-based.”

“We have a policy whereby we don’t buy anything from anywhere

overseas unless either myself or Ian have met the local manufacturers on the ground and have inspected the premises, their product and their processes - particularly in quality control,” John added.

John said the cost of this exercise is worth the knowledge attained.

“There is a lot of cost and time involved when we travel to our overseas suppliers, but we pick up new ideas which then turns into new equipment that we can be proud of.”

AGENCY BRAND PARTNERSHIPS IN LIFTING AND RIGGING PRODUCTS

Apart from their own brand, Titan also has a number of overseas agency partnerships such as Wirop

markings to ensure the products comply with or exceed Australian standards,” John said.

Once a shipment has passed Titan’s Quality Assurance (QA) process, relevant test documentation is filed according to batch numbers.

International, Van Beest Green Pin from the Netherlands, Tractel from France, and Probst from Germany.

Recently back from his annual trip to China and Taiwan, John explains how regular site visits help best inform his decisions when it comes to collecting information on current and future developments.

“Most of the factories we visit in China are ISO 9000 accredited and they are well organised too, with advanced machinery and robotics. This makes us feel incredibly confident about

the products we are bringing back to Australia.”

John explained that if the products are not up to Australian standards at the overseas warehouses he visits, then it’s not worth pursuing either the factory or products at all.

But Titan’s strict testing regime is quite extensive.

Once a batch of new products arrives at its facilities, John says Titan quarantines the shipment in the first warehouse until it undergoes a battery of comprehensive tests.

“Apart from testing, we then check factors such as the packaging and the

Titan’s traceability mechanisms are in place to ensure that in the incredibly rare situation where a product seems faulty, Titan can trace back all recipients of that particular batch of product and conduct further investigations, as well as tracing the products to the overseas manufacturer.

“It’s one of our biggest litmus tests,”

“If there are any issues out in the market, we can then go back to our factory and identify the batch number. Then they trace back to see what could

With high quality control standards and a list of well-designed and innovative products, Titan products are widespread across Australia, and also overseas.

“We have over 200 distributors in Australia and supply a broad range of

“We are in the business of helping businesses ensure their haulage or lifting systems are strong with our

distributors internationally, sending its reliable Titan products to 13 other countries, such as the USA, South Africa, New Zealand, Indonesia, Thailand, Malaysia and Fiji.

John said Titan’s approach has been recognised in the industry as incredibly diligent when it comes to quality and therefore safety upkeep.

“We’ve been told that we do more than what’s required to ensure our products are reliable,” he said.

“But I want to sleep at night knowing everyone goes home at the end of the day, and I know our products allow this.”

Over the past eight years, husband and wife team Ben and Jess Fitzgerald have put their hearts and souls into the family business, Queensland Rigging Hire. Financially, they continue to put everything on the line, firstly to develop and now to maintain their reputation as a successful, highly driven ‘customer service’ business. Ben discusses recent developments, how he and Jess have never forgotten their roots and how they continue to support local communities and initiatives.

“JESS AND I STARTED THE BUSINESS WITH basically nothing, but we soon realised that by working seven days, 60 to 70 hours a week, you can achieve anything. After years of blood, sweat, tears and sacrifice we are as dedicated as ever to making something of ourselves without losing focus on what really matters, and that’s providing the best levels of service, world class equipment, industry experience and knowledge to ensure we provide the right solutions to our customers, each and every time,” said Ben.

Like any new family business, the first few years were really tough, says Ben.

“Jess and I were raising our young family, working in the business fulltime and for a long time, we didn’t have $10 to rub together. But we never strayed from our fundamental beliefs of investing in good people, world class equipment and providing customers with the best possible service we could,” he said.

“We’re a service-based business. Our business isn’t just hiring rigging equipment, it’s service. Our customers ring not because they want to use us but because they need assistance, and they need suppliers to be reliable. Providing reliability is exactly what we do, and we do it well.

“They know they can ring us at the 11th hour, and we will deliver on what we promise. This lets our customers focus on what they need to do and not worry about the rigging element of their project. They know our equipment is of the highest quality, it is well maintained and compliant to the Australian Standards,” said Ben.

Although the first few years were tough, Ben and Jess’ belief in themselves and the

business was unwavering. They continued to invest in new equipment as well as the right people and gradually the business grew. Ben says that everything went up a few gears 12 months ago.

“A year ago, we started thinking about what was next, and how we could move forward. Again, we decided to effectively put everything on the line and reinvest in more people and equipment and ‘super charge’ the growth of the business.

“It was a high-risk strategy with our costs increasing substantially, and there were no guarantees. But the strategy has really paved the way for us to capitalise on the current construction boom, particularly in South-East Queensland,” said Ben.

“We invested in a lot of equipment, and we started saying yes to everything our customers were asking in terms of hiring rigging equipment. Today, there are

very few jobs we can’t help with. Because we were saying yes and employing more people, our previous premises could not accommodate the business.

“We have a few emerging industry leaders developing in our business, with our operations Manager Trey Yee currently studying a Certificate IV in Leadership and Management at the Australian Institute of Management to up his level of skills. We hope at some stage Trey can take over the running of the business. We also have Claire who over the last 12 months has project managed the integration of our hire program Syrinx, which has enabled us to control our assets much more efficiently, including maintenance and delivery scheduling. Claire is quickly becoming a huge part of our business, and we can see a very bright future for her at Queensland Rigging Hire,” said Ben.

“We had grown to a team of nine and we were literally on the top of each other and with so much equipment we were aware that we needed to minimise the Occupational Health and Safety risks and started looking for a larger premises,” said Ben.

It took approximately eight months for Ben and Jess to find the right facility.

“We looked at building a bespoke premises with overhead cranes etc., but we’re self-funded and it is our bank account that has to pay for it all, so we had to find a compromise with a facility that provided a lot more space but was still economically affordable.

“We’ve moved into a much larger facility in Willawong which is only nine minutes from our old location. It features 1200 square metres of warehouse and we have already added an additional 160

square metres of mezzanine as a part of the fit out. The new facility provides a much safer working environment and enables us to continue to grow and fill the gaps in the market,” said Ben.

Jess and Ben are committed to the continued investment in the team and new equipment.

“We have always recognised the importance of training our team and over the next three months, we’ll have another four team members taking their Dogging and Rigging tickets. It’s important for the team to understand who we are and what we do. Training helps them understand how our business works and the challenges our customers face,” said Ben.

“We treat our team like family, and it is no coincidence that in our eight years only one member has left us, and he came back! We look after them, we organise barbecues and lunches, celebrate birthdays and go on camping trips together. We attend social events and have big Christmas parties, we try to make it feel like a ‘work family’.”

more accurate, which is really important to square things up,” said Ben.

“We’ve also invested in a 40m lattice beam spreader bar which is the first in Queensland available for rent to the open market. It’s taken me many years to finalise the design and the best part about it, is that it’s designed to fit in an open top 40 foot shipping container and can be transported on one single trailer. No other lattice beam spreader bar in Australia can do that. It is Australian designed and Australian manufactured by Maxirig in Geelong.

“We’ve also added some more JDN air hoists in 16 and 20 tonne capacities and they’ve all been converted to wireless remote control, in-house by our own technicians. We’ve also added a couple of Ingersoll Rand five tonne air winches to the fleet,” he said.

Social responsibility and local community engagement remain high priorities for Jess and Ben. Because they come from humble, working class backgrounds, ‘battling’ is in their DNA and wherever possible

“We’ve also invested in a 40m lattice beam spreader bar which is the first in Queensland available for rent to the open market.”

Investing in the latest technology remains a key business strategy for Ben and Jess. A recent and significant investment has been in an Enerpac Synchronous Hoist System. The Synchronous Hoist System is a below-the-hook sling adjuster (hydraulic turnbuckle) which typically includes multiple specialised hydraulic cylinders mounted directly in-line with the rigging which provides the operator the freedom to precisely monitor and adjust each lifting point independently. The system enables a single crane to precisely position heavy and unbalanced loads.

“This system will open up so many doors around in the engineered heavy lifts space, where accuracy is absolutely essential. In a nutshell, they’re hydraulic turn buckles that can be extended or retracted under load, so that you can adjust your rigging weights up to a metre and a half before you position your load. You can get things balanced, and

communities and deserving causes. An example of this is the support they offer Justin Clements, a Masters boxer who works on the Cross River Rail project.

“We see Justin a lot through business and he’s competing in the Pan Pacific Masters Boxing next year. We’ve sponsored him over the last three or four years, basically since we’ve known him, and we’ve provided a healthy donation to help pay for his costs and enable him to concentrate on his training.

“He’s 53, and he gets the gloves on, and pushes hard. He’s actually fighting later this month for Men’s Mental Health raising money for charity. He’s bloody upstanding, decent person and it’s easy to get behind someone who’s a likable fella and good person. He always wants the best for people and wears his heart on his sleeve, and we are very happy to get behind him,” said Ben.

Jess and Ben have just renewed their sponsorship relating to the Beaudesert Kingfishers Rugby League Club footy shirts. Beaudesert is a working-class country town, where little things go a long way. The footy club is an important part of the community, says Ben.

“A few years back, we donated over 400 training shirts to the club so that every single kid had one to train in. It was a really

big success. As a kid personally growing up, we didn’t have a lot of money, so when I played footy, and we got a shirt, that was the only shirt that I wore for a whole year, because you valued it so much. You’re part of a club, part of a team. I think it’s really important for kids to have that feeling as well,” said Ben.

“For the last couple of years, we’ve sponsored three age groups with jerseys including the little fellas, the juniors, and we’re going to sponsor them for the next couple of years. We also sponsoring the under-16 girls, and couple of the other teams. They’re the ones that are the underdogs and coming up in sport and we want to give them a hand as well,” said Ben. Sailing program Sailability is another cause close to Ben and Jess’s hearts.

“One of our best mates’ family is part of the Warwick community (about 130 kilometres south-west of Brisbane) I doubt

there is anyone in that community who would not know his brother Leigh, he’s a bloody legend. Leigh has Down Syndrome and their family have been strong advocates for disability support for the 25-plus years we’ve know them

“We were talking one night and he mentioned the charity Sailability and how it was designed to get people with disabilities onto the water, and teach them how to sail. He explained they needed shipping containers to store the boats in. We instantly organised and paid for one, had it painted to their specifications and had it delivered to the Leslie Dam near Warwick.

“Sailability is a national program with lots of different locations and having one in the bush on the Leslie Dam provides a lot of people with challenges, who live nowhere near the ocean, the opportunity to learn to sail. we think it’s a great thing,” said Ben.

MAXbase Equipped

The GMK4080L is an outstanding four-axle taxi crane that, with its 60-meter-long boom, offers both the longest boom and the lowest gross vehicle weight in its class. Within 10 t per axle, the crane can carry 5.2 t counterweight and even 13.3 t counterweight with 12 t axle load.

•60 m boom length and capacity matches the 90-100t class (4.8 t @ 60 m)

•Main boom: 11,3m - 60m, 7-section

•Bifold swingaway jib: 8,7 m /15 m (optional)

•Minimum width 2,55 m and overall length 12,82 m

•Carrier cab: Latest generation of Grove carrier cabs

•Increased safety and flexibility with MAXbase variable outrigger system

•Faster Intuitive set-up with CCS (Crane Control System)

•Engine: Mercedes-Benz OM470LA, 300kW

•Capacity: 80 t

•Main boom: 60 m

•Maximum jib: 15 m (0°-40° luff)

•Maximum tip height: 77 m

•GVW: 48000 kg 3

Bylor partners with Modulift to supply custom lifting equipment to Hinkley Point C.

manufacturer Modulift is facilitating civil engineering installation works at Hinkley Point C, the first nuclear power station to be built in the United Kingdom in over a generation.

One milestone moment saw the 730-tonne reactor cavity precast pool installed with Modulift underslung

beams and “Big Carl,” the world’s largest crane, at the Somerset worksite.

BYLOR, a joint venture of Bouygues Travaux Publics and Laing O’Rourke, is the contractor delivering Hinkley Point C’s main civil engineering works. Appointed in 2022 due to its ability to innovate and modify beyond standard lifting equipment, Modulift

has delivered bespoke lifting systems tailored to the unique demands of this major infrastructure project. Sarah Spivey, Managing Director at Modulift, said “All lifting equipment is precisely designed using state-ofthe-art engineering technology and Finite Element Studies. By leveraging our engineering expertise and 20+

“Modulift custom lifting beams play a crucial role in the ongoing construction of Hinkley Point C, supporting the installation of key infrastructure elements.”

years of experience in the nuclear sector, we ensure all lifting equipment adheres to rigorous UK compliance standards such as BS EN. We are proud to be part of such a critical energy infrastructure project”.

Artur Osicki, Temporary Works Lead at Bylor said “Modulift custom lifting beams play a crucial role in the ongoing construction of Hinkley Point C, supporting the installation of key infrastructure elements. Modulift’s reputation for precision engineering and quality assurance

provides us with the confidence that all equipment complies with regulations for the UK market. Each custom piece of equipment comes with comprehensive User Instructions ensuring safe and efficient operations on site.”

Once complete, Hinkley Point C is expected to deliver zerocarbon electricity to approximately 6 million homes, solidifying its place at the forefront of the UK’s clean energy transition.

For more information about Modulift visit https://www.modulift.com/