MEET THE INDUSTRY FIRST MINOTAUR DL550.

GET IN TOUCH WITH YOUR LOCAL DEALER TO LEARN MORE ABOUT THE INNOVATIVE HYBRID DOZER LOADER AND ADD ANOTHER CASE TO THE FAMILY.

MEET THE INDUSTRY FIRST MINOTAUR DL550.

GET IN TOUCH WITH YOUR LOCAL DEALER TO LEARN MORE ABOUT THE INNOVATIVE HYBRID DOZER LOADER AND ADD ANOTHER CASE TO THE FAMILY.

LEARN MORE

Get a true edge on the job site with the Lippmann 1200j Heavy Duty Mobile Jaw Crusher. With a 1905mm deep jaw chamber, this go-to crusher tackles the toughest applications in mining and aggregates. Rely on the 1200j for smooth operation and maximum throughput as Lippmann engineers have optimized the material flow and jaw chamber design for high productivity.

Komatsu’s autonomous trucks hit major milestone; Colbrook partners up to sell autonomous mowing robots; and Caterpillar unveils tech updates for its wheel loaders 6 –8, 56–69

ITR Pacific showcases its range of undercarriage components, ensuring smooth operation of tracked machinery 10-11

Case Construction Equipment highlights its range of heavy excavators 12

Brisbane Mini Excavator Sales’ takes delivery of Sunward compact track loaders 14-16

888CSE introduces Lippmann’s latest fuel-efficient line of crushing and screening equipment to Australia 18

Shantui’s DH-series dozers are highly popular machines at Cobra Equipment Sales 20-21

Don Clark Tractors showcases its brand new parts warehouse in Canning Vale 22-23

Caterpillar hosts its inaugural global technician challenge in Melbourne 26

Peely’s Earthmoving highlights the importance of strategic partnership with Tilly’s Crawler Parts 28-29

CCF QLD unveils this year’s winners of its Earth Awards, People’s Awards and Industry Training Awards 30-31

UKW’s Brisbane branch is helping companies source high quality machinery parts 32-34

CJD Equipment highlights the services and tech on offer from Volvo Construction Equipment 36-38

ANT International builds quality earthmoving attachments that are built to last in Australia 40-42

Editor

catherine.fitzpatrick@primecreative.com.au

Journalists

Darragh Bermingham, Jackson Haddad

Contributors Damian Long, NAWIC

Managing

Art Director Daz Woolley

South Australia’s biggest infrastructure project reaches a major milestone University of Cambridge researchers have developed a method to produce low emission concrete

CCF QLD’s Damian Long highlights the need for change in the construction industry amid the CFMEU fallout

NAWIC’s campaign highlights the importance of leadership opportunities for women to encourage recruitment and retention in the construction industry

Calendar of upcoming industry events

Marketplace / DIY advertising Digger deals – hot classified deals! Private advertising coupon Index

52-54

Cutting-Edge Technology: Maximise efficiency with features like Load Sensing hydraulics for unmatched control.

450 kW Volvo Engine: Dominate any material with effortless digging force.

Safety & Operator Comfort: Experience a panoramic view and intuitive controls in a safe, ergonomic cab.

Volvo’s unique ECO Mode and an advanced electro-hydraulic system, achieving outstanding fuel efficiency.

Celebrating its 30th year of operation, a Victorian plant hire company has purchased a brandnew Huski skid-steer loader from Toyota Material Handling Australia – in honour of its original unit

Graham Koschman’s G.K. Auto and Hire, a small plant supplier in Horsham, Victoria, has become the proud owner of the latest evolution of a Huski 5SDK5 skid steer loader from Toyota Material Handling Australia (TMHA).

He made the call to upgrade his second hand 2SKD, after it had been anchoring his business since it started in 1995.

“I bought my first, a second-hand blue 2SKD, when I was running a mechanical repair business and was looking for additional income,” he says.

“It already had 8,000 hours on it, and I added at least 2,000 more” Confidence in the quality of the machine convinced Koschman to dry hire it, which led to the formation of his rental business with an inventory of more than 30 machines and implements.

“The Huski is bulletproof, even in the hands of multiple hirers,” he says.

“It’s not something you can say for a lot of machines.”

Koschman noted that the Huski’s reliability has been a standout

Colbrook Industries has partnered with RC Mowers to offer the USAbased manufacturer’s Autonomous Mowing Robot in Australia

feature, handling the punishing use that it gets when being hired out.

It was that reliability that he looked for in his latest purchase, a machine that would go the distance with an operator who often works around the clock to get a job finished – a trait which has earned him a strong reputation in the Horsham area.

The Huski 5SDK5 was a perfect fit, he says, having specifically ordered the machine to meet demand for short-term hireable machines for work in tight access situations, like domestic back gardens.

established dealership and believes our AMRs are a great solution for the Australian market.”

Colbrook’s relationship with RC Mowers started when it began selling the USA-based company’s RemoteOperated Robotic Mowers – prior to the development of the AMR.

With the potential of AMRs to help landscapers address labour shortages and profit challenges, RC Mowers says Colbrook was eager to add the autonomous product to its offering.

“We feel it is our responsibility to offer world-class and industry-leading products where we can, and the RC Mowers AMR does exactly this,” Colbrook managing director Rob Plageman says.

, Melbourne-based Colbrook Industries has announced it will be an authorised dealer of RC Mowers’ Autonomous Mowing Robot (AMR).

The partnership will see RC Mowers expand its AMR dealer network outside of the USA for the first time.

“Like the USA, Australian landscape companies are experiencing a severe ongoing labour shortage – and our AMRs solve that problem,” RC mowers sales and marketing vice president Tim Kubista says.

“Colbrook Industries is a well-

In addition to providing a solution for the landscaping industry’s worldwide labour shortage, Plageman says the robotic machines provide vital data that professionals can use to make business decisions.

Caterpillar has announced a host of technology and performance updates on its next generation wheel loaders

Caterpillar (Cat) has updated the design of its next generation medium wheel loaders, changes it says will improve operating efficiency and performance.

A new auto front differential lock has been added to all 950 to 972 models with joystick steering, and all 966 to 972 models with HMU (steering wheel) steering.

The auto front differential lock engages the differential lock to recover or maintain traction.

Upgrades to both auto front and rear differential locks are additional options for the wheel loaders.

These medium wheel loaders also feature improvements to the integrated brake system (IBS) and new engine RPM deceleration. The new transmission features smooth engagement and disengagement with the IBS pedal.

A new standard job-aid widget helps the operator in load-and-carry work by automatically placing the bucket at the optimal height for stability and maximum material retention.

Now linked to the work tool centre, improvements to the zero-angle work tool widget enable the setting of different zero angles for different work tools and attachments.

Three programmable buttons on the implement control pod have been added, offering quicker access to regularly used functions. Each

Design updates have been made to improve efficiency and performance of Cat next generation wheel loaders.

Image: Caterpillar

operator can pull from over 25 different functions to customise and save their personal settings.

To improve efficiency further, key operating features – including Cat Payload, manual tip-off, neutraliser settings and tips, and application profiles – are now available in the onboard display system.

A new option for Cat Advanced Payload, e-Tickwweting, can send the generated on-board weighing ticket as an electronic ticket to any preprogrammed email address within seconds of finishing the loading cycle – reducing paper ticket handling in the cab.

For the Cat 966 XE, 972 XE, 980 XE and 982 XE models, two new settings in application profiles allow each operator to set customised forward and reverse default speed ranges and rimpull limits.

These speed and rimpull set limits are now visible to the operator on the front dash, while set site limits are shown on the operator settings screen – informing the operator of the established upper limit.

In addition, a new optional tyre pressure measuring system displays the information on the main machine display..

Komatsu’s autonomous haul trucks have each reached a 100,000-hour milestone.

Image: Komatsu

Komatsu’s autonomous haul trucks have chalked up a significant number of hours on the road

Ten Komatsu autonomous haul trucks have achieved a benchmark of 100,000 autonomous operating hours each – an industry first, the company says Komatsu’s worldwide autonomous fleet consists of 750 haul trucks, with the company saying its customers have hauled more than 10 billion metric tonnes of material without a driver in the cabin.

The company launched the FrontRunner Autonomous Haulage System (AHS) in 2008 - Komatsu says it was the world’s first commercial application of an AHS.

“Since paving the way with the first commercial autonomous haulage operation in the marketplace 17 years ago, Komatsu is proud to continue being an industry leader in autonomy,” Komatsu Autonomous Systems business development manager Martin Cavassa says.

“Our highly skilled AHS team comprises of application and technical experts, as well as training and support specialists who possess in-depth knowledge and expertise.

“In every engagement, we bring that expertise to the table to help our customers achieve all the value that FrontRunner can deliver to their operations.”

Customers who have adopted Komatsu’s AHS have improved their safety practices, productivity and reduced costs. In addition to this, they have seen improvements in tyre and brake life and reductions in overall maintenance, the company says. =

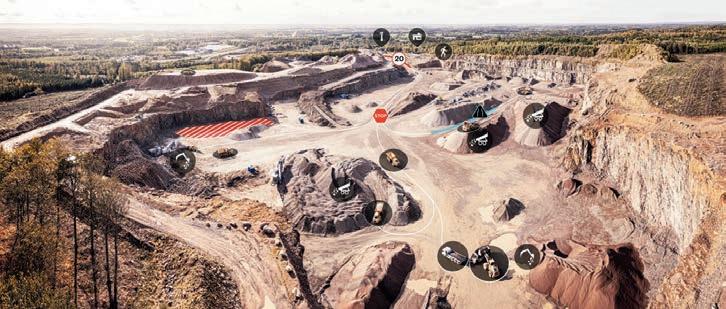

Offering adaptable drive options, PrecisionScreen’s Contractor 604 is designed to meet the diverse demands of the quarry and mining industries

In the dynamic landscape of crushing and screening, staying ahead of the curve with cutting-edge technology is paramount.

The PrecisionScreen Contractor 604 mobile screen embodies this forward-thinking approach, offering a solution for those seeking efficiency, versatility and performance.

With its adaptable drive options – hydraulic system, electric drive, or a hybrid of both – the Contractor 604 is designed to meet the diverse demands of the quarry and mining industries.

This level of customisation ensures that the machine can be tailored to specific job requirements, environmental regulations and operational preferences.

For those who prioritise power and reliability in their operations, the hydraulic drive option is a proven choice.

The hydraulic system is robust, delivering consistent performance even in the most challenging conditions, PrecisionScreen says.

It is ideal for remote sites where access to a stable power supply may be limited, providing the strength

needed to handle heavy-duty tasks with ease.

As industries increasingly shift towards sustainable practices, PrecisionScreen says the electric drive option of the Contractor 604 stands out as a game-changer.

This drive system offers enhanced energy efficiency, reducing operating costs and minimising the environmental footprint.

It is also quieter than its hydraulic counterpart, making it an excellent choice for operations in urban areas or noise-sensitive environments.

Additionally, with lower emissions, the electric drive aligns with global trends toward greener and more sustainable industrial practices.

By combining the hydraulic and electric systems, the hybrid option provides the best of both worlds.

This can lead to significant cost savings, as the machine can operate efficiently under varying conditions without compromising on performance, PrecisionScreen says.

The hybrid system also contributes to the Contractor 604 running more quietly and cooler than the fully hydraulic option, while also providing a large throughput of material.

PrecisionScreen’s Contractor 604 offers varying drive options, including a hydraulic system, electric drive, or a hybrid of both.

PrecisionScreen says the availability of these drive options on the PrecisionScreen Contractor 604 is a testament to the machine’s design philosophy – to meet the demands of a dynamic and diverse industry.

Whether you’re working in a remote mining operation, a bustling construction site, or an environmentally sensitive area, PrecisionScreen says the Contractor 604 offers a tailored solution that maximises productivity and minimises downtime.

In today’s competitive market, versatility is more than just a luxury –it’s a necessity, the company adds.

Having the choice of different drive options on PrecisionScreen’s Contractor 604 equips operators with the tools they need to succeed in any environment.

“This machine is not just a piece of equipment, it’s a strategic asset that adapts to the unique challenges of each job,” PrecisionScreen says.

“It paves the way for a more efficient, sustainable and profitable future in screening.”

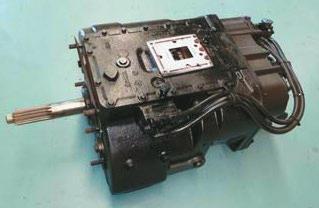

2015,AccugradeReady,Multi-Shank, Enclosed,Scarifier.N9D00466. TA1232534.

2019,3dTopConSystem,Air Conditioner,AuxiliaryHydraulics,Boom CheckValve

2018,2SpeedControl,4IN1MPBucket, AirConditioner,Coupler,Hydraulic .FD203075. TA1192196.

2020,3DSystemfitted,AirConditioner, AuxiliaryHydraulics,BoomCheckValve CATERPILLAR320-07

2018,AirConditioner,AirSuspension Seat,DPFMigrationKitFitted,Tailgate .2T401160. TA1172011. $489,500

2019,AirConditioner,BoomCheckValve, HandandFootControl,Undercarriage, Long.MGR00178. TA1228811. $467,500 CATERPILLAR352-07

2020,AirConditioner,AirSuspension Seat,RearViewCamera,Tailgate .3F300510. TA1173354. $577,500 CATERPILLAR730-04LRC

2021,AirConditioner,Beacon,Bucket, RideControl,Joystick,Weight MonitoringSystem.M8W20255. TA1213828. $456,500 CATERPILLAR972M

2018,AirConditioner,Beacon,PadShell Kit,ROPS-Enclosed.M7800163. TA1207398. $154,000 CATERPILLARCS78BLRC

ITR, a world-renowned Italian brand and leading supplier of aftermarket earthmoving machinery parts, talks about its undercarriage expertise

In the realm of heavy machinery, the undercarriage accounts for up to 50 per cent of a machine’s owning and operating costs, ITR Pacific says.

For dozers, excavators and other tracked equipment, a quality undercarriage ensures stability, durability and optimal performance on challenging terrains.

ITR, the world-renowned Italian brand best known for its complete range of aftermarket earthmoving machinery parts, has cemented itself as a world-leading supplier of undercarriage components.

Understanding its background, engineering expertise and product offerings sheds light on how ITR stands out in a competitive market.

ITR Pacific, a key player in the Australian aftermarket earthmoving

parts market, is a part of the USCO ITR group.

The USCO ITR group has a longstanding reputation for delivering high-quality solutions to the heavy machinery sector.

Established as a global leader, the USCO ITR group has an extensive network of over 76 distribution centres across five continents, capable of reaching over 174 countries around the world.

ITR Pacific is a vital part of this network, specialising in aftermarket undercarriage solutions that meet or exceed original equipment manufacturer (OEM) standards.

Its integration into the USCO ITR group amplifies its capabilities, leveraging the group’s extensive resources and technological advancements to enhance its product offerings.

The undercarriage can account for up to 50 per cent of a machine’s owning and operating costs

One of the cornerstones of ITR’s undercarriage success and the main thing separating it from its competitors is its 100 per cent owned production facilities, allowing ITR full control of the manufacturing process of the entire undercarriage product line, from start to finish.

ITR’s ISO-certified production facilities and stringent quality control measures have also resulted in a consistent, high-performing and reliable product that has attracted the business of original equipment manufacturers (OEMs) and other aftermarket companies globally.

ITR Industries’ South Korea and China bases manufacture all ITR track chains, track shoes, rollers, sprockets and idlers, with full control of the main production processes which include forging lines, machining and heat treatments. The engineering, research and development departments within each manufacturing facility are coordinated by the group’s Italian Engineering Department.

Numerous quality control checks are performed before, during and after production.

All these tests are performed

ITR Pacific is a part of the USCO ITR group, that has over 76 distribution centres across five continents

ITR has full control of the manufacturing process through its 100 per cent owned production facilities

in-house, according to OEM standards, using specially designed pre-calibrated testing equipment ensuring the integrity of the results.

Offering a comprehensive range of undercarriage parts designed for most makes and models of tracked machinery in the Australian market, ITR Pacific has the parts needed to maintain the performance of your machine and ensure reliability. With an expansive network of branches, warehouses and workshops strategically positioned throughout the Australian market, alongside industry experts stationed in every region, ITR Pacific is uniquely positioned to deliver an exceptional customer experience. Its range includes:

1. T rack Chains: ITR track chains have undergone extensive research, resulting in an improved design. ITR’s range offers a variety of sealed and lubricated track chains (SALT) and sealed and unsealed track chains, suitable for standard to specialised heavy-duty applications. Premium tracks are now fitted with newly designed Seal Groups, engineered to the highest quality standards in the industry, to perform in applications such as mining and quarrying.

2. T rack Shoes: Manufactured from top-quality materials to ensure high wear resistance in even the most abrasive conditions. Suitable for most makes and models of crawler machines and applications with a large range of single, double and triple grouser track shoes, as well as swamp shoes and special application shoes.

3. T rack Rollers: Forged products manufactured from selected materials such as certified Boron steel, high toughness castings and top-quality components. Deep heat treatments and precise machining guarantee consistency of the production. All rollers are lifetime lubricated due to the increased oil capacity and seal design.

4. Idlers: Designed based on the application requirements, offering solid cast or fabricated drumtype Idlers. Extended wear life is assured by specific heat-treatment processes to harden contacting surfaces. ITR Idler Seals are engineered to perform in extreme conditions with temperatures of between -40 and +50 Degrees Celsius.

5. Sprockets: The USCO ITR group has invested heavily into research and development of its sprockets and segment groups to improve wear time and reliability. The surface and core hardness provide a longer wear life, with a higher resistance to bending or breaking in tough conditions.

6. T rack Pads: These are manufactured with the highest-quality rubber and steel, which ITR says typically makes them 13 per cent thicker than competitor pads. This gives them the benefit of reduced noise and vibration when the machine is tracking. ITR’s rubber pad range is competitively priced and suitable for all applications.

ITR’s commitment to engineering excellence, quality manufacturing and comprehensive product offerings makes it a standout choice for undercarriage components.

As a part of the USCO ITR group, ITR Pacific leverages extensive resources and expertise to deliver products that meet the highest industry standards. For operators and fleet managers, investing in ITR undercarriage parts means choosing reliability and performance. Its range of undercarriage products ensures that heavy machinery operates smoothly, efficiently and with minimal downtime. In an industry where performance is critical, the USCO ITR group provides the solutions needed to keep crawler machines in peak condition, ready to tackle any challenge the job site presents.

For more information, visit www.itrpacific.com.au or call 1300 820 214.

Case Construction Equipment’s heavy excavator range is displaying high-power and efficiency througout Australia

Case Construction Equipment’s heritage dates back to 1842, maintaining a commitment to building practical, intuitive solutions that enhance both productivity and efficiency.

Paul Davies, general manager of Case Construction Equipment’s Australian distributor, McIntosh CE, says Case is continuing this legacy to the present day.

“In the world of earthmoving and construction, efficiency and power are paramount, and Case’s heavy excavator range displays these qualities, offering high-performance and flexibility for the most demanding tasks,” he says.

One of the standout features of Case heavy excavators are their versatility. Whether trenching, loading, or tackling various tasks, Davies says these machines excel with precision and reliability.

A robust design and advanced hydraulics ensure high performance on every job, enabling operators to dig deeper and achieve more, even in challenging conditions.

Visibility is crucial for precision work, and the visibility on offer in Case’s heavy excavator range does not disappoint.

Davies says the wider glazed surface and single-piece side window maximise visibility, providing a 360-degree view that enhances operational accuracy and safety. This feature is particularly

beneficial in confined spaces, where precision is essential.

With a variety of models available for different requirements, the heavy excavator range provides customers with more choice, from wheeled machines to mini, midi, large crawler and specialty excavators.

Each model is equipped with intelligent hydraulics and designed to deliver substantial power, ensuring continuous operation without interruption, Davies says.

With support customers can rely on, Case offers flexible financing and insurance options, making sure customers have different options –depending on their needs.

This professional partnership ethos ensures that Case does what is right by its customers and communities,

building trust and reliability in every interaction.

“For over 180 years, Case has been building a strong portfolio of products in the construction industry,” Davies says.

“Case’s heavy excavator range is a testament to its legacy, delivering the power, efficiency, and reliability that earthmoving professionals demand.”

Financing options are available on Case’s range of heavy excavators. To find out more, visit www.casece.com

Case provides a range of equipment including excavators, loaders and dozers –to name a few

winwithcastrol.com.au/rollupandwin

AU residents 18+ only. Between 12:01am AEST 1/9/24 & 11:59pm AEDT 30/11/24, spend required amount in 1 transaction on any Castrol product or lubricant ($200 - $1,299.99 for Prize Pool 1, or $1,300+ for Prize Pool 2), from participating Castrol outlets (excl online), visit www.winwithcastrol.com.au/rollupandwin & fill out entry form incl. receipt upload and select a roller door on screen to see if you have provisionally won an instant prize. Max 1 entry per qualifying purchase and per itemised receipt. Keep original itemised receipt/s. Prize Pool 1 prizes: 100x Castrol Reignite Cooler Packs ($100), 10x Castrol WAECO Icebox ($300), 100x Castrol/Frank Green Bottle ($100), 30x Castrol Laptop merch ($100), 10x Wanderer Quad Fold Beach Cart ($200), 50x Castrol Eftpos Giftcards ($100) & 10x Signed Framed Tickford Racings Polos ($750). Prize Pool 2 prizes: 20x Weber Baby Q ($568), 20x Makita 18V brushless 2pc kit combo ($800), 10x Castrol Branded Bar Fridges ($1k), 10x Apple iPhone 15 256GB Midnight Black ($1,700), 10x Samsung 65” Q70C QLED 4K Smart TV ($1,895), 10x PS5 Bundle ($1K) & 10x Gran Lattissima Automatic Capsule Coffee Machine Black ($649). See

New stock of Brisbane Mini Excavator Sales’ Sunward compact track loader has arrived, a machine that’s ideal for customers seeking greater lifts and more stability on uneven terrain

Brisbane Mini Excavator Sales (BMES) is known for being Australia’s exclusive distributor of Hercules machinery, consisting of loaders, graders and telehandlers, to name a few products.

For the last four years the Yatalabased business has also been Queensland’s exclusive supplier of Sunward equipment, taking on the brand for its expansive range and quality build.

A leading machinery OEM in China and selling more than 5,000 units a year throughout Europe, Sunward equipment’s baby blue colour profile is sure to stand out on any job site.

Following lots of research, BMES sales executive Steven Ragenovich said the company was impressed with Sunward’s Chinese operation, and the distributor is proud to have the brand as part of the BMES product portfolio.

Sunward’s 4528 compact track loader provides better stability in uneven terrains than wheeled machines

“Sunward is a major company in China and they have a huge state-ofthe-art factory over there,” he says.

“They employ thousands of people and have a diverse range of products, including excavators, track loaders, skid steers, cranes and drilling rigs.”

For the last four years, BMES has been offering its customers Sunward’s mini excavators and skid steer loaders, but now its excited to introduce new stock of Sunward’s 4528 compact track loader (CTL).

Weighing 4.4 tonnes (4,400kg), the 4528 model produces 74 horsepower (55.2kW) of power through a twospeed genuine Kubota engine, and has a rated load capacity of 1,200kg.

Compared to traditional skid steers, Ragenovich says the Sunward CTL provides larger load capacities and better stability on uneven terrain, due to the tracks that it moves on.

It is particularly effective in wet and sandy environments, with Ragenovich saying the unit achieves

Vertical lift allows the machine to have greater lifting capacity than skid steers

“CTLs like the 4528 have more rubber on the ground so they are more stable than wheeled machines,” Ragenovich says.

“It also has greater balance and lifting capacity than skid steers.”

He adds that a quality 4 in 1 bucket comes standard with a quick coupler, allowing operators to switch between various attachments depending on what is needed to get a job done in a hurry.

Safety is always a priority, and the 4528 ensures this with a roll over protection system (ROPS) and falling

Its hydraulic vertical lift path allows the CTL to lift materials higher than machines using a radial lift path, meaning the 4528 is ideal for tasks that require higher reach – such as loading trucks and materials.

Other features include an adjustable high back suspension seat, LED lights and joystick control, as well as the high-flow system as standard.

Customers can feel more than confident, as the Sunward 4528 is sold with a 3,000 hour or threeyear comprehensive warranty

It is particularly effective in muddy and sandy environments

– whichever comes first.

To back up this sense of comfort, Ragenovich says BMES is a ‘one stop shop’ for servicing, repairs and spare parts, stocking everything needed to maintain customers’ machinery.

“BMES has become a known brand name due to over 35 years of industry experience, selling new and used machinery, as well as a full range of attachments and accessories,” he says.

With the increased popularity of the CTL models, customers should get in quick to avoid missing out on one of the new 4528 CTLs.

“Our customers can also look forward to a new Sunward machine towards the end of the year,” Ragenovich says.

“For customers wanting increased horsepower and lift, keep an eye out for the new 5.3-tonne, 100 horsepower (73.5kW) Sunward CTL model.”

BMES also has a rental fleet dubbed ‘Earthmoving Rentals’, which has several machines in its fleet for hire, so customers can hire before they buy.

For more information on the Sunward 4528 compact track loader, visit www.brisbaneminiexcavators. com.au or call (07) 3807 4333.

A 4 in 1 bucket and quick coupler come as standard

Bred Toyota tough, Huski skid steer loaders are the perfect mix of performance, reliability and durability. Developed and tested in Australia, Huski features best in show strength, manoeuvrability and driver comfort, and can handle operating loads from 320kg to a whopping 900kg.

Best of all Huski skid steer loaders are backed by Toyota’s trusted reputation for delivering quality equipment and loyal after sales support. So if you’re looking to put your business at the head of the pack, you can’t go past a Huski. Australia’s Top Dog in the Dirt.

888CSE has introduced Lippmann’s latest fuel-efficient line of crushing and screening equipment to Australia, including an electric-powered jaw crusher

After celebrating 100 years of Lippmann in 2023, 888 Crushing and Screening Equipment (888CSE) has partnered with the USA-based company to bring a new line of tough and fuel-efficient mobile crushers and screeners to Western Australia, the Northern Territory and South Australia.

Lippmann has built a reputation for premium quality solutions from its philosophy of creating the heaviest and most durable machines in the industry.

For over ten years 888CSE has delivered and supported numerous static and modular Lippmann jaw crushers and feeders to the Australian market and says it looks forward to continuing this with the new line of equipment.

“The new fuel-efficient line offers reduced greenhouse gases (GHG) and the lowest Scope 1 emissions,” 888CSE says.

These Lippmann crushers have successfully processed millions of tonnes of rock and ore in the harshest climates in remote areas of Australia.

“The Lippmann Jaw Crusher reputation is legendary,” 888CSE says.

Now stocked at 888CSE, Lippmann’s heavy duty track mounted mobile crushers and screens are suited for the aggregate, mining and recycling industries.

Among the new items is the impressive L1300j-e, a 125-tonne electric-powered track mounted jaw plant that 888CSE says is one of the largest mobile crushers in the market.

“It offers professional operators the highest production and performance efficiency in mining and large quarry operations,” 888CSE says.

Capable of processing over 1,000 tonnes per hour in certain mining applications, the electric-powered jaw crusher features a Cat genset to provide self-contained on-board power.

The L1300j-e can also be plugged into a mains power supply for the lowest cost of operation. Alternatively, the plant can run off a single larger genset, which can be used to power a complete Lippmann Crushing Circuit, for the most fuel efficient and cost saving operation.

Additional ‘dual power’ dieselelectric Lippmann ‘Legendary’ machines include the 300c and 400c cone crushers with 300hp (225kW) and 400hp (300kW) hydraulic adjust cones, as well as the Lippmann

Lippmann’s L1300j-E electric-powered and track-mounted jaw plant is one of the largest mobile crushers in the market

1200j-e 75-tonne class jaw crusher which is capable of processing up to 600 tonnes per hour.

The L620R heavy duty scalper screen with apron feeder is also offered, as well as Lippmann’s L622-3 triple deck sizing screen with classleading 22ft by 6ft (6.7m by 1.8m) side tension screening system for the highest efficiency.

Lippmann dual power units are suitable for any high-capacity mineral ore processing requirements including iron ore, gold ore, lithium mining, bauxite mining and any other large mining, quarry or recycling operation.

For more information on the complete range of Lippmann ‘legendary’ crushing and screening systems, please contact 888CSE on 08 9550 6388. (WA / SA and NT only).

The L1300j-E is capable of processing over 1,000 tonnes per hour in certain mining applications

Able to tow various types of equipment and to be fitted with attachments, the Shantui dozers from Cobra Equipment Sales impress on a number of fronts, including its fuel-efficient engine

Shantui’s DH-series dozers have been a highly popular machine at Cobra Equipment Sales, due in no small part to their versatility.

In addition to pushing materials, the Shantui dozers have the capacity to tow equipment and can also be fitted with many attachments to suit the operator.

As an authorised dealer and distributor of Shantui equipment, Cobra has recently seen some of its earthmoving customers attach agricultural machinery to the back of their dozers for land preparation purposes.

One customer taking advantage of the towing capacity is Owen Lane, who is the owner of small earthmoving business – Hiregrade –which he has been running for over 30 years.

He has attached an anchor chain to a heavy-duty drawbar on the back of his Shantui DH17-C3 crawler dozer –enabling him to clear brigalow scrub.

In order to knock over regrowth timber, the anchor chain has been hooked between his 20-tonne and

204 horsepower (152kW) Shantui dozer and another-branded dozer.

“This is the first major job I’ve done with the Shantui dozer, but I’m already impressed,” Lane says.

“It’s highly manoeuvrable and easy to operate.”

Thanks to a highly fuel-efficient Weichai engine, Lane has also been pleased with the amount of money he’s saved in fuel costs.

In comparison to equivalent dozers of leading brands, he says the Shantui machine uses 30 to 40 litres less diesel fuel over a 12-hour shift.

Considering the high price of diesel fuel in the current market, the Shantui engine is making all the difference for him.

“Over a period of time, the fuel savings all add up,” Lane says.

Cobra founder George Nason attributes the fuel-efficient engine to the many years of research and development undertaken by Shantui.

“Shantui has acquired a wealth of knowledge from other machines

Cobra Equipment’s customers have been reaping the benefits of the Shantui dozers’ fuel-efficient engine

over the years, and they’ve come up with their own engine,” he says.

“They’ve been building it for many years, and now you can see the benefits through fuel-efficiency and power.”

Another Cobra Equipment customer, Lachlan Smith, owner of H.L. Smith Earthworks, says his Shantui DH17-B2 dozer is also providing significant fuel savings.

“Shantui’s engine is much more fuel efficient compared to other dozers,” he says.

“It consumes half the amount.”

Based in Casino, New South Wales, Smith has also been towing agricultural machinery on the back of his Shantui dozer.

A four-metre-wide disc plough has been attached to lend a hand in a land development project – involving rehabilitating scrub and improving pasture.

Impressed with the dozer’s power and towing capacity, Smith says the dozer is a perfect alternative to wheeled machinery when having to work in rough terrain.

Owen Lane is towing an anchor chain on the back of his Shantui dozer to clear brigalow scrub

“The regrowth I’m driving through would damage or destroy any machine that has tyres, but my Shantui dozer’s tracks aren’t affected when it runs over the top of the regrowth,” he says.

Performance, price and reliability were big selling points for Smith, a key factor in deciding to go with the Shantui brand over other dozer manufacturers.

Reinforcing these reasons for going with Shantui, Lane also says the affordability of the dozers were a big standout.

“I think the quality is just as good as some of the other leading brands, but the Shantui machines are less than half the price,” Hiregrade’s owner says.

“I believe the Shantui brand is going to continue to become more popular in Australia, and the dozers will retain their resale value.”

Farmer Peter Campell is also fond of the Shantui brand, and is using his DH24-C3 crawler dozer on his own rural property in Goondiwindi – on the border of New South Wales and Queensland.

His dozer has been fitted with a variety of attachments, including a tree spear, stick rake, blade plough and heavy-duty forestry protection guards, to clear country for his cattle and prepare the ground for crop planting.

Another standout of the Shantui dozers for Cobra’s customers has been the large cabin space, providing plenty of room to make sure that comfort is maximised throughout the day.

What Cobra’s founder, Nason, finds most special about these dozers is the independent hydrostatic drive of each track – providing easy manoeuvrability of the machine.

“When you steer, it just speeds one side up and slows the other side down, but you never lose traction on both sides,” Nason says.

“Being hydrostatic drive, our customers are finding that the dozers are much easier to operate.”

In addition to Lane’s Shantui dozer, he also owns a Shantui grader which he finds highly affordable, and hopes to add a Shantui excavator from Cobra Equipment to his fleet soon.

Already a big fan of the machine,

customers like Lane can trust the Shantui, Nason says, as the company is the world’s largest manufacturer of bulldozers.

“Shantui is the number one seller of bulldozers in many countries, due to its affordability, reliability and ease of operation,” he says.

“At Cobra Equipment, we’ve been selling a lot of DH17s up to the DH24s which are suitable to smaller contractors, and interest in larger models is also growing due to the Shantui brand’s proven track record.”

For more information on the ‘DH’ Shantui range of dozers, visit www.cobraequipmentsales.com. au or call (07) 3379 9419.

A new Canning Vale facility will allow DCT to better service Perth and the surrounding areasn, the parts supplier says

Don Clark Tractors (DCT) has been in business for just over six decades – and the family-owned and operated company is still expanding to this day.

In July, DCT established a parts centre in Canning Vale in Perth, WA, allowing the company to better service Perth and the surrounding areas.

The new 1,000 square metre warehouse, located at 2 Mordaunt Circuit, will focus mainly on civil construction while DCT’s Kalgoorlie operation will remain mining-related.

Prior to opening the new warehouse, DCT already boasted warehousing facilities of over 4,000 square metres between strategically placed warehouses in Castlereagh, Dubbo and Orange in NSW as well as Kalgoorlie in WA.

DCT was established in 1963 by

Don Clark, to provide service and maintenance support to the local earthmoving industry.

In 1984, the company expanded – not for the last time – with the beginning of the parts division which today consists of a multi-million dollar computer-controlled inventory that numbers over 100,000 line items.

Today, DCT offers parts and services to everyone from sole owner/operators to some of the world’s largest mining, construction and agriculture companies.

Spanning three generations and still family owned and operated – four of Don’s grandchildren are now actively involved in managing the company – DCT sources, manufactures and supplies OEM quality aftermarket and replacement parts with a quality and life equal to the original part.

DCT’s new 1,000 sq metre warehouse in Canning Vale

The DCT service division operates out of purpose-built workshops in Castlereagh and Orange NSW, while its Dubbo, Kalgoorlie and now Canning Vale operations are parts-only.

Both service workshops have welding, boring, milling and machining capabilities, as well as the correct tooling and personnel to complete everything from a simple hydraulic cylinder repair to a complete machine rebuild – with all the technicians experienced in working on Caterpillar machines.

DCT’s company director Brett Clark – son of founder, Don – speaks to Earthmovers & Excavators about the company’s new parts facility in Canning Vale, working closely with family members and how the business has expanded from day one.

“We took ownership of the Canning Vale site in July and we’re still setting up but we’re open and ready for business,” Brett says.

“We’re in and we’ve begun work.

“We’re ready to go now really – we’re putting in stock and shelving and racking, and we’re just loading it all up at the moment, ready for business.

“The new parts centre means we will be able to service the Perth

area better than we were out of Kalgoorlie,” he adds.

There is already a manager in place at DCT’s Canning Vale site, and Brett says the company plans to hire additional staff for the facility in the coming weeks and months.

He admits that, no matter what part of the country you’re in, finding quality staff can be a tricky endeavour – but adds that DCT is confident of building a strong team in Canning Vale.

“We’re hoping and expecting the new site to get busier and busier as time progresses,” Brett adds.

Being a family-owned and operated business makes DCT stand out from the crowd – the company spans three generations of the Clark family and shows no signs of deviating in the near future.

Working so closely with family members presents its own unique dynamic as well as some unique challenges, Brett explains.

“It’s certainly a different dynamic –challenging would be a good word,” he laughs.

“We work our way through and it works.

“You say things to family that you don’t say to employees, and they say things to their boss that they wouldn’t say to any other boss.

“I suppose it does make us stand out from the crowd – customers understand and appreciate that we all have skin in the game and that we’re here as not just regular employees.”

After 61 years in business, a company might be forgiven for resting on its laurels – that prospect never crossed the minds of those behind DCT.

“It’s great to see continued expansion even after so many years,” Brett says.

“We’ve expanded from day one really – it’s just something we’ve always done.

“It depends really on what market you’re in but there is plenty of

Stocked shelves inside DCT’s new warehouse.

expansion available to us. There’s always demand for parts and there’s always demand for service work,” he adds.

“The biggest hurdle you’ve got with the service work is keeping service technicians.

“We still do some service work on the east coast, but we’ve figured the smarter thing for us to do here in Canning Vale is focus on parts for the existing local repairers.

“This parts centre is another step in the right direction and it’s exciting times.”

For more information, visit Don Clark Tractors at www.donclark.com.au

TheTerexMDSM4133SplitTrackisidealforscreeningfromlightmaterialtorecycling demolitionwaste.

INSTOCK&AVAILABLENOW.030124_1. TA1211054.

TheTerexMDSM515HeavyDutyTrommelexcelsatcraftingRipRapandreclaiming rocksentangledwithclayandotheradhesivematerials.

INSTOCK&AVAILABLENOW.070224-1. TA1209482.

TheTerexMDSrangeofmobileconveyors are designedtoworkinconjunctionwiththe entirerangeofTerexMDSHeavyDutyTrommels. INSTOCK&AVAILABLENOW.030124_3. TA1210853.

TheTerexMDSM412MobileTrackTrommelisperfectforscreeningeverythingfrom lightweightmaterialstorecyclingheftydemolitionwaste.

INSTOCK&AVAILABLENOW.0702/24-2. TA1209481.

TheM518Risacompactrecyclingtrommelthatisdesignedtobeusedinvarious applicationswithhugestockpilingcapabilities.

INSTOCK&AVAILABLENOW.110724_2. TA1228793.

TheTerexMDSMT24TrackedMountedConveyorissuitedtoaggregateandquarrying applications.Highlymobileandbuilttolast.

INSTOCK&AVAILABLENOW.040124. TA1210854.

2023,TheAggredryDewateringWasher,acombinationwetscrewanddewatering screen,canbeusedanywhereafinematerialwashermightbeused.

INSTOCK&AVAILABLENOW.090524_3. TA1222479.

LIPPMANN1200JMOBILEJAWCRUSHER

SUPERIORINDUSTRIESFINEMATERIALWASHER36"

SuperiorsFineMaterialWashers are capableofremovingclays,silt,andunwanted lightweightcontaminants.Finematerialisusuallydefinedas9.5mmandless.

INSTOCK&AVAILABLENOW.3724_7_1. TA1222484. POA

GetatrueedgeonthejobsitewiththeLippmann1200jheavydutymobilejawcrusher. Witha1905mmdeepjawchamber,thisgo-tocrushertacklesthetoughestapplications.

INSTOCK&AVAILABLENOW.211223_4. TA1211051.

TheLippmann300cisaheavydutyconecrusherwithaninnovativematerialflowthat maximizescapacityandthroughputwhiledeliveringaconsistentlyhighqualityproduct.

INSTOCK&AVAILABLENOW.201223. TA1211053.

The1060jisdesignedtomaximizeoutputofhighqualitymaterial,withaheavyduty buildandhighqualitywearpartsandcomponentstominimizedowntime.

INSTOCK&AVAILABLENOW.S674. TA1200401. POA

LIPPMANN1300JTRACKMOUNTEDHYBRIDJAWCRUSHER

Animpressive51"x39"crushingjawthatfeaturesalargeintakethatacceptssomeof thelargestofminingandaggregatematerialintheindustry.

INSTOCK&AVAILABLENOW.220524_1. TA1223014. POA

Technician challenges will be held in Europe, the Middle East and Americas this year and next, with the top three winners from each regional qualifier going on to participate in the semi-finals

Caterpillar hosted its inaugural Australian Global Dealer Technician Challenge in Melbourne last month, with three Aussies now set to showcase their skills on the global stage.

The manufacturer is presenting the first-ever Global Dealer Technician Challenge to celebrate the role dealer technicians play in providing excellent customer service.

For the independent Cat dealers that choose to participate, the challenge is designed to showcase how skilled technicians are part of a

high-tech, high-impact, high-demand career.

The Melbourne leg of the competition took place from August 12 to 15, with seven technicians taking part.

Leon Archibald from WesTrac WA (1st), Rhys Bishop of Hastings Deering (2nd) and Brenton Page from Terra Cat (3rd), qualified on the day and will now go on to the next stage of the competition.

Similar events will be held in Europe, the Middle East and

From right to left, Leon Archibald, WesTrac WA (1st), Rhys Bishop, Hastings Deering (2nd) and Brenton Page, Terra Cat (3rd), who will now participate in the semi-finals in Malaga, Spain. Image: Cat

Americas this year and next, with the top three winners from each regional qualifier going on to participate in the semi-finals in Malaga, Spain.

Ultimately, the top 10 finalists will compete in a finals to be held at CONEXPO/CON-AGG in Las Vegas in March 2026.

“This hands-on, skills-based competition will test the technicians’ agility, resilience and versatility,” says Caterpillar Global Service Vice President Henry Venneman.

“These trained experts are on the front line of support, working to keep machines and engines up and running to help ensure our customers’ critical projects are completed.”

By the end of 2026, it is estimated that Cat dealers may need to hire more than 44,000 technicians.

This competition is also designed to help raise awareness of the opportunities in this career field, Cat says.

“There are thousands of opportunities available globally for those who are interested in a handson career,” adds Venneman.

“Cat dealers are often looking for individuals who are problem solvers, mechanically inclined and tech savvy.”

►High-end enlarged cabin ►Tier 3 engine ►Forestry protection ►UHF radio ►OPTIONS: Wider 610mm track shoes ►Alligator track links ►SALT tracks

“What attracted me to it is that it’s basically a third of the price of other brands and I think the quality’s just as good”

“The hydrostatic steering is far better than what we used to call a clutch-type tractor. They’re just a lot better to operate and a lot more user-friendly.” - Owen Lane, Hiregrade, NSW 19.65 tonne (approx. with forestry) bulldozer with Weichai WP7 Tier 3 152kW (204hp) 1800rpm six cylinder engine, hydrostatic drive, semi U tilt or straight blade, three-shank rear rippers, 510/560/610mm track shoes and track guard plate, engine side guards, air-conditioned ROPS/FOPS cabin with forestry protection, radio, UHF radio and suspension seat. $240,000 plus GST = $264,000*

16.8 tonne grader with Cummins 6CTAA8.3-C215 160kW (214.56hp) 2200rpm six cylinder engine (Cummins Australia warranty), 14 foot blade, rear rippers, ZF type powershift transmission - six forward / three reverse, with transmission guarding, no-spin self-locking differential, reverse camera, 17.5R25 tyres, air-conditioned cabin with radio and suspension seat. $218,000 plus GST = $239,800*

Tilly’s Crawler Parts has provided Peely’s Earthmoving with top-tier parts that deliver exceptional value

For over 35 years, Peely’s Earthmoving in Spring Ridge NSW, has been a name synonymous with quality, dedication and reliability in the earthmoving industry.

Founded by Warwick Peel, Peely’s Earthmoving has become a cornerstone of the community, delivering top-notch service that has stood the test of time.

Today, the business is in the capable hands of Warwick’s son Grant, who took over eight years ago, ensuring the continuation of a proud family legacy.

Grant’s leadership has maintained the high standards set by his father while introducing new efficiencies and innovations.

He says a key factor behind Peely’s success is its strategic partnership

with Tilly’s Crawler Parts, a company known for its high-quality machinery parts and excellent customer service.

In the earthmoving industry, the brand of parts used can be crucial. Traditionally, an OEM badge has been a symbol of trust and reliability, something that customers often insist on.

However, Grant’s experience has shown that while some businesses avoid non-genuine parts, there are alternatives that offer the same, if not better, performance at nearly half the price.

For example, the cutting edges used in Peely’s machinery have over 3,000 hours of service life, matching the performance of genuine parts at a fraction of the cost. “I have throughly tested compared and tested

products, and the results speak for themselves,” Peel says.

Tilly’s Crawler Parts has provided Peely’s Earthmoving with top-tier alternatives that deliver exceptional value. Its Bedrock rippers, for instance, have clocked over 10,000 hours and are still going strong.

Grant also favours the Bedrock stick rake, which outperforms more expensive competitors while being half the price.

“It’s not just about cost savings; it’s about selecting the right parts for the job,” he says. Peely’s sources a wide

Crawler Parts has provided Peely’s

range of components from Tilly’s, including wear parts, track blades, ripper boots, rollers, idlers and buckets for excavators.

Each of these parts is chosen for its reliability and performance, ensuring Peely’s Earthmoving continues to operate at peak efficiency.

Grant says he is mindful of warranties, knowing that there are potential trade-offs when using nongenuine parts, especially for critical components on some units

“Balancing cost-efficiency with warranty considerations is key, and with Tilly’s, I know we’re in good hands,” he adds.

The Tilly’s sales team plays a crucial role in this successful partnership. Its expertise and dedication ensure that Peely’s always has the best parts and support.

Grant often refers others to the team at Tilly’s, confident in the excellent service they will receive.

Peely’s Earthmoving continues to thrive, not just because of its history, but because of smart decisions, trusted partnerships, and a commitment to quality.

Under Grant’s leadership, and with the support of Tilly’s Crawler Parts, this second-generation business is set to continue serving Yannergee, Spring Ridge, and beyond for many years to come.

Distributed by Tilly’s, Bedrock has a reputation as one of the world’s

largest construction machinery attachment manufacturers, providing cost-effective alternatives driven by quality and built to last.

With a rapidly increasing level of demand for Tilly’s range of genuine, low-hour OE machines has come matching demand for quality, compatible attachments.

Attachments currently in stock at Tilly’s Toowoomba HQ include rippers, stick-rakes, scrub canopies, sweeps and cutter bars for dozers; front blades, mouldboards, push blocks and belly guards for graders; quick hitches that can carry buckets, forks, stick-rakes, lifting jibs and rippers for wheel loaders; and buckets, thumbs, grabs, tynes, cab guards and long-reach booms kits round out the range for excavators.

Customers purchasing machines from Tilly’s inventory can make

The partnership allows Peely’s to serve Yannergee, Spring Ridge and beyond.

their selection of complementary attachments and have them fitted by the experienced Tilly’s team in their onsite workshop prior to delivery. Add to this the extensive range of over 40,000 new alternative partlines in stock and Tilly’s customers are guaranteed quality, long-term solutions for their machinery maintenance and repairs.

Contact the team at Tilly’s who are always happy to assist, or check them out at www.tillys.com.au

Bedrock has a reputation as one of the world’s largest attachment manufacturers.

CCF QLD has announced this year’s winners of its Earth Awards, People’s Awards and Industry Training Awards

Civil Contractors Federation Queensland (CCF QLD) held its Excellence in Civil Construction Awards in front of a sold-out crowd at the Brisbane Convention & Exhibition Centre in August.

Recognising outstanding quality in civil construction – including roads, bridges, railways, marine structures and utilities – the CCF QLD Earth Awards acknowledge engineering techniques and achievements by the Queensland civil construction industry over the past 12 months.

These awards were presented in six groups according to project, shown here with their respective winners.

The People’s Awards were introduced in 2018 and celebrate the excellence of people working in civil construction across the state. Below are the winners of the 2024 CCF QLD People’s Awards.

Projects valued $5 to $10 million: DriveIT NQ Pty Ltd: BMD Constructions

Projects valued $10 to $30 million: QR Tablelands Bridge Replacement: Doval Constructions (QLD)

Projects valued $30 to $75 million: Smith’s Gap Fauna Crossing: RMS Engineering & Const. Pty Ltd

Projects valued greater than $150 million: Bruce Highway Upgrade: Caboolture-Bribie Island Road to Steve Irwin Way – Contract 2: Fulton Hogan Const. Pty Ltd

The CCF QLD Industry Training Awards recognise emerging talents in the Queensland civil construction industry who are currently studying, or have recently completed their studies with Civil Train (RTO #5708).

Certificate II in Civil Construction Student of the Year

Aaron Young, WorkCon

Certificate III in Civil Construction Student of the Year– Baxter McCort, CC P & C Pty Ltd

Certificate IV Student of the Year

Dimitrios Sofatzis, McIlwain Civil Engineering Pty Ltd

Encouragement Award

Rogan Rodgers-Falk, McIlwain Civil Engineering Pty Ltd

“We are fortunate to have such highly skilled individuals entering our industry, it is crucial that we recognise their accomplishments, ” CCF QLD CEO Damian Long says.

Diploma Student of the Year

Tomasz Walczak, KPI Services

Outstanding Commitment to Training and Skill Development (Individual) John Fonua, Bielby Holdings Pty Ltd

Overall Student of the Year

Baxter McCort, CC P & C Pty Ltd

Outstanding Commitment to Training and Skill Development (Employer) Albem Operations Pty Ltd

UKW prides itself on providing fast, cost-effective parts solutions to clients across Australia and further afield

The machinery industry is feeling the pinch of global market turmoil, brought on in part by uncertainty in the United States and ongoing conflicts worldwide.

With rising costs and increased difficulty in obtaining the right piece of machinery or the right part, customers are turning to companies like UKW Spares, which has overseas connections, knowledge of machinery and fast delivery times ensure that it stands out in a crowded marketplace.

Established in 1996, UKW Spares first specialised in dismantling old Komatsu machinery to on-sell the stripped parts to customers.

Eventually, the business branched out into different avenues and soon began importing its own catalogue of new parts to sell.

Today, UKW sells new and reconditioned parts, largely for Komatsu and Hitachi products, and boasts locations in Brisbane, Townsville and Campbellfield, Victoria .

Speaking to Earthmovers & Excavators, UKW’s sales development supervisor Edmond Woodford explains that his customers are finding it difficult to source good value, high quality machinery parts quickly – so they are turning to UKW for help, and the company is more than happy to be of service.

Woodford is based at UKW’s Brisbane branch, which opened for business in July 2022, and has experienced considerable growth and demand since. The branch stocks undercarriage,

UKW’s Brisbane branch opened for business in July 2022 and has experienced considerable growth and demand since

pins, bushes, o-rings, engine parts and a large range of filters all for the Komatsu and Hitachi ranges.

With two experienced salespeople on the ground – Ryan Webdale makes up the team with Woodford – and a large number and range of parts, UKW’s Brisbane branch is ready, able and willing to support clients right away.

“We’ve got two salespeople here and we hold a fair amount of stock so we are quite capable of helping people out straight away,” says Woodford.

“And anything we don’t have, if it’s accessible from overseas, we can usually have it here, depending on

CATERPILLARD5K2XL 2019,4,500hrs, VPAT, AROwired,sweeps,screensandMS ripper. 250hrservice,workshopreport..S1201. TA1225199. $249,900plusGST

CATERPILLARD8RSERIES2 2003,11,500hrs, SUtilt,CAT4Cylinderripper,servicedwith workshopreport.S1197. TA1225194. $369,900plusGST

CATERPILLAR259D3 2021,1,850hrs,4in1 bucket,250hrservice,verygoodtracks..S1200. TA1225198. $94,900plusGST

KOMATSUD61EX 2018,5,800hrs,6wayblade, MSripper,TopConwired.S1067. TA1163362. $309,900plusGST

CATERPILLARD5K2XL 2018,2018 CATERPILLARD5K2XL233.233. TA1166133. $258,390inc.GST

CATERPILLAR12M3 2015,2015 CATERPILLAR 12M3239.239. TA1166139. $362,890inc.GST

CATERPILLAR12M3 2016,Graderwith4,950hours. 14ftblade,joysticksteering,Autoshift,Lightpackage, soldwithMSripperandpushblock.This12M3Grader willbesoldclean,detailedandservicedwithour comprehensiveworkshopreport.S1013. TA1139678.

CATERPILLARD6K2XL 2017,4,900hrs, VPAT, AROwired,sweeps,screensandMS ripper. 250hrserviceandworkshopreport..S1199. TA1225197. $269,900plusGST

KOMATSUD39EX-24 2021,1,200hrs,6wayblade, 95HP,MSripper,suitnewbuyer.ThisD39EX-24willbe soldclean,detailedandservicedwithour comprehensiveworkshopreport..S1108. TA1173489. $274,890IncludingGST

JOHNDEERE450K 1400hrs,6wayblade, sweeps,screensandMSrippertobefitted. S1063. TA1163359. $229,900plusGST

CATERPILLARD6TLGP 2017,6,590hrs,ARO wired,6wayblade,tankguarding,Conventional undercarriage,rearscreen.Soldwith250hr serviceandworkshopreport.S1165. TA1198871. $419,000plusGST

CATERPILLARD6TXL 7,150hrs,VPAT,ARO wired,nextgenMSripper,goodU/C.Soldwith 250hrserviceandworkshopreport.S1198. TA1225196. $439,900plusGST

weight, within five to six working days.

“That’s a big benefit for clients, especially when they might have to wait three times that length to get it directly from OEMs (original equipment manufacturers).”

UKW is experiencing a high level of demand for parts as machinery operators seek quality parts at an affordable price, amid increasing costs globally.

“We certainly are seeing more demand due to the cost of things worldwide – globally, prices are going through the roof – and it’s great to give people a cheaper alternative,” says Woodford.

He adds that, with many people turning to parts instead of new, expensive machinery, UKW is in a great place to provide for customers,

thanks to the company’s strategic locations, expertise and ability to source quality parts in a timely and cost-effective manner.

“There are a lot of machines in northern New South Wales and south / south east Queensland and we can look after them, helping clients to maintain their machines without going out and buying new machinery – so being cost effective at the same time.

“We also help out in the Northern Territory and Western Australia as well.

“Between the three branches –Townsville, Brisbane and Victoria – we provide our services across Australia, New Zealand, Papua New Guinea and even New Caledonia.

“We’ve also got customers here in Brisbane that deal specifically with overseas clients as well.”

UKW says it is experiencing a high level of demand for parts as machinery operators seek quality at an affordable price.

UKW’s Brisbane branch has seen a lot of demand and growth in the two years it has been open, and Wood ford says the company is keen for that to continue.

“It’s basically a brand new branch – everything is nice, new and tidy and we’re willing to help customers wherever we can in any way that we can,” he says.

“We’re really keen to keep going and keep growing, and to give people a better service than they’re currently getting.

“That’s always the aim.”

For more information about UKW Spares visit ukw.com.au

MCCLOSKEYR155

2018,16'x5'twodeck,apronfeeder,readyforwork condition.SM177. TA1203700.

$295,000+GSTExMSCdepot

MCCLOSKEYJ50V2

2018,1270x735jawopening,Catengine,magnet,sidebelt 54tonne.KM83. TA999690.

$490,000+GSTEXDepot

MCCLOSKEYR70

Doubledeck,CatC4.4(130hp).SM330. TA1227402. POA

MCCLOSKEYJ50V2

2019,1270x735jawopening,Catengine,wellmaintained andregularlyserviced.KM91. TA1232332.

$620,000+GSTExKingIsland

MCCLOSKEYS130

2019,14'x5'doubledeck,Catengine,15'hopper.SM225. TA1198773.

$290,000+GSTExMSCdepot

MCCLOSKEYS190

2020,20'x5'twodeck,100mmgrid,readyforwork condition.SM237. TA1203702.

$345,000+GSTExMSCdepot

MCCLOSKEYI3CR diesel/hydraulicpowered,adjustableimpactapron 27,500kg.KM138. TA859307. POA

MCCLOSKEYI44RV3

2024,12x5doubledeckscreen,Catengine.KM137. TA1092446. POA

Distributor CJD Equipment discusses the services and technologies offered by Volvo Construction Equipment, and how these changes are revolutionising the earthmoving industry

Volvo Construction Equipment

(Volvo CE) is one of the world’s leading earthmoving machinery manufacturers.

Its Australian dealer, CJD Equipment, says the company is transforming how construction sites function through its focus on efficiency, safety and sustainability. By combining machine technologies with real-time data analysis, CJD says Volvo CE provides construction experts with the tools to improve operations and elevate productivity.

The partnership with CJD has also allowed Volvo CE to extend its solutions to the Australian earthmoving, quarry and mining markets, which have all seen Volvo’s machines making a difference.

Here, CJD outlines how Volvo CE is transforming the earthmoving and construction industry with its services and technologies.

CJD says the integration of its innovative technologies is a key way Volvo CE is leading the earthmoving and construction industry.

The Load Assist and Dig Assist technologies are important examples of this.

Dig Assist provides various tools for precise excavation, eliminating the need for manual site marking and depth checking.

It includes features like 2D profiling for levelling the site and in-field design for tasks such as trenching and foundation preparation.

On the other hand, Load Assist includes Volvo’s On-Board Weighing app, that helps operators move the right material – improving efficiency and reducing waste.

Volvo Co-Pilot further enhances the capability of these technologies, providing real-time insights into work performance.

Volvo CE’s Dig Assist provides various tools for precise excavation

The system can be updated wirelessly, so it is always able to be improved with the addition of new functionalities over time.

Committed to providing a safer construction environment, Volvo CE’s technologies are designed to enhance site-wide awareness, implement safety measures and facilitate real-time communication.

One of its essential tools is the Connected Map Office Portal, which CJD says not only improves safety, but also increases productivity.

This positioning service gives site managers a real-time visual overview of all machines, operators and temporary visitors on site.

Real-time adjustments to site conditions can be made, such as implementing one-way traffic or restricted zones, that can be instantly communicated to all users.

Having this level of visibility and control significantly improves awareness, reduces accidents and increases productivity, CJD adds.

The system works by extracting positioning data from machine telematics or Android and iOS devices with SIM cards and uploads it to a cloud-based Volvo platform.

As a result, a total site positioning solution is created for both Volvo and non-Volvo machines and temporary site visitors.

CJD says this can enhance site operations in several ways, including providing the ability to track machines in real time and tell operators where to load and unload on a site.

It can also help avoid traffic congestion, as the operator will be notified if another machine is approaching within a predefined single lane section. Operators can also be assisted in navigating the site and avoiding restricted areas.

As part of this solution, site managers can use the Safety Zones feature to set speed restrictions to actively control vehicle speeds in high-risk areas.

Borders and maximum speed limits can be set for specific areas,

Anaconda TD620

$356,500 + GST

Tracked Trommel Capacity up to 200T/H.

Terex Fuchs MHL331F

$380,200 + GST DEUTZ TCD engine. 12m reach. FOPS & front guard.

Hyundai R35Z-9

$55,000 + GST 2023, 100 hours. Quick Hitch and Mud & GP Buckets. OR123

JCB 3CX Backhoe Loader

$115,000 + GST 2019, 1040 hours. Tilting Quick Hitch. U582

Hyundai R80CR-9

$59,000 + GST 2020, 2300 hours. Quick hitch and mud & GP buckets. OR100

Dressta TD20MEXTRALT POA (stock image) Cummins QSC8.3, tier 3 engine. 179kW (240 fwhp).

Striker HQ1312

$695,000 + GST 2022, 1600 hours U581

Terex Fuchs MHL350D

$65,000 + GST 2008, 15,140 hours. Material Handler. U571

Hidromek HMK110CS Roller

$110,000 + GST 2021, 11T Smooth Drum Vibrating Roller. Tier 1. OR113

Hidromek HMK230 MG

$280,600 + GST 12ton, 3.1m blade with 360 degree turning angle.

Tigercat LH855C

$245,000 + GST 2016, 15,945 hours. Waratah HTH625 Attachment. U555

Anaconda SR520 POA

Finishing Screen, 2 & 3 deck models avaliable.

Anaconda FTR150

$187,400 + GST Feeder Loader. Capacity up to 700T/H. Stock image.

Anaconda TR7542

$142,000 + GST 1522 hours. Tracked Stacker Capacity up to 500 T/H. SN0231

Hidromek HMK310LC-3H4

$277,300 + GST 31.9ton DA hydraulics, quick hitch piping. HD bucket.

View over 100 new & used machines available for immediate delivery.

such as hazardous stretches of road – reducing the risk of accidents, injuries and damage.

The Office Portal function of Connected Map will enable Australian site managers to streamline operations and oversee multiple locations simultaneously, CJD says.

With the ability to provide instant communication of site changes to all users, safety is enhanced further, and the likelihood of accidents is reduced. This is because every team member is made aware of current site conditions and any new safety measures in place.

CJD adds that Volvo CE is looking at improving safety even more, by exploring the use of real-time data from customer vehicles.

This approach would include equipping vehicles with advanced sensors to allow for continuous and faster improvements to customer vehicles – constantly elevating safety levels.

By integrating its safety technologies currently, and with the vision for further advancements, Volvo CE has demonstrated its commitment to protecting workers, while enhancing site operations.

For those wanting to reduce their carbon footprint and increase

efficiency, Volvo CE offers its Site Optimisation service, which involves a three-step approach.

Starting with a pre-study, which validates the investment for the main study, experts visit a site, carry out interviews and conduct an initial analysis of available data.

The main study then goes more in-depth, using simulations and root cause analysis to develop an improvement plan.

This comprehensive approach provides insights that help construction firms become more profitable while reducing their carbon footprint.

Also setting targets to reduce its own greenhouse gas emissions, Volvo CE is aiming for net-zero value chain emissions by 2040, with further targets striving for a 50 per cent reduction in carbon dioxide

Dig Assist eliminates the need for manual site marking and depth checking

emissions across its operations and a 30 per cent reduction in product use emissions by 2030.

It has also introduced its CO 2 Reduction Program to support Australian customers’ carbon reduction efforts. The program follows a four-step approach – insight, analyse, improve and sustain – to help customers work towards their own goals.

Insight is the first step, which involves establishing a baseline using telematics data from connected machines to visualise CO 2 emissions over time.

Once this is completed, customers can analyse and assess machine data, material flow, fleet composition and operator behaviour to identify areas for improvement.

Actions can then be implemented to improve, such as Eco Operator training and efficiency services, with the aim of sustaining and maintaining lower CO 2 levels and setting stronger reduction targets.

It’s initiatives like this that showcase Volvo CE’s dedication to taking care of the environment and its role in shaping a more sustainable future for the construction industry.

To learn more about Volvo CE’s solutions and how they can transform construction projects, please contact your local CJD branch on 1300 139 804 or visit cjd.com.au

Connected Map provides site managers with a real-time visual overview of all machines, operators and temporary visitors on site

A municipal works, civil and commercial construction event.

17-18 September 2025,

In September 2025, a new event will be landing at the Melbourne Convention and Exhibition Centre. Converge will bring together leading decision makers in the Municipal Works, Civil and Commercial Construction space, to share the tools, ideas and technologies that are shaping these sectors.

Ant International designs its products to suit the preferences of its customers, with the capacity to produce attachments for some of the largest machines

Family owned and run, Ant International knows what it takes to build a quality earthmoving attachment.

From its workshop in Rocklea, Brisbane, attachments are manufactured for Australian conditions and are built to last.

Ant’s philosophy is that nobody knows what they want in an attachment better than an operator – it’s why the business carefully listens to what style and design its customers are looking for and offers tailor-made solutions.

Ant’s attachments are designed not only to suit individual working conditions, but to also suit the preferences of the customer.

In listening to its customers, Ant International builds every large bucket to specific requirements. Buckets can then be customised with wear packages and hardfacing, to better protect them from the elements – helping to last over a long period of time.

Offering further customisation, Ant International also offers various bucket tooth styles to make sure the attachment is suited to the job environment of the customer.

Whether it’s heavy duty or a standard tooth style, Ant has the capacity to add it.

“Every one of our large attachments is made to order and built for the customer, so they can do what they need to,” Ant production

manager Lex Treloar says.

“We want our customers to enjoy years of service from their new attachment.”

When it comes to designing large buckets, Ant takes into consideration what’s important to its customers.

It strives to ensure that its buckets perform well, allowing maximum productivity and attachment life.

“Our large buckets are designed with an aggressive digging angle for better penetration, used in combination with a double radius floor to reduce floor wear in the bucket heel region,” Treloar says.

With an emphasis on quality and durability, he says an Ant attachment is built to work hard for a long time –paying for itself time and time again.

Ant International’s attachments are built specifically for Australian conditions

According to general manager Charlotte Liao, Ant International has a manufacturing ability that stands out in the market.

“Usually, only bucket manufacturers and suppliers can offer attachments over 45 tonnes,” she says.

“Part of our strength is that we can build attachments for that size class and up to 100 tonnes.”

Low-cost imported attachments can attract customers through price and

Buckets can be customised with wear packages and hardfacing

With Yellowgate you don’t have to choose between hiring and buying machinery.

Our Rent Now, Buy Later solution lets you rent the gear you need today, with the flexibility of ownership options in the future.

There’s no need to lock yourself into long term finance agreements. At the end of your 12 month rental you can return, purchase at a reduced rate, or continue renting. Easy.

Discover why Australian businesses are making the smart choice to Rent Now, Buy Later.

1300 601 432 ygg.com.au

Attachments can be produced up to 100 tonnes

availability, but Ant International believes large size attachments need to take a different approach.

Sourcing a wide selection of premium high-grade steels, including the world class Swedish Hardox abrasion resistance wear plate, the business can tailor the type of steel to the working conditions of the attachment.

“We don’t have a generic off-theshelf approach when it comes to large attachments, and carefully consider how an attachment will be used when selecting the steel grade for our customers,” Liao says.

By creating products that are made of first-class steel, Treloar says it delivers the highest level of wear resistance and impact strength –saving time and money over the lifespan of the attachment.

He adds that choosing quality steel reduces overall bucket weight by 20 to 25 per cent, with its useful life being extended by 50 per cent.

By reducing the bucket weight, the capacity of a machine can be increased – with less wear occurring. Depending on the maximum load of a machine, the reduced bucket

weight will also allow more materials and heavier loads to be lifted.

“Many of our rock and quarry buckets are constructed using 400/450 grade abrasion resistant steel in the bucket shell,” Treloar says.

“This ensures our customers reap

the benefits of long-lasting wear and lower maintenance costs.”

For more information on Ant International’s attachments, visit ant-get.com or call 07 3710 6700.

The successful consortium has confirmed it can deliver the T2D project on budget.

Once finished, the T2D project will allow motorists to avoid 21 existing sets of traffic lights between the River Torrens and Darlington

The largest and most complex infrastructure project in South Australian history has reached a major milestone, with a preferred alliance partner now selected for the T2D project.

Following a procurement process which commenced in January 2023, a consortium comprising John Holland, Bouygues Construction, Arcadis Australia, Jacobs and Ventia was selected as the preferred alliance partner.

Arguably South Australia’s biggestever infrastructure project, the T2D project is the final section of the non-stop 78-kilometre North-South Corridor between Gawler and Old Noarlunga.

Once finished, the 10.5km section of road will allow motorists to avoid 21 existing sets of traffic lights between the River Torrens and Darlington by means of tunnels –which will make up about 60 per cent of the project.

The successful consortium says it can deliver the T2D project on budget, delivering significant travel, economic and community benefits for South Australians.

The consortium’s tender detailed a plan to procure three tunnel boring machines (TBM), instead of the two previously anticipated – which will mean both north and south tunnels can be constructed concurrently.

The three TBMs that will be used to excavate the T2D tunnels will be purpose-built for the local conditions they will encounter on this project.

The SA government says the additional TBM gives a reasonable expectation that this state-shaping

project can not only be completed by the stated 2031 deadline – but even earlier.