Komatsu’s proven intelligent Machine Control (iMC) concept has now penetrated markets worldwide. Thousands of operators and owners enjoy the safety and precision of Komatsu’s exclusive technology, factory fitted on both dozers and excavators, and the outstanding improvement in productivity it brings to the jobsite. Customer productivity is the driving principle behind Komatsu intelligent Machine Control.

Call us today on Sales: 1300 074 249 | Support: 1300 445 978 komatsu.com.au

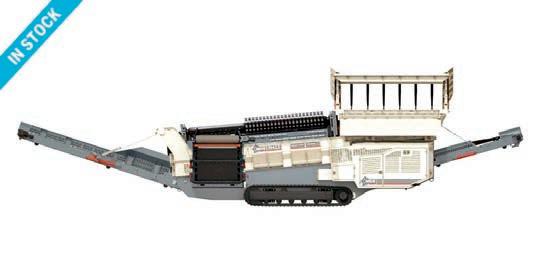

Production and efficiency are the hallmarks of the LIPPMANN 4244i-r impact crusher. An progressive material flow path from feeder to output material stockpile minimizes problematic material build up and results in less maintenance and downtime. The heavy duty build allows the crusher to stand up to the toughest conditions and materials.

Western Australia 8, 54–70

Unleash the future of farming with the revolutionary ECR25 Electric compact excavator and L25 Electric compact wheel loader from Volvo.

Proven performance

• Same performance as a diesel equivalent

• Outstanding visability and operator comfort

• Range of Volvo attachments

Innovative battery technology

• Lithium-Ion 48V battery - 40kWh

• Fast Charging possibilities

• Theft protected fixed battery

Big Enough to Trust, Small Enough to Care

Less maintainance

• Maintenance-free electric motors featuring auto shutoff to save wear

• Easy ground access to lubrication and maintenance points

Zero Emissions

• No power consumption when machine is not working

• Low noise level

• No emissions locally

CONTACT YOUR LOCAL BRANCH FOR MORE INFORMATION

Diesel Dirt & Turf will once again return to Sydney Dragway for a three-day event on April 12–14

Diesel Dirt & Turf returns to Sydney this month, bringing exhibitors from across the earthmoving industry into one place.

Friday 12 April will see Pickles once again undertaking a live equipment auction on the site from 1pm with around 100 lots scheduled to go under the hammer, covering mining, quarrying and construction equipment, forklifts and access equipment, mowers and farm utility vehicles.

Items donated by Semco Equipment will be auctioned off to raise money for The Children’s Hospital at Westmead, including a Toro riding lawn mower valued at $4,500, a Toro push mower valued at $2,000, a $2,500 Honda

generator and a $2,500 Dynavac compaction plate.

Takeuchi and Semco are sponsoring this year’s National Operator Excavator Champion event, with a live operator challenge taking place at the show. Each day the best operator will receive $1,000 in prize money.

Also on the site will be a demo area for live demonstrations of machinery as well as a wide variety of food and drink options for attendees.

With over 160 companies already signed up, here are a couple of names to keep an eye out for:

ITR Pacific Earthmoving machinery parts supplier ITR Pacific will be on site

Komatsu

Turf 2024. Image: Prime Creative Media

with its Track Group, three different sizes of rubber tracks, its off-road tyre range and a suite of final drive, ripper shank and excavator bucket products and tools. Also on the stand will be an engine rebuilt with ITR parts and a Just Easy Tools forklift. Visit Stand #L2 for more info.

Doherty Couplers and Attachments will be displaying its range of machinery attachments for construction, demolition, quarrying and mining. Key products include the manufacturer’s DH D-Lock coupler range, DH D-Lock Tilt coupler range and Powerdig bucket range as well as a variety of other bucket options. Visit Stand #D9 for more info.

CJD Equipment, the Australian distributor of Volvo and SDLG equipment, will have a selection of machines on site, including the new Volvo ECR25D electric excavator. There will also be the EWR170E wheeled excavator, ECR145 short swing excavator, EC300E excavator, ECR58F compact excavator and L70H2 wheel loader from Volvo alongside several items from the SDLG range: the ER616F mini excavator, ER636FL mini excavator, E660FL mini excavator and L938HS H-series wheel loader. Visit Stand #D11 for more info.

NSW distributor of construction and agricultural implements Ag-Pride will be showcasing its range of Berti mulcher attachments designed for excavators in the three to 10tonne range. Diesel Dirt & Turf will provide a snapshot of the extensive

Italian-built range of mulcher heads that are designed to cover everything from roadside vegetation management to pasture clearance. Visit Stand #A13 for more info.

The National Association of Women in Construction (NAWIC) will be in the demo area of the site this year, so if you’re checking out the diggers pop by and say hi. With the aim of promoting and supporting women to join and build their careers within the construction industry, have a chat with the team to find out more about upcoming events and how industry conditions can be improved for all workers, irrespective of gender. Visit the demo area for more info.

Onetrak is bringing a selection of Hidromek machinery to DDT, including the HMK210 wheeled excavator, HMK310 tracked

excavator, HMK600 motor grader, HMK62T backhoe and HMK130 roller, as well as an Anaconda DF410 scalping screen. Visit Stand #D4 for more info.

To get your ticket, visit: www.dieseldirtandturf.com.au

Komatsu has introduced a new 11-tonne underground hard rock haulage machine to the global market – the WX11 LHD

Komatsu has introduced the WX11 LHD to the global market, offering what the company says is ‘best-in-class’ breakout force and payload – helping to maximise productivity and provide a lower total cost of ownership.

The new machine boasts a 280 horsepower (209kW) engine and a 35,250kg operating weight, with the company saying the 11-tonne size provides a payload boost (an 8-10 per cent increase) above other machines in class.

Komatsu says the new machine offers underground hard rock miners an exceptional load, haul and dump (LHD) solution, integrating next-generation data management capabilities, operator ergonomics, intuitive controls and compliance with EU Stage V emission requirements, though a Stage III version is also available.

Komatsu says the machine offers several competitive edges in the 10-tonne LHD class for underground mine operators and contractors.

Aside from having adjustable ride control and onboard telemetry, the WX11 also has swing-out radiator fan assemblies to support quick washdowns, heavy-duty axles and optimised kinematics for what Komatsu says is superior breakout force. Its ease of operability, superior performance and ground-level maintenance position make the machine a game changer, Komatsu says.

“Developed through a close partnership between our experienced team and our longtime customers, this product reflects a shared commitment to design excellence,” Komatsu LHD and truck products director Ryan Karns says.

“The WX11 is the LHD every miner will want to have in their operation.”

Shipping to Australia this year, John Deere has introduced the next phase of its P-Tier dozers – the 950 P-Tier and the 1050 P-Tier

Replacing the large 950 K and 1050 K dozers in the market is John Deere’s next generation of P-Tier dozers.

The 950 P-Tier and 1050 P-Tier dozers offer enhanced visibility and improved safety features, John Deere says.

“The new P-Tier machines offer the durability and reliability our customers demand from machines of this size class,” construction & forestry product marketing manager Matt Costello says.

“The 950 P-Tier and 1050 P-Tier dozer models were updated with the customer in mind, helping them increase efficiency, visibility, and gradeability in even the most demanding conditions.”

Boasting an increase in engine power, the 1050 P-Tier features a revamped 13.6 L engine which replaces the 13.5 L engine in the 1050K.

John Deere says the new engine enhances durability, reduces fuel consumption and uses a single canister in the aftertreatment system to meet emission regulations without the need for a diesel particulate filter.

The 1050 P dozer also boasts upgrades to functionality and

efficiency, including a tag link and blade design that brings the 4.27m blade 25cm closer to the frame and gives the operator a better view of blade corners during precision work.

The 950 P features John Deere’s SmartGrade system, enabling mastless 3D grade control and giving it the power for both heavy cuts and finishing grades.

Both the 950 P-Tier and 1050 P-Tier models are now equipped with LEDs to make work easier at night or in lowlight conditions.

The company says safety is taken to the next level when using these two dozers – using its Operator Presence System.

This ensures the operator is sitting in the cab with the seat belt fastened, before the park brake is released –preventing accidental movement before the operator is buckled in.

Both new models now feature an optional heated and ventilated seat, which is air-suspended with adjustment controls.

Komatsu is back as Gold Sponsor of Diesel, Dirt and Turf Expo for another year, with new machinery and Retrofit kits on display

Komatsu is back again as the Gold Sponsor of the Diesel Dirt and Turf Expo, taking place April 12–14 at Sydney Dragway, with the team excited to showcase the next steps in Komatsu’s electric offering to Australian customers.

Located at Stand B1, on the aptly named Komatsu Street, Komatsu will have one of the largest displays of machinery and technology at the expo, with everything from excavators to wheel loaders and graders on display.

Komatsu will be out in force at DDT, with new electric machinery being unveiled to attendees

Komatsu sales manager – central region Chris Moroz says Diesel Dirt & Turf is a great opportunity to showcase Komatsu’s latest equipment and technology, which this year includes two electric excavators for customers to get a first look at.

“The PC210LCE-11 hydraulic electric excavator prototype will have its first official appearance at the expo, alongside the PC33E-6 electric mini excavator,” Moroz says.

“Both these pieces of equipment are battery-powered and deliver zero-emissions, without compromising on productivity or

Komatsu employs virtual reality as part of its training for new employees. For info on opportunities available, speak to the team on stand B1

comfort – something that is a big focus for us as a brand as we work towards a more sustainable future.”

Komatsu has committed to reaching zero carbon emissions by 2050 and taking its carbon dioxide emissions from product operations to half their 2010 levels.

“We’re excited to have them both on the ground and get real time feedback from customers and attendees on what they think of the machines, before they head off on a roadshow right across the country,” Moroz says.

Komatsu will also have some of its Smart Construction offerings on display, with a Retrofit Kit (RFK3DMG) on the PC138US-11 mid-sized excavator. Moroz says RFK-3DMGs allow conventional machinery to perform digital construction

techniques, using features such as 3D machine guidance, payload management and 3D construction data collection.

“RFK-3DMG can be fitted to a variety of machine sizes, makes and models, including older machines, making it an appealing addition for many attendees at Diesel Dirt & Turf, who come from a variety of businesses, whether that is large earthmoving fleets to smaller weekenders looking for their next piece of DIY equipment,” he says.

“We’re excited to have these machines on site for all to have a look at and showcase Komatsu’s latest innovations.”

For those interested in a career with the global machinery brand, the Komatsu team will be on site to chat about the opportunities

and roles available with the awardwinning company.

“We’re always on the lookout for more people to join our team, whether that be in service tech roles, sales, IT, or even engineering and white-collar roles,” Moroz says.

“The opportunities at Komatsu are endless. So come by Stand B1, and find out more about Komatsu, its products and services, and its people. We look forward to seeing you there.”

For more information on Komatsu’s electric and Retrofit Kit offering, visit: komatsu.com.au

The PC210LCE-11 hydraulic electric excavator prototype will be on show for the first time in Australia at DDT

Volvo Group member Rokbak is receiving positive feedback from Australian customers due to its dedicated sales team and aftermarket support

Since rebranding from Terex Trucks to Rokbak in 2021, the company has seen Australia become a key market for articulated haulers.

Based in Motherwell, Scotland, the manufacturer says Australia is firmly placed in the top 10 for its articulated dump truck (ADT) global market sales.

In 2023, Rokbak built relationships with new and existing customers, including delivering 22 trucks to an Australian infrastructure project.

Rokbak says customers and operators praised the trucks’ performance, comfort and low fuel consumption.

The size of Australia often means Rokbak trucks are working in remote locations, enduring long hours and tackling challenging terrain.

Due to these conditions, high performance and reliability are

non-negotiable and the trucks need to be operated correctly, as well as serviced, maintained and supported, Rokbak says.

Having a strong dealer partner in Porter Equipment, which holds healthy spare parts stock incountry, helps ease any spare parts concerns customers may have.

Dealer partners know they also have a Rokbak customer support manager on hand for any technical support and training, the manufacturer says.

“The fact that Rokbak has dedicated sales and aftermarket support based in Australia is critical and very much appreciated by our customers and dealer partners,” Rokbak regional business manager Lee Irving says.

“It’s not only about assisting new sales and new fleets of trucks, we have many older machines working in the region that we also support.

Rokbak regional business manager Lee Irving supports customers and dealers across the Asia-Pacific and Oceania

“Customers are dependent on these trucks, and we’re adaptable and ready to support them and our dealers whenever they need us.”

Since the 2021 rebrand, Irving says the company has generated heavy interest and been positively received across the Asia-Pacific and Oceania regions.

Rokbak currently offers two ADT models, the RA30 and RA40.

“Customers like the fact that both trucks are durable, powerful, easy to operate, comfortable and reliable,” Irving says.

Both truck models are made for tough jobs and worksites – from mines to quarries, infrastructure developments and commercial construction projects.

The RA30 features a 370 horsepower (276kW) engine and has a 28-tonne maximum payload and a 17.5 cubic metre heaped capacity, while the RA40 boasts a

Originally from England, Irving currently resides in Perth, WA, which he sees as great location to best serve Rokbak dealer partners and customers.

The Rokbak regional business manager often travels long hours across Australia or overseas due to the diversity of locations where the RA30 and RA40 articulated haulers are now operating.

“Those are the joys of job – we can be in a major city on one visit and then

the next we can be on a remote job site that takes a full day to get to,” he says.

This process is exciting for Irving and he sees job site visits as equally important to initial sales, and he is willing to go wherever Rokbak dealer partners and customers require support.

“We’ll gather operator and job site manager feedback, offer on-the-spot recommendations and get to see first-hand the dealer and customer appreciation for original equipment manufacturer support,” he says. Irving supports dealer partners and customers across a vast part of the world, allowing him to see the performance of Rokbak ADTs in a

wide variety of terrains and climates.

“You can find yourself on a call and the next thing you know you’re on the plane to Jakarta, Kalgoorlie or Kalimantan [Indonesia],” he says.

“Customers want to be reassured that they have both the local dealer and Rokbak support behind them, and that you’re dependable. That is what we do and that is what Rokbak offers.”

For more information on the RA30 and RA40 articulated haulers head to www.rokbak.com

The HMK600MG grader is used mostly for agricultural work on the Hay Plains, NSW

When the time came to upgrade his grader fleet, Kevin Walter turned to Hidromek and its HMK600MG to get the power and manoeuvrability he required

The charming town of Hay, located in the western Riverina region of New South Wales, serves as the administrative centre of the Hay Shire local government area. Situated in a fruitful agricultural district on the expansive Hay Plains,

the town is conveniently located approximately halfway between Sydney and Adelaide.

This is the home base for Kevin Walter, who recently bought a Hidromek HMK600MG grader from Onetrak for his

work with agricultural clients, primarily graziers.

His work includes constructing tracks and roads, clearing channels, building trenches for the installation of polypipes, dozing old fences and levelling the ground for new fences, ground tanks and dams. With 46 years of experience in the field, his business covers up to 100km in all directions of the Hay Shire area.

Walter takes on the majority of the work himself, calling on additional operators when needed. With a fleet of four graders, he can leave one machine on-site as necessary. For customers who require trenching, he typically digs the trenches, leaves a grader, moves on to another job while the pipe is being laid and then returns to fill the trenches.

In addition to his fleet of graders, Walter has several rollers, which he primarily uses for constructing bush tracks. If necessary, he can also hire other equipment such as a water truck or a scraper to complete the job.

The HMK600MG stood out for having both wheeled and joystick control as well as a powerful air conditioning system

Walter decided to purchase a new Hidromek grader as his three existing graders have over 17,000 hours on them, necessitating an upgrade for his fleet. With the Hidromek brand catching his eye, he contacted Onetrak to source the HMK600MG.

Walter says the HMK600MG stood out for him as it comes with a steering wheel and a joystick, as well as a powerful air conditioner, which is crucial when working in Hay’s hot climate.

He also highlighted the importance of the HMK600MG’s reversible radiator fan, which is a standard feature. This is especially helpful because the dusty conditions of Hay require daily radiator maintenance, however, with a reversable radiator fan, the job of cleaning the radiators is so much easier. Walter notes that this is an expensive added option for many other brands.

After putting the Hidromek grader to the test, Walter, a seasoned user of graders, has compared it with other leading brands.

“It is the most stable grader I have ever driven, and I have driven them all over the years,” he says.

Although the joystick controls were different from the normal pedestal joysticks he was used to, he found it surprisingly easy to adapt to the new system. He has been able to construct trenches with stable batters for recycled channels up to 3m deep, and he feels secure knowing that the Hidromek grader can handle this challenging task with ease.

He is also impressed with the HMK600MG’s speed, boasting over 200 horsepower (150kW), allowing it to reach a maximum forward speed of 45km/h and reverse speed of 42km/h. The Hidromek grader’s quickness, combined with its great turning circle and the other features highlighted, has made Walter an avid supporter of the brand – even though he had never encountered Hidromek or its graders before.

For the past three years, Walter has been working closely with Onetrak’s Tumut branch in NSW, saying that Onetrak and Hidromek have been excellent partners.

Based on his work, Walter made a small change to the side mesh

panel that helps to prevent grass from entering the radiator. He also added his own hinges, so the panels could be lifted, allowing access to the radiator to blow it out.

Hidromek was made aware of this and when Tim Jackson from the Onetrak Tumut branch came out to do the 1,000-hour service, Hidromek had redesigned the side panel to include the hinge and installed it on the machine at no extra cost.

Walter says that the Onetrak team, particularly Jackson, has been outstanding in terms of service and promptness in resolving any minor issues that have arisen, adding that proper backup and maintenance are critical to ensure smooth operation.

Onetrak is the official dealer for Hidromek equipment in Australia. Visit www.onetrak.com.au or call 1300727 520 to get in touch with Onetrak and the team.

Developed and tested in Australia, Huski features best in show strength, manoeuvrability and driver comfort, and can handle operating loads from 320kg to a whopping 900kg.

Best of all Huski skid steer loaders are backed by Toyota’s trusted reputation for delivering quality equipment and loyal after sales support.

So if you’re looking to put your business at the head of the pack, you can’t go past a Huski. Australia’s Top Dog in the Dirt.

Bred Toyota tough, Huski skid steer loaders are the perfect mix of performance, reliability and durability.

XCMG has partnered with Shell to launch XCMG tailored lubricants

XCMG has announced a global partnership between XCMG and Shell Lubricants.

This strategic partnership leverages the lubrication expertise of Shell with the cutting-edge technology of XCMG to provide stateof-the-art XCMG-branded lubricant solutions that optimise equipment performance, reduce downtime and enhance operational efficiency.

“Locally, XCMG Australia is excited by the prospect of teaming up with the exclusive Shell Lubricants Macro Distributor in Australia, Viva Energy, to bring XCMG-branded lubricants to our XCMG customers,” XCMG Mining Equipment Australia national parts and warehouse manager Gary Koglin says.

“The launch of XCMG tailored lubricants will provide XCMG’s customers with confidence in their lubricant supply and performance.”

Viva Energy lubricants sales and marketing manager Renee Reilly adds: “Since the establishment of XCMG Excavator Division in 1999, Shell has been co-operating with XCMG in the field of lubrication.

“In recent years, with the accelerated pace of XCMG’s equipment business, Shell and XCMG have strengthened their partnership, jointly launching lubricants tailored for XCMG to bring the best out of XCMG equipment.”

The new range of lubricants is tailored to XCMG machinery

Viva Energy technical specialist

Silvana Farrugia says: “Lubricant is an indispensable part of the operation of construction machinery. The XCMG tailored lubricants developed by Shell will bring even better protection to XCMG’s equipment with world-class product standards and quality assurance.”

Lubricants are used to reduce friction, wear and corrosion, and can also remove dirt and deposits inside the machinery, providing protection for industrial equipment and improving its operating efficiency and life.

“Contaminated fluids are known to cause up to 75 per cent of repair costs and equipment downtime, including 65–75 per cent of bearing failures*,” Farrugia adds.

“Routine fluid analysis combined with high-quality lubricants developed with Shell Lubricant

technology can better protect construction machinery, resulting in less downtime.”

Shell has five R&D centres around the world and more than 300 scientists and engineers engaged in the research and development of lubricants and greases. With the industry’s leading technologies, Shell continuously invests in R&D and makes breakthroughs in innovation, always putting customers at the centre of its efforts to provide highquality products, which have won the praise and trust of its customers around the world, it states.

“Indeed, Shell Lubricants has been named the world’s leading supplier of finished lubricants for the 17th consecutive year by Kline & Company,” Reilly says.

Koglin encourages workshop and equipment owners to get in touch with XCMG Australia.

“By stocking genuine XCMG lubricants, users can be sure that they will have the right oil for their equipment,” he says.

“Come and visit us at Diesel Dirt and Turf, April 12–14, Sydney Dragway, Eastern Creek.”

For more information about Shell’s range of XCMG lubricants, contact Gary Koglin directly on 03 9796 3075 or 0423 528 314 or contact Viva Energy, Shell Macro Distributor, Technical Helpdesk on 1300 134 205.

* Part Marketing & Uptime,

In addition to XCMG Lubricants, as an Authorised Shell Lubricants Reseller we offer a comprehensive range of Shell Lubricants and will assist in selecting the right lubricants for your equipment needs.

Specialist services company XR3 has purchased a Shantui amphibious excavator from Cobra Equipment Sales to support its hydraulic mining operations

As the services and product deployment arm of the broader Xenco group, XR3 combines experienced onsite personnel with the right equipment, services and products to deliver agile, rapid response solutions to their clients.

With a team boasting extensive expertise across diverse industries, XR3 specialises in providing tailored solutions that enhance business efficiencies and drive commercial success.

XR3 supplies rapid response and fit for purpose solutions for each business’ specific requirements. Its range of expertise includes hydraulic mining, dewatering solutions, amphibious excavation, industrial services and a wide selection of industrial products.

XR3 also undertakes hydraulic mining contracts, such as recovering waste from tailings dams for reprocessing.

Right now, XR3 operations manager Michael Hyde says the company is reclaiming coal tailings at an operation in Central

Queensland, which means it will be recovering coal for steel production that otherwise would have been left in the waste dam.

“After the mining process, you’ve dug materials up and put it through processing plant that separates out the materials that can be sold from the rest,” he says.

“The waste product at the end comes out like a sludge or a slurry. This is then pumped into a dam to settle and let the water drain out of it.”

With the tailings dam material presenting unique challenges around how to safely operate heavy machinery on unstable, sludgy ground, XR3 recently called on the expertise of Cobra Equipment Sales, which has provided the ideal solution – a Shantui SE305LCW amphibious excavator.

Hyde says that the site requires the excavator to get into places that other standard machines can’t.

“We are operating on a tailings dam, which is essentially the partially dried

XR3 has called upon a Shantui SE305LCW amphibious excavator to be used in a tailings dam

remains of a reject slurry so there are some restrictions on the equipment that can operate on it,” he says.

“The amphibious excavator will be able to give us more flexibility to access wet areas to help cleaning and set up in tailings dams.

“This model was of particular interest to us because it is mounted on pontoons, which essentially allows it to float on water,” Hyde says.

While the amphibious excavator might not be used to float on pure water in this operation, Hyde says this capability can be a handy asset.

“The idea for us is to have a lowground pressure machine that can move on loose materials and get into places other excavators can’t.”

With pricing also being an important factor for XR3 when deciding on an amphibious excavator model, the Shantui SE305LCW stood out for value for money, with Cobra Equipment Sales offering a cost-effective machine compared to other brands, Hyde says.

Cobra Equipment Sales Based in Brisbane, Cobra Equipment

Cobra Equipment Sales imported the 48,200kg excavator specifically for XR3

Sales is an authorised dealer and distributor of Shantui equipment, importing it from China. Established in 2005, Cobra has long focused on high quality Chinese manufacturing – partnering with Shantui since 2018, which it says is the world’s largest manufacturer of bulldozers.

When XR3 called with an inquiry about an amphibious excavator, Cobra Equipment Sales imported the 48.2 tonne (48,200kg) machine specifically for Hyde’s team.

“We wanted to show XR3, as well as our other customers, that we can do orders that are a little bit out of the box,” Cobra Equipment Sales founder George Nason says.

Nason says larger companies will tend to focus on standard earthmoving machinery, but with Cobra Equipment Sales being a smaller operation, this gives it the capability to diversify into different areas.

“We’ve always been able to tailor to customer needs and if they want something unique we can source the specific equipment to meet their requirements,” he says.

The amphibious excavator is mounted onto pontoons, allowing it to operate in wetland areas

After liaising with XR3, Cobra Equipment Sales brought in the 2024 model amphibious excavator to work in the wet mining operation.

Nason says the Shantui SE305LCW can be used in a range of different applications, particularly those with waterlogged land.

“Lots of these machines have been used to clear marshland or used for drainage,” he says.

“They can move through mud easily, virtually float on water, dig channels to drain areas and are also able to clean waterways out.”

He adds that amphibious excavators are a rare sight in Australia, so the new Shantui will stand out on the dam.

“You would see a lot more of these amphibious excavators in Asia because there are a lot more lowlying marshlands,” he explains.

Shantui specialist

When asked what separates the machine from other amphibious excavators, Nason says it comes down to the quality and cost-effectiveness of the Shantui brand.

“Most of the other big excavator companies have their own amphibious excavator but they’ll probably be three times the price of the Shantui models,” Nason says.

“The Shantui amphibious excavators are much more costeffective and provide the same quality as the other competing brands.”

Focusing on selling quality machines, he says that Shantui is an example of a premium brand being exported from China.

“Sometimes imported products lack in quality, but we stand behind the Shantui brand and its durability for Australian customers.”

Cobra Equipment Sales backs every machine with a warranty and prides itself on supplying high level ongoing aftersales support.

“If anybody has a problem, we don’t make a fuss, we just fix it,” Nason says.

For more information about the Shantui SE305LCW amphibious excavator, visit cobraequipmentsales.com.au or call (07) 3379 9419.

• Intelligent, AI-powered cameras accurately detect and track humans, while ignoring inanimate objects.

• Real-time audible and visual alerts warn the operator of pedestrian proximity and exclusion zone breaches.

• Up to 360° protection from up to 4 cameras.

• Video and event data stored locally or sent to the cloud for remote access and management notifications and reporting.

• Doesn’t require RFID tags, specific safety vests or other hardware.

• Modular and customisable to suit any machine and application.

Designed for tough Australian conditions, Doherty Couplers & Attachments’ DH D-Lock Tilt coupler range is well-known for being compact in design, powerful and virtually maintenance-free

The D-Lock Tilt range, which incorporates a precision-built actuator ensuring trouble-free operation, allows operators to simply tilt all attachments up to 180 degrees rather than having to move the entire machine. Doherty QLD & NT territory manager Jack Hartley explains that this versatility improves productivity; increasing profits for the end user.

The D-Lock Tilt coupler has been purposely designed with a compact and narrow body for better visibility and performance. In addition, Doherty’s D-Lock coupler with its patented DPL+ safety system always comes standard on the D-Lock Tilt range, “giving it serious benefits over other brands”, Hartley says.

In fact, Doherty is one of the few manufacturers globally to offer quick couplers that are 100 per cent compliant to Australian standard AS13031:2023, European standard EN474, International standard ISO 13031 and all major contractor policies.

“Our patented DPL+ system reassures the operator by having three impressive safety measures in place in the event of a loss of engagement force,” Hartley says.

“Both the front and rear pins are locked and the primary jaw safety lock is backed up by an independent heavy-duty compression spring, preventing the primary lock from releasing.”

Because the jaw lock pawls are spring biased to the locked position, “unlocking will only occur when the operator intends to do so in a controlled and safe manner”, he adds.

Along with the D-Lock’s safety system, Hartley highlights that the chassis has allowed for a more compact design and improved the basic weldment strength.

“The lifting eye forms an integral part of the side plate for structural integrity and fits multiple bow shackle sizes while retaining a high, safe working load,” he says.

“We’ve increased the cylinder size on the 240 and above models

range incorporates a precision-built actuator, ensuring trouble-free operation

The strength and sturdiness of the D-Lock Tilt coupler handles heavy loads with ease, as seen here on one of K.V.A Excavations’ machines

to match this power increase, and our 14-tonne and above models also feature multi-pin size pickup capability – further increasing its versatility.”

With the D-Lock Tilt range covering machines from one to 50 tonnes, Hartley says customers love the performance.

“Customers like the D-Lock Tilt’s durability – it continually proves its strength when working in the rough civil conditions that our clients are accustomed to,” he says.

“The range also comes with an industry-leading two-year or 3,000-hour [whichever occurs first] warranty for further peace of mind.”

Located in a purpose-built, stateof-the-art facility in Wacol, Brisbane, Doherty’s impressive 3,350 square metre internal workshop and storage space, with an extra 1,200 square metres of undercover storage and 2,000 square metres of yard area provides ample space to further expand its manufacturing and assembly operation.

“With additional investment in people, machinery and space, it gives us increased productivity, an ability to service a broader range of industries and a more widespread reach for our D-Lock Tilt range and other earthmoving attachments across Australia,” Hartley says.

For more information contact

Doherty Couplers and Attachments on 1800 057 021 or email

sales@dohertydirect.net

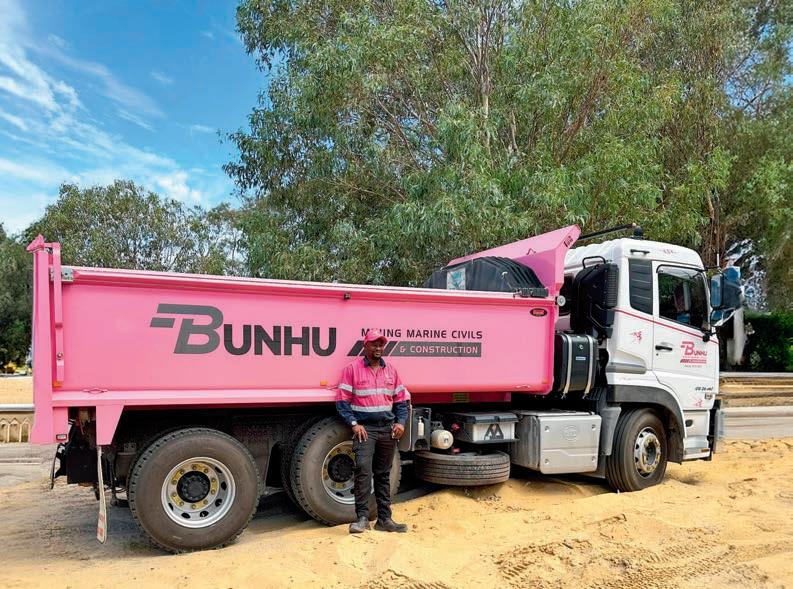

For Bunhu Mining owner Terry Danda, Yellowgate’s rent-to-buy approach to supplying equipment has been a huge boost for his business as he looks to expand his fleet

The path to accessing finance for equipment isn’t always as straightforward as going to the bank. Particularly for small business owners who may not have an extensive credit history, the bank lending algorithm can be a hurdle to those looking to grow their fleets.

Terry Danda, who set up Bunhu Mining in Perth after emigrating from Zimbabwe, is one such business owner who faced significant challenges in establishing himself in the industry.

“I started my business here in Australia in 2017 as a sole trader, but

Yellowgate has helped Terry Danda purchase the earthmoving gear he needs to grow his business

I’ve worked in the industry since 2003,” he says.

“I’m a qualified boiler maker, but when I first moved to Australia, I couldn’t get any work doing that. So, I started doing little bits of everything – working as a brickie’s labourer, doing home renovations, gardening, fencing and roofing.

“I raised money to start buying earthmoving gear. I was buying equipment from farms down south, refurbishing it and using it.”

After trying his hand at a variety of trades, Danda eventually decided to make the move towards running his own business – Bunhu Mining.

“We do mining, haulage, crushing, processing, civil works, a bit of construction, and we’re working on starting a full-blown marine side too,” he says.

“I started doing earthmoving and demolition first. From there, I bought trucks and got into civil works in Marble Bar, WA in 2020.

“I got a contract to do mining and haulage in Port Hedland, then expanded into processing and crushing, as well as major civil works.

“We’ve done some very rewarding jobs as a contractor for Main Roads

WA projects, including for major civil company Fulton Hogan.”

The business has continued to grow in recent years, with Danda applying his experience of running a trucking firm back in Zimbabwe where he managed an operation of 26 haul trucks carting coal, grain and general goods.

“I also have experience doing site works for acreage properties, as well as demolition and earthworks,” he says.

When he was looking to get his new Bunhu Mining business off the ground, Danda says his equipment procurement options were limited. As a result, everything was financed off his own back – raising money and funnelling it back into the business.

“Whatever money I was being paid was going back into Bunhu Mining, because as such a new business, my other options were limited,” he says.

“That changed in 2019 when I started getting a bit of funding. I was able to buy some small earthmoving gear to do some demolition work, but still needed to find another solution to help keep the business growing.”

Yellowgate, with its rent-tobuy option for a wide range of earthmoving machinery, provided

the solution. Danda has subsequently purchased four pieces of equipment from Yellowgate, with more planned in the near future.

“Yellowgate is structured in a way that they are very flexible, and willing to go that extra mile,” Danda says.

“Nowadays it can be very difficult to find equipment solutions backed by common sense.

“For some, procuring equipment is just about numbers and spreadsheets. They haven’t been on the ground to see what’s really happening. But Yellowgate speaks the language of the earthmoving and mining industries, and is willing to provide an ear.

“And for any business owner who can take an opportunity like that and use it wisely, they can very quickly build something successful.”

Yellowgate Group offers equipment rentals across various sectors including construction, civil, mining, agriculture, transport and manufacturing.

With a focus on 12-month rental agreements, a client can access the machinery it needs, for as long as it needs, without having to commit to a purchase. If project needs change or further work is procured, the client has the opportunity to buy the machine if it suits their circumstances, providing a greater degree of flexibility compared to pure hire or purchase options.

The process is a matter of three simple steps:

1. T he customer specifies the equipment needed, or Yellowgate can help source it

2. Yellowgate purchases the equipment and rents it to the customer

3. At the end of the rental term, the customer can rent, recontract, purchase or return the equipment.

To find out how you can leverage Yellowgate’s service on your next project, visit: www.yellowgategroup.com.au

The heavy-duty Hercules HD668D wheel loader has been one of the most popular models at Brisbane Mini Excavator Sales (BMES), with the company saying it is the perfect size for most earthmoving needs

As one of its most popular wheel loader models, it’s no surprise that BMES only has limited stock left of its Hercules HD668D loader.

The Hercules distributor is encouraging its customers to get in quick before this impressive machine sells out.

This 2024 model loader is part of Hercules’ Heavy Duty range, designed for many different applications.

BMES has sold this model for customers to use in vegetation clearing, with a six-metre rake, as well as general earthworks and ripping –once fitted with hydraulic rippers. Customers have also purchased

this loader to be used for the building, repairing and cleaning of dams, which is a crucial factor in today’s environment of water management.

The heavy-duty loader boasts a 245 horsepower (182.7kW) Caterpillar nominated engine, a 21 tonne operating weight, six tonne rated load and a 4.2 cubic metre bucket capacity.

A hydraulic quick hitch also comes with the loader, allowing attachments to easily be connected and disconnected by the operator.

Sales executive Steven Ragenovich attributes the Hercules HD668D’s popularity to the way this loader can act like a toolbox for operators.

The Hercules HD668D wheel loader has been one of the most popular models at BMES

When purchasing the Hercules HD668D loader, customers are offered optional attachments, such as the three-pronged hydraulic rear rippers – which can be fitted inhouse at BMES’ engineering shop.

Ragenovich says the hydraulic rear rippers are a heavy-duty attachment easily capable of loosening and breaking up hardened soil.

The loader itself can also have connected protective guard attachments to shield the vital components of the loader with side protection and undercarriage plating.

Images: BMES

“The transmission guard attachment prevents foreign objects, like rocks, from damaging the transmission, while the rear-guard protects the back of the loader – also acting as counterweight,” Ragenovich says.

Balancing the loader’s centre of gravity, Ragenovich says the rearguard can add an extra 500kg to the rear end of the machine, giving greater stability.

To complement the Hercules HD668D, a 6m three-piece stick rake attachment can be installed for clearing vegetation and scrub. An additional cutter bar can also be fitted on request from the customer.

Capable of lifting up to six tonnes, a pallet fork attachment can be

fitted onto the quick hitch to lift a variety of heavy items.

“I’ve seen the pallet fork attachment being applied to lift 40-ft (12m) containers and cattle troughs, just to name some examples. Operators generally know what they can lift with this attachment,” Ragenovich says.

“The loader acts as a tool carrier in a way when it has all these attachments connected to it.”

Having been well received with BMES’ customers, Ragenovich describes the loader’s ‘A1 premium quality’ as a motivation to buy.

“This particular machine is one of our most popular models, customers like that its highly torqued,” he says.

“Customers have said the air conditioning is of top-notch quality

and they have found the loader’s maintenance to be very easy and very accessible when being serviced.”

Customers can also be assured that when it comes to parts and technical information BMES is more than capable, through its dedicated parts and workshop divisions.

BMES promises a 2,000 hour/twoyear factory warranty on the entire machine, while the engine has a 4,000 hour/four-year warranty.

For more information on BMES’ Hercules HD668D wheel loader, call (07) 3807 4333 or visit bmesales.com.au

To meet the housing needs of Australia’s growing population, state governments need to assert more control to get projects moving

The cost of living and housing crisis is dominating the headlines at the moment across the country. It is a symptom of a system under stress exacerbated by poor government policy now and in the past.

There are several initiatives being touted to provide more and cheaper housing for the growing Australian population.

In Queensland, the government’s policy to build a million homes by 2046 is underpinned by:

• i mproving the planning system to deliver more quality homes in the right locations faster than ever before

• bu ilding on current support options and law reforms to assist renters

• support for first home buyers

• boosting social housing

• providing more funding for service providers and help for vulnerable groups to support ending homelessness.

Whilst these initiatives are headliners, those close to the development industry understand that the issues of providing more homes quicker and cheaper are complex but not insurmountable. The problem is there are years of locked-in red tape and political blockades that need to be unwound and eliminated.

Queensland’s announcement is, and will be, like other announcements across the country, and all will be a double-up of targets set by the federal government.

Federal government policy will need to assist each scheme in each state and can’t be developed in isolation.

Damian Long, CEO CCF QLD

Damian Long, CEO CCF QLD

If we look at the numbers in Queensland, one million homes by 2046 will be approximately 45,400 homes each year.

The Queensland government’s own data for dwelling approvals shows that since 1983 this figure has only been achieved five times.

For 2022 to 2023 there were a total of 35,222 dwelling approvals in Queensland and a 10-year average of 40,284. There is a comparable difference between approvals and completions, but regardless of the dataset the magnitude of the ambition is very high.

People choose different locations to live in for different reasons. These reasons will differ depending on their stage of life. The location and types of housing must consider this.

The state government must go further than its headlines to achieve its target.

It must take control of state-wide planning and take the decisions for approval of development applications out of the control of local government. Whilst local amenity and environmental impacts must be considered, the planning of housing must be made against the needs of where housing should be located. These considerations must be made in conjunction with overall infrastructure planning.

Additional housing requires supporting infrastructure to be put in place first, such as stormwater management systems.

Image: Olha/stock.adobe.com

There are plenty of developments that have been held up for years, and in some cases as much as 20 years, due to local governments’ reluctance to quickly process applications or consider providing visionary infrastructure. Whilst their concerns may be legitimate based on the want of their local constituents or their financial position, this does not help to deliver dwellings fast enough to outstrip demand.

An observation is that the cost of housing is based on the house itself. Queensland is looking at alternative housing products such as modular construction. Whilst these initiatives will help to reduce the cost of the dwelling, the biggest impact will be on everything else that supports the dwelling.

Apart from speeding up the approval process, which will reduce holding and consultancy costs, attention must be given to the balance of the iceberg.

Dwellings cannot be constructed unless supporting infrastructure is in place first.

Infrastructure such as sewerage and water supply, including storage and treatment plants, stormwater and stormwater quality systems, telecommunications, power, roads and other transport infrastructure all need to be built first and contribute to the cost of the dwelling.

Government policy must focus on delivering this infrastructure more productively.

This can be done by addressing productivity in human capital, less rigid specifications that leverage emerging technologies, rationalisation, economies of scale and speed to market. The infrastructure cost should not be borne by the developer who will in turn pass it on to the consumer.

Financial assistance may take the edge off some of the demand pain points , but it does little to help supply.

Whilst immigration both from overseas and interest remains high and is projected to remain so, I fear the strategies to date are going to miss the mark.

Here are upcoming construction events for 2024.

Information was current as of going to press

Diesel Dirt & Turf is Australia’s premier earthmoving industry event that continues to attract support from all market sectors in earthmoving, infrastructure, residential development, public works and public space management. Located at Sydney Dragway, the event will include an operators challenge and Pickles equipment auction.

WHEN: April 12–14, 2024

MORE INFO: www.dieseldirtandturf.com.au

This two-day event focuses on the construction, architecture, engineering and infrastructure industries, bringing together contractors, architects, engineers, housebuilders, developers, government and construction professionals. Ten stages cover topics such as BIM, construction safety, site safety, architecture, infrastructure, digital construction, new rules, HVAC, sustainability and government, while more than 400 exhibitors will fill four exhibition halls.

WHEN: May 1–2, 2024

MORE INFO: www.sydneybuildexpo.com

Located in Paterson, NSW, Tocal Field Days is an agricultural field day event that includes some construction machinery exhibitors.

WHEN: May 3–5, 2024

MORE INFO: www.tocalfielddays.com

The Trades Fit expo demonstrates the exciting world of trade and tech industries and the rewarding, well-paid career opportunities they can provide to young women.

WHEN: May 8–9, 2024

MORE INFO: www.vic.gov.au/trades-fit-youngwomen-trades-and-tech

Organised by the Australian Constructors Association, the Future of Construction Summit provides an opportunity for leaders representing all sectors of the construction industry to engage in discussions about reform and the opportunity to create a more productive and sustainable industry.

WHEN: May 14–15, 2024

MORE INFO: futureofconstructionsummit.com

Primex works with specialists within the civil construction and forestry industries to build an event that features leading national suppliers committed to servicing NSW and southern Queensland industry sectors. The latest services, technologies, equipment and machinery are presented with demonstrations and contractor, trade and operator networking activities.

WHEN: May 16–18, 2024

MORE INFO: www.primex.net.au

The Workplace Health and Safety Show will feature a program of events including live demonstrations, seminars, interactive forums and round table discussions on health, wellbeing, manual handling, major hazards, innovation, technology advancements, new safety products, injury prevention and height safety, amongst other topics.

WHEN: May 22–23, 2024

MORE INFO: www.whsshow.com.au

The 13th Annual Queensland Transport Infrastructure Conference returns to the Brisbane Convention Centre to profile a vast range of transport and infrastructure works critical for a growing state. The program will highlight the $32.1 billion investment towards a range of infrastructure including road, rail, marine, passenger transport and active transport projects, which will all contribute to enhancing connectivity, improving safety, and supporting economic growth across the state.

WHEN: May 22–23, 2024

MORE INFO: www.qldconference.com.au

Focused on the equipment rental market in Australia, HIRE24 will be held over two days in Sydney. Focusing on the latest in technologies and equipment, the program includes keynote speakers, networking opportunities for young industry professionals and workshops alongside an exhibition.

WHEN: June 4–6, 2024

MORE INFO: www.hriaconvention.com.au

A primary industry field day, Elders FarmFest promotes a wide range of earthmoving and excavating machinery alongside tools, attachments and equipment.

WHEN: June 4–6, 2024

MORE INFO: acmruralevents.com.au/farmfest/ home

MCCLOSKEYR155 2018,16'x5'twodeck,apronfeeder,readyforwork condition.SM177. TA1203700. $295,000+GSTExMSCdepot

MCCLOSKEYJ50V2 2019,1270x735jawopening,Catengine, 54tonne.KM87. TA1096688. $490,000+GSTExMSCdepot

MCCLOSKEYTS4080 24mtrackedstacker,1000mmbelt,hydraulictail andtopfold.CM171. TA908173. POA

MSCHYDRASCREW100 2023,hydraulicorelectricdiveinstock.w69. TA1096697. POA

MCCLOSKEYS130 2019,14'x5'doubledeck,Catengine,15'hopper. SM225. TA1198773. $298,000+GSTExMSCdepot

MCCLOSKEYS190 2019,20'x5'twodeck,100mmgrid,readyforwork condition.SM226. TA1203702. $295,000+GSTExMSCdepot

MCCLOSKEYWS3250 15mstockpiler,800mmbelt,electric/hydraulic/diesel .CM166. TA1113822. POA

MCCLOSKEYI44RV3 2023,I44Rv3impactor,12x5doubledeckscreen,Cat engine.KM124. TA1092446. POA

www.msc.net.au

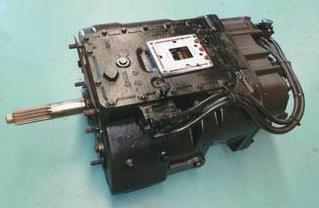

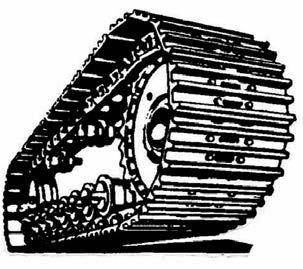

Quality is key to ITR’s comprehensive parts and servicing offering

In the dynamic landscape of the Australian earthmoving industry, ITR stands out for its unwavering commitment to quality, performance and customer satisfaction. The world-renowned Italian brand, best known for its complete range of aftermarket earthmoving machinery parts, is one of the fastest-growing companies in the industry, providing a one-stop solution for most makes and models of earthmoving equipment.

With an expansive network of branches, warehouses and workshops strategically positioned throughout the Australian market, alongside industry experts stationed in every region, ITR Pacific is uniquely positioned to deliver an exceptional customer experience.

Offering a comprehensive range of undercarriage parts, rubber tracks and pads, ground engaging tools, repair parts, tyres and more, ITR Pacific provides a high level of stock accessibility and support. This extensive local inventory, coupled with the backing of the broader group, gives ITR Pacific the capability to cater to a diverse array of sectors within the Australian market, spanning mining, construction, plant hire, agriculture and forestry.

Range

From rubber tracks and undercarriage components, to ground-engaging tools and repair parts, to OTR tyres and diesel engine parts, ITR prides itself on offering premium quality products.

ITR parts are designed and engineered by the group’s inhouse R&D department in Italy and manufactured in ISO-certified production facilities with stringent quality control measures, resulting in a consistent and reliable product that has attracted the business of numerous OEM and other aftermarket companies globally.

The range covers parts suitable for most makes and models of dozers, excavators, graders, loaders, scrapers, dump trucks, drill rigs, harvesters, apron feeders and more - ranging in size from 0.5 tonnes up to 800 tonnes.

ITR says that what sets it apart from the competition in an industry where performance and downtime are not an option is its servicing capabilities. With two undercarriage track shops located in Brisbane and Sydney, an on-site rubber track installation team in South East Queensland, a robotic welder for hardfacing ground engaging tools and track shoes, as well as a team of specialists in the field performing undercarriage and bucket inspections country-wide, ITR Pacific can provide end-to-end solutions for its customers beyond just the parts.

As well as focusing on the quality of its parts, ITR has also strongly invested in its track shop equipment. Heavy-duty track beds and track winders, custom-made for Australian conditions, are capable of handling chains up to 10 tonnes in weight, comfortably covering the large Cat D11 and Komatsu D475 track groups.

ITR Pacific will have its parts range on display at Diesel Dirt & Turf in Sydney.

Image: ITR Pacific

The services on offer include:

• track bolt-ups and track plate swaps

• track lengthening and shortening

• complete track frame refurbishments, track frame crack repairs and modifications

• robotic, abrasive-resistant tungstencarbide hard facing of ground engaging tools, such as bucket teeth and cutting edges

• hardfacing of dozer track plates with tungsten-carbide grit for added wear resistance.

As it looks to the future, ITR remains steadfast in its ongoing commitment to providing customers with streamlined and efficient services and parts with quick turnaround times. The company is continuously expanding its presence in the Australian market through industry acquisitions and new developments, allowing it to build its product range and service offering with additional locations and industry experts.

ITR Pacific will have a range of its products on display at this year’s Diesel, Dirt and Turf Expo in Sydney, which will take place April 12–14, so be sure to drop by Site L2 and say hello to the team.

To find out more about ITR’s full product offering and services, give them a call at 1300 820 214 or visit www.itrpacific.com.au.

We are an innovative, forward thinking organisation that make the procurement of heavy machinery quick and easy.

We get to the point.

So you can #GetToWork.

1300 225 594

ygg.com.au

Precisionscreen’s SM conveyer stockpile range provides a cost-effective solution for moving material around a site – while working in tandem with imported machines

Precisionscreen is seeing a lot of interest and applications for its SM conveyer stockpile range, offering customers the ability to hire its machines, with the option to purchase at the end of hire.

Showcasing the versatility that the Brisbane-based company offers, its stockpile range also has the capability to work with other imported machines.

Focusing on the SM450, SM650 and SM750, Precisionscreen’s standard conveyers come with hydraulic drive and poly rollers and return slides.

All conveyers are also fully designed and manufactured in-house in its Brisbane workshop, with the SM450 reaching 10m (30ft), the SM650 12.5m (40ft) and the largest model, the SM750, coming in at 15m (50ft).

Moving mostly sand, soil and reclaimed materials, these conveyers essentially grab fine material from the screening process and then

stockpile it in a convenient location.

Once this process is done, the fine materials can be loaded onto trucks to be transported.

Precisionscreen’s SM conveyer range can also radially stockpile, as all its machines come with radial wheels.

“Part of the benefit of our SM conveyors is it reduces the need for an extra loader or a different handling solution on site,” chief operating officer Jonny McMurtry says.

“These machines provide a cost-effective way to stockpile and move your material once it’s gone through the screening process.”

An Anaconda trommel unit was recently set up to work with a SM750 conveyer in Felton, in southeast Queensland.

“We had a couple of discussions with our customer and spoke directly to Anaconda as well, just

Precisionscreen’s SM conveyer stockpile range eliminates the need for loaders, helping to reduce costs

to make sure that we had sufficient hydraulic power and flow, which we did,” McMurtry says.

“We were then able to tap into the machine, claiming some hydraulic power from the current power pack and hydraulic system on the screen and plant.

“This was sufficient enough to drive our SM750 stockpiler.”

Working off the powerpack of the existing screening plant, the SM conveyer range eliminates the need for using a wheel loader that burns diesel – reducing costs.

“A lot of our customers are looking for a quick hire or modification to their existing fixed or mobile plant,” McMurtry says of typical applications for the conveyor.

“They’re looking for these 10, 12 and 15m conveyers just to do their shortterm contracts or add on to their existing sites.”

This versatility provides customers with more choice and security, knowing that they can purchase in

Induction Hardened Chrome Bar — the ideal answer for your next heavy duty cylinder job.

If you have an application that commands a durable, corrosion resistant steel to meet demanding conditions, our 38MnVS6 Chrome Bar is up to the task. Engineered with heightened alloying elements, this steel delivers superior tensile strength and ensures long lasting performance.

Available in a range of sizes we’ve got Australia’s largest range of Chrome Bar, in stock and ready when you need it.

38MnVS6 PRODUCT FEATURES

Corrosion Resistant

High-strength Induction Hardened

Close Tolerances

Excellent Reliability and Straightness

Good Machinability and Weldability

Available in a range of sizes up to 250mm

Suitable for cylinder rod and heavy equipment applications in Construction, Agriculture, Infrastructure, Transport, Waste and Mining

hydraulicsteels.com.au

full, or hire to see how the machines perform before purchasing.

Precisionscreen is happy to do hire and purchase agreements with customers, offering flexibility to those who decide they want to keep a machine.

“Depending on what the customer needs, based on their contracts, we can offer a rebate at the end of hire,” McMurtry says.

He attributes the increased demand for these machines to the lack of stockpiling capabilities that come with imported machines.

Imported machines usually have a small stockpiling height, he says, but Precisionscreen can add its conveyors to run off the hydraulic system or existing power pack of the screen plant.

“This is a cost-effective way of increasing your throughput and production as well as reducing the running costs for your screening application, whether it be per contract or on your existing site,” he says.

Customers are also able to modify Precisionscreen’s standard conveyers, with the business

adapting to customer needs, whether it be for hire or purchase.

“Whether it be modifications such as a rear wheel drive or large feed boots, we can add pretty cool attachment kits on the end of the conveyors,” McMurtry says.

When asked what makes the Precisionscreen conveyers stand apart from others, he emphasised the fact that they are built in Australia for local conditions, while also placing a large focus on customer support.

Precisionscreen stocks and carries all the spare parts for the conveyers it builds as an Australian original equipment manufacturer.

“It’s our responsibility to look after these units and we make sure we have sufficient stock on hand for any machines that are on hire or recently sold,” McMurtry says.

Relationships are integral to the Precisionscreen and it’s why the business goes out of its way to satisfy the customer.

“Depending on production lead times, we can offer a new conveyor if we have space in our production line – within two weeks if we had to.”

Having been designed and built

with the Australian environment in mind, customers can be assured that the SM conveyers will thrive in harsh climates.

“We put on triple-sealed bearings onto our conveyor just to manage the harsh Australian climates,” McMurtry says.

“Our poly rollers are also manufactured to suit Australian standards and expectations. This includes a deeper inset bearing to protect it from the harsh, hot and gritty Australian environment.”

Precisonscreen’s aftersales support team also stands out for customers –getting back to customers swiftly.

With multiple different centres, the company can offer spare parts for its conveyers from Brisbane as well as Melbourne.

“We can service all corners of the country from those two locations,” McMurtry adds.

For more information on the SM conveyer stockpile range visit precisionscreen.com.au or call 1800 727 991.

tillys.com.au

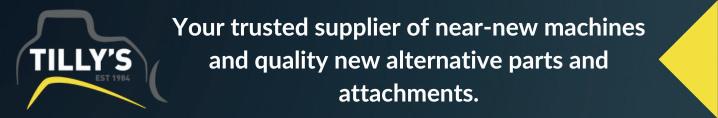

2020 CATERPILLAR 330LC KEL Machine #ZM008967

2016 KOMATSU WA380-6 DZAC0353

2023 CATERPILLAR 950GC M5K

XXT00846 Machine #ZM009060 Machine #ZM009020

2012 TEREX PT80 *DWS01681* Machine #ZM009058

2020 CATERPILLAR 330LC KEL Machine #ZM008967

2016 KOMATSU WA380-6 DZAC0353

2023 CATERPILLAR 950GC M5K

XXT00846 Machine #ZM009060 Machine #ZM009020

2012 TEREX PT80 *DWS01681* Machine #ZM009058

With a rise in mental health concerns and suicide in the construction industry, what can be done to increase support for workers?

In Australia, construction workers are six times more likely to take their own lives than have an accident at work, with an incredibly alarming rate of one construction worker taking their life every two days – this statistic is haunting and now is the time for change.

So, how do we get there? The rise in mental health concerns across the construction industry is alarming, long working hours, poor work/life balance, high risk environments, bullying and harassment, a culture of silence and the bystander effect are all key factors.

It’s hard to imagine how small changes can create impact, but they can, and here’s where we can all begin.

The bystander effect is a theory where individuals are less likely to step in when others are around. This may be due to how the supporting individual may be perceived for standing up against the perpetrator, which therefore affects their own safety in the situation.

Feeling safe enough to call someone out for their behaviours can feel intimidating, but the power in speaking up for those being affected is far greater. Whether it is small remarks made towards

NAWIC is a not-for-profit organisation, with a vision to create an equitable construction industry where women fully participate. Our mission is to drive change that will aid in the increased recruitment, retention and further vocational development of women within all facets of the construction industry. You can stay connected with NAWIC through our social media platforms, The Leaky Pipeline Podcast or become a member. You can learn more about the impactful work we do at www.nawic.com.au.

someone’s physical attributes and/or abilities, personal choices, sexuality, and/or gender, lived experiences or anything else, they are being discriminated against.

Speaking up on the spot and calling out the behaviour is an incredible catalyst for change and will show that this behaviour isn’t tolerated. You will soon notice others will follow in standing up against bullying and this is where change begins.

Having a workplace that actively promotes good mental health practices may feel rare in the

Checking in with work mates can help build a culture of positivity around discussing mental health at work. Image: SpaceOak/stock.adobe.com

industry, but it does exist. Tools include having your business aligned with an employee assistance program (EAP) service for mental health and wellness, having mental health crisis documents or guidelines in easily accessible places for those who aren’t sure where to begin supporting a co-worker or themselves, taking part in awareness days such as R U OK Day and having these resources available and actively promoting a message in your workplace of supporting mental health. Creating a culture where mental health support is available, championed and promoted is incredibly beneficial to your workplace. Organisations could also start a mental health support committee, where key people are available to support workers who are in need of further guidance.

Imagine coming to work and feeling safe to speak about your mental health and how you are feeling. This should be the norm, so let’s start advocating for it.

Start actively promoting and

engaging in open conversations. Checking in on co-workers and taking the time to have real and authentic conversations can save a life.

If you notice a co-worker is unusually silent, withdrawn or starting to not show up to work or bring the same enthusiasm for life – these are strong indicators that something isn’t right. If you aren’t sure how to start the conversation, just being an active listener is the perfect place to start, and continuing to check in on that person. If you don’t feel you have the capacity to hold space for that person, recommending them support services is also a great way to help.

Promoting and providing flexibility for workers is a key catalyst for the mental health crisis in the construction industry. People are creating a movement for shorter working hours, safer working conditions and more balance in their working lives.

Gone are the days where workers needed to be onsite 10+ hours a day, in extreme conditions and were expected to show up six or seven days a week. Let’s advocate for men picking their kids up from school and participating in social activities in

the afternoons, let’s support women in the industry who need to work around school hours and family/ carer appointments and activities that relieve their burnout, let’s rally for all workers to not leave work so physically and mentally fatigued that it affects their health to a point of crisis and intervention.

Let’s support and encourage working from home where possible, showing flexibility is achievable from leadership and top levels, and allow this to filter through the workplace.

Productivity and mental health boosts with flexibility and work/ life balance, and in our fast paced and busy world, let’s promote and encourage balance and its benefits.

At NAWIC we are passionate about advocating for women in the construction industry, and through research, lived experiences and feedback we know that women in construction are suffering.

As published in the NAWIC Journal, Dr Adedeji Afolabi and a group of researchers discovered that the major factors leading to mental health issues among female workers in construction are: sexism, lack of access to flexible and parttime work options, family and carer commitments, long working hours,

Offering an ear if a coworker is more withdrawn than usual is one way of improving a workplace’s approach to metal health support.

Image: Kikujiarm/Shutterstock.

negative perceptions surrounding their ability to perform similar roles to men, macho culture, male-dominated recruitment processes, low career progress and the inability to balance career and personal goals, plus the gender pay gap and it’s affects.

We need to support our women in the construction industry and the burnout they feel working within it. At NAWIC we provide a safe place for all women, empowering and advocating for their rights in the construction industry.

We support women (and men) through individual and corporate membership, and offer access to events, awards, scholarships, networking, professional development and our EAP program that provides 24/7 free confidential support.

If you, or someone you know is struggling with their mental health, here are free support services that may support you: Beyond Blue –1300 224 636; Headspace – 1800 650 890; Mates in Construction –1300 642 111.

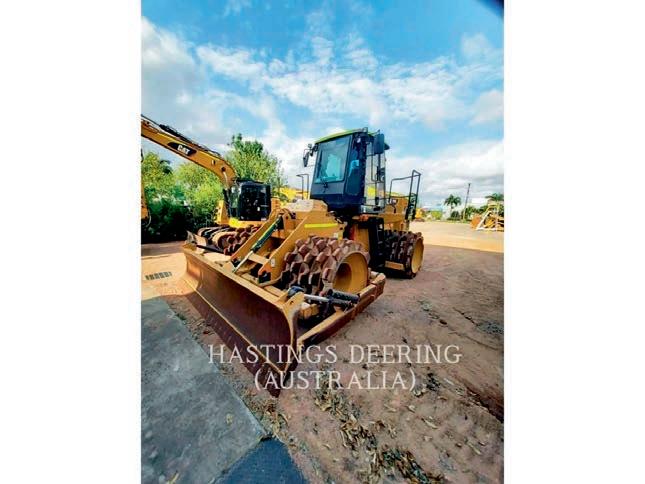

Hastings Deering is bringing a whole-of-life approach to machinery maintenance with its free undercarriage inspection service, helping Cat customers get the most from their equipment

With a machine’s undercarriage often taking the brunt of wear and tear, applying a regular maintenance schedule is imperative to avoid unplanned downtime and costly repairs.

To help Cat machinery owners better manage their machinery maintenance and get the longest lifespan possible from their undercarriages, authorised Australian dealer Hastings Deering offers a free undercarriage inspection service.

Hastings Deering customer support representative David Onn says that as up to 50 per cent of a machine’s operating costs come from maintaining and replacing parts of the undercarriage, keeping a close eye on the wear rates of the various components can lead to significant cost savings.

“It’s about helping a customer plan and budget for future repair costs, but it’s also about highlighting any concerns that an owner might

be having, so that we can make adjustments along the way,” Onn says.

“As well as physically inspecting the machine, we also talk to the customer about how they’re operating it, the conditions it’s being used in and the applications it’s used for, so that we can adjust the maintenance schedule to help the undercarriage last longer and keep the customer’s cost per hour as low as possible.

“We also look at the machine as a whole, not just the undercarriage, which sets us apart from other non-genuine competitors who may just focus on one component. Caterpillar designs their machines to work as a system [powertrain, hydraulics, attachments etc], and the undercarriage forms part of that system.

“The overall aim is to ensure that customers gain the most value, for the lowest possible cost, for the whole machine, over its entire life.”

During an inspection, Hastings Deering isn’t just looking for broken components or missing bolts – it’s a process of understanding the wear rate of all the different aspects of the undercarriage, finding solutions to extend life where possible and get an accurate assessment of when parts will need replacing.

“We measure each of the undercarriage components to see how much they have worn as well as visually checking the entire machine to make sure everything is the way it should be,” Onn says.

“We use the Caterpillar Wear Management System (CWMS) Program that utilises an Ultrasonic Wear Indicator Probe and other specialist tooling to measure the undercarriage, and from the information gathered the CWMS Program calculates how much each component has worn over however many hours, giving a per cent worn and a projection of life.

With the undercarriage responsible for half of a machine’s maintenance costs, regular inspections can have significant benefits

“We can then give the customer a Custom Track Service (CTS) report of how the undercarriage system is performing. With all of this information we’ll make recommendations on what we need to do or be aware of, to reach that maximum life of the undercarriage. That may include rotating components [as in moving idler or roller positions] to ensure balanced wear life, performing a pin and bush turn or resealing the tracks themselves, for example.”

“We also talk to the operator or owner of the machine to see if the undercarriage has been performing as it should in the conditions it’s working in.”

Fechner Bros

One long-term Hastings Deering customer who has been seeing the

benefits of a regular undercarriage inspection is Queensland earthmoving contractor Fechner Bros.

Steven Fechner is the second generation of the family to run the business from its base in Beaudesert in the Scenic Rim region, mainly focusing on farm work in the local area.

“We offer a wide range of services

from dams and drains to general earthmoving, right through to car parks and roads for the rural sector here, mostly farmers and land holders with a bit of government and civil work,” he explains.

“We also do a bit of soil conservation work with Healthy Land and Water [the government natural resource management body for South East Queensland]. They work with landowners and, if there’s a soil erosion problem, we might end up rebuilding riverbanks or addressing erosion in gullies where we need to divert water away from it.”

Fechner says his family has been a fan of Caterpillar machinery for decades, ever since his business’ beginnings in 1962.

“We’ve always bought Cat machines, so we have a long standing relationship with Hastings Deering,” he says.

“At the moment we have a D6R dozer, 320D excavator, 140 grader, 232D skid steer, a new 305 CR Next Gen excavator and a little CC34B roller, which has the smooth drum

and the multi tyres on the back.” Hasting Deering undertakes preventative maintenance of the fleet, making regular visits to ensure the machinery is kept in top condition.

“With Hastings Deering doing the inspections, we can factor in any maintenance that needs to come up, or they might pick up on an issue,” he says.

“Understanding where and how a machine is wearing is important to us, because we deal with various soil types where we are, from very abrasive to black soil. With Hastings monitoring it, they are giving us the advice on how long we’re going to get out of an undercarriage before we need to do something.

“It’s mainly about keeping an eye on the condition and picking up on problems if wearing has increased, so

we can get maximum life out of the components.”

From April 1–June 30 Hastings Deering customers who spend $2,000 or more on an undercarriage will be entered into a draw for a Cat 301.5 excavator with a trailer. During this period, Hastings Deering is also offering 20 per cent off all General Duty Undercarriage transactions made on parts.cat.com when code PCC_UC20 is used.

To find out more about Hastings Deering’s undercarriage inspection service, visit: www.hastingsdeering.com.au

KOMATSUD475A-3

2011,TidyOneownerlocalmachine,fittedwithACROPSCabin,14ftBlade, RearRippersandScarifiers,17.5R25Tyres,WindowTint,UHFRadio, ConstructionSpec,TrimbleGPSwired.MachineCurrentlyworkinginCentral QLD.S234. TA1199486. EARTHMOVINGTYRES29.5R25,26.5R25,23.5R25,17.5R25,2700R49,2400R35 Morecontainersjustarrived,mostsizesavailable,17.5R25/23.5R25/26.5R25/ 29.5R25/2400/R35/2700R49.ExcellentqualityL3/E3/E4radials,suitarticulated dumptruck,graders,rigiddumptrucksandwheelloaders.Wealsofittyresanddo inhouseCertifiedRIMCrackTesting(AINDT).TyresinstockinYatala,QLDand pleasecallformoredetails.S174. TA1010799. POA

1999,tidylocal860HP,100Tmachine,12,000indicatedhours,completewithAC ROPScabin,SUblade,dualTilt,4BBLsinglegiantripperwithpinpuller,OEM undercarriageatestimated70%liferemaining,800mmwidegrousers,service historyavailable.MachineislocatedinSEQLDandcanbeinspectedworking.Price justreduced.S212. TA1133395. $265,000PlusGST

KOMATSUPC450LC-8

2013,TidyunitcompletewithACROPSCabin,OPG2CabinGuard,Crane Valves,Aux.Plumbing,Quickhitch,RockBucket,CivilSpec,Good Undercarriage,Bellyplate.MachinelocatedinNorthQueenslandandcan inspectworking.S235. TA1204813. Priceis$225,000+GST

Cat’s new 973 track loader has replaced the 973K worldwide and provides up to 10 per cent better fuel efficiency, more productivity, cab improvements and optional payload technology, the company has announced.