Electric impressions

Komatsu will display two electric excavators at this year’s Diesel, Dirt and Turf Expo.

$7.95

CASE STUDIES:

+ Pacific Hire & CJD Equipment

+ Metropolitan Memorial Parks & Cat® Equipment

+ Gorilla EPH & Kobelco

+ ABM & LiuGong

+ Earthworx and Cat Equipment

FEATURED TOPICS:

+ Innovative Products

+ Eye On The Industry

+ Industry Events

+ Association News

+ Dealer Profile

inc GST APRIL - MAY 2024

Bonus upgrade to 3-year/6000 hour component warranty and free 3-year Volvo Active Care subscription is valid for every new 14-35 tonne Volvo excavator purchased between 1st January 2024 and 30th June 2024. Offer available on new Volvo excavator models EC140D, EC140E, ECR145E, EC220D, EC220E, ECR235E, EC250D, EC250E, EC300D, EC300E, EC350D, EC350E, ECR355E, including Dig Assist and hybrid models (excludes Volvo wheeled excavators). Machine must be delivered by 31st of August 2024. Warranty is valid on component only. The warranty is limited to three years or 6000 operating hours, whichever occurs first, commencing from the date of delivery. Normal manufacturer’s warranty terms and conditions apply. Images are for illustration purposes only. CJD Equipment reserves the right to withdraw this offer at any time without notice. CJD.COM.AU | 1300 139 804 | ENQUIRIES@CJD.COM.AU CONTACT YOUR LOCAL BRANCH FOR MORE INFORMATION Big Enough to Trust, Small Enough to Care Purchase a new Volvo 14-35 tonne excavator between 1 January & 30 June 2024 and receive: make every hour count 3-YEAR ACTIVECARE CONNECTIVITY Package * 3-year /6000 hour extended warranty & bonus 3-year support package

Introducing Electric

Low noise, zero emissions and an ergonomically designed cab make the new Volvo Electric ECR25 excavator and L25 wheel loader quiet, clean and comfortable. A perfect fit for a modern worksite.

Proven performance

• Same performance as a diesel equivalent

• Outstanding visability and operator comfort

• Range of Volvo attachments

Innovative battery technology

• Lithium-Ion 48V battery - 40kWh

• Fast Charging possibilities

• Theft protected fixed battery

The Volvo Electric Range is backed by a 2-year/2000-hour warranty on genuine Volvo parts, while the battery and electric components are covered for 5 years/5000 hours, whichever comes first.

Less maintainance

• Maintenance-free electric motors featuring auto shutoff to save wear

• Easy ground access to lubrication and maintenance points

Zero Emissions

• No power consumption when machine is not working

• Low noise level

• No emissions locally

CJD.COM.AU | 1300 139 804 | ENQUIRIES@CJD.COM.AU CONTACT YOUR LOCAL BRANCH FOR MORE INFORMATION Big Enough to Trust, Small Enough to Care

Welcome

Ray Chan Editor

Ray Chan Editor

What a bumper issue you hold in your hands! At more than 200 pages, it’s the biggest edition we have produced in recent times. And as such, it’s filled with some great content.

As always, our case studies prove to be indispensable reading.

We often link earthmoving activities to building projects or landscaping work, but what about burial site management? Find out about how Metropolitan Memorial Parks in Sydney has chosen a range of Cat® machines for excavation and maintenance work around the cemeteries it oversees.

Across the border in Adelaide, leading earthmoving company Gorilla EPH is beating its chest over the performance of its Kobelco excavator, while in Melbourne, equipment hire specialist Pacific Hire tells us about why its fleet is always stocked with the full suite of Volvo products.

The spotlight also shines on family business Earthworx, which has evolved into a leading provider of site preparation and early works services, thanks

largely to the performance of its fleet of Cat® New Gen excavators; and we discover how a set of LiuGong machines is helping a civil industry specialist fill a gap in the market for mid-size contractors.

Meanwhile, there are interesting articles on how Leica Geosystems tools have navigated a budding Victorian earthworks company towards prominence in the industry; and on how a fleet of Doosans and Develons are transforming a civil construction business as much as they are the red landscape of WA’s Mid West.

Of course, there’s plenty more in this jam-packed issue: a plethora of innovative products, dealer profiles, and plenty of eyes on the industry.

We also welcome the National Association of Women in Construction to our ranks of industry partners, who continue to provide updates on their respective industries.

Happy digging!

Ray Chan Editor

3 www.earthmovers-magazine.com.au | E ARTHMOVING EQUIPMENT MAGAZINE

FROM THE EDITOR

Volvo CE Head of Region International Joakim Arndorw (right), pictured with CJD Equipment Managing Director Alan Barnett, flew in from Sweden to visit several CJD branches throughout Australia recently, with the trip culminating in the equipment distributor’s 50th anniversary celebrations in Perth. Image: Prime Creative Media

Call us today on 1300 074 249 or visit komatsu.com.au

hydraulic rock grab

Single cylinderup to 4 tonne machines

Hydraulic option includes hoses and couplings

Static or Hydraulic options available

• Serrated edges enhance grip and stability for secure handling of irregular rocks and debris.

• Increased durability and reduced wear and tear in tough environments.

Suited to excavators ranging from 1.5 tonne - 25 tonne

Dual cylinder5 to 25 tonne machines

WIDE OPEN JAWS

• Wide open jaws allow for securely grasping large or awkwardly shaped materials, increasing versatility in handling diverse types of debris.

• Protected cylinders reduce damage risk, ensuring reliability and lower maintenance.

• Improves operational e ciency by enabling quick capture and release of materials.

Ph:

• Shields hydraulic components from harsh conditions, enhancing safety and lifespan.

QUEENSLAND

(07) 3376 3177 sales@normeng.com.au 787 Boundary Road Darra QLD 4074 VICTORIA

Ph:

(03) 9775 1965 vicadmin@normeng.com.au

Frankston Gardens Drive Carrum Downs VIC 3201

2/45

46.

Mark O’Donoghue

Mark O’Donoghue is the CEO and founder of Finlease, financing over $700 million p/a in equipment for private business owners in civil and related industries. A family business with a nationwide network, Finlease has a 30-year track record of establishing long term relationships with clients, finding them the best finance solutions to support their business growth. The company’s goal is to make the finance process simpler for businesses so they can focus on what they’re good at.

Scott is the Director of Australian Earth Training, a niche operator proficiency training organisation who work across the globe. He has over 25 years’ experience in heavy equipment operation and was an accredited Caterpillar Dealer Instructor (CDI) Trainer-Demonstrator. Scott’s unique skill set enables him to operate and train on a broad range of machines across the mining, construction, quarrying and waste industries, helping his customers to boost their productivity while lowering their owning and operating costs.

Ann Callaghan

Ann has been the Manager of Allied Earthmovers Association for the past 19 years, bringing many years’ experience into the role. After gaining business qualifications and managing a retail shopping centre in Sydney CBD, Ann first started her career in earthmoving when she joined the long-established family business in Penrith, which specialised in Caterpillar graders and dozers. Working in a male-dominated industry, Ann brings a different aspect to the Association. She has met many people in the industry and knows what the owner operator needs, from the importance of paperwork to machine availability. It’s an industry she respects and is proud to be a part of.

8 EARTHMOVING EQUIPMENT MAGAZINE | www.earthmovers-magazine.com.au CONTENTS 13. On the Cover 20. Meet The Expert 24. Industry Auctions 29. Machine Control 32. Business and Finance 34. Industry Insurance 37. Business Solutions 40. Industry Training

Technology Expert

Public Relations/Marketing

42.

44.

Meet The

Product Review

D ealer Profiles

Industry Anniversary 68. Piping S olutions 70. C ase Study 96. Innovative Products 190. National Association of Women in Construction 191. Civil Contractors Federation Queensland

Expert 50.

53.

64.

Allied Earthmovers Association

192.

CONTRIBUTORS

An earthmoving business located in the MidWest of WA has flourished, thanks to its fleet of Doosan and Develon excavators. Image: Lambron Contracting

Scott Lidster

Earthmoving

CEO

John

COO

Christine Clancy

Sales Director

Bradley Buchanan Editor

Ray Chan

ray.chan@primecreative.com.au

Brand Manager

KahChi Liew

kahchi.liew@primecreative.com.au

0421 474

Production Editor

Michelle

michelle.alder@primecreative.com.au

Art Director/Design

Daz

Subscriptions

P.

Website

The

9 www.earthmovers-magazine.com.au | EARTHMOVING EQUIPMENT MAGAZINE

Murphy

407

Alder

Woolley, Cat Zappia

+61 3 9690 8766

subscriptions@primecreative.com.au

www.earthmovers-magazine.com.au

Equipment Magazine is published bimonthly by Prime Creative Media Pty Ltd.

Earthmoving Equipment Magazine is owned by Prime Creative Media and published by John Murphy. All material in Earthmoving Equipment Magazine is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical, including information and retrieval systems) without written permission of the publisher. The editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions, or for any consequences arising from reliance on information published.

Copyright

opinions expressed in Earthmoving Equipment Magazine are not necessarily the opinions of, or endorsed by, the publisher unless otherwise stated. © Copyright Prime Creative Media, 2024. Articles All articles submitted for publication become the property of the publisher. The editor reserves the right to adjust any article to conform with the magazine format. Head Office 379 Docklands Dr, Docklands VIC 3008 P: +61 3 9690 8766 enquiries@primecreative.com.au www.primecreative.com.au Sydney Office Suite 3.06, 1-9 Chandos Street Saint Leonards NSW 2065, Australia P: +61 2 9439 7227 $7.95 inc GST APRIL MAY 2024 CASE STUDIES: + Pacific Hire & CJD Equipment Metropolitan Memorial Parks & Cat® Equipment + Gorilla EPH & Kobelco + ABM & LiuGong + Earthworx and Cat Equipment Komatsu will display two electric excavators at this year’s Diesel, Dirt and Turf Expo. Electric impressions FEATURED TOPICS: + Innovative Products Eye On The Industry + Industry Events + Association News + Dealer Profile The Komatsu team will showcase the next steps in the company’s electric offering to Australian customers at Australia’s largest construction industry expo. ON THE COVER Earthmoving Equipment Magazine Earthmoving Equipment Magazine earthmoving_equipment_mag

DOWNLOAD OUR NEW CATALOGUE:

AVAILABLE INCLUDING:

Bobcat - Case - Caterpillar - Doosan - HyundaiJCB - John Deere - Kobelco - Komatsu - KubotaTakeuchi - Volvo - Yanmar and many more

ANY QUESTIONS?

constructionparts.au@tvh.com

OVER 20 BRANDS

T 1300 505 005

GET ON THE RIGHT TRACK. WWW.TVH.COM ADELAIDE 62–64 Wingfield Road Wingfield SA 5013 MELBOURNE 7/66–74 Micro Circuit Dandenong South VIC 3175 PERTH 2/15 Colin Jamieson Drive Welshpool WA 6106 SYDNEY 4/463 Victoria Street Wetherill Park NSW 2164 BRISBANE 735 Boundary Road Richlands QLD 4077

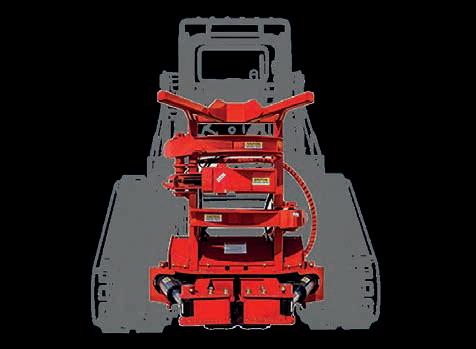

TRACKED CARRIER

Engineered and factory built tough for Australian conditions, Bell’s evolutionary approach to design delivers exceptional safety, control, performance and uncompromised reliability.

EVOLUTIONARY IN DESIGN NEXT GENERATION IN SAFETY

SALES PHONE 1300 791 672 For any enquiries please visit www.otraustralia.com Yatala | Perth | Mildura | Muswellbrook | Emerald | Karratha | Port Hedland | Kalgoorlie | Geraldton The biggest range of OTR tyres & wheels for the Mining, Industrial & Construction sectors

Australia supply earthmover, agricultural, truck, bus and light vehicle tyres and rims from 6” through to 63” in diameter, to blue chip mining, civil contracting, road transport companies, agricultural dealerships and end users. We maintain a healthy inventory of new and used earthmover tyres of critical sizes and have the ability to custom manufacture Australian Made wheels in 1 of our 10 locations Australia wide.

OTR

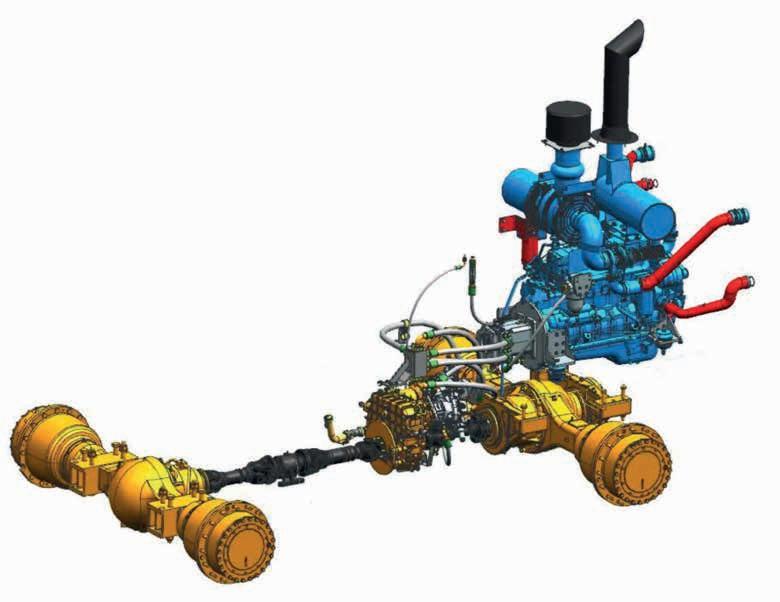

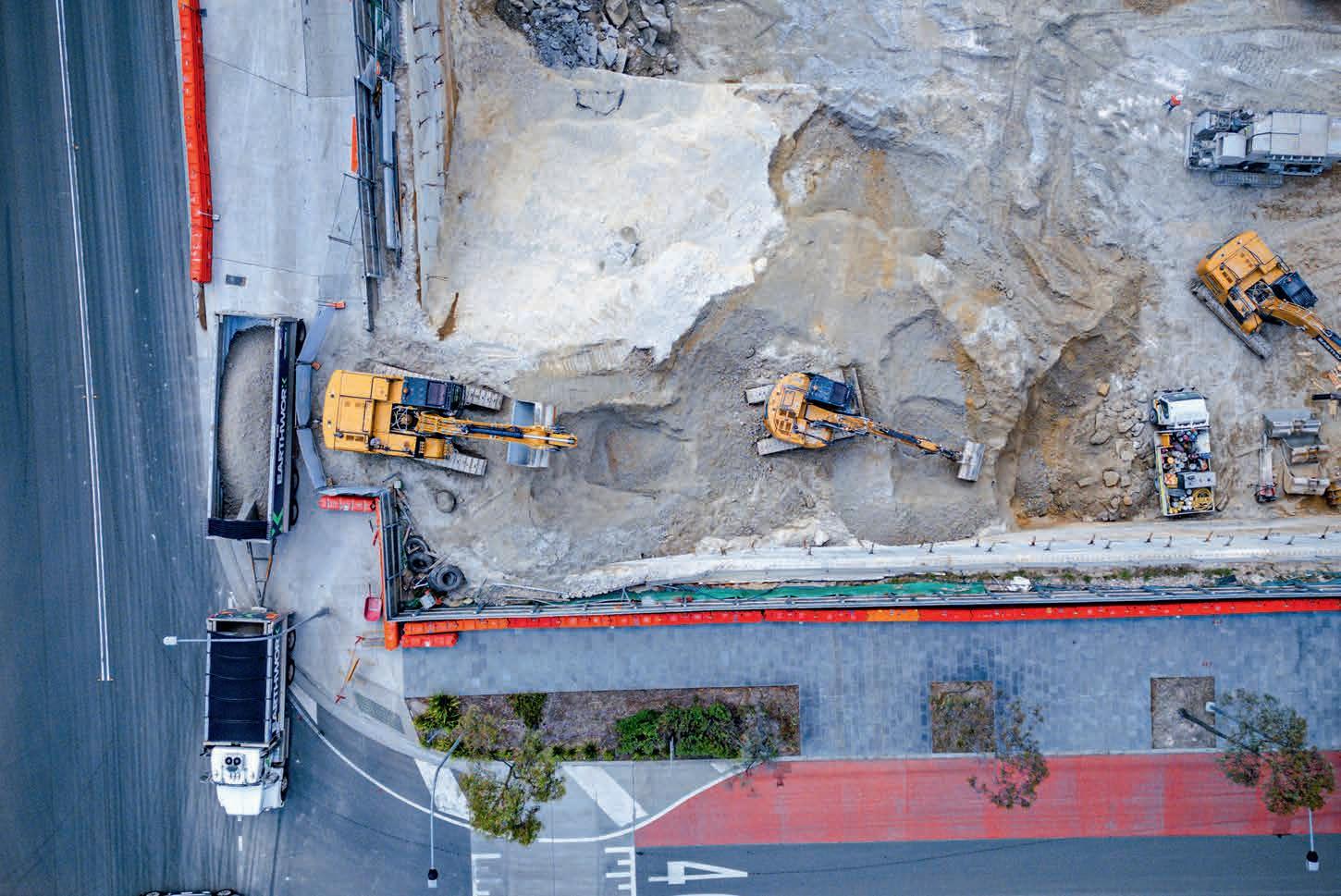

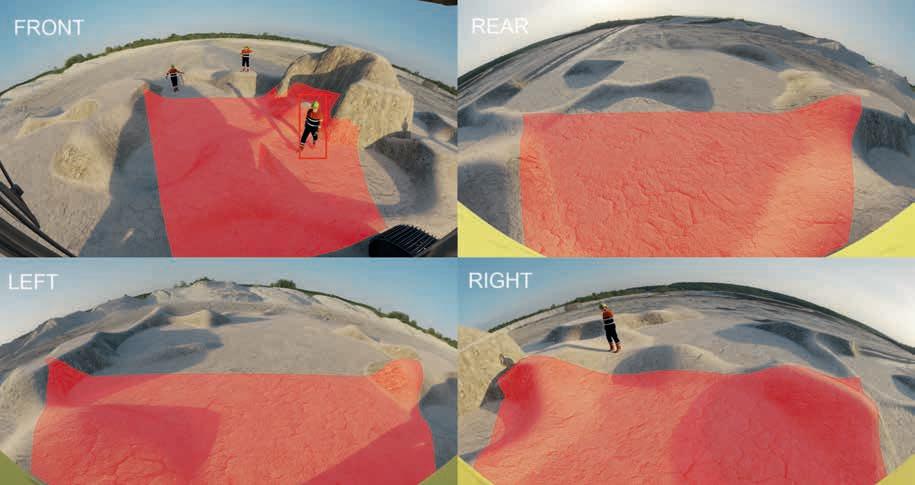

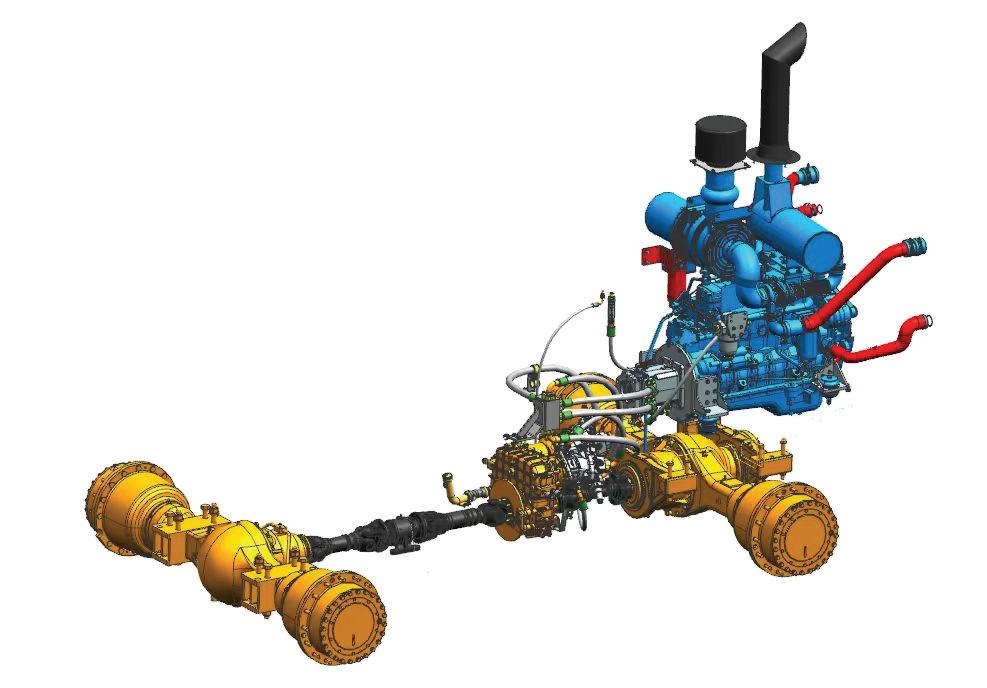

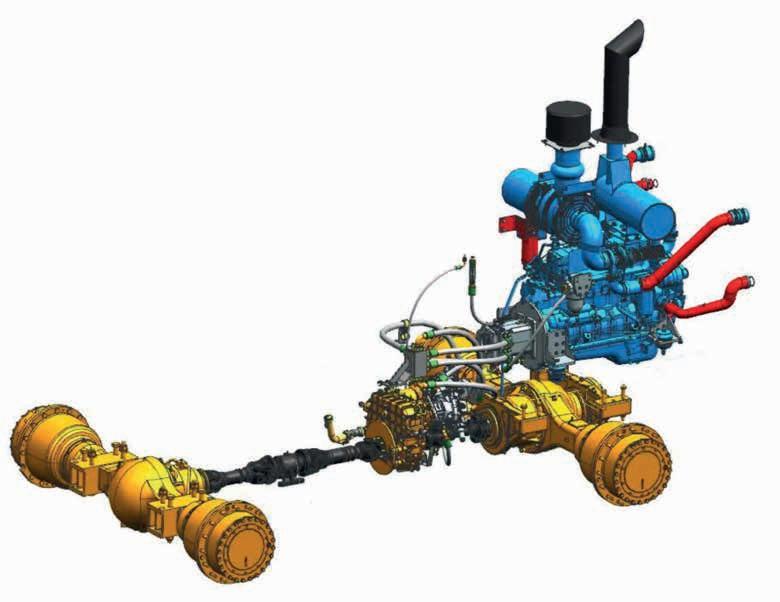

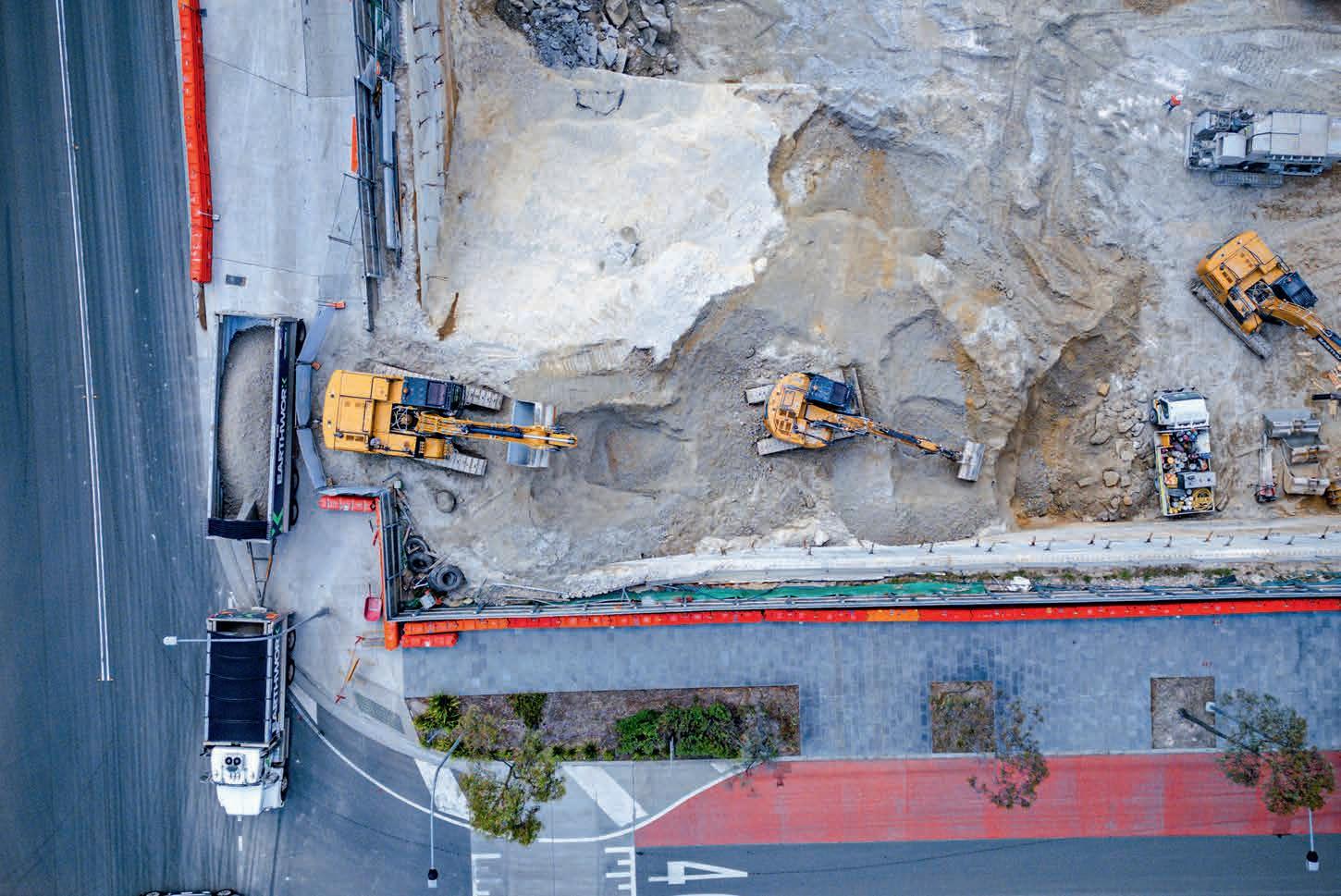

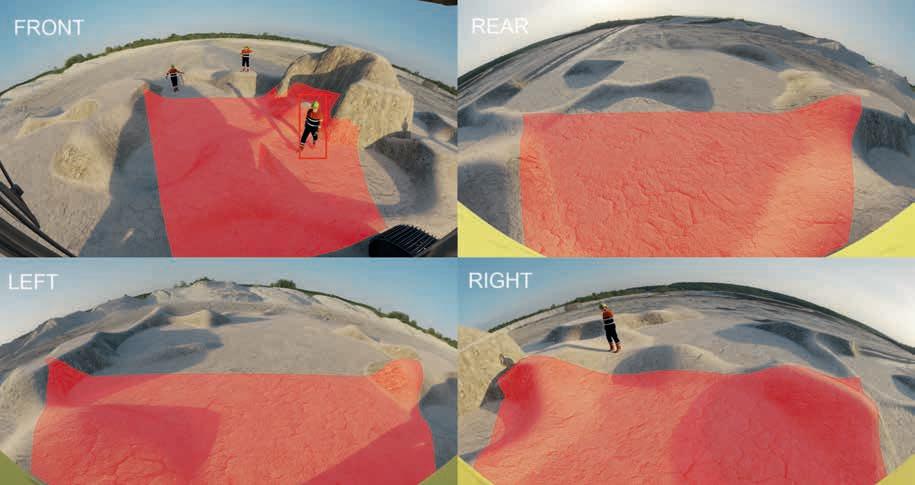

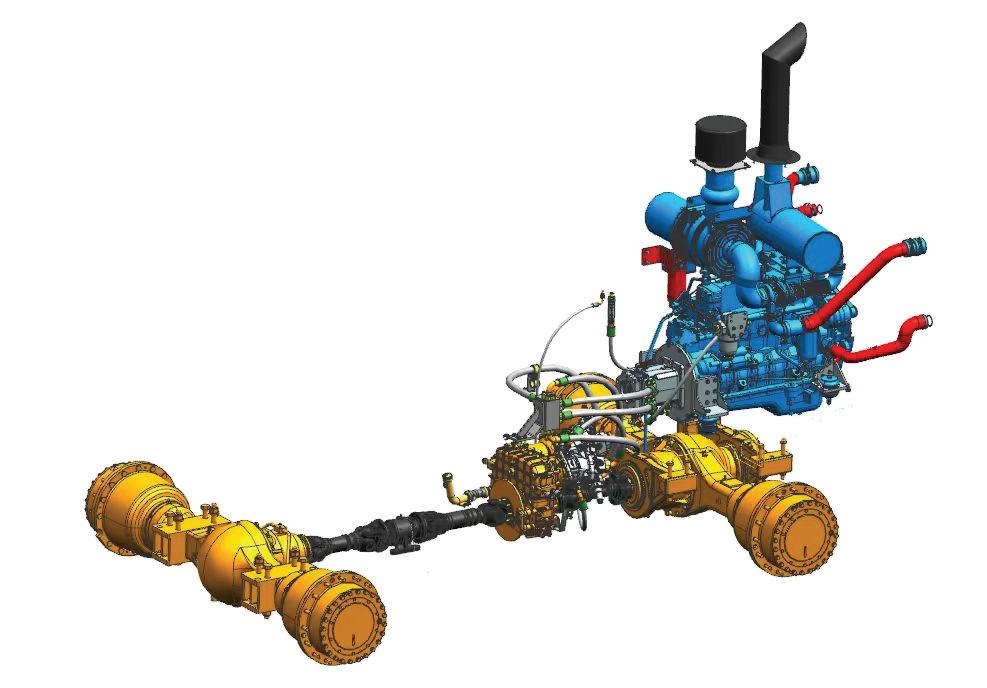

The Komatsu team is excited to showcase the next steps in the company’s electric offering to Australian customers at Australia’s largest construction industry expo.

Located at Stand B1, on the aptly named Komatsu Street, Komatsu will have one of the largest displays of machinery and technology at the event, with everything from excavators to wheel loaders and graders on display.

Komatsu’s Sales Manager - Central Region, Chris Moroz, says the annual expo is an opportunity to showcase the latest equipment and technology, which this year includes two electric excavators for customers to get a first look at.

“The PC210LCE-11 hydraulic electric excavator prototype will have its first official appearance at the expo, alongside the PC33E-6 electric mini excavator,” he said.

“Both these pieces of equipment are batterypowered and deliver zero-emissions, without compromising on productivity or comfort, something that is a big focus for us as a brand as we work towards a more sustainable future.”

Komatsu has committed to reaching zero carbon emissions by 2050 and halving its CO2 emissions from product operations from 2010 levels.

Komatsu will also have some of its Smart Construction offerings on display, with Retrofit Good

“We’re excited to have them both on the ground and get real time feedback from customers and attendees on what they think of the machines, before they head off

on a roadshow right across the country,” Chris said.

13 www.earthmovers-magazine.com.au | E ARTHMOVING EQUIPMENT MAGAZINE

ON THE COVER

as gold Komatsu is back again as the Gold sponsor of the National Diesel Dirt & Turf Expo.

The PC210LCE-11 hydraulic electric excavator prototype will be on show for the first time in Australia at DDT.

Images: Komatsu

Visit Komatsu at the DDT Expo at stand B1, located on Komatsu Street.

Kit (RFK ) on the PC138US-11 mid-sized excavator.

RFKs allow conventional machinery to perform digital construction techniques, using ICT features such as 3D machine guidance, payload management and 3D construction data collection.

“RFK can be fitted to a variety of machine sizes, makes and models, including older machines, making it an appealing addition for many attendees at DD&T, who come from a variety of businesses, whether that is large earthmoving fleets to smaller weekenders looking for their next piece of DIY equipment,” Chris said.

“We’re excited to have these machines on site for all to have a look at and showcase Komatsu’s latest innovations.”

For those interested in a career with the global machinery brand, the team will be onsite to chat about the opportunities and roles available with the award-winning company.

“We’re always on the lookout for more people to join our team, whether that be in service tech roles, sales, IT, or even engineering and whitecollar roles,” Chris said.

“The opportunities at Komatsu are endless. So come by Stand B1, and find out more about Komatsu, its products and services, and its people. We look forward to seeing you there.”

The National Diesel, Dirt & Turf Expo will be held from Friday to Sunday, April 12-14, at Sydney Dragway, Eastern Creek, NSW.

14 EARTHMOVING EQUIPMENT MAGAZINE | www.earthmovers-magazine.com.au

ON THE COVER

Komatsu employs virtual reality as part of its training for new employees. For info on opportunities available, speak to the team on stand B1.

The PC360LCi excavator going through its paces at last year’s DDT Expo.

Racing into the future

Leading heavy equipment manufacturer Komatsu has signed a multi-year deal with Williams Racing to become the Principal Partner of the British team from the start of the 2024 FIA Formula One World Championship (F1) season.

Komatsu was a key partner of Williams Racing in Formula One during the 1980s and 1990s, a period of abundant success for the team.

The most notable achievements were in 1996 and 1997 when Komatsu supported Williams Racing to Constructors’ and Drivers’ Championships with Damon Hill and Jacques Villeneuve, respectively.

With an eye to the future, both brands are excited to build on their shared history as they embark on a new era.

Tokyo-based Komatsu has been leading innovation in the equipment manufacturing sector for more than 100 years.

As embodied by its brand promise, “Creating value together”, the company believes that collaborative partnerships are the optimal way to create a lasting positive impact.

Komatsu’s official designations with Williams Racing reflect the companies’ shared focus on the long-term development of engineering, technology, and new generations of talent.

It will be the Official STEM and Early Careers Partner, Esports Partner, and Construction Machinery Partner.

These areas will overlap and combine within the partnership.

Komatsu endeavours to engage and bring focus to the next generation of innovators through STEM events enriched by the Williams Racing Esports platform.

Komatsu president and CEO Hiroyuki Ogawa said Komatsu and Williams Racing had shared values around innovation and the development of their people.

“Through our partnership, we look forward to creating value together, both on and off the track,” he said.

“Our partnership with Williams Racing is aligned with Komatsu’s mission to create value through manufacturing and technology innovations to empower a sustainable future where people, businesses, and our planet can thrive together.”

One of the driving forces behind the partnership was the alignment of vision that the two brands share.

The characteristics embedded in Komatsu’s DNA and values, such as cutting-edge

technology, outstanding quality, and unwavering reliability, are all demonstrated by Williams Racing at the highest level of motorsport.

This new partnership creates a foundation for future cross-collaboration between Williams and Komatsu.

Komatsu is looking forward to working with Williams across a range of disciplines, especially relating to the development of their people and exploring potential opportunities in the technical engineering ecosystem.

Williams Racing Team Principal James Vowles said Williams Racing was delighted to

15 www.earthmovers-magazine.com.au | E ARTHMOVING EQUIPMENT MAGAZINE

SUSTAINABLE SOLUTIONS

The 2024 Williams Racing FW46. Images: Williams

SUSTAINABLE SOLUTIONS

be rekindling its relationship with Komatsu.

“We have enjoyed huge success together in the past, and reuniting is a significant step in Williams Racing’s long-term mission to return to the front of the grid,” he said.

“Both Williams and Komatsu are committed to attracting and developing the best young talent in pursuit of our goals, and we look forward to working together again.”

Komatsu’s logo and branding will feature prominently on the 2024 Williams Racing livery, as well as the team’s overalls and kit, during the upcoming Formula One season.

The livery is a contemporary tribute to Williams Racing’s legacy, which includes nine Constructors’ World Championships, seven

Drivers’ Championships and 114 race wins.

It will adorn the FW46 car, following the FW naming tradition introduced by legendary team founder Sir Frank Williams.

The livery seamlessly blends past glory with future aspirations to make history again, featuring a vibrant colour transition from Heritage Navy Blue to New Era Williams.

A red and white pinstripe, reflecting Williams’ position as a British icon and inspired by historic cars from the 1985 FW10 driven by Nigel Mansell and Keke Rosberg to the 1997 Championship-winning FW19 piloted to glory by Jacques Villeneuve, is meticulously integrated for a classy yet powerful look.

The addition of branding from multiple new

team partners injects an energetic feel to this year’s design.

With operations in more than 140 countries, Komatsu is a global provider of premium heavy equipment, services, and solutions.

The company introduced the world’s first autonomous dump truck in 2008 and is helping customers advance towards carbon neutrality with its growing range of electric, hybrid and fuel cell construction and mining equipment.

Williams Racing is one of the world’s most iconic Formula One teams. The British outfit has been competing at the highest level for almost five decades, amassing 114 victories, 313 podiums and 128 pole positions in that time.

Komatsu and Williams Racing have shared values around innovation and the development of their people.

16 EARTHMOVING EQUIPMENT MAGAZINE | www.earthmovers-magazine.com.au

�

manufacturing delays, all ramps listed online are in stock at our warehouse in Mordialloc, Victoria.

� We can also supply Custom built ramps - made to your specifications for your particular needs.

� Free Delivery Australia wide.

MOVING YOUR MACHINERY WITH US, YOUR SAFETY IS OUR PRIORITY 0420 815 988 jetlandramps@gmail.com Rear 211-219 Boundary Road Mordialloc Vic. 3195 jetlandramps.com.au HEAVY DUTY LOADING RAMPS $200 COUPON JETLAND10YEAR Valid until 30 April, 2024

is a leading supplier of

& heavy duty

in Australia.

material and safety

safe and reliable product.

JETLAND

high strength

Aluminium loading ramps

High quality raw

testing systems ensure a

No

AUSCHANCE Pty. Ltd AUSCHANCE Pty. Ltd is celebrating 10 years of moving machinery

R Con Civil’s Cat® 140H Motor Grader is ‘rebuilt and ready to rumble’

R Con Civil has given its 17-year-old Cat® 140H Motor Grader a new lease on life with a Cat Certified Rebuild

After 17 years of faithful service, R Con Civil Managing Director Ryan Hewatt decided his beloved Cat® 140H Motor Grader was ready for a rebuild.

“We know what it’s like, its history, plus our operators know and love its steering wheel and levers,” he said.

On a cost basis, it made sense for Ryan and his team to choose to rebuild, rather than replace.

“We’re looking forward to getting another life out of our machine and being back on the job quickly,” he said.

Every component rebuilt in four weeks

The rebuilt machine was returned to R Con Civil in just four weeks.

“It was a quick turnaround on the 140H Cat Motor Grader," Ryan said.

"It looks amazing, we’re really stoked with the outcome and can’t wait to get it back to work."

20 EARTHMOVING EQUIPMENT MAGAZINE | www.earthmovers-magazine.com.au

MEET THE EXPERT

Julian Caruana (left), WesTrac; Sophie Enzerink, Caterpillar; and Ryan Hewatt, R Con Civil, with the Motor Grader prior to the rebuild.

This 140H Motor Grader has undergone a Cat Certified Powertrain Rebuild. Images: Caterpillar

WesTrac Rebuild Specialist Julian Caruana recommended the rebuild to R Con Civil.

“This Cat 140H has undergone a Certified Powertrain Rebuild. What that means is all the major components such as the engine, transmission, torque converter, differential and final drives have been restored to zero hours.

So we expect this machine to see an entire second life,” Julian said.

Great communication - the key to a successful rebuild

WesTrac offers its customers a collaborative rebuild approach. R Con Civil took up the offer and chose to be involved from day one.

“When we dropped the machine off it was all hands on deck scoping the work. Throughout the build I came back in to make sure we were going ahead with an item, or if there were things to add on or touch up. The WesTrac Canberra brand team was in communication from start to finish,” Ryan said.

Consistent communication meant that R Con Civil was able to provide input and make decisions at all stages.

“Ryan did identify a few more items that he wanted to restore when the machine was apart and we were able to address all of those items without deviating from the original timeline,” Julian said.

New look, new technology

Ryan’s Cat Certified Rebuild included the installation of new Product LinkTM hardware, which will allow him to monitor his machine using VisionLink® fleet management technology.

This technology can help customers stay upto-date with machine requirements.

“VisionLink will keep us ahead of the game in terms of servicing and maintenance. We’ll be able to keep our clients happy and the ball rolling,” Ryan said.

Rebuilding was a great decision

Ryan and R Con Civil couldn’t be happier with the rebuild experience.

“It’s met all our expectations. The WesTrac Canberra branch has been really great to deal with throughout the whole project," Ryan said. WesTrac returned the sentiment.

“For the most part, everything went to plan. This is a 17-year-old machine so we did expect to see a couple of surprises when we pulled it apart, but thanks to Ryan and his team and the top notch maintenance that these machines undergo, a lot of what we anticipated wasn’t required,” Julian said.

Cat Rebuilds mean a lot to WesTrac. “It’s an important part of our business so we want to make sure that every customer has the same experience whether it’s done at our business here or any of our other branches in the state.” Julian said.

For R Con Civil, the inclusion of a Cat Equipment Protection Plan (EPP) with five-year warranty and Customer Value Agreement (CVA) which includes three years’ servicing, has reinforced that they made the right decision. “It gives us more peace of mind,” Ryan said.

More rebuilds on the cards

On the back of the 140H rebuild, R Con Civil is looking to rebuild again.

“This has given us confidence to move forward with more Cat Certified Rebuilds in the future. We’ve got a massive amount of work in the pipeline. Giving this machine a new lease on life couldn’t have come at a better time. It’s rebuilt and ready to rumble,” Ryan said.

There’s a Cat rebuild option to suit your business. To find out more, contact your local Cat dealer or visit Cat.com/CertifiedRebuilds-AU

21 www.earthmovers-magazine.com.au | E ARTHMOVING EQUIPMENT MAGAZINE

Scan the QR code to see Ryan's rebuild story.

R Con Civil couldn’t be happier with their rebuild experience.

To find out more about the full range of Cat ® rebuild options, visit Cat.com/CertifiedRebuilds-AU

& TECHNOLOGY UPDATES IMPROVED

& EFFICIENCY

SERVICE & SUPPORT

A CAT® CERTIFIED REBUILD TO SUIT YOUR BUSINESS NEEDS

LATEST ENGINEERING

PRODUCTIVITY

SAME-AS-NEW

THERE'S

NSW/ACT WesTrac 1300 881 064 SA QLD/NT Hastings Deering 1300 952 701 WA VIC/TAS William Adams 1300 923 267 NZ © 2024 Caterpillar. All Rights Reserved. CAT, CATERPILLAR, LET’S DO THE WORK, their respective logos, “Caterpillar Corporate Yellow”, the “Power Edge” and Cat “Modern Hex” trade dress as well as corporate and product identity used herein, are trademarks of Caterpillar and may not b " OUR OPERATORS KNOW THIS MACHINE AND A CAT® CERTIFIED REBUILD MADE GOOD FINANCIAL SENSE." RYAN HEWATT MANAGING DIRECTOR R CON CIVIL

Take the opportunity to speak with Pickles’ experts and obtain information on the range of sales and services accessible to Australian buyers. Images: Pickles

The importance of industrial events in 2024

It’s time to get the engines revving in the lead-up to the National Diesel Dirt & Turf Expo in Sydney.

In the dynamic landscape of Australia’s construction sector, events serve as a crucial platform for networking, innovation, and community building.

As the industry prepares for the national DDT Expo, auction house Pickles delves into the importance of events in 2024 and why they are important not just for businesses, but as a catalyst for progress, collaboration and market growth.

To gear up for the event, Pickles is outlining why these events are important to attend in 2024 and for many years to come.

Building communities

The 20s have so far been greatly impacted by difficulties in hosting events, which makes it more important than ever to keep kicking Australian affairs back into gear.

Not the least of which because industrial events serve as a focal point for community building, drawing people of all backgrounds and regions to come together and discover more about each other as they learn about the industry.

Whether it is a large event like DDT, or

smaller opportunities, coming together to create a sense of belonging and unity, create connections and uplift the construction community is key.

Coming together to view exhibitors is a way to share stories and experiences, and use these gatherings to strengthen the fabric of local communities and promote pride in Australian industry.

Networking opportunities

One of the most important reasons to attend Australian industrial events such as DDT is that they hold immense networking opportunities.

Industrial events often serve as a hub for professionals, businesses, entrepreneurs and industry leaders to meet and exchange ideas, create partnerships and explore business collaborations. These events provide a fertile ground for growing meaningful business partnerships that can move the industry forward.

Showcasing assets

For businesses like Pickles, renowned for its surplus of incredible assets, having the

opportunity to display the biggest and best of these to the general public is something that cannot be missed.

While Pickles has many civil construction buyers who get up close and personal with its assets, it’s not often that the wider community has occasion to see large industrial machinery and equipment on display from the auctioneers.

From the everyday enthusiast, to the business owner looking for their next buy, industrial events are the perfect opportunity to check out Pickles’ latest and greatest assets.

Uplifting the industry

Pickles understands the value of fostering a thriving community, recognising that a healthy industry supports healthy businesses, which in turn supports Australia’s growth.

That’s why Pickles participates in large industrial events alongside other incredible industrial vendors, drawing in crowds and creating opportunities for growth.

Events like DDT act as a hub for knowledge exchanges, helping businesses come together to share new equipment, trends, market dynamics, regulatory changes, and foster a

24 EARTHMOVING EQUIPMENT MAGAZINE | www.earthmovers-magazine.com.au

INDUSTRIAL AUCTIONS

culture of working together for the overall benefit of the industry.

Charitable giving

Pickles takes great pride in its commitment to a variety of charitable initiatives that it supports each year, with many Pickles-supported events like the DDT Expo contributing donations from proceeds recouped from the event.

Not only do these events generate donations, they serve as a way to network and create opportunities for other charitable initiatives.

The tight-knit construction industry often

comes together throughout the year for a range of events that generate funds for charity.

Recently, Pickles offered free auction services to raise funds for the Cancer Council, which saw State Sales Manager Matt Blanch successfully generate $13,950 for the initiative.

This event is one of many that happens throughout the year that features DDT partners in attendance for a good cause.

Educating attendees

DDT has evolved into the perfect platform to showcase Pickles’ extensive services,

recruitment opportunities, and update current clientele on all the exciting developments happening within the business.

For attendees, having the opportunity to speak with Pickles’ experts can be the most efficient way to source information on the range of sales and services accessible to Australian buyers.

Instead of searching themselves, visitors are able to gain valuable insight through informal conversations with Pickles staff. It is also a way for Pickles to encourage industry enthusiasts to check out job listings and traineeship programs available for those looking to stick their foot in the door of the sector.

Convinced?

DDT needs little advertising: as Australia’s largest construction industry expo, it is a must-attend occasion for industry insiders.

From networking opportunities, to showcasing the power of Pickles, the importance of attending industrial events cannot be overstated.

By actively participating in these gatherings, the industry can thrive through collaboration, innovation and joint strength.

The National Diesel Dirt & Turf Expo is Australia’s largest construction industry expo and will be held from Friday to Sunday, April 12-14, at Sydney Dragway.

For more information about the expo, head to dieseldirtandturf.com.au. And make sure to visit the Pickles stand and live auction at the show.

One of the highlights each year at DDT is the feature auction run by Pickles.

25 www.earthmovers-magazine.com.au | E ARTHMOVING EQUIPMENT MAGAZINE

The Pickles stand at last year’s DDT Expo.

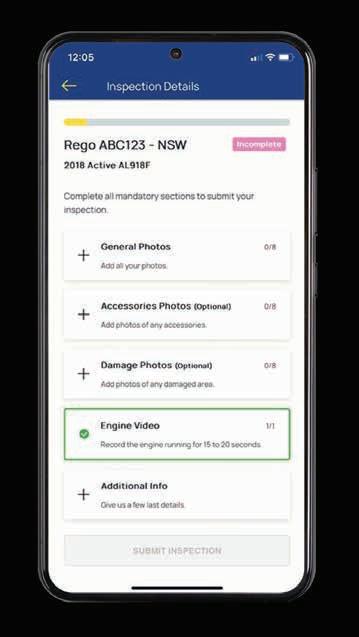

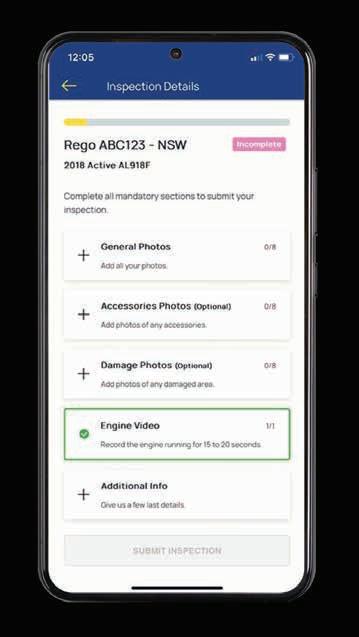

Need to offload your used trucks and machinery? DIYinspect is a self-inspection app powered by Pickles. Asset owners can simply download the app, complete an in-app inspection and receive an offer to purchase equipment. Start the process anywhere, at any time.

Why use DIYinspect?

DIYinspect helps customers sell their assets with ease and in their own time and space. By conducting remote inspections, sellers can maximise their time and return on their assets.

Customers receive data-led offers to purchase, eliminating the expense and hassle of conducting in-person asset inspections.

Sellers can offload a range of equipment including trucks, buses, excavators, and loaders.

Head to DIYinspect.com.au for more information, or simply download and get started!

Download DIYInspect Today

The entire process only takes 15 minutes and you simply follow the steps below to get started.

STEP 1

STEP 2

Download DIYinspect from the App Store or Google Play

STEP 3

Register a business account using your information incl. your ABN

STEP 4

Select the asset type you want inspected

STEP 5

Upload information, notes, photos and videos of your equipment

Submit your DIY inspection and we’ll get back to you within 48 hours!

STEP 2

STEP 4

Mapped, measured and modelled

Leica

Geosystems tools have proven to be indispensable for a specialty business making a solid mark in the industry.

Based in Victoria’s Mornington Peninsula, Dirtworx has made a name for itself in the earthmoving industry since its inception in 2014.

From humble beginnings with just a Kanga mini loader on the back of a ute, director JC has grown the business to a boutique earthworks operation comprising a team of nine and a fleet of about 23 plant machines, trucks and trailers.

And for the company to make such an impression in such a short space of time, it was important for it to keep an eye on the latest technological innovations and use them where needed to improve efficiencies.

JC said a great example of this were the geospatial units offered by positioning specialists C.R. Kennedy.

The company is the sole and exclusive distributor in Australia for Swiss solutions provider Leica Geosystems and a host of other manufacturers and brands.

“On our equipment, we currently have two Leica Geosystems MC1 units and an iCON iCG160 Rover from C.R. Kennedy,” JC said.

“They have enabled me to save money on labour costs and it has enabled me to work three times faster than if we were doing it by hand.”

The Leica Geosystems MC1 is a one-for-all software solution platform that consolidates all machine applications to help guide and automate all heavy construction equipment.

It simplifies design data handling and is open to all standard design data types, enabling a flexible dataflow to support common workflows on a job site.

It works in tandem with Leica’s iCON site software, which offers smart and customised positioning solutions for road construction and civil engineering applications.

With all platforms running on the same design data structure, a seamless data transfer between machines, field units within the job site and office is guaranteed.

“With the MC1 unit, you are able to upload survey plans straight into the system and then we are able to dig and be guided according to those plans,” JC said.

“Through allowing my team and I to see things faster, we are able to correct and adjust the way we are working and avoid errors, in turn enabling the team to be able to think on their feet faster and be able to make decisions quickly.

“The benefit is not just about saving money; it is about the speed that we are gaining information and picking up on errors that we normally wouldn’t. It helps us troubleshoot issues on the fly and allows us to get the job done quicker and accurately without any help.

“Our quality of work has improved significantly and our attention to detail is now on an elite level.

“The Leica system has allowed us to learn about earthmoving on a different level and how

we gain information. It has really changed the way we run our business and it has given our team the opportunity to upskill in a way that we are able to stay sharp, keeps us thinking outside the box and delivering a competitive advantage.”

JC said the whole setup had given the company the ability to not require any additional labour onsite, saving more than $80,000 a year.

“We can now work faster than ever, as a labourer is never as fast as the operator in the machine,” h said.

“The MC1 system is able to keep up with our needs, giving us the opportunity to have more trucks on site and move more material than we have ever done before. This allows us to complete quoted jobs faster, increasing profitability for our customers and our business.”

The Rover uses a Global Navigation Satellite System (GNSS) smart antenna designed to deliver unparalleled versatility and reliability in the construction industries.

It provides unmatched versatility supporting rover, base station, vehicle and various onmachine applications.

“The hand-held iCG160T tilt Rover device features a large colour display with intuitive navigation,” JC said.

“It enables quick and effortless setup without the need for extra hardware, while its user-friendly interface ensures a seamless experience, allowing users to get started promptly.

“The Rover is a pole-mounted GNSS unit with touch screen tablet. It communicates with the MC1 unit and gives us the opportunity to do spot checks.

29 www.earthmovers-magazine.com.au | E ARTHMOVING EQUIPMENT MAGAZINE

MACHINE CONTROL

The Leica iCON GPS100 GNSS machine antenna.

Dirtworx’s Takeuchi skid steer has been installed with the Leica Geosystems MC1 system. Image: Dirtworx

“It’s easy to set up and use. All you have to do is turn it on and click one or two buttons and that is how easy it is. Even with no experience you would be able to use the system easily.”

JC said the screens had so much detail that users were able to zoom in and see the finest details.

“This increases our ability to deliver our customers the most accurate earthmoving service. The products have no limitations and have been able to handle anything we throw at it,” he said.

“The MC1 unit is compatible with our tilt rotator and swing boom excavator, affording the ability to dig in all types of environments and bucket angles whilst giving us precise cut fill levels in any orientation.”

JC said he first contacted C.R. Kennedy about three years ago, when he was curious to see if its products suited the company’s needs.

“About one and a half years ago I made the jump. I was initially apprehensive about the purchase because of the outlay, but as soon as I used the equipment, I knew I had made the right decision,” he said.

“All the staff at C.R. Kennedy from sales to tech support were highly invested in my business and they took the time to learn about me and how I run my day-to-day operations.

“They took the time to analyse what I needed and made sure the Leica Geosystems product was the product for me. They were not just there to sell the product, but wanted to ensure the solutions were the right fit for my business, whilst helping realise a good return on our investment was achievable.”

The first machine to be fitted with the MC1 unit was a Takeuchi TB2150 16t excavator, which was complemented by a subsequent purchase of an iCG160T tilt Rover.

“We have used the MC1 system as a tool to be able to show our customers and other people that do not have an earthmoving background how the system works, and it also gives us the opportunity to show our customers what the requirements are on their sites,” JC said.

“This gives them and us the confidence that we are quoting and completing jobs accurately and correctly. We have all the appropriate information not to make mistakes.”

Dirtworx has recently purchased a Takeuchi TL12 V2, on which the MC1 system was also installed.

“This decision was a no-brainer and has become one of our greatest achievements,” JC said.

“The thing we are most excited about is the amount of effort the team at C.R. Kennedy have gone into to find a solution for our TL12.

“The setup enables the GPS and total station to give me heights and dig according to the plans, by taking levels from the bucket and multiple other attachments.

“We have already pushed it to our limits and we can’t wait to see what else it can do. We have no plans of changing from the Leica Geosystems and in particular C.R. Kennedy and will continue using them for many years to come.”

JR reiterated that the customer service from C.R. Kennedy was second to none.

“I am very fussy about my machines and I was very impressed by the installation and attention to detail,” JC said.

“They also provided me with training and they were happy to answer any questions I had. C.R. Kennedy conducted multiple training days at our yard and have call and text support whenever I need.

“C.R. Kennedy machine control manager Luke Fulton-Tindal has come out on site a handful of times to make sure everything was uploaded correctly and to ensure I was up and running perfectly.

“I am not a very tech savvy person, but the team at C.R. Kennedy have given me and my team the confidence to be able to use a system like this. The fact that they could set up the MC1 unit on our TL12, has enabled us to integrate the MC1 unit with the rover so they can work hand in hand.

“We have now created a more efficient business model and we can now push our limits further than we could have before.

“It is incredible to see how far the earthmoving industry has come and it has been an honour to be able to experience such a revaluation in the industry. The system is actually amazing and I don’t know what I would do without it now.”

About C.R. Kennedy

With its head office in a landmark Melbourne building C.R. Kennedy also runs major state offices in Brisbane, Adelaide, Hobart, Sydney and Perth with Regional offices in Cairns and MacKay servicing Far North Queensland. The family-run business celebrates its 90th anniversary this year.

C.R. Kennedy also offers a complete national after-sales service network, including training, service and repairs, technical support, hire equipment and customer care agreements.

The company services local Government, utility providers, mining companies, builders, surveying professionals, civil construction, and geospatial industries, delivering a level of service that matches the calibre of the brands it carries.

Luke said a significant aspect of the C.R. Kennedy offering was that it had access to partners around the world to source the latest in high tech spatial measuring equipment and related software solutions.

“The real success comes from our ability to partner with Leica Geosystems, and more importantly our customers, to offer them solutions that fit their business today with the ability to grow with them as their business grows,” he said.

“We also offer industry leading support and service and focus on the customer first, understanding the importance of clients having the right solutions for their business and coming alongside them as a consulting partner when it comes to their technology needs.

“Our products include land surveying equipment, unmanned aerial vehicles (UAVs), high definition 3D scanners, machine control, mobile mapping tools, underground service locators, ground penetrating radar, geospatial information systems (GIS) and an extensive array of software packages to suit the equipment and the application.

“To support our valued clients and customers, we now employ more than 260 people across all divisions.

“All our product specialists, qualified surveyors, support staff and factory trained service technicians can advise on the best solutions and provide customers with the very best equipment for their needs. Customers have support and service from an unmatched national network.”

30 EARTHMOVING EQUIPMENT MAGAZINE | www.earthmovers-magazine.com.au

MACHINE CONTROL C M Y CM MY CY CMY K

JC is more than happy with the performance of the Leica Geosystems products, and service from C.R. Kennedy.

For new

out

Owning the first machine: a finance roadmap

Starting an earthmoving business takes guts, and securing the right financing shouldn't be the biggest obstacle.

While traditional banks might hesitate to lend to newcomers, there are smart ways to get the equipment needed to build the future. Finance broker Finlease offers these recommendations.

Alternative finance options

Banks often favour established businesses, leaving start-ups feeling frustrated. Fortunately, alternative lenders understand the potential of new ventures and offer specialised equipment finance options.

Options for used machines and private sales

A reliable, used machine can be a wise first investment, allowing companies to start generating income and build equity, instead of spending money on rentals.

Used equipment can come at a significantly lower price point, reducing upfront costs. Plus,

with proper maintenance, it can deliver years of reliable service, getting the business off the ground without breaking the bank.

The 12-month strategy

A common approach for newcomers is to finance with a second-tier lender for 12 months, often with a 60 per cent or 70 per cent residual. After a year, there’ll be “runs on the board,” making it easier to refinance with a lower-rate lender.

The power of a small deposit

If you're a homeowner, consider leveraging equity to secure a deposit for the equipment loan. This can unlock better interest rates and more favourable terms.

Timing your ABN registration

If you’re planning to start a business, consider

registering your Australian Business Number (ABN) sooner rather than later. Having an ABN for over a year can make financing easier, even with mainstream lenders.

Consult a trusted broker

Finally, finding the right finance broker is crucial, especially for a new business. Seek a broker who understands the earthmoving industry and can connect to lenders who specialise in new businesses. They'll guide you through the options, advocate on your behalf, and help you get the best deal to launch your business with confidence.

Ready to get your earthmoving business off the ground? Contact a Finlease Equipment Finance Specialist to discuss financing solutions tailored to your needs. www.finlease.com.au

32 EARTHMOVING EQUIPMENT MAGAZINE | www.earthmovers-magazine.com.au

BUSINESS & FINANCE

businesses starting

and wanting to buy equipment, there are many finance options available. Image: sergeyryzhov/Shutterstock

ACN 003 752 636 ACL 390584 *T&C’s apply

If you’ve had an incident with your mobile plant or equipment (MPE), the first thing to do is call your insurance provider.

Ideally, your insurance provider should connect you with a specialist MPE recovery team. A good team will handle the entire process for you, including site recovery, cleanup, and salvage.

That's where NTI comes in.

Recovery specialists can save your business

When things go wrong, you want the right people to turn up on the scene. As NTI Technical Claims Officer Lisa Naylor says, the company carefully selects its preferred recovery partners to ensure they can do the job quickly and efficiently.

“We’ve got strict criteria,” Lisa said. “An important part of that is to be using up-to-date equipment. We require constant training and updates because there’s new technology for things all the time.

“Say a piece of equipment falls off a trailer for some reason.

"An experienced team will right the machine and lift it in such a way as to minimise any additional damage.”

It’s similar with site clean-up and remediation.

“You need to have an accreditation to be able to appropriately clean up and manage these sites,” Lisa said. NTI’s preferred suppliers aren’t just skilled; they’re also more cost-effective.

“We’ve seen clients use external contractors who’ve billed a million dollars for a site cleanup,” Lisa said, “where our preferred suppliers could have done the job for $700, 000.”

Case study: Bogged or total loss?

Not getting the right people on-site to deal with an incident can turn a relatively simple situation into a total loss. Lisa recalls a case involving a $392, 000 Kobelco excavator with only 50 hours on the clock.

On its first job, working on boggy land near salt water, it bogged with mud about halfway up its tracks.

The operator tried pulling the machine out with its boom and bucket, which only sunk it further.

Over the next four days, the operator tried several times to free it, from dragging to digging and putting down logs to create a solid path. But with tides coming in and out, rain, and the suction of the mud, the excavator was eventually fully submerged.

Only then did the operator call NTI. After spending nearly $100, 000 on failed recovery

job

MPE incidents: get the right

attempts and losing five days’ work on the project, the unit was deemed a total loss (due to the damage to its electrics) – adding nearly another $400, 000 to the bill. Then, they had to wait almost 12 months for a replacement machine.

If the owner had instead called NTI as soon as the excavator became bogged, a specialist team could have recovered it that day likely with less damage and with only minimal delay to the project.

Call the experts

NTI’s expert MPE claims team includes technical MPE claim specialists, risk surveyors and specialist MPE repair managers.

Team members have hands-on, real-life experience operating all types of plant and equipment. This experience gives them a deep understanding of the machines they look at every day when assessing claims.

Its specialist MPE repair managers come to NTI from backgrounds in servicing, maintaining and repairing plant and machinery. As with other team members, their previous experience means they can offer invaluable insight, support and guidance to our customers.

In short – NTI has got the right experts on the job to get you back to business faster.

34 EARTHMOVING EQUIPMENT MAGAZINE | www.earthmovers-magazine.com.au

people on the

call in

save

time and money. INDUSTRY INSURANCE

When things go wrong on site, having the right people to

is vital to

both

When making decisions about our insurance, consider the relevant PDS and TMD available through nti.com.au. National Transport Insurance is an equal joint venture administered on behalf of the insurers (CGU Insurance ABN 11 000 016 722 AFSL 227681 & Vero Insurance ABN 48 005 297 807 AFSL 230859) by its manager NTI Limited ABN 84 000 746 109 AFSL 237246.

Getting the right people on the job as soon as possible can prevent a bad situation getting worse. Image: DL80WES/stock.adobe.com

In-house trade-qualified Repair Managers Unique trading accounts with manufacturers, dealers & distributors Talk to your broker or visit Yellowcover.com.au An in-house parts procurement team As Australia’s #1 plant and equipment insurance provider, YellowCover provides insurance that Australian’s can rely on for the job. Specialist underwriting and claims teams are just the ticket to the game. We’re an insurance provider that’s with our customers from the start of a claim and repair - not just reimbursing at the end. That’s why we have: Insurance products are provided by National Transport Insurance, a joint venture of the insurers Insurance Australia Limited trading as CGU Insurance ABN 11 000 016 722 AFSL 227681 and AAI Limited trading as Vero Insurance ABN 48 005 297 807 AFSL 230859 each holding a 50% share. National Transport Insurance is administered on behalf of the insurers by its manager NTI Limited ABN 84 000 746 109 AFSL 237246. NTI.M034.1.19072021

We are an innovative, forward thinking organisation that make the procurement of heavy machinery quick and easy.

#GetToWork. 1300 225 594 ygg.com.au

We get to the point. So you can

Common sense equipment solutions

When Terry Danda relocated from Zimbabwe to Australia, he had to start from scratch with very little help on the equipment procurement front. Now, with the assistance of Yellowgate, his dedication and hard work is paying off in a big way.

As any business owner in the earthmoving and mining industries will tell you, getting equipment procurement right is a cornerstone for sustained success.

But for some, doing all the right things is not always enough. Some have to go the extra mile and work harder than the rest to get the results they need.

Terry Danda of Bunhu Mining is a perfect example. Since relocating from Zimbabwe several years ago, he has had to do many things the hard way.

“I started my business here in Australia in 2017 as a sole trader, but I’ve worked in the industry since 2003,” he says.

“I’m a qualified boiler maker, but when I first moved to Australia, I couldn’t get any work doing that. So, I started doing little bits of everything – working as a bricky’s labourer, doing home renovations, gardening, fencing, and roofing.

“I raised money to start buying earthmoving gear. I was buying equipment from farms down south, refurbishing it and using it.”

Digging deep

Off the back of his hard work, Terry laid the foundations of Bunhu Mining, which now offers a wide range of services.

“We do mining, haulage, crushing, processing, civil works, a bit of construction, and we’re working on starting a full-blown marine side too,” he says.

“I started doing earthmoving and demolition first. From there, I bought trucks and got into civil works in Marble Bar, WA in 2020.

“I got a contract to do mining and haulage in Port Hedland, then expanded into processing

and crushing, as well as major civil works.

“We’ve done some very rewarding jobs as a contractor for Main Roads WA projects, including for major civil company Fulton Hogan.”

Despite setbacks, the business has grown quickly – but much of that can be attributed to Terry’s wealth of experience.

“I used to run a business back in Zimbabwe, where I ran about 26 haulage trucks, carting coal, grain, and general goods,” he says. “I also have experience doing site works for acreage properties, as well as demolition and earthworks.”

In getting the Bunhu Mining business off the ground, Terry says his equipment procurement options were limited. As a result, everything was financed off his own back – raising money and funnelling it back into the business.

“Whatever money I was being paid was going back into Bunhu Mining, because as

37 www.earthmovers-magazine.com.au | E ARTHMOVING EQUIPMENT MAGAZINE

Yellowgate has helped Terry Danda raise money for his earthmoving gear. Images: Yellowgate

Terry gets to work with one of his dump trucks.

BUSINESS SOLUTIONS

Bunhu Mining offers a wide range of services, including mining, haulage, crushing, processing, civil works, and a bit of construction.

such a new business, my other options were limited,” Terry says.

“That changed in 2019 when I started getting a bit of funding. I was able to buy some small earthmoving gear to do some demolition work, but still needed to find another solution to help keep the business growing."

This process of hard work kept Terry going, but it still felt a little like treading water.

Things turned a corner when Yellowgate entered the picture. With its versatile rent-tobuy options, backed by industry knowledge, Yellowgate turned out to be just the right solution for Terry’s business.

And in the past few years, the two businesses have worked together to acquire four pieces of equipment, with more on the horizon.

“Yellowgate is structured in a way that they are very flexible, and willing to go that extra mile,” Terry says.

He says this is owing to the Yellowgate team's understanding of the industry, and a willingness to see the bigger picture. This means the kinds of work Bunhu Mining is undertaking, which Terry says is tied to some very stable resources markets, is factored into the equation.

“There’s a high demand for iron ore, as well as for lithium,” he says. “There’s a lot of jobs that need doing, and that could keep us busy for up to four years. But nowadays it can be very difficult to find equipment solutions backed by common sense.

“For some, procuring equipment is just about numbers and spreadsheets. They haven’t been on the ground to see what’s really happening. But Yellowgate speaks the language of the earthmoving and mining industries, and is willing to provide an ear.

“And for any business owner who can take an opportunity like that and use it wisely, they can very quickly build something successful.”

About Yellowgate

Yellowgate Group is a versatile company offering equipment rentals across various sectors including construction, civil, mining, agriculture, transport, and manufacturing.

It is known for providing quick and easy rental solutions, catering to a wide range of industry needs.

Yellowgate’s “Rent Now, Buy Later” offering is designed to maximise flexibility for businesses of any size and shape.

The process is a matter of three simple steps:

1. You specify the equipment you need, or Yellowgate can help source it

2. Yellowgate purchases the equipment and rents it to you

3. At the end of the rental term, you can Rent, Recontract, Purchase or Return the equipment.

To find out how you can leverage Yellowgate’s service on your nextproject, visit: www yellowgategroup.com.au

38 EARTHMOVING EQUIPMENT MAGAZINE | www.earthmovers-magazine.com.au BUSINESS SOLUTIONS

Terry Danda on one of his excavators.

Yellowgate has helped Terry drive his business forward.

Being a top gun roller operator

Scott Lidster elaborates on soil compaction, a critical process in earthmoving operations, essential for creating stable foundations, roads, and infrastructure.

Following on from a healthy stint on a “banjo” (shovel), the roller was generally the launching pad for most operators.

Proper compaction ensures that soil particles are densely packed together, minimising settling and improving load-bearing capacity.

To achieve optimal results and maximise efficiency in soil compaction, there’s a process you must follow to get the ground you’re working harder than trying to decipher a Jo Biden sentence.

Follow on to learn more soil compaction.

Understanding soil properties

Get down amongst it! Before beginning the compaction process, it's crucial to assess the soil's properties, including its moisture content, particle size distribution, and compaction characteristics. Different types of soil require different compaction methods, so understanding these properties is essential for selecting the appropriate compaction equipment and techniques.

Moisture management

This is critical. Proper moisture content is vital for effective compaction. Soil that is too dry will not compact well, while soil that is too wet will become muddy and difficult to work with. You need to constantly monitor soil moisture levels closely and adjust water content as needed to achieve the optimal moisture range for compaction.

Equipment selection

Get the right tool for the job. Choosing the right compaction equipment is key to achieving desired compaction results. “Sheep’s foot” rollers, smooth drum rollers, and pneumatic tire rollers are commonly used for soil compaction, each offering unique advantages depending on the soil type and project requirements.

• Sheep’s foot rollers: These are a type of compaction equipment used in soil compaction, featuring cylindrical drums

studded with protrusions resembling the hooves of a sheep, hence the name. This design helps to break up rock, knead and compact cohesive soils effectively.

• Smooth drum rollers: These rollers have smooth steel drums and are ideal for compacting asphalt and fine-grained soils. Pneumatic tyre rollers: These rollers use rubber tires to apply pressure and knead the soil, making them suitable for compacting cohesive soils and finishing surfaces.

• Selecting the appropriate equipment size and configuration is essential for achieving uniform compaction across the entire surface area.

Proper technique

When compacting soil, it's important to follow proper technique to ensure even compaction and avoid over compaction. Operators should make multiple passes over the soil surface, overlapping each pass slightly to ensure uniform compaction. It's also important to vary

the compaction direction to minimise the risk of soil layering and achieve consistent compaction throughout the depth of the soil.

Quality assurance

Obviously testing and monitoring are essential for ensuring compaction quality. That’s when the soil testers, aka ”dirt doctors”, join the chat. They perform field density tests, such as the sand cone or nuclear gauge test, to verify compaction levels to see what kind of compaction job you’ve done.

Righto, there you have it. By following these guidelines and utilising best practices in soil compaction, you can become a “top gun roller operator” and achieve optimal results, ensuring the long-term stability and durability of infrastructure projects across Australia.

Australian Earth Training: scott@australianearthtraining.com.au www.australianearthtraining.com.au

40 EARTHMOVING EQUIPMENT MAGAZINE | www.earthmovers-magazine.com.au

INDUSTRY TRAINING

There are proper procedures to follow to achieve optimal results and maximise efficiency in soil compaction. Image: Australian Earth Training

Choosing the right compaction equipment is key to achieving desired compaction results. Image: LiuGong

1300 820 214 itrpacific.com.au BRISBANE | MACKAY | SYDNEY | MELBOURNE | ADELAIDE | PERTH | KALGOORLIE UNDERCARRIAGE COMPONENTS | RUBBER TRACKS & PADS GROUND ENGAGING TOOLS | REPAIR PARTS TYRES & MORE STAND L2

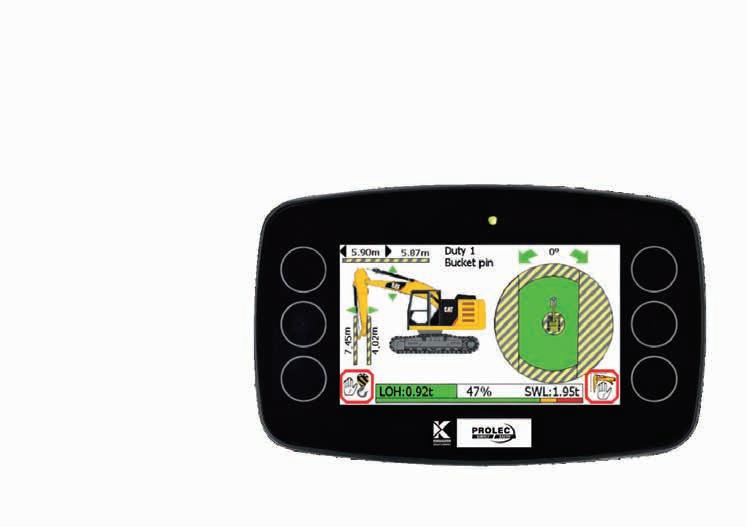

The link to greater jobsite efficiency

VisionLink® Productivity offers high-level fleet and jobsite visibility to users, allowing them to keep track of operations and maximise efficiencies.

See more, know more, and do more with VisionLink® Productivity. The easy-to-use, cloud-based platform offers high-level fleet and jobsite visibility to users, allowing them to keep track of operations and maximise efficiencies.

It gathers, analyses and summarises machine telematics and jobsite data from equipment. By delivering actionable insights, VisionLink ® Productivity allows businesses to:

• improve site productivity

• lower cost per tonne

• improve fleet utilisation

• lower fleet costs

• decrease idle time

• reduce fuel burn

One construction business reaping the benefits of VisionLink Productivity is MDM Mining and Civil, a 100 per cent Indigenousowned and operated business on a mission to return the decommissioned mine to its pre-mining formation through remediation and rehabilitation work.

Led by Tiltuwam Traditional Owner Mika McLennon, their mission is personal; and partnering with VisionLink Productivity means the next generation of custodians can connect technology with traditional Indigenous knowledge.

The Argyle diamond mine rehabilitation program

At Rio Tinto’s Argyle diamond mine in Australia’s East Kimberley region, MDM Mining

and Civil is delivering a major rehabilitation program. The rehabilitation program is a comprehensive and detailed process that’s expected to take five years.

Mika is the Director of MDM Mining and Civil. As a Traditional Owner of the land himself, he ensures operations are environmentally safe, culturally respectful and that he can contribute to his family’s obligations to continue being for the country that had been disturbed by mining operations.

“Argyle’s actually my grandmother’s country,” Mika said. “I had a very strong connection with my grandmother, she’s passed now but I know she’d be proud that we’re all involved in healing country.”

Taking the load off

Mika would rather not waste time tracking and monitoring his 22 Cat® machines when VisionLink Productivity can do it for him.

“We’ve seen the competitors trying to use outdated methods, having the whiteboard up there and tracking all their utilisation, manning and resourcing,” Mika said.

“With VisionLink Productivity, we’ve got all our data and information at our fingertips. It doesn’t take a lot of manhours to capture it or display that data back to the team, which then generates conversation about how to do it better. That’s our advantage.”

Making better decisions

WesTrac Technology Application Specialist

Neil Dodge says customers who measure their productivity can generally improve their operations.

“If you haven’t got any data to understand where you’re currently at, all you’re doing is really making assumptions,” Neil said.

“Once you have data, you look at your data, you analyse it, and then you start putting in ways of improving simple stuff like idle times, or shift management when people take meal breaks.”

Visibility from afar

With most of Mika’s operations occurring in remote parts of the East Kimberley, VisionLink Productivity acts as an extra set of eyes watching his machines and operators.

“We have another project, towards Halls Creek, on the Tanami, 200kms away from Argyle,” Mika said.

“We can tell if a person has their seatbelt on in a machine, so it’s a tool I would use to help train and monitor safety on the job as well.”

Want to get started with VisionLink Productivity? Contact your local Cat dealer or visit cat.com/productivity

42 EARTHMOVING EQUIPMENT MAGAZINE | www.earthmovers-magazine.com.au

TECHNOLOGY EXPERT

Mining and Civil is using VisionLink®

to assist its major rehabilitation program in the East Kimberley. Image: Caterpillar

MDM

Productivity

CONTROL PIPES YOUR SWINGING

PIPEBOSS is a new attachment that controls, lays and aligns pipes with full view, directly from the excavator’s cabin.

Starting a new pipe laying project?

Worksite injuries can include crush injuries, neck and back injuries, amputation, spinal injuries, permanent disablement, or even cause wrongful death. Swinging pipes lifted on chains or straps are dangerous! PIPEBOSS is your safe & efficient option.

What is PIPEBOSS?

Pipe movement and placement can be undertaken mechanically via the PIPEBOSS attachment, with workers able to be within a safe distance to minimise injury. Because the pipe is being held in a fixed position and it’s movement being controlled by an operator, worker injuries are minimised due to the pipe not moving freely on a chain or sling while the worker is in the trench.

Got a project coming up?

Go to www.pipeboss.com.au to get a quote.

Advanced alignment technology

Firm grip technology Safety assurance

Advanced alignment technology

Firm grip technology Safety assurance

Come see a live, in action display at: Sydney - Diesel, Dirt & Turf Show Laneway stand 10 &1 1 – 12th-14th April Melbourne - FutureAg Expo Stand 306 – 17th-19th April www.pipeboss.com.au Sales@pipeboss.com.au (07) 5597 0511 32 Jade Dr, Molendinar Qld 4214

Mastering TikTok for your brand

Even if you’re not on TikTok, even if it’s not the right channel for your brand, even if you don’t care about it one bit – TikTok is shaping the content that performs well in every other social channel. The team at Hardman Communications has advice on getting the tik without the tok.

Did you know that TikTok has 1.5 billion users globally and one billion users are active each month? Those are not figures you ignore.

A lot of TikTok content makes it to other channels and performs really well there. That Instagram video everyone is talking about could very well have shown up in TikTok first.

So if you are on other channels, think about how you can inject a little TikTok magic by trying ‘TikTok style videos’ on Instagram or Facebook.

You don’t need a TikTok account to make this happen. There are several software programs you can use to create these styles of videos, like Canva or CapCut (both free).

Here are some tips to make TikTok style videos for your business:

• Just start. Don’t over think or over plan your content because trends might change by the time you think you’re ready.

• You don’t need to run paid ads to be successful

• Your video determines the success, NOT the time of day you post or the hashtags you use. If your video falls short, it’s because the early viewers didn’t like it, so the algorithm didn’t promote it. It’s time to test something new

Your first goal should always be brand recognition. People need to get to know you before you build leads. Remember, Gen Z might not ‘buy’ from you now, but they could later

Try lots of different video styles at first to see which ones perform best. Adapt that formula for a while then test again. Keep some consistency so people get to recognise your videos but don’t be afraid to experiment Dedicate some time to it: allocate one day a month for shooting video content. Post two to three videos per week, ideally.

• Social media users LOVE finding mistakes. Consider having something funny in the background or give four tips instead of five. Even ‘bad’ content can be good, and the more comments and engagements you get, the higher your reach. A word of caution, though: stay true to your brand and don’t undo your brand work to get some extra engagement on a video

• Videos with people in them perform better, especially if they evoke emotion. Have a face for your brand, if possible

• B2B content should be informative but not boring – for example a cyber security company went viral for “How we saved our client $500,000” and spoke of preventing a firewall break in

Tik Tok-style videos can be a big boost to businesses. Image: Rokas/AdobeStock

• Media often reports on TikTok videos. If you have a great video, you can outreach to media to feature in their news

• Don’t blindly copy trends, incorporate some of them into your campaign or adapt the trend to suit your style. Always revert to your social media strategy to stay on track.

About Hardman Communications

The company offers the full spectrum of strategic communications and PR support, whether you are running a single campaign or need a complete communications program.

With extensive experience in complex project development and delivery, the team helps customers find the sweet spot where business goals intersect with meaningful stories, and uncover the insights that will drive your business forward.

Specialist fields include agribusiness, at every point in the supply chain; infrastructure,

mining, and construction; regional communications – especially for big businesses who want to connect with regional audiences; and Western Sydney clients who want to be part of the transformation of this region. Their work covers the full range of communications activity:

• Planning starting with understanding the client, goals and market

• Doing includes everything from writing content to training staff to setting up social channels and getting your business in the media (or keeping you out of it)

• Measuring is about looking at the results and learning from them

Connecting is about bringing together clients with others in the industry and creating winwin opportunities.

Learn more about Hardman

Communications: visit hc.net.au

44 EARTHMOVING EQUIPMENT MAGAZINE | www.earthmovers-magazine.com.au

MARKETING AND PUBLIC RELATIONS

Knowing precisely how long specific functions take — including travel loaded and empty times; load, dump, and roading times; swing, dig and wait times — is key to making smart, informed decisions. Images: CAT

Gaining the edge

Caterpillar® Senior Strategy Consultant Michael Miller outlines the benefits of using a production-management system. This advanced construction technology delivers timely, accurate information that can help spot inefficiencies, improve production and enhance safety.

With today’s construction technology, contractors can get a wealth of accurate data that tells them exactly what’s going on with machine health, production levels, fuel burn and idle time. That’s highly useful for operations of any size.

But for bigger operations, with multiple jobsites running fleets of machines, being able to view the data from an individual machine level all the way up to the organisation level is essential. And that’s what a production management system does. It allows a high-level overview of an operation, and drills down to find the detailed information needed to make decisions that will reduce costs and enhance safety.

An accurate picture with productivity management

Specialising in productivity, Michael said it was all about giving the decision maker an accurate picture of their operation and providing them with opportunities to implement change and make improvements to machine utilisation and operational efficiency.

Knowing precisely how long specific functions take — including travel loaded and empty times;

Implementing a production-management system like VisionLink Productivity can open up new opportunities to get more from your operation.

46 EARTHMOVING EQUIPMENT MAGAZINE | www.earthmovers-magazine.com.au

MEET THE EXPERT

load, dump, and roading times; swing, dig and wait times — is key to making smart, informed decisions. Production-management systems help managers track all those measurements and analyse them to spot bottlenecks and inefficiencies.

As an example, Michael cited the issue of excessive waiting time in the load area. Using the analytic tools built into a good productivitymanagement system such as VisionLink® Productivity, he said: “You can track material movement and, importantly, see how much time is spent in each part of the cycle. By slowing the machines down on the return, you could keep a more consistent flow of traffic and potentially reduce the non-productive waiting time and fuel consumption.”

Engage your operators

“Better still,” Michael added, “imagine being able to replay an event to identify areas for improvements based on relevant, real-time data. Guesswork is eliminated.

“Being able to include your operators in this review, with powerful visuals including maps and graphs, allows you to work together to identify inefficiencies and find solutions. Discussions like these – based on hard data – strengthen partnerships with operators. It facilitates objective, informed conversations that promote solid operator buy-in.”

Tighter, more accurate estimates

Michael went on to explain reliable construction data is a huge help when pulling together quotes for future work. With a productivity-management tool, an assessor can feel confident in their ability to estimate competitively because they’re using actual machine and project data from the past.

Relying on accurate data helps put together a tighter, more competitive bid. It’ll also allow monitoring the project as it happens and measuring against targets to ensure completion on time and on budget.

A good productivity-management tool also allows the building of cost dashboards that show where and when the key cost impacts are happening. Miller noted these kinds of dashboards the real cost of moving material at a glance – the operating cost-per-hour and payload, and whether there are idle time costs that could be reduced.

Construction technology gives an edge

Modern construction technology has the power to help you to reduce costs and inefficiencies, increase productivity and profitability, and enhance worksite safety. Michael concludes that implementing a production-management system like VisionLink Productivity can open up new opportunities to get more from your operation every day.

•

•

•

•

•

•

47 www.earthmovers-magazine.com.au | E ARTHMOVING EQUIPMENT MAGAZINE

Caterpillar Senior Strategy Consultant Michael Miller specialises in productivity.

Contact your local Cat dealer now: