THE KOBELCO SK850LC MAKES LIGHT WORK OF BASEMENT EXCAVATION IN MELBOURNE.

+ Bio Gro and Cat® Equipment

+ Earthfix and Komatsu

+ Newcastle Sand and CJD Equipment

+ Thurkles Earthmoving and Cat Equipment

+ Holcim and LiuGong

+ Innovative Products + Dealer Profiles

+ Eye On The Industry

+ In Focus: Cat 255 Loader + Association News

JUNE - JULY 2024

Better Bigger is $7.95 inc GST

CASE STUDIES FEATURED TOPICS

Finance available on models; PC18MR-3, PC30MR-5, PC35MR-5, PC45MR-5, PC55MR-5, PC78UU-11, PC88MR-11

Terms and conditions apply. 1300 119 534 | komatsu.com.au

Unearth Big Savings: low rate finance on 1.8T - 10T excavators

1.99 %

Hurry offer won’t last p.a

Welcome

Ray Chan Editor

Ray Chan Editor

Technological advancements in all industries have been accelerating at an unprecedented pace in recent years, and the earthmoving sector of course is no exception.

A constant stream of innovations is revolutionising the way construction and excavation projects are undertaken, driven by a combination of factors including increased demand for efficiency, safety regulations, environmental concerns, and the availability of advanced materials and computing technologies.

This issue delves into some of the latest products to hit the market, spearheaded by our cover story on Kobelco’s SK380SRLC-7, the company’s heaviest and most capable short radius excavator to date. Providing large conventional capability in a compact design, and loaded with new features, the machine is suited to working on urban and residential jobsites and is gaining popularity due to ongoing requirements for roadworks and utility maintenance. Meanwhile, the all-new, next generation Cat® 255 is stirring up waves after making its Australian debut at the recent DDT Expo in Sydney.

A ground-up redesign of the previous series, the loader boasts improved engine performance, lift and tilt performance, stability, operator comfort and technology.

And with the growing emphasis on

decarbonisation, more and more electric machines are making it onto the market. Read about Volvo Construction Equipment's L25 electric wheel loader, the first in a new range of electric compact equipment from the company, as well as LiuGong's battery-powered 856HE, characterised by improved load-sensing hydraulics, advanced safety and comfort features, and able to work for long periods without the need for charging.

Overall, the pace of technological progress shows no signs of slowing down. As new advancements continue to emerge, you can be assured that we’ll keep you abreast of the latest developments to help you remain competitive in an increasingly dynamic market.

And that’s just the tip of the iceberg for this edition: or, perhaps, in our case, the tip of the dirt pile.

We have our usual informative series of case studies that take you from one end of the country to the other, looking at various ways earthmoving companies are carrying out their operations with the best equipment available to them.

Of course, there’s plenty more: an abundance of innovative product and dealer profiles, the informative contributions from our industry partners, and lots of eyes on the industry.

Happy digging!

Ray Chan Editor

4 EARTHMOVING EQUIPMENT MAGAZINE | www.earthmovers-magazine.com.au

FROM THE EDITOR

The durability and reliability of Komatsu equipment continues to be the backbone of the operations of Earthfix, the sustainable smart farming initiative set up by Gold Coast-based civil construction hire company Sniffers Group. Image: Prime Creative Media

6 EARTHMOVING EQUIPMENT MAGAZINE | www.earthmovers-magazine.com.au CONTENTS 11. On The Cover 18. Meet The Expert: Parts And Aftermarket 22. Industry Leaders 26. Industry Auctions 29. Machine Control 33. Business And Finance 36. Industry Insurance 40. Technology Expert 42. Industry Training 44. Meet The Expert 49. D ealer Profiles 56. Business Solutions 58. Meet The Expert: Shoring 60. Marketing And Public Relations 62. C ase Studies 96. Product Review 100. Si te Dumpers/Dump Trucks 108. R oads And Paving 114. Innovative Products 159. Eye On The Industry 165. National Association Of Women In Construction 166. Civil Contractors Federation Victoria 167. Civil Contractors Federation Queensland 168. Allied Earthmovers Association CONTRIBUTORS Scott Lidster Scott is the Director of Australian Earth Training, a niche operator proficiency training organisation who work across the globe. He has more than 25 years’ experience in heavy equipment operation and was an accredited Caterpillar Dealer Instructor (CDI) Trainer-Demonstrator. Scott’s unique skill set enables him to operate and train on a broad range of machines across the mining, construction, quarrying and waste industries, helping his customers to boost their productivity while lowering their owning and operating costs. Mark O’Donoghue Mark O’Donoghue is the CEO and founder of Finlease. financing over $700mil p/a in equipment finance for private business owners in Civil and related industries. A family business with a nationwide network, Finlease has a 30year track record of establishing long term relationships with clients, finding them the best finance solutions to support their business growth. The company’s goal is to make the finance process simpler for businesses so they can focus on what they’re good at. Ann Callaghan Ann has been the Manager of Allied Earthmovers Association for the past 19 years, bringing many years’ experience into the role. After gaining business qualifications and managing a retail shopping centre in Sydney CBD, Ann first started her career in earthmoving when she joined the long-established family business in Penrith, which specialised in Caterpillar graders and dozers. Working in a maledominated industry, Ann brings a different aspect to the Association. She has met many people in the industry and knows what the owner operator needs, from the importance of paperwork to machine availability. It’s an industry she respects and is proud to be a part of. Earthmoving Equipment Magazine Earthmoving Equipment Magazine earthmoving_equipment_mag

Earthmoving Equipment Magazine is published bimonthly by Prime Creative Media Pty Ltd.

CEO John Murphy

Christine Clancy Sales Director Bradley Buchanan Editor Ray Chan

ray.chan@primecreative.com.au

Brand Manager KahChi Liew

kahchi.liew@primecreative.com.au 0421 474 407

Production Editor

Michelle Alder

michelle.alder@primecreative.com.au

Art Director/Design

Daz Woolley, Cat Zappia

Subscriptions

P. +61 3 9690 8766 subscriptions@primecreative.com.au

Website www.earthmovers-magazine.com.au

Kobelco’s

Copyright Earthmoving Equipment Magazine is owned by Prime Creative Media and published by John Murphy. All material in Earthmoving Equipment Magazine is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical, including information and retrieval systems) without written permission of the publisher. The editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions, or for any consequences arising from reliance on information published.

The opinions expressed in Earthmoving Equipment Magazine are not necessarily the opinions of, or endorsed by, the publisher unless otherwise stated. © Copyright Prime Creative Media, 2024.

Articles

All articles submitted for publication become the property of the publisher. The editor reserves the right to adjust any article to conform with the magazine format.

Head Office 379 Docklands Dr, Docklands VIC 3008 P:

7 www.earthmovers-magazine.com.au | EARTHMOVING EQUIPMENT MAGAZINE

COO

+61 3 9690 8766 enquiries@primecreative.com.au www.primecreative.com.au

Office Suite 3.06, 1-9 Chandos Street Saint Leonards NSW 2065, Australia P: +61 2 9439 7227 JUNE JULY 2024 THE KOBELCO SK850LC MAKES LIGHT WORK OF BASEMENT EXCAVATION IN MELBOURNE. Better Bigger is $7.95 + Innovative Products + Dealer Profiles + Eye On The Industry + In Focus: Cat 255 Loader + Association News + Bio Gro and Cat Equipment + Earthfix and Komatsu + Newcastle Sand and CJD Equipment + Thurkles Earthmoving and Cat Equipment + Holcim and LiuGong CASE STUDIES FEATURED TOPICS

fleet of Volvos has helped NSW-based sand extraction business Newcastle Sand quickly establish itself in the industry.

Media

Sydney

A

Image: Prime Creative

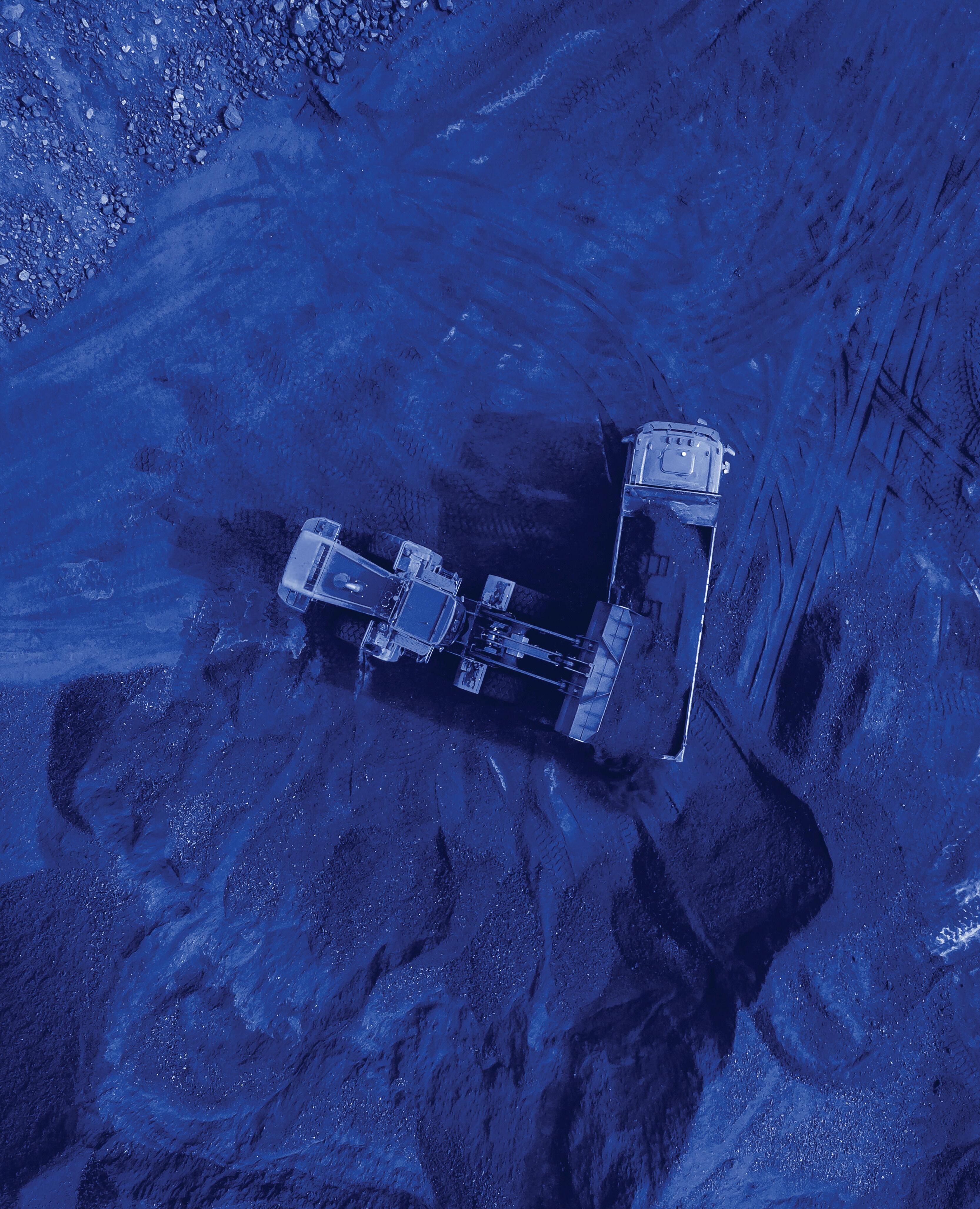

largest production-class excavator, the SK850LC, has been used to help build a five-level office basement in the heart of Melbourne. ON THE COVER

Fahey

is the General Manager of the National Association of Women in Construction (NAWIC). With a strong background in behaviour change, leadership and a passion for advocacy, Lauren is dedicated to driving NAWIC’s vision of creating an equitable construction industry where women fully participate. NAWIC strives to empower women through community building, personalised member experiences, and fostering meaningful connections and exchanges among women in construction.

Lauren

Lauren

JETLAND is a leading supplier of high strength & heavy duty Aluminium loading ramps in Australia. High quality raw material and safety testing systems ensure a safe and reliable product.

No manufacturing delays, all ramps listed online are in stock at our warehouse in Mordialloc, Victoria.

We can also supply Custom built ramps - made to your specifications for your particular needs.

Free Delivery Australia wide. MOVING YOUR MACHINERY WITH US YOUR SAFETY IS OUR PRIORITY 0420 815 988 jetlandramps@gmail.com Rear 211-219 Boundary Road Mordialloc Vic. 3195 jetlandramps.com.au HEAVY DUTY LOADING RAMPS

TRACKED CARRIER

Engineered and factory built tough for Australian conditions, Bell’s evolutionary approach to design delivers exceptional safety, control, performance and uncompromised reliability.

EVOLUTIONARY IN DESIGN NEXT GENERATION IN SAFETY

DISCOVER MORE 1300 505 055 CONSTRUCTION.AU@TVH.COM WWW.TVH.COM UNEARTH UNDERCARRIAGE PARTS Turn to TVH to buy sprockets, idlers, rollers, and other associated undercarriage parts to keep small earth-movers going. TVH AUSTRALIA PTY LTD • HEAD OFFICE BRISBANE ABN 67 117 701 587 • 60 Bernoulli Street • Darra QLD 4076 • Australia T +61 7 3717 3222 • F +61 7 3275 3881 • info.au@tvh.com • www.tvh.com ADELAIDE 62–64 Wingfield Road Wingfield SA 5013 T +61 8 8359 1155 F +61 8 8359 0600 adelaidesales@tvh.com BRISBANE 735 Boundary Road Richlands QLD 4077 T +61 7 3277 0877 F +61 7 3277 0026 brisbanesales@tvh.com MELBOURNE 7/66–74 Micro Circuit Dandenong South VIC 3175 T +61 3 9544 6622 F +61 3 9544 2617 melbournesales@tvh.com PERTH 2/15 Colin Jamieson Drive Welshpool WA 6106 T +61 8 9358 2200 F +61 8 9358 2822 perthsales@tvh.com SYDNEY 4/463 Victoria Street Wetherill Park NSW 2164 T +61 2 9756 6677 F +61 2 9756 3555 sydneysales@tvh.com SCAN OR CONTACT US

The perfect digging machines

Kobelco’s massive new SK850LC excavator has taken durability to the next level.

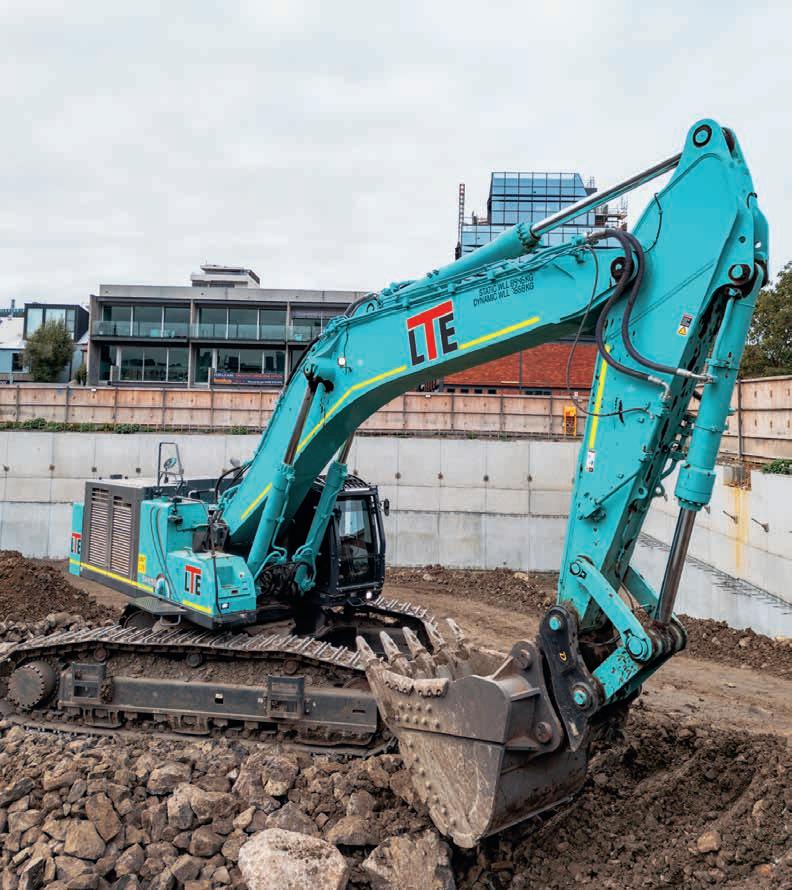

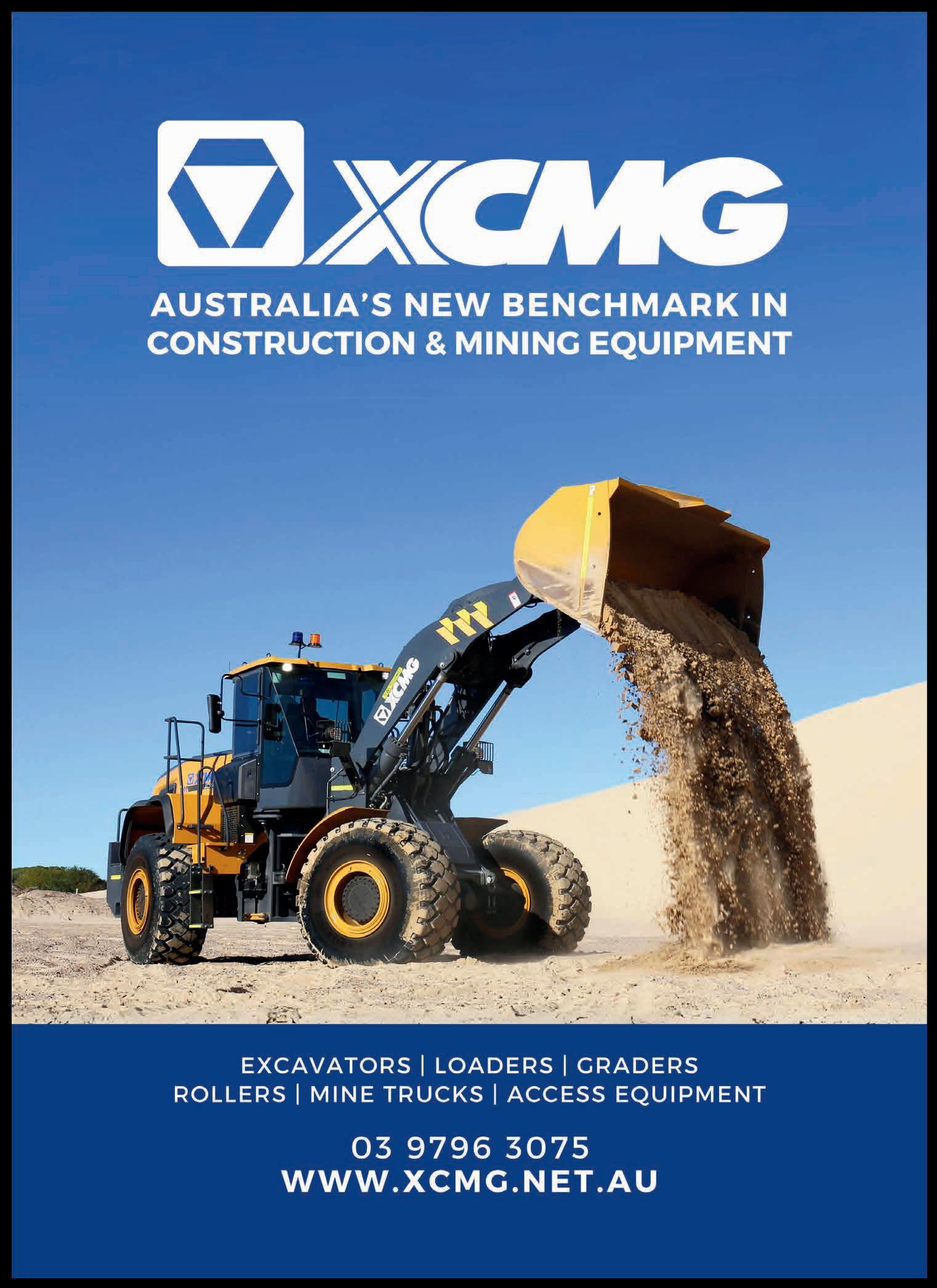

How many is too many? When it comes to Kobelco excavators, it seems that no amount is ever enough for Victorian earthmoving contractor LTE Construction Group.

Melbourne has been a hive of activity in recent years when it comes to construction work, as the city advances through Victoria’s Big Build programs.

And if you look at any of the many works being carried out in the city, chances are you’ll see that they’re carried out by LTE, a family-owned and operated foundation piling contractor, civil earthmoving contractor and transport provider, with a combined relevant industry experience of 40 years.

Operational manager Nemanja Maric said the love affair with Kobelco has lasted for the 18 years he’s been with company, with purchases of at least 40 of the blue machines in that time, and a total of 87 since the business began.

And there’s good reason for that.

Owned and started by Managing Director Nick Maric in 1998, LTE carries out tasks that range from bulk excavation, rock drilling, CFA piling, basement retention system design to various constructs.

The clients typically include major property developers, large construction builders, local and state government authorities, civil infrastructure companies, landfill operators and private developers.

“Our team consists of experienced engineers, piling and machine operators, truck drivers and traffic controllers,” Nemanja said.

"They have the capability to re-design projects to provide clients the greatest flexibility and most cost-effective solution for even the most difficult challenging projects.

“Our fleet comprises piling rigs along with a diverse array of heavy earthmoving equipment such as excavators, cranes, loaders, bulldozers, graders, compactors and truck and trailers.

“And of these, Kobelcos make up the majority. They’re resilient, durable, dependable, efficient.”

The worth of the machines was demonstrated aptly on a recent project involving the completion of a five-level office basement for the Pace Development Group in Flemington.

“Our confidence in undertaking such a largescale project stemmed from having our range of reliable Kobelco excavators,” Nemanja said.

“We had excellent service support from Kobelco, which gave us the assurance and peace of mind needed to successfully complete the project.

"The project site was all rock. We used a range of excavators which efficiently handled all the detailing. We had a 23 tonne Kobelco, a 38-tonner and a 52-tonner, topped off by our new SK850LC 85t monster on the job.

“We’re doing the slabs on-ground for the site, including two crane bases, with the required strip and pad footings.

The SK850 digs through with ease at the Flemington project. Images: Prime Creative Media

11 www.earthmovers-magazine.com.au | EARTHMOVING EQUIPMENT MAGAZINE

ON THE COVER

Getting through the hard rock at the site was no problem with the Kobelco excavators.

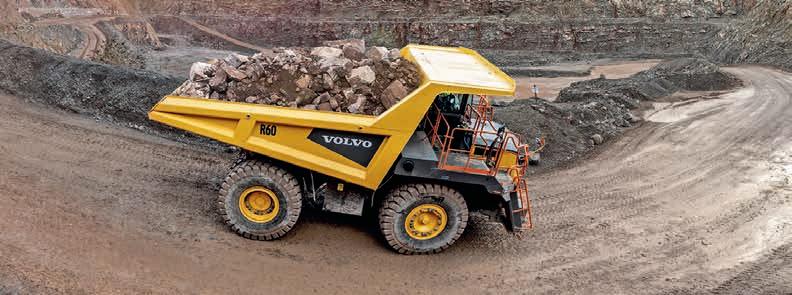

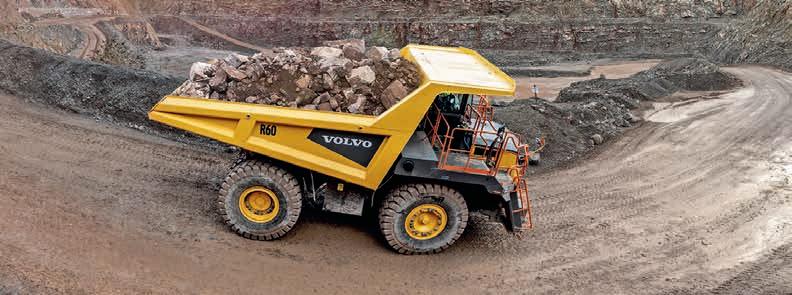

“Completing such a large-scale project like this is always a great feeling. It’s a testament to the hard work, dedication and collaboration of everyone involved, and of course the machines.”

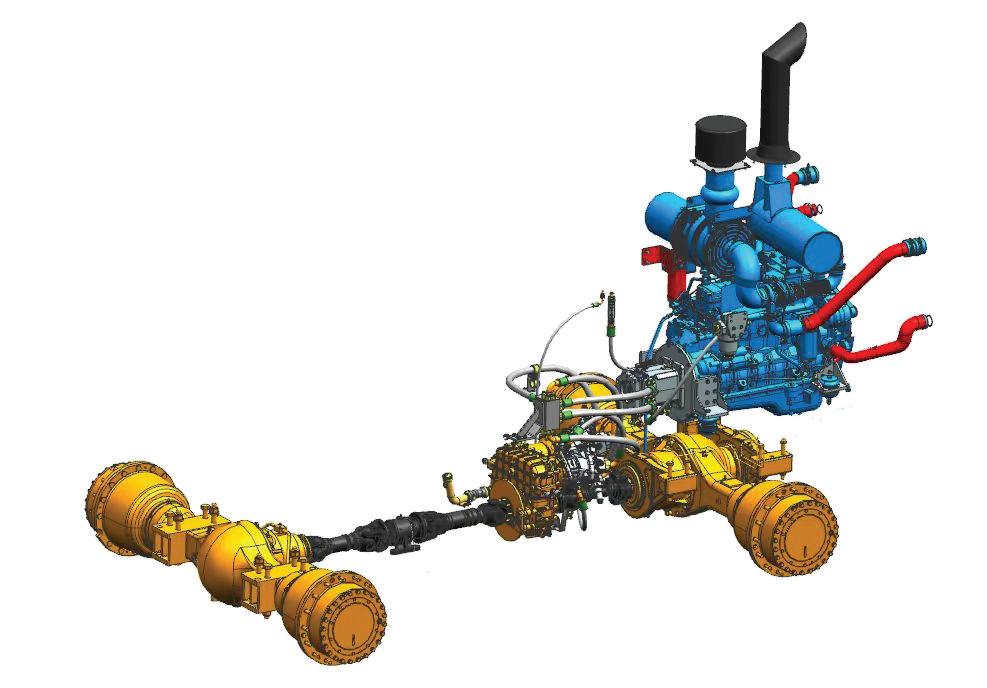

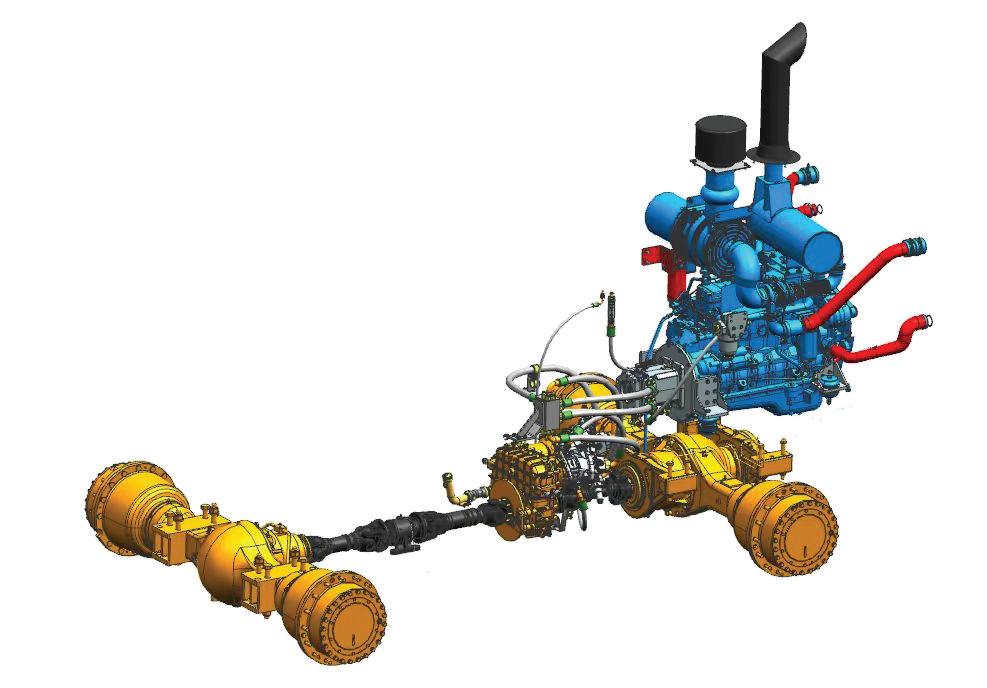

The SK850 is currently the biggest productionclass excavator in the company’s range.

While it’s a far cry from LTE’s first Kobelco purchase, an SK100, it maintains the same high standards of performance.

the machine is fantastic as well.

“This machine is helping us out in having very efficient and very productive timelines when we cart out the dirt.”

SK850LC specifics

The excavator features cutting-edge power and efficiency capabilities. With a base operating weight of 80,800 kg and built to withstand the rigours of the toughest jobsites around the world, the SK850 takes durability to the next level.

“We bought this about six months ago and initially used it for a project at Truganina where we were carting out one million cubic metres of dirt,” Nemanja said.

“Then we got this machine out over here at Flemington because of the hard rock. It’s very easy to rip off all the rocks with the SK850, and it’s easy to load.

“And the production is really fast and the fuel consumption is really good. The efficiency of

The SK850LC has undergone extensive development, after being put to the test in demanding quarry and mining conditions across the globe.

The 12.9 litre turbo-charged and intercooled Hino engine delivers an outstanding 380 kW of power for superior strength and unbeatable performance. Class-leading work volume is achieved with powerful bucket breakout force and arm tearout forces, delivering fast digging cycle times and impressive productivity.

Combined with an intelligent hydraulic system

12 EARTHMOVING EQUIPMENT MAGAZINE | www.earthmovers-magazine.com.au

ON THE COVER

The LTE team at the project site: Project Manager Prashant Chahal (left), Nemanja Maric, and Site Foreman Pedja Stefanovic.

The team of Kobelcos used by LTE at the worksite.

When extra lift capacity is required, a heavy lift mode can be activated.

built for speed and control, the SK850 delivers an impressive average fuel consumption of under 50 litres per hour—substantially boosting operating profit in a production environment.

Operators can climb stockpiles with ease with the class-leading drawbar force, ensuring plenty of tractive power for the most extreme site conditions. Three heavy-duty track guides are also installed on each crawler side frame to further increase undercarriage durability.

Kobelco excavators are also highly regarded for their advanced technology in fuel efficiency, and the SK850 is no exception.

The enhanced hydraulic system design reduces energy loss to ensure outstanding performance by minimising hydraulic pressure resistance.

The excavator also features Kobelco’s latest cooling system – a hydraulically-driven twin fan engine cooling system.

This hydraulic version also prevents overcooling by use of integrated sensors to reduce the speed of the twin-fan unit, helping to improve fuel economy and reduce noise, a

feature welcomed by Nemanja.

“Fuel efficiency holds significant importance for our business as it helps minimise our operational costs,” he said.

“We are continuously upgrading our fleet to the latest Kobelco models to ensure optimal efficiency and cost-effectiveness.”

Users can select the best operation mode for the job at hand, with three work modes to choose from: H-mode, S-mode and ECO-

mode, allowing for minimum fuel consumption while optimising digging efficiency.

Inside the cab, it’s an operator’s dream. They can look forward to staying safe and comfortable, thanks to an air suspension seat, combined with a 25 percent reduction in lever control force that reduces fatigue during long hours of operation.

A standard 12V port and AUX jack is provided, while the standard Bluetooth integrated stereo

13 www.earthmovers-magazine.com.au | EARTHMOVING EQUIPMENT MAGAZINE

The SK850 boasts powerful bucket breakout and arm tearout forces, delivering fast digging cycle times and impressive productivity.

Built to withstand the rigours of the toughest jobsites around the world, the SK850 takes durability to the next level.

system allows the operator to stream audio.

The operator friendly colour multi-display LCD screen uses easily recognisable graphics for quick navigation of important information, including fuel consumption and maintenance intervals. An intuitive one-touch attachment mode switch lets the operator confirm the proper configuration at a glance.

“The feedback from most of our operators regarding the Kobelco machines has been consistently positive, highlighting their high reliability and ease of use,” Nemanja said.

The Melbourne Tractors connection LTE sources its Kobelcos from Melbourne Tractors, a leading Victorian supplier of new and used construction and earthmoving equipment, with four branches throughout the state, including Melbourne branches in Somerton and Dandenong.

The relationship stretches back to the first time Nick bought a Kobelco from salesperson Brad Miller, who established a firm rapport with LTE over the next few years.

That legacy has continued to today, with current Melbourne Tractors Managing Director Ken Bennett keeping in frequent contact with Nick.

Ken was quick to reiterate the strong

relationship that Melbourne Tractors has had with LTE.

“Over the years this connection matured enough for LTE to invest in the heaviest and most reliable dirt moving monster available in Australia, the SK850,” he said.

“Only 10 of these units were produced globally in 2023. Three have now been sold in Australia, and two of those went through Melbourne Tractors.

“It’s a premium product and if you need an 85 tonner, then this is probably the one you want.”

Ken said Melbourne Tractors first began more than 20 years ago and continues to grow from strength to strength.

Now leaders in both construction and agriculture machinery within Australia, Melbourne Tractors stock everything from excavators and backhoes to tractors and skid steers.

“We take pride in providing quality products, exceptional service and training, and boast a very knowledgeable team so you can get the most out of your machine – and Kobelco is our main brand,” he said.

“Melbourne Tractors is all about the customer. Regardless of whether you buy an 85T machine, or an SK008 (1 tonne) – we will do our best to give you after sales service that is second to none.”

Nemanja said having established a partnership with a trusted supplier of excavators in Australia had consistently resulted in a smooth business operation.

“With minimal issues with the machinery and a reliable service support from our Kobelco dealer, it greatly aids our teams in completing projects on time,” he said.

“We relied on Melbourne Tractors’ guidance for selecting machinery that aligned with our project needs and meet our company’s expectations.”

Nemanja also had nothing but praise for the follow-up and maintenance services available from the dealer.

“It has been excellent thus far. We’ve established a professional and personal trust between us,” he said.

“It’s just another reason why we have become repeat buyers of Kobelco excavators. Not just their reliability, but also the dependable service backup provided by Melbourne Tractors.”

Nemanja said LTE’s vision of future growth involves staying integral to the vibrant building and construction industry.

“We aim to evolve alongside the industry, remaining at the forefront and sustaining our strong position within it,” he said.

“We are strategically focused on nurturing existing business relations while expanding our operations and actively pursuing the expansion of our fleet to meet the growing demands and to enhance our operational capabilities.

“Continued support from both Melbourne Tractors and Kobelco is instrumental in fostering the growth of our business, ensuring we receive the high level of service needed to thrive.”

And did we say LTE never has enough of Kobelco?

LTE has just purchased another 10 additional machines, ranging from eight to 38 tonnes.

“Our latest delivery was in March and I think the next delivery will be this month (June),” Nemanja said.

Read more about the SK850 on page 161.

14 EARTHMOVING EQUIPMENT MAGAZINE | www.earthmovers-magazine.com.au ON THE COVER

Melbourne Tractors Managing Director Ken Bennett.

AUSTRALIA’S # 1SELLING HEAVY EXCAVATORS

Experience the unmatched excellence of Kobelco – Australia’s favourite heavy excavator brand.

Renowned for its quality Japanese craftsmanship, Kobelco delivers legendary reliability, backed by an expert network of dealers across Australia. Kobelco excavators are well-known for their durability, fuel efficiency and precision hydraulic systems, with class leading operator comfort across the range.

That’s why Kobelco is the trusted choice of business owners and operators alike, making it the #1 selling heavy excavator brand in Australia. Choose Kobelco today – the first choice in heavy excavators.

kobelco.com.au | 1300 562 352

*PowerStats Construction Equipment Industry Australia sales statistics, full year 2023.

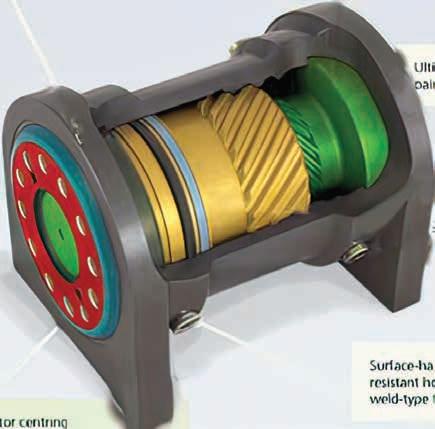

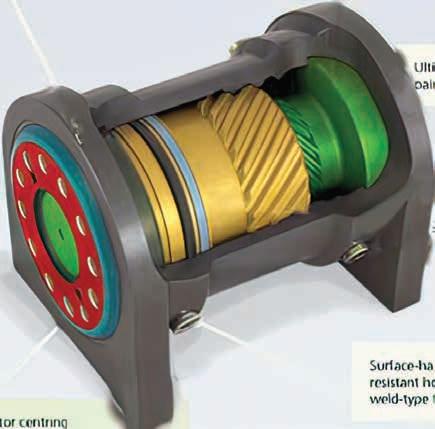

Be aware of your wear

Plan your maintenance with the Cat® Track Wear Sensor for Cat D6 Dozer HDXL undercarriages.

If you own or operate a Cat® D6 Dozer fitted with an HDXL undercarriage, you can now stay ahead by monitoring its undercarriage wear remotely with Cat Track Wear Sensor.

A small embedded electronic sensor is in your HDXL undercarriage track link and the new Caterpillar technology will detect the track wear for you.

This can help improve inspection scheduling, maintenance planning and fleet coverage.

It’s an innovation exclusive to Cat machines and Cat undercarriage and can be retrofitted on other eligible Cat dozer undercarriages.

How the Cat Track Wear Sensor works

The Cat Track Wear Sensor will come embedded in each of your dozer’s tracks. This will create two smart track links that will wear down over time, along with the other track links.

The Cat Track Wear Sensor can then monitor your track wear over its lifetime.

The more you know the better

As wear occurs, the Cat Track Wear Sensor wirelessly relays information from your machine to your Cat dealer who can then oversee wear via the Cat Wear Management System.

This means you can increase your fleet coverage, view track wear remotely, reduce manual inspections and streamline the ordering of replacement parts.

Inspect more of your dozers from afar

The Cat Track Wear Sensor has a ‘no touch’ track link measuring function, which means your Cat dealer can inspect the track wear of your entire fleet of D6 Dozers remotely.

They will be notified at key wear percentages when action is required.

Key Track Wear Intervals

• Track wear at 40%: Consider an inspection to determine the need for undercarriage maintenance such as bushing turns.

• Track wear at 70%: Schedule an inspection and plan track replacement, bushing turns and other maintenance.

• Track wear at 10%: Plan track replacement and schedule machine downtime.

With the Cat Track Wear Sensor, your Cat dealer will ensure you get the most out of your Cat D6 Dozer's HDXL undercarriage. With real-time track wear status updates, they can order your track replacement right away so it’s there when you need it.

Plus, you can effectively plan your jobsite operations by factoring in dozer maintenance, replacement and downtime well in advance.

Key Features and Benefits

Predict wear-out to help maximise undercarriage life

• Ensure simple maintenance planning with key wear alerts

• Trigger notifications at 40, 70 and 100% wear intervals

• Enhance undercarriage reliability with remote wear monitoring

• Increase uptime by avoiding costly and inconvenient interruptions

Available for Cat D6 Dozer HDXL undercarriages and can be retrofitted on eligible dozers.

To find out more or to book a free* undercarriage inspection, contact your local Cat dealer or visit cat.com/undercarriage-au Scan to find out more *Terms and conditions apply. See cat.com/undercarriage-au for details.

18 EARTHMOVING EQUIPMENT MAGAZINE | www.earthmovers-magazine.com.au

MEET THE EXPERT: PARTS AND AFTERMARKET

The Cat® Track Wear Sensor helps to monitor undercarriage wear remotely.

Images: Caterpillar

LARGE PO RTAB LE & LOC KABLE DIESEL

FLOW RATE OPTIONS BETWEEN

Unlock a new era of efficiency and security with Alemlube’s revolutionary Diesel Management Solutions with a tough construction and a range designed to streamline onsite fuel handling.

Elevate your operations with Alemlube’s innovative and reliable fuel storage & delivery solutions.

FUELING THE FUTURE

TOUGH.

EFFICIENT.

PORTABLE.

1300 159 311 www.alemlube.com.au

PIUSI PUMP KITS

REF UELLING STORAGE & DISPENS ING POD S L120080PA

• WATER SUPPLY PRESSURE SYSTEMS •

DEWATERING • SEWER BYPASS • WATER SUPPLY • POLYMER & BENTONITE GET PUMPED! Email sales@toolkwippumps.com or visit us online toolkwippumps.com VIC: (03) 8805 0500 NSW: (02) 7251 3499 QLD: (07) 3523 5777 Available in: VIC • NSW • QLD • SA • TAS ECO FRIENDLY PUMPING

• DIESEL POWERED DEWATERING PUMPSETS • ELECTRIC SUBMERSIBLE PUMPS • HYDRAULIC SUBMERSIBLE PUMPS

STANDPIPES • HOSES & FITTINGS

Komatsu on track at the Australian Grand Prix

Komatsu employees and customers were lucky enough to be a part of the Australian Grand Prix in March.

As part of Komatsu’s multi-year deal as Principal Partner of F1 team Williams Racing, two of Komatsu’s leading apprentices, selected by their peers, were given the opportunity to get up close with some of the fastest cars in the world, as they spent the weekend in the Williams Racing pit, learning the tricks of a different trade.

Alexander Connell from Komatsu’s Campbellfield branch in Melbourne, and New Zealand apprentice Brittney Lyon, got to see firsthand the fast-paced nature of an F1 pit and what is involved in keeping the car running for the elite event.

“It was an incredible experience. I was close to buying tickets for the GP this year, so as a fan to be given this opportunity, and see all the action in the pit is one I definitely won’t forget,” Alexander said.

“The way their teams work to process and understand all the data from the cars and their laps, and use that to improve performance was fascinating, especially as we do similar things with our own Komatsu systems and machines, but on a slightly different scale.”

In the lead-up to the GP week, Williams Racing driver Logan Sargeant made a pitstop at Komatsu’s Innovation Hub in Brisbane, where

he met with staff and customers and was taken on a tour of the Innovation Hub, pre-delivery inspection and remanufacturing facilities.

Komatsu Global Brand Transformation VicePresident Todd Connolly said it was rare for Brisbane to receive a visit from an F1 driver.

“We were excited to have Logan and some of the Williams Racing team visit our facilities and see the vast scale of Komatsu’s massive mining and construction machines, as well as the technology and people behind them,” he said.

“Our shared focus on innovation and the development of our people was clear during the tour.

22 EARTHMOVING EQUIPMENT MAGAZINE | www.earthmovers-magazine.com.au

INDUSTRY LEADERS

“Our partnership with Williams will focus on how we can create value together, both on and off the track, particularly through our manufacturing and technology innovations to empower a sustainable future where people, businesses and our planet can thrive together.”

Williams Racing is one of the world’s most iconic Formula One teams. The British outfit has been competing at the highest level for almost five decades, amassing 114 victories, 313 podiums and 128 pole positions in that time. Williams Racing has also won 15 championships, making them the second most successful team in the history of the sport.

Komatsu’s logo and branding will feature prominently on the 2024 Williams Racing livery, as well as the team’s overalls and kit during the Formula One season.

“The Australian GP sets the foundation for our partnership with Williams Racing, and we’re looking forward to further exploring collaboration opportunities, for both our people and our customers on this new venture,” Todd said.

23 www.earthmovers-magazine.com.au | EARTHMOVING EQUIPMENT MAGAZINE

Komatsu apprentices Brittney Lyon and Alexander Connell got the experience of a lifetime in the pit with Williams Racing at the Australian GP.

Williams Racing F1 driver Logan Sargeant made a pitstop at Komatsu’s Innovation Hub in Brisbane before making his way to Melbourne for the Australian GP. Images: Komatsu

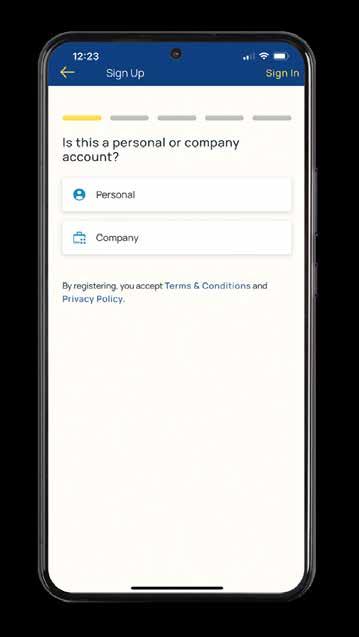

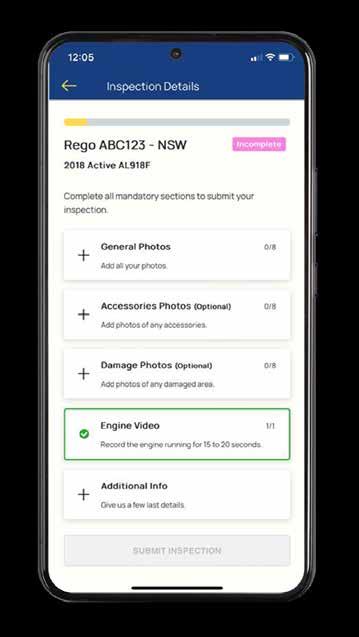

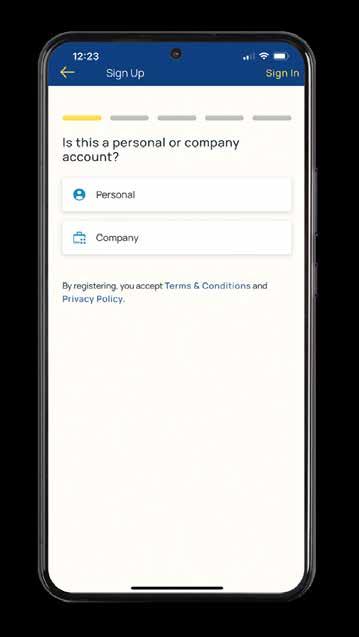

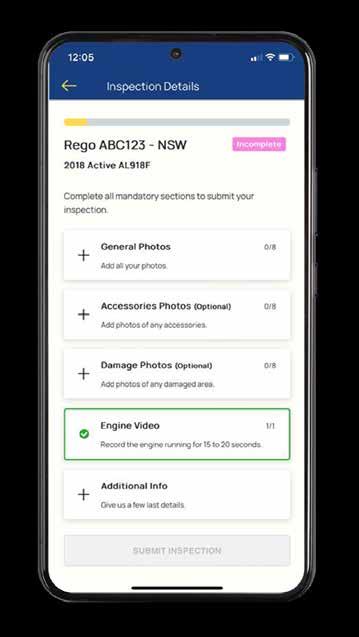

Need to offload your used trucks and machinery? DIYinspect is a self-inspection app powered by Pickles. Asset owners can simply download the app, complete an in-app inspection and receive an offer to purchase equipment. Start the process anywhere, at any time.

Why use DIYinspect?

DIYinspect helps customers sell their assets with ease and in their own time and space. By conducting remote inspections, sellers can maximise their time and return on their assets.

Customers receive data-led offers to purchase, eliminating the expense and hassle of conducting in-person asset inspections.

Sellers can offload a range of equipment including trucks, buses, excavators, and loaders.

Head to DIYinspect.com.au for more information, or simply download and get started!

Download DIYInspect Today

The entire process only takes 15 minutes and you simply follow the steps below to get started.

Download DIYinspect from the App Store or Google Play

Register a business account using your information incl. your ABN

Select the asset type you want inspected

Upload information, notes, photos and videos of your equipment

Submit your DIY inspection and we’ll get back to you within 48 hours!

STEP

STEP

STEP

STEP 4 STEP 5 STEP 2 STEP 4

1

3

2

Auction preparations include working on presentation, evaluating the location and market, transporting equipment, evaluating assets and managing all operations.

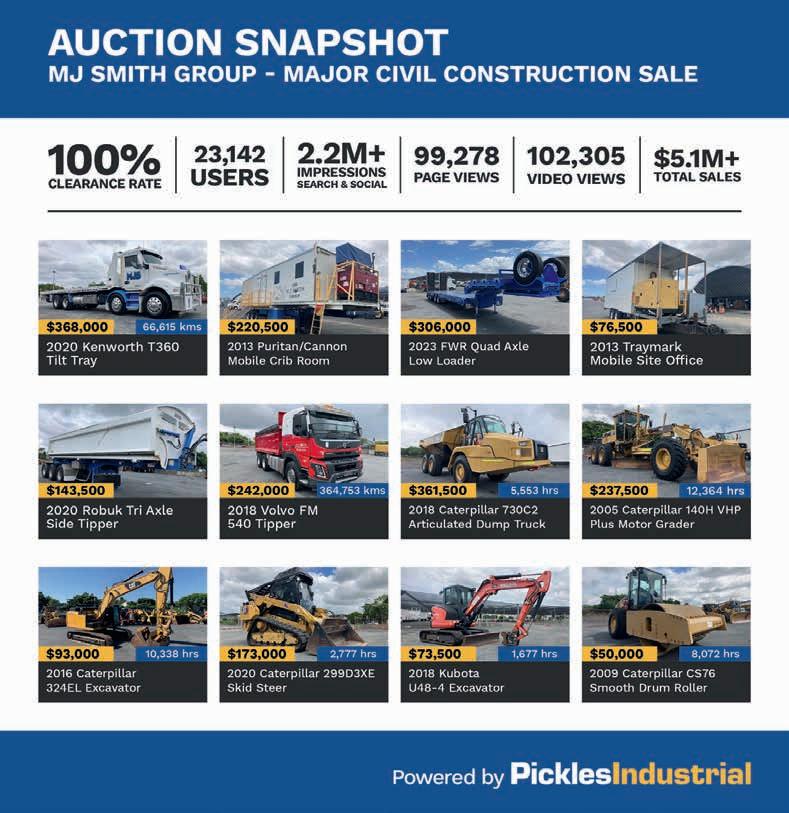

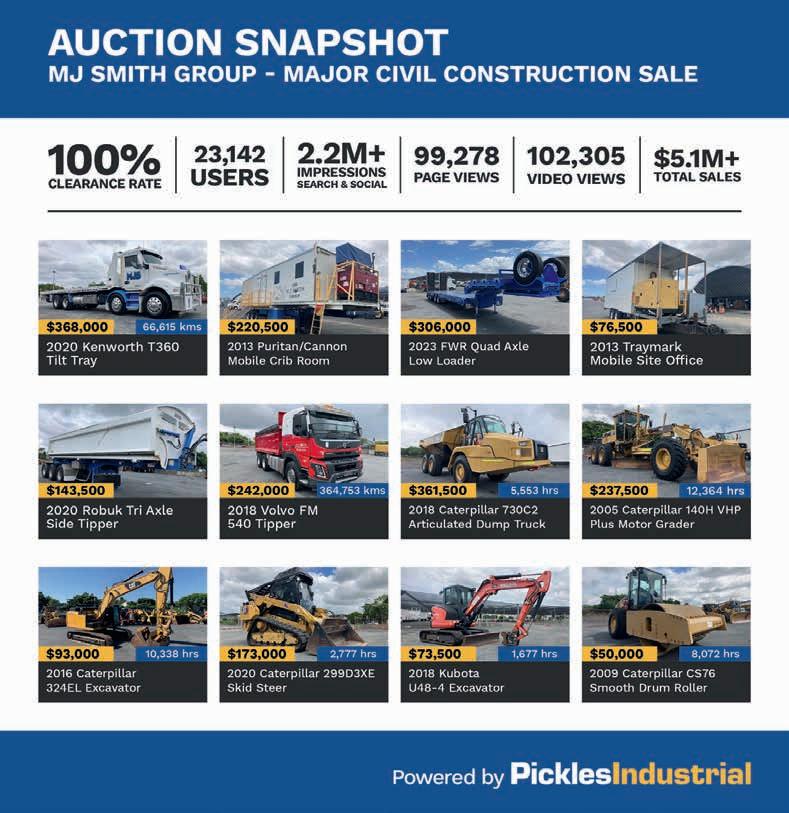

Pickles prepares for event sales revival

Industrial businesses are jumping at the opportunity for big ‘blowout’ events in 2024.

The digitisation of Australian auctions has been at the forefront of industry developments for the last decade, with a wave of businesses focusing on online sales as a way to expand opportunities for buyers and sellers.

The transition to digital-led auctions have been fortuitous and advantageous for all, but have left some businesses longing for a big blowout event sale, which luckily, auction house Pickles is able to provide.

That’s why businesses are looking towards Pickles in 2024, for the opportunity to experience huge, standalone event auctions with sky-high results.

What makes event sales so successful?

Before Australia’s migration to digital auctions, event sales were just known as sales.

In 2024, these sales refer to exciting, standalone auctions that are expected to cause a commotion amongst buyers.

These events are reserved for big sales, featuring a very large range of quality, used assets that we know will draw big crowds for inspections and to online listings.

The sales are unique to every vendor’s needs, with Pickles providing an end-to-end tailored service resulting in events that can be run over multiple auctions, days and even locations depending on the requirements of the business.

The resurgence in event sales has offered the incredible opportunity to open our doors and show off what Pickles is capable of, resulting in big events and even bigger results.

For Pickles, becoming digitally-focused while keeping old school values has been key to keeping decades-long relationships while also driving towards the future.

This attitude is integral to Pickles’

More and more businesses are looking towards Pickles for the opportunity to experience standalone event auctions.

partnerships, like that of its long and proud working relationship with Michael Smith, Director of MJ Smith Group.

With a 12-year relationship between Pickles and MJ Smith Group, working together for an event sale in 2024 was as easy as breathing.

It’s this trust and easy-going relationship that keeps Michael working with only Pickles.

“I wouldn’t work with anyone else. I enjoy working with Pickles because everything is done with a handshake,” Michael said.

“They make it easy, there’s no long contracts or drawn-out conversations, they just get it done. They’re so quick to pick up on exactly what I need.”

The MJ Smith Group held its Major Civil Construction event in February, which proved to be a huge success and offered the opportunity for Pickles to put on a big song and a dance.

Held over three days, the event sale featured a range of trucks, trailers, vehicles, prime movers, graders, dozers, excavators, side tippers, tilt trays and many more assets.

With a 100 per cent clearance rate and over $5 million in total sales, the results speak to what can be achieved when businesses and remarketers collaborate effectively.

For Pickles’ experts, event sales are considered their specialisation.

With 60 years of experience, more than national employees and industry-best digital presence, Pickles has the power to make an impact for any business.

But it’s not only people power that makes sales successful, it's the flexibility and tailored solutions available that makes happy players of anyone using the Pickles’ marketplace.

Before event sales take place, Pickles

26 EARTHMOVING EQUIPMENT MAGAZINE | www.earthmovers-magazine.com.au

INDUSTRY AUCTIONS

Images: Pickles

employees work tirelessly behind the scenes in order to put their best foot forward.

This includes experts working on presentation, evaluating the location and market, transporting equipment, evaluating assets and managing all operations.

While industrial experts are handling the assets, the huge team of marketing experts grind away to attract the right buyers to the sale.

By the time a piece of equipment goes under the hammer, dozens of Pickles people have worked together to best present the asset.

With so many well-oiled cogs in the machine working together, it's no wonder Pickles sells hundreds of millions of industrial assets each year.

While the results are big, the business keeps well-grounded. Pickles’ humble beginnings as a rural stock and station agent 60 years ago has never been forgotten.

And it's with salt-of-the-earth staff that Pickles wins sales and vendor appreciation.

“I have close relationships in Pickles and consider some of them family,” Michael said.

“I know if I pick up the phone they’ll always answer and it’ll be the same person I’ve been working with for 10 years.

“I even had some of the team sit down at the dinner table with my wife and kids the night before the auction.”

The MJ Smith sale was a solid way to kick off event sales in 2024.

With results that speak for themselves, Pickles is gearing up for more and more big blowout events to come throughout the year.

27 www.earthmovers-magazine.com.au | EARTHMOVING EQUIPMENT MAGAZINE

Pickles meticulously prepares assets ahead of event sales.

The result of the MJ Smith Group event sale speaks for itself.

Eyes for the legs

Leica Geosystems tools are proving to be the perfect complement for the specialist land clearing tasks of a Victorian terrain management company.

Menzi Muck walking excavators are a sight to behold when seen in operation on steep and inhospitable terrain.

Often referred to as spiders because of their extendable and articulated arms, their ingenious high-tech chassis make them widely used in sectors such as construction, specialist civil engineering, forestry, gardening and landscaping, municipal technology, drilling technology, and more.

One company that has been making the most of the machine has been Vertx Civil, a subsidiary of Hicks Mining Australia, which focuses on supplying consulting and specialised labour.

As Managing Director Nathan Hicks explains, Vertx Civil is based in north east Victoria within the Kiewa Valley near Albury-Wodonga.

“We are a small company specialising in mining, quarrying, and civil projects that require a specialist approach or change of day-to-day conventional methods,” Nathan said.

“These are usually projects that are restrained by geology, limited access, steep terrain, emergency situations and surrounding infrastructure. We offer skilled support personnel and equipment that ensure the project is completed to high standards and overcome the limiting constraints.

“This may be ground support (above and below ground), landslip remediation, bush firefighting and hazard reduction, infrastructure installation, pile installation and limited access excavation/underground development.”

With 19 years’ experience in the mining and civil industries home and abroad, and with knowledge of methods of specialised work used in many different countries, Nathan realised there was a lack of machines within

the local region that could undertake work in inaccessible areas without disturbing the surrounding habitat or infrastructure.

So when Vertx was formed, the first item procured was a Menzi Muck M5x, which could handle a range of applications.

Clients have been lining up to use the machine, including the likes of AGL, Alpine Resorts Victoria, and Whelans Group Investments, which is currently working to repair two landslips in Victoria’s high country on behalf of Major Road Projects Victoria.

“Our client base is constantly growing, and it has been booked out since January this year,” Nathan said.

“It’s a one-machine-that-does-all. Yes, it lacks the bulk digging capacity that a conventional excavator would.

“However, its speed and operational angles are untouchable within various terrain and limited access areas. It also includes the rototill R4 hitch, which again changes the dynamics of excavation angles.

“The spider has an incredible hydraulic flow for its size, that provides drilling capacity in areas that other conventional excavators with a similar attachment would not reach or have the capacity to drive.”

Nathan acknowledged that the Menzi Muck did not come cheap.

29 www.earthmovers-magazine.com.au | EARTHMOVING EQUIPMENT MAGAZINE

MACHINE CONTROL

The Menzi Muck’s speed and operational angles are without par within various terrain and limited access areas. Images: Hicks Mining

The spider uses Leica Geosystems navigational tools to obtain full coverage when slewing around or transversing steep terrain.

“These machines come at a significant cost within a seven-figure number. Understandably, the hourly rate of this machine, in particular, would be significantly increased from what one would pay in comparison to a 20t excavator equivalent,” he said.

“However, this cost is offset by access speed and how it moves within hills, creeks, over fences and positioning over road edges.

“This is not limited to building and maintaining access roads or damaging vegetation, rivers, and streams. In some cases, we simply drive along a sealed road, step over a barrier and mulch or clean out drainage infrastructure immediately.

“Once the clients witness the machine in operation in person, they will see how safely the excavator works over various terrains, guaranteeing mobility and stability.

“We commonly conduct demonstrations and documentation for interested parties, and 99 percent of the time, they walk away with confidence in what we do and how the machine will perform safely.”

And Vertx will soon add a tree felling head option within the company, focusing on emergency works and hazardous tree removal.

“As we are based in the Victorian Alpine region, bushfires are common, and we are looking for ways to reduce fuel loads by maintaining vegetation and fighting fires when the inevitable happens. The Menzi is quick to respond, being registered and on rubber tyres,” Nathan said.

The operations of the spider are amplified by various support equipment and attachments, including compressors, rock drills, piling core barrels, auger hitches, and mulching attachments.

But undoubtedly some of the main valueadding components have been the range of surveying and geo-navigational solutions offered by C.R. Kennedy.

The C.R. Kennedy connection Nathan said the majority of mines within Australia and throughout the world use Leica Geosystems, which offeres machine control solutions comprising software, hardware, and cloud services to enable efficient, productive, and sustainable heavy construction operations.

The Leica iXE3 MC1 platform allows for full 3D GPS and antimony of tilt rotators, as well as full functionality using a Robotic Total Station.

“Hicks Mining first procured a Leica MS60 multistation from C.R. Kennedy in 2022, which was heavily utilised in the business not just for mining applications but civil surveys, setouts and designs,” Nathan said.

“Following this, we procured a Leica GS18 for rapid on-ground feature survey pickups, asbuilt staking and setouts. This can also be set as an onsite base when required.

“In addition to the mentioned platforms, we know first-hand that clients today want to know where we dig and how much. It's becoming more common to have drones flying overhead and 3D model creation for all types of projects, not just large applications but small works are becoming common.

“Due to the company's business focus and

The machine helps reduce fuel loads by maintaining vegetation and fighting fires when the inevitable happens.

where we operate, we need systems that provide solutions when the going gets tough. This may be in a steep gully, on the side of a steep hill, or in an underground environment.

“Satellites and GNSS (Global Navigation Satellite System) are not always available, so we then rely on the MS60 for accurate location.”

Nathan said that depending on the size and tolerance requirements, operating the spider under GNSS (RTK correction) is a simple and straightforward system.

“We receive the various design data and/ or boundary line work containing the limiting work areas and sensitive receptors,” he said.

“Some clients may produce data from two or more departments, such as environmental, not just from designers or engineers. We compile this in a project package within a Leica MC1 software device located within the spider and we are ready to work.

“Or alternatively, we may build an infield design based on grabbing points with the bucket to create a drain or pad.

“The spider can be pretty crossed up in some situations, so having this option helps ensure it will be right the first time. The MC1 platform reads all the functions of the spider, including the tilt rotator and telescopic boom.

“If GNSS cannot be obtained due to steep terrain or underground environments, we have optioned the MS60 to guide the spider.

“The MC1 solution allows for two total stations or multistations to be connected at once. This provides full coverage when slewing around or transversing steep terrain, ensuring you are always locked.

“We commonly achieve 10mm accuracy at

the bucket with this system.”

Nathan said it was becoming more of a requirement to have guided equipment rather than a cost saving.

“Clients are requesting it from contractors, and if you're not up with it, then prepare to miss out on the opportunity,” he said.

“This is the first spider excavator within Australia to have 3D guidance and one of very few within the world (and a first for the Leica MC1 platform).

“It is setting the level for ensuring that regardless of the terrain or area you are working in, you can ensure that you're marking the right spot, whether it’s within work zone boundaries that can't be set out due to terrain or the size of the area; or where surveyors cannot gain access during work, such as hills where ropes may be required.”

Nathan was also full of praise for C.R. Kennedy’s after-sales service and maintenance, which he feels was exceptional.

“As the first spider equipped with the Leica MC1, C.R. Kennedy went above and beyond to make it work,” he said.

“The install quality was excellent, with the crew going out of their way to make it look neat and tidy. We recommend C.R. Kennedy to anyone wanting an equipment guidance package or surveying equipment, for that matter.

“We need to be confident in what we survey and build to in any application. Confidence requires trust, and we believe that we have that covered with C.R. Kennedy and their key organisational personnel. Support has always been second to none.”

30 EARTHMOVING EQUIPMENT MAGAZINE | www.earthmovers-magazine.com.au

MACHINE CONTROL

Making finance easy

When banks and other lenders proved difficult for a fledgling earthmoving company, equipment finance specialist Finlease stepped up to the mark.

Started up two and a half years ago, NSWbased Dalwick Contracting has made a name for itself as earthmoving specialists for various kinds of civil and residential work across the Great Sydney area and regional NSW, as well as the ACT, Queensland and Victoria.

The company was the brainchild of director Trent Dalzell, who, having worked more than 15 years in the construction industry in various capacities, felt he was experienced enough to start up his own business.

“My first job was as an operator on a roadwork project, and I moved into other roles in drainage, sub-divisions and the like,” he said.

“Having accumulated so much knowledge, I felt it was a good time to make my own mark in the earthmoving field.”

Dalwick began with a main focus on retaining walls, excavation and haulage, but such has been its growth that it has now has expanded into doing “any type of excavation”.

“This encompasses basement digs, rock sawing/grinding , major civil and construction works , subdivisions, road works, rural works , mulching, land clearing, dam construction and liners, hourly hires, dry hires, augering/piers, site preps, and everything in between,” he said.

Building retaining walls are still a particular point of expertise. “We do are any form of gravity wall (precast/sandstone/gabion) and post and panel walls/sleeper walls,” Trent said.

“We also carry out haulage, up to 25t and 3.5m wide.

“With projects ranging from small private jobs to the Tier 1 works, our service is available to all clients, big or small.”

Getting a business off the ground initially had been no easy task though.

“To establish ourselves in the industry and to ensure our jobs are done to requirement, we needed good staff,” Trent said.

“We certainly have that at the moment, with

four excellent members on board, including two very good operators and a supervisor.

“But equally as important, we need the best equipment possible and we need to maintain them to the highest standards.”

Dalwick started off small, with a Tier 1-spec 13t digger. Obtaining finance for that machine wasn’t difficult, but when Dalwick started to expand, necessitating the purchase of more equipment, the initial lender was reluctant to take on further debt.

“Our company has grown steadily since we started,” Trent said.

“Our first jobs was with clients who knew me from previous work I had been involved with, and who recognised my expertise in the industry.

“From there, the business expanded through word of mouth, and we gradually got more jobs as we were recognised for our good, honest work and capabilities.”

33 www.earthmovers-magazine.com.au | EARTHMOVING EQUIPMENT MAGAZINE

BUSINESS & FINANCE

Dalwick carries out all kinds of excavation and haulage work. Images: Dalwick Contracting

BUSINESS & FINANCE

As the job list expanded, so too did the need for more machines and attachments in the operation.

That was when plans hit a snag.

“Our previous lender couldn’t finance equipment with the necessary attachments as it believed the risk was too great for such a fledgling business,” Trent said.

“And we had problems with the major banks having unrealistic criteria for new businesses. Banks are completely out of touch with the earthmoving industry and are difficult to deal with.

“We were forced into a situation of financing the equipment separately, and fortunately we came across Finlease representative Chris Lawrence.”

It may have been the best leap of faith Trent has taken.

“Chris managed to get not only the attachments, but also a brand new machine for us with one loan with a balloon payment and a cheaper finance rate,” Trent said.

Indeed, equipment now acquired by Dalwick through Finlease include a Kobelco 20t digger, two Western Star trucks, a Freightmore tipper trailer and assorted mulchers and digger augers.

“Finlease has taken care of 90 per cent of our purchases to date since our paths crossed trying to finance the attachments,” Trent said.

“Chris has gone above and beyond for us and has been a huge part of our company’s growth.

“Our relationship with Chris is now to the point that if I needed to finance a pencil sharpener, he would be the first call.

“For any new business that’s trying to secure finance, no one teaches you the correct/

easiest/most cost effective way of securing finance for your machinery.

“Some lenders also don’t go in and try to secure the best deal for you.

“If Finlease can’t help you, then you genuinely don’t deserve to be financed.”

34 EARTHMOVING EQUIPMENT MAGAZINE | www.earthmovers-magazine.com.au

Find out more about Dalwick Contractors at https://www.dalwick.com.au/. To find out how Finlease can help grow your business, contact Chris Lawrence on 0407 627 561; or visit www.finlease.com.au

One of the machines financed through Finlease is a Kobelco SK 135SR excavator.

The Cat 926E wheel loader owned by Dalwick.

Contact your local dealer today 1300 522 232 www.jcbcea.com.au PRODUCTIVE, COMPACT & AGILE JCB 18Z MINI EXCAVATORS ROBUST 100% steel bodywork for maximum impact protection and ease of repair EFFICIENT Premium, Class-Leading precision hydraulic flow share for ease of use and maximum output SAFE 10 integral easily accessible tie-down points make the transportation process safer and quicker COST EFFECTIVE 500-hour Dig-End greasing intervals to reduce regular downtime EASY TO SERVICE Swing-out counterweight provides unrivalled and easy service access 0% * Only available to ABN holders through CEA Financial Services, provided by De Lage Landen Pty Ltd ABN 20101692040. 0% p.a. based on $10,000 deposit, no repayments for first 6 months, followed by 24 equal monthlies in arrears. Subject to credit approval, terms, conditions and fees apply. Offer ends 28/06/2024 or until stocks last, machine must be purchased and settled by 28th June 2024.The purchase of additional attachments or a trailer may result in a blended rate. OFFER ENDS 28TH JUNE 2024 or while stocks last SECURE YOUR NEW MACHINE AND A GREAT FINANCE RATE TODAY! per annum FINANCE *

Fan favourite truck to be raffled

Motoring enthusiasts have the opportunity to get their hands on the wheel of a highly sought-after 1946 Ford Jailbar truck.

Australia’s largest transport and logistics insurance experts, NTI, is raffling the truck, affectionately named Bonnie, to raise funds for medical research.

NTI Chief Executive Officer Tony Clark said Bonnie was the seventh truck to be restored and raffled by the business, with ticket sales totalling $2 million for Motor Neurone Disease research over six years.

“Motorists may recognise the black dual cab 4x4 as one of the first vintage trucks modified by NTI,” he said.

“Bonnie has been the organisation’s promo truck and has gained a large following after appearing at events across the country over the past two and a half years.”

NTI Chief Customer Officer, Janelle Greene, said it was truly a one-of-a-kind vehicle, and it was no surprise that it’s a fan favourite.

“We are constantly asked by fans if they can purchase Bonnie, and after last year’s incredible fundraising efforts, we thought it was the right time to say a special thank you to our supporters by finding Bonnie a new home,” she said.

Bonnie was one of the toughest and most technically challenging restoration projects to date.

The building process took 2500 hours, lengthening and widening the cab to include two rear doors, along with a custom-made bonnet, tub tray, side steps and rear guards.

The interior is kitted out with a full leather trim, air conditioning and touch screen media.

With a 5.2 litre turbo diesel engine already under the hood, the team were tasked with also enhancing its off-road capabilities, turning it in to a 4WD with a 6.5 tonne electric winch, LED spotlights and rear air suspension.

“This makes it the perfect vehicle for both on and off the road, featuring all the latest technology while honouring the vintage style

of the 1946 Ford Jailbar,” Janelle said.

NTI Special Projects Lead Don Geer said the excitement around the truck made the hard work worth it.

“It’s like a swarm of bees around honey,” he said. “Every time I duck into Bunnings I come back and spend an hour in the carpark just talking to people.

“Bonnie has that wow factor. Everyone is taken aback by the superb technology and engineering, and they always want to know how they can get their hands on it.

“They all hurt a little bit when we let them go,

but this one especially, just because it’s such a good vehicle, it’s bullet-proof.

“It’s still very young, not even at 23,000kms yet, so it’s the right time for somebody else to get it and enjoy it as much as I do.”

The truck will be displayed at Cooly Rocks On (Gold Coast, June 5-9), with the final appearance and raffle being drawn at the NTI Supercars Round in Townsville (July 5-7).

Tickets available online at https://www.raffletix.com.au/ ntimndresearchraffle2024

36 EARTHMOVING EQUIPMENT MAGAZINE | www.earthmovers-magazine.com.au

INDUSTRY INSURANCE

Bonnie has been turning heads at NTI events over the years. Images: NTI

The interior is kitted out with a full leather trim.

Bonnie is powered by a 5.2 litre turbo diesel engine.

OTR Australia supply earthmover, agricultural, truck, bus and light vehicle tyres and rims from 6” through to 63” in diameter, to blue chip mining, civil contracting, road transport companies, agricultural dealerships and end users.

We maintain a healthy inventory of new and used earthmover tyres of critical sizes and have the ability to custom manufacture Australian Made wheels in 1 of our 10 locations Australia wide.

SALES

Yatala | Perth | Mildura | Muswellbrook | Emerald | Karratha | Port Hedland | Kalgoorlie | Geraldton

PHONE: 1300 CALL OTR For any enquiries please visit www.otraustralia.com

The biggest range of OTR

sectors

& Ag tyres & wheels for the Mining, Industrial, Construction & Ag

AUTO-LOCK TILTING QUICK HITCH

Compact in design, powerful and virtually maintenance free, the Gardner Engineering Auto-lock

Tilting Quick Hitch incorporates a precision built actuator ensuring trouble free operation.

✓ Australian Made

✓ Hi tensile steel construction

✓ Compact design –improving machine performance

✓ Integral overload protection

✓ Fully guarded hoses

✓ Up to 180 degrees of tilt

✓ Actuator only has two moving parts and is 100% sealed

✓ Automatic dual lock

✓ Multicoupler design

✓ Fully compliant with current legislation and Australian standards

GARDNER ENGINEERING AUSTRALIA 7 Babdoyle Street, Loganholme, QLD 4129 PHONE:

3801 3855 EMAIL: sales@gardnerengineering.com.au WEB: www.gardnerengineering.com.au

(07)

Torque of the town

The all-new, next generation Cat® 255 turned heads when it made its Australian debut at the recent National Diesel, Dirt and Turf Expo in Sydney.

Building on the success of the Cat D3 series Compact Track Loaders, the Cat® 255 model, along with its bigger brother the 265, are a ground-up redesign of the earlier series, improving on the features that made the previous versions so popular.

The first next generation models in the compact track loader line, the 255 and 265 elevate the Cat loader reputation through improved engine performance, lift and tilt performance, stability, operator comfort and built-in technology.

Caterpillar ® Product Specialist Rohan Mills did the unveiling honours at DDT, revealing the long-awaited Cat 255 to a huge crowd.

"It’s the first of our new line of Cat next gen compact track loaders. The 255 at DDT was the very first that's landed in the country, and we were really excited to launch this to Australian customers,” he said.

The machines have retained the DNA of the D3 series while reimagining the possibilities of loader performance using voice of customer feedback.

“Both next gen models leverage the many benefits offered by the vertical lift design. The new Cat 255 replaces the 259D3, while the 265 replaces both the 279D3 and 289D3 machines,” Rohan said.

All Cat next generation compact track loaders are identified by the ending model number 5. The simplified nomenclature uses the middle number to represent machine size.

A new performance standard

Rohan said the new 255 and 265 loaders are powered by Cat C2.8T and Cat C2.8TA engines respectively, with the 255 offering 74.7hp and the 265 offering 74.2hp.

The new engines maintain horsepower across a wider RPM range and boast significant torque

Cat

increases – gains of 13 per cent for the 255 and 43 per cent for the 265 – for improved working performance.

“Standard hydraulic system pressure is increased to 3500 psi (24,130 kPa). New for these next gen machines, the closed-centre auxiliary hydraulic system allows the 255 and 265 to operate all Cat Smart Attachments, including the Cat Smart Dozer Blade, with the standard auxiliary hydraulics provided,” Rohan said.

“Increasing the hydraulics on the machine has

been a popular feature and has ticked a lot of boxes for operators.”

Also present at the launch was Caterpillar skid steer loader/compact track loader manager Dante Thomas, part of the design team in the US, and who flew in to meet Expo visitors and discuss the new machine.

"The machines allow the user to do more work in terms of dumping,” he said.

“Having a machine that can do more work is absolutely important. You need a job, you need it done fast, and having a 255 or 265 track loader would be a great option.

“The torque and pushing power really shines on the new machines and is ideal for moving dirt or large amounts of material.”

A redesigned engine compartment mounts the engine and cooling package lower into the frame for improved stability, giving the operator confidence in handling heavy loads and throughout all aspects of their work cycles.

The new 255 loader delivers class-leading lift height, and compared to the 259D3, delivers 36 per cent more tilt breakout, 26 per cent higher lift breakout force and a 24 per cent increase in rated operating capacity (ROC).

Height to the B-pin for the 265, compared to the 289D3, increases by 7.6 in (193 mm), resulting in a class-leading maximum lift height of 11 ft (3.35 m) for easier truck loading. The 265 also delivers 19per cent higher tilt breakout force and 22 per cent higher lift breakout force.

Rohan said re-engineering of lower machine components have resulted in

40 EARTHMOVING EQUIPMENT MAGAZINE | www.earthmovers-magazine.com.au

TECHNOLOGY EXPERT

Lift more, lift higher. The

255 has more performance, more power and more operator comfort. Image: Prime Creative Media

Rohan Mills unveils the Cat 255 at DDT.

a stronger and stiffer undercarriage for improved machine stability and less pitching when filling the bucket with material.

The torsion suspension undercarriage delivers better operator comfort, track wear and material retention, plus the stiffer design results in smoother graded surfaces. The 255 loader offers a new 12.6-in (320-mm) bar-tread narrow track option.

"The crowd at DDT loved the improvements we've made with the undercarriage: a single piece track frame for that extra stability,” Rohan said.

“Also, they like the simple little things like tie down points on the track frame and the new and improved hydraulic coupler.”

More space and comfort

Another popular feature of the machine was the extra roominess of the cab.

Both models feature a larger cab design with 22 per cent more overall volume and 26 per cent additional foot space.

With a 2.75-in (70-mm) increased interior width, the new cab expands footwell-to-ceiling height by 1.8 in (46 mm) and allows for an additional 1.5 in (40 mm) of hip room and 1.1 in (28 mm) more width between the joysticks for improved operator comfort.

“You notice the difference by just climbing around the machine,” Rohan said.

One thing operators are really appreciating is the size of the cab.

“We've heard people asking for a big man cab. The general feedback has been that Caterpillar really delivered with this, with many bigger guys coming in to check out the cab for themselves.”

Featuring a low entry point, entering and exiting the 255 and 265 loaders is now much easier.

The redesign allows the operator to open the cab door without the lift arms being fully lowered to the frame stops, a feature that gained applause at the DDT presentation.

“A simplified two-step door removal process allows operators to quickly remove it without tools,” Rohan said.

A range of new mechanical and air-ride suspension seat options are available, including a high-comfort seat that is both ventilated and heated.

New auto temperature control plus vent outlet positioning above the operator helps the new HVAC system to quickly cool the cab’s interior.

Next generation loaders are equipped with either a 5-in (127-mm) standard LCD monitor or an 8-in (203-mm) advanced touchscreen monitor, depending on the technology package selected. Like the D3 series’ advanced display, the standard monitor features Bluetooth connectivity and supports

functionality for rearview camera feed, creep, job clock, maintenance reminders and 32 languages.

Rohan said the advanced touchscreen monitor provided a higher level of control over standard monitor functionality, delivers advanced radio control, and supports the multicamera 270˚ option and 32 language choices.

The new advanced joysticks provide integrated control of the advanced touchscreen monitor so all machine function control and adjustments can be made without the operator removing their hands from the controls.

The three key pillars

Both Rohan and Dante stressed that the new loaders were built around three key pillars.

“We want more performance, more power, and more comfort," Rohan said.

“We've got a Cat C2.8 turbo charged engine. In this machine, we've increased the engine torque. Operators are loving that these new loaders will give them more pushing power and more ability to move dirt faster.

“We've got more hydraulic capability, more performance. We've increased that bucket breakout force by 36 per cent. That's massive!

"We've increased the rated operating capacity from 910 kilograms up to over 1100 kilograms, so that's a 24 per cent increase.

“And then from an operator comfort perspective, we've made massive changes to the cab: it's bigger, it's wider and it's tall. You’ve got more leg room and more space over your hips, plus the option of a ventilated seat.”

Rohan said there has already been a strong response to the Cat 255.

"We’re looking forward to getting the first machines arriving at the dealerships because we know there’s a queue of customers that are wanting to get into these machines,” he said.

“We've already pre-sold a bunch and orders are coming in fast.”

• Cat 255 test drive: page 92

For more information about the new next generation Cat 255 and 265 Compact Track Loaders, contact a Cat dealer or visit: www. cat.com.

41 www.earthmovers-magazine.com.au | EARTHMOVING EQUIPMENT MAGAZINE

Earthmoving Equipment Magazine videographer Tom Buchanan (left) caught up with Dante Thomas, as he talked about the merits of the 255. Image: Prime Creative Media

The spotlight was on the new Cat® 255 at the DDT Expo. Image: Caterpillar

Get smart with G.E.Ts

Scott Lidster of Australian Earth Training provides tips to machine operators on maximising the lifespan of ground-engaging tools.

Ground Engaging Tools (G.E.T) are vital components of heavy machinery, playing a crucial role in earthmoving operations across construction, mining, and other industries.

The longevity and efficiency of these tools significantly impact the overall productivity and cost-effectiveness of a project.

As such, machine operators must employ proper techniques and maintenance practices to extend the life of their G.E.T and optimise equipment performance.

Here are some essential tips for maximising the lifespan of your Ground Engaging Tools:

• Routine inspections: Conduct regular visual inspections of G.E.T components before and after each shift. Look for signs of wear, damage, or misalignment. Early detection of issues allows for timely repairs or replacements, preventing further damage and downtime.

• Proper operating techniques: Train your operators to use equipment with precision and care. Avoid excessive force, overloading, or improper use of G.E.T, which can accelerate wear and cause premature failure. Operate machinery at recommended speeds (the faster you’re going, the more friction is created. More friction = accelerated wear) and avoid harsh impacts on the ground or other objects.

• Maintain sharpness: Keep bucket teeth, cutting edges, and ripper points sharp and properly aligned. Dull or worn-out G.E.T can decrease efficiency and increase fuel consumption. Keep your G.E.T sharp. If your G.E.T can be turned mid-life, do it, as this can help maintain a sharp tip. Replace worn components to ensure optimal performance

“When applying G.E.T, some operators can make the hard look easy, and some can make the easy look hard.”

and penetration in various ground conditions.

• Adjust work practices: Adapt work practices to minimise wear on G.E.T. Avoid dragging bucket teeth or cutting edges against abrasive surfaces unnecessarily. Utilise proper ground engagement techniques, such as angle and depth adjustments, to reduce friction and

wear during excavation and loading tasks.

• Implement ground protection measures: Utilise wear protection solutions such as wear bars, wear plates, and protective coatings to shield G.E.T components from abrasive wear and impact damage. These preventative measures help extend the service life of G.E.T and reduce maintenance costs over time.

• Regular maintenance: Follow manufacturerrecommended maintenance schedules for lubrication, tightening, and component replacement. Keep G.E.T assemblies clean and free of debris to prevent buildup and corrosion. Proper maintenance ensures that G.E.T components operate at peak performance and remain in service for longer durations.

Get to know G.E.T: It’s important that stakeholders (owners, maintenance, operators) are educated that not all G.E.T is the same and in a lot of incidents, bigger is not always better. If you’re going for penetration, a tip with a lean, focused profile could be what’s required. If you have low impact, abrasive conditions, perhaps a tip that’s more broad is the way to move forward. Approach your local G.E.T specialist to learn more.

By incorporating these practices into their daily operations, machine operators can significantly increase the life of their ground engaging tools, improve equipment reliability, and minimise downtime.

Investing in proactive maintenance and operator training pays off in the form of improved productivity, reduced operating costs, and increased profitability for earthmoving projects.

Australian Earth Training scott@australianearthtraining.com.au www.australianearthtraining.com.au

42 EARTHMOVING EQUIPMENT MAGAZINE | www.earthmovers-magazine.com.au

INDUSTRY TRAINING

Always keep bucket teeth, cutting edges, and ripper points sharp and properly aligned. Images: Australian Earth Training

Avoid excessive force, overloading, or improper use of G.E.T, which can accelerate wear and cause premature

failure.

The new Cat® Track Wear Sensor remotely monitors track link wear to better predict wear-out, improve maintenance planning and minimise downtime for your Cat D6 Dozer.

• Patented innovation, exclusive to Cat machines and Cat undercarriage

• Automated alerts at 40%, 70% and 100% wear intervals to help you plan for maintenance or replacement

• Increase your fleet coverage with automated inspections and visibility in remote locations

• Available for Cat D6 Dozer HDXL undercarriages and can be retrofitted on eligible dozers.

To find out more or to book a free* undercarriage inspection, contact your local Cat dealer or visit cat.com/undercarriage-au

*Terms and conditions apply. Visit cat.com/undercarriage-au for details. © 2024 Caterpillar. All Rights Reserved. CAT, CATERPILLAR, LET’S DO THE WORK, their respective logos, “Caterpillar Corporate Yellow”, the “Power Edge” and Cat “Modern Hex” trade dress as well as corporate and product identity used herein, are trademarks of Caterpillar and may not be used without permission. NSW/ACT WesTrac 1300 881 064 SA Cavpower 08 8343 1600 QLD/NT Hastings Deering 131 228 WA WesTrac 1300 881 064 VIC/TAS William Adams 1300 923 267 NZ TERRA 0800 93 39 39 BE AWARE OF YOUR WEAR PLAN YOUR MAINTENANCE WITH THE CAT® TRACK WEAR SENSOR.

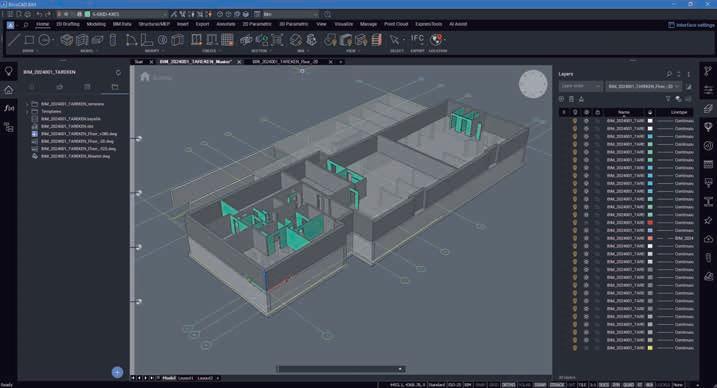

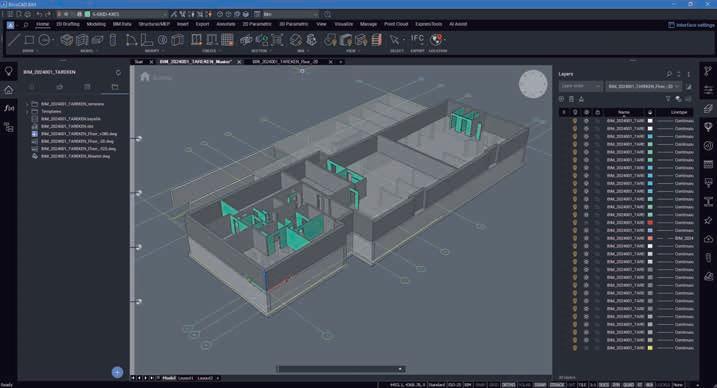

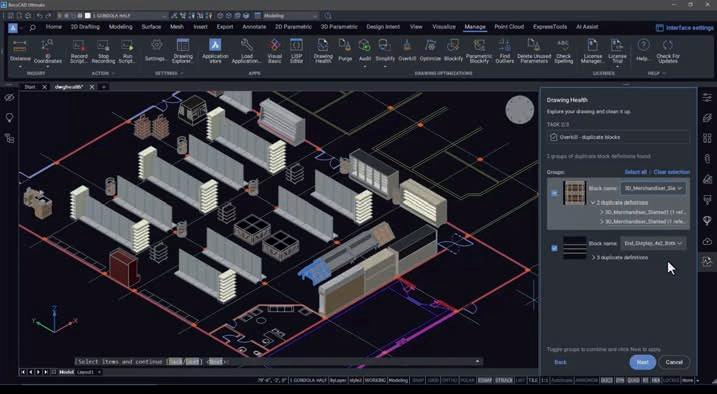

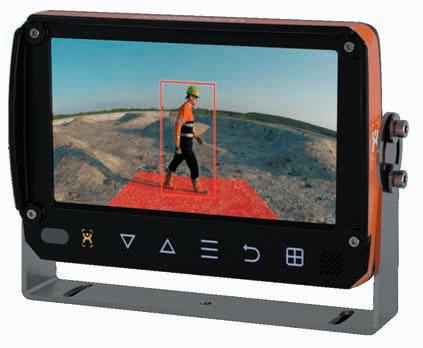

Master productivity with mastless GNSS technology

Caterpillar Product Specialist Darren Hodge introduces the latest construction technology from Cat® designed to increase performance and accuracy.

Caterpillar revolutionised the operation of motor graders with the introduction of joystick controls and a suite of advanced machine control solutions delivering enhanced operability and boosting productivity.

More than a decade ago, Cat® introduced three-axis joystick control for steering, implement and transmission control on the allnew M Series.

The new technology machine with joysticks included electro over hydraulic (EH) valve control systems and has proven exceptional in reducing operator fatigue and allowing easier multi-function work compared to traditional lever controlled hydraulic systems.

“Construction technology has evolved rapidly, and the industry has embraced new innovations that simplify work and finish grade with greater accuracy and higher productivity,” Darren said.

“The EH valves and joystick controls are

the catalyst for Caterpillar designers to continuously develop automated grade control features solutions to keep the construction industry moving ahead,” Darren said.

"Caterpillar's innovation in leading technology has long been a foundation in design and development for new products and in fact for Motor Graders this started back in the 1960s when they developed a basic grade control feature. ABC (Automatic Blade Control) was designed to automatically raise and lower blade to follow intended road design.”

“Where possible, technology integration in the original machine design is most beneficial for positive aesthetics, seamless fit and finish, reliability and end-to-end service and support Cat dealers.”

For basic 2D slope control, the integrated Cat Grade Control Cross Slope System was developed as a factory-installed option over 10

years ago, replacing aftermarket installs.

“This feature, although an option, was quickly accepted by over 90 per cent of our customers as a minimum requirement,” Darren said.

“Operators appreciated the autonomous benefit of maintaining the desired cross slope in a road without the need of external grade slope checks. Using the basic 2D guidance and automatic control of one side of the blade for road maintenance results in greater accuracy, and more timely completion of the job.”

For road and infrastructure designs with complex curves, slopes and contours, customers install aftermarket 3D Grade control technology that utilised much of the hardware. EH valves and electronics are already integrated into the machine.

“This higher technology provides vertical height and horizontal positioning guidance or by controlling the blade relative to an electronic design,” Darren said.

44 EARTHMOVING EQUIPMENT MAGAZINE | www.earthmovers-magazine.com.au

MEET THE EXPERT

Automatic blade control reduces operator inputs and the number of passes to finish the job. Images: Caterpillar

“Whilst these systems are highly accurate to achieve design elevation parameters, they do have some limitations when using typical machine operations such as Articulation and Circle rotation and remaining accurate to design.

"The hardware associated with masted technology is cumbersome. Tall, heavy GNSS antenna masts are installed at one or both ends of the blade for 3D control. In some jobs these masts restrict operation in steep slope applications, and if caution is not used damage from masts impacting the cab can occur.

“The mast mounted antennas are costly and prone to theft, so for security at the end of the workday operators remove them and securely store them, a heavy burden on the operator.

“For greatest accuracy using masted 3D technology, best practice is to keep the machine in a straight heading and restrict drawbar positioning, blade tip changes and articulation movements.“

“These operations usually limit the machines operation and productivity, so with limitations in movement some applications can’t be completed effectively using masted 3D GNSS technology.”

More than four years ago, the Cat 3D GNSS Mastless option was introduced to the market on the T4f emissions-built Motor Grader product to overcome issues associated with blade mast antenna systems.

“The take-up of this option has significantly exceeded our expectations,” Darren said.

“To provide greater customer reach with this technology, Caterpillar has introduced Grade 3D Mastless on our T3 emission platform now.”

“The new Mastless GRADE 3D system on Cat motor graders integrates the receivers and IMU grade sensors that work to compensate for the machine’s acceleration and position changes to deliver a superior finish.

“The operator can position the grader and blade in the most productive position with no compromise to grade accuracy and with no masts to interfere with visibility or performance.

“Wheel lean, drawbar offsets and frame

articulation can be re-positioned to process the material effectively for greater productivity and performance.

“This expands the use of the grader in other applications such as side slopes and drains where guidance was not previously possible due to the mast restrictions in drawbar positioning.”

Automatic blade control reduces operator inputs and the number of passes to finish the job – saving time and money. The operator also benefits from the updated 10-inch touch screen display, which has been improved for faster performance.

The Grade display puts the design plan clearly in front of the operator. Grade control buttons are integrated into the advanced control joysticks for seamless operation.

“Mastless GRADE 3D assists the operator to get to the design plan faster and with more accuracy and increased efficiency,” Darren said.