Biomethane: from pipe dream to pipeline

OFFSHORE WIND: taking shape on Australia’s horizons Why

will be pivotal for the energy transition

Biomethane: from pipe dream to pipeline

OFFSHORE WIND: taking shape on Australia’s horizons Why

will be pivotal for the energy transition

Your NEW all-in-one test solution to verify PV system performance and safety and expedite client reporting.

On-location I-V curve results: compare manufacturer I-V curve data to measured data instantly in the field, no laptop required

Automatic testing saves time: on-screen instructions provide an easy walkthrough of tests on a colour screen

Less time wasted on set-up: with “Keep the Leads” system, configuration of test leads is only required once

Wireless irradiance and temperature measurements: the IRR2-BT Irradiance Meter Pro communicates in real time with the SMFT-100 0

Critical testing features:

IEC 62446-1 compliant for full safety and system performance testing

Spend less time processing test results and compiling reports with TruTest™ Solar Data Management Software

•Quickly create inspections and reports compliant with IEC 62446-1.

•I-V curve analysis with easy pass/fail visuals; see changes in I-V curve over multiple site visits.

The last financial year showed that the energy sector continues to innovate, challenge, and invest in new solutions for the nation’s future.

As many in the industry know the pace of change and growth needs to accelerate if Australia is to reach future goals in time. This was evident, and a keen topic of discussion, at the recent Australian Energy Week conference.

During the event, AEMO CEO, Daniel Westerman, AEMC Chair, Anne Collyer, and other industry experts urged the sector to take action before it's too late. Despite the challenge, and the puzzle of the transition, Ms Collyer said, “We all have pieces to contribute”.

This is a fitting analogy for the industry. The net zero by 2050 goal requires vast work, and every solution, no matter the scale, is beneficial.

The 23-24 Federal Budget, released in May, showcased the necessity for varied government support and investments, such as the $20 billion in funding announced for the Clean Energy Finance Corporation, the Hydrogen Headstart program, and the Net Zero Authority, as Australia’s energy sector continues to evolve.

In this issue of Energy, we discuss large-scale solutions, Australia’s growing wind industry, including offshore assets in Gippsland, and what’s ahead for New South Wales’ newly crowned national offshore wind zone.

The specified zone in the Hunter region includes over 1,850 square kilometres, and the DCCEW has estimated the area has the potential to generate 5GW of wind energy – enough to power 4.2 million homes. With

feasibility licence applications open until November, I’m sure we’ll continue hearing about more offshore wind proposals.

This edition also covers energy efficiency and storage – the building blocks supporting decarbonisation and grid stability – with an exclusive feature from the Climateworks Centre regarding the potential of 'negawatts', and ANU research on how solar hours heating can support regional locations with battery storage requirements.

It’s also been great to hear about from the ever-important energy workforce on the ground. This edition highlights Origin Energy’s Nick Bristol and his work on the Australia Pacific LNG project.

I’m excited to see where the next few months take the industry, and as always, if you have a story or project to share, I’d love to hear it.

Holly Tancredi EditorIf you have a story idea, tip or feedback regarding Energy, I’d love to hear it. Drop me a line at holly.tancredi@monkeymedia.net.au, and don’t forget to follow us on social media – find us on LinkedIn, Twitter or Facebook.

12

12 An introduction to CSIRO’s new Energy Director: Dr Dietmar Tourbier

14

14 Leading the charge in Australia's offshore wind industry

As Australia's transition to a sustainable and low-carbon energy future gains momentum, offshore wind continues to emerge as a crucial component of this transformation. Flotation Energy, a global offshore wind developer, is at the forefront of this movement and globally renowned for pioneering floating offshore wind and energy transition projects.

18 Winds of change: geotechnical innovation in wind farm construction

20 Retiring wind turbines: reuse, repurpose or recycle?

24 Precision flying speeds up connection works

26 The benefit of experience in extending the life cycle of wind turbines

28 The new horizon: Australia’s developing offshore wind industry

There’s something new taking shape on Australia’s coastlines. Wind power has been used in Australia for decades, but now in 2023 – supported with federal offshore electricity acts and regulations – offshore wind power is set to blow fossil fuels out of the water. Supporting this industry growth is the latest declaration of the Hunter region as the nation’s second offshore wind zone.

30

30 ‘Negawatts’ will enable the energy transition in Australia

Why is building energy efficient infrastructure important? Due to physical infrastructure lasting 50-100 years, building it to be energy efficient will continue to pay us back for a very long time. This is because ‘negawatts’ – or the watts saved through energy conservation or energy-efficient choices – in buildings, transport and industry are the most cost-effective way to reach zero emissions.

34 Innovative, intelligent solutions for the energy transition

36 EN2024: Unparalleled networking and collaboration opportunities

38

38 Storage: A ‘sweet spot’ lies in the distribution network

The challenge of decarbonisation rests on us all; industry, government, and households alike across Australia.

42 The technology solving Australia’s battery storage needs

44 Solar hours heating redefining regional battery storage requirements

Developing more sustainable and energy efficient ways to store and use energy does not always have to require fancy or complex technologies. A recent collaboration from the Australian National University and a regional Victorian town has had surprising and positive results in proving that moving electric hot water heating from nighttime to during solar hours has the potential to massively reduce required battery storage.

46 It’s the destination, not the journey: the federal strategy to reduce EV uptake barriers

Evolving an entire transportation industry is no small feat. State and territory governments, leading energy organisations and experts have been working in recent years to ensure Australia’s passenger transport future is electric, but there is a piece missing from the puzzle. In April 2023, the Federal Government, after long industry and consumer consultation, released the country’s first Federal National Electric Vehicle Strategy. Finally outlining the work ahead to legislate a fuel efficiency standard and more, the strategy shares Australia’s plan to grow the uptake of electric vehicles (EVs).

48 Connecting EVs across Australia’s energy grids 46

52 Guaranteeing hydrogen some get up and GO

Most of us are familiar with the green and gold kangaroo or the Health Foundation tick. These quickly identifiable certification schemes are designed to give customers confidence in the product they are purchasing, with the assurance that the “premium” products they buy are what they are purported to be. Australia’s hydrogen Guarantee of Origin scheme would work in much the same way. The scheme is under development and will be an important tool in the policy toolbox to support the transition to renewable gas.

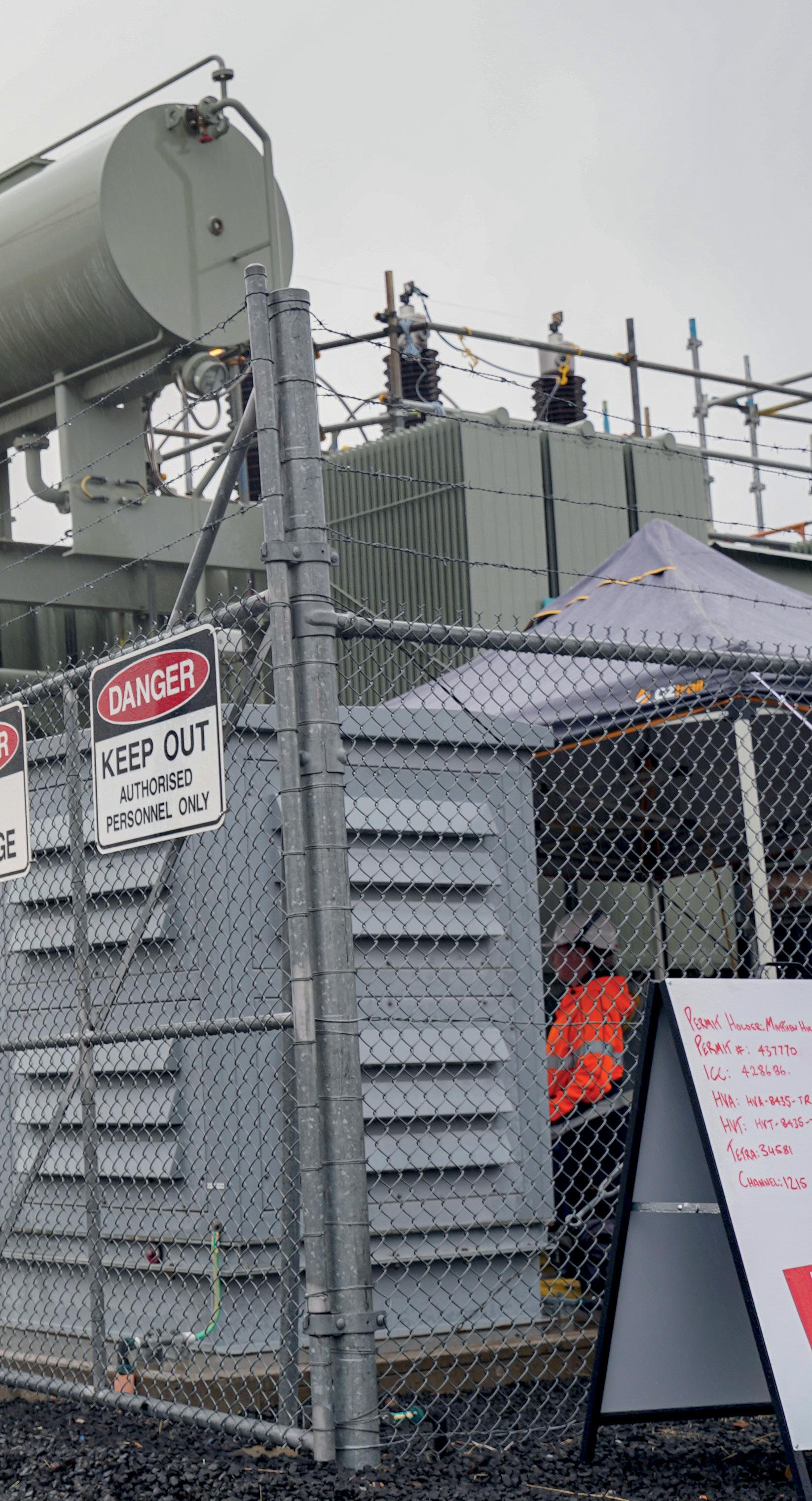

54 Solving challenges in high voltage power across the Australia Pacific LNG project

56 Taking biomethane from pipe dream to pipeline

60 From fossil to renewable: Australia's liquid fuel transition

1

4 Financial close on VIC hydrogen plant

5 WA’s second big battery begins construction

6 $20.5 billion allocated to CEFC

7 Indigenous partnership to deliver green hydrogen project

8 AEMO releases engineering priorities to ready NEM for renewables

8 ‘Big Bessie’ battery switched on

9 New FY – the perfect time to check the health of your super

10 Engineering climate solutions: CSE23

Australian Gas Infrastructure Group (AGIG) has reached financial close on the Hydrogen Park Murray Valley renewable hydrogen plant, a major milestone in the project’s development.

The Australian Renewable Energy Agency (ARENA) announced a $36.1 million commitment to AGIG for the 10MW electrolyser deployment in Wodonga, Victoria.

The project builds on ARENA’s existing work in renewable hydrogen and strong track record of delivering transformative projects in the energy transition in pursuit of net zero.

The Hydrogen Park Murray Valley project will produce renewable hydrogen to initially be blended into the local natural gas distribution network, owned by Australian Gas Networks, part of AGIG.

The facility will be located next to North East Water’s Wodonga Wastewater Treatment Plant. Once complete, the project will be the largest renewable hydrogen facility on the east coast and equal largest in Australia.

The renewable hydrogen produced will displace natural gas supplied to local customers and industry at blends of up to ten per cent, reducing carbon emissions with no change to amenity for gas users.

With more than 40,000 connections to the local gas network, the project will supply hydrogen to an estimated 85,000 people spanning the border of Victoria and New South Wales. At a blend of ten per cent, the project is predicted to cut approximately 4,000 tonnes of CO₂ each year.

Wodonga’s strategic location along a major road freight route also provides access to other end use markets, particularly in heavy vehicle transport.

The Victorian Government is supporting the project with $12.3 million through the State Department of Energy, Environment and Climate Action (DEECA), with additional financial backing from the Clean Energy Finance Corporation (CEFC).

Hydrogen Park Murray Valley is the second 10MW project supported by ARENA to reach financial close after the first, Engie’s Project Yuri in the Pilbara, achieved the milestone in September 2021. Both were funded as part of a $103 million competitive funding round for commercial scale hydrogen electrolyser projects.

ARENA Chief Executive Officer, Darren Miller, said the project is paving the way for renewable hydrogen in Australia.

“It’s essential to scaling up Australia’s renewable hydrogen industry that we get these first-generation projects up and running,” Mr Miller said.

“Producing renewable hydrogen on this scale has never been done in Australia. The lessons we learn here will help inform our hydrogen industry as it grows from its early stages to a pillar of the net zero economy.

“ARENA has been at the forefront of advancing renewable hydrogen projects and will continue to play an integral role, as we support the Australian Government’s Hydrogen Headstart program and other large scale projects.

“What’s exciting about this project is that it will be producing hydrogen that reduces local emissions from day one, with the potential to supply additional markets as they move towards net zero.”

AGIG Chief Executive Officer, Craig de Laine, said that AGIG is proud to work with both the Federal and Victorian Governments on this landmark project.

“The strong support received from both the Federal and State Governments demonstrates the importance of renewable hydrogen to decarbonising energy across Australia. We thank all our project partners and key stakeholders, including the AlburyWodonga community for their contribution to the project to date.”

Construction on the project is due to commence in 2023, with the site operational by 2025.

Construction has begun on the $625 million Kwinana Stage Two Battery.

Funded by the Western Australian Government, the Kwinana Battery Stage Two will provide 200MW of energy capacity with 800MWh of energy storage – four times that of Kwinana Battery Stage One.

The big battery is being built on 3ha at the former Kwinana Power Station, adjacent to the first grid-scale battery.

As Western Australia’s second gridscale battery energy storage system, the new battery will comprise 288 shipping container-sized battery modules and will feature 72 inverter units.

These inverters use new-generation technology to support grid stability by storing electricity when demand is lowest and delivering it back into the grid during peak times.

More than 160 jobs will be created during the construction of the second big battery, which is expected to be completed by late 2024.

Western Australia’s first transmissionconnected big battery was switched on in June 2023 and provides 100MW or 200MWh of energy capacity and storage, respectively.

Big batteries are an important initiative under the Western Australian Government’s Energy Transformation Strategy and commitment to net zero emissions by 2050.

Western Australian Premier, Roger Cook, said the State Government is getting on with delivering its plan for cleaner, reliable and affordable energy.

“The start of construction for Western Australia’s second grid-scale battery energy storage system is an important milestone in the State’s energy transformation.

“Western Australia is a leader in the uptake of residential solar energy, and

these big batteries help to ensure our energy system remains reliable as we transition away from coal-fired power.

“It is particularly fitting that we’re building the infrastructure of the future at the site of the old Kwinana Power Station – keeping the Kwinana industrial strip front and centre as our energy system transitions to a new future.”

Western Australian Energy Minister, Bill Johnston, said the big battery features new technology and will strengthen the reliability of the power supply to the state’s main electricity grid.

“Western Australia is unique in its energy security because we are not connected to other networks,” Mr Johnston said.

“Our energy management sets us apart from the rest of Australia. By investing in renewable energy and battery storage solutions, the government is safe-guarding the long-term resilience and flexibility of our electricity network.”

The Clean Energy Finance Corporation (CEFC) has been allocated an additional $20.5 billion by the Federal Government to accelerate progress towards Australia’s transition to net zero emissions by 2050.

The Australian Parliament has passed the Treasury Laws Amendment (2022 Measures No. 4) Bill 2022, allowing for the CEFC to receive the first $11.5 billion and for a further $9 billion to be added by other new appropriations.

The additional funding provides for the creation of three new investment priorities to be delivered by the CEFC:

» $19 billion to help deliver the Rewiring the Nation program, with investments including high voltage transmission, long duration grid storage and electricity distribution network infrastructure

» $1 billion to create the Household Energy Upgrades Fund, to provide discounted consumer finance to increase sustainability across the housing sector

» $500 million for a new Powering Australia Technology Fund, to support the growth or expansion of clean technology projects, businesses and funds to facilitate the development, commercialisation and take up of clean energy technologies

CEFC Chair, Steven Skala AO, said this support from the Federal Government for CEFC’s work as Australia’s ‘green bank’ was significant.

“The additional funding recognises the success of the CEFC model in investing to lead the market, proving up investment opportunities and operating with commercial rigour,” Mr Skala said.

“The Rewiring the Nation program, Household Energy Upgrades Fund and Powering Australia Technology Fund substantially expand the role of the CEFC, alongside its ongoing core businesses. New large-scale investments in priority grid infrastructure projects complement our existing work in transforming our energy system and bringing the benefits of decarbonisation to key sectors of our economy.

“After a decade as Australia’s specialist clean energy investor, the CEFC has the experience and track record to finance complex infrastructure projects, back clean energy generation and support significant decarbonisation across the Australian economy. With this additional $20.5 billion capital allocation, we recognise the challenges and opportunities of building on our investment portfolio in our second decade of operation.”

CEFC CEO, Ian Learmonth, welcomed the substantial increase in CEFC’s investment capacity and acknowledged the demonstrated confidence in the unique role it is playing across the Australian economy.

“This additional capital will enable the CEFC to make a significant contribution to the achievement of net zero emissions by 2050, an ambitious and important national goal that will transform our economy and improve our environment,” Mr Learmonth said.

“Subject to commercial considerations, we expect to make substantial grid-related investment decisions within the next 12 months. While these transactions are often large and complex, we must move quickly to invest in the expansion and augmentation of our grid and related infrastructure to deliver on Australia’s net zero objectives.

“Analysis from the Intergovernmental Panel on Climate Change provides an important reminder of the scale of the climate challenge and the urgency to accelerate meaningful action in this decade.

“In Australia, this means transforming our energy system to low cost, low emissions renewables, backed by large-scale energy storage and a modernised two-directional grid, connecting distributed generation with industrial, commercial and residential power users.

“This must occur in parallel with an unprecedented adjustment in the way we use energy across our economy, transforming the way we farm, manufacture, travel and extract our resources.

“At the intersection of this revolution in low emissions energy generation and distribution is Government and private sector capital, delivered via new and tailored investment models that leverage the considerable market momentum toward sustainable green investment opportunities.

“We do not underestimate the scale of the challenge or the pace at which this transformation must occur, especially in light of the economic and supply chain headwinds impacting many sectors of our economy, including energy.”

The CEFC said it will provide further information on the investment approach for each of the three new investment priorities in due course.

Indigenous communities are partnering with climate change advisory firm Pollination to deliver one of Australia’s largest clean energy projects, producing green hydrogen products for domestic and export markets.

The East Kimberley Clean Energy Project will take advantage of the region’s abundant sunshine, fresh water and export-ready harbour to create Australia’s first 100 per cent renewable energy hydrogen and ammonia production hub.

The project is being created under a first-of-its-kind partnership in which the traditional owners of the land – MG Corporation and Balanggarra Aboriginal Corporation, will join the Kimberley Land Council and Pollination as equal shareholders of the project development process and the company created to oversee it, Aboriginal Clean Energy (ACE).

Project scoping has been completed and development will continue over the next 12 months. Pending the completion of feasibility and capital raising stages, construction could commence as early as late 2025 with first production by the end of 2028.

Stage one of the project involves building a greenfield 900MW solar farm – the largest in Australia – and a 50,000tpa hydrogen production facility – on MG Corporation freehold land near Kununurra, Western Australia. Electrolysis will convert fresh water from Lake Argyle into green hydrogen, which will be transported via a new 120km pipeline to the existing Port of Wyndham.

The hydro facility at Lake Argyle will supply baseload renewable energy to an ammonia production facility in Wyndham, producing approximately 250,000tpa of green ammonia. The result will be Australia’s first and only 100 per cent renewable green hydrogen and ammonia project.

Green ammonia produced by the facility will be used locally in agriculture and for export to key trading partners in Asia and Europe.

Stage one is designed to leverage the region’s existing assets including:

» The Port of Wyndham, which has an ideal location and is well suited for exports to Asia

» The existing Ord Hydro facility and electricity transmission network

» Road networks and airport facilities that link key sites to be used for production and distribution

Pollination Head of Projects, Rob Grant, said that this project represents a just, ambitious and achievable vision for Australia’s clean energy future.

“It leverages the natural advantages and existing energy and port infrastructure already in place in the East Kimberley region to create a major new clean energy export hub that will help Australia and our region decarbonise, grow new industries and ensure traditional owners and local residents are shareholders, not just stakeholders, in the benefits,” Mr Grant said.

“The main requirements for green hydrogen production are clean water, sunlight and renewable energy sources and all are abundantly available in this project,” Mr Grant said.

“Dozens of governments worldwide, many of them in our

neighbourhood, have already issued a hydrogen strategy –flagging how critical this resource is going to be as the world moves towards net zero.

“The Federal Government has placed green hydrogen at the heart of its plans to become a clean energy superpower in the future global economy and this is exactly the kind of project that will be critical in making good on that ambition.”

The project will be planned, created and managed by the ACE Partnership, the new company in which equal shares are owned by MG Corporation, Kimberley Land Council, Balanggarra Ventures and Pollination.

The partnership model allows an integrated development process for heritage, native title, environmental and engineering approvals using true co-design and co-decision making from the partnership’s shareholders.

The ACE Partnership said the model is a fairer and more just approach compared to how resource projects have traditionally been developed. It is also one that significantly reduces project development risk and shortens the project’s development schedule.

Balanggarra Aboriginal Corporation CEO, Cissy Gore-Birch, said the ACE partners bring differentiated but crucial individually lived experience and knowledge to this project.

“From cultural heritage, social engagement and remote land management to renewable energy and green hydrogen project and industry experience, the suite of skills required to effectively deliver this ambitious project on traditional lands in the East Kimberley exists only within this consortium,” Ms Gore-Birch said.

MG Corporation Executive Chair, Lawford Benning, said the partnership represented an important way forward for Traditional Owners.

“A focus on First Nations economic empowerment has led groups like ours to reject the historic passive engagement model of receiving royalties for agreeing to give up control of our lands,” Mr Benning said.

“This project gives us a chance to be active shareholders, understanding the risks and rewards, and making informed decisions about long-term strategic projects on our Country. Anything we do must be sustainable, intergenerational and connect culture and heritage.”

KLC CEO, Tyronne Gartsone, said the partnership represented an entirely new model for First Nations involvement in large infrastructure projects and the clean energy sector and could be replicated across Australia in order to help deliver on the nation’s climate change commitments.

“The recent Melbourne and Queensland University Net Zero Australia report shows that at least 45 per cent of the renewable energy we need to decarbonise our domestic and export energy supply will be located on land that is subject to native title,” Mr Gartsone said.

“We cannot have a just transition to net zero without First Nations ownership of the solution and projects that ensure we can get there.”

he Australian Energy Market Operator (AEMO) has published the Engineering Roadmap FY2024 Priority Actions Report, which outlines the actions AEMO plans to take to help prepare the National Electricity Market (NEM) for the growing renewable transition.

The AEMO said as Australia increasingly observes new renewable energy milestones, completing the necessary engineering work will be paramount to enable secure and reliable electricity supplies during periods when there are no fossil fuelled generators online.

This report seeks to continue the work from the Engineering Roadmap to 100% Renewables, by providing transparency on the specific activities the AEMO is progressing in 2023-24, while also providing an update on the extensive progress made in 2022-23 by AEMO and industry to increase preparedness.

AEMO Manager of Future Energy Systems, Chris Davies, said that readiness for 100 per cent instantaneous renewables is a critical enabler for being able to operate the power system regularly with high penetrations of renewables, in turn supporting the transition to a net zero energy system.

“The transition requires a concerted effort across industry, and this report summarises the major engineering and operational

The Bouldercombe 50MW/100MWh grid-scale battery has been officially switched on in Queensland.

The battery, nicknamed ‘Big Bessie’, is part of the Queensland Government’s Energy and Jobs Plan, and will take Central Queensland’s role in generating the state’s energy and supercharge local energy affordability.

The battery, located just outside of Rockhampton, will help revolutionise the way energy supply and demand can be managed in the region during peak times.

When fully operational at the end of 2023, the large-scale storage system will provide ancillary services to also support the stability and reliability of the transmission network that supplies power to more than five million Queenslanders.

Minister for Energy, Renewables and Hydrogen, Mick de Brenni, said that the energisation of the Bouldercombe Battery Project signals yet another step towards making the Queensland SuperGrid a reality for local communities and putting downward pressure on household energy bills.

readiness activities that AEMO intends to progress in this next financial year,” Mr Davies said.

The AEMO intends to make progress towards over 80 different actions throughout 2023-24, with this report spotlighting a subset of activities where AEMO is seeking to drive significant progress in the year ahead.

This includes activities where:

» AEMO believes significant uplift in effort is required to prepare for associated Roadmap preconditions

» Engagement with external stakeholders is crucial and not fully captured through other work programs

» Delayed progression may pose a risk to power system security in future

Based on these principles, the priority actions identified for 2023-24, cover four objectives:

1. Enabling high penetrations of distributed energy resources (DER)

2. Enabling new technologies to address system needs

3. Conducting future power system studies

4. Building operational readiness

“Batteries are fast and flexible, with the ability to ramp up and down instantaneously to support the stability of the power system and reduce wholesale price volatility,” Mr de Brenni said.

“This battery, along with our Cost-of-Living Rebates, show that the Queensland Government is committed to helping keep costs down for households.”

Genex CEO, James Harding said the energisation of the Bouldercombe Battery Project is a significant milestone for Genex, as it marks the start of commissioning of the company’s first large scale battery energy storage system and will play an integral role in diversifying the Genex portfolio of assets which includes solar, wind, pumped hydro and battery storage.

“Given the acceleration of the clean energy transition over the past 18 months, the successful connection of the project is timely, as it will store and supply up to 35,200MWh of power per annum and enable the further penetration of renewable energy in the state.”

As the new financial year kicks off, it is time to ensure your current superannuation is supporting your future plans.

righter Super has been supporting energy and electrical utility workers for over 40 years to reach their retirement dreams and is committed to doing this as much as possible face-to-face.

Brighter Super CEO, Kate Farrar, said while it's a busy administrative time of year, don’t forget to plan ahead to ensure you are getting the most out of superannuation.

“We have been listening to what our industry members want and need, and one of those things was not to lose our personalised approach as we grow. We really listened and today have more than 40 consultants on the ground, more than any other superannuation, ready to meet members and support them on their retirement journey.”

Brighter Super has seen thousands of members in the last year, and there are the three C’s that they recommend all employees should consider at this time of year.

1. Check – that your retirement is on track. Request a super health check with your super fund

2. Consolidate – find out if you’re paying fees on multiple accounts and discuss consolidation with your super fund

3. Contribute – Consider your budget and whether you are able to make additional contributions

A little planning now can go a long way to making 2024 a brighter financial year.

Brighter Super is a proud Queensland not-for-profit fund, and with 259,000 members and $29 billion funds under management, it is also one of Queensland’s largest non-government financial institutions.

This article provides general information only and does not consider your individual objectives, financial situation or needs. You should consider your own circumstances and needs, and obtain and consider the Product Disclosure Statement (PDS) before making any decision to acquire any products. A Target Market Determination (TMD) is a document that outlines the target market a product has been designed for. Find the PDSs and TMDs at https://www.brightersuper.com.au/about-us/governance. Produced by LGIAsuper Trustee (ABN 94 085 088 484) (AFSL 230511) (the Trustee) as trustee for LGIAsuper (ABN 23 053 121 564) (RSE R1000160) (the Fund) trading as Brighter Super. Brighter Super may refer to the Trustee or LGIAsuper as the context may be. Brighter Super products are issued by the Trustee on behalf of the Fund.

With headquarters based in Queensland, we are the industry super fund that has been supporting energy workers for over 40 years.

Now with greater scale, we manage the retirement savings for over 250,000 members, which means we are able to increase the personal service our members want, and keep their fees lower.

Registration is open for Engineers Australia’s flagship conference, Climate Smart Engineering 2023 (CSE23), to be held at the world-class sustainable Melbourne Convention and Exhibition Centre on 29-30 November 2023.

Now in its third year, the program for CSE23 includes some of the profession’s brightest and boldest minds as well as key leaders across government and industry offering diverse perspectives on climate mitigation and resilience, the clean energy transition and opportunities in the circular economy.

This is a conference for knowledge-sharing, networking and engaging debate on engineering-led climate solutions – reflecting the critical role the profession will play in driving the economy-wide transition to net zero. Speakers will demonstrate why it is important for sustainable practices and environmental considerations to be at the forefront of everything we do.

The conference will feature a full technical program supported by plenary sessions, networking opportunities and exhibitors that will challenge, confront and inspire attendees. The key themes that underpin this year’s conference program include adaptation and mitigation, resilience, social impact, business management, regeneration and systems thinking, energy transition, the circular economy, technology and innovation.

Join Engineers Australia for the must-attend sustainability conference of 2023.

29-30 November 2023

Melbourne Conference and Exhibition Centre

For program information and to register visit engineersaustralia.org.au/cse

Connecting engineering minds, ideas and opportunities, Climate Smart Engineering Conference (CSE23) will showcase the latest solutions to pave the way for net zero emissions in Australia. Register

Taking on a director role in Australia’s national science agency is certainly not for the faint of heart – or a pessimist. The industry is experiencing rapid change and enduring pressures from not only political and environmental sectors, but also from everyday Australians who want more affordable, reliable and cleaner sources of energy. It would seem new Director of Energy, Dr Dietmar Tourbier, has his work cut out for him.

If destiny had played its cards slightly differently, Dr Dietmar Tourbier could have embarked on a career as an astronaut. With a Master’s Degree in aerospace engineering from the University of Stuttgart and a PhD with a focus on computational fluid dynamics from the University of Arizona under his belt, Dr Tourbier's first industry job was working on technology development for an aerospace company.

But ten hours spent in a vacuum chamber at NASA’s Johnson Space Centre testing a glove prototype revealed Dr Tourbier’s claustrophobia and cut short his ambitions for space exploration.

“I’m still fascinated with space,” Dr Tourbier said, speaking from his home in Victoria.

“I really appreciate the technology development we gained through space flight. But after that test – that time spent panicking in a small capsule – I knew I was never going to do it again.”

A loss for the aerospace sector was a gain for the energy industry. Dr Tourbier moved on to a highly successful 20-year career with General Electric (GE), starting with a role at their solid oxide fuel cell (SOFC) division in California, where he developed a passion for clean energy through fuel cell development.

When GE stopped working on fuel cells in 2007, Dr Tourbier remained with the company but returned to his home country of Germany – first in a leadership position with the global power electronics technology research group, and then as their European Research Leader.

It wasn’t until 2018, when GE started closing all their corporate research centres outside the US, that Dr Tourbier eventually moved to Australia with his family, and took up a position as Director of the Australian Solar Thermal Research Institute (ASTRI) – an elevenyear, $110 million international research collaboration led by CSIRO.

“My wife is originally from Arizona, but she had been living in Australia and we had been splitting our time going back and forth between Australia and Germany,” Dr Tourbier explained.

“When GE closed down their international centres, I took that as a sign that it was the right time to move again. My wife discovered this job advert from a place called CSIRO. I assumed that as I was German and it was the Australian national science agency, they would never hire me. But, to cut a long story short – they did!”

During his tenure as Director of ASTRI, Dr Tourbier brought together an impressive team of research organisations and engaged industry partners to incorporate solar thermal technologies developed by the institute. While there are not yet any solar thermal plants running in Australia, ASTRI’s research continues to bring the goal of efficient, affordable solar thermal much closer.

Dr Tourbier’s success in this initial role with CSIRO, along with the experience gained through two years as Deputy Director of the Energy Business Unit, meant that he was an obvious candidate when the Director of Energy position became vacant in 2022. His appointment to that role was formally announced in May 2023.

It’s an exciting, but enormously challenging time to step into the role as CSIRO’s Director of Energy. Australia’s energy sector is undergoing a radical transformation – not just in terms of electricity generation, but also across industry, transport and exports. New technologies, changing consumer preferences and ambitious emissions reduction targets are driving the transition at a rapid pace – and while that’s definitely a good news story, it’s also raising some challenges that need to be addressed.

As the national science agency, CSIRO is tasked with providing robust, actionable energy research to government, industry and other stakeholders, allowing them to target investments, implement policies, and adopt new technologies over the coming decades.

Steering Australia through the complexities of an energy transition to net zero emissions will require Dr Tourbier to draw on every bit of his deep industry knowledge, his networks of national and international stakeholders, and his passion for innovation and technology. However, he is keen to emphasise that CSIRO’s strength lies in its breadth of expertise and collaborative approach to research.

“At CSIRO we are working on solving Australia’s greatest challenges that we have identified,” Dr Tourbier said.

“We are addressing those across the whole organisation and taking a multidisciplinary approach. There are six focus areas, which include Health and Wellbeing, Future Industries, Food Security and Quality, Secure Australia and Region, and Resilient and Valuable Environments. I am responsible for the Sustainable Energy and Resources challenge.”

Within each challenge, there are a number of Missions: large-scale, impact focused scientific and collaborative research initiatives aimed at making significant breakthroughs with a tangible end goal.

“Missions are portfolios that have, by definition, a finite time to deliver impact,” Dr Tourbier explained.

“We have discovered that they help us work much more effectively across different business units. For Sustainable Energy and Resources, the first two Missions we have established are Hydrogen Industry and Towards Net Zero.”

CSIRO’s Hydrogen Industry Mission was established in 2021, with a focus on building commercially-viable Australian hydrogen energy. Towards Net Zero was established in 2022 with an initial investment of $90 million, with the goal of helping Australia’s regions and hardest-to-abate sectors halve their emissions by 2035.

There are currently two additional Missions in development that are of particular relevance to the energy sector and will be a major focus for Dr Tourbier over the coming months: Renewable Energy Powerhouse and Smart Energy.

“We have all the ingredients here in Australia for the critical energy minerals that are required to power the clean energy transition,” Dr Tourbier said.

“But at the moment we dig those up, ship them elsewhere, and then have to buy back the products. What we’d like to do with the Renewable Energy Powerhouse Mission is explore how we can move Australia further along the value chain. There’s an International Energy Agency (IEA) analysis that shows Australia can have the lowest cost clean energy of all OECD countries – we want to help achieve that.”

“Smart Energy is about how we design a system with far more connectivity between transport, heavy industry, communities and consumers. Where hydrogen, gas, water and electricity are more interlinked than they are today. We’re moving to a far more dynamic energy system, and working out how to operate it is a complex challenge.”

“We need our energy system to be clean,” Dr Tourbier said.

“But we also need it to be sustainable, reliable and affordable, and we need that to happen as quickly as possible. I am excited to play my part in that.”

Solar research and testing facilities at CSIRO Newcastle includes a field of 200 heliostats which concentrate the sun's energy on to a receiver that sits on a 26 metre high tower. With this concentration, peak temperatures of more than 1,000 degrees celsius can be achieved, suitable for many industrial processes.

By Carolyn Sanders, General Manager Australia, Flotation Energy

By Carolyn Sanders, General Manager Australia, Flotation Energy

As Australia's transition to a sustainable and low-carbon energy future gains momentum, offshore wind continues to emerge as a crucial component of this transformation. Flotation Energy, a global offshore wind developer, is at the forefront of this movement and globally renowned for pioneering floating offshore wind and energy transition projects.

Our founders, Allan MacAskill and Lord Nicol Stephen, developed Kincardine, the world’s largest floating wind farm. The company is rapidly growing, with the focus on delivering more than 13GW of commercial scale fixed and floating offshore wind farms and has plans to expand into key markets.

In Australia, these include the 1.5GW Seadragon Offshore Wind Project off Gippsland and the 1.5GW Southwest, Perth and Wannaroo Arrays.

The opportunities for offshore wind in Australia are boundless.

The Gippsland region has a 50-year proud energy legacy. These skills are certainly transferable and Flotation Energy is committed to continuing this legacy for decades to come.

In fact, I myself have transitioned from the oil and gas sector. An Engineer by degree, I worked for 19 years in the Bass Strait oil and gas industry, gaining experience in facilities and pipeline engineering, risk management, safety and environmental management of offshore activities and commercial operations.

Working closely with the Gippsland community, I witnessed firsthand the impact and prosperity that the oil and gas industry brought to the region. As we started to plan for the ultimate decommissioning of the Bass Strait facilities and it became increasingly clear that the world needs to rapidly transition away from fossil fuels, I wondered what the future held for communities like these.

In offshore wind, I could see the future of the Bass Strait offshore energy industry; a chance for the capable local workforce to use their skills and for the region to transition from being known for fossil fuels to being known for large-scale renewable energy. Many of the Flotation Energy team have previous experience in offshore oil and gas and have made the transition smoothly into offshore wind, as I have.

Flotation Energy firmly believes that Australia's offshore wind industry has the potential to replicate the success of the UK offshore wind industry. However, to realise this potential, the Federal Government needs to establish a clear policy framework that includes generation targets and timelines.

Certainty in policy drives investment, innovation, job creation and economic growth. Victoria has taken a significant step by setting its own offshore wind policy at the state level, but a nationwide approach

is needed to unlock the industry's full competitive potential.

Clear federal generation targets will go a long way to providing the necessary confidence needed to drive investment.

Clear policy guidelines serve as a powerful catalyst for investment and commitments from Original Equipment Manufacturers (OEMs) and suppliers. Without a well-defined offshore wind policy, OEMs and suppliers are unlikely to invest in the Australian market.

The UK's commitment to achieving 50GW of offshore wind capacity by 2030 has attracted substantial investments, including commitments from OEMs and the development of a robust supply chain.

Furthermore, government policies play a critical role in the success of the offshore wind industry in Australia and can make or break the fledgling offshore wind industry. It’s critical to learn the lessons of other markets and embrace the successes. The UK Sector Deal is one such example, which has led to significant cost reductions in new projects.

The UK sector deal includes investment of £250 million to develop the UK supply chain, helping to leverage £48 billion of investment and 27,000 jobs – including jobs from the oil and gas sector.

If Australia can look to the UK to learn the hard fought lessons, it is clear that smart policy, coordinated enabling infrastructure and working hand in hand with industry will deliver the renewable energy solutions needed to meet Australia’s commitment to reduce its emissions.

Promoting local content production is crucial for creating jobs and supporting local economies. However, it is essential to strike a balance to avoid unintended consequences.

In Taiwan for example, unplanned and unrealistic local content policies have driven up power prices. Carefully designed policies that encourage local content without hindering the industry's growth potential are what is needed to ensure growth of an industry.

There has been no major energy technology that has successfully been brought to market without support mechanisms to build that industry. The offshore wind industry is no different. Certainty around power price support – such as a well-defined contract for difference mechanism or similar – is the single biggest requirement for a positive

Final Investment Decision (FID) for an offshore wind farm.

Capital contributions by governments to individual projects tend to be small compared to the significant capital costs of building these projects (billions) and aren't the key driver towards positive FID. Governments should channel their capital investment into supporting infrastructure including transmission and ports, which will enable the industry as a whole.

Again, the UK Sector Deal is a strong example of how to best unlock a new industry. Significant investment by the UK Government has led to a strong supply chain and a proliferation of new jobs.

Australia can harness these lessons to ensure it attracts investment and drives industry growth.

Flotation Energy's team has a track record of delivering offshore wind projects and has demonstrated its global experience and expertise. The Seadragon project off Gippsland will bring $6.5 billion of investment into the region.

This forms part of an estimated $40 billion of proposed energy projects in Gippsland that are already creating employment opportunities and will

ultimately lead to a construction boom and long-term operation and maintenance jobs.

Seadragon can be ready in five years and power up to one million homes. The project will create 100 jobs during the development phase, 800 to 1,000 jobs during construction, and 150 to 200 ongoing jobs over its 30-year operational life.

Flotation Energy is also working directly with the University of Melbourne to ensure the future workforce has the skills needed for the offshore wind industry.

The Memorandum of Understanding with the University of Melbourne will help to deliver graduates ready to work in the new offshore wind industry, along with cutting-edge research specific to Australian conditions. This is a clear demonstration of the opportunities of the energy transition.

In our view, community engagement is what sets us apart from other proponents. Since 2019, we have been engaging with the local community and we have well-established relationships with key community stakeholders. Ensuring the community can be part of the transition, benefit from the transition and have agency over the developments in their communities is what drives our engagement.

Recognising the strength of Flotation Energy’s projects, in November 2022, Tokyo Electric Power Company (TEPCO) Renewable Power Inc acquired Flotation Energy, making its first equity investment into overseas offshore wind power.

TEPCO is Japan’s largest electricity utility and one of the largest in the world. This partnership unlocks significant capital and expertise across all of Flotation Energy’s projects.

Australia has incredible potential to unlock a booming offshore wind industry. Flotation Energy has been working with the Gippsland community since 2019 and is deeply committed to delivering one of its first offshore wind projects.

Smart policies, learning the hard fought lessons in other countries and strong industry incentives will ensure the government paves the way for a thriving offshore wind industry.

By Prasanna Punchihewa, Energy Sector Lead, Tonkin + Taylor

By Prasanna Punchihewa, Energy Sector Lead, Tonkin + Taylor

We find ourselves at a critical juncture in Australia’s energy journey. The winds of change continue to propel our renewable energy progress, and harnessing wind power will be essential to meet a lofty but crucial goal of an 82 per cent renewable share of the National Electricity Market by 2030.

With any project, starting with a strong foundation and understanding ground conditions is key. For wind farm construction this is where specialist geotechnical expertise is needed to guarantee long-term success.

At Stockyard Hill Wind Farm, a Goldwind Australia project in Victoria, diverse geological conditions required innovative solutions to be found for the safe construction of its 149 turbines.

While most of the turbine footings were constructed as gravity foundations, the other types – anchored and hybrid footings (a composite of gravity and anchored) –were strategically chosen based on the unique ground characteristics of each site.

Addressing the challenges posed by the diverse geological conditions, cutting-edge technology became instrumental. Experts from Tonkin + Taylor (T+T), a specialist engineering consultancy, utilised Plaxis 3D modelling techniques to simulate and analyse the gravity foundations. This allowed them to refine the design

and mitigate risks. Through several iterations, the team ensured that every unique set of ground conditions was meticulously addressed.

Heavy components on-site were carefully managed and transported. The detailed analysis of the pavement conditions, and crane lift studies, ensured the safe and efficient movement of materials and equipment, including the installation of a 170-tonne transformer at a substation.

Investigations and testing were essential to ensure the safety and integrity of the infrastructure. To facilitate this during the construction phase, Chadwick Geotechnics established an onsite NATA-accredited laboratory, with their specialist laboratory in Melbourne supervising and testing the initial investigation. Their services were pivotal during wind farm construction, drilling, and test pitting, as they performed proof rolling, plate load testing, and foundation inspections.

Another important aspect was understanding the soil composition and groundwater conditions, and their potential impacts on the project. T+T undertook detailed assessments to tackle the complex

geological and hydrogeological challenges. The hydrogeological studies brought attention to the presence of a high water table, prompting further enhancements to the foundation design.

The construction of four substations within the wind farm presented additional complexity, necessitating expert geotechnical input for ground investigations and foundation design.

Renewable energy and sustainability go hand-in-hand, and creative thinking was needed to meet the project’s sustainability goals. Pavement designs by T+T incorporated silt as a subgrade to minimise excavations, and external pavements were rehabilitated, where possible, to accommodate the wind farm material delivery and manage increased traffic. At full capacity it can provide power for approximately 391,000 homes and is expected to prevent the emission of two million tonnes of carbon dioxide per year into the atmosphere annually. Stockyard Hill Wind Farm stands as an example of how geotechnical solutions can contribute to the success of renewable energy infrastructure today.

Australia’s renewable energy growth is accelerating. Tonkin + Taylor’s geotechnical specialists are trusted advisors in the design and construction of renewable energy projects.

To learn more, please visit www.tonkintaylor.com.au or email australia@tonkintaylor.com.au

As a specialist provider of engineering and environmental services, Tonkin + Taylor brings your project ambitions to life.

With proven experience on large-scale projects across Australia and New Zealand, we are the specialist partner of choice.

From land development, transport, renewable energy, waste + resource recovery; to water resource management, industry, and mining – we are passionate about creating and sustaining a better world together

Find out more at...

www.tonkintaylor.com.au

Wind energy generation is a vital part of Australia’s electricity system and the second largest contributor to the clean energy transition. However, end-of-life wind turbines can have a significant environmental impact. A new report from the Clean Energy Council (CEC) explores the reuse, repurposing and recycling of wind turbines, highlighting how industry and governments must work collaboratively to develop circular solutions.

Roughly 85 to 94 per cent of a wind turbine (by mass) is recyclable and can be recycled in Australia2. This recovery rate is well above the national average for commercial and industrial streams in 2018-2019 (57 per cent)3 and exceeds the National Waste Policy Action Plan target of 80 per cent average resource recovery rate from all waste streams by 20304. However, there is still potential for the wind industry to go further and avoid any disposal of waste.

One significant opportunity for further reducing waste in the industry is establishing an end-of-life pathway for turbine blades, which are mainly made of fibreglass and carbon fibre (composite materials). There are currently very limited commercial or feasible end-of-life options for composite materials.

It is estimated that by 2034, a total of 15,000 tonnes of blade composite waste will have been created in Australia due to decommissioned wind farms, and up to 4,000 tonnes in any given year. Without a clear pathway for the management of composite waste, there is a risk that these blades will be disposed of into landfill.

The CEC’s report provides an overview of environmentally and socially responsible approaches and practices for the decommissioning of wind farms. It highlights existing pathways for decommissioned wind turbines and sheds light on areas requiring improvement in recycling capabilities.

The first option for turbines that have reached their end of design life but remain in good condition is lifetime extension. If turbines are serviced and maintained according to performance standards and any identified issues are resolved, the design life of many wind farms can be extended with minimal investment.

The second option is a partial repowering, which typically involves an upgrade of the nacelle, rotor and blades while retaining the existing tower. This is designed to generate more energy from the wind farm, improve its availability and extend the operational life.

There are several critical considerations when determining whether a wind farm is a strong candidate for partial repowering. This includes assessing the integrity and capacity of the existing wind turbine foundations and towers, and assessing the impact additional years of operating would have on the electrical equipment.

A full repowering refers to the retrofitting of power plants on existing sites with new or refurbished technology. This can include building taller, more efficient wind turbines to increase productivity while utilising existing grid connection infrastructure. A full repowering is similar to constructing a new wind farm.

When a wind farm is decommissioned, owners must handle the components of a wind turbine. The CEC’s report utilises the waste hierarchy to explore a variety of options for wind turbine waste management.

While a significant portion of wind turbines can be recycled, the greatest barrier to zero waste turbines are the blades. These are made of epoxy and composite materials such as fibreglass or carbon fibre. Composite materials are currently difficult to recycle as the polymers used are ‘cross-linked’ in an irreversible process to obtain the desired material durability and strength while retaining a low weight.

The most common technology used to recycle blades is mechanical grinding, which utilises a grinding machine to process the composite materials into short fibres and ground matrix

(powder). Although this method is cost-effective and less energyintensive than other technologies, the end product is less valuable than the original composite material. The shredded material can be used as fillers or reinforcement in construction or manufacturing, such as panels for decking and construction, light poles, and possibly cement.

Without a clear and secure end market, this process is yet to be considered as a sustainable recycling option. However, there are some innovative solutions being explored.

Among those solutions is a recently developed chemical technology that can be applied to blades that are currently in use. The new process can chemically break down epoxy resin into virgin-grade materials. Renewable energy firm, Vestas, is now working to scale up the novel chemical disassembly process into a commercial solution.

Once fully developed, the solution will signal the beginning of a circular economy for all existing, and future epoxy-based turbine blades, possibly providing the opportunity to produce new turbine blades made from reused materials.

Another solution is electro-mechanical. High-voltage pulse fragmentation is a pilot-scale process that uses electricity to separate fibres from the composite matrices. Recovered fibres are short, but cleaner and longer than those generated from the mechanical process.

The low volume of composite wind blade waste has made it difficult to develop a recycling business built purely off wind blade waste streams. However, wind turbine manufacturers are starting to develop new blades that can be recycled, as part of their commitment to zero waste turbines by 2040.

For example, Siemens Gamesa has created the RecyclableBlade, the world’s first recyclable offshore wind turbine blades ready for commercial use. The recyclable blades use new types of resin that can be separated from the other components of the blade (fibreglass, plastic, wood and metals) through a chemical process, allowing the materials to be reused for new applications.

Reusing turbines or turbine parts is also an effective way to support zero waste in the wind generation industry. Pre-owned turbines and parts can provide lower-cost systems for smaller projects and developing markets. One potential market for pre-owned wind turbines in Australia is the mining sector, which is turning to renewable energy behind-the-metre and for off-grid applications in order to decarbonise its operations.

Another option is repurposing, which involves using the original engineered structure and properties for a new, different purpose and involves less processing than recycling.

Wind turbine blades can be repurposed for several, alternative functions. For example, in Europe, blades have been transformed into bus stops, playground equipment and public seats.

The Re-Wind Network, a research partnership comprising Irish and American universities, has developed a catalogue that presents designs and details of different structures and products made from repurposed wind turbine blades, including bridges, poles, sound barriers, roofs and farming equipment made from repurposed wind turbine blades.

While this repurposing avoids the need for using new materials to build those structures, the current options for blades are not easily scaled to commercial production and are not very sustainable.

The main barriers to repurposing include:

» Perceived lower quality of used materials

» Unknown residual structural properties

» Lack of end markets for the materials

» Unfamiliarity with sourcing and using recycled products

» Unpredictable material availability

» Uncertainty as to whether repurposing is truly better environmentally

Cement co-processing is one method for recycling wind turbine blades and other composite waste. This process is categorised as energy recovery as the polymer matrix is burned as fuel.

Using fibreglass blades as energy recovery reduces the carbon footprint of cement production by up to 16 per cent. Currently used by wind farms in Germany, the process is only available for fibreglass. While it is a scalable, simple and cost-effective solution, the process is very energy-intensive.

There are several other issues with this process. First and foremost is that recovery is low in the waste hierarchy. Other issues include the energy intensity required and the original structure of the blades is lost.

According to the CEC, instances of blades being disposed of via landfill in Australia have been minimal and mainly due to replacement of faulty or damaged blades from operating wind farms. However, as the number of wind farms requiring decommission increases, it becomes increasingly important to establish suitable recycling and recovery pathways for composite materials. There are potential solutions, such as using recycled composite material for construction or manufacturing, but greater focus and action is required by both the public and private sectors.

The CEC report makes four key recommendations for the wind industry, government and other composite-using industries:

» Support research and development

» Establish pathways and set targets

» Support recycling supply chains

» Share knowledge

Whether it's solar, wind or batteries, these critical clean energy technologies are composed of materials that wear down over time. Moving forward sustainably must involve a consideration of what happens to materials at the end-of-life stage.

To read the full Clean Energy Council Report, Winding Up: Decommissioning, Recycling and Waste Management of Australian Wind Turbines, visit: https://assets.cleanenergycouncil.org.au/documents/Wind-turbine-recycling-report-2023.pdf

1. Excludes wind farms with refurbished wind turbines and Coral Bay Wind Farm in WA. Includes two single turbine installations (Bremer Bay and Rottnest Island). Data is from November 2022.

2. Vestas, Zero-Waste, vestas.com/en/sustainability/environment/zero-waste

3. Department of Agriculture, Water and the Environment, National Waste Report 2020, 4 November 2020, dcceew.gov.au/ sites/default/files/env/pages/5a160ae2-d3a9-480e-9344-4eac42ef9001/files/national-wastereport-2020.pdf

4. Department of Climate Change, Environment, Energy and Water, National Waste Policy Action Plan 2019 dcceew.gov.au/ sites/default/files/documents/national-waste-policy-action-plan-2019.pdf

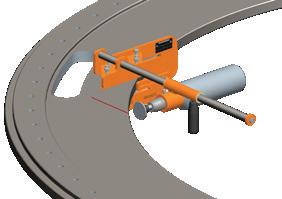

From a distance, it might look like an aerial performance, but the work being carried out by a helicopter above the MacIntyre Wind Precinct is more than just a visual spectacle – it signifies the final stages of an important transmission connection project in south-west Queensland.

About 60km west of Warwick, the MacIntyre Wind Precinct is a mega wind farm being developed by ACCIONA Energia. At completion, it will have a generation capacity of close to 1,000MW of electricity and the potential to power up to 700,000 homes.

Powerlink Queensland has been engaged to ensure this renewable development is connected to the grid and its clean energy is accessible to Queenslanders and the wider National Electricity Market. The transmission construction works include 65km of 330kV transmission line, consisting of 166 structures and two new switching stations.

Transmission connection construction works kicked off in May 2022 and with more than 150 of the high voltage transmission structures already built, the stringing of transmission conductors and optical ground wire (OPGW) line is well underway.

Every year, more transmission lines are being constructed to facilitate the renewable energy transformation and help Queensland reach its renewable energy targets. Many of these lines are being planned in remote, less dense and geographically challenging terrain.

At the same time, the completion period for renewable energy projects is getting shorter which means it’s essential for transmission network service providers to employ the latest

advances in technology and construction approaches to deliver projects as safely, quickly and economically as possible.

Powerlink Project Director, Jahanzeb Rahman, said helicopters performing transmission line stringing is becoming more common across the industry particularly because it reduces community, landholder and environmental impacts, as well as construction timeframes.

“In the past this type of work had been carried out with heavy duty plant and equipment that had a significant impact on the environment as well as lots of manual handling and associated risk,” Mr Rahman said.

“On average a helicopter team can prepare and string up to 25 towers in a couple of days which helps to reduce the overall construction related impacts on the environment and landholders. It’s also considerably faster than on-the-ground methods, so what used to take weeks now only takes days.

“Every aspect of aerial stringing is meticulously planned by Powerlink and its contractors to ensure safe outcomes are achieved, with strict operational protocols in place such as installation of hurdles, traffic management, exclusion zones and on the ground spotters.”

The technique to string the transmission line involves using the helicopter to pull a steel cable, known as ‘draw wire’, from a brake winch on the ground. The helicopter pilot guides the draw wire onto a pulley attached to the arms of the tower. Once this has been completed, the draw wire is attached to the transmission line conductor (cable), and a winch is used to pull the conductor off conductor drums and onto the towers.

The MacIntyre Wind Precinct transmission connection project involves 65km of transmission line, 166 structures (consisting of both towers and poles) and by the end of their activity the helicopters will have facilitated the installation of 1,245km of conductor and 130km of OPGW – which provides vital communication functions and protects the infrastructure from lightning strikes.

John Caldwell, Managing Director and Chief Pilot at Leading Edge Helicopters, has dedicated his career to this industry with over 5,500 hours of power line operations across the country and has been working on Powerlink projects since 2006.

For Mr Caldwell, the number one aspect of the works is safety with a lot of time spent at the front end of the job to plan works effectively with ground crew that operate the brake/winch sites and aerial crews on towers.

During the course of its program of work at MacIntyre, the helicopter will hang more than 33,810 insulators on tower cross arms, fly 18 conductor pull missions using draw wire (11x10km sections and 7x400m sections) and complete 45 direct OPGW pulls over the course of nearly 200 hours of flying.

So skilled are these pilots and so highly specialised is their training, that only a handful of people are capable of carrying out this work in Australia.

“They’re in high demand and tend to work all year round all over the country which can pose challenges in terms of project logistics and timing,” Mr Rahman said.

“This means we are constantly scanning the horizon for new technology and ways of work to add to our capability and streamline construction, maintenance and other work we need to do on our network across Queensland.

“We are currently investigating the potential for drone transmission line stringing on other projects in our portfolio and looking to incorporate this into our construction activity elsewhere.”

Meanwhile helicopter stringing will continue at MacIntyre Wind Precinct where it is expected to complete stringing and other transmission line work by August 2023.

Powerlink’s construction work is expected to be completed by late 2023 with the wind precinct planned to start generating in stages from late 2024 onwards.

In an industry in a constant state of flux, and with environmentally-conscious decisions at the forefront of energy conversations, it’s becoming increasingly important to consider sustainable options – and reusing, repowering or upgrading parts to extend equipment service life is a clear way to do this.

Managing wind turbines is no easy feat. From protecting workers from the dangers of wind turbine brake dust, to protecting surrounding communities from yaw noise and managing the general ageing of infrastructure and parts, it requires expertise and experience.

In its 2023 report, Winding Up: Decommissioning, Recycling and Waste Management of Australian Wind Turbines, the Clean Energy Council discussed the importance of upgrading wind turbine parts to support a longer usage lifetime.

“Reusing turbines or turbine parts, considered to be the option with the highest value for decommissioned wind turbines, is an effective and feasible way of obtaining a second life cycle,” the report said.

With over 599 turbines in Australia over 15 years old, the CEC said it was more important than ever for wind turbine owners to consider making more sustainable end-of-life cycle choices.

Getting the most from wind farms must include inspections and maintenance to ensure operation beyond the design life. Five major components that are regularly assessed include: blades, blade bearings, hubs, nacelles and towers. Structural components – tower, yaw systems, bed plates, main shafts and pitch systems – also have regular, necessary inspections to ensure safe and efficient operation.

The CEC report stated that a major issue in Australian wind farms is the limited number of wind turbines in operation that are compatible with refurbishments and repowering components. This is due to the low level of domestic access to necessary replacement parts.

With partial repower, drivetrain repower and component refurbishment supporting the potential lifetime extension of parts by 20 years or more, replacing and upgrading ageing parts should be a pivotal part of wind farm’s sustainability and financial practices.

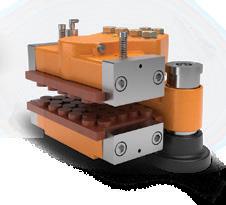

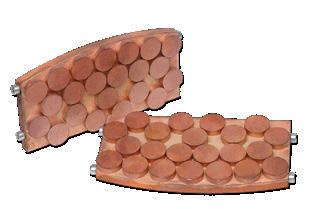

Regal Rexnord, an international supplier of essential products that ensure smooth systems in mission-critical applications, includes a large portfolio of power transmission products. This includes yaw brakes, rotor brakes, high speed shaft couplings, clutches and brakes to service

the Australian wind energy market.

Regal Rexnord finalised the acquisition of wind turbine brake manufacturer and service partner Altra Motion in March 2023.

Altra Motion Australia Managing Director, Junior Eltagonde, said the companies have an exciting future ahead.

“From a strategy point of view, Regal Rexnord has really left us to continue on our growth initiatives and ensure that we keep supporting and looking after our customers,” Mr Eltagonde said.

“Down the line, there’s obviously some synergies that we can work on with our sister companies; however, particularly for us, we're very much business as usual and Regal Rexnord has really given us the autonomy to continue doing what we do best.”

Mr Eltagonde said that Altra Motion Australia may have a new owner, but it was the same Altra Motion that has supported the Australian energy industry with reliable power transmission and renewable energy solutions and service for decades.

“We are proud of this achievement and acknowledge this will continue as Regal Rexnord and Altra Motion collaborate and deliver their like minded people, ideas, and capabilities,” Mr Eltagonde said.

Regal Rexnord Australia is continuing to uphold Altra Motion’s three decades of experience in wind turbine braking systems and offers solutions to meet the needs of the entire wind turbine life cycle – with an emphasis on upgrading existing projects and equipment.

Working in close partnership with original equipment manufacturers (OEMs), Regal Rexnord will ensure it’s ‘business as usual’, developing products, components and assemblies to suit designs and specific requirements from the initial prototype phase.

Regal Rexnord Australia has multiple facilities across the country, including Sydney, Melbourne, Mackay, Newcastle and Perth. The service centres in Sydney, Perth and Queensland also serve as certified rebuild centres for Svendborg, Marland, Stromag, Ameridrives, Stieber & Industrial clutch products.

Fully staffed with local technicians, Regal Rexnord Australia provides fast-response onsite service, installation and commissioning support including a 24/7 breakdown callout service. With correct adjustments to OEM specifications and qualified and experienced OEM technicians, Regal Rexnord Australia provides unmatched power automation support.

For more information about Regal Rexnord Australia and their genuine spare parts and service capabilities, head to www.altramotionaustralia.com

There’s something new taking shape on Australia’s coastlines. Wind power has been used in Australia for decades, but now in 2023 – supported with federal offshore electricity acts and regulations – offshore wind power is set to blow fossil fuels out of the water. Supporting this industry growth is the latest declaration of the Hunter region as the nation’s second offshore wind zone. Here, Energy Magazine looks at the upcoming offshore wind projects in development or under proposal across the country.

Midwest

Size: 3,000MW

Operational: 2028

Technology: Fixed

Status: Announced

Size: 1,900MW

Operational: 2026

Status: Under feasibility

Bunbury

Size: 2,000MW

Operational: 2026

Status: Under feasibility

Leeuwin

Size: 3,000MW

Operational: 2028

Technology: Fixed

Status: Early concept/ planning

Wind farms are currently the second largest contributor to Australia’s clean energy transition after rooftop and large-scale solar combined, accounting for almost 37 per cent of renewable power generation in 2022.

There are currently 36 wind farms operating on mainland Australia and around 25 offshore projects at various stages of development. The new offshore projects underway feature a mix of fixed and floating platform designs.

Fixed (or fixed-bottom) platforms are closer to their land equivalents. Fixed platforms that are connected to the sea bed, can have four different foundations depending on the sea bed ground type and depth of underwater placement.

The four different foundations are:

Monopile

» Maximum depth of 30m

» Precast concrete foundation

Southern Winds

Size: 1,200MW

Operational: 2030

Technology: Fixed

Status: Undergoing site selection

Gravity

» Suitable for 25m depth

» Made of steel and driven into seabeds

Tripod

» For deeper waters around 35m

» Welded foundations with steel piles

Jackets

» For deeper water >40m

» Steel welded beams and often weighs more than 500t

The International Renewable Energy Agency said that floating platforms create three unique opportunities compared to fixed designs; access to deep-water sites, easy turbine set up and a less invasive installation on the ocean seabed.

Floating offshore platforms have three current varieties in design: Spar buoy

» Ballasted cylinder

» Taut spread mooring lines with drag or suction anchors

» Designed for deeper waters >100m

» Large columns, connected by submerged pontoons

» Hydrostatic stability

» Positioned by taut spread mooring lines and drag anchors

Tension leg platform

» Highly buoyant, low mass

» Central column that is connected with three arms and tensioned tendons

» Foundation is secured to piled anchors

» Designed for ocean depths around 50-60m

Just the beginning

Our map below is certainly not inclusive of all projects underway, or comprehensive regarding their details, as some projects have not announced the technology they plan to use but it’s clear the nation is understanding the value of utilising our offshore wind resources. Australia’s offshore industry, while in the early stages compared to its global counterparts, is, no doubt, going to significantly impact our net zero targets.

Hunter-Central Coast

Size: 1,650MW

Operational: 2030

Status: Intends to apply for feasibility licence

Newcastle Size: Up To 3,000MW

Eden

Size: 2,000MW

Operational: 2032

Technology: Floating

Status: Announced

Blue Marlin

Size: 2,000MW

Operational: 2028

Technology: Fixed

Status: Early concept/ planning

Greater Gippsland Size: 2,085MW

Operational: 2030

Technology: Fixed

Status: EIS/ESS preparations

Technology: Floating

Status: Proposed

Eastern Rise

Size: 1,725MW

Technology: Floating

Status: Undergoing public consultations

Wollongong

Size: 1,600MW

Operational: 2030

Status: Early concept/ planning

By Dr Glen Currie, Program Impact Manager –Energy System, Climateworks Centre

By Dr Glen Currie, Program Impact Manager –Energy System, Climateworks Centre

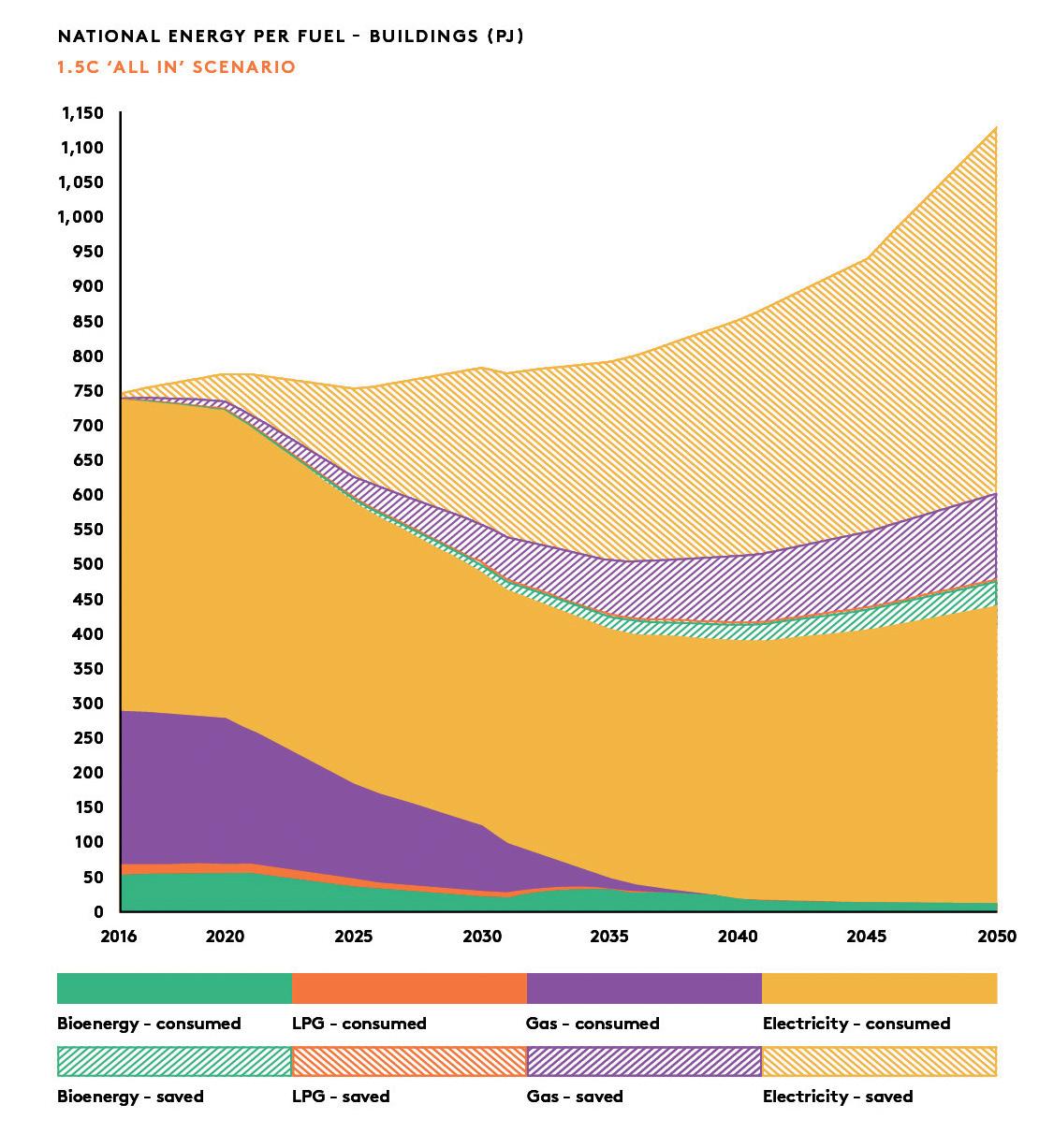

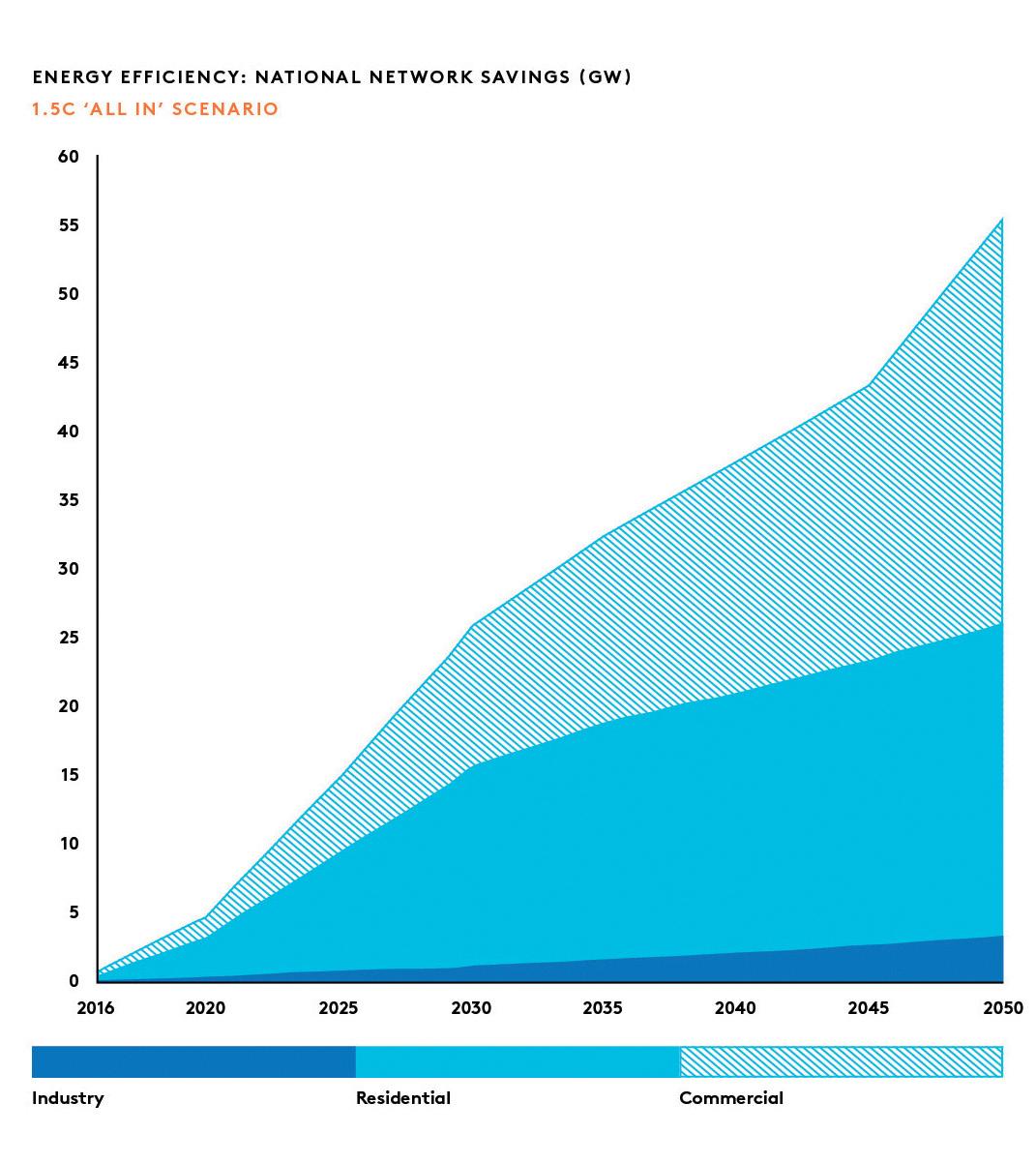

Why is building energy efficient infrastructure important? Due to physical infrastructure lasting 50-100 years, building it to be energy efficient will continue to pay us back for a very long time. This is because ‘negawatts’ – or the watts saved through energy conservation or energy-efficient choices – in buildings, transport and industry are the most cost-effective way to reach zero emissions.