25 minute read

MANUFACTURING

from Food Jul 2020

by Prime Group

Out of the darkness, comes some light

Diversifying your offering during a pandemic might be an issue to some companies. However, industrial partnerships with suppliers prove, more than ever, to be key in easing this process. Mike Wheeler explains.

Change is something that can be embraced, or seen as an unnecessary disruption that can cause anxiety. But what happens if that disruption is unexpected and takes away, literally, your whole market share.

COVID-19 has had a negative impact on a lot of industries and businesses. And while food and beverage have generally come out of it okay from a consumer point of view with regard to supply and demand (pasta anybody?), there are certain sectors that have suffered considerably. Imagine you are a caterer who specialises in weddings, or a major supplier to airlines. One way to try and make up the deficit is to diversify.

And quite a few companies have, according to food-grade gas supplier Air Liquide’s Modified Atmosphere Packaging (MAP) specialist Remi

Darren Taylor and his team produce ready meals that can last longer on retail shelves thanks to the food-grade gases it uses.

Saget. Like a lot of companies hit by COVID-19, Air Liquide has seen a downturn in some of its areas of business, but there has also been interest in other aspects.

Some impacted food manufacturers have decided to expand offerings and started looking at other markets, whether it is online with home deliveries or via retailers. Supplying food products to such channels helps tremendously

when shelf life is extended, which is possible using MAP. And in order for MAP to work, you need a good gas supply, which is where Air Liquide comes into its own.

Saget said there has been an increase in queries from SME manufacturers about how they can get longer shelf life for their food. Indeed, supermarket chains and independent grocers need products to stay on the shelf for longer than a day

or two, often making it part of their requirements.

“We have had an upturn in requests,” said Saget. “We have seen more demand for food-grade gas, especially for ready meals. For some companies this is already their business, but many restaurant chains and catering companies had to change quickly to the same business model that would allow for home deliveries, selling at supermarkets, or selling online.”

In order for a company to be able to pack ready-to-eat meals, it needs to have a packaging machine that is capable of getting the meal prepared for being sold in store.

“It’s not a difficult transition to make if you have the correct packaging machine,” said Saget. “Obviously, you need to have one that has a gas flushing capability. You cannot gas flush manually.

“Packaging machines come in all sizes. Even your local butcher has a bench-top vacuum machines that could gas flush, or be retrofitted to do so.”

He said that gas is the last piece of the puzzle. Ultimately, manufacturers need to have the food right, then the packaging machine, the plastic tray and film, and then the gas. For ready meals, Air Liquide recommends a mixture called Aligal 15, which is made up of 50 per cent food-grade nitrogen and 50 per cent food-grade CO2. But this ratio may be adapted on a case-by-case basis.

“How it works is that the machine takes all the air out. It is the oxygen that will spoil the food eventually,” he said. “Then you add the gas. It takes a few seconds. The gas is food-grade, it is not chemical or anything like that. It’s considered a processing gas, so it is not an ingredient or a preservative and does not need to be on the label.”

Saget is confident that while some of these companies have had to look for new markets out of necessity, he doubts they’ll stop producing gas-flushed food products once the industry gets back to normal.

“It’s probably going to be the case for most companies that have gone into the ready meal business that they will stay in there once things have gone back to normal,” he said. “They have been doing it for a few months now and they realise that it is working well, and it would allow them to have an extra stream of revenue. People are used to buying online, so they can

Food-grade gases are designed to help extend the shelf life of produce.

easily keep their online shop open and keep delivering to people.”

One such firm is catering company Harvest By Darren Taylor, which saw the bottom fall out of its business, with 100 per cent cancellations of weddings and other events it had been booked to supply food prior to COVID-19.

“They also operate a bakery and make great pies and croissants for cafes across NSW,” said Saget. “The sale of bakery products they did went down by 95 per cent. They had to rethink their business model.

“The good thing was for founder Darren Taylor, he could start pretty much right away thanks to a machine he purchased earlier.

“I helped him with the right gas mix according to his food. We did some tests together to make sure the gas was flowing okay. Now he is selling online and is also selling to independent supermarkets across NSW. He also sells to a big chain of butchers where his packed dishes are available in the open fridge next to the counter where you buy your meat. He is very happy.”

Taylor said he got an opportunity to get into the ready meals market in late 2019 and was planning on getting started halfway through 2020, but due to the effects of COVID-19, he decided to enter the market sooner.

The majority of outlets require prolonged shelf life to avoid dealing with products that are past their use-by date. This is especially true for ready meals, where they are packed in air, and they usually stay fresh for only a few days. A preservative-free conservation method like MAP helps.

“We got a packaging machine in Melbourne, and we looked at all the ways of extending the shelf life of the product and we decided to go with the MAP method,” said Taylor.

“We went with MAP because of the look of the product, it keeps the integrity of the product and it is very safe and reliable. After ordering the machine and getting it in, we did a whole lot of tests. We developed a product that we thought would suit that application.”

Taylor was very pleased with the service from Air Liquide in terms of getting it all set up.

“Remi and his team were amazing,” he said. “Remi was extraordinary. He came in at the very beginning and we got the machine working in a way we were happy with it. Remi helped us with our gas levels, our oxygen levels, etcetera. ”

The beauty to the system, according to Taylor, is that he cooks the food, trays it up straight away, puts it in the blaster until it comes down to 1˚C, and then packs it.

“It’s as good as you can get in terms of packaging. The film, the tray and the label – which is stuck on – are all microwave-oven proof. It has zero additives or preservatives,” he said. “By using MAP, you don’t have to put any chemicals in it.”

With the eyes on the future, Taylor and his food manufacturing business emerges from the COVID19 crisis better positioned to face ever-changing market demands. The fact that he was able to swiftly adapt his operations is a reminder that tight partnerships with suppliers goes a long way when help is required to come out of a dark time, pandemic or not. F

How one company handled the COVID-19 crisis and came out on top

Unwanted disruption can be a blight on a company, but it’s how an interruption is handled that can be the making of a company. Food & Beverage Industry News gives an insight into one company’s journey.

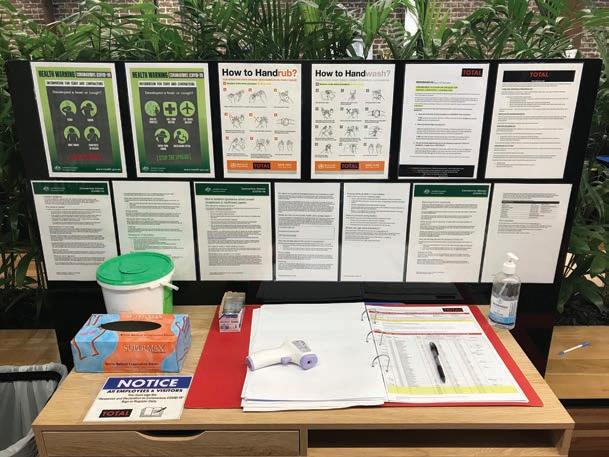

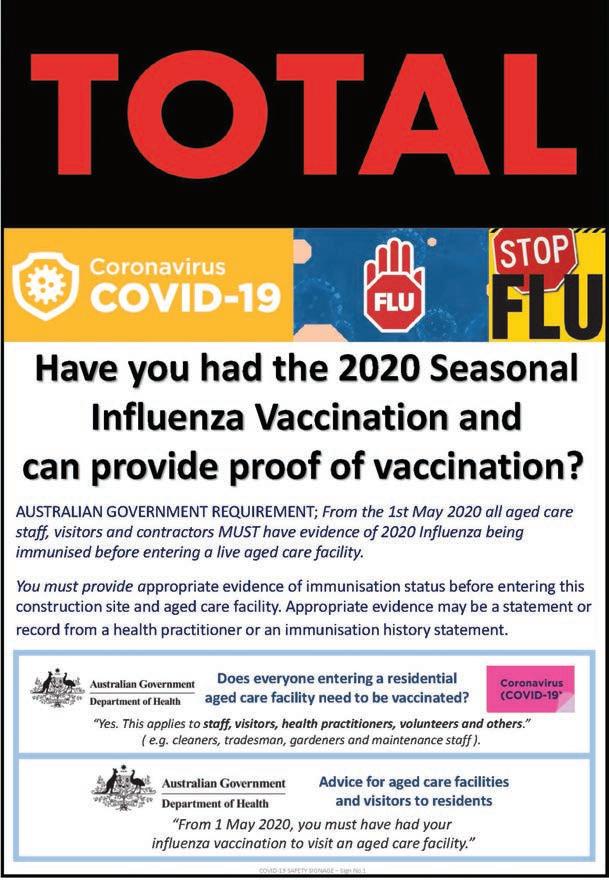

Total Construction made sure that a sign like this was not up at any of its sites due to having a range of practices in place that negated the chances of COVID-19 appearing onsite.

Contracts are signed, tradies are ready to start, the building site is now open, and there are deadlines to meet. Then a once in a century event happens – the COVID-19 pandemic. What happens now? Does the site close down? How long will government restrictions last? How will staff be looked after? What about penalty clauses in the contract if deadlines are missed? These and a dozen other questions go through the collective heads of many executive committee members at construction companies.

For food and beverage construction specialist, Total Construction, it was a matter of building on health and safety procedures it already had in place before COVID-19 struck and restrictions were enforced. The company’s CEO, Jeff Jones, said they were being proactive from the get-go.

“We adopted temperature testing before it was put out there by the government,” said Jones. “We were testing every single person who came onsite. We asked people to sign declarations about whether they had travelled overseas. We did all the virtualisation of the office space – less people on site where possible. We had project managers dialling in – all that sort of stuff.”

Throughout the first couple of weeks, the company did have a couple of scares, resulting in a site being shut down, and a hygienic clean of the whole area. However, there have been no reported cases on any of Total Construction’s worksites.

Procedures in place included the company’s Code Red process, which was part of its administration online tool. It lets Total Construction know it has a notification of an incident onsite and controls who communicates to the client and contractors. Because if it is not controlled properly, issues will arise, according to Jones.

“We decided early on there would be one source of information and that would be me for the vast majority of it,” he said. “There are updates for the staff throughout the process about an infected site or possible infected cases. They come to me and I was responsible for communicating to clients and subcontractors.”

One of the key ingredients to making sure operations ran smoothly was how staff reacted to the changes. Without their cooperation and buying into the new “normal”, it would have been harder to implement the new processes, said Jones.

“Our workers were amazing,” said Jones. “Two things – their willingness to adopt change was better than I thought it would be and we asked them to do a few more things outside the norm, such as asking them to take reduced pay or extra leave. I suppose this is where your work culture really sings true. The loyalty we have received from staff has been great.”

Jones said it wasn’t until the crisis came about that he saw the Total Construction workforce take initiative in its true sense, whether it was dislocated from a workplace, or dealing with a client’s needs remotely. As for the business itself,

there was the expected downturn in terms of projects going ahead. Total Construction had almost 40 projects ready to go to tender at the beginning of the year, but when COVID came around, only eight actually came through. The good news is that another 10 have re-commenced the tender process since the beginning of June. However, some of the issues were not so much if the client was ready to green light the project, but whether supplies – especially those sourced from overseas – were available.

“We did have some early concerns about some supply items. We were caught short sometimes due to deliveries not arriving,” said Jones. “We were lucky. We didn’t suffer too much delay from that. We did see a little drop in productivity due to the social distancing. In its early stages, certain trades were finding it hard to get people to turn up to site if there was a concern about health. But by making our sites as healthy as we possibly could, we saw a swing around the other way, where we had contractors wanting to turn up to our site because they knew we protected their workforce better than some other contractors. It became an opportunity to have more resources on site.”

Then there was the issue of reassuring clients there were not going to be cost blowouts.

“We had some conservative clients that weren’t sure if the pandemic was going to increase the construction costs because the project got delayed ” said Jones. “Now, there is certainty and it doesn’t seem to have as much time impact as we first thought it might with supply items or productivity. I think a lot more is known now compared to two months ago and projects are starting up again.”

With the food and beverage industry, some builds have gotten underway while others have had to be put on hold, but not for reasons related to the COVID-19 pandemic itself, but peripheral issues, too.

“It’s been a mixed bag with food and bev builds,” said Rob Blythman, general manager for the company’s Engineering Construction Group. “When they are crucial projects, and when they are vital to their operation, time wise and production wise, they have all gone ahead.

Rules and regulations were paramount for Total Construction staff. Total Construction was proactive in making sure staff were kept up to date with any changes with the COVID-19 virus.

Whereas there have been others that have stalled because even though they’re sort of necessary works, they can wait. Some are sitting back and waiting for things to change in the general environment, particularly with regard to government stimulus and things of that nature before they push the go button.

“There was a food and bev project in Queensland we were set to start on in mid-March, but they had to shut it down before we began. This was because their particular product was deemed essential, and they didn’t want any potential risks to their production. Across our clients, there are some projects that have been delayed where they are not a priority and they can afford to push it back,” said Jones. “There are others that can’t afford it and we’ve had to start it straight away and there are a few in the middle that can’t risk disruption due to construction.”

Having food and beverage and aged care expertise it certainly meant that Total Construction was more cognisant to dealing with health issues across the whole spectrum because it was already working in high-risk live environments. It meant that its safety committee didn’t differentiate between an industrial sector project environment to any other project. Safety is safety, said Jones.

Jones finishes by stating that he believes that COVID-19 might even tweak the way some companies now do business.

“It might even change the longterm employment relationship,” he said. “This is because we’ve talked in the past about people used to work in one job for their whole life and how there is loyalty both ways. Over the last two decades this has deteriorated. As a result of the pandemic it has emphasised the value of loyalty going both ways as businesses work together with their staff to firstly survive and then thrive.” F

Global effort delivers technology to enhance the cooking processes

Acrylamide is an unhealthy chemical that forms when certain foods are heated to high temperatures and cooked using processes such as frying, baking and roasting. New technology is trying to fix this. Food & Beverage Industry News explores a new way of reducing health risks in some of the country’s favourite snacks.

Most major food safety authorities around the world are aware of acrylamide and its potential health danger to consumers and it has now become a growing concern for snack food manufacturers.

S nack food producers are challenged with finding ways to reduce acrylamide formation during frying without making fundamental changes to their manufacturing process, and without compromising on taste or quality.

To meet this challenge, food processors looked to equipment suppliers, such as Heat and Control, to work with them to develop equipment solutions for potatoes.

A global collaboration In one such collaboration, Australia-, US- and the UK-based Heat and Control teams worked with a European snack processor and a Swedish tech company ScandiNova to bring to market a solution that has enhanced the cooking process. It made the reduction of acrylamide possible and provided potato processers with a host of valuable additional benefits including improved yield and product quality, increased line efficiency and reduced operational cost.

It came about after research and development, the result of which was an equipment solution that would apply Pulsed Electric Field (PEF) processing to potatoes prior to manufacturing in order to reduce acrylamide. This solution became the E-FLO system, by Heat and Control.

The science of PEF PEF is a unique non-thermal method of inactivating microorganisms, including many common food pathogens, without heating the product to the usual pasteurisation temperatures. The destruction or inactivation of the microorganism is achieved by the breakdown of the microorganism’s cell membranes during exposure to electric fields.

PEF has previously been used in the food industry with juices, wine and olives as a means for sterilisation, preservation and for retaining nutritional values.

Heat and Control’s innovation was by the use of this method in a new application and for a different purpose.

For potatoes processors, the use of PEF treatment delivers cell disintegration, in place of the preheater operation. In this application, pulsed electrical fields create micro-pores in cell membranes, which enable the loss of primarily of liquid contents such as asparagine and reducing sugars but not starch loss. Structural and textural changes are also realised, reducing wear on cutting blades, increasing line yield and reducing water usage.

The benefits of this processing method have seen food processors across various industries incorporate this technology into their processing lines.

A January 2020 report by Technavio stated the global food industry PEF systems market is poised to grow to more than $325 million during 2020-2024, progressing at a CAGR of about 24 per cent during the forecast period.

Developing E-FLO to deliver PEF Partnering with ScandiNova, a provider of solid-state, high-power pulse modulators and RF systems, Heat and Control developed the patent-protected E-FLO Electroporation System to deliver the PEF process to the new product of whole potatoes and with the overall goal of reducing acrylamide levels in potato chips.

The technology worked by sending PEF through the cell walls of the potatoes to perforate cell membranes with microscopic holes.

This allowed sugars and asparagine to be released from the vegetable before it was cooked, thereby reducing the harmful acrylamide.

The process Peeled and washed potatoes are supplied in measured quantities by upstream equipment and delivered to the E-FLO infeed chute.

The rotating E-FLO wheel transports the potatoes through the processing area

as a compact, packed bed through a water bath.

Processing takes place in a water bath so that the electrical pulses can influence the product as desired. After a short exposure to the electric field pulses, to perforate the cell walls, the potatoes are lifted and discharged from the water bath by the continuing rotation of the wheel into the discharge chute. The potato then continues down the production line where greater amounts of sugars and asparagine can be removed during the slicing and washing stages.

In the case of the European snack processor, E-FLO saw excellent results with a reduction of acrylamide in its potato chips. As have other E-FLO installations, with some processors experiencing a reduction of acrylamide (in most cases) by over 50 per cent in their potato chips.

The E-FLO had met the original goal of reducing acrylamide while ensuring no degradation to the original taste and texture of the product. To the delight of the Heat and Control design team, the technology was able to offer other benefits.

Lower processing costs In addition to reduced acrylamide formation, the use of PEF technology in the E-FLO system was shown to also provide yield savings with faster processing of the potatoes, cutting improvements for a longer blade life and lower oil content in the final product.

Aside from reducing acrylamide and creating a healthier product, other benefits of using electroporation included increased line efficiency and reduced operation cost. In addition to a return on capital investment due to increased yields processors enjoyed the following benefits: • Reduced acrylamide allowed them to meet EU legislation. • Reduced preparation time, water and energy usage. • Less blanching – electroporation allows the tissue of potatoes to become more permeable removing the need for blanching before cooking. With less blanching, starch loss was avoided and yield was increased • Reduced wear and tear of slicing blades – slicing thousands of potatoes daily results in dull slicer blades. PEF processing softens the tissue of the potato, allowing blades to slice between the cells of the potato rather than through them. This lessens the pressure and friction on tools, which equates to less down time and longer equipment life. • Reduced oil use – slicing

The E-FLO system provides yield savings as well as faster processing times.

between the cells of the potato also produces a smoother chip surface. A smoother surface means the chip absorbs less oil, which significantly reduces oil expenditure in the long run. Health benefits – PEF treatment typically reduces fat content of the final potato by two to three

The PEF market is set to grow by $325 million between 2020 and 2024.

per cent. This is due to increased starch content in the outer cell layers of the potato slices and smoother surface after cutting, which enhances the oil drip-off effect after frying. This creates a more desirable, crunchier and premium product.

Today, the European snack processor continues to use the E-FLO to produce its potato chips with less acrylamide and meet EU regulations. The E-FLO Electroporation system is an example of innovative technology made in Australia with the help of global partners.

The right partner Reduction of acrylamide is an important issue and one that industry is beginning to embrace on a global scale, regardless of regulation. Potato processing is a significant investment and the key to success is choosing a supplier who can work with a company to meet their objectives.

The right partner can create a line that meets performance, quality, and efficiency targets from the outset.

Importantly, the total cost of ownership, rather than the individual cost of single pieces of equipment, should be considered. F

Having a plan is important to helping customers

Simplifying control processes and building partnerships are key to Bürkert’s new business development manager’s plans. Mike Wheeler talks to Luke Houlihan about his role.

Luke Houlihan has spent most of his working life around wine and wineries and up until recently had his own boutique brand vineyard producing vintages out of the Yarra Valley.

With a Bachelor in of Applied Science in Wine Science, it made sense when a position became available to become part of the team at process, automation and control specialists Bürkert’s Australian operation. He jumped on board in a heartbeat and he couldn’t be happier.

“There’s such a huge amount to get my teeth into,” he said. “There is massive scope for me and Bürkert to cover off, so I have a lot to look forward to. We are already getting traction from a large international wine group and the momentum is just starting. The next five years is going to be extremely exciting.”

One of the key focuses for Houlihan is to help winemakers, brewers and distillers streamline their production using innovative process and automation equipment. Houlihan said the industry is traditional, but it is about balancing the art of winemaking with the science of winemaking.

“It’s about maintaining that natural, organic way of winemaking with new processes that will help improve product,” he said. “By maintaining or improving quality, you end up with a better proposition for your customers, in the sense you are offering best value for money in terms of your product. It is in a winemaker’s interest to look at those things. And I think the industry is at a stage where they are in a real consolidation phase. There are a lot of medium-sized and upwards wineries that are ready to recapitalise. They’ve paid down their debt on infrastructure and are in a position where they can put some more money into improving their processes.”

What makes Houlihan stand out from other BDMs is that he has on-theground experience in making wine so is well aware of some of the pitfalls that can occur in the process. He knows how important it is to have reliable equipment that won’t fail at a critical stage – something that Bürkert has in abundance.

“A key for us is also being able to offer for example, a simple valve that is good for five million cycles,” he said. “They can put it into place and forget about it. It’s not going to pack up mid-vintage and cause grief because their cooling system has gone down

because they’ve put in a cheap valve. The unseen thing is about offering a value proposition to a winemaker and saying ‘Spend a little bit extra now. Put this valve in and forget about it. It’s not going to cause you grief.’

“Mid vintage there are times when you’re running around seven days a week, working 20-15 hour days. If something packs up, you don’t want to try getting hold of a plumber at 11 o’clock at night to sort it out. It is a pain and is not what you want to be doing.”

It has been a baptism by fire of sorts for Houlihan as he came on board in May, right in the middle of the COVID19 pandemic, which meant he couldn’t get out and meet clients. However, that is about to change.

“I’m really keen to get out and look at the different control systems that are in place at the different installations. It is much easier to talk about those applications when you can see them in situ rather than on a PDF file, which is how I’m seeing a lot of things at the moment,” he said.

In 2012 Houlihan took a new role

Houlihan (left) has been in the wine industry for over 20 years. Houlihan is looking forward to helping beverage manufacturers streamline processes.

in the wine industry with a company that provided technical support and wine supplies, such as yeast and wine additives, as well as filtration equipment. In that role, he developed a strong technical understanding of water treatment for various industries including brewing and distilling. Having offered such technical and sales support in the past, Houlihan knows a lot of people in the industry and has the expertise to help.

“I especially love the integration with network technologies to do jobs remotely,” he said. “I love that stuff. There’s such a huge amount for me to do.”

Houlihan also believes in a holistic approach when it comes to helping clients out. He thinks it is important to develop a long-term relationship and strategy with a client, as opposed to fixing an issue and then moving on. And he has his own reputation to think about, too.

“My goal is to partner with companies,” he said. “Most of my

friends are in the wine industry, I couldn’t on face value go to a friend and say ‘buy this valve, you’re helping me out’. I’m not going to burn my friendships over dodgy products. Being able to represent a company that is the Mercedes of process control is really exciting. You’re putting your reputation behind a really strong product. We look at their processes and rather than going into a winery and saying, ‘Right, here’s this valve.’ Or, ‘Buy this or that.’ We’re looking at asking the questions; ‘Where are you guys going? What do you want to achieve and how do you want to get there?’”

Bürkert puts a lot of effort into refining and developing equipment that will suit the customer’s needs. Houlihan sees himself building on the networks and relationships he has already to talk to winemakers, brewers and distillers and help them develop strategies that will help their business grow.

“They need to have a blueprint in place so that when they are going forward, they are putting infrastructure in that will support where they want to be in another five to 10 years,” he said.

“At the end of the day we’re here to help make beverage manufacturers lives easier,” he said. “We are focusing on increasing and improving their production processes and reducing overall costs of production as well as simplifying production, too. We are also looking at ways automation and control can help improve their processes. It’s also about making them more sustainable environmentally, too. Reducing wastage in areas like energy costs, excess compressors – there’s a whole range of ongoing savings with the right fit out. In summing up it’s about Bürkert making their lives easier in partnering with them for the long haul.” F