37 minute read

NEWS

Aquaculture is now the largest sector of the seafood industry

Farmfresh Fine Foods fights back on frozen imported food

Australia’s aquaculture sector is continuing on a trajectory of steady growth, but the industry has experienced disruption due to the COVID-19 pandemic, according to the latest edition of ABARES’ Australian Fisheries and Aquaculture Statistics.

Australia’s aquaculture sector has been steadily increasing in both value and share of gross value of fisheries production (GVP).

“The GVP of the Australian aquaculture sector grew 10 per cent in 2019−20,” said ABARES executive director Dr Jared Greenville.

“While total Australian fishery and aquaculture GVP in 2019–20 decreased slightly by 2 per cent to $3.15 billion, higher aquaculture GVP offset lower GVP in the wild- catch sector.”

Last year, aquaculture made up over half of the total GVP share of the Australian fisheries and aquaculture industry, up from 43 per cent in 2015–16 and 34 per cent in 2005–06.

This created a 12 per cent contraction in the GVP of the wildcatch sector.

“This trend isn’t limited to exports. Domestically, buyer behaviour has also changed,” Greenville said.

“Australians consumed around 335,000 tonnes of seafood in 2019−20, a decrease from around 341,000 tonnes in 2017–18, including imported seafood products.”

The total value of fishery and aquaculture product imports decreased by 4 per cent to $2.2 billion last year, driven mostly by decreased imports of prawns, squids and octopus. F

Australia’s aquaculture sector grew 10 per cent in 2019-2020, making it the largest in the seafood industry.

Farmfresh Fine Foods, a Bundaberg fresh food processor, will expand its facilities to enhance its production and packaging capabilities through support from the Queensland government.

This project will help Farmfresh Fine Foods fight back against frozen imports and create an estimated 24 local jobs.

“The Queensland government’s $175 million Jobs and Regional Growth Fund will help Farmfresh Fine Foods put the bite on frozen food imports,” said deputy premier and minister for State Development Steven Miles.

“We’re supporting a $4.3 million expansion of this family-owned Bundaberg success story, making them even more competitive when pursuing national supply contracts.”

The state government’s support will accelerate the company’s project by 12 to 18 months.

“The Queensland government funding means we’re ready to expand production capacity across all our products to 3,270 tonnes annually in the short term,” said Farmfresh Fine Foods general manager Andrew Gerry.

“This will include a new forming, battering and fry line, which will add to the extensive range of roasted frozen products, as well as pureed and pickled vegetables.

“We’re planning to hire another 24 labourers and machinery operators by our second year of expanded operations, an increase of about 45 per cent to our current workforce of 53.

“This will be a very exciting new growth phase for us – and for Bundaberg and other regional growers.” F

foodpro 2021 important event announcement

Diversified Communications Australia, organisers of foodpro, have announced the cancellation of the planned 2021 exhibition due to the impact of continued border uncertainty and extended lockdowns.

The event will now return 23- 26 July 2023 at the Melbourne Convention & Exhibition Centre.

Since the postponement, back in June, the foodpro team has been working closely with the industry and monitoring the COVID-19 situation and multiple lockdowns across the nation. With the situation in Sydney showing no signs of improvement, the decision was made to cancel foodpro 2021, scheduled to run 10-13 October at Sydney Showground.

foodpro aims to bring together Australia’s food manufacturing community, connecting exhibitors and visitors from across Australia.

It’s important to sustain a high standard of event delivery, and without continued certainty around borders remaining open, foodpro organisers made the call not to run this year.

Although disappointed in not being able to host the event in 2021, the foodpro team said it appreciated the continued support its has received from exhibitors, partners, sponsors, speakers, and suppliers. The event team is committed to reuniting the industry at foodpro in 2023, 23-26 July at Melbourne Convention & Exhibition Centre. F

Due to the ongoing COVID-19 situation in Sydney, foodpro will return to Melbourne in July, 2023.

The food service industry has managed to see a rise in spending and traffic despite the pandemic.

The NPD Group, a global data analytics company, has reported that the total foodservice consumer spend and traffic in Australia was up by 25 and 23 per cent respectively, comparing Q2 2021 with Q2 2020.

For a pre-pandemic view, industry spend and traffic declined 8 per cent and 14 per cent respectively, versus Q2 2019.

“The recovery of Australia’s foodservice industry continues to improve, but it will take time before we see pre-pandemic levels of spend and foot traffic,” said NPD Group senior vice president and deputy managing director Asia Pacific Gimantha Jayasinghe.

“While there were periods of lockdown across the country in the second quarter of this year, Australia operated with minimal restrictions for the most part.

“This has led to stronger than expected performance within some foodservice segments, helping to boost overall industry growth when compared to last year.”

The cheque growth rate was up 2 per cent versus Q2 2020, and 7 per cent when compared to Q2 2019.

The increase in price per item was the key factor in the cheque growth across all ordering methods excluding pickup, which saw cheque growth driven by items per eater.

All channels saw average eater cheque gains versus Q2 2019, though QSR declined 2 per cent versus Q2 2020.

The decline of foodservice traffic versus Q2 2019 was driven by Quick Service Restaurants (QSR), and Full-Service Restaurants (FSR), dropping 12 per cent, and 38 per cent respectively. However, Retail saw traffic growth of 4 per cent versus Q2 2019.

QSR and Retail showed positive spend performances in the quarter, with both channels experiencing growth when compared to both Q2 2020 and Q2 2019.

FSR rebounded from the drop in the market in Q2 2020 but was down when compared to Q2 2019, due to the channel being the one most impacted by the recurrence of government restrictions imposed on the industry. F

Charles Sturt Univeristy scientist Gaye Krebs said the pilot study looked at hemp as a feed source.

Charles Sturt University scientists are playing a key role in new research to understand the opportunities to use industrial hemp as a feed source for sheep and cattle.

Industrial hemp is an emerging crop that shows great potential, but further investigation is needed around its potential for grazing.

“Hemp is a fast-growing, waterefficient annual crop that can be grown in a number of Australian states under strict licence conditions for seeds and fibre,” said Charles Sturt School of Agricultural, Environmental and Veterinary Sciences associate professor, Gaye Krebs.

“A pilot study carried out at Charles Sturt University in Wagga Wagga identified potential for the crop to be used in livestock feed. But it also highlighted the need for more information, particularly around residues of tetrahydrocannabinol (THC) in meat.”

Industrial hemp contains low levels of this psychoactive compound and under current regulations, no detectible THC should enter the food market through animal products.

Globally, there’s been very little research about the breakdown of THC in sheep and cattle and how long it remains in tissue after animals have been fed industrial hemp.

“Our research aims to fill in some of those knowledge gaps to provide the information needed by regulators to allow the crop to be grazed by animals destined for the food chain,” said DPIRD project lead Dr Bronwyn Blake.

The research will build on the findings of the 2020 pilot study, which highlighted the potential value of industrial hemp as a feed source, along with other potential benefits. F

Victorian agribusinesses go global in China, Malaysia and the UAE

Three agriculture export specialists have been appointed by the Victorian government to help agribusinesses establish more global trade pathways.

The new agriculture-focused specialists will provide in-market support from Victorian government Trade and Investment Offices in China, Malaysia and the United Arab Emirates.

“Our specialists will provide dedicated agriculture export support in key markets so that our premium food and fibre can be made available for more people around the world to enjoy, creating even more jobs and opportunities for Victorians,” minister for Agriculture Mary-Anne Thomas said.

In Kuala Lumpur, in-market specialist Ian Thompson will provide insights to Victorian agribusinesses looking to grow their exports and diversify their markets in Southeast Asia.

“There is a significant opportunity in South-east Asian markets, and the demand for quality Victorian food and agricultural produce is high,” Thompson said.

Dubai-based in-market specialist Emma Page has a mandate for the Middle East and North Africa (MENA) region. She will support Victorian agribusinesses in responding to the strong demand for premium food and beverage products coming from the MENA market.

Beijing-based in-market specialist Davis Tao Xu will deliver tailored advice to Victorian businesses in Victoria’s biggest food and fibre export destination. The state’s food and fibre exports to China were valued at $4.7 billion in 2019-20.

“China is a very dynamic place to do business with a lot of opportunities for agribusiness,” Tao Xu said.

“I look forward to providing an expert’s view to the latest developments and trends from the market.”

Agriculture Victoria’s in-market specialists are funded through the $5 million Pathways to Export Program. The program is a fouryear Agriculture Strategy initiative, which is dedicated to creating export opportunities for Victorian agribusinesses. F

The VIC government appointed three agriculture export specialists to establish global channels.

New soil carbon method could reduce costs for farmers

The federal government has released a draft soil carbon method for public consultation under the Emissions Reduction Fund (ERF), helping farmers to benefit from soil management.

This new method will support greater uptake of soil carbon projects by overcoming barriers to participating in the ERF, reducing costs and introducing new activities to store carbon.

“Through the new soil carbon method, we’re making it easier for our farmers to be rewarded for their contribution to reducing Australia’s greenhouse gas emissions,” said minister for Energy and Emissions Reduction Angus Taylor.

“For the first time it will allow modelled estimates of soil carbon change to be used, in combination with measurement approaches, which is expected to materially reduce costs and increase returns.

“Reducing the cost of soil carbon measurement to less than $3 per hectare per year is a priority under the government’s Low Emissions Technology Statement, and one of five low emissions technology priorities under our Technology Investment Roadmap.”

The proposed method will enable agricultural activities that store carbon in soil to generate Australian Carbon Credit Units (ACCUs).

These activities include improving fertiliser application, re-establishing pasture and modifying grazing practices.

Under the ERF, over 98 million ACCUs have been issued and it is on track to reach 100 million ACCUs in the coming months. The Clean Energy Regulator (CER) expects the ERF to credit a record 17 million tonnes of emissions reductions in 2021 alone, a major milestone for the new soild carbon method.

Another big advanatge is projects under existing soil carbon methods will be able to transfer to the new method and reap the benefits of doing so. F

Under the ERF its expected 17 million tonnes of emissions reductions in 2021.

goodbye data entry. hello efficiency. automate your order management process

Esker’s automated Order Management solution uses AI and RPA technology to address the most repetitive, low-value areas of order taking all through one secure, centralised, cloud-based platform.

Process orders faster

with automation technology that optimises staff productivity & reduces costly errors Increase visibility

over entire order flow, regardless of course, enabling users to track monitor & improve KPIs Improve customer experience

through faster fulfillment, improved transparency, self-service & collaboration tools Enhance bottom line

by reducing operational costs, increasing business agility & generating new revenues

www.esker.com.au Esker Australia Pty Ltd . +61 2 8596 5100 . info@esker.com.au

Tasmanian scallop fishery reopens in September

Ayear on from the largest outbreak of avian influenza ever seen in Australia, Victorian poultry farms are benefiting from biosecurity lessons learnt during the response to the episode.

Victoria’s poultry flocks are free from avian influenza due to the combined efforts of poultry farmers, businesses, local community, scientists and emergency response personnel.

The outbreak had to be controlled quickly as it could have decimated businesses and some strains had the potential to be transmitted to humans.

On 31 July last year, birds tested positive for avian influenza on a Golden Plains free-range egg farm. Over the following four weeks, a further five farms tested positive – in Golden Plains, East Gippsland and Gannawarra Shires.

In total, three different strains of avian influenza were found on six Victorian poultry farms, infecting three bird species, H7N7, H5N2 and H7Ng avian influenzas.

National freedom from the highly pathogenic avian influenza was declared on 26 February 2021.

To achieve this, almost 1,400 surveillance visits were undertaken, and 2,700 surveillance text messages were issued.

As part of the response to minimise the risk of more poultry testing positive, an Australian first “Housing Order” was introduced at the time for Golden Plains Shire.

This required all people with domestic poultry to house their birds, to reduce their interaction with wild birds and reduce the risk of developing further cases that could cause it to spread further.

The Victorian Agriculture Strategy highlights the importance of protecting the state from exotic pests and diseases that have the potential to cause great harm. F

The enhanced biosecurity is in response to the largest outbreak of avian influenza seen in Australia.

After being closed for six years, the Tasmanian scallop fishery will reopen for commercial harvesting next month following the analysis of stock surveys in June and July this year.

Having been closed since 2015 due to low stock numbers, the decision to reopen the fishery was made succeeding a research plan developed by the Institute of Marine and Antarctic Studies (IMAS).

The IMAS analysis of the survey results gave an indication of scallop abundance, catch rates and size and the results in the vicinity of Babel Island, east of Flinders Island met the acceptable sustainability criteria for opening.

The Scallop Fishery Advisory Committee – which comprises representatives of fishers, processors, IMAS and the Department of Primary Industries, Water and Environment (DPIPWE) – has advised that the Total Allowable Catch (TAC) for the fishery has been set at 1,494.9 tonnes, or 145 kg/unit.

The season will open in an area east of Flinders Island from Wednesday 1 September to Friday 31 December 2021.

The Tasmanian scallop fishery is an important part of Australia’s seafood industry and operates under a fishery management plan supported by strict fisheries rules that need to be adhered to in order to keep stocks up. F

Kinglake Distillery, a whisky producer based near the Yarra Valley, Victoria, has announced it will produce Australia’s first government certified carbon neutral whisky by the end of the year.

This will be achieved in offsetting its carbon footprint, increasing the sustainability of its processes and undertaking rigorous auditing. Kinglake Distillery is also setting aside land for the re-planting of Indigenous native forest.

Founded in 2018 by owners Sam Lowe and Chantal Daniels, the off-grid distillery functions using a mixture of solar and generator power, a tank for gas and an onsite dam for recycling cooling water. Surrounded by deep forests, bush, mountain streams and national parkland, it is designed to use its location to its advantage.

All the whisky produced at Kinglake Distillery is made from scratch. Its single malt is made from the mountain stream that rises on the property, which has the perfect mineral content for making whisky. It uses barley, 80 per cent of which is farmed and malted in NSW, supporting Australian growers.

Lowe and Daniels focus on vatting different barrels – typically small-format ex-bourbon barrels re-coopered in Australia, well suited to ageing conditions in the Kinglake Ranges. A 2,500L copper pot-still was handmade by Tasmanian premier still-maker, Knapp Lewer, and was engineered to produce a heavy, flavourful spirit.

Nature influences every stage of the whisky distilling process, and the result is an exceptional whisky that can only be made in Kinglake.

The owners foster a strong brand ethos centred around authenticity, honesty and integrity. This is reflected in the reasonable price point of their single malt whisky, using the best ingredients to produce outstanding quality, consumers can purchase a 500ml bottle for $100.

Kinglake Distillery is set to become a genuine Victorian distilling landmark. With the commitment to produce Australia’s first certified carbon neutral whisky, the company is dedicated to ensuring that drinking its whisky has no negative impact on the environment. F

The carbon neutral whiskey will be produced in the Yarra Valley, Victoria.

“Digital twins” concept from UQ boosts food production

Scientists at the University of Queensland are creating “digital twins” of mango and macadamia orchards to help boost food production, using simulation technology called DigiHort.

Centre of Horticultural Science at Queensland Alliance for Agriculture and Food Innovation (QAAFI) director Professor Neena Mitter said it was an example of how computers are changing the industry.

“Developing a digital model for an orchard with slow growing crops like mango and macadamia enables us to run virtual experiments at a scale and speed never before possible,” said Mitter.

“Digital technologies offer an unprecedented acceleration in innovation that will help make food production more productive, resilient and sustainable.”

Lead researcher Dr Liqi Han said the technology would particularly benefit slow growing crops like fruit trees.

“The digital modelling provides untapped opportunities for users to rapidly trial new ideas and acquire a reliable indicator of how to best optimise production systems,” said Han.

“We call this technology ‘DigiHort’, short for Digital Horticulture.”

The computer simulations can be a conceptual design of an orchard that doesn’t yet exist, a digital twin or detailed replica of an existing orchard, or a digital variant, where changes are made to a digital twin.

“All three forms can be integrated with environmental and management simulators,” said Han.

Virtual trials start with the design, with software users able to decide where in a landscape to plant trees, the density of the canopies and the configuration of the rows.

Users then consider how the trees are maintained, wielding virtual pruners and testing the impact of different – and even unconventional – tree training systems.

This innovation is based on new LiDAR scanning technology applications undertaken with industry partner, Riegl Australia, and state government research stations.

It relies on High Performance Computing (HPC), which allows Han to run extremely fast virtual experiments without loss of accuracy. F

Researchers from UQ are creating “digital twins” of mango and macadamia orchards to boost production.

Australian pulses meet the global demand for alternative proteins

Sunshine state powers Australia’s biggest brewery

Australian pulses will help meet the growing demand for alternative meats, dairy and other plant protein foods under newly funded research from the University of Sydney.

The Transitioning Australian Pulses into Protein-based Food Industries project was awarded $993,573 in the latest round under the Global Innovation Linkages Program.

Looking at ways to convert Australian grown pulses into plant protein ingredients and foods, the project will be funded over three years and receive private sector support.

The annual value of the alternative meats, dairy, beverage and egg food sectors is set to rise globally to around $55 billion by 2025. Australia’s plant protein market is forecast to be worth $4.03 billion a year by 2030.

Currently most plant proteins are derived from soybean and yellow pea, which have limited scope in Australian agriculture. The University of Sydney (USYD) team from the faculties of Science and Engineering will investigate turning Australian-grown pulses into plant protein ingredients and foods.

“Australia produces about three million tonnes of chickpeas, faba (or fava) beans, mung beans, lupin, field peas and lentils a year,” said USYD Faculty of Science lead researcher, from the Sydney Institute of Agriculture, Professor Brent Kaiser.

Kaiser and professors Fariba Dehghani, Roman Buckow and Timothy Langrish will investigate refining processes to extract protein concentrates and isolates from Australia’s commonly grown pulse varieties.

Working alongside industry partners AEGIC, Roquette, Clextral, All G Foods and Wide Open Agriculture, they aim to develop and commercialise pulse-specific processing technologies.

“Our aim is do this while also minimising water and energy consumption,” Kaiser said.

“At the end of this three-year project, we envisage Australia’s plant protein food and ingredient sector will be sufficiently established to encourage local investment in protein fractionation plants. F

New research from the University of Sydney is designed to meet growing demand for alternative meat.

Australia’s biggest brewery, Asahi Beverages Yatala on the Gold Coast, is brewing beer with the help of the Queensland sun after installing solar panels on its roof.

Around 7,000 solar panels directly harness the Queensland sun to produce Australia’s favourite beers, including Great Northern, Victoria Bitter and Carlton Draught.

The new 3.01 MWp system on the brewery’s rooftops is one of the biggest installations of its kind in Australia.

The panels were spread across 15,000 square metres, an area larger than Suncorp Stadium’s playing surface.

“The solar power we now generate is enough energy to power more than 800 homes and nearly 9,000 beer fridges annually,” Yatala Brewery plant manager Tom Robinson said.

The installation took 18 months and was completed without interrupting brewing operations. More than 150km of cable was laid.

Yatala is owned and operated by Carlton & United Breweries, which was acquired last year by Asahi Beverages. This project is a significant step towards Asahi Beverages achieving its ambitious sustainability target of sourcing all its electricity across the country from renewable sources by 2025.

The project was led by Smart Commercial Solar in partnership with AMPYR Energy. It is one of the most complex projects the company has undertaken in Australia due to its size. F

Angove Organic reports growth for Australian Organic Awareness Month

September was the annual Australian Organic Awareness Month, which continues to bring unprecedented growth in sales – including for Australian-certified organic winemaker, Angove Organic.

Angove Organic has seen 38 per cent year-on-year export growth as shoppers have aligned their tastebuds with good health. The future introduction of a mandatory standard for using the word “organic” to market wine will help alleviate consumer concerns, according to Australian Organic CEO Niki Ford.

This is key, given Australia’s organic industry is estimated to contribute over $800 million of GDP in 2020, rising by a further 7.9 per cent during the pandemic.

“Buyers of organic goods should be able to have complete trust in the integrity of every single product they purchase, that’s why our Bud Logo has become a key proof point for what is truly Certified Organic,” Ford said.

The Angove Organic vineyards have replaced chemical pesticides with Indian Runner Ducks, microbats and bees. The brand plays a role in the lives and health of millions of people worldwide, according to joint managing director Victoria Angove.

“Australians have made it clear they are committed to doing better for people and planet, now acutely aware of the effect of the potential damage pesticides can have on our bodies and our environment,” Angove said.

Angove Organic has seen a 38 per cent growth, year over year, mainly due to consumer habits changing.

“COVID-19 has given us pause for thought to consider what is important to use to ensure a healthy future.”

There is freedom working in certified organic vineyards as well, in removing the usual masks, gloves and protective gear to protect workers from synthetic pesticides, herbicides and fertilisers.

“Angove Organic has come full circle from the days in the late 1800s when Dr William Angove, a medical doctor found himself experimenting with wine making, initially using it as a tonic for his patients to help with their ailments and support their health,” Angove Organic winemaker Tony Ingle said. F

Leader in Low Flow Fluidics Handling Technology

Flow ranges for gases from 0 - 0,7 mln/min up to 0 - 11000 m3 n/h

Flow ranges for liquids from 0 - 100 mg/h up to 0-600 kg/h Pressure ranges from 0 - 100 mbar up to 0 - 400 bar Laboratory, industrial (IP65), Class I Div. 2 or ATEX approved design Analog, RS232, FLOW-BUS, PROFIBUS DP, PROFINET, DeviceNet™, Modbus, EtherCAT®

Tasmanian dairy industry celebrates record milk production

The Tasmanian dairy industry has celebrated a new annual record for milk production, having produced 961 million litres of milk – up 1.2 per cent from the previous year.

These results reflect the ongoing success of Tasmanian dairy.

This latest record exceeds the previous 2019-20 record for milk production, which saw 950 million litres of milk produced. Confidence amongst dairy farmers remains high and solid milk prices have been announced by all Tasmanianbased milk processors for the coming 2021-22 season.

With this confidence, the state is seeing many farmers reinvest in their businesses through upgrades, such as irrigation, effluent systems, calf rearing sheds and more.

As reported by Dairy Australia, Tasmania’s results from the National Dairy Farmer Survey resulted in almost all respondents (96 per cent) making an operating profit in 2019/20 and a similar proportion expect to do so this financial year.

The Tasmanian government has been a strong and consistent supporter of the state’s dairy industry and aims to continue to do so as the industry grows.

The 2021-22 Tasmanian Budget has provided $100,000 in further funding to DairyTas to support the Cows out of Creeks program. This program has helped build over 111 kilometres of fencing and 150 water troughs on 37 dairy and beef farms in Circular Head, meaning some 240,000 cattle are limited from accessing waterways, providing a win-win for stock health and the creeks and rivers in the region. F

The Tasmanian dairy industry produced 961 million litres of milk this year, beating its previous record.

Calabria Family Wine Group is launched after continual growth

The Calabria family has launched the Calabria Family Wine Group, signifying a new era for the Griffith-based family winery and growing its portfolio.

Following a year of brand acquisitions such as McWilliam’s

The Calabria Family Wine Group has officially been launched after a year of acquisitions.

Wines, Hanwood Winery, Deakin Estate and La La Land Wines, the family business has rapidly grown, cementing them among the largest family-owned wine groups in Australia.

The Calabria Family Wine Group will house the family’s collection of brands and aims to ensure each of the brands carry their distinct identities, portfolios and distribution strategies.

Vintners & Co. Merchants is the new distribution arm of the company representing Calabria Family Wines’ international distribution partnerships.

It includes many international brands including the Italian labels Canti and Librandi, Portugal port house Dow’s, Argentinian winery Dona Paula and French champagne producer Champagne Deutz.

The brand has also celebrated its 75th anniversary. Its offerings in the international wine space allows it to work with a broad range of wine cellars and on-premise channels, a company spokesperson said.

With the new acquisitions, Calabria Family Wine Groups’ portfolio has grown from 140 SKUs to 283 SKUs in the past 10 months. The brands and products will be serviced by the Calabria Family Wine Group sales team, which has added seven new members – mainly from McWilliam’s Wines – to ensure the knowledge of these wines is carried over to the newly established group.

The Calabria Family Wine Group will be operated by Bill Calabria and the third generation of the Calabria Family. F

Loryma produces wheat textures to create meat alternatives

Loryma, a globally distributed wheat producer, has released its portfolio of Textured Vegetable Protein (TVP) comprising of six basic types, in the Lory Tex range.

While serving as a protein base, the Loryma TVPs also give meat alternatives an authentic mouthfeel. Through targeted selection, combination and hydrogenation of the dry texturates, different types of meat and fish can be replicated. This includes an array of processing variants such as sausage meat, fillets and minced meat.

The neutral taste of the ingredients means there is no need for masking flavours.

The texturates are available in powder format, which can be used for protein enrichment or vegetable sausage meat, and as granules for products that imitate minced meat. The long fibres, flakes and chunks can be used on their own or in combination to reproduce grown meat structures like poultry, pork or veal alternatives.

The Lory Tex range consists mainly of wheat gluten – a renewable raw material that forms meatlike fibres through an extrusion process. As a dry product, it can be transported unrefrigerated, easily stored and rehydrated individually.

The bite strength determines the water absorption of the ingredient, with a texturate to water ratio between 1:2 and 1:2.5. It is available in three shades – light brown, coloured with natural malt extract and reminiscent of cooked pork, along with versions in brown and dark brown, which are coloured with caramel and resemble cooked beef.

Depending on the combination, different vegan or vegetarian applications can be realised with the textured wheat proteins. If softer granulates are combined with firmer ones, popular “home style” burger patties are created. The use of Lory Tex Fibres for a homogeneous fibrous texture authentically replicates a schnitzel. F

Options for meat alternatives continue to grow with production of wheat textures.

Eight Australian start-ups shortlisted for FoodBytes! Pitch 2021

Eight Australian start-ups are among 45 global food system innovators shortlisted for the food and agri discovery program: FoodBytes! Pitch 2021.

Recognised for outstanding innovation in the fields of sustainable supply chains, improved resource management and the next frontier of nutrition, the Australian cohort represent 18 per cent of this year’s FoodBytes! Pitch top 45, and includes five female- founded and led entrepreneurial businesses.

The top 45 start-ups globally will now vie for selection in FoodBytes! Pitch 2021’s top 15, and the opportunity to participate in FoodBytes!’ live streamed public pitch competition on 8-10 November. The ultimate winner will be chosen in each of three sectors: FoodTech, AgTech and CPG.

Australian start-up, Perthbased Swan Systems, took out last year’s global Agtech Award, in FoodBytes! Pitch 2020 for its precision irrigation and fertiliser platform. This platform helps growers schedule, monitor and optimise management of water, nutrients and crop health to improve economic and environmental outcomes.

From 45 shortlisted companies this year, 31 companies directly address areas of food and agriculture that have been affected by the impacts of COVID-19.

Corporate members play a pivotal role in the FoodBytes! by Rabobank platform – assisting with scouting criteria, scoring applicants, providing mentorship and fostering connections.

With continued interest from participants to implement realworld solutions within their respective industries to drive change, FoodBytes! has seen a 120 per cent increase in corporate membership globally since 2020. Additionally, since 2017, participating corporate members have gone on to directly invest nearly $216 million in the program’s alumni.

Membership enrolment for 2022 is already underway. F

Eight Australian start-ups are on the global shortlist for food and agri discovery.

Foodland delivers first Retail Ready Program for local producers

Foodland Supermarkets helped release the Retail Ready Program for more than 50 food and beverage producers.

Foodland Supermarkets, together with Food South Australia, have delivered its first Retail Ready Program to more than 50 local food and beverage producers to inform how brands can scale up operations and successfully enter the retail space.

The Foodland brand currently supports a 95-store network across South Australia. The inaugural program was designed in collaboration with Food South Australia.

“This is an opportunity for us to engage with new and exciting brands and provide valuable insights that will see them establish their first commercial relationship with us at Foodland,” said Foodland Supermarkets general manager of Merchandise and Strategy Christopher Villani.

“Our network is trusted, strong and reliable and we want to educate smaller operators across the food and beverage industry to understand the business fundamentals and best practices that will see their product grow in the current retail climate.”

Expert advice will be delivered on areas including financial considerations and pricing, production scale, sustainable practices, marketing and promotion, distribution and merchandising.

Area specialists from Norman Waterhouse, Moore Australia, KWP! and sustainability consultant Peter Wadewitz will present to those attending.

“We’re bringing together all the advisors that we trust and work with to ensure we maintain a strong business now and in the future,” Villani said.

The brands are excited to take part in the workshop and explore the possibility of one day entering the retail space, Food South Australia chief executive officer Catherine Sayer said.

“It’s not every day that an opportunity like this presents itself,” Sayer said.

“This program gives up-andcoming business owners a chance to ask all the questions you have about how to successfully create a product and brand that people will want to purchase time and time again.

“We look forward to seeing each operator learn and grow from this experience.” F

Australian family-owned packaging supplier acquired by global company

Global packaging company, TricorBraun, has announced it has entered into an agreement to acquire Cormack Packaging, an Australian familyowned packaging supplier. This will establish the company’s footprint in the region.

Serving customers with rigid packaging needs for more than 80 years and spanning three generations, Cormack Packaging primarily serves the food and beverage, pharmaceutical, personal care, industrial and household cleaning industries.

“We are incredibly excited to mark our first entry into Australia with the acquisition of Cormack,” TricorBraun president and CEO Court Carruthers said.

All the Australian company’s team members, including managing director Mathew Cormack and the company’s executive team, will remain with TricorBraun.

The team will continue to work out of the company’s existing locations across Australia and New Zealand.

Effective with the closing of the transaction, Cormack Packaging will operate as “Cormack Packaging, a TricorBraun company”.

“Joining the world-class TricorBraun team is the next great growth chapter in Cormack Packaging’s 82-year history,” Cormack said.

Since it was founded, TricorBraun has partnered with management teams to successfully acquire and accelerate growth for more than 25 packaging companies. Cormack Packaging marks TricorBraun’s third acquisition this year.

“I am truly excited for the opportunities this brings to Cormack Packaging to better serve this region’s customers. Sharing like values, as well as a common passion and commitment to be the best partner for our valued customers, make TricorBraun the ideal home for Cormack Packaging to thrive,” said Cormack. F

Packaging company TricorBraun has acquired Cormack Packaging.

South Australian wineries enter the US market through Wine Australia

Sixteen South Australian wine producers will be supported to grow their businesses by entering and expanding into the US market through the Wine Australia US Market Entry Program – with the South Australian government subsidising 50 per cent of the cost.

Delivered by Wine Australia, the 12-month program is designed to educate wine producers about the technicalities of the US market, including compliance, marketing, pricing, sales, PR and logistics.

The program offers both real-world guidance and market introductions with Wine Australia providing advice on how best to approach the US market guiding clients towards like-minded customers in the US who share a wine producer’s vision and market goals.

The program will provide participants with insights into one of the largest and most complex wine markets in the world.

The South Australian government’s $5.4 million Wine Export Recovery and Expansion Program commenced on 1 July 2021 and will run for four years.

Just days before Christmas in 2019, the Cudlee Creek bush fire tore through Golding Wines’ Adelaide Hills property, burning 95 per cent of its vineyards, destroying machinery, irrigation systems and infrastructure for several wine tourism experiences.

The winery then endured the impact of COVID-19 and having to close its doors during lockdown.

The US Market Entry Program will support Golding Wines in its efforts to diversify exports into the US market.

The program is said to make a difference to South Australian wine producers looking to enter or expand into the US market. F

The South Australian government’s $5.4 million Wine Export Recovery and Expansion Program started in July of 2021.

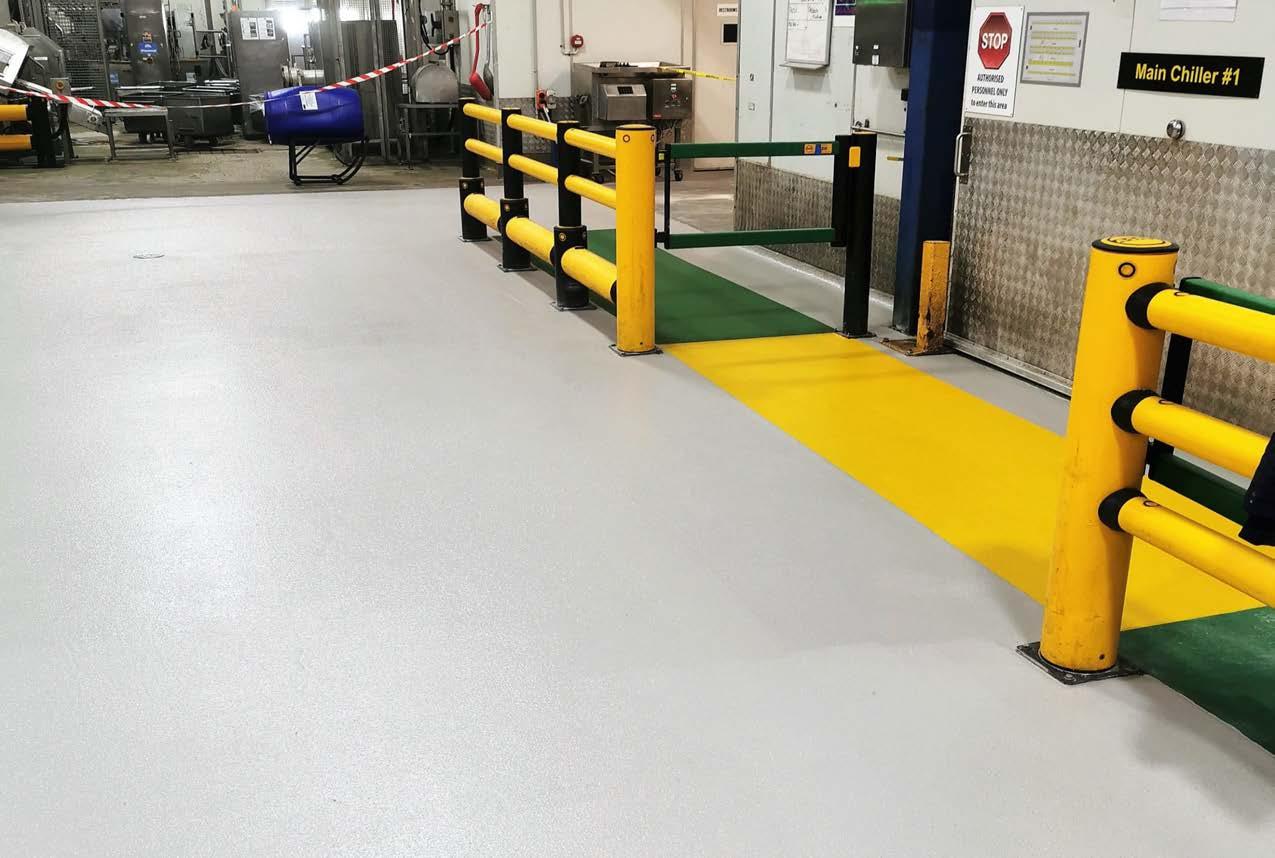

Antimicrobial Flooring Solutions

FOR FOOD & BEVERAGE MANUFACTURING FACILITIES

1800 033 444 | helpdesk@alliedfinishes.com | www.alliedfinishes.com

Solve agricultural challenges with Agtech and Logistics

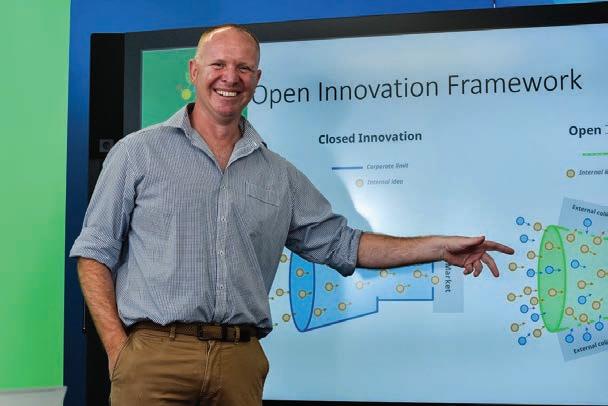

Agtech and Logistics Hub manager Owen Williams said open innovation was a key part of the hub.

Anew Agtech and Logistics Hub based in Toowoomba, Queensland is preparing to scour Australia to solve realworld challenges in the agricultural industry, bridging the gap between research and industry adoption.

Identifying issues within the sector will provide a clearer picture of what problems need solving, Agtech and Logistics Hub manager Owen Williams said.

“Using this as inspiration, we’re able to be on the lookout for teams and individuals who will collaborate, interact with industry, then develop, test and grow new business ideas, products and services,” Williams said.

“This open innovation concept is a major focus of the hub to allow us to further grow the industry,” he said.

The Agtech and Logistics Hub will deliver a series of open programs that will fast-track the development of agriculture technology.

To help deliver these programs, the Hub has announced a new partnership with Innovation Architects, a Queensland-based advisory group.

“We recognise the importance for industry groups to actively participate in our innovation ecosystem and collaborate with universities, government and start-ups to increase commercial opportunities and outcomes, to focus our innovation efforts on areas of competitive advantage such as agriculture,” Innovation Architects managing director Mark Gustowski said.

“Solving industry challenges through innovation and technology is very exciting and we are confident that working with Innovation Architects’ framework and experience, that we will be able to fast track and deliver on validated solutions for the industry,”

The Agtech and Logistics Hub is jointly funded by the Queensland government in association with the FKG Group, Toowoomba and Surat Basin Enterprise, University of Southern Queensland and the University of Queensland. F

Australian scientists create a new, superior faba bean variety

University of Sydney scientists have released a new faba bean variety called FBA Ayla, providing an improved faba bean for growers in the northern New South Wales and southern Queensland region.

The faba bean is the second most important grain legume after the chickpea in the sub-tropical grain growing region of Australia. The University of Sydney has been breeding faba bean varieties for this region from its Plant Breeding Institute in Narrabri since 2010.

Development of high-yielding and disease-resistant varieties with superior seed quality is the focus of the breeding program at the Institute.

The new variety was developed by the Faculty of Science’s Dr Kedar Adhikari, program leader and senior plant breeder at the Plant Breeding Institute, Narrabri; part of the Sydney Institute of Agriculture.

“Farmers will benefit from growing FBA Ayla without any compromise in disease resistance and seed quality,” said Adhikari.

The highlights of using the FBA Ayla include high yielding across all faba bean growing areas of northern NSW and southern Queensland region and a similar level of tolerance to bean leaf roll virus, a significant disease in the northern region.

Another highlight is Its uniform and superior seed size over PBA Warda will make it readily acceptable for marketing, while being a smaller seed than PBA Nasma will improve handling at seeding.

FBA Ayla is suggested as a replacement for PBA Warda and PBA Nasma.

Limited quantity of seed will be available for commercial production in 2022 season from the commercial seed partner, Seednet.

Faba bean breeding is a collaborative project with New South Wales Department of Primary Industries and the University of Adelaide and supported by the Grains Research and Development Corporation. F

Scientists have named the new faba bean variety FBA Ayla, which has an improved grow rate for farmers.

Beta Glucan market projected to reach USD 525 Million by 2026

The global beta glucan market is projected to witness phenomenal growth over the span of 2020 to 2026, subject to the rising incidence of chronic health disorders including diabetes, heart problems, and obesity worldwide. In fact, as per WHO, obesity prevalence has nearly tripled since 1975 globally. Moreover, the year 2016 recorded over 650 million obesity cases. These daunting numbers and an increasing paradigm shift towards consumption of processed foods with nutritional benefits have offered a demand spurt for beta glucan, in turn impelling the overall dynamics of market over the years.

It has been estimated that overall beta glucan market would account for a valuation of USD 525 million by the end of 2026.

The growth is attributed to several trends including burgeoning product adoption across Europe for ensuring proper health and wellness, increased dominance of soluble product solutions, prolonged use in animal feed, the rising preference towards yeast-based products with 70 to 85 per cent purity and ongoing efforts by industry majors.

Enormous health benefits associated with consumption of beta glucan has indeed propelled various companies and businesses to bring forth products that are high on beta glucan content. Not only this,

The global beta glucan market is experiencing strong growth on the back of several factors including more product adoption.

various states, as well as central governments, have also granted approval for use of these compounds in various F&B products and animal feeds.

Recently, Kemin Industries had announced receiving approval across the economies in EU and Brazil, allowing its algae-extracted beta glucan ingredient- BetaVia Complete to be commercialized on both these markets. It has been reported that the ingredient is generally manufactured via a patented process using a proprietary strain of algae, Euglena gracilis ATCC, making it the first and only ingredient extracted from this strain to be approved as a novel food by the EC. F

The University of Southern Queensland’s Dr Kiran Ramesh Mahale has discovered ways to convert food waste into reusable materials.

For Mahale, food has always been considered next to godliness. As a child, he was taught not to waste the precious commodity and this lesson set him on the path to food waste research.

Mahale started his PhD at the University of Southern Queensland in 2017, studying how to convert food waste into useful materials. Or in his words, creating ways to generate revenue for farmers.

“I first started looking at winery waste. I found after they had crushed the grapes and taken the juice, the residue was discarded,” Mahale said.

“That solid residue has many different chemical compounds which are pharmaceutically very important and in high demand.

“One of the compounds I extracted and purified was malvidin3-glucoside, which has a market price of $317 for 10mg,” he said.

“This shows that, in some cases, wineries can make more money by reprocessing their waste than selling wine.”

Repurposing food waste can also help save another precious

A pan-genome describes every generic variation within any crop species.

resource – water.

“According to the Department of Agriculture, Water and the Environment, food waste costs the Australian economy around $20 billion every year,” Mahale said.

“Fight Food Waste Cooperative Research Centre statistics have shown that around 25 per cent of the total water our country uses for food production goes into waste products.”

After extracting the chemical compounds from the leftover grape residue, Mahale then converted the remaining material into graphiticactivated carbon, which he used to purify contaminated water.

He also delved into the reuse of pineapple waste for water purification and soil enrichment.

“If we can convert waste into a value-added product – which can provide revenue for our farmers while helping to tackle our environmental issues – it’s a win-win for everyone,” Mahale said. F