PLUS, THE MAXAM AGRIXTRA RANGE DELIVERS MINIMAL SOIL COMPACTION, A COMFORTABLE RIDE AND IMPROVED TRACTION WHICH SURPASSES ALL AGRICULTURAL TYRE EXPECTATIONS. WHEN PACKAGED WITH ONE OF THE BEST WARRANTIES IN THE INDUSTRY, THE AGRIXTRA DELIVERS THE PERFORMANCE YOUR FARM DESERVES!

36 Bobcat telehandlers the only choice for Queensland poultry company

45 Hercules graders excelling for Brisbane Mini Excavator Sales

48 Jetland Loading Ramps provides easy access to solutions

68 Cobra Equipment Sales’ Shantui machines proving handy on farms

15 National research program to evaluate fertiliser efficiency

15 New round of On Farm Connectivity Program launched

16 Commercial food waste turned into animal feed

16 Telstra and Optus further delay 3G network shutdown

17 GRDC urges grain growers to assess silo safety

17 Virtual farm fencing technology trialled

18 Plan launched to protect grains industry biosecurity

18 Victoria invests into biosecurity projects

58 Tractor sales declined in July, however smaller tractors defied the trend, TMA’s Gary Northover says

60 WAFarmers CEO Trevor Whittington says a growing global middle class will drive increased grain demand

65 World’s biggest tractor to be unveiled in Carnamah

4 Editor’s note

62 Calendar of upcoming events

78 List your item for sale!

81 In the loop

Upgrades to the D3 Distributed Control System will help eliminate guesswork around valves, Valmet says

81 AC Easy

Eniquest signs generator distribution deal with Power Equipment

At Farms & Farm Machinery, we aim to bring readers a variety of content in each edition covering every aspect of Australian agriculture.

New machinery releases have always been a primary focus of the magazine –and we have ticked that off thanks to New Holland’s exciting CR11 combine harvester which was launched last month.

We talk with dealers Intersales about the benefits this new harvester will bring to the farmers that work the land in Australia daily.

For machinery which has had time to be established in the market, we love to speak directly to Australian farmers who are using it in their daily lives to get genuine feedback and opinions.

This month, we have spoken to a Queensland farmer and contractor – who also dabbles as a TikTok star – to hear about how JCB’s Fastrac iCON 8330 tractor’s speed is making major changes to his efficiency.

We also chat to another Queensland-based business – Woodland Enterprises – and get one of the most glowing endorsements imaginable for its fleet of Bobcat telehandlers.

Tornado Pumps & Sprayers is so much more than simply an Antonio Carraro deal er, as we discover the long history between t he brand and dealership and the suitabili ty of the Italian-made tractors for Lismore’s macadamia industry.

In other cases we go straight to the source and speak with Jetland Loading Ramps, Brisbane Mini Excavator Sales and Cobra Equipment Sales about their products and what they can do for you.

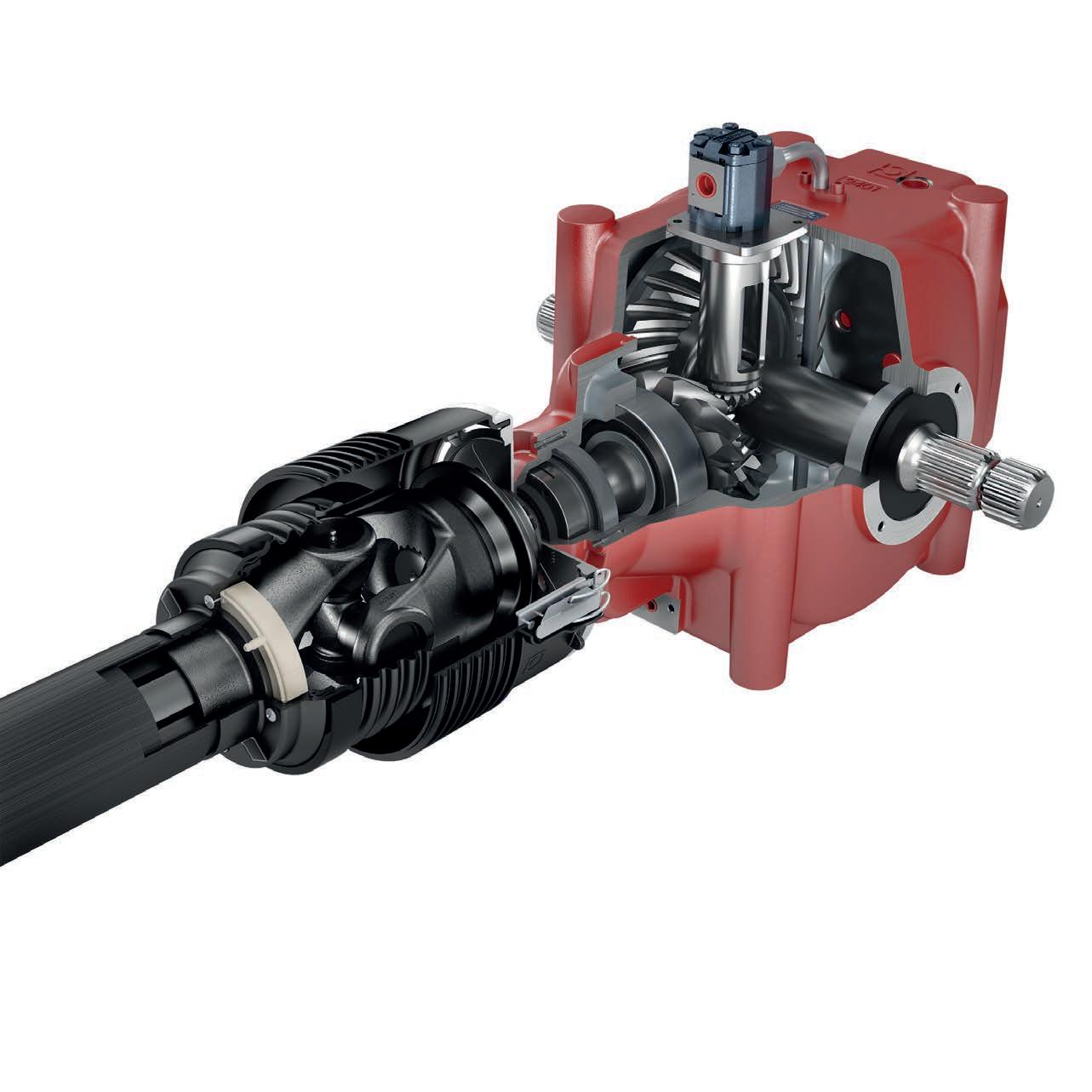

We have spoken to BYPY Transmissions to discuss more about the importance

of servicing shafts and gearboxes before using older machinery.

Technology is continuing to change agriculture – and we have profiled Sververken’s F 100 Auto Steer System along with Nutrien Ag Solutions’ Farm Emissions Profile, both of which are providing new opportunities for Australian farmers.

New innovations and opportunities present themselves in all sorts of ways.

T his edition goes into depth about how agricultural waste could present a new economic opportunity in the form of sustainable aviation fuel, along with a profile on a v ineyard owner who has become the first in South Australia to plant agave crops which are used to produce tequila.

There is also plenty of industry news to keep readers across what is happening, along with a look ahead to an exciting and quirky upcoming event – the unveiling of the Big Tractor in Carnamah, Western Australia.

The Farms & Farm Machinery team also attended last month’s AgQuip and an extensive wrap of all the highlights from Gunnedah will feature in our following

Lincoln Bertelli Editor

($100) & 10x Signed Framed Tickford Racings Polos ($750). Prize Pool 2 prizes: 20x Weber Baby Q ($568), 20x Makita 18V brushless 2pc kit combo ($800), 10x Castrol Branded Bar Fridges ($1k), 10x

solu�ons that maximize yields while keeping costs under control. Let's take a look at Sveaverken's Farm Management System (FMS), and how it tackles challenges faced by modern farmers.

Sveaverken's FMS Solu�on

Imagine a farm's command center, right in your hands. That's the aim with the FMS, allowing you to get a real-�me map of your fields right from your office. Plan your plants, and monitor your equipment, with a system that allows you to assign your whole team and provide live updates to your farm.

Sveaverken's FMS integrates with their F100 Auto Steer System and leverages ISOBUS TC technology, allowing for a holis�c approach to farm management.

At the heart of the FMS is its ability to collect, analyze, and u�lize vast amounts of data. From weather pa�erns to your current equipment performance, the FMS provides farmers with the insights needed to make informed decisions.

Time is a precious commodity on the farm. So you'll want to know that with each decision you make, you've made an effec�ve one. By automa�ng tasks, reducing paperwork, and providing ac�onable insights, the FMS frees you up to focus on bigger decisions.

By integra�ng with the F100 Auto Steer System and u�lizing ISOBUS TC technology, the FMS enables precise control over agricultural machinery. Whether you're plan�ng seeds, applying fer�lizers, or spraying pes�cides, as you're working through your fields, it works to ensure you're working op�mally.

Say goodbye to overlap, skips, and wasted inputs - you’ll achieve be�er results while minimizing your environmental impact, too.

A Sustainable, Profitable Future

Easily create accurate boundaries and generate precise guidance lines using a user-friendly map interface, enabling seamless task assignment to the auto steer system.*

File Sync

Effortlessly import and export boundary and guidance line files in GeoJSON/Shapefile formats, simplifying the transfer process to auto steer systems.*

*Note: This feature is available on F100's Advanced Mode only.

Streamlining Opera�ons

Ul�mately, the ability to gain this overview of your farm's opera�ons and delegate tasks means op�miza�on. And if you're op�mizing opera�ons, you've spent your �me strategically - such is the vision of employing the FMS. Your team can be assigned roles and keep you updated on their progress right within the FMS interface, giving you a true visualiza�on of what's happening at any given moment. Any worker is able to contribute and keep tabs on inventory and their tasks, giving you peace of mind that you know exactly what's going in and out, and what the situa�on is on the ground. Truly the digital age of farming!

A Sustainable, Profitable Future

From field mapping and task planning to equipment monitoring and maintenance, the FMS helps you op�mize how you run your farm, saving you �me and money. Sveaverken's FMS takes care of the complexi�es and translates it into something all farmers can understand, allowing you to focus on what ma�ers most – growing your business. From precise field management to real-�me monitoring and data analysis, the FMS provides a comprehensive solu�on for modern agriculture. Get in touch with Sveaverken to learn more about their growing list of precision agriculture solu�ons and more.

Used to produce tequila, agave crops have been commercially planted in South Australia for the first time. Jackson Haddad caught up with vineyard owner Oli Madgett to find out how this first step could help build a new industry in Australia

Based in McLaren Vale, South Australia, The Madgett’s Block vineyard is now the site of the state’s first commercial agave tequilana plants – growing what is a key ingredient in tequila.

Also known as blue agave, up until this point the crop had only been grown and distilled in certain areas of Mexico, but The Madgett’s Block vineyard has taken the first step to change this.

The vineyard is set to grow 1,200 agave tequilana plants, primarily to produce agave spirit, while also experimenting with other agave varieties that can be used for animal feed and as a source of fuel.

The Madgett’s Block Originally emigrating from London to McLaren Vale, vineyard owners Oli and Tara Madgett have now been grape growers for nine years.

Coming from non-agricultural backgrounds, the Madgetts purchased the 6.5-hectare (16 acre) established vineyard on a hunch that it felt right, with the previous owners helping to kickstart the takeover period.

“We didn’t have much knowledge of what we were taking on and we were probably led by our hearts more than our mind. The previous owners have done an amazing job on this block, so that helped encourage us take on the risk,” Oli says.

A previous grape-supplying contract with Treasury Wine Estates was in place when the vineyard was bought, so this was then inherited to the new owners to help get them up and running.

“It was a really smooth transition, the help was invaluable,” Oli says.

“Having the previous owners available to hold your hand through the first year made all the difference.”

Since the COVID-19 pandemic in 2020,

Oli describes the wine industry as having been a roller coaster, which has made it hard for him as a smaller producer.

In 2020, tariffs were imposed on Australian wine exported to China – one of Australia’s biggest wine export markets.

Because of this, less wine was being exported and more was being backed up in tanks, Oli says. With an oversupply and more wine in storage, demand softened, with Oli describing the industry as being hit by a ‘perfect storm’.

“Suddenly we found that the market had flipped, from growers not being able to meet the demand, to there being a significant oversupply,” he says.

Facing a lack of demand, he decided enough was enough and some of the vines started being removed at The Madgett’s Block to reduce the economic losses, with the Madgetts looking about at what they could do to diversify.

Working with plant-based technology company Vircura, a solution was found –planting agave crops.

The agave crop has many varieties, presenting a range of opportunities including being used as a fuel source – alongside the ability for it to be distilled into tequila.

Although the primary goal is to use the crop for distillation and spirit production, other agave varieties will be trialled for the creation of renewable biofuels.

This could be a huge win for sustainability, as the crop produces biomass that can be used to produce renewable biofuels.

Oli says there may be requirements for using alternative fuels in the near future, so he plans to look at whether the crop’s leaves can be harvested for this biomass.

“We’re looking at whether we can harvest these leaves while the agave is still growing, and trim them off at set points in time,” he says.

Agave usually takes up to 10 years to grow in Mexico for distillation, without any irrigation, and now Oli wants to see if environmental changes will lead to a quicker harvest.

“We can give the crop water that it usually wouldn’t have, put it into better soil and place it an environment that it wouldn’t normally be grown in,” he says.

“In these conditions, we want to see if we can speed up the harvesting process.”

In addition to being distilled for tequila, Oli says agave can be processed as silage for animal feed. Because it is also fire resistant, it could be strategically planted as firebreak to protect crops from bushfires.

Looking to the future of the crop, Oli sees agave as an option for growers that are looking to diversify in the wine industry.

Although he is taking a risk as the first to commercially plant this crop in South Australia, Oli says he’s willing to take on the challenge, as it will provide invaluable information for other interested growers.

“It’s an emerging space and we’re wanting to help to create an agave industry in Australia,” he says. I’m looking forward to sharing the journey that we’re on and the learnings that come from it, and hopefully we see more people step in and help build the industry as well.”

Pressurized cabins as low as 1.74 m. narrow as low as 1.05 m. Our Range reaches 110 hp manual or true Hydrostatic! NO COMPROMISE on power!

Visit your closest dealer

web: www.antoniocarraro.it/au

A Queensland farmer and contractor is impressed with his new JCB Fastrac iCON 8330 tractor and has been showing his online fan base

He is a TikTok star with his finger on the pulse of farm machinery worldwide, so

Lance Wise’s decision to go with JCB’s Fastrac iCON 8330 tractor was not one taken lightly.

The Queensland farmer and contractor has more than 35,000 followers on the social media platform, sharing videos of his life working the land in the state’s Darling Downs region.

His videos give his audience an insight into real-world farm machinery use, while the knowledge sharing goes both ways as

Lance is also exposed to new machines, techniques and ideas thanks to the platform.

Having spent much of his farming life using another brand of tractor, it was after a demonstration of the Fastrac iCON 8330 early last year that Lance made his first leap into JCB machinery.

“We were pretty impressed with it, so we decided to go ahead towards the end of last year and it’s been running well,” Lance says.

“It’s just very smooth, doing every operation you put it towards – smooth in the

paddock, and smooth on the road.

“We’ve normally run other tractors and this is just far better and a lot more comfortable to ride in.”

Lance is primarily a grain farmer, operating across 1,650 hectares at Bowenville near Toowoomba, while also doing contract harvesting around the Darling Downs region and hiring out some machinery.

One of the features which JCB tractors are known for, particularly the Fastrac iCON 8330, is their speed.

A modified Fastrac broke a Guinness World Record in 2019 for the world’s fastest tractor, while the ‘standard’ Fastrac iCON 8330 boasts a top speed of 70km/h.

This additional speed is invaluable for an operation like Lance’s, where hire and contracting machinery can be located at different sites and travel time between these can be significant.

“When we’re moving machines around, you can’t tow them with a truck or ute or anything like that, so the tractor reaching 70km/h means you can get there fairly quickly and cruise home at 25-30km/h with an implement on the back,” he says.

“Some instances could take six hours or more to get one machine and move it on to the next person, and I’ve almost halved it –or definitely taken off one-third of the time.

“It’s just made that a lot quicker and then obviously the suspension is a lot smoother as well. “That’s one of the reasons why we bought it, and it just fits in with our farming quite well.”

The Fastrac iCON 8330’s speed is a huge point of difference, but the tractor is far from a one-trick pony.

The iCON part of the name refers to the manufacturer’s new technology and control suite, which was only launched in Australia less than two years ago.

JCB says iCON has been designed to bolster the tractor’s technological capability while remaining simple and efficient for users.

It features a new armrest console and 30cm touchscreen display with fully integrated ISOBUS connectivity, precise GPS guidance and implement control applications, plus simplified operation on the joystick.

One simple change for operators is now pushing the joystick forward to increase tractor speed, rather than tapping to the right-hand side.

There are five configurable buttons and a roller thumb control on the main joystick, and another four with a rocker switch on the second joystick.

This has also made a difference for Lance, with JCB’s intentions when introducing the iCON suite being reflected in h is experience.

“It’s very user friendly and very easy to configure the controls to each implement

that you hook up to it,” Lance says.

“Once you work out your configurations and how you want to run the machine and control layout, it’s just far easier to use than other tractors.

“Everything’s one or two clicks away instead of needing to dive into the screen and go through five, six or seven steps to find out how to do something.

“It’s all just there and it’s been quite good that way.”

JCB’s Fastrac iCON 8330 is a powerful unit, producing 348 horsepower (260kW) and 1450Nm of torque.

Its rear lift capability of 10,000kg means it can handle even the most demanding of implements with ease.

It is one of two models in the JCB Fastrac iCON range, with the smaller 4220 model offering 235hp (175kW) of power, 1000Nm of torque and 8,000kg rear lift capacity.

For Lance, it is the 8330’s versatility and strength which makes it ideal for his needs.

“We’re mainly using it for the running around type jobs - so tow-behind spraying, spreading, three-point linkage spreading, chaser bin, those type of things,” he says.

“It definitely pulls harder than our other 350 horsepower tractor, so it can do that work quite well.”

Many farmers may know Lance through his TikTok profile ‘Lancey86’, where he is showing the benefits of his machines such as the JCB Fastrac iCON 8330 while also learning from other farmers around the world.

“It’s seeing what people do in different parts of the world, how they do it and how that can translate to what you do and give you different ideas,” he says.

“That’s been a good experience for us, looking over the fence and seeing what’s around.

“You’re also showing a different point of view to people that want to watch.

“It gives them a thought process where they might go for this piece of gear instead of that piece of gear - they’re actually getting a point of view from somebody who’s using the thing.”

Fastrac iCON tractors are distributed nationwide by JCB CEA’s extensive dealer network.

JETLAND is a leading supplier of high strength & heavy duty Aluminium loading ramps in Australia. High quality raw material and safety testing systems ensure a safe and reliable product.

No manufacturing delays, all ramps listed online are in stock at our warehouse in Mordialloc, Victoria.

We can also supply Custom built ramps - made to your specifications for your particular needs.

As part of the project, a network of field trials in representative soils and cropping systems will be established across the nation, where commercially available EEF technologies will be put to the test alongside conventional nitrogen fertilisers.

The EEF technologies will include urease inhibitors (to reduce ammonia loss), nitrification inhibitors (to reduce nitrous oxide, nitrogen and leaching loss), dual (urease and nitrification) inhibitors and controlled release fertilisers (both target-

EEFs trialled will target key nitrogen loss mechanisms (denitrification, nitrate leaching, volatilisation) in different cropping regions and measure crop nitrogen uptake to determine nitrogen use efficiency and return on investment. This will be achieved using nitrogen-15 stable isotope labelled fertilisers, allowing the fate of fertilisers to be tracked in soils and plants.

GRDC sustainable cropping systems manager Cristina Martinez says EEFs have been raised across several GRDC National Grower Network forums, particularly in Western Australia, and were front-of-mind for many growers – given increasing sus-

“Enhanced efficiency fertilisers are a potential option for reducing on-farm greenhouse gas (GHG) emissions while

A research project will examine the potential of enhanced efficiency fertilisers to improve nitrogen use efficiency. Image: Arjun Pandey/ University of Melbourne

tions,” communications minister Michelle Rowland says.

“We listened to stakeholder feedback from industry and after a successful first round we are expanding the eligibility, enabling more farmers across more agricultural sectors to take part.”

also improving nitrogen use efficiency,” Martinez says.

With current adoption of EEFs low among grain growers, Martinez says this is due to premium prices compared to standard fertiliser products, uncertainty about how they perform and return on investment.

The four-year research program aims to address these queries by demonstrating the effectiveness of these technologies and by providing growers with clear recommendations on what performs best, to maximise return on investment.

Project research partners include the University of Melbourne, Department of Primary Industries and Regional Development Western Australia, University of Queensland, New South Wales Department of Primary Industries, CSIRO, Queensland Department of Environment and Science, Queensland University of Technology, La Trobe University, Birchip Cropping Group and South Australia’s Hart Field Site Group.

Technologies that have been invested in are already assisting farmers to optimise soil quality and nutrient levels, monitor livestock, improve efficiency of water use and streamline farm logistics. The OFCP is also allowing farmers to invest in on-farm safety and safeguards for farming equipment, livestock and fuel supplies.

OFCP round one closed in May, with

Funding of the OFCP program has been boosted. Image: DiedovStock/ stock.adobe.com

more than $13 million provided in rebates to suppliers. Equipment funded through round one of the program included:

• Soil moisture probes

• A ntennas

• L iquid level monitors

• L ivestock monitoring systems

• Weather monitors

• B oosters and repeaters

• Radio transmitters

• C ameras

• Water flow and pressure monitors.

Australian company Food Recycle has developed technology that can turn commercial food waste into animal feed

Food Recycle has developed a food waste to animal feed technology, that it says could reduce the amount of waste ending up in landfill and reduce carbon emissions – while contributing to a circular economy.

Its technology efficiently processes food waste from a variety of sources such as restaurants, abattoirs, farms and processors – turning it into animal feed.

According to the Australian government’s Department of Climate Change, Energy, the Environment, and Water,

globally 30 per cent of all human food is wasted, but Food Recycle is taking action to change this statistic.

Food Recycle CEO Norm Boyle says each food waste stream is processed individually, analysed and stored separately as ingredients.

The nutritional and amino acid profile of each ingredient is then mixed together to make complete feeds, Boyle adds.

Telstra and Optus have delayed their 3G shutdown, giving Australian farmers and businesses more time to prepare

Previously set to turn off their 3G networks in late August, Telstra and Optus have now delayed their network switchovers to October 28, in a move that has given farmers and businesses more time to prepare.

Originally set to be switched off on June 30, Telstra and Optus faced backlash from farmers and others living in

According to the company, two tonnes of food waste can be converted into one tonne of complete feed suitable for poul-

Food Recycle CEO Norm Boyle (pictured) co-founded the company to tackle the global problem of food waste. Image: Food Recycle

try, pigs and aquaculture.

Food Recycle’s processing of food waste also eliminates most biosecurity risks, at no additional cost, the company says.

A series of trials conducted by the Commonwealth Scientific and Industrial Research Organisation (CSIRO), Western Sydney University and University of New England have tested the viability of Food Recycle’s technology.

“The trials show that the technology works, food waste is taken out of landfill and put back into the food chain, with our animal feed producing larger, healthier hens and eggs, and fish – for example,” Boyle says.

Food Recycle is now seeking to commercialise the technology in Australia and New Zealand through a crowd-fund platform.

aboutmomentsimages/stock.adobe.com

rural areas, with claims these groups were being left behind.

With limited mobile phone reception in rural areas, NSW Farmers rural affairs committee chair Deb Charlton says farmers and others rely on 3G networks to communicate, especially in emergency situations.

She adds that one of the problems that rural and regional farmers are having is trying to identify everything on their farm that is still operating through the 3G network –including machinery.

“There are still a lot of things operating under this network that will be effected by the shutdown, including water monitoring systems, fuel systems and remote diagnostics in tractors,” she says.

D ue to this, she had been pushing the telecommunication companies to delay the network switch off until everything using the network was identified.

Much to her delight, this is now the second time the network shutdown has been delayed, firstly delayed from June 30 to August 31, and now to October 28.

National Farmers’ Federation (NFF) president David Jochinke says while farmers now have longer to prepare, it’s important that they don’t leave it to the last minute.

“This is not the time to take a ‘she’ll be right’ attitude,” he says

“I urge people to check their devices urgently and make sure they are compatible w ith the 4G and 5G networks.”

Beyond mobile phones, the NFF urges rural Australians to think about what other technologies might be using the 3G network.

This includes ag tech such as livestock and dog trackers, weather stations, soil moisture probes, yield monitors and variable rate technology.

If you don’t know whether your device runs on the 3G network, you must contact the manufacturer to find out,” Jochinke says.

Both telecommunications companies have now also committed to undertaking a national public media campaign, ensuring Australians are informed of the impacts for some handsets.

The public media campaign is expected to reach more than 90 per cent of Australians and will emphasise the impact on both t raditional handsets and other devices that rely on the 3G network, such as personal medical alarms, emergency lift phones and fire alarms.

After a series of on-farm collapses, the Grains Research and Development Corporation is urging growers to assess the safety of their silos

Grains Research and Development Corporation (GRDC) grain storage extension team specialist Chris Warrick is calling on growers across the nation to assess and either maintain or decommission their older silos.

Recent on-farm incidents, including the collapse of silos in southern Australia, has proven to be a reminder of the dangers of silos that haven’t been maintained.

While silos can last more than 30 years if taken care of properly, Warrick says growers should check, assess and recognise when they’re no longer fit for purpose or when its structure has been compromised.

“The potential risks to family members or farm staff if a silo fails is very serious, there are also implications for grain or other losses, so this is an issue that growers need to pay attention to,” he says.

If silos are not structurally sound, Warrick recommends seeking an alternative storage option, making repairs or decommissioning it to prevent further damage, i njury or silo failure.

“Storing pulses and fertilisers can be higher risk than cereal grains, with higher bulk density and different flow characteristics

placing greater loads on silos,” Warrick says.

“This can cause them to fail if structural weak points are apparent in either the design, materials, corrosion, damage or modifications undertaken.”

He adds that these commodities require stronger wall sheets and/or wall supports, as well as stronger cone bases than for central grains. Known contributors to silos failing under load include cracked concrete bases, unlevel bases, damaged silo legs or wall sheets and corroded rivets or bolts.

Warrick says a checklist for growers assessing silo integrity should include:

• I s the foundation the silo is sitting on stable?

• A re the support legs and base rings free of damage and rust and in sound condition?

• A re the wall sheets free of damage and rust?

• A re all fixings (rivets and bolts) in sound condition?

• I s the ladder structure (if applicable) in sound condition for safe use?

• D oes cleaning and operating the silo pose a safety risk?

Agriculture Victoria and New Zealand-based company Halter have partnered to trial the use of virtual fencing technology

Virtual fencing is a step closer to reality for Victorian farmers, after Agriculture Victoria and Halter partnered to trial virtual fencing technology at the state government’s smart farm in Ellinbank.

Victorian Farmers Federation (VFF) welcomed the partnership, with president Emma Germano saying it is a step in the right direction in making the technology more accessible.

“This year the VFF has been engaged in direct discussions with the minister for agriculture to progress the use of virtual fencing technology on Victorian farms,” she says.

GRDC grower relations manager – north, Graeme Sandral also urged growers to take extra care when outloading fertilisers as they can absorb more moisture than stored grain.

“Growers should be aware that the northern and western sides of silos often have lower moisture, with higher moisture in the southern side of the silo,” Sandral says.

“This can present risks when outloading with the dry side generally emptying first, in the worst-case scenario this can lead to silo collapse.”

In addition to structural integrity, Warrick encourages growers to consider safe operation as part of the assessment.

“Whether it be for maintenance or monitoring grain, access to the top of silos is necessary, so safe access is a requirement,” he says.

“Many older silos have unsafe ladders, some silos have been purchased without

“The VFF has been encouraging the Victorian government to work on the regulations that will be required to enable its use commercially.”

Germano adds that virtual fencing would bring great benefits to Victoria, which has already been seen in other states and territories who already can use virtual fencing, i ncluding Queensland, Tasmania, Western Australia and the Northern Territory.

International markets such as New Zealand, the UK, Canada and the USA also already have the ability to use virtual fencing technology.

“Virtual fencing has a broad application across the livestock sectors but will also provide substantial benefit for our dairy industry,” Germano says.

“It will save farmers’ time, improve safety outcomes for farm workers, better manage pastures and improve environmental outcomes.

Advocating for this technology in Victoria, she says there is already scientific evidence that virtual fencing creates and supports animal welfare benefits.

A new plan has been launched to further safeguard the Australian grains industry from biosecurity outbreaks

The Australian Grains Industry Biosecurity Plan will give industry, governments and stakeholders an expert framework to help prevent, prepare for and respond to grains-specific biosecurity issues.

More than 1,300 different plant pests and disease threats have been identified in the plan, that was developed in collaboration with industry leaders and biosecurity experts.

These include Plant Health Australia (PHA), Grain Producers Australia (GPA), Grains Research and Development Corporation (GRDC), the Australian Government’s Department of Agriculture, GrainGrowers and state and territory governments.

The plan also details the specific programs and activities needed to take proactive measures and protect growers, industry and the economy from biosecurity threats.

GPA chair and WA grain producer Barry Large says the launch of the plan is a good news story for all Australian grain producers and the wider grains industry and economy – and the start of a longer journey, to increase biosecurity capacity and capability.

A new plan has been developed to protect the grains industry from biosecurity threats. Image: Phoebe/ stock.adobe.com

“This plan, however, will implement the projects and initiatives we need to fight back against these pests and diseases that pose a constant threat to our livelihoods.”

A series of threat summary tables were developed in the plan, identifying exotic pests known to affect grain crops overseas. These were assessed by their overall risk to the industry based on four criteria –entry, establishment, spread potential and economic impact.

The plan also includes details on current mitigation and surveillance activities being undertaken and identifies contingency plans, fact sheets and diagnostic protocols that have been developed for pests relevant to the grains industry.

More than 50 new and existing activities have been identified by PHA and GRDC as targeted investments to strengthen biosecurity efforts.

“Khapra Beetle is public enemy number one for our industry, with a potential $15 billion plus hit to the economy – and that’s just one of many grains-related biosecurity challenges we face,” he says.

16 organisations will receive grants to deliver projects that aim to improve livestock biosecurity in Victoria.

Image: Olga K/stock.adobe.com

$6.1 million has been invested into Victorian projects that help prevent, monitor and control diseases in varying industries

Victoria’s biosecurity system is set to be bolstered with a $6.1 million investment by the state government.

The investment will go towards projects that help prevent, monitor and control diseases in cattle, sheep, goat, swine and honeybee industries.

As part of this, 16 organisations will receive grants, allowing them to deliver 38 projects that provide solutions and

use emerging technologies to improve livestock biosecurity in Victoria.

“The Livestock Biosecurity Funds Grant Program helps industry meet emerging challenges at a time when biosecurity risks and threats are constant, and allows us to be more proactive as we protect our state from pests and diseases,” Victorian minister for agriculture Ros Spence says. By raising funds through duties on the

These include ramping up surveillance efforts and their coordination, expanding the Grains Farm Biosecurity Program to drive plan activities and increasing education, training and simulations to prepare industry for a potential biosecurity outbreak.

The plan will also be regularly reviewed and updated for any newly identified biosecurity issues .

sale of livestock and beekeeper registration fees, the Livestock Biosecurity Funds Grant Program will reinvest back into the sector to help meet emerging biosecurity challenges head-on.

Warragul-based Veterinary Support Services will receive $1.4 million to deliver a two-year Victorian Livestock Veterinary Scholarship program.

This will include supervision and training that provides early-career veterinarians with the skills, experience, networks and support to launch and sustain a livestock veterinary career in regional Victoria.

Western Plains Pork has been awarded $155,000 to run a pilot program to map contact between feral and domestic pigs to understand disease transmission risks.

This program will enhance participation and engagement from land managers – helping the industry prepare for and reduce the impact of diseases on the Victorian pig industry.

For a full list of the 2024 Livestock Biosecurity Funds Grant Program recipients as well as Livestock Compensation Advisory Committee members, visit agriculture.vic.gov.au/ livestockbiosecurityfunds.

The TRX is reversible, making it perfect for both front and rear mounted implements

“They have the benefit of reversibility, meaning that their steering and driving position can be changed, which renders them very good for a lot of implements that require a machine that’s concise in

“Orchards today are becoming more and more dense in terms of their plant, tree and vine density - land is very expensive and labour is very expensive.

“These tractors are made very small because their row densities in a lot of orchard situations are very tight, so that’s one of the pinnacles of why they work very well in very specialised orchard scenarioseven under igloo type or hothouse type conditions - they’re very strong and very versatile,” he says.

Antonio Carraro’s TRX 9900 is powered by an 89hp (66kW) four-cylinder Kubota engine and offers a 2,400kg lifting capacity.

This makes it one of the more powerful tractors in the manufacturer’s offering, but still comes with the choice of either a rollbar or fully-enclosed cabin while also

providing 16 forward and 16 reverse gears.

The TRX in its model name is an acronym, with the letters representing steering front axle (T), reversible console (R) and equal size wheels front and rear (X).

Bianco also praised the tractor’s strength in hillside conditions, with the TRX9900 able to handle up to 33 degrees of incline without overturning, and up to 38 degrees when stopped on an incline.

It is also fitted with the manufacturer’s patented Actio chassis, where the front and rear axles oscillate independently up to 15 degrees, which helps the tractor crawl over uneven ground and keeps it in constant 4WD.

To fully grasp the mutually beneficial relationship between Antonio Carraro tractors and the macadamia industry requires delving into the history of the latter, with Bianco and Tornado Pumps & Sprayers being key players.

“Trying to harvest macadamias back in those early days was very difficult,” Bianco says.

“It was all done by hand and there was no real machinery for harvesting, except for a hand rake, bags and a lot of labour.”

A company in the Lismore area saw the benefits of an American machine with small spikes on the wheels which was primarily used to collect golf balls from fairways, Bianco says, and converted this with reasonable success into a macadamia harvester that was paired with conventional tractors.

At the time, Bianco was in business with his uncle and regularly bought products for the macadamia industry from Paul

Blassuto, who is now his boss at Tornado.

Blassuto was bringing in Antonio Carraro tractors to Australia, which first exposed Bianco to their unique capabilities such as the reversible driving.

“It’s not the modern thing you see today, but it was obviously a step in the evolution of it,” Bianco says.

“Both my uncle and I saw what it was capable of. We both looked at one another and said ‘we’ve got to build a harvester for this’ because the tractor was reversible with its seat and steering position.

“That’s where it ended up evolving from. We had another man that made the harvester for us, we put it on the linkage and we turned the seat and steering around and we drove into the orchard.

“A year on, and all of a sudden we had a new concept that the industry was able to take advantage of.

“The first three or four machines were difficult to sell because it was a bit out of left field – nobody had seen them before and nobody knew what they were - but if you look at the numbers that are out there today, there are literally thousands of them out there that are doing this exact job.

“The TRX 9900 is the pinnacle of what is sold here because it’s a great package fitted with a macadamia harvester that’s also manufactured here in Lismore.”

Antonio Carraro is the only tractor brand sold by Tornado Pumps & Sprayers, given these clear benefits for the industries in which it specialises.

Bianco’s admiration of the Antonio Carraro product – including the TRX 9900 - comes from the considerable and

long-term benefits he has seen for the macadamia industry, but also from the experience of dealing with the family-owned manufacturer directly.

“They’re very family oriented, they’re very good people to get on with and the product is extremely well supported worldwide,” he says.

“This is this whole thing about the company - you are somebody to them. I know it sounds a bit far-fetched, but I’ve had the experience.

“I’ve been over to Italy quite a number of times and you’re like family over there when you go over.

“One year I went to the factory and the Australian flag was flying outside because I was there on that day.”

Tornado is also a manufacturer, primarily of sprayers for the macadamia and grape sectors.

Bianco says Tornado’s philosophy is to offer personalised and specific service to ensure their machinery will do exactly what is required – getting maximum benefit from both that machine and the Antonio Carraro tractor it is frequently paired with.

“We want every product to be right for them and we’ve always done that - I wouldn’t have it any other way,” he says.

Antonio Carraro’s full tractor range can be viewed at www.antoniocarraro.it/au

New Holland’s newest product, the CR11 combine harvester, has been praised by Intersales, the newest member of its national dealer network

New Holland has unveiled a big addition to its combine harvester lineup, adding new technologies and capacity thanks to a full ground-up rebuild.

The CR11 combine was debuted at Perth’s Convention and Exhibition Centre last month and it has already got eastern states dealership group Intersales excited.

The CR11 boasts a 15.9L engine producing 775hp (578kW) along with a 20,000L grain tank capacity.

New Holland’s CR10, which is a companion model coming to Australia later in the year, offers a 12.9L engine producing 635hp (473kW) and a 16,000L grain tank.

These twin-rotor combine harvesters are the result of extensive planning and testing by New Holland, promising to increase profitability for farmers by reducing the total harvesting costs.

Intersales general resource officer Jarrod

Stephenson attended the Perth launch and says the CR11 is an exciting machine which boasts significant benefits.

“One of the most impressive things about it is that it’s a full ground-up rebuild,” he says.

“It’s not just adding a couple of features to what’s currently in the CR10.90s and 9.90s - they’ve taken it back to the drawing board over the last 10 years and redesigned the cleaning area and bigger rotors, right the way through.

“Obviously there’s a few commonalities, but rather than just looking at a couple of improvements, it’s been restarted from scratch - looking at what works and what doesn’t and focusing on the good things.

“It’s an enormous machine and I don’t think anyone matches it for capacity and efficiencies out there on the market.”

New Holland’s latest combines have

been built at the company’s Centre of Excellence in Belgium and has undergone comprehensive validation testing in Australia.

The CR11 was also awarded the Gold Medal Innovation Award at Agritechnica in Germany last November, which was the first time the machine had been seen globally.

Its next step for the local market will be in-field demonstrations and limited production of new machines for the 2025 harvest.

Stephenson believes the trend towards larger machines such as the CR11, along with ongoing labour shortages in Australian agriculture, will make it popular with not only Intersales’ catchment area but across the nation.

With dealerships in Temora, Griffith, Wagga Wagga and Albury/Wodonga,

Intersales took on the sale of New Holland products earlier this year after acquiring Cadmac Machinery.

“Looking at the way the global market is going, we are adopting bigger and bigger machines,” he says.

“I think it’s certainly got a place for multiple unit farms or the bigger contractors.

“The west will definitely take it on in a big way and we will have some of our bigger guys over this way use it along with the corporates.

“The other thing is that good people are hard to come by in this day and age.

“If you could have two machines doing the job of three or four, or one machine doing the job of two, it cuts down on an extra driver.”

Close to zero grain loss, improved residue management and maximum uptime

provide greater capacity for the crop to circulate and the grain to be threshed and separated.

The CR11 provides a 210L per second unloading rate while the CR10 offers 159L/ second.

They both feature a revised and improved IntelliSense automation system, which will make automatic adjustments according to the chosen harvest strategy – whether it be limited loss, best grain quality, maximum capacity, or fixed throughput.

Another big development has been a totally new cleaning shoe.

The Twin-Clean cleaning shoe consists of two sieve systems in sequence, New Holland says, with each having its own upper and lower sieve and clean grain auger.

This cross-distribution mechanism

difference, it is this new cleaning shoe which will help users maximise the combine’s benefits.

“One of the things that New Holland has always been good for is that they don’t lose grain out the back of the machine,” he says.

“It’s all well and good to punch horsepower and pull more material through a machine, but if you haven’t got the cleaning area to get the capacity out of it and still keep the grain in the header then there’s no point.

“The new cleaning area design is where they’re getting the extra capacity from and this is an impressive feature.”

New Holland has also introduced a totally new residue management system to the CR combines.

The IntelliSpread feature uses twin radars which continuously measure, in-

A driveline which New Holland says is the cleanest in the market will significantly reduce downtime and maintenance, while the number of drive components have been reduced by 25 per cent and all drive chains have been completely eliminated.

All of this leads to a machine which aims to reduce the cost of harvesting and be a savvy long-term investment for Australian farmers and contractors.

“One of the big focuses for New Holland is that whatever they’ve done to this machine had to show that it was going to reduce the cost of harvest,” Stephenson says.

“Bigger machines cost more money, but at the end of the day, they need to be able to satisfy the farmers’ need to reduce their cost at harvest time.

“Whether that’s in efficiency with the ma chine, reducing grain loss down to next to nothing means you’re not wasting money out the back.

“New Holland has already got the header which holds the record for the highest ca pacity - and they’ve gone and redesigned and improved it. It’s pretty impressive.”

To find out more, visit Intersales online at www.intersales.com.au

Understand your greenhouse gas (GHG) emissions and consider production efficiency strategies to reduce emissions.

Get started today. Speak to a farm sustainability specialist.

To find out more, scan the QR code or visit NutrienAgSolutions.com.au/FarmEmissionsProfile

Able to be retrofitted, Sveaverken’s F100 Auto Steer System increases cost efficiency for farmers, by enabling automated driving of tractors

Accuracy is key in the world of precision farming, but it requires high attention to detail, otherwise human errors can be easily made.

To eliminate this issue, Swedish farming solutions company Sveaverken has recently introduced its F100 Auto Steer System into Australia, increasing cost efficiency for precision farmers.

Able to be installed onto existing tractors, the system essentially turns older t ractors into a self-driving machine that can follow accurate driving paths.

Powered by global navigation satellite system (GNSS) and real-time kinematics (RTK), the F100 system can achieve an accuracy of 2.5cm, even in low-light conditions – no matter what kind of path the farmer wants to follow.

It could be as simple as following a straight line, or making a U-turn, or more complex shapes and paths, the system allows a tractor to do it all by itself – with high accuracy and precision.

With this technology the possibilities are endless, it could be used to make

life easier when spraying or sowing, as well as automating the harrowing and harvesting processes.

Already well-established and popular in European markets, Sveaverken has identified Australia as a landscape where the F100 could thrive.

“With rising economic pressures and increasing labour shortages, we believe there’s a huge need for more efficient automated agriculture systems,” Sveaverken vice president of global operations Felix Tian says.

“Our auto-steer system can increase the efficiency and lower the cost for farmers all around the country.”

There are already some farmers in Victoria and New South Wales that have adopted the F100 technology and have been thrilled with the benefits, Tian adds.

Some of the benefits which Tian says farmers have seen include savings of fuel, fertiliser and inputs such as seeds.

“This is because paths are pre-planned

and optimised, so any potential for human error is eliminated,” he says.

Without the potential of mistakes, it can help reduce farmer fatigue as they don’t have to concentrate as hard on the task at hand. This can then help to increase the wellbeing of Aussie farmers and make their lives easier when doing demanding work.

Without the use of the F100 Auto-Steer System, farmers must be highly focused in precision applications, but this technology allows them to sit back, relax and watch the technology do what it does best – achieving accurate paths.

In Europe, happy customers have said the technology has also helped them to improve their yields, while reducing the costs associated with precision farming, according to Sveaverken.

Sveaverken’s F100 includes automatic terrain compensation that can adjust for slopes and bumps, ensuring lines stay precise – no matter the field conditions.

The system is ISOBUS compatible, with Tian saying that the technology not only controls a tractor, but also can communicate and control with other implements or equipment that are connected to the tractor.

This two-way communication eliminates the need for separate screens controlling different systems, and puts all valuable information in one place –known as the universal terminal.

“All the implements come to one screen, where you can see the data, progress and control everything,” Tian says.

“ We’re very excited about the progress of this feature, we believe it’s very important and valuable to Australian farmers.”

Various kinds of guidance line templates are included as part of the F100 system, giving customers more options to suit their needs. From straight lines to curved ones, and different U-turns, the F100 can follows the path – regardless of the shape of a farm.

An optional field management platform can also be included, which helps manage tasks, monitor progress and collect valuable data.

Tian says he’s proud of the job that Sveaverken has done in making the F100 readily available to customers.

Helping more farmers get access to this kind of technology at an affordable price, he believes that a lot of other similar

Sveaverken’s farm management system monitors progress and collects data

technologies are only available for those farmers that are willing to spend big.

“A lot of these precision navigation technologies are quite expensive, and it makes it difficult for the majority of farmers to gain access to them,” Tian says.

We think we’ve done a pretty good job at helping more farmers adopt this

technology at a reasonable price.”

For those farmers open to new technologies and automation, the F100 is a match made in heaven, with Tian saying it can reduce the need for new machinery.

“Some farmers may be looking to buy a new sophisticated tractor that comes with auto-steering functions, but the

Farmers in Victoria and New South Wales are already using the F100

F100 reduces the need for a new machine, because it can be installed onto an existing tractor,” he says.

“The F100 serves as an upgrade on their tractor, to make it drive automatically.”

With farmers in Victoria and New South Wales already reaping the benefits of the F100 Auto Steer System, Tian expects many more across the nation to adopt this technology to make life easier for themselves.

“Imagine you’re sitting in a tractor and you don’t have to be fully focused on if it’s driving on a straight line, if you’re making too much overlap, if you missed a spot or if there’s too much gap,” he says.

“With the F100 Auto Steer System, it gets rid of all your accuracy worries.”

For more information on Sveaverken’s F100 Auto Steer System, head to www.sveaverken.com

As farmers look to get machinery out of the shed ahead of spring, BYPY Transmissions has the know-how to keep it running smoothly

BYPY Transmissions wants to get farmers out of the “she’ll be right” attitude when it comes to parts servicing.

Before farmers start to bring machinery out for a new season, BYPY says it is important that gearboxes, shafts and clutches are given adequate attention to ensure these oft-forgotten but crucial parts are functioning at their best.

“For a lot of farmers, as soon as they get their slasher out for the first time in spring every year, they just literally drag them out, put them behind the tractor, turn it on and hope for the best,” BYPY’s Ashley Male says.

“That’s not the way it should be done, so farmers need to think about this.

“With a lot of clutches on agricultural equipment, if they’re left out in the open, even during winter, they can actually rust up and basically form a solid connection instead of being a clutch.

“When farmers then expect that clutch to go off with an overload situation, it doesn’t. It can then break the machine and be a lot more costly in the long run.”

This year is shaping up as a particularly important one, Male believes, as the wider economic climate and tightening of belts will lead to more farmers looking to get additional use out of older equipment.

He says BYPY Transmissions is already seeing evidence of this occurring, making the need to adequately prepare this older machinery even more important.

“The economic environment is making people get some older equipment out of the shed and trying to get it up and service able again, and we’re seeing a little bit more of that already,” he says.

“I think this year is going to highlight this, due to the reduction of the instant tax write offs along with obviously the economic environment.

“Some of the shafts in this machinery may have sat for several years. Farmers will get the machine serviced, and they should service the shaft as well to make sure that’s operable rather than just pull it out of the shed and hope for the best.

“We can provide the services around doing that.”

While specialising in Bondioli & Pavesi products, BYPY can also test other clutches.

Image: BYPY Transmissions

One of the many services which BYPY can offer comes through the state-of-theart clutch tester in which it has invested.

Imported from Europe, Male says BYPY invested around $30,000 to purchase the clutch tester and believes it is one of very few such testers in Australia.

Available at a “realistic charge” to customers, it enables BYPY to test and repair most clutches regardless of brand, giving customers a printed report on their clutch’s performance ahead of it being used.

BYPY is based in the Melbourne suburb of Dandenong and welcomes customers from around the country sending their clutches to be assessed, tested and repaired if required.

“Safety is probably the primary concern with any of this equipment because it is so dangerous, and we don’t want people getting hurt using older equipment that is not up to the safety standards,” Male says.

“It also gives farmers the knowledge that it will work as it should when they’re going to start using it for the season.”

Safety covers are another area in which BYPY Transmissions is well versed, giving

farmers further confidence they are dealing with a company that can meet all their needs.

BYPY’s specialty is Bondioli & Pavesi, a brand used by many of the world’s leading agricultural machinery manufacturers and for which it is the Australian distributor.

The Italian-made Bondioli & Pavesi product is backed by over 70 years of history and is increasing in popularity in the likes of New Holland, Case IH and Kuhn machinery, Male says.

While quality European manufacturing makes Bondioli & Pavesi shafts well suited to Australian needs, Male says customers can come to BYPY for support regardless of their existing shaft brand.

“Not only do we have complete brandnew shafts, we do have the full range of spare parts to repair their existing Bondioli & Pavesi shafts and access to the market to get the parts to repair their shafts in general, regardless of the brand,” he says.

A fleet of Bobcat telehandlers is ensuring a Queensland poultry company can get the job done every single time

There can be no greater endorsement of a machinery manufacturer than a realworld user staking his job on being able to use that brand exclusively.

For Woodlands Enterprises clean out manager Mick O’Keeffe, the fleet of Bobcat TL30.60 telehandlers which he oversees has proven such a winner that he simply would not consider doing the job without them.

“Put it this way – if the big boss said to me tomorrow ‘that’s it, we’re not buying any more Bobcats, we’re going to another brand’, I’d say ‘well I’m not the manager any more’,” O’Keeffe says.

“I wouldn’t do it and I can’t do it. It’s impossible. I mean every word of it.”

It is a huge call to make, but one which is based on several years of experience using Bobcat telehandlers, along with having previously test driven other brands for comparison.

Woodlands Enterprises is a major poultry producer based at Beerwah on Queensland’s Sunshine Coast.

Daily life is a constant cycle of turning over chicken sheds for their next use, with O’Keeffe in charge of making sure the sheds are cleaned properly and sanitised, ready for the next lot of baby chickens to go in.

“We turn over probably 170 chicken sheds every couple of months with broilers, then we’ve also got our breeders and our layers as well,” he says.

“I’ll push out 15,000 cubic metres of manure every month - it’s a non-stop event, and I’ve got two full time crews running.”

These crews are operating a fleet of six Bobcat TL30.60 telehandlers, the first of which was purchased about five or six years ago, and which have excelled despite the constant work in tough conditions they are subjected to.

Given this, it is little surprise what O’Keeffe cites as the most important feature.

“Comfort is one of the big things, but I think the biggest thing I praise them for is the reliability. That’s a big factor for us,” he says.

“If I have a machine down for two or three days, that’s a big no-no because we are on a time schedule.

“I’ll get to a farm and it might have 10 sheds. I get a placement date saying the chickens are coming on the following Wednesday, so I’ve got until that Wednesday to get everything cleaned.

“We just can’t afford breakdowns because we’ve got chickens coming and we can’t stop that.”

The trusted telehandler for Woodlands - the Bobcat R-Series TL30.60 - offers a 3,000kg rated lift capacity, 5.8m lift height and 3.1m maximum reach.

Powered by a 100 horsepower (74kW) engine, it offers 90L/minute of auxiliary standard flow, while the unit itself weighs in at 5,300kg and measures 4.5m long, 2.1m wide and 2.14m high.

Like many machines, it has had subtle upgrades with each new year to add extra convenient features – many of which are making a difference for the Woodlands team.

Bobcat introduced the R-Series in 2021, with standout features including a five-inch LCD display, all-in-one joystick with improved ergonomics, plus intuitive automotive-style controls.

Another upgrade cited by the manufacturer when the R-Series was launched was a new engine hood with steeper profile, which along with the new dashboard design reduced blind spots and increased overall visibility.

O’Keeffe says this increased visibility has made a difference for Woodlands, also mentioning a change to the positioning of the windscreen wipers, which has removed a small gap in its coverage.

Two other changes also show Bobcat’s desire to innovate and meet real-world customer needs, O’Keeffe believes.

The first of these is reducing the time before the reverse fan kicks in from 30 minutes to 15.

“This is handy if you’re really in a dusty environment that it can come on,” he says.

“I’ve never had an issue with overheating, but they can obviously because they’re in a dusty shed.

“If the radiator is getting clogged up, you’ve got to hit that reverse fan so you

clear everything and the machine can breathe, so that was a good thing that they changed that to 15 minutes.

“There’s also an override button, for instance, which they’ve moved and is a lot easier to get at if you do need it, which we very rarely do.

“Bobcat have certainly been thinking about them, put it that way. They are a good machine.”

Using telehandlers in the poultry industry creates a different set of circumstances and challenges compared to more ‘standard’ uses, such as broadacre farming, he says.

The first of these comes via the additional dust created in chicken sheds, which O’Keeffe mentioned in the context of its reverse fan, but he also praises the Bobcat’s reliability in terms of its air-conditioning in this environment.

“A chicken shed will be very dusty once the brooms start working, but the aircon just holds up,” he says.

“We do change the filters every 500 hours, but it holds up and it keeps cold.

“With every other brand I’ve tried, you get to 500 hours and the aircon is no good so you’ve got it in the workshop for three days trying to fix it, because you can’t

have no aircon in a chicken shed.”

Telehandlers, by definition, are designed to reach heights which other machines cannot – however their use in a poultry setting means they must do so while being low-profile and nimble enough to work comfortably in tight spaces and under a chicken shed roof.

Once again, Bobcat passes this test with flying colours for O’Keeffe and the Woodlands team, thanks in part to the flexibility of using different sized wheels for specific needs in their fleet.

“I’ve got a couple with 20-inch wheels on, which I use for the broiler farms, and

we’ve put 17-inch wheels on the other ones, which we can get under nesting boxes and all that sort of thing,” O’Keeffe says.

“They’re not too high and they fit in the shed perfectly, and also you need something that’s going to also reach into a truck.

“My main truck we use is 4.2m high, so you’ve got to get that telescopic boom up over top of it as well and they fit that bill perfectly.”

Bobcat telehandlers are distributed nationally by Bobcat Australia, which is a division of Clark Equipment.

O’Keeffe’s nearest branch is Clark Equipment Sunshine Coast, based at Kunda Park.

He is full of praise for the entire team’s service, particularly the branch’s service coordinator.

“I can ring Amanda up and she’ll juggle things - she will either be there that afternoon or the next morning first up,” he says.

“I can’t fault them.”

The full Bobcat range can be viewed at www.bobcatofaustralia.com.au

WA co-operative grain exporter CBH is providing growers with an online software to map their crop and hectares planted – enabling accurate harvest plans

Said to be Australia’s largest co-operative and grain exporter, CBH is owned by 3,500 Western Australian (WA) grain growing businesses.

As a leading agribusiness, CBH operates the grain supply chain in WA on behalf of its members – from upcountry storage and handling, transport and logistics, port terminals, marketing and trading, shipping, fertiliser and grain processing.

Ahead of the upcoming harvest season, CBH has put the annual call out to growers to submit their hectares planned

for 2024/25 through an online software system.

Paddock Planner

Paddock Planner is an interactive online software package that allows growers to map their properties and enter what hectares and crop they have planted – down to a paddock-by-paddock level.

This enables CBH to better prepare and plan for harvest, while also aiding it in making more informed long-term network decisions.

Growers can access this software by logging into their account on CBH’s online transaction portal – LoadNet – which CBH chief operations officer Mick Daw says makes doing business with the company easier.

“It is important that growers tell us what they have planted so we can plan accordingly and to enable the network to operate as efficiently as possible,” he says.

“Growers can adjust their hectares at any time in Paddock Planner as the season progresses, and it’s helpful for us if they

start letting us know early what they have planted.”

In previous years, Daw says some sites experienced grain delivery amounts that were more than what had been submitted – which had the potential to result in short falls and to impact services to growers at those sites.

By submitting hectares and crops planted into the software, Daw says the in formation provides CBH with a better level of accuracy and validation that facilitates its long-term investment in storage.

Daw says the role Paddock Planner played in identifying the need to build 95,000 tonnes of additional permanent storage at CBH’s Munglinup site in the Espe rance Zone is the perfect example of this.

“This investment will cater for a growing crop size, broaden the site’s service offer ing for growers and enhance supply chain agility within the Esperance Zone,” Daw says.

The online software also identified CBH’s Shark Lake receival site in the Esperance Zone as a precinct that needed to increase its permanent storage capacity.

“The information helped us identify where grain deliveries were coming from and gave us the confidence to expand the site with 157,000 tonnes of permanent storage to accommodate the needs of growers in the area,” Daw says.

Increased up-take

Now in its eighth year of using Paddock Planner, Daw says CBH is seeing a con tinued increase in the use of the online software.

Newdegate grower Rochell Walker has been using the software since 2019 and has seen value in the program both on farm and for CBH.

“We’ve been using Paddock Planner for a several years now and the process is really quick and simple,” she says.

“You just enter the commodity, variety and start creating your paddocks – the preloaded data helps make the process even quicker.”

Emphasising how easy the tool is to use, Walker says she has used it to help CBH plan for her deliveries this season.

“It really helps to inform segregation decisions based on our real information,” she says.

Whilst helping both growers and CBH accurately plan for harvest, Daw says Pad dock Planner is also playing a key role for

CBH in achieving its ‘Path to 2033’ strategy target of exporting a peak of three million tonnes per month by 2033.

Daw reinforces that the Paddock Planner software is straightforward to use and says that growers can adjust their hectares planted as the season progresses.

“Knowing what growers have planted is critical for CBH to offer the services and segregations they need locally on site.”

Growers who need help submitting their hectares planted can call the CBH Grower Service Centre on 1800 199 083 or their area manager.

The data entered provides CBH with a better level of accuracy that facilitates investment in storage

tronics, engine control unit (ECU) and sensors clusters, Ragenovich says mechanical lever controls make it much easier for farmers to operate and maintain.

“The functions of the grader range are simplistic, so any farmer can operate it without the complicated electronics seen

Most of BMES’ grader customers own rural and heavily isolated farms, Ragenovich says, so if breakdowns ever occur these farmers need to be able to work on

Ragenovich says the Hercules range is well-suited to these farmers, being easy to maintain and able to be worked on without any of the training that may be required for other graders.

“The Hercules range are built for the Australian outback and isolated farms, so in the unfortunate event of a breakdown, maintenance can be done easily,” he says.

Having the ability to perform maintenance by themselves, Hercules grader customers can reduce the costs of calling

One of the optional attachments available are 360-degree bush guards

out external parties, such as mechanics, air conditioning specialists and hydraulic fitters.

Easy and quick maintenance also makes for reduced downtime and increased on-farm productivity, so farmers never waste a second with their Hercules machines.

“These graders don’t rely on ECU sensors, so they’re straightforward and easy to maintain without needing special software to repair them,” Ragenovich says.

“If there’s ever a breakdown, you don’t need a program or a computer to plug into the ECU to see what’s wrong.”

To complement the ease-of-maintenance that the Hercules machines provide, BMES and Hercules provide a ‘one stop shop’ for parts, attachments and servicing.

With dedicated staff, BMES and Hercules have everything on-hand for farmers needing to maintain their machinery.

All Hercules grader models come with a host of optional factory attachments. One example of this is a hydraulic front blade, that can tilt left to right in addition to the

up and down motion that the standard blades provide.

Optional scarifiers and three-tyne or five-tyne hydraulic rear rippers are also offered as heavy-duty attachments, easily capable of loosening and breaking up hardened soil.

For farmers wanting extra safety features, 360-degree bush guards are also offered, providing enhanced protection inside the cabin.

With increased popularity in the Hercules graders, it seems that the success of the Hercules loader range in Australia has contributed to further diversification – a new dozer range.

“Hercules machinery will be bringing two new dozer models to Australia pretty soon,” Ragenovich says.

“The Hercules brand has been a success story throughout Australia, starting off with its loaders, it’s now been successful with its graders, and we hope the same can be said for the dozers.”

For more information on the Hercules grader range available from BMES, visit www.brisbaneminiexcavators.com.au or call (07) 3807 4333.

Jetland Loading Ramps aims to provide easy access to a variety of products suitable to all agricultural needs

Agriculture can be complex, but Jetland Loading Ramps aims to make one part of the job easy.

Firstly, by offering a huge variety of ramps, farmers can shop with confidence knowing that something will be available to suit their individual needs.

Next, Jetland offers free delivery around Australia to any commercial address with loading facilities, while the company also has access to a network of depots where its products can be delivered.

For those within the vicinity of Melbourne, free pickup can also be organised from Jetland’s warehouse in the south-eastern suburb of Mordialloc – meaning a customer could be using their new ramp on the same day as it is purchased.

Its ramps are designed to be strong and robust enough to handle the heavy ma-

chinery moved around Australian farms such as tractors and excavators, while simultaneously being lightweight enough to ensure they are portable.

As a result, Jetland’s ramps are increasingly appealing to Australian farmers –a long with more urban environments such as earthmoving contractors and plumbing businesses.

Its ramps can be divided into four different series – A, B, C and D - all of which are bu ilt to handle Australian conditions.

Jetland’s A Series ramps are suitable for rubber track machines and models are available with load capacities between 2 and 6 tonnes and in lengths between 2.5m and 4.5m.

The B Series is suitable for rubber track and rubber tyre machines. This is available in 2 to 6 tonne load capacities and 1.8m to 4.5m lengths.

Like the B Series, Jetland’s C Series is also suitable for both rubber track and rubber tyre machines but it offers an increased capability.

C Series ramps come with 4 to 21 tonne load capacities and 2.5m to 4.5m lengths.

Jetland’s heaviest duty offering, the D Series, is suitable for steel track, rubber pads on steel, rubber track and rubber tyre machines, and is available in 2.5m to 4.8m lengths.

These ramps are one of Jetland’s star attractions, having also recently been upgraded to support much heavier loads.

Designed by Japanese engineers, the D Series now supports up to 42 tonnes, where it was previously only rated up to 21 tonnes.

Jetland says this makes it the only 42-tonne rated loading ramp available in Australia and also highlights the company’s commitment to innovation.

While the nature of a customer’s machinery - such as its track or tyre style, overall weight and length - will largely determine which ramp is best suited, Jetland says there are also other factors to look at when making a decision.

The company says it is important for customers to consider the machine wheelbase when evaluating their ramp loading capacity.

Jetland also advises that a customer should choose a ramp with an internal width that is at least 5cm wider than the wheels or tracks of the loaded machinery.

Regardless of which path a customer ultimately goes down, they can be assured t hat high-quality aluminium in the ramps and various safety features have created a product which will meet their needs.

The Jetland team has ensured its ramps not only meet but exceed safety standards, firstly being fitted with safety pins to g uarantee the ramp remains securely in place during use.

The ramps also feature anti-slip surfaces, helping to provide maximum traction for vehicles and machinery during both loading and unloading.

Other features available across various Jetland models include a non-skid surface, flat rungs for smooth loading and heavy-duty raised tread on flat rungs.

All Jetland ramps are also backed up by a 12-month warranty, giving users additional peace of mind in their purchase.

For a company that provides ramps for everything from ATVs through to 42-tonne machinery beasts, along with other items such as walk ramps, the choice can be overwhelming.

The choice of four different series, plus a host of models and sizes in each, means that Jetland’s expertise can be invaluable in helping farmers decide exactly what they need.

In addition to providing excellent customer support, Jetland’s website is also a significant resource.

Rather than just providing a generic catalogue, it is continually updated to reflect t he stock which is physically available in its Melbourne warehouse.

This means that customers can browse and purchase with confidence, knowing what they see is what they can immediately get – rather than finding the perfect ramp before ending back at square one due to it being unavailable.

The company’s full range, along with delivery options, can be viewed online at www.jetlandramps.com.au, while its warehouse is located at the rear of 211219 Boundary Road, Mordialloc.

Using government and industry approved models, Nutrien Ag Solutions’ Farm Emissions Profile helps farmers understand the source of their emissions

When sugarcane farmer Christian Lago wanted to measure his on-farm greenhouse gas (GHG) emissions, he turned to his Nutrien advisers.

With increasing pressures to reduce these on-farm emissions in response to the COP21 Paris Agreement and Australia’s national target of net zero by 2050, farming businesses like Lago’s may need to understand their own GHG footprint sooner rather than later.

According to Nutrien Ag Solutions, Australia’s agricultural industry accounts for approximately 14 per cent of the nation’s total GHG emissions.

While online calculators offer insights into this information, Nutrien Ag Solutions sustainability field manager for Queensland and New South Wales, Charles Starkings, says accuracy and consistency are important.

“The quality of the output of digital tools is dependent on the data input, every farm is unique and many tools don’t offer the flexibility that is required to perform these complex calculations - this can lead to a

misleading output,” Starkings says.

Instead of farmers doing complicated calculations on their own, Nutrien Ag Solutions offers a solution, combining the knowledge of Nutrien’s local farm advisors and its team of sustainable farming specialists, with its Farm Emissions Profile.

It uses government and industry approved models to help farmers understand the source of their emissions and put that data into a context that is more understandable.

Lago worked with Starkings to develop a Farm Emissions Profile for his sugarcane operation, based in far North Queensland.

The third-generation farmer says the insights have helped inform his priorities for future emissions reduction activities.

The report showed that most of his emissions were due to the application of nitrogen fertilisers, then highlighted techniques for reducing these nitrogen losses.

“We wanted to get an understanding of how our farming carbon footprint is calcu-

lated, and what the major contributors are in our system,” Lago says.