Now imported by MJM Equipment, it was a chance encounter overseas that led to Balzer chaser bins first bolstering one broadacre farmer’s operations >> Page 10

Now imported by MJM Equipment, it was a chance encounter overseas that led to Balzer chaser bins first bolstering one broadacre farmer’s operations >> Page 10

PLUS, THE MAXAM AGRIXTRA RANGE DELIVERS MINIMAL SOIL COMPACTION, A COMFORTABLE RIDE AND IMPROVED TRACTION WHICH SURPASSES ALL AGRICULTURAL TYRE EXPECTATIONS. WHEN PACKAGED WITH ONE OF THE BEST WARRANTIES IN THE INDUSTRY, THE AGRIXTRA DELIVERS THE PERFORMANCE YOUR FARM DESERVES!

19 Farmers have their say in National Priorities Survey

20 Study measuring crop residue emissions

20 Charles Sturt Uni hub to enhance biosecurity defence

23 National Ag customer benefiting from Merlo addition

27 Michael’s Group offering Bernard van Lengerich mixer wagons

31 Automatic Electric Cartridge Pump helping JSG Industrial Systems customers

35 New Dieci national sales manager praises Poultry Pro

38 Baler shaft maintenance crucial, BYPY Transmission says

41 Shandong Lingong wheel loaders a winner for CJD Equipment

44 Farmers just one group enjoying Jetland Loading Ramps

50 Dixie Holdings thrives on Kais Hire’s challenge

60 Machinery highlights from AgQuip 2024

54 Tractor sales slipped again in August, TMA’s Gary Northover says, but balers and one tractor category increased

56 WAFarmers

CEO Trevor Whittington says mining companies should stop planting trees to ease corporate guilt at the expense of usable land

4 Editor’s note

58 Calendar of upcoming events

70 List your item for sale!

81

Australian welders are highly productive and ready to work, according to a new survey, but new technologies could help boost the industry, Weld Australia says.

the latest

As a farm machinery magazine, naturally our primary focus is on how the equipment we write about will perform – its specifications, upgrades on previous models, most i mportant features and how it will help farmers get the most out of their land.

Another important aspect which should never be overlooked though is the importance of relationships.

W hether it is between a customer and a dealer, a dealer and the manufacturer’s head office, or from farmer to farmer through word-of-mouth recommendations, these relationships influence purchasing decisions, and a positive or negative experience have significant bearing on what farmers do when they next need equipment.

We have highlighted several examples of these relatinonships in this edition.

The first is between Merlo Australia and National Ag – a New South Wales dealer which has been thriving since taking on the brand’s telehandlers.

Another is between Dixie Holdings and Kais Hire, where a word-of-mouth recommendation led to Kais seeking out Dixie –a nd multiple purchases have followed.

We also hear from Jetland Loading Ramps’ customers about how that company’s products have been a success, while a lso speaking to Dieci Australia’s new national sales manager Bob Mules about the i mportance of customer relationships.

That is not to say machinery itself has been neglected in this edition.

For starters, we have an extensive wrap of what was on display at this year’s AgQuip.

We have a feature on grain handling, just in time for when farmers start turning their attention to this topic.

In this, we highlight Collins Machining & Fabrication’s Power Wheel, while we also explore Balzer chaser bins – now distributed by MJM Equipment – by hearing from an early importer of these machines.

Keeping machinery in the best shape possible is always critical – and this edition has advice about baler PTO shaft maintenance from BYPY Transmissions, plus an extensive look at the Automatic Electric Cartridge P ump from JSG Industrial Systems.

We also look at Bernard van Lengerich mixer wagons which are available through Michael’s Group, highlight Sveaverken’s unique AI-powered RoboPusher Nimbo, and discuss the Shandong Lingong range of wheel loaders at CJD Equipment.

This is all complemented by the latest industry news, which includes the latest set of industry forecasts from ABARES along with an acquisition involving two companies which are regulars on the field day circuit, plus profiling some of agriculture’s future leaders who have received Nuffield Scholarships.

Lastly, we are again running our Contractor Showcase in 2024. More details will follow in our next edition, but please scan the QR code below to register your details

Kerfab’s bale forks are proudly designed and manufactured in Australia to withstand the harshest conditions, delivering exceptional durability, efficiency, and safety.

Trusted by professionals across Australia and New Zealand, Kerfab attachments provide the reliability and performance that top operations demand. Reach out to the Kerfab team or your machinery dealer today to experience the difference.

JETLAND is a leading supplier of high strength & heavy duty Aluminium loading ramps in Australia. High quality raw material and safety testing systems ensure a safe and reliable product.

No manufacturing delays, all ramps listed online are in stock at our warehouse in Mordialloc, Victoria.

We can also supply Custom built ramps - made to your specifications for your particular needs.

bearing on the health of rural communities more broadly,” Redcliffe says.

“The Future Drought Fund’s scholars will tackle the challenges drought poses

In addition to the opportunity to research overseas, each 2025 Nuffield Scholar will receive a $40,000 bursary to invest in travel and research.

Nuffield Australia says the scholars will visit, learn from and collaborate with some of the world’s leading agricultural businesses and research institutions.

Cailan Byrnes, from Tolga, Queensland, has been awarded a Nuffield Scholarship to study developing cost-effective beef grading systems with innovative technology to optimise eating quality.

Supported by Meat and Livestock Australia, Byrnes is the chief operating officer of his family’s processing operation,

More than 50 local producers supply to the abattoir, which has an average weekly throughput of 150 beef cattle and 100 pigs.

The family’s business, Byrnes Meats,

offers a paddock-to-plate service and has two butchering facilities in Cairns, supplying meat to butcher shops, hotels, restaurants and consumers from the Torres Strait to Townsville.

As the third generation to run a vertically integrated grazing and butcher enterprise, Byrnes understands the importance of beef grading to the bottom line.

“My passion and goals are to help the meat industry achieve cost-effective eating quality solutions and promote youth progression and education,” he says.

“Having transitioned from an electrician four years ago, my enthusiasm, commitment and drive have motivated me to absorb knowledge and build connections enhancing my expertise.”

His Nuffield scholarship will allow him to travel to countries with well-developed grading systems including the USA, Japan, Canada and countries in Europe.

As part of his travels, the aim is to establish a practical methodology that allows the u se of beef grading cameras to be implemented and certified within any abattoir.

Byrnes has also established groups that aim to build the skills of professionals in far north Queensland, including the NQ Grassfed Beef Group, RCA Carcass Competition, and Byrnes Meats training program.

Another scholar, Brisbane’s James Carter, received a Northern Pastoral scholarship to study how technology has the potential to drive profit for producers and processors in a collaborative approach.

Carter is passionate about the topic, having been the seventh generation of his family to work on the ‘Lake Edward’ cattle property near Crookwell, New South Wales.

He is now the assistant production manager at the Australian Agricultural Company, based in Brisbane, where he helps manage a team overseeing two service kills at JBS Beef City and Australian Country Choice.

His daily focuses revolve around coordinating livestock movements, maximising yield recovery, achieving customer specification, revenue maximisation and quality assurance, all while utilising as much of each carcass as possible.

“There is huge potential for the industry to drive higher profits through better

breeding decisions, and these can be enabled by technology,” he says.

Carter aims to study how the data and information that underpins these types of decisions can be communicated back to producers through a platform, which he says will allow an increase in profitability from paddock to plate to benefit each part of the supply chain.

This could also help the industry become more sustainable, he adds.

“We will be harvesting more usable red meat from each carcass through better muscle conformation, while maintaining eating quality,” he says.

“Through technologies like yield cameras we can build an understanding of what ‘good’ looks like, and we can share that information with a producer or feedlot and begin to make decisions to reach those better outcomes.

“We could even see genetic decisions made based on the predicted potential amount of saleable red meat from a carcass.”

Through using these technologies, Carter hopes they will be a catalyst for driving more automation and artificial

intelligence in processing facilities.

Nuffield Australia and the CSIRO has an established partnership that promotes understanding between Australian scientific research and the agriculture industry.

In 2025, Jonathan Richetti will be the eighth CSIRO scientist to participate in key components of the Nuffield program, including the awards dinner and national conference, the Contemporary Scholars Conference and the Global Focus Program GFP.

The full list of 2025 Nuffield Scholars is:

New South Wales: Jock Barnett, Campbell Chesworth, Nikki Gilder, Maggie Jarrett, Alice Jorgensen, Kate Lumber and Iain MacLennan.

Northern Territory: Kari Moffat, Trudi Oxley and Tarun Richards.

Queensland: Cailan Byrnes, James Carter, Krystal Caton and David Woods.

South Australia: Claire Catford, Lucy Dodd and Paul Evans.

Tasmania: Connor Wass and Tom Youl. Victoria: Joe Druce, Tom Polkinghorne, Hamish Robertson and Thanh Truong. Western Australia: Tyson Cattle.

web: www.antoniocarraro.it/au

($100) & 10x Signed Framed Tickford Racings Polos ($750). Prize Pool 2 prizes: 20x Weber Baby Q ($568), 20x Makita 18V brushless 2pc kit combo ($800), 10x Castrol Branded Bar Fridges ($1k), 10x

Now imported by MJM Equipment, it was a chance encounter overseas that led to Balzer chaser bins first bolstering one broadacre farmer’s operations

Australian agriculture is full of innovators, people willing to take a leap of faith on a new product.

And even a decade after that first experiment, when the trialled product is now entrenched in the local market, it should not be forgotten that somebody was the first to say ‘yes’ to trying something different.

In this case, the product is a Balzer chaser bin, imported to Australia by broadacre farmer Chris Dowling before the product even had a formal national distributor.

That Australian distribution role is now undertaken by MJM Equipment, which has overseen a growth in the Balzer’s popularity across the nation, but it was a trip to the United States which started Dowling’s connection to the product.

He visited the National Farm Machinery Show in Louisville, Kentucky almost 15 years ago and came across the 50-tonne Balzer chaser bin.

“It was just sitting there in the middle and it stole the show.,” Dowling says.

“I knew I needed one but I couldn’t justify one for a year or two but like all farmers do, we made it happen and brought one out.

“We’ve still got that bin and we haven’t

even worn the augers out. It’s been a great bin and we’ve bought quite a few since.”

Dowling’s base farm is near Yarrawonga in northern Victoria, however the land he farms alongside sons Tom and Sam stretches more than 400km north to Condobolin in central New South Wales.

It is undeniably a big farming operation and one which requires equipment that not only boasts high capacities, but also durability, reliability and convenience.

Since purchasing the original 50-tonne chaser bin – which is still going strong today – Dowling has expanded by purchasing two 72-tonne bins and a 78-tonne unit, the latter of which is the largest in the Field Floater 7 range imported by MJM Equipment.

Estimating that he has handled “hundreds of thousands of tonnes” of grain in his time owning the Balzer bins, there are several reasons why Dowling is an unabashed fan of the product.

“It’s all about efficiency, safety and getting your truck loaded right,” he says.

“You can have a road train pull in with a 72-tonne bin and six minutes or less later it can be leaving the paddock with 54 tonnes

in the right place and no rejections for being overweight at the other end.

“We’ve tried a lot of older bins and you thought a 30-tonne bin was good, which it was, but you couldn’t keep up. You couldn’t drag product any distance and you were always guessing your load weights.

“When the first Balzer came along we couldn’t believe the difference, especially when we had some wet harvests.”

Balzer offers plenty of features which makes its Field Floater 7 range of chaser bins desirable to customers.

It is available in various sizes - between 42 tonnes and 78 tonnes - with unloading speeds reaching up to 30 tonnes per minute.

Each model includes a 61cm (24-inch) diameter unloading auger system as a standard feature, which is complete with Balzer’s patented hydraulic engagement clutch system for the horizontal auger.

All chaser bins are equipped with independent running gear and a distinct axle arrangement that uses the patented Auto-Trail steerable axle system.

over 15 years of development and refinement,

Balzer says this leads to heavy loads feeling effortless, while facilitating superior manoeuvrability and reducing ground compaction.

The unloading auger spout offers ex ceptional precision by adjusting in every di rection.

The Field Floater 7’s various features can be conveniently operated from a central location using the joystick control, while the chaser bins also have a cutting-edge elec tronic scale system, ensuring precise data management and instant yield reporting.

This latter feature is what Dowling cited as one of the most advantageous for his farming operation.

Other standard features include steering axles, horizontal sweep auger clutch, inter nal access door and hydraulic suspension to distribute the ground pressure propor tionately.

Optional extras across the range include a three-way camera kit, hydraulic jack, hydraulic brakes, tyre upgrades and an Agrimatics Libra Cart for additional data collection and sharing.

Across the range, there is an overall machine length of 11.02m and bin length of 8.4m.

The travel height varies depending on the size of the tank – which sits at 55,000L for the smallest (42-tonne) unit up to an im pressive 100,000L on the largest (78-tonne) chaser bin.

Dowling’s leap of faith made him a trendset ter and he has observed other farmers are starting to catch on to the Balzer chaser bin’s benefits, particularly around weight accu racy, intuitive operation, maintaining soil structure and minimising flotation issues.

Another benefit of the Balzer chaser bins growing in popularity is the fact there is now an official Australian distributor – MJM Equipment – based in the Victorian town of Wilby, close to Dowling’s home farm in Yarrawonga.

While the Balzer bins have proven to

be a reliable machine with minimal issues, Dowling is full of praise for the service, parts access and back-up provided by MJM Equipment.

“It’s good that we have someone that’s importing them now, because we did it ourselves for a long time and probably didn’t keep enough parts because like anything you do need back-up and spares,” he says.

“I’ve got to take my hat off to the boys at MJM – they’ve stocked a fair bit of stuff which is not cheap and that makes a huge difference to how you can operate. That’s what makes it work.

“For people that were probably a bit gun-shy early, that makes all the difference because you’ve got to have parts and backup and you’ve got to have good pre-delivery which I reckon MJM are really doing.

“It’s a credit to them because the pre-delivery and assembly is 50 per cent of the battle.

“ I think it will keep going forward now we’ve got someone that can back us up with parts and service – it’s all systems go.”

As the headers get bigger, naturally the accompanying machinery must also get big-

ger – but Dowling realises that “everything g rows together, it’s just the natural progression” and has not experienced any bottlenecks in his daily operation.

Despite their growing size, there have also been no issues with transporting them around – or between – his properties.

“They might be a bit bulky to shift but not half as bad as an air seeder or anything like that,” he says.

“They’re actually pretty compact for what they do. It’s just so easy and you’re not running people back to a field bin to unload it and get it down enough so you can shift it.

“That’s just a real time saver. You pull into the next paddock and just start harvest –there’s no messing around.”

Since Dowling imported the first of his Balzer chaser bins after seeing them in their United States homeland, the range has naturally been upgraded over time as all machines are.

He believes these have made the chaser bins even more user friendly while withstanding the test of time.

“ I reckon they are very user friendly. These newer ones are just easy – they’re made for anyone,” he says.

“You’ve got a joystick that’s simple and you’ve got a couple of sets of hydraulics –you don’t have to worry about the steering axles, they make their own arrangements.

“They’re pretty bulletproof and the good thing is there’s not much in there that is hard to fix – it’s all pretty simple in there.

“They’re a pretty basic thing, but a basic thing that works.”

Reliability and efficiency are arguably the two biggest buzzwords in agriculture, with every farmer looking for machines which will meet these criteria.

Dowling’s endorsement of the Balzer chaser bins comes based on multiple units which have been worked hard over an extended period – arguably the most thorough test they could be put through.

“It’s definitely the cheapest way to ship grain out of the paddock for us,” he says.

“We wouldn’t be able to operate the way we do without them.

“We’ve never had anything that couldn’t be fixed and nothing that really stopped us – that’s the main thing

“It’s just been a great experience owning Balzers.”

Collins Machining & Fabrication’s ‘Power Wheel’ is making the grain handling process safer by eliminating the manual and dangerous task of moving an auger

Lugging an auger or grain mover around is often considered a painful and hazardous task due to the heavy nature of the machinery involved.

These machines can be moving on uneven surfaces, which presents a farmer with the difficult task of placing the machines in and under a silo.

Due to the heavy pushing and lifting that is required as part of this grain handling task, it can be a safety issue that can potentially lead to injury.

Collins Machining & Fabrication has identified this and found a solution.

Based in Corowa, on the New South Wales and Victoria border, the family-owned and operated engineering business has built a reputation with its customers as the ‘home of the Power Wheel’.

The Power Wheel is a self-propelled electric jockey wheel that takes the pain out of moving an auger or grain mover.

This simple yet effective solution streamlines this task with a press of a button.

“If you’re sick and tired of the back breaking and dangerous task of lugging your auger around the yard, this is the solution,” Collins Machining & Fabrication administration manager Lindsy Rhodes says.

“ There’s no manual lifting or pushing required with the Power Wheel.”

Manufactured by Collins, the aftermarket accessory is powered from the auger’s 1 2-volt battery and uses an electric motor with a chain drive to move the heavy grain handling equipment.

By pressing a button, the auger can move forward or in reverse, and a brake winch provides safe raising and lowering of the machine – making it easier to get under silos.

“Simply drive the auger into position and lower the break winch,” Rhodes says.

“It’s engineered for ease of use and it’s simple retracting design makes for easy towing.”

This also eliminates the manual lifting of hooking up an auger to a vehicle, Rhodes adds.

With a robust design, Rhodes says the Power Wheel is designed for Australian

conditions and is built to last.

It’s also highly versatile, as it can be retrofitted to any diameter of auger.

Further increasing farmer safety, the Power Wheel is fitted with a worm drive gearbox to prevent freewheeling.

With orders heading out the door every day, Rhodes says its Power Wheels are available all year round, with constant production to keep up with the demand.

It’s no surprise that some of the Power Wheel’s happy customers have come back to Collins saying things like ‘my back is thanking me every day’ and ‘you’d be silly to move an auger without one’.

“Our team of locals are renowned in the area and look forward to servicing your needs,” Rhodes says.

Collins Machining & Fabrication was born in 2023, when the Collins family purchased J Leahy & Co from its original founders.

To ensure the transition period was smooth and uninterrupted, the J Leahy & Co founders provided guidance, with some

of the Collins team even completing their fitting and welding apprenticeship with the help of the original founders.

Apart from the Power Wheel, Collins also offers a broad range of welding and fabrication services, with some of its recent work including everything from boat repairs and custom flooring, to semi-trailer divider inserts and repairs.

Its fully equipped workshop has the capacity to provide steel fabrication and machining, stainless steel welding, sheet metal work, mig and tig welding and industrial maintenance.

Our business is operated by local skilled fabricators who provide custom work tailored to our customers,” Rhodes says.

“Our priority is to work with our customers to create small or large scale projects t hat ensure customer satisfaction and quality results with every fabrication, welding a nd repair project

The Auger Power Jockey Wheel is available for pick up at Collins Machining & Fabrication, 33 Thiess Rd, Corowa, NSW or it can be shipped Australia-wide.

For more information on the Power Wheel, visit www. collinsmachiningfabrication.com.au or call 02 6033 0277.

ABARES’ agricultural outlook is tipping significant growth in production in the 2024-25 financial year, driven by higher livestock values and increased rainfall

The Australian Bureau of Agricultural and Resource Economics and Sciences (ABARES) has forecasted that the gross value of agricultural production will increase by

The predicted result, increasing from $82.5 billion in 2023-24 to $86.2 billion in 2024-25, would be the third highest output on record.

It is being driven by driven by higher livestock and livestock product values ($2.9 billion higher), as well as the rising gross value of crop production ($760 million higher).

Livestock prices are expected to rise in 2024–25, due to a strong global demand and constrained global supply.

With this anticipated spike in global demand, the gross value of production for livestock and livestock products is forecast to reach $37.6 billion in 2024–25.

Increased export prices for beef, lamb and mutton – combined with higher domestic processing capacity – is expected to increase competition between processors in saleyards, driving a strong recovery in livestock prices.

Beef and lamb saleyard prices are forecast to rise by 29 per cent and 24 per cent respectively.

Livestock production volumes are also tipped to rise with increased turn-off, driven by strong global demand and price recovery from the lows in 2023–24.

These factors are forecast to outweigh improved seasonal conditions and greater pasture availability, which ABARES says will incentivise some producers to rebuild herds and flocks, rather than sell them.

Beef and veal production volume is forecast to rise by 2 per cent in 2024–25, and sheep meat production volumes are expected to rise by 3 per cent.

In 2024–25, Australian winter crop production volumes are forecast to rise by 17 per

cent, due to increased rainfall driving higher areas planted and yields on average.

Timely rainfall in New South Wales, Queensland and Western Australia is expected to support wheat, barley, canola and pulse production volumes.

“Crop production across Australia has been driven by New South Wales and Queensland, and better than expected seasonal conditions in Western Australia,” ABARES executive director Jared Greenville says.

“We have seen more favourable seasonal conditions across large parts of the country, easing input prices and higher livestock prices supporting farm incomes.”

While this is the case, Greenville says he does not expect to see improvement across all regions in Australia.

“Unfavourable conditions in north and western Victoria and most of South Australia following below average winter rainfall have resulted in lower-than-expected crop production,” he says.

Because of this, soil moisture in large parts of South Australia and Victoria remains below average.

Although winter crop productions are expected to rise, domestic prices are set to fall for most crops – largely driven by lower global prices, due to higher global grain and oilseed production.

Canola, sugar and cotton values are all considered likely to follow this trend, expected to fall $860 million, $450 million and $390 million respectively.

Bucking this trend is the value of wheat, pulses and horticulture.

Wheat value is expected to increase by $950 million to reach $10.7 billion.

Favourable seasonal conditions in New South Wales and Queensland, and an improvement in Western Australia, are forecast to increase production volumes, more than offsetting a drop in prices.

Pulses and horticulture values are both forecast to reach record highs of $3.6 billion and $17.8 billion respectively.

The increase of $900 million in pulse

There has been more favourable seasonal conditions for crop production across Australia.

values is being driven by high international prices, which are expected to influence an increase in total area planted, particularly for chickpeas and lentils, leading to increased production volume.

Rising by $620 million, the predicted horticulture value is being reflected by higher production volumes – due to improved growing conditions, high water availability and easing input pressures.

The report is forecasting agricultural exports to fall by $3.1 billion to $68.5 billion in 2024-25, and $72.6 billion when including fisheries and forestry.

The forecast fall is mostly driven by reduced exportable supplies of grain and oilseeds following significant stock drawdowns in 2023–24.

This year has seen less carryover stocks of grain available for export in comparison to the past two record-breaking years.

Crop export values are expected to fall by $4.3 billion to $37.9 billion in 2024–25, due to declining global prices and lower export volumes.

Despite the fall, agricultural export values are still expected to be the third highest on record.

Australia’s red meat exports continue to be in demand in key markets, with Greenville saying that this category is performing well in the United States and Middle East.

Largely due to this, but also the contribution of increased domestic production, livestock and livestock product export values are expected to rise by $1.2 billion to $30.6 billion in 2024–25.

Red meat exports already increased significantly in 2023–24 and are now expected to reach a new record high in 2024–25.

It is expected that there will be record high values for beef and veal exports to the USA, sheep meat exports to Middle East and record high volumes of lamb exports to the USA.

The Victorian state government is aiming to increase the representation of women in agricultural leadership roles, through a leadership and mentoring program

Applications have opened for the Victorian Rural Women’s Network 2024 Leadership and Mentoring Program.

The program seeks to increase the representation of women in agricultural leadership roles by fostering their leadership capabilities, enhancing their skills and instilling confidence in decision making.

Twenty women will have the opportunity to participate in specialised mentorship and leadership training, learning from influential leaders across industry and government.

According to the state government, women have made up approximately a third of the agricultural workforce over the past decade and remain under-represented in leadership roles.

As part of the program, training will be tailored to the unique challenges and opportunities faced by women in agriculture, providing participants with the tools, support and visibility they need to be leaders in their industry and communities.

The program curriculum will cover

Image: AgriFutures

Indigenous affairs advocate Tanya Egerton has been named the national winner of the 2024 AgriFutures Rural Women’s Award

Tanya Egerton from Katherine, Northern Territory, was crowned as the national winner of the 2024 AgriFutures Rural Women’s Award, for her work in empowering the entrepreneurial aspirations of Aboriginal and Torres Strait Islander peoples across remote Australia.

Egerton is the founder and CEO of Circulanation, which helps to provide entrepreneurship education in the Northern Territory, and the Remote OpShop P roject, which supports the development of op-shops in Aboriginal communities.

In addition to the $15,000 Westpac

Twenty women will have the opportunity to participate in specialised mentorship and leadership training. Image: cherryandbees/stock.adobe.com

effective leadership and advocacy, government and private sector decision making, and setting career advancement goals.

Former program graduate Libbe Paton says the program encouraged her to be brave and know her value and strengths.

“Each session allowed us to enhance what we knew, gain new ideas and grow in a safe environment,” she says.

“If you’re considering an application, then you are already thinking about what you could learn and where the program could take your leadership - you should definitely apply.”

The state government says accommodation, childcare and travel costs will be covered in acknowledgement of the financial barriers that many women face which can prevent participation in leadership programs.

To learn more about the program or apply visit agriculture.vic.gov.au.

grant already awarded to the seven state and territory winners, Egerton will receive an additional $20,000 to further develop her projects.

“This is a significant honour, and I am deeply appreciative of AgriFutures and Westpac for their belief in my mission to empower Aboriginal and Torres Strait Islander peoples,” she says.

“This award is a game changer for us and will significantly enhance what we can achieve in the next 12 months.

“With the additional $20,000 Westpac grant, we can develop a First Nations Leadership Council and establish a robust governance framework for the Remote Opshop Project.

“Our goal is to ensure high-quality, affordable essential goods are redirected from landfills and redistributed to remote communities, fostering empowerment and self-determination.”

Victorian rural health campaigner, Grace Larson, was announced as the National runner-up of the Rural Women’s Award.

As a paediatric critical care nurse, Larson has been working to address the health disadvantages faced by rural children through The Sisterhood Project.

She will receive an additional $15,000 to further develop her project.

Applications for the 2025 AgriFutures Rural Women’s Award are now open and will close on October 9, 2024 (January 24, 2025 for NT Applicants).

McCormack Industries, affectionately known as ‘the front-end loader people’, has been acquired by Digga Australia

Digga Australia Group has announced that it has acquired McCormack Industries Pty Ltd.

McCormack Industries has been a cornerstone of Australian manufacturing since 1984, Digga says, manufacturing cotton handling equipment, agricultural and earthmoving attachments and the frontend loaders that lead to the company being known as “the front-end loader people”.

Located in Aubigny on the Queensland Darling Downs, McCormack Industries has grown from a small family-owned

More than 1,000 Australian farmers have had a say in the second National Farmer Priorities Survey, presenting mixed positivity levels

The second National Farmer Priorities Survey has found most farmers love the work that they do and are happy with the community that they live in, but are becoming increasingly concerned with key issues that face the industry.

Created by the National Farmers’ Federation (NFF) in partnership with Seftons, 1,026 Australian farmers responded to the survey, outlining what they consider are the biggest issues in the industry.

Two of the key positive findings were that 89 per cent agreed with the statement “I love what I do” and 78 per cent said their community is a great place to live.

These measures rose by 18 per cent and 10 per cent respectively compared to the previous survey, with NFF president David Jochinke pleased with the outcome.

“Despite a growing list of challenges, it’s positive to see this uptick in farmers being

on manufacturing quality and reliable agricultural and industrial attachments.

“We see this acquisition as a perfect fit for our business as an avid supporter of Australian manufacturing,” Digga Group CEO Zoe Conde says.

“McCormack Industries has built a strong brand in the agricultural and indus-

Aubigny factory with previous owner Brendan McCormack and his team staying on to continue growing the brand.

McCormack Industries and Digga Australia sales will operate independently from one another, ensuring that both brands remain running smoothly.

“We are excited to welcome Brendan and

“Farming is meaningful work where you get up each day knowing you are making sure people have food in their bellies and clothes on their back.”

Although farmers remain passionate about their industry, the survey found increased levels of concern across several issues compared to last year – up by an average of 8 per cent across all metrics.

Farmers were able to respond to 14 industry issues as ‘very concerned’, ‘concerned’ and ‘not concerned’.

Topping the list of concerns was protecting the nation’s biosecurity, with 94 per cent of farmers voicing this concern. This was also the largest swing in concern level compared to 2023 (12.7 per cent increase), and the largest percentage of respondents that were very concerned (64 per cent).

and processors (93.9 per cent), while federal environment laws ranked third (92.5 per cent) – both up more than 10 per cent on 2023.

Another key issue for farmers is the phase-out of live sheep exports, which saw the second largest rise in concern from last year (up 12.2 per cent) and saw 62.8 per cent of farmers respond as very concerned.

“Despite only 10 per cent of respondents hailing from Western Australia, the live sheep export ban rated as one of the highest areas of concern,” Jochinke says.

There has also been steep decline in farmers’ confidence in the federal government, with only one in 10 believing the government has a positive plan for the farming sector – a drop of nearly 38 per cent from 2023

A national study measuring greenhouse gas emissions from crop residues is set to help the grains industry accurately report its carbon footprint

An $8 million national study led by the Queensland University of Technology (QUT), will measure greenhouse gas emissions (GHG) from the decomposition of crop residue, with potential benefits for future market access and price.

QUT Professor David Rowlings, a soil scientist in the sustainable agriculture program at the university’s Centre for Agriculture and Bioeconomy, will lead the project - which will involve two years of fieldwork across a range of crop types, climates and soils.

Crops such as cereals, oilseeds and legumes will be tested at five sites across the country, including Gatton (Queensland),

that the study will have significant benefits for growers and marketers.

Crop residues emit GHG as they decompose in the paddock, Rowlings says, with n itrous oxide making up most of these emissions.

“Australia includes these emissions in its sector-level accounting to the Intergovernmental Panel on Climate Change (IPCC),” he says.

“While the global default emission decomposition factor is one per cent of total residues, international research has shown that 0.5 per cent may be more accurate for dry climates.”

However, with approximately 23 million hectares of land under cropping, Rowlings says growers can still benefit by being able to use accurate, locally derived emissions data for IPCC reporting.

At each trial site, nitrous oxide will be measured for the 12 months following harvest to gain accurate data on the emissions from the decaying crop residues.

Crops being studied include wheat, faba beans and canola in NSW and Victoria, sorghum, wheat and faba beans in Queensland, and wheat and canola in WA.

The research builds on earlier work done by GRDC in partnership with CSIRO for the Australian Grains Baseline and Mitigation Assessment.

This 2022 report showed crop residue accounted for 20.4 per cent of all Scope 1 (on-farm) GHG emissions in Australian cropping – more than fertiliser (15 per cent), lime application and other farm operations (11 per cent each).

The initial study also concluded that the use of internationally derived emissions factors may be overestimating reportable GHG emissions from the Australian grains sector.

A new hub launched by Charles Sturt University aims to enhance Australia’s biosecurity defences against pests and diseases

part of the Biosecurity Hub, which will focus on leadership in research and development, traceability innovation, education and training, capacity-building initiatives and building and maintaining strong partnerships.

and training will specifically respond to threats outlined by the Commonwealth Scientific and Industrial Research Organisation (CSIRO), which estimates that invasive species cost Australia approximately $25 billion a year.

A multidisciplinary team of expert researchers, scientists and trainers from various fields have been brought together as

“Charles Sturt University is a national leader in biosecurity research and training initiatives, spearheading innovation and transformation efforts to safeguard Australia’s food, farms, environment and communities from the increasing threats posed by pests, weeds, and diseases,” Charles Sturt vice-chancellor and president professor Renée Leon says.

Trial sites will be coordinated and monitored by the project’s research partners i ncluding Agriculture Victoria, University of Queensland and the departments of Primary Industries and Regional Development in both NSW and WA.

To learn more about the program or apply visit agriculture.vic.gov.au.

“Our Biosecurity Hub focuses on strengthening Australia’s capacity to detect, prevent and respond to pests and diseases that threaten our food, farms and our future.”

Biosecurity Training Centre academic director David Mackay says Charles Sturt is at the forefront of training frontline personnel who are protecting Australia’s borders a nd those of its Asia-Pacific partners.

“Charles Sturt University has been working with the Department of Agriculture, Fisheries and Forestry (DAFF) since 2022, utilising the University’s teaching and research strengths to train more than 840 frontline biosecurity officers in capabilities, contributing to the sector’s goal of growing the country’s agricultural production to $100 billion by 2030,” he says.

Partnerships with the likes of the Department of Agriculture and DAFF, have allowed Charles Sturt to be equipped to tackle a range of current or emerging biosecurity threats in the Indo-Pacific region.

•

•

•

•

•

Zero tail swing

Energy-saving hydraulic system

Accommodates wide range of attachments

• Highly efficient Kubota engine Outstanding fuel economy

Compact and powerful

Ergonomic designed spacious cab

High-quality digital instrument display

360-degree field of vision

TOPS protected canopy

Suspension seat

Dual arm rests

National Ag might be one of the newest additions to Merlo’s dealership network, but sales and relationships are already thriving

Some dealer-manufacturer relationships can be a leap into the unknown, but it did not take long for National Ag and Merlo Australia to realise they were a logical fit.

With plenty of the manufacturer’s telehandlers already operating within National Ag’s catchment area and developing a positive reputation, the only thing missing was an active dealer in the area.

National Ag is based in the northern New South Wales town of Moree and serves an area of about 300km radius from its home base with the Merlo product, encompassing areas such as Dubbo, Walgett, Tamworth and even the Queensland border town of Goondiwindi.

National Ag is a family-run business, with managing director Colin Underwood working alongside son Munro, who is kept busy hrough roles in both sales and service.

Its catchment area is very much broadacre country, with materials handling being ited as the most popular use for Merlo’s products on farms.

“The most interest we find is for materials handling - specifically grain handling and fertiliser handling,” Munro says.

“When people are unloading bunkers, they use the big grain buckets to scoop the grain up and dump it into trucks.

“Recently we even had two pilots come in who wanted to use it for loading planes, which again was for handling fertiliser.

“The second biggest area of interest with Merlo would probably be in loading cotton bales.”

National Ag joined the Merlo network in early 2023, with the dealer entering the partnership confident it would be a success.

“The reputation the machines had is what drew us most to them,” Munro says.

“It was the fact there were a fair few machines out there already and there wasn’t a close dealer to us relatively, along with the reputation of Merlo.

“Before taking on the brand, we went to talk to customers who had Merlo machines from past dealers and they couldn’t really say anything bad about them – they all love the machines.

“The only thing they didn’t like is that they didn’t have a dealer close by, so we changed that.”

Two of Merlo’s most popular agricultural products – the Turbofarmer 35.7 and Multifarmer 44.9 – were being showcased as part of National Ag’s extensive site at this year’s AgQuip, held in NSW in August.

Merlo’s Multifarmer, which combines the benefits of both telehandlers and tractors, is a unique machine which provides farmers with the best of both worlds.

Munro says the Multifarmer has “probably generated the most interest” since entering National Ag’s line-up.

Two Multifarmer models are imported into Australia, with the MF44.9 on display for National Ag during AgQuip being the larger of these.

The MF44.9 offers an 8.8m lift height, along with a 5.8m maximum reach.

Its maximum load capacity is 4,400kg and there is a maximum reach of 1.7m while carrying this load.

Merlo’s Turbofarmer is more of a conventional telehandler and is available in a variety of sizes.

Munro says the most popular model with National Ag’s customers in the TF35.7 – which was on display at AgQuip – and which offers a 3,500kg maximum lift capacity, 6.5m maximum lift height and 3.5m maximum reach.

It is the overall quality of Merlo’s machines which makes them stand out, according to Munro, with this quality being apparent in several ways.

It firstly influenced the decision for National Ag to take on the Merlo brand and has held true since.

“We thought the Merlo was just a better machine - more compact, better finish, easier to use and smoother controls,” he says.

We build a lot of machines and we use telehandlers a lot. I can honestly say the

Merlo is definitely the smoothest machine to use as far as the hydraulics go.

“A lot of them are very jerky when you’re going down, but the Merlo is the smoothest – it’s a brilliant machine.

“The reliability of the machine is one big thing, while the other thing is the serviceability - you open up the side and everything’s there.

“All the filters are easily interchangeable which is a big thing, plus the compactness of the machines and just the ease of usability.

“They’re so simple to use. Everyone who has one loves it and it’s the most used machine on the farm.”

As a family-owned business, National Ag understands the value of personal relationships.

It stems from the Underwood family being ex-farmers themselves and therefore u nderstanding what farmers need.

“Because we’ve been there on the farm, we really value service and understand that when someone rings you’ve just got to be there,” Munro says.

“A day or two can be critical and cost enormous amounts of money, so we understand that when someone rings and needs something, it’s important and you can’t just leave it for a couple of days.”

This sense of urgency and frequent communication also explains why National Ag’s relationship with Merlo Australia – and its dealer support manager Norm Atkinson – has thrived.

We’ve got a really good relationship with Norm, he always answers the phone,” Munro says.

“I don’t think I’ve ever rung Norm and

he hasn’t rung back within 10 minutes or at least sent me a text.

“As far as Merlo’s support goes, that is fantastic too and their service support is great.

“In terms of their backup and getting back to you and actually talking to a real person – it’s fantastic.”

The positive feeling is mutual, with Merlo Australia’s national sales manager Chris Wilson being full of praise for the National Ag team.

“We identified early days that the Moree region was an area that we needed to have representation,” Chris says.

“The guys at National Ag, especially being a family business ,which in essence we are, was appealing and coming from the land and understanding the land was something that meant we knew we could work closely together.

“The relationship today has been faultless. We see a good growth area over the next 12 to 18 months, so we’re pleased with National Ag and we’re more than happy to grow it further,” he says.

Merlo Australia’s full product range can be viewed at www.merlo.com/aus/en and National Ag can be contacted via www.natag.com.au

Australia’s No1 locally built mulcher for the last 25 years. Available in Low Body or High Body models in various sizes. Great for clearing up paddocks and bush blocks.

The best value for money Front End Loader mounted post hole digger on the market. Standard with Eurohitch connection with other styles available. Various augers sizes and types available

Large range of linkage and trailing disc ploughs to suit all tractors and applications.

Australian made aerators using the Shattertine technology. Great for cracking open hard ground and rejuvenating pastures.

Australian Made slashers with 5 year gearbox warranty. Various sizes and models in single and twin rotor set-up. Great value and strength. Also available in galvanised.

10 ‘ & 12’ Trailing Grader Blades. 2000kg in weight Best value for money blade of its type

Huge range of linkage models available also.

Offered by Michael’s Group, the BvL mixer wagons can blend different types of feed and minerals together to provide optimal nutrition for livestock

With more than 150 years of experience, family-owned German company Bernard van Lengerich (BvL) is renowned for its feed mixer wagons.

This type of machine has the capa bility to blend a variety of feed types together, producing a nutritious feed for livestock.

By using a BvL mixer wagon, farmers can ensure their animals are provided with a ‘total mix ration’, with the correct balance of energy, protein, fibre and minerals.

It also allows for the use of minerals and supplements that may not be normally palatable for the animals to be incorporated into feed.

This is because the minerals and supplements are blended within the rest of the feed, and therefore hidden, so the animals feed on it without realising they are taking in these additives.

Whether you’re dairy farming or feed-lotting, this can help to increase feed utilisation for livestock.

Some of the essential factors that

should be considered when feeding are correct feed selections, maintaining production, saving time and providing optimal nutrition.

Due to this, the BvL V-Mix Plus mixer wagons can be a handy tool.

BvL’s importer for Australia and New Zealand, Webbline Agriculture, has recently appointed Michael’s Group as an Australian BvL dealer and has seen success with the V-Mix Plus range.

With the machines having the ability to mix different types of feed, farmers have greater choice – for example, using high-cost or low-cost products, as well as commodities such as grains or silage.

Once it is all mixed together, farmers can provide their animals

with a nourishing feed – which can be particularly effective when dealing with seasonal changes.

“At certain times of the year, farmers can find themselves low on natural environment feeds like grass,” Webbline Australian sales manager Tim Currie says.

“The BvL mixer wagon gives a farmer an opportunity to bring in feed, store it on their property and then mix it all together for their animals.”

Looking at the design of these machines, there are several augers, separated by wedges, that direct the flow of feed. When the feed is processed it comes through one auger and is forced into another.

An asymmetric design sees the mixing wedges offset from the augers, a key feature of the BvL brand.

“BvL is well-known for being the only brand of mixer wagons that are designed with this asymmetric mixing pattern,” Currie says.

By having this design style, he says the machine provides a more even mixing blend.

“When you’ve got multiple types of feed in the mixer, you don’t want big lumps of one type of feed and nothing of the other,” he says.

“You want to have an even and consistent blend throughout the mix and that’s what BvL is renowned for – it’s perfection of mixture.”

Another key feature of the BvL mixing wagons is what Currie calls the ‘shark’s bite’ on the rotating part of the auger.

This allows feed to drop down further into the mix wagon, creating a faster and more efficient blend.

“Rather than trying to wind its way through like a screw, the machine has room down the bottom for that mix to drop down and blend at the bottom.”

“That’s where the mix will consistently produce a good quality blend.”

Build quality is a particular standout of these mixer wagons and is further emphasised by a Double Anti Spill Ring – situated on the inside of the top of the machine.

As the name suggests, this prevents feed from spilling out of the top of the machine, but it also increases its strength –in case of being hit by loading tractors and telehandlers.

Even when the BvL V-Mix Plus machines are full to the brim, Currie says the Double Anti Spill Ring will hold dry materials inside. This enables the mixer wagon to blend feed quicker and with maximum consistency.

“As it gets full, the feed naturally pushes to the top and could spill out,” Currie says.

“However, the ring will push the feed to

the centre again, preventing this from happening.”

With the ability to be used in different environments – such as feedlots and barns – as well as catering to different size requirements, the BvL V-Mix Plus range is highly versatile.

Further emphasising this, there are many options and variations to choose from, including different tyres.

BvL customers can choose from super single, duals and flotation tyres. It all depends on the weight of the load and what type of ground the machine is driving over, Currie adds.

These machines also come in various sizes, from 17 cubic metres up to 34 cubic metres, so farmers can choose the mixer wagon that is most suited to their farm size and number of animals.

Technology is a key feature of these mixer wagons, as they come with weigh scales

and a monitor that can be connected to a smartphone via Bluetooth.

A feed management system can be set up using this feature, where rations can be uploaded all from the comfort of the farmer’s home.

“Once a ration is uploaded, the driver of the mixer wagon can get a notification on their smartphone telling them what feed needs to be used,” Currie says.

“The weighing system will allow farmers to track their numbers if needed.

“These mixer wagons enhance feeding practices and boost productivity on-farm.”

BvL V-Mix Plus mixer wagons available at Michael’s Group include the 17N-2S (17 cubic metres capacity), 20H-2S (20 cubic metres), 24H-2S (24 cubic metres) and 343S (34 cubic metres).

For more information, contact your local Michael’s Group branch - Michael’s Moama, Michael’s Of Donald, JCB Gippsland or JCB Ballarat.

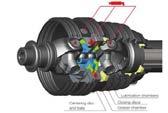

A compact and fully automated system that fits neatly on farm machinery is taking care of ongoing lubrication needs

For much of Australian agriculture – particularly machinery required for demanding broadacre work – bigger is often seen as better.

One area defying that trend is lubrication, where a newly-released pump is fitting seamlessly onto existing equipment and taking care of ongoing greasing needs while the machine works.

Manufactured by SKF Lincoln and distributed nationally by JSG Industrial Systems, the Automatic Electric Cartridge Pump (AECP) has a name that perfectly sums up its purpose.

First released late last year, the AECP has received a positive reception from customers keen to have a simple, compact and automatic solution for their daily machinery lubrication needs.

It is well suited to tractors, JSG’s National OEM Manager Charlie Mouawad says, while also being ideal for other machinery often used on farms - including smaller telehandlers, excavators and skid steers.

The AECP works by being hooked up to each grease point on a machine, with regular lubrication being automatically provided throughout the day, with the operator’s only required to replace the 400g

cartridge when empty.

The product has a 50 per cent smaller footprint than standard reservoir pumps, which Mouawad says is one of the AECP’s biggest advantages.

“The footprint is the biggest thing with the AECP,” he says.

“It doesn’t require a bracket to be made, it can just be mounted on any flat surface and it doesn’t protrude too high - that’s the best thing about it.

“One of the other good things is not everyone has access to a pump with a filling station with air.

“A cartridge is more readily available, the operator just swaps out a cartridge and off they go - there’s less work to be done compared to a larger pump.”

One example of the AECP in the Austral ian market this year has been its installa tion on a Manitou 3300V skid steer.

This customer, who was using the skid steer in an industrial setting, came to JSG wanting a lubrication system that would maintain durability but also had limited space, making the installation of a stand ard lubrication pump impossible.

The AECP was the answer.

It was installed in two of the customer’s

skid steers without having to engineer brackets and was seamlessly integrated to one metering device to build a small progressive lubrication system, supplying lubricant to 12 points while the skid steers were running.

Connected to an SKF IG502 universal controller installed in the cab, the controller provided output of the low-level signal, adjustable timer settings and a manual push button for easy operation.

As the AECP is only a single block, it is limited to machinery sizes with no more than approximately 20 grease points – with JSG’s larger automated grease pumps being better suited to these bigger machines.

Mouawad says in addition to skid steers, the AECP appeals to farmers because it works well with tractors.

“Tractors only have 10 or 12 points on them and they can be quite large tractors, but have a small amount of points, and the AECP is perfect for these as well,” he says.

“They can be used for a number of industries, not just agriculture. We can use for construction and any industry that you can potentially put an auto-lube system.”

Currently, the AECP has been designed for 12-volt operation although an expansion to 24-volt is planned for the coming months which will increase the machinery size it can be paired with.

While the fully automated AECP used in the Manitou skid steers represents the top end of automation, it is not the only option available for customers looking to increase their lubrication efficiency.

“There are multiple levels of service in one particular machine for a grease system - all the way from a manual grease gun to a battery grease gun to a semi-automatic to a full-automatic system,” Mouawad says.

“You can spec it up all the way and have a fully automatic grease system with a controller and an indicator light that shows when the cartridge is low and so forth inside the cab, otherwise you can actually go a level down to a semi-automatic system.

“This relies on the operator to press a button inside the cab to activate the pump but still has a low-level indicator function.

“If someone wants a semi-automatic system that’s one way you can go, otherwise you can go with a fully automatic system with the controller inside the cab and all the bells and whistles to go with it,” he says.

The AECP, along with other SKF Lincoln lubrication systems, can be viewed online at www.jsgindustrial. com while a case study can be read at www.jsgindustrial.com/ case-study-manitou-3300v-skid-steer/

“As someone that’s leading a sales team with a product, it’s making sure that the customer gets the best possible experience

“It’s about making sure our aftersales, parts and service all interacts together as a team to make sure the customer is looked after, whether it’s one machine or 20 machines.”

Amid a wide selection of telehandlers designed for unique purposes, Mules highlights the Poultry Pro 30.7 as one which showcases both Dieci’s quality and

This is one of Dieci Australia’s most popular units, catering to an industry

whose needs are different to many other agricultural sectors.

With much of the Poultry Pro’s work being done inside sheds and under gantries, which are typically used for feeding, the telehandler must be able to reach both high and outwards while simultaneously remaining compact enough to operate in these confined spaces.

Dieci achieves this by offering smaller wheels and a low cabin height to help operators navigate more efficiently in these spaces.

Despite its smaller size, the Poultry Pro 30.7 is still a powerful unit, capable of handling up to three tonnes.

A maximum lifting height of 6.35m adds versatility to the Poultry Pro, which can also produce up to 98hp (73.4kW) and can reach speeds of 35km/h when the largest diameter wheels are fitted.

It measures just 2.04m as a standard height, with the ability to add low-profile tyres to bring the machine’s overall height under 2m.

The Poultry Pro 30.7 offers a full cabin to give operators complete comfort and ensure they are working in a dust-free environment.

The Poultry Pro 30.7 also has a custom-designed air filter system, Kubota d iesel engine, automatic reversing fan, rollover boomhead for efficient bucket emptying and LED lights designed to avoid startling poultry.

It features an advanced telescopic boom which is made of high resistance steel and includes load sensing and flow sharing distributors which allow for more simultaneous movements during operation.

A load limiter device analyses the

telehandler’s stability in real time, while an inching pedal allows the operator to momentarily slow down or come to a complete stop while still maintaining maximum power to boom functions.

This feature increases precision and productivity for delicate operations in tight spaces, something which is particularly pertinent to the poultry industry.

T he boom can also be controlled by the four-in-one joystick, which has been designed for ease of use.

Another aspect of Dieci’s wider telehandler range is the fact they are manufactured in the same region of Italy as Ferrari and Maserati sports cars and have the same focus on luxury and high-end performance.

Each Dieci telehandler has been built to meet local Australian design and compliance standards, with an independent

external engineer signing off on every new machine or attachment, including attachments developed in-house.

While Dieci’s Poultry Pro 30.7 is a popular unit and caters specifically for the poultry industry, it is far from the only telehandler in its range.

Dieci also offers other specialised telehandlers including the Piggery Pro and Cotton Pro.

While the Piggery Pro’s specifications are broadly similar to those of the poultry unit, the Cotton Pro is a sizeable beast and offers a lift capacity of 7,000kg.

This honour is shared with the Agri Max 70.10, which slightly eclipses the Cotton Pro’s maximum reach with 9.65m compared to 9.5m.

Within Dieci Australia’s general agriculture range, of which the Agri Max 70.10 is part, another popular model is the Agri Plus 40.7.

So named for its 4,000kg lift capacity and 7m reach, this telehandler is powered by a 125hp (93kW) engine and is capable of

handling big jobs.

One of Dieci Australia’s strengths is the depth of product which it can offer customers, something which Mules has quickly identified.

“We have quite a diverse range, starting with a 2.5 tonne compact machine all the way up to a 23 tonne Hercules,” Mules says.

“We’ve got the Poultry Pro, we’ve got larger cotton machines, we work in

piggeries, and we can help farmers with their harvest and collections.

“We’ve even got rotational machines which can help construction companies on their job sites which shows the broad range of products we have and the industries we can help.”

All Dieci telehandlers are available nationwide through Dieci Australia’s flagship branches in Sydney, Brisbane, Melbourne and Perth

BYPY Transmissions urges farmers to consider the health of its PTO shafts before using their baler for the new season

As baling season ramps up for farmers around Australia, the last thing they can afford is costly downtime due to poor maintenance.

Baler servicing is a common practice for farmers ahead of the time when their machines receive a heavy workout, but Ashley Male from BYPY Transmissions says this standard servicing may not cover all potential problems.

“Farmers should really be having a good inspection of their PTO shafts,” he says.

An 80-degree wide angle driveshaft.

“A lot of them have had their balers serviced but this doesn’t necessarily mean t he shafts have been checked thoroughly, although they need to be.

“Any minor wear can exacerbate quickly and can cause vibrations and shudders t hrough the drivetrain of the baler and through the back end of the tractor.

“Nipping the problem in the bud early can save damage further down the drivetrain.”

I n addition to balers themselves, machines such as silage wagons and pick-up wagons also have PTO shafts which Male says may require attention.

BYPY Transmissions specialises in the Italian-made Bondioli & Pavesi product, of which it is the Australian distributor, but is able to help new and existing customers regardless of brand.

BYPY is based in the Melbourne suburb of Dandenong but is willing and able to help customers around the country –firstly by accepting PTO shafts being sent to their Melbourne warehouse.

“We can service, repair or replace any manufacturer’s and supplier’s shafts,” Male says.

“We’re happy to field and answer any questions that they may have about their shafts and whatnot and are happy to lead them through any remedies or rectifications.”

Male says a lot of clutches on agricultural equipment including balers can rust up and form a solid connection instead of acting as a clutch if they have been left out in the open during winter, potentially causing significant problems.

While that advice applies to farm machinery on a broader scale, there is also baler-specific maintenance advice which BYPY T ransmissions urges farmers to consider.

“Balers predominantly have a wide-angle joint on one end of the shaft and that w ide-angle assembly can wear rather quickly if not maintained correctly with regular greasing and an adequate amount of greasing,” Male says.

“We recommend that customers don’t use power grease guns on the CV assemblies because they deliver the grease too quickly and don’t actually get the grease into the assembly.

“Due to no fault of the owner or operator,

they are doing what they believe is the right thing but not necessarily achieving what they’re trying to achieve.”

Instead, Male recommends farmers not neglect regular greasing and maintenance checks as part of their daily routine, with some specific tips for the greasing of their PTO shafts.

“Manual greasing and overgreasing is actually recommended, rather than the opposite,” he says.

“You can’t really damage them by overgreasing, but pneumatic and power grease g uns aren’t necessarily the best option for greasing them.

“Overgreasing is actually a friend of these wide-angle joints, if I can put it that way,” he says.

“We strongly recommend daily greasing as part of each day’s pre-operational checks, and regular greasing and checking is not something which should get pushed under the carpet.”

One of the products which BYPY recommends is the Bondioli & Pavesi extra heavy-duty baler shafts, which is designed for use on large, high-density balers.

The SH series is the extra heavy-duty option, built specifically for the needs of Australian farmers working their machines in demanding conditions.

Made from premium quality materials, it is easy to grease and built to withstand

long working hours under harsh conditions – ensuring it will last longer, reduce downtime and lower overall operating costs.

This shaft is designed with a double centering disk system for increased grease distribution and greater overall reliability from the wide-angle joint.

It can be fitted with a heavy-duty overrun clutch which BYPY says has proven to be the longest lasting overrun clutch on the market.

The SH wide-angle joint is capable of temporary driveshaft angles of up to 75 degrees for tight corners, while the recommended maximum continuous working angle is 25 degrees.

“They are near indestructible, they have done thousands of bales without issues,” one Victorian hay contractor who is also a BYPY customer says.

Male says BYPY Transmissions is ready to go for the new season, with good stock availability of PTO shafts to suit silage and baling requirements of farmers across Australia.

This includes brand new shafts, a full range of spare parts to repair existing Bondioli & Pavesi shafts, plus access to the market to get parts for all brands of PTO shafts.

BYPY Transmissions is located at 16 Dingley Avenue, Dandenong and can be contacted via www.bypy.com.au or 03 9794 5889.

Distributed by CJD Equipment, SDLG loaders are renowned for being on-farm ‘workhorses’, complemented by CJD’s extensive after sales support network

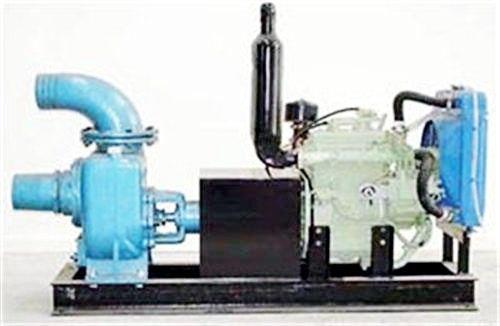

Shandong Lingong (SDLG) wheel loaders have increasingly been making a name for themselves in the construction and agricultural sectors.

Part of the Volvo Group, SDLG’s machines have become a symbol of reliability and productivity, national distributor CJD Equipment says.

This is thanks to the brand’s reputation of manufacturing durable and fuel-efficient wheel loaders.

As the demand for high-performance wheel loaders continues to grow, SDLG is ready to grow its market share.

Established in 1972, SDLG has become one of China’s fastest-growing construction equipment manufacturers.

Over this time, it has developed an internationally renowned brand, which CJD says is now available in more than 130 countries.

In addition to the reliability and productivity that the SDLG loaders provide, the machines are also known for their simple operation and being good value for money.

This has contributed to the reputation

of SDLG loaders as being the workhorse of the farming industry, CJD adds.

Since 2007, SDLG has been a member of the Volvo Group, integrating Volvo’s design influence and high-quality standards into its machinery.

The collaboration has allowed SDLG to establish a strong position in the wheel loader market, and successfully enter the excavator market with Volvo Construction Equipment’s (Volvo CE) technological support.

CJD maintains an extensive inventory of spare parts and attachments

As the national distributor for SDLG, CJD offers comprehensive aftersales support to its customers, ensuring these machines are providing optimal performance and the durability that SDLG is renowned for.

The importance of proper maintenance and timely repairs is critical when it comes to maximising the lifespan of a wheel loader.

It’s why CJD’s commitment to customer satisfaction goes beyond the initial sale of an SDLG loader and expands to providing comprehensive aftersales support.

With this support, SDLG loader owners can rest assured their machine will perform at the highest level with minimal downtime.

To help facilitate warranty support and aftersales service, CJD boasts an extensive national branch and dealer network across Australia.

This network covers major capital and regional cities such as Perth, Darwin, Brisbane, Melbourne, Adelaide, Sydney and Launceston, ensuring that help is always within reach – regardless of the customer’s location.

To further support SDLG loader owners, CJD maintains an extensive inventory of spare parts and attachments that allows the national distributor to cater to varying requirements.

Minimising machine downtime is crucial to improving productivity, and with this in mind CJD’s service network strives to ensure quick response times when resolving on-site service or maintenance issues.

If a specific part is not immediately available in its inventory, the business says it can source it swiftly, with delivery options including overnight and express services depending on part availability.

“It’s one thing to buy an affordable machine, but all machines break down,” SDLG product specialist Andrew Egan says.

“It’s a matter of how quickly you can get back operating again and how much you can rely on the person who sold you the machine.”

Offering genuine parts and accessories, CJD is committed to ensuring that SDLG loader owners experience peak performance and longevity.

CJD’s parts range covers various SDLG

equipment, including wheel loaders and excavators from past and current models –ensuring that owners have access to parts when they need them.

With a comprehensive product range covering more than eight models, SDLG customers are well supported through CJD’s genuine parts offering.

The use of genuine SDLG parts significantly improves the reliability and durability of the loaders, CJD says, allowing users to operate them comfortably and freely.

This approach is driven by its responsibility to each customer, which enables the best machine performance, CJD adds.

Strategically placing branches throughout Australia, CJD’s distribution system also stocks many essential components, such as lubricating oils, filters, batteries and everything in between.

Having this nationwide network provides customers with 24/7 sales, parts and service support backed by over 600 experienced staff.

CJD Equipment offers a range of SDLG wheel loaders in Australia that cater to various applications. These loaders are

CJD says SDLG loaders are renowned for their durability, fuel efficiency, power and safety features

known for their versatility, engine power and safety features, which CJD says makes them well-suited for farm work.

The SDLG wheel loader lineup includes:

• L958F: 3 cubic metre bucket capacity, 17,560kg operating weight, 217hp (159.6kW) power.

• L946H: 2.3 cubic metre bucket capacity, 13,455kg operating weight, 173hp (127.2kW) power.

• L938H: 2.1 cubic metre bucket capacity, 11,750kg operating weight, 141hp (103.7kW) power.

• L936HLA: 1.8 cubic metre bucket capacity, 11,925kg operating weight, 141hp (103.7kW) power.

*0% over 36 month finance is offered on new Bobcat telehandlers on a chattel mortgage with 10% deposit required, followed by equal monthly repayments and no balloon. Finance is subject to credit approval and is only available to approved ABN holders. Not available in conjunction with any other offers. Terms and conditions apply. For further details, contact Clark Equipment.

Australian farmers are just one sector of the market benefiting from Jetland Loading Ramps’ heavy-duty product

With a quality product, a website which accurately shows current stock availability, plus free and quick delivery – Jetland Loading Ramps is ticking the boxes of what its customers need.

It should therefore be little surprise that Jetland has built up an ever-growing list of satisfied customers across the nation in various sectors.

Its core product is heavy-duty ramps which are designed for machinery such as ATVs, excavators and skid steers.

Jetland can provide ramps rated up to 42-tonnes while also catering to the likes of walk ramps and wheelchair ramps.

For Australian farmers, much of their machinery carries significant weight and there is little point trusting their transport needs to a product which cannot do the job.

Victorian customer Jack Holden is one who can vouch for the quality of Jetland ramps.

He runs an earthmoving business while living on an eight hectare property, using his ramp to transport an 80hp 4WD tractor, along with excavators, onto a small truck.

“I don’t just move things around the property, I cart things around the jobs we do and we also do work on other farms,” he told Farms & Farm Machinery earlier this year.

“The truck tray is a metre high off the ground and I can comfortably drive my tractor up on that.

“My tractor weighs near six tonnes and I’ve driven that up on the ramp – it works well.”

“The ramps that I’ve been borrowing and using are nowhere need the strength of this. It’s a brilliant ramp.

“We think they’re great, they’re good value for what they cost and they are a very good product.”

He is far from the only satisfied customer.

With Jetland’s ramps being ideal for the likes of skid steers and excavators, there is considerable crossover to the earthmoving sector.

Within Melbourne alone, Jetland has sold ramps to earthmoving and excavation contractors, along with plumbing contractors, synthetic grass installers and swimming pool installers.

All of these industries require heavy-duty ramps capable of handling significant weight, but also being nimble enough to transport between job sites quickly.

It is for this reason that Jetland can confidently say it has a ramp for everybody across its four series’ – A, B, C and D - all of which are built to handle Australian conditions.

The A Series is suitable for rubber track machines. Models are available with load capacities between 2 and 6 tonnes and in lengths between 2.5m and 4.5m.

The B Series is suitable for rubber track and rubber tyre machines and is available in 2 to 6 tonne load capacities and 1.8m to 4.5m lengths.

Like the B Series, Jetland’s C Series is also suitable for both rubber track and rubber tyre machines but it offers an increased capability.

C Series ramps come with 4 to 21 tonne load capacities and 2.5m to 4.5m lengths.

Jetland’s heaviest duty offering, the D Series, suits steel track, rubber pads on steel, r ubber track and rubber tyre machines, and is available in 2.5m to 4.8m lengths.

These ramps are one of Jetland’s star attractions, having also recently been upgraded to support much heavier loads.

Designed by Japanese engineers, the D Series now supports up to 42 tonnes, where it was previously only rated up to 21 tonnes.

Jetland says this makes it the only 42-tonne rated loading ramp available in Australia and says this also highlights the company’s commitment to innovation.

With such a wide selection available, customers have plenty of choice.

Visiting Jetland’s website provides a quick – and accurate – snapshot of what the company has in stock, with these available ramps ready to be dispatched from its warehouse in the Melbourne suburb of Mordialloc.