Local HERO

Kerfab’s

Kerfab’s

PLUS, THE MAXAM AGRIXTRA RANGE DELIVERS MINIMAL SOIL COMPACTION, A COMFORTABLE RIDE AND IMPROVED TRACTION WHICH SURPASSES ALL AGRICULTURAL TYRE EXPECTATIONS. WHEN PACKAGED WITH ONE OF THE BEST WARRANTIES IN THE INDUSTRY, THE AGRIXTRA DELIVERS THE PERFORMANCE YOUR FARM DESERVES!

43 Cobra Equipment customers praise Shantui machinery

17 National Farmers Federation CEO Tony Mahar to step down

17 Topcon releases Value Line Steering solution

18 Government invests in Western Sydney Uni Agri Tech Precinct

18 Nutrien Ag Solutions to triple domestic manufacturing capacity

19 Victorian horticultural netting grants fully allocated

19 Drought support package available in Victoria

20 Sustainable aviation fuel production facility gains funding

20 Report tips fertiliser prices to remain volatile

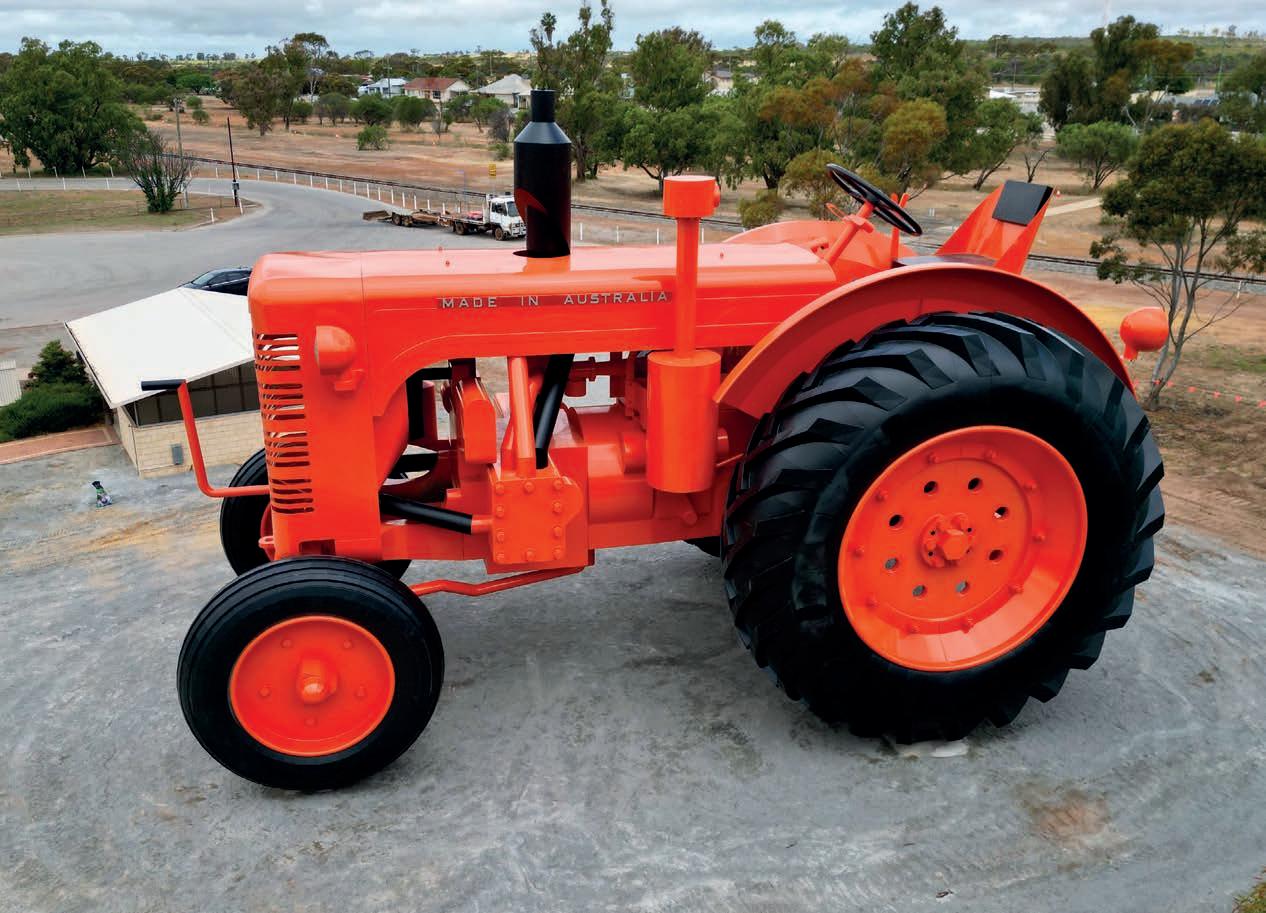

7 World’s Biggest Tractor unveiled in Western Australia

60 Elmore Field Days machinery wrap

54 Tractor sales were again modest in September, TMA figures show, but WA’s provided a bright spot along with combines and balers

56 Protecting WA’s water supply requires long-term policies that are properly funded, WAFarmers CEO Trevor Whittington says

4 Editor’s note

58 Calendar of upcoming events

70 List your item for sale!

81 High Clearance The Elevating Work Platform Association’s Yellow Card Operator Licence is now available digitallymaking it secure for inspection.

81 Leading Light Vailo takes out design awards for Zenith Gen-V PC Amber Floodlight

As Australia moves into the busy harvest season, attention naturally turns to the machinery involved in this process.

Recent field days, including those at Henty and Elmore, showcased much of this machinery, and the highlights from our visit to Elmore feature in this edition.

One machine which caught the eye was New Holland’s Next Gen CR combine.

Having secured a demonstrator unit, dealer AEH Group will run a series of onfarm demos near its branches in New South Wales and Victoria in the coming weeks.

We speak to the group about these demos and the excitement surrounding New Holland’s latest release.

Maintaining farm machinery, and all components of it, is naturally an important task and we catch up with BYPY Transmissions which reminds farmers of the need to keep clutches and PTO shafts in working condition ahead of this crucial season.

Speaking of harvest time, it is when many rely on the services of contractors.

For this reason, Farms & Farm Machinery is again running our Contractor Capability Showcase following its first version late last year.

This edition contains further details of what the showcase will involve and how Australian contractors can submit their information and participate free of charge, therefore promoting their services to a national audience of active farmers.

Farming can be a constant game of looking forward – and our focus is to keep readers informed of the latest machinery trends and how it can boost productivity.

It is always worth keeping an eye on the past though for a healthy dose of nostalgia.

This is what happened when we spoke to volunteers of the Gunnedah Rural Museum during AgQuip earlier in the year, to learn about their vintage machinery and hear more than a few tales from life on the land.

Vintage machinery and the present day have also collided, thanks to the unveiling of the World’s Largest Tractor in Western Australia. We have spoken to several key players to learn more about the project.

Also in the west, independent dealer CNE Ag Innovations has widened the catchment area in which it sells JCB products a nd we discover more about this move.

A new telehandler is also bound for Australia – namely Dieci’s Agri Pivot T70 – and t his unique machine combines the benefits of a telehandler and a wheel loader.

Often a machine is only as good as its attachments, which is why we have customer testimonials about Rata Equipment’s Power Claw along with Kerfab’s pallet forks and four-in-one buckets, the latter of which is our cover story.

All of this is complemented by a healthy dose of industry news to ensure readers are aware of every aspect of Australian agriculture.

Bertelli Editor

Kerfab’s bale forks are proudly designed and manufactured in Australia to withstand the harshest conditions, delivering exceptional durability, efficiency, and safety.

Trusted by professionals across Australia and New Zealand, Kerfab attachments provide the reliability and performance that top operations demand. Reach out to the Kerfab team or your machinery dealer today to experience the difference.

After years of planning and fundraising, the World’s Biggest Tractor has finally been unveiled in the Western Australian town of Carnamah

Standing at 11.5m tall, it is impossible to miss the World’s Biggest Tractor.

In a nation renowned for its ‘big’ structures that have helped to put various towns on the map, it was only fair a particular agricultural icon got its turn.

The Western Australian town of Carnamah, located about 300km north of Perth, is now the proud home of the World’s Biggest Tractor.

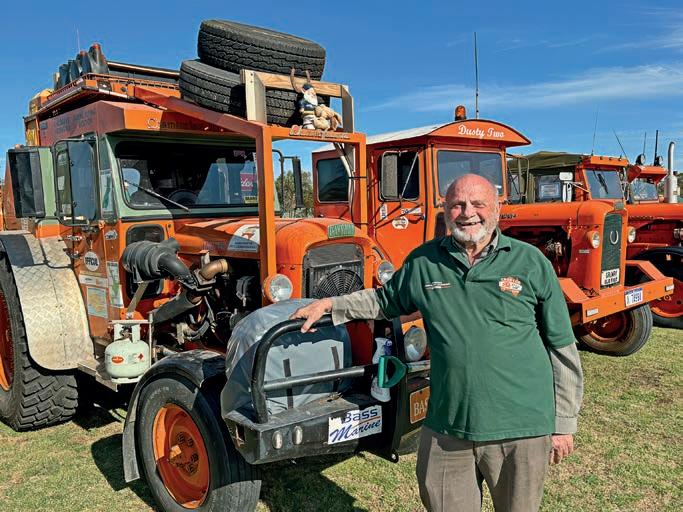

It was officially unveiled before a crowd of about 2,000 at a grand opening last month, which included a day of family fun and a vintage tractor parade.

Fittingly, the replica is of a Chamberlain 40K, a now-discontinued tractor which holds a significant place in WA’s history as the first tractor commercially produced in the state.

The dream has now been realised, with the project becoming reality and Carnamah now instantly associated with the big tractor, but the process to reach this point has been anything but instant.

The project’s origins can be traced back almost 30 years, when Bob Lukins – the founding president of the Vintage Tractor & Machinery Association of WA – had the idea of honouring the Chamberlain 40K through a massive replica.

The association – better known as TracMach – now has John Piavanini as the president, and he was heavily involved in overseeing the project from concept to design stage, while engineer Frank Kidman donated about 450 hours doing working drawings. The Geraldton base of Diab Engineering then took over the design, fabrication and construction.

While Piavanini played a key role in making the project a reality, his hands-off approach during building meant he was able to experience a feeling of excitement when finally seeing it in person.

“After six years on the job, it was quite overwhelming,” he says.

“The biggest thing that that struck me

was I followed it through from the first sketch on a bit of paper right through the build, right up until there was a picture of it outside of the factory at Geraldton.

“I never saw it again until I arrived in Carnamah the day before the launch and looked up and saw this great orange thing.

“I think the orange paint made it look twice as big as I’d imagined.”

More than $600,000 has been raised to turn the project into reality, with nearly all money coming from individuals and companies from across the state, along with contributions from the Shire of Carnamah and Midwest Development Commission.

Set backs along the way included rejections for other government grants, along with rising costs for both labour and materials during this time, but Piavanini says there was a moment where the organisers made a leap of faith, backed up some of its supporters, to finish the project.

“At about 90 or 100 grand short we decided to hit the start button and issue the

order on the promise of some very loyal supporters who guaranteed to pay the bill, which has been done with interest free loans,” he says.

“We are still raising funds to pay those people back and that’s really helped us.”

While the project has now been unveiled, fundraising will continue for this purpose, but also to enhance the tourist experience of what is available.

“We need to get some more signage up, some more history and put a bit of seating around the site,” Big Tractor Committee chairman Brendon Haeusler says.

spent, but it will be a work in progress.

“It will be good to get a viewing platform as well one day so we can get up to the driving area, but that’s going to be a health and safety and engineering job in itself.”

The big day

Carnamah’s big moment in the spotlight was a full day event, which also included a Country Carnival.

Live music, food vans, children’s activities and a tractor pull all featured, along with a tractor parade of about 50 vintage Chamberlain tractors, of which about 20

um, with others from private collections and 9G tractor club members.

The North Midlands Agricultural Society was responsible for organising the entertainment, and the group’s president Angela Dring says the positive atmosphere made for a successful day.

“It was just a happy day and everyone was getting into it,” she says.

“We had great stalls - all the sponsors set up a stall and TracMach had a stall there and the tractors were on display so people could see them.

“For the town and community of Carnamah it was a very positive event,

“We’ve had a really positive response and feedback about the day and what the tractor will bring for our community.”

Her sentiments were endorsed by Haeusler, who says the event “went extremely well”.

“Everyone seemed really happy with the end result of the tractor and we’ve just got a couple of finishing touches to go on the site such as putting up a shed up to house the original 40K that’s been donated to us as well,” he says.

“It’s going to be here forever, so for four years of work for us, it’s going to benefit Carnamah and the entire midwest region of WA for many, many years to come.”

The original 40K was donated by Dick and Barbara Garnett of Gnowangerup, who led the parade and will live onsite with the Big Tractor once its shelter is built.

Leaving a mark

Carnamah is located on the Midlands Road, which travels north of Perth through the northern parts of the Wheatbelt towards Geraldton, but Piavanini says this road has often been overlooked – with the World’s Biggest Tractor aiming to rectify this.

“Since that road was put in many years ago, you’ve got the Indian Ocean Drive and you’ve got the Brand Highway and the quickest way to get to Geraldton is up either of those two roads,” he says.

“Carnamah’s been the side track, so this will probably bring a lot of people, mainly the tour ists, up through the Midlands Road again.

“ It will be a big advantage to Carnamah I’m sure and they have a very good tourist wildflower season, so they’ve got something to put w ith their wildflower tourism promotion.”

Ideas are flowing plentifully in terms of how the tractor can be the catalyst for further tourist activity.

“There was some talk about the potential of building a tractor highway,” Dring says.

“We’re trying to bring people back inland and we’re thinking all the farms could put out their old tractors on the side of the road and

create this tractor highway.

“I’m sure every farm’s got at least one of them hanging around here and there. We could put them out and add to our theme.”

Haeusler’s focus remains on finishing the tractor project, including housing the original tractor and sorting the signage and seating.

This is not to say grander ideas have not been floated.

“There’s also talk of a giant Chamberlain plough to go behind it, but I think we’ll just

let the dust settle on this one before we go making any bold moves to build a giant plough,” he says.

The World’s Biggest Tractor is located in the Lions Park on Midlands Road, Carnamah.

Donations are still being accepted for the project’s finishing touches and can be made by visiting www.carnamah.com. au/donate

Pressurized cabins as low as 1.74 m. narrow as low as 1.05 m. Our Range reaches 110 hp manual or true

Hydrostatic! NO COMPROMISE on power!

Visit your closest dealer

($100) & 10x Signed Framed Tickford Racings Polos ($750). Prize Pool 2 prizes: 20x Weber Baby Q ($568), 20x Makita 18V brushless 2pc kit combo ($800), 10x Castrol Branded Bar Fridges ($1k), 10x

Kerfab’s pallet forks and fourin-one bucket have made light work of a New South Wales vineyard rejuvenation

Attachments manufacturer Kerfab prides itself on making products that are easy to use and that stand the test of time.

The experience of The Wild Vine vineyard has had with two of the company’s attachments shows how a well-made product can create significant benefits for the user – despite its apparent simplicity.

Primarily operating as a wedding venue, The Wild Vine is located just outside the New South Wales city of Wagga Wagga. It is spread across 7.7 hectares (19 acres) and about half the property is used to grow several different grape varieties.

The “beautiful but tired little vineyard” is also being slowly rejuvenated, having been purchased by Nick and Kate

Shepherd in late 2018, when it was also rebranded to The Wild Vine.

Ever since the Shepherds decided to give new life to the vineyard, Kerfab’s pallet forks and four-in-one bucket played key roles in the work being undertaken.

The Wild Vine’s relationship with Kerfab first came about after the Shepherds needed a new tractor and approached Hutcheon & Pearce, which is part of both Kerfab and John Deere’s dealer network.

While discussing the tractor purchase, the salesman was “pretty complimentary” about Kerfab’s attachments, which led to the Shepherds investing in the Kerfab bucket and forks to be paired with a new 42hp (31kW) John Deere 4044R tractor.

Sometimes in farming, new and innovative uses are discovered for machinery and attachments well beyond their original intended purposes.

Other times, simply ‘doing what it says on the tin’ and doing so to an exceptional standard is all that is required.

The latter provides an accurate summary of Nick’s experience with both the Kerfab pallet forks and four-in-one bucket.

“The pallet forks are a bit of a Godsend really,” he says.

“It’s just simple – it’s so easy to use, and easy to attach and detach. It’s a great bit of kit.

“The four-in-one bucket is nice and solid.

“They’re well built, plenty of power, easy to attach and easy to connect up your hydraulic lines and everything else – it’s a really good bit of gear.

“The quick attachment system is simple to install and take off, so it’s not a huge chore to try and change from the bucket to the forks.

“It makes it a really simple task and

Local manufacturing

Kerfab is based in the northern Victorian town of Kerang, where it recently opened a second factory to cater for increased demand for its attachments.

Everything is manufactured in-house and is backed by more than 30 years of experience, meaning customers can have confidence their attachments are built

something which resonates with Nick.

“Being Australian made is always a good thing - that’s something we try and support wherever we can,” he says.

In addition to its products being suited to local conditions, another benefit of Kerfab being an Australian manufacturer is that products can reach farms quickly without the risk of shipping delays from overseas.

As a result, Kerfab offers an Attach + Go promise on its core products, including its pallet forks and four-in-one buckets, along with bale forks.

Kerfab’s Attach + Go promise involves firstly providing an official quote within two hours and then getting these attachments dispatched within seven working days of the order confirmation.

Free delivery around Australia is also included to further sweeten the deal.

A warehouse and office in Perth also help with product distribution across the country, while a strategically placed network of dealers nationwide means customers such as The Wild Vine can access Kerfab’s products and receive support near to them.

Kerfab’s headquarters in Kerang are the heartbeat of its production, with the second factory having been necessary to keep up with national demand.

Opened in 2022, this 2,000 square metre facility is primarily dedicated to the attachments covered by Kerfab’s Attach + Go promise and features an array of new

technology to streamline the production process – along with an investment in more staff including expert design engi neers and qualified welders to maintain quality control throughout.

Before investing in the pallet forks and their accompanying tractor, Nick and The Wild Vine team were using forklifts to complete a lot of jobs in the vineyard.

His description of these pallet forks as a “Godsend” is based on the extra capabil ities they have provided, along with the ease of use in what he says can sometimes be a challenging environment – with the property located at Oura, just east of Wag ga Wagga, and close to the Murrumbidgee River.

“We’re on fairly silty, muddy land not far from the river and the slightest hint of rain means everything turns to a bit of a bog,” Nick says.

“The number of times we’ve had to tow our forklift out means the pallet forks on the 4WD tractor have been an absolute Godsend, particularly during winter.

odd jobs around the property.

“It’s much more practical than trying to get a forklift out into the paddock,” he says.

has been a significant benefit, the Kerfab pallet forks have also been extremely useful beyond just this use.

“It gets used for everything from collecting firewood to lifting posts to moving bins around, and the girls use it all the time for landscaping and cleaning up around the property,” Nick says.

“A fair bit of work goes into keeping gardens and everything mulched, cleaned, tidied and trimmed. It’s very, very useful and it’s been a really good tool.”

Kerfab’s pallet forks are specifically designed for tractors, although similar units for skid steers, telehandlers and wheel loaders are available.

Offered as either ITA or floating pallet forks, they offer capacities between 600kg and 2,500kg and have a load guard for extra strength during heavy-duty lifting and to protect against potential load damage.

Standard tines are 1.07m long, with the option of increasing this to 1.22m on the high back frame version.

The distance between the tines can be

easily adjusted and securely locked into place.

On both models, the open back frame enables maximum visibility and increases operational safety.

It is also customisable to exact specifications required, as is Kerfab’s range of four-in-one buckets for tractors.

The bucket is offered in various sizes, with widths ranging from 1.58m through to 2.4m and capacities varying between 0.3 cubic metres and 0.6 cubic metres.

Also built to be versatile and heavy-duty, it has an opening in the middle which Kerfab says can be used to grapple green waste and clamp large rocks, tree trunks, logs and other obscure objects.

A pivoting jaw in the middle allows the user to control how much material is emptied by opening at different widths, while the rear fixed bucket section is an ideal tool for back blading and levelling.

Its hydraulic rams and connecting pins on either side at the rear of the bucket are well protected, and all main pivots have replaceable self-lubricant bushes which make the bucket easier to maintain.

Kerfab’s attachments are all backed up by a 12-month warranty, but customers like Nick are seeing them as worthwhile and reliable investments for a much longer period than that.

“They are just rock solid, built to last, really well put together and I can’t see us having any issues with it over the lifespan of the tractor – that’s for sure,” he says.

“It’s made work a whole lot easier and since getting it, it’s paid for itself over and over.”

Kerfab’s factory and head office is at 11 Tate Drive, Kerang, while its full product range and national dealer network can be viewed at www.kerfab.com.au

National Farmers Federation CEO Tony Mahar will conclude his role in December, after a decade of service to the organisation and agricultural sector

National Farmers Federation CEO Tony Mahar has resigned, with president David Jochinke thanking him for his contributions to the organisation and agricultural sector.

Mahar joined the NFF as general manager of trade and economics in 2013 and became CEO in 2016.

He will now take up the position of Australian Energy Infrastructure Commissioner – an independent role appointed by the Federal government, reporting to the Minister for Climate and Energy.

“During his tenure, Tony has strengthened NFF’s position as the leading national advocacy body for agriculture through his integrity, stakeholder management skills and dedication to the industry,” Jochinke says.

“His passion, professionalism and approachability earned him respect across industry, government and corporate partners, and we have greatly appreciated

Topcon Agriculture hopes its new ‘Value Line’ auto steer system will provide more farmers access to precision technologies.

Topcon Agriculture has released its new Value Line Steering solution, designed specifically for farmers using mid-range tractors on small to medium-sized farms.

The autosteering solution includes a Global Navigation Satellite System (GNSS) receiver, electric steering wheel controller, touchscreen console and Horizon Lite software, which is compatible with frontwheel-steer tractors.

his leadership.”

Jochinke says Mahar’s efforts have resulted in NFF’s growth from a small team to a staff of over 40, with a broader membership base and a consolidated and stable financial position.

His ability to build and maintain relationships across the industry has established NFF as a key stakeholder for both government and industry bodies, NFF adds.

Jochinke praised Mahar’s industry leadership, relationship management and tireless efforts to represent Australian agriculture both domestically and internationally.

“It is a challenge to lead a national peak body, in this case bringing together all elements of our primary industries and engaging effectively with supply chains

Jochinke says.

One key achievement under Mahar’s leadership was leading the development of the NFF 2030 Roadmap together with former president Fiona Simson, which set a target of $100 billion national farm gate value by 2030, gaining bipartisan support and industry-wide adoption since its launch.

The NFF board will begin the process of

Farmers also have the option to add local, satellite or RTK correction services, such as Topcon’s Topnet Live, for enhanced precision based on their unique needs.

The company says its Value Line Steering solution represents a significant step in making this type of technology more accessible to a broader range of farmers.

“With the Value Line, we are opening up opportunities for farmers who have older

farms, to boost the value of their machinery,” Topcon Agriculture executive vice president and general manager Antonio Marzia says.

“It is an integrated system designed to seamlessly work with a variety of tractors, including compliance with ISOBUS-UT functionality to offer universal compatibility and ease of use.”

Autosteering systems allow for more efficient use of resources, leading to reduced input costs for seeds, fertilisers and fuel.

Topcon says this not only improves the

more sustainable farming practices. It can also lead to improved crop yields due to the increased accuracy in the field.

“There is tremendous potential for growth in the agriculture industry, and Value Line is another step for Topcon in being a preferred partner in this evolving landscape by fostering adoption and effective collaboration both with original equipment manufacturers and the farmer,” Marzia says.

The Value Line Steering solution is available through Topcon Agriculture’s global network of authorised dealers.

Nutrien Ag Solutions has announced plans to expand its local manufacturing footprint to better serve Australian farmers and increase supply chain security

Nutrien Ag Solutions has commenced work to establish a new plant nutrition, crop chemical and animal health product manufacturing facility in Laverton, Victoria.

The company says the facility will be able to produce critical farming inputs for growers on the east coast of Australia.

With increasingly volatile global supply chains, Nutrien Ag Solutions Australia managing director Kelly Freeman says it makes sense to expand the company’s onshore manufacturing capability and inject more reliability in the local supply chain.

“Over the past few years, geopolitical tensions, cost of energy and fuel, shifting global economies, longer shipping lead times, congestion at ports, extreme weather events and labour shortages have all contributed to an increasingly unpredictable supply chain,” Freeman says.

“Having the ability to manufacture significant volumes on both sides of the country is vital for us.

“That’s why we’ve made the decision to invest in more manufacturing capacity on the east coast of Australia to give even more confidence to our farmers that they will have reliable access to all the key inputs they need to make the most of varying seasons and markets.”

The new Laverton site will triple Nutrien’s domestic manufacturing facility, according to national manufacturing manager Cherine Kerbaj.

“Transporting goods from our plant in Western Australia to east coast customers can be costly and complicated, so it makes sense to boost our capacity on the east coast as well,” Kerbaj says.

In addition to the work-in-progress Laverton facility, Nutrien Ag Solutions’

Western Sydney University received a large investment into its Agri Tech Precinct, which will advance sustainable and resilient food systems

million to be invested into Western Sydney University’s Agri Tech Precinct, at its Hawkesbury campus, located just outside Richmond, NSW.

The investment will be delivered under the government’s Priority Community Infrastructure Program and will be jointly funded by the university.

Western Sydney University says the approximately $30 million Agri Tech Precinct will be a world-leading hub of

production to advance sustainable and resilient food systems.

It is also set to host Australia’s first hightech commercial, teaching and research greenhouse, driving agricultural innovation for Western Sydney, the university’s vice-chancellor and president George Williams adds.

“The precinct will draw on the university’s expertise and research innovation ecosystem, with a focus on challenges

current manufacturing portfolio includes a facility in Kwinana, Western Australia and one in Dandenong, Victoria.

Kerbaj adds that the new site will produce plant nutrition products and adjuvants, alongside crop chemical and animal health products.

“This is a great news story for farmers focused on more reliability, more flexibility and increased production of much needed agri-chemicals right here in Australia,” Kerbaj says.

“Given we work in a rain-dependent industry, having more capacity on home soil also allows us to be flexible with our volumes in a far shorter timeframe, so we can successfully meet the seasons’ needs.”

The fit out of the site is underway with the first line of products expected to commence at Laverton in 2025.

The Agri Tech Precinct will include a high-tech, industry-partnered greenhouse array

faced by communities globally, to be advanced in genuine partnership with industry, government and community,” he says.

“Offering exceptional work-integrated learning opportunities for students in agriculture and food production, it will create much-needed career pathways and a future jobs pipeline for Australia’s agricultural sector.”

Delivered across two stages, the precinct will span approximately 50 hectares and will comprise a high-tech, industry-partnered greenhouse array.

State-of-the-art agriculture technology will also be housed for teaching, research and commercial food production at scale, Western Sydney University says.

Stage one of the precinct is expected to open to students in late 2025, generating 150 direct jobs during the construction phase of the project and up to 240 jobs in day-to-day operations once open –creating more opportunity for those in the region.

A support package will be provided to farmers impacted by drought in Victoria’s southwest

The Victorian state government is providing a support package to farmers impacted by drought conditions in the state’s southwest, helping deliver on-farm infrastructure grants and increase the region’s resilience into the future.

A $13.28 million package will go towards farmers in 11 local government areas in the state’s southwest, including Glenelg, Southern Grampians, Warrnambool, Moyne, Corangamite, Colac Otway, Surf Coast, West Wimmera, Ararat, Pyrenees and Golden Plains.

Farmers in this region are currently facing the lowest rainfall on record, which is impacting stock and harvest, as well as putting pressure on feed and water.

As a result of this, the state government will invest $12.1 million to help farmers prepare their properties for increasing dry conditions.

Eligible farmers will receive up to

$5,000 as a co-contribution grant to support water infrastructure upgrades to pipes, tanks, troughs, dams, stock containment areas and grain and fodder storage.

The package also includes a $1.18 million investment in counselling and advice for farmers experiencing financial and emotional distress, to help them make informed financial decisions and protect their wellbeing.

A dedicated drought regional coordinator will be also appointed to make sure support is reaching people effectively.

“I’ve heard directly from farmers in the southwest about the impact drought conditions are having on our communities,

A grant that supports the installation of new netting is helping Victorian horticultural producers protect their crops and increase productivity

The $15.9 million Horticultural Netting Program is now fully allocated with 190 grants delivered to 150 Victorian producers over three rounds.

Funded by the federal and state government, it has provided up to $150,000 to producers of commercial horticulture crops, excluding wine grapes, to purchase and install new netting over production areas.

Besides protecting produce from environmental damage such as hail and sunburn, the Victorian state government says horticultural netting can also help to keep out pest animals and can reduce orchard water use by up to 20 per cent.

The state government adds that new netting installed will increase fruit quality, while reducing the impacts of adverse weather and pest damage – leading to more revenue for growers.

“The Horticultural Netting Program has enabled Victorian producers to build more resilience into their businesses and

continue to provide Australians with high quality produce for which we are renowned,” Federal Minister for Agriculture Julie Collins says.

One happy grant recipient is Temhem Pty Ltd, a grower and packer of fresh fruit for the domestic and export markets.

Based in Lemnos, near Shepparton, the grant supported the installation of netting over four hectares of Nashi Pears to limit hail damage and protect against birds and bats.

“These grants have enabled us to significantly expand our netted land area, leading to a substantial increase in the production of premium-quality fruit and boosting the profitability of these blocks,” Temhem Pty Ltd director Shannan Mehmet says.

For more information on how Agriculture Victoria is supporting the horticulture industry, visit agriculture.vic.gov.au/ crops-and-horticulture

A $13.28 million package will go towards farmers in 11 southwest Victorian local government areas

and this package will drive the long-term resilience the south west needs,” Victorian Minister for Agriculture Ros Spence says.

The support package builds on existing support available for farmers to prepare for and respond to drought, including through providers such as the National Centre for Farmer Health, farmer workshops and field days, and a database of practical information on the Agriculture Victoria website.

For more information on the drought support package, visit agriculture.vic. gov.au/dryseasons.

Horticultural netting can help to keep out pest animals and protect against environmental damage

Australian farmers can expect a volatile global fertiliser market in the year ahead, according to a Rabobank report

Rabobank’s Semi-annual Global Fertiliser Outlook report expects that 2025 fertiliser prices will be unpredictable, with Australian farmers depending on other countries for their supply due to a lack of local manufacturing.

Report co-author, RaboResearch agri-

escalator but coming down via the stairs in terms of the pace of the price correction,” he says.

“International supply and demand issues have a direct impact on Australian fertiliser prices and ability to procure fertiliser.

Nitrogen, phosphates and potash have seen prices ease from the highs of 2022

dollar and US dollar to rise to US72c to A$1 over the next 12 months. If this comes to fruition, Joules says it will make fertiliser purchases more affordable.

“The strength of the Australian dollar and waning global demand point towards lower prices for Australian farmers,” he says.

“However, ongoing global supply-side issues for nitrogen and phosphate fertilisers will likely limit downside potential.”

Phosphate and potash usage rates are strongly correlated to price, Joules adds.

“It’s important to remember that this is happening against a backdrop of declining grain and oilseed prices, high interest rates and high machinery costs in Australia. Negative sentiment surrounding these pressures could impact fertiliser application decisions,” he says.

“As a relatively small player in the global buyer market, Australia is not in a position

In terms of nitrogen prices, the Rabobank report states there is no clear direction. This could lead to potential overactions in prices of urea, either in an upward or downward trend, the report says.

“We should continue to expect price volatility, a common pattern in the nitrogen market,” Joules says.

Townsville is set to gain a sustainable aviation fuel production facility, which could drastically cut domestic carbon emissions, through the help of farmers.

The federal government has announced it will support a homegrown sustainable aviation fuel (SAF) project that will convert ethanol – made from agricultural waste – into jet fuel.

Through the Australian Renewable Energy Agency, the Commonwealth has committed $9 million, with the Queensland state government contributing an additional $5 million to the project through the Queensland New-Industry Development Strategy to grow local production capabilities and establish SAF value chains in Queensland.

Farms & Farm Machinery reported in September that Australian farmers could play a key role in decarbonising the

nation’s aviation industry through the development of a SAF refinery, and now this is possible.

With a total value of $36.8 million, the project would support the development of a Townsville production facility capable of producing approximately 110 million litres of low carbon liquid fuels such as SAF and renewable diesel each year.

“This presents an opportunity for farmers to sell their waste products into a supply chain that ultimately ends up as SAF,”

Airbus chief representative for Australia and the Pacific Stephen Forshaw says.

“It would essentially turn the farming sector’s waste into a new fuel source which could contribute $13 billion to Australia’s

gross domestic product annually.”

Domestic aviation approximately for about 2 per cent of Australia’s greenhouse gas, with the bulk of emissions coming from medium to long haul flights.

Based on initial modelling, the Townsville plant could cut net domestic aviation carbon emissions by 70 per cent per litre compared to conventional fossil fuel use, displacing up to 225,000 tonnes of CO2 annually.

Airbus, Qantas and Japanese petroleum company Idemitsu Kosan have already invested heavily into companies looking to develop and produce SAF, one of which is Jet Zero Australia.

Jet Zero Australia has now formed a consortium of partners to support delivery of the project with the technology to be supplied by US-based LanzaJet.

The technology, known as alcohol-to-jet (ATJ), uses ethanol created by sugars in agricultural food products.

The project will include a Front-End Engineering Design study and further project development work to assess the viability of a subsequent commercial scale ATJ production renewable fuels facility.

This will see agricultural byproduct-based ethanol being converted into low carbon liquid fuels, with the project being due for completion in late 2025.

Independently-owned JCB CEA dealer CNE Ag Innovations has expanded its footprint in Western Australia, aiming to use its local knowledge to grow both tractor and telehandler sales

Being “genuine country people” and providing specialised service by focusing on specific brands might sound like a simple formula for a dealership, but it has proven to be a winning one for CNE Ag Innovations and JCB CEA.

The Western Australian dealer has announced an expansion of its JCB catchment area from the Esperance district in the state’s south – to now take in both the Avon Valley region and an area it is dubbing the ‘western wheatbelt’ that encompasses towns such as Moora.

It is a logical step for CNE Ag Innovations, with father and son co-owners Bryan and Dylan Crane being recognisable faces in the Avon Valley region, having previously farmed in the area.

Having sold JCB products in the state’s south for about 18 months, CNE Ag Innovations is proud that they continue to grow while remaining both independent and family-owned - in a farming landscape increasingly being swallowed up by large dealership groups.

“We’re just genuine country people that are passionate about the farming community in Western Australia,” Dylan says.

“There’s been a big shift in not just farming becoming more corporatised, but in the machinery industry as well, hence it opened up some opportunities for an independent like ourselves to come in.

“We’re not a corporatised business, it’s still only my father and I that own the business and we have a clear plan in place

to try and grow and support the farmers in the areas.

“We used to farm in that area, so we know the area really well.

“We know a lot of the people and have a great network through that area and it’s pretty exciting for us.”

The traits that CNE Ag Innovations highlights about itself have also been praised by JCB CEA’s dealer network general manager Paul Barry, who believes CNE’s focus on customer service and specialised nature makes them an ideal partner for the brand.

“I think CNE are the new dealer of the future,” he says.

“They’re a dealer that’s a bit more of a specialist rather than a generalist.

“We’re not looking for them to be a one stop shop, rather they’re specialising with their sprayers and material handling and are really good at it.

“For them, customer service is the ulti mate thing rather than having something for everyone.

“Bryan is from the farm so they really un derstand what their customers need from a machinery dealer and we hold them in very high regard.”

CNE Ag Innovations’ expansion means it will be catering to two distinct groups –broadacre growers in the Wheatbelt region plus farmers on the smaller properties more common in the Avon Valley.

This creates opportunity for two major JCB product lines – telehandlers and Fastrac tractors.

Dylan says JCB telehandlers have been the most popular product with existing customers in the Esperance region, something which he expects to continue in the dealer’s new areas, while also seeing plenty of growth opportunities for the Fastrac tractors.

“JCB telehandlers have good market share in the country,” he says.

“There are also a lot of the tractors out there, but people have generally got into a JCB telehandler first and then explored the idea of the Fastrac.

“With our expansion, I think it will be a similar pattern because there is a lot of hay in those areas.

“There’s still a heap of work for a telehandler to do, and it’s such a diverse, flexible machine.

“You can get attachments for basically everything now to fit on a telehandler, so I think the telehandler is the one that that will be the most prominent throughout that Avon Valley.

“We also see a heap of growth with Fas trac. It’s such a comfortable, flexible tractor around that 330 to 350 horsepower mark.

“You can’t put a price on the comfort of the thing if you’re sitting in all day. That’s where it comes into a class of its own.”

The jewel in the crown of JCB’s tractor range is the Fastrac 8330 iCON.

It is a powerful beast designed for broa dacre environments, boasting a 348hp (260kW) engine and 1450Nm of torque.

Arguably its most impressive feature is its maximum speed of 70km/h, enabling farmers to get between paddocks consid erably quicker, while doing so in a tractor praised for its superior comfort.

The Fastrac 8330 iCON also has a 10,000kg rear lift capacity to handle the

most demanding of implements, while the smaller Fastrac 4220 iCON still offers an 8,000kg lift capacity.

That smaller tractor gives operators a 235hp (175kW) engine and still has the same 70km/h maximum speed and impressive operator comfort as the 8330.

JCB’s iCON concept relates to its new touchscreen display and armrest console.

This technology-packed suite gives operators fully integrated ISOBUS connectivity, precise GPS guidance and implement control applications, all of which are controlled through a new 30cm colour touch screen display.

JCB’s telehandler range is diverse, designed for a wide variety of industries and to be applicable anywhere in Australia.

Honing in on the manufacturer’s agricultural models reveals a selection of

sizes and capacities designed to suit both broadacre and smaller operators.

The largest telehandler offered by JCB is the 560-80, which offers a powerful 145hp (108kW) engine, 5,500kg lift capacity and 7.9m maximum lift height.

In addition to being its most powerful telehandler, the 560-80 offers an impressive 6.7 tonnes of breakout force and has also been designed in a way that its wheelbase is no larger than any of the other machines in its range.

It is also fitted with a Z-bar linkage, which forms what JCB describes as its toughest-ever telescopic boom.

JCB also offers the 542-70 telehandler, which has a maximum lift capacity of 4,000kg and lift height of 7m while also being powered by a 145hp (108kW) engine.

It is available in many configurations, in-

cluding the top-end Agri-Pro model which boasts a two-in-one variable transmission that enables seamless transition from hydrostatic to powershift transmission.

One South Australian farmer who Farms & Farm Machinery spoke to last year said the 542-70 Agri-Pro helped to cut their working hours by about 30 per cent while producing 45,000 hay bales.

Other telehandlers in JCB’s agricultural range include the 532-60 and 525-60.

These offer lift capacities of 3,000kg and 2,500kg respectively, with maximum lift heights of 6.2m and 6m and engines capable of 109hp (81kW) and 74hp (55kW) respectively..

United front

CNE Ag Innovations has thrived since joining the JCB CEA dealer network about

18 months ago, and Barry is full of praise for how they have represented the brand.

“They’ve hit every mark we’ve set them so far,” Barry says.

“The Western Australian machinery market has been very depressed the last 12 months off what has been extraordinary highs, but through all of that CNE has outperformed what we thought they would do.

What they’ve been able to do with the Fastrac products has stood out.

“They have very quickly got their head around the concept, they’ve spent hours and hours demonstrating products to customers and will continue to do so.

The Fastrac does need that ‘bums in seats’ approach and they’ve done extremely well in doing that.”

F rom the dealership’s perspective, Dylan says the quality of product combined with JCB’s reputation makes it a brand he is proud to be associated with, saying he is excited for what lies ahead.

“It’s an incredibly well renowned brand already and it’s a premier product which is what we like,” he says.

The 560-80 is JCB’s largest agricultural telehandler. Image: JCB CEA

thing which is important to us is JCB is still a family-owned business – there are a lot of values that align with our business.

“We’re also not starting from scratch and we’re not bringing a new product because there are already a lot of machines out in the market already and a big client base, so it’s about us getting out and supporting them.

CNE Ag Innovations’ head office and warehouse is at 52 Mordaunt Circuit in the Perth suburb of Canning Vale. They can be contacted on 1300 026 604 or via www.cneaginnovations.com.au

JCB’s full product range can be viewed at www.jcbcea.com.au

Adding a Rata Equipment Power Claw is expected to bring both short-term and long-term benefits for Victorian family business Fankhauser Apples

Brad Fankhauser is a farmer with an eye on machinery trends and farming technology.

As the fifth generation to work on Fankhauser Apples in Victoria’s west Gippsland region, where he is general manager, any purchasing decision he makes has been carefully considered for its potential to maximise productivity.

Located in the town of Drouin, the family’s farm constantly innovates –having tested a harvest robot over several years, operating its own weather station and introducing harvest platforms from overseas.

The most recent purchase was a Power Claw from Rata Equipment, bought through his local dealer Gendore Tractors and Machinery.

The simplest definition of Rata’s Power Claw is as an alternative to a four-in-one bucket, with the added advantage of its claw-like nature opening additional capabilities and making materials handling easier.

While farmers around Australia have

found advantages beyond the straightforward definition when buying a Power Claw, Fankhauser’s purchase was inspired by its textbook use – albeit accelerated by the need to clean up fallen trees on the family’s property after recent heavy winds.

“I’ve got a wheel loader and I’ve got a four-in-one bucket on it, which I’ve been using as a grab for last five or six years,” Fankhauser says.

“It keeps tearing the hitch point out of the bucket, so I’m obviously using it for what it’s not designed.

“The Power Claw was the fairly logical thing I needed to buy,” he adds.

“I spoke to the guys at Gendore about it probably six months ago and then after the wind storm, I had no choice but to follow up because I’ve got gum trees down everywhere.”

Rata Equipment’s Power Claw is available in three different models – standard, mid-range and compact – which are designed to suit different sizes and types of farm machinery.

Rata’s compact models are designed for tractors between 25-45hp, while the midrange Power Claw is suitable for tractors between 45-75hp, along with small loaders such as Fankhauser’s.

The standard range is aimed at tractors above 75hp, plus telehandlers.

Rata offers the standard Power Claw in five different size options with widths of between 1.6m and 2.6m, ensuring all customers have access to a unit ideally suited to their specific requirements and their machine’s power.

There is also the ability for further customisation in the form of tine spacings, with Rata able to efficiently turn around units to ensure they are quickly operating on Australian farms in situations when they are needed – such as Fankhauser’s.

Despite the surge in popularity of Power Claws in the Australian farming landscape, Rata Equipment has shown it is a company not resting on its laurels.

Late last year, the compact model was redesigned to add a new folded-plate back frame.

This upgrade made the compact Power Claw more efficient to build, the company says, while further protecting the hydraulic hoses inside from branches or any other obstacles.

Across the Power Claw range, AR450 abrasion resistant tines provide excellent strength and durability, while these are also interlocking to ensure an excellent grip on whatever it being handled.

This means anything from large logs to small debris can be handled with ease, while grips on the irons are a further benefit when dealing with slippery materials.

While Rata says anecdotal evidence is that farmers are choosing to keep the Power Claw on their tractors permanently, another unexpected benefit has emerged from the company’s packaging.

The Power Claws are stored in Rata’s warehouse on stands, which are delivered with the product and have proven to be a handy storage method for farmers, who are able to reuse them when the claw is not in use.

All of this speaks to the Power Claw’s versatility and its ability to handle multiple jobs on farm, even beyond what it was initially bought for.

This rings true for Fankhauser, whose purchase may have been recent and necessitated by storms, but who is already eyeing off long-term benefits to his farm productivity.

“When we pull out apple trees, and we pull out a hectare or two hectares every other year, you’ve got to go through and

pick up all the roots,” he says.

“We do that by hand and we have a couple of guys following the trailer around.

“Hopefully this means we can eliminate needing the three guys walking behind a trailer for two days and just have one person on a tractor solely pulling out roots with the grab part of it.

“That was the other reason for buying it – it will be used as a root rake as much as a grab.

“It certainly looks heavy enough that it’s going to withstand anything that I’ll use it

with - it looks impressive.”

Gendore Tractors and Machinery, where Fankhauser purchased his Power Claw from, has only recently joined the Rata network as its exclusive dealer for the west Gippsland region.

Gendore has four branches in Tooradin, Leongatha, Warragul and Maffra.

It was the Warragul branch – and specifically sales representative Brad Carpenter – who Fankhauser bought his Power Claw from.

“I’ve known Brad, who we deal with

mainly, for a long time – but they’ve always been very helpful and honest with their products,” he says.

“They’re really good at Gendore and I couldn’t complain about them.”

As an experienced user of various machinery types, Fankhauser’s final testimonial of the Power Claw sums up the product’s ‘ready to work’ nature.

“We have a saying on the farm that what we can’t buy, we build, and what we can buy, we modify,” he says.

“I can honestly say the grab is only about the third piece of machinery I don’t feel the need to modify.”

Rata’s Power Claw, along with its full product range, can be viewed online at www.rataequipment.com

Fresh from its eastern states debut at the Henty and Elmore field days, New Holland’s Next Gen CR10 combine harvester will continue its tour with on-farm demos by AEH Group

New Holland’s latest generation of combine harvester has made waves since being launched to the local market in Perth in August, with this momentum and popularity now spreading across the country.

Eastern states dealership group AEH Group had the Next Gen CR10 combine on display at the recent Henty Machinery Field Days and Elmore Field Dayswhere it was a standout attraction and gained “a lot of traction.”

AEH Group has one of only four CR Next Gen combines currently in Australia – and the only CR10 – and will be demonstrating it across properties near the group’s New South Wales and Victorian dealerships during November and December.

The CR10, along with its companion model CR11, were both introduced to Australian customers and dealers at a launch event in Perth following its international unveiling at last year’s Agritechnica in Germany.

Both combine harvesters are the product of a complete ground-up rebuild, rather than minor adjustments, leading

New Holland to describe the CR units as an “absolute game changer”.

The CR10 boasts a 12.9L engine producing 635hp (473kW) and a 16,000L grain tank capacity, while the even larger CR11 offers a 15.9L engine producing 775hp (578kW) along with a 20,000L grain tank.

The CR11 and CR10 have unloading rates of 210L/sec and 159L/sec respectively, while both also feature twin 600mm rotors of increased diameter and length, which New Holland says provides greater capacity for the crop to circulate and for the grain to be threshed and separated.

Also featuring are New Holland’s revised and improved IntelliSense automation systems, which make automatic adjustments according to an operator’s chosen harvest strategy, whether that is limited loss, best grain quality, maximum capacity or fixed throughput.

The Next Gen CR combines also include a totally new Twin-Clean cleaning shoe, which consists of two sieve systems in sequence, with each having its own upper and lower sieve and clean grain auger.

As a result, New Holland says the CR combines can handle all materials coming from the rotors and can reduce grain loss “close to zero”.

Another major improvement has been the development of a driveline described by the manufacturer as the cleanest on the market.

Helping to significantly reduce maintenance and downtime, the number of drive components inside the combine harvester have been reduced by 25 per cent while drive chains have been totally eliminated.

This clean driveline was one of the main features which AEH Group’s demonstration coordinator Steve Dinham believes will appeal to customers.

“Having the cleanest driveline on the market is a huge advantage and that redesign is going to be a huge benefit to the machine in general,” he says.

“You’ve got the latest technology in the cab with the IntelliView 12 guidance system, which has been implemented from our high horsepower tractor range like the T7, T8 and T9.

“The increased capacity is obviously a given and it all comes back to your total cost to harvest - are we decreasing our costs while maintaining increased capacity?”

New Holland’s combine harvesters are units designed for high capacity, with the previous CR10.90 – along with the CR9.90 – having broken world records for the most wheat harvested in eight hours.

The CR9.90 remains a popular part of the New Holland range and Dinham believes it appeals to a different demographic to the new CR10.

The CR9.90 will also feature in the upcoming swing of on-farm demonstrations, sometimes in the same environment as the CR10 demonstrator unit to test them side-by-side for customers choosing between the two models, but also separately on occasion.

Dinham is excited to demonstrate the CR10 – along with the newly released MacDon FD261 Flex Draper - on farms near AEH Group’s six New South Wales dealerships for the remainder of 2024,

with plans for the unit to then travel south to farms near the group’s Victorian locations.

“We’ll be getting this demonstrator unit out and about to paddocks to essentially show off what the latest machine is, plus all the technology that comes along with it and how it performs,” he says.

“We’re really trying to push what this new product is and test it to compared to what the farmers currently have on their properties.

“Doing this allows us to get the machines on to farms and farmers get to see it operating in a familiar setting.

“From our point of view, we’re also very open to try and bring that new customer base in.

“There’s a lot of potential out there that we may not know about or see, so there’s no point in hiding.

“We do obviously demo these to our current customers, but we’re really trying to get that new customer base and strengthen our foothold.”

AEH Group’s desire to get the CR10 in

front of a new customer base is already proving successful if the experience at the recent Henty and Elmore field dayswhere it was first shown to eastern states farmers - is anything to go by.

“It’s obviously a very new product to Australia, and while there has been plenty of testing over the years, I think there is a huge interest to see it and a lot of hype around it as far as the regular customer goes,” Dinham says.

“We’ve got interest from all over the state, even interstate, for dealers to come and they want to bring customers along to look at this machine.

“Henty and Elmore definitely had a lot of traction around it. Those big contractors and your bigger farmers all made a bit of an effort to get there just to see it, being the launch on the eastern side of the country.

“When we were at Henty it was non-stop from when the gates opened until when the gates shut.

“Everyone was at that machine and there was actually a path worn in the dirt and grass around it,” he says.

AEH Group kicked off its run of on-farm demonstrations in late October and these will continue for several weeks.

They are planned so farmers located near AEH Group’s six New South Wales dealerships – which are in Cowra, Forbes, Parkes, Temora, West Wyalong and Young – will have the opportunity to see the CR10 demonstrator in action near them.

Customers near Rural Group’s three dealerships in Cobram, Echuca and Shepparton will then get the opportunity to see it operating on farms.

New and existing customers can get in contact with their local AEH dealer to find when and where their nearest demonstration will be held.

To find your nearest dealer and explore AEH Group’s full product range, visit www.aehgroup.net.au

The Farms & Farm Machinery Contractor Capability Showcase 2024 is a resource for farmers and rural asset managers to easily find contractors for work on farms across Australia.

Participation is FREE!

If you would like to feature in the showcase, scan the QR code to organise your listing

Whether you specialise in cropping, hay, tillage and seeding or livestock work, or provide earthmoving, fencing, irrigation, precision agriculture or transport services – or all of the above, we want to hear from you. For

or email georgia.doherty@primecreative.com.au

Calling all contractors to participate in the Farms & Farm Machinery Contractor Capability Showcase 2024

After introducing the concept last year, Farms & Farm Machinery is again running our Contractor Capability Showcase.

This is a resource for farmers and rural asset managers to easily find contractors for work on farms across Australia.

Whether you specialise in cropping, hay, tillage and seeding or livestock work, or provide earthmoving, fencing, irrigation, precision agriculture or transport services –or all of the above, we want to hear from you.

The showcase – which will be published in an upcoming edition of Farms & Farm Machinery – will include all submissions and act as a one stop shop for anybody seeking a contractor’s services, with the directory to

If you would like to promote your contracting business in the showcase, please scan the QR code on the opposite page and submit your details.

*0% over 36 month finance is offered on new Bobcat telehandlers on a chattel mortgage with 10% deposit required, followed by equal monthly repayments and no balloon. Finance is subject to credit approval and is only available to approved ABN holders. Not available in conjunction with any other offers. Terms and conditions apply. For further details, contact Clark Equipment.

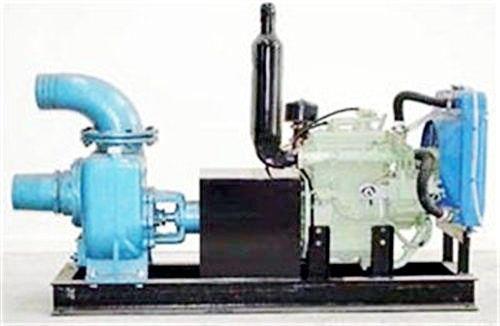

Dieci Australia’s product range is set to grow, with a unique new model on its way to the country

Farmers will soon have the benefits of a telehandler and wheel loader in the one machine, thanks to Dieci’s new Agri Pivot T70.

This articulated telehandler expands on Dieci’s existing range, offering the height benefits of a telehandler with its 5.2m reach along with the agility and movement of a wheel loader.

This makes the Agri Pivot T70 ideally suited to agricultural jobs such as animal feeding, moving and dumping sand and soil, according to Dieci Australia’s national sales manager Bob Mules.

“The new Agri Pivot T70 with its 80-degree steering angle will be ideal for feeders,” he says. “With its agile and precise movements, when you need to carry feed to your troughs, the articulated centre allows you to place the feed where you need to, even in the tightest of areas.

“This also means you reduce waste and save money as the placement of the feed is much more accurate.

“The new T70 Pivot has been developed to use a variety of attachments including forks, buckets, lifting hooks and more.

“This machine is ideal for tasks that require precise placement of a load into a bucket.

“With a standard telehandler, you can side shift, but you typically can’t swivel the bucket. However, because this machine has the arm positioned at the front, you can rotate it to align the bucket precisely with where you’re placing the load.”

The latest addition to Dieci Australia’s range will complement the existing telehandler models, such as the industry-specific Haymaster, Poultry Pro, Piggery Pro and Cotton Pro, along with other units such as the Agri Plus and Agri Max.

Its raw numbers show the Agri Pivot T70 weighs in at 7,150kg and has a maximum lift capacity of 3,000kg, in addition to the 5.2m lift height.

It is powered by a 115hp (86kW) Perkins engine, has a pull-out force of 6,000 daN,

towing force of 6,650 daN and a maximum speed of 40km/h.

Dieci Australia says it is perfect for operating in confined spaces or when a high-performance compact vehicle with affordable running costs is needed.

One important benefit of combining a telehandler with a wheel loader lies in the articulated chassis.

By having a double-joint central articulation joining the front and rear chassis, Dieci says this ensures stability, strength and manoeuvrability in all movements.

A steering angle of 80 degrees helps the Agri Pivot T70 to remain stable even in extreme conditions, while the rear oscillating axle makes it adaptable to all types of ground and guarantees four support points.

A 45 per cent differential lock, which is a standard feature across Dieci’s range, is another feature which Mules says will be appreciated by operators.

Agile steering and precise movements

make it a practical and easy-to-use vehicle for agricultural needs, along with those of other industries.

It has also been designed to handle a variety of implements such as forks and buckets, with quick and easy changeover plus a double-cylinder, double-action hydraulic accessories lock for maximum stability.

Dieci has also added a number of features to ensure farmers can get maximum functionality while using the Agri Pivot T70.

One of these is Shift on Fly transmission, which allows for gear changes without stopping and less time spent on manoeuvres.

This, along with travel direction and boom functions, are controlled exclusively by the new joystick.

An Eco function reduces both fuel consumption and noise emissions, even while travelling at the maximum speed of 40km/h, while another function automatically limits the speed of travel while the boom is raised.

An electronic accelerator and inching pedal provide accurate and controlled movement at any speed, even with the boom at full power.

Dieci has also added four advanced controls to the boom – which are shake, wall, memory and floating – and each are

designed to make different aspects of daily work easier.

The boom is centrally located, guaranteeing high visibility and removing the r isk of accidental impacts, while Dieci’s patented compensation cylinder inside the lifting cylinder protects all components.

T he engine has been installed longitudinally to ensure maximum balance and accessibility.

Other advanced technology in the Agri Pivot T70 includes an anti-tipping system and an easy dumping system, the latter of which is specifically designed to increase the service angle and provides benefits when the bucket in moved to the ground and when it is unloaded at the maximum height.

Inside the cabin, the seat has been moved slightly back to offer increased legroom, while the redesigned dash-

board and new monitors provide clear access to all important information.

It also has a clear instrument panel, two doors which both open 180-degrees, large windows and an elevated seat for 360-degree vision even with the boom raised.

The Agri Pivot T70 is on order and is expected to arrive to Australia by February 2025.

Dieci Australia’s comprehensive range of telehandlers, mixers and dumpers is accessible nationwide through their

flagship branches located in Sydney, Brisbane, Melbourne and Perth

For further product information, visit www.dieciaustralia.com.au

might not be the most glamorous parts of farm machinery, but their smooth operation is critical to ensuring minimal downtime and therefore maximum productivity.

The team at BYPY Transmissions has the products and expertise to make sure farmers can go about their business with complete confidence in these often neglected components of their machinery.

As the Australian distributor of Bondioli & Pavesi products, farmers can go to BYPY confident the company is backed by premium products, which are made in Italy from high-quality raw materials.

While the name of a parts manufacturer may not be as familiar to some as the names of tractor and machinery brands themselves, Bondioli & Pavesi gearboxes and PTO shafts are the preferred brand for

many large-scale contractors and farmers across the nation – along with multiple OEMs.

Boasting more than 70 years of manufacturing history, Bondioli & Pavesi’s popularity has increased in recent years – seeing the company become the go-to for numerous European machinery manufacturers.

The brand’s PTO shafts and gearboxes provide a longer life span, less downtime and reduced operating costs, according to BYPY, meaning they are ideal for any Australian farmer needing their machinery to work for long hours in harsh conditions.

Applicable to everything from tractors to balers, the rising demand for Bondioli & Pavesi products has meant BYPY Transmissions has stocked up, ready to dispatch orders around the country – generally on the same day to ensure any downtime is minimised.

BYPY is not just a reactionary company though, as its service goes far beyond just providing replacement parts when breakdowns occur.

Located in the Melbourne suburb of Dandenong, BYPY’s national warehouse also includes a computerised clutch testing facility.

Customers can send their torque overload clutches directly to BYPY for testing, ensuring they are in working condition and ready to excel.

This is particularly crucial when a machine is brought out for the start of a new season after sitting dormant for an extended period, with older machinery even

more susceptible to issues and requiring pre-season maintenance.

“If they’re left out in the open, even during winter, they can actually rust up and basically form a solid connection instead of being a clutch,” BYPY’s Ashley Male says.

“When farmers then expect that clutch to go off with an overload situation, it doesn’t. It can then break the machine and be a lot more costly in the long run.”

Male and the experienced BYPY team want to be more than just salespeople, firstly aiming to go above and beyond through their ability to customise all its PTO shafts based on a customer’s horsepower requirements and different applications.

The team also prides itself on being problem solvers and is always ready to help and do all that they can together to find a solution to sometimes difficult-to-meet driveline requirements.

While BYPY is a Bondioli & Pavesi specialist and has both completely new shafts along with a full range of spare parts in stock for that brand, the team is ready to help customers regardless of which brand’s products they are using.

“We can service, repair or replace any manufacturer and supplier’s shafts,” Male says.

“We have the full range of spare parts to repair their existing Bondioli & Pavesi shafts and access to the market to get the parts to repair their shafts in general, regardless of the brand.

“We’re happy to field and answer any questions that they may have about their shafts and whatnot and are happy to lead

them through any remedies or rectifications.”

BYPY’s focus on these aspects of machinery comes from not only wanting to help farmers maximise productivity but also to help them operate safely.

One area in which BYPY can help farmers with safety is through PTO shaft covers.

Designed to protect the area where implements connect to tractors, this is a simple solution which can have significant safety benefits.

BYPY offers a comprehensive set of shaft covers for the entire Bondioli & Pavesi range which meets both Australian and overseas safety standards.

It also supplies covering systems that are external to the shaft safety covers, while also having an extensive network that means it can generally get any special products it does not have in stock.

Adequate safety covers are so important because a high percentage of driveline accidents occur when safety shielding is missing or does not function properly, Male says.

With shafts rotating at high revolutions per minute, accidents caused by not replacing broken safety covers can lead to catastrophic consequences, he adds.

It is important for users to ensure the implement input connection shield is compatible with the driveline and the application, while damaged or missing components must be replaced with original equipment spare parts, correctly installed, before using the driveline.

BYPY’s expertise means farmers can confidently approach the company for both advice and parts, with Male saying even mobile phone photos sent to him have enabled the identification of some problems.

Calling on BYPY’s knowledge – whether virtually or by physically sending a part – can determine whether replacement or repair will be the better option.

“Generally replacing is one of the quicker, easier and more convenient options, but depending on what’s broken there are certain components of the safety systems that are obtainable separately,” Male says.

“More often than not, by the time they’ve become damaged to the point where they need servicing as such, replacing is probably a better option.

“We’re here to support the customer in identifying what they’ve got, what they need, and how soon we can get it to them.”

BYPY Transmissions’ national warehouse is at 16 Dingley Avenue, Dandenong and they can be contacted via www.bypy.com.au or 03 9794 5889.

Cobra Equipment’s Shantui machines continue to thrive in rural applications, evidenced by their work building farm fences for a contractor and moving materials in a sawmill

With a wide range of equipment, spanning everything from excavators and loaders to graders and dozers, Shantui has something for every operator.

Authorised dealer and distributor of Shantui machinery Cobra Equipment Sales can attest to this, having seen the machines thrive in the earthmoving and construction landscapes, and increasingly in rural applications.

This is evidenced by one of its customers, M&B Farms, a family-owned contracting business specialising in all styles of rural and farm fencing.

Based in the northern New South Wales town of Kyogle, M&B Farms serves the coast and the northern parts of the state with a Shantui SE25SR mini excavator supplied by Cobra Equipment Sales.

M&B Farms owner Mike Sneath says this machine, which weighs in at only 2.5 tonnes, is easily transportable and ready to tackle any job that is thrown at it.

“As a contractor there’s obviously a lot of travel, so we need to be able to drive our equipment from job to job,” he says.

“Having the Shantui mini excavator means we can put it in a trailer with all the attachments and tow it with a ute.”

Due to the compact nature of the machine, Sneath can rock up to a job and knows he’ll have all the equipment required to build a fence or gateway entry.

To assist him in his jobs, a post hole digger attachment has been fitted to the 19.9 horsepower (14.6kW) mini excavator.

Using the attachment’s auger, Sneath can complete fence-making tasks such as

digging holes and installing fence posts.

The Shantui SE25SR also comes with a tilt quick hitch, allowing Sneath to switch between a variety of attachments to suit different sized posts.

One of these attachments is a power head that rams fence posts into the ground after the hole has been dug. With the ability to tilt the quick hitch, Sneath can adjust the hammer to make sure it is directly in line with the post – which is important when working in uneven terrain.

Sneath has a plethora of experience working on rural properties, having been farming for more than 20 years.

Originally working with a tractor, the Shantui mini excavator has provided him with even greater success.

“We always wanted a mini excavator, so we could easily transport it to service

smaller jobs,” Sneath says.

“Compared to the tractor, the mini excavator can access tight areas a lot better.”

Cobra Equipment Sales founder George Nason said he was happy to hear this, having recently visited Sneath’s property to see how the mini excavator was performing.

“It’s quicker and easier to manoeuvre than the tractor he was using, particularly in difficult terrain,” Nason says.

“In this application, the 2.5 tonne excavator will do everything that a tractor can, but it’s faster and easier to move around.”

In addition to supplying the ready-to-go Shantui SE25SR, Nason and Cobra Equipment also sourced the post-hole digger attachment for Sneath, making sure the machine would thrive in his field of work.

This speaks to Nason’s dedication to the customer, with the ability to source parts and attachments that are requested.

Another rural customer that has benefited from this dedication is Dan Hanna, of Hanna Timbers.

NSW farmer Stuart Tait is exploring on-farm production of modular fertiliser made from crop residue. He has since been recognised with a prestigious award for his business development plan that seeks to make the idea a commercial reality

Born and raised on a Mandurama-based farm on the New South Wales Central Tablelands, Stuart Tait’s family has been farming in the same location for more than four decades.

Working with his father, their business Tait Agriculture has three different enterprises involving cropping, cattle breeding a nd cattle trading.

They also own a farm in Lyndhurst, just down the road from Mandurama, and another in Canowindra, roughly 50km west of Mandurama, which solely focuses on cropping.

Although he grew up in Mandurama, Stuart wasn’t always working for the family business. After finishing school, he made his way to Victoria to study at Geelong-based agricultural institution Marcus Oldham College, before applying his agricultural training in New Zealand for another year.

Upon returning to the family business, Tait looked to improve profitability and was soon awarded as a Nuffield Australia Scholar for his research about cost-effective ways to manage and fill the seasonal feed gap in pasture-based beef systems.

Using the scholarship, Tait travelled across 14 different countries in 2017, visiting a variety of farming businesses.

“It really opened my eyes and broadened my horizons to the world of agriculture and what there is to see out there,” he says.

“It helped me think outside the box a little bit which has probably contributed to the project I’m working on now.”

Looking to improve Tait Agriculture financially and explore potential expansion, he performed a review of the business with the help of an external consultant.

While productivity was high, the financial returns weren’t reflecting it.

“We were keen to continue to expand our farming operations within a 50km radius of Mandurama, but profitability was a challenge due to the high asset value of local farmland,” he says.

Looking for expansion alternatives, Tait’s interest was sparked at a field day when he came across Australian hydrogen technology startup HydGene Renewables, which turns biomass into products, such as hydrogen.

At the time, there was a gap in the market for urea fertilisers due to shortages, so Tait identified on-farm fertiliser production, using crop residue, as a potential opportunity to expand.

“Small-scale modular production of nitrogenous fertiliser on-farm presented

a growth opportunity for us and also addressed a number of critical industry issues, including fertiliser market volatility, CO2 emissions and utilising crop and straw residue,” he says.

“Due to reduced domestic supply of fertiliser and an increased reliance on global supply chains, the supply and price of fertiliser has become increasingly vol atile, placing additional strain on farming businesses to procure product at suitable prices.”

Straw and crop residues can provide soil benefits to broadacre farming systems through moisture retention, Tait says, but can also present many challenges as resi due can host a range of pests and can be a physical impediment for the next crop.

The breakdown of straw, either through deliberate burning or retention, is also a significant source of carbon emissions on farm, he says.