Diverse machinery is backed up by specialised knowledge at Clark Equipment, with McCormick and Bobcat being two brands on offer >> Page 11

Diverse machinery is backed up by specialised knowledge at Clark Equipment, with McCormick and Bobcat being two brands on offer >> Page 11

PLUS, THE MAXAM AGRIXTRA RANGE DELIVERS MINIMAL SOIL COMPACTION, A COMFORTABLE RIDE AND IMPROVED TRACTION WHICH SURPASSES ALL AGRICULTURAL TYRE EXPECTATIONS. WHEN PACKAGED WITH ONE OF THE BEST WARRANTIES IN THE INDUSTRY, THE AGRIXTRA DELIVERS THE PERFORMANCE YOUR FARM DESERVES!

37 A ntonio Carraro tractors catering to diverse applications

41 M iller Nitro sprayers a winner for AEH Group

20 Better than expected harvest boosts WA confidence

20 WA government grants help establish carbon farming

21 Drought infrastructure rebates for SA farmers

21 Mental health handbook available for Victorians

22 NSW trial exempts registration for farm firefighting vehicles

22 Global Conference for Sandy Soils to be held in Perth

23 WA biosecurity response centre unveiled

46 With big money spent on inner city museums, WAFarmers CEO Trevor Whittington argues the nation’s farming heritage is also deserving of a voice

48 TMA data shows another drop in monthly tractor sales to end 2024, but small tractors bucked the trend

50 Fundraiser invites Australians to host a BarbeCure for cancer

4 Editor’s note Image:

71 Fuelling the demand A micro-credential program that trains welders in 12 weeks has been created in response to Australia’s welding workforce shortage

The new year is well and truly under way now, and while the farming calendar may not necessarily have the Christmas break of other industries – January still provides an opportunity to take stock and look ahead.

Christmas may seem like a distant memory now as the day-to-day requirements need to be met in order to keep the farm functioning and thriving.

Farms & Farm Machinery has published the second edition of our Contractor Capability Showcase this month, which provides a f ree database of contractors around the country to help farmers source specialists wherever they may need it.

This is planned to be an annual publication and more details will follow later in the year of how to be involved next time if you missed out.

Speaking of contractors, we have interviewed well-known contractor and farmer S am Monk to learn about what is involved with keeping such a large-scale operation running – plus how his fleet of JCB Fastrac tractors is making such a difference.

On the cover of this edition, we take an extensive look at Clark Equipment’s suite of products and how the likes of McCormick and Bobcat tractors are complemented by its other machinery, along with discussing how the company itself has become so large in recent years.

Another company experiencing a growth pattern is Dixie Holdings.

The Queensland based machinery dealer, known for its transport and customisation of equipment has recently poured resources into developing its hire division and we explore what this will mean for customers.

Across the spectrum of machinery, we also look in depth at Landpower’s range of

silage equipment along with tips on how to produce silage of the best quality.

Miller Nitro sprayers - available through AEH Group – are profiled, as are two tractors from Antonio Carraro’s range.

Tractor and Machinery Association data gives a look at how the year just gone played out in terms of sales, while we have also profiled several farmers doing innovative things.

One of these is Victorian apple grower Brad Fankhauser, whose family has long been at the forefront of innovation, while another company innovating is Queensland’s Bartle Frere Bananas.

We also speak to Andrew Nixon from Narrain Grain in New South Wales, highlighting not only the business but the social media following he has built.

If you know a farmer whose story deserves to be told, please get in touch.

T here is also product news from John Deere in this edition, expansion news from Waringa Distribution, and industry news from across the nation.

It is another jam-packed edition and we are excited to bring it to readers.

Whatever happens in the year ahead, the Farms & Farm Machinery team look forward to sharing it with you.

Bartle Frere Bananas has invested in a host of innovative technologies to ensure it is preserving one of the seven natural wonders of the world

Far North Queensland family-run banana production business Bartle Frere Bananas has been operating for over 30 years with the environment always front of mind.

Named after the tallest mountain in the state, Mount Bartle Frere, the business was founded by Gavin Devaney’s parents with 80 acres close by to the 1.6km peak. It was based there for around a decade before moving to the southern side of

Innisfail, approximately 100km south of Cairns.

Devaney now runs the business on 250 acres of land, encompassing rivers and rainforest that meet the Moresby River –only 30 km from the Great Barrier Reef.

Given its close proximity to the world’s largest coral reef system, Bartle Free Bananas is doing everything it can to be more environmentally friendly.

Bartle Frere Bananas purchased a neighbouring 60-acre sugarcane block in 2019, successfully transferring it to a banana farm.

Partnering with Hort Innovation, the grower-owned, not-for-profit research and development corporation for Australia’s horticulture industry, Bartle Frere Bananas piloted this block as a smart farm to

learn new ways of mitigating the environmental impacts of its farming practices.

A range of innovative technologies were installed on the property, including advanced sensors, an integrated data dashboard and real-time monitoring of nitrate leachate.

An underground vegetated drain was also built, designed to absorb nutrients and retain soil, to see if water could be de-nitrified prior to meeting the Moresby River.

“Hort Innovation wanted to see if I would

be willing to install a TriOS sensor, to remotely read and sensor that water in real time, every five minutes,” Devaney says.

Measuring nitrate concentration of leachate leaving the farm, the advanced sensor was paired with a rated flume and real time pressure transducer to measure flow rate and total volume of leachate passing through the subsurface ag pipe.

The combination of sensors now provides constant data to support Bartle Frere Bananas’ fertiliser and irrigation decisions.

The user interface dashboard provides Devaney all the necessary data in one place

It can track the groundwater at the head of the drain and understand what is coming out of the farm and what is leaving the property. This means the business can tell how de-nitrified the water is.

“We were able to find the right levels for water runoff, how the water runs and where its runs to,” Devaney says.

Devaney aimed to access all this data in one place, which led to the development of a specially designed user interface.

Created by data solutions company Hitachi Vantara, Bartle Frere Bananas uses a dashboard to monitor leachate and sediment to ensure it is environmentally friendly – all monitored from a digital control tower.

Using information from the tower every morning, Devaney can access the weather forecast to know how he must irrigate on specific days.

This has led to significantly improved irrigation practices, as Devaney is able to determine when, where and how much is required.

“There were areas that I believed I was overwatering, but it turned out I was actually underwatering,” he says.

By implementing this change, Devaney says the business now has healthier plants and reduced water usage.

Data from the dashboard also helps ensure that the business’ Cavendish bananas are getting enough fertiliser to grow properly, but not too much where it leads to waste in deep drainage and run-off.

“Runoff water can be a problem in our location, because we’re farming along the edge of the Great Barrier Reef with major rivers flowing through our property,” Devaney says.

“We’re also located in one of the highest rainfall areas in Australia, so being able to track that runoff water allows us to see if we are losing any nitrogen from fertilisation.

“With the way we fertilise, I was able to

prove that Bartle Frere Bananas wasn’t losing any nitrogen through the ground water.”

Manual labour is one area of the busi ness that has been improved, as Bartle Frere can track if jobs are being done properly, while advanced sensors allow the business to track its vehicles, leading to further benefits.

“We have 13 or 14 trackers on our machin ery that monitor all the jobs done on the property,” Devaney says.

“Having these remote sensors means we don’t have to physically check specific areas with machinery, so we’ve minimised our soil compaction.”

Looking to the future, Devaney believes his data driven smart farm operation is just the start of where the agricultural industry is headed.

“Working with Hort innovation has given us a chance to actually make changes to our practices on the property,” he says.

“This has benefited us financially but also helping us to become more environ mentally friendly.”

Clark Equipment’s constant growth has allowed the company to operate on a large scale, with diverse machinery backed up by specialised knowledge

There is so much more to Clark Equipment than first meets the eye.

Starting life as an American company more than 100 years ago, the name first gained prominence in Australia during World War II when it assisted the logistics of Allied forces in this country.

Its Australian presence grew, being a wholly owned subsidiary of the New York Stock Exchange listed Clark Equipment Co, before a 1988 buyout by the company’s local senior managers saw it become an independent, Australian-owned company.

Fast forward to the present day and Clark Equipment – which remains a family business - is thriving. Its business includes manufacturing,

importing, distributing, selling and supporting equipment not only in agriculture, but other sectors such as construction and materials handling.

Clark’s footprint is significant, with 21 branches and 45 dealers supported by a further 30 service agents – all of which is spread across Australia, New Zealand, Papua New Guinea and Singapore.

Clark employs more than 500 people while its annual turnover exceeds $500 million, putting it into the IBIS top 500 private companies list.

It is undoubtedly a big player in the Australian farm machinery space but remains one which has not lost sight of its core purpose – its customers.

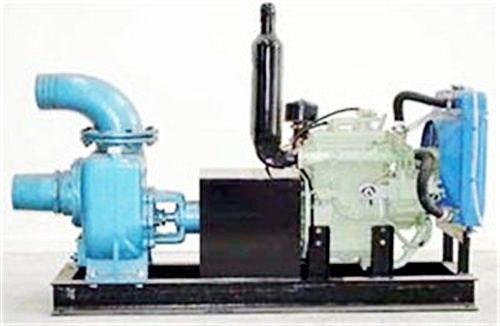

Clark Equipment’s product range is extensive, with even just its agricultural offering giving a snapshot as to the company’s size.

The main tractors represented by Clark Equipment are McCormick and Bobcat, while the likes of Enorossi hay equipment, Orsi mulchers, Muratori hoes, plus Daken electric fencing also feature in the group’s range.

Clark customers can also access zero-turn mowers, telehandlers and construction equipment from Bobcat, while Develon (formerly Doosan) products such as excavators and wheel loaders also come under the Clark umbrella.

Clark Equipment even sell Stetson hats,

Clark completed a customer

providing a further insight into just how much is available through the company.

Clark also does its own manufacturing in the materials handling side of the busi ness, while its agricultural equipment is imported from around the world – includ ing the United States, Europe and Asia.

Supporting this volume of product across the country requires a strong business model, which is why Clark has agricultural branches in every state to ensure backup service is readily accessible.

National product manager David Knoke says the diversity of products available is one of the most exciting aspects of being involved with Clark Equipment.

“I love that it’s an Australian owned and operated business and the fact that you are exposed to so much product and history,” he says.

“It’s the ability to meet customers with differing challenges to overcome and being able to offer a solution.

“It’s exciting, you get exposure to different products and business strategies from countries and cultures all around the world. Personally, that’s what gives me the buzz.”

Strong endorsements

Having had such a long history in business, Clark Equipment knows there is no ‘one size fits all’ approach to Australian business.

Different farming areas require different products, which is why many of its attachments and implements are specialised and exclusively available through Clark.

Conversely, the company also knows that general purpose equipment will appear to the widest market possible – which is why McCormick and Bobcat’s utility tractors are so desirable.

Combined with expert knowledge from its product specialists and national backup, it is little surprise there is a long list of customers happy with both their purchasing experience and product itself.

One such customer is Tom Pearce, a dairy farmer in the New South Wales town of Bega.

Farming alongside his father, it is a combination of brand loyalty from yesteryear plus the reputation of Clark Equipment as distributor which encouraged Pearce to not only buy a McCormick tractor but also add a second one when it came time to expand.

Pearce’s nearest Clark Equipment

branch is in Fyshwick, and he is thankful for both the skill of the mechanics and speed of work when they have been called upon, with Clark’s size as a company helping to give him confidence that any issues which arise will be quickly resolved.

It is rare for brand loyalty to extend as far as one staking their entire job on a product, but Woodlands Enterprises clean out manager Mick O’Keeffe is one who would do so.

The Queensland-based poultry company uses Bobcat telehandlers exclusively – and that is the only way he will have it.

Such a strong endorsement is based on the quality of the product, which O’Keeffe speaks glowingly about, but the service received from his closest Clark branch at Kunda Park on the Sunshine

Coast further solidifies his love for the Bobcat telehandlers.

For a company which offers manufactur ing, sales and service while juggling both importing and exporting of machinery, there is always something happening at Clark Equipment.

The company’s growth journey has been so sustained that Knoke admits the extent of the growth has somewhat crept up on him.

“It is actually still a family business that’s got big without even actually realising that we’ve got so big in a lot of ways,” he says.

“We’re so diverse and I think that access to so many products you can’t get else where is a big deal for sure, and then you add the history and the strength of the company.”

Clark Equipment’s head office is at 30 Salisbury Road in the Sydney suburb of Hornsby.

Its full branch network and product range can be viewed online at www.clarkfarmequipment.com

Sam Monk’s farming and contracting business has a huge network, which is why the reliability and backup of JCB’s Fastrac tractors is crucial

By any measure, Sam Monk is a major player in the Australian agricultural space.

He admits he could not immediately list his entire machinery fleet, such is the volume of the operation, but with new equipment frequently being added, he has a clear idea of what he needs.

JCB machinery has proven to meet those criteria, so much so that his fleet of the manufacturer’s flagship Fastrac 8330 tractors totals not one or two – but a staggering 19.

To describe Sam as a dairy and cropping farmer plus a silage contractor would be barely scratching the surface.

Based at Cobden in south-western Victoria, Sam started his business – Monk and Son – at the age of just 16.

Having now ticked into his thirties, and married with three young children, the business has grown exponentially to the point he is employing about 130 people during peak season.

His fleet of tractors alone is estimated at around 75, plus there is every other piece

of machinery required to maintain his 1,100-hectare dairy and fodder farm plus the 1,140 hectares of cropping land which he leases.

Add in the contracting business and it clear that Monk and Son is an intense operation which needs to run like a welloiled machine.

With so many machines, the possibility of having an issue to deal with is always there.

Backup service is crucial to Sam, which is why even reliable machines like his JCB Fastrac tractors need to be well supported.

Through his local dealer Michael’s Group, plus the national head office JCB CEA, Sam is getting the combination of products he likes along with the benefits of strong relationships.

“A new product comes down to service –that’s number one,” Sam says.

“It can be as good a machine as you want, but you’ve got to have the backup on the machine.

“The backup service out of Michael’s Group is fantastic and their warranty is a

big attraction as well with the way they set up their extended warranty.

“What’s also important is the reliability of the machine. Then, obviously, the people that you’ve got to deal with on a day-today basis. Both JCB CEA and Michael’s are fantastic.

“Michael’s Group is the main one we deal with – Brad and Terry – but I do deal with [national product manager] Andrew Hacker at JCB CEA a little bit as well.”

JCB’s Fastrac 8330 is the largest tractor offered by the manufacturer, boasting a maximum engine power of 348hp (260kW) combined with a fully suspended chassis providing unrivalled operator comfort and productivity.

Another major selling feature of the Fastrac is its top speed of 70km/h – something which Sam says is one of its biggest benefits to his operation.

Largely used for haulage work such as towing trailers and doing silage, he says the speed which his Fastrac tractors can

reach is a “massive advantage” during the day-to-day tasks required.

JCB has also recently overhauled its Fastrac range, adding the technology-packed iCON control suite.

A new armrest console and touchscreen display forms the basis of this, along with fully integrated ISOBUS connectivity and simplified operation on the joystick.

Bolstering the technological capabilities of the tractor while remaining simple for operators to use has been the ambition for JCB since bringing the iCON concept to the local market about two years ago.

It is a concept which the manufacturer is proud of, but its product offering – and Monk and Son’s fleet – is not solely restricted to tractors.

Sam’s association with JCB began with the 435S Agri wheel loaders, which has grown to a fleet of nine, along with a brand new 20-tonne flagship 457S Agri wheel loader, for ultimate loading performance and silage productivity.

For a large-scale operator who is familiar

with a wide range of brands and can easily jump to another familiar product if he is dissatisfied, Sam’s continued investment in JCB machinery is telling.

The growth of Monk and Son is even more remarkable when you consider it started with just a single tractor and baler.

During peak silage season, Monk and Son contracts across four states and has become a go-to for various requirements across the agricultural spectrum.

Cultivation and tillage, sowing, bulk silage, hay and silage baling, hay transport and sales, effluent and fertiliser spreading, spraying and excavation are all jobs which Monk and Son has the machinery to offer contracting services for, along with a “fully elite” service for corn that includes strip tilling, planting, spreading and chopping.

This depth of service shows the need for tractors which can pull the heavy weights of the accompanying machinery required

while also getting the job done quickly.

When a farmer puts their needs into the hands of a contractor like Monk and Son, the need for reliability is even more paramount – hence Sam’s faith in the fleet of JCB Fastracs.

With such a large number of staff members spread across the country, Sam’s day-to-day job varies but includes a lot of time ensuring the wider operations are running smoothly.

“An average day is that I’m on the ground organising a lot,” he says.

“At the moment there’s a workshop manager, he looks after the fleet and he deals with the mechanic side, so I talk to him everyday.

“I talk to the office every day and then I’ll also take a lot of the calls from the farmers, booking in their work. I’m still on the ground doing a lot of that.

“Dealing with the customers is the bit that I love most.

“The customers and our staff are what has helped to build it, so it’s the people in

the business I enjoy the most.”

The growth since Monk and Son’s inception has been impressive, but Sam also believes his business is at a point where further major expansion is unlikely.

This does, however, show an even greater endorsement of his JCB tractor fleet as it is not something he is planning to replace any time soon.

“Machinery wise, we’ll probably just run with what we’ve got,” he says.

“We’re always having a little expansion here with another combine or another forage harvester or something, but it won’t be massive growth.

“Hopefully, one day, the kids come back and want to take over. That’s the aim, to run it until then and hopefully they’re interested and want to take over or at least be a part of it.”

Fastrac iCON tractors are distributed nationwide by JCB CEA’s extensive dealer network. For more information, visit www.jcbcea.com.au

John Deere has revealed two autonomous machines that could help address skilled labour shortages in the agricultural sector

John Deere has announced two new self-driving agricultural machines, the Autonomous 9RX Tractor for large-scale agriculture and the Autonomous 5ML Orchard Tractor for air blast spraying.

Both machines were on display at John Deere’s CES 2025 booth, held at the Las Vegas Convention Centre from January 7-10, highlighting potential solutions to skilled labour shortages.

“Our agriculture, construction, and commercial landscaping customers all have work that must get done at certain times of the day and year, yet there is not enough available and skilled labour to do the work,”

John Deere chief technology officer Jahmy Hindman says.

“Autonomy can help address this challenge, that’s why we’re extending our tech-

Waringa Distribution has grown its national presence by opening a new distribution centre in NSW

The addition of a distribution centre in Wagga Wagga well significantly bolster Waringa Distribution’s support to the eastern states, the equipment distributor says.

Headquartered in Perth, Waringa’s new facility – which was officially opened last month - will complement a smaller distribution centre at Horsham in Victoria, where several equipment brands in its stable are assembled for machinery dealers and customers.

Waringa general manager Sam Abbott says the new Wagga Wagga distribution centre comprises 2,000sqm of offices and workshop area for assembly and servicing, another 600sqm of hardstand, plus a parts holding centre to support the entire east coast.

A seven member team works across the divisions, he says, including two service and training technicians, with the company expecting the local team to double in size over the next 12 months.

“Our core focus with the facility is to

John Deere’s autonomous machines can help address skilled labour shortages. Image: John Deere

nology stack to enable more machines to operate safely and autonomously in unique and complex environments.

“This will not only benefit our customers, but all of us who rely on them to provide the food, fuel, fibre, infrastructure, and landscaping care that we depend on every day.”

Building on John Deere’s autonomous technology first revealed at CES 2022, the company’s second-generation autonomy kit combines advanced computer vision, AI, and cameras to help the machines navigate their environments.

T he Autonomous 9RX Tractor features 16 individual cameras arranged in pods to enable a 360-degree view of the paddock, allowing farmers to focus on other jobs while the machine carries out its own work.

John Deere adds that the advanced au-

tonomy kit calculates depth more accurately at larger distances, allowing the tractor to pu ll more equipment and drive faster.

The Autonomous 5ML Orchard Tractor features the latest autonomy kit with added Lidar sensors to address the dense canopies found in orchards.

John Deere says the initial machine will be offered with a diesel engine, while a battery electric tractor of comparable size and capacity to existing diesel 5M/ ML models on the market today will follow.

Both machines are managed via John Deere Operations Centre Mobile, the company’s cloud-based platform. Through the app, users also have access to live video, images, data and metrics, and the ability to adjust various factors like speed.

Distribution.

increase our servicing support, including our response times, through to growers,” he says.

“The Wagga Wagga distribution centre will mirror our western operations, conducting all assembly and pre-delivery work and providing a centralised parts distribution centre to support the whole network.”

Once the Wagga Wagga facility is fully operational, Waringa Distribution also says it plans to expand further by establishing another distribution centre to service the northern New South Wales and southern Queensland regions.

“We have a strong intent to listen care-

fully to different markets and our team is passionate about the equipment ranges we support and working closely with growers, ultimately to help them produce food as productively and cost-efficiently as possible,” Abbott says.

Commencing as Agri-Spread Australia, Waringa Distribution has added other equipment brands from Europe, Canada and South Africa including Elmer’s chaser and in-field storage bins, Highline hay bale and rock handling equipment, Equalizer seeding systems for the east coast, Gregoire Besson tillage equipment and Geringhoff header fronts.

$3 million in funding will go towards supporting six reforestation projects. Image: ltyuan/stock.adobe.com

More than $3 million is being invested to help Western Australian farmers develop carbon farming projects

The Western Australian government is investing more than $3.2 million to support the state’s farmers establish carbon farming projects under the latest round of the Carbon Farming and Land Restoration Program.

Funding will support six reforestation projects, which utilise less productive land to protect surrounding agricultural land, and two soil carbon projects.

A

The eight projects span more than 7,300 hectares and are set to remove a projected 395,000 tonnes of carbon dioxide from the atmosphere over the next 25 years.

“We are continuing to drive carbon farming investment to advance onground projects that help farmers adapt to have more productive, sustainable and profitable farming systems,” agriculture

better-than expected harvest in Western Australia is leading many of the state’s farmers to feel more confident in the year ahead

Increased confidence levels show WA farmers want to invest more into their businesses in the year ahead. Image: oticki/stock.adobe.com

Western Australian farmers have seen a significantly better harvest than expected, leading to increased confidence levels in the immediate future, according to the latest Rabobank Rural Confidence Survey.

After a very dry start to this year’s grain season, Rabobank WA state manager Steve

Kelly says the west is closing in on what is forecast to be the third largest crop on record.

The survey also found that WA was also only one of two states in Australia to record an increase in net farmer sentiment in quarter four, with most of the country seeing a decrease.

Positive commodity prices are said to be the most significant driver of optimism among WA farmers in quarter four, cited by 31 per cent, while seasonal conditions and overseas markets were cause for optimism for 21 per cent and 19 per cent respectively.

“Canola prices have been at high levels, especially when considering oil bonuses,” Kelly says.

“Cattle prices have also been holding steady this year at a lot higher levels than last year, despite record cattle production being seen in Australia.

“Lamb prices have lifted and are significantly higher than they were seven months ago, when things were feeling dire.”

Kelly adds that this is providing some support for lamb producers, as many are reviewing mating numbers and altering enterprise mix, in response to the upcom-

and food minister Jackie Jarvis says.

“Carbon farming projects offer income diversification opportunities for farmers, along with a range of environmental and community benefits.”

Successful projects include the Locherbie Carbon Project, a 55-hectare reforestation project in Cuballing, which will connect remnant vegetation in 14 planting areas and re-establish habitat in the Dryandra Woodland for native fauna such as numbats.

The Kunmallup Tree Project, another successful recipient, will drive 232 hectares of biodiverse plantings across low productivity land on a Woodanilling-based farm to provide cover, connect remnant vegetation with nearby reserves, and reduce salinity.

ing ending of the live export trade.

Of the various farm sectors in WA, confidence was highest across grain, beef and sheep producers, although around two thirds expect little change to the current agri economic conditions.

The state’s farmers also reported an increased desire to invest in their farm businesses, with 90 per cent saying they intend to either increase or maintain their investment levels in the 12 months ahead – up from 82 per cent in the previous quarter’s survey.

The percentage of those specifically planning to increase investment jumped to 23 per cent – up from 13 per cent previously.

In the year ahead, WA farmers are intending on investing most significantly in on-farm infrastructure, such as fences, silos and yards (55 per cent), new plant and machinery (40 per cent) and adopting new technologies (26 per cent).

Kelly says farmers had originally ‘backed off’ on their investment activity earlier in 2024, particularly in machinery and capital expenditure because of concerns about the season.

“ It was only in October when hopes of a more promising harvest were realised, that they have reset and are ready to go again,” he says.

WA farmers also reported a strong interest in investing in property acquisition, recording the highest in the country at 23 per cent.

South Australian farmers suffering from record drought conditions can apply for rebates for on-farm drought-assisting infrastructure projects

The South Australian government has announced that applications are open for its $ 5 million On-Farm Drought Infrastructure Rebate Scheme.

With farmers across the state experiencing some of the driest conditions on record, primary producers can apply for rebates for on-farm infrastructure projects that assist in managing drought conditions and strengthen drought preparedness.

Eligible projects include water infrastructure upgrades, stock containment areas, grain and fodder storage, soil moisture monitors and weather stations, with businesses being reimbursed with a

A new mental health handbook is available for all Victorian farmers, offering advice and tips to help save lives

The Victorian Farmers Federation (VFF) has launched its Harvesting Change handbook aiming to tackle mental health in rural communities.

Released as part of the VFF’s Making our Farms Safer Project (MOFS), the handbook is available to all Victorian farmers and offer practical mental health tips, informa tion and advice that are critical to helping save lives.

“It’s a sobering reality that nearly half of Australian farmers say they have recently felt depressed, with almost two thirds of them experiencing anxiety,” VFF vice-president and chair of the MOFS committee Danyel Cucinotta says.

Farmers in South Australia are experiencing some of the driest conditions on record. Image: arliftatoz2205/stock.adobe.com

rebate of up to 75 per cent (to a maximum of $5,000 GST exclusive).

“Building our economic, environmental, and social resilience to droughts is crucial to maintaining our state’s robust primary industries and agribusinesses which generate more than $18 billion in revenue and employ over 78,000 people,” minister for primary industries and regional development Clare Scriven says.

The rebate scheme was announced as part of the state government’s $18 million package aimed at assisting farming communities across South Australia affected by drought.

The package has been informed by drought roundtables held across the state, and the SA Drought Advisory Group which includes representation from key primary industries groups, as well as state,

“This is absolutely devastating, and this handbook is a great first step towards giving farming communities the support and resources they need.”

She adds that the handbook fills a hole within the industry, having been written by farmers and industry experts for farm-

The handbook has been written by farmers and industry experts for farmers and their communities. Image: Phoebe/stock.adobe.com

ers and their communities, while keeping the unique challenges that they face front of mind.

“This vital resource is available to all Victorian farmers and stands alone as the only fit-for-purpose mental health guidebook made specifically for farmers and rural Victorians,” Cucinotta says.

“Mental health doesn’t just impact those

suffering directly, it’s a huge issue for families and the community as a whole.

“This handbook is made for those people in mind and acts as a tool to begin those important conversations.”

VFF MOFS is a free farm safety education and support service for Victorian farmers, funded by the Victorian Government through Agriculture Victoria.

Farm Fire Fighting Vehicles in New South Wales will not need to be registered under a new trial that will help support farmers this bushfire season

The New South Wales government is encouraging farmers to take part in a trial that exempts vehicles used to fight fires from registration.

As part of the trial, participants can nominate a Farm Fire Fighting Vehicle (FFFV), or a vehicle used for firefighting purposes, to respond to emergency bush fire incidents on public roads within 100km of their home.

FFFVs can be utility vehicles fitted out with hoses and other firefighting equipment. The state government says these vehicles aren’t typically used outside

Perth is set to host a major international conference in 2025 on the mysteries and potential of sandy soils

the farm, so registering them can seem unnecessary.

Many farmers and rural landholders with FFFVs can play an important role fighting fire on their own or neighbouring properties, especially before emergency services arrive.

“A fire can break out at any time and sometimes help can be far away – so we know it’s critical that neighbours are able to pitch in and help,” minister for regional transport and roads Jenny Aitchison says.

“The ability to legally use dedicated farm

fire fighting vehicles and trailers is a key aspect of this.”

Legal use of FFFVs on public roads to access fire-impacted areas is a change that rural advocates have been calling for, according to the state government.

An initial trial was run between December 2023 and March 2024, with the second trial now open and running until March 31, 2025.

Transport for NSW, the NSW Rural Fire Service and NSW Farmers are working together to continue to examine ways to introduce a permanent scheme.

The Western Australian government has announced the Global Conference on Sandy Soils 2025 will take place in Perth from July 21-24.

With the theme of ‘Shifting Sands to Sustainable Solutions’, it will focus on the challenges of managing and protecting sandy soils around the world in the face of a changing climate.

The conference will attract scientists from broadacre and irrigated agriculture, landscape rehabilitation and environmental conservation from across the world, the state government says.

“WA is home to many leading sandy soils researchers with expertise in managing sandy soils for agriculture, mining, coastal, indigenous knowledge, biodiversity, rehabilitation and environmental stewardship outcomes,” agriculture and food minister Jackie Jarvis says.

“This conference will be a great opportunity to share some of WA’s great work on managing sandy soils to optimise agricultural productivity and resource opportunities, alongside efforts to conserve the landscape.”

The Department of Primary Industries and Regional Development (DPIRD) and

the CSIRO are leading the event, supported by the Grains Research and Development Corporation, SoilsWest and Business Events Perth, alongside Machinery Specialists and VRT Solutions.

National and international researchers will have the chance to collaborate with WA researchers and industry partners to explore opportunities to work together to better understand and manage sandy soil landscapes.

There are approximately 900 million hectares of sandy soils worldwide, located particularly in arid and semi-arid regions, of which 22 million hectares of arable land is found in western and southern Australia, according to the state government.

These soils are crucial for food production and a valuable source of mineral sands, including titanium and zircon, while being home to world-recognised native vegetation systems that support biodiversity.

The conference program will feature discussions on irrigated and dryland agricultural systems, natural systems, engineered systems, soil and water conservation, soil fertility and overcoming constraints to plant growth.

A new Western Australian stateof-the-art biosecurity centre will manage pest and disease threats to safeguard agricultural exports

The Western Australian government has unveiled its $97.3 million State Biosecurity Response Centre, which will be the state’s headquarters for all biosecurity operations.

Located in the Perth suburb of Canning Vale, the state-of-the-art headquarters will house the Department of Primary Industries and Regional Development’s biosecurity operations, incident response teams and diagnostics, and laboratory services to manage pest and disease threats to WA.

investigations, diagnostics and response activities.

When fully operational, the centre will accommodate between 200 to 300 staff. These facilities will support the state’s core biosecurity functions of surveillance,

Response teams to the polyphagous shothole borer and Queensland fruit fly will be some of the first to operate from the new centre, with other teams to follow in stages.

“This new State Biosecurity Response Centre provides a modern and functional workplace for our biosecurity staff which

reflects the vital work they do managing pest and disease threats to the state,” agriculture and food minister Jackie Jarvis says.

“We are investing significantly in biosecurity to ensure we are well placed to respond to increasing pest and disease threats and to safeguard our state’s valuable agricultural export industry.”

Quality silage is essential for optimal livestock health and productivity

Silage production is an important aspect of any livestock farmer’s operations.

Perfecting the process, and therefore getting the best quality silage possible, requires a combination of a carefully considered management plan along with the machinery to effectively carry it out.

Landpower and Claas Harvest Centre understands the importance of making every step of the silage-making process a winner and knows what farmers should be looking for along the way – ultimately ensuring they succeed in creating a high-quality product.

Creating the best silage possible is becoming increasingly important for farmers, with the end product helping to manage on-farm costs, improve livestock performance, assist seasonal feed supply and improve overall farm sustainability.

While these benefits apply to silage as an overall concept, there are even more advantages to be found by ensuring the silage which animals have access to is of the highest quality.

The better the silage quality, the more essential nutrients are retained – some-

thing which is crucial towards optimising livestock health and farm productivity.

High quality silage is both more palatable and easier to digest for livestock, while bringing the health and welfare benefits associated with maximum nutrient absorption.

Multiple economic benefits can also be experienced by ensuring silage is of the best quality. Firstly, quality silage reduces the need for expensive feed supplements as the nutritional needs of livestock are already being met.

For livestock being planned for meat production, feeding them quality silage helps to promote better weight gain to reach market weight as quickly and economically as possible.

Dairy cows fed high quality silage can also produce more milk with better fat and protein content, Landpower says, which also increases the farm’s profitability.

High quality silage will also undergo proper fermentation, lowering the pH and reducing the risk of spoilage.

By preserving its lifespan, farmers can ensure a consistent silage feed supply throughout the year while minimising waste.

Creating perfect silage is both a science and an art, Landpower says, and adds that it all begins with the right tools.

These tools are numerous – and Claas has engineered its Disco mower, Liner rake, Jaguar forage harvester and Torion wheel loader to work together seamlessly during silage production.

As both a science and an art, there is plenty which can go wrong during silage production.

Landpower has broken down the process into several steps – including cutting, wilting, additives, compaction, sealing and packing – to help ensure the correct techniques and harvesting tools are used throughout.

The first crucial step is cutting, where farmers must make sure silage is chopped at the correct maturity and moisture.

Silage will have very high nutritive value and be very palatable to livestock if it is cut at the right time and is not affected by rain or left on the ground for too long.

Contamination such as soil, debris and ash will often contribute to poorer-quality silage, which is why it is important to cut

the crop with the right implement.

Harvesting forage when it is above its respective dry matter ranges often results in mould and yeast growth in the silage due to too much air being trapped between the dry material when packed, so it is best not to harvest over-mature crops.

Well-cut silage should be free from contaminants such as soil, debris and ash.

Ideally, the harvest should be completed within 24 to 36 hours as pasture continues to ‘live’ after being mown, with its nutrient value declining as it sits on the paddock.

Claas’ Greenline and Jaguar product manager Luke Wheeler says using the right machinery can help avoid these problems, while the cutting height should be set to avoid soil contamination.

“Disco Mowers offer the cleanest of cuts with the Max Cut cutterbar and Active Float Hydro-pnematic suspension ensures ground contour following and contamination free mowing,” he says.

“Using mower conditioners or tedders helps break the wax layer on the crop which increases the rate of wilting and decreases the drying time limiting the risk of loosing valuable nutrients.

“Efficient gathering with Claas Liner rakes provides perfect windrows and 3D ground contour following and undercarriages with up to six wheels under each rotor to ensure contour following and contaminant-free forage.

“From the precise cut of Claas Disco mowers, ground adaptation of the Liner rakes and the unparalleled performance of our Claas Jaguar forage harvester, Claas tools can help ensure that your crop is cut to the highest quality.”

The Jaguar forage harvester also comes with easily adapted knife configurations to ensure the correct cut length.

Understanding the processes that occur during fermentation is critical to an effec-

tive silage system, Landpower says.

Fermentation-enhancing inoculants speed up fermentation and reduce dry matter losses, which is why farmers should consider using a proven inoculant that improves aerobic stability.

“The Claas Jaguar’s Actisiler 37 additive applicator technology can control flow rates and application, providing on-thefly response to varying throughput and harvest conditions,” Wheeler says.

The fermentation should be fast and efficient, as a slow and inefficient process leads to considerable activity of spoilage organisms and high nutrient losses.

If fermentation is poor, the silage will be of poor quality regardless of how good the original crop was.

Achieving high quality fermentation and avoiding losses during feedout also requires good compaction.

A silage stack is well compacted when it is difficult to push your fingers into the surface beyond the fingernails.

Stacks should also be well sealed as soon as harvesting is completed to prevent air from entering.

Landpower’s advice is to keep the stack face tight and tidy to reduce aerobic spoilage and avoid heating, because uncovered silage suffers both aerobic spoilage and spoilage losses from rainfall.

Wheeler says the Claas Torion wheel loader will help achieve a well-compacted silage pit.

When packing the silage pit, farmers should select an appropriate clean site and not let loose material gather at the base. When hauling material, debris should not be driven through the clean area by your machinery.

The primary purpose of silage is to be a feed supplement for livestock, and a good

Producing high quality silage requires getting multiple factors right

quality product will lead to better animal health and wellbeing.

present in poor quality silage, which can significantly impact animal health.

Claas machinery is distributed in Australia by Landpower and Claas Harvest Centres, with branches nationwide

With machinery and experience to help farmers carry out high quality silage production, Wheeler says the company is ready to help Australians succeed.

“Landpower and Claas Harvest Centre understand the importance of every step in the silage-making process,” he says.

“We’re the trusted choice for professionals who demand nothing but the best.

“Our comprehensive range of equipment is designed to deliver consistent, high-quality results that you can rely on. We know that making perfect silage begins with the right tools.”

The full Claas silage harvesting range can be viewed online at www. claasharvestcentre.com/deals-offers/ perfect-silage-partners

The company’s growing transport fleet means it can handle every step of the process

Already known for its workshop and haulage capabilities, Dixie Holdings has invested further into helping its hire division grow

In more ways than one, Dixie Holdings is a business on the move.

Already well established as being an equipment dealership which specialises in customising machinery for sectors

a nd networks which Dixie has already developed across the wider business.

“The key where we differentiate ourselves is that a lot of businesses are just hire on ly – you hire the machine and that’s it,”

Dixie Holdings – originally known as IJ McDonald and Sons – was formed in the 1970s by Geoffrey McDonald, whose son Tom is currently the company director.

The family-owned business, based at Woongoolba between Brisbane and Gold Coast, has nearly a half-century worth of experience and relationships to draw upon when offering this “turnkey solution” to customers needing equipment.

It is these long-term relationships which Dixie puts a lot of time into developing and nurturing, both with customers and suppliers, knowing it will reap rewards in dealing with any challenges which may arise.

the on-site support and management of the

“Dixie utilises our network of industry partners, which is important because the more remote you get, the harder it is to get things done,” Gardner says.

“Because Tom has had such a good network and long-term relationships with these guys, generally speaking it’s not too much of a turnaround time to get a machine fixed, regardless of where it is.”

Flexibility and adaptability are words which come to mind when describing how each facet of Dixie Holdings’ operations come together.

For example, Gardner highlights Dixie’s willingness to move machines from its sales fleet into the hire business should a customer request a specific machine –including customisations – for a long-term hire.

This enables the customer to get their desired machine quicker, while Dixie’s skilled workshop team can ensure any requested modifications to the unit can take place before the haulage team begins delivery.

To cite one example of this, Dixie Holdings took a call from a Perth-based hire business it had previously dealt with.

The request was for a Cat D9 Next-Gen dozer fitted to full mine specifications, including automatic GPS, fire suppression, isolators and emergency stops.

Destined for a mine site in WA’s Pilbara region, the clincher was that the machine needed to be modified to the client’s needs and delivered to Perth within three weeks – no easy feat when Dixie is based in Brisbane.

This was a challenge which Dixie willingly took on though, and excelled in.

“It’s very hard to get that kind of spec

requirement done in three weeks, but it can be done,” Gardner says.

“We have the ability to find late model machines that might not be available in the market and might not be in our fleet, but we can go out and purchase these machines or convert a sale machine to a hire machine at a moment’s notice.”

It is this willingness to adapt to meet customer requests, combined with only using quality equipment and providing backup service to match that is standing Dixie Holdings in good stead.

While still new to the company, Gardner knows this aspect well – having been a client of Dixie’s during his previous roles at other hire companies.

“I think what’s been good is I’ve been on the client side to Dixie where it was a smooth process,” he says.

“The machine itself had some problems, which were just unlucky circumstances, but it was never too big a problem to be fixed.

“Tom had it fixed very quickly compared to what most people would have.

“Dixie looks at the long-term relationship and working with the client so, if there is a problem, then let’s resolve it, let’s fix it and let’s move on to the next job.”

Backup service is also paramount for any hire machinery, but particularly when it will be headed to such remote locations.

Dixie’s strong networks around the country has it well placed to meet ongoing customer needs, wherever they might be located, and by extension help to support these long-term customers.

“There’s nothing worse than having a machine broken down on a remote job for two weeks because you can’t get a part there,” Gardner says.

“There’s such a big network now that we could get a part, regardless of how it got there, but it would be there in a day or two.”

While Australia’s harsh conditions can push even the most reliable machinery to its limits, the best way of ensuring minimal problems is by using quality equipment and conducting modifications to a high standard.

“The key is we only run good equipment,” Gardner says.

“Sometimes it might not be late model, and a good example is we’ve got a 2011 Cat D8T dozer going out on hire, but it’s been fully rebuilt from the ground up, so it’s a zero hour rebuild.

“It might not be late model, but it is late hour.”

For Dixie Holdings, second hand does not mean second rate – with these modifications ensuring machinery is functioning at its best.

In some instances, farmers even prefer some of the older models due to their simplicity, Gardner says, with a rebuild getting their favoured machine back to an as-new standard.

“Some people don’t like the newer equipment and that is particularly key for the farming side,” he says.

“Some of the farmers might want an older 16H grader over a 16M, but they want a reliable H.

“You’ve got to rebuild that H and put a few dollars into it to get it reliable, but

then it covers what the client wants and you’ve covered that need for reliability.”

Having been brought in to nurture customer relationships and streamline the hire process for customers, Gardner is excited about the growth potential for Dixie’s hire division.

“You don’t want customers to wonder who they need to call at Dixie Holdings for the hire – I’m the hire person,” he says.

“My pure role in this now is to drive the hire and this also gives it time to be focused on and given the right drive that it needs.

“Everyone knows Dixie is a sales and haulage business and does the manufacturing, but the hire side has somewhat fallen under the radar, so it’s just making that front of mind for a lot of people in the industry that Dixie Holdings is a leading hire company.

“Over the next two to three years, with the current and future projects in Queensland, New South Wales and the Northern Territory, we can see our hire fleet growing exponentially off the back of some repeat clients and new client work out there which are targeting that late model, reliable equipment.

“With hire in the agriculture sector, civil, mining and even gas and rail – the jobs don’t go forever, so I think trying to entrench ourselves in those longer-term relationships is important.”.

Dixie Holdings is located at 1343 Stapylton Jacobs Well Road, Woongoolba and its product range is online at www.dixieholdings.com.au Will Gardner can be contacted on 0437 791 685.

With the original intention of using social media to recruit employees, Narrain Pastoral Company’s online following has grown into something it never could have imagined

Sixth-generation family-run grain farm Narrain Pastoral Company, or Narrain Grain as it’s more commonly known on social media, has over 30,000 followers on its social media pages across Facebook, Instagram and TikTok.

Posting general on-farm videos and photos of its operation, its pages have become popular with not just other farmers but also with other businesses – opening the doors for new partnerships.

Based in Oaklands, in the New South Wales Riverina, but with three other properties close by towards Savernake and Berrigan, social media is still relatively a new part of the business.

Having only started Narrain Grain’s online pages in the last five years, the original idea behind it was to recruit new employees to help the operation that grows wheat, canola, barley and corn.

“I’ve always been comfortable with social media, so I decided to create our accounts to look for employees,” managing director and social media representative Andrew Nixon says.

“I didn’t really think it would work initially, but it did, and it’s now grown into something much more than that.”

Opening doors

Now highly active on all forms of social

media, ironically, Andrew originally hated the idea of TikTok.

As the social media application gained increasingly more prevalence, he decided to post Narrain Grain’s first video, which amassed more than 20,000 views.

Nixon remembers thinking ‘this isn’t so bad’ and started uploading more consistently. This was the turning point that helped Narrain Grain’s social media pages take off.

One of the biggest successes of Narrain Grain’s socials has been the way it has opened the doors to new relationships.

“A lot of people who didn’t know us before, know us now because of our social media – not just other farmers, but also other businesses,” he says.

“We managed to get onto another company that helped us manage our input costs, such as fertiliser and chemicals, a lot more effectively than what we were doing.

“Through this relationship, we’ve been able to save tens of thousands of dollars over the years.”

With 16,000 followers on Facebook, 11,000 on TikTok, and more than 6,000 on Instagram, Narrain Grain’s content

focuses on videos of machinery, farming practices and interesting photos.

Andrew attributes Narrain Grain’s popularity to a lack of Australian farming content.

“There’s not a lot of channels that are actively putting out content on all the different social media platforms,” he says.

“I like seeing farm content and people showcasing what they do, and I think others do too.”

Since Narrain Grain has taken off, it has also established its own merchandise that has proved popular with its followers, however, the main catalyst for the merchandise was its employees.

In a similar way to how a uniform creates a sense of togetherness, Andrew says employees wanted something to wear onfarm – forming the idea of Narrain Grain’s merchandise.

With all the usual merchandise, from hoodies and truckie cups to beanies and stubbie holders, he says that everyone loves it and most of it is given back to customers as a token of appreciation.

“We’re all one big family at the company and the kids love the merchandise as well,” he says.

Apart from Andrew, at the helm of the family company also stands his father, Richard, and brother, James.

Also contributing to the business is Andrew’s wife Samantha, who is head of marketing and merchandise for the social

media enterprise Narrain Grain, as well as James’ wife Tamara, who is the office manager for Narrain Pastoral Company.

Growing up on the very same farm at Oaklands, Andrew recalls learning everything from riding motorbikes and driving utes to operating tractors from a very young age.

“I harvested my first crop when I was about 10,” he says.

“I would have been about 13 when I did my first solo job with a with a tractor and harrows.”

Although he had been living on the farm full-time up until that point, it wasn’t always set in stone that Andrew wanted to continue working there.

For a long time, he thought about becoming a pilot, and eventually started working on agricultural aircraft, loading them with chemicals in Queensland.

After moving to Finley, NSW, only 60km west of the Oaklands farm, Andrew was asked to come back to help with harvest, and didn’t hesitate to support his family.

That was 14 years ago, and Andrew has stayed at Narrain Pastoral Company ever since, thanks in large part to his brother James.

“He’s nine years older than me so he’s seen many more seasons than I have,” Andrew says.

“I’ve leant on his expertise quite a lot and still do.”

Growing wheat, canola, barley and corn, Narrain Pastoral Company stores nearly all its harvested grain on-farm, with Andrew saying it has 25,000 tonnes worth of silo storage.

It also has a fleet of four on-road trucks and one on-farm truck that transport the

grain all over NSW and Victoria, including as far as Geelong.

With two employed truck drivers, Andrew takes on the mantle as the third, driving to different locations as needed.

“I probably have a million kilometres under my belt in the truck now, and my other drivers have probably got double that,” he says.

“I like to say I’m a 50 per cent farmer and a 50 per cent truckie.”

In terms of its farm machinery fleet, the business has everything you can imagine, including three harvesters, two seeders and numerous other machines.

“The bigger the machine, the less labour we need, so we’ve worked on that strategy forever,” Andrew says.

These machines, as well as the company’s truck fleet, can be seen in action on Narrain Grain’s social media pages.

From time-to-time Andrew will also post tips to help new farmers using different machinery.

“I recently posted a video to help people get their header set up, which was well received, and I may move that way with my content to extend my reach” he says.

“At the end of the day, I’d like to help people as much as possible. A lot of the experienced farmers already have this knowledge, so I want to help the newbies out as much as I can.”

You can follow Narrain Grain on Facebook, Instagram and TikTok @narrain_grain For more information on Narrain Pastoral Company, visit narraingrain.myshopify.com

Highlighting two models in Antonio Carraro’s tractor range shows the extent of unique features offered as standard, along with further specialisation for different conditions

While Antonio Carraro’s point of difference is providing tractors that meet specialised needs, this doesn’t mean the manufacturer’s entire range can be treated as fulfilling an identical purpose.

Designed and manufactured in Italy, Antonio Carraro tractors are built to excel in horticultural environments, with its European origin influencing design in ways which are creating unique benefits for Australian growers.

Taking a look at two models at opposite ends of its offering shows that while many of the manufacturer’s distinctive features are present on both, its areas of excellence and target markets reveal that Antonio Carraro is certainly not a one-trick pony.

With a 38hp engine, the TTR 4400 is the smallest of the brand’s hydrostatic transmission tractors and contrasts in many ways to the TRX 9900 – which with

an 89hp engine is among the largest of Antonio Carraro’s tractors.

Looking deeper into both the similarities and differences between these two machines highlights what Antonio Carraro has available across its Australian range.

Arguably the most unique feature which Antonio Carraro offers on many of its tractors – including both the TTR 4400 and TRX 9900 – is reversible driving.

This, as the name suggests, means the steering and driving position can be completely turned around 180 degrees by simply rotating a turret.

This impressive feature enables operators to work equally comfortably with front and rear-mounted implements by having identical vision and operating

function for both, rather than the operator needing to look behind themselves to see rear-mounted implements.

Complementing this feature is the transmission, with both tractors having the same number of forward and reverse speeds to provide seamless operation with all implements.

The TTR 4400 is fitted with hydrostatic transmission and offers a mechanical selector with three speed ranges, an independent two-speed PTO, and front and rear differential lock.

Another common feature to both tractors, and one which also points back to Antonio Carraro’s European influence, is its ability to handle hilly conditions.

They have a low centre of gravity, helping to provide excellent stability, which is in part due to the manufacturer’s patented Actio chassis.

With this, the front and rear axles oscillate independently up to 15 degrees, which makes the tractor crawl over uneven ground and operates in constant 4WD.

Their stability is also highlighted by manufacturer data which shows the TTR 4400 HST can handle slopes of up to 43 degrees longitudinal while ascending or descending and up to 36 degrees while inclined either side.

The TRX9900 can handle up to 33 degrees of incline without overturning when stopped either uphill or downhill in a longitudinal position, and up to 38 degrees when stopped on an incline.

These common design features are based on what Antonio Carraro knows all tractor buyers require, however each is also fitted with additional characteristics to meet even more specialised needs.

Antonio Carraro’s TTR 4400 might only have a 38hp engine, but it has been designed to do a variety of specialised jobs to an exceptional standard.

Its versatility means it is ideal not only for agricultural uses, but also in other environments such as golf course and sports ground maintenance as well as in nurseries and construction sites.

The stability offered by the Actio chassis makes it ideally suited to these environments, which often have more varied terrain than broadacre country.

Its short wheelbase and tight steering radius help to make the tractor extremely agile in crop rows, while its compact overall nature – capable of being just 1.13m wide depending on tyre settings – makes it well suited to orchard and vineyard settings.

Further versatility is offered by the choice of cabin or ROPS configurations, both of which still mean the machine measures under 2.1m high and is therefore suited to the low rows favoured in some horticultural environments.

Its PTO shaft enables easy switching of implements, enabling users to complete a variety of tasks not only in orchard rows but around the farm and in gardens.

Operation is via an intuitive joystick, while the cabin option brings the additional advantages of air conditioning and soundproofing.

Different scenarios require different tractors, which is where the TRX 9900 enters the equation.

Offering the same reversibility and stability of the TTR 4400 but with extra power and other features – it has been described as the “pinnacle” for macadamia farmers by one New South Wales dealer with almost 40 years of experience using the Antonio Carraro product.

Macadamias are just one industry where the TRX 9900 excels, with it also being suited to larger farms with open fields as a general purpose tractor, along with being ideal for horticultural settings that require additional power.

Its four-cylinder engine produces 89hp, making it one of Antonio Carraro’s most powerful models, and a 2,400kg lift capacity gives further evidence of its strength.

It comes with the choice of either a rollbar or fully enclosed cabin and provides 16 forward and 16 reverse gears.

Despite its increased size and power, the tractor can still measure under 1.4m wide, depending on tyre settings, and less than 2.2m high to maintain its strength under low-hanging fruit.

It also has equal-sized front and rear wheels, helping its stability and usability while the steering position is reversed.

Other features include two double-act-

ing hydraulic distributors – one of which has a floating position – and one oil reflow, making five rear couplings in total, plus adjustable three-point linkage arms. It also contains simple manual transmission without complex electronics –something the manufacturer believes has

Quality proven over the long term, along with a host of features and technology, is just part of what makes Miller sprayers ideal for Australian farmers

Put simply, Miller sprayers are built for

The brand’s national presence has steadily grown thanks to the reliability and capacity that makes them ideally suited for Australian farming require -

gricultural Equipment Holdings Group, which has dealerships in New South Wales and Victoria, is a key part of the brand’s network and promoted Miller sprayers to its customer base last year through a series of on-farm demonstra-

iller prides itself on equipment which meets the needs of farmers – strong and durable construction, high capacities to handle broadacre environments, a suite of technology to make life easier, plus plenty of customisation options to suit

Its range is based around the Nitro 7000 series, which consists of the 7310, 7380 and 7420 self-propelled models.

This selection means customers can access sprayers with tank capacities of up to 6,100L as standard (with the option of increasing this to 8,000L), up to 48m

boom widths and 434hp of peak power.

Even the smallest of these three models – the 7310 – offers a 4,500L capacity tank and a minimum 27m boom.

The three models are rated for 285hp, 322hp and 372hp respectively but each can produce peak power of 310hp, 382hp and 434hp.

These raw numbers point to sprayers equipped to handle the needs of largescale Australian farms, along with a selection of power, capacity and boom widths to fit individual requirements.

It is not just the size which makes Miller sprayers ideal though. One of the biggest benefits attached to Miller’s Nitro series is the range of spraying options available.

It can be paired with the ISOBUS-compatible WeedSeeker 2 system, which uses “advanced optics and processing power” to apply herbicide directly to weeds, which can lead to up to 90 per cent less chemical being required.

Its sensors are lightweight and can also automatically adjust to changing

temperatures, light quality and backgrounds, while its expanded coverage area means even the biggest booms – such as the 48m widths available in the Nitro series – can be fitted with WeedSeeker 2.

Turn compensation and section control mean no targets are missed due to changes of speed and automatic shutoff will occur in areas already treated.

Another option is Bilberry’s spot spraying system, which uses a combination of an embedded camera network, computers and highly developed algorithms.

The system’s computer analyses field images in real time, controlling the nozzles to ensure only identified weeds are sprayed.

It enables green-on-green and green-onbrown spraying, with its algorithms also allowing users to identify specific weeds.

Inside the cabin, the user has full control of the system and can select weeds to target along with the crops to protect.

This technology can also work alongside Miller’s IntelliSpray II, which allows for easy switching between blanket and spot spraying without removing the system.

IntelliSpray II, described as “the most precise application system on the market”

comes standard with individual nozzle control to help reduce over application while maintaining constant pressure.

Miller also offers Spray-Air, a unique air nozzle spray system that provides deep canopy penetration.

This range of technology helps to maximise efficiency while lowering input costs, but it is not the only area in which Miller has aimed to excel.

Miller Intelligence is a focal point of the sprayers, providing seamless connectivity and real-time data access.

The 30cm SprayView 12 display controls

all sprayer functions and provides data access, all of which can be seamlessly uploaded to the Cloud if fitted with the factory option Raven Vaper 4+.

Inside the cabin, a Sidewinder Ultra console enables critical adjustments to be made.

Comfort and practicality are also at the forefront thanks to features such as two chassis monitoring systems, which are mounted in the roof lining so as to not disrupt the operator’s line of sight to the boom, along with two spraying monitoring systems – including one mounted on an adjustable swing arm.

Vast glass windows offer 270 degrees of

vision and makes sure the operator has an uninterrupted view of their surroundings so they can work both safely and productively.

Climate control, footpegs on the steering column, dimmable switches, push-button start and Bluetooth compatibility also increase comfort levels for sprayer operators inside the cabin.

Miller’s Nitro sprayers are fitted with twowheel steer as standard with four-wheel steer available as an option.

There is also consistent weight distribution between the front and rear axles to maintain optimal stability and performance regardless of the tank volume.

Excellent ground clearance of 1.8m for the 7380 model and 2m for the 7310 adjustable, depending on tyre selection, helps to increase crop protection.

Miller Nitro sprayers are sold through the AEH Group dealer network in New South Wales and Victoria.

These locations, along with the full Miller Nitro range, are available online at www.aehgroup.net.au

In 2023, Farms & Farm Machinery published its first ever Contractor Capability Showcase. This is our follow up, based on new submissions received

This showcase is intended as a resource for farmers to easily find contractors servicing their specific needs, with entrants sorted by state. All information were submitted specifically for this edition and all information was correct at the time of submission.

AK, NZ JG FENCING ltd jnhgemmell@gmail.com021889957Manukau

QLD Conway Ag mundagai@live.com.au0429650213Oakey Harvesting

QLD Gore Earthmoving Pty LtdAlisonH@goreearthmoving. com.au 0746714911 GOONDIWINDI Cattle Grids, Dams, Drainage Works, Grading, Land Clearing, Stump Removal, GPS Field levelling, Irrigation Channels, Repairs, Water Storage, Other Trucking, Oversize haulage of all machinery

NSW McClenaghan Contracting amcclenaghan@bigpond.com0417895898Narrabri Fertiliser spreading, Harvesting, Machinery Hire, Spraying, Windrowing, Control Traffic Farming, Yield Mapping, Seed Drilling, Sowing, Grain

NSW Aj and Sl keatley andrew.keatley@hotmail.com 0429317838 Giulburn Fertiliser spreading, Harvesting, Post & Rail, Post & Wire, Electric, Stockyards, Round Baling, Seed Drilling, Sowing, Tillage, Beef Cattle, Sheep

NSW Lee carrow partnership leecarrow2@bigpond.com0428951059Delungra Machinery Hire, 20ft Slashing and 6mtr speed tillage, Cultivation, Horse agistment and breaking

NSW Central West Weed Spraying pty ltd darren.gaffney@live.com.au0400530288 Cowra Spraying, Pump Stations, Repairs,

NSW BJ, EA & PR Dwyer admin@dwyercontracting. com.au

0429653237Alectown Fertiliser spreading, Harvesting, Spraying, Gypsum, Lime & Chicken Manure supply. Variable rate spreading, Sowing, Hay, Grain, Fertiliser cartage and drop deck.

NSW Coopers final trim luke@coopersfinaltrim.com0402169592Medowie Cattle Grids, Dams, Drainage Works, Grading, Land Clearing, Post & Rail

NSW All-Ways Earthworx & Slashingm74@live.com.au

NSW Hausfeld Contracting P/L hausfeldwarren@yahoo. com.au

0458000973Lowanna Machinery Hire, Spraying, Cattle Grids, Dams, Drainage Works, Grading, Land Clearing, Stump Removal, Post & Wire, Irrigation Channels, Repairs Water Storage

0459493446 Werris Creek Harvesting, Round Baling, Cultivation, Rock Picking, Seed Drilling, Hay

NSW TOMEC Contracting Tomec209@gmail.com0458653151Gloucester Fertiliser spreading, Machinery Hire, Bulk Spreading, Disc Seeding, Mid-Large Area Slashing, Loader work, Drone footage, Cultivation, Seed Drilling, Sowing, Tillage,

NSW Terrana civil admin@terranacivil.com0408170447Lake Bathurst Drainage Works, Trenching and service install, Pump Stations, Repairs, Trench and install pipeline/ irrigation

VIC Ross Hosking Contracting rosshosking@hotmail.com 0499991297 Lara Dams, Grading

SA R&M Farming smythricky@msn.com0439873727Pinnaroo Fertiliser spreading, Harvesting, Machinery Hire, Spraying, Square Baling, Sowing

WA Kingspan Rhino & Heritage Water Tanks thomas.hall2@kingspan.com1800 632 410Perth Airport Water Storage

With big money being spent on inner city museums, WAFarmers CEO Trevor Whittington argues the nation’s farming heritage is also deserving of a voice

Across Australia, we’ve become experts at spending vast sums of money on glittering museum projects that often feel more corporate than cultural.

Take Western Australia’s $400 million WA Museum Boola Bardip.

Sure, it is a stunning structure, but it is one that could easily pass for a Silicon Valley headquarters.

Next in line is the planned Aboriginal Cultural Centre (ACC) by the Swan River, an equally eye-watering venture.

While celebrating history and culture is essential, it’s time we asked if we could stop building temples to the past and start preserving the past itself?

The contrast in the bush couldn’t be starker.

Australia’s farming heritage – the backbone of rural communities and a pillar of t he nation’s economy – is rusting away in paddocks, sheds and old farm tips.

Scattered across the countryside are relics of agricultural innovation: old tractors, headers, and trucks that revolutionised farming and fed the nation.

These aren’t just simply machines; they’re artefacts of grit, ingenuity and the stories of the men and women who worked the land.

While Perth is busy making architectural statements, small farming museums across rural Australia are fighting to preserve this heritage on shoestring budgets.

T hese museums, run by passionate local volunteers, are desperate for funding to build sheds, restore machinery and protect collections from the elements.

Meanwhile, their urban counterparts enjoy state-of-the-art facilities and Instagrammable backdrops.

Sure, Boola Bardip is a triumph of design, but where’s the Chamberlain 40K

on display inside it? Where’s the WD-9 International?

T hese iconic machines cleared the Wheatbelt, yet visitors wander through Perth’s museums with barely a nod to the machinery that shaped the nation’s agricultural history.

It is as if we’re embarrassed by our farming roots, preferring abstract ‘conceptual journeys’ to the dust, grease and noise of real history.

This isn’t just about preserving old tractors; it’s about saving the stories of the people who used them.

The pre-war generation is gone. The post-war farmers who cleared land with Sherman tanks and worked with horsedrawn ploughs are dwindling fast.

Soon, farmers of the 1950s and 1960s, who doubled the output of machinery through ingenuity, and the innovators of the 1970s who built the first home-made four-wheel drives, will also be gone.

If we don’t act now, these stories – and the machines they revolve around – will vanish forever.

With this, future generations will lose their connection to the resilience and resourcefulness that built our agricultural legacy.

T he WA government has committed $250 million to the Aboriginal Cultural Centre, which is a project that tells an essential story.