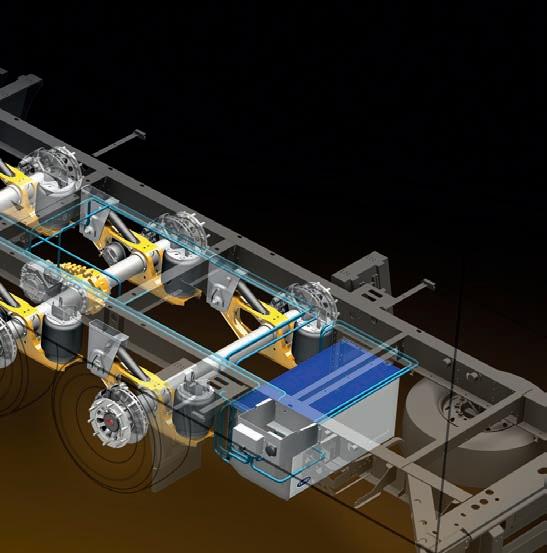

INDIVIDUAL RUNNING GEAR SOLUTIONS FOR SPECIAL TRANSPORT TASKS.

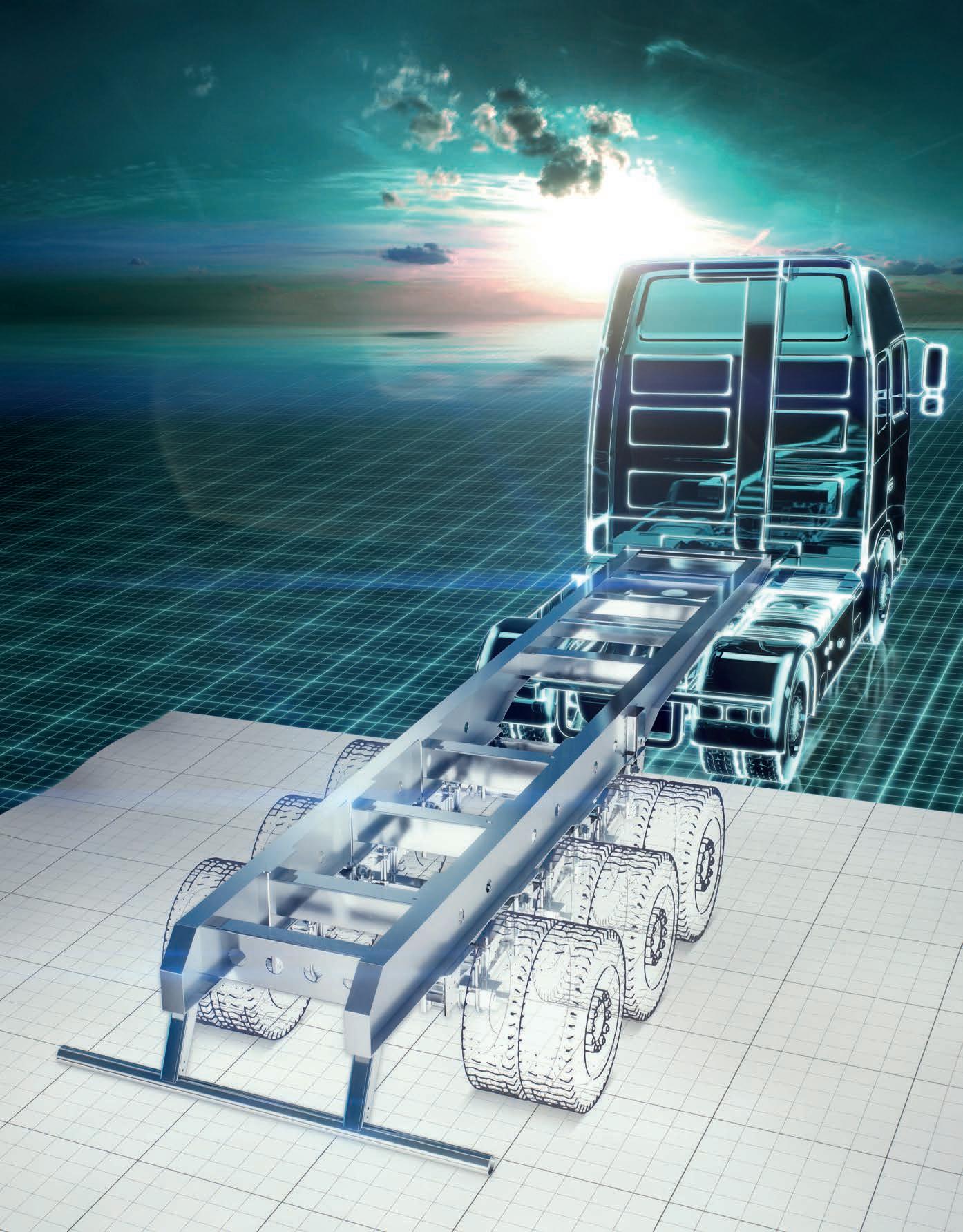

With our running gears and special axle solutions, there is nothing that can’t be transported. Your requirements motivate us to create new things. They inspire us to use our entire engineering expertise and decades of experience to develop innovative and reliable solutions together with you – customised for the type of vehicle and intended use.

The vehicle concepts for low-loaders are as varied as the transportation tasks. The use of air-sprung modules with rigid and steering axles is just one solution from our uniquely wide range of running gear systems for low-loaders. Challenge us!

Intermodal infrastructure projects at Europe’s largest port will be key to driving more e cient

transportation and sustainability

OEMs from around the world were asked to con rm their total trailer production number for the period 1 July 2023 to 30 June 2024.

Australia’s largest integrated conference and exhibition dedicated to the logistics industry returns to Melbourne this September.

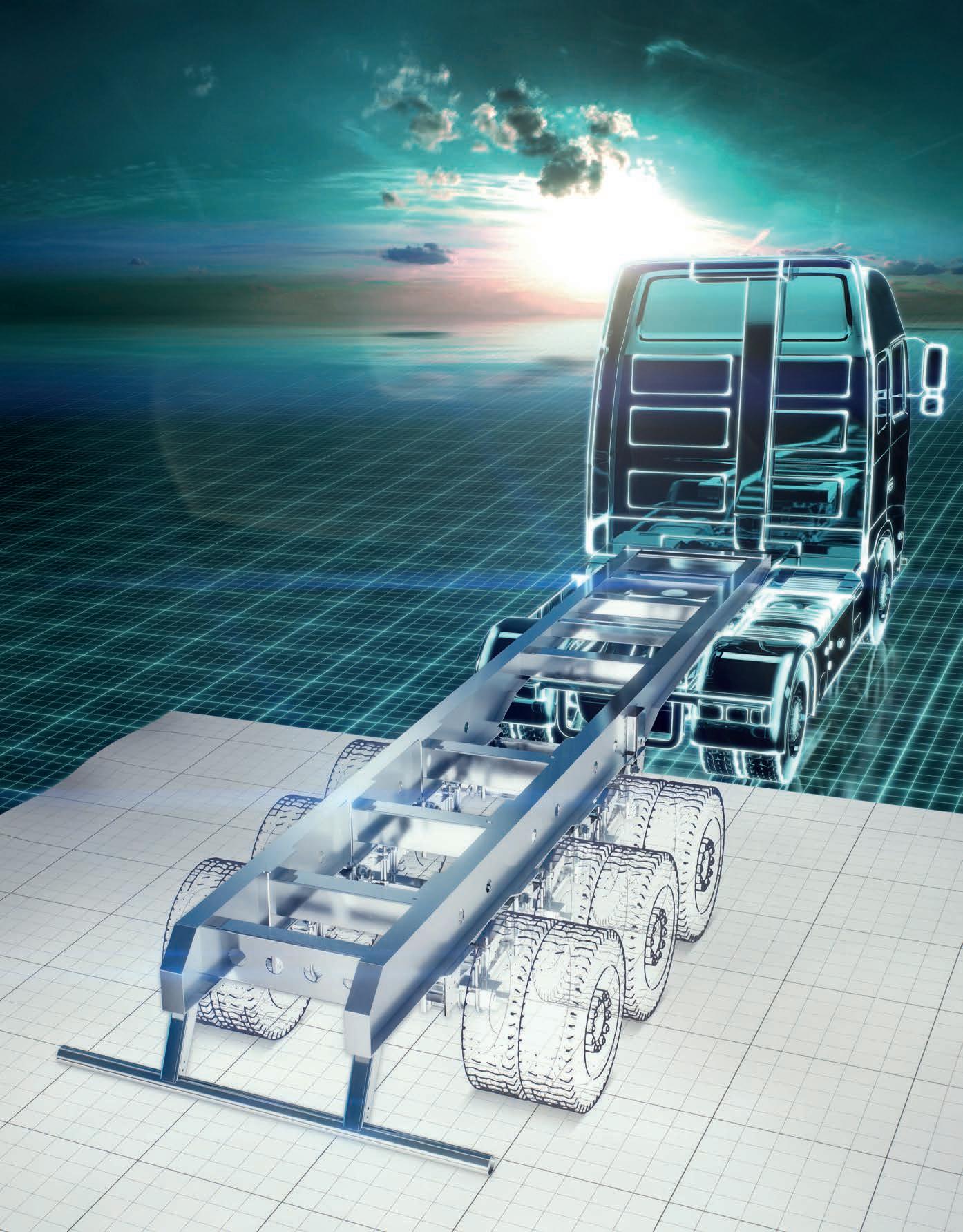

For decades, Wabash has been known as an innovator with a commitment to producing high-performance solutions for the transportation sector. But it’s an industry that is rapidly evolving, forcing the American trailer and truck body manufacturer to strategically pivot to prepare for the future.

“OUR FORWARD-THINKING APPROACH HAS ALLOWED US TO ANTICIPATE AND ADAPT TO CHANGES IN THE LOGISTICS INDUSTRY, ENSURING OUR CUSTOMERS RECEIVE COMPREHENSIVE, END-TO-END SOLUTIONS.”

Touted as the world’s most important industry meeting for transport and logistics in Hanover, Germany, IAA Transportation 2024 expo will draw in exhibitors from around the world. Find out who from the commercial vehicle sector will be there and what to expect.

SSAB steel has bolstered the e ciency and durability of Zetterbergs’ tipper truck bodies.

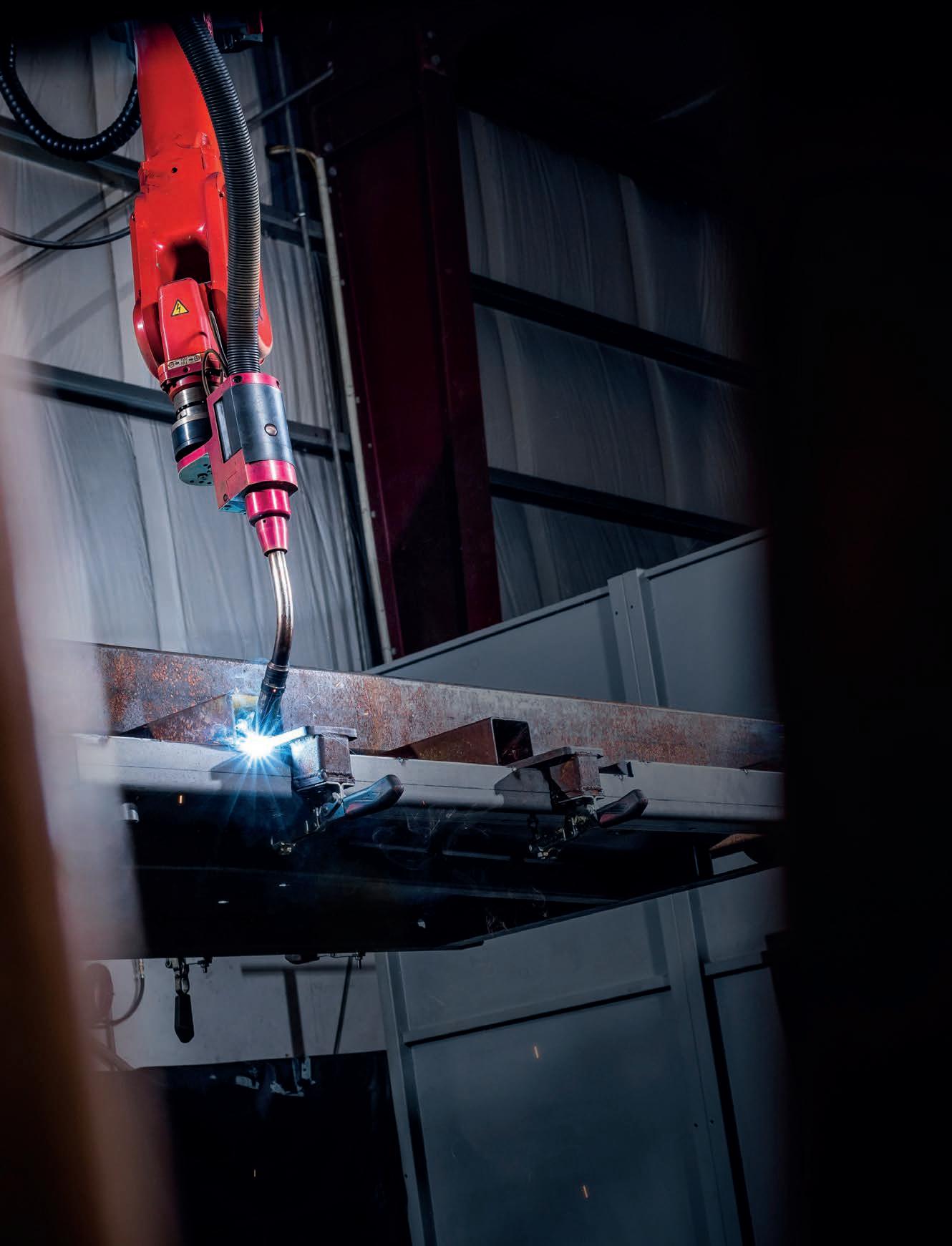

Netherlands-based trailer builder, Broshuis, is pioneering automatic robot programming with Valk Welding.

It comes as no surprise, at least to me, that our annual Global OEM Ranking List continues to be the most popular Global Trailer editorial year-on-year. I’m glad – overjoyed – that it is well received by our audience and remains a valuable industry resource because the work that goes into it behind the scenes is truly epic. At a glance, there’s a digital form for trailer builders to plug their numbers into and it all looks rather straightforward. We’re only asking one big question which results in a single gure but that’s only part of the equation.

Truth be told that form only captures a fraction of the data we implement in the nal version of the ranking list. We don’t simply set and forget this data collection task, trusting passive results to trickle in. Instead, we take the initiative and treat this undertaking as an opportunity to reconnect with everyone and not only bolster established rapport with our industry partners but also discover fresh prospects and build new relationships. A er all, it is our mission to grow individuals, organisations and industries.

In the long-term, there’s still much work to be done. Every year we encounter new trailer builders around the world which goes to show how dynamic and busy the trailer manufacturing scene, and the broader transport and logistics landscape, is. In addition to ranking the world’s top

trailer builders based on production, other developments from across the industry have garnered plenty of attention. Just look at the sheer number of acquisitions and mergers that have been announced and completed in recent months. In July, SAF-Holland acquired Italian axle and suspension specialist, Assali Stefen. Meanwhile, South African trailer manufacturer, GRW, expanded its European presence following its purchase of Belgiumbased OEM, Van Hool Industrial Vehicles. Schmitz Cargobull brought Berger products into its portfolio and Krone among others strategically invested in the electric trailer startup, Trailer Dynamics. A joint venture was also announced between Schmitz Cargobull and Utility. ere’s loads more – especially JOST’s expansion plans for Asia and Brazil –but you get the idea.

Every year we’re delighted to meet new faces in the trailer manufacturing scene especially at premier international commercial vehicle events such as IAA Transportation in Hanover, Germany.

Once again, our team have prepared a special report, a preview of what to expect from OEMs and suppliers, on what should be a sensational show. ere’s new technology, planned press conferences and so much more. Subscribe to our e-newsletter and follow the o cial LinkedIn showcase page to ensure you don’t miss any important updates.

CEO John Murphy john.murphy@primecreative.com.au

COO Christine Clancy christine.clancy@primecreative.com.au

INTERNATIONAL SALES

Ashley Blachford ashley.blachford@primecreative.com.au

MANAGING EDITOR

Luke Applebee luke.applebee@primecreative.com.au

JOURNALISTS

Louise Surette louise.surette@primecreative.com.au

HEAD OF DESIGN

Blake Storey

DESIGN

Laura Drinkwater

CLIENT SUCCESS MANAGER

Salma Kennedy salma.kennedy@primecreative.com.au

COVER Image: Wabash

HEAD OFFICE

Prime Creative Pty Ltd

379 Docklands Drive Docklands VIC 3008 Australia +61 3 9690 8766 enquiries@primecreative.com.au www.globaltrailermag.com

SUBSCRIPTIONS

+61 3 9690 8766 subscriptions@primecreative.com.au

Global Trailer is available by subscription from the publisher. e rights of refusal are reserved by the publisher.

All articles submitted for publication become the property of the publisher. e Editor reserves the right to adjust any article to conform with the magazine format.

Global Trailer is owned by Prime Creative Media and published by John Murphy. All material in Global Trailer is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. e Editor welcomes contributions but reserves the right to accept or reject any material. While every e ort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. e opinions expressed in Global Trailer are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

Follow us on twitter @Globaltrailer

Logistics provider, Dimerco Express Group, has introduced a new Expand to India advisory service in Chennai/Tamil Nadi.

It aims to establish new production and distribution operations in the Indian market.

The Expand to India advisory service will focus on customs brokerage, legal consultancy and other services, designed to help manufacturers navigate the complexities of India’s customs regulations, legal requirements and trade compliance.

The service will also be offered countrywide.

“India’s cost-effective workforce, government incentives and vast consumer market make it an attractive location for manufacturing expansion,” said Dimerco India Country Managers, Rajesh Srinivasan.

“But despite India’s many advantages as a manufacturing hub, it can be quite challenging to navigate the intricacies of the country’s customs, regulatory and logistics requirements.

“Our new Expand to India advisory service and experienced team will provide manufacturers with the guidance and support needed to achieve a smooth and fully compliant entry into the India market, including claiming relevant policy benefits.”

In response to a large number of manufacturers chasing growth opportunities in India, Dimerco has established eight offices in the country. India, according to Dimerco, also offers compelling financial advantages to growth-minded companies such as relatively low labour costs and government Production Linked Incentives (PLI) to support new, jobcreating factories and distribution centres in the country.

Srinivasan said companies anxious to capitalise on these advantages often move too quickly, underestimating the complexity of India’s customs, regulatory, logistics and supply chain requirements. As a result, their expansion projects experience massive delays, added costs and damaged customer relationships.

“That’s why Dimerco has established our

new Expand to India advisory service in Chennai to serve the entire country,” said Srinivasan.

“Companies need support that goes beyond traditional logistics services.

“Our local expertise in legal and regulatory requirements will help growth-minded companies achieve fully compliant, hassle-free expansion to India.”

Supply chain business, Mondiale VGL, has acquired a transport, warehousing and logistics operation in Southeast Asia.

Prior to the acquisition, Mondiale VGL held an existing stake in Interunion and the two companies have partnered together since 2012.

The acquisition of Interunion is expected to further enhance opportunities for the customers of both organisations to access a wider network of global offices both in Southeast Asia via Interunion’s network and globally with Mondiale VGL.

Interunion operates in five rapidly growing markets in Southeast Asia (Singapore, Indonesia, Malaysia, Thailand and Vietnam).

The Interunion team, service offering, branch network and brand will all remain the same, and there will be no change for customers or agents on a day-to-day operational level.

Mondiale VGL is a growing freight forwarding company that employs over 1500 staff across 56 offices in New Zealand, Australia, Asia, Europe, and the USA, supported further by over 500 agency offices worldwide. Mondiale VGL has been focused

on building a global supply chain operation with its roots in the Asia Pacific region.

The Interunion acquisition supports this strategic objective well and further extends Mondiale VGL’s existing presence in the region alongside its customer service offering.

The International Road Transport Union (IRU) and the Asian Institute of Logistics (ASIL) in Malaysia are cooperating to boost driver training and examination capacity for Dangerous Goods (DG) transport based

on international standards.

Malaysia, a member of the Association of Southeast Asian Nations (ASEAN), is, according to IRU, implementing the ninth protocol of the association’s Framework Agreement on the Facilitation of Goods in Transit, a key instrument simplifying and harmonising transport, trade and customs regulations across its 10 member states.

The ninth protocol specifically targets DG transportation, making it safer and more efficient via mutual recognition of standards aligned with the UN Agreement on the International

Transport of Dangerous Goods by Road (ADR).

“Transport professionals in Malaysia will need to demonstrate high levels of knowledge and skills to comply with the international standards,” said IRU.

“Once the ADR training capacity is in place, IRU and its local partners will look at boosting ADR examination capacity, allowing the Malaysian road goods transport industry to benefit from IRU ADR certification.

“IRU training programs for road transport managers are also being considered to reinforce standards in the sector.”

Two family-owned trailer building businesses in Europe will cooperate to strengthen their production and service capabilities.

The Krone Group this week has announced its investment in the Schwarzmüller Group.

With its annual turnover of 390 million euros and 1,950 dedicated employees, the Austrian Schwarzmüller Group from Freinberg near Schärding is a major European manufacturer of specialised vehicles in the commercial vehicle sector. The broad portfolio in the long-distance transport, construction and infrastructure sectors is characterised, among other things, by lightweight construction and a wide range of product customisation options. Particularly noteworthy are the popular lightweight trailers, the robust tipper semi-trailers or highquality tankers as well as the container transporters in the waste disposal sector from the subsidiary Hüffermann. The product portfolio is rounded off by a wide range of truck bodies, low-loaders,

walking floor trailers and timber/ stanchion vehicles.

The Schwarzmüller Group contributes four modern production sites in Germany, Hungary, the Czech Republic and Austria, each of which is specialised and reflects the manufacturer’s broad range of production expertise. This gives both companies the opportunity to consolidate their local presence in the entire European market. In addition, branches in nine other countries strengthen Krone’s European presence and extensive sales network, which will be consolidated by this partnership. The integration of these locations under the umbrella of the Krone Commercial Vehicle Group also promises an increase in distribution capacity, the expansion of competent service networks and thus a clear commitment to customer proximity throughout the European market.

The new industrial partnership respects the independence of the Schwarzmüller Group’s strong brands. This approach emphasises the common goal of preserving the identity for the individual

customer approach and at the same time using synergies for innovation and growth. Supported by expertise from Krone, the Schwarzmüller Group will continue to operate under the existing management. The personal involvement of the owner family Paletar will also remain on the boards and in the operational business.

“We see this partnership as a significant step towards an even broader product portfolio and an expanded service world,” said Bernard Krone, Chair of the Supervisory Board of the Krone Group.

“Our aim is for customers to find the right transport solution from us at all times.

“The inclusion of Schwarzmüller in the Krone Commercial Vehicle Group ensures that we can meet this requirement to an even greater extent.”

The owner of the Schwarzmüller Group, Beate Paletar, said: “We see the industrial partnership in the new ownership structure as an opportunity to further professionalise our modern, traditional company together, to optimally counter regulatory obstacles and thus ensure a secure future with stable jobs. Both family-run companies have proven in the past that they have very similar values. We look forward to a fruitful collaboration in these exciting times.”

Following the expected approval of the shareholding by the antitrust authorities in the near future, Krone and Schwarzmüller are embarking on a future together that will be characterised by a strong European presence. This new strategic alliance demonstrates the commitment of both companies to continue to be active shapers of the commercial vehicle industry and to proactively serve all customer needs with suitable products and innovative services.

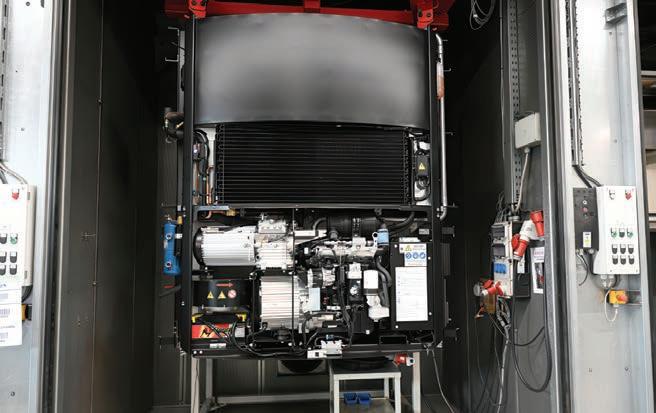

A state of the art, upgraded and fully integrated global manufacturing centre of trailer systems and On/Off highway systems. Expertly designed and engineered with worldwide accessibility, offering you private label and OEM manufacturing solutions.

Drawing upon decades of expertise spanning Asia, Australia, US, and in Europe, Fuwa stands as a global manufacturing powerhouse, unrivalled as the foremost network of specialists in truck and trailer components across the globe.

The vertical alignment of product teams is expected accelerate global transport and logistics solutions for CEVA Logistics.

Bolloré Logistics was acquired by the CMA CGM Group, CEVA’s parent company, on 29 February 2024. CEVA Logistics will soon integrate the new business which will improve its air, ocean, ground, rail transport, contract logistics, finished vehicle logistics, project logistics and custom solutions services.

“Our teams have been working toward this moment for many years, and I’m so proud of where we are as a company,” said CEVA Logistics, CEO Mathieu Friedberg.

“CEVA Logistics is moving to a vertical, product-driven organisation that will benefit our team and our customers as we compete among the Top 5 of the logistics industry.

“The vision we put in place for CEVA with the support of the CMA CGM Group is taking its final form. Our ability to innovate and collaborate with our customers to improve their global supply chains through truly end-to-end solutions is unmatched in some market segments.”

CEVA Logistics is a major player in third-party logistics, provides global supply chain solutions to connect people, products and providers all around the world.

Headquartered in Marseille, France, CEVA Logistics offers a broad range of logistics services to 170 countries worldwide thanks to its approximately 110,000 employees at approximately 1,500 facilities. It also reported a pro forma 2023 revenue of $20.2 billion USD.

Despite geopolitical and macroeconomic conditions, SAFHolland exceeded its financial forecast figures.

In a report to shareholders, Alexander Geis, SAF-Holland SE CEO, confirmed the war in Ukraine, conflict in the Middle East and high inflation presented the supplier of truck and trailer components with challenges.

In FY2023, SAF-Holland achieved new records for sales and profitability. It increased group sales by 34.6 per cent to €2.1 billion and experienced a boost in the share of the aftermarket business following the acquisition of Haldex.

Looking further ahead at Q1 2024 and the outlook for FY2024, Geis said sales growth of 5.2 per cent to 505.4 million demonstrates the robustness of the company’s business model with its strong aftermarket business and pronounced ability to adjust costs even in a weaker market environment. “We are therefore optimistic about the rest of the year,” he said.

DHL has appointed a new CEO of DHL Global Forwarding Germany and Switzerland.

Markus Panhauser will assume dual responsibility for both country organisations in his new role, succeeding Tobias Schmidt. He joined the Group in 2020 after working at various global logistics companies.

“We are convinced that Markus Panhauser, with his expertise in the freight forwarding business, will contribute to further expanding DHL Global Forwarding’s market

share in the two important markets of Germany and Switzerland and strengthen the organisation in both countries for the future,” said CEO DHL Global Forwarding, Tim Scharwath. Schmidt, the company said, has successfully led both country organisations alongside his role as CEO of DHL Global Forwarding Europe since November 2021 and is now focusing purely on his role as CEO of DHL Global Forwarding Europe. Meanwhile, taking over from Panhauser, Barbara Eleota, will assume the position of Head of Ocean Freight DHL Global Forwarding Europe. Joining DHL Group from DB Schenker, Eleota brings more than 25 years of experience in the logistics sector.

Schmitz Cargobull has acquired a majority stake in Atlantis Global System – AGS.

The acquired business is reported to be represented in most of the top 50 cold chain carriers in Spain.

The AGS telematics system for realtime refrigeration data will be available with immediate effect for all Schmitz Cargobull refrigerated semi-trailers produced at the Zaragoza plant.

The data from the TrailerConnect telematics system, which Schmitz Cargobull integrates as standard in all its semi-trailers, will also be

made available on the AGS telematics platform. On customer request, the OEM said the telematics data from the AGS system will be available within the Schmitz Cargobull TrailerConnect portal.

AGS will remain an independent cold chain specialist within the Schmitz Cargobull Group and will continue to operate independently in the market.

Founder Rafael del Pino, who will continue as CEO of AGS.

“The partnership with Schmitz Cargobull is an important step to strengthen and further develop the solutions developed by AGS in Spain,” he said.

“It offers a great opportunity to promote new products and further develop advanced fleet management solutions.”

To celebrate the cooperation, Schmitz Cargobull and AGS are offering a special welcome package for customers in Spain.

Together with the Schmitz Cargobull refrigerated box body, the TrailerConnect telematics and the AGS intelligent temperature recorder (thermograph) will be combined with refrigeration units from Schmitz Cargobull and other manufacturers. The complete package will be manufactured and installed at the new Schmitz Cargobull plant in Zaragoza with Schmitz Cargobull taking full responsibility for a seamless integration.

Spain-based OEM, Lecitrailer, completed its ‘Lecitrailer Tour Experience’ convention with French distributors and dealers earlier this year.

For three days, from 17-19 June, attendees had the opportunity to see first-hand the company’s facilities in Casetas, Zaragoza, as well as enjoy the rich Aragonese culture and gastronomy.

The event began with a visit to the Lecitrailer factory. Participants were able to closely observe the production process, the innovative technologies used in the manufacture of semitrailers, as well as see an exhibition with the latest vehicle developments. This visit was a valuable occasion to strengthen the links between Lecitrailer and its French distributors, sharing knowledge and experiences that will contribute to improving collaboration and service to the end customer.

In addition to the business focus, the convention included moments dedicated to culture and leisure. Attendees enjoyed a tasting of typical products of Aragonese gastronomy, highlighting the quality and variety of

local flavours.

Later, the convention moved to the Pyrenees, a place of natural beauty.

During this trip, attendees visited the emblematic cathedral of Jaca and the historic Ciudadela, two jewels of Aragonese cultural heritage.

Chemical and pharmaceutical transport and warehousing specialist, Tapfreight, has taken delivery of 11 Schmitz Cargobull S.CS Fixed Roof curtainsider semi-trailers.

The Barnsley-based business will pair the new trailers – built at Schmitz Cargobull’s production facility in Manchester – with its modern DAF and Mercedes-Benz tractor units to transport chemical goods and general freight across the UK.

“These are the first trailers we have had from Schmitz Cargobull and we’ve been hugely impressed from start to finish,” said Tapfreight Director, Bob Milton.

“The price point was very appealing and when I went to inspect the trailers, I was really struck by the build quality.

“Now we have physically taken delivery of the trailers that quality has been reinforced.”

Supplied by Aaron Howarth, Area Sales Manager East Midlands at Schmitz Cargobull, the new S.CS Fixed Roof curtainsiders comply with DIN EN 12642 Code XL load security regulations and feature a bulkhead specific for the British market. They are built on Schmitz Cargobull’s fully galvanised Modulos chassis which comes with a 10-year warranty against rust-through and have ROTOS axles covered by a 1,000,000km or six-year warranty, whichever comes first.

Each S.CS Fixed Roof semi-trailer has a straight front wall for free side loading and tarpaulin tensioning, an XL load securing side curtain with standard anti-theft protection and a Schmitz Cargobull aluminium roof which allows a side loading height of 3,100mm. They are also fitted with Schmitz Cargobull’s TrailerConnect telematics as standard, which provides 24/7 monitoring of the trailer’s exact location, plus other important data including tyre mileage, speed and axle load.

“The lead time was another plus point for us,” said Milton.

“And the level of service we have received has been first class. Aaron has been hugely helpful, and the whole Schmitz Cargobull team has been a pleasure to work with.”

SSAB has entered a partnership with UK-based manufacturer Firth Steels, which includes the immediate delivery

of SSAB Zero, commercial steel made of recycled steel and produced with fossil-free electricity and biogas. This long-term deal will reportedly see the supply of steel made with virtually zero fossil carbon emissions.

The steel, SSAB said, will be used as a key component of Firth Steels’ Protex Voyage which is a low embodied carbon building envelope solution.

“We are absolutely thrilled to have been selected by SSAB to embark on this great journey in reducing carbon emissions in all aspects of our steel process,” said Firth Steels Managing Director, James Firth.

“As a UK-based roll-former of steel profiles, Scope 3 emissions represent the largest portion of our carbon footprint. By forming strategic partnerships with the world’s leading mills, we can significantly reduce these emissions and forge a sustainable future for our planet from the outset, not offset.”

Dave Williams, SSAB Swedish Steel Managing Director, said that by cutting carbon emissions, SSAB can help its customers reduce their indirect missions from the materials they use.

Traditional steel production represents a significant source of global CO2 emissions, with both virgin and recycled steel production contributing to emissions. By changing the way steel is produced, SSAB wants to cut emissions and create a fossil-free value chain with customers and partners regardless of whether the raw material is scrap or iron ore.

To this end, SSAB has created two unique steels with virtually zero fossil carbon emissions: SSAB Zero and SSAB Fossil-free steel. SSAB Fossil-free steel

is made from iron ore with the unique HYBRIT technology, developed by SSAB with mining company LKAB and energy company Vattenfall. Instead of using coal to remove the oxygen from the iron ore to make iron, the HYBRIT technology uses hydrogen produced with fossil-free electricity, thus emitting water instead of CO2.

SSAB Fossil-free steel is currently available for pilot deliveries to selected partners, with volumes expected to increase in the coming years.

In addition to cutting indirect Scope 3 emissions, Firth Steels has several sustainable initiatives, under their ‘For Good’ campaign to reduce emissions from its own operations including energy used (Scope 1 and 2). The company has a battery storage facility on site and solar arrays which provide grid-free storage and production off grid if need be. It is certified by Planet Mark, an independent sustainability certification that measures carbon and social data.

In related news, SSAB’s near- and long-term carbon emissions reduction targets have been approved by the Science Based Targets initiative (SBTi). Approval is reported to mean that the targets are scientifically based an in line with SBTi’s raised requirements for companies to deliver on the goal of limiting global warming to 1.5°C.

SSAB is in the process of replacing its Nordic blast furnace-based production system with state-of-the-art mini-mill technology and electric arc furnaces that run on fossil-free electricity. Once completed, the transformation will eliminate about 10 percent of Sweden’s and 7 percent of Finland’s total CO2 emissions.

Vehicle component manufacturer, ZF, has appointed a new President for its North America unit.

Ramiro Gutierrez is to become the top executive in North America and will be based in Northville Michigan.

He has a bachelor’s degree in business administraion from Vigo & Santiago de Caompostela University in Spain.

Gutierrez has 30 years of experience in the automotive industry and has previously worked at Aptiv, ZF-TRW and Dalphimetal.

He was once President of Engineered Structures at Howmet Aerospace.

Gutierrez will be based out of ZF’s North America headquarters in Northville, Michigan.

“ZF has experienced an impressive transformation from a world-class provider of transmission technology to one of the largest global technology companies,” said Gutierrez.

“We are helping make mobility safer and cleaner for everyone. I’m excited to be back with this team and to continue to strengthen our ability to help our customers with the future of mobility.”

Gutierrez will report to Board of Management member, Dr Peter Holdmann.

Trailer and transport equipment manufacturer, NAZ Industries, has been awarded ‘Great Place to Work’ certification for the first time.

For the Dubai-based company, which has consistently put an emphasis on workplace culture, the award demonstrated that 95 per cent of its employees voted NAZ Industries a great place to work — 59 per cent more than the average US company.

“Great Place To Work Certification is a highly coveted achievement that requires consistent and intentional dedication to the overall employee experience,” said Vice President of Global Recognition at Great Place To Work, Sarah Lewis-Kulin, adding that certification is earned by the real-time feedback of employees regarding their company culture. “By successfully earning this recognition, it is evident that NAZ Industries stands out as one of the top companies to work for, providing a great workplace environment for its employees.”

“Happy CEO is the key success for every business. The CEO means,

Clients, Employees and Owners,” said NAZ Industries CEO, Adel Mir. “NAZ Industries aims to maintain its status as the best place to work over the years, creating an environment where employees feel comfortable and balanced, making work more enjoyable than ever.”

Logistics company, Kuehne+Nagel, has established a cross dock warehouse network in the US to streamline efficiencies.

The network includes eight temperature-controlled GxP-compliant facilities for cross-docking operations.

US expands healthcare logistics.

The cross-dock concept, according to Kuehne+Nagel, involves the loading and unloading of sea freight temperature-controlled containers in a GxP-compliant warehouse near an ocean port, allowing for the prompt return of empty containers to the port. At the temperature-controlled warehouse, the containers are sorted and optimised for road transportation to their final destination. This is reported to reduce the use of multiple containers and eliminates or lowers detentions charges due to a fast turnaround of container management. Kuehne+Nagel’s expanded network

of cross-dock facilities now includes warehouses in Philadelphia, Pennsylvania; Atlanta, Georgia; Wilmington, North Carolina; and Los Angeles, California.

Four additional locations across the country will open in 2024.

All of the facilities offer multiple temperature ranges and comply with Kuehne+Nagel’s HealthChain certification, ensuring the highest global quality standards for transporting, handling, and storing of healthcare products.

“Cross-docking optimises the time that products spend in transit, streamlines

the handling process, and reduces costs and CO2 emissions,” said Kuehne+Nagel Industry Champion Healthcare, Jeff Garcia.

“We began this concept as a pilot program with a large, global human and animal health customer for their animal health division at one warehouse, resulting in a doubledigit savings of costs in the container inbound process and cutting CO2 emissions by nearly half.

“Based on this success, we are proud to be expanding this offering to the healthcare market across the United States.”

FedEx has reportedly ended the financial year in a strong position.

FedEx President and CEO, Raj Subramaniam, said the business has delivered four consecutive quarters of expanding operating income and margin in a challenging revenue environment.

“These results are unprecedented in this current environment, reflecting our continued execution of our DRIVE initiatives and our resolve to transform FedEx while we deliver outstanding service to our customers,” he said. “We expect this momentum to continue in fiscal 2025 as we advance our efforts to create the world’s most flexible, efficient and intelligent network.”

FedEx Ground operating results increased due to reduced structural costs resulting from DRIVE initiatives, increased yield, lower self-insurance costs, and growth in ground commercial volume.

FedEx Freight operating results increased due to higher yield and effective cost management. FedEx Freight has announced plans to further optimise its operations and match capacity with demand through the planned permanent closure of seven facilities.

FedEx Express operating results declined primarily due to lower international yields, partially offset by reduced structural costs from DRIVE initiatives and higher US domestic package yields.

During the quarter ended 31 May 2024, FedEx Express permanently retired certain aircraft and related engines as

part of its fleet modernisation program. As for the FY2024 results, FedEx reported a revenue of $87.7 billion USD (FY2023: $90.2 billion USD); operating income of $5.56 billion USD (FY2023: $5.37 billion USD); an operating margin of 6.3 per cent (FY2023: 6.0 per cent); and a net income of $4.33 billion USD (FY2023: $3.84 billion USD).

“As we advance our transformation, we continue to focus on reducing structural costs and lowering the capital intensity of the business,” said FedEx Executive Vice President and Chief Financial Officer, John Dietrich. “Improved earnings and enhanced capital discipline enabled us to return $3.8 billion to stockholders during fiscal 2024 while prudently investing in our business and maintaining a strong balance sheet.”

Utility has announced the opening of a new facility.

Utility Trailer Manufacturing Company is opening a new Cargobull North America (CBNA) assembly plant and warehouse in Eagle Pass, Texas, to support their latest innovations. Adjacent to the Utility Trailer Southeast Texas dealer location in Eagle Pass, Texas, this new Utility and CBNA facility will focus on the final assembly operation of CBNA transport refrigeration units (TRU). The plant will also work on final assembly of remote evaporators, solar panels, telematics hardware, and other essential TRU parts. The facility will also be a warehouse that will store materials and parts for CBNA and Utility.

“It’s an exciting time for Utility’s production efforts,” said Utility

President and COO, Steve Bennett. “The plant and warehouse are centrally located to best serve most of North America. Utility dealers can order CBNA parts directly with rapid response.”

The new Eagle Pass facility, in addition to a network of six Aurora Parts distribution centres, is expected to bolster the accessibility and availability of CBNA parts and accessories.

The Cargobull 625 Hybrid (singletemp) and 655MT Hybrid (multi-temp) ultra-low emission TRUs are factoryinstalled options exclusively available on Utility’s 3000R refrigerated trailers.

Supply chain management company, United Parcel Service (UPS), is selling a logistics partner in North America to focus on its core business.

UPS has agreed to sell Coyote Logistics to RXO for $1.025 billion USD.

This follows a decision by UPS to position itself as a premium small package provider and international logistics partner.

“RXO’s highly accretive acquisition of Coyote will immediately increase the scale of our brokerage business, providing customers with more

capacity across a wider array of power lanes,” said RXO CEO, Drew Wilkerson.

“RXO will realise significant synergies from the acquisition by quickly integrating Coyote’s business into RXO and leveraging our cutting-edge technology. The addition of Coyote’s customer base will diversify RXO’s vertical mix and will increase the number of customers that do more than $1.0 million in business with us by approximately 80 per cent.

“This acquisition will provide RXO with both immediate and long-term opportunities for revenue and earnings growth and will generate significant returns for shareholders.

“I look forward to welcoming Coyote’s employees to our team and working together to achieve excellent results for our customers, shareholders, carrier partners and employees for years to come.”

Coyote Logistics is based in Chicago and is reported to work with 100,000 network carriers and manages 10,000 loads daily.

The deal is expected to close by this year’s end and is subject to regulatory review and approval.

North American OEM, Manac, has closed a major financing deal to expand and modernise its operations. The close of $170 million in financing with Investissement Québec, BDC and Desjardins will catalyse the company’s growth strategy.

Specifically, the expansion of its largest manufacturing plant, established since 1967 in Saint-Georges, Quebec, as well as the deployment of new sales and service centres in Quebec and

elsewhere in Canada.

“Maintaining an efficient, competitive manufacturing site for over 55 years in a highly cyclical industry is quite a challenge and requires the commitment of many partners,” said Manac President and CEO, Charles Dutil.

“The project we have just initiated is designed to enhance our competitiveness and maintain the trust of our customers and partners for many years to come.”

Logistics company, Leschaco, headquartered in Bremen, will change the name of four of the five Colombian subsidiaries it acquired as part of its purchase of Coltrans S.A.S., effective 1 July 2024.

• Coltrans S.A.S. will in future operate under Leschaco Colombia S.A.S.,

• Coldepositos Logistica S.A.S. under Leschaco Logistica S.A.S.,

• Coldepositos Bodega Nacional S.A.S. under Leschaco Bodega Nacional S.A.S. and

• Colotm S.A.S. under Leschaco OTM S.A.S.

• The name change of Colmas S.A.S. is planned for 2025.

This step arises as part of Leschaco’s strategy to integrate and optimise its global operations, improving its synergies and strengthening its presence in key markets.

The acquisition of Coltrans S.A.S. on 20 December 2022 marked an important milestone for the Leschaco Group, further expanding its presence in Colombia, one of the largest emerging markets in Latin America. With a collaboration of more than 30 years,

Coltrans had been an integral part of the Leschaco agent network. By integrating the Colombian subsidiaries into the Leschaco Group and aligning their names with the company’s global identity, the organisation aims to leverage the strength and reputation of its brand to increase market presence and customer recognition.

This strategic move underscores Leschaco’s commitment to providing seamless, integrated logistics service solutions across its network.

“We are pleased to announce that the smooth integration of our Colombian subsidiaries as part of the Leschaco Group is now also evident in the rebrand,” said Leschaco Group CEO, Constantin Conrad.

“This decision reflects our continued efforts to optimise our operations and better serve our customers in Colombia and around the world.

“By integrating these entities under a unified brand identity, we are strengthening our presence in one of the most dynamic markets in Latin America and reinforcing our commitment to delivering exceptional value to our customers.”

Grupo Empresarial Coltrans S.A.S., which in the future will operate under the framework of the Leschaco Group, has positioned itself as a leading player in Colombia’s logistics landscape since its creation in 1988.

With a comprehensive set of global logistics services that encompass import and export, customs clearance, warehousing and intermodal transportation, the renowned entities will continue to maintain the highest standards of excellence in service and

customer satisfaction.

Martin Sack, Regional Director of Leschaco for the Americas, emphasised the importance of the rebranding initiative and said: “The integration of our Colombian subsidiaries under the Leschaco Group brand represents a key milestone in our expansion strategy in the Americas region. “By introducing a unified brand identity, we are improving our market positioning and creating new opportunities for growth and innovation.”

With the rebranding of its Colombian subsidiaries, Leschaco further reinforces its commitment to driving

operational excellence, fostering greater collaboration and offering value-added solutions to its clients around the world.

The Leschaco Group is a traditional owner-run logistics services provider offering intercontinental logistics solutions for sea and air transport, as well as contract logistics and tank container. As an accredited partner of leading companies in plant construction and mechanical engineering, automotive, chemical and related industries, manufacturers of consumer goods and pharmaceutical products.

To celebrate its 55th year of operation in Brazil, Librelato produced a special batch of four-axle bulk carrier semitrailers.

Librelato said the Series 55 trailers inaugurate the use of stainless steel in the grain line, with the ‘Made to Last’ durability concept – 410D is a type of stainless steel formed from

a low carbon alloy with additions of chromium and nickel and, therefore, has excellent resistance to corrosive and abrasive materials, such as fertilisers, offering high mechanical resistance and durability and, consequently, fewer maintenance stops.

For Librelato CEO, José Carlos Sprícigo, Series 55, as well as all the company’s

achievements during this period, are the result of the contribution of everyone involved with the Librelato brand, including management, Board of Directors, professionals, commercial partners and customers.

“As we look to the future, with the goal of becoming a century-old company, we recognise the dedication of everyone who has brought us here,” he said.

“After all, the commitment to integrity and excellence will remain as a pillar, to make Librelato even stronger.”

To celebrate 75 years of history, Brazilbased OEM, Randon, a Randoncorp company, has launched a special commemorative trailer series.

The commemorative line features all of Randon’s technology and performance, the products come in the special colour ‘New R 75’ and have a distinctive finish and gold details. They also come with a certificate and personalised plaque with the client’s name or logo. The

Hall 27, Booth C33

transporter that purchases a product from the limited series will also have Randon Smart technology available on board and exclusive spare parts plans in the first year.

“In these 75 years, as we stated in the motto of the promotional campaign, we have pushed history forward,” said Randon Chief Operating Officer, Sandro Trentin.

“We want, with exclusive actions like this special series, to value the long-standing relationship with our clients. To celebrate this achievement, we present several new features that elevate our history and embrace the

new moment we have reached. Randon exports semi-trailers and has an international network of 190 distribution points.

In addition to the commemorative line, Randon also launched a campaign for the internet that portrays the brand’s legacy, narrating the past, present and future through research carried out at the Randon Memorial. Among the attractions of the production are the artificial intelligence resources to reconstruct exciting historical moments that show the development of the business over more than seven decades of operation.

The world‘s most colour and gloss resistant GRP material keeps your investment looking like new.

FMH Group has merged with a parcel delivery firm. Together, with a total annual revenue of $1.3 billion AUD, they have created one of the largest logistics companies in Australia.

CouriersPlease and FMH Group have completed a merger, effective 27 June. This development sees consumer parcel delivery combined with broader logistics, transportation and warehousing capabilities which is reported to make it one of the top five largest logistics companies in Australia.

“Our merger with CouriersPlease represents an exciting milestone for us,” said FMH Group CEO, Simon Slagter.

“They are a renowned brand in consumer parcel delivery with a rich history spanning more than 40 years. “Together, we will leverage our unique

strengths and capabilities to improve our operational excellence, enhance our service offering, and ultimately, better serve our customers.”

CouriersPlease and FMH Group are both subsidiaries of Singapore Post. The merger represents a strategic decision to optimise excellence across the two organisations.

“We are thrilled about the possibilities that lie ahead,” said CouriersPlease CEO, Richard Thame.

“FMH Group has achieved significant growth in a short amount of time due to its technological innovation and vision to create a new logistics ecosystem that creates true supply chain efficiency.

“By joining forces, we are wellpositioned to deliver superior value to our customers, create new opportunities for our employees

and Franchise Partners, and drive sustainable growth.”

CouriersPlease will continue to operate under its own brand, from its own offices and with its existing team of employees and franchise partners.

“The driver of this strategic merger is growth,” said Slagter.

“Our people have always been and will continue to be critical to our success.”

FMH Group said it will remain business as usual for the two businesses as they gradually integrate their systems to strengthen their ability to deliver more value to our customers.

Last year, another subsidiary of Singapore Post acquired Border Express.

In other news, CouriersPlease launched a new facility in Perth, Australia, to bolster its e-commerce services.

CouriersPlease, CEO, Richard Thame, said the facility will more than just enhance logistics services for businesses and consumers throughout the region but allow CouriersPlease to better support the people of Perth and its retailers.

“The larger footprint of this innovative facility allows us to ramp up our processing speeds and essentially do what do now, but better, to help [Western Australia] businesses flourish further.

“This space also enables us to process parcels more efficiently and, thanks to that added volume, we can quickly

expand and provide density for our new franchise partners.”

As CouriersPlease continues to expand logistics operations in Western Australia, WA State Manger, Jamie Burgess, said the new facility will enhance operational capacity and streamline processes.

“[it will allow] us to efficiently manage a projected volume of over four million parcels per year,” said Burgess.

“The strategic location in Kalamunda allows us better access across Perth, directly benefiting our delivery efficiency and the overall customer experience.”

The new Perth facility features EV charging stations, solar arrays and internal ventilation and rainwater harvesting.

New signage will be rolled out on road trains and other heavy vehicles in Western Australia that measure over 22 metres in length this month.

The new visual signage, to be displayed on the rear of restricted access vehicles, is designed to assist other drivers in making more informed decisions when sharing the road with heavy vehicles. The new visual signage will show the

number of trailers and total length of road train combinations, including a graphic which shows the total length of the heavy vehicle as an equivalent number of car lengths.

The signage will replace the existing road train and long vehicle signage on all WA vehicles between 22 and 60 metres in length.

WA Acting Transport Minister, John Carey, said the initiative is all about making roads easier to navigate and safer for all drivers by giving motorists the length of larger vehicles they may be sharing the road with.

“We rely on road trains to keep our economy moving and we know how intimidating it can sometimes be to try to overtake one,” he said.

“This way other drivers have the information in front of them regarding how long the vehicle is which helps them to make a more informed decision when overtaking.”

WA is the only state to have this type of signage, and according to the State Government, it has generated interest from other interstate road authorities.

The new change is introduced after 90 per cent of respondents voted in favour of the new signage following its trial on freight vehicles throughout 2022 and 2023.

“There was great feedback following the successful trial last year and I look forward to the rollout in coming months,” Carey said.

Interstate heavy vehicle operators travelling across the border to WA will not be penalised, as existing warning signage will be recognised and accepted. There will be a six-month transition period to the new regulatory signs, starting from 1 July.

The Australian Government and National Heavy Vehicle Regulator (NHVR) are backing a safer, cleaner heavy vehicle industry by implementing the Safer Freight Vehicles reforms.

As part of these reforms, heavy vehicles of up to 2.55 metres wide will now be provided with general access to Australia’s road network.

Wider vehicles are required to be fitted with additional safety features, including an enhanced set of devices for indirect vision, stability control, advanced emergency braking, lane departure warning, side underrun protection and conspicuity markings.

The implementation of the Safer Freight Vehicles reforms is a significant step forward for heavy vehicle operators, with this increased general width limit now reflected in the Heavy Vehicle National Law (HVNL).

Assistant Minister for Infrastructure and Transport, Carol Brown, said it has been a collaborative effort from the Australian Government, NHVR, states and territories and the heavy vehicle industry to reach this stage.

“The Australian Government heard industry’s concerns that the previous width limits were a barrier to them installing critical safety technologies, and we have acted,” she said.

“By granting general access to vehicles up to 2.55 metres wide, we are promoting the highest level of road safety, supporting truckies to do their vital work more safely.”

This follows the Australian Government’s changes to the Australian Design Rules (ADRs) last October to allow an increase in the maximum

width of heavy vehicles fitted with the most modern safety features, from 2.50 to 2.55 metres.

“We have gotten on with the job of delivering the Safer Freight Vehicles reforms, which is now in place for New South Wales, Victoria, Queensland, South Australia, Tasmania, the Northern Territory, and the Australian Capital Territory,” said Federal Minister for Infrastructure, Transport, Regional Development and Local Government, Catherine King.

“This means these safer heavy vehicles will have general access to the road network in these jurisdictions, supporting improved road safety for all.”

The NHVR will now start working with key industry associations to develop a process to allow existing vehicles already in-service to be certified as Safer Freight Vehicles, given only new vehicles are currently eligible. This process is expected to be finalised in early 2025.

“The implementation of the Safer Freight Vehicles marks the completion of another action from the NHVR’s Vehicle Safety and Environmental Technology Uptake Plan (SETUP),” said NHVR CEO, Sal Petroccitto.

“As a modern and progressive regulator, the NHVR wants to ensure heavy vehicles are equipped with the latest safety technology, and make sure there are no regulatory barriers when it comes to manufacturers identifying and installing new systems.

“This announcement is a game changer for both operators and manufacturers and will ensure the safest vehicles are available in Australia, helping keep all road users safe.”

FOR DECADES, WABASH HAS BEEN KNOWN AS AN INNOVATOR WITH A COMMITMENT TO PRODUCING HIGH-PERFORMANCE SOLUTIONS FOR THE TRANSPORTATION SECTOR. BUT IT’S AN INDUSTRY THAT IS RAPIDLY EVOLVING, FORCING THE AMERICAN TRAILER AND TRUCK BODY MANUFACTURER TO STRATEGICALLY PIVOT TO PREPARE FOR THE FUTURE. WABASH PRESIDENT AND CEO, BRENT YEAGY, TALKS TO GLOBAL TRAILER ABOUT WHAT THAT LOOKS LIKE.

It was a momentous occasion for all involved. Wabash, North America’s largest trailer manufacturer, was saying goodbye to its long-serving Chief Executive O cer, Richard Giromini, who was one of the architects of the well-known brand. at was 2018 and since then, Brent Yeagy, the home-grown talent that lled his shoes, has steered the company, ensuring it not only continued to produce high-performance vehicles and solutions, but also navigate the convergence of physical and digital technologies in the trucking and logistics sector.

Looking back, Yeagy admits that the change in leadership was at a time that required a new mind-set.

“We had to shi our strategy and our operating philosophy to the new and fast-moving forces we would face in the future,” he said. “It required a new way of thinking and doing.”

Yeagy started his career serving in the United States Navy as a nuclear engineering o cer. He then went into private industry with Rexnord and DelcoRemy before joining Indiana-based Wabash in 2003. He held a range of positions in the company, each with increasing responsibility, including Vice President of Manufacturing, Vice President and General Manager of Commercial Trailer Products, and then SVP/Group President of that same division. He worked alongside Giromini as Chief Operating O cer for two years until taking on the Chief Executive O cer role.

Positioned at the pointy end of the industry, Yeagy has a bird’s eye view and has seen signi cant transformation in the US and North American markets in recent years. e changes, he said, are driven by trends such as the e-commerce boom, decarbonisation, technological advancements, supply chain resiliency, as well as regulatory changes. en there are trailer lead times, which are close to pre-pandemic levels, so keeping trailers on the road can be a challenge for many eets due to parts and services shortages.

In response, Wabash is proactively adapting to meet client needs through several key initiatives.

In the rst instance, Yeagy explained, it is simply through constant equipment design innovation – developing versatile, e cient and eco-friendly trailers tailored for e-commerce and urban logistics. Secondly, it is integrating technology by investing in telematics and real-time health analytics to improve eet monitoring, proactive maintenance and operational e ciency.

Wabash is also enhancing its parts distribution and a ermarket support by streamlining its distribution network and expanding a ermarket services to ensure timely access to necessary parts and services.

Finally, Yeagy explained, the company is forming strategic partnerships by collaborating with dealers and other stakeholders to improve parts availability and service o erings. ere is also the impact of cross-border trade and nearshoring trends on supply chains, a shi ing landscape that needs close monitoring. In response, Wabash has developed a Trailers as a Service (TaaSSM) platform, which is addressing emerging needs. e all-inclusive, subscriptionbased o ering provides exible access to trailers and accompanying services.

“By leveraging our traditional sales channels and developing new value-added services, Wabash is committed to staying ahead of market trends and delivering comprehensive solutions that meet the evolving needs of our clients,” Yeagy said.

Wabash National Corporation was founded in 1985 when a small group of transportation professionals decided to join forces with the goal of improving how semi-trailers were designed and built. Over the years it has transformed from semi-trailers to adding adjacent categories.

“Today, we are proud to be the preferred provider of solutions for many of the largest eets in North America,” said Yeagy. “Our forward-thinking approach has allowed us to anticipate and adapt to changes in the logistics industry, ensuring our customers receive comprehensive, end-to-end solutions.”

In 1996, Wabash revolutionised semi-trailers with a new trailer sidewall technology –DuraPlate®. e composite technology o ered durability and damage-resist performance. DuraPlate ®, and next-generation DuraPlate Cell Core ® panels, are today used in dry freight and truck bodies, portable storage containers as well as a growing number of

Wabash employs approximately 6,700 full-time sta across 13 manufacturing and 13 parts and services locations in the US and Mexico. In 2023, the company delivered 44,450 new trailers and 16,070 new truck bodies. It has almost 300 global patents.

Transportation Solutions

• Dry and Refrigerated Van Trailers

• Dry and Refrigerated Truck Bodies

• Platform Trailers

• Tank Trailers

Parts and Service segment

• OE Component Parts

• Process Systems

• Aftermarket Parts

• Repair and Maintenance Services

• Up tting and Equipment Services

• Wabash Marketplace

other diverse industries.

Wabash then followed up with EcoNex Technology, a next generation molded structural composite o en used in products that transport temperature-sensitive freight.

Panels with EcoNex Technology are lighter in weight, stronger in construction, and more thermally e cient, which means the vehicle requires less fuel.

ey also have a longer life than panels built with conventional technology.

“Our R&D investments in advanced material technologies re ect our commitment to delivering groundbreaking bene ts to the market,” Yeagy said.

Wabash has also focused on trailer aerodynamics, using sophisticated computational uid dynamics modeling, wind tunnel and track testing. e company was the rst OEM to develop a side skirt to alleviate the challenge of improving fuel economy. Today, eets

and trailer operators can save up to 4.2 per cent in fuel with Wabash’s impact-resistant AeroSkirt and AeroSkirt CX with the DuraPlate technology.

In 2023, Wabash opened an advanced manufacturing facility for its dry van trailers, the largest investment in a single operation in the company’s history. e facility features advanced manufacturing technology that enhances the worker experience and ensures a more repeatable process.

A er more than a decade of acquiring leading brands, Wabash National uni ed its family of brands in 2022 under the Wabash name as a way, it said, to serve its customers all while fostering a collaborative culture. Whether internally or with outside industry players, Wabash views collaboration as another method of dealing with the current disruptions

within the logistics industry.

“When you think about all of the players that make up the transportation and logistics markets, they are all facing unprecedented challenges,” Yeagy said. “Everything from disruption of global supply chains as we retreat from an overall globalisation footprint, to advances in technology at a rate that’s unprecedented. When you think about the vulnerabilities that have been created and exposed by recent societal, political, and environmental events, it is really showing weaknesses in the global supply chain. ings are too broad, too intertwined, and changing in such a dynamic way that we strongly believe an ecosystem approach is what’s needed to solve problems at scale.”

Yeagy goes on to explain that Wabash views its own ecosystem as a diverse group of parties looking at problems di erently. It believes in bringing di erent capabilities to the party, and looking at how solutions can be created di erently, and combined in a way that’s more powerful than what a company could do on its own or with just a couple of partners.

“With that in mind, we regularly try to bring together our customers, legacy and emerging technology partners, suppliers, dealers and research institutions to explore some of the challenges in the industry and seek new ways to innovate and meet evolving customer needs,” he said.

As an example, in 2022, the company launched Wabash Parts distribution network, a

“OUR FORWARD-THINKING APPROACH HAS ALLOWED US TO ANTICIPATE AND ADAPT TO CHANGES IN THE LOGISTICS INDUSTRY, ENSURING OUR CUSTOMERS RECEIVE COMPREHENSIVE, END-TO-END SOLUTIONS.”

single-channel network that encompassed the entire Wabash a ermarket portfolio. It featured a new e-commerce site with an increased inventory of transportation parts and faster shipping. Earlier this year it made its Wabash Genuine Parts available exclusively through its dealer and preferred partner network.

In 2023, Wabash and the Fernweh Group announced a strategic joint venture aimed at enhancing the digital transformation of the transportation and logistics industry.

Within ve months, the company launched the Wabash Marketplace, an end-to-end digital platform that improves the overall experience for dealers, customers, and suppliers through a connected partner ecosystem. is platform will continue to expand in service features and capabilities as new o erings become available to customers.

“Since the launch of the joint venture, we have made considerable strides in expanding our technology roadmap,” Yeagy said. “We are actively working on forging new partnerships with third parties within the logistics ecosystem. ese partnerships are crucial in reducing friction for our customers and suppliers, ensuring a smoother exchange of services and solutions.”

Wabash’s Trailers as a Service program (TaaS) is an all-inclusive, subscription-based o ering providing exible access to trailers which has been attracting a growing number of companies. Launched in 2023, TaaS includes managed care for assets, telematics for real-time tracking and advanced analytics.

This service enables logistics providers to e ciently position trailer capacity using the “drop and hook” strategy, which minimizes downtime, streamlines operations, enhances e ciency and reduces costs. E ective use of TaaS can also reduce empty miles, fuel consumption, and emissions.

Third-party logistics provider, Loadsmith, is an asset light business that has a very small footprint and no real estate. Using the TaaS program, the Denver, Colorado based company has been able to operate a eet of trailers without requiring the infrastructure of a shop network and the infrastructure of mechanics.

For Loadsmith CEO, Brett Suma, TaaS allows the company to scale in either direction without the signi cant capital costs associated with it.

“We are able to win business and then scale trailers, as opposed to scaling trailers in the hopes of winning business,” he said, adding that the downtime of its trailers is signi cantly less because of the Wabash maintenance team. “We are able to compete in a di erent, yet growing segment of the industry.”

TaaS provides its customers with a team to support the trailer, the eet management and the service of the trailer, meaning Loadsmith doesn’t have to worry about the road worthiness or load worthiness of its trailers. Consolidated monthly billing also simpli es nancial management, and the inclusion of insurance allows businesses to predict and manage costs more e ectively.

Looking to the future

Wabash is focusing on several key strategies to address ongoing freight challenges and enhance operational e ciency for eets as it continues to serve a growing eld of industries including food and beverage, pharmaceutical and biotech.

Its priority is to strengthen its relationships with dealers and partners by streamlining parts distribution through a single-channel system as well as leveraging technology to improve efficiency and reduce downtime. It is also looking to breaking down internal barriers and collaborating with dealers to ensure timely parts availability.

Additionally, Wabash is expanding its Trailers as a Service o erings and real-time trailer health analytics to enable proactive maintenance and reduce operational burdens on trucking companies. Recognising the industry’s driver and capacity shortages, Wabash’s TaaS model provides greater exibility and e ciency, helping eets manage volatility and meet growing demands such as drop-and-hook loads.

“ ese strategies position Wabash to not only address current industry challenges but also to support evolving logistics trends,” Yeagy said. “ is will ensure sustained growth and innovation in the transportation sector.”

Wabash is also committed to innovation with a number of projects involving educational institutions like Purdue University and the University of Delaware.

“We are constantly growing our technology ecosystem and our academic partnerships through projects where we have the opportunity to advocate for our customers in areas that we know are going to require disruptive innovation, such as vehicle electri cation,” he said.

Looking forward, Yeagy said he is most excited about what the company is becoming, describing it as evolving into an entity that has a more diverse team, is more process disciplined, more innovative and ultimately a company that is rising to meet industry challenges.

While that is something to be proud of, Yeagy said his biggest pride is much more speci c.

“It’s the people I work with,” he said. “We ask a lot, and they show up and deliver daily. I can’t say enough about how proud I am of all of them.”

www.onewabash.com

INTERMODAL INFRASTRUCTURE PROJECTS AT EUROPE’S LARGEST PORT WILL BE KEY TO DRIVING MORE EFFICIENT FREIGHT TRANSPORTATION AND SUSTAINABILITY OUTCOMES FOR THE NETHERLANDS.

Integrated logistics company, A.P. Moller – Maersk, inaugurated a specialised cross dock warehouse in Rotterdam on its Maasvlakte II terminal earlier this year. It is expected to accelerate the ow of cargo signi cantly from arrival on a vessel to the point of sale –especially in the Benelux, German and French hinterland.

A er discharging containers from an arriving vessel, the products can be unpacked, transloaded to conventional trucks and dispatched to their nal destination within hours. Maersk welcomed Starbucks as the rst customer in the warehouse which features a total space of 23,000 square metres, 120 docks as well as interim storage space.

e launch of the specialised cross dock warehouse right next to where the containers are being discharged from Maersk’s vessels showcases the company’s capability to control and manage its customers’ supply chains at every step from factory to consumer. It also bolsters resilience, exibility and visibility to supply chains in times of increased disruption and geopolitical risks.

“In our new cross dock we are speeding up a part of the supply chain where others are losing days in some cases,” said Maersk Managing Director – North Europe Continent Area, Ole Trump eller.

“With our priority ow o ering, it will be a question of hours to get cargo from a vessel on the road and to its nal destination. e new warehouse will allow an unmatched delivery of cargo. e interim storage space adds exibility to customers’ supply chains, for instance in case of peaks when their storage facilities are at full capacity.”

e cross dock facility is located on the Maersk owned terminal Maasvlakte II, in the heart of the Port of Rotterdam. e terminal and cross dock have a direct internal road connection. Another direct road leads to the signi cantly enlarged STAR depot for an immediate return of emptied containers to the depot, which should reduce D&D costs. e cross dock site also o ers a fully bonded customs environment plus a dedicated area for value added services. For customers with temperature sensitive cargo like fresh produce, pharmaceuticals, meat, sh and other frozen food, a large cold store warehouse is under construction on the same site at Maasvlakte II. It will have 40,000 square metres of space with several temperature zones and is scheduled to start operations from the end of this year.

“We are creating an interconnected eco system on Maasvlakte with excellent connectivity to road, rail and barge,” said Trump eller. “Here, all the individual elements and value adding services of

logistics and supply chains t in nicely together into a comprehensive o ering which simpli es logistics for our customers. It is a great example how the integrator strategy of Maersk is brought to life.”

Maersk has set itself ambitious goals for decarbonising logistics on land, ocean and in the air with a net-zero target in 2040. erefore, all new assets from vessels to warehouses are made for very low greenhouse gas emissions. e cross dock is built according to the BREEAM Excellent sustainability standard and will bene t from the cold store warehouse next to it. By re-using the le -over heat from the cold store in the cross dock, Maersk will save annually more than 200,000 Kilo-Watthours in electricity.

Netherlands economy in review e Organisation for Economic Co-operation and Development, headquartered in Paris, France, is an intergovernmental organisation with 38 member countries, founded in 1961 to stimulate economic progress and world trade

According to an economic outlook published in May, OECD Chief Economist, Clare Lombardelli,

said that despite modest growth and geopolitical risks, cautious optimism has begun to take hold in the global economy.

Disappointing growth, she said, underscores the case for strengthening global trade and productivity.

“Trade and industrial policies should aim for resilient global value chains through diversi cation without undermining the bene ts of open trade.

“At the same time, accelerating decarbonisation requires bold policy measures, such as investing in green and digital infrastructure, enhancing carbon pricing, and promoting technology transfer.

“ e developments in Arti cial Intelligence (AI) provide a welcome and much needed opportunity to raise productivity. Ensuring the bene ts materialise and are broadly shared requires investments in education and training and strong and internationally consistent competition policy.”

With speci c reference to the Netherlands, growth, the OECD reported, is projected to improve from 0.7 per cent in 2024 to 1.3 per cent in 2025, supported by private consumption as purchasing power increases. Annual headline in ation is set to fall from 2.8 per cent in 2024 to 2.3 per cent in 2025. Core in ation will slow to 2.3 per cent in 2025, as some upside pressures from a tight labour market persist. Wages will rise by 5.2 per cent in 2024 before slowing to 3.8 per cent in 2025. Unemployment is expected to increase marginally from 3.7 per cent in 2024 to 4.0 per cent by the end of 2025.

“ e scal stance is projected to be broadly neutral over the projection period,” said the OECD. “Following underinvestment in budgeted funds in 2023, government expenditure on debt interest, climate policy, social and health care and defence is set to increase. While prudent scal policy is still required, the government should continue to tackle structural

challenges, focusing on investment in the green transition and reducing labour shortages.” e economy is also reported to show moderate signs of improvement.

“A er three quarters of contraction, output picked up by 0.3 per cent in the fourth quarter of 2023,” said the OECD. “Following a gradual decline, headline in ation has picked up slightly in the rst quarter of 2024, reaching 3.1 per cent in March. Core in ation remains persistent at 3.1 per cent in March as a tight labour market continues to exert upward pressure. Collective labour agreement wage rates rose by 6.5 per cent in March compared to a year earlier and vacancies per unemployed person remain well above pre-pandemic levels.

Consumer con dence improved in early 2024, but business sentiment remains subdued amidst persisting labour shortages. e number of bankruptcies has been rising since May 2022, but is only slowly catching up with its pre-pandemic level.”

e Dutch economy, according to the OECD, is sensitive to global trade developments and depressed global trade growth has weighed on exports and output. It added the trade balance has been a ected particularly by reduced demand from key EU trading partners.

It is expected, though, that the economy will return to moderate growth.

“Gross Domestic Product (GDP) is set to grow by 0.7 per cent in 2024 and 1.3 per cent in 2025,” said the OECD.

“Private consumption will be a key driver, boosted by rising real incomes. Annual headline in ation is set to slow to 2.8 per cent in 2024 and 2.3 per cent in 2025 helped by lower energy prices and core in ation slowing to 2.3 per cent in 2025 as businesses have now passed on higher energy costs.

“Wage growth is projected to moderate from 5.2 per cent in 2024 to 3.8 per cent in 2025 and unemployment is expected to increase from 3.7 per cent in 2024 to 3.9 per cent in 2025, as the rate of bankruptcies continues to normalise. Investment will recover only slowly supported by gradually declining interest rates. External demand is expected to slowly improve as economic growth in key EU trading partners recovers. e outlook is surrounded by signi cant risks.

“Heightened geopolitical tensions could hit external demand and weigh on export growth. A tighter labour market than in the rest of the European Union could increase domestic in ationary pressures as euro area policy rates are lowered, weighing on purchasing power and household consumption. On the upside, higher income households could also support growth

by spending a greater share of their excess savings.” To tackle a tight labour market, policy e orts will likely be needed.

“ e Netherlands is in a comfortable scal position, but spending pressures are looming in the medium term from an ageing population and investment needs for advancing the green transition,” said the OECD.

“To increase the share of renewables in the energy mix, the government should support green technology, particularly at early stages of development, and lower the administrative burden for rms in accessing funds.

“ e incoming government should also address long-standing structural challenges, focusing on easing labour market pressures. Simplifying the tax system and removing distortions towards certain types of investment and labour supply could strengthen government revenues and ease tensions in the labour market.

“Moving to a system with fewer allowances and tax credits could o er greater transparency for the net bene ts from an additional hour worked and thereby increase working hours. Continuing to align tax rates and social security contributions between contract types for workers doing similar jobs could ease the transition into regular employment and thereby increase productivity through better upskilling opportunities.”

www.globaltrailermag.com

SAFETY, SUSTAINABILITY AND PARTNERSHIP ARE SAF-HOLLAND’S FOCUS AT IAA TRANSPORTATION 2024 IN HANOVER, GERMANY. THE INTERNATIONAL COMPONENT MANUFACTURER WILL BE PRESENTING ALL ITS BRANDS AND A PRODUCT RANGE THAT PROVIDES THE VERY LATEST IN TRANSPORT EQUIPMENT SOLUTIONS.

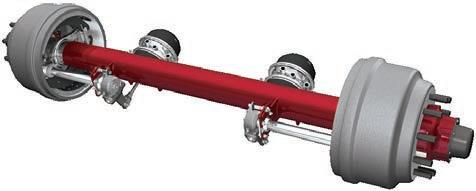

With a product selection that ranges from trailer axles and suspension systems, to h wheels and coupling systems for trucks, trailers and semi-trailers, as well as brake and trailer EBS systems, the SAF-Holland stand will be a busy spot at this year’s IAA Transportation Expo in Hanover, Germany.

Under the “SAF-Holland for Better Transportation” motto, visitors can nd out all about the international manufacturer’s pioneering technologies, safety and sustainability for commercial vehicles, including trailers, trucks and buses.

“Visit the stand we are sharing with Haldex where you will see the latest mobility solutions and a wide range of products and brands for your transport tasks,” said President EMEA and Chief Technology O cer, Christoph Günter, adding that this year’s motto is based on three pillars – more safety, more sustainability and more partnership.

Safety in the commercial vehicle and transport industry is crucial when it comes to the reliability and e ciency of modern logistics processes. New technologies, current regulations and safety requirements are challenging for vehicle manufacturers. Issues such as cybersecurity are becoming increasingly important for electronic and mechatronic components, such as the Haldex EB+ 4.0 Trailer EBS.

SAF- Holland is closely connected to its customers, and supports the shaping of future legislation in working groups, to help proactively shape new developments in the industry and maximise customer added value.

Haldex is expanding into the truck market with the innovative ModulT system truck disc brake. is is an important step forward for ModulT technology, as the single-punch

design comes with signi cant weight savings and cost bene ts. e ModulT truck brake will be tted as standard by a major truck manufacturer from the third quarter of this year.

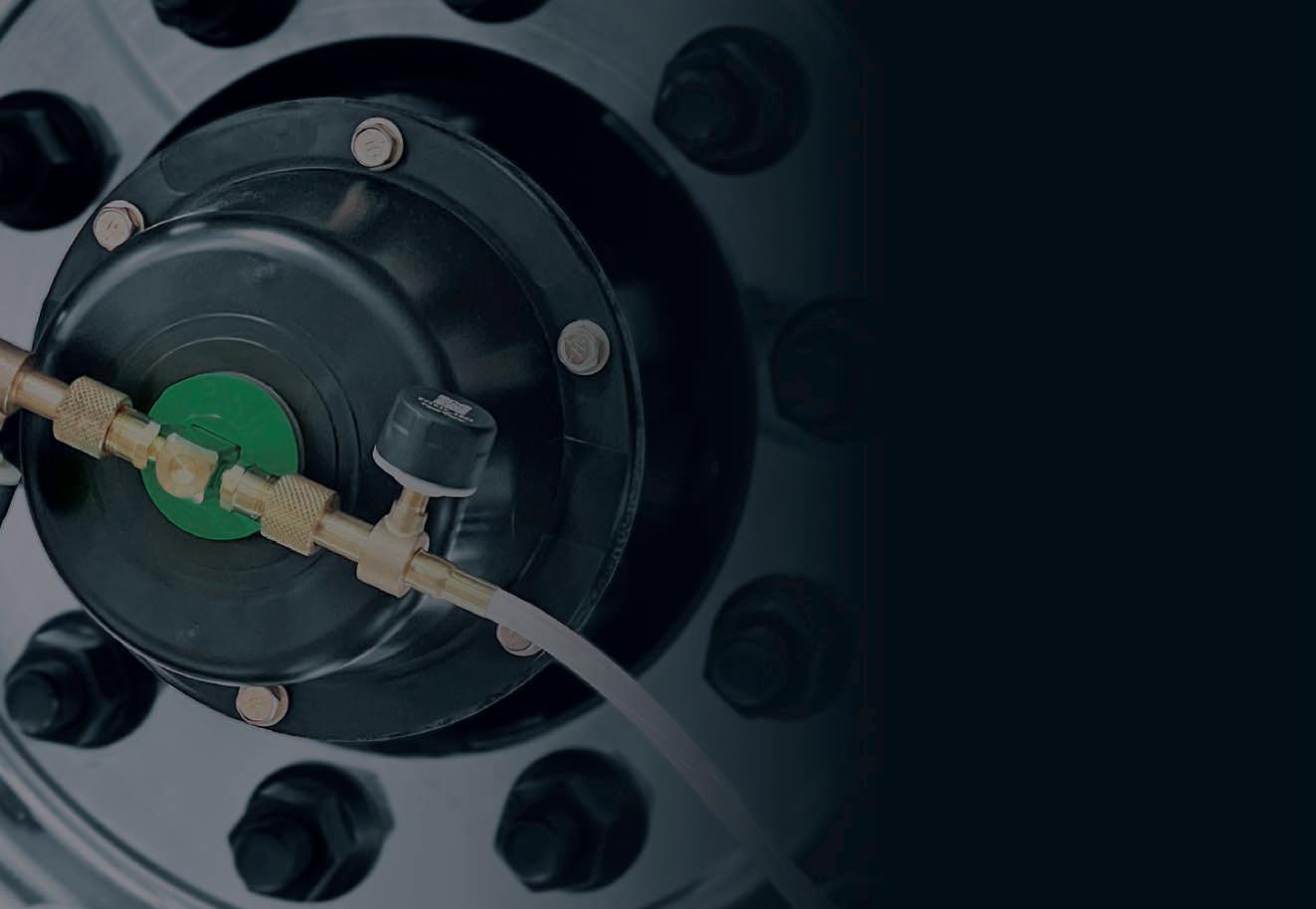

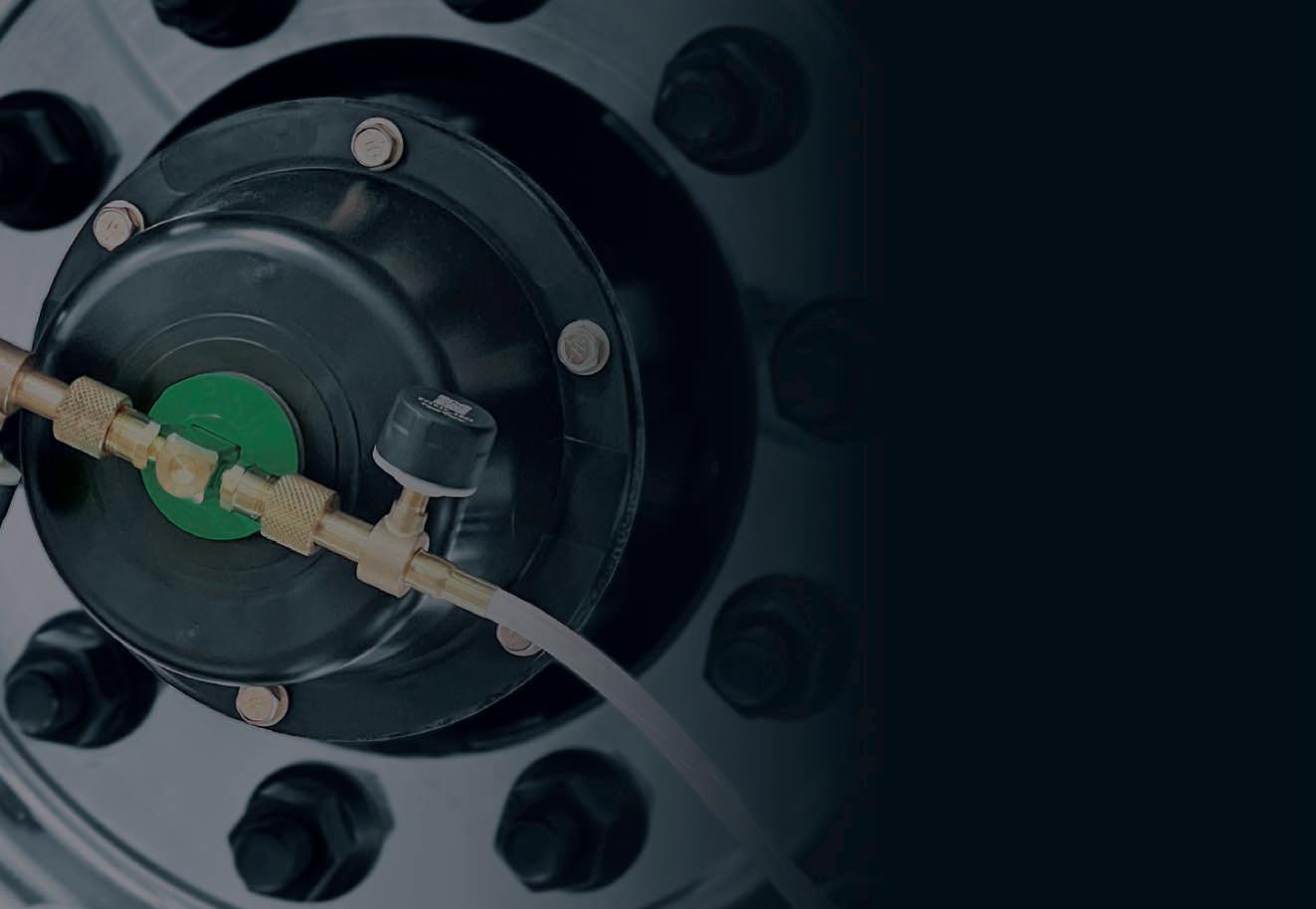

Meanwhile, modern tyre pressure monitoring systems make sure your tyre pressure is correct and minimise the risk of a tyre being damaged or failing.

e SAF TIRE PILOT I.Q. and the Haldex TPMS 2.0 monitors the tyre pressure in accordance with the requirements of UN ECE-R-141, although the SAF TIRE PILOT I.Q. goes one step further by not just warning, but also automatically topping up on pressure lost.

Holland h wheels, with integrated locking protection and visual safety indicator, guarantee a safe connection between truck and trailer. e advanced version of the Automated Coupling sees SAF-Holland demonstrating pioneering technology where the truck and trailer are coupled automatically without the driver having to leave the cab. Sensor and remote control options can be added to the robust and user-friendly trailer couplings from V.ORLANDI.

Sustainability and environmental protection are becoming more and more important. EU regulations to reduce CO2 emissions, such as VECTO certi cation, present new challenges for the transport and commercial vehicle industry.

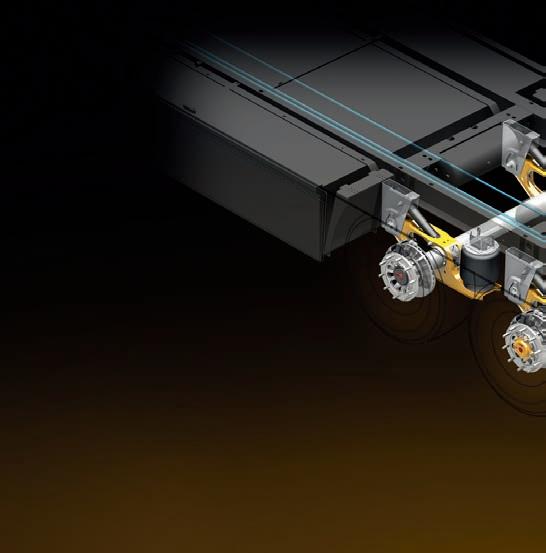

SAF- Holland supplies energy-e cient and environmentally friendly products and solutions, such as the SAF TRAKr electric trailer axle, which uses regenerative braking to reduce CO2 by converting the trailer’s kinetic energy into electrical energy.

For steering systems, the electro-hydraulic steering systems from VSE contribute to fuel savings thanks to low weight and optimised steering angle.

e lightweight and robust bar (SEM) and cable steering (GreenSteering) systems improve manoeuvrability, as lower friction when cornering reduces tyre wear and improves fuel consumption.

Meanwhile, the HOLLAND RECOLUBE BIOPOWER SKX 023 special lubricant