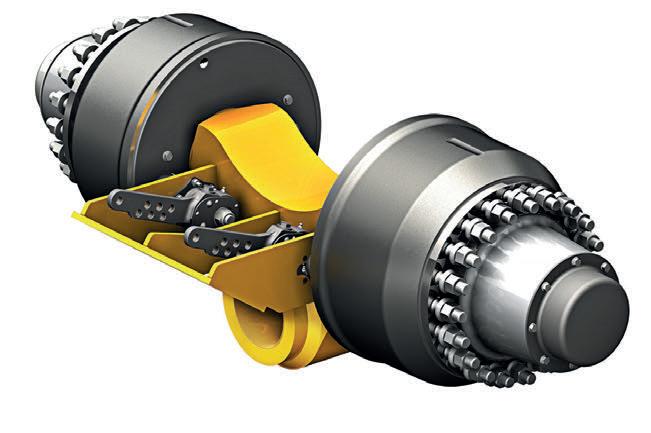

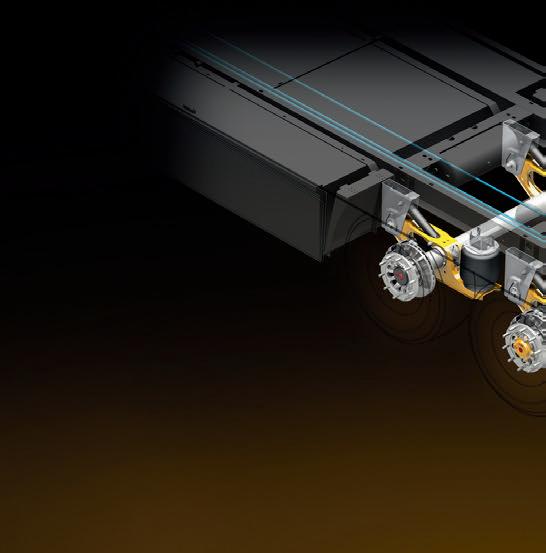

INDIVIDUAL RUNNING GEAR SOLUTIONS FOR SPECIAL TRANSPORT TASKS.

With our running gears and special axle solutions, there is nothing that can’t be transported. Your requirements motivate us to create new things. They inspire us to use our entire engineering expertise and decades of experience to develop innovative and reliable solutions together with you – customised for the type of vehicle and intended use.

The vehicle concepts for low-loaders are as varied as the transportation tasks. The use of air-sprung modules with rigid and steering axles is just one solution from our uniquely wide range of running gear systems for low-loaders. Challenge us!

What

With records broken, tough issues broached and an industry looking positively to the future, IAA Transportation 2024 organisers are declaring this year’s event a rousing success.

e Belgium-based trailer

See the Next Generation Curtainsider Series and the other innovations that follow.

Ivan Fornazaric, owner and Chairman of GORICA, shares his impressions of the

market in the

e electri cation of landing legs is boosting

Transport data is reported to be crucial for a transparent supply chain.

Learn more about a partnership in so ware and robotics.

With a broad portfolio of transport equipment, SAF-Holland makes the customer a priority.

What does it take to innovate and remain competitive in a sustainable commercial transport industry?

See how technology investments have enhanced JOST’s value proposition.

Accelerate curtainsider operations with the Penta system.

For Kögel CEO, Christian Renners, winning the workplace was the proudest aspect when it came to launching the company’s long-awaited, award-winning o ering at IAA Transportation 2024. He talks to Global Trailer about this important company moment and what it took to get there.

“WE

Kögel CEO, Christian Renners

Renewables are expected to meet almost half of the world’s electricity demand by the end of 2030 following the rapid deployment of solar PV systems. A report published last month by Parisbased autonomous intergovernmental organisation, International Energy Agency, has found that the world is set to add more than 5,500 gigawatts of new renewable energy capacity between now and 2030. at is almost three times the increase seen between 2017 and 2023.

China, according to the report, will account for 60 per cent of all renewable energy capacity installed worldwide between now and 2030 based on current market trends and government policies.

While this would make China home to almost half of the globe’s total renewable power capacity by this decade’s end, India is growing at the fastest rate compared to other major economies.

Solar PV is forecast to account for 80 per cent of the growth in global renewable capacity and this will take the form of new large solar plants as well as an increase in roo op solar installations by companies and households.

e wind sector is poised for recovery and is expected to double its expansion between 2024 and 2030 compared with the 20172023 period. In almost every country, solar PV and wind are the cheapest options to add new electricity generation.

Nearly 70 countries that collectively account for 80 per cent of global renewable

power capacity are expected to reach or surpass their current renewable ambitions by 2030. However, growth is not aligned with the goal set by nearly 200 governments at the COP28 climate change conference in December 2023 to triple the world’s renewable capacity this decade. e forecast is closer to 2.7 times its 2022 level by 2030. International Energy Agency analysts con rm, though, that meeting the triple target is possible if governments action near-term opportunities. is would entail reinforcing international cooperation on reducing nance costs in emerging and developing economies which are restraining renewables growth in high potential regions including Africa and Southeast Asia. Meanwhile, a journal that explores the Net Zero debate and the promise of a circular carbon economy, contends that hydrocarbons will remain a signi cant energy source and input for the manufacturing and services industry for the next couple of decades. Current global strategies to reduce the use of hydrocarbons, the journal elaborates, bring about various economic and political problems regarding their adoption and implementation. Speci cally, energy transition policies are generally not incentive compatible. Instead, emission reduction at each step of the value chain from extraction to end user might lead to a more sustainable, low-carbon future.

CEO

John Murphy john.murphy@primecreative.com.au

COO

Christine Clancy christine.clancy@primecreative.com.au

INTERNATIONAL SALES

Ashley Blachford ashley.blachford@primecreative.com.au

MANAGING EDITOR

Luke Applebee luke.applebee@primecreative.com.au

JOURNALISTS

Louise Surette louise.surette@primecreative.com.au

HEAD OF DESIGN

Blake Storey

DESIGN

Laura Drinkwater

CLIENT SUCCESS MANAGER

Salma Kennedy salma.kennedy@primecreative.com.au

COVER Image: Kögel

HEAD OFFICE

Prime Creative Pty Ltd

379 Docklands Drive Docklands VIC 3008 Australia +61 3 9690 8766 enquiries@primecreative.com.au www.globaltrailermag.com

SUBSCRIPTIONS

+61 3 9690 8766 subscriptions@primecreative.com.au

Global Trailer is available by subscription from the publisher. e rights of refusal are reserved by the publisher.

All articles submitted for publication become the property of the publisher. e Editor reserves the right to adjust any article to conform with the magazine format.

COPYRIGHT

Global Trailer is owned by Prime Creative Media and published by John Murphy. All material in Global Trailer is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. e Editor welcomes contributions but reserves the right to accept or reject any material. While every e ort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. e opinions expressed in Global Trailer are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

Follow us on twitter @Globaltrailer

DHL Express has successfully relocated Chocolat, a female chimpanzee and orphan of the illegal bushmeat trade in the Republic of Congo.

The special cargo has arrived in her new long-term home in Monkey World – Ape Rescue Centre, Dorset, UK. Throughout the journey DHL Express provided Chocolat with VIP service, transporting her in a custom-built crate supported by a team of specialist keepers, aircraft engineers, cargo handlers, security personnel and pilots. While travelling, Chocolat snacked on fresh fruit, nuts and sweet potato. Her journey, which was carefully planned to reduce the amount of time she spent in transit, began at Nairobi Airport, included a brief stop in Bahrain, and concluded with a seven-hour flight to East Midlands Airport. From there, she was transported by road to her new home at Monkey World.

Chocolat was an infant when her family were hunted and killed. When she was rescued, she was found with injuries from shotgun pellets that left her with a paralysed hand and foot on her right side. After spending the past twenty years in

Kenya being looked after by her original rescuer, Chocolat has now found a long-term home at Monkey World, which provides specialist care for chimpanzees that have been smuggled from the wild and/or suffered abuse or neglect.

A Carrier Transicold solution has helped a well-known farm in Rwanda cut its product loss to nearly zero per cent.

The global transport refrigeration company has improved Kigali Farms cold chain, reducing food loss and saving it approximately $100,000 in operating costs with a Supra 750 truck refrigeration unit.

Kigali Farms started growing oyster mushrooms in 2010 to provide sustainable income opportunities for small-scale farmers in Rwanda, help fight malnutrition and create local jobs. The business later expanded to produce button mushrooms that are packaged and shipped to Kenya.

Mushrooms are highly perishable and require constant temperature control during transport. Kigali Farms initially faced challenges with inconsistent results from various third-party transporters.

To overcome this, Kigali Farms invested in its own refrigerated truck equipped with Carrier Transicold’s Supra 750 unit, which offers constant evaporation airflow for controlled humidity, a robust design, high reliability and high-cooling performance. Rather than being lost in transit, fresh, nutritious mushrooms could now be delivered to East African supermarkets and outlets, reducing food waste, supporting sustainability and encouraging increased agricultural diversity. Today, the truck continues to operate in Nairobi delivering various types of perishables before returning to Kigali with fruit or third-party goods.

Logistics company, Leschaco, has achieved Authorised Economic Operator (AEO) certification in South Africa. Following closely on the heels of its Indonesia’s AEO certification, Leschaco South Africa’s new status underscores its reputation as a trusted partner in customs clearance for international trade, the company said in a statement.

The Level 2 Accreditation is the highest AEO level in South Africa, focusing on supply chain security through risk assessment and mitigation. Achieving AEO status involves a rigorous audit by customs authorities, requiring compliance with standards in record-keeping, financial solvency and security measures. AEO certification is increasingly crucial in the South African logistics sector, enhancing global trade security and efficiency, the company said adding that this certification facilitates closer cooperation with customs authorities, leading to improved planning, enhanced customer service and reduced delays and costs.

A state of the art, upgraded and fully integrated global manufacturing centre of trailer systems and On/Off highway systems. Expertly designed and engineered with worldwide accessibility, offering you private label and OEM manufacturing solutions.

Drawing upon decades of expertise spanning Asia, Australia, US, and in Europe, Fuwa stands as a global manufacturing powerhouse, unrivalled as the foremost network of specialists in truck and trailer components across the globe.

Mediterranean Shipping Company’s MSC Marie, measuring 366 metres in length and 51 metres in width, boasts a maximum capacity of 17,640 TEUs which set the new record. This achievement surpasses the previous record held by the EVER MAX vessel, which made the transit at a capacity of 17,312 TEUs during an inaugural passage in August 2023. The arrival of the MSC MARIE in Panama, coming from the port of Manzanillo in Mexico, not only highlights the canal’s ability to handle the largest and most modern ships, but also its importance as a key hub in global trade, the Canal Authority said in a statement.

Having been battered by a severe

36 transits a day from this month. Preparations for a $2 billion (USD) expansion of one of the canal’s water reservoirs, following approval by Panama’s Supreme Court, are expected to take 18 to 24 months.

Scan Global Logistics (SGL) continues to grow in Latin America with the acquisition of Blu Logistics Brasil.

Headquartered in São Paulo and employing more than 200 people across eight offices, Blu is considered one of Brazil’s leading freight forwarders. It offers complete air and ocean freight services, including customs clearance, trucking and cabotage.

“Growing our presence in Latin America

operational platform will help pave the way for SGL to establish a strategic presence in Brazil and expand our global reach, benefiting our valued customers. Importantly, Blu brings comprehensive industry expertise and local insights and provides us with a strengthened network in Latin America.”

SGL has rapidly expanded its footprint in the region through a combination of new market entries, expansions and acquisitions. Currently operating in Argentina, Colombia, Chile, Peru and Mexico, adding Brazil fortifies its presence in a region that has significant economic and developmental potential, and a unique geographical position relative to the Americas, Asia-Pacific and Europe.

A record $1.9 billion will be invested into the Bay of Plenty region of New Zealand, through its National Land Transport Programme.

The project will include highway upgrades, bridge replacement, road connections and a four-lane highway.

“Transport is a critical enabler for economic growth and productivity in the Bay of Plenty,” said New Zealand Transport Minister, Simeon Brown. “Over the next three years, this investment will deliver critical infrastructure that reduces travel times for motorists and freight travelling to the Port of Tauranga, along with supporting population growth in the rapidly growing Western Bay of Plenty.”

More than $640 million will be invested on maintenance and pothole prevention including resealing and rehabilitation works on 349 kilometres of state highway.

DHL Supply Chain has consolidated the New Zealand warehousing operations of a leading biopharmaceutical company at its recently opened Auckland Life Science facility.

Boehringer Ingelheim selected DHL to take over management of its pharmaceutical and animal care product warehousing operations, thanks to the company’s experience in delivering standardised coldchain warehousing and transport services.

The move to DHL consolidates

Boehringer’s pallet operation to the Airpark II site, which is located close to Auckland Airport. The site features temperature and humidity-controlled areas, cold chain storage capable of temperatures between two and eight degrees Celsius and freezers capable of minus 20 degrees Celsius.

Along with DHL’s transport offerings, Boehringer is also taking advantage of DHL’s reusable Platinum packaging

products, which are built for safe transportation of pharmaceutical items that must be kept between two to eight degrees Celsius.

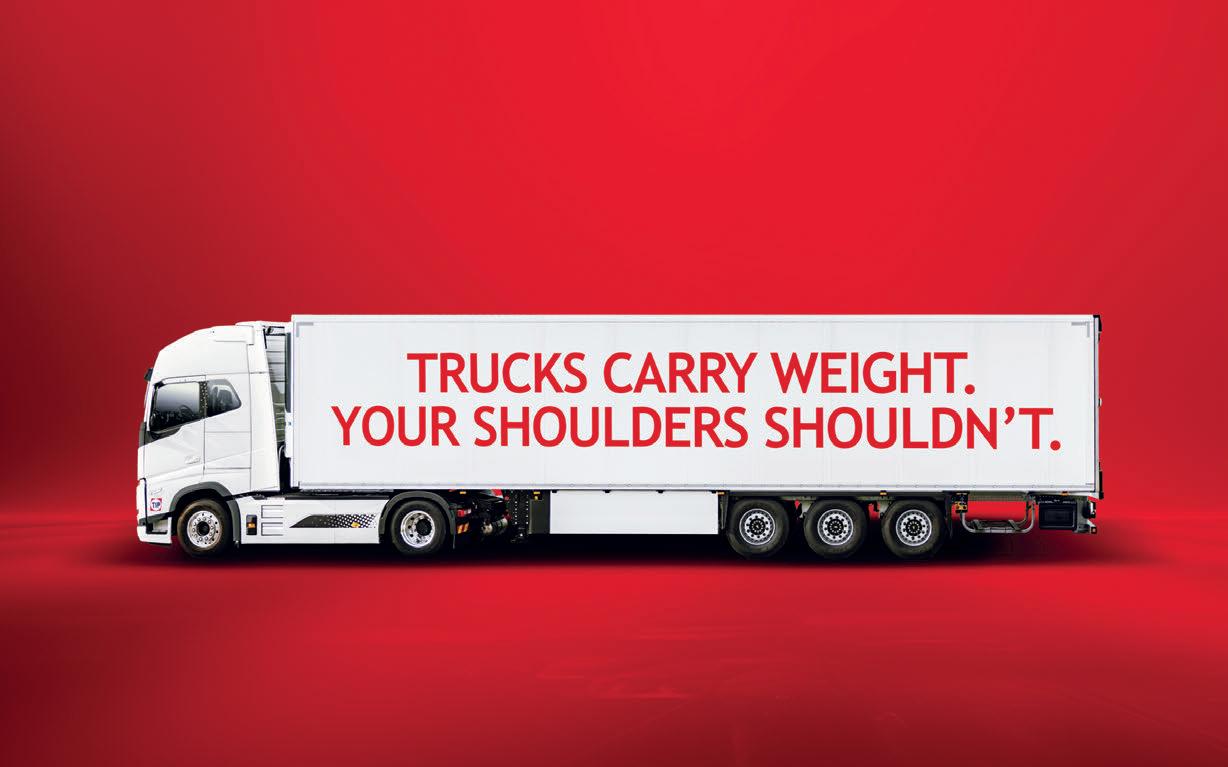

Road transport advocates are urging the Australian Government to establish a $3 billion Clean Transport Fund to support the trucking industry’s transition to net zero emissions.

In a new policy paper Stronger Economy, Lower Emissions and its recent submissions on the Transport and Infrastructure Net Zero Roadmap and Low Carbon Liquid Fuels, the National Road Transport Association (NatRoad) highlighted the critical need for financial backing to ensure the sector can effectively reduce emissions without jeopardising its future.

“Trucking is an essential part of Australia’s economy, yet our industry is under immense pressure,” said NatRoad CEO, Warren Clark.

“With an average profit margin of just 2.0 per cent, a shortage of 26,000 drivers, and the weight of extensive red tape, the proposed roadmap falls short of offering the support needed to help road freight businesses reduce emissions effectively.” Transport, according to NatRoad, is poised to become the highest-emitting sector by the end of the decade due to Australia’s growing freight task and the projected reduction in emissions from the electricity sector.

NatRoad’s policy paper underscores the necessity for a cost-effective transition strategy for road freight transport and advocates for a Low Carbon Fuel Standard (LCFS) to facilitate the gradual integration of renewable diesel and other low carbon fuels.

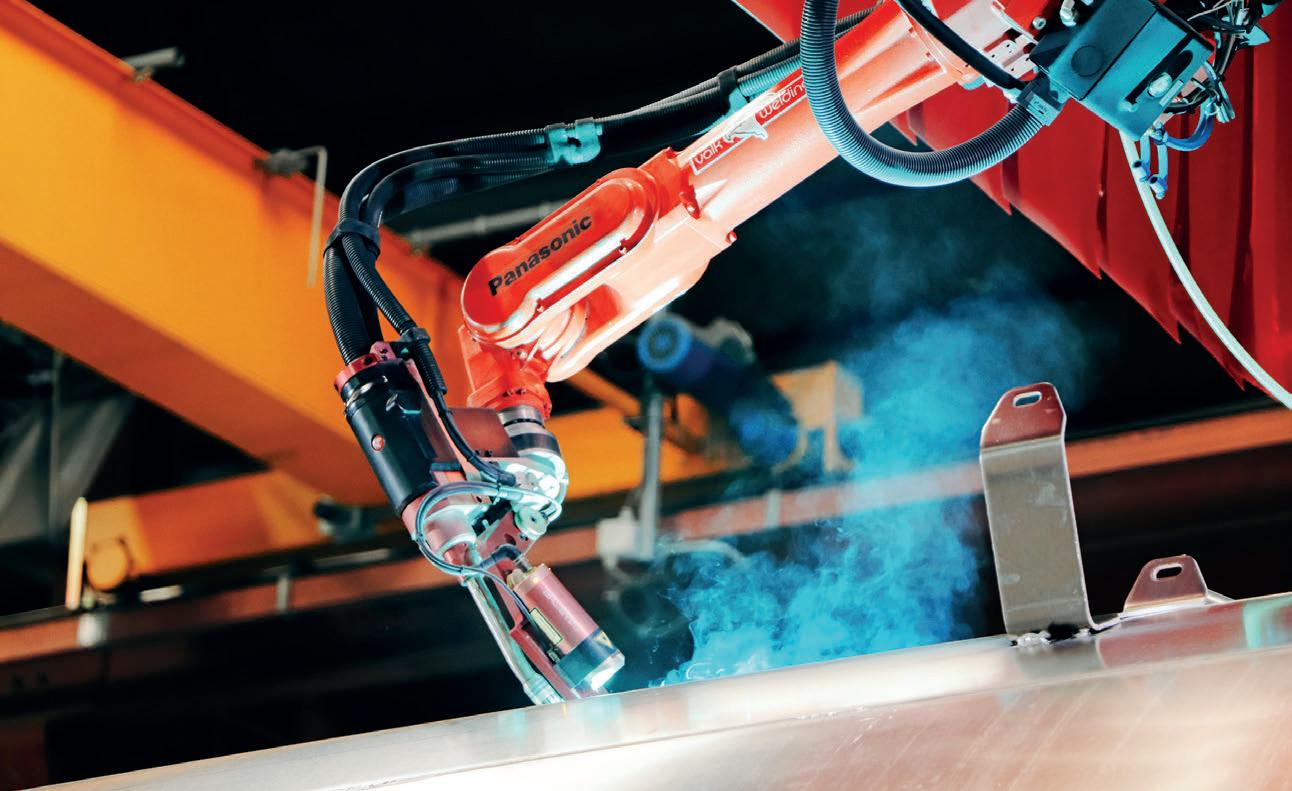

Are you interested in switching to robotic welding, and would you prefer to have one point of contact rather than several? With more than 45 years of experience in robotic welding, Valk Welding offers tailor-made total solutions, including welding wire, consumables, software, training and support. This way, you are never alone before, during and after your changeover.

Valk Welding for large and small

We can help you with production automation from large series to single pieces and from small to large products. Our systems are suitable for various types of steel, stainless steel, aluminium and plastic.

The strong connection

Schmitz Cargobull has expanded its central warehouse for spare parts in Altenberge, Germany.

The move is expected to ensure an increased level of material available for service partners and customers.

The new, manually operated narrowaisle warehouse has eight aisles and a rack height of 14 metres. It offers about 3,300 pallet spaces and stores pallet cages, Euro pallets and half pallets. The relocation of materials in the warehouse is improving process quality, while increased material availability is leading to shorter delivery times. With the new narrow-aisle warehouse, more storage space for additional spare parts has been created. Spare parts for Berger lightweight vehicles are also distributed from the site.

“Compared to independent dealers, Schmitz Cargobull offers a decisive advantage,” said Managing Director at Cargobull Parts & Services, Britta Sprey. “One-stop shopping and parts identification via the chassis number in the EPOS spare parts portal, which enables fast repairs and high uptime for Schmitz Cargobull trailers.”

Schmitz Cargobull’s European spare parts business has grown strongly in

recent years, continuously expanding its range of services to offer the fast delivery of more than 80,000 spare parts.

TIP is embarking on a major refurbishment project for half of Howdens Joinery’s 800-strong fleet. TIP will transform 400 tri-axle curtainsider trailers over the next 10 months with the support of its service provider partners.

The process will involve shotblasting the chassis and superstructures of the trailers, repainting, mechanical refitting, fitment of new strapping, a livery refresh and the adding new curtains. The addition of TIP Insight telematics means the fleet will have an Electronic Braking Performance Monitoring System.

The existing units are expected to get a 10-year working life extension thanks to the project.

According to TIP, this refurbishment initiative will save approximately 3.9 tonnes of CO2 emissions per trailer by avoiding a new trailer manufacturing process. TIP is also providing nine new Volvo LNG trucks to Howdens as it expands its truck fleet to further reduce its carbon footprint.

“Using the expected lifetime mileage and scope of refurbishment of each trailer across the Howdens fleet, we are able to calculate the carbon dioxide savings for the business in taking the refurbishment route, as opposed to purchasing from new,” said Head of ESG at TIP, Markus Pretzl.

Further environmental benefits are being made by recycling all 400 sets of trailer curtains. Buckles and poles are being salvaged for the metal, while the curtains and straps are being cleaned and recycled, avoiding approximately 60 tonnes of landfill.

Global port operator, PSA International has agreed to acquire an 85 per cent stake in one of Poland’s leading intermodal operators.

Loconi International is owned by publicly traded Polish freight forwarder ATC Cargo.

The move aims to develop new rail products to support PSA’s European container hubs, offering its customers additional options to execute the modal shift from road to rail. With this acquisition, PSA said it will enhance hinterland connections from the Baltic Hub Container Terminal in Gdansk, Poland and extend the port’s reach into new markets in Central and Eastern Europe.

Established in 2011, Loconi provides logistics solutions for shipping companies and freight forwarders that integrate rail transport, last mile road transport and depot services for containerised cargo. It runs 220 trains every month across five corridors in Poland and handles approximately 250,000 TEUs each year.

Following Italy’s move earlier this year, Austria has become the latest country to enforce digital consignment notes for its road transport sector.

The country has taken on e-CMR, the digital protocol to the United Nations CMR convention for international road freight, which sets a legal foundation for fully paperless road freight. Austria is the 37th country to join e-CMR.

The switch from paper-based to fully digital consignment notes is expected boost the efficiency and safety of goods transport across Austria and, ultimately, into neighbouring countries, according to the International Road Transport Union (IRU).

By eliminating paperwork, e-CMR lowers handling costs, eliminates administrative and invoicing delays and reduces discrepancies at delivery sites. e-CMR

also elevates transparency and security across the entire logistics chain, offering more accurate data to trace shipments with real-time access to pick-up and delivery information.

Western Norway’s largest wholesale warehouse for groceries is hoping to advance its environmentally sustainable distribution network by partnering with Thermo King.

ASKO VEST AS, a subsidiary of NorgesGruppen, has begun operating new electric city and drawbar trailers, refrigerated with Thermo King’s electric V-1000 and Frigoblock HKi systems, independently powered by E-COOLPAC battery packs.

The company aims to be fully electric by 2026, having begun its transition from diesel to electric vehicles in 2021, and

now pioneering the use of independent electric refrigeration systems. Thermo King, a brand of Trane Technologies, has provided its V-1000 units and battery-electric city trailers equipped with Frigoblock’s HKi units to operate across Bergen, Tromsø, and Oslo. The refrigeration units are powered by the Thermo King 70kWh and 105kWh E-COOLPAC battery packs that enable a chassis-independent, fully electric and autonomous operation, ensuring reliable and efficient temperature control. Providing electric solutions for refrigerated transportation is part of Thermo King and Trane Technologies’ overall approach to reducing carbon emissions. It aligns with the company’s 2030 Sustainability Commitments, including the Gigaton Challenge to reduce customer greenhouse gas emissions by 1 billion metric tonnes.

Trailer and truck component supplier, SAF-Holland has strengthened its market position following its latest acquisition.

SAF-Holland announced that it acquired Assali Stefen, an axle and suspension specialist based in Verona, Italy

With the acquisition of Assali Stefen, SAF-Holland is expanding its product portfolio for standard and special applications, ranging from standard rigid axles to self-steering axles for trailers. It also bolsters SAF-Holland’s presence in the EMEA region and New Zealand. The purchase price is reported to be in the lower double-digit millioneuro range.

The transaction is expected to be completed, and the company included in the consolidated financial statements of SAF-Holland SE for the first time in Q3 2024.

Global logistics company, Dachser, has put a new warehouse into operation at its Dutch site in Waddinxveen near Rotterdam.

With space for 10,000 pallets, the new 6,900 square-metre storage facility increases the site’s capacity to a total of 55,000 pallet spaces.

The warehouse is Dachser’s fourth building in the strategically favourably

located industrial area. It is located opposite the warehouse for contract logistics, which opened at the end of 2020. Transports depart daily from Waddinxveen to all parts of Europe.

“Dachser opened its first branch in the west of the Netherlands in Waddinxveen in 2007,” said Waddinxveen General Manager, Edwin Vermeulen. “Back then, with just 3,000 square-metres and 16 employees, nobody could have imagined that we would open our fourth logistics building here in 2024.”

The new warehouse will increase the total storage capacity in Waddinxveen to 55,000 pallet spaces. With this expansion, Dachser can continue to keep up with the increasing demand for storage space.

Lineage has completed the acquisition of Luik Natie, a cold storage and transport service provider located in the Port of Antwerp-Bruges, Belgium.

The acquisition expands the global temperature-controlled warehouse REIT’s presence in Belgium and enhances its current capabilities in the region.

Luik Natie operates a collection of facilities on a single campus spanning more than 61,000 square metres, generating most of its own energy through wind, solar and battery sources.

The campus is equipped with advanced freezing and cooling services to keep perishable goods fresh, as well as container storage solutions.

“The strategic location of Luik Natie at the Port of Antwerp-Bruges – the second largest port in Europe – will help to support our current transport and storage services across Belgium and Europe,” said President of Europe at

Lineage, Harld Peters. “This acquisition represents a significant step in our ongoing efforts to innovate the global food preservation industry, aiming to maintain the highest quality and safety standards.”

The new campus includes a transportation division and offers freight forwarding services, providing an integrated solution for the full supply chain.

This is Lineage’s first acquisition after its IPO on July 25, 2024, the company said, demonstrating its commitment to supporting global food and retail sectors and leveraging a network that includes more than 480 facilities worldwide.

Hellmann Worldwide Logistics is relying on a mix of alternative drive systems to reduce the CO2 footprint of its heavy goods transport.

As part of the initiative, the logistics company is putting two new fully electric 40-tonne Volvo swap body trucks into operation, including charging infrastructure, and is expanding its e-truck fleet by adding four more distribution vehicles.

Hellmann has also, since the beginning of this year, used only bio-LNG to fuel its LNG fleet.

The two all-electric trucks will be used on the difficult-to-decarbonise middle mile – initially primarily on routes between the two German cities of Osnabrueck and Bremen, covering between 550 and 700 kilometres a day. The company is also building its own 300 kW charging infrastructure, including buffer storage. The e-fleet will be expanded to include four all-electric 16-tonne trucks to provide emission-free

deliveries in urban areas.

In addition to electrifying its fleet, Hellmann is also relying on bio-LNG as a climate-neutral alternative to conventional diesel trucks on long-haul routes. The company sources its bioLNG, which is made exclusively from organic residues such as liquid manure and dung, from regional production. The aim is to run more than a third of all Hellmann trucks on alternative fuels by the middle of the year.

Beauty retailer, Sephora, has appointed DHL Supply Chain as its lead UK logistics provider for the next five years.

DHL will be responsible for warehousing, eCommerce fulfilment and Sephora’s

UK transport network, supporting the company’s retail growth strategy.

As part of the partnership, Sephora and DHL will launch a new omnichannel Distribution Centre in Coventry. The multi-user facility, entirely powered by renewable electricity, is DHL’s first operationally carbon-neutral new build site in the UK. It is also DHL’s most sustainable site in Europe in terms of green energy and sustainability.

DHL’s Digital Manufacturing division has developed tailored, in-house solutions based on Sephora’s needs and its specialist knowledge of the beauty industry. DHL is deploying pick assisting robots to support fluctuating demand, while maintaining high quality control. Each order will

be quickly and efficiently picked and packed across a high number of SKUs.

Yusen Logistics Benelux has opened a new warehouse for Belgium’s largest pharmaceutical company.

The 40,000 square metre facility, located in Gembloux, is equipped with innovative technologies such as autonomous mobile robots, automated packaging systems and sorting equipment.

Pharmaceutical company GSK will store and export millions of vaccines and raw materials to more than 160 countries from the site.

Additionally, an on-site ‘Packaging Solutions Centre’ will ensure the

integrity of products during transport with a range of passive packaging solutions suitable for all types of transport.”

The warehouse can house up to 42,000 pallets, stored at various temperatures thanks to a 7,000 square metre cold storage area and a 700 square metre freezer compartment. Advanced technologies like autonomous mobile robots, self-driving vehicles and sorting equipment will help GSK efficiently manage raw materials and distribute vaccines, exporting one million doses daily.

SSAB has announced its new President and CEO who will succeed longstanding incumbent Martin Lindqvist.

Johnny Sjöström, who is currently head of the Special Steels division, will begin the new position on October 28, 2024. Lindqvist is leaving the company for a board career.

Sjöström, SSAB said in a statement, has extensive experience from the industry and from international work. He has been Head of SSAB Special Steels since 2019, where he developed and grew the company’s business for special steels

and oversaw the green transformation of SSAB’s steelwork in Oxelösund. Sjöström has previously been CEO of Uddeholm and held different management positions at Outokumpu Stainless Oy.

Sjöström is a Docent in material science from Karlstad University and has an executive MBA from Stockholm School of Economics.

UK-based, clean technology company, Sunswap, has secured £17.3 million through a funding round led by investment company BGF.

A pioneer in combined solar and battery technology for refrigerated trailers, Sunswap will use the funding to accelerate the rollout of the low carbon alternative to diesel powered refrigeration across the UK and Europe. In addition to BGF, the investors include Shell Ventures, Dutch venture capital fund Move Energy, and existing backers Barclays and Clean Growth Fund.

Sunswap’s Endurance transport refrigeration unit is a fully electric solution that combines advanced battery technology, solar power and

rapid charging. In combination with a first-of-its-kind modular battery and energy-efficient system, the unit provides an emission free solution to power the trailer’s refrigeration unit. The technology has undergone rigorous commercial trials with industry leaders and TIP Group has committed to a 12-month trial of the Endurance unit.

Braking system specialist, KnorrBremse, has announced the sale of a supplier in the UK.

UK-based private equity fund, Rcapital Partners, is expected to purchase GT Emissions Systems, a supplier of emission control systems for diesel engines in on-highway commercial vehicles and off-highway vehicles. The transaction is expected to close Q4 2024.

“For us, the sale of our GT Emissions Systems subsidiary represents the next critical progression in the optimisation of our truck division’s portfolio,” said Bernd Spies, member of the Knorr-Bremse AG Executive Board and responsible for the Commercial Vehicle Systems division. “In future, we are going to concentrate even more strongly on our core competencies.

In Rcapital Partners, we have found a buyer for GT Emissions Systems capable of excellently developing and fully leveraging the company’s potential.”

The global Engine Air portfolio of GT Emissions Systems comprises exhaust throttle and exhaust gas recirculation valves, among other things.

GT Emissions Systems’ sales in the 2023 fiscal year came to approximately €70 million.

The Canadian province of Alberta is amending its driver eligibility criteria to allow Ukraine evacuees to obtain a Class 1 driver’s license.

The province currently has a shortage of 4,000 commercial truck drivers, which has been a factor in ongoing supply chain issues over the past few years, according to the government.

The amendment to the Class 1 Experience and Equivalency Program will allow Ukraine evacuees who hold or have held category CE licences, to reduce the time and cost to obtain their Alberta Class 1 driver’s licences.

Ukrainian driver licensing standards meet or exceed Alberta’s standards in most cases, particularly in driver training requirements.

Ukrainian drivers with five or more years of equivalent experience, within the last 10 years, are eligible for a waiver from the Mandatory Entry-Level Training (MELT) program. Ukrainian drivers with between two and five years of driving experience will need to take the Class 1 Experience and Equivalency Program, which includes 40 hours of training.

has closed on lease purchases for seven former Yellow Transportation terminals across the United States.

In total, the North American company has purchased 29 terminals, and ten Estes-owned terminal leases once possessed by the former trucking company, which declared bankruptcy last year. Estes has remained a debt-free following these acquisitions, it said in a statement.

Estes will be relocating six terminals into the new facilities in the following cities: The transaction adds a net-positive of

Download the app to operate and monitor multiple Razor Systems at a glance.

will be its largest in the country with 275 doors. Year to date, Estes has a total of 11,832 doors, up 508 doors since January 1, which is a 4.5 per cent yearover-year increase. The company plans to add an additional 940 doors over the next nine months.

Since the start of 2024, Estes has also purchased 6,800 additional trailers, increasing its total to more than 45,000 across the country.

Thermo King has added Klinge Corporation to its portfolio.

The Pennsylvania-based company provides transport container solutions for various industries and is one of the world’s leading providers of specialised ISO refrigerated containers.

The addition of Klinge complements Thermo King’s suite of sustainable solutions, which includes container refrigeration units which transport temperature-sensitive goods for government and other vertical industries. “Klinge is a natural extension of our strategy, and they share a passion for improving lives through innovative, ultrareliable temperature control solutions,” said President of Thermo King Americas, Adam Wittwer. “We look forward to working together with the talented Klinge team to accelerate growth, create new value for our respective customers, and, above all, ensure communities around the world receive important goods safely and efficiently.”

North American freight provider, XPO, has announced a major expansion of its cross-border service between the US and Mexico.

With the launch of XPO Mexico+, the company is expected to more capacity, coverage and technology to its longstanding cross-border routes. The move is in response to growing customer demand, as supply chains shift from overseas to North American production. According to the company, highlights of the expanded service include:

• Expansion to seven border-crossing points to further accelerate delivery times;

• CTPAT-certified service with coverage to 99 per cent of postal codes in Mexico;

• A significant increase in capacity available for cross-border services;

• Real-time online tracking of freight from pick-up to delivery;

• A dedicated, bilingual XPO Mexico+ concierge desk for customer support; and

• Instant online access to shipping quotes.

“For more than 40 years, our North American network has set the standard for LTL freight transportation between the US and Mexico,” said XPO CEO, Mario Harik. “Now, we’re at the forefront of growth in cross-border trade, with nearshoring trends driving increasing demand for LTL services.”

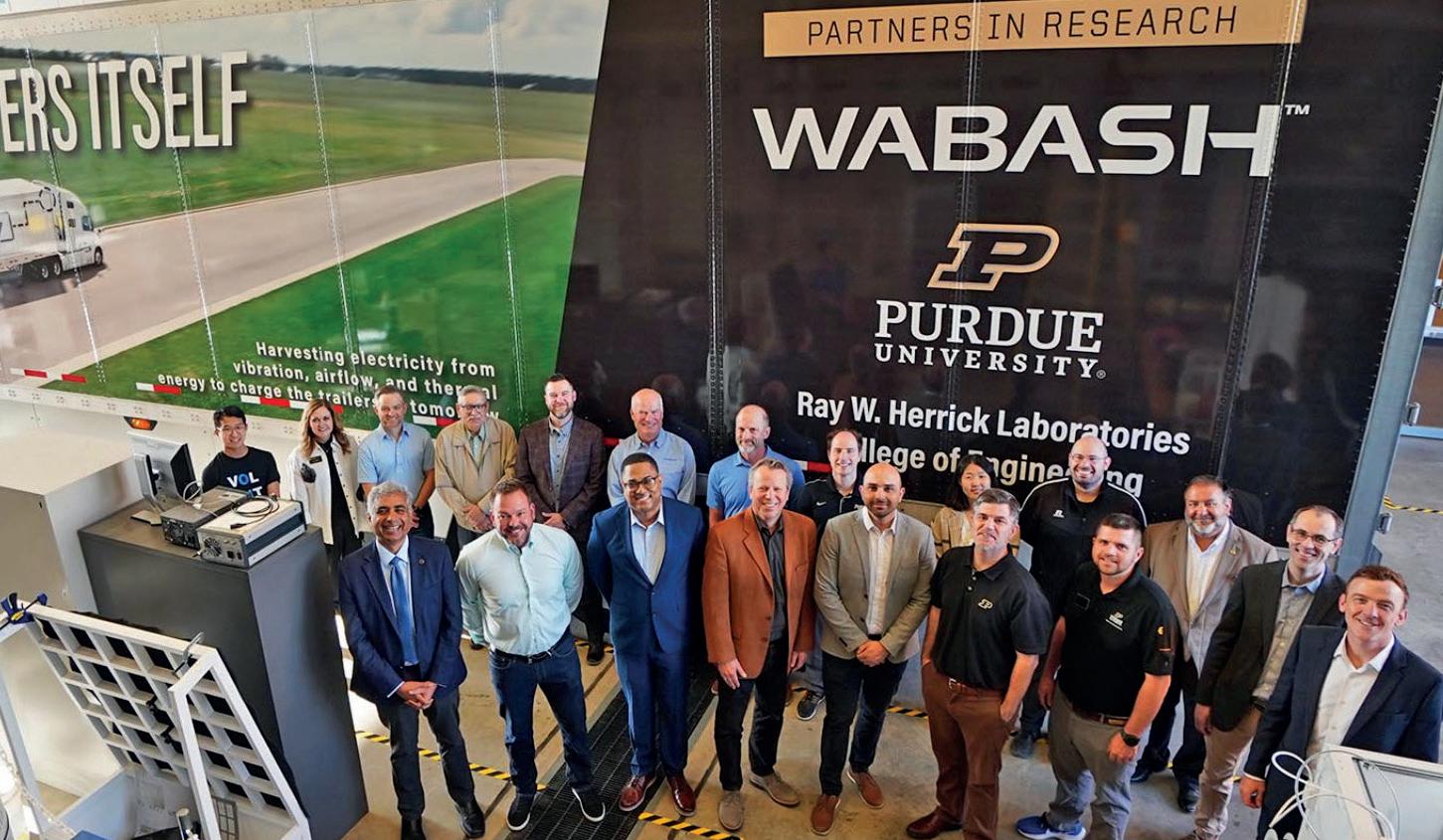

American commercial vehicle manufacturer, Wabash, has announced a number of executive leadership changes.

Mike Pettit will transition from his current role as Senior Vice President, Chief Financial Officer to the newly created position of Senior Vice President, Chief Growth Officer. He will now focus on driving growth initiatives and expanding market reach.

Patrick Keslin is promoted to Senior Vice President, Chief Financial Officer from his previous role as Vice President, Finance. He will oversee Wabash’s financial strategy, reporting and performance.

Donald Winston will become Senior Vice President, Global Operations, moving from his previous position as Vice President, Global Operations. In this expanded role, overseeing global procurement, in addition to leading manufacturing and supply chain operations, he will continue to drive operational efficiencies.

Drew Schwartzhoff is promoted to Senior Vice President, Strategic Marketing from his previous position as Vice President, Marketing. Schwartzhoff’s role will expand to include product management.

American logistics company, J.B. Hunt, has surpassed more than 80,000 autonomous long-haul trucking kilometres.

The result, the company said, is thanks to a collaboration with autonomous trucking company, Kodiak Robotics, and Bridgestone.

The company’s autonomous trucks have been used to ship Bridgestone passenger car tyres with no accidents and a 100 per cent on time pickup and delivery record.

Using Kodiak’s hub-to-hub autonomous delivery model, the 1200-kilometre long-haul stretch of the route is completed using Kodiak autonomous driving technology, which is fitted with Bridgestone M719 drive tyres and R213 steer tyres.

The companies leverage J.B. Hunt 360box, a fluid network of 14,000plus company trailers, to secure capacity for the return trip from Dallas, preventing empty miles and improving route efficiency.

The collaboration provides a round-trip solution for delivering Bridgestone passenger car tyres and minimising empty miles.

The American Trucking Associations has commended the House Appropriations Committee for voting in support of a provision to end predatory towing.

The provision is part of the fiscal year 2025 transportation funding bill which would facilitate discussions with local, state and private sector stakeholders to develop guidelines for towing and recovery regulations at all levels of government.

Predatory towing entails any incident in which a towing operator severely overcharges; illegally seizes assets; damages assets by use of improper equipment; or illegitimately withholds release of a truck, trailer and/or cargo.

“Charging truck owners thousands of dollars for each unwanted tow and holding cargo hostage with excessive invoices are egregious practices that disrupt our supply chain,” said American Trucking Associations President and CEO, Chris Spear. “ATA and our federation of state associations are fighting back against these predatory towers and ransom payments that target the truckers we depend on to deliver our nation’s goods.”

Global supplier of truck and trailer components, SAF-Holland, has opened a technology facility in India. Tech Center India (TCI), will play a central role as a globally integrated location for research and development activities, the company said in a statement.

“The new Tech Center India is an important addition to our global R&D network and part of our corporate strategy to expand our global backbone in the area of development,” said President EMEA & CTO, Christoph Günter. “It is an important step in mastering the increasing complexity at system level and, among other things, deepening our expertise in the software area to further develop our mechatronic systems.”

The TCI will play a key role in the development of software for SAFHolland’s mechatronic products, such as the Electronic Braking System for trailers. The company sees strong growth potential in the trailer sector and the increasing global demand for mechatronic safety systems.

The location in Pune, India, is close to a SAF-Holland production site under the YORK brand, and was carefully selected due to its strategic advantages. By

expanding its capacities in India, the company is not only expanding its global R&D and IT backbone, but also strengthening its commitment to deliver innovative and high-quality solutions to customers worldwide, it said.

Dimerco Express Group has announced a partnership with Acer and Cathay Cargo to reduce emissions in aviation. The collaboration will aim to reduce carbon emission through the use of Sustainable Aviation Fuel (SAF). Sustainable Aviation Fuel, a biofuel made from renewable resources such as plant or animal materials, has the potential to reduce aviation’s greenhouse gas emissions by up to 80 per cent. The International Air Transport Association highlights SAF as a critical contributor, potentially accounting for 65 per cent of the emissions reductions required for the aviation industry to achieve net-zero emissions by 2050. “We work closely with our customers to reduce freight-based carbon emissions and although the scarcity makes the alternative expensive, SAF stands out as a game-changer, slashing greenhouse gas emissions up to 80 per cent compared to fossil fuels,” said President Demerco Air Freight, George Chiou. “By joining forces with Acer and Cathay Cargo, we’re taking concrete action towards a more sustainable world.”

Intercontinental logistics provider, Leschaco Group, has announced the appointment of a new Managing

Director for operations in Malaysia. Jens Osterwald, who will assume his new role in September, began his professional career in 2005 with a three-year dual study programme at Leschaco’s headquarters in Bremen. He then worked for two years as a sales representative in the tank container department, before moving to Leschaco Korea Ltd. in Seoul, where he held various management positions, most recently as General Manager Warehousing & Contract Logistics. “Jens extensive experience and proven leadership in the logistics industry make him the ideal candidate to lead our operations in Malaysia,” said Regional Head APAC, Alexander Donau.

DHL Global Forwarding has appointed a new President Director in Indonesia. Based in Jakarta, Nicholas Bongsosartono will report to Thomas Tieber, CEO of DHL Global Forwarding, Southeast Asia and South Pacific. “Indonesia represents one of the dynamic markets in the region, with an expected GDP growth of 5.1 per cent this year, said Tieber. “We are delighted that we have managed to promote internally, a testament to our dedication to nurturing talent and providing opportunities for our employees to thrive and excel in their roles.”

Bongsosartono joined DHL Global Forwarding Indonesia in May 2023 as Head of Airfreight. Before this, he was the Head of Product Management at AP Moller-Maersk for Indonesia and the Philippines where he designed and managed a comprehensive portfolio of commercial products and services.

Dubai-based NAZ Industries has formed a partnership with SKA International Group, which will see its trailers help advance logistics capabilities in East Africa. Under the NAZ Industries’ Mammut Trailers brand, the company will supply both flatbed and lowbed trailers, custom-designed to withstand the unique climate and terrain in Somalia. SKA International Group provides logistics and transport solutions to high-risk areas. The company said in a statement that the trailers boast advanced features tailored to the

specific needs of SKA’s operations in Somalia, including enhanced structural integrity, reinforced chassis and specialised corrosion-resistant coatings.

The trailers are also equipped with safety mechanisms and ergonomic designs to streamline loading and unloading processes.

info@versus-omega.com

www.facebook.com/versusomega

www.versus-omega.com

Dubai-based NAZ Industries has formed a partnership with SKA International Group, which will see its trailers help advance logistics capabilities in East Africa.

Under the NAZ Industries’ Mammut Trailers brand, the company will supply both flatbed and lowbed trailers, custom-designed to withstand the unique climate and terrain in Somalia.

SKA International Group provides logistics and transport solutions to high-risk areas. The company said in a statement that the trailers boast advanced features tailored to the specific needs of SKA’s operations in Somalia, including enhanced structural integrity, reinforced chassis and specialised corrosionresistant coatings. The trailers are also equipped with safety mechanisms and ergonomic designs to streamline loading and unloading processes.

Together, Maersk and the General Ports Authority of Saudi Arabia have officially opened the logistic company’s Jeddah Islamic Port-based Logistics Park.

At a cost of $250 million (USD), the 225,000 square-metre Logistics Park is the largest single-site logistics and services facility in the Middle East. The site was chosen because of its advanced infrastructure, with berths capable of accommodating new generations of giant ships and modern, automated, environmentally friendly equipment.

“The Maersk Logistics Park

represents a significant milestone for Maersk,” said A.P. Moller-Maersk CEO, Vincent Clerc. “It is a testament to our commitment to be an enabler of global trade in the Kingdom of Saudi Arabia, which sits strategically at the crossroads of three continents.”

DP World has inaugurated 51 new freight forwarding offices across Asia Pacific, bringing its active trading office global total to 161.

The move is aimed to solidifying its position as an end-to-end supply chain solutions provider, the company said in a statement.

“Global trade is in the midst of an unprecedented era of flux in the face of growing geopolitical and economic uncertainty,” said CEO & Managing Director Asia Pacific, Glen Hilton.

“We have an opportunity to help businesses navigate increasingly complex supply chains, as they seek enhanced market access and streamlined but resilient logistics from factory floor to customer door.”

In addition to managing the flow of trade through its ports and terminals, DP World is now in a stronger position to offer a more comprehensive suite of logistics services, and greater flexibility in meeting client needs across various sectors. In cities where the company already operates a port or terminal facility, this expanded presence allows customers to tap into the existing network, for a more seamless flow of goods.

The full range of logistics services, include order and origin management, port handling and freight

management for ocean and air, as well as at-destination services such as customs clearance and bonded warehousing services. The company also offers a variety of value-added services including embedded trade finance, commodity-specific services, cars in containers, transload and advanced hubs and more.

Logistics company, DB Schenker, has announced an alliance with a real estate development company as it looks to enhance logistics infrastructure in Saudi Arabia. In partnership with Riyadh-based Kaden, the extensive project will progress through several phases, each designed to accommodate different verticals, storage modes and temperature-controlled spaces. The first phase will be located in the Jeddah city.

“The importance of the partnership is underscored by the significant advancements it brings to DB Schenker’s logistics services,” said Vice President of Contract Logistics and Supply Chain Management for DB Schenker Middle East and Africa, Ako Djaf. “The state-of-theart facilities within these logistics complexes will not only improve our service delivery, but also support the Kingdom’s economic diversification goals outlined in Vision 2030.” Under the agreement, DB Schenker and Kaden will work together to develop custom-designed warehouses and logistics facilities that cater specifically to DB Schenker’s operational needs. Kaden’s design approach focuses on understanding

client requirements to provide tailored solutions that enhance operational efficiency.

Freight forwarder Scan Global Logistics (SGL) has announced the establishment of new locations in Riyadh and Jeddah.

The move gives the company an immediate footprint in the economic Central and West Provinces of Saudi Arabia as part of its strategic expansion plan. An additional office is planned for 2024 in Dammam in the East province.

The expansion, the company said, is driven by Saudi Arabia’s strategic location as a central gateway to the Gulf Cooperation Council (GCC) countries, which makes it an ideal distribution hub.

“Saudi Arabia is one of the world’s fastest-growing economies and a major player in international trade,” said Global CEO, Allan Melgaard. “By establishing our own organisation and presence, we can better control our service offerings to local and global customers.”

The new offices will start with 20-25 employees in the first year and are

expected to grow to 50 employees in the second year. Mohamed Afifi has been appointed as the new Saudi Arabia Managing Director.

THERE’S A WELL-KNOWN BUSINESS QUOTE THAT SAYS, “TO WIN IN THE MARKETPLACE, YOU MUST FIRST WIN IN THE WORKPLACE.” FOR KÖGEL CEO, CHRISTIAN RENNERS, WINNING IN THE WORKPLACE WAS THE PROUDEST ASPECT WHEN IT CAME TO LAUNCHING THE COMPANY’S LONG-AWAITED, AWARD-WINNING OFFERING AT IAA TRANSPORTATION 2024. HE TALKS TO GLOBAL TRAILER ABOUT THIS IMPORTANT COMPANY MOMENT, AND WHAT IT TOOK TO GET THERE.

Sporting trendy white New Balance sneakers with more formal business attire, Renners had an aura of approachability, eclipsed only by his passion for the company he has led for the last three years.

On stage at IAA Transportation 2024, he was clearly in his element.

Kögel’s Marketing Director, Maximilian Franz, says the passion is real and that Renners can’t help it because the Kögel Cool Liteshell is essentially Renners’ “baby.”

When asked, Renners laughs and concurs that a er inheriting the project when he began as CEO in 2021, and guiding it to fruition, it has been his pride and joy.

It’s been a busy year of hiring at Kögel with the company solidifying its executive team. It has only recently announced the appointment of Thore Bakker as Chief Sales O cer, with responsibilities that include Kögel’s global sales strategies and operations, with the aim of driving growth a further strengthening its market position.

The industrial engineer brings with him more than 20 years of experience in the automotive industry, beginning his career in the truck sector at Daimler. Most recently he served as General Manager at BPW Bergische Achsen KG.

“Thore’s ability to lead strong sales teams and develop innovative strategies will be instrumental in achieving our growth targets and strengthening our position in the industry,” CEO, Christian Renners said.

Bakker joins, Christian Spengler, who was appointed to the executive team as Chief Financial O cer earlier in the year.

Spengler, who is a quali ed banker and a graduate of business economics, has had a long-standing career as a nancial expert and controller, as well as experience in various commercial leadership positions.

Along with his appointment, Spengler became a member of the Kögel Trailer executive board.

Spengler said he is determined to optimise processes for greater e ciency and to put Kögel’s long-term future on solid ground.

As well as implementing a sustainable nance strategy, as CFO, he will also work to advance digitalisation in the company, improving the networking of the individual company divisions and departments. This is expected to strengthen internal cooperation between the individual Kögel divisions and the new leadership structure, as well as administrative communication with customers.

He also believes that e ciency must pay o and a focus on sustainability is especially important during the current consolidation of the trailer industry and persistent recession, adding that all future measures will follow the company’s guiding principle: “Economy meets ecology – because we care.”

For Spengler, the advancement of customer bene ts in terms of ecological footprint, are an essential prerequisite for securing Kogel’s future.

Kögel has been delivering German engineering for more than 90 years. Founded in the town of Neu-Ulm in 1934, Franz Xaver Kögel transformed the workshop where he worked into a coachbuilding company. Since then, the Bavaria-based company has gone on to reach new heights in the development and production of trailer solutions. These include the rst refrigerated semi-trailer in all-plastic construction, the patented central axle tipper trailer and the rst cathodic dip-paint coating for optimum corrosion protection.

Today, Kögel employs 1,200 people in 11 countries, transforming from an initial production of oors, side walls and substructures for truck beds, to become a leading trailer supplier. The company headquarters and main production facility are located in the Bavarian town of Burtenbach, while there are branches also found in Ulm and Duingen, Germany, Choceň, Czech Republic, Verona, Italy, Gallur, Spain, Kampen, Netherlands, Corcelles-enBeaujolais, France, Schärding, Austria and Padborg, Denmark.

“ anks to the experience I’ve had, I know what it means to run a project including all the many stakeholders you have to deal with,” he said, taking time a er a busy media conference to talk to Global Trailer. “Everyone has a di erent wish. e sales guy wants a product to be at the lowest price, technology wants it to be the most innovative possible. So, if you don’t have a proper management style, company culture and team, you’ll have a di cult time.”

Renners understand the industry from the bottom up. He is a quali ed machine tter and graduate mechanical engineer, who also holds a Master of Business Administration. He has held numerous managing roles in the industry, gaining experience in the automotive-adjacent industries and in transport and logistics.

For Renners, his job was making sure everyone was running in the same direction to get to the goal, which was the Cool Liteshell and the green light to begin manufacturing.

“I saw the challenge immediately and felt it was absolutely my responsibility to see it through to the end,” he said. “I think that is why I see it as my baby.”

His e orts, and that of the team, paid o with the vehicle winning rst place in the concept category at the International Trailer Awards, with the winning refrigerated vehicle concept aiming to address the cold chain’s stricter regulations for the transportation of sensitive and perishable goods, as well as growing market requirements ensuring quality and sustainability.

e Kögel Cool Liteshell uses an innovative panel technology that reduces the vehicle’s weight, while simultaneously increasing its resilience – o ering economy and sustainability.

“ e main standout we have here is the weight reduction. at is the main advantage,” he said. “We haven’t had an innovation or an opportunity like this in a century.”

Compared to the current Kögel refrigerated vehicle, Kögel Cool Liteshell is, according to the manufacturer, 700 kilograms, or more than nine per cent, lighter.

The weight reduction is achieved through specially manufactured panels for the sides, the roof and the oor. Kögel dispenses with the usual steel top layer and instead uses milled hard foam blocks made of polyurethane and a top layer made of breglass mats with thermoplastic polyurethane.

is material combination is also intended to eliminate corrosion on the structure.

Reducing the tare weight also positively impacts fuel consumption. According to the company,

Cool Liteshell can save 0.30 litres of fuel per 100 kilometres, which leads to a reduction in CO2 emissions of 0.8 grams per kilometre. is could save every 32nd trip when fully loaded.

e Kögel Cool Liteshell was equipped with the Axlepower system from BPW and ermo King at the trade fair. is technology stores energy recovered during driving and braking in a battery, which powers the cooling unit both during travel and while stationary. is solution contributes to reducing fuel consumption and CO2 emissions and improves comfort for the driver.

One of the most exciting moments of the whole process was the nal weigh-in. e trailer had to be 700 kilograms lighter and while they knew the weight of the components individually, there was still a little bit of trepidation.

“We were keeping Mr Humbaur (company owner Ulrich Humbaur) up to date all the time because this was a historical project for the company, he recalled. “So we went out to the scale with him,” Renners said. While the outcome was what they had all hoped for, it didn’t matter for Renners. He was prepared to continuing ghting for and nurturing his “baby.”

Kögel Port 20

Another of Kögel’s new products, also unveiled at IAA Transportation in Hanover, was the new Port 20, an expansion of its container chassis range. e three-axle, 20-foot chassis is one of the lightest in its class with a tare weight of 2,900 kilograms. It features optimal h wheel load distribution and a wide array of equipment options.

e Port 20’s chassis design features a rearwardo set wheelbase, which increases the h wheel load and enhances driving stability. For cross-border transport, an optional second loading position is available, which boosts the h wheel load by up to 30 per cent.

It can also be customised with various innovative and proactive features, including a rear ladder for easier access, an optimised rear design to provide enhanced protection for lightweight load carriers and an integrated toolbox in the rear.

Because we care

While the demand for sustainable products such

as the Cool Liteshell are on the rise, Renners said the impetus stems originally from the nature and culture of Kögel as a company, where sustainability isn’t just a market demand or a legislative imperative. Hence the company’s long-time slogan, “Economy meets Ecology - Because we Care.”

“We have a culture of sustainability and a culture of reducing weight,” he said, adding that Kögel has been in the unique position of having its own metalworks, allowing it to be in full control of weight reduction.

“In the beginning it might have been about cutting costs, but now the users can see that the emissions are lower, and this ts well with the innovative DNA the company has,” he said. “We also know that we are part of an important social movement within the industry.”

e market uptake doesn’t worry him, as he points out that companies were buying electric trucks when they were triple the price. e motivation to do right by the planet, especially among large retail corporations, is there and, he predicts will only get stronger and the pressure on transport companies to have sustainable vehicles will grow.

“Not everyone wants this product, but there are people out there who do want these innovations,” he said. “In fact, there are more people out there than we have the capacity to service because we are in a growth phase.”

e dichotomy of the rapidly moving and exciting innovations in the industry are in stark contrast to the economic downturn it has faced in the last few years, but Renners says counteracting that is a long-term view and passion.

“You need to have patience in this industry and that is something our investor has.”

For Kögel the short-term future will be about production and while the company did look to other countries, a local loyalty won out and it will be manufactured at the factory in Germany. Components are expected to begin being manufactured by the end of the year.

“We know what our steps are, and we are ready, the machine is ready, and we know it works.”

www.kogel.com

AMONG THE EXCITING BUZZ OF IAA TRANSPORTATION 2024, THERE WERE SOME NOT-SO-QUIET WHISPERS ABOUT THE STATE OF THE EUROPEAN TRAILER MARKET. WHILE THE MARKET IS ENCOUNTERING A WEAK PERIOD AND THE PRESSURE IS ON, THERE IS LIGHT AT THE END OF THE TUNNEL.

It wasn’t panic stations among the trailer industry leaders at this year’s IAA Transportation expo. For the most part, they acknowledged the market in Europe isn’t at is best, with demand signi cantly down, but companies are generally maintaining the ‘business as usual’ mentality.

“Of course, there will be moments that our market is a little bit quiet, but you cannot sit and relax,” said LAG Trailer CEO, Rob Ramaekers, who is pushing forward with factory upgrade plans and expansion in Poland. “You have to look to the future. You have to work together and look to the future.”

e second half of 2023 was a weak period for trailer demand in Western Europe, and it became clear in early 2024 that the rst half of the current year would also have weak registrations gures.

A er some strong years, faltering transport demand sparked a downturn in the European trailer market in 2023. Trailer ‘hoarding’ led to a delay in investments and long lead times disappeared, said Senior Transport and Logistics Economist, Rico Luman in report published earlier this year.

“We still expect to see a contraction in 2024, albeit smaller, as the economy is expected to remain sluggish and road transport only mildly recovers,” he wrote. “With economic growth catching up, expansion could happen in 2025.”

While the reasons for the downturn are varied and include post Covid adjustments and political unrest, especially in Ukraine, for BPW Personally Liable Managing Partner, Achim Kotz, a lot of it is a re ection on the state of the German economy.

“ e economy in Germany is not great at the moment and in such an economy you don’t transport as much, and you don’t invest in transport or trade.”

e root cause, he admits, isn’t clear but for BPW, the answer is to continue to carry on producing with what they have.

“We have to concentrate on using our capacities as they are, and be cost e ective and e cient,” he said. “Of course this isn’t going to last forever, transport has to exist.”

e Gross Domestic Product (GDP) in the European Union expanded 0.80 per cent in the second quarter of 2024 over the same quarter of the previous year. In Germany, economists forecast a growth in economic performance of only 0.1 per cent for 2024. Only in 2025 is stronger growth of 1.2 per cent expected.

US trailer orders declined year over year for the fourth consecutive month in August, according to ACT Research.

Preliminary net data showed orders fell 40 per cent year over year to 7,700 units. However, the total increased by about 500 units from July.

Seasonally adjusted results at this point in the annual order cycle boost the total for the month to 9,500 units. The only year-over-year increase this year was a 37 per cent rise in April.

“Despite the sequential order improvement, August data continue to bear witness to our expectations of weaker demand against the backdrop of elevated order velocity the past few years, continuing weak for-hire truck market fundamentals, and already- lled dealer inventories,” said the Director of Commercial Vehicle Market Research at ACT Research, Jennifer McNealy.

SLOW AND STEADY WITH A CLEAR MISSION HAS BEEN THE LAG TRAILERS ETHOS, AND THE METHOD APPEARS TO BE PAYING OFF, WITH BIG PLANS ON THE HORIZON. ON HAND AT IAA TRANSPORTATION 2024, LAG TRAILERS CEO, ROB RAMAEKERS, TALKED TO GLOBAL TRAILER ABOUT THE ROAD TO ITS SUCCESS.

With a milestone anniversary on the horizon, CEO Rob Ramaekers has made 2027 his deadline to make LAG Trailers’ goals a reality.

e Belgian trailer manufacturer, which focuses on the manufacturing of tankers for the transport of liquids and powers, will hit 80-years-old in three years. Today its products are grouped into ve categories: fuel trailers, tank trailers, silo trailers, containers and container chassis.

“We want to be one of the top three tank and intermodal transport equipment manufacturers in Europe,” Ramaekers said, adding that he would like to see production numbers increase to approximately 3,000 units.

LAG’s mission, he said, is to provide reliable, innovative and modular road transport equipment to the European tank and intermodal transport industry, all while ensuring both customer satisfaction and safety are always at the forefront.

To achieve its goal, all while adhering to company principles, means LAG is planning on investing in new facilities, some of which are strategically located.

Ramaekers, who is an engineer by trade and has been with LAG for more than 35 years, has seen the company’s ups and downs rst hand and his future goals have a solid plan.

“Good trailers are all about being e cient trailers, and you can’t build those without proper factories,” Ramaekers said, referring to the rst phase in LAG’s investment plans, which will focus on its current factory in Belgium.

“Our factory is now 77 years old and while parts of the buildings are young, we still have some old facilities, so we want to get rid of the old ine cient product facilities.”

The upgrade is expected to include new inspection stations, a combined spray and drying hall, six o ine assembly stations for custom trailers, an expansion of the solar panel park, as well as a showroom where the team will have the opportunity to communicate directly with their customer.

“If you have contact with your customer, you need to be able to show them the product and explain why it will work for them and their needs,” he said.

Another focus will be LAG’s production plant in Poland, which Ramaekers sees as an important asset for a number of reasons.

“ ere are de nite advantages to having this Polish plant. e rst is because you don’t need to have all the best people in one spot, as it is easier to nd them and have them join the company if you are located in two di erent countries,” he said pointing out that there is a shortage of tters and welders in Belgium.

“And the second advantage, of course, is that in Poland, the wages are lower than Belgium.”

LAG’s portfolio includes a wide range of diverse semi-trailers and intermodal applications for the transport of liquids and powders.

While there isn’t a agship product as such, said Ramaekers, of the ve products it does have, the fuel tanker, which is a regional product, is quite popular. LAG also has the highest selling dry bulk container in Europe.

“We have an almost perfect split between the ve di erent products,” he said, adding that he is happy with this situation as it leaves the company less vulnerable if there are big market demand shi s.

www.lag.eu

The LAG Group, with its head o ce in Bree, Belgium, has new construction and service activities spread over three countries and is supported by a team of 450 employees.

The LAG Group has experienced stable growth over the last 10 years, with trailer production gures rising from 1.700 to 2.200 units. This increase has consequently led to a surge in turnover from approximately €80 million to €125 million.

Recent growth – chassis assembly capacity – is a result of an investment made in 2021 with the founding of a new assembly plant in the Netherlands, named CIMC Intermodal Equipment NL (CIENL)

LAG Trailers employs 365 people on the site in Belgium. The neighbouring divisions in the Netherlands, LAG Service (Burg Trailer Service) and the assembly entity CIENL (CIMC Intermodal Equipment NL), together employ 45 people. The branches in Poland employ a total of 40 people, working out of locations in Poznan, Jasin and Radzionkow.

1947

LAG Trailers is established

1949

Pioneered the development of the rst steel tank trailer

1951

Introduced the rst stainless steel tank triailer

1958

Became the rst European company to launch the aluminium fuel trailer

2007

Purchased by CIMC

2008

Reverted back to its rst initial o ering of tanks

THE EFFORT PUT INTO THE DEVELOPMENT OF KÄSSBOHRER’S NEXT GENERATION CURTAINSIDER SERIES RESULTED IN 12 NEW PATENTS AND 36 PATENTS OVERALL. ITS INNOVATIVE PROWESS WAS OFFICIALLY UNVEILED AT IAA TRANSPORTATION 2024 TO A GLOBAL AUDIENCE.

The Kässbohrer team held an enthusiastic unveiling of its vehicles in Hanover, Germany and front of stage was its Next Generation Curtainsider Series.

“We have been very busy in 2024 presenting our new products, starting with our new generation container chassis series, and then our new generation reefer series at the beginning of the year,” Kässbohrer Board Member, I et Turken told the audience. “And now the star of the show is our New Generation Curtainsider.”

More than a vehicle, the trailer builder declared it an example of engineering excellence and a customer focused approach to design.

During the curtainsiders’ development, Kässbohrer engineers produced 12 new patents and three new utility models. Overall, it features 36 patents and seven utility models.

Developed at Kässbohrer’s new second research and development centre, the series underwent rigorous testing, simulating 2.5 million kilometres

of challenging road conditions to guarantee stability, load safety, vehicle reliability and longevity.

e vehicles were tested on torsional and buckling performance, as well as lateral-force-resistance to ensure both performance and safety on even the roughest roads, during high-speed turns and tight curves.

e Next Generation Curtainsider Series was built using fully automated robotic welding and advanced surface coating technologies. A six-layer surface protection, made up of Kässbohrer’s KTL coating with zinc phosphate technology, provides the chassis corrosion resistance, with ten years of rust perforation protection.

It provides a user-friendly experience, the company said, by featuring aspects such as lightweight roof caps, central pillars and user-friendly roof-li ing system. e patented integrated cross-tensioning system, K-Tension, in the roof tarpaulin, ensures a stable roof structure that resists lateral stress, preventing sagging and o ering safe loading.

Kässbohrer was the winner in the chassis category of the International Trailer Awards 2025. The award is Kässbohrer’s seventh in the last ve consecutive terms, and it’s second championship of chassis category.

The winner, Kässbohrer’s 12-15 Flexi curtainsider, is a further development of longer and higher capacity vehicles, presenting an all-in-one-vehicle compliant with all EU wide vehicle dimensions.

Built on Kässbohrer’s award-winning extension engineering, the 12-15 Flexi is an extendable and retractable curtainsider vehicle. When fully retracted, the vehicle is 12 m in length and while fully extended the vehicle is 15 m in length.

The 12-15 Flexi eliminates multiple vehicle investments for transport companies. It increases the load factor in operations, saves on raw materials for the manufacturing of new vehicles, and saves on time and cost of cargo handling operations.

Within the EU, there are di erent regulations for vehicle dimensions and capacities. While Nordic regions allow for 25-25 m and 32 m longer higher capacity vehicles, the standard in EU is 13.6 m semi-trailers. Meanwhile, ten EU countries and the UK allow for 15 m vehicles and most urban areas permit a maximum length of 12m.

Additional features include a multi-bolt xed oor with a 7.2 tonne forkli axle load capacity and water-resistant sealing, allowing for long-term durability with minimal maintenance. With its Code XL certi ed durable front panel, developed with new generation bolted aluminium panels and aluminium front pillars, the vehicles o er rustfree, long-term use to its users.

Meanwhile, secure docking is further supported by welded rear pillars, high-friction resistant ramp bu ers, and reinforced rear door hinge guards, delivering safety during loading and unloading operations.

e new chassis is engineered with the K-Fix system, patented load-strapping technology, o ering 17,000 ways to x a load through strapping holes spaced every 70 mm and 13 x 2 securing rings along the frame.

Additional load securing bars, 400daN capacity side walls, pillar pockets and pallet stoppers complete the full load securing features. is total load security ensures no load shi ing, providing safety in motion for diverse transportation needs and ensuring optimal load security for all transportation needs.

Engineered for intermodal excellence, the Next Generation Curtainsider excels in both road, rail and sea transport. Its anti-de ection capabilities ensure smooth and reliable loading for trains, while the sliding bumper minimises damage during ferry boarding. Additionally, the reinforced closed king-pin area enhances safety and e ciency in port operations.

www.kaessbohrer.com

Kässbohrer Board Member, I et Turken, introduces the “star of the show.” Image: VDA/ IAA Transportation 2024.

FROM THE FARMLANDS OF CURRENT-DAY SLOVENIA, TO THE RAPIDLY GROWING KINGDOM OF SAUDI ARABIA, GORICA GROUP OWNER AND CHAIRMAN, IVAN FORNAZARIC, HAS HAD A COLOURFUL CAREER AND WITNESSED THE CHANGING LANDSCAPE OF THE MIDDLE EAST MARKET. HE SAT DOWN WITH GLOBAL TRAILER AT IAA TRANSPORTATION IN HANOVER TO SHARE HIS IMPRESSIONS.

Trying to work out a way to get his family’s peaches from the farm to market was Ivan Fornazaric’s rst taste of the transportation industry.

For close to the past forty years, however, he has made the Middle East home, growing GORICA Group from importing to assembling, and now as one of the leading manufacturers of trailers, tankers and frigo bodies, in the Middle East and North Africa.

“When I arrived in the Middle East there were almost no manufacturers at all and trailers were imported from Europe,” he recalled. “Slowly local manufacturing began, supported by the growth in the construction industry, as well as it being di cult and expensive to get trailers shipped to the Gulf. e preference became local manufacturing.”

e Middle East’s growing population, urbanisation, and its economic development, present opportunities for the trailer manufacturing industry, but analysing and predicting

the transportation market in the Middle East can be more di cult than other jurisdictions. Among these reasons are regulatory changes, economic uctuations and geopolitical instability.

“I would say the market is currently doing okay,” he said. “Last year was good, but the year before there was a drop in oil prices, political problems in Yemen and boycotting of Qatar, which all created

Over the past year, GORICA has developed and launched several new bodies, catering to speci c demands and applications. These include:

• A street washer featuring both high and low pressure, with a hydraulically operated washing nozzle system, suitable for both medium and heavy-duty chassis.

• A tunnel cleaner with a hydraulically operated roller arm, suitable for tunnel cleaning, under pass cleaning and large signage cleaning.

• Multi compartment refrigerated bodies catering to grocery deliveries combining ambient, chiller and freezer temperatures in single body.

• Ice cream delivery bodies with the required temperature of -30°C

a bit of a struggle and then there was post-COVID which was actually more di cult than during COVID.”

GORICA arguably has one of the largest range of trailer products in the Middle East, born primarily out of market need in a rapidly growing country with robust and varied industries. Fornazaric explained that this position is both a challenge and an advantage.

Advantageous because GORICA isn’t dependant on one particular industry to sell its products, but on the other hand, a lot goes into design and development and industry demands change quickly.

“We might have a year where construction products sell heavily, and then the trend slows to general transportation, or to waste collection, so we have to be ready for anything,” he said.

Currently GORICA’s top vehicle output is for the waste management industry –transporting both liquid and solid waste bodies.

is is closely followed by the perishable goods industry, especially among pharmaceutical companies in need of refrigerated bodies, as well as the construction industry, due to large scale projects in Saudi Arabia and the United Arab Emirates.

GORICA considers all Gulf Cooperation Council (GCC) countries to make up its local market. is includes United Arab Emirates, Saudi Arabia, Oman, Kuwait, Qatar and Bahrain. In all but Bahrain, the company has its own workshop, where bodies are locally mounted and delivered to clients.

For more than 30 years, its international market has been made up of East Africa, West and Sub-Saharan Africa and Iraq, while more recently it has opened up in Commonwealth of Independent State (CIS) countries such as Azerbaijan, Armenia and Kazakhstan.

In general terms, the trailer market in the Middle East is currently doing well, and while there is still some political unrest to contend with, as well as economic uctuations, it is still be buoyed by ongoing investments from both within and outside the Kingdom into transportation infrastructure, including roads, railways and ports. ese are all driving demand for trailers used in construction, logistics and transportation sectors.

e region’s growing population and urbanisation are also leading to increased demand for goods and services, which in turn also requires e cient transportation and logistics solutions.

As for future growth, Fornazaric said GORICA is currently on an organic growth path, eyeing Saudi Arabia as well India, as well looking to invest in more local infrastructure. In terms of any future partnerships, he said GORICA is open to the concept down the track, but in the meantime, will continue doing what it does best – building trailers.

www.goricagroup.com

WITH MORE THAN 20 YEARS IN THE INDUSTRY, RAZOR INTERNATIONAL HAS A RANGE OF ELECTRIC PRODUCTS ALL AIMED TO MAKE DRIVERS’ JOBS EASIER. AMONG THOSE PRODUCTS, LANDING LEGS HAVE BECOME THE COMPANY’S STAR PRODUCT. IN FACT, THE TECHNOLOGY IS SO GOOD, IT’S CAUGHT ATTENTION FROM SOME UNIQUE PLACES.

From li ing semi-trailers, to keeping zoo animals safe in their enclosures, Razor has spawned a product capable of adapting to many di erent applications and o ering a multitude of solutions.

Blue and Gold Fleet, a marine service company in Canada, wanted a product to raise and lower ramps when the local ferries dock. Razor was able to provide a solution, giving the operators one less manual job to worry about.