13 minute read

SPECIAL REPORT

from Global Trailer 63

by Prime Group

EXHAUST

OPTIONS

RESTRICTIONS PLACED ON THE EXPORT OF UREA IMPACTED AUSTRALIA’S ADBLUE SUPPLIES. GOVERNMENT AND INDUSTRY HAVE WORKED TOGETHER TO KEEP THE NATIONAL ROAD TRANSPORT FLEET ON THE MOVE.

News of a diesel exhaust fluid shortage at the end of 2021 had Australia’s trucking industry in a flurry. Transport bodies and government agencies scrambled in the face of what would be a critical supply chain crisis.

A global shortage of urea from which diesel exhaust fluid, more commonly known as AdBlue, is refined threatens to sideline thousands of trucks in Australia.

The additive helps reduce pollution released into the atmosphere from the exhaust of diesel-powered commercial vehicles.

The issue had been exacerbated by China heavily restricting its exports of urea and Australia is the latest nation to likely sustain significant impacts to its supply chain.

Western Roads Federation Chief Executive, Cam Dumesny, told radio station 6PR the road transport industry was facing a major problem.

“We’re going to need to support our manufacturers, we’ve got about three manufacturers in Australia, we’re going to have to help them find strategic sourcing of the base agent from anywhere in the world if we can get it,” he said.

“If we can’t do that you’ve got the worst case scenario … we start rationing it, if you follow the logic of that,” Dumesny continued. “Which areas of transport to you want to prioritise?”

ING

The National Road Transport Association (NatRoad) has been fielding calls from members reporting retail shortages of the fluid, which ensures diesel-powered trucks comply with national emission standards. It met with the Federal Government in December to brief Transport Minister, Australia’s Deputy Prime Minister Barnaby Joyce, on the potential impact on the national supply chain and to discuss the looming shortage of diesel exhaust fluid.

NatRoad CEO, Warren Clark, said the situation was serious and the Federal Government needed to act fast.

“Our industry isn’t the only one that will be affected, but we will be hit first and hardest,” he said.

“These issues go beyond NatRoad and the trucking industry.

“We are calling on the Government to convene a task force of industry groups to look at options to mitigate the situation in the immediate term.”

Clark called for leaders from industry, government, supply chain and major consumers to work together to manage the foreseeable challenges which are many.

“If we learned one thing from Covid-19 it’s that a lack of co-ordination only compounds problems,” he said. “While those issues reflected different health rules in different jurisdictions, the ball is squarely in the Federal Government’s court in terms of finding an alternate source.”

South Korea was permitted to fly a military oil tanker into Australia to airlift 27,000 litres of urea solution in November following China’s decision in October to introduce an export requirement that effectively stopped exports to boost supplies to its own domestic market.

In South Korea, approximately two million diesel vehicles, mostly cargo trucks, are required by government to use the additive.

The way of life of 25 million Australians stood at a critical juncture as supply chain headwinds destabilised economic security, consumer confidence and threatened the standard of living previous generations of Australians had grown accustomed to.

This was the view of Victorian Transport Association CEO, Peter Anderson, who in December 2021, following revelations that diesel additive AdBlue was at critically low levels and likely to ground thousands of trucks nationwide.

Unless governments, according to Anderson, were to do more to support the transport industry’s pivot to attaining supply chain sovereignty our ability to supply the basic needs of Australians all over the country was at stake.

“Supply chains in Australia have been under immense pressure at the best of times over the past decade, but Covid has exposed the deep structural flaws that have put them on the brink of collapse,” he said in a statement. “Labour shortages and an ageing workforce of drivers has been an issue for years, but Covid and the way it has driven workers from the industry through restrictions, compliance and vaccination mandates is starting to resonate in the community.”

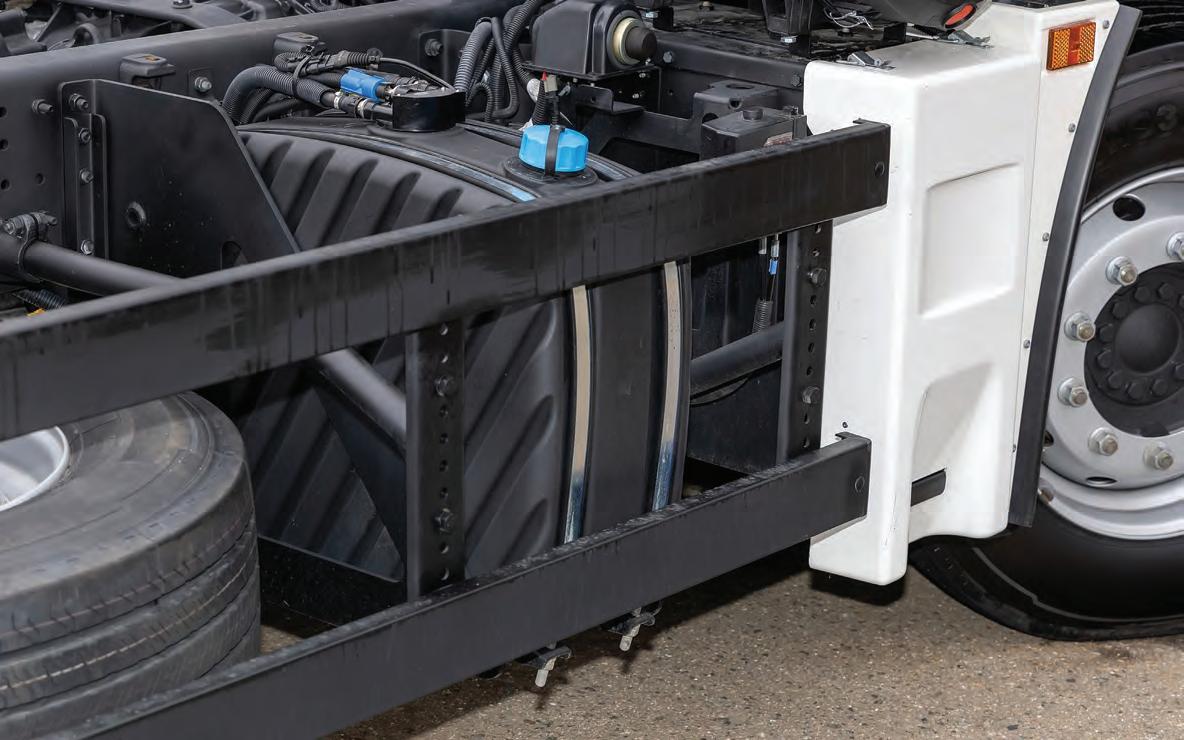

AdBlue also known as diesel exhaust fluid.

He cited the heavy vehicle licencing system that discourages young and capable people from considering a career as a professional transport worker.

It is alienating a new generation of workers and undermining renewal of an essential workforce Anderson said in the statement.

The oncoming crisis anticipated by a dearth of urea solution, the essential ingredient used in diesel exhaust fluid like AdBlue, signalled a giant blunder on the part of government and industry.

“If we as a nation can’t maintain supply of a basic engine additive relied upon by hundreds of thousands of commuter and commercial vehicles, we’re in huge strife,” said Anderson.

A recent VTA industry survey, according to Anderson, showed labour availability, costs and rates management, and fuel pricing are the most pressing issues for freight operators.

He said that only by attaining higher rates of supply chain sovereignty – defined by maintaining supply chains that are less vulnerable to international disruptions – would Australians be able to have economic security and confidence in living standards being upheld.

“We desperately need regulatory and legislative settings to identify the greatest risks that inhibit us from standing on our own two feet when it comes to basic things like labour and fuel security, which means ensuring we have a growing – not shrinking workforce, – sufficient reserves of fuel and energy, and the associated inputs necessary to keep road, rail and sea transport supply chains intact,” said Anderson.

Despite the adverse impact Covid continued to have there was, after all, a silver lining.

“Australian consumers are starting to have an appreciation of how supply chains work because so many of their online orders during two years of disruption have been delayed,” said Anderson.

“In the past, people only cared about supply chains when they didn’t have uninterrupted access to the things they enjoy, and with shortages, delays and disruption now routine people are starting to ask ‘why?’.

“On the verge of an election year, the politicians and public servants tasked with setting legislation and regulation that impacts supply chain sovereignty must factor this into their decision-making because the status quo of shortages and delays is not acceptable or sustainable for Australia.”

In a joint media release with Minister for Trade, Tourism and Investment, Dan Tehan, and Minister for Industry, Energy and Emissions Reduction, Angus Taylor, the Australian Federal Government acted to keep the trucking industry on the move.

Taylor, with the AdBlue Taskforce, struck an agreement with fertiliser manufacturer, Incitec Pivot, to secure local production of refined urea for the supply of diesel exhaust fluid (AdBlue).

Under this agreement, Incitec Pivot will rapidly design, trial and, on completion of successful tests, scale-up manufacturing of significant quantities of Technical Grade Granular Urea (TGU), a critical component of AdBlue.

Incitec Pivot will supply quantities as needed by current suppliers.

AdBlue is used in modern diesel engines to control nitrogen oxide pollutants including in trucks, large passenger buses, mining equipment and agricultural vehicles.

Taylor said this announcement is a step in the right direction and provides the trucking industry with certainty.

“Australia currently has adequate stocks of AdBlue stock on hand, but this agreement with Incitec Pivot will enable domestic production of TGU or supply of an AdBlue product to domestic manufacturers to ensure current supply chain disruptions don’t impact on Australian businesses,” he said.

“The ramping up of production by Incitec Pivot will be done without impacting agricultural fertiliser supply to local farmers or disrupting local distribution chains for AdBlue.

“This agreement is another important part of the Government’s broader strategy to build supply chain resilience, which

includes addressing shipping issues, ensuring local supplies of critical products and bolstering local manufacturing capability.”

Boosting local capabilities will be complemented by the ongoing work to secure additional supplies from international sources, to ensure Australia is prepared for any contingency.

Following outreach from Tehan, Australia’s embassy in Jakarta has confirmed with the Indonesian Government that Australia accepted iyd offer to provide 5,000 tonnes of refined urea in January. This is enough urea to make around an additional month’s worth of AdBlue. Tehan said Australia is leveraging its strong relationships with international partners to open up new sources of supply to meet our future needs for refined urea.

“By working closely with our partners, we have been able to secure this critical supply for Australia,” said Tehan. “We will continue to strengthen our close relationships around the world to support and further Australia’s interests.”

The Australian Government has been working with the manufacturers and the shipping companies to ensure shipments of urea and AdBlue that are already on their way to Australia to ensure they get priority for loading and delivery.

“Shipping companies have been helpful in prioritising the loading of a number of containers coming through Singapore to ensure that supplies arrive in Australia as soon as possible,” said Taylor. “I would like to thank those companies that have supported and offered support to this effort.”

This builds on work already underway by the AdBlue taskforce, led by James Fazzino, Chair of Manufacturing Australia and former CEO of Incitec Pivot, along with Andrew Liveris, former Chairman and CEO of The Dow Chemical Company and Director at Saudi Aramco, and Dr Cathy Foley, Australia’s Chief Scientist.

By January 2021 the Australian transport, freight and logistics sector welcomed the National Cabinet’s decision to relieve pressure on the industry’s workforce.

Assistant Minister Scott Buchholz said the changes from a recent National Cabinet meeting were the result of Australian Government working with and listening to the needs of industry.

“Throughout this pandemic we have worked closely with the transport and freight industry, including peak bodies and the Federal Government has today acted swiftly and decisively.

“Following today’s announcement [13 January 2021], transport operators that have a driver who was previously deemed a close contact, if they are non-symptomatic and return a negative test - they can leave isolation, return to work behind the wheel and keep supplies moving.

“As the Prime Minister said, ‘the goal is to protect our hospitals and keep our society and economy functioning’, this is recognition of the critical nature of the transport, freight and logistics sector.

“We cannot keep the economy functioning and Australia moving, without a strong transport, freight and logistics sector and the workforce.

Additives such as AdBlue help reduce pollution from the exhaust of diesel-powered commercial vehicles.

“These changes will help address some of the pressures industry has been telling us about and will enable critical workers to get back to work, we are encouraged by the increase in people returning to work from the previous changes made to close contact classifications.

“I encourage all in the industry, as I know the peak bodies have done, to get vaccinated if they are not already and to book in for their booster shot when they become eligible,” Assistant Minister Buchholz said.

“We are aware other pressures exist but we are optimistic about the changes being made and we will keep working with industry and working to get the balance right,” Assistant Minister Buchholz said.

Chairman of the Australian Trucking Association (ATA), David Smith has welcomed the Prime Minister’s announcement and agreed there is more work to do.

“Whilst the ATA agrees it is a great step forward and these changes will support our industry, the sector knows that there is no silver bullet. As the Prime Minister said, we are recalibrating our approach regularly,” said Smith.

“We will continue to explore entrepreneurial ways, alongside state and federal government initiatives, through the National Cabinet process, which support the industry during this pandemic.

“I want to acknowledge the Prime Minister Scott Morrison and Assistant Minister Scott Buchholz for the work they have done on supply chain issues.

“Workforce shortages were a problem pre-pandemic and the new driver apprenticeship announced last year is a longer-term approach, right now we need to find more non-traditional means of support and I acknowledge the work the Federal Government has undertaken to address the issues and shortages pertaining to AdBlue supplies for the nation.

“The ATA will continue to work closely with its members, state and federal governments – to bring certainty to the national supply chain.”

The Australian Competition and Consumer Commission (ACCC) is allowing manufacturers and other industry stakeholders to collaborate on arrangements for the supply of AdBlue.

In a media statement late 2021, the ACCC said AdBlue manufacturers are seeking to share information and work together to develop solutions to any potential future shortages of refined urea, a key ingredient in AdBlue.

“The ACCC’s interim authorisation allows AdBlue manufacturers to cooperate in a number of ways without the risk of breaching competition laws,” said ACCC Chair, Rod Sims.

“This permits the industry, in conjunction with government, to co-ordinate and respond more quickly and effectively to any supply constraints of urea.”

Following the interim authorisation, the parties can collaborate on issues such as sharing information about stock levels, supply channels and manufacturing opportunities, prioritising access to refined

urea and AdBlue according to need (for example, to particular geographical areas or consumers), collaborating on the production of AdBlue and implementing sales limits.

“This enables AdBlue manufacturers and the Australian government to consider the best way to respond to any potential future supply constraints,” said Sims.

“The manufacturers’ coordination of their response with the government is an important step in providing a regular supply of AdBlue which is critical to our nation’s transportation sector, food production and the broader economy.”

Sims said AdBlue manufacturers are also required to invite the ACCC to any meetings where these issues are discussed.

Authorisation has not been sought, and interim authorisation has not been granted, for AdBlue manufacturers to share information about or reach agreements on price.

Around the same time, Incitec Pivot Limited (IPL) released a statement saying it had ‘quickly mobilised expert teams’ to work on expanding its manufacturing capability at its Gibson Island plant in Brisbane and increase Australia’s supply of AdBlue.

IPL said the planned increase in production will not impact the supply of fertiliser grade urea for Australian farmers, following IPL successfully securing supply for the agricultural market.

While most of the urea produced is fertiliser grade used by Australian farmers, a small portion is used to make AdBlue, supplying around 10 per cent of the Australian market.

Meanwhile, Taylor has called in the ACCC to monitor price gouging amid a shortage of the AdBlue diesel additive according to a report from The Australian.

ACCC chair Rod Sims said any AdBlue producers pushing up prices to exploit the national shortage could be found to be engaging in unconscionable conduct or “named and shamed”.

Sims urged anyone concerned about high AdBlue prices to contact the ACCC, saying “SUPPLY CHAINS IN AUSTRALIA HAVE BEEN UNDER IMMENSE PRESSURE AT THE BEST OF TIMES OVER THE PAST DECADE, BUT COVID HAS EXPOSED THE DEEP STRUCTURAL FLAWS THAT HAVE PUT THEM ON THE BRINK OF COLLAPSE.”

Peter Anderson Victorian Transport Association CEO

there was a lot of competition between suppliers and an expectation for prices to rise.

DGL Group CEO, Simon Henry, the founder of the largest formulator and distributor of AdBlue, also told The Australian that the issue was that for the past 25 years, Australia had “become accustomed to a very reliable ‘just in time’ stock management system”.

“It broke,” he said. “We pushed it too hard and it snapped … Supply chain managers got very skilled at running their stocks very low, expecting materials to turn up from China … but it doesn’t anymore.”

Henry said soaring prices were the product of plants in China and Japan going offline and congested shipping channels around the word, which had created a supply crisis placing enormous pressure on the Australian model.

www.globaltrailermag.com