We’re keeping communities connected through elegant culvert solutions

We’re keeping communities connected through elegant culvert solutions

4

6 Eire Construction

Family and community come first with Eire Construction as it continues to expand its footprint in the water and sewer industry.

YOUNG PROFESSIONAL

10 Sam Skinner

The Young Water Professional of the Year award at OzWater’24 has displayed his professionalism and passion for the industry.

14 Maira Alvi

Deep learning is one area that that wastewater treatment can benefit from.

INDUSTRY INSIGHT

18 Anita McKenzie

The water industry is known for its support of people with disabilities. The new WaterAble Chair seeks to make a difference.

ASSOCIATIONS

54 Water Industry Operations Association of Australia (WIOA)

Collaboration between stakeholders in the water industry brings the benefit of shared learning, particularly around closed-loop water systems.

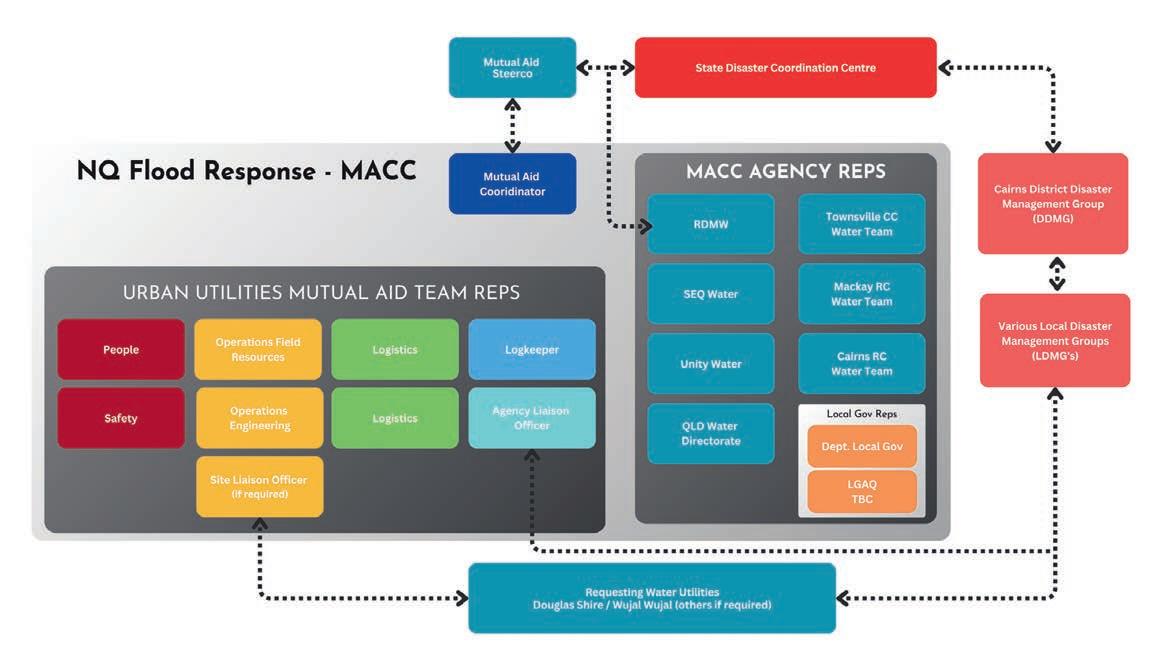

55 qldwater

Queensland’s water industry has united in supporting disaster recovery. By taking a mutual aid approach, more people across the state can improve emergency management.

22 Detection Services

Assessing the condition of a pipeline is essential for many industries. However, doing it noninvasively is a different matter.

24 SUEZ Australia and New Zealand

A chemical-free and cost-effective pipe-cleaning method has been developed to deliver quality water and wastewater services.

26 Interflow

Culverts play a critical role in allowing waterways to flow freely. In an era of growing uncertainty and funding challenges, it is increasingly important to recognise their essential role.

28 VicWater

Three Victorian water utilities collaborate on a unique circular economy solution to reduce the industry’s carbon footprint as part of The Water Minister’s Climate Innovation Challenge.

32 Iota

Iota technology has been implemented into Barwon Water’s Smart Networks program, targeting customer-side leak detection.

36 Iplex

Recycling and reusing pipe is an essential part of the circular economy. One program seeks to close the loop and give back.

38 eWater

Most Australians are used to having access to clean water, instantly. Much needs to go on behind the scenes to make this possible. The eWater Group is working to provide better outcomes at home and abroad.

42

The human touch of the Internet of Things (IoT) requires companies to provide a proper plan for rolling out a digital campaign in local councils and water utilities.

44

Integrating any new digitalisation project for local government can be an enormous challenge, so understanding how it all comes together is vital.

46

With No Dig Down Under coming in 2025, the themes of sustainability and innovation will undoubtedly be central.

48

The Women in Industry Awards filled the Doltone House Hyde Park Ballroom in late June. Do you know who won?

52

An innovative approach for using ultraviolet light aims to improve water treatment processes in Melbourne’s west.

WE’VE REACHED A significant milestone of two years with Inside Water! Looking back, I would have been astounded if someone had told me a decade ago that I would be celebrating two years as the editor of a groundbreaking magazine dedicated to the water industry.

Reflecting on these two years, having steadfast partners such as Taggle and Interflow continually contribute to each issue has been an incredible journey. Adapting to your evolving interests has been a priority over the past two years. It’s always gratifying to showcase industry professionals relentlessly striving for excellence in diverse ways.

In this edition, I had the pleasure of interviewing two remarkable individuals, Sam Skinner and Maira Alvi, who were honoured with the Young Water Professional of the Year and the Student Water Prize, respectively, at the prestigious Australian Water Association Awards during the OzWater’24 event in Melbourne.

Anticipation is building within the industry for the upcoming 2025 event in Adelaide, with many already vying to be acknowledged for their outstanding contributions.

The cover story spotlights Eire Construction, a company renowned for its innovative construction techniques and fostering a robust company culture and a deep commitment to the community.

Eire Construction’s distinctive emphasis on a familial work environment is noteworthy. It prioritises the wellbeing of employees and fosters a supportive atmosphere for individual growth and success. This investment in the workforce translates into a team that is passionate about their work and dedicated to delivering exceptional results.

Beyond its corporate sphere, Eire Construction demonstrates a profound sense of community responsibility, as evidenced by its support of local initiatives and partnerships with

organisations addressing critical social issues.

Trenchless technology, a revolutionary approach that minimises surface disruption during underground infrastructure projects, is gaining prominence within the industry. This approach not only reduces environmental impact but also minimises disturbance to communities.

In today’s world, where efficient water management is paramount, trenchless technology has emerged as a gamechanger for installing and maintaining water pipelines and sewer systems. This issue provides an in-depth exploration of the growing importance of the circular economy in the water industry. By adopting a closed-loop approach, we can minimise water waste and maximise its reusability. Imagine a system where treated wastewater isn’t simply discharged, but instead becomes a valuable resource for irrigation, industrial processes, or even further treatment for potable use. This is the essence of the circular economy in water management. Notably, innovative water meters play a pivotal role in this circular economy. Our featured articles delve into the latest advancements in smart water metering technology, highlighting how real-time data collection enables early leak detection and proactive water management strategies. I sincerely hope you enjoy delving into our 12th issue.

Chief Executive Officer John Murphy john.murphy@primecreative.com.au

Chief Operating Officer Christine Clancy christine.clancy@primecreative.com.au

Publisher Sarah Baker sarah.baker@primecreative.com.au

Managing Editor Lisa Korycki lisa.korycki@primecreative.com.au

Editor Chris Edwards chris.edwards@primecreative.com.au

Design Daz Woolley/Tom Anderson

Head of Design Blake Storey blake.storey@primecreative.com.au

Design Production Manager Michelle Weston michelle.weston@primecreative.com.au

Brand Manager Marina Milisavljevic marina.milisavljevic@primecreative.com.au p: +61 411 833 795

Client Success Manager Glenn Delaney glenn.delaney@primecreative.com.au

Head Office

Prime Creative Pty Ltd 379 Docklands Drive, Docklands, Victoria 3008 p: +61 3 9690 8766 enquiries@primecreative.com.au www.insidewater.com.au

Subscriptions

+61 3 9690 8766

subscriptions@primecreative.com.au

Inside Water is available by subscription from the publisher. The rights of refusal are reserved by the publisher

Cover image

Eire Construction

Articles

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

Copyright

Inside Water is owned by Prime Creative Media and published by John Murphy. All material in Inside Water is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in Inside Water are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

Eire Constructions was founded by the Kelliher family patriarch, Tom Kelliher, in 1978 in Terrigal, New South Wales. From the beginning, Eire blazed a trail in innovative civil infrastructure solutions, specialising in water and sewer. In 2000, Eire underwent its first transformative growth initiative, expanding into Port Macquarie and eventually Newcastle. Tom’s sons, Eamon and Tadhg, joined the group in 2005 and 2007, respectively. From there, the business has continued to expand.

Eire has developed an enviable reputation for innovation and collaborative, customer-focused civil infrastructure solutions. Under the

what Eire Constructions represents for the water and sewer industries in Australia.

“We’ve traditionally been a sewer

Being a family business is one reason Eire Constructions has thrived in a challenging industry.

It’s not just about having a good product; it’s being supported by good people within the company.

Eire has the capability of a top tier contractor but with the heart and agility of a family business.

“We have been very lucky to have a very supportive customer base,” Tadhg said. “We’ve always positioned ourselves as a specialist company. Water and sewer infrastructure is our bread

Having close client centric relationships has influenced the direction of Eire. This is a twoway conversation that highlights the successful history of broad civil construction experience Eire has. This is why their clients have trusted them to do specialised and complex projects.

“While we have that lengthy background, we try to get projects that challenge us intellectually,” Tadhg said. “We want projects that involve some complexity to ensure we use our grey matter. By taking that approach, we ensure our engineers and project managers are seeking solutions to problems.”

Eire’s expertise is represented in the ‘highly commended’ award for the $7.9 million Gordan Street Upgrade for Port Macquarie Hasting Council. This project was a masterclass in positive multistakeholder engagement.

A major consideration for the project was the lengthy disruption to a major arterial road servicing over 30,000 vehicles a day, multiple business’, residents, and the

community in general. Ensuring collaborative consultation with Transport for NSW, Port Macquarie Hastings Council and the community was the foundation that created project success.

Challenging and complex projects, including bridges and water treatment infrastructure, often have complex staging or quality requirements. Another example is the current $37 million Grahamstown Water Treatment Upgrade for client Hunter Water.

“We use these projects to differentiate ourselves from the more generalised jobs,” Tadhg said. “Eire likes to show how we can stand out from our competition. The skills we have developed are extremely transferrable. It’s how we can continue to support our water division work because we have the expertise in general civil construction to enhance what we do in water.”

The role of clients in driving Eire’s water industry penetration, particularly Hunter Water, has been vital. Hunter Water is investing considerable funds into rehabilitating its stormwater network. Eire

Ben from Eire Constructions underpins the importance of proper surveying and preparation.

Image: Lindsay Moller Productions, Eire Constructions

have been tasked with the $10.5 million Macquarie Street portion of the 96 kilometres of the ageing infrastructure due for completion in August 2024.

“Eire has been managing this for some time with Hunter Water,” Tadhg said. “They’ve seen us manage smaller projects, so Hunter Water wanted us to step up to take on multimillion-dollar projects. We’ve had considerable success and positive feedback for our project management approach.”

It’s this work that has allowed Eire to get involved in reservoirs, wastewater treatment plants, and other complex pieces of infrastructure.

“It’s been a natural progression for us,” said Tadhg. “We’ve grown larger and become more sophisticated because our clients have led us to additional opportunities that have allowed us to undertake these projects. We’ve developed excellent relationships with all our clients along the Mid-North Coast of New South Wales. This includes the Mid-Coast Council, Port MacquarieHastings Council, and Kempsey Shire Council.”

At the heart of Eire’s reputation and success in water and wastewater lies innovation. Its design, estimating, and project specialists are experts in water and sewer infrastructure work. Eire staff proudly sit on supply panels for many regional government and semi-government water and sewer utilities. The team actively engages clients regarding water and sewer projects during the design phase. Tadhg believes this is where Eire adds the most value by lending the team’s extensive knowledge and experience to the design and execution of client projects.

This is how the full-service approach to water and sewer infrastructure projects originated.

“We developed our full-service capability because we don’t want our customers to go anywhere else,” Tadhg said. “We want to ensure that we can cater to their whole network and their portfolio of assets. The goal is for Eire to receive the first call when a project comes up.”

community initiatives. It’s the right thing to do for any business.”

It’s undoubtedly a client-led initiative, where Eire’s clients are coming to them for solutions. “If it’s not in our wheelhouse, our clients know that if they have a challenging project, there’s a good chance we can help them with it.”

As a family-owned business, the entire team at Eire believes it is only fair and right to play a positive role in the community. Part of this stems from the fact that they prefer to hire locally for all projects.

Community engagement is vital to the success of all Eire projects, and they pride themselves on doing it best. The recent completion of the $1.2 million Beach 2 Beach D3 section of 11 kilometres of uninterrupted footpath stretching from North Haven Break

Eire’s philanthropic endeavours not only drive community benefit but economic activity and tourism. Eire are the naming rights sponsor of the Port Macquarie Runfest and the 9pm New Year’s Eve Fireworks. Eire employees volunteer, attend and participate in both events, and they are excitedly marked on the calendar by locals each year. The funds from both of these sponsorships go directly towards running and marketing the event to both locals and the visitor economy. Feedback from the community is that events like these give them something to do with their families, attract tourism to the area and boost economic activity for local business.

Eire also have The Hive Community Grants program, designed to help community organisations in the Mid-North Coast, Hunter, and New England regions.

The grants are a one-off financial contribution. Any organisation can apply for up to $10,000 in funding to help boost their community-based events and projects. The purpose

their work for Eire Constructions.

Image: Eire Constructions

of the grants is to strengthen local economies, social and environmental-based hubs.

“We allocate funds every year and encourage organisations to apply for those funds for any community initiative they might have,” said Tadhg. “I’m a passionate runner, so I like to support the running community wherever possible. Past beneficiaries have used funds to fit out a new Science, Technology, Engineering, and Maths (STEM) classroom for a local school.”

The grants have also been used to fund the construction of libraries in small towns, community rooms, and other projects.

Eire have led the way in all areas of water treatment, water network infrastructure and transport infrastructure for more than 45 years. Their people make the difference. The entire team is committed to working collaboratively with clients and the communities they work in to achieve the best outcomes.

For more information, visit www.eirecon.com.au/

Sam Skinner has gone from strength to strength in his career. His dedication to the water and wastewater industries saw him win the Young Water Professional of the Year award at OzWater’24.

“Water was central to everything we did,” said Sam Skinner, Lead Process Engineer at Aurecon. “Living in Mildura was a very formative experience. I grew up on the banks of the Dhungala, or the Murray River (also known as Millewa/Mille/ Mirri). There was work on the family vineyard, swinging out into the river on a rope swing when it was too hot.

The Millennium Drought rammed home the importance of water management and its importance to life.”

This insight helped drive Skinner into water and wastewater management. It was with Laurie Curran Water, under director Laurie Curran, that Skinner enhanced his appreciation for the industry.

“Laurie would talk to clients about different water challenges,” Skinner said. “It was a great opportunity

to learn about a range of different things, including operations and commissioning water treatment plants. I was at university while working for Laurie, and I have to acknowledge the role of my supervisors, Peter Scales and Anthony Stickland, in taking me on to research solid-liquid separation.”

Another aspect of Skinner’s development and passion for the water industry was his senior high school teaching in Tanzania. When he had to wash himself with a bucket for six months, it created an appreciation for the availability of water and wastewater infrastructure in Australia.

According to Skinner, there are many issues impacting the water and wastewater industry. One such

challenge was responding to and recovering from the Black Summer bushfires. The Australian Water Association ran a hackathon (an event in which many people meet to engage in collaborative problem solving) that brought together a vast array of stakeholders to work together to look at the preparation for the next round of bushfires.

“I think that is one of the industry’s big challenges,” he said. “It often takes a crisis to prompt action, preparation, or investment in resilience. That’s why the best time to plan for something like a drought is when there’s plenty of water. Sadly, that doesn’t happen often.”

One of the issues Skinner has noticed is the need to trade off spending to build resiliency against water bills and innovation against water security and safety. All of these come together to impact people in different ways that society will have to deal with in preparing for the future.

“Adaptive planning and approaches have been one method for dealing with these trade-offs,” he said. “It’s

used more frequently as a key part of good decision-making. Balancing current needs with the needs of the future while also tackling a range of other objectives will need to be managed with some urgency.”

As part of his work, Skinner is working to help water utilities work towards achieving their net zero goals. He believes that the collective efforts to achieve net zero are having a significant impact on the industry.

“Over the past decade, we’ve seen a real shift in expectations of the industry beyond core issues like delivering water and wastewater services,” he said. “There is now a need to play key roles as thought

installing solar panels. That portion of the emissions pie has seen great efforts and is on its way to being eliminated.

“The next big challenge is dealing with scope 1 emissions,” said Skinner.

“That includes direct emissions from

AWA/IWA Australia-New Zealand YWP Conference 2022 in Sydney.

Professor Leslie (Phil) Duncan with his Water

His role at Aurecon Skinner works on hydrogen, energy, water, and oxygen, also known as HEWO. This section provides an opportunity to bring multiple industries together to work towards

“Renewable hydrogen production requires a source of renewable energy, and, of course, water is central to the equation.”

Splitting water into hydrogen and oxygen creates opportunities for energy use. Skinner points to using oxygen in different areas, including its use as a high-purity oxygen source or as ozone for wastewater treatment.

“There are all these different elements that water touches on and is central to,” he said. “One of the exciting things at the moment is around the push towards a hydrogen economy. A lot is being made of it now, and it will be a pivotal moment. Funding is being directed to a range of hydrogen hubs around Australia, and that investment is driving the increased excitement about

renewable hydrogen’s role in the country’s decarbonisation.”

While the existing schemes offer many opportunities for success and failure, Skinner believes there will be successful application areas as part of the overall renewable energy mix. These projects will be needed to tackle some hard-to-decarbonise industries that rely on fossil fuels.

“The Goulburn Valley has great potential for developing a hydrogen ecosystem,” said Skinner. “Many industries across the region depend on natural gas as part of their processes, and there are not many alternatives to help them get to net zero. However, one way to get there is an ecosystem approach that

centred within the Goulburn Valley, they can all work together to develop an ecosystem of energy producers and users that can help decarbonise the region and produce regional prosperity.”

Supporting sustainability

That commitment to sustainability and working towards a circular economy has seen Skinner and Aurecon continue to support its clients. Different approaches have worked for different groups, and as an engineering consultancy, Aurecon can play the role of provocateur and challenge its clients.

“We can spark challenging conversations that our clients may

with me. One of those conversations Skinner speaking at the 2016 Fresh Science

has been around community attitudes to water recycling. Getting out there in the community and talking to them about water recycling, understanding their attitudes towards it, and engaging with them about the benefits has been fascinating. Gauging how their attitudes after the community consultation and engagement can change through education.”

These days, Skinner is finding that people are more knowledgeable about the wastewater treatment and water recycling processes. More knowledge leads to greater support for these projects than he might otherwise anticipate.

With so much investment and interest in water infrastructure, Aurecon is playing a vital leadership role in the water industry to develop a circular economy. Understanding the ecosystem and communicating with the community are essential parts of the development of the circular economy.

“As part of that discussion, we are talking to energy and water utilities,

along with local government, community organisations, and First Nations groups,” Skinner said. “We’re trying to embed Traditional Owner values right at the start of the project so we can go into projects and set a clear vision for everyone.”

When asked what this recent award meant to him, Skinner took a few seconds to consider. He hasn’t had much time to reflect on what becoming Young Water Professional of the Year means for him.

“In the immediate aftermath, it was brilliant,” said Skinner. “It was really nice to feel the support from friends and colleagues across the industry. Going through the award process was a chance to reflect on all the people who have supported me personally. Laurie Curran and Jack Timmons are examples of those who gave me a chance.”

Skinner also cited his supervisors at the University of Melbourne and his colleagues on the Australian Water

(bottom, holding trophy) with his colleagues from Aurecon at the 2024 Australian Water Association (AWA) Awards. Image: Aurecon

Association committees he has served on.

“There are so many smart individuals working on so many different aspects of water and across industries,” he said. “Just being involved in the community is a reward in itself.”

Similarly, Aurecon has been fantastic for Skinner and his development. He has learned from some great engineers, communicators, and mentors. In the future, he hopes to continue helping water authorities, clients, and the community achieve net zero and beyond.

“It’s about leaving the place better than we found it,” Skinner said. “By changing the mindset from do no harm to regeneration, the water and wastewater treatment infrastructure of the future can provide societal, ecological, economic, and environmental benefits.”

For more information, visit www.aurecongroup.com/ and www.awa.asn.au/

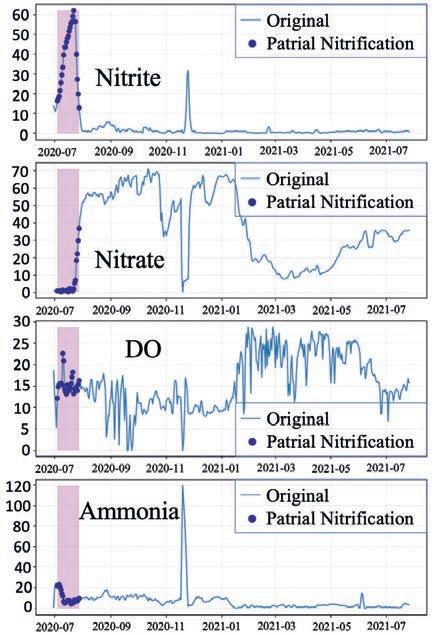

The role of Artificial Intelligence (AI) and deep learning within the water and wastewater industries continues to grow in prominence. One researcher in Western Australia is enhancing treatment efficiency and management of wastewater by integrating AI and deep learning into these processes.

Maira Alvi is a researcher at The University of Western Australia (UWA). A project she worked on, “Deep Learning for Prognostics of Wastewater Treatment Facilities,” won her the Student Water Prize at the Australian Water Association (AWA) Awards.

This project developed a costeffective prognostic framework using machine learning to forecast key parameters of wastewater processes, enabling better decision support and preventing failures. An automated state extraction enhances system insights for monitoring remote-site events. The framework improves treatment efficiency, advancing knowledge in sustainability and resource optimisation.

“I wanted to enter the water industry to contribute to green technology,” Alvi said. “Another key factor was the industrial Ph.D. opportunity I received through The University of Western Australia and Urban Utilities.”

Originally from Pakistan, Alvi completed her master’s at the University of Engineering and Technology (UET) Lahore. She then moved to Dubai with her husband before relocating to Western Australia to complete her Ph.D.

“Both of us wanted to complete our doctorates,” she said. “We believed we would benefit from completing our higher education in a multicultural environment among the top one per cent of universities worldwide. UWA has an excellent research environment, so we moved to Perth in 2017.”

Through her Ph.D. work, Alvi has been involved in the water and wastewater industry. In her opinion, computer science supports these facilities in many aspects, from data monitoring to predictive maintenance.

“It can be implemented in a range of areas, from data monitoring to analytics, and from predictive maintenance to automation,” said Alvi. “Computer science holds a lot of potential for the industry, particularly with the recent advancement of artificial intelligence.”

Alvi’s research supports her thinking. It was part of a larger research package at UWA funded by a Cooperative Research Centres Projects (CRC-P) grant. This developed low-cost solution seeks to transform inefficient sewage treatment ponds into self-contained environmental assets benefiting regional communities. It has strong market potential worldwide due to its ability to retrofit existing assets.

The integrated technology can potentially recover water and valuable nutrients suitable for local agricultural uses with minimal odour and greenhouse emissions. A robust control and monitoring system will be incorporated, modernising regional treatment plant operations.

“My Ph.D. research was a subproject of this CRC-P that sought to transform wastewater treatment in regional Australia,” said Alvi. “It was a collaborative initiative involving key stakeholders such as Urban Utilities (Qld), Power and Water

Maira Alvi receiving her Student Water Prize at the Australian Water Association (AWA) Awards.

Images: Maira Alvi

Corporation (NT), Lockyer Valley Regional Council, Aquatec Maxcon, and Queensland Department of Environment and Science. We were specifically interested in how deep learning and artificial intelligence could provide benefits in terms of resource optimisation and improved treatment efficiency and monitoring of wastewater facilities.”

Alvi has long wanted to support green technology and environmental sustainability. With her background in computer science, she sought to provide a different perspective to the project.

“Deep learning has provided answers across many different domains, including autonomous driving,” she said. “I was interested in what I could do and what benefits I could extract for the wastewater industry, which is essential and impacts everyone.”

Findings and challenges

Focusing on environmental sustainability and resource optimisation, Alvi’s research has discovered novel ways to improve the efficiency of wastewater treatment plants. One of her projects uses deep learning models to replace traditional laboratory analysis, providing real-time results and eliminating the need for labourintensive and time-consuming lab work. This advancement can enhance treatment efficiency and enable real-time adjustments to treatment targets, potentially saving both capital and labour.

Additionally, Alvi’s work features a forecasting model capable of predicting wastewater parameters ahead of time, aiding compliance checks and management decisions.

Moreover, an automated state estimation model summarises system dynamics and can anticipate remote site events, enabling timely interventions. These advancements directly enhance the efficiency and sustainability of wastewater treatment processes, aligning with Alvi’s vision of transforming traditional treatment facilities into smart, proactive systems.

“It’s really important to work together and engage in multidisciplinary collaboration,” Alvi said. “It has helped me expand my research endeavours, emphasising the value of diverse perspectives and expertise in pushing the boundaries of knowledge and innovation.”

Alvi identified several data-centric challenges in the wastewater industry, notably the scarcity of quality datasets. She attributed this scarcity to the high costs of sensors and the need for skilled professionals for offline laboratory analyses. Alvi emphasised the significance of this challenge, stating that it hinders deep learning’s potential due to its data-intensive nature. Moreover, she highlighted issues such as

Integrating UASB-HRAP data with existing and logging control system.

imbalanced data due to seasonality, anomalies, and the absence of benchmark or public datasets. These challenges impede the effective application of deep learning in wastewater treatment processes.

Explainability is another aspect Alvi believes is essential and central to model deployment. Also known as eXplainable AI (XAI), it ensures humans can retain intellectual oversight over AI systems, focusing on the reasoning behind the decisions or predictions made by the AI, making them more understandable and transparent.

“By increasing our understanding between inputs and outputs, this method opposes the black-box tendency of machine learning,” Alvi said. “We always want to know that given this input, we should expect this output, but we also want to understand why this is occurring.”

Resilience in modelling

Alvi found that predictive models would change from expected outcomes by adding noise.

“These deep predictive models need to be robust to noise and resilient

to small changes,” she said. “This is especially important when we don’t have control over the system’s input. When unexpected events occur, we need to assess them to understand what and why it is happening. These models should be able to generalise across different scenarios within the industry. Robustness is crucial as we move forward.”

Alvi’s research has identified opportunities to enhance the resilience and robustness of predictive models in wastewater treatment processes. By addressing the challenges of noise and unexpected events within these models. Her findings suggest that developing models with greater robustness and generalisation capabilities can benefit the industry. However, realising these benefits requires ongoing effort and collaboration across disciplines. Alvi emphasises the importance of not only building resilient models but also ensuring their explainability, enabling broader engagement and co-operation between stakeholders from various fields.

“I want to have a model that does not behave differently with any small tweaks,” Alvi said. “I’m also interested in the explainability of the models. It’s important to be able to take these models to people in other disciplines and have them understand what is happening. That way, they can work with these models and look at them from their perspective. It can help us all work together to improve the deep learning models and algorithms.”

Alvi emphasises the importance of not only building resilient models but also ensuring their explainability, enabling broader engagement and collaboration among stakeholders from various fields.

Winning and the future

Alvi believes that winning the Student Water Prize of the Year award is recognition of the effort she has put in over the past few years.

“This award holds significant meaning for me as it acknowledges the efforts I’ve dedicated to my work over the past few years,” she said.

The IoT platform, built for water.

Lentic delivers meter data management, data validation and alarm management.

Through Lentic’s in-built IoT bridge, the platform also simplifies device management, removing the need for another device management platform.

Lentic is enabling digital metering at scale for:

WaterAble is a network for people with disability and their allies in the Australian water industry. Last month Anita McKenzie took over the reigns as the organisation’s new chair.

The past 12 months have been momentous for WaterAble. In August 2023 the organisation expanded its reach and is now partnering with organisations throughout Australia. WaterAble also commenced delivering a unique leadership program for people with disability in the water industry.

As WaterAble goes from strength to strength, its new chair recognises there is much more work to be done.

“I have long wanted to support community,” McKenzie said. “During COVID, I worked for a state Member of Parliament. I got to the point where I needed to do something different, but I wanted to keep working with the community. When I

saw this job advertised at South East Water, leading its community grants program, I immediately applied. I was so excited about the change and getting into the industry.”

McKenzie has relished working in South East Water, where she manages the community grants program that distributes funding to community groups. Seeing the impact of her work in the local community has helped her balance all the things she wants in her life.

“I joined WaterAble as a member not long after I started at South East Water. And then last year I became a member of the organising committee.

“It’s a great privilege to take

Anita McKenzie is the Community Grants Program Lead at South East Water.

Images: South East Water

over the role of chair. We have a great organising committee and are privileged to work alongside Llewellyn Prain, WaterAble founder, who continues to deliver key programs.”

Broader challenges

In McKenzie’s eyes, the water industry faces many challenges. These include a growing population, changing climate, ageing infrastructure, and constantly improving technological capabilities, including artificial intelligence (AI). The industry is also highly regulated, with organisations needing to work within a vast array of requirements.

“I believe that having people in our organisations that can work flexibly, collaboratively, and crossfunctionally is key to adapting within an increasingly digitised environment,” McKenzie said.

“Keeping pace with change while meeting and exceeding the needs of our customers and community needs a workforce that is representative of the diversity of the population and demographics we serve. This includes disability, neurodiversity, culture, gender, sexual orientation and language diversity.”

Diversity in people generates diversity in thinking, ideas, and creativity while generating great debate, a more profound understanding and ownership of agreed solutions.

Listening to people with different lived experiences can inform how the industry works. The best outcomes in any organisation are achieved when people work together to reach a consensus. McKenzie believes that this builds individual and organisational resilience while enhancing performance.

One area that McKenzie strongly advocates for is neurodivergent people in the water industry. Neurodiversity explains the different ways everyone’s brains work. A neurodivergent person is someone whose brain works differently from the average or neurotypical person.

“My passion for this comes from both my lived experience and my desire to improve workplace experiences for the current and future generations of neurodiverse people and people with disability,” she said.

McKenzie’s children are both neurodivergent. She advocates for their needs while working with various specialists. McKenzie has also had her own diagnosis in recent months.

“I lived my whole life not knowing I was neurodivergent,” McKenzie said. “My diagnosis is very new, so I’m still working through what that means in

a practical sense for me. Living in a family with multiple neurodivergent members as the primary caregiver has been a challenge.”

McKenzie has been working with therapists and attending a range of workshops and conferences. These include Amaze, the peak body for autistic people and their supporters in Victoria, and Yellow Ladybugs, an Australian charity run by and for autistic girls, women, and genderdiverse people and their families.

“It’s been really special to attend their conferences and learn,” she said. “It led me to realise why I understood my daughters so well because my brain operated similarly to theirs.”

People with neurodivergent brains are all different. They have both strengths and needs in the workplace that require adjustments. From McKenzie’s perspective, diversity in all forms will bring about positive

McKenzie (right) has been working with the team at WaterAble, and is now its Chair.

outcomes for the water industry. Many neurodivergent people can analyse systems and processes in great detail. These skills differ from those of neurotypical people, who might struggle to focus on this fine detail.

As part of her advocacy role, McKenzie has looked at how workplaces can improve their environments for people with disability and people who are neurodivergent. This can start with the recruitment process.

“Recruitment processes are generally designed for a neurotypical brain, not a neurodivergent brain,” she said. “Neurodivergent people would say that they need the questions in advance to think about their answers. They would also prefer to interview from home via a web camera.”

McKenzie pointed out that many workplaces are open-planned, making them noisy. People with

recruitment processes. It can provide access to reasonable adjustments in the process and enable neurodivergent people to be recruited in a way that differs from what we would normally do. We also need to work with individual neurodivergent people to accommodate their needs on a case-by-case basis.”

The need for education at a cultural and corporate level within organisations can enhance the performance of diversity and inclusion processes. This will allow for reasonable adjustments to be introduced and utilised without significant organisational cost.

development program

• An event to celebrate the International Day for People with Disability in December

• Forums and other activities to promote disability inclusion and disability pride.

“Culture change takes time and is incremental,” McKenzie said.

“People’s knowledge about disability and inclusion will improve, and workplaces will continue to evolve. Organisations don’t change, but people do. It’s important that organisations think about what they can do differently, and WaterAble can help organisations achieve

greater disability inclusion.”

Allies and individuals can also be the change they want to see by being brave and having conversations about disability and differences in the workplace. It’s about creating environments that enable people with disability to feel safe at work and shine in their unique way.

“Leadership, culture, systems and process can all make a difference in supporting people who are neurodivergent or who have disability,” she said. “We perform best when we feel safe at work. It’s important that the water industry creates psychologically safe workplaces where all employees feel they can be their authentic selves at work. We know often that people who are neurodivergent don’t share that they are neurodivergent. Often, they don’t do that because they don’t feel safe in the workplace.”

WaterAble is continuing to grow across Australia. It has formally partnered with all 18 Victorian water utilities, as well as Sydney Water, Seqwater and Sunwater.

The vision is for different to become normal, and reasonable workplace adjustments will not need to be requested. They become a normal way of life in the workplace.

“I see WaterAble as a catalyst for change across the industry by growing awareness and knowledge while supporting people with disability to develop their knowledge and skills. This will allow for diverse voices to be amplified, resulting in enhanced individual and organisational performance.”

To find out more, visit www.waterable.com.au/

The sewer solution that makes sense

Lightweight and easy to install across a range of sewer applications.

Polypropylene is resistant to sulphuric erosion common in traditional gravity sewers.

The watertight seal resists infiltration, exfiltration and root intrusions.

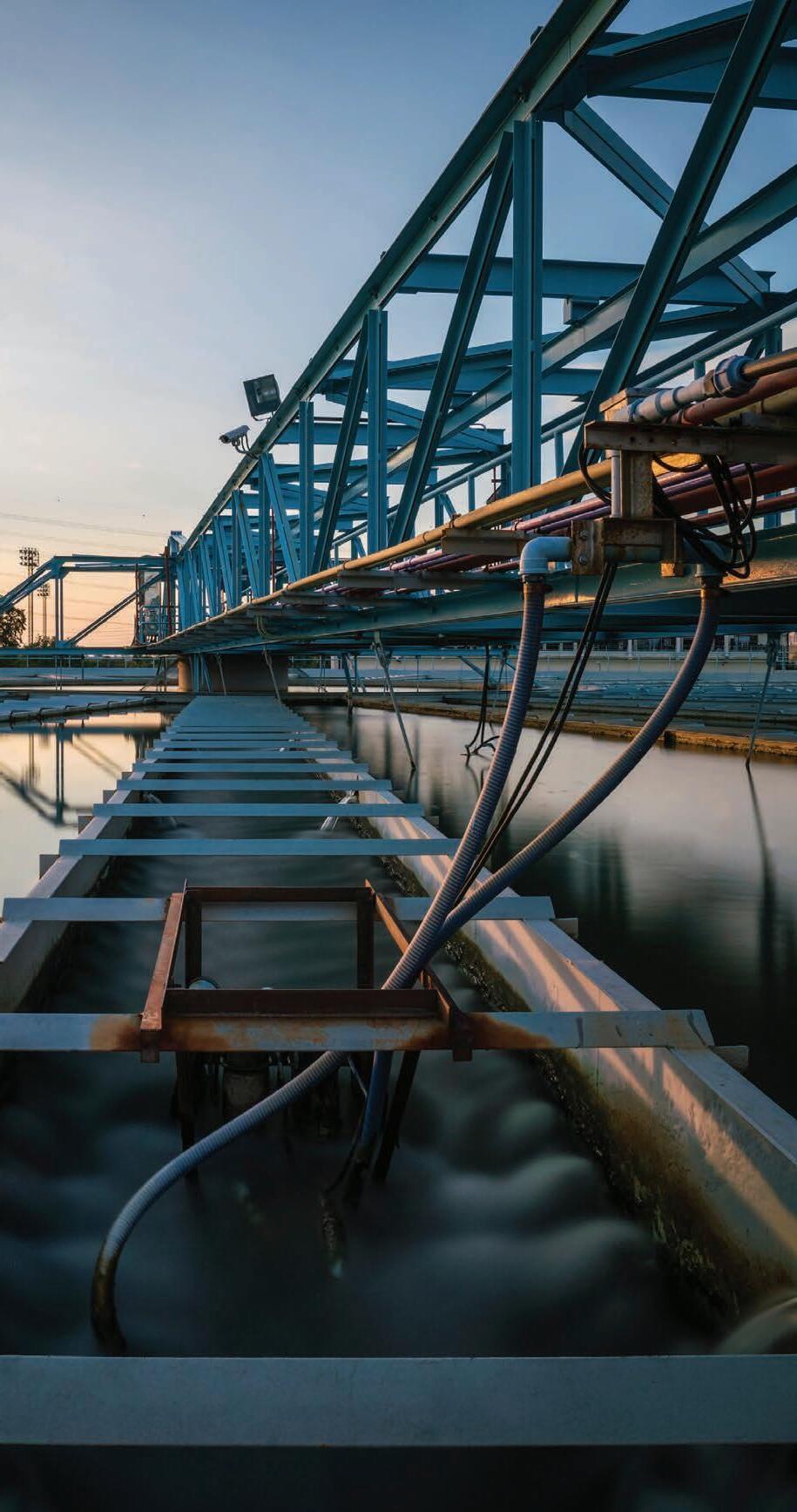

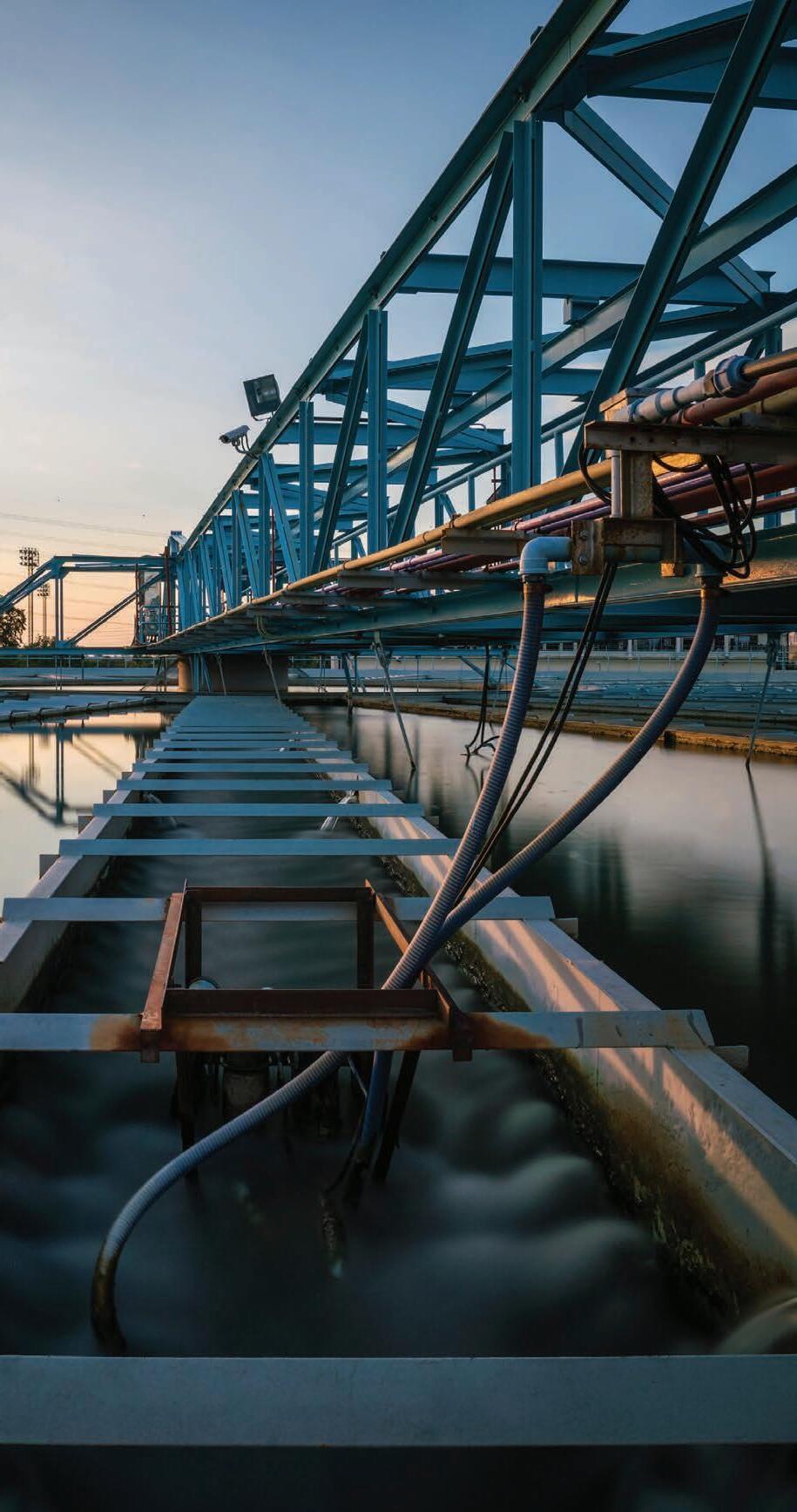

Trenchless technology is critical in checking already-buried pipes and keeping them operating and properly maintained.

Detection Services is changing the game when it comes to assessing the condition of pipelines worldwide using Australian-designed and developed technology. With projects across Australasia, North America, Europe, the Middle East and Asia, the company leads the way in multidiscipline pipe solutions and stateof-the-art technologies.

Detection Services is committed to extending the life of pipeline assets through its innovative solutions, including pipeline inspection and assessment, monitoring, maintenance, data collection, and analysis.

Penny Wrightson is a project manager and senior analyst at Detection Services. She has nearly 10 years’ experience with the company, starting just after graduating from university.

“A friend of mine was working on a significant project called p-CAT

with Detection Services,” she said.

“At the time, the University of Adelaide and Detection Services were highly interconnected, so when a meaningful position opened up at Detection Services, she pointed me to it. I’ve been there ever since.”

The deteriorating state of water infrastructure can lead to pipeline failures, emergency repairs, reduced reliability, and increased financial costs. This is all before considering the environmental and community impact and the loss of a social license.

This is why Detection Services focuses on applying innovative non disruptive pipeline technologies as expectations surrounding critical infrastructure continue to grow. Its condition assessment technologies can translate data into actionable results, enabling utilities to evaluate

Non-Invasive and NonDestructive: The technology is used to conduct assessments without disrupting the pipeline’s operation or compromising water quality Images: Detection Services.

risk and prioritise asset rehabilitation or replacement. The efficient allocation of resources can optimise pipeline reliability while improving outcomes for local governments and water utilities.

Of course, achieving this requires the right technology. Detection Services offers a technique called p-CAT, a non-invasive and nondestructive technology designed for pipe condition assessment. It can determine wall thickness over long pipeline sections while also detecting and locating defects such as air pockets, internal blockages, unknown connections, and changes in pipe material.

How does it work?

p-CAT analyses the partial reflection of a small, controlled transient signal injected into the pipeline. Sensors temporarily installed on exiting pipe fittings monitor and record this reflection. By picking up the partial reflections when encountering changes in the pipeline structure, Detection Services can separate known changes from unknown changes.

“p-CAT uses a water transient signal in a similar way that people use radar,” Wrightson said. “We send a small and controlled transient signal down the pipe and collect all the reflections that come back. Our technology can detect all the changes that we typically find in a pipe. That includes wall lining loss, material loss and changes in pipeline configuration. All that information is collected by our instruments and compared against existing maps and any other provided information.”

Water utilities and local governments can determine what might be happening in any specific location by comparing the information against maps.

“For example, we can identify

if a wall is thinner in a particular part,” she said. “If there’s a sharp change in the signal, we can see if there might be a blockage or an air pocket or a number of anomalies. It’s an opportunity to verify the provided client data to see if there is a logical explanation for what is causing this change.”

One significant benefit of the p-CAT system is its ability to be implemented across a large pipe network. Wrightson explained that the teams typically operate over two-kilometre sections. Depending on conditions, they can cover up to 12 kilometres or more per day.

“In reality, we can detect the smallest of defects and remaining wall thickness across hundreds of kilometres of pipe network,” said Wrightson. “Our pinpoint methods yield valuable information which allows asset owners to focus their attention to defective sub-sections

of well under 10 metres in length. The p-CAT method is less risky and more efficient than more invasive techniques.”

Reflecting on previous challenges faced by Detection Services, Wrightson described a project in New Zealand. The project involved a pipe that was believed to require an additional pump due to significant pressure and capacity constraints.

“We conducted tests and analysed the situation over Christmas,” said Wrightson. “We discovered that there was no need for a new pump. In reality, there was a halfclosed valve that had become stuck in the middle of the pipe. Installing a second pump would have essentially meant pumping against a closed valve. This example demonstrates how we can perform remedial work to prevent further damage to the network system. It’s a quick way to identify significant issues and evaluate the overall system.”

Unlike techniques that require excavation or intrusive inspections, p-CAT can assess pipeline conditions without disrupting operations or causing damage to surrounding assets.

Designed for people

It’s not just the technology that is simple. The associated software platforms are designed for endusers to understand the information they receive. Properly analysing the data comes in the form of a colourcoded priority list and a geographic information system (GIS) map.

“We provide the data in these ways, so it is easy for our end-users to understand and implement,” Wrightson said. “We work with our clients to determine their priorities and build them into the system. We can consider the impact of various issues, including the number of affected customers, the damage that could be done, wall thickness, and any other qualifiers they want.”

That sort of customised understanding of individual clients has helped Detection Services rise to the top of the hill regarding remote pipeline condition assessment. By drilling down to a specific address, it is providing better value for its customers and any potentially affected residents.

The improved value also highlights the cost savings on offer. One project in Queensland could have cost the local council more than $30 million to replace the pipe that they considered to be in poor condition, but with p-CAT, the ultimate refurbishment cost came to less than half a million dollars.

Technology like this continues to drive innovation in the trenchless technology space.

“We’re helping them save a lot of money. Generally speaking, it’s cheaper per kilometre to do a big stretch of pipe rather than a small one,” Wrightson said. “If you consider it bulk buying, we can do most distances in a single day.”

For more information, visit www.detectionservices.com.au/

Have you ever looked for a chemical-free and costeffective pipe-cleaning method? SUEZ has pioneered a unique approach that minimises downtime, ensures quality water and wastewater services, and prioritises environmental sustainability.

Over time, drinking and wastewater infrastructure may develop issues that affect water quality and network reliability. Iron, manganese, and biofilms can cause water quality problems, discolouration, consumer complaints, and health risks. Iron and manganese can accumulate due to poor filtration at the water treatment stage or with the deterioration of water network infrastructure. Biofilms are biological growths on the internal surface of pipes that typically grow in environments with high manganese or aluminium content or where the chlorination of water is not possible.

This is where SUEZ steps in with its ice-pigging solution. It is a pipelinecleaning process in which an ice slurry is pumped into a pipe and forced through under pressure. This process removes sediment and deposits to leave the pipe clean.

A semi-solid ice slurry can be applied uniquely because it is pumpable like a liquid but behaves as a solid when an ‘ice pig’ forms within a pipe. Ice pigging can clean pipelines ranging from 60 to 700 millimetres in diameter without excavating the pipe. It’s fast, effective, and exceptionally low risk using significantly less water than most comparable techniques. If the ice pig were ever to become stuck within a pipe, it would quickly melt and be washed away.

Ice pigging is also used in the wastewater network as an extremely effective and low risk way of cleaning pumped sewer mains, reducing blockages and significantly improving flows and pumping efficiency (up to 150%). Its gentle yet thorough cleaning action preserves pipe integrity, making it a preferred choice for maintaining water supply,

sewage, and industrial systems. This method has been widely adopted across municipalities and industries worldwide, lauded for its efficiency and cost-effectiveness. Unlike traditional mechanical or chemical cleaning methods, ice pigging is environmentally friendly, minimises water usage, and significantly reduces downtime. Further developments will see the creation of the Beer Pig. This technique would freeze the product itself rather than water, so that the ‘waste’ produced is consumable, saving money for both the producer and the customer.

In Australia, it’s people like Ed Petts, who graduated from Southampton University, have played a pivotal role in advancing ice pigging technology. Starting his career as a Graduate Engineer, Petts developed this technique for the water industry, where ice pigging was first established. His contributions have helped make ice pigging an essential tool for pipeline maintenance worldwide.

(NaCl).

As the Product Manager at SUEZ Australia and New Zealand, Petts works with clients nationwide alongside Jerome Douziech, the

General Manager of Operations for SUEZ Australia and New Zealand. Both found themselves in the water industry with the desire to do better and have a positive impact on society.

SUEZ has led the charge with ice pigging across Australia and New Zealand, delivering its cutting-edge equipment to any location across the country. While there are other players in the field, SUEZ has made significant strides, undertaking projects in diverse regions nationwide.

This technology isn’t limited to urban centres; regional areas have also harnessed the benefits of ice pigging, witnessing remarkable improvements in pipeline maintenance and efficiency.

“We have worked across Australia, in every state and territory,” Petts said. “We have a semi-mobile setup for ice pigging. We travel to the site with four 20-foot sea containers, which include our ice machine. It takes about two days to set up and about a day to pack it back down again. However, once we are set up, it’s a straightforward process, with up to 5,000 metres of pipe being cleaned each day.”

Aside from the vast size of Australia, the current equipment in Australia limits ice-pigging to pipes of no more than 450 millimetres. In Europe, available equipment allows for the cleaning of pipes of up to 700 millimetres in diameter.

Why this process?

Ice-pigging sounds like a challenging process, but it is thought to be twice as fast as traditional cleaning technologies.

“One of the biggest benefits is that you only need one pass of the ice slurry,” said Petts. “Other techniques might require multiple passes to get the job done properly, but ice-pigging does not have that problem.

“There’s also no need to drain the

pipeline at all,” Petts added. “We can isolate the pipe from mains pressure and then pump the ice in. That tends to take between 10 and 15 minutes, depending on the diameter and length of the pipe. An upstream valve is then opened to push the slurry to the other end of the pipe. The whole process tends to take two to three hours.”

Many customers with whom Petts and Douziech work have mentioned the ease of the process. In most cases, those customers do not need to undertake any pre-works, as the ice-pigging process can use existing fittings, such as hydrants for the ice to enter and exit the pipe. This eliminates the need for new infrastructure.

“We provide a wide range of services on the water network in Australia, and SUEZ is known in Australia for its experience and capabilities in water production or wastewater treatment,” Douziech said. “However, when you look at our global footprint, just over half of our activities are on the water or wastewater network. SUEZ focuses on low-customer impact, environmentally focused, and assetfriendly services.”

is why SUEZ opted to retain the

The Ice Delivery Unit transports 10,000 litres of ice to site in an insulated tank, keeping the ice cool for up to 12 hours.

patent that relates to its ice-pigging operation. It has invested heavily in this capital-intensive technology and machinery, while also training operators to be highly effective in using the technology.

The future of ice-pigging Ice-pigging has been a positive process for SUEZ. PUB, Singapore’s National Water Agency, has used the technology and has enhanced its reputation in Australia. SUEZ has demonstrated its ability to design, construct, and operate large treatment facilities while developing other business streams simultaneously.

Ice pigging samples from a drinking water pipe – the fouling removed

“We see ice-pigging as part of a set of services we can deliver to a water distribution or wastewater collection network,” said Douziech. “SUEZ is keen to invest in its team and capabilities to provide high-quality network services. We believe that our people in this space could be the right team to deliver other types of service on water and wastewater networks, including advanced leak detections. It’s why we are

Culverts, which are often unseen, play a critical role in allowing waterways to flow while supporting roads and rail networks. In an era of growing uncertainty and funding challenges, it is increasingly important to recognise their essential role in our infrastructure.

Recently, a major Australian international airport conducted a regular condition assessment of its stormwater assets and found that one of the stormwater pipes running under a taxiway showed some emerging defects. Consequently, the taxiway was closed, as any potential risk of collapse as an aircraft travelled overhead was deemed unacceptable.

“Closing down any critical infrastructure at a major airport has a very high daily cost,” said Interflow Business Development Manager Stephen McGowan. “They asked if we could provide a solution and how quickly could we mobilise. We came up with a solution, verified by our in-house Chartered Engineers, and

completed the work just weeks after they first approached us. We delivered the site works over three days and were awarded the contract based on our competence and their trust in our ability to meet the high standards expected of an international airport.” This case study is valuable in demonstrating two essential points. Firstly, culverts can be found in many situations vital to the performance and safety of the land and infrastructure above and around them. Secondly, advanced and highly effective maintenance and renewal solutions are available to asset owners, with outcomes that don’t involve digging trenches, the closure of roads or runways, or requirements

A culvert relining project in South Australia required Interflow to develop an innovative solution. Images: Interflow

of other costly and time-consuming stakeholder issues.

Why culverts? Why now?

Typically, once culverts are installed, they don’t receive a great deal of attention.

That has been for various reasons, McGowan said. One is because they’re a cost to the organisation responsible for their management. They don’t attract a revenue stream, unlike wastewater and potable water.

Another is that it was assumed these assets would have a 100-year service life. That assumption is proving wildly incorrect in most cases.

Due to factors such as increased traffic loads, more frequent major weather events, and assumptions around materials and coatings, many culverts show signs of failure in less than half that time. Some materials in place, such as zinc-coated corrugated metal pipes, are deteriorating much earlier than assumed, McGowan said.

“For many culvert asset owners in

local council, rail and arterial roads, that’s right about now,” he said. “There’s research initiated by V/Line’s Principal Structures Engineer, Ali Chaboki, that presents findings regarding the remaining life in buried corrugated steel culverts at particular service life stages. That research is vital to V/Line, which relies on 5000 culverts and 1200 bridges on the Victorian regional rail network. But the information in the report can also be extrapolated to other culvert applications.”

Infrastructure managers can use data from this research and similar studies to reassess the performance life of their culverts, ensuring maintenance and renewal work is carried out before major failures impact various stakeholders.

Interflow culvert experts regularly discuss such insights with infrastructure managers and can devise trenchless solutions for culverts that are reaching or have reached the end of their functional life.

Remote-controlled culvert renewal

Interflow’s operation is fundamentally based on the safety of its people. It also offers non-person-entry options when it’s difficult or dangerous for people to go in and do a culvert repair or renewal job.

culverts, and that’s a major safety improvement. When a culvert is close to collapse, that’s a far better option.” He said no two culvert projects are ever the same. After a deep dive into each customer’s specific needs and those of their stakeholders, a unique solution is designed for each.

“We have two of Australia’s top pipe rehabilitation thought leaders in our business, with over 65 years of experience between them,” said McGowan. “That’s why I mention comfort and confidence. Every engineer wants to know they’re making the very best choices for the future of the infrastructure they manage. We all leave a legacy through our work. At Interflow, we strive to be the very best at what we do, creating a better legacy.”

An excellent example of a project involving innovation, a deeply customised solution that required

rehabilitation can keep the road operational for as long as possible.

Remotecontrolled trenchless technology means that there is no need to send a person into a pipe or culvert.

of Transport and a tier-one civil engineering contractor,” McGowan said. “The contractor was responsible for the rehabilitation of 11 bridge structures. One of them had a culvert of three cells of RCP pipe, each 1.8 metres in diameter. So, they were a significant size and channelled water under a major high-traffic arterial road.”

The water under the bridge was tidally influenced, gushing in and out twice daily. But the culvert pipes, installed in 1992, had begun to fail, threatening the physical security of the road overhead.

The original solution’s design involved diverting traffic and digging up the road to lay new pipes.

Interflow recommended a trenchless fix, which would eliminate any need for detours and delays for road users.

“Our solution was to install a temporary coffer dam, which is an isolation dam, and re-line each culvert, one at a time,” McGowan said. “We delivered the project in 12 days and didn’t have to dig up the busy road. It was a completely trenchless solution for a great outcome without disrupting the traffic above. This was an excellent example of doing something innovative in the culvert space to solve customer problems and to minimise disruption for stakeholders, which is very much aligned with our purpose – to improve the lives of the communities we serve for generations to come.”

For more information, visit www.interflow.com.au/

The Water Minister’s Climate Innovation Challenge had three Victorian water utilities collaborate on a unique circular economy solution to reduce the industry’s carbon footprint.

The water industry in Victoria is well-known for its collaborative approach to innovation, which is reflected in the Water Minister’s Climate Innovation Challenge. This challenge provided a unique opportunity for water corporations to demonstrate their commitment to creating positive outcomes in the face of climate challenges. The goal was to strengthen Victoria’s climate resilience and shape the water industry’s future through collective effort. Winners of the challenge received funding to support the aims of their projects.

Intelligent Water Networks (IWN) was entrusted by The Hon. Harriet Shing, Minister for Water, and collaborated with the Department of Energy, Environment and Climate Action (DEECA) to run the program. Thirteen submissions were made to

the Climate Innovation Challenge, and six progressed to the final stage. One of the winning submissions came from three water utilities: Yarra Valley Water, Barwon Water, and North East Water (NEWater). The combined project was titled “Meta-analysis of low-carbon cement alternatives for water industry applications.” It sought to find a new approach for water utilities that would focus on lowering the greenhouse gas emissions associated with cement use in the water industry.

Dr Lisa Ehrenfried (Yarra Valley Water), Hayley Vinden (Barwon Water) and Dr Jill Fagan (NEWater) presented their project to the awards ceremony.

“Cement generates about eight per

Hayley Vinden, Lisa Ehrenfried, and Jill Fagan, receiving their Climate Innovation Challenge

would have the third largest carbon footprint in the world.”

The group estimated that if the Victorian water corporations were using low carbon cement alternatives, it would take the equivalent of 25,300 cars off the road over the next five years.

Carbon emissions in construction

Dr Ehrenfried has a background in materials science, which led her to the water industry. Her expertise has given her a unique perspective on increasing the use of recycled materials in construction and maintenance processes.

“When pipes are installed underground, they are usually embedded in aggregate or sand,” she said. “It’s important to note that the aggregate or sand doesn’t have to be brand new. We now have approval to use recycled aggregate, sand, or crushed glass to secure our sewer pipes. Given the high carbon emission from concrete, we are

ubiquitous material more sustainable,

thus reducing its carbon footprint and environment impact overall.”

Several of the low carbon concrete products on the market utilise waste material such as slag or fly ash.

One of the major challenges of the industry is understanding scope three emissions, separate from scope one and two emissions. When the team investigated scope three emissions, they found that water utilities tended to have significant emissions.

“A considerable part of these emissions come from cement,” Fagan said. “Since cement contributes a substantial portion of global carbon emissions, the water industry’s extensive use of cement and concrete presents a significant opportunity to lower emissions by using environmentally friendly concrete products.”

The team understood that the market existed for these products, but there had yet to be much uptake within the water sector. That’s why they wanted to set the industry on a path to an increased

uptake of low-carbon products, particularly cement.

“Early last year, I hosted a discussion on green concrete with other water corporations,” Vinden said. “The discussion was initially focused

Simpson

Construction, Yarra Valley Water

on Victorian water corporations but grew to include many water corporations from across the country. During that meeting, I realised we were all working to reduce our carbon footprint. Still, there was no one-stop shop to showcase innovative and sustainable products for water and wastewater infrastructure.

of the project

“We wanted to create a comprehensive list of lowcarbon products, suitable for water infrastructure, so that the entire Victorian water sector could benefit,” Vinden said. “This would help to drive the entire sector towards zero net emissions.”

“We know that these low carbon concrete products are already in use in other industries, such as transport and office buildings,” said Fagan. “We wanted to understand the alignment of these products with the water sector specific codes and standards.

“The consultants have produced a pathways document to guide

widespread uptake of low carbon concrete within the sector, as well as a tool to support all users to determine the best low-carbon product to utilise,” said Vinden.

In addition to low-carbon concrete, opportunities for using recycled products are rapidly expanding within the water industry.

For example, in the creation of access tracks to assets water utilities are using recycled materials to promote the circular economy.

“We are using recycled aggregate to build access tracks to our sites,” Dr Ehrenfried said. “We are also using bollards made from recycled plastics. One specific contractor we work with uses recycled car tyres to make protective ramps over temporary pipes that many people would see in their local area during water main replacement works. This way, we are protecting the temporary pipes without generating additional plastic.” These products, alongside many others, are collated in the Recycled Products Database, a separate project funded by DEECA, which will benefit all Victorian water corporations.

What was

One of the most important things learned is what low carbon concrete is available for which water industry applications, and how the industry needs to evolve to maximise use of the alternative materials.

“It’s good to have that rigour and assessment around what we know, what we don’t know, and where we need to go next. We now have an excellent overview of all the materials we should consider when it comes to low-carbon cement,” said Dr Ehrenfried.

“There are still meetings to be had with DEECA and IWN, as well as the Water Services Association of

Australia (WSAA), in order to show the water sector how they can make best use of and progress in concrete alternatives.

Fagan said the project delivered exactly what they sought. She was pleased with the outcome and was surprised by the levels of interest from across the country.

“We heard many fantastic stories from overseas,” she said. “Some of those organisations are not only using low carbon construction materials, but have also started to intentionally use construction methods that lower emissions, such as trenchless techniques. They are a couple of steps ahead. There is so much for us to learn. We have set up ongoing knowledge exchange and discussions every six months.”

The industry has embraced this project, and receiving $30,000 from the Water Minister’s Climate Innovation Challenge has helped it get off the ground.

“We had a workshop that was incredibly interactive,” said Dr Ehrenfried. “The project shows that there is real momentum building within the water sector to think more deeply about the carbon footprint through construction. The Climate Innovation Challenge saw us focus on low-carbon cement and what is available on the market now. As part of that, we had some fascinating discussions with people working within the water industry in the UK. It was great to hear about some of the lessons learned so we could apply them to our own backyards.” Fagan pointed to the wide range of conversations they had across the industry. There is considerable interest and enthusiasm for what the project could provide for different water utilities.

“We are now looking at what the

best path forward is,” she said. “Part of our funding will be used for a couple of targeted presentations to water industry groups, to explain what we have learned and done over the past couple of months. It gives industry stakeholders an opportunity to learn about the opportunities and collaborate on next steps.”

Vinden agreed that there is considerable enthusiasm across the industry to see what products could be used in the future.

“There are many opportunities and interest in using green concrete,” said Vinden. “That’s fundamentally circular in nature, given the use of recycled fly ash and slag. This will help all water corporations to reduce their scope 3 carbon footprint. Trialling recycled or greener products will allow the industry to study these products to determine whether or not they meet the strict quality criteria.”

For more information, visit www.iwn.org.au/ and www.vicwater.org.au/

Barwon Water is integrating Iota’s Lentic technology encompassing device management and meter data management into its Smart Networks program. The aim is to target customer and network leaks to reduce non-revenue water and improve water security.

Barwon Water has teamed up with Iota to meet the shared challenges facing the Victorian water sector. The rollout of cutting-edge technology developed by South East Water will accelerate and expand Barwon Water’s digital meter rollout to save water across the region.

The Smart Networks program is pivotal to Barwon Water’s longterm digital transformation and water-saving strategies. Its primary goal is to conserve water, enhance efficiency and reduce customers’ water bills. The program is designed to identify leaks within the Barwon Water network and foster closer engagement with customers to support them to understand their water usage and reduce bill shock.

Lentic is an enterprise IoT platform supporting digital metering to provide near real-time monitoring of water usage, device health, and leaks. The technology ingests and validates digital meter data

and applies domain specific rules enabling a utility to proactively monitor network health, including device related issues and water loss. Utilities can configure and create their own water specific rules to drive operational efficiencies that assist in streamlining management of their meter fleet at scale.

When issues are detected, Lentic visualises system generated alarms and device-based alarms for operators to investigate. This will enable Barwon Water to proactively and efficiently respond to network issues early, saving time and money.

David Snadden is the Executive General Manager for Smart and Sustainable Infrastructure at Barwon Water. He’s been in the water industry for more than 25 years.

“I’m very connected to delivering services to the community and caring for the natural environment,” he said. “When you put those two things together, the water industry

Apollo Bay is the site of a major collaboration between Barwon Water and Iota Services.

Image: Barwon Water

is a natural fit for me. There are so many strengths within the water industry, particularly when you look at its role in society and the community.”

Reducing water loss at scale Barwon Water started its collaboration with Iota with a trial project in Apollo Bay, focusing specifically on Marengo. Barwon Water rolled out about 300 digital meters installed with integrated Sotto vibration sensors. These smart meters detected leaks on customer properties and within its network.

“There are several different strategies for reducing water loss at scale,” Snadden said. “At a macro level, it’s all about understanding and monitoring how water is used across the network. From there, we can target and focus interventions on different leakage programs.”

Digital metering sensors allow water utilities to act in near realtime. This is where Iota’s enterprise IoT platform, Lentic, steps in. It is being deployed to enable the effective rollout of digital meters at scale, optimise device management, and streamline alarm management.

“We are in the initial stages of the program,” Snadden said. “We’ve

We are collaborators and innovators, that gives us the opportunity to build on the fabulous work of others and share our learnings and insights.

”

entered an agreement with Iota to use their Lentic platform, as we want to leverage not just the capabilities of their platform but also the learnings from South East Water’s digital utility program.”

The agreement leverages not just the technology but also Iota’s meter managed services and learnings from other water authorities, including at South East Water, who have deployed one of Australia’s largest rollout of 93,000 digital meters.

As part of the partnership Iota is providing service management for the platform. Iota will provide daily system and device health monitoring, over-the-air device updates and configurations, and training and education to Barwon Water employees through an extended transitionary period.

The first stage of the rollout involves building capability and expanding deployments to specific areas in Barwon Water’s network, targeting leak reduction and water savings. The second stage will focus on a broader rollout to customers across Barwon Water’s service region, which has a population of more than 370,000 people,

with expected annual savings of approximately 1,200 million litres.

Delivering savings for customers

In these early stages of delivery Barwon Water is verifying the savings that can be achieved for customers and the community. The utility is initially aiming to roll out 41,000 meters to about 20 per cent of its customers over the next four years, with plans to roll out digital meters to all its customers over coming years.

“Once we are fully rolled out to our entire network, we would expect to have saved around five gigalitres of water over 10 years,” Snadden said. “Through the early concept trials, we have been able to save about 38 megalitres and repaired more than 90 leaks. We’ve also supported a reduction in bills to customers of about $81,000, since we established the program in 2020.”

Barwon Water has estimated that 260 megalitres of water could be saved annually just across the first phase of the program. These savings come in conjunction with enhanced network and customer leak detection, as well as improved customer engagement.

Barwon Water and Iota partnership highlights the practical value of shared knowledge between Victorian water utilities, where insights gained by one are directly applicable and beneficial to another.

“The things we have really focused on is ensuring that we, as an organisation, are making the necessary changes to support the successful deployment and rollout of the technology,” Snadden said. “This is one of the benefits of partnering with Iota and using the Lentic platform, as it is a turnkey solution. We can leverage the capacity and capability, and we are focused on ensuring that we are delivering the benefits to our customers.”

Different approaches to customer engagement is one area in which

applications of the Lentic technology.

“We want our work with this collaboration to be a success,” Snadden said.

“By partnering with Iota, we’re tapping into a wealth of knowledge from South East Water. As two Victorian water utilities working collaboratively, it’s a great opportunity to showcase the potential that comes with sharing information and growing together”.

Unique challenges and nonrevenue water

Barwon Water is headquartered in the large regional city of Geelong. However, its services extend across regional areas of southwest Victoria, including towns like Colac, Anglesea, Queenscliff and Apollo Bay.

David Snadden

is the Executive General Manager for Smart and Sustainable Infrastructure at Barwon Water. Image: Barwon Water