Revolutionising leachate management

WaterGroup

future shaping the of water

WaterGroup future shaping the of water

Insights into sensors and IoT devices for a better water future

Insights into sensors and IoT devices for a better water future

Sailing the seas of safety and wellbeing

Sailing the seas of safety and wellbeing

Optimism key to a happier workforce

Optimism key to a happier workforce

ISSUE 08

2023

SEPTEMBER/OCTOBER

.com.au ISSUE 08

2023

SEPTEMBER/OCTOBER

Revolutionising leachate management

Discover how we took on the sand and sea to rehabilitate a beachside structure

We’re Creating the Future of Water through creative pipeline solutions

We’re Creating the Future of Water through creative pipeline solutions

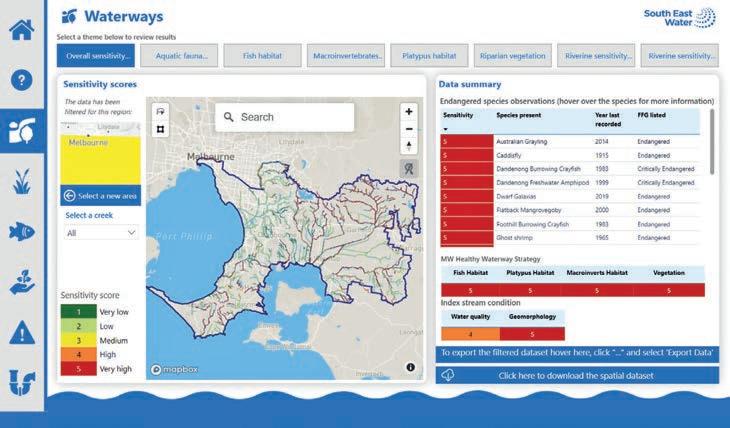

www.insidewater.com.au INSIDE WATER 3 CONTENTS Issue 08: September/October 2023 4 Editor’s Note COVER STORY 6 WaterGroup WaterGroup shaping the future of water through Internet of Things YOUNG PROFESSIONAL 10 Mikayla Rodger Slaying algal blooms with the sun and recyclable products 14 Minh Duc Nguyen No wasting time for award winner and waste researcher INDUSTRY INSIGHT 16 Annette Davison Assessing risk with Annette and the Risk Group ASSOCIATIONS 54 VicWater Optimism central to a happier workforce in the water industry LAST WORD 58 The lighter side of water WASTEWATER 18 Aerofloat Revolutionising leachate management 22 Hydroflux The changing face of wastewater in Australia 24 Pulsar Understanding the different types of sensors for the wastewater industry 26 Xylem Xylem’s wastewater approach provides solutions for the industry at all levels 28 Polymaster Polymaster providing proper solutions 30 Interflow Mereweather upgrade for merry weather WATER MANAGEMENT 36 NT Government Water planning in the Northern Territory on track REGULAR FOCUS 14 26 38 48 WORKFORCE MANAGEMENT 38 SUEZ ANZ Sailing the seas of safety and well-being 42 Voeu Measure, benchmark and improve SOFTWARE 44 South East Water Map it out for biodiversity SENSORS 48 Taggle Gladstone invests in advanced water metering PRODUCTS 50 kwik-ZIP Barwon Water implements spacers and centralisers EVENTS 48 Women in Industry Awards 2024 Women in Industry Awards head to Sydney in 2024

EDITOR’S Note

Flush with success

WHEN WE FIRST launched Inside Water in the middle of last year, I did not anticipate how much I would learn about what some have dubbed as the dirty side of the water industry.

That’s a literal turn of phrase –wastewater is dealing with waste in all its elements. It struck me to think about how there is both a clean and dirty side. While I acknowledged that both were different, it was not until I started working in the industry that I realised how important the wastewater industry is to Australia.

WaterGroup is one of the largest integrated corporate water savings companies in Australia. What is less discussed is the group of Guenter Hauber-Davidson, Aimi Macready, and Holly Guy. These three business unit leaders are having a significant impact on the growth of the company as WaterGroup leverages the Internet of Things, innovation and sustainable solutions.

Also, in this issue, we talk to Mikayla Rodger. One thing that everyone likes to hear about is award winners, particularly given the collegiate attitude across the industry. Rodger is a student of Meriden School who recently represented Australia at the Stockholm Junior Water Prize. Her development of a cost-effective and recyclable device to prevent algal blooms in farm water offers enormous potential across Australia.

Further to that, Minh Duc Nguyen won the Student Water Prize at OzWater’23, the premier event for the water industry. The Australian Water Association has long given young water professionals the opportunity to shine. Nguyen’s research at Deakin University into biosolids has shown that every researcher can stand out in different ways.

We also look at risk. Risk is a basic component of life, but how does a business assess all its risks and work

to minimise their negative impacts?

Dr Annette Davison has been involved in the industry for a long period, and The Risk Group is taking a leading role in supporting business in its understanding of its risks.

Managing wastewater is a challenging task, particularly given the range of regulations at the local, state, and federal levels designed to protect the population. It’s why companies like Aerofloat, Hydroflux, Xylem, Polymaster and Interflow play a critical role in supporting local councils and water authorities in keeping people safe and finding valuable resources from waste.

While moving sideways from wastewater, I had the pleasure of interviewing one of the most optimistic people I have ever spoken to. Victor Perton could be the most optimistic person in the world, and his thinking about how optimism impacts workforce management was incredibly insightful. If you ever get the opportunity to meet Victor, grab it with both hands.

As we move into our second year, we are still a young publication. However, the continued interest by the industry in Inside Water is immensely promising. We are rapidly approaching 2024, and I have no doubt that the partnerships we have developed with the industry will continue to grow.

Chief Executive Officer John Murphy john.murphy@primecreative.com.au

Chief Operating Officer Christine Clancy christine.clancy@primecreative.com.au

Group Managing Editor Sarah Baker sarah.baker@primecreative.com.au

Managing Editor Mike Wheeler mike.wheeler@primecreative.com.au

Editor Chris Edwards chris.edwards@primecreative.com.au

Design Daz Woolley/Tom Anderson

Head of Design Blake Storey blake.storey@primecreative.com.au

Design Production Manager Michelle Weston michelle.weston@primecreative.com.au

Brand Manager Chelsea Daniel chelsea.daniel@primecreative.com.au p: +61 425 699 878

Client Success Manager Glenn Delaney glenn.delaney@primecreative.com.au

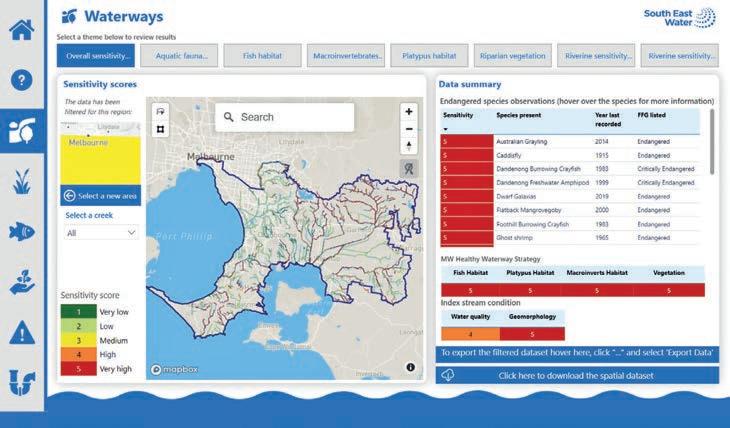

Head Office Prime Creative Pty Ltd 379 Docklands Drive, Docklands, Victoria 3008 p: +61 3 9690 8766 f: +61 3 9682 0044 enquiries@primecreative.com.au www.insidewater.com.au

Subscriptions +61 3 9690 8766 subscriptions@primecreative.com.au

Inside Water is available by subscription from the publisher. The rights of refusal are reserved by the publisher

Articles

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

Copyright Inside Water is owned by Prime Creative Media and published by John Murphy.

All material in Inside Water is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in Inside Water are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

4 INSIDE WATER September/October 2023

WaterGroup shaping the future of water

Aimi Macready, Head of Sales and Marketing at WaterGroup, Holly Guy, Head of Smart Metering Operations, and Guenter Hauber-Davidson, Managing Director, provide insights into implementing sensors and IoT devices for a better water future.

“AS A SMALL child, I could never walk past a trickle of water without playing in it, much to my mother’s great dismay. I’ve always had an affinity for water. This might suggest that I would have become a dam builder. Instead, I work to avoid the need for new dams.”

Guenter Hauber-Davidson has been instrumental in developing water conservation designs, tools, and models. To date, he has developed and delivered more than 100 water savings projects and a smart water meter. Hauber-Davidson

is among a handful of water conservation experts who can claim involvement in implementing largescale integrated water conservation schemes.

“I did initially start on the dirty side of water, focusing on wastewater,” said Hauber-Davidson. “However, during the first millennium drought, I found an opportunity to work in the water efficiency space. I’m a greenie at heart, so I loved the opportunity to work on managing water better.”

Starting WaterGroup

As one of the founders of WaterGroup, Hauber-Davidson’s goals for the company were to help the world with cost-effective and sustainable solutions that allow

6 INSIDE WATER September/October 2023

Cover Story WaterGroup

society to manage water better and more efficiently. In the intervening 17 years, he believes the overall solutions and goals remain the same. What has happened is a shift in focus around water efficiency and Internet of Things (IoT) devices.

“When we began 17 years ago, Australia was generally horrible at water efficiency,” he said. “Most Australians did not think about water because it just came out of the tap and was always there. When the Millennium Drought arrived after the Olympics, we saw our dams rapidly deplete; the Murray Darling River was just a series of ponds in some parts of Australia, and water dwindled everywhere across the country.”

Around this time, there was a

focus on water efficiency, which saw the introduction of dual flush toilets, water-efficient taps and showerheads, among other things. The implementation of this equipment was quickly followed by legislation and regulation, such as the Water Efficiency Labelling and Standards (WELS) scheme. According to the WELS scheme website, Australians could save more than $2 billion by 2030 through water-efficient products – working out at an average saving of $175 per household per year.

“The legislation and regulation very quickly eliminated the worst offenders when it came to water efficiency,” said Hauber-Davidson. “Then there was a lot of funding for rainwater and stormwater harvesting.”

Other involvement in WaterGroup

Similarly, Aimi Macready has been involved in technology for over 18 years. She is passionate about getting to the heart of individual

business needs, with over 25 years of experience working across world-class technology and related organisations. Macready is strongly determined to solve ongoing business challenges with the help of IoT-based solutions. When it comes to the water industry, she believes that it has advanced so much technologically.

“I like how technology creates better outcomes for people, businesses, and the environment,” said Macready. “I wanted to be a part of the water industry and its advancements.”

Holly Guy came into the water industry and smart metering field more recently. After finishing a job in the financial services industry, she wanted to find something new. With a progressive view of the industry and utilising the latest IoT and LPWAN technologies, she is set to successfully manage many of WaterGroup’s largest smart metering projects for key clients.

www.insidewater.com.au INSIDE WATER 7

Aimi Macready (left) and Holly Guy (right) are driving the future of water.

The devices installed by WaterGroup are proven Internet of Things (IoT) products.

Cover Story WaterGroup

“I wanted to work for a company that was actively investing in ways to revolutionise how we manage global resources,” said Guy. “I was lucky to come across a sales role at WaterGroup in 2019.”

She’s been with WaterGroup ever since and now heads up the smart metering operations team. She has moved quickly to develop a lot of knowledge. Her career path within WaterGroup has satisfied her desire to work on optimising water resource usage while enhancing environmental conservation.

Internet of Things

On reflection, Macready stumbled into the Internet of Things (IoT) industry. Her first role in a technology integration and consulting business had just started to talk about IoT in the early to mid-2000s.

“I became more interested in IoT when I moved into the Connected Lighting Industry — it was a light bulb moment,” she said. “The intake and evolution of IoT has and continues to impact customers and businesses across lighting and water. Commercial, industrial, retail, and tertiary segments are, in my experience, the ones that have been benefiting the longest. Our case studies and results for these clients are hard proof that technology and the data it provides significantly impact how a business runs and becomes more sustainable.”

Guy believes that the smart water industry has changed significantly with the introduction of IoT technology.

“I’d say that’s significantly accelerated,” she said. “It has led to more advanced sensors and data analytic capabilities. In smart water monitoring, IoT has outpaced 3G or other radio networks due to energy efficiency, scalability, interoperability, and diversity in connectivity options.”

A treasure trove of data

“To be honest, we squandered a huge opportunity when the funding from the government for water harvesting and recycling schemes was available,” Hauber-Davidson said.

“We should have been monitoring and measuring all these systems. Imagine the treasure trove of data we could be sitting on now. Yet, we’ve barely scratched the surface of possibilities.”

Hauber-Davidson believes that understanding how systems funded have been operating has helped us to work out what has been achieved – and what has not.

Still, he believes we are now at a reasonable level of basic water efficiency. The focus now is on monitoring and understanding what is happening across the system.

“In water conservation, slow and steady loses the race, to coin a phrase,” said Hauber-Davidson. “If you have just a small leak of one litre a minute, it doesn’t look like much on its own. It is a fast-dripping tap but not a stream of water. Yet, it works out to nearly 1,500 litres a day. That is about as much water as 10 people use.”

Like Hauber-Davidson, Guy believes in the importance of examining the data. Understanding the data generated by smart IoT devices is critical for water utilities and municipal governments.

“Smart systems generate a lot of data,” said Guy. “Businesses that adopt smart monitoring need to have addressed how they will effectively manage the data coming in. WaterGroup places a lot of importance on ensuring our clients can interpret and use the data efficiently. As a company, we want our clients to instantly have access to the information they need without getting lost in the volume of data coming through.”

Water savings and software

She emphasised that while the basic water savings and water efficiency measures are now in place, the industry is moving to a high-tech level of monitoring. With all the software, monitoring, and IoT devices, the industry can understand what is happening, keep efficiencies high and avoid wastage.

“The advantages enable real-time monitoring, predictive maintenance, and seamless integration with existing infrastructure,” said Guy.

“We’ve seen an evolution in how we collect, analyse, and use the data we collect from meters.

WaterGroup is continuously gaining insights into our water networks which in turn is making us more efficient in the upkeep and

8 INSIDE WATER September/October 2023

The SmartEAR IoT Acoustic Logger helps reduce water loss and minimise water leakage.

“

I firmly believe that if we look after our water properly, there is plenty for everyone on this planet.

”

maintenance of those networks. One of the biggest advantages is improved resource management and customer satisfaction. We’re a society that thrives on having data at our fingertips, and software advancements are making it readily available, allowing us to action issues as they arise or even ahead of time.”

Guy’s involvement in the industry has seen the impact of software improve the quality of data received.

“I reckon software developments have ensured the data we’re receiving from smart meters is more user-friendly whilst being easily interoperable with other business technologies,” said Guy. “We’re part of the evolution of smart cities, so integration with multiple systems is a must for success. WaterGroup’s Software as a Service (SaaS) platform UtiliOS is one of the ways we ensure our clients negate the need for multiple systems. We maintain the capability of integrating with other software whilst providing a deviceagnostic platform allowing you to display all your smart monitoring data in one place.”

Technology supports savings

With the wide range of IoT devices available in the market, WaterGroup needs to understand many aspects of the systems in which they work. There are differences between the biggest and smallest installations.

“If we’re just dealing with a few points, we want devices that can connect through narrowband IoT (NB IoT),” Hauber-Davidson said. “Those devices, like our mobile phones, can connect to the existing telecommunications network. On the other hand, if we’re doing a mass rollout of hundreds or thousands of devices, we might look at long-range wide-area networks (LoRaWANs). Such a dedicated network can look after many devices.”

By using IoT devices, WaterGroup is trying to pick up when, where and how abnormal usage occurs. The data collected from sensors monitoring how water flows through a system can pick up unusual patterns. Artificial intelligence (AI) and machine learning can help identify where a leak might occur.

“Every leak has a pattern and a fingerprint,” Hauber-Davidson said.

“Our software and algorithms can pick that up and verify it through years of data monitoring and experience. We have spent enough time on those sites to know what is normal and abnormal. As a result, we can get pretty close to the cause of a leak and its location, saving money for our clients.”

The future for WaterGroup

Hauber-Davidson would like to see every single 40 mm and larger water meter monitored online. That would prevent any further undetected water leaks throughout Australia’s water network.

“We know when more water is used than necessary. AI can help streamline the procedures to make sure people know what to do,” he said. “As a company, we are working hard to automate these things to scale them up and become significantly bigger.”

WaterGroup has been around

since 2006. Hauber-Davidson, Macready, and Guy are part of a company known for its ability to address many of the water industry’s challenges. Macready pointed out how WaterGroup was the first to bring Australian Utilities a commercially ready NB-IoT, fully integrated, ultrasonic smart water meter, an industry favourite now.

“We’re an effective team when it comes to communication, transparency and collaboration,” said Guy. “This is not just about communication between our clients but our providers too. I think that is what makes us one of the strongest companies in providing fully integrated end-to-end solutions. By embracing change, being adaptable and fostering a culture of innovation, we’re confident in our ability to positively impact water management in the future.

In looking forward, Macready is looking to its history. She knows that WaterGroup will continue to evolve and make an impact.

“With a progressive view of the industry and utilising the latest in IoT and LPWAN technologies, WaterGroup has won awards for excellence in this area,” said Macready.” We see water network monitoring as the next frontier.”

For more information, visit www.watergroup.com.au

www.insidewater.com.au INSIDE WATER 9

Guenter HauberDavidson is the managing director of WaterGroup.

Slaying algal blooms with the sun

The Australian Stockholm Junior Water Prize winner is a Year 10 student from Meriden School in New South Wales. Mikayla Rodger talked about her inspiration to tackle the problem of cyanobacteria and her future.

“I BELIEVE IT is important for young women to become more involved in STEM, pursue their interests and strive to make real change in the world around them,” said Mikayla Rodger, the 2023 Australian Stockholm Junior Water Prize winner.

Cyanobacteria is a microscopic phytoplankton responsible for an irreversible decline in water quality. Many substances deal with cyanobacteria, also known as bluegreen algae. Few deal with their root causes, which is where Rodger steps in.

A student at Meriden, Rodger won the prize due to her research investigating an eco-friendly and affordable system that could help prevent a cyanobacteria bloom. Her solar-powered machine, called SolarCyanoSlayer, can reduce cyanobacteria blooms by circulating, oxygenating, and filtering a body of water. The system, designed to be used by farming dams, is made from recycled materials and is suitable for both short- and long-term implementation.

“Mikayla started work on her machine in 2022,” said Meriden’s

Head of Science, Tara Richards. “She worked with her classroom teacher to expand on her original idea. Her original project ran for about 12 months as part of an application for the CSIRO CREST Awards.” Creativity in Research, Engineering, Science and Technology (CREST) is a national education program made available by CSIRO. It is designed for students in Years K to 12 to develop their science, technology, engineering, and mathematics (STEM) skills. Based on an inquiry approach to teaching and learning, students are engaged at all levels in science investigations and technology projects to progress from structured inquiry to open inquiry.

“Applying for the CREST Awards meant Mikayla had to make some adjustments to her original project and flesh out her proposal,” said Richards. “As part of the school’s annual Science Showcase, she got further feedback from the judges. That meant more fine-tuning before Mikayla came second in the Science Teachers Association of New South Wales (STANSW) Young Scientist

Awards in the Innovations and Engineering Design, Grades 9-10. She actually finished second to one of our other students.”

How did she get involved in this research?

“For me, science is a vessel for discovery. I get to learn about how things work and apply it to the world around me,” said Rodger. “Science allows me to question, explore and uncover. It provides results that can help to develop solutions to some of the world’s greatest challenges.”

Rodger has always been a fan of the outdoors. She is involved with some of Meriden’s extracurricular environmental clubs and programs. Finding herself an award winner was something unexpected.

“My research on cyanobacteria was not something I saw as a global issue,” she said. “Rather, I did a small project that evolved into something much bigger. It started with just a tub of cyanobacteria, and then I designed a system to help prevent them from occurring.”

Inspiration for Rodger came from spending time bushwalking. While walking, she came across a waterway covered in what she described as “this layer of murky green.” On returning home, Rodger discovered that it was cyanobacteria, which was devastating the local ecosystem.

“I did some research on the impact

10 INSIDE WATER September/October 2023

YOUNG PROFESSIONALS Mikayla Rodger

Mikayla Rodger and Meriden’s Head of Science, Tara Richards.

of cyanobacteria around the world. The Murray River in Australia has been devastated by it, and the Selwyn River in Canterbury, New Zealand, has had similar ecological damage. I looked at the Selwyn River as a case study, but it’s a global issue. I just thought I could do something about it,” she said.

In the words of the Australian Water Association, “Rodger’s project involved research into the causes of toxic cyanobacteria blooms and the development of a system that mitigates the risk. Cyanobacteria blooms plague global waterways and seriously impact the health of aquatic organisms, terrestrial animals, and humans. This threat is growing in prevalence alongside climate change.”

Rodger aimed to design a system that prevents uncontrolled cyanobacteria reproduction (a bloom event) while allowing natural populations to exist. Her design, the SolarCyanoSlayer, is also aimed to be self-sustaining for longterm implementation.

It was made of biologically derived and recycled materials, reducing the embodied energy of construction.

When placed in simulated eutrophic conditions, the invention was demonstrated to be highly effective in countering cyanobacteria blooms and subsequently improving overall water quality.

What did she want to achieve?

“There were three critical issues for me to deal with cyanobacteria,” she said. “The first is eutrophication, which represents too much phosphorus and nitrogen in the water. It normally comes about when the water is stagnant. The other two aspects are low oxygen levels and high water temperatures.”

When combined, these three factors result in the exponential

entirely made of recycled and biodegradable components,” she said. “This increases the viability of implementing it as something affordable and environmentally ethical. It’s made up of recycled PVC pipes, solar panels, biofilters and a pump.”

Rodger’s machine targets high mineral concentration with its biofilter. The solar panels power a low-level circulating pump and the oxygenator. The pump moves the water around to prevent stratification. Similarly, the oxygenator sucks in oxygen from the atmosphere and pumps it into the

small aquariums.

“The whole device is painted white. It’s a small decision, but the advantage is that there is less radiant heat transmitted into the water. This maintained the environmental quality of the device because it would not encourage further bacterial growth,” said Rodger.

When it comes to operating the biofilter, it is critical to prevent the growth of cyanobacteria. The oxygenator’s chemical reactions inhibit the bacteria’s development, reducing the algal blooms’ toxicity. It also works in tandem with the biofilter to prevent eutrophication.

www.insidewater.com.au INSIDE WATER 11

Water Prize at the Ozwater’23 Gala Dinner.

The SolarCyanoSlayer is solar-powered and can reduce cyanobacteria blooms.

YOUNG PROFESSIONALS Mikayla Rodger

Experimenting with cyanobacteria

Cyanobacteria is not something you can buy from a store. Rodger had to source it herself and then conduct her experiments. Collecting cyanobacteria was not a particularly difficult task.

“I went for a bike ride to a swamp that I know is prone to eutrophication and, therefore, algal blooms,” she said. “I had one tub with the cyanobacteria and a second tub as my control water. I also added some minerals to both tubs of water to try and simulate the conditions that would be present in farming dams. That meant adding fertiliser and minerals in the right concentration to ensure I could get as close as possible to what would happen in the real world.”

After adding those fertilisers and minerals, Rodger let both samples settle into place. That was when she was able to put her device into action. Solar power ensured that her devices would continue to operate without her presence, and she could check the progress where necessary.

The future of the SolarCyanoSlayer

Following her success at the Australian Water Awards, Rodger has received several offers to attend conferences and do work experience.

However, she is concentrating on attending the Stockholm Junior Water Prize in late August as part of World Water Week in Sweden.

“If there is any interest from companies in commercialising the design, I’ll deal with that once I get back from Stockholm,” she said. “That is where it will be presented on a global scale, and I can potentially have a larger impact.”

Another aspect of Rodger’s research is looking at the bacteria created in waterways after bushfires. With the large amounts of organic material and minerals ending up in the water, the SolarCyanoSlayer could become invaluable.

“This year, I worked a bit more on cyanobacteria that bloom after bushfires,” she said. “It’s essentially black water after a bushfire – that’s when the water goes completely black. It’s a different type of bacteria that blooms, but that’s because there are so many minerals in the organic matter. Think about the volume of burnt leaves, trees, and other organic materials – they all end up in the waterway. Bacteria will break that down and use up all the oxygen in the water. As a result, the bacteria will be able to bloom exponentially from that because it’s such a reliable food source.”

The role of Meriden

Meriden School is located in Strathfield in Sydney’s inner west. An Anglican day school for girls, it has a strong focus on STEM subjects, which is reflected in the success of Meriden in the Stockholm Junior Water Prize. Meriden student Annabelle Strachan won in 2021 by studying and developing a bioflocculant for reducing turbidity. The school’s performance matches those of Newton Moore Senior High School (2001 and 2002 winners as Newton Moore College) and the Illawarra Grammar School (2017 and 2019 winners. It lags only behind the Queensland Academy for Health Sciences (2011, 2012, 2015, and 2016 winners).

“Meriden is very passionate about STEM,” said Richards. “We continuously support our student’s ideas and provide them with as many options as possible, both in and out of the classroom. We want the students to explore their passions and develop a wide range of skills. In our science classes, many of our lessons are very practical and handson. We want the girls to collaborate, ask many questions, and conduct those investigations. Relating them to real-world applications is where they succeed in STEM subjects.”

12 INSIDE WATER September/October 2023

Mikayla Rodger presenting the SolarCyanoSlayer at Meriden’s Science Showcase.

No wasting time for award winner and waste researcher

Fourteen years ago, Minh Duc Nguyen was completing his bachelor’s degree at Hanoi Architecture University. Now, he is a well-regarded water and wastewater engineering researcher, a consultant at Isle Utilities and the 2023 AWA Student Water Prize winner.

“WHEN I STARTED my career, I was very focused on water, specifically the drinking water side. It wasn’t until later that I realised that wastewater is not just waste, but a resource.”

These are the words of Minh Duc Nguyen. He has recently completed his PhD in the beneficial reuse of sludge from drinking water treatment process at Deakin University in collaboration with Barwon Water. Nguyen’s research examines how a cost centre for water utilities can be a source of revenue.

“I’m more interested in the recycling, circular economy and

said Nguyen. “When it comes to the lifecycle of the economy, I want to work out how we can reuse waste. Ideally, the industry would be retrieving all the nutrients and resources normally considered waste and finding a way to reuse them, so it’s a circle.”

Wastewater has reached a new nadir where nothing is wasteful; it’s all a resource. Along with others within Australia and worldwide, his goal is to work out how to return those resources to life.

“We need to work to reduce our environmental footprint and bring about a more sustainable way of

From Hanoi to Geelong

When reflecting on his career path, Nguyen believes that he has one of the more unusual career paths.

“I’ve walked the line between academia and private industry,” he said. “I tended to swap between the two for a few years but questioned what I could do next. About three and a half years ago, I was reviewing the Water Research Australia (WaterRA) website and found a lot of exciting projects. The one that captured my attention the most focused on reusing and recycling waste from drinking water processes. That’s what brought me to Australia to complete my PhD.”

Despite his less-than-traditional career path, Nguyen believes his movement between academia and industry has given him unique skills.

“Because I’ve walked the line between academia and industry, I understand both languages. It’s also helped me understand what each area is doing and how to collaborate with both groups,”

Moving on from the Australian and New Zealand Biosolids Partnership (ANZBP)

For the past two and a half years, Nguyen has been a program manager for the Australian and New Zealand Biosolids Partnership (ANZBP). ANZBP is an Australian Water Association’s industry program of utilities, consultants, academics, and government bodies committed to the sustainable management of biosolids. It provides interested parties with factual information about biosolids, how they are produced, what is in them, how they might be used, as well as their benefits and potential risks associated with their use.

The ANZBP believes biosolids are

14 INSIDE WATER September/October 2023

YOUNG PROFESSIONALS Minh Duc Nguyen

Nguyen (2nd from left) received the Australian Student Water Prize at

a valuable product and provides information supporting biosolids’ application to land and other appropriate uses.

“Being a part of ANZBP allowed me to understand and learn far more about biosolids,” said Nguyen. “It was previously an unknown field of study, but I have since realised that it is a beautiful resource that we can bring into a wide range of beneficial applications.”

The ANZBP is playing a role in promoting research and collaborations with the water and wastewater industries. It is also driving the industry towards a more sustainable approach to biosolids. However, the management of biosolids has its challenges.

PFAS causing problems in biosolids

PFAS are a group of chemicals used to make fluoropolymer coatings and products that resist heat, oil, stains, grease, and water. Officially known as per-and polyfluoroalkyl substances, work is underway worldwide to remove and eliminate these chemicals from almost everything.

“With any regulatory change from the government, the biosolids

space is hunting for a long-chain polymer that can replace PFAS,” Nguyen said. “Currently, PFAS starts at the industrial level and winds up everywhere, including wastewater and biosolids. While people seem fine with PFAS in their dental floss, mascara, clothes or cookware, they tend to freak out about PFAS in their waste.”

Nguyen has a passion for helping people understand the beneficial use of biosolids. There are many

His presentation at OzWater’23 attracted significant attention from the industry.

Nguyen (2nd from right) also won the Student Water Prize at the AWA’s Victoria branch in 2022.

opportunities to treat waste products as a valuable resource and keep them out of landfill. He is convinced that continuing to throw biosolids out is working against the goals of resilience, sustainability, and combatting climate change.

“The thermal treatment of biosolids and waste, also known as pyrolysis, provides new developments for the circular economy. One area of particular interest is alum sludge,” he said.

www.insidewater.com.au INSIDE WATER 15

YOUNG PROFESSIONALS Minh Duc Nguyen

Alum sludge

The focus for Nguyen in his PhD was on alum sludge. It tends to be a quiet area of research, with a small amount being done in this field. Also known as alum sludge, it is the byproduct of purifying drinking water. A salt containing aluminium is used as a coagulant, capturing impurities and contaminants in drinking water. However, the remaining sludge has long been treated as waste, winding up in landfill.

“As part of doing my PhD at Deakin University, I found that the alum sludge could be a vital resource when considering the circular economy. As technology improves yearly, it shows we can develop better ways to recover resources,” said Nguyen.

The majority of alum sludge is stockpiled and eventually dumped in landfill. Alum sludge has enormous potential to absorb PFAS or prevent algal blooms.

“The contaminant absorption capacity of alum sludge appears significant,” Nguyen said. “Alum sludge tends to be comparable to biochar developed from biosolids

in terms of PFAS adsorption. The big advantage is the significantly reduced energy requirements. This comes from the thermal requirements to generate biochar.”

“If we can turn that waste into a useful resource that can be used in multiple areas, then we are closing the loop,” he said. “That’s a great example of how we can create a circular economy, and it should be a new focus for the future.”

Winning the Student Water Prize

The Australian Water Association’s OzWater in Sydney also received several awards. One of the award winners was Nguyen, who won the Student Water Prize for his research. He views this as a tremendous honour.

“It has meant a lot to me,” he said. “I’m just a Vietnamese-Australian doing a tiny amount of work to try and improve waste management in Australia. Being recognised for all the hard work and ups and downs was an absolute pleasure. I arrived in Melbourne just a few months before the pandemic. I could not visit my family during that time, so it was

a massive struggle. However, the award is an amazing payoff for all the time, hard work, sweat and tears I have spent on my PhD.”

Biosolids in wastewater have received a lot of attention, but this is different from Nguyen’s focus on alum sludge. He believes that by receiving this award, he is raising awareness for alum sludge, along with its recycling and reuse. Australia has enormous potential to become a globally recognised hub for alum sludge recovery and reuse, off the back of Nguyen’s research.

Future of biosolids and wastewater

Nguyen believes that the vast majority of players within the wastewater and biosolids industry are moving towards the circular economy. He hopes that more will continue to help turn biosolids and wastewater into something valuable and reusable.

“I think that the increased focus on sustainability, resource recovery, and the circular economy will increase efficiency, costeffectiveness, and become more environmentally friendly,” he said.

“With the increased uptake of artificial intelligence and smart technologies, I hope we can transform the wastewater and biosolids industry to create a better environmental aspect.”

When it comes to his role, Nguyen wants to be a continuing influence in Australia. However, he is looking beyond that.

“I hope we can expand our expertise and technology for developing countries. It would be great to be supporting countries like Vietnam, Cambodia, and the Pacific Islands. Australia can be a leader in tackling issues in the water and wastewater industries.”

16 INSIDE WATER September/October 2023

He (left) has won many awards, including the Victorian International Education Awards (202122).

1300 365 088 sales.au@ifm.com | www.ifm.com/au moneo is a self-service, easy to use, predictive maintenance toolbox that can integrate seamlessly into your existing system. It is revolutionising operations and facilities – digitalising facilities to protect what is needed now, well into the future. ifm have combined decades of expertise in sensor technology to bring you the latest in the IIoT technology space – moneo What is moneo? How can it help your business? Need to digitalise your operation and quickly? Visit our brand-new website to discover how to enhance your business operations TODAY! moneosolutions.com.au NEW You can also register for a FREE 30 day trial!

Assessing risk with Annette

branch and the National branch of the Australian Water Association.

“THE WATER INDUSTRY found me, as opposed to me finding the water industry. I’d spent enough time working in contaminated sites and found it a bit mucky. I wanted to go somewhere cleaner and thought the water industry might be it, but my first job was in sewage.”

have planned to land in the water industry, she has been making waves since arriving. With her first job at Sydney Water as a senior consultant 25 years ago, Davison has continued to excel when it comes to having an impact on the industry.

Award-winning work

Davison and The Risk Edge Group have won so many awards that she cannot place them all on her CV. Her recognition as the Water Professional of the Year by the Australian

Water Association in 2021 was of particular note.

“When you know the work you are doing is important and meaningful, you shouldn’t need awards and accolades to know the value in your work, but it makes it all the more

“It’s important to acknowledge that you don’t win awards alone. You’re standing tall on the shoulders of others,” she said. “These awards are really a recognition of everyone who has helped me get to that point in my career. It recognises the strong relationships you make in the water industry because it’s more of a family. They are not just colleagues but integral parts of your life. It was also a win for my wonderful friends, my family, and of course, my gorgeous husband. Without your wider cheer squad, you don’t get to where you are, and the wins aren’t as satisfying anyway, as there’s no one to share them with.”

Risk Edge Group supporting utilities

The Risk Edge Group is a risk assessment and management company. It specialises in governance, enterprise, water cycle and resource management risk. Its staff help businesses better understand their risks, increase certainty, and meet their objectives. Such a company does not come about on its own, and Davison saw an opportunity.

“I was working in government at a time where risk was starting to rear its head as something organisations needed to be aware of,” she said.

“Our company came into being about 10 years ago. Risk Edge, as it was called at the time, was filling that gap in the market. The goal was to help utilities understand where their uncertainties lay and do something about them.”

Davison highlights the importance of knowing that risk and uncertainty are not necessarily negative. Under ISO 31000, risk is defined as the effect of uncertainty on objectives.

“If you think about it, we are all risk

18

When it comes to finding a leader in risk management and assessment, more water utilities are turning to Annette Davison. As founder and co-owner of The Risk Edge Group, she understands the challenges faced.

INDUSTRY INSIGHT Annette Davison

STEAM (science,

managers,” she said. “Every time you cross the road, get in the car, eat out, go to the hospital or make a decision, we’ve done some risk assessment and management in our heads. Water utilities are responsible for tens of thousands, if not millions, of customers. They need to understand what can go wrong with their water products and ensure that they are managed to protect those customers.”

Most importantly, understanding risk allows organisations to optimise their businesses and become more efficient. Risk management has been mandated for essential services across Australia. While there are different systems for different states, every provider needs some urban water risk management system in place. Otherwise, there can be serious penalties and consequences.

Water quality and security

When it comes to managing drinking water, scarcity is something that would rarely enter the minds of urban consumers. As far as Davison is concerned, water security is about both quantity and quality.

“You can have all the water you like, but if it’s not the right quality for your desired end use, you can’t do anything with it. Ultimately, you would have to spend a lot of money to bring it to the right level. That can get prohibitively expensive,” she said.

It’s why Davison and The Risk Edge Group offer risk workshops to utilities, local government, and other organisations. It helps those organisations understand their water quality risks and implement improved procedures.

“It could be bringing a new water source online, considering the purification of recycled water, or any number of other options,” she said. “It’s important to remember that there is a lot of work in the options

analysis space as well. That is to help organisations corral and identify potential options before assessing them against specific criteria and set objectives. Understanding the risks is vital to making informed decisions because we are looking at projects that often involve tens of millions of dollars.”

These decisions are often challenging for council-run, regional water utilities. Municipal governments usually have a range of competing objectives that can seem vast. This is where Davison and The

Risk Edge Group can step in.

“We help them review the risks associated with each objective to develop a balanced outcome,” she said. “We’ve been working with utilities across New South Wales recently to help them navigate new regulatory requirements. With the large array of legislative requirements, there is a series of things that utilities have to do. We’ve been working with a range of utilities to help ensure that their water quality requirements are properly considered.”

www.insidewater.com.au INSIDE WATER 19

Annette Davison is the founder and co-owner of The Risk Edge Group.

INDUSTRY INSIGHT Annette Davison

Future of risk management

Davison believes that utilities in Australia are mature in their understanding and attitudes to risk management. This has arisen because utilities have dealt with risks for many decades, with Australia leading the way in this space.

“In 2004, the Australian Drinking Water Guidelines were amended to introduce the concept of quality assurance rather than quality control,” she said. “It led to the development of a Framework for the Management of Drinking Water Quality based on ISO 9000 and HACCP. Instead of relying just on monitoring the water coming out of the tap at the customer’s end, utilities now look upstream along the water treatment process to check multiple different points in the system. The idea is to stop non-conforming products from ever reaching customers.”

A significant change from implementing the Framework was the introduction of critical control points — a development that came out of the food safety industry.

Davison believes the water industry has come a long way, but there is more to learn.

“One way the water industry can learn is to look at other industries.

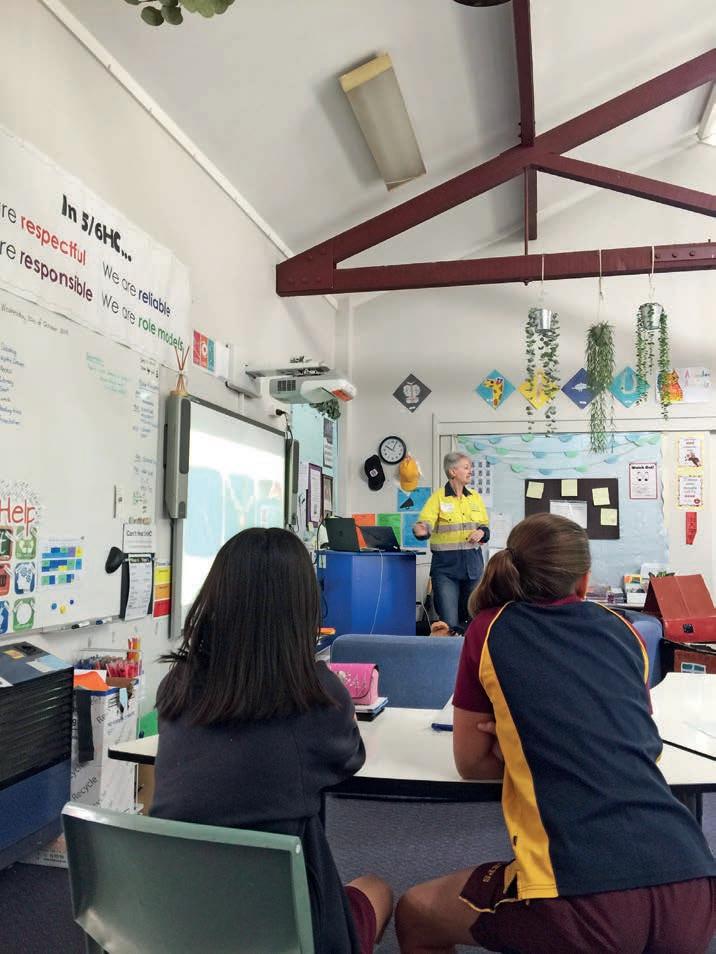

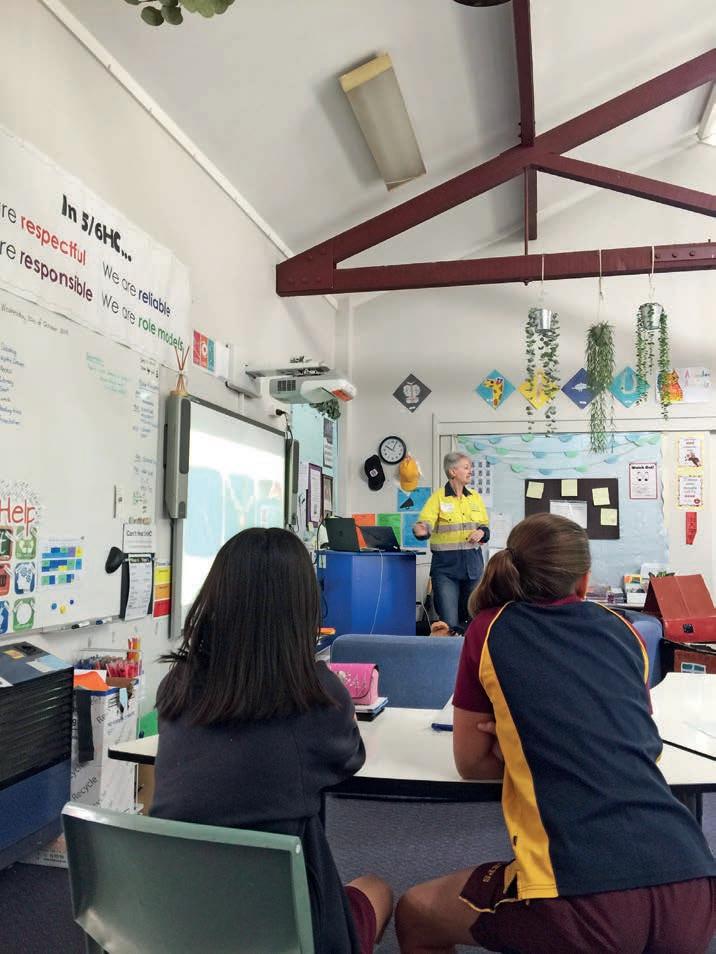

Sectors like food safety and aviation deal with risk in a range of different ways, and there are opportunities in those spaces that we can bring into our industry,” said Davison. Further down the line, Davison is passionate about working with and learning from First Nations people. She is convinced that their knowledge is integral to water management and understanding, especially including the cultural aspects and importance of water. School students are another group that Davison enjoys interacting with and whom she believes have incredible power to make changes.

“The current generation of school students is far more savvy than I was at their age,” she said. “They have access to so much more information, and influencing them will be challenging. It’s why The Risk Edge Group does a lot of pro bono education work, as part of its value of generosity.”

The importance of giving back to the community is also reflected in its OneCreek initiative, with Rotary Community Networks as a key partner. OneCreek is a grassroots initiative championed by The Risk Edge Group together with OneStreet, a not-for-profit started by Davison during COVID. It has since grown as a

rich resource for community-building. The idea behind OneCreek is to increase awareness of and care for our urban waterways, one creek at a time.

“The idea is that the local community works out what it wants for the creek,” she said. “My local creek is Rocky Creek, and it sure takes a beating. We want to give that poor creek some love and improve awareness of it as a valuable component of our environment and deserving of care and respect in its own right. Creeks can also form practical learning environments for students. For instance, students from local schools close to the creek can learn all sorts of things like hydrology, pollution, environmental science, design elements and First Nations’ importance. A natural laboratory!”

Her thinking is that if the students are genuinely aware of the entire catchment system that the creek forms part of, they will understand what happens with their dumped rubbish.

“Having awareness from an early age is key. Not only will the message stick with these students for decades, but the kids can also educate and influence their parents – well, that’s the plan!”

For more information, visit www.riskedge.com.au

20 INSIDE WATER September/October 2023

The Risk Edge Group recently won the Office and Professional Services Award at the Better Business Partnerships Award. Credit: Better Business Partnerships, photographer Gavin Little.

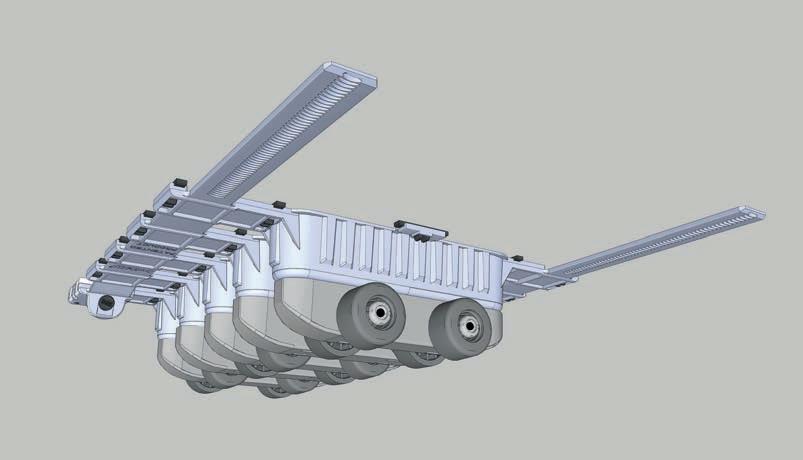

Revolutionising leachate management

Australian wastewater treatment company, Aerofloat, has been working in the leachate space for several years, making a name for itself for custom-built designs that meet the specific needs of councils and companies.

MICHAEL ANDERSON IS the general manager and one of the co-founders of Aerofloat. He’s created patented wastewater products that improve maintenance requirements, increase product efficiencies and lower costs for Australian councils and companies.

“The safe and sustainable management and treatment of industrial waste poses significant challenges to councils across Australia,” said Anderson. “Aerofloat has emerged as a pioneering force in designing cutting-edge leachate treatment plants that exemplify environmental responsibility and innovation. We have worked with several councils across Australia to manage complex wastewater, including leachate waste.”

Leachate can be contaminated and potentially hazardous, as it can contain a mixture of organic and inorganic substances, ammonia, heavy metals, and other pollutants. Leachate composition depends on the types of waste materials in the landfill, their

decomposition stage, and various environmental factors.

“Leachate is a complex mixture of dissolved contaminants that arise from the percolation of rainwater, moisture from waste materials, or other liquids through landfills and waste disposal sites,” he said. “Often referred to as “landfill juice,” it can be a highly contaminated liquid that results from this interaction of water with the decomposing waste materials in landfills.”

Managing leachate essential task

Managing leachate is a challenge for waste management facilities to prevent environmental pollution. Proper containment and treatment of leachate are essential to avoid the contamination of groundwater, surface water, and soil.

Landfills and waste disposal sites require robust systems to collect and treat leachate to minimise the environmental impact. Managing leachate waste requires a design based on understanding the leachate and its contaminants.

“Leachate can contain numerous pollutants,” said Anderson. “If not properly managed, it can infiltrate surrounding soil and groundwater, leading to widespread environmental degradation, water pollution, and health hazards.”

Shellharbour City improving systems

Shellharbour City Council contracted Aerofloat to design and construct a new leachate treatment plant for the Dunmore Recycling and Waste Disposal Depot to combat rising disposal costs. The site lacked upstream storage. As a result, the leachate quality was highly variable, with ammonia reaching 2000 milligrams per litre.

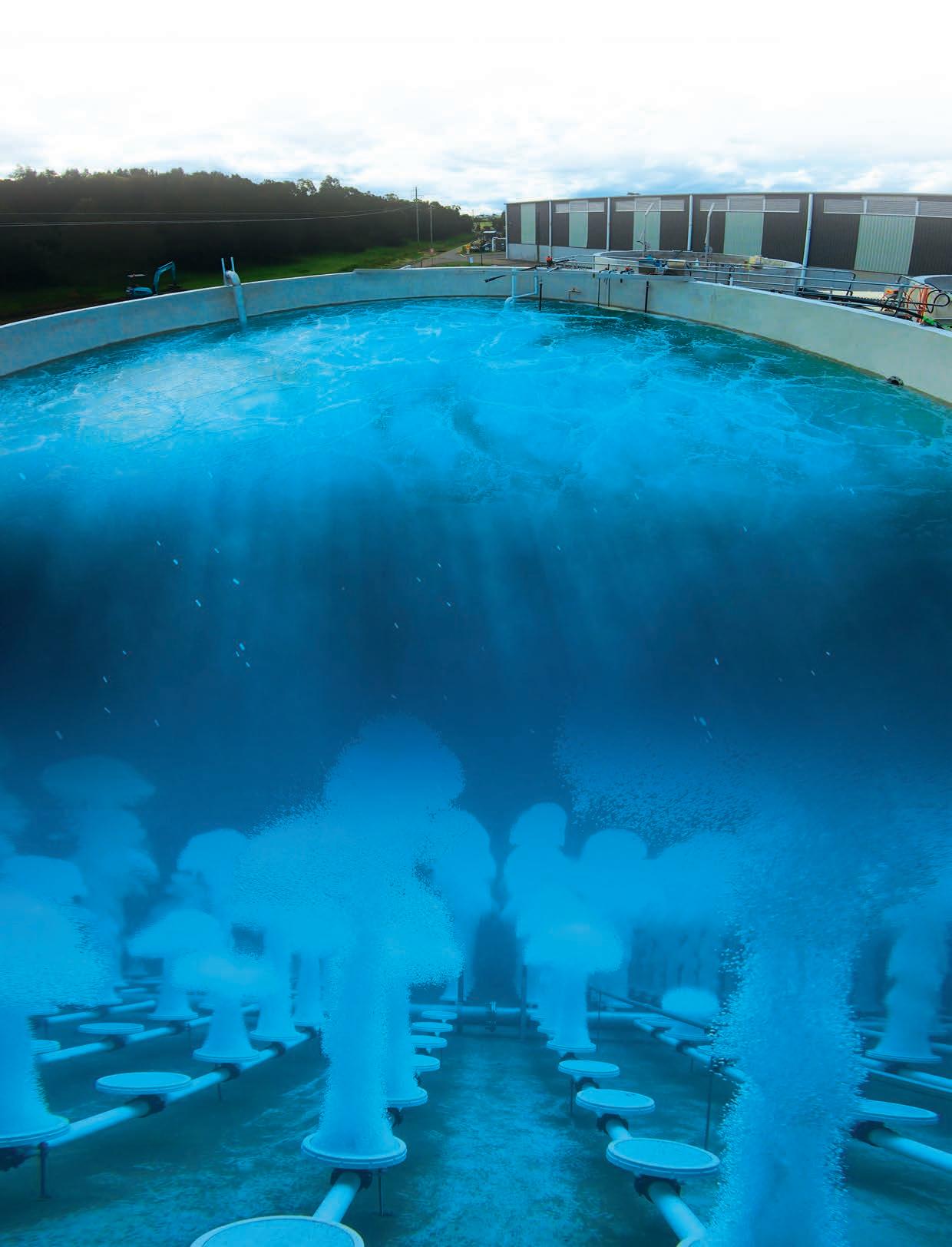

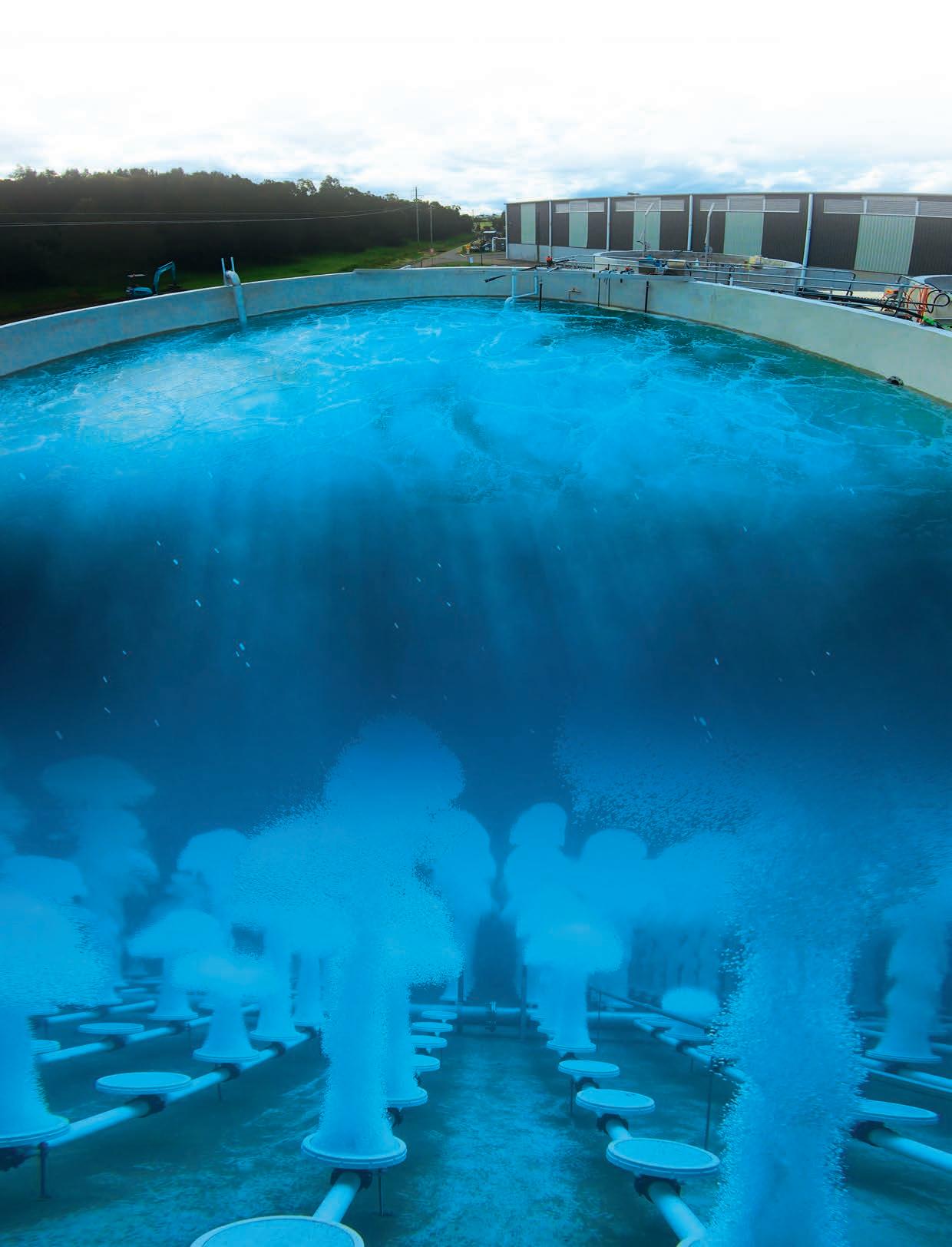

Aerofloat installed three large concrete tanks comprising an anoxic reactor, a nitrifying reactor, and its unique sequence batch reactor (AeroSBR).

“The site at Dunmore has been operating effectively since installation well over a year ago, ensuring a sustainable solution for Council and Dunmore Recycling and Waste Disposal Depot,” said Anderson.

“To complete the build, internal recycle pumps were installed between the reactors,” he said. “Treated effluent was decanted into a tank then pumped to the sewer.”

22 INSIDE WATER September/October 2023

FOCUS Wastewater

The Dunmore Recycling and Waste Disposal Depot manages leachate more efficiently because of the Aerofloat partnership.

Chemicals are added during process phases to optimise the effluent quality and technology performance, including sucrose as a carbon source and caustic soda for pH correction. Any excess biosolids are pumped into a thickening tank for disposal by Council.

Key to any leachate treatment plant is managing the nitrification and denitrification processes to remove ammonia nitrogen from the leachate before discharge to the sewer.

“The nitrification and denitrification processes are critical in treating the leachate. Aerofloat effectively treats the high ammonia levels so that only high-quality effluent is discharged to the sewer,” said Anderson.

Kicking goals in leachate treatment

Aerofloat’s leachate treatment system for Shellharbour City Council achieves an effluent quality suitable for discharge to Sydney Water’s sewer, with a design capacity of around 65 cubic metres per day and an average ammonia concentration of 1250 milligrams per litre.

“Aerofloat critically analysed the process design from the beginning. The team leveraged its in-house knowledge and experience in treating industrial wastewater. Once the civil works and large tanks were constructed, Aerofloat made the

build seem simple, despite being a very complex project,” said James Brumpton, Shellharbour City Council Project Manager.

The plant was contained within a concrete bund and included a purpose-built mezzanine floor that kept all critical mechanical and electrical systems safe. An automated PLC system allows operators remote monitoring capabilities so that they have eyes on the plant even when not on site.

Aerofloat’s success for the Dunmore leachate plant was just the tip of the iceberg for moving into the leachate area. It is currently working

on multiple leachate plant builds for councils and Australian companies in Queensland and New South Wales.

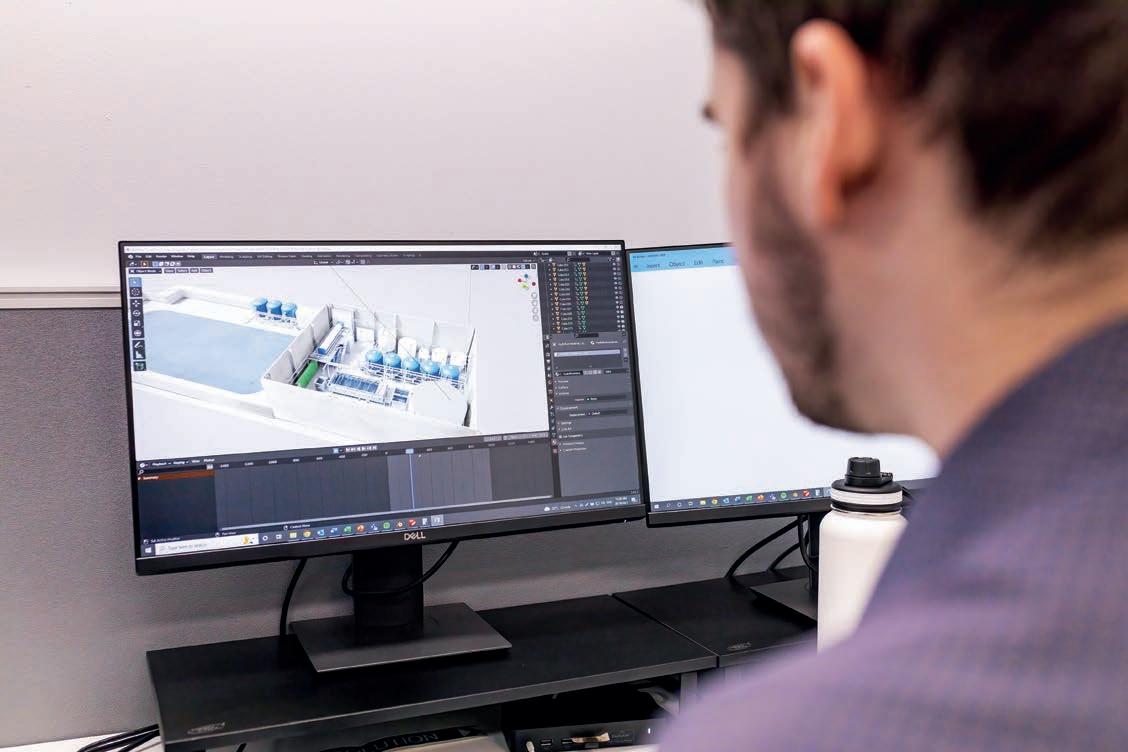

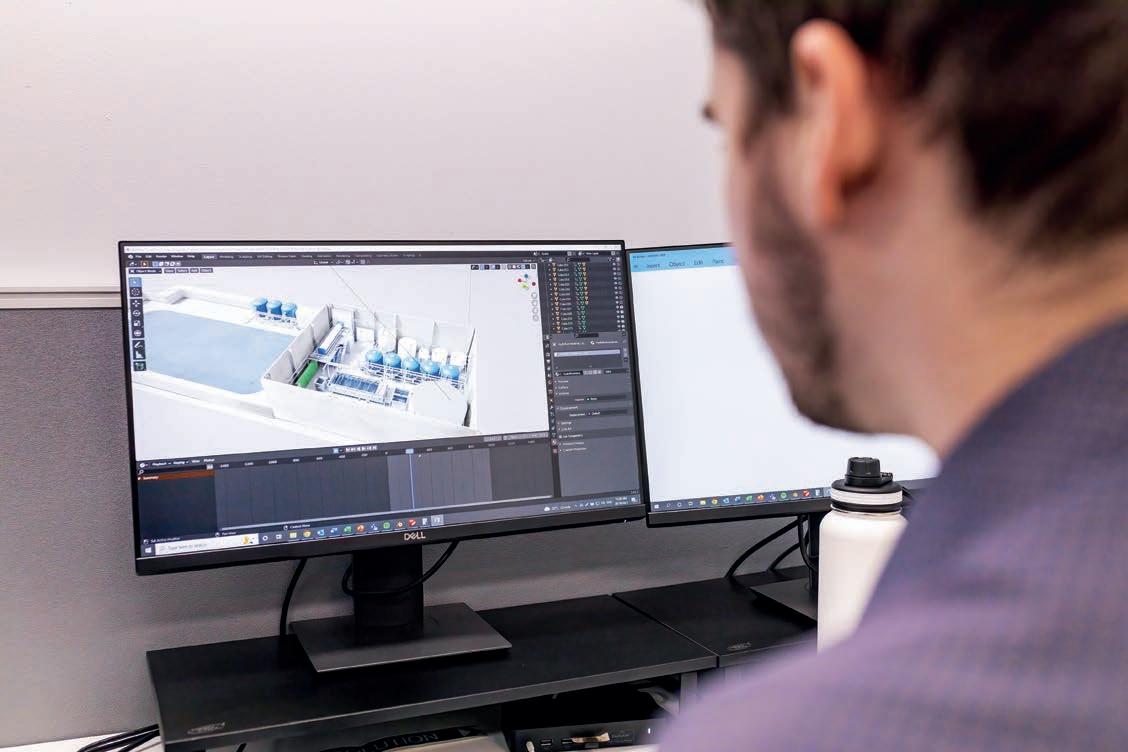

“We’ve built in-house expertise, and our delivery process is unique compared to others in the market,” said Anderson. “We design our electrical control systems, circuit boards, switchboards, and automation processes in-house. It’s part of our design philosophy and unique to the industry. This remains a strength of Aerofloat, as we can provide highly customised and automated layouts for anything our customers throw at us. We also create 3D models of each project. That way, we can make any

www.insidewater.com.au INSIDE WATER 23

The Dunmore Recycling and Waste Disposal Depot provides high-quality leachate management in its custom-built facility.

A modern facility requires a comprehensive and sensible layout.

FOCUS Wastewater

“Our plant at Dunmore can manage peak loads of 2000 milligrams per litre of ammonia and can readily treat load increases of over 50 per cent. We’re currently working on similar projects in Queensland that demand a complex understanding of how to effectively treat the leachate specific to those sites.”

A detail-oriented approach ensures Aerofloat’s projects all achieve the same high standards.

“Aerofloat’s leachate treatment plants employ a combination of advanced treatment processes that ensure effective removal of contaminants from the leachate. Each leachate treatment scenario is unique, depending on factors such as the composition of the leachate, site-specific conditions, and regulatory requirements,” said Anderson. “Our job is to ensure that we understand the specific requirements of the regulatory authority and meet the Council or company’s mandates.”

Tailor-made for every customer Aerofloat provides tailormade solutions optimised for maximum efficiency and minimal environmental impact. It integrates energy-efficient technologies into its leachate treatment plants, reducing operational costs and lessening the overall carbon footprint of the treatment process for its clients and the community.

“Aerofloat’s designs are not only

international regulations pertaining to waste management and water quality. Non-compliance is not an option for us; our designs must ensure a sustainable, compliant result for our clients both now and long-term,” said Anderson.

This adherence to regulatory standards underscores the company’s commitment to responsible engineering and environmental stewardship. It is also known across the wastewater industry for being pioneers in innovation.

“Innovation remains at the heart of Aerofloat’s approach, and we invest in research and development to continuously improve the efficiency and effectiveness of our treatment

in place for dealing with leachate is critical.

Innovation key focus of Aerofloat

This commitment to innovation enables its engineering team to stay at the forefront of leachate treatment technology.

“Aerofloat’s leachate treatment plants are designed for long-term sustainability. By incorporating robust materials, efficient maintenance protocols, and adaptable designs, our plants contribute to the longevity of waste management infrastructure for all of Australia,” said Anderson. Aerofloat has firmly embedded itself into the industrial wastewater management sector, offering patented technology and off-the-shelf products to address a range of industrial wastewater treatment needs.

Developing customised solutions improves outcomes for

Through its advanced treatment processes, energy-efficient designs, and customised solutions, Aerofloat paves the way for a cleaner, safer environment, proving that environmental challenges can be transformed into opportunities for positive change with the right blend of expertise and innovation.

For more information, visit

24 INSIDE WATER September/October 2023

Is your pipe spacer compliant? Call us for details on ordering P (08) 9725 4678 sales@kwikzip.com www.kwikzip.com The only casing spacers successfully appraised by WSAA HDX and HDXT KWIK-ZIP’S HDX & HDXT CASING SPACERS COMPLY WITH WSAA PRODUCT SPEC #324 - CASING SPACERS; REFER WSAA PRODUCT APPRAISAL REPORT #1523

The changing face of wastewater

HYDROFLUX DIRECTOR JAMES

Hall is a chemical engineer. He’s had various roles in and around the wastewater industry, including corporate management and technical consultancy. His extensive experience and understanding of the needs of businesses across Australia, New Zealand and the Pacific means Hall and Hydroflux can help companies achieve their sustainability goals. It means he and the company can also ensure that society’s water and wastewater treatment products and solutions align with its customers’ critical needs.

“I’ve always had an affiliation with water, including Sydney Harbour and the ocean,” said Hall. “I’ve also had an engineering background of sorts. As a child, I liked to pull things apart and put them back together as a problem-solving exercise.”

As he grew up, his parents would ask him the age-old question of what he would do when he grew up. While he did not have a direct answer then, Hall decided to put a few of his passions together.

“With my interest in water and my passions for engineering and problem-solving, it was inevitable that I wound up in the wastewater industry,” he said. “I studied chemical engineering at university and always had an eye on the environment. I fell into the wastewater industry, and, fortunately, I’ve stumbled into something I love.”

Industry adapting to change

In the eyes of Hall, the most significant change he has seen is

how water is valued, specifically clean water.

“When I first started, water was just seen as something that was abundant and available,” he said.

“There was no real cost associated with water. There was a cost of water disposal, as opposed to a cost of acquiring water.”

Over the past three decades, Hall has seen the industry shift to recognising water as a valuable resource. This is not just the case for the water industry but for companies across the corporate spectrum.

“The cost of water is now a significant part of the operations of many businesses,” said Hall. “That cost attracts attention and creates a desire to improve water use, water

treatment and wastewater disposal. To take that to the next logical step, the industry model is moving away from treating water as a cost to reduce and shifting towards treating water as a valuable resource. That treatment results in an increased value and respect for water, and that’s also occurring at the societal level.”

Hydroflux at the cutting edge

Hall reflected on the attitude at Hydroflux. He focused on how the company has taken the approach of “Why can’t we do more?”

“Early on, Hydroflux focused on recycling and reusing water,” he said. “We also looked at how to take wastewater from food production systems and turn that back into potable water. That grabbed my interest as someone who loves water, the environment, and problem-solving because it’s not that simple. Hydroflux has taken that even further as now wastewater can be converted into potable and renewable water.”

When Hall refers to renewable water, he is looking at how water can

26 INSIDE WATER September/October 2023

When James Hall gives his opinion, the wastewater industry listens. A veteran of more than 20 years in the industry, he shares his thoughts on the development and changes he has seen.

FOCUS Wastewater

James Hall is a director at Hydroflux.

be fed through a hydrogen electrolysis plant, turning it into ultra-pure water. By looking at that point, Hydroflux has fine-tuned the processes that run advanced systems.

“The other factor that has kept Hydroflux at the cutting edge is that it has become a more holistic business,” said Hall. “Hydroflux does not just look at wastewater. We are looking at where the water comes from and how we can enhance and improve it. We look at the entire water cycle, from the beginning right through to potential reuse and recycling.”

Future of the industry

Consolidating wastewater treatment plants could be the future of wastewater in Australia. Hall believes the country has room for developing wastewater treatment precincts to service large populations or multiple regional towns. He also sees Hydroflux continuing as a leader in the industry.

“There is a social accountability that is required of businesses these days,” he said. “It’s shown by action rather than words. Hydroflux is a certified carbonneutral business and advocates for water stewardship as part of its day-to-day life.“

For more information, visit www.hydroflux.au

SmartEAR Acoustic IoT Logger for Water Network Leak Detection FOLLOW US ON www.watergroup.com.au water@watergroup.com.au SmartEAR-GO App for easy and fast installation Cloud Software for leak localisation, prioritisation, monitoring and alerting

Designing wastewater plants requires skill and expertise.

Understanding sensors for the wastewater industry

FOR EVERY JURISDICTION in Australia,

wastewater sites need to know the volume of treated wastewater travelling through their outlet pipes. No one wants poorly treated water to go into local water sources, and the fines for breaching this can reach millions of dollars. This is where Pulsar Measurement can support the industry with its technology. The AVFM 6.1, Ultra 4, and MantaRay create new opportunities for water and wastewater operators. The company’s experience in the United Kingdom is insightful, and many operators in Australia can benefit from the technology.

AVFM 6.1 – Outlet pipe measurement

Wastewater sites must know the volume of treated wastewater that goes through their outlet pipes and back into the local water source to comply with local permits and prevent prosecution for over-pumping or spills. Pulsar Measurement was asked to help find a solution to identify the amount of treated wastewater flowing through the outflow section of a client’s site. The team decided to try the AVFM 6.1 area velocity flow meter.

The AVFM 6.1 uses a submerged ultrasonic sensor to continuously measure both velocity and level in the channel. The sensor resists fouling, corrosion, and abrasion as the exposed materials on the sensor are stainless steel. The best accuracy arises when the water is not very turbulent and velocity is evenly distributed across the channel. The channel should not have drops or

direction changes immediately upstream of the sensor location. The AVFM was placed into the outlet sewer pipe on-site to measure the treated wastewater pumped. Inlet flow at the site was monitored elsewhere, and the customer controlled the pump frequencies to adjust the amount of flow that went through the application. Pulsar Measurement’s AVFM 6.1 monitored the flow travelling through the outflow pipe.

Once installed, the system performed admirably, and the readings obtained were in line with what the customer was expecting to see. End-users were satisfied with the results. Several tests were conducted to confirm that the system-reported flows, at different rates, were in line with the customer’s expectations.

family of controllers and is the first controller with an onboard localised display with trend analysis. It allows the user to get a glance at process trends over time. The unit follows a simple, easy-to-use, menu-led setup system. Installation of the unit is quick, easy, and straightforward. The on-screen trend analysis and view of echo profiles featured in the Ultra 4 unit give the user a quick and clear indication of trends over a period. The controller features embedded memory and comes with an 8GB SD memory card as standard. It allows for enhanced data logging and ensures that no historical data is lost, even if the site loses power.

28 INSIDE WATER September/October 2023

Innovative devices are transforming the wastewater industry, providing accurate and reliable solutions for efficient and sustainable wastewater management.

The ultrasonic sensor attached to the ACFM 6.1 to measure both velocity and wastewater levels.

FOCUS Wastewater

An open channel flow meter like the MantaRay can make a difference for wastewater treatment sites.

including a V-Notch weir and Parshall Flume, with two alternative options for the end-user to enter up to 32 pairs of head-toflow breakpoints.

Various communication options for the Ultra 4, including HART, Profibus, and Modbus RTU, help communication in existing site systems without expense or hassle.

This new and improved unit’s sophistication and advanced features allow water companies to comply with the new regulations. It is a small but crucial building block in a much bigger development. The noncontact nature of the Ultra 4 and ultrasonic technology means little to no maintenance is required.

MantaRay flows the right way

An array of wastewater treatment sites are required by law to measure their environmental impact, and the discharges from any industry can vary in type. A client of Pulsar’s was concerned about the increased volume of water runoff into the surrounding environment. Together, it was decided to implement an open channel flow meter, and MantaRay was the device chosen.

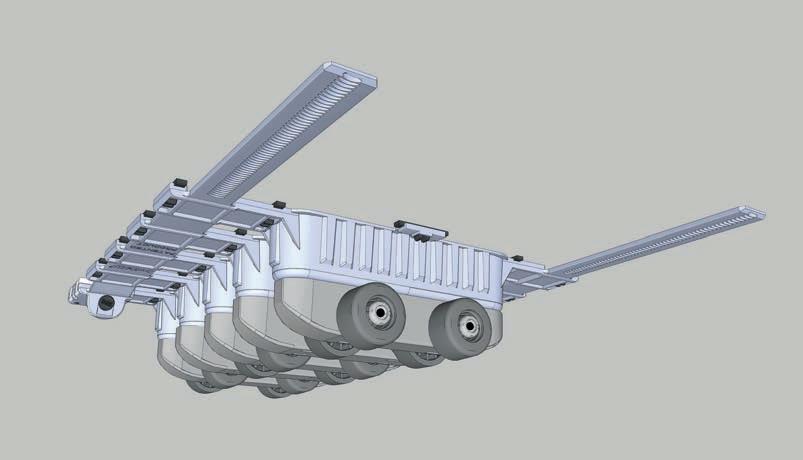

The MantaRay is a portable areavelocity flow meter that measures flow using a submersible ultrasonic sensor. The unit is designed for flow surveys in open channels, partially full sewer, and surcharged pipes – making the portable flow meter suitable for sewer monitoring, industrial flow monitoring, irrigation flow, and natural streams.

The digital display, outputs, and non-essential functions are

suspended using the ‘Sleep Mode’ function to extend battery life while logging flow. Based on the logging interval, the MantaRay activates the sensor for 12 seconds to obtain flow readings and then resumes low power mode until the next logger sample interval.

The battery operation has proved to be a success for many users. This is due to the remote location of the measurement point, allowing the unit to collect the flow data required for the expansion permit. The unit’s compact size has also meant it could be installed discreetly in a cabinet on the side of a small bridge. Accurate flow data is now being recorded and logged, which ensures that data from multiple years can be stored for regulatory requirements.

For more information, visit pulsarmeasurement.com

www.insidewater.com.au INSIDE WATER 29

The Ultra 4 provides a great vision

of what is really happening.

Transforming wastewater transportation

Pumping and transporting wastewater appears to be a simple thing to do. However, the demands of wastewater transport are far from basic and challenge the best of us. Xylem sets the standard for both efficiency and reliability in transporting wastewater to treatment facilities.

“XYLEM OFFERS A comprehensive package of technology, hardware, software, algorithms, and connectors that enable utilities and local councils to immediately enhance their operational efficiency,” said Jason Morris, Xylem Australia and New Zealand (ANZ) - Product Manager for Pump Stations.

Older systems need to be replaced, and original equipment must be upgraded. Utilities are challenged to be smarter in transporting wastewater to the treatment plant. They need to squeeze more efficiency from their equipment, reduce energy use and add advanced processes. Newer pump stations must predict the future, plan for expandability and stricter environmental controls.

People like Morris are leading the charge, having joined Xylem 16 years ago and established himself in the wastewater industry.

“Much of my career has been involved in environmental monitoring,” he said.

Morris got involved in the wastewater industry through his instrumentation and process engineering background.

Making a difference

Xylem is providing innovative solutions that help utilities meet an array of issues that are helping Australian water utilities and local councils move towards better wastewater transport through well designed pump stations.

“One of the biggest challenges that

Australia faces, is such a vast area and distributed population results in network infrastructure stretched over long distances,” he said. “We are seeing small towns working harder on treating their wastewater than they did about 50 years ago.”

Xylem supports water utilities and municipal councils to improve operational efficiency, reduce energy consumption, and optimise network processes. Much of this comes from the design of the wastewater pump stations — an area that Morris focuses on.

“Most utilities are using Xylem’s FLYGT-branded pumps that work to optimise the pump stations. All the utilities want their pump stations to work efficiently and transport the wastewater fluids to the treatment plant uninterrupted. Any spill could cost large fines and substantial environmental cleanup.”

Design is key

The design of wastewater pump stations is crucial because it directly impacts the performance and reliability of the system. A welldesigned pump station reduces the likelihood of unscheduled call outs and ensures efficient and effective wastewater management.

“The last thing any operator wants is to get an unscheduled call out,” said Morris. “Calling on maintenance teams at night to attend the site to unclog a pump is highly inconvenient and uneconomical. It is why optimising the design of a pump station is critical.”

Morris explained that the bottom of the pump station should not be flat because it leads to sedimentation in the corners of the station. As sedimentation increases, it increases the risk of blockages. Even though pumps are designed to handle solids, it’s when the solids start to coagulate and clump together that big problems begin.

“Fatbergs are also a big problem for pump stations,” he said. “Breaking up fatbergs and unsettling the coagulating sedimentation in wastewater systems is the solution. We have the equipment to break up the collection of fat, oil, and wet wipes using mixers or flush valves. They can be pointed at the mass to stir the materials and put them back into suspension. The pumps can then process those materials.”

Providing safe and reliable safety systems keeps staff healthy and

Individualised, customised design Understanding what each project needs is critical to designing the

30 INSIDE WATER September/October 2023

FOCUS Wastewater

importance of examining the issues that are happening on-site.

“Every site is unique, and the site’s situation relative to other factors can reflect the number of solutions that Xylem implements,” he said. “For example, if we know that there’s going to be a lot of fat and oil in the wastewater, we can put those specific solutions in place. “Greenfield sites have different challenges, as we need to flush the pump station regularly. It’s important to bring the flow up to scouring velocity. This minimum velocity is required to keep the solid particles in suspension with water, and particles keep moving with water.”

He also pointed to the importance of having pumps that can detect blockages themselves, such as the FLYGT CONCERTOR range that can spin backwards to remove blockages and have another go at processing the materials. Morris stressed that Xylem has a range of different solutions for different situations.

“We ask customers about the problems they are facing. Once the client starts talking about the specific problems they want to solve, Xylem can help by offering a range of solutions to improve the efficiency of the pump stations,” he said.

Algorithms and software

Xylem‘s FLYGT SECAD software supports the optimal design of pump stations. It utilises advanced engineering techniques and data analysis. FLYGT SECAD considers factors such as hydraulic requirements, site conditions, and specific project needs. It helps the company generate tailored and efficient pump station designs. The software also helps reduce operational issues, maximise performance, and enhance overall wastewater management by optimising the design process.

design,” said Morris. “It leverages the experience and expertise of Flygt to design pump stations that are robust and optimised for efficiency. This results in enhanced performance, reduced downtime, and improved overall operational effectiveness.”

“We do a lot of 3D modelling to understand how the pump stations would work,” Morris said. “We can show where the inlets are going to be, how the valve chamber is going to be set up, and where some of the accessories for the valve chamber can be installed.”

The wastewater network flow can be monitored and optimised using a digital twin, Xylem Vue Powered by GoAigua platform. This can iron out peaks and troughs in the flow to the treatment plant. It is a significant part of the digital transformation that water utilities are working on. The algorithms used in Flygt pumps help achieve high-quality pump operations. These algorithms enable functions like unblocking, cleaning, and energy optimisation. Each algorithm contributes to the pump system’s reliability, efficiency, and performance.

Xylem’s data scientists have been working hard on algorithms that optimise not just products but the entire network operation. Eventually, AI will optimise those algorithms even further. “Digital twins allow utilities to develop a digital equivalent, or twin, of their assets in the field,” he said. “It allows utilities to experiment with different asset settings under the

algorithms will support water utilities as they digitise their entire network.”

Supporting sustainability and net zero

Net zero and being sustainable can be challenging for wastewater pump stations. Given that they must be on much of the time, pump stations tend to consume significant amounts of power.

“Optimising the pump duty point means that Xylem can help utilities optimise their energy consumption,” said Morris. “If we’re pumping into a network that has some semi-closed valves, the algorithms will indicate excessive energy consumption. It allows utilities to find the problem and solve it.”

By providing advanced water and wastewater treatment technologies, Xylem enables utilities to improve energy efficiency, reduce water consumption, and optimise process performance. Its data-driven solutions and digitisation facilitate the identification of areas for improvement. Utilities can implement predictive maintenance strategies and optimise operations. These efforts contribute to net zero goals by minimising environmental impact and maximising resource utilisation. “Solving water challenges is what we do best at Xylem. Our technology helps utilities and local government to optimise their wastewater systems,” said Morris.

For more information, visit www.xylem.com/au.

www.insidewater.com.au INSIDE WATER 31

with time and innovative due to companies like Xylem.

Polymaster providing proper solutions

Storing wastewater and other hazardous chemicals is not a market opportunity for the faint of heart. Getting it wrong can cost millions in fines, not to mention a loss of reputation. Polymaster is setting the standard.

“WE DON’T SEE a huge range of chemicals in the water industry, as opposed to the wastewater industry. We build our tanks out of material that will be inert to the chemicals.”

That’s Jason Egan, the National Key Account Manager for Polymaster. Polymaster is an Australian manufacturer of liquid storage solutions. The family-owned national business has offices and facilities throughout Australia, and its vision is to become the industry standard for liquid storage.

Egan has been with Polymaster for about four years. He came to the industry after years in rail and logistics.

“Polymaster is a good business. It’s growing and knows what it will do and where it will expand. Its progress and growth combine well with the people and the culture. Our staff

turnover tends to be low, so I’m happy to be here,” he said.