AUTOMATING OPERATIONS WITH GTP

Dematic experts compare the latest in automated order fulfilment solutions

CHARTING THE COURSE

Körber brings Elevate to Sydney for the first time TMHA onboards its largest crop of apprentices since 2007 RECRUITING AND GROWING TALENT

JUNE 2024

COVER STORY

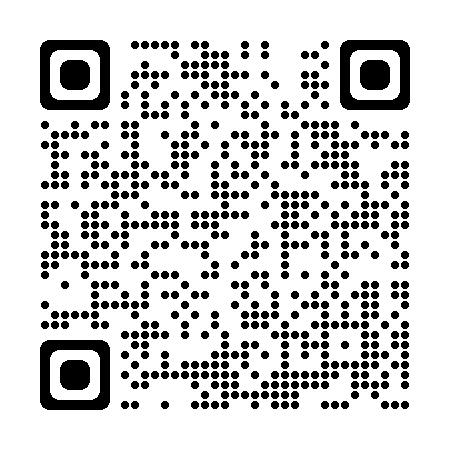

A Leader

The new 2024 Gartner® Magic Quadrant™ for Warehouse Management Systems is out and for the 6th year in a row, Körber has been named a Leader.

Scan the QR code to get your free copy of the report and discover why Körber stands out among the competition. koerber-supplychain-software.com

Scan for your free copy of the report

for six years

Supply Chain Solutions

CONTACT

MHD Supply Chain Solutions is published by Prime Creative Media

379 Docklands Drive, Docklands VIC 3008

Telephone: (+61) 03 9690 8766

Website: www.primecreative.com.au

THE TEAM

CEO: John Murphy

Chief Operating Officer: Christine Clancy

Managing Editor: Syed Shah

Assistant Editor: Joseph Misuraca

Business Development Manager: William Jenkin

Design Production Manager: Michelle Weston

Art Director: Blake Storey

Graphic Designers: Blake Storey, Laura Drinkwater

Client Success Manager: Ben Griffiths

FOR ADVERTISING

OPTIONS

Contact: William Jenkin william.jenkin@primecreative.com.au

SUBSCRIBE

Australian Subscription Rates (inc GST) 1yr (6 issues) for $78.00 2yrs (12 issues) for $120.00 – Saving 20% 3yrs (18 issues) for $157.50 – Saving 30%

To subscribe and to view other overseas rates visit: www.mhdsupplychain.com.au or Email: subscriptions@primecreative.com.au

ACKNOWLEDGEMENT

MHD Supply Chain Solutions magazine is recognised by the Australian Supply Chain Institute, the Chartered Institute of Logistics and Transport Australia, the Supply Chain and Logistics Association of Australia and the Singapore Logistics and Supply Chain Management Society.

ARTICLES

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

COPYRIGHT

MHD magazine is owned by Prime Creative Media. All material in MHD is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in MHD are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

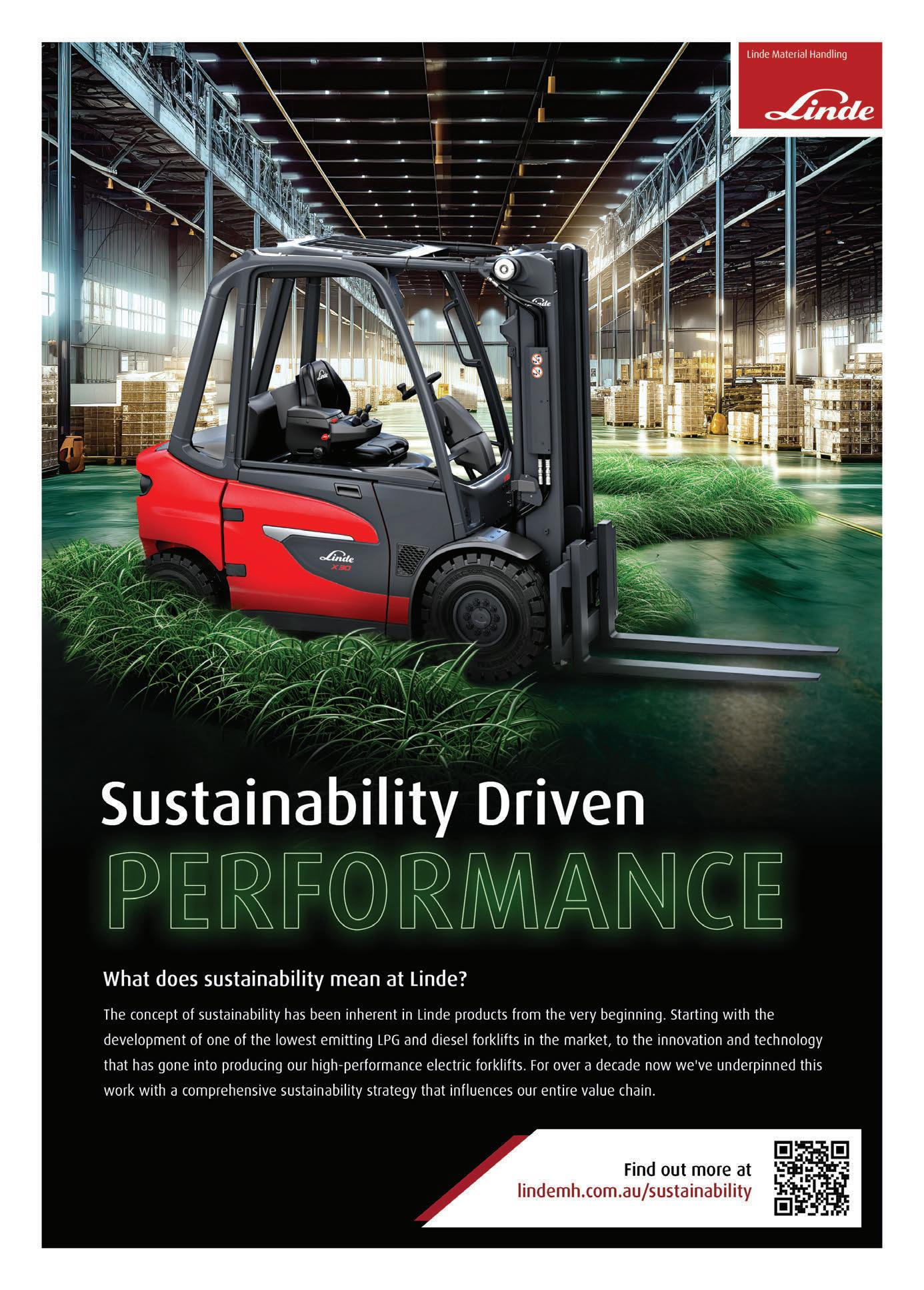

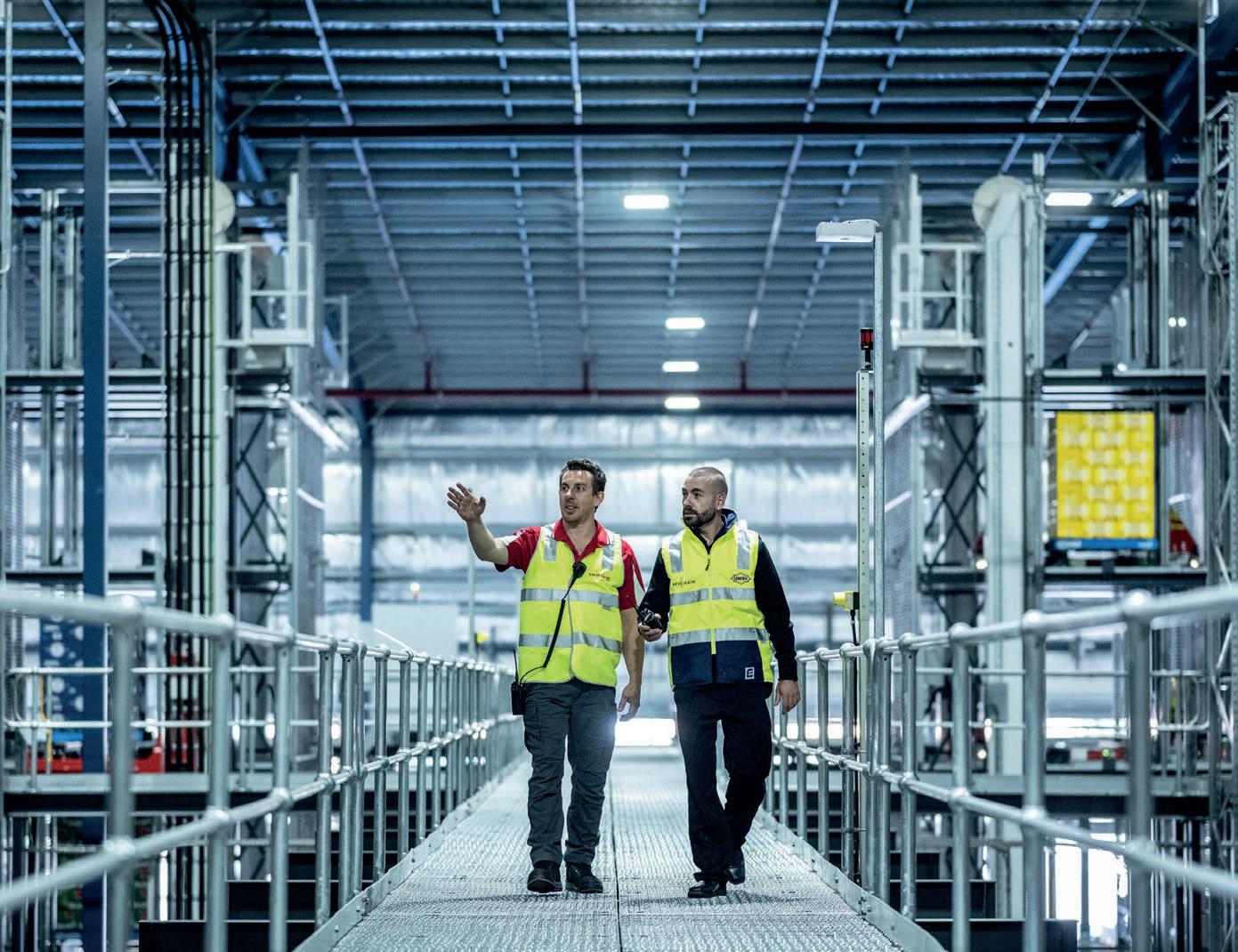

PIONEERING A SUSTAINABLE FUTURE IN LOGISTICS

The logistics and supply chain sector is not just evolving; it is leading the charge towards a sustainable and resilient future. This month, MHD Supply Chain spotlights pioneering initiatives that demonstrate the industry’s commitment to environmental stewardship, economic growth, and operational excellence.

At the forefront is Stockland’s new development at Melbourne Business Park, a shining example of how sustainability and profitability go hand-in-hand. This facility, aiming for a Five Star Green Star rating, is a testament to the future of logistics: lower operational costs, enhanced employee wellbeing, and reduced environmental impact. It’s a blueprint for what modern, sustainable infrastructure can achieve in driving the local economy and supporting communities.

Turning to manufacturing, the latest report from Beyond Zero Emissions (BZE) lays out a bold vision: by boosting Cleantech supply chains, we can unlock $215 billion in revenue and create up to 53,000 jobs by 2035. This strategy not only diversifies our economic landscape but also builds resilience against global disruptions. For supply chain decision-makers, the message is clear—investment in clean technology is investment in Australia’s future.

On the workforce front, Ampol’s initiative with Morsl’s micro markets at its Brisbane refinery showcases an innovative approach to employee wellbeing. Offering nutritious, accessible food options round-the-clock not only supports a healthier workforce but also drives productivity. This strategy reflects a broader trend: operational success is deeply intertwined with employee health and satisfaction.

Finally, the transformation at Australia Post highlights the agility necessary to thrive in today’s market. Adapting its delivery model to focus more on parcels than letters, Australia Post is aligning itself with the e-commerce boom, ensuring it remains indispensable in the digital age.

Each of these stories underscores a pivotal shift in the industry towards practices that are sustainable, economically viable, and forward-thinking. For those who are steering these changes, the message is clear: innovative, ecofriendly solutions aren’t just good for the planet—they’re good for business and essential for continued success. Let’s commit to being at the forefront of this exciting era.

Warm regards and insightful reading,

Syed Shah Managing Editor, MHD Supply Chain Solutions syed.shah@primecreative.com.au

MHD EDITOR’S LETTER

MHD

MHD JUNE 2024 | 3

AUSTRALIA’S LEADING FORKLIFT COMPANY

FOR ALL YOUR MATERIAL HANDLING NEEDS

Known for market leading Toyota forklifts and warehouse equipment, Toyota Material Handling is also proud to o er an unparalleled range of products suitable for Australian businesses. With a huge range of forklifts, elevated work platforms, scrubbers and sweepers, Taylor-Dunn electric vehicles, plus Huski skid steers, scissor lifts, and mini excavators available, chances are we’ve got the equipment that will suit. So, if you’re looking to buy hard working, fully backed equipment for your business, Toyota Material Handling has all you need to add value to your operation. That’s the Toyota Advantage.

toyotamaterialhandling.com.au 1800 425 438

TOYOTA FORKLIFTS & WAREHOUSE EQUIPMENT ELECTRIC

VEHICLES SWEEPERS AND SCRUBBERS ELEVATED WORK PLATFORMS

MINI EXCAVATORSSKID STEER LOADERS

SCISSOR LIFTS

THIS ISSUE

COVER STORY

32 Dematic on the best automated GtP systems

SUPPLY CHAIN

40 Körber brings Elevate to Sydney for the first time

48 Logical Outlook on making the most of consultants

MATERIALS HANDLING

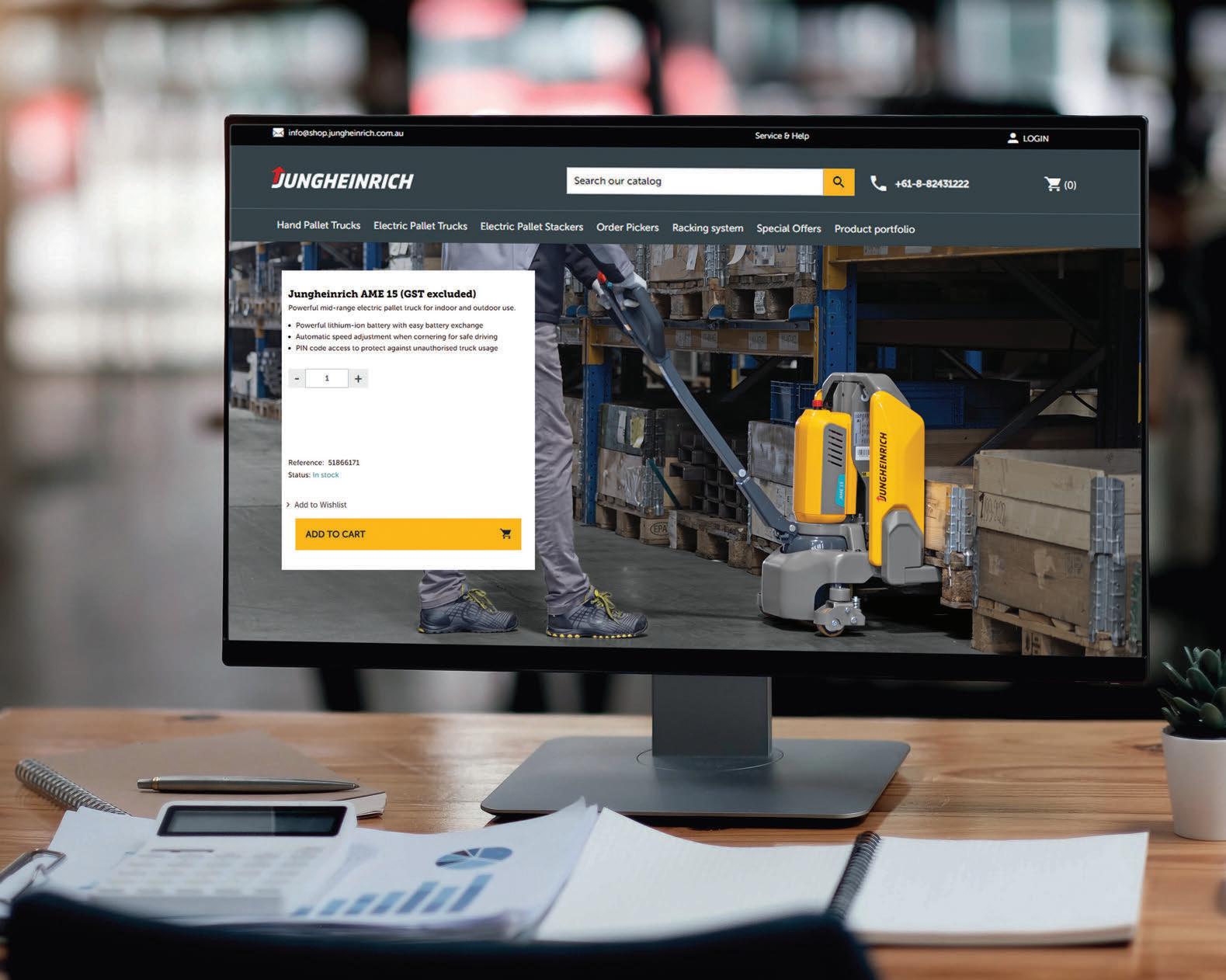

42 Jungheinrich on investing in forklifts

46 TMHA recruits and grows new talent

WAREHOUSING

37 Conquest clearing the air with HEPA

44 CoGri automating logistics

54 Swisslog optimises automated pallet handling

ASSOCIATIONS, EVENTS, AND REGULARS

51 Schmitz Bull Cargo showcasing at MEGATRANS

58 ASCI’s courses and accreditations

57 RWTA turning up the temperature

62 People on the Move

61 Product Showcase

Körber brings Elevate to Sydney for the first time TMHA onboards its largest crop of apprentices since 2007 RECRUITING AND GROWING TALENT CHARTING THE COURSE JUNE 2024 Dematic experts compare the latest in automated order fulfilment solutions AUTOMATING OPERATIONS WITH GTP COVER STORY ON THE COVER Dematic experts compare the latest in automated order fulfilment solutions JUNE 2024

40 COVER STORY 32 ISSUE 03 VOLUME 56 46 MHD JUNE 2024 | 5

TENNANT LAUNCHES NEW COMPACT SWEEPERS

Tennant has raised the bar with the launch of its latest compact battery ride-on sweeper models S680 and S780 – designed for light to mediumduty cleaning.

These sweepers offer a selfcleaning filter system, operator ease of use, unparalleled efficiency, and versatility.

Delivering exceptional performance in both indoor and outdoor cleaning applications, leaving traditional cleaning methods in the dust.

THE POWER OF TENNANT’S LATEST SWEEPERS

The S680 and S780 sweepers are Tennant engineered to deliver exceptional cleaning performance, thanks to its advanced features and

robust design.

Equipped with a powerful vacuum fan and dual side brushes (standard) for a cleaning path of up to 1050 mm (S680) and 1200mm (S780), these electric sweepers can provide single pass, edge-to-edge sweeping capturing dust, debris, and litter in high-traffic spaces such as warehouse and logistic aisles, loading docks and car parks.

Extend cleaning shifts with the S680 (70 L) and S780 (65 L) large hopper capacity, allowing operators to cover more area. The compact design further offers a tight turning radius and front-wheel steering, enabling easy maneuverability in narrow spaces and aisles.

“Small to mid-sized warehouses have eagerly adopted our new

models,” says Tennant’s Regional Sales Manager, Aaron Skinner.

“The S680 and S780 are comfortable, easy to use, and maintain, and importantly, they feature a high-performance filtration system to maintain air quality in working environments. These new sweepers have been designed to offer all the benefits of our larger industrial machines but on a smaller footprint and at a lower price point.”

UNLEASHING A NEW ERA IN EFFICIENCY

One of the standout features of the S680 and S780 sweepers is its versatility, allowing it to tackle a wide range of indoor and outdoor spaces with ease.

From smooth concrete floors on the factory floor to uneven outdoor surfaces, even to soft flooring (S680), the self-leveling main brush automatically adapts to surfaces making the transition between flooring types seamless.

Tennant understands the importance of ease of use in ensuring optimal productivity. The S680 and S780 ride-on sweepers feature an ergonomic design that prioritises user comfort during extended cleaning sessions.

The S680 and S780 intuitive operator controls ensure successful operation with a range of setting features that includes:

• Simple forward and reverse direction control.

• Pre-programed working settings.

• Adjustable vacuum fan and side brush rpm that allows operators to easily adjust brush speed to its application.

• Programmable self-cleaning filter shaker system.

• Automatic self-leveling brush technology which facilitates the ability to clean hard and soft floor surfaces, indoors and out, providing effective performance in a variety of applications (S680).

• Tool-free main brush replacement.

MHD INDUSTRY NEWS 6 | MHD JUNE 2024

One of the standout features of the S680 and S780 sweepers is its versatility. Image: Tennant.

As one of the world’s largest authorised Cat® equipment dealers, WesTrac knows that the smallest of parts can make or break a machine, and have a big impact on site operations.

At its headquaters in Tomago, NSW, WesTrac implemented an AutoStoreTM automated spare parts storage and fulfilment system from Dematic, which allows WesTrac to keep stock organised, use warehouse space efficiently, and prioritise urgent orders to be ready in just 5-10 minutes.

With the AutoStore solution, WesTrac can get vital parts to customers quickly, keeping Australia’s heavy industry moving.

Learn more at dematic.com/westrac

Rapid spare parts fulfilment you don’t need to move the Earth for. Vital parts ready to go in 5 Dematic.com 02 9486 5555 info.anz@dematic.com Scan to watch the video! AutoStore Natalia Trewin and Georgia Denton WesTrac Tomago, NSW

ARGON & CO ANZ INTRODUCES THE ACADEMY

Global management consultancy specialising in operations strategy and transformation, Argon & Co, is delighted to announce the launch of the Academy within the ANZ region.

Specialising in Lean Operations and Leadership training across all levels, the Academy is dedicated to helping businesses navigate the dual challenge of delivering on strategy while fostering a positive culture.

“Cultivating a culture of continuous learning and growth is at the heart of Argon & Co,” says Paul Eastwood, Managing Partner at Argon & Co APAC.

“The Academy approach allows our clients to build and sustain improvements in their teams’ capabilities, giving them new skills to move their business forward.”

By prioritising strategic excellence and continuous adaptation of training strategies, The Academy ensures that businesses meet the ever-changing demands of the marketplace.

The Academy offers a range of services to address various capability enhancements, aligning to our scprime® curriculum (Argon & Co’s proprietary end-to-end supply chain framework and assessment tool).

“By applying a positive, flexible and personalised approach, coupled with a willingness to challenge norms where necessary, we ensure widespread acceptance across all levels of your organisation,” adds Stephan Mang, Partner at Argon & Co Australia and Academy Service Line Lead.

Through a blend of technical expertise, operational wisdom, business acumen, and personalised approaches, the Academy helps businesses overcome obstacles, see real change and most importantly the development of their people.

MHD INDUSTRY NEWS 8 | MHD JUNE 2024

The Academy offers a range of services to address various capability enhancements. Image: Argon & Co.

MACQUARIE CONSULTING’S UNIQUE APPROACH TO SUPPLY CHAIN SUCCESS

Macquarie Consulting is not your average business consultancy. With over two decades of expertise across operations, logistics and supply chains, the Sydney-based firm is proud to do things a little differently to enhance operations for their clients.

From a refreshingly personal approach to a deep understanding of how things ‘really’ work when it comes to logistics, Macquarie Consulting is proving that a nontraditional approach can yield better results for business.

The company’s founder, Shane Hafiz, shares his insights on how Macquarie’s unique approach is helping supply chain businesses transform their results.

‘ON-THE-GROUND’ EXPERIENCE

While Macquarie Consulting has all the credentials and qualifications you’d expect from a leading business consulting firm, it’s the ‘realworld’ experience of its consultants that provides the company with an invaluable advantage.

“Our years of on-the-ground experience means we’ve got to know first-hand the processes, problems, and challenges faced by teams from the warehouse to out on the road”, says Shane. “It’s this knowledge that allows us to make strategic recommendations that deliver ongoing improvements.”

By leveraging this practical experience, Macquarie’s team helps its clients level up their operations, often in creative and innovative ways.

A DIFFERENT SPIN ON SUPPLY CHAIN CONSULTING

According to Shane, breaking the mould is a key part of Macquarie Consulting’s ethos.

“We’re not ‘traditional’ business consultants and we don’t believe in taking a prescriptive approach. By focusing on close and personal

Macquarie Consulting has all the credentials and qualifications you’d expect from a leading business consulting firm. Image: Tim/stock.adobe.com

collaboration, we can design our solutions around our clients – not the other way around”.

What’s more, Macquarie’s consultants are particularly mindful of the cultural and commercial elements of the companies they support, taking care not to adversely impact these aspects.

“The best and most sustainable solutions will strengthen company culture, rather than impede it,” says Shane.

OPTIMISATION ACROSS THE BOARD

Success in the supply chain and logistics industry relies on maximising efficiency in every corner of your business – which is why Macquarie Consulting takes an organisation-wide approach to identifying opportunities for efficiency gains.

“One thing that sets us apart – and enables us to achieve better results –is our holistic, hands-on approach”, explains Shane. With a team of consultants who bring experience across all levels of an organisation, Macquarie Consulting is wellplaced to understand exactly how to optimise operations in every area.

“From the warehouse to the boardroom, no stone is left unturned when it comes to finding ways to improve”.

SMALL ENOUGH TO CARE

Shane is quick to point out that Macquarie Consulting isn’t the biggest fish in the consulting sea. “We’re by

no means the largest consulting firm in the market. And I think that gives us an advantage when it comes to the personal attention and service we can give to each of our clients”.

Being accessible, approachable, and transparent is a big part of what keeps the firm’s many satisfied clients coming back time and again. That, and the passion for logistics that all of Macquarie’s consultants bring to the table.

“While our business expertise is obviously a key factor in our success, beneath this lies a true passion for what we do – and this is what drives us to keep on striving for the best possible outcomes”.

A SOLID UNDERSTANDING OF CHANGE

With the supply chain and logistics industry constantly facing new challenges and evolving demands, Macquarie Consulting knows that helping its clients manage change effectively has never been more important.

As Shane points out, “We know that in business, change can be daunting and difficult – which is why we’re here to make the process as comfortable and seamless as possible.”

As specialists in change management, Macquarie Consulting goes beyond just advising on how you can improve operations today, instead proposing simple yet fundamental changes that can deliver ongoing benefits well into the future.

MHD INDUSTRY NEWS 10 | MHD JUNE 2024

DEMATIC’S COLBYRACK LICENSED AS “AUSTRALIAN MADE”

Dematic its ColbyRACK racking systems have received official licensing as “Australian Made.” The iconic green and gold Australian Made, Australian Grown (AMAG) logo will now adorn Dematic’s range of storage products, signifying their genuine Australian origin.

ColbyRACK, Dematic’s brand of selective pallet racking, has been manufactured in Sydney’s northern beaches for over 55 years. Available in various configurations, including single-deep, double-deep, narrow aisle, and drive-in or drive-through, ColbyRACK prioritises quality and safety. Designed, engineered, and manufactured by Dematic’s Australian team, it meets rigorous

Australian standards.

“We take immense pride in our long history of Australian manufacturing,” says Lee Koutsos, head of Dematic ANZ Storage Equipment Division.

“The Australian Made license applied to our ColbyRACK range underscores our commitment to local manufacturing. It assures our customers that the products and solutions we provide are locally made, locally supported, and designed to meet Australian safety and quality standards.”

The Australian Made Campaign, a not-for-profit organisation, promotes and supports Australian businesses and producers.

By choosing Dematic’s Australianmade ColbyRACK racking systems, consumers directly support local manufacturers and contribute to the Australian economy.

BENEFITS OF BUYING AUSTRALIAN MADE:

• Supporting Local Businesses: Purchasing Australian-made products directly benefits local manufacturers and families.

• Quality Assurance: Australianmade goods adhere to high-quality standards.

• Environmental Impact: Supporting local production reduces the carbon footprint associated with transportation.

ColbyRACK prioritises quality and safety. Image: Dematic.

MHD INDUSTRY NEWS 12 | MHD JUNE 2024

Emergency Cleaning End of Lease Fleet Scaling Deep Cleaning Hire a sweeper or scrubber from as little as one day. Scan the QR code or call 1800 826 789 conquesthire.com.au DON’T CLEAN FLOORS THE HARD WAY. “I was blown away by Conquest Hire”

Simon Ward, Jace Cleaning Serivces

WHAT IS THE ROADMAP FOR YOUR SUSTAINABLE SUPPLY CHAIN?

Navigating the complex landscape of sustainable supply chain management requires a comprehensive roadmap. Brendan O’Keeffe, from Circular Supply Chain Advisory, provides insights into key questions to address when developing your strategy.

To kickstart your journey towards a sustainable supply chain, Brendan emphasises the importance of a materiality assessment that integrates seamlessly with your risk assessment.

He advises, “It’s about understanding what material to your business is, and then integrating that into your risk assessment process.” This integrated approach ensures that your sustainability efforts are aligned with the most significant issues affecting your supply chain, which enables you to prioritise effectively and mitigate risks proactively.

Brendan highlights the invaluable role of supply chain assessment in shaping your sustainability strategy and framework.

He explains, “By understanding where your biggest impacts and significant risks are, you can then start to think about the alignment of your strategy and framework around sustainability.”

This proactive approach empowers organisations to identify areas for improvement, establish clear goals, and implement targeted initiatives that drive positive economic, environmental and social outcomes throughout the supply chain.

In the pursuit of decarbonisation, Brendan underscores the importance of evaluating critical opportunities and adopting robust scope reporting mechanisms, in particular Scope 3.

He suggests, “Start by understanding where your emissions are coming from in your external supply chains and what those critical opportunities are for your business to decarbonise.”

This strategic assessment enables

companies to identify emission hotspots, implement effective mitigation measures, and track progress towards carbon reduction targets, ultimately contributing to a greener and more sustainable supply chain.

This will support supplier partnerships and drive towards common objectives.

Embracing resource recovery and circular procurement presents significant opportunities for circular and sustainable supply chain management.

Brendan advises organisations to focus their efforts on circular economy impacts, stating, “There’s a lot of opportunities around resource recovery and circular procurement, and it’s really about focusing your efforts there.”

By adopting circular practices, such as product refurbishment, remanufacturing, returns and finally recycling, businesses can minimise waste, conserve resources, create economic value across the entire supply chain and benefit their products long-term.

Navigating governance and legislation

a sustainable supply chain requires a systematic approach.

frameworks is essential for ensuring compliance and fostering responsible supply chain reporting practices.

Brendan stresses the need to address these challenges, stating, “It’s important to understand the governance and legislation frameworks in which you operate; both local and global impacting regulations.”

By staying abreast of regulatory requirements and industry standards, organisations can mitigate legal risks, uphold ethical standards, and demonstrate their commitment to sustainability to stakeholders and consumers alike.

Developing a sustainable supply chain requires a systematic approach that encompasses materiality assessment, strategic evaluation, emissions reduction, circular procurement, and compliance with governance frameworks.

By following the roadmap outlined by Circular Supply Chain Advisory, companies can not only enhance their environmental performance but also drive operational efficiency, resilience, and long-term value creation across their supply chains and their integrated partnerships.

MHD INDUSTRY NEWS 14 | MHD JUNE 2024

Developing

Image: CSC Advisory.

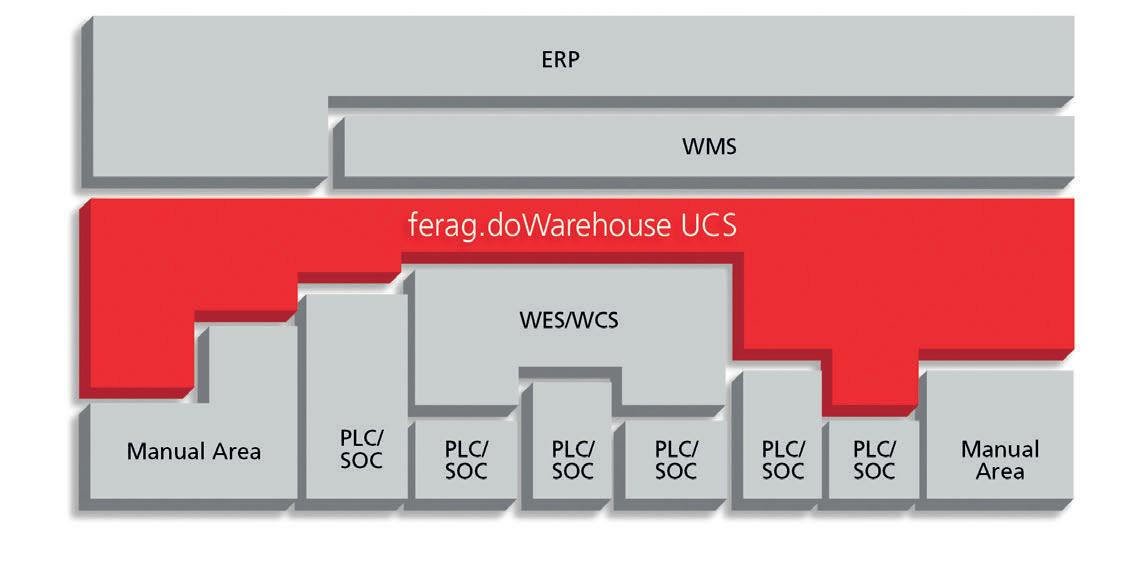

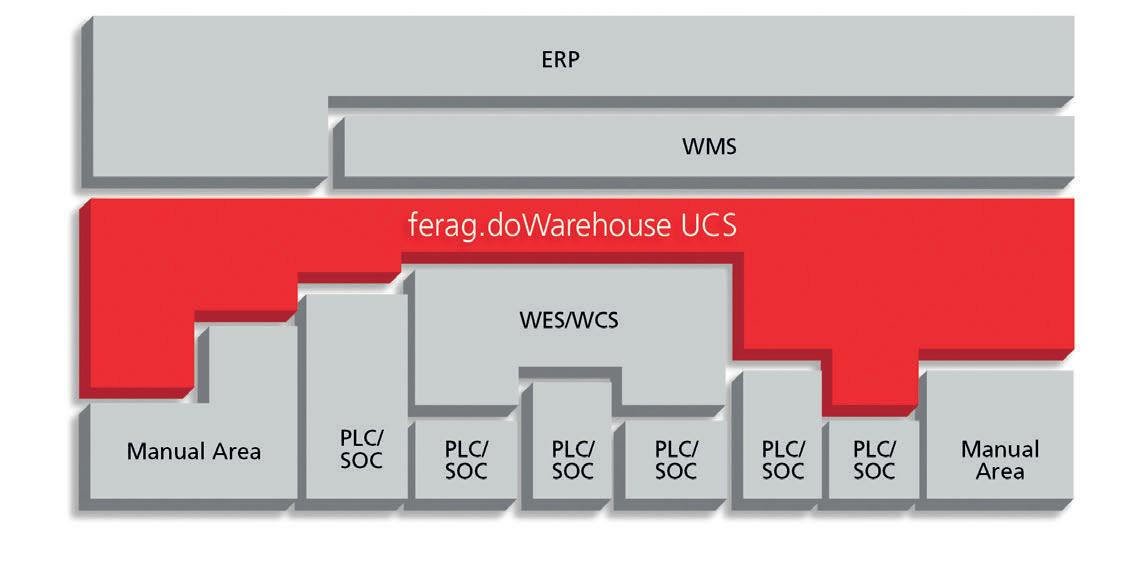

PRESTIGIOUS AUSTRALIAN BRANDS IMPLEMENT FERAG WMS

In the last few months, some of Australia’s largest and most prestigious brands have implemented ferag.doWarehouse (previously from dereOida).

This roll-out includes major department stores, online retailers, third-party logistics providers (3PLs), amongst others. Most of these industry leaders are either in the process of going live, or already live with doWarehouse!

So, what sets this upstart Warehouse Management System apart? Like every other WMS, it increases warehouse operations’ efficiency, boosts productivity, reduces order times, enhances stock accuracy, and supports cycle counting.

However, doWarehouse’s innovative approach distinguishes it from competitors. It is much more than just a WMS. It is a Unified Control System, which means it is a WMS, Warehouse Control System, Warehouse Execution System and/ or anything in between.

Interfacing from your Enterprise Resource Planning (ERP) software all the way down to Program Logic

Controller (PLC) level.

It is fully and truly agnostic, offering best-in-class abstraction and optimisation, allowing for highly flexible and easy integration with equipment.

In layman’s terms, doWarehouse not only manages your entire warehouse – it can also seamlessly integrate with your robots, warehouse hardware, and machinery, resulting in significant time and cost savings.

You are no longer locked into outdated or unsuitable hardware, and you can select equipment that best suits your processes with the confidence that doWarehouse will manage them effortlessly.

Unlike other WMS providers, doWarehouse doesn’t require you to change your processes to fit the software. Most systems force you to mould your well-honed processes to their configuration – not so with doWarehouse.

It also provides the flexibility to adapt new processes and functionalities as business needs evolve, such as shifting from retail to an online platform or integrating

automated processes.

Its seamless integration and analytics enable quick and effortless setup and provides ongoing control and visibility of not only the different warehouse tasks, but also of their costs via meaningful reports and dashboards.

doWarehouse has been developed from the ground up utilising a stateof-the-art technology stack. This provides independence from the server operating system; it also offers scalability and excellent utilisation of server resources.

In addition, dowarehouse’s modern architecture facilitates significantly quicker and cheaper modification and customisation.

In summary, doWarehouse UCS enables you to choose the equipment that best meets your warehouse requirements as well as stay up to date with the latest technology, without having to compromise on functionality.

doWarehouse was previously a part of dereOida. In September 2023, Ferag acquired dereOida, bringing doWarehouse and the Australian dereOida team into its fold.

MHD INDUSTRY NEWS 16 | MHD JUNE 2024

Ferag’s WMS is fully and truly agnostic, offering best-in-class abstraction and optimisation. Image: Ferag.

AUSTRALIA’S FIRST EVER ONLINE PORTAL DEDICATED TO BUYING, SELLING, AND HIRING LOGISTIC & INTRALOGISTICS EQUIPMENT. From mining companies looking to upgrade their portable generators, to waste treatment centres looking to hire a fleet of forklifts, MHD Marketplace will be the one-stopshop for equipment to support supply chains across Australia. For advertising opportunities, contact ben.coleman@primecreative.com.au or call 0466 545 664

Through multidirectional movement and sequencing, Vanderlande’s shuttle-based automated storage and retrieval system (AS/RS), ADAPTO, delivers goods fast and accurate in the appropriate order, enabling same-day deliveries.

Learn how Vanderlande customers benefit from FASTPICK to efficiently handle both their e-commerce and store orders.

> vanderlande.com

FASTPICK High

efficiency

easily scalable

unpredictable growth

operator

and

for

Learn more:

TIM PALLAS TO ADDRESS

VTA TREASURER’S BREAKFAST

The Victorian Transport Association (VTA) is pleased to announce Tim Pallas, the Treasurer of Victoria, will address the VTA Treasurer’s Breakfast on Tuesday June 04 at The Hotel Windsor.

The Treasurer’s Breakfast continues the VTA series of Ministerial Breakfast events, which has seen several Victorian ministers, the Treasurer, and the Premier address VTA members and associate members on key issues confronting the transport industry. Tim is also Minister for Industrial Relations and Minister for Trade and Investment.

“At the breakfast the Treasurer will reflect on the key objectives of the budget, along with the associated implications for the policy and

economic priorities of the Allan Labor government,” says VTA CEO Peter Anderson.

“The breakfast comes at a critical juncture for the Victorian economy and weeks after Tim Pallas delivering a record 10th State Budget, making him Victoria’s longestserving Treasurer.”

Tim was elected to the Victorian Parliament in 2006 and is the state member for Werribee, previously serving in the Bracks and Brumby governments as Minister for Roads and Ports, and later added Major Projects to his responsibilities.

As Minister for Roads, Tim delivered EastLink, oversaw the M1 Upgrade, the construction of the Deer Park Bypass and Geelong Ring Road, completed the upgrade of the Calder

Freeway to improve links to Bendigo, and was responsible for commencing the Peninsula Link project on the Mornington Peninsula.

“There is significant interest from many stakeholders in this year’s Victorian and federal budget – set for delivery next week – in view of the challenging state and national economic conditions, and I’m certainly looking forward to hearing from the Treasurer,” adds Peter.

Tim’s first budget as Treasurer in May 2015 delivered the biggest education budget and investment in public transport in the state’s history.

His second budget in April 2016 included the single biggest school capital investment in Victoria’s history as well as the new Metro Tunnel.

MHD INDUSTRY NEWS MHD JUNE 2024 | 19

Tim Pallas, the Treasurer of Victoria. Image: Victorian Transport Association.

OPTIMISE YOUR WAREHOUSE SPACE WITH KARDEX

Optimising warehouse space is essential for meeting increasing customer demands. Traditional storage methods can be ineffective as it consumes excessive resources in relation to time, man hours and space.

That’s where Kardex’s cutting-edge intralogistics solutions come into play. Kardex’s automation technology offers high-density storage within a minimal footprint helping to optimise your warehouse space.

It is smart to exploit the height of your warehouse, efficiently utilising the floor-to-ceiling void thereby maximising the use of available space.

Vertical storage systems such as Vertical buffer modules (VBM), Vertical lift modules (VLMs) and vertical carousels utilise the vertical space in your warehouse.

These systems can store items in a compact and organised manner, reducing the need for large aisles and maximising storage capacity.

It’s no secret that automated

retrieval systems significantly increase storage density. The use of robotics to retrieve items and bring the item directly to the operator, is another sure way of minimising the number of aisle and liberates additional areas within your production facility, further eliminating the need for manual searching and thus reducing the space required for aisles.

A major benefit of automated solutions is digitalisation. With smart software such as Kardex Power Pick, a warehouse can increase picking speeds and efficiency to ensure all stocked items are delivered on-time for efficient picking whilst delivering a tailored solution based on material process and fulfilment flow.

In the end it is worth talking to the experts so that they can assess your warehouse layout and provide customised solutions to optimise space utilisation. They can help you design an efficient warehouse layout that maximises storage capacity and minimises wasted space.

Kardex has created warehouse insights and case studies so you can see real-world examples of how Kardex solutions are creating more warehouse space and increasing productivity.

Kardex’s technology streamlines processes without the need for moving or extending current facilities, saving you time and resources.

In today’s competitive market, optimising warehouse space is crucial for meeting increasing demands. Traditional storage methods are no longer sufficient, and businesses must adapt to innovative automation solutions.

Kardex’s cutting-edge technologies provide high-density storage within a minimal footprint, maximised floor-to-ceiling space, and increased storage capacity.

Discover how businesses are revolutionising their storage capabilities, streamlining their processes without the need for costly facility expansions.

MHD INDUSTRY NEWS 20 | MHD JUNE 2024

Kardex’s automation technology offers high-density storage. Image: Kardex Remstar.

STOCKLAND COMPLETES SUSTAINABLE MELBOURNE DEVELOPMENT

Stockland has recently completed the first logistics development in its portfolio to target a Five Star Green Star Buildings v1 rating at 90 Melbourne Drive in Melbourne Business Park, Truganina.

The modern 31,567 sqm facility is the first building to be delivered in the 260-hectare estate – one of Melbourne’s largest masterplanned industrial precincts and ideally located in the rapidly growing western corridor.

Stockland’s national $6.5 billion logistics development pipeline of modern, flexible, and future-proofed facilities is essential to driving the economies of cities and suburbs, while reducing environmental impacts through sustainable design, construction, and operation.

The Five Star Green Star rating will help e-commerce tenant New Aim reduce its occupancy costs with reduced water and energy consumption together with air pollution reduction inside the building to support employee wellbeing.

Advanced sustainability construction and operational features of 90

Melbourne Drive include:

• Using 30 per cent less energy compared to a typical warehouse through intelligent, energy efficient LED lighting and 198kW of rooftop solar PV.

• Fully electric building with tenancy power supplied via a renewables power purchasing agreement through a commitment by New Aim.

• Minimum 10 per cent reduced embodied carbon footprint for the development using low carbon alternative materials.

• 75 per cent less potable water compared to a typical warehouse and onsite rainwater collection for landscape irrigation.

• Water and energy metering systems to monitor building performance and detect incidence of wastage.

• 40 per cent of internal finishes (by cost) comply with third-party certification and independent verification for responsibly sourced and manufactured products.

• Adopting circular construction practices with an onsite rock

crushing facility used during estate civil works to crush excavated rock material for reuse in the surrounding precinct reducing CO2 emissions from heavy vehicle movements and third-party handling of the crushed rock.

• Indoor pollutants are maintained at lower than acceptable levels through the provision of high volumes of outside air. Air quality testing at the end of construction confirmed indoor pollutants were at best practice levels throughout the facility.

• The project has achieved a construction waste landfill diversion target of greater than 90 per cent.

• Building contractor Texco’s Environmental Management Plans ensured their construction practices promoted workplace diversity and reduced physical and mental health impacts.

• All carbon emissions related to air conditioning refrigerants and diesel used by fire pumps have been offset with certified Australian carbon offsets.

MHD INDUSTRY NEWS 22 | MHD JUNE 2024

The Five Star Green Star rating will help e-commerce tenant New Aim reduce its occupancy costs. Image: Stockland.

Zebra’s fixed industrial and machine vision scanners automatically track and trace items from production to distribution

Focused on driving higher levels of process efficiency and productivity, these fast-emerging solutions are simpler to use, provide a broader range of capabilities and easily integrate into existing operations.

AUSTRALIA | NEW ZEALAND

info@skywire.com.au

www.skywire.com.au

Skywire Australia is excited to offer you a no-obligation, exclusive opportunity to put Zebra devices to the test in your warehouse and retail operations.

SCAN TO GET STARTED

Skywire is part of the Renovotec Group of Companies

AMPOL REFINERY INSTALLS MORSL MARKET, PRIORITISING EMPLOYEE WELLBEING

Ampol has taken a leading position in Logistics and Manufacturing, partnering with Morsl to address access to fresh and nutritious food, with their micro market earning rave reviews from the team.

Ampol’s forward-thinking move to install a micro market acknowledges the significant impact that access to wholesome food and drinks can have on employee health and wellbeing. With a workforce of 800, working 24/7 across a large, protected area, it is challenging for the Brisbane refinery team to leave the premises during their breaks.”

The recent CSIRO Healthy Diet Score Report showed employees working in logistics and manufacturing have some of the worst diets of any occupation, scoring 51.5/100 and 51.9/100 respectively. This is below the average Australian score of 55/100, which itself has been on a downward trajectory for the past eight years.

The report confirms that workplaces represent an important venue for influencing dietary behaviours. The challenges, especially within the logistics and manufacturing sectors, are shift work, the physically demanding tasks and the often remote location of the workplace.

Ampol recognised that the traditional café set-up they had was not supportive of a 24/7 operation. With the café closing weekdays at 2pm, night shift workers were not always able to purchase fresh or nutritious foods at times when they wanted it.

To solve this challenge, Ampol has partnered with Morsl, an innovative food solution provider that is transforming the industrial landscape across Australia with its better-for-you micro markets. Micro markets began in the US and

Morsl’s micro markets operate as a self-service café or unattended store within a breakroom space. Image: Morsl.

are now the fastest growing food service channel across the US, with the largest concentration currently across manufacturing sites.

Morsl’s micro markets operate as a self-service café or unattended store within a break room space that provides a rotating range of fresh sandwiches, wraps, salads, ready meals, sushi, and ready-toeat options. This is combined with a broad variety of snacks and drinks that are managed according to a 70:30 balance between better-for-you and more indulgent options.

In such a micro market, the employee selects a product from an open rack display, or reach-in refrigerator, and scans the item at the self-checkout kiosk. The market, which operates under a monitored framework, is tailored to the demographics and working habits of the site to create a unique solution for each workplace.

Ampol not only recognised the need for a new food solution for their employees but also the need to provide an engaging and fresh breakroom space for their vast array of teams to come together. A barista bar was also incorporated into the design to complement the Morsl

micro-market, ensuring the team still has access to the theatrics and joy of fresh coffee.

When the Morsl micro-market and their new break room space was recently launched, the Ampol team was blown away.

“It’s a dramatic change and I think it’s really what we need,” the Ampol team said.

“It’s great to have 24-hour options.

“A lot of different options, especially for me as a coeliac.”

The positive feedback has reinforced the significant impact access to good food can have on the daily working lives of an employee, which should be a fundamental part of any company’s wellbeing strategy.

With Morsl’s mission to improve the eating habits of Australian employees, its partnerships with the likes of Amazon, Inghams, Primo, DB Schenker and now Ampol, means it can play a key role in improving the diets of logistics and manufacturing workers to bring the industry above the national average according to the CSIRO Healthy Diet Score.

Achieving such success will depend on more companies leading the charge just like Ampol.

MHD INDUSTRY NEWS 24 | MHD JUNE 2024

GEOTAB RELEASES SUSTAINABILITY REPORT

Geotab has released its 2023 Sustainability and Impact Report, Trust. Transparency.

Transformation.highlighting how data-driven insights are helping Geotab and global organisations better measure and achieve their climate goals.

The report also delves into the tougher challenges of managing business and environmental impact, including increased business travel and much-needed transparency associated with Scope 3 emissions.

“The climate crisis demands action,” says Neil Cawse, Founder and CEO of Geotab.

“The transportation industry is one of the largest sources of CO2 emissions with a tremendous opportunity in the near term to make a positive impact.”

Geotab’s greatest impact is in supporting customers and partners to drive transformation through data-driven insights and AI, enabling informed decision-making as they report and track progress on all stages of the sustainability journey.

In a recent survey by Geotab, 87 per cent of U.S. fleet professionals expected their cost of business to rise in 2024, and 40 per cent confirmed they use data intelligence to create a more sustainable fleet by flagging and improving fuel economy and idling.

“As a close partner to that industry, we have a moral obligation to do our part in supporting carbon reduction — not just for ourselves, but for our customers too,” adds Neil.

“This has to be a collaborative

approach. There are too many challenges to address and solve in isolation.”

Data insights regarding fuel use, better routing, emissions management, better driving behaviour such as reducing harsh braking, and the integration of EVs into fleets help address cost and improve the bottom line.

As part of its commitment towards a more sustainable world, Geotab has pledged to reach net-zero emissions by 2040 — a decade earlier than called for in the Paris Agreement — and is aiming for a 50 per cent reduction in emissions across Scopes 1, 2 and 3 by 2030.

The latest report shows Geotab has made progress in reducing direct and indirect operational emissions over the past year.

MHD INDUSTRY NEWS MHD JUNE 2024 | 25

Geotab has pledged to reach net-zero emissions by 2040. Image: Geotab.

COMBILIFT SAFE-LIFT RAISES THE BAR IN FORKLIFT SAFETY

Combilift has responded to universal customer needs and reduced the risk of forklift overloading with its patented Safe-Lift device.

Forklifts have long held potential for safety implications and the manufacturer prioritises constant improvement to mitigate the risks of lifting. Understanding that some operators are more aware of the risks than others, the Safe-Lift ensures there is minimal chance of unsafe operation with audible and visual alerts.

While some teams may believe their operations are already safe enough, Combilift Managing Director, Martin McVicar, says operators can never be too safe.

“We offer the Combi Safe-Lift as an option at the moment, but we believe that this simple and cost-effective system should become a standard option on all counterbalance trucks in future,” he says.

“Fitting a straightforward device

such as the Combi Safe-Lift is an effective way to reduce risks for the operator and other personnel, and also to avoid product damage as well as costly repairs.”

The solution incorporates a strain sensor on the mast section of the forklift and a cut-out valve on the hydraulic line. When a forklift is potentially overloaded, this device will disable lifting.

This addition to Combilift forklifts has the potential to protect stock and staff from harm, as overloaded forklifts can pose a serious risk to all. Forklifts can become overloaded in many ways, depending on the type, weight, height, and centre of the load. The latter is an especially important consideration, as it can greatly affect an operator’s handling of certain loads. Identifying the centre is made especially difficult when handling non-uniform or liquid loads, and the Safe-Lift is designed to suit these situations.

When an overload occurs, an

audible alarm will alert the operator, and the “load moment indicator” will flash green, amber, or red, accordingly.

Combilift Country Manager for Australia, Chris Littlewood, says his clients Down Under have been calling out for a solution like this.

“Australia’s heavy industries are heavily regulated, and zero-harm is the goal for most of our customers,” he says.

“Thanks to the Safe-Lift, it’s safe to say that they’ll be very pleased by this option, and I expect most new orders to be fitting it.”

Of course, the Safe-Lift is designed as a failsafe and shouldn’t be relied upon to avoid all overload situations.

Chris recommends all forklift operators undergo regular training to understand what an overload may look and feel like, helping them to avoid one on the job.

“Get to know your load capacity,” he says. “Drive slow, drive low, and stay safe.”

MHD INDUSTRY NEWS 26 | MHD JUNE 2024

The Safe-Lift ensures there is minimal chance of unsafe operation with audible and visual alerts. Image: Combilift.

TECH INVESTMENT CRUCIAL TO NAVIGATE ANTICIPATED CHALLENGES

The latest international survey by software recommendation site

GetApp reveals that economic pressures, supplier location, and cybersecurity threats are plaguing global supply chains, particularly within small to midsize enterprises (SMEs).

GetApp’s Supply Chain Plans Survey of 1100 supply chain management (SCM) leaders across Australia, the U.S., Germany, France and the U.K. reveals critical issues currently impacting SMEs and how they’re building supply chain resilience in these challenges.

Insight from industry leaders reports on the following market trends affecting supply chains, providing SMEs with a guide to navigate anticipated challenges:

1. Conduct a risk assessment to follow mitigation strategies

Nearly half (49 per cent) of Australian SMEs cited inflation as their top concern, slightly above the international average of 45 per cent. With inflation affecting procurement,

43 per cent said that product availability issues were the most significant procurement challenge they have faced in the last six months, followed by product quality issues (35 per cent) and delays in procurement (32 per cent).

2. Evaluate supplier locations and consider local options

Australia’s location is a potential challenge, so 61 per cent of SMEs continue switching to suppliers in or near Australia, and 20 per cent are starting to do so. Forty-five per cent of SMEs in Australia say most of their suppliers are currently nearby, and a further 27 per cent say all of theirs are within proximity, second only to the U.S. (36 per cent). Overall, 39 per cent of Australian businesses plan to have all suppliers in or near Australia in 2024.

3. Invest in software solutions to improve operations

The research shows that adopting software can assist with specific areas of supply chain operations. Over a

third (37 per cent) of Australian companies plan to continue adopting new SCM software, and 30 per cent plan to start this year. Only 36 per cent of Australian companies plan to allocate more than five per cent of their budget to supply chain technology, compared to 48 per cent of the international average.

To measure the success of tech investments, 59 per cent of respondents said they use customer satisfaction, 44 per cent say they compare cost reductions, 41per cent say logistics key performance indicators (KPIs) are used, and 41 per cent say they measure employee satisfaction.

4. Analyse how potential cyberattacks can impact the supply chain GetApp found that 59 per cent of Australian businesses say advanced cybersecurity is crucial to success. This year, 47 per cent of companies plan to maintain or increase spending on advanced cybersecurity, followed by advanced data analytics (46 per cent) and artificial intelligence (39 per cent).

Notably, nearly a quarter (22 per cent) of Australian respondents expect cybersecurity disruptions to be a top supply chain challenge in 2024, with potential cyberattacks cited as a top concern for 72 per cent of Australian SMEs. In the past 12 months, over a third (35 per cent) of Australian companies have experienced disruptions due to a cyberattack.

5. Monitor supply chains to pre-empt disruptions Businesses must aim to manage supply chain disruption occurrences to reduce their impact on business operations. Supply chain management software helps strategically pre-empt disruptions, plan accordingly to mitigate their effects, and manage supplier relationships.

MHD INDUSTRY NEWS MHD JUNE 2024 | 27

GetApp found that 59 per cent of Australian businesses say advanced cybersecurity is crucial to success. Image: Adobe Stock/panuwat+phimpha.

KÖRBER UNVEILS SOLUTIONS FOR WAREHOUSE MANAGEMENT

Körber has announced the launch of three solutions set to augment warehouse operations, including Gamification, Slotting.IQ and its Unified Control System.

With a focus on innovation beyond Warehouse Management Systems, these products address common productivity and workflow pain points across the supply chain, unlocking new capabilities and offering enhanced functionalities.

Supply chain companies face increasing challenges, necessitating the addition of software solutions to extend WMS capabilities. Körber’s latest developments provide a holistic approach to supply chain execution, ensuring end-to-end visibility, scalability, and flexibility.

“Körber’s commitment to pushing the boundaries of warehouse technology is reflected in these solutions,” says Sean Elliott, CTO and acting CEO Software, Körber Business

Area Supply Chain.

“Whether it’s revolutionising inventory placement with Slotting. IQ boosting workforce engagement through Gamification, or combining automation with human workflows with UCS, Körber continues to drive warehouse innovation.”

With 82 per cent of workers motivated by recognition, Körber’s Gamification boosts productivity by encouraging worker engagement and introducing healthy competition. Management sets targets and milestones to encourage users to progress through the experience, as they collaborate as a team and accomplish tasks. This solution redefines worker engagement, emphasising efficiency, productivity, and employee satisfaction.

Körber’s Slotting.IQ allows warehouses to harness management of complex inventories. Dynamic slotting algorithms optimise

inventory placements, improving order-picking efficiency and accelerating order processing. By integrating with the WMS, re-slotting strategies can be implemented seamlessly and enhance overall operational productivity. Slotting. IQ’s automated approach also saves valuable time and resources compared to traditional, manual slotting methods.

Körber’s Unified Control System provides a single point of management and control for fulfilment processes driven by warehouse staff, AMR, and other automation technologies. It seamlessly orchestrates automated and manual workflows, enabling faster order processing and improving throughput. UCS integrates with the WMS and other warehouse technologies, to enable operational flexibility, streamline workflows and boost productivity.

MHD INDUSTRY NEWS 28 | MHD JUNE 2024

Körber’s latest developments provide a holistic approach to supply chain execution. Image: Körber.

TMX HELPS NZ POST WITH APC

NZ Post, with the help of TMX Transform, has opened a DC in Auckland for processing domestic parcels – a milestone in its $200 million-dollar, 10-year investment plan and transformation project known as the ‘Te lho’ program.

The Auckland Processing Centre (APC) now has the most capacity of any parcel sorting facility in New Zealand’s history – with more than 30,000 parcels per hour at peak capacity.

“NZ Post is evolving to meet the needs of New Zealanders,” says NZ Post Chief Executive David Walsh.

“Our new 30,000 sqm hub of international and national processing will bring together NZ post, New Zealand Customs Service (Customs) and the Ministry for

Primary Industries (MPI) on one site, continuing our long working relationship with both agencies.”

Rated a NZGBC five-star Green Star Rating, the APC includes equipment built from recycled materials and chutes made from bamboo.

Workers on site will use electric forklifts, and soft-plastic waste will be redistributed for recycling.

This site is the third to open under NZ Post’s $200 million investment in parcel processing infrastructure.

The Wellington Super Depot and the Southern Operations Centre opened in 2022. Supply chain consultant TMX Transform provided full end-toend technical and program support, including program management, network design, automation procurement and assurance during

installation, build design, property procurement, and construction advice.

“The delivery of the Auckland Processing Centre marks the key milestone in the execution of NZ Post’s network strategy, which commenced several years ago,” says TMX Transform Supply Chain Director, David Sim.

“APC is the largest investment in the transformation of NZ Post’s backbone to underpin and support its customer base. Bringing together both its domestic and international processing centres, NZ Post is well positioned for growth in the coming years.”

International parcels will follow at the APC when the Ministry for Primary Industries (MPI) and the New Zealand Customs Service (Customs) move into the site later in 2024.

MHD INDUSTRY NEWS MHD JUNE 2024 | 29

The APC includes equipment built from recycled materials and chutes made from bamboo. Image: TMX Transform.

CEVA LOGISTICS UNVEILS

SUSTAINABLE WAREHOUSE

As part of the CMA CGM Group, CEVA Logistics is committed to finding better ways to transport and manage customer shipments and reach net zero carbon emission by 2050.

With a strong business presence across Australia and New Zealand, CEVA has been expanding and implementing its green initiatives across its 41 facilities in the two countries.

Recently, CEVA unveiled its Kemps Creek warehouse, a new 34,000 sqm facility with notable features including market-leading temperature control technologies, state-of-the-art racking, and traffic management for seamless flows.

“With the unveiling of our

warehouse in Kemps Creek, CEVA is demonstrating our dedication to investing locally and expanding our footprint of sustainable logistics in Australia,” says Michael Harich, Head of Contract Logistics for CEVA Logistics in Australia and New Zealand.

“Together with our existing sites in Orchard Hills, Eastern Creek, and two other upcoming facilities in Erskine Park, we are forming a logistics cluster in Western Sydney to better serve the region.”

The facility is strategically located near the Western Sydney Airport and has access to key transportation routes, including the M4 and M7 motorways.

The Kemps Creek distribution

warehouse was built to carbonneutral specifications and 5-star Green Star certification standards. Sustainability features include:

• 1510 solar panels for an 830kW photovoltaic system with battery, alongside translucent roof sheeting

• LED lighting with motion sensors

• Rapid roller shutter doors for the temp-controlled area to minimise energy consumption

• Rainwater harvesting systems for water conservation, with recycled water being used for gardening and toilets

• Building monitoring system for tracking and analysis of site-wide power and water consumption

• Electric vehicle charging points

MHD INDUSTRY NEWS 30 | MHD JUNE 2024

CEVA unveiled its Kemps Creek warehouse, a new 34,000 sqm facility with notable features. Image: CEVA Logistics.

FLUENT CARGO ANNOUNCES GLOBAL TEAM EXPANSION

Fluent Cargo, a fast-growing and cutting-edge cargo routing solutions provider, is thrilled to announce its revamped executive team, poised to drive the company’s commitment to excellence and growth in logistics routing software.

Cargo transportation continues to be a huge challenge for customers, shippers, and logistics service providers. Non-central schedules, limited collaboration and huge variations of systems and formats means there are multiple sources of truth. Planning a shipment has never been more complex, difficult, and error prone.

Fluent Cargo’s approach to central routing provides customers with an easy, carrier agnostic solution regardless of mode, service, or origin to destination pair. Planning a shipment from city to city, airport to airport, or seaport to seaport now takes seconds.

Furthermore, the team is tackling two critical issues, supply chain disruption and sustainability.

NEW LEADERSHIP, ONE VISION

Fluent Cargo has recently brought on Archival Garcia as the Chief Executive Officer to lead its expansion efforts.

Archival previously served as the VP & GM, ANZ & SEA for project44 and has also held leadership roles at Microlistics (a WiseTech Global Company) and Manhattan Associates.

“Disruptions to global transportation has driven the need for more agile and intelligent tools,” says Archival.

“The Panama Canal incident during the pandemic and the current situation over the Red Sea route has provided us with key gaps in the market for transportation planning.

“As we expand our offerings, it’s important to have executive advisors, like Jerome and Christophe, that deeply understand

the intricacies of the global transportation market.”

Archival refers to the addition of Jerome Lorrain as Executive Chairman and Christophe Cachat as Strategic Advisor.

Jerome has more than 25 years of supply chain, logistics and transportation industry experience across the globe in senior positions for companies including CEVA, Kuehne+Nagel and Wallenborn while Christophe is a well-known and well-respected, technical guru with senior leadership experience at Kuehne+Nagel and CEVA.

“To date, there are a small number of decisions made due to emissions, however, as Scope 3 regulations tighten and carbon emissions

across the globe is enforced by governments, the criteria for shipping will be cost, speed and emissions,” says Jerome.

“The way we deal with data right now is a differentiator and data is going to be central in logistics planning and execution,” adds Christophe.

“More importantly, we want our customers to have easy access to data, to help them make smart and informed decisions. I’m looking forward to bringing our vision to fruition with Arch and Jerome over the coming months.”

In the coming weeks, Fluent Cargo plans to release key planning and routing solutions to the market to quickly expand its market offerings.

Fluent Cargo’s approach to central routing provides customers with an easy, carrier agnostic solution regardless of mode. Image: Fluent Cargo.

MHD INDUSTRY NEWS MHD JUNE 2024 | 31

MAXIMISING SUPPLY CHAIN COMPETITIVENESS

A comparative analysis of leading automated Goods-to-Person (GTP) order fulfilment solutions. By

Dave Lamb, Consulting Manager – ANZ, Dematic

& Philip Makowski,

Director

Marketing – APAC, Dematic.

In today’s global marketplace where customer expectations are constantly evolving, supply chain efficiency is paramount for businesses seeking to gain a competitive edge. A key differentiator has become the ability to handle diverse products and deliver orders rapidly, accurately and at the lowest cost to various channels —including businesses, brick and mortar stores, and online customers. However, supply chains face numerous challenges: labour shortages, increasing costs, and land and real-estate constraints to combat transportation challenges and be close to customers who expect speedy delivery. With these fluctuating market dynamics, supply chains can become a competitive differentiator.

Customers demand products to be

In AMR systems, robots can easily be added or removed as throughput requirements change. Images: Dematic.

affordable, readily available, delivered quickly, with minimal errors and a seamless returns process. Additionally, the rise of e-commerce has further heightened the need for efficient order fulfilment processes. To remain competitive, businesses must navigate complexities such as SKU proliferation, seasonal fluctuations, and disruptions caused by environmental and geopolitical factors.

Automation technologies have emerged as valuable tools for addressing these challenges and enhancing supply chain resilience and agility. By automating key processes such as order picking and fulfilment, businesses can improve efficiency, accuracy, and responsiveness.

Four leading automated goodsto-person (GTP) order fulfilment solutions — Dematic Multishuttle® GTP, AutoStore™, Autonomous Mobile Robots (AMR) Shelf-to-Person and AMR Bin-to-Picker — have emerged globally and in APAC as the leading solutions for supply chain optimisation.

So, which automation solution is the best fit for your operations? Let’s look at the challenges supply chains currently face and compare the leading systems available today.

ENHANCING ORDER FULFILMENT EFFICIENCY WITH GOODS-TO-PERSON (GTP) SYSTEMS

Within warehouse and distribution centres, picking stands out as one of the most labour-intensive tasks, particularly when it comes to eaches or item picking. In manual operations, this process can consume a significant portion of staff time, with up to 65 per

cent of employees dedicated to picking tasks. However, much of this time is inefficiently spent travelling between locations rather than the actual picking task.

To address this inefficiency, GTP systems emerged to optimise the picking process by eliminating unnecessary travel. In GTP systems, workers remain stationed at designated picking areas while items are automatically delivered to them from storage as needed, precisely sequenced for efficient fulfilment. These systems can accommodate various picking methods, including discrete or batch picking, and can be tailored to fulfil different types of orders, whether that’s store shelves or online purchases.

While GTP solutions like Multishuttle, AutoStore, AMR Binto-Picker and AMR Shelf-to-Picker operate on similar principles, they differ in their storage and pick station technologies, resulting in variations in operator pick rates, ergonomics, suitable products, storage density, throughput flexibility, security features, scalability, and maintenance requirements. Therefore, when implementing a GTP system, it’s crucial to consider these factors alongside specific business and operational needs to design the most effective solution for the operation.

AMR BIN-TO-PICKER

The AMR Bin-to-Picker systems represent the cutting edge in Autonomous Mobile Robot (AMR) technology, designed for order picking tasks. These systems feature an AMR tower unit responsible for storing

MHD COVER STORY 32 | MHD JUNE 2024

Offering ultra-high-density storage, AutoStore™ systems can reduce space requirements to 25 per cent.

and retrieving totes from shelves, transferring them to an AMR tote mover, and ultimately delivering them to a designated pick station.

Key features include storage height up to 10 metres high in shelves and single or double-deep configurations.

Pros:

Quick system implementation, reducing setup times.

Pick rates from 400 order lines per hour per picker.

Exceptional accuracy in order fulfilment.

Flexibility to adjust throughput by adding or removing AMRs.

Scalability, enabling easy expansion to accommodate growing storage and throughput demands.

Maintenance-friendly design allows for easy rotation of AMRs for servicing. Robots have low energy requirements.

Cons:

Storage height capped at 10 metres. Lower storage density than Autostore. Pick rates may not match those of some Multishuttle GTP systems.

AMR SHELF-TO-PERSON

AMR Shelf-to-Person systems are

the original AMR order fulfilment solution, where AMRs bring a shelf of products to an operator for picking. The shelves can be used to store a variety of items, such as small units, large items in cartons, through to hanging garments.

With storage in shelves, Shelf-toPerson systems are limited to storage heights of less than 3 metres, with pick slots ranging from ankle height to upper slots requiring a small step ladder for access. If higher warehouse headroom utilisation is required to maximise capacity, companies typically utilise mezzanines for additional Shelf-to-Person modules (or other storage solutions if applicable to a particular storage and order profile).

As pickers pick items from shelves in this solution, AMR Shelf-to-Person systems tend to have the lowest pick rates of the four main GTP systems. With pickers having to find and select the correct storage slot in the shelves, there is also more room for error.

With these factors in mind, AMR Shelf-to-Person systems are typically applicable in small order fulfilment

systems or where headroom utilisation, storage capacity, pick rates, and ergonomics are less of a consideration.

Pros:

Potentially fastest implementation times.

Lower cost for smaller systems.

Cons:

Pick rates typically at 150 order lines/ hour, the slowest of the four GTP solutions.

Headroom utilisation.

Mezzanines, if required, add considerable capital costs.

Lower accuracy – can be addressed with product scan, which impedes pick rates.

Picking ergonomics are not optimal.

AUTOSTORE

AutoStore is an all-in-one storage buffer and order fulfilment solution. Offering ultra-high-density automation storage for small items, an AutoStore system can reduce space requirements down to 25 per cent compared to conventional shelf storage. With a flexible, modular design, AutoStore systems can fit into

MHD COVER STORY MHD JUNE 2024 | 33

With exceptional throughput capabilities, Multishuttle solutions offer the highest pick rates among all GTP systems.

existing facilities, around building columns and in compact spaces, and be readily expanded as required. The storage is in a cubic grid up to 24 bins high and it self-organises products according to throughput.

Pros:

Highest storage density of any GTP solution.

Ultra-high accuracy.

Robots have low energy requirements. Easily expandable.

Flexible system layout.

Throughput and storage scalability independent of each other – can increase throughput by adding robots or increase storage by expanding the grid.

High product security as storage locations accessible only by robots.

Cons:

Flat SKU profiles can reduce robot efficiency if they spend more time ‘digging’ relative to ‘delivering’. May pose challenges to fire regulations in certain situations.

MULTISHUTTLE GOODSTO-PERSON SYSTEMS

Multishuttle Goods-to-Person systems integrate advanced pick stations with Dematic Multishuttle systems, employing multiple shuttles within an aisle to store and retrieve products for seamless delivery to pickers. With exceptional throughput capabilities, this solution offers the

highest pick rates among all GTP systems. With the patented Dematic Inter-Aisle Transfer (iAT) technology for enhanced storage, retrieval, and picking flexibility, these systems offer optimal height utilisation of up to 20 metres and can store products in single, double, and triple-deep storage configurations.

Pros:

Pick rates exceeding 600 order lines per hour per station, the highest among GTP solutions.

Significant return on investment (ROI) despite higher system costs, thanks to unparalleled productivity gains and potentially lower building expenses.

Dematic iAT technology enables product redirection to any pick station, reducing the need for connecting conveyors and resulting in a reduced building footprint. Maximised headroom utilisation.

Cons:

Longer system implementation time compared to other GTP solutions.

COMPARATIVE ANALYSIS

Each automation solution offers unique advantages and considerations, making it essential for businesses to carefully evaluate their options before making a decision.

AMR Bin-to-Picker systems prioritise speed and flexibility, making them ideal for dynamic environments with

fluctuating order volumes. AutoStore excels in maximising storage density and space optimisation, making it suitable for businesses with space constraints. Multishuttle systems prioritise throughput and scalability, making them ideal for high-volume fulfilment centres where productivity is of utmost importance, and with the capability to go high, they potentially provide the highest storage capacity in tall warehouses.

PARTNERING FOR SUCCESS

Selecting the right automation solution requires careful consideration and collaboration with a trusted partner. Working closely with suppliers like Dematic, who offer all the leading GTP technologies, ensures businesses receive tailored solutions that address their specific needs and objectives. By leveraging the expertise of experienced providers, businesses can navigate the complexities of supply chain automation and gain a competitive advantage.

AUTOMATION A NECESSITY

Automated GTP solutions offer tremendous potential for enhancing supply chain efficiency and agility. In an era defined by rapid change and intense competition, automation is not just a luxury but a necessity for businesses seeking to thrive in the modern marketplace.

MHD COVER STORY 34 | MHD JUNE 2024

AMR CASE STUDY: RADIAL

Radial Europe, a leading global e-commerce third-party fulfilment provider recently sought to enhance its operations in response to the growing demands of the fashion and health & beauty industries and the evolving needs of consumers. Radial Europe’s customers include doTERRA, Calvin Klein, Cole Haan, Express, Gymshark, Lucky Brand, TaylorMade and Tommy Hilfiger.

With a commitment to customer satisfaction and operational excellence, Radial Europe embarked on a journey to modernise its manual distribution centre in Ommen, Netherlands, recognising the need to streamline processes and improve efficiency amid the rapid growth of e-commerce.

Facing challenges associated with high-volume volatility, a sprawling storage area, and a diverse array of 20,000 constantly changing SKUs and 67,500 bin locations, Radial Europe identified the need for a cuttingedge automation solution to meet the escalating demands of the industry. In collaboration with Dematic, Radial Europe deployed an innovative Bin-toPicker Autonomous Mobile Robot (AMR) system at a new facility in Groningen.

The Dematic solution, incorporating nearly 300 Bin-to-Picker and tote transport AMRs, transformed Radial Europe’s operations by significantly reducing storage space, enhancing storage density, and accelerating picking productivity. One of the key highlights of the solution was the implementation of GTP functionality, eliminating the need for extensive travel and optimising efficiency.

Following the successful implementation of the automation solution, Radial Europe witnessed a remarkable improvement in operational performance, with picking speed quadrupling and packing performance increasing by one-and-a-half times. Moreover, the error rate significantly decreased, attributed to the elimination of long walking routes and the seamless integration of AMRs into the workflow.

“We are now in a stronger position where we can fulfil every requirement a customer has. They simply tell us what they want to have happen and we can do it. Automation has proven

to be a tremendous help in achieving the goals we had from the start,” said Ron Kleinsmit, Warehouse Manager at Radial Europe in Groningen.

AUTOSTORE CASE STUDY: BENETTON GROUP

Benetton Group, one of the bestknown fashion companies in the world with brands such as United Colors of Benetton and Sisley, has a retail network of over 4,000 stores.

Working in partnership with Dematic, Benetton Group implemented an AutoStore™ system in its logistics facilities in Villorba, Italy to boost the company’s e-commerce channel by optimising storage capacity and order processing.

The Dematic AutoStore system, comprising 60,000 bins and 53 mobile robots, was seamlessly integrated into Benetton’s logistics operations, transforming the order picking process. The mobile robots, traversing the top of the storage units and descending into the bins to retrieve items, significantly enhance picking efficiency while reducing the travel distances previously undertaken by Benetton staff. Additionally, Dematic’s advanced software oversees and manages the entire operation, ensuring seamless integration and optimal performance.

“We chose Dematic because we were interested in a partner with significant experience in the e-commerce sector and a solid international background,” says Valentino Soldan, Head of Logistic at Benetton Group. “The AutoStore-based solution will meet our business needs perfectly, and we are confident in facing an increasingly challenging market with a structured and technologically advanced solution, capable of accompanying our development for many years to come.”

MULTISHUTTLE GTP CASE STUDY: BOLLORE LOGISTICS

Bolloré Logistics is a global leader in international transport & logistics and a tier-1 partner to some of the world’s best-known brands. The company’s Singapore operations have grown into a key regional centre with the largest distribution operations for the company in Asia-Pacific.

GTP systems are designed to eliminate operator travel and optimise the picking process.

Building on the success of its Dematic Multishuttle GTP automated solution for its ‘Green Hub’ facility, Bolloré planned its new ‘Blue Hub’ facility to support further growth of its business and to help it expand the number of clients it could service, particularly in the perfume and cosmetics sector.

At the heart of the 50,000sqm ‘Blue Hub’ distribution centre, is an eightaisle Dematic Multishuttle storage and retrieval system which securely stores more than 35,000 totes of products. The Multishuttle works as a high-rate fulfilment engine, delivering totes to pickers at seven ergonomically designed workstations, where operators fulfil orders whilst remaining in the one place, streamlining the fulfilment process, improving productivity, reducing operating costs, and improving workplace safety and health for operators.

Frederic Marcerou, Managing Director at Bolloré Logistics Singapore points out three main business drivers in mind when building this customised distribution centre,

“Here in Singapore, a big component is the cost of the space. So, automation is helping us with storage densification to reduce our footprint. And this is the first big advantage.

“The second one is in terms of productivity. We are able to be much more productive than we were in the past when pickers went into the aisles, to each shelf, doing manual picking.

“And the third one, which is as important, is operational excellence. This system allows us to improve our operational excellence and the service we are giving to our clients,” said Frederic. ■

MHD COVER STORY MHD JUNE 2024 | 35

• National warehouse footprint

• Controlled ambient, cold chain and frozen storage

• TGA licensed cGxP compliant storage

• ISO 9001, ISO 13485 accreditation

• cGxP compliant tailored active and passive packaging solutions

• Smart sensor technology devices and loggers

• Real-time GPS tracking and temperature control

• Mobile status alerts and dashboard reporting

• End-to-end solution design and optimisation

• Reusable shippers for delivery and return

• Unique customer asset tags applied to monitor usage

• Reduced landfill and wastage with lower costs

• Standard and “white glove” return, same day or overnight delivery

tollgroup.com/solutions/industries/government-defence/healthcare-logistics healthcaresales@tollgroup.com For further information

We excel in cold chain management, ensuring the safe warehousing

reliable transportation of temperature-sensitive pharmaceuticals and medical supplies.

and

Cold

Chain Storage Customised Solutions Sustainable Reverse Logistics

CONQUEST CLEARING THE AIR

Conquest Equipment’s Product Solutions Specialist, Jared Muller, speaks to MHD about HEPA filtration and the cleaning equipment company’s new electric FSW and FSR sweeper models.

Conquest Equipment’s latest sweeping innovations combine high efficiency particulate air (HEPA) filters with 100 per cent electric operation to improve air quality in the work environment.

Sometimes referred to as ‘H-class’ filters within the industry, HEPA filters remove dust particles to a finer micron of just 0.3. HEPA filter systems therefore capture more dust particles during the cleaning process and prevent them from being re-released airborne into the environment.

Conquest’s Safe Air technology combines multiple filters, which together make up higher filtration levels to retain particulate matter. The suctioned air passes through the filters, capturing visible matter such as dust, as well as invisible particles and microorganisms such as bacteria, allergens, mould and pollen. One hundred per cent electric operation means zero emissions are produced during the cleaning process.

With labour already stretched in many organisations, minimising respiratory health risk is critical for productivity. Less dust, microorganisms and carbon emissions in the air allow

operators and employees to breathe easier, decreasing personal leave taken due to preventable illness and the risk of compensation claims. It also satisfies the increasing scrutiny of environmental regulators. This is why Conquest is invested in supplying floor cleaning solutions that support air quality improvement.