13 minute read

In the warehouse

MHD IN THE WAREHOUSE INSIDE THE MHD WAREHOUSE In this month’s MHD warehouse we feature the latest from Combilift, Cohesio, Tennant and OPEX.

M17 ELECTRIC SWEEPER SCRUBBER

With the largest battery capacity in its class, the M17 Battery Powered SweeperScrubber machine will quickly improve your facility’s overall image.

More info: au.tennantco.com

COMBI-CB

The Combi-CB is the original compact multi directional counterbalance forklift, It’s manoeuvrability means it is perfect for handling palletised loads both indoors and out. Combine this with the ability to carry long loads such as timber and steel beams in sideways mode makes the COMBI -CB one of the most versatile all-round forklift available.

More info: www.combilift.com

SURE SORT™

A scalable, configurable, and cost-effective small-item robotic sorting system. OPEX’s® Sure Sort™ solution has changed the way companies handle small items, particularly as it relates to parcel sorting, multi-line orders, and reverse logistics.

More info: www.opex.com

COHESIO’S GOODS-TO-PERSON AMR, POWERED BY GEEK+

Geek+ Picking System realises Goods-to-Person picking by enabling robots to carry shelves, breaking from the traditional Person-to-Goods law. This reduces the travel path for operators, thus achieving fast, accurate and efficient order delivery.

More info: www.cohesiogroup.com KÖRBER AUTOSORT MOBILE

Maximise your operational capabilities through flexible, affordable and scalable automation. Körber AutoSort Mobile allows dynamic sortation, taking the shortest and most direct path. Now you can free up space in your DC and reduce your investment in traditional and fixed automation.

More info: https://cohesiogroup.com/

TRANSPORT LEADER EXCLUSIVELY TOYOTA FORKLIFTS FOR 25 YEARS

Queensland’s largest family-owned transport company, Followmont Transport, has had new Toyota Material Handling forklifts exclusively at the heart of its warehousing operations for over 25 years.

With 18 owned regional depots, a combined 40,000m 2 warehousing and storage facilities and a network of local contractors, the Brisbaneheadquartered business claims to operate Queensland’s fastest transport network, which also covers New South Wales.

With seven-day-a-week services to most locations, Followmont is the preferred carrier for many tier 1 accounts, including many businesses that are household names.

They are also the delivery companyof-choice for many interstate transport companies, SMEs, online retailers, farmers, mums and dads and regional businesses - carrying everything from pharmaceuticals and fresh produce to spare parts and paint.

Followmont CEO, Mark Tobin, says the business prides itself on going the extra mile to deliver in the fastest time possible, whether a single parcel or a complete transport, warehousing and logistics solution, and that this performance has helped the second-generation family business experience rapid growth. It is presently building three new depots and two new warehouses - to the tune of a $20million investment - to further expand and improve its network.

“We’ve had a massive transition over the past 15 years and pretty huge growth over that time. Today we employ over 850 people and have around 250 forklifts spread out across our depots, with the majority being Toyota 62-8FD25 8-Series 2.5 tonne diesel-powered machines,” Mark says.

Mark attributes the business’ success

Followmont Transport relies on Toyota to deliver goods on time.

to number of factors including its principles, business partnerships and performance. “We are a close-knit family business and we adhere to our values. We are personal first, and commercial second. We pride ourselves on speed-of-delivery and customer satisfaction.

“That’s our approach and those values are behind our longevity and continued expansion.”

Followmont Transport has always striven to seek partnerships with like-minded suppliers and such is the case with its forklift supplier Toyota Material Handling Australia (TMHA), with whom shared values have formed the basis of a relationship extending back 25 years.

“We are dedicated to our customers, our people and our suppliers. This is key to our values and behaviours. It’s all about our people and our partners, making sure we’re engaged with them and viceversa,” Mark says.

“We have a couple of key suppliers and Toyota Material Handling Australia is one of those. The Toyota relationship goes back a long way, being key to our business for 25 years- plus, which is a pretty amazing duration.

“So in a way, they have been part of our business and we still look at it like they are part of our business. Likewise, Toyota really values our business and it shows.”

TMHA Corporate Account Manager, Jason Fennell, concurs. “We hang our business on our Toyota Advantage - part of which is Tailored Business Solutions - and have been proud to have been available to provide advice on the best business solutions and the right equipment and service support for Followmont Transport over such an extensive duration. Our solutions are fully tailored to their needs,” he says.

Another key Toyota Advantage known to be vitally important to Followmont’s success is the demonstrated quality, durability and reliability of TMHA’s equipment.

“Followmont’s business hinges on being able to deliver goods on time and it simply cannot sustain any delays caused by equipment failure,” Jason says.

“They love our forklifts because they have been proven to be reliable. We think that’s why they keep on coming back to us.”

After working his way up in the business from humble beginnings, Followmont’s Mark Tobin has settled on a model he is confident in. “I started out as a mechanic by trade and have since done every job in the business - all the way from sweeping the

For Followmont, the durability of Toyota’s forklifts is a major benefit.

floor to CEO. So I know our business insideout and that extends to the performance of the products we deal with,” he says. As such, Followmont adheres to a policy of buying new Toyota forklifts outright, every four years or 10,000 hours. “Whenever we hit that mark, I trade them in for new ones, year in year out.

“Toyota durability is already very good, but this way even less can go wrong and it ensures they’re not pushed too hard, even accounting for misuse.

“We as a business simply can’t afford any down-time. The volume of our deliveries is too great. One of the reasons I buy new Toyota forks is that I don’t see them in our repair workshop. Nothing goes wrong with them. They just keep going, just keep working.

“Because of this, I don’t have to buy other new forklift brands. I haven’t purchased a new forklift that wasn’t a Toyota for over 20 years.”

And is this relationship likely to continue? “Yes, we strive to be the best and we need the best partners and equipment to meet our own high service standards and customer expectations.

“We’re expecting to continue strongly with TMHA into the foreseeable future. The relationship has proven so successful for our business, why would we change?” ■

THE 2020 FORKLIFT MARKET

We delve into the results from MHD’s biannual Forklift Survey and reveal the latest trends and technologies that are shaping today’s forklift market.

Back in February this year, MHD launched its biannual Forklift Survey. It was released to the industry pre COVID-19 in Australia and once the survey closed at the end of April, MHD can reveal that the survey received the most amount of responses that it has ever received in its history of conducting this survey.

The last time the Forklift survey was available to industry respondents was two years ago in 2018. Results from 2020 show drastic changes in forklift consumer behaviour

and the expectations they have for forklift providers.

The past few months have seen

unprecedented events unfold around the world. However, what remains the same despite a world of uncertainty, is the

demand for quality forklift trucks.

Forklifts are even more vital than ever, aiding supply chain operations transport essential goods across local and international markets. Due to the spotlight on material handling during the COVID-19 era, the effectiveness and service of forklift companies and their products have never been more important.

Australian forklift users were encouraged to take part in the 2020 forklift survey to help influence improvements of future forklift models. A wide variety of executives, operators, managers, supervisors, consultants, analysts and technicians took part in the 2020 Forklift Survey. Majority of respondents were part of 3PL, retail and logistics and transport businesses, however automotive, construction and FMCG were common areas of employment too.

SHIFT IN TRENDS

Results from the survey will improve technology and enhance services offered to industry that meets the needs of material handling equipment owners.

Enhanced operations with cost effective technologies have proven to be implemented since analysing feedback from forklift users who previously participated in the prior forklift survey 2018 survey.

Two years ago, 83 percent of forklift users said safety was the most important attribute when evaluating forklifts. Performance, operator comfort and control were also highly noted by users as the most important features of a forklift.

Fast-forward to now and almost 90 per cent of forklift users said safety was the most important attribute, highlighting the importance of products that help eliminate the risks in the workplace.

With heightened operations across the region, forklift safety is more crucial compared to 2018, largely due to the recent pandemic. The results clearly indicate that safety is strongly rooted as a deciding attribute when making a forklift purchase.

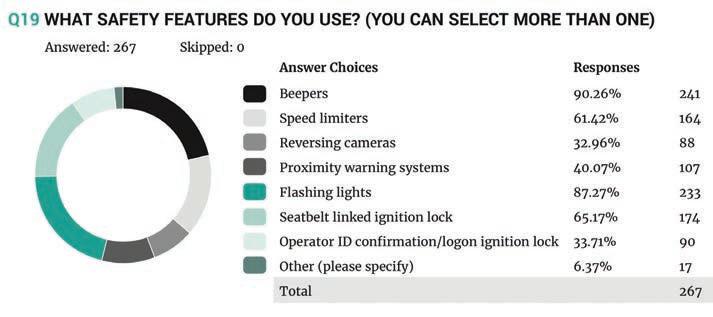

However, a shift in market from 2018, results this year showed that reliability, operator control, ergonomics and parts availability are highly favourable attributes in a forklift too. Beepers, flashing lights and speed limiters are the most used safety features, with reverse cameras and operator ID confirmation on the rise as the most used tools to maximise safety too.

According to the results, more than 55 per cent of forklift users are involved in the purchase of forklift products for their company. This further highlights why operator control and comfort, durability and performance were noted as ‘very important’ attributes when purchasing a forklift.

Compared to 2018, there is a slight increase in companies choosing to lease forklifts rather than purchase. Forty six per cent of current forklift users purchase a new forklift when required, and 53.9 per cent choose to lease instead. This may be due to leases becoming more economical for businesses, opting for 25 to 60

month leases that some companies choose to offer. Some forklift users have indicated they prefer the option to make an offer to purchase after their lease is at the end of the term.

In 2020, 45 per cent of forklift users are choosing to lease directly from the manufacturer. Prior results showed that over 50 per cent of forklift users lease with the supplier or distributor, however now, under 40 per cent lease with the supplier or distributor. A 10 per cent drop is a major shift in the market and provides a healthy outlook for forklift manufacturers.

AUSTRALIA’S FAVOURITE BRANDS

In a drastic shift from prior results, more companies are choosing to purchase, and lease forklifts more frequently than they have before. Prior data reported 58 per cent of companies purchase or lease a new forklift more than every four years.

Now, significantly under 50 per cent of companies are waiting more than four years to purchase or lease a new forklift. In fact, 38.5 per cent of respondents this year said their company purchases between one and four years, a noteworthy jump from just over 30 per cent two years ago. Further on that, there is a 3.7 per cent increase in the market purchasing or leasing a new forklift within 12 months, which is music to manufacturers ears.

In even more promising news for forklift providers, the majority of respondents this year are looking to purchase a new forklift within the next 12 to 24 months. So, which brands are they choosing to purchase?

The first brand that forklift users consider when planning to purchase or lease a forklift is Toyota. 60 per cent of respondents said Toyota is very favourable as a

Compared to 2018, there is a slight increase in companies preferring to lease rather than buy forklifts.

forklift truck manufacturer.

In 2018, Toyota celebrated its 50th anniversary celebrations for Toyota forklift sales in Australia, proving to be a legacy brand and on-going first choice amongst consumers as prior results also indicated Toyota as the first brand they would consider.

Cameron Paxton, Vice President and Chief Operating Officer, Toyota Material Handling Australia, previously has stated that Toyota Material Handling Australia (TMHA) is a technology leader in forklift safety and is particularly focused on automation. “Toyota’s massive ongoing investment in research and development means our materialhandling technology and product technology is continually progressed and refined,” he says.

Logistics companies are increasingly relying on their equipment suppliers to develop solutions for new high-density warehouses. This is an area where Toyota’s material handling engineers have access to the corporation’s automotive research and hence can take advantage of this everdeveloping technology.

Following Toyota, the second brand companies consider when planning to purchase or lease forklifts is Crown, and Linde as the third brand forklift users would consider. 36 per cent of respondents said Crown and 34.6 per cent of respondents said Linde are very favourable forklift truck manufacturers.

Two years ago, forklift users were most familiar with brands including Crown, Hyster, and Toyota. In 2020, almost half of the respondents said they would consider a Chinese brand of forklift. With a vast range of manufactures now available to the market, respondents have shown their familiarity to these brands but also smaller manufacturers that are emerging in the competitive market too.

ALTERNATIVE SOURCES

Fuel options in forklifts offer industries a range of options to meet different materials handling applications and

convenience for owners. Forklifts on the market today are designed to meet a range of industrial & handling applications including cold storage, flame-proof, confined spaces, warehousing to name a few.

An overwhelming 91.7 per cent, proving to be the clear majority of respondents opt for battery electric as the power of choice for forklifts. However, this is down five per cent since the last biannual forklift survey. In 2018, petrol was closely following battery electric as the power of choice. Whereas now, LPG is trailing close behind battery eclectic, with 82.7 per cent choosing it as their most favourable power of choice.

Unlike electric forklifts, LPG forklifts do not require substantial

time for refuelling, it generally only takes around five minutes to refill or change an LPG cylinder, a desirable choice for companies with demanding operations. 64.7 per cent of people said they would be interested in a guaranteed buy back and full maintained service agreement, showing that proven performance is highly valuable for consumers too.

When it comes to alternative fuel sources, such as hydrogen fuel cells and lithium ion batteries, more than half of the survey respondents

said they are of interest and they would be prepared to pay more upfront for the technology. This shows the shift in the market towards efficient and conventional technologies that significantly reduces energy costs and CO2 emissions. ■

SURVEY PARTICIPANT WINNER Congratulations to Jeffrey Moon from Dematic for winning 2 x Ionic Fitbits.