4 minute read

Breaking barcode barriers

BREAKING BARCODE BARRIERS With product traceability becoming more important to industry, selecting the best method of product identification is increasingly difficult.

While linear barcodes are still the most common method of identifying a product, they are very limited in the information they can contain.

For this reason, 2D barcodes and RFID tagging solutions are becoming more popular, but what is the best solution for your application? Darryl Blackeby, Product Sales Manager at ifm efector presents the options available.

2D BARCODES Whilst most of us would be familiar with QR codes that typically contain URL information to link to a website, other 2D barcodes such as ECC200 Data Matrix Code, PDF-417 and Aztec code are also available.

In particular, the ECC200 DMC is ideally suited for industrial applications due to its compact size, high data density and ability to be read with significant damage or soiling.

In addition to the standard printing methods, ECC200 DMC can also be laser marked, electrolytic chemical etched or dot peened onto a surface.

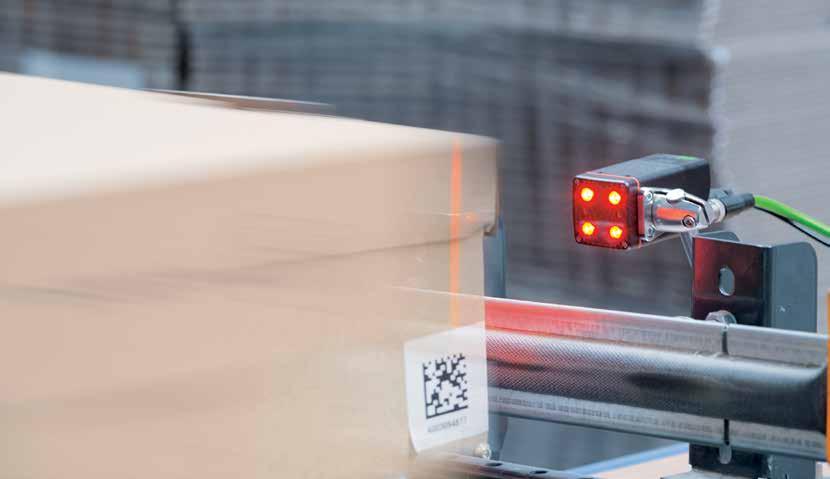

2D barcodes require a camera-based code reader and therefore the code must be presented in a defined region within the cameras field of view. Reading ranges of up to two metres are possible depending on the code size and resolution, but typical reading ranges are less than 200mm. Being a camera-based system the lighting is

also critical for consistent results. The ifm O2I Multicode Readers are capable of reading both 1D and 2D barcodes, as well as character recognition and verification. The code information can be transmitted via TCP/IP, Ethernet IP, Profinet or RS232, with other industrial Ethernet protocols also possible using the ifm AC14 Smart PLC as a gateway and a dedicated app.

The latest O2I5xx Multicode Readers also offer unparalleled simplicity, with a one touch teach function to learn the code type, set up lighting exposure time and automatically focus the camera. A mobile phone app can be utilised to set the IP address and make other minor changes.

RFID SOLUTIONS RFID is common in many everyday applications such as toll collection, smart cards and livestock identification, and the uses in industry are growing rapidly. RFID technology is grouped into three main technologies – UHF, HF and LF depending on the operating frequency utilised. RFID systems offer the advantage over 2D barcodes in that the codes can be read when completely soiled, and independent of lighting. Information can also be written to the tags using the same devices that read the codes, meaning the tag data can be updated readily.

Ultra High Frequency (UHF) systems can operate in the 800 – 900 MHz

range, although in Australia the frequency is restricted to 916 – 927 MHz to comply with ACMA standards. UHF systems confirm to ISO 18000 standards to ensure tag compatibility and offer long read distance of up to 10 metres with passive non-powered tags.

Whilst the cost of the UHF antennae and controllers is higher than for the other RFID systems, the tag costs are typically lower and can therefore still be a cost-effective solution for consumable products. Due to the capability of reading multiple tags at once, UHF systems are ideally suited for warehousing and logistics applications.

The ifm DTE920 UHF RFID Controller can monitor up to four ANT9xx series antennae, and the code information is transmitted via Ethernet IP with other industrial Ethernet protocols also possible using the ifm AC14 Smart PLC as a gateway and a dedicated app. High Frequency (HF) systems operate at 13.56 MHz to ISO 15693 standards to ensure compatibility of tags. Read distances are limited to around 200mm, making them ideal for monitoring conveyed items such as trays and part carriers as well as access control. Other applications include tool identification for machine tools and mobile

machines to match the operating parameters to the tool in use.

ifm efector offer UHF antennae with IO-Link and ifm proprietary ID-Link protocol for industrial applications, as well as CANopen and J1939 for mobile applications. Both the IO-Link and ID-Link antennae utilise modules to interface with standard industrial Ethernet protocols such as TCP/IP, Ethernet IP, ProfiNet, EtherCAT and Modbus TCP. Low Frequency (LF) systems operate at 125 kHz and do not comply with international standards meaning tags from one manufacturer may not be readable by antennae from another supplier. Read distances are usually limited to around 100 mm, and the data stored on the tag is small. Due to the low operating frequency LF tags can be direct mounted to metal surfaces without any significant reduction in range, making them ideal for identification on conveyed part carriers.

ifm efector offers the DTE100 evaluation units with TCP/IP, Ethernet IP, ProfiNet & EtherCAT protocols along with antennae for LF applications, along with the DTS125 system with AS-interface as an ideal solution on conveyors. ■

TOLL CHOOSES SWISSLOG FOR A MORE EFFICIENT DISTRIBUTION SYSTEM

SCAN FOR MORE!

An extension of the existing long-term partnership between Swisslog and Toll Moving to automation increased productivity by 200% Higher distribution volumes of retail ready cartons