AUTOMATING WITH TMHA

Toyota continues to handle materials with its new range of autonomous solutions

Automate X, the Kiwi company taking on the ANZ region Körber offering cloudbased solutions for warehouses UP IN THE CLOUDS DISRUPTING THE MARKET

Toyota continues to handle materials with its new range of autonomous solutions

Automate X, the Kiwi company taking on the ANZ region Körber offering cloudbased solutions for warehouses UP IN THE CLOUDS DISRUPTING THE MARKET

The new 2024 Gartner® Magic Quadrant™ for Warehouse Management Systems is out and for the 6th year in a row, Körber has been named a Leader.

Scan the QR code to get your free copy of the report and discover why Körber stands out among the competition. koerber-supplychain-software.com

Scan for your free copy of the report

MHD Supply Chain Solutions is published by Prime Creative Media

379 Docklands Drive, Docklands VIC 3008

Telephone: (+61) 03 9690 8766

Website: www.primecreative.com.au

THE TEAM

CEO: John Murphy

Chief Operating Officer: Christine Clancy

Managing Editor: Mike Wheeler

Assistant Editor: Joseph Misuraca

Journalist: Mannat Chawla

Business Development Manager: William Jenkin

Design Production Manager: Michelle Weston

Art Director: Blake Storey

Graphic Designers: Danielle Harris, Jacqueline Buckmaster

Client Success Manager: Ben Griffiths

FOR ADVERTISING OPTIONS

Contact: William Jenkin william.jenkin@primecreative.com.au

SUBSCRIBE

Australian Subscription Rates (inc GST) 1yr (11 issues) for $99.00 2yrs (22 issues) for $179.00

To subscribe and to view other overseas rates visit: www.mhdsupplychain.com.au or Email: subscriptions@primecreative.com.au

ACKNOWLEDGEMENT

MHD Supply Chain Solutions magazine is recognised by the Australian Supply Chain Institute, the Chartered Institute of Logistics and Transport Australia, the Supply Chain and Logistics Association of Australia and the Singapore Logistics and Supply Chain Management Society.

ARTICLES

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

COPYRIGHT

MHD magazine is owned by Prime Creative Media. All material in MHD is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in MHD are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

As September springs upon us, the largest logistics and transport exhibition in Australia, MEGATRANS, runs in Melbourne from September 18-19 with the Mercury Awards taking place in the evening of the first day. This means that the first MHD Sustainable Warehouse Award will also be handed to one lucky recipient.

In this MEGATRANS-themed edition of MHD Supply Chain Solutions, Toyota Material Handling Australia (TMHA) gives us the lowdown on its range of new autonomous solutions as it continues to sift through the exciting terrain of automation.

From across the ditch, three Kiwi companies based in Auckland: Automate X, Sandfield and vWork, dig deeper into the Australian market as they tell us why their software and hardware solutions are suited to digitising Aussie warehouses and streamlining their operations.

Then there is Toll, who talks about its new Tullamarine warehouse.

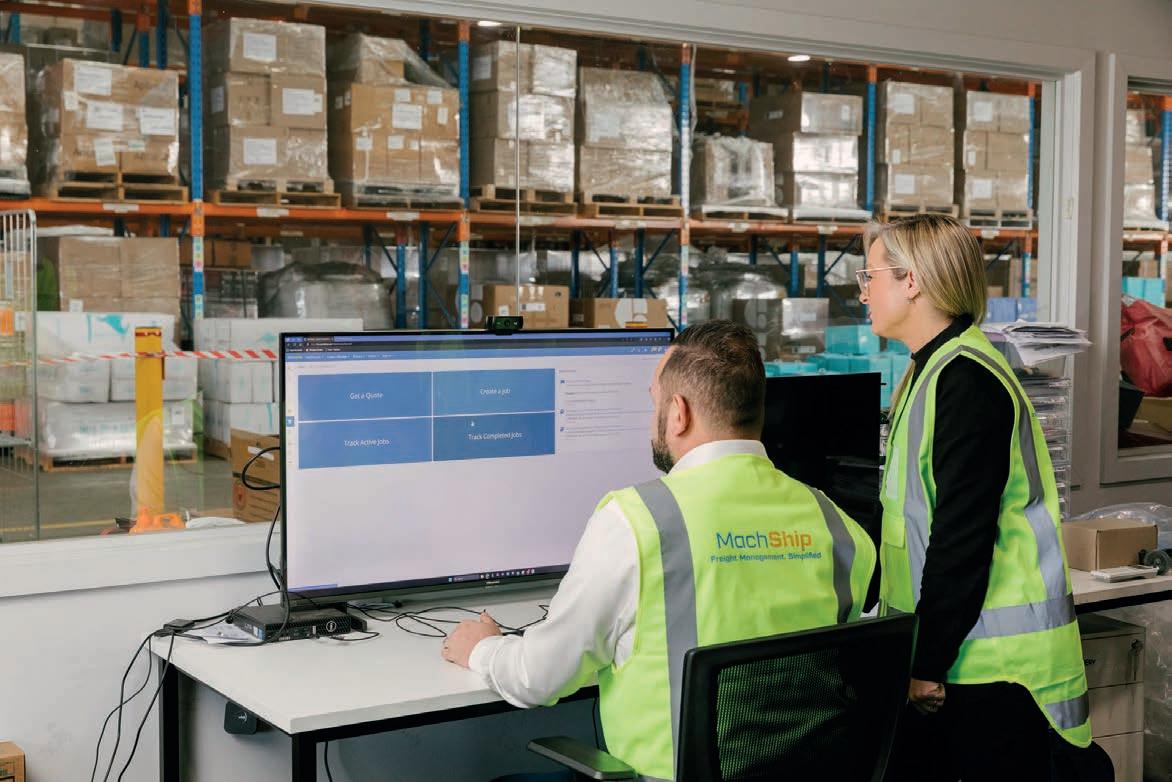

With supply chain visibility and telematics as the promo for this edition, companies like MachShip, Körber and Santova explore freight forwarding and cloud-based solutions, as well as harnessing the power of artificial intelligence for supply chains.

Material handling enterprises are always busy lifting heavy stuff. Linde, Jungheinrich and Combilift are no exceptions as they share what projects they’ve been working on and new solutions they have on offer.

We have Peter Jones from Prological sharing his wisdom in an op-ed for the Logical Outlook column.

Finally, as the new season begins and the months get warmer, keep yourself informed and up to date on this fast-changing industry by reading this special showguide edition of MHD.

Mike Wheeler

Managing Editor, MHD Supply Chain Solutions mike.wheeler@primecreative.com.au

Known for market leading Toyota forklifts and warehouse equipment, Toyota Material Handling is also proud to o er an unparalleled range of products suitable for Australian businesses. With a huge range of forklifts, elevated work platforms, scrubbers and sweepers, Taylor-Dunn electric vehicles, plus Huski skid steers, scissor lifts, and mini excavators available, chances are we’ve got the equipment that will suit. So, if you’re looking to buy hard working, fully backed equipment for your business, Toyota Material Handling has all you need to add value to your operation. That’s the Toyota Advantage.

12 TMHA displays its autonomous solutions

18 Logical Outlook on automation, people and data

24 MachShip launches new software solution

31 Körber shifting to cloud-based solutions

37 Sandfield managing complex projects

40 GS1 exploring sustainability

43 Toll opens new facility

46 Kardex partners with Douglas Pharma

58 Santova explores AI in supply chain

75 vWork on last mile delivery

82 Bonfiglioli on why cranes need drives

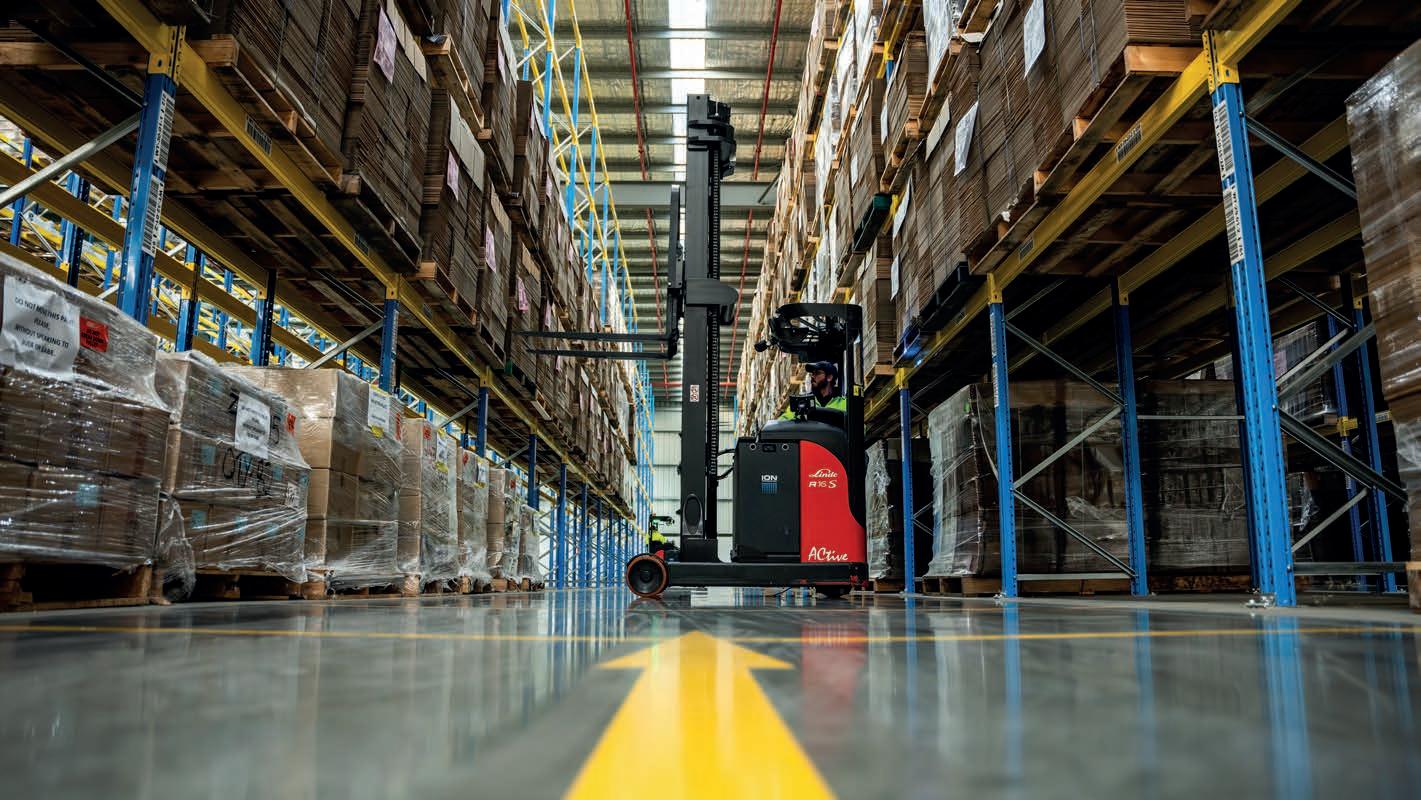

27 Linde improves Chemist Warehouse’s operations

34 Jungheinrich on advantages of lithium-ion batteries

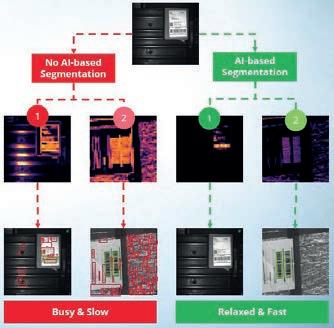

49 Combilift innovating solutions

55 NORD delivering tailored solutions

21 Automate X on its offerings and innovation

61 Vanderlande automating with FASTPICK

64 Kärcher on its showcase at MEGATRANS

67 SICK improving efficiency

70 Adept Conveyor on its multifunctional conveyor systems

72 Falcon Autotech’s transformative journey

78 Nilfisk on sustainable cleaning solutions

80 Airstack Intralogistics – a one-stop shop

06 People on the Move

08 Industry Focus

52 Future of logistics at MEGATRANS

74 SCLAA on the ASCLAs

77 SCLAA on the ASCLAs

84 ASCI’s seminars, classes, and cer tificates

86 Product Showcase

Nathan Busuttil has been appointed as the head of the newly established Bulk and Warehousing Division of Visy Logistics. With more than 25 years of experience in logistics, Nathan excels in overseeing large-scale operations and maintaining high safety standards. Known for his leadership, strategic planning, and problemsolving skills, he has a track record of optimising supply chains, reducing costs, and enhancing productivity. Nathan is committed to delivering excellence and ensuring customer satisfaction in all aspects of bulk operations.

Sandfield, a provider of IT solutions, has named Matthew Keith as its new Chief Executive Officer. Matthew, a 23-year veteran of Sandfield, brings a wealth of experience in IT, logistics, and supply chain management. He has been instrumental in nurturing the company’s 35-year partnership with Mainfreight, a key client and one of New Zealand’s largest supply chain companies. In his new role, Matthew will oversee all aspects of Sandfield’s business, including its specialised supply chain division, Origin.

intralogistics and seven years in the APAC region, has joined Ferag as the APAC Service Director. He has experience in service and support roles, showcasing a passion for customer support and team development. Michael began his career as an electric and electronic engineer, progressing to site management and field service engineer roles, gaining global experience. His passion for service led him to establish a UK service organisation, growing it to 185 employees. His APAC journey includes senior roles at Daifuku, Schaefer Systems International, and Vanderlande, focusing

Jeff Triantafilo joined Argon & Co in 2022 after the merger with Fuzzy LogX and has now been made a partner of the company. He comes with an engineering background, and expertise in warehousing and logistics. Jeff has worked across various sectors such as pharmaceuticals, retail, and mining. His grasp of the latest technologies and advancements in automation and logistics reflects his dedication to emerging industry shifts and driving transformative solutions.

With 30 years of supply chain experience in automation and IT, Michelle Van Driel has held senior IT management roles in ASX 200 companies and MNCs. She has joined Ferag as Head of Intralogistics. Michelle specialises in ERP/WMS software, business transformation project management, and SAP implementation. She has led streams within major supply chain projects like Australia Post’s Future Network program and Kmart’s Automated Sorting Program. She has consulted on large automation, business transformation, and IT programs across diverse industries including retail, manufacturing, health, FMCG, resources, and NFP, bringing process expertise to complex supply chains.

Katie Budd has recently made the move from the UK to Australia and has been made ANZ Sales Manager for Vanderlande. In the UK, she began her career in the Intralogistics world eight years ago. Katie has worked in both sales and solutions design, understanding end-to-end systems.

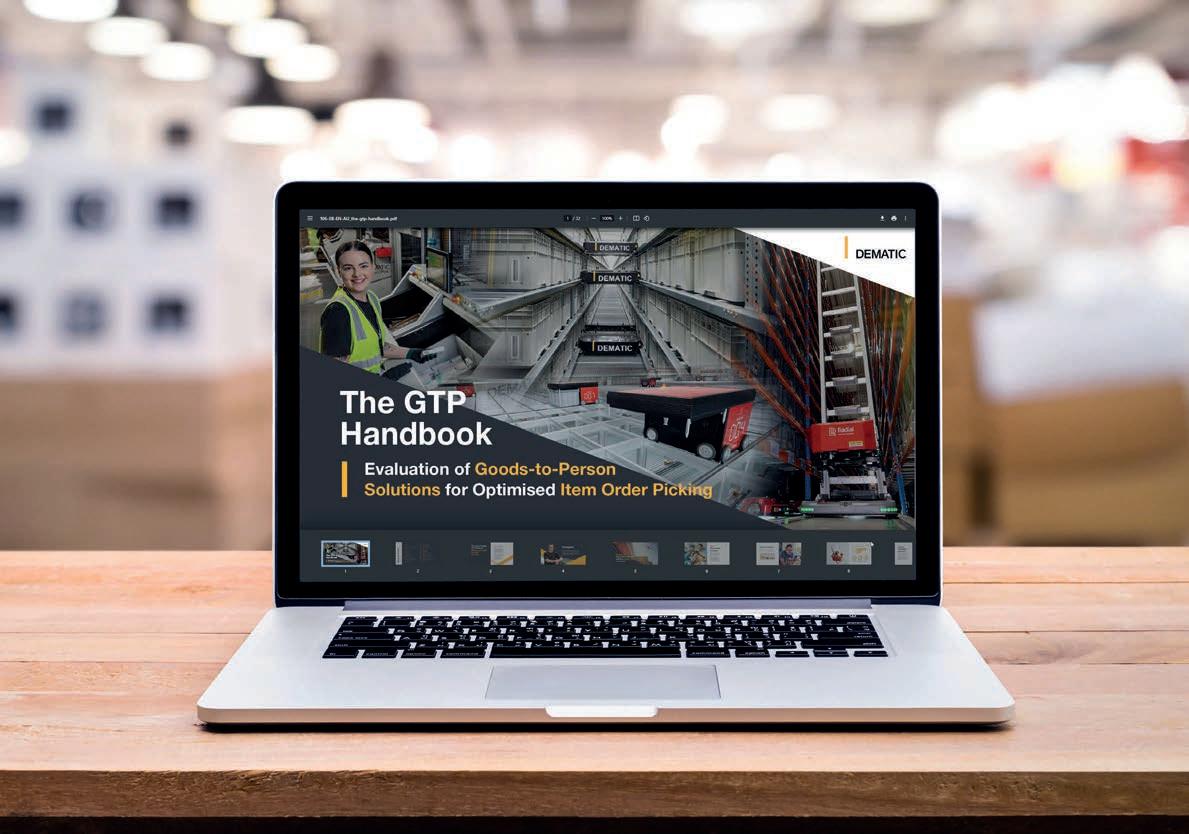

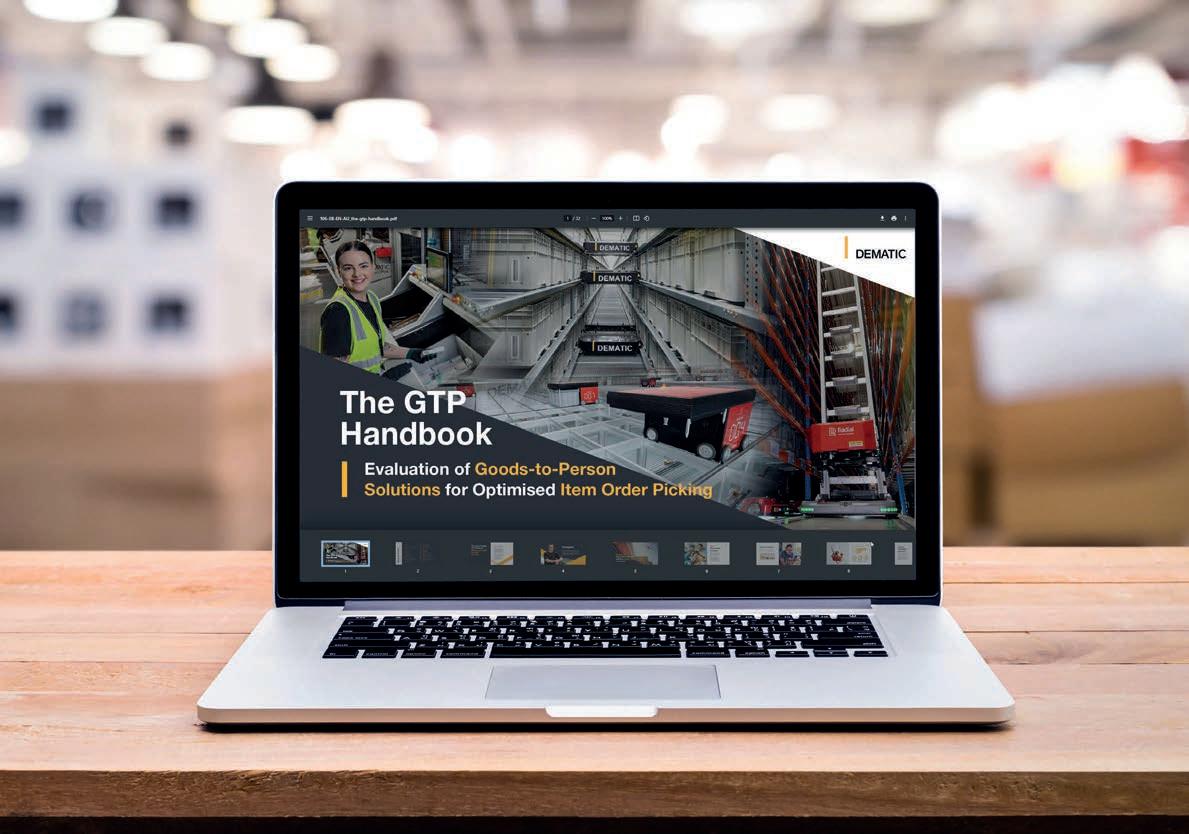

■ Learn about the megatrends driving today’s supply chain challenges.

■ Understand how GTP solutions address these challenges whilst providing a competitive edge.

■ Discover the features and benefits of the leading solutions – AutoStore , Multishuttle GTP , and Autonomous Mobile Robots (AMRs) .

■ Read a detailed analysis and comparison of the technologies and how they align with business throughput and storage requirements.

Tennant Australia has recently unveiled its new Sydney-based Recon division, dedicated to the repair and resale of industrial and commercial cleaning machines.

This move marks a step forward in providing local businesses with sustainable and cost-effective alternatives.

The Recon Division is a step forward towards sustainability and reducing waste. This initiative supports a circular economy, where products are reused and recycled, thereby reducing the demand for new resources and lowering carbon footprints.

Tennant’s commitment to quality and durability means that every piece of equipment, whether Certified Pre-Owned or Used, meets high performance and reliability standards.

A feature of the Recon Division is the refurbishment process. Each

Cby technicians to ensure it performs like new.

The purpose of the new division is to allow businesses to maintain high hygiene standards without the high

factory direct warranty, meaning our customers can have peace of mind with purchasing from the Manufacturer,” says Jye Jones, Tennant’s National Service Manage.■

mbilift’s first multi-directional forklift is just one of dozens of patented designs where company stalwart, Mark Whyte, was instrumental in its design and development. After 26 years of service, Mark has made his mark on materials handling worldwide.

From the Combilift multi-directional C4000 in 1998, to the Pedestrian range’s tiller arm in 2012, Mark has helped Combilift reinvent forklifts so that they improve safety, maximise storage, and increase efficiency for customers.

Now working as a research and development manager, Mark remains loyal to the company ethos of continuous development.

“The company has a very good

can-do attitude, from higher management right through the entire workforce,” says Mark.

“In development, we listen to our customers and our salespeople as to what’s needed in the market.”

This has led Combilift to register roughly 140 patents worldwide.

The Pedestrian tiller arm has been one of Combilift’s most popular patents. This innovation has allowed warehouses worldwide to narrow their aisles by repositioning the operator to the side of the truck while increasing visibility.

Mark describes the moment he and Combilift’s co-founders – Robert Moffett and Martin McVicar –dreamt up the solution.

“The invention on the pedestrian model’s tiller arm was like a light bulb moment around my desk one day with Robert and Martin,” says Mark. “We said, ‘Imagine if you could just stand to the side of the forklift’. That was the beginning of a great idea.” ■

Heli Oceania marked a milestone with the opening of its new Warehouse in Australia and the launch of the G3 Series Compact Rough Terrain forklift.

The event, held on 4 July 2024, was attended by industry partners, important HELI China Staff and media representatives from across the region, showcasing Heli Oceania’s commitment to advancing material handling solutions.

The event commenced with the arrival of guests, Anguo Yang (President of the Anhui Forklift Group) and Guo Yang (General Manager of Heli Industrial Vehicle Imp. & Exp.).

“For more than 20 years, Heli’s products have crossed the ocean to Australia. Deeply cultivating this

market,” says Anguo Yang.

“Today, we bring an excellent team to take root here.

“Not only does Australia have an open business market but a gathering of outstanding talents and infinite innovative potential from all over the world.”

This year marks the 10th anniversary of the establishment of the strategic partnership between China and Australia and the 66th anniversary of Heli.

Heli values sustainable development and pays attention to environmental, social and corporate governance. no

A spokesperson said that the company not only pursue scommercial success but aims to make a positive contribution to local social and economic development.

Heli Material Handling Oceania will

Job scheduling and dispatch software that delivers on the bottom line •Proof of delivery, time stamped and auditable •Three-way SMS between dispatch, truck & customer •Real-time invoicing •Template driven software - works the way you do •Integrates with existing business tools

6,000+ active users

Over 400,000 jobs per month dispatched

Customers in 10 countries

vworkapp.com

create job opportunities for Sydney and its surrounding areas and actively participate in local social welfare undertakings.

The new warehouse is designed to enhance operational efficiency and provide faster local customer support to Heli Oceania’s growing customer base.

One of the highlights of the event was the unveiling of the G3 Series Compact Rough Terrain Forklift. ■

Toyota Material Handling Australia’s, Neil Beveridge, talks to autonomous solutions showcased at CeMAT 2024 in Melbourne.

Toyota Material Handling Australia (TMHA) has been a prominent player in the forklift and materials handling sectors, known for its innovative approaches and commitment to quality.

Over the past few years, TMHA has further ventured into the realm of autonomous solutions, a move that reflects the broader industry’s shift towards automation.

Neil Beveridge, Product Manager Automation at TMHA, shared insights into this transition, highlighting the reasons behind the company’s new focus and detailing the products that are set to revolutionise the logistics landscape.

TMHA also offers semi-autonomous solutions designed to streamline tasks such as order picking, while enhancing safety and costeffectiveness. As this technology becomes more sophisticated –particularly with the integration of virtual reality – its applications will continue to expand.

“We already lead the market with our manual forklift equipment,” says Neil. “Introducing autonomous solutions is a complementary extension to our existing range. The industry is rapidly moving towards automation, and not embracing it would mean falling behind.”

This strategic decision aligns with the industry’s trend towards integrating automated systems, driven by the need for efficiency, safety, and

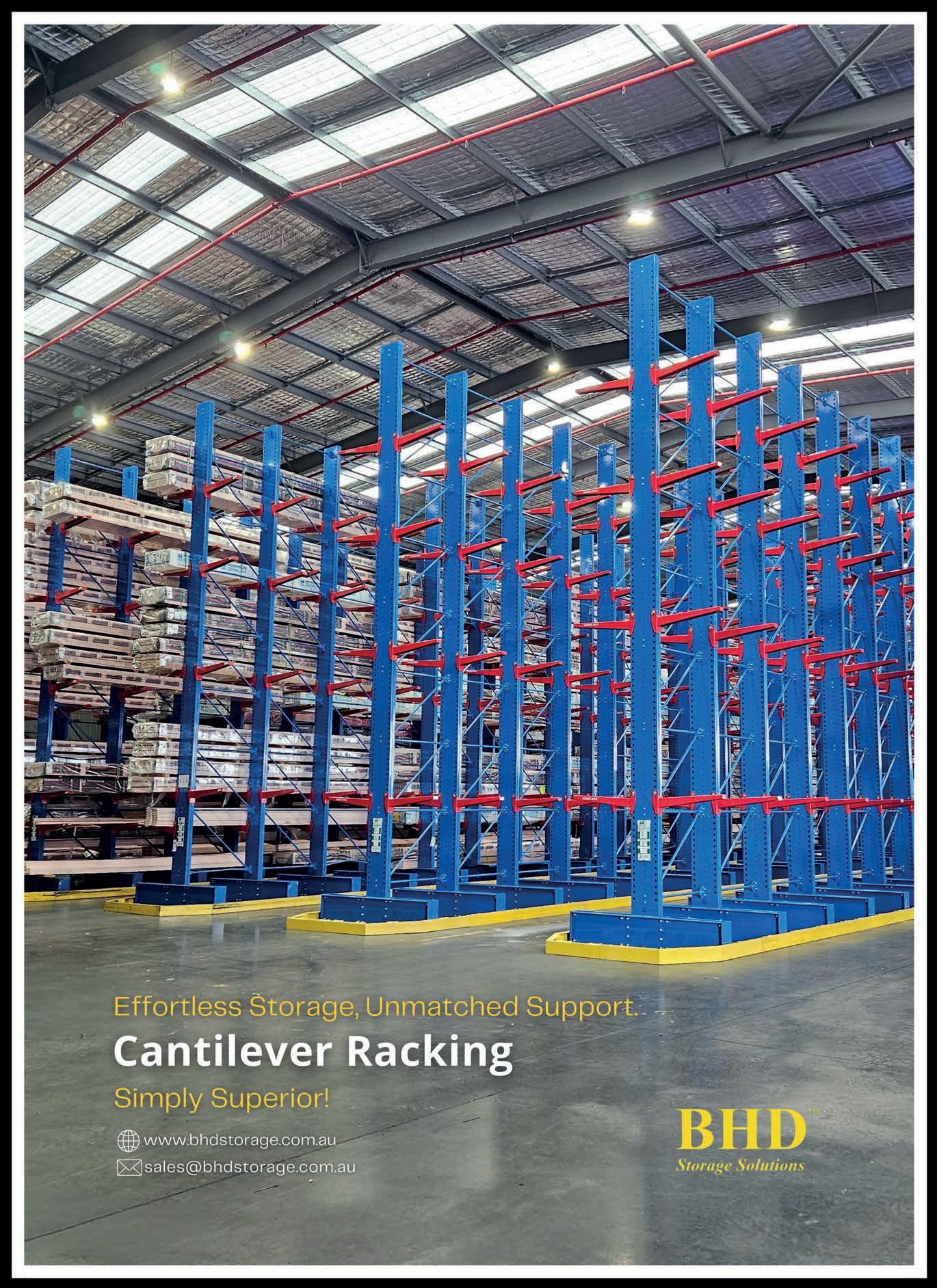

At the forefront of Toyota’s new offerings are two Automated Guided Vehicles. Images:Toyota Material Handling Australia.

“The primary reasons businesses are automating their warehouses are labour security, safety benefits, and cost reduction,” says Neil.

“It’s increasingly challenging to secure reliable labour, and automation helps mitigate this issue while also addressing warehouse safety and the high labour costs in Australia.”

At the forefront of Toyota’s new offerings are two Automated Guided Vehicles (AGVs).

“The SAE160 is an automated stacker designed for ground transport and low-lift operations in production/ warehouse facilities,” says Neil.

“It’s an automated unit that is able to support larger higher reach units, providing a seamless transition from ground-level tasks to more complex high-reach operations.”

The CDI120, on the other hand, is tailored for facilities requiring the shuttling of goods.

“It’s a platform AGV that handles ground transport tasks without the need for forks,” explains Neil.

“Businesses appreciate it because it removes the need for forklifts in the area, enhancing safety and efficiency.

“It still requires platforms for moving goods, but it excels in basic transport tasks while allowing larger vehicles to manage the lifting tasks.”

For businesses considering the shift to automation, the question of return on investment (ROI) is crucial.

Neil outlines that, depending on the operation, a typical ROI timeframe for a three-shift, 24/7 operation is around two years.

“Achieving ROI within two years is considered a good result, especially

with continuous operation. As the number of shifts decreases, the ROI period may extend, but the benefits of automation often justify the investment.”

The move towards automation is not solely driven by cost concerns. Neil highlights labour security as a pivotal factor.

“The ability to secure skilled labour is becoming increasingly challenging, and automation helps bridge this gap,” he explains.

“Additionally, automation improves product quality by reducing the risk of damage and human error, ensuring consistent and reliable operations.”

Toyota’s commitment to sustainability extends beyond the products themselves to the manufacturing processes.

operated trucks, our autonomous Toyota also provides dedicated standard for industrial driverless

trucks,” explains Neil.

This compliance ensures that the vehicles and systems adhere to safety regulations, including speed governance and clearances. Toyota also offers maintenance packages, leveraging its network of technicians across Australia.

“We have technicians in every capital city and several remote hubs, ensuring coverage for our customers nationwide,” adds Neil.

“Our support includes both hardware maintenance and system support, with options for 24/7 assistance.”

Toyota’s participation at shows like CeMAT marks a significant moment, showcasing its commitment to innovation and customer engagement.

“CeMAT is an intralogistics show, and our combination of forklifts and AGVs fits perfectly within this space,” says Neil.

“It’s a great opportunity to connect with existing customers and showcase our offerings to potential new ones.”

The show also provided a platform to demonstrate Toyota’s dual systems – combining AGVs and forklifts –highlighting its integrated approach to intralogistics.

“Being at CeMAT allows us to reinforce our presence in the market and ensure we are at the forefront of the industry’s evolution,” adds Neil.

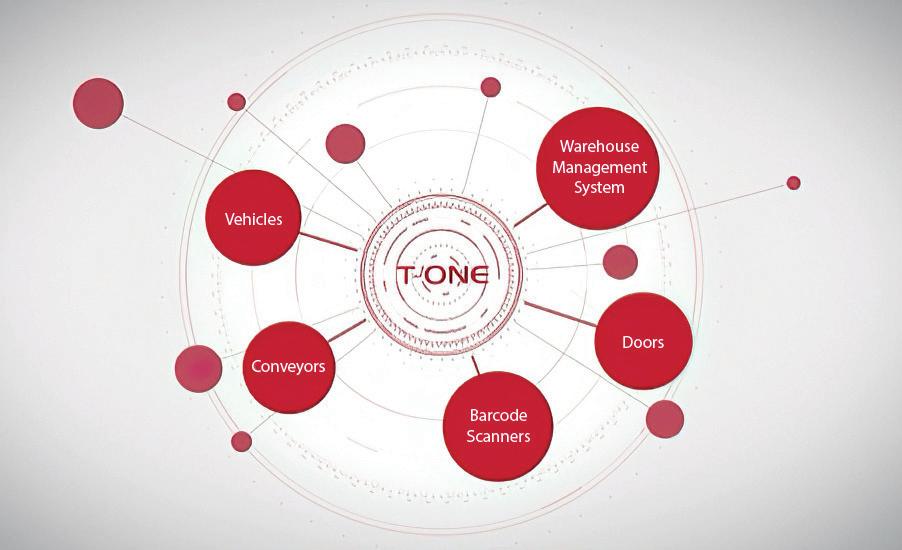

While leading AGVs represent one part of Toyota’s foray into autonomous solutions, these go hand in hand with intelligent automation software such as TMHA’s T-ONE.

It’s in-house software developed and installed as an integration layer communicating with the Toyota Autopilot AGVs and existing infrastructure such as warehouse management systems, goods identification and other material handling equipment.

“T-ONE offers a modern, servicebased architecture, with well-defined APIs (Application Programming Interface) for easy integration to the platform,” says Neil.

“This intelligent software offers

operational robustness and flexibility for easy scaling of your operations and quick commissioning, making it suitable for applications with a significant number of vehicles.”

The solution can be configured for a variety of flows and provides a customisable user interface for the operator supporting manual interaction with the AGV system. T-ONE also provides a set of performance metrics, with graphs presented in the user interface. What does T-ONE stand for?

Optimise your flow and efficiency.

• Optimises how your transport orders are executed and reduces order processing time due to the intelligent dynamic order allocation function.

• A llows easy scalability to expand a system as a business continues to grow.

Navigate intelligently and quickly.

• A lways chooses the most ideal path for the Autopilots by scanning the system and adapting to changes of the planned travel path.

• A llocates orders to the best-suited autopilots, taking the entire operations flow into account. Execute safely and accurately.

• Ensures that all loads are delivered when and where you need them, due to intelligent order allocation.

• Provides a robust order execution to guarantee a steady logistic flow according to the expected throughput.

How T-ONE orchestrates a company’s operation

T-ONE is at the heart of Toyota’s automated solutions: it supervises

and optimises a company’s operation. This intelligent automation software takes care of the order and traffic management of the Toyota AGVs and offers functions such as:

• order initiation;

• destination setting;

• t ransport management;

• metrics and error visualisation;

• use and security management;

• system integration; and

• battery management.

As Toyota continues to innovate in the field of automation, the company remains committed to meeting the evolving needs of the logistics industry.

With a focus on sustainability, efficiency, and safety, Toyota’s autonomous solutions are poised to play a pivotal role in shaping the future of logistics.

For businesses considering automation, Toyota offers a suite of products backed by a support network and a commitment to quality.

Toyota’s foray into autonomous solutions is not just a strategic move, but a response to the changing landscape of the logistics industry.

“Automation is about staying ahead and delivering the best solutions to our customers,” says Neil.

TMHA provides an extensive range of forklifts and warehouse equipment to its Australian customers, including AGVs (driverless forklifts), integrated pallet shuttles, elevated work platforms, scissor lifts, sweepers and scrubbers, and cutting-edge fleet management software.■

Prological’s Managing Director, Peter Jones, explains how matters of automation, people, and data were central to CeMAT 2024.

There were three take homes from CeMAT 2024: automation for small business is now real; importance of data continues to grow; and supply chain is still a people business.

With 28 years in the supply chain industry under my belt, I am excited to see how much more there is to learn. The event only confirmed the complexities amid the ever-broadening array of possibilities, not only emerging, but available today.

This year I believe I saw the largest transition in ‘intra-logistics’ capability, the most uniform communication from the event’s Knowledge Theatre and saw greater possibilities to improve supply chain capability – especially smaller businesses.

Expanding on the three key takeaways at CeMAT 2024, I’d say that:

• Automation is evolving and is becoming more accessible for smaller operations.

• People are still at the centre of supply chain. There’s an evolving awareness that with the emergence of the digital supply chain, compounded by automation, the people-related issues in supply chain have to evolve with these changes.

• Data. It’s got to be clean and accessible, ready to be turned into information in minutes – not weeks.

We have all seen the Tier-1 materials handling companies performing

incredible automated tasks with AutoGuided Vehicles (AGVs), Automated Mobile Robots (AMRs), auto-stores, pallet shuttles, Automated Storage and Retrieval Systems (ASRS), and so on.

Tier-1 companies with these tools have separated themselves from the pack previously, with smaller organisations longing for such capability in smaller, humbler facilities.

This year’s event displayed a new reality in that automation is no longer the domain of large companies, but accessible and value adding for many small companies. The world has changed.

I saw cost accessible automation that will work in 1000 sqm and 1500 sqm warehouses, with store product

at high density from floor to roof in multiple-sized totes, enabling fast and accurate picking and packing.

Also, there are modularised sortation systems that can be installed and up and running in just hours.

In 2023 I received a question from the floor after I had spoken –“what about the small businesses?” What a difference a year makes. In 2024, there is no shortage of smart automation options for smaller operations.

Today, there is a plethora of smaller, entrepreneur-led firms armed with mechatronics degrees, bravery, and the tenacity to deliver automation capability to transform smaller businesses. An expanding business inside a 1500 sqm warehouse now mightn’t need to move into the 3000 sqm warehouse to grow; automation solutions targeted at these businesses might now be the better stepping stone.

Automation for small business in small warehouses is now real, and Prological is excited to see where these improvements lead.

Because automation was such a big theme on the exhibition side of this year’s event, it was only natural that the impact on people would be a major topic from the Knowledge Theatre. I heard many speakers discussing the impact of digitisation and automation in the supply chain on people.

While re-affirming the reality that supply chain is still a people business, there’s no doubt that some of these people, moving forward, will be different to the people of the past.

Transitioning a facility and its team from traditional warehouse practices to a more automated environment will require investment in training and patience.

Some people mightn’t transition well, while others will thrive in the opportunities, finding new possibilities for themselves in the new roles required.

Mechanical and electrical engineers will become part of the supply chain team, software engineers and robot technicians will be added, while the

skillset of those ‘on the floor’ will change.

Several attendants and speakers at CeMAT discussed the importance of the transitional leadership team to prioritise the people in at least equal measure to the operational transition. It’s easy to see the new shiny toys in the warehouse – it’s much harder to see the early signs of stress and concern of those who have enabled the operation to evolve to this new state but are not sure about what their future is in this ‘brave new world.’

I live in Wollongong. Do you know how many ways there are to misspell Wollongong? If your customer data base has more than one way something is represented, that is a problem. We have all seen or heard of instances where a street has been labelled an avenue, or a package has a post code for the right suburb, but in the wrong state. When we get to our product master files, typically it is even worse.

Master data files with these errors make it more difficult to turn data into information, and in too many

Product master and order files must be complete and accurate to both specify and design any automation additions to your warehouse to enable quick and accurate decision making within the business.

Frank Bucolo, Country General Manager from Slimstock, spoke at length about the data rich, but information-poor environments he sees as his firm supports businesses and takes a fresh perspective on inventory management.

The clear message from both was the importance of quality, complete, and accurate data.

Both speakers emphasised the importance of high-quality, accurate data when undertaking changes to warehouse operations and inventory management, and how for those projects to succeed, data must be transformed into empowering information to be understood by decision makers who may not be logisticians.

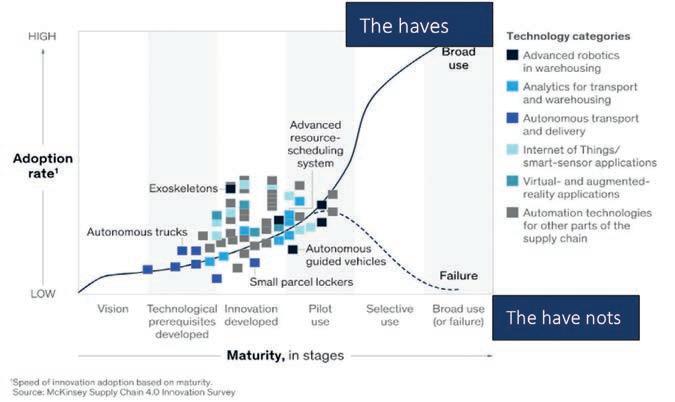

Over the next five to seven years, two categories of supply chain execution will emerge. The table below by McKinsey suggests that we are at a fork in the road to the future.

Over the next five to seven years, two categories of supply chain execution will emerge.

businesses, this creates an impossible situation. This was brought home with great strength by two speakers. Michael Kemeny, Managing Director of Knapp Australia, spoke of the importance of data as it relates to progressing your operational environment, specifically your product master file and order files.

One path leads to success and will be full of businesses that get data, people and automation right. The other group will be diminishing in number and will be known as the ‘have nots’ because they didn’t get this transitional season right.

If you would like to investigate any of the above for your business, please contact Prological Consulting. ■

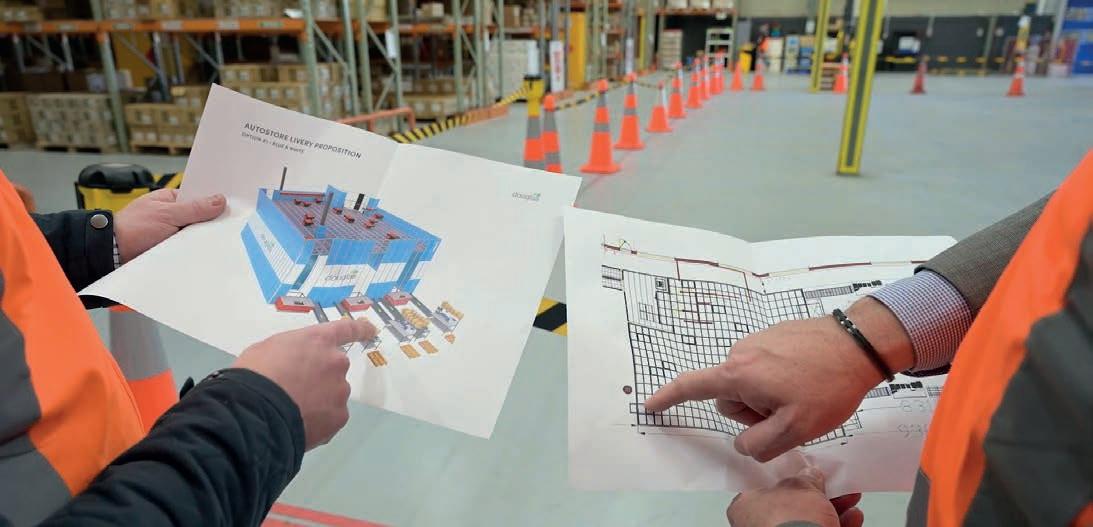

Ben Haughey and Jordan McFall from Automate-X, the industrial automation solutions company founded in Auckland, New Zealand, explain its offerings and projects it’s worked on.

n the midst of the COVID-19 pandemic, a new player emerged in the automation industry –Automate-X, founded in 2020 in New

As businesses faced challenges in their supply chains, the demand for automation solutions grew. Automate-X seized this opportunity to innovate across various sectors.

“We saw a significant boom in automation demand due to labour restrictions and the need for efficient Director of Operations and Co-founder

“Our solutions have been diverse, initially focusing on manufacturing machine vision, and now expanding

From the outset, Automate-X has technological advancements and offer comprehensive support systems. This collaborative approach ensures that we’re not just service providers, but also strategic partners in their growth. We offer turnkey solutions, including project management, engineering, and ongoing support,” says Jordan McFall, Business Development Manager for

“Our clients appreciate that we provide end-to-end services, from conceptualisation to implementation

and beyond. This partnership model has been crucial in our projects, especially as we expand into new markets.”

Automate-X has been active across a range of industries.

“We work with some of the largest companies in the dairy and manufacturing sectors in New Zealand,” says Ben.

“Our projects have included innovative solutions like the four-way shuttle system for a food distribution company and bespoke machine vision applications for quality control.”

““We’re proud to introduce the first mobile goods-to-person system to a client in New Zealand,” explains Ben. “This project, on the back of our first project with Geek+ in Melbourne,

Australia, marks a milestone as Automate-X expands its footprint beyond New Zealand.”

As Automate-X enters the Australian market, the focus is clear.

“In Australia, we’re concentrating on logistics automation, particularly within warehouse environments,” says Jordan. “We aim to handle everything from bulk storage to intricate logistical challenges.”

“Our team is heavily involved in every stage of the project,” explains Ben.

“Our engineers are trained in the specific technologies we use, such as Geek+. This hands-on approach makes us an extension of our client’s team, ensuring seamless integration and optimal performance.”

Automate-X’s values are partnership, nimbleness, and excellence. Images: Automate-X.

Automate-X is committed to providing robust post-implementation support.

“We offer tailored maintenance and service level agreements to meet our clients’ specific needs,” says Jordan.

“Our service team is available 24/7, providing preventive and corrective maintenance. This comprehensive support structure is crucial in ensuring our customers realise the full benefits of their automation investment.

“Our team is diverse and skilled, covering everything from machine vision and machine safety to system engineering,” adds Ben. “This versatility allows us to be nimble and responsive, adapting to any challenge that arises.

The team at Automate-X is a blend of experienced professionals from various backgrounds, united by a shared vision of robotics.

“Our team members are not just experts in their fields; they are problem solvers and doers,” says Ben. “We look for individuals who are flexible, nimble, and ready to learn new skills. This mindset is what sets us apart and enables us to deliver exceptional solutions.

“Our values – partnership, nimbleness, and excellence – are at the heart of everything we do. We aim to do things well, ensuring that our clients receive the best possible service and support.”

As Automate-X looks to the future, its plans are ambitious.

“We’re growing our team in Melbourne and plan to establish a presence in Sydney later this year,” says Ben.

“This expansion is part of our strategy to offer local support and strengthen our position in the Australian market.”

“We’re also working on several key projects, including warehouse

solutions to our clients.”

Automate-X aims to be more than just another player in the automation industry; it seeks to disrupt the market.

“We want to make a big impact and provide real value to our clients in Australia and beyond,” says Jordan.

“Our focus on long-term

“It’s not just about selling a product; it’s about educating and guiding our clients through the entire process,” adds Ben.

“We believe that automation is a journey, and we’re here to help our clients every step of the way.”

As Automate-X continues to expand and innovate, it wants to be known for its partnership-driven approach and commitment to excellence. ■

At its best when high volumes of inventory need to move in and out of storage in the right order – and at the right time.

> high performance on a small footprint

> built-in sorting and sequencing capabilities

> the fastest and most predictable lead times

> accurate item and order delivery

> less dependency on increasingly scarce labour

> adaptability to deal with new items, peaks or events

> and easy scalability to handle long-term growth

Learn more on vanderlande.com or contact our Australian experts directly at sales.au@vanderlande.com or call 1300 375 028.

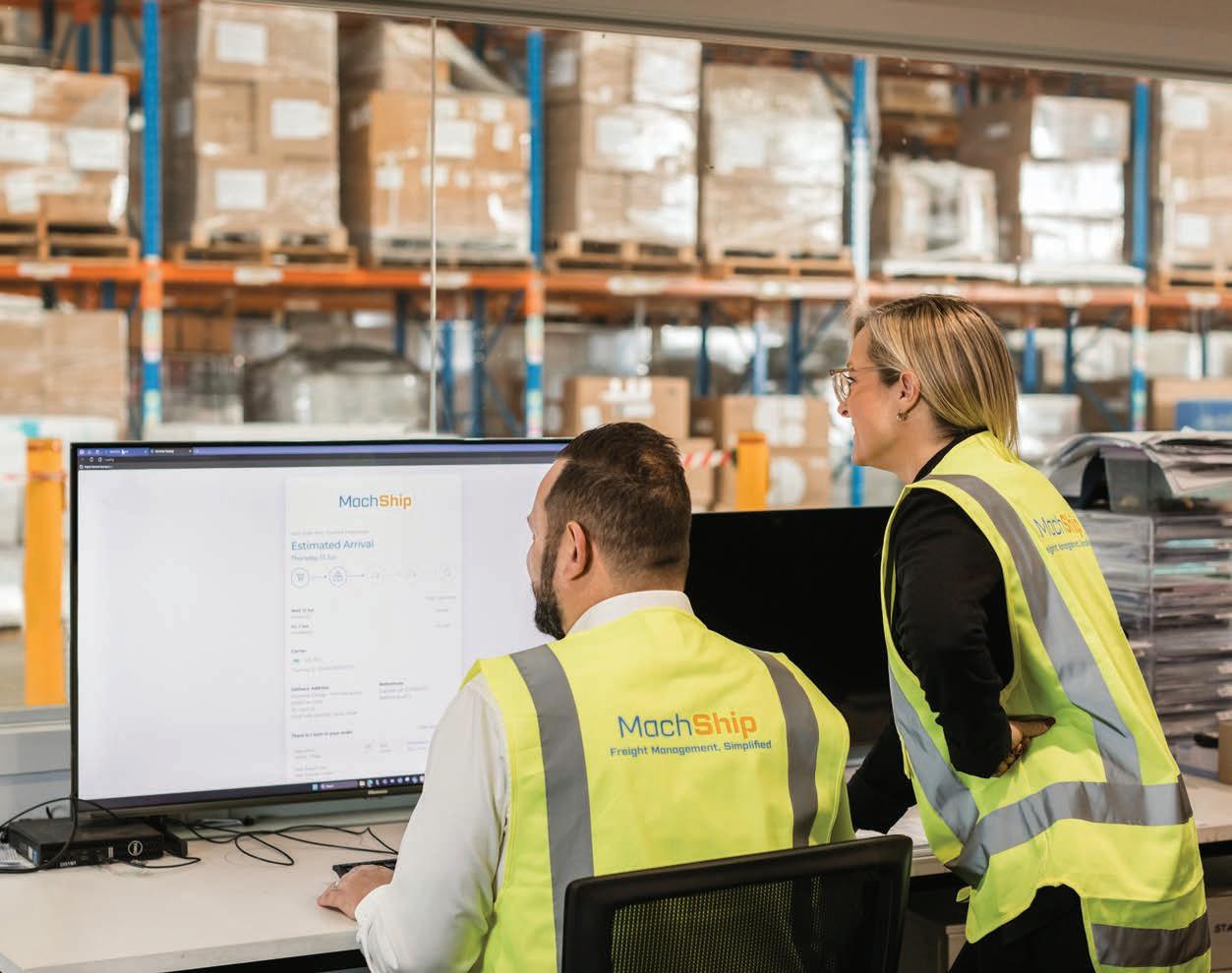

MachShip’s Sam Rowse gives an insight to the company’s latest

MachShip is known for its robust logistics platform, seamlessly integrating with more than 250 Australian carriers and processing more than a million consignments monthly.

The current system automates numerous administrative tasks, providing consolidated tracking visibility across multiple carriers.

“The existing version of MachShip is well-placed to address the trend towards automation,” says Sam Rowse, Chief Revenue Officer, MachShip.

“We already deliver strongly from an automation perspective, handling routine and mundane tasks efficiently.”

The forthcoming MachShip V3 promises to elevate this foundation, introducing a sophisticated workflow engine that enhances automation capabilities.

This new feature will enable users to customise system workflows, aligning logistics operations with specific and complex business rules.

“One of the cornerstone features of MachShip V3 is our sophisticated workflow engine,” says Sam.

“It allows users to automate routine tasks even further, customising workflows based on data such as the origin warehouse, the destination address, or customer preferences.”

This engine will support intricate

logistics scenarios, such as determining the carrier mix based on the warehouse location or providing different notifications based on delivery types.

“It’s a classic ‘if this, then that’ scenario, where the workflow can be configured to handle various contingencies, provided the data is available.”

A feature of MachShip V3 is the ability to manage multi-leg and multi-carrier consignments. This feature will allow users to plan and execute shipments involving multiple stages and carriers, akin to booking multi-city flights.

“We’re introducing a feature for multi-leg consignments, similar to multi-city travel bookings,” says Sam. “This will offer more choices and visibility around freight, especially for regional or specialised areas.”

This innovation is not commonly found in competing systems, making it a good selling point for MachShip.

The increased choice and visibility are expected to be beneficial for businesses needing to manage complex logistics scenarios, including those with specialised freight profiles.

The MachShip V3 platform is designed with the current market trends in mind, where value and certainty are paramount.

“Customers today are more discretionary than ever,” says Sam.

“It’s not just about the cheapest or fastest option anymore; it’s about providing certainty around delivery times.”

The platform’s ability to offer detailed carrier analysis and reporting capabilities helps businesses understand the costbenefit balance, ensuring they can meet customer expectations reliably.

This focus on certainty is crucial, as poor shipping experiences can impact customer satisfaction.

“An overwhelming number of one-star reviews are due to shipping issues, not product quality,” adds Sam. “Meeting shipping expectations is crucial to avoid negative reviews and ensure customer satisfaction.”

MachShip V3 will also introduce an enhanced reporting engine, moving beyond the current Excelbased reports to offer more visually engaging and meaningful presentations of data.

This upgrade will support retailers and other businesses in making data-driven decisions.

“V3 will bring our data to bear in a far more meaningful, useful way,”

This flexibility ensures that businesses can access and analyse their data in the most suitable format for their needs, whether for internal assessment or regulatory reporting.

The visibility provided by MachShip V3 will help users track key performance indicators, monitor supply chain efficiency, and identify areas for improvement.

As the trend towards omni-channel retail continues to grow, MachShip’s integration capabilities become increasingly vital.

The platform’s ability to integrate seamlessly with various retail systems, including shopping carts, marketplaces, warehouse management systems, and ERPs, ensures a unified and efficient operation across all channels.

“We fit into existing processes, whether through file-based integrations, APIs, or even simple email-based setups for smaller operations,” says Sam.

This flexibility allows businesses to operate efficiently from their preferred systems, ensuring a smooth logistics operation from order placement to delivery.

MachShip’s integration capabilities provide a seamless customer experience, essential for retailers looking to excel in an omni-channel environment.

In response to growing concerns about sustainability, MachShip V3 will introduce a carbon calculator.

“The carbon calculator will enable

make more sustainable choices, such as optimising delivery routes and selecting eco-friendly transport options.”

The introduction of the carbon calculator aligns with the increasing demand for sustainability in logistics, offering users the tools to make actionable steps towards reducing their environmental impact.

Beyond the immediate enhancements in V3, MachShip aims to evolve into a comprehensive logistics-focused ERP platform.

“We currently focus on freight management, but we’re looking to expand into areas like inventory management and order management,” explains Sam.

“We’re also exploring tools for international shipping, customs clearance, and more.”

This ambitious roadmap reflects MachShip’s commitment to continuously improving and expanding its offerings, ensuring that the platform remains at the forefront of logistics technology.

MachShip V3 represents an advancement in logistics technology, building on an already strong foundation to offer enhanced automation, sophisticated reporting, and integration capabilities.

With features like the sophisticated workflow engine, multi-leg consignments, and a carbon calculator, MachShip V3 is poised to set new standards in the industry.

As businesses navigate the complexities of modern logistics, MachShip V3 offers the tools and flexibility needed to stay ahead of the curve, delivering value and certainty in a rapidly changing market. ■

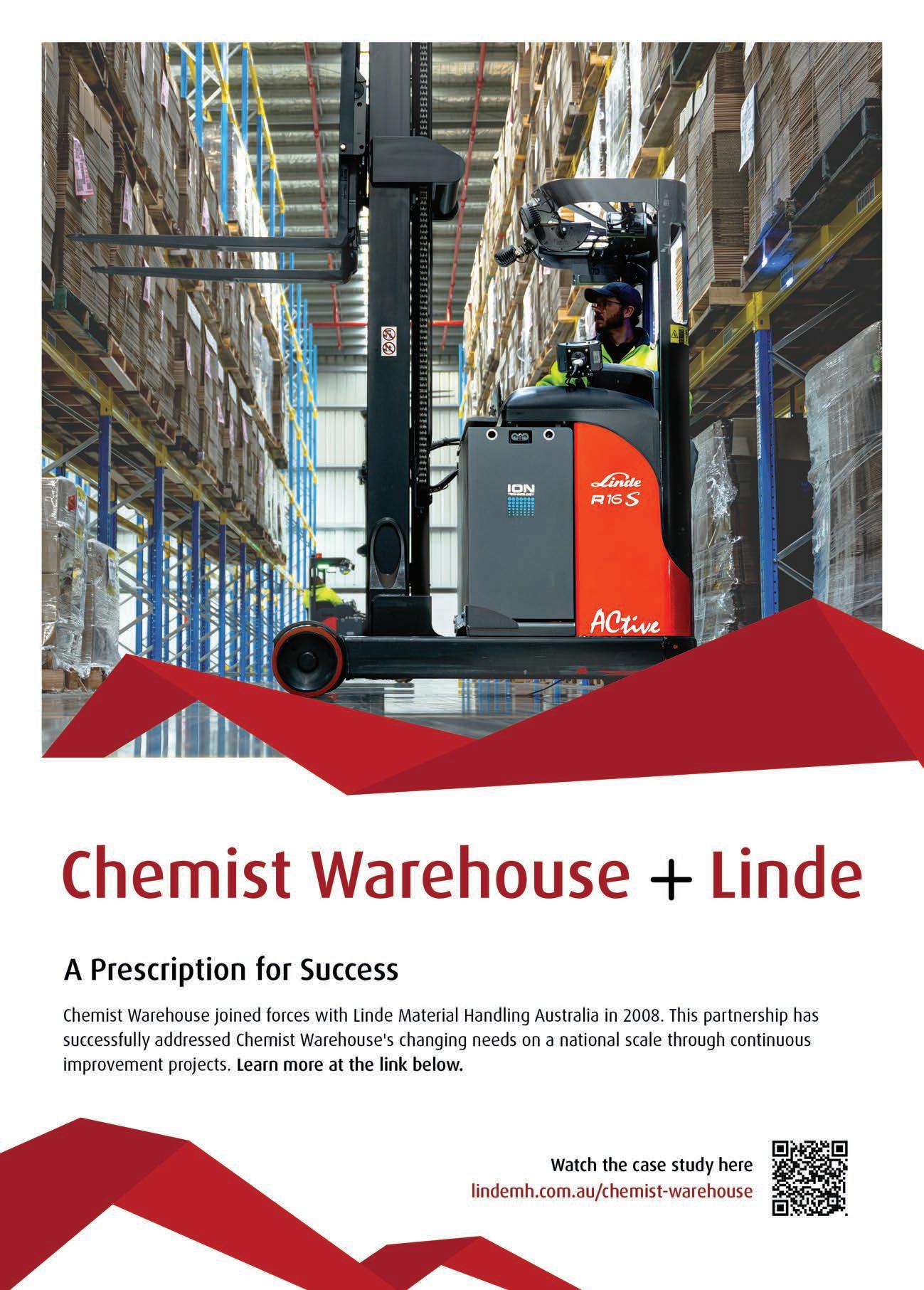

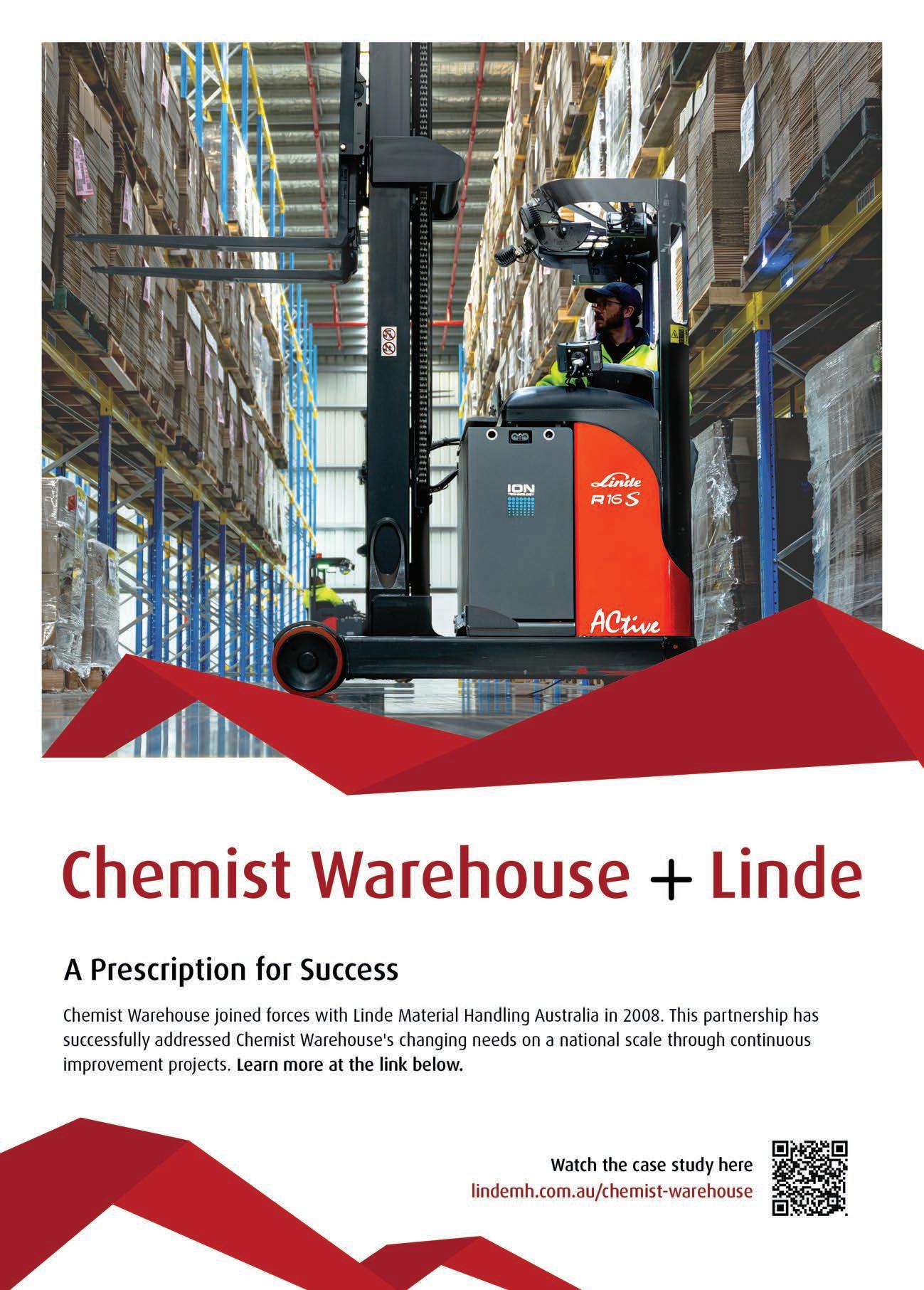

Chemist Warehouse’s David Brennan and Jude Thomas talk about why the pharmaceutical wholesaler is using Linde Material Handling Australia’s lithium-ION solution.

Chemist Warehouse has partnered with Linde Material Handling Australia since 2008, and over the years, both companies have worked together on multiple projects that have continuously improved Chemist Warehouse’s operations.

David Brennan, GM of Supply Chain at Chemist Warehouse stated, “Chemist Warehouse’s journey with Linde started as a short-term rental

only. Over the years, that expanded based on the excellent customer service we received, the reliability of their trucks, the technology advancements they could provide, and their ability to quickly and efficiently service our needs which in turn allowed us to service our customers.”

The partnership has adapted to suit the changing needs of the business. The most recent upgrades include the introduction of FleetFOCUS, Linde’s

Telematics system, and the rollout of a Lithium-ION battery technology solution across their national fleet.

UPGRADING FROM LEAD-ACID TO LITHIUMION BATTERIES

Chemist Warehouse made the decision to upgrade its entire fleet from lead-acid batteries to LithiumION battery technology based on the recommendation of trusted advisers at

Linde who knew the intimate details of Chemist Warehouse’s application needs. This upgrade resulted in:

• P roviding more uptime: As Li-ION batteries have a longer run time than lead-acid and can be fast-charged at any time; and

• L ess maintenance: In that it removed the requirement of weekly watering of the lead-acid batteries, as well as needing to expose the batteries during charging.

A huge benefit that Chemist Warehouse has experienced from this upgraded solution is increased utilisation of their fleet. This was a key driver behind the decision to change, particularly the fact that operators could fast-charge the trucks via opportunity charging — where operators can put the truck on charge at any time for any amount of time.

Brennan stated, “On any given week, Chemist Warehouse will be delivering anywhere within the vicinity of 70,000 boxes to our stores across Australia. What we’ve been able to do has been incredible. Linde’s system and their fleet work when we need them to work, and we’ve been able to push out incredible volumes as a result.”

Another recommendation from Linde to Chemist Warehouse was the introduction of their FleetFOCUS telematics software. Once FleetFOCUS had been rolled out across their national fleet, Chemist Warehouse was able to immediately identify operational issues that needed to be addressed.

Brennan stated, “What we noticed immediately upon implementation is that everybody has their favourite truck. Some trucks were being utilised for 30-40 hours a week and others 0-10 hours per week. FleetFOCUS gave us the visibility to better manage the trucks to ensure they were all being utilised equally.”

Another benefit from the introduction of FleetFOCUS was that it removed the need for a paper-based pre-start checklist. With the removal of all paperwork, all faults, reports and accidents were immediately inputted into the system and were easily managed across the country.

Jude Thomas, National Safety & Facilities Coordinator at Chemist

Warehouse commented, “It’s been very important to have FleetFOCUS in place because of our large fleet and the number of operators we have.” When it comes to the visibility FleetFOCUS provides, as well as the usefulness of the reporting function, Jude commented, “FleetFOCUS has improved our reporting immensely given the fact we can generate any report in real-time. It gives our managers a better understanding of where their fleet is, which trucks are operational, and which are out of action and why. It empowers our team to make more informed decisions on how to better utilise the staff and set operations up as best as possible at the beginning of each shift.

“Safety-wise, FleetFOCUS has massively improved our ability to manage our fleet.” Brennan added, “As incidents have happened, we’ve been able to alert users and key decision-makers in real-time.”

FleetFOCUS empowers businesses to address all accidents as they happen and organise servicing as quickly as possible so trucks can get back into operation as fast as possible. ■

Falcon Autotech is a global intralogistics automation solutions company. With over 10 years of experience, Falcon has worked with some of the most innovative brands in E-Commerce, CEP, Fashion, Food/FMCG, Auto and Pharmaceutical Industries.

CONTACT US:

Email: salesenquiry@falconautoonline.com Website: www.falconautotech.com

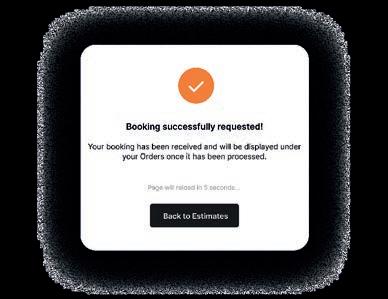

Körber’s Darren O’Connor and Jamie Sterling speak to MHD about managing warehouse operations with cloud-based solutions.

Cloud-based solutions, particularly SaaS, have revolutionised the way businesses manage their operations. Images: Körber.

The shift to cloud-based solutions represents a leap forward in the supply chain and logistics industry. The cloud offers businesses scalability, flexibility, and efficiency, while alleviating the burdens of technical administration and infrastructure management.

As more companies turn to Software as a Service (SaaS) for their logistics needs, it’s worth exploring how these innovations are shaping the industry.

“The SaaS offering takes away the technical administration of the solution,” says Darren O’Connor, Director of Solution Delivery, Körber. “You no longer need to be worried about the technical resources to maintain it.”

The ability to adjust resources based on demand without substantial upfront investments in hardware is a game-changer for many businesses.

This relief from technical upkeep allows companies to focus on their core competencies instead of the complexities of IT infrastructure.

“With SaaS, we can scale that out to suit all the users on all the systems that we look after,” adds Darren.

“This scalability is a significant benefit that you wouldn’t typically have if you managed everything on-premise.”

One of the features of cloud solutions is their integration capabilities.

“None of our warehouse management solutions operate as islands,” says Jamie Sterling, Head of APAC Sales Software, Körber.

“They are all integrated into something, whether that’s a source of orders, an output, or integration with a transport provider.”

This seamless integration

ensures that the systems can work harmoniously within the broader IT landscape, enhancing efficiency and coordination while being designed to be adaptable.

“We go to market with an adaptability capability,” adds Jamie.

“You can take our solution, create your own or adapt existing processes, feature enrichment.”

This means businesses aren’t limited by the out-of-the-box functionalities of the software; they can customise and bolster features to meet their specific needs.

Another aspect of cloud software is the empowerment they provide to businesses.

“We enable our customers to hold their own destiny, enrich their own solution, and manage their own changes,” says Darren.

This autonomy allows businesses

to innovate and adapt without being tied down by the original software provider’s roadmap.

Körber also offers training through its academy, ensuring that clients are equipped to make these changes independently. This approach not only enhances customer satisfaction but also reduces reliance on external support for routine adjustments.

“We encourage customers to take ownership because we are a software company that wants to sell solutions, not just services,” says Jamie.

In addition to operational benefits, cloud-based solutions also offer environmental advantages.

“The cloud-based model does lower your environmental footprint,” says Jamie.

“Cooling large data centres is more efficient than cooling smaller, scattered facilities.”

This efficiency translates to lower energy consumption and reduced costs, which is particularly beneficial for businesses looking to improve their sustainability profile.

“With scale comes economics and reduction in costs, including those associated with air conditioning and electricity,” adds Jamie.

These savings can be significant, especially for companies with large warehouse operations.

A well-managed disaster recovery plan is crucial for any business, and cloud solutions offer a reliable option.

“For customers who have done on-prem implementations without a disaster recovery plan, moving to the cloud ensures they have a genuine disaster recovery solution,” explains Darren. Regular testing and verification of these plans provide peace of mind that, in the event of a disaster, the business can quickly recover. The return on investment (ROI) from these solutions is also noteworthy.

“Our SaaS solution can accommodate businesses from 15 to 500 users,” says Jamie.

“As they grow, they acquire more subscription licences, enabling scalability without significant additional investments. Flexible scaling ensures that businesses can grow at their own pace without being constrained by their IT infrastructure.”

The versatility of these solutions is evident in their widespread adoption across various industries. This diversity showcases the adaptability of the systems to different operational needs, whether it’s managing cold storage for perishable goods or handling complex logistics for spare parts.

“Our client base ranges from large retail brands to mining and healthcare sectors,” says Darren.

“If you’re operating a distribution centre and moving goods, our solutions can be adapted to manage those activities,” adds Jamie.

The trend towards increased automation in warehouse management is expected to continue.

“The entry point for automation is now lower, and the physical modifications needed are being

reduced,” says Jamie.

This shift means that more businesses can access automation technologies, enhancing productivity and efficiency.

Furthermore, voice technology is improving in warehouse management systems, which makes it easier for businesses to integrate voice commands into their operations, improving workflow, and reducing errors.

“Voice is now available in multiple ways and runs on standard industry devices rather than specialised ones,” adds Jamie.

As the logistics industry continues to evolve, the shift towards cloudbased solutions represents an opportunity for businesses to enhance their operations.

The benefits are clear: scalability, integration, adaptability, environmental efficiency, and robust disaster recovery.

For businesses considering this transition, the message is clear: embrace the future of warehouse management and reap the rewards of a well-managed, scalable, and environmentally conscious operation.

“The breadth of our offerings ensures that businesses can find a solution tailored to their needs, whether they’re a small enterprise or a large corporation,” says Darren. ■

MHD speaks to Anthony Zhao from Jungheinrich Australia about the advantages of lithium-ion batteries, their lifecycle, opportunity charging, and better efficiencies, benefits, safety, stability, sustainability, and cost effectiveness.

As the material handling industry continues to evolve, advancements in battery technology have become a crucial factor in enhancing efficiency and sustainability.

Jungheinrich’s lithium-ion batteries represent a major leap forward compared to traditional lead-acid batteries, offering numerous benefits for businesses looking to optimise their operations.

Anthony Zhao, National Sales Technical Support – Energy Solutions at Jungheinrich Australia, shares insights into the advantages of Jungheinrich’s lithium-ion batteries and the innovations driving its customers’ success.

Lead acid technology is more than 100 years old and hasn’t advanced much in the past decade, while lithiumion technology has seen a greater investment that leads to faster development and wider applications.

“Lithium-ion batteries have experienced rapid development and diverse applications, from electric vehicles to power tools,” says Anthony.

The familiarity with lithiumion batteries in everyday devices has made the technology more accessible and desirable for industrial applications.

They possess greater efficiency during both charging and discharging compared to lead-acid batteries. With the recuperation brake energy, they can achieve energy savings of 20 per cent or more.1

Lithium-ion batteries save time by

charging faster. They can recharge up to 50 per cent within 30 minutes of opportunity charging.2

There’s also no need for battery exchanges for multi-shift applications. Furthermore, battery bays aren’t required for charging additional shift batteries and neither is operator maintenance for cleaning the batteries.

One of the most notable advantages of lithium-ion batteries is their extended lifecycle.

“A standard lead-acid battery typically offers around 1200 life cycles,” adds Anthony. “In comparison, our lithium-ion batteries can reach up to 3000 cycles or more, translating to significant cost savings.”3

This longevity not only reduces the frequency of replacements but also minimises maintenance needs.

No flammable gas emissions are emitted during charging, meaning they’re safer to use. They’re sustainable and eco-friendly because

they’re 90 per cent recyclable and release 20 per cent less CO2 overall.4

Jungheinrich can provide a full energy solution package to its customers thanks to its ability to combine efficient lithium-ion batteries with chargers and forklifts.

Lithium-ion batteries offer superior efficiency compared to their lead-acid counterparts.

“The efficiency of lithium-ion batteries ranges from 93 per cent to 97 per cent, which means more of the energy you pay for is actually used,” explains Anthony.

This high efficiency, coupled with the ability to opportunity charge, significantly boosts productivity.

“With opportunity charging, you can quickly recharge the batteries during short breaks, keeping the equipment ready to go and reducing downtime,” adds Anthony.

Lithium Iron Phosphate (LFP)

Jungheinrich offers a wide lithium-ion battery range.

safety rating. The solution not only has cost saving benefits, but also ensures higher Electric Materials Handling Equipment (eMHE) availability, which maximises utilisation to increase productivity.

Safety is another critical aspect where lithium-ion batteries excel. Unlike lead-acid batteries, which can emit flammable gases during charging, lithium-ion batteries are sealed and free from such risks.

Traditional lead-acid batteries require regular maintenance, including checking water levels and cleaning terminals to prevent corrosion.

In contrast, lithium-ion batteries are virtually maintenance-free.

“The fully enclosed design of our lithium-ion batteries eliminates the need for regular upkeep,” explains Anthony.

This feature not only reduces labour costs but also enhances the overall reliability of the equipment.

Environmental sustainability is a growing concern across industries, and the material handling sector is no exception.

“Our lithium-ion batteries are 90 per cent recyclable and require less water to produce than lead-acid batteries,” adds Anthony.

Additionally, the energy efficiency of lithium-ion technology contributes to lower carbon emissions, aligning

Jungheinrich’s approach to integrating lithium-ion technology into its forklift models focuses on customisation and adaptability.

“We work closely with our customers to tailor energy solutions that meet their specific operational needs,” says Anthony.

This includes assessing the appropriate battery capacity and charging infrastructure, ensuring that the transition to lithium-ion technology is seamless and costeffective.

“We introduced the first production-ready lithium-ion forklift truck over a decade ago, and we’ve continued to refine our technology since then,” adds Anthony.

The latest iteration of Jungheinrich’s BMS offers enhanced data analytics capabilities, providing valuable insights into battery performance and usage patterns.

The new charger has up to 97 per cent efficiency and optional capability for Load Management.

Lithium-ion serviceability is assessed at the truck’s end of life for potential reuse in a new truck and/or the cells can be repurposed for use in energy storage systems.

Anthony sees a bright future for lithium-ion technology in the material handling industry.

Data logging is accessible for

Expertise in providing customdesigned packages best suited to individual customer applications including Total Cost of Ownership (TCO) assessment demonstrating cost and CO2 reduction forecast.

Jungheinrich’s new POWERLiNE range with integrated lithiumion batteries reduces physical dimensions by up to 30 cm, with an ergonomic operator compartment and CO2 neutral footprint up to the time of delivery.

“As battery technologies evolve, we’re seeing greater focus on sustainability and efficiency,” explains Anthony.

“Our new chargers, with up to 97 per cent efficiency, are a testament to our commitment to reducing energy consumption and carbon footprints.

“By embracing lithium-ion technology, we’re not just improving operational efficiency; we’re also making a positive impact on the environment,” adds Anthony.

“Our focus on customisation and innovation ensures that our customers can fully realise the benefits of this technology in their unique settings.”

In an industry where efficiency and sustainability are paramount, Jungheinrich’s lithium-ion batteries stand out as a forward-thinking solution that meets the needs of modern material handling operations.■

1.https://www.jungheinrich.co.uk/your-solutions/lithium-ion-technology/lithium-ion-products/li-ion-battery-life-cycle-1291296#:~:text=Lithium%2Dion%20 batteries%20reducethe%20carbon,trucks%20with%20lead%2Dacid%20batteries.

2.https://www.jungheinrich.com.au/products/batteries-charging-technology/forklift-batteries/lithium-ion-batteries-534690

3.Lead acid 1200 cycles in general industry excepted standard. Li-ion cycles: https://www.jungheinrich.com.au/products/batteries-charging-technology/forkliftbatteries/lithium-ion-batteries-534690

4.https://www.jungheinrich.co.uk/your-solutions/lithium-ion-technology/lithium-ion-products/li-ion-battery-life-cycle-1291296#:~:text=Lithium%2Dion%20 batteries%20reducethe%20carbon,trucks%20with%20lead%2Dacid%20batteries.

TGA licenced, custom-built 10,000m2 facility dedicated to Life Sciences and Healthcare Logistics. Strategically located in the Melbourne Airport Business Park with prime access to the airport, seaport, rail terminals and key road-freight arterials.

Key features include:

• Controlled ambient, cold chain and ultra-low frozen product storage

• Cold chain storage +2°C - +8° capacity for 1173 Pallets

• Controlled ambient storage (+15°C to +25°C) capacity for 7,796 pallets

• Schedule drug storage

• Value added services

• Validated active and passive cold chain solutions

• Tier 1 WMS system backed by quality assured processes

• ISO 27001 (Cyber Security accreditation)

• 5 star green star rating compliant*

*Certification is in process

Sandfield’s Alan Dowsett, who is head of its specialist supply chain division, Origin, tells MHD what software solutions are available for businesses managing complex logistics-related projects.

Logistics Service Providers (LSP) across the supply chain industry have historically struggled to incorporate technology solutions that help them meet their current and longrange objectives.

Origin, Sandfield’s supply chain division, not only caters to the core requirements that are universal across the logistics sector, but also thrives when supply chain operations invariably get “creative.”

With more than 30 years of experience delivering supply chain software, Origin uses its suite of products and development expertise to help its customers differentiate themselves from the competition.

Origin partners with organisations across the entire market but has often found it aligns best with businesses whose supply chain needs are both unique and complex. This includes specialised freight types used in the transport of containerised goods, break bulk, bulk goods, and general freight.

“These businesses are not just looking for software; they’re looking for a unique way of working that the software can showcase,” says Alan Dowsett, Head of Origin, Sandfield.

Some of Origin’s customers include Qube, Tasman Logistics, PrixCar, Mainfreight, and HW Richardson to name a few.

Many LSPs (like those involved in mining contracts or operations at ports) need specialised logistics solutions to secure contracts and provide services to their customers in the way they demand.

In some cases, the physical requirements dictate that entirely new types of equipment need to be built to properly service the contracts. Lateral thinking is the key to helping these companies succeed.

“Typically, customers come to us because they are trying to do something complicated, something different from their competitors,” says Alan.

“They’re responding to unique customer requirements or new contract demands.”

Generally speaking, these businesses are utilising processes that involve a level of specificity (both in terms of equipment and infrastructure) that is unable to be adequately served by off-the-shelf software systems. As an example, one Origin customer manages the transport of industrial steel coils and beams using rail.

In recent years, there has been a shift in how logistics companies view their technology stack.

Many of these companies have not historically viewed technology as a way to differentiate themselves; rather, they saw software technology as a tool to meet basic operational needs.

“In the logistics sector, if you’re not approaching things with a unique mindset, you’re going to struggle to win new contracts,” says Alan.

Previously, the industry relied on large ERP systems that attempted to cover all aspects of the business without really standing out in any particular area. Over time, the market has evolved and now there’s a growing

preference for the flexible and scalable capabilities that SaaS (Software as a Service) options provide.

The rise of SaaS solutions has further complicated the landscape. While these solutions often excel in their niche areas, they can be challenging to modify and integrate.

“Many large logistics companies still look for solutions they can alter to fit their business needs, but SaaS solutions don’t always play nicely with that requirement,” says Alan.

This situation creates a dilemma: companies want the flexibility to adapt software to their unique processes, but they also want the efficiency and scalability that SaaS offers.

Origin’s journey from a custom software developer to offering a suite of productised solutions reflects its growth and expertise in the logistics sector.

“We built a platform to support our custom solutions, which over time, has evolved into productised offerings in transport management systems, container freight station solutions, and customer portals,” says Alan.

This evolution allows Origin to offer robust solutions that not only supply the core capabilities needed to cover the bulk of industry-standard operations, but also provide the flexibility to pivot to additional capabilities, as needed.

Due to the varied and specific requirements of most logistics operators, companies will always lean towards software solutions that not

only integrate seamlessly across various platforms, but also offer the flexibility to adapt to unique business needs.

Through various projects Origin has been able to work with supply chain partners to create solutions that did not exist. This focus on customisation, integration, and direct client collaboration positions Origin as a leader in providing innovative logistics solutions.

“For us, it’s about ensuring our clients have the tools they need to differentiate themselves in a competitive market,” explains Alan.

LSPs’ customer expectations around the digital experience have also changed over time.

“Digital experience used to just mean you could email the customer,” says Alan.

Now, customers expect real-time, accurate information, accessible through portals and integrated directly into their systems.

They also want to receive timely, accurate data in a format they can work with. Without this functionality, it’s nearly impossible to productively interact with the data so that basic tasks can be completed, such as updating order statuses or disputing charges.

This shift towards customer visibility and self-service is a critical factor in the logistics sector’s digital transformation.

Origin’s collaborative approach extends beyond software development to implementation and support.

Rather than outsource these functions, Origin’s dedicated teams work directly with clients throughout the process.

“Our developers, who are also experts in the software and supply chain, help implement and support it,” says Alan.

This direct involvement ensures that clients receive tailored solutions and timely support, a key distinction in the market.

One of the biggest technology challenges in logistics today is managing and integrating a variety of systems across the supply chain that may have been built by multiple providers and were never specifically designed to work together.

This often results in applications that don’t communicate effectively with each other, leading to siloed data and labour inefficiencies.

“If you’re moving goods around your supply chain and those goods touch each of your different systems, which one do you look at to find out where the goods are right now?” asks Alan.

Origin addresses this challenge by utilising Sandfield’s integration solution, Crossfire, to connect both the internal and partner systems creating a single source of truth across the supply chain.

“We collect and organise all the necessary data together to provide visibility and orchestration across these solutions,” adds Alan.

Crossfire has been designed specifically for the high-performance requirements of supply chains, processing more than 1.4 billion messages annually.

Alan emphasises two key aspects: internal integration within a company’s systems and external integration with

customers’ systems.

“It’s not just about logging into a portal to see where something is; it’s about having that data integrated directly into the customers’ systems,” says Alan.

The single source of truth provided by Origin is crucial for companies that need to coordinate activities across multiple systems and provide real-time visibility to their customers.

“Crossfire connects these different systems together and then Origin makes sure they can work together in a meaningful way,” says Alan.

One example of Origin’s unique approach is its work with a prominent LSP in the vehicle transport sector, a niche market with few available solutions.

Origin provided a middle ground between a custom option and a productised solution, helping its client meet the conditions unique to its business without having to build a solution from scratch.

Another example is Origin’s technology managing the complexities associated with the loading, unloading, and tracking of specialised bulk container transport used to move ore from mines to destination ports. Due to the complex nature of the operation, Origin’s client was looking for a partner who could examine the problem creatively.

In the end, Origin was able to accommodate the nuanced processes of this large logistics provider and allowed it to streamline its operations and improve performance.

What sets Origin apart from other logistics software providers is its ability to efficiently adapt its product suite to meet specific business needs.

Origin’s core range of technology products have a long history of streamlining operational processes across the supply chain. Origin works closely with its customers to adapt its software to fit its customers’ unique requirements.

“We never say no to a challenge,” says Alan. ■

SICK at CeMAT 2024: INNOVATE. AUTOMATE. ELE VATE.

Experience our latest Ident Gate System for seamless, automated goods identification at the loading dock, and our advanced DWS track and trace system for large pallets with 4-sided image-based label reading, dynamic weighing, and dimensioning. Tailor your logistics with our modular solutions, and leverage our digital tools to visualise and analyse all collected data. Connect with our team to transform your warehousing operations now. https://s.sick.com/CeMAT-Australia-2024-DWS

GS1 Australia’s Dharshi Hasthanayake reveals how the company’s traceability standards enhance the end-user experience of rail freight services to promote its role as a more sustainable method of transporting goods.

With the Federal Government’s legislated commitment to achieve net zero by 2050, several industries, including transport and logistics, are beginning to focus on reducing emissions

Commitment to rail freight is one of the ways the industry has looked to diversify, as it can reduce carbon emissions, air pollution, congestion and road crashes.

According to an Australasian

Railway Association (ARA) submission into NSW Governments Freight Policy Reform, rail freight accounted for just 4 per cent of total transport emissions, despite handling 56 per cent of Australia’s total freight. An ARA commissioned report in 2020 from Deloitte Access Economics even outlined that rail freight produces 16 times less carbon pollution than road freight.

But more can be done. The

transport and logistics industries are now beginning to explore ways to make rail freight even more sustainable.

Manager of Sustainability and Circularity at GS1 Australia, Dharshi Hasthanayake, aid the sector is now actively, for example, investigating ways to reduce the reliance on diesel for rail freight operations by considering alternative fuel types.

“This includes moving away

from reliance on diesel for rail freight operations using alternative fuel types including batteries, electrification, hydrogen and ammonia,” she said.

Hasthanayake said that the ARA are core to driving this shift, and are engaged in multiple initiatives to promote rail freight. The ARA has collaborated with other key industry players on the Future of Freight campaign, and the Rail Freight Productivity Review: Establishing an Efficient Freight Transport Network.

The ARA’s most recent key report on supporting the sector to net zero, the Rollingstock Decarbonisation Critical Path, identified a potential road map transitioning rail to low and zero emissions, which includes opportunities for further decarbonising the rail freight sector.

One company that is embracing the potential of rail freight to lower emissions is GS1 Australia, a leading provider of standards for over 25 industry sectors.

GS1 Australia is a not-for-profit organisation focused on providing supply chain solutions for its over 22,000 member companies.

With road freight expected to increase significantly over the next decade, Hasthanayake said the company is playing its part in enhancing the experience of rail freight services to attract more end-users.

“GS1 Standards can assist rail freight in improving the end user experience, providing the confidence and reliability that customers seek from their supply chain services,” she said.

“Growth in this area will reduce the reliance on road transport and support achieving our national net zero targets.”

GS1’s global supply chains standards streamlines experience of rail freight services by implementing a standardised barcode system that tracks goods and enhances operation visibility.

Hasthanayake said a flagship for GS1 Australia is ‘Scan4Transport,’ a global standard for encoding transport data. This initiative captures key information from a freight transport label and

GS1’s global supply chains standards streamlines experience of rail freight services by implementing a standardised barcode system. Image: GS1 Australia.

accurately processes and integrates its data into the relevant systems.

“The standard supports companies across the transport process including first mile, sortation and last mile activities and enables them to keep pace with the growing needs of their customers,” said Hasthanayake.

‘Scan4Transport’ then sends vital details regarding the shipment, such as its recipient and destination, to be managed through the supply chain network.

“Scan4Transport standards enable interoperability across networks and supply chains which will allow Customers agility to utilise rail freight services and maintain traceability that is standardised within the Road freight networks,” said Hasthanayake.

Hasthanayake mentioned that Global GS1 standard barcodes – a part of this standardised system – offer several advantages that enable businesses to move away from manual paper-based systems. She said the use of these barcodes allows for the storage of a large amount of digitally embedded data that couldn’t otherwise be handled by traditional systems.

“2D barcodes are particularly useful for storing information relevant to the transport process – for example ship to address, dangerous goods information, weight – as it enables the information to be available in both on-line and off-line environments by simply scanning the barcode,” said Hasthanayake.

Hasthanayake continued by saying that GS1 barcodes, such as the GS1-128,

offer quick and highly accurate data capture.

“Barcodes such as the GS1-128 are used to encode data like the serial shipping container code. They allow for quick and accurate data capture, which is essential for managing logistics on rail, ensuring that goods are efficiently loaded, transported, and unloaded,” she said.

Hasthanayake also detailed GS1s adoption of Application Identifiers (AI) that are now a part of the company’s standardised barcoding system.

“The new Application Identifiers released are part of this standard. They unambiguously indicate the meaning of the data element following it. Enabling the data to be encoded in a globally standard manner that all stakeholders can understand,” she said.

To underscore the effectiveness of the company’s standards and barcode services in the logistics industry, Hasthanayake recalled a recent case study involving an Australian steel manufacturer.

“An iconic Australian steel manufacturer implemented barcode scanning for the picking and loading function of reinforced steel bundles. With the implementation of SSCC barcode labelling, warehouse staff were able to load trucks 2.5 times faster,” she said.

By utilising the standards developed for transport labels, Hasthanayake said that customers will begin to experience smoother processes.

Specifically, she noted that GS1 Australia customers often see improvements in first and last mile processes, sortation, visibility of task requirements, efficiency and interoperability.

Not to mention, GS1 standards will also enable businesses to comply with environmental regulations.

“With the additional of the benefits of Project i-Trace, the GS1 Standards will enable businesses to comply with environmental regulations, providing the framework for reporting and verification,” said Hasthanayake.

Going forward, GS1 Australia will continue to support rail freight by enhancing its end-user experience, in turn encouraging more in the industry to adopt this sustainable mode of transporting goods. ■

The ceremonial ribbon has been cut and operations are now in full swing at Toll’s largest specialised healthcare warehouse facility in Victoria, which is now open for business.

A$20 million TGA-licensed healthcare facility at Melbourne’s Tullamarine Airport Business Park has been custom designed to support the requirements of its growing customer base. It will support the warehousing and distribution of medical supplies, including pharmaceuticals, vaccines, antivenoms, medical devices, and overthe-counter medicines.

Constructed by CMW Design & Construct (VIC) the facility’s development also has a focus on sustainability, targeting a 5-Star Green Star building certification. This building is set to be the first within the Melbourne Airport Business Park to achieve such an accreditation.

Mel-Air, CMW and Toll recently held a ribbon-cutting ceremony with several dignitaries to mark the official opening of the site and the precinct in which it resides.