Dematic automates South West

Healthcare's logistics hub

MAKING IT GREEN

Prological explores sustainability at MEGATRANS Körber on planning for the peak season

MEETING DEMANDS

Dematic automates South West

Healthcare's logistics hub

MAKING IT GREEN

Prological explores sustainability at MEGATRANS Körber on planning for the peak season

MEETING DEMANDS

The new 2024 Gartner® Magic Quadrant™ for Warehouse Management Systems is out and for the 6th year in a row, Körber has been named a Leader.

Scan the QR code to get your free copy of the report and discover why Körber stands out among the competition. koerber-supplychain-software.com

Scan for your free copy of the report

MHD Supply Chain Solutions is published by Prime Creative Media

379 Docklands Drive, Docklands VIC 3008

Telephone: (+61) 03 9690 8766

Website: www.primecreative.com.au

CEO: John Murphy

Chief Operating Officer: Christine Clancy

Managing Editor: Mike Wheeler

Editor: Phillip Hazell

Assistant Editor: Joseph Misuraca

Journalist: Mannat Chawla

Business Development Manager: William Jenkin

Design Production Manager: Michelle Weston

Art Director: Blake Storey

Graphic Designers: Danielle Harris, Jacqueline Buckmaster

Client Success Manager: Janine Clements

FOR ADVERTISING OPTIONS

Contact: William Jenkin william.jenkin@primecreative.com.au

SUBSCRIBE

Australian Subscription Rates (inc GST) 1yr (11 issues) for $99.00 2yrs (22 issues) for $179.00

To subscribe and to view other overseas rates visit: www.mhdsupplychain.com.au or Email: subscriptions@primecreative.com.au

ACKNOWLEDGEMENT

MHD Supply Chain Solutions magazine is recognised by the Australian Supply Chain Institute, the Chartered Institute of Logistics and Transport Australia, the Supply Chain and Logistics Association of Australia and the Singapore Logistics and Supply Chain Management Society.

ARTICLES

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

COPYRIGHT

MHD magazine is owned by Prime Creative Media. All material in MHD is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in MHD are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

As I step into the role of editor, I’ve had the privilege of immersing myself in the dynamic and ever-evolving supply chain sector.

It’s been a fascinating journey, learning first-hand about the innovative developments that are shaping the future of this industry.

In this edition of MHD Supply Chain Solutions, we take a closer look at how digitisation is transforming the supply chain industry.

As we explore the theme of “digitising operations with AI, data, and cybersecurity,” we can see how automation, smart data usage, and security measures are essential for the future of global logistics and trade.

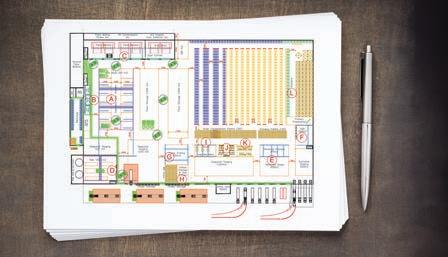

The cover story features Dematic’s automation of Southwest Healthcare’s Warrnambool facility, where the implementation of the AutoStore GTP system is a game-changer.

By enhancing capacity, improving accuracy, and driving operational efficiency, this innovation reflects the broader industry shift towards technology-driven solutions.

With the increasing reliance on digital systems, cybersecurity is becoming more than just a precaution; it’s a necessity.

In recent months, we’ve seen other major developments highlighting the critical importance of resilient supply chains.

The MoU between Australia, the United Kingdom, and the United States is a step forward.

The formation of the AustraliaUnited Kingdom-United States Supply Chain Resilience Cooperation Group will enhance our ability to manage disruptions to critical supply chains, starting with telecommunications.

Closer to home, Victoria’s top exporters were celebrated at the 45th Governor of Victoria Export Awards, demonstrating the power of local businesses in the global marketplace.

These awards are a reminder of the critical role exports play in Australia’s economy, contributing billions and supporting hundreds of thousands of jobs.

Initiatives like these, alongside cutting-edge infrastructure such as Sydney’s Western International Airport and Avalon Airport’s new freight facility, are key to unlocking greater trade potential, especially as the demand for faster, more efficient e-commerce logistics continues to surge.

The development of the 24-hour Cargo Precinct at Western Sydney Airport, which will increase Sydney’s air cargo capacity by 33 per cent, and Avalon Airport’s new $8 million freight processing facility, are clear indicators of Australia’s commitment to futureproofing supply chains.

These projects not only drive economic growth but also highlight the critical role supply chains play in connecting Australian businesses with global markets, from advanced technology exporters to small businesses going global.

As we move forward, the adoption of AI, data analytics, and advanced cybersecurity measures will underpin the next era of supply chain management. These tools are no longer just innovations but necessities for ensuring efficiency, safety, and resilience in our increasingly interconnected world.

As supply chain managers, business owners, and logistics professionals, these advancements offer practical tools to optimise operations, protect data, and stay competitive. It’s an exciting time for the industry, and I’m thrilled to share how these innovations are shaping the future of supply chain management with you.

Phillip Hazell Editor, MHD Supply Chain Solutions

Known for market leading Toyota forklifts and warehouse equipment, Toyota Material Handling is also proud to o er an unparalleled range of products suitable for Australian businesses. With a huge range of forklifts, elevated work platforms, scrubbers and sweepers, Taylor-Dunn electric vehicles, plus Huski skid steers, scissor lifts, and mini excavators available, chances are we’ve got the equipment that will suit. So, if you’re looking to buy hard working, fully backed equipment for your business, Toyota Material Handling has all you need to add value to your operation. That’s the Toyota Advantage.

12 Dematic automates Southwest Healthcare’s Victorian facility

17 Logical Outlook on achieving sustainability with MEGATRANS panel discussion

20 Körber explains the benefits of leveraging technology for peak season challenges

32 EnerSys minimising costs by utilising data

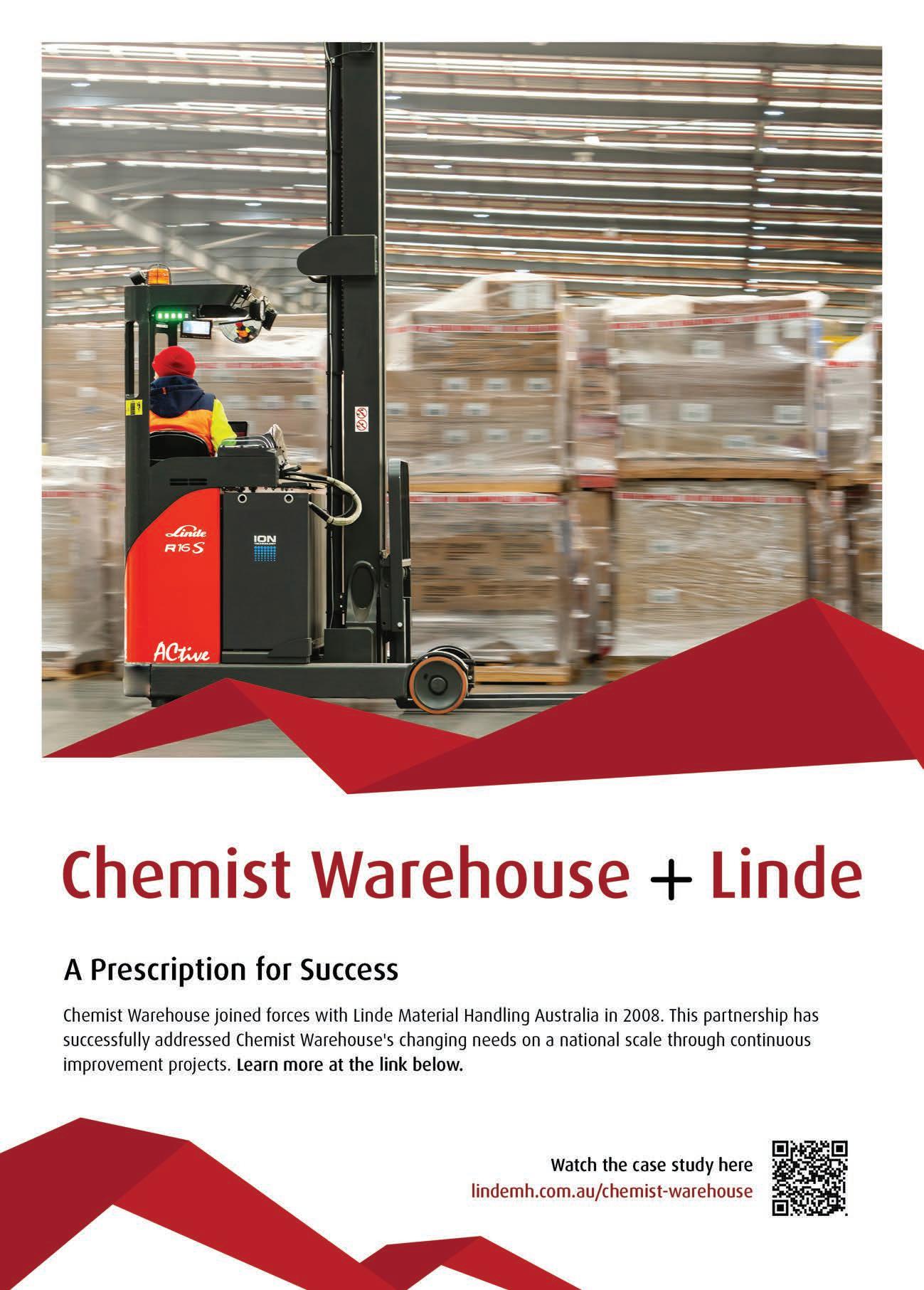

23 Linde introduces FleetFOCUS for monitoring materials handling equipment

26 Toyota supplying Remedy Drinks with forklift solutions

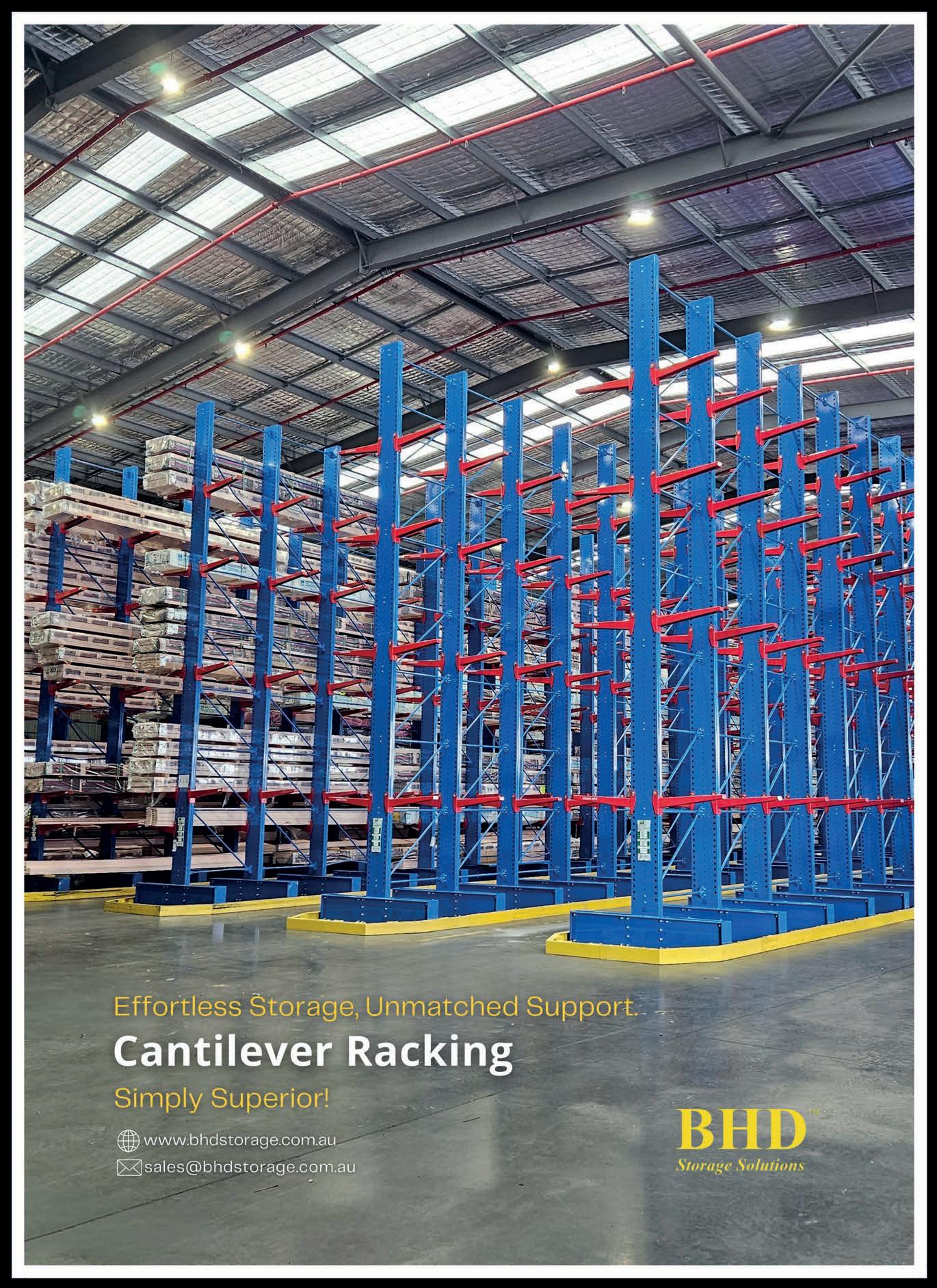

29 BHD opens its first Queensland-based DC

35 Airstack Intralogistics and CIMC Pteris Global introduce ALUS

39 Falcon Autotech provides advanced automated solutions for e-commerce demand

42 CEVA Logistics expands its footprint by venturing into new sectors

44 Terre Property works with Flinders Port Holdings on South Australian project

46 Kuehne + Nagel collaborate with LEGO Group on Victorian fulfilment centre

EVENTS, AND REGULARS 03 Ed letter

Industry News

MEGATRANS

ASCI courses

SCLAA News 56 People on the Move 58 Product Showcase

DHL Express has announced price increases that will take effect on January 1, 2025. The average increase in will be approximately 4.9 per cent on its published tariff.

“We are committed to delivering stable and dependable services globally despite the ongoing impact of geopolitical dynamics and supply chain disruptions on the logistics landscape,” said Phil Corcoran, Managing Director, DHL Express Australia and Papua New Guinea.

Prices are adjusted on an annual basis by DHL Express, taking into consideration inflation and currency dynamics as well as administrative costs related to regulatory and security measures.

National and international authorities regularly update these measures in the more than 220 countries and territories that DHL Express serves. Depending on local conditions, price adjustments will vary from country to country. ■

The Australian Government will open applications to Round 1 of the Quad Clean Energy Supply Chain Diversification Program in November 2024.

Grants will fund research and development projects and feasibility studies to develop more diverse solar photovoltaic, hydrogen electrolyser

and battery supply chains. Projects must be delivered as joint projects between Australian and Indo-Pacific organisations.

The Australian Government has committed A$50 million to this program. Up to A$25 million will be available under this round, with grants ranging from A$100,000 to A$2.5 million.

The program was announced by the Quad – Australia, India, Japan and the United States – at the 2023 Leaders’ Summit. It supports the implementation of the Quad Principles on Clean Energy Supply Chains – a foundation for engagement in clean energy supply chains in the IndoPacific. ■

Justin Carnaby Head of Logistics, AS Colour

When AS Colour started out, the trend was for tight tees and baggy pants. But while clothing fashion trends come and go, the trend that doesn’t change is that customers want their orders delivered on time and accurately.

Dematic’s Multishuttle Goods-to-Person (GTP) fulfilment system enables AS Colour to process orders with higher productivity, faster and with increased accuracy, down to the sequence of items in the package.

As a result, AS Colour has seen a big increase in sales as customers see how fast and accurately their orders reach them.

Learn more at dematic.com/as-colour

Melbourne Airport moved 205 million tonnes of freight in 2022, valued at $22 billion. Image: anek.soowannaphoom@ shutterstock.com.

Coles has officially opened its first Customer Fulfilment Centre (CFC) in Victoria, bringing together world-class technology and automation to enhance the shopping experience for Coles Online customers in greater Melbourne.

Located just over 20 kilometres west of Melbourne’s CBD, the Truganina CFC was opened on 20 September by the Victorian Acting Premier Tim Pallas MP, Coles Group Chairman James Graham and Coles Group CEO Leah Weckert. It’s the first of two CFCs to launch this year as part of a $400 million partnership with a global leader in online grocery transformation, Ocado.

Once fully operational, the modern facility will deliver an enhanced shopping experience for online customers – with better availability, fewer substitutions, an increased range of products and improvements in the shelf-life of staples like mince and milk.

“The transition from a local, storebased fulfilment model to a central, world-class facility will enable us to better serve the greater Melbourne region, home to more than five million people,” says Leah Weckert, Chief Executive Officer, Coles.

The Victorian CFC’s delivery catchment will span the growing Melbourne region from Ballan in the west across to Bunyip in the east, and from Beveridge in the north down to the Mornington Peninsula.

The Truganina site has a footprint of more than 87,000 square metres and can hold three million units of stock while having the ability to process more than 10,000 customer orders per day when running at full capacity.

The site features a centralised hub, known as ‘The Hive’, where a fleet of more than 700 bots will fulfil a customer order containing 50 items in just five minutes, while an artificial intelligence ‘air traffic’ control system will oversee the bots as they move around giant 3D grids, transporting containers of grocery items to be packed and delivered by Coles team members.

The CFC will employ more than 1,000 team members, including drivers and fulfilment roles that will use hightech packing equipment, and there will be a fleet of more than 200 home delivery vans specially designed with dual compartments to ensure fresher products while reducing emissions and

a side door to make it easier and safer for delivery drivers to unload.

“The opening of this CFC is the result of a five-year partnership with Ocado, whose world-class experience is helping Coles to innovate and meet the changing needs of our customers,” says Coles Group Chairman James Graham.

The Truganina CFC features of the build include a two-megawatt solar installation, sensor lighting, a water recycling system, and 100% recycling of cardboard.

The official opening of Truganina will be followed next month by a second CFC site in Wetherill Park, New South Wales.

The Truganina CFC is proudly named Brungilo Curran, meaning Stringybark Gum Tree. The site of the Truganina CFC — Brungilo Curran — is home to the Bunurong People.

Coles recognises the importance of developing a relationship with the people of Bunurong Country, where Coles has established operations. The name and associated artwork at the Truganina CFC were developed through consultation with the local Bunurong community and local artist Kobi Sainty. ■

Online shoppers and businesses in the Greater Geelong area and Melbourne’s west can expect quicker deliveries to their doorsteps, with a new dedicated freight processing facility coming to Avalon Airport – backed by the Allan Labor Government.

Minister for Jobs and Industry

Natalie Hutchins announced a new $8 million facility will boost freight processing and handling at Avalon Airport, with packages set to be processed at a much faster rate.

In the financial year ending June 2023, Avalon Airport handled over 10,000 tonnes of cargo from 52 aircraft. Once operational, the new 24/7 freight facility will be able to process over 100,000 tonnes of cargo each year including both domestic and international freight.

The facility will be equipped with advanced scanning technology, making it one of the first airports in Australia to comply with the new Border Force security screening standards.

The new facility will halve the number of trucks that are currently transporting freight between Avalon Airport and Melbourne Airport with more packages and parcels going out directly from Avalon.

On track to open in 2025, the new facility will create six new direct jobs and hundreds of flow-on jobs in cargo handling, warehousing and distribution.

“This new facility at Avalon Airport will create jobs, attract new businesses, get trucks off the road and expand trade and commerce opportunities for the whole region,” says Natalie Hutchins, Minister for Jobs and Industry.

The new freight processing centre is part of the Greater Avalon Employment Precinct and will bolster its role as an economic hub for the surrounding areas. The Avalon Airport Industrial Precinct is already home to distribution centres for large businesses such as Australia Post, Cotton On and Petstock.

The freight and logistics industry keeps our state moving and employs more than 260,000 Victorians.

“The establishment of this stateof-the-art freight processing facility will strengthen Melbourne Avalon Airport’s role as a critical logistics hub and the creation of a multi-modal hub for Victoria. This investment ensures we can meet the growing demands of e-commerce and trade, driving efficiency and creating new jobs in the region,” says Ari Suss, CEO Melbourne Avalon Airport. ■

In a major boost for Australia’s critical supply chains, construction of an integrated 24-hour Cargo Precinct is taking flight at Sydney’s new international airport, with both Qantas Group and Menzies Aviation signing up to operate at the premier precinct.

The new hub at Western Sydney International (Nancy-Bird Walton) Airport (WSI) will increase Sydney’s air cargo capacity by around 33 per cent upon opening and provide dedicated access via the upgraded Northern Road and proximity to growing freight and logistics centres at Kemps Creek and the Aerotropolis.

“The airport continued to create high-value job opportunities for Western Sydney locals, with the Cargo Precinct expected to support up to 2,000 jobs during construction and more than 19,000 direct and indirect jobs across the precinct and connected supply chains, upon opening, each year,” says Simon Hickey, WSI CEO.

“We’re pleased to welcome two top-tier operators, Qantas Freight and Menzies, to Sydney’s new, integrated Cargo Precinct that will enable direct connectivity between freighters, the terminal and road transport.

Qantas Group is our first freight

airline to sign up to our 24-hour Cargo Precinct, which will provide unparalleled opportunities for farmers, manufacturers and other exporters to grow their businesses.”

The new hub will also be capable of facilitating Qantas’ transformed freighter fleet of new and upgraded Airbus A321 and A330 aircraft.

“We’re already responding to growing market demands, including significant spikes in e-commerce purchases initially prompted by changing spending habits during the COVID-19 pandemic, by increasing the airport’s opening air cargo capacity,” Simon said.

“We’ve secured external financing of $805.4 million to develop the infrastructure for a stand-alone futureproof Cargo Precinct and our Business Precinct to meet business and customer needs now and for decades to come.

This additional funding will support the development of roadways, taxiways and buildings to maximise the value of the airport over the long-term. In turn, this will deliver more socioeconomic benefits like jobs for the people of Western Sydney and beyond, and a greater financial return for all Australian taxpayers.”

World-leading airport services partner Menzies Aviation, which currently handles more than two million tonnes of cargo globally each year, was another fantastic addition to WSI’s Cargo Precinct.

“In a strong signal of the precinct’s critical cargo capacity and future growth opportunities, Menzies has signed a long-term lease with WSI that will see the business operate a facility over the next two decades, specialising in pharmaceutical and cool chain products handling as well as e-commerce and heavy cargo services,” Simon added.

The construction of the precinct –which will include up to 75,000 square metres of warehousing and be capable of servicing eight wide-body aircraft at any one time – began earlier this year and remains on track for cargo operations to commence in 2026.

While WSI’s construction partner is responsible for delivering a range of aeronautical and precinct infrastructure works, the gradual fit-out of the warehouse facilities will be carried out by precinct partners to ensure the layout and design is fitfor-purpose and meets their individual customer’s needs. ■

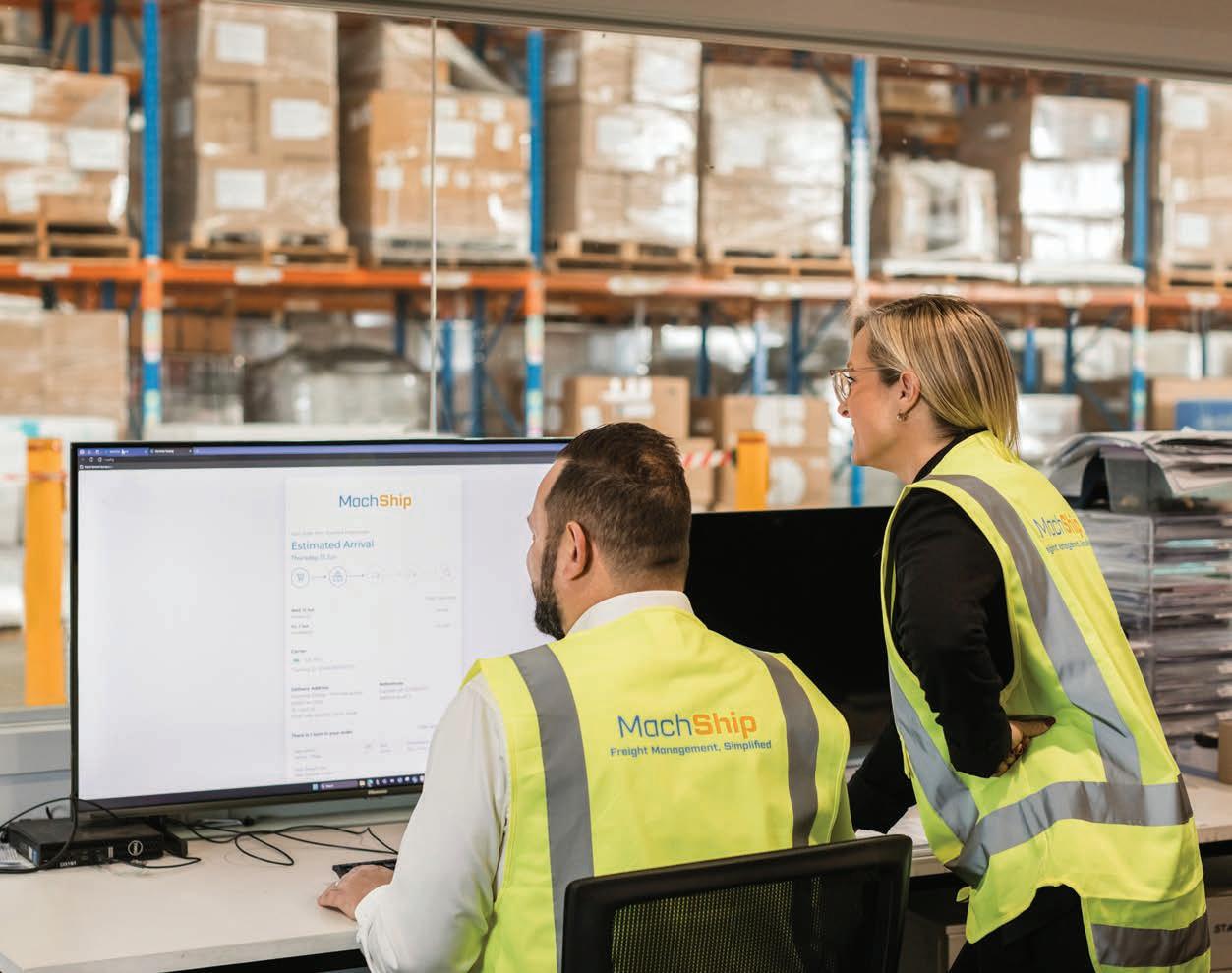

South West Healthcare, based in Warrnambool, Victoria, is a key provider of healthcare services to communities across Southwest Victoria. As a healthcare hub, the organisation operates several campuses, including the Warrnambool Base Hospital, as well as smaller facilities in Camperdown, Lismore, Hamilton, and Portland. Serving this area requires a sophisticated logistics network capable of ensuring timely delivery of essential medical supplies, linen, food, and equipment to 13 hospitals in the region.

“We provide more than 150 medical, nursing, mental health, allied health and community health services to the 110,000 people who live across the Southwest of Victoria and in Warrnambool, one of the fastestgrowing regional cities in Victoria,” says Michael Farley, Construction Project Manager at South West Healthcare. “We are also the region’s largest employer, with 2158 people working for South West Healthcare across various locations.”

The increasing population in the region, coupled with ageing infrastructure at the Warrnambool Base Hospital, created an urgent need for a modernised logistics system that could handle the demands of today, while being flexible enough to accommodate future growth. South West Healthcare recognised that its Regional Logistics Distribution Centre (RLDC) in Warrnambool required an upgrade to address these challenges.

Faced with growing demand, the need for more storage capacity, and the constraints of outdated facilities, the entity embarked on a project to build a state-of-the-art RLDC. The organisation turned to Dematic for a solution that would not only meet the region’s immediate supply chain needs but would also future-proof operations for years to come.

The new RLDC allowed for South West Health’s laundry and supply and

logistics services to move from its original location at the Warrnambool Base hospital campus to make way for the Victorian Government funded Warrnambool Base Hospital redevelopment project. This project freed up space for vital health services within a new multi-storey clinical services building at the existing hospital site.

At the core of the challenge for South West Healthcare was a lack of space. The distribution centre’s existing facilities were limited in size.

According to Michael, the RLDC was becoming increasingly stretched as the healthcare needs of the region continued to grow.

“Warrnambool and the surrounding region are growing rapidly,” says Michael. “Our logistics facility, which once met our needs, was simply no longer large enough to handle the increased demand. We needed to build a larger warehouse and adopt a more modern approach to logistics to keep up with the region’s growth.”

Previously, the logistics team had to place frequent orders for highusage items, which not only created inefficiencies in procurement but

also increased the risk of stock shortages. The warehouse operated with traditional shelving and manual picking systems, which were not equipped to handle the high volume of orders and stock rotations necessary to support 13 hospitals across the region.

“Our old facility couldn’t store more than a week’s worth of stock for many high-usage items,” says Shane Grundy, Warehouse Logistics Manager. “This meant we had to reorder frequently and handle the same goods multiple times, increasing the workload for our staff and the chance of errors.”

Compounding these space and operational challenges was the need for the RLDC to serve as a critical part of the redevelopment plan for the Warrnambool Base Hospital. It has to act as a logistics hub, as well as support the base hospital and other regional facilities while new clinical service buildings, including emergency departments and operating theatres, were being constructed.

To address these challenges, South West Healthcare sought a solution that could increase storage capacity, improve order accuracy, and reduce the time spent handling stock. After an evaluation process, Dematic’s AutoStore goods-toperson (GTP) system emerged as the choice for the RLDC’s modernisation efforts.

“Once we understood that AutoStore was the right solution for our needs, Dematic’s presentation really stood out,” says Michael. “Their ability to service regional Victoria and their commitment to a five-year maintenance contract, gave us confidence that they were the right partner for this project.”

The Dematic solution requires up to 80 per cent less space than a traditional manual racking layout, which needs wide aisles for forklifts and personnel. AutoStore totesstack vertically, eliminating the need for clear aisles.

The AutoStore solution is a highdensity storage system that maximises the use of vertical space, allowing more goods to be stored in a smaller footprint. It utilises robots that move through a storage grid to retrieve totes and deliver them to ergonomic pick stations.

Items required to fulfil orders arrive from the AutoStore storage system to the GTP workstations when they are needed. Operators then build orders at the ergonomically designed, high-rate workstations efficiently and safely.

This automation eliminates the need for manual stock handling and reduces the risk of errors.

“One of the key benefits of the AutoStore system is its ability to store more items in a much smaller space,” explains Terry Jamieson, Business Development Manager at Dematic. “For South West Healthcare, this was critical. The laundry services at the RLDC needed to expand, so reducing the footprint of the storage facility was essential to making space for other functions.”

The system’s modular design also provides flexibility for future expansion, allowing South West Healthcare to easily add more robots and pick stations, or increase the size of the modular storage grid as demand grows.

The service provider also chose Dematic’s selective pallet racking, ColbyRACK, for storing bulky items that weren’t suitable for the AutoStore GTP system. Designed, engineered, and manufactured by Dematic’s Australian team, ColbyRACK meets rigorous Australian standards.

Installing the AutoStore GTP system was a complex process, particularly due to its integration with South West Healthcare’s existing Oracle-based ordering system. However, Dematic’s project team worked closely with South West Healthcare to ensure that the installation was as seamless as possible.

“The biggest challenge we faced during the installation was integrating the AutoStore system with our Oracle ordering system,” says Michael. “It was a highly complex task, but Dematic’s Software Engineering team worked diligently to ensure that the integration was smooth and effective.”

Despite these technical challenges, the overall installation process was completed on schedule, and Dematic provided extensive training to ensure that South West Healthcare’s staff could operate the system efficiently.

“The training provided by Dematic was top-notch,” says Shane. “Our team was excited to learn the new system, and they adapted to it quickly. The AutoStore system has not only improved our operations but has also provided an opportunity for staff development as they get to work with cutting-edge technology.”

Since the implementation of the AutoStore GTP system, South West Healthcare has seen significant improvements in its supply chain operations. The system has provided a range of benefits, including:

1. Dramatically Increased Storage Capacity

One of the most immediate benefits of the AutoStore GTP system was the increase in storage capacity. The RLDC now holds up to 6500 totes, allowing South West Healthcare to store six to eight weeks’ worth of stock for high-usage items, compared to the one-week capacity in the previous facility. This increase in capacity has reduced the need for frequent reordering and has allowed the warehouse team to focus on more value-added tasks.

“We’ve increased our stock holdings by nearly $200,000,” says Shane. “That means our purchasing team can focus on strategic tasks rather than spending time reordering the same products every week. We’ve also been able to reduce backorders and improve our service levels across the region.”

2. Improved Accuracy and Reduced Errors

The AutoStore GTP system has greatly improved order accuracy by automating the picking process. In the previous system, staff manually picked items from shelves using paper-based picking slips, which created the potential for errors. With AutoStore, the correct product is automatically delivered to the pick station, reducing the chance of human error.

“The system has virtually eliminated picking errors,” explains Shane. “Now, the right product comes directly to the operator, which has significantly improved the accuracy of our orders and made the entire picking process much more efficient.”

3. Optimised Space Utilisation

The high-density design of the AutoStore GTP system has allowed South West Healthcare to maximise the use of available space, freeing up room for the expansion of other critical services. By consolidating storage into a smaller footprint, the RLDC has been able to accommodate the growing needs of its laundry services, which are essential for supporting hospitals in the region.

“One of the major benefits of the AutoStore system is that it reduced the footprint required for storage,” says Terry. “This allowed South West Healthcare to allocate more space to other essential functions, such as the laundry, which is critical to the operation of hospitals in the region.”

4. Futureproofed and Scalable

The modular design of the AutoStore GTP system ensures South West Healthcare can easily expand the system in the future as demand increases. The RLDC has the option to add more robots, increase the size of the storage grid, or add additional pick or replenishment stations as needed.

“The system is designed to grow with us,” says Shane. “While we’re not planning any immediate expansions, it’s comforting to know that we have the flexibility to increase capacity if the demand continues to grow in the coming years.”

5. Faster Turnaround Times and Improved Service

The streamlined operations provided by the AutoStore GTP system have enabled South West Healthcare to improve its

“Dematic’s project team worked closely with South West Healthcare to ensure the AutoStore GTP system installation seamless.

service levels. Orders from regional healthcare facilities are now processed and delivered more quickly, with same day delivery for Warrnambool Base Hospital and next-day delivery for other regional campuses becoming the norm for most items.

“We’ve seen a significant improvement in our order fulfilment times,” says Shane. “The system processes orders much more efficiently, allowing us to get supplies to our hospitals faster. This has been a huge benefit for the region, particularly in emergencies when time is of the essence.”

The partnership between South West Healthcare and Dematic has been a key factor in the success of the project. Dematic provided ongoing support throughout the installation and continues to deliver maintenance and remote IT support to ensure the system operates smoothly.

“Dematic’s commitment to supporting regional Victoria was a big reason we chose them as our partner,” says Michael. “Their team has been fantastic to work with, and their ongoing support has been instrumental in ensuring that the system continues to run efficiently.”

Dematic’s Victoria-based service team provides regular maintenance visits every three months, checking the system to ensure it is functioning as expected. Additionally, remote IT support is available 24/7 to address any issues that arise, allowing the RLDC to operate with minimal downtime.

“Dematic’s support has been excellent,” adds Shane. “Whenever we’ve had an issue, they’ve responded quickly.”

The implementation of Dematic’s AutoStore GTP system has successfully transformed South West Healthcare’s RLDC into a modern, efficient, and future-proof operation. By overcoming space constraints, improving accuracy, and streamlining processes, the new system has enabled South West Healthcare to meet the increasing demands of the region’s healthcare facilities while ensuring long-term scalability.

“Our partnership with South West Healthcare demonstrates how automation can be tailored to meet specific needs and challenges. We’re proud to have delivered a solution that not only meets today’s demands but is also ready to scale for the future,” says Terry.

South West Healthcare will continue providing exceptional service to its healthcare partners across the region, supported by a robust and flexible supply chain infrastructure.

“The AutoStore system has been a game-changer for our operations. The technology is cutting-edge, the support has been excellent, and our staff are excited to work with such a modern system. We’re better equipped than ever to meet the demands of our region,” explains Shane.

Dematic’s AutoStore GTP system has proven to be the ideal solution, offering both immediate improvements and long-term sustainability, ensuring that South West Healthcare can continue to deliver vital services efficiently and reliably.

As the region continues to grow, South West Healthcare’s RLDC will continue to highlight the benefits of strategic automation in the healthcare logistics space.

“We needed a solution that would allow us to manage today’s needs while preparing for the future,” says Michael.

“Dematic’s AutoStore system has exceeded our expectations in terms of efficiency, scalability, and service, allowing us to provide the best possible care for the region’s healthcare facilities.” ■

On Day 2 of MEGATRANS, Peter Jones, Managing Director, Prological, moderated a panel called

Sincreasingly important focus for businesses globally, but achieving tangible results requires navigating complex challenges.

At the 2024 MEGATRANS Expo, industry leaders gathered for a panel discussion titled Beyond Good Intentions: How to Move from Ambition to Action in Supply Chain Sustainability.

Sponsored by Prological, this session offered an exploration of how sustainability goals can be implemented in Australian supply chains, drawing on both local insights and international best practices.

Peter Jones, Managing Director and Founder of Prological, moderated the panel and kicked off the discussion

“Sustainability is now on the agenda of every business we speak with,” says Peter.

“The challenge is taking the global ambitions of large corporations and figuring out how to make them work in the Australian context. There’s often a gap between what’s being asked and what’s achievable here.”

The country’s unique geography, regulatory environment, and economic conditions mean that what works elsewhere may not be as easily implemented.

The panellists shared examples of attempts to bridge this gap, including Global Express’s recent $200 million grant to trial electric vehicles (EVs) in metropolitan Australia, marking a step forward in sustainable logistics.

Richard Phillips, Head of Supply Chain at JLL, highlighted how industrial real estate plays a central role in the sustainability conversation.

“In industrial real estate, we’re faced with a bit of an oxymoron,” explains Richard.

“The process of building warehouses inherently involves tearing up greenfield land and generating massive amounts of embodied carbon. About 80 per cent of the carbon footprint of a building is generated during the construction phase, so there’s a limit to how much we can improve its sustainability once it’s built.”

He points out that in Europe, sustainability has become a key consideration in industrial developments, with initiatives like carbon-neutral buildings being

implemented. However, he admits that replicating such models in Australia presents commercial challenges.

“It’s about finding a balance between what’s financially viable and what’s environmentally sustainable,” says Richard.

“We’re seeing innovations like solar panels becoming standard in new developments, but the cost of green materials like concrete and steel is still prohibitive for most developers.”

Despite these barriers, Richard remains optimistic about the future, suggesting that industrial sites could soon play a role in electricity production.

“We’ve started to hear discussions about installing wind turbines on industrial properties, following examples from Europe. It’s still early days, but this could be part of the long-term solution for making industrial developments more sustainable,” he says.

Andrew Newman, Director at Victoria’s Department of Transport and Planning, emphasised the government’s role in supporting industry efforts to decarbonise the freight sector.

“Government is on a journey as well,” says Andrew. “We’ve set highlevel targets, like achieving net zero by 2050, but now we’re beginning to dig into what needs to happen in transport to make that a reality.”

One of the key challenges, he explains, is the long lifespan of heavy vehicles in Australia.

“The average truck is on the road for about 15 to 16 years, so a truck bought today will still be in use in 2045. We need to encourage the uptake of EVs and other low-emission vehicles now if we want to reach our targets,” says Andrew.

He also emphasised the importance of aligning public policy with private investment to drive meaningful change.

“Governments need to send clear signals to industry that there’s a commercial benefit to investing in sustainable technologies.”

Dr Eamon McGinn, Partner at Deloitte Access Economics, added that in the transport sector, sustainability goals don’t always have to come at the expense of commercial success.

“There’s actually an overlap between financial and environmental sustainability in transport,” says Eamon.

“For example, some technologies, like EVs, can offer lower operating costs and improved reliability over time, which helps both the bottom line and the environment.”

However, Eamon warns that businesses should be realistic about the pace of change.

set ambitious sustainability targets a few years ago are now delaying those targets, because they’re realising just how difficult it is to achieve them,” he said. “The focus should be on achieving smaller, incremental wins rather than aiming for an overnight transformation.”

Throughout the discussion, the panellists stressed the need for practical, achievable solutions. Peter highlighted that many businesses focus on symbolic gestures rather than meaningful change.

with a beehive or two and call it an environmental initiative, but that’s not enough,” he says. “We need to think bigger, like using industrial roofs for solar panels or providing charging stations for EVs.”

adding that while the challenges are considerable, progress was being made.

to cover the entire roof of a new industrial building with solar panels,” he said. “That’s a real step forward, but we need to keep pushing the boundaries and looking for new opportunities to integrate sustainability into the design and operation of these facilities.”

One of the less obvious drivers of sustainability supply chains is the availability of capital.

“It’s not always the Australian customer or developer pushing for sustainability,” explains Richard. “Often, it’s the global investors providing the capital who are setting strict sustainability criteria. They’re mandating that developments meet certain environmental standards, whether or not the local market is ready for it.”

This international pressure is forcing Australian developers to adopt sustainable practices, even if the immediate financial return isn’t clear.

ANTHONY BEAVIS, MANAGING DIRECTOR ANZ AT KÖRBER SUPPLY CHAIN SOFTWARE

From Black Friday to Christmas Eve, every year peak season tests the limits of supply chains worldwide. As consumer expectations soar, companies must evolve their supply chain strategies to stay competitive. Here we explore how organisations can leverage technology to meet the challenges ahead.

Today’s consumers, particularly younger generations, have redefined the meaning of convenience and consumer loyalty. Körber‘s 2023 State of Shipping and Returns survey found that 90 per cent of respondents are less likely to buy from a brand again after a poor online shopping experience, while 29 per cent say they are increasingly willing to share a negative review online. These expectations are pushing retailers to unprecedented levels of agility.

A steep rise in expectations is happening alongside a revolution in the digital marketplace. Platforms like TikTok Shop are introducing new dimensions of virality to online shopping, further amplifying the pressure on supply chains. In this high-stakes arena, agility and innovation in warehouse operations are no longer optional – they’re essential for survival.

Forward-thinking organisations are distinguishing themselves through

strategic investments in smart technology and setting new standards in customer service and operational efficiency.

THE FUTURE OF FULFILLMENT: PROXIMITY, FLEXIBILITY, AND INNOVATION

In response to these rising expectations, many companies are adopting a proximity strategy, moving products closer to the end customer. This approach is manifesting in two

primary forms: micro-fulfillment centres and leveraging existing brickand-mortar stores.

The debate between Buy Online Pick Up In Store (BOPIS) and microfulfillment strategies continues to evolve. While micro-fulfillment centres in urban areas present a compelling long-term solution, many retailers are finding their brick-andmortar stores to be a viable mid-term alternative. However, the ultimate goal remains clear: doorstep delivery.

One thing for certain is that the future of retail lies in operational hybridity – stores that can seamlessly transition between traditional shopping and fulfillment centres will have the flexibility to meet consumers on their terms, wherever they may be.

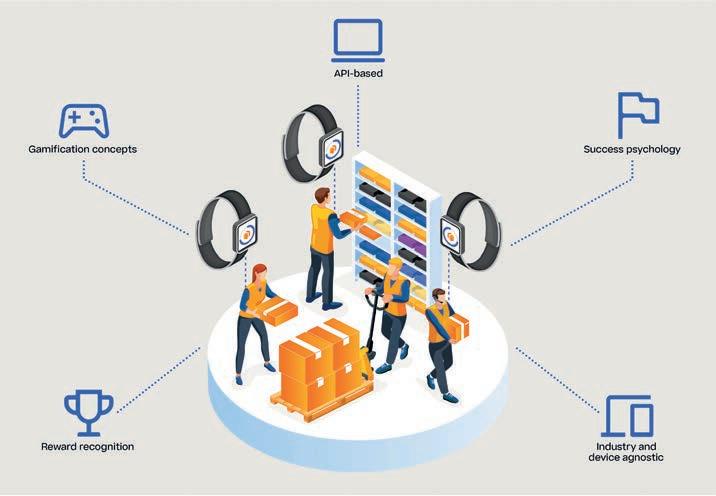

Technology is also increasingly imperative, but a strong and reliable team of people remains essential to achieving new levels of efficiency. One innovative approach when it comes to engaging employees, is the gamification of warehouse management.

By introducing elements of game design into the work environment, companies can boost employee engagement and productivity. A recent report from WorkhumanGallup reveal that gamification can decrease turnover and reduce absenteeism by an impressive 81 per cent, while also lowering the risk of quality defects by 41 per cent.

Moreover, the transition from legacy systems to more adaptable warehouse management software is accelerating in fulfilment strategies. The use of Autonomous Mobile Robots (AMRs) is also increasing in warehouses worldwide, not only reducing reliance on manual labour but also introducing unprecedented flexibility into operations.

AMRs are more affordable than traditional automation and easy to scale once in place, supporting either long-term growth or short-term seasonality.

Creating meaningful connections between software solutions is crucial for building resilient and costeffective supply chains. While supply

chains have increasingly adopted planning platforms, execution and fulfilment often remain fragmented. The key to overcoming this challenge lies in the seamless integration of Order Management Systems (OMS), Warehouse Management Systems (WMS), and Transportation Management Systems (TMS).

This integration creates a unified ecosystem where each component of the supply chain communicates effectively. The result is a more agile operation, capable of rapid responses to disruptions and changes in demand. Whether adapting to sudden shifts in consumer behaviour or managing supply shortages, an integrated system provides the flexibility needed to maintain continuity while optimising costs.

One of the most significant advantages of connecting OMS, WMS, and TMS is the enhanced visibility and real-time insights they provide. An integrated systems addresses the common challenge of a lack of transparency and delayed information head on by leveraging data from across the supply chain in concert. This visibility enables quick, informed decision-making and helps identify potential issues before they escalate, resulting in smoother operations, improved costeffectiveness, and enhanced customer satisfaction.

The integration of OMS, WMS, and TMS expands optimisation capabilities beyond traditional silos.

Boosting employee engagement and productivity with game design elements.

In today’s global market, where demand fluctuates and supply chain disruptions can range from raw material shortages to blocked shipping canals, this flexibility is invaluable.

The final mile of delivery often presents the most complex and costintensive challenges in the supply chain. Once again, the integration of OMS, WMS, and TMS ensures that this critical phase is optimised for both resilience and cost-effectiveness.

With detailed tracking and optimisation tools, companies can manage final mile deliveries with precision. This capability ensures timely and reliable delivery while controlling expenses. Moreover, it provides the added efficiency needed to react swiftly when something goes wrong – an important advantage in an era where customer expectations for fast, affordable delivery are at an all-time high.

As we navigate the challenges of labour shortages and evolving consumer expectations, the path to success in peak season management lies in embracing technological integration, leveraging real-time data, and maintaining the flexibility to meet customers where they are. Supply chain leaders who use these strategies will do more than just cope with peak season this year - they’ll also drive innovation and gain a competitive edge in the market. ■

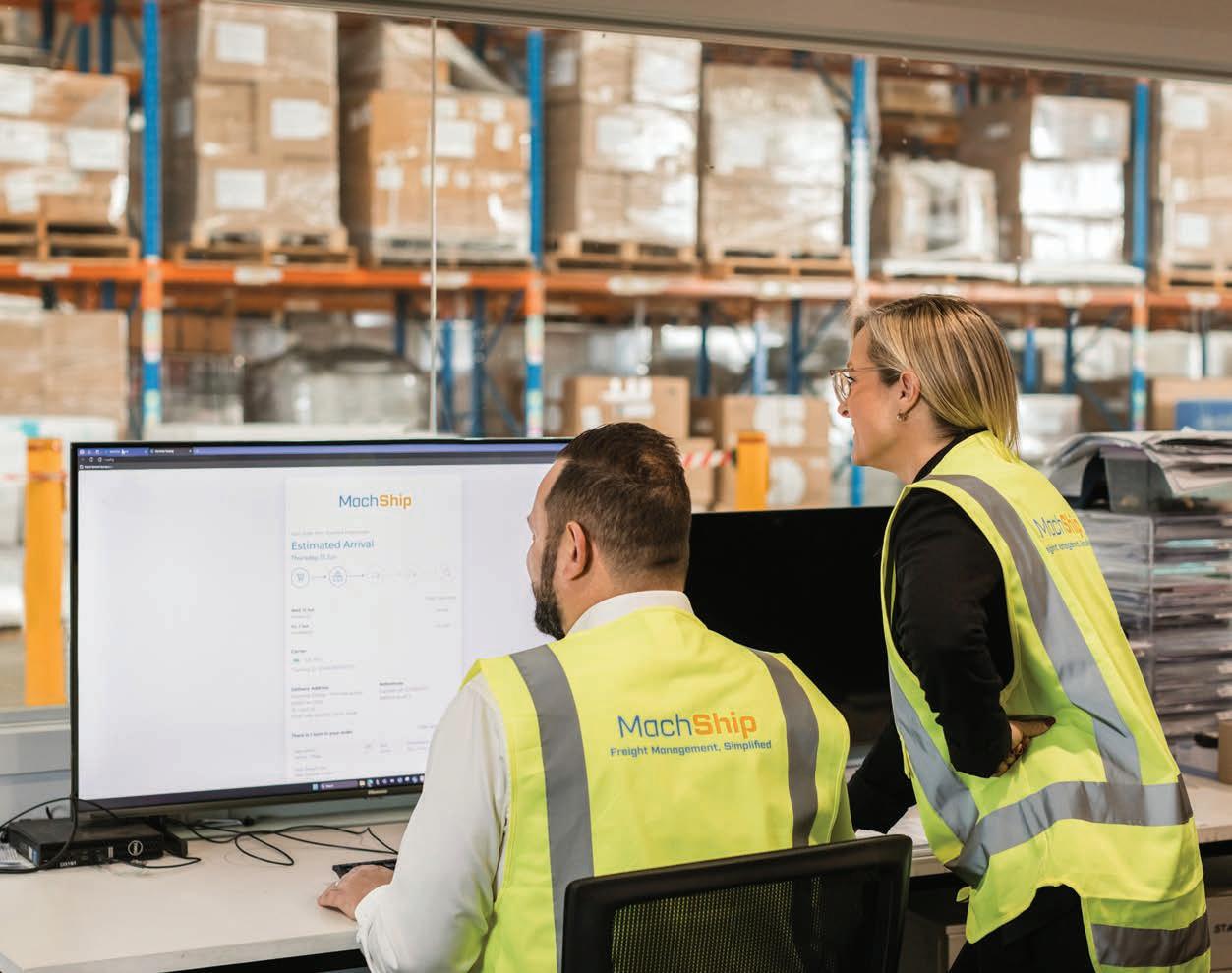

Businesses are embracing digital solutions to enhance their operations. As technology advances, modern logistics systems continuously collect and analyse data, using it to optimise complex warehouse and transportation processes.

Forklift trucks are becoming increasingly autonomous due to advanced sensors, making fleet management and real-time data access crucial.

“Fleet management provides vital insights into your equipment’s operation, ultimately improving safety, efficiency, and productivity while ensuring compliance with government regulations,” says Stuart Hitchens, National Fleet Contract Manager at Linde Material Handling Australia.

One such solution leading the charge in this area is Linde’s FleetFOCUS, a fleet management system designed to help businesses optimise their material handling operations. It provides a top-of-the-range Workplace Health and Safety (WHS) solution, allowing real-time communication between

businesses, their fleets, and their operators.

FleetFOCUS is a tool designed to give businesses control over their resources. The system facilitates realtime monitoring and management of fleets, providing the insights needed to enhance operational efficiency.

Businesses can monitor daily equipment usage, identify under- or over-utilised vehicles, observe driving patterns, control vehicle access, and review WHS compliance in real time.

FleetFOCUS isn’t just about visibility. It’s about intelligent management –businesses can take control and make informed decisions to ensure that their fleets are operating at optimal levels.

FleetFOCUS offers several benefits to businesses, each targeting key aspects of fleet management and operational efficiency:

• Optimised Fleet Utilisation – It enables businesses to identify

and address fleet utilisation and operational issues before they affect the bottom line. By analysing equipment usage, businesses can adjust their resources to where they are needed most.

• Workplace Safety Transformation – Safety is paramount in material handling operations, and FleetFOCUS plays a crucial role in monitoring forklift usage and identifying infrastructure damage. The system enhances workplace safety by providing immediate feedback on operator behaviour and equipment conditions.

• Access to Real-Time Information –FleetFOCUS continuously collects and organises data, allowing 24/7 access to fleet information through an online portal. This real-time access ensures that decision-makers are always informed and able to act quickly.

• Cost Savings – By identifying overused or underused equipment, businesses can optimise resource allocation.

One of FleetFOCUS’s strengths is its reliable Wi-Fi and GPRS (3G and 4G) connectivity.

• Customised Solutions – The system can be tailored to meet a company’s unique equipment and operational needs, and integrates with existing security systems, allowing operators to use a single card or fob for access.

Intelligent features include customisable firmware, shock reporting, preoperational questionnaires, driver access control, electronic tag-out systems, and GPS tracking.

• Reprogrammable Firmware – FleetFOCUS can adapt and customise software to meet unique requirements. With efficient two-way messaging, it enables seamless communication between drivers and supervisors. The system is also designed to support a range of security cards and fobs, making integration smooth and efficient.

• Shock Reporting – a standout feature, which helps businesses ensure safe operation following vehicle shocks. Any shocks that exceed the predetermined level automatically reduce the vehicle to ‘limp’ mode, and the supervisor must reset the unit, ensuring accountability and WHS compliance.

• Pre-Operational Questionnaires – it includes a customisable preoperational questionnaire that drivers must complete before using the equipment. These questions can be tailored to specific sites or vehicle types and ensure that each operator confirms the equipment is safe to use before operation.

• Driver Access Control – access can be limited to authorised personnel only. The system accommodates security

cards, fobs, or pin codes, further enhancing security and operational control.

• Electronic Tag Out for Unsafe Vehicle – FleetFOCUS also includes an electronic tag-out feature that allows supervisors to lock out unsafe vehicles, ensuring that only qualified personnel can move them to safe locations.

• GPS Tracking - GPS comes as standard in FleetFOCUS, providing businesses with a powerful tool to monitor the movement and location of their equipment.

One of FleetFOCUS’s major strengths is its reliable Wi-Fi and GPRS (3G and 4G) connectivity, allowing seamless fleet management even in large or complex environments.

“Our system was the first Australian fleet management solution with dual Wi-Fi and GPRS connectivity, ensuring uninterrupted data access,” explains Stuart.

The system also features memory card backup in the event of a network loss, ensuring that data is always preserved and automatically updated when the connection is re-established.

FleetFOCUS offers up to 30 realtime reports, providing businesses with critical data to identify areas for continuous improvement. “These reports enable informed decisionmaking, helping businesses optimise battery consumption, monitor hardware conditions, and track operator licensing,” adds Stuart.

The system’s interactive dashboard offers real-time updates on impacts, battery charge, and operator checks,

eliminating the need to log into multiple systems or wait for email reports.

FleetFOCUS doesn’t just collect data for the sake of it – it uses data to drive real improvements in fleet operations.

“FleetFOCUS utilises data from forklifts to monitor hydraulic traction and driver presence, helping businesses see how their equipment is being used,” says Stuart.

This allows companies to identify inefficiencies, such as using an expensive reach truck for tasks that a more cost-effective pallet jack could handle.

These data-driven insights also extend to operational decisions. For instance, if data shows that equipment is only being used during certain times of the year, businesses can adjust their fleets accordingly.

“FleetFOCUS gives businesses the information they need to manage their fleet effectively, ensuring they don’t overspend on equipment that’s not being fully utilised,” explains Stuart.

FleetFOCUS helps businesses reduce costs. By identifying underutilised equipment and highlighting opportunities for resource reallocation, the system ensures that businesses are making the most of their assets.

“It’s all about optimising resources, not just adding more equipment unnecessarily,” says Stuart.

The system’s customisation capabilities also make it a highly flexible solution. Pre-operational checks can be tailored to specific equipment models, while the data collected from each piece of equipment can be used to tailor future fleet strategies.

“We’re constantly receiving feedback from our customers, and we use that to improve the system,” explains Stuart.

As FleetFOCUS is developed locally, any changes or improvements specifically made by Linde, or our fleet management partner are rolled out quickly and free of charge to all users. ■

Australian beverage manufacturer Remedy Drinks has steadily and successfully built its business using the help of battery-electric Toyota Material Handling forklifts to distribute its products.

Over the past decade, Australian beverage company, Remedy Drinks, has rapidly expanded its operations, with its distinctive kombucha becoming a household name.

As the company scaled up, one crucial factor in its success has been its reliance on Toyota Material Handling Australia’s (TMHA) battery-electric forklifts.

These vehicles have played an essential role in Remedy’s ability to meet growing demand while maintaining sustainable practices and high operational efficiency.

Founded in 2012 by Sarah and Emmet Condon, Remedy Drinks emerged as a healthier alternative to sugary soft drinks. Its home-brewed kombucha, made from 100 per cent natural ingredients with no added sugar, gained popularity among health-conscious consumers.

The company has expanded its product range to include Sodaly natural soft drinks, Kick Natural energy drinks, miniature energy shots, and apple cider vinegar-based beverages.

What started as a small operation in Melbourne’s south-eastern suburbs has now grown into a thriving business. Remedy Drinks occupies a large dual warehouse and production facility in Dandenong South, where demand for its products continues to soar.

Throughout this journey, Remedy has relied heavily on its partnership

with TMHA, which dates back to the company’s first forklift – a secondhand Toyota unit.

Today, Remedy’s material handling fleet includes eight reach forklifts and four counterbalance forklifts, all powered by electric battery technology.

These battery-electric forklifts are at the heart of Remedy’s distribution operations, offering the dual benefits of efficiency and sustainability. Zero emissions during operation mean the forklifts align perfectly with Remedy’s commitment to environmentally friendly practices.

Ryan Stark, Remedy Drinks’ Warehouse Manager, attributes much of the company’s logistical success to these forklifts.

“The warehouse and logistics team’s primary role is to ensure our product is delivered to our customers and knowing that our equipment on-site can do that is our number one priority,” says Ryan.

“It’s great to know that putting our pallets into racking, loading trucks, and picking orders, our equipment can do that and does it reliably.”

Reliability is key to Remedy’s operations, and Ryan is quick to praise the performance of TMHA’s forklifts. Over the years, the partnership between the companies has strengthened, with both working closely to ensure the forklifts are always performing optimally.

“From an operational perspective, they are an easy vehicle to operate,” says Ryan. “They have all the bells and whistles that I think are required on a forklift, particularly from a safety perspective.”

The user-friendly design of Toyota’s

forklifts has proven invaluable to the Remedy team. With intuitive controls and a suite of safety features – these machines are built to maximise both productivity and operator safety.

This is important in a fast-paced production and logistics environment like Remedy Drinks, where safety and efficiency go hand in hand.

In addition to the forklifts themselves, TMHA has provided Remedy Drinks with advanced fleet management tools, including the I_Site telematics system. This technology allows the company to monitor and optimise its forklift fleet in real time. For Ryan, the introduction of I_Site has been a game-changer.

“In particular, the I_Site software for us is huge, as we’re able to have live data in terms of collisions,” explains Ryan.

By eliminating the need for manual checklists and paper-based tracking systems, I_Site has streamlined many of the processes in Remedy’s warehouse.

“You’re doing away with manual checklists and books on the forklifts – that’s all done through the I_Site software, which is a huge thing,” adds Ryan.

Enhancing safety with proximitylinked speed limiting

Safety is a top priority for Remedy Drinks, and TMHA’s forklifts come equipped with safety technologies. One such feature is proximity-linked speed limiting, which automatically reduces the speed of the forklifts in certain areas of the warehouse.

This is particularly useful in zones with high pedestrian traffic, such as the production area, where forklifts must navigate around workers.

“Some of our production forklifts have speed limiters on them,” says Ryan. “Once they move from the

warehouse to the production area, the speed is limited.

“There’s more pedestrian traffic in production, and there’s a little more interaction between forklifts and pedestrians, so this safety feature is invaluable.”

By automating these safety controls, Remedy can ensure the wellbeing of its employees while maintaining smooth and efficient operations.

Remedy’s long-standing relationship with TMHA has been nurtured by Grant Owen, TMHA’s Area Sales Manager, who has been with the company since Remedy first purchased its second-hand forklift.

Over the years, Grant has facilitated Remedy’s forklift needs, from its first new purchase – a pair of Toyota RRE140 reach forklifts – to its ongoing expansion.

As Remedy Drinks continues to grow, securing contracts with major retailers such as Coles and Woolworths, the company’s material handling needs have evolved. Yet, the partnership with TMHA remains steadfast, with TMHA providing the equipment and support required to keep pace with Remedy’s rapid growth.

Remedy Drinks shows no signs of slowing down. With plans to continue expanding, the company is confident that TMHA’s range of equipment will continue to meet its needs.

“Knowing that we’ve got a relationship with a supplier that has a large variety of equipment, we know we can stay with TMHA as our supplier,” says Ryan.

“If we need to have new equipment on site, with the range that Toyota has, we know we’re not going to be in a situation where we can’t get a specific piece of equipment. We can rest assured that TMHA will probably have it in some form.”

For Remedy, this long-term partnership with TMHA ensures that its warehouse operations can scale with the business.

“It allows us to stay within one brand, which obviously helps with our servicing and our relationship. We can get the equipment that we really need to run the warehouse,” adds Ryan.

Sustainability has always been a key part of Remedy Drinks’ philosophy, and the use of battery-electric forklifts has allowed the company to maintain its eco-friendly approach.

By choosing electric forklifts that produce zero emissions during operation, Remedy is not only reducing its carbon footprint but also contributing to a cleaner, greener logistics operation.

This focus on sustainability is something TMHA shares, as the company continues to innovate with electric powertrains and eco-friendly technologies in its material handling solutions.

With both companies aligned on the importance of reducing their

environmental impact, the partnership between Remedy Drinks and TMHA is one that will continue to thrive as the industry moves towards a more sustainable future.

As Remedy Drinks continues to grow, it can do so with confidence, knowing that TMHA will be there to provide the equipment and support it needs to succeed.

For Ryan and his team, the partnership with TMHA is more than just about forklifts – it’s about ensuring that the company’s logistics are always running smoothly and sustainably, allowing Remedy to focus on what it does best: brewing great-tasting, healthy beverages. ■

Racking is designed for storing long or bulky items.

BHD Storage Solutions has opened its first Queensland distribution centre, BHD QLD, to enhance operational efficiency and customer service in a region ripe for growth.

n the world of industrial warehousing, BHD Storage Solutions has emerged as a key player since its inception in the early 2000s. With a mission to revolutionise warehouse fit outs, BHD began its journey by offering modular pallet racking systems.

Over the years, it has expanded its portfolio to include cantilever racking, shelving, and customised storage solutions.

“As the market evolved, BHD adapted by integrating advanced technologies and automation into its fit outs designs, optimising space and enhancing operational efficiency,” says Jason Lovett, Sales Manager, BHD QLD.

“By the 2010s, BHD Storage Solutions was known for its commitment to quality and customer service. We embrace sustainability by incorporating eco-friendly materials and energyefficient practices in our warehouse designs.”

BHD offers expert support from

initial consultation to installation, tailoring each project to clients’ needs.

Committed to innovation, the company helps businesses enhance storage capabilities and streamline operations, solidifying its reputation as a trusted partner in industrial warehouse fit outs.

In September 2024, BHD took a step forward with opening its new facility in Slacks Creek, Queensland, just 20 minutes south of Brisbane.

“This strategic move is not just about expanding physical space; it’s about enhancing operational efficiency and customer service in a region ripe for growth,” says Jason.

The facility is designed to reduce transport lead times, enabling faster delivery and better access to storage solutions. It aims to streamline logistics, enabling BHD QLD to respond more rapidly to customer needs

while minimising costs associated with transportation. By establishing a local presence, the company can provide faster turnaround times for both storage services and support, ultimately enhancing the customer experience.

Additionally, this expansion aligns with BHD’s commitment to sustainability. The new facility incorporates energy-efficient technologies, reducing the environmental impact of its operations.

“As BHD continues to grow, our investment in Queensland underscores our commitment to meeting the evolving demands of businesses while supporting local economic development,” says Jason.

“With the opening of our Slacks Creek facility, we are well-positioned to deliver innovative, cost-effective, and timely storage solutions, reinforcing our status as a key player in the industry.”

pallet racking and cantilever racking, each tailored for specific applications.

Pallet racking is suitable for warehouses and distribution centres, providing an efficient way to store pallets of goods. Its adjustable shelves allow for flexibility, accommodating various product sizes and weights. This system maximises vertical space, enhancing inventory management and accessibility.

Cantilever racking is ideal for storing long or bulky items such as pipes, timber, and plasterboard. Its open design allows for easy loading and unloading while eliminating the need for vertical supports at the front of the rack. Cantilever racks can be configured in single or double-sided setups, optimising space in both small and large facilities.

“Our diverse storage solutions ensure that businesses can effectively manage their inventory while improving operational efficiency,” says Jason.

need for interstate transport, businesses

Additionally, the local presence allows for better inventory management, reducing the need for excess stock that often accumulates due to long lead times. This streamlined approach minimises holding costs and optimises warehouse space.

Businesses also benefit from reduced handling and transfer costs associated with interstate logistics, further contributing to overall savings. By consolidating operations in Queensland, BHD QLD enables its clients to operate more efficiently, allowing them to allocate resources to other critical areas of their business.

BHD QLD offers end-to-end project support, ensuring a smooth transition from initial design to final installation. The process begins with consultations to assess client needs, storage requirements, and operational

goals. This critical first step sets the foundation for tailored design solutions, where detailed layout plans are created, and appropriate storage systems are selected, all while ensuring compliance with safety standards.

Following the design phase, the team helps clients choose high-quality materials and equipment that align with their budget and operational needs. This is followed by the dedicated project managers, who then take charge of overseeing timelines and coordinating with stakeholders to align every aspect with the client’s expectations.

The installation team then executes the plan with precision, adhering to industry best practices. After installation, BHD QLD continues to support clients with training, maintenance services, and necessary adjustments, ensuring optimal performance of the storage solutions tailored to their specific needs.

“Our clients consistently highlight the positive impact of BHD QLD’s local presence, reporting reductions in freight costs and delivery times that enhance their operational efficiency,” explains Jason.

“Clients also appreciate the ease of communication with our local team, which enables faster response times and personalised support for smoother project management. Furthermore, our tailored solutions, informed by local market knowledge, help businesses enhance efficiency and productivity.”

At BHD QLD, a commitment to continuous improvement drives its operations. Understanding the evolving business landscape and client needs, it actively seeks feedback and maintains open communication to ensure its solutions remain effective.

“With a focus on advanced analytics, sustainable practices, and refined design strategies, BHD QLD tries to stay ahead of industry developments,” says Jason.

“We also invest in ongoing training and development, equipping our staff with the skills needed to meet new challenges.”

As the company embraces the future, it remains committed to driving success for its clients, solidifying its position as a key player in industrial warehouse fit outs. Visit - www.bhdqld.com.au. ■

Falcon Autotech is a global intralogistics automation solutions company. With over 10 years of experience, Falcon has worked with some of the most innovative brands in E-Commerce, CEP, Fashion, Food/FMCG, Auto and Pharmaceutical Industries.

CONTACT US:

Email: salesenquiry@falconautoonline.com Website: www.falconautotech.com

Harold Vanasse from EnerSys shares insights on addressing the evolving challenges of optimising material handling equipment in modern operational environments.

Fconstant pressure to maintain and increase throughput, even as resource constraints challenge these efforts,” says Harold Vanasse, Global Senior Director of Sales Enablement at EnerSys. “As a result, many managers are shifting their focus from the initial price of equipment to the total cost of ownership (TCO) over its service life.”

A study conducted by Sapio Research revealed that 63 per cent of those responsible for obtaining material handling equipment are more concerned with total lifetime ownership costs than with the initial purchase price. Labour, hardware, and downtime costs associated with equipment maintenance, repair, and replacement remain concerns.

Facility and fleet managers now seek opportunities to improve operational efficiency by evaluating how equipment power systems affect their overall TCO.

While many managers are exploring capital

management systems, and advanced technologies, they are often surprised to find that meaningful improvements can be achieved by optimising the power sources for their material handling equipment.

However, achieving these efficiencies requires a partner that understands the relationship between power needs and operational requirements.

At EnerSys, the process begins with advanced tools that leverage operational data to optimise equipment operation.

One of these tools is EnSite modelling software, an EnerSys product that simulates how different power systems will perform in a facility before any investment is made.

This approach allows managers to make informed decisions about batteries and chargers, ensuring their equipment is powered optimally for both current and future needs.

In many facilities, fleet managers

hand calculations or spreadsheets – to compare batteries and chargers.

However, with the ever-increasing complexity of technologies and the high volume of operational data, these methods often fall short.

Even intricate spreadsheets cannot accurately account for the variables involved, reducing them to little more than a “best guess” for a critical decision.

EnerSys takes a scientific approach, using computer simulation technology to conduct an application assessment. EnSite modelling software allows for a multi-dimensional analysis, testing the performance of various battery and charger combinations in a virtual environment.

This not only saves time and money but also ensures the system is neither underpowered nor oversized, providing just the right amount of power for the operation.

“The software can even account for fluctuations in facility throughput due to seasonality or varying requirements

between multiple locations,” says Harold.

By simulating these changes, EnerSys can predict how power system performance will be affected, ensuring consistent throughput regardless of operational shifts. In addition, EnSite modelling software provides return on investment (ROI) projections, helping managers justify their power system selection to internal stakeholders.

As more companies face pressure to improve their sustainability efforts, many are considering a shift from internal combustion-powered equipment to battery-powered alternatives.

EnerSys helps ease this transition by using EnSite modelling software to estimate the carbon footprint reductions associated with the switch.

By analysing current fuel usage and projecting electricity equivalents, the software can quantify the sustainability impact of moving to battery-powered equipment, helping companies meet their environmental goals without sacrificing operational efficiency.

“Achieving true optimisation of equipment power systems requires access to a broad range of options,” says Harold.

“Facilities often vary in terms of equipment usage patterns, shift profiles, and the nature of the operations themselves, leading to different power requirements.

“For example, a reach truck used to pick items from high shelves has different power needs than a pallet jack used for loading semi-trailers. Even within the same facility, different departments may require varying power capacities.”

EnerSys provides a portfolio of battery and charger options, ensuring the right solution is available for every scenario.

“Working with a vendor that only offers one type of battery technology can severely limit a facility’s ability to optimise its power system,” explains Harold.

“In some cases, a hybrid approach

– using different battery technologies across departments or equipment types – offers the best solution.”

Unfortunately, many fleet managers make power system decisions based on limited options from a singletechnology provider.

This can lead to either underpowered equipment that disrupts operations or overpowered, overpriced systems that provide more capacity than necessary.

To avoid these pitfalls, EnerSys offers a range of solutions, from Ironclad flooded lead-acid batteries to NexSys Thin Plate Pure Lead (TPPL) batteries and robust Lithium-ion options like NexSys iON batteries.

This array ensures that every facility can find the perfect fit for its unique power demands.

Once the optimal power system has been implemented, routine monitoring and managing of the fleet’s power usage is essential to achieving long-term efficiency.

This step is often overlooked, but it plays a critical role in reducing TCO,” says Harold.

“EnerSys offers Wi-iQ battery monitoring devices that track key parameters such as power usage, temperature, and operator charging behaviour.

“This data is transformed into

actionable intelligence, allowing fleet managers to maximise battery service life and protect equipment from unnecessary wear.”

The data collected by Wi-iQ devices also assists the EnerSys service team in maintaining peak battery performance.

With more than 550 authorised service technicians globally available around the clock, EnerSys provides support, including installation, maintenance, repair, and fleet monitoring services.

This ensures consistent equipment uptime, keeping operations running smoothly.

For facility managers looking to optimise their operations and reduce TCO, EnerSys offers a tailored, data-driven approach. By leveraging advanced tools like EnSite modelling software and Wi-iQ battery monitoring devices, EnerSys provides power solutions that align with both operational needs and sustainability goals.

“Managers should explore these opportunities to improve efficiency and minimise ownership costs,” says Harold.

EnerSys can help facilities achieve true power optimisation with its range of technologies and service support. ■

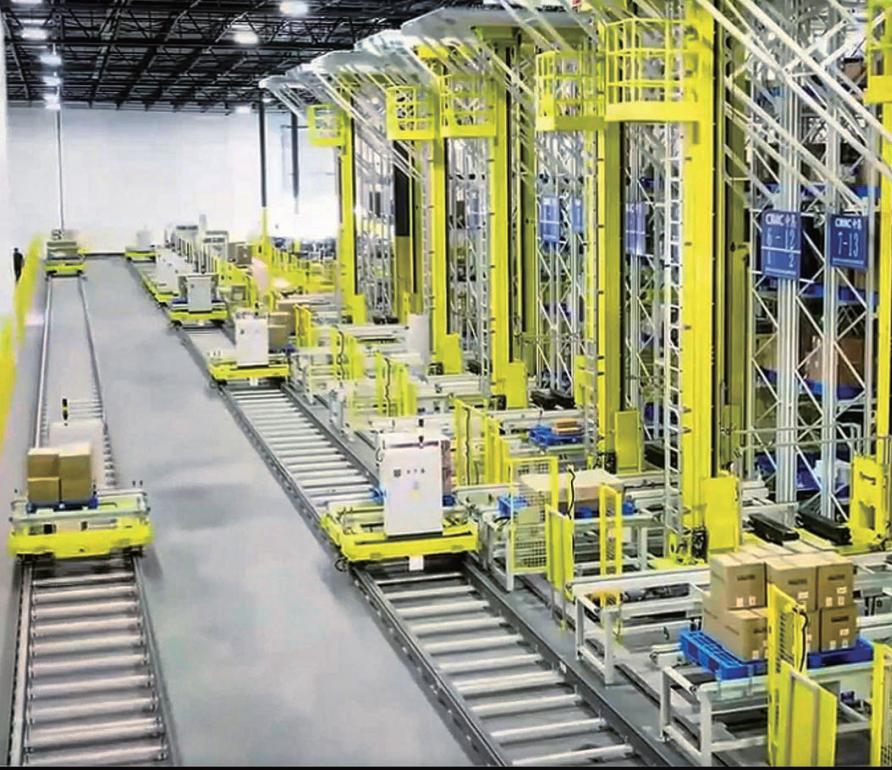

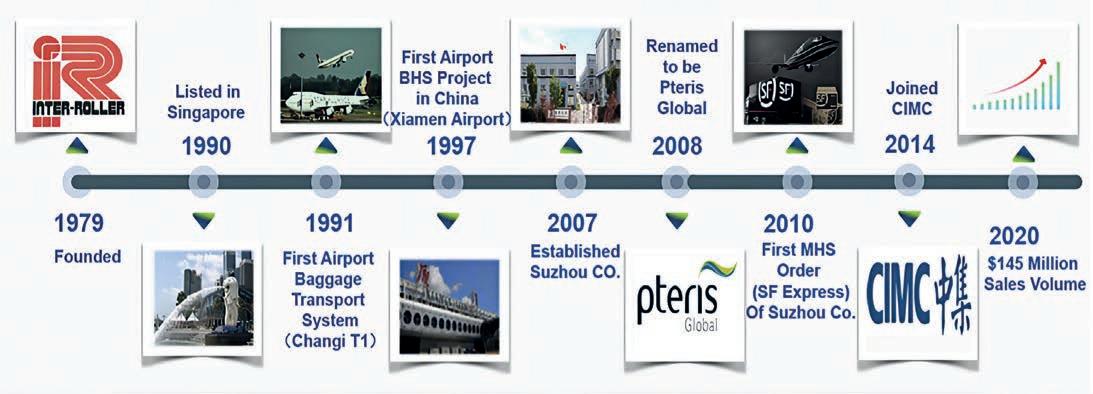

Henry Hui, who works closely with CIMC Pteris Global, talks about introducing automatic loading and unloading solutions in Australia.

As the demand for automation grows across the globe, CIMC Pteris Global is setting its sights on Australia. Known for its expertise in automated logistics, the company is entering the Australian market for Automatic Loading and Unloading Systems (ALUS).

With a well-established reputation in automation and logistics, CIMC Pteris Global is prepared to meet the unique demands of the Australian industry.

CIMC Pteris Global has long been a player in the automatic logistics sector, with a track record of innovation and operational efficiency. As it ventures into the Australian market, the company aims to tailor its solutions to meet the needs of local businesses.

“Our strategy is to leverage our extensive expertise in logistics and manufacturing operations, enhancing productivity and reducing costs for Australian businesses,” says Henry Hui, Director of Airstack Intralogistics and CIMC Pteris Global collaborator.

“We plan to work closely with local partners and stakeholders to ensure that our systems are seamlessly adapted to the unique demands of the Australian market. This means offering scalable solutions that can integrate smoothly into existing supply chains.”

E-commerce has boomed in Australia, particularly in the wake of the COVID pandemic, creating new challenges for logistics and retail sectors.

Speed has become a critical factor for consumers, and businesses are

increasingly seeking automation to meet these growing demands.

Automated loading and unloading systems, such as those provided by CIMC Pteris Global, offer a solution to streamline logistics and warehousing processes.

Henry emphasises the importance of speed in today’s market.

“E-commerce is all about how fast you can get products to consumers,” he says. “Automated systems play a crucial role in this process, allowing businesses to move goods more quickly and efficiently. Whether it’s unloading containers or getting products onto shelves, speed is critical, and automation is a key driver of this efficiency.”

“With our automated systems, companies can reduce the need for manual labour, which not only improves safety but also increases productivity.

“The high costs of labour and the ongoing workforce shortages in Australia make automation an attractive option for businesses looking to maintain competitiveness.”

Australia’s size presents a unique set of challenges for any logistics solution. With distribution centres spread across major cities and remote regions, automation systems must be versatile and reliable under diverse conditions.

CIMC Pteris Global recognises this challenge and has developed adaptable solutions to meet the needs of businesses operating in different environments.

“While the majority of demand will likely come from major cities and distribution centres, where freight volumes are high, we are also developing solutions that can be scaled for use in remote regions,” says Henry.

“Our systems are designed to handle the complexities of Australian logistics, ensuring that businesses, regardless of location, can benefit from automation.

“Automation will be particularly valuable for medium to large firms that have high freight volumes.

“By eliminating the need for manual unloading and loading, these systems can enhance safety and efficiency. While remote areas may not have the same volume as urban centres, we believe automation will still play a role as logistics systems evolve.”

“There are several factors we need to take into consideration when designing the system for our clients” adds Jimmy, Marketing Manager from CIMC Pteris Global. “First, we need to assess the possible safety risks during the operation of the automatic loading system, such as mechanical or electrical issues, and their potential consequences; ensuring operator safety through proper training and emergency response skills. Second, the system’s ability to function reliably in various conditions, including different temperatures, humidity levels, and dust, as well as its performance with different types of cargo and loading scenarios.

Last but not least, the automatic loading system needs to be designed to accommodate various vehicle sizes and loading needs, ensuring it works effectively in all scenarios.”

High labour costs and workforce shortages are two of the most pressing issues faced by Australian businesses.

Automation offers a way to mitigate these challenges by reducing the need for manual labour and improving operational efficiency.

CIMC Pteris Global’s ALUS solutions