WP:

Journalist

Business Development

ith the lingering chill in the air, you could almost be forgiven for forgetting that spring is very much upon us. Though the temperature is still relatively cool, we’ve filled our Spring edition with all the hottest topics across the mining industry, to be distributed at some of the sector’s biggest events.

This issue marks Mining’s two-year anniversary and we’re celebrating the occasion by bringing you the biggest stories and analysis from key players across the resources sector.

The last few months have seen industry make significant headway on its decarbonisation journey, with electrification of onsite machinery occurring in leaps and bounds and major miners partnering to secure renewable energy for operations. Exploration shows no sign of slowing down and uranium, tungsten, magnetite and vanadium projects are all in various stages of progress.

David Michael, about the importance of industry events and what he’s looking forward to at WA Mining.

The Spring issue of Mining takes a deep dive into the topic of sustainability and the many ways this presents itself in the industry. We also use our crystal ball to glimpse into the future of the sector, unpack the technological advancements boosting operations and explore how the next generation of miners are being inspired.

Mining is also proud to be the official show guide of the 2024 WA Mining Exhibition and Conference, compiling

With additional features on minerals in focus, environmental management and the circular economy, Mining keeps its finger on the pulse of the industry to bring you the topics that are rocking the sector.

As always, if there’s a topic, project, technology or challenge you’d like to read about in future editions, please feel free to flick me an email – I'd love to hear from you.

Rebecca Todesco Editor

Drop Rebecca a line at rebecca.todesco@primecreative.com.au or feel free to call her on 03 9690 8766 to let her know what you think. Don't forget to follow

Financial Performance Management

Ditch outdated spreadsheets.

Streamline budgeting, forecasting, reporting, & more — all in one platform.

Turn

Master Data Management

Centralise your data. Eliminate siloes & ensure business critical data is in one place.

Unlock

Rock-chip sampling carried out at Aurumin Limited’s 100 per cent-owned Central Sandstone project uncovered high-grade iron.

Located 520km northeast of Perth, the project is part of the company’s Sandstone Operations, which also includes the Birrigrin and Johnson Range Projects, and has a total resource of 946koz (gold).

The drilling work recognised an opportunity for high-grade iron ore in addition to gold mineralisation, returning up to 67 per cent iron. Planning for drill testing of the high-grade iron formations is underway.

Albemarle launched a review of its operating and cost structure, which saw it take immediate asset actions at the Kemerton lithium hydroxide conversion site in Western Australia.

The company said it took these steps to proactively respond to ongoing industry headwinds – particularly in the lithium value chain – and to preserve long-term competitiveness.

As part of the initial review to optimise its network, Albemarle announced changes to the operating footprint at its Kemerton site, including:

Aurumin’s Managing Director, Brad Valiukas, said the results represent a real discovery.

“There is a 6km strike of banded iron outcrops with potential widths of five to 40m requiring further exploration. The first-pass rock chip sampling returned numerous high-grade DSO quality results, with a peak of 67 per cent and represent an exciting complementary opportunity at Central Sandstone.

“Full credit to the team for identifying and working up this opportunity. Generations of operators

have walked over this potential and we are delighted to bring it forward. Sandstone is already on the haulage route for iron ore producers to Geraldton Port.

“Aurumin’s focus is firmly on Sandstone and generating the critical mass required for future production. The close proximity of the iron ore to some of our gold deposits, not to mention the potential value of the iron ore itself, could significantly alter the project’s economics. We are already spoilt for targets, and this adds a big one to the mix.”

♦ Stopping construction activities at Train 3

♦ Idling production at Train 2 and placing the unit in care and maintenance

♦ Focusing manufacturing efforts on the continued ramp and qualification of Train 1

Albemarle said its actions regarding Kemerton are part of a broader effort that focuses on the following key areas:

♦ Preserving Albemarle’s world-class resource advantages

♦ Optimising its global conversion network

♦ Improving the company’s cost competitiveness and efficiency

♦ Reducing capital intensity

♦ Enhancing Albemarle’s financial flexibility

Albemarle Chairman and CEO, Kent Masters, said, “The long-term growth potential for our end markets remains strong, and we plan to leverage our core capabilities while ensuring we remain competitive.

“Given the dynamics of the global markets we serve, we must be able to pivot and pace as necessary to maintain our leading position.”

Tailings waste from mine operations flows into tailings pond.

Tailings management is a major challenge in the mining industry and requires continuous, efficient oversight by professionals and machinery adhering to the highest standards.

For decades, tailings pumping systems have been optimised to meet the rigorous demands of the production process. Additionally, ponds or dams used for tailings have limited storage capacity, necessitating effective pumping systems to handle maximum solid concentrations.

Positive displacement pumps are ideal for this task, extending the lifespan of ponds or dams by accommodating a wide range of solid percentages in the tailings. Kelair Pumps offers three reliable technologies: piston-diaphragm pumps, piston pumps and peristaltic (hose) pumps.

Efficient and sustainable solutions

Kelair Pumps Australia provides different options for handling paste and mud

tailings: the Abel SH and HMQ series. The Abel SH piston pump, driven by a hydraulic unit, efficiently pumps highly viscous tailings. The Abel HMQ, a modern piston-diaphragm pump, features spring-returned check valves and a membrane separating the hydraulic piston from the paste, offering smooth, low-pulse pumping.

Both pumps handle conventional and cemented tailings with yield stress values over 350pa. The Abel HMQ achieves flow rates up to 450m³/h at 230bar, while the Abel SH handles up to 110m³/h at 160bar.

Water management is crucial in mining. Peristaltic pumps, like the Albin hose pump, ensure only fluid contacts

the hose, preventing contamination. Increasingly, mining clients are choosing peristaltic technology.

An Albin ALH-125D pump was recently selected for a North Queensland gold mine's tailings treatment project, addressing plant expansion and increased pumping distances to new tailings storage facilities.

Ensuring you have the right pump for the right application involves a thorough set of considerations. Consult a knowledgeable pump supplier like Kelair Pumps to discuss your pumping requirements.

For more information, visit kelairpumps.com.au

Liontown Resources locked in a buyer for ramp-up spodumene concentrate volumes from its Kathleen Valley Lithium Project.

The short-term binding offtake agreement with Beijing Sinomine International Trade Co (BSIT) is for the supply of up to 100,000 dry metric tonnes (DMT) over a ten-month period to commence by 30 September 2024.

Pricing is determined using a formula-based mechanism referencing market prices for batterygrade lithium carbonate.

BSIT is a well-known company operating in the lithium chemicals industry and is active in both hard rock lithium mining and refining of spodumene concentrates into battery-grade lithium chemicals.

The offtake agreement with BSIT is in addition to existing long-term offtake contracts with Tesla, LG Energy Solution and Ford, which will be progressively brought into effect over the next 12 months as Liontown ramps-up the Kathleen Valley to full-production.

Anglo Pacific Holdings acted as the adviser to the buyer.

Liontown’s Managing Director and CEO, Tony Ottaviano, said, “Securing a near-term offtake with an established lithium refiner to sell initial volumes over the ramp-up period, de-risks sales during our ramp-up of the plant towards nameplate capacity.

“This complements our existing long-term offtakes, which we will progressively bring into effect over the next 12 months as we increase production towards nameplate to support our offtake commitments.”

The 2024 Queensland Mining Awards winners were celebrated at a black-tie gala held in Mackay as part of the Queensland Mining and Engineering Exhibition.

Presented by the Bowen Basin Mining Club alongside the Queensland Resources Council, the 2024 awards recognised Queensland’s best and brightest resources contractors, suppliers and producers, with peer-judged awards presented over eight categories addressing safety, collaboration, environment and innovation, with a mammoth 70 entries this year.

Award winners across the various categories included StrataLock, Corehesion, MacKellar Group, Coronado Global Resources, Bigmate, Pembroke Resources, and BMA and Astute.

Queensland Resources Council CEO, Janette Hewson, said it was fantastic to see what’s often a behindthe-scenes effort brought into the innovation spotlight.

“It’s our industry’s commitment to world’s best practice that has earned the Queensland resources sector an international reputation for excellence.

“Much of that innovation is driven right here in Mackay, home to Queensland’s internationally renowned METS industry.”

A$798 million proposed project involving the development of a greenfield open-cut mine and processing plant to extract vanadium, high purity alumina and molybdenum has received coordinated project status.

The ‘coordinated project’ declaration from Queensland’s CoordinatorGeneral for the Vecco Critical Minerals Project paves the way for multiple environmental approvals.

The $798 million proposed project would see an open-cut mine built around 70km north of Julia Creek, along with a critical minerals processing plant. The plant would supply minerals for use in the local manufacture in Townsville of rechargeable batteries for grid scale energy.

The project is predicted to create up to 300 jobs over the construction period and up to 274 jobs during the mine’s operational phase. Pending approvals, construction on the project is anticipated to start in 2025, with the operational phase expected to begin in late 2026.

The declaration allows the CoordinatorGeneral to facilitate environmental approvals from the Queensland and Federal Governments.

Queensland Minister for State Development and Infrastructure, Grace Grace, said Queensland’s status as a

world leader in renewable energy is built on its abundant natural resources and skilled workforce.

“We can further enhance this status through an exciting proposal with the potential to further expand the North West’s critical minerals industry and generate local manufacturing jobs.

“With demand for battery storage set to increase tenfold by 2030, this is a once-in-a-lifetime opportunity for Queensland to become a driving force in the development, manufacture, and deployment of new energy storage technologies.”

Queensland Coordinator-General, Gerard Coggan, said, “It is important we facilitate and responsibly progress projects that help transition Queensland’s economy and provide pathways to realise the potential for new industry and new jobs creation as we move towards the state’s low emissions targets.

“The community and stakeholders should have a say in evaluating the economic, social and environmental effects. The coordinated project declaration allows this to happen in a consistent, considered and sequenced way.”

Mr Coggan said that in his role as Coordinator-General, he would oversee the project evaluation by all government

agencies, considering community issues and possible impacts.

“The declaration fosters a whole-ofgovernment approach to developing critical mineral projects and to support positive outcomes for North West Queensland communities.”

Mr Coggan said critical minerals are referred to as ‘critical’ because they are of high economic importance to the transition to renewable energy.

“The critical minerals proposed for mining in this area would be used for batteries that will provide grid energy storage, and other electronic devices.”

Vecco Group Managing Director, Thomas Northcott, said that demand for vanadium flow batteries is rapidly increasing to meet the world’s energy storage demands.

“Australia’s demand for medium and deep duration storage by 2045 has been estimated at over 100GWh by the market operator, and vanadium flow batteries made right here in Townsville from Queensland’s minerals can help meet this need while creating good jobs in regional areas.

“We will be able to integrate mining and manufacturing and apply our expertise in critical minerals into the downstream supply chain to assist Queensland to achieve its renewable energy target.”

When Evolution Mining needed an underground support vehicle for its Ernest Henry copper-gold mine, it turned to a leading equipment and vehicle manufacturer to deliver the solution.

In January 2024, Elphinstone introduced the new low-profile E15 series to the market, a welcome addition to the existing range of E10 underground support vehicles.

The E15 series features a ‘built for purpose’ range comprising

Your industry personnel roundup – we cover who’s moved where, which boardrooms have been shaken up and the new leaders making big decisions in organisations across the industry.

In June, Alcoa Corporation announced the appointment of a new Vice President Operations – Australia and President of Alcoa Australia, with a projected start date in October. Elsabe Muller was selected for the position, to be responsible for the company’s bauxite mining and rehabilitation, alumina refining and aluminium smelting activities in Western Australia and Victoria.

Also in June, Core Lithium announced the appointment of James Virgo to the role of CFO. Mr Virgo has been with Core since 2023 and served as Interim CFO from March before officially stepping into the role.

June also saw the resignation of Non-Executive Director, Stef Loader, from gold producer St Barbara. Ms Loader held the role from November 2018 to 30 June 2024, having served on both the Audit and Risk Committee and the Safety and Sustainability Committee.

In July, Evolution Mining welcomed Fiona Hick as a Non-Executive Director

and member of the Sustainability Committee. Bringing 29 years of experience in the minerals and energy industries, Ms Hick previously held senior roles at mining companies such as Rio Tinto, Woodside Energy and Fortescue. Global Lithium Resources announced the resignation of a Non-Executive Chairman as well as the appointment of the role’s successor in July. Geoff Jones’ resignation was effective immediately, with the Board appointing previous Managing Director, Ron Mitchell, to the role.

In July, Rio Tinto announced that Katie Jackson would lead the company’s copper business, moving into the role concurrently with Bold Baatar’s move into the Chief Commercial Officer position. Before assuming the Chief Executive Copper role, Ms Jackson served as Rio Tinto’s President of National Grid Ventures, taking responsibility for the development and operation of largescale energy infrastructure assets.

Fortescue announced a leadership shake-up in July, with the management and organisational updates designed to keep the company structure “lean, impactful and agile”.

As part of the changes, acting CFO, Apple Paget, moved into the role of Group Chief Financial Officer. At the same time, Chief Corporate Officer, Shelley Robertson, became Chief Operating Officer. Assistant Company Secretary, Navdeep (Mona) Gill replaced Phil McKeiver as Company Secretary, with Mr McKeiver remaining as the company’s Chief General Counsel.

Finally, in August, Pilbara Minerals Chief Operating Officer, Vince De Carolis, stepped down from the role with immediate effect. At the same time, the company also announced the promotion of General Manager of Operations, Brett McFadgen, to Executive General Manager of Operations.

Enabling you to deliver the most sustainable green hydrogen, Danfoss will provide you a grid friendly, approved solution with impressive energy efficiency. Low harmonics and a high power factor ensure that you have a competitive power supply for your electrolyser at hand. Long experience in power conversion combined with a leading position in the world, Danfoss is your ideal partner for your investment in the hydrogen market. Take advantage of our experience to ensure that your system is scalable and economically viable. Recognized world-wide as a reliable supplier, Danfoss adheres to the highest international standards in production and development quality.

Danfoss has solutions to get your business on target for a decarbonized economy.

Learn more at Get on target in Power-to-X on our website drives.danfoss.com

The unique characteristics of gruelling fly-in, fly-out mining rosters – including long shifts and short windows of rest – are well understood, but access to premium entertainment can go a long way in easing the FIFO lifestyle strain.

There’s nothing quite like sitting down and watching your favourite show after a long day of work, and this satisfaction is amplified in FIFO workers. Having highquality entertainment options waiting for them in their rooms after a tiring shift can go a long way in helping workers relax and unwind after an exhausting day of work.

Recent years have seen increased attention directed at the facilities that mining organisations are offering their FIFO workforce. Where it may once have been sufficient to offer basic facilities and amenities, a concerted effort to boost the mental health of FIFO workers is seeing an increase in FIFO offerings that include wellness centres, pools, increased dining options and even entertainment facilities.

A mining company that partners with premium entertainment providers like Foxtel can demonstrate its dedication to caring for the mental health and well-being of its workers, in addition to bringing top-quality entertainment to its workforce.

With its quick and easy installation and lifetime warranty, Foxtel takes the backache out of FIFO entertainment, going so far as to deliver the entertainment right to workers’ rooms.

An entertained workforce is a happy workforce and Foxtel can offer FIFO workers access to the premium sports they love, including AFL, NRL, UFC and cricket. On top of this, Foxtel’s exclusive range of blockbuster movies, world-class drama TV series and 24/7 news means there is something for everyone and no worker needs to unwind from a hard day without something to watch.

The FIFO lifestyle often means spending long stretches of time away from family and friends, which can leave workers feeling disconnected and can breed feelings of loneliness and isolation.

Having all their favourite shows, movies and sports at their fingertips provides a welcome distraction and can lessen the disconnect workers feel by bringing a small piece of home to their rooms onsite.

As well as bringing comfort to workers in the peace of their own rooms, Foxtel gives mining organisations the opportunity to create a fun social atmosphere by showing sport in common areas, or the ‘wet mess’.

This added benefit encourages socialising with fellow workers, boosting camaraderie and relationship building as they sit and enjoy their favourite sports with their fellow workers. Mining companies can show major sporting events in the wet mess, including UFC, which is exclusive to Foxtel in Australia.

In addition to its wide range of sport, Foxtel is easy to access and offers non-interrupted content via satellite, meaning workers don’t have to miss out on watching the biggest sporting events. Although FIFO is a necessary part of the Australian mining industry, workers are increasingly in search of mining companies providing an elevated FIFO lifestyle for its workforce. Offering top quality perks – like Foxtel – to workers will help mining organisations ensure they are attracting top-quality talent.

In the past, protecting assets meant safeguarding tangible facilities and equipment, but in the age of data, IoT and AI, keeping digital assets safe has become just as vital.

In recent months, the mining industry has seen several malicious cyber-attacks against operations, highlighting a potential lack of industrial cybersecurity in Australia.

Two notable attacks in 2024 were made against Sibanye-Stillwater and Evolution Mining.

On 11 July, Sibanye-Stillwater announced that a cyber-attack had affected its IT systems around the globe, and that it had initiated containment measures in line with its incident response plan to isolate its systems and safeguard critical data as soon as it became aware of the incident.

Evolution Mining revealed that it had come under attack on 8 August, also by ransomware that impacted its IT systems. The company said that it worked proactively with external cyber forensic experts to contain the incident, with a focus on protecting the safety and privacy of its people, systems and data.

While in both cases the companies’ quick responses ensured minimal disruptions to systems and reduced the loss of private data, these attack attempts highlight a trend in cybersecurity risks in the industry that is likely to continue.

The critical nature and large scale of mining operations makes them particularly vulnerable, with potential cyber-security incidents posing significant threats to operational productivity, safety, employee privacy and future planning.

Industry operations increasingly rely on digital systems which are used to optimise productivity and minimise health and safety risks. As distributed control systems become more critical

to the operation of mines, so does the need to protect these systems from interference.

The mining industry has become a lucrative target for cyber-attacks. With such large operations – sometimes spread across multiple countries – the amount of data being shared to the cloud leaves operations vulnerable to malicious attacks.

Mining companies play a pivotal role in the economies of many nations, including Australia. By exploiting this vital industry, cyber criminals can enact major disruption across global supply chains and exfiltrate masses of data for future financial gain and competitive advantage. Cyber-attacks can take a wide variety of forms. Some of the most concerning types of attacks for the mining industry include:

Mining companies are continuously generating valuable data. This data can be stolen for financial gain, to give a competitor an industrial advantage, or to hijack sales and mergers. As such, cyber-attackers may execute spyware and other techniques in a cyber espionage campaign to gather that information.

Attackers can leverage attacks on other parties in a supply chain to gain a backdoor into a mine operator’s corporate network. Third-parties, such as contractors, with poor security behaviours can be a significant threat, even to

companies that are well prepared for a direct attack. For example, a connected contractor may allow a virus to migrate into the mine environment and shut down operational control systems.

This is the leading source of malicious attacks across all industries. Phishing typically comes in the form of emails that contain malware disguised as innocuous links or attachments. The goal of such an email is to acquire the credentials of a system’s user, thereby getting a foothold into the corporate network and subsequently, operations.

A holistic approach to asset protection requires companies to extend their defences to include company data and cyber assets. Building robust, proactive security systems, as well as providing quality cybersecurity awareness training for all staff, is a key step on this journey.

Investing in active defence systems that continuously scan for threats can ensure that potential attacks are detected immediately and can be acted upon. Regular penetration testing is also a useful practice. Professional ethical hackers can be employed to attempt to break through a security system, revealing weaknesses and allowing companies to shore up their defences.

Finally, having a thorough incident response plan can allow security personnel to isolate malicious attacks when they do occur, minimising an attacker’s access and keeping data, operations and staff safe.

Pumps play a role in industries around the world, including mining, with end-users choosing to purchase solutions from experts who are committed to customer satisfaction.

There’s a famous saying – ‘a jack of all trades is a master of none’ – and this can be applied to companies who stretch themselves thin by trying to supply a large quantity of products across industries.

With such a broad range of equipment alongside their pumping solutions, trying to supply and service all these products and applications can see companies lose industry-specific, in-depth product knowledge that pump end-users want from experts, leading to increased customer dissatisfaction.

A focus on satisfaction

Sacrificing expertise is not a concern for ROTO Pumps, whose focus on pumps has enabled it to hone its industry knowledge and establish itself as a pumping expert that prioritises customer satisfaction.

With its laser focus on pumps, ROTO Pumps’ world-class research and development has not only enabled it to develop customised, state-of-the-art pumping solutions, but has also helped it cement itself as a front runner in the market.

Even with its R&D team boosting product reliability and efficiency and reducing the lifecycle cost of its products, ROTO pumps is so committed to customer satisfaction that it services exchange pumps at its Dandenong head office, taking worn or damaged pumps from customers and completely rebuilding them like new.

With its extensive knowledge of pumps, ROTO Pumps understands industry needs and is committed to delivering high-quality pumping solutions to the global market.

Building international reach

Established in 1968, ROTO Pumps is the pioneer manufacturer of progressive cavity pumps in India, with more than 50 years’ experience providing high-quality, efficient and reliable pumping solutions to a wide variety of industries.

Most major pump manufacturers around the world own or have partnerships with manufacturing plants in both India and China, and ROTO Pumps prides itself on its authenticity and its ability to consistently and reliably provide top-quality products to the global market.

ROTO Pumps has exported its pumping solutions to more than 50 countries around the world, demonstrating its dependability as a manufacturer and supplier of highquality equipment.

ROTO Pumps has been supplying directly into Australia since 2001 – its first warehouse outside of India. With its head office in Dandenong and satellite sales managers in Sydney, Brisbane and Perth, ROTO Pumps’ reach is steadily growing as end-users recognise its high-quality products and expertise.

Pumping equipment must be especially robust to withstand the harsh conditions of mining applications. Responding to the needs of Australia’s critical mining industry ROTO Pumps offers a range of solutions to be used in a variety of applications, including mineral processing, slurry transfer, dewatering, water spray for dust suppression and other general applications.

For more information, visit rotopumps.com.au

E mpowering your mine operations with Roto’s high pressure flexible shaft series pumps. Unleash the solution that challenges excess wate r, ensuring safe and efficient operations ; the Underground Maintena n ce Engineers’ Choice for ground water control.

Features:

•Robust construction for prolonged life and reliable performance

• Adaptable for challenging underground environments, available in fixed station configurations for single lift or staging along with portable packaged solutions

• Forge a direct connection with the manufacturer, ensuring personalised support,

To ensure they are getting products and services that match their needs, mining organisations want to partner with suppliers that have in-depth industry knowledge and proven experience.

Along history of servicing an industry displays a high level of industry knowledge, as well as an in-depth understanding of the unique requirements of the sector.

Celebrating its 40th year servicing the mining industry in 2024, Black Duck started out as a manufacturer of roll tarps and motor trimming in the agricultural sector.

Black Duck’s CEO, Phil Grace, explained that the company was based in a small farming town at the beginning, and relied on farmers for its work.

“With the seasonal nature of farming, we found it very tough, as during the busy seasons we were overloaded with work but then would have almost nothing for the next few months,” Mr Grace said.

“I had been trying to work out how to get consistent work year-round when a local farmer came in and enquired whether we would make him a removable canvas cover to go over the seats on his brand new LandCruiser.”

Mr Grace said that his initial instinct was to refuse due to the costly nature of creating seat covers from scratch, but he had a “light-bulb moment” later that evening.

“That night I was thinking about it – why not get a range of reusable patterns for the most common farm vehicles and make them in batches?”

Black Duck’s break into the mining industry was achieved by introducing its seat cover products to the dealers and motor body builders who were supplying and fitting out fleets for the mining industry.

Despite facing many challenges as a small business entering a large industry, Black Duck’s products proved to be capable of withstanding the conditions of the mining sector and secured its place as a valued supplier in the industry.

Now, Black Duck has been a part of the mining industry for decades, growing, changing and adapting alongside the sector.

Mr Grace said that in his years supplying the industry, the biggest change he’s witnessed is the introduction of seat mounted side airbags.

“It created major problems for us, as initially the vehicle manufacturers said that users were not allowed to put a removable seat cover on the seats.

“We overcame this problem and after much research and testing we had a final, safety-approved product.”

While delivering top-quality products that suit the industry’s needs has gotten increasingly complicated, Black Duck’s commitment to excellence and integrity has cemented its place as a respected manufacturer and supplier.

Mr Grace said that Australia has benefited immensely from the resources sector, and that he is grateful to be a part of such an important industry.

He also said that Black Duck is eager to offer its customers new products in addition to its quality seat covers.

“We have a few other niche vehicle protection products and we have also been working on expanding the range. Once we have done the required testing, we will release these to the market.”

Mr Grace said that he is excited to see what the future holds for Black Duck, for the mining industry and for Australia.

Since Black Duck® started in 1984, we understand how much the Australian Mining Industry has changed over the years. This is why Black Duck® has been pioneering product development to ensure our seat covers offer your vehicle the heavy-duty protection it needs while complying with all health and safety requirements.

Working in mines means a lot of dust and dirt gets in your vehicles. Our materials, Can vas and 4Elements®, are tightly woven to stop any dust, sand or dirt from ever touching your original seats, safeguarding your mining fleet vehicles' value and helping you avoid unnecessary charges or loss of value due to wear and tear. Our seat covers are the perfect fit for the mining and civil environments.

From labour costs to the specialised, large-scale equipment required, operations in the mining industry are some of the most capital-intensive in the world. Realising savings wherever possible is crucial.

Surveying is integral to every stage of a mining operation and, as such, it can take up a large portion of a project’s time and budget allocations. Selecting a surveyor that utilises the most efficient equipment and possesses in-depth industry expertise can make all the difference.

Light detection and ranging (LiDAR) technology uses remote sensing to measure distances to the earth. It has significant benefits for surveying in the mining industry as it ensures accuracy, saves time and boosts productivity.

LiDAR technology streamlines the surveying process, reducing the time required for data collection and analysis.

After extensive market research on selecting the right tool for the job, West Coast Surveying selected a scanner that can accurately deliver 5mm repeatability, even in complex environments involving dense foliage and tree canopies.

Capable of scanning at 500,000 points per second with scanning speeds of 250 scans per second, the technology significantly enhances the detail in aerial mapping.

Each pixel is coloured to match the point measured and point clouds are colourised with an intergraded 45MP orthographic internal camera. This makes the data more visually pleasing and a welcome change from previous greyscale images.

Director, Malcolm Clinton, said that LiDAR captures surfaces seamlessly when compared to other methods, reducing time in the field and providing results that can easily be repeated.

Without the extensive time barriers of fieldwork and data processing, LiDAR provides easy-to-generate reports with processing times of under an hour, much less than traditional methods.

Surveying that utilises LiDAR technology plays an important role in reducing a mining operation’s overall costs.

The accurate and high-quality data collected by LiDAR offers critical insight for mining applications involving tailings dams, bulk earthworks and road construction.

LiDAR is significantly more reliable than photogrammetry, particularly when it comes to calculating volumes moved. With its laser technology, LiDAR provides precise volume measurements, which prevents costly payment errors for material miscalculation.

No two mining projects are the same and West Coast Surveying understands the unique priorities and goals different clients have. The company offers a distinct approach, with each project perfectly tailored to the needs of the client.

The experienced team of professionals use advanced technology and techniques, including LiDAR, to ensure customers’ expectations are not only met, but exceeded.

Since its establishment in 2021, the company has continued to offer its clients the latest in surveying technology.

“West Coast Surveying is the industry leader in utilising this technology; we have invested time and resources and believe that we can embrace tomorrow’s future today,” Mr Clinton said.

West Coast Surveying offers start to finish support – delivering time and cost savings from tendering stages, through to project construction.

Li-DAR – using the latest technology coupled with DJI drones, we're able to capture data and efficiently clean the natural bush to a ground truth surface.

Machine Control set up GPS base and co-ordinate your site to maximise the productivity of your earth moving equipment. Models can be transferred by the 4G/5G network or installed manually to the system.

Volumes and design can be created to suit your criteria and reports created show how the site is progressing in EOM reports.

Since inception in 2021 we have successfully completed projects from Ravensthorpe to the Kimberly with repeat clients that have appreciated our services and professional staff.

Get in contact to see how we can help

P 0424 324 490 E

By Timothy Weber and Professor Andrew Blakers, Australian National University

The world is rapidly moving towards a highly electrified, renewable energy future and the mining industry has a key role to play in the transition.

When it comes to generating electricity, solar photovoltaic and wind have effectively won the energy race. Solar and wind inherently need energy storage systems that can be charged when there is a surplus of electricity supply and discharged to fill the gaps when the sun is not shining and the wind is not blowing.

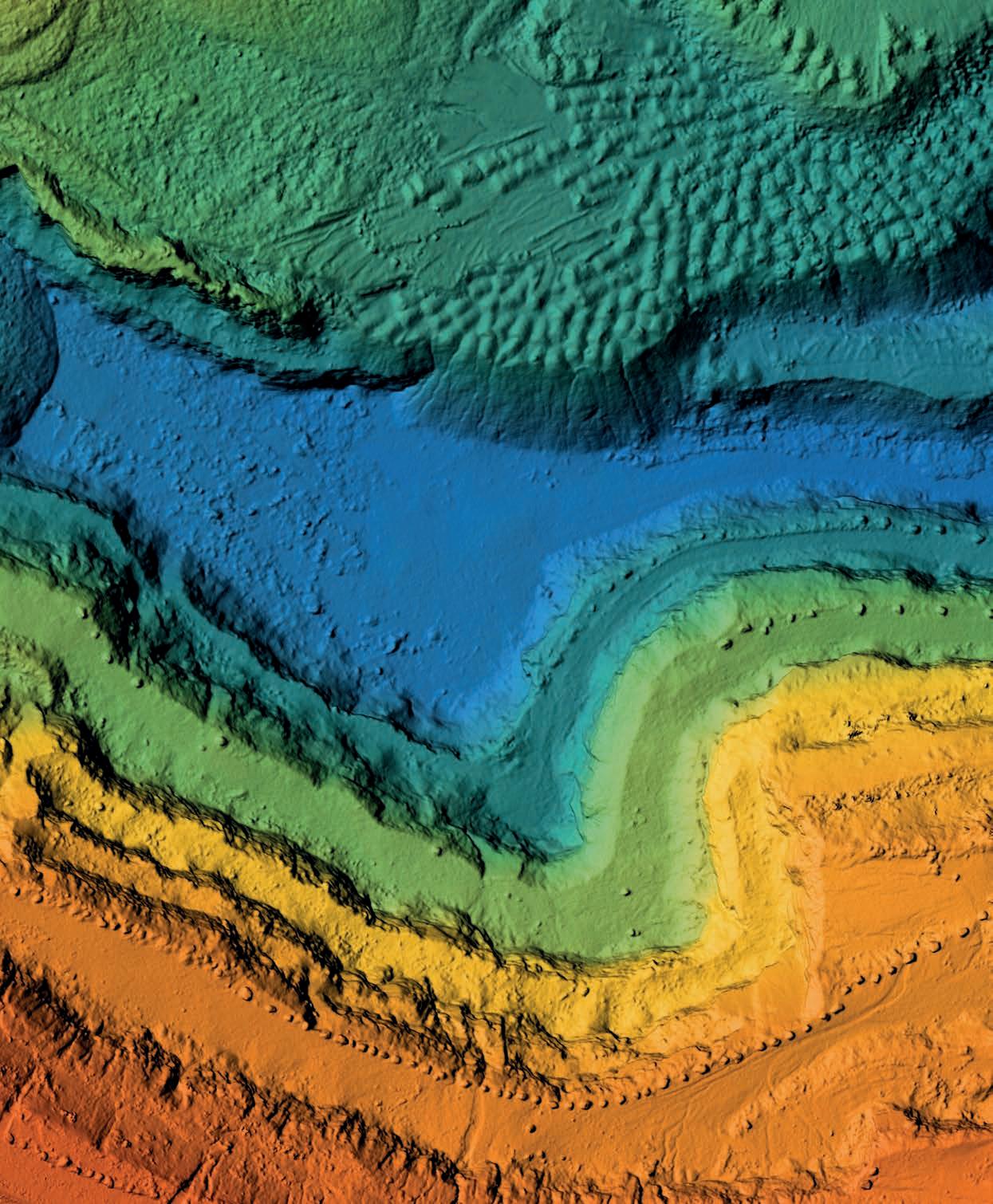

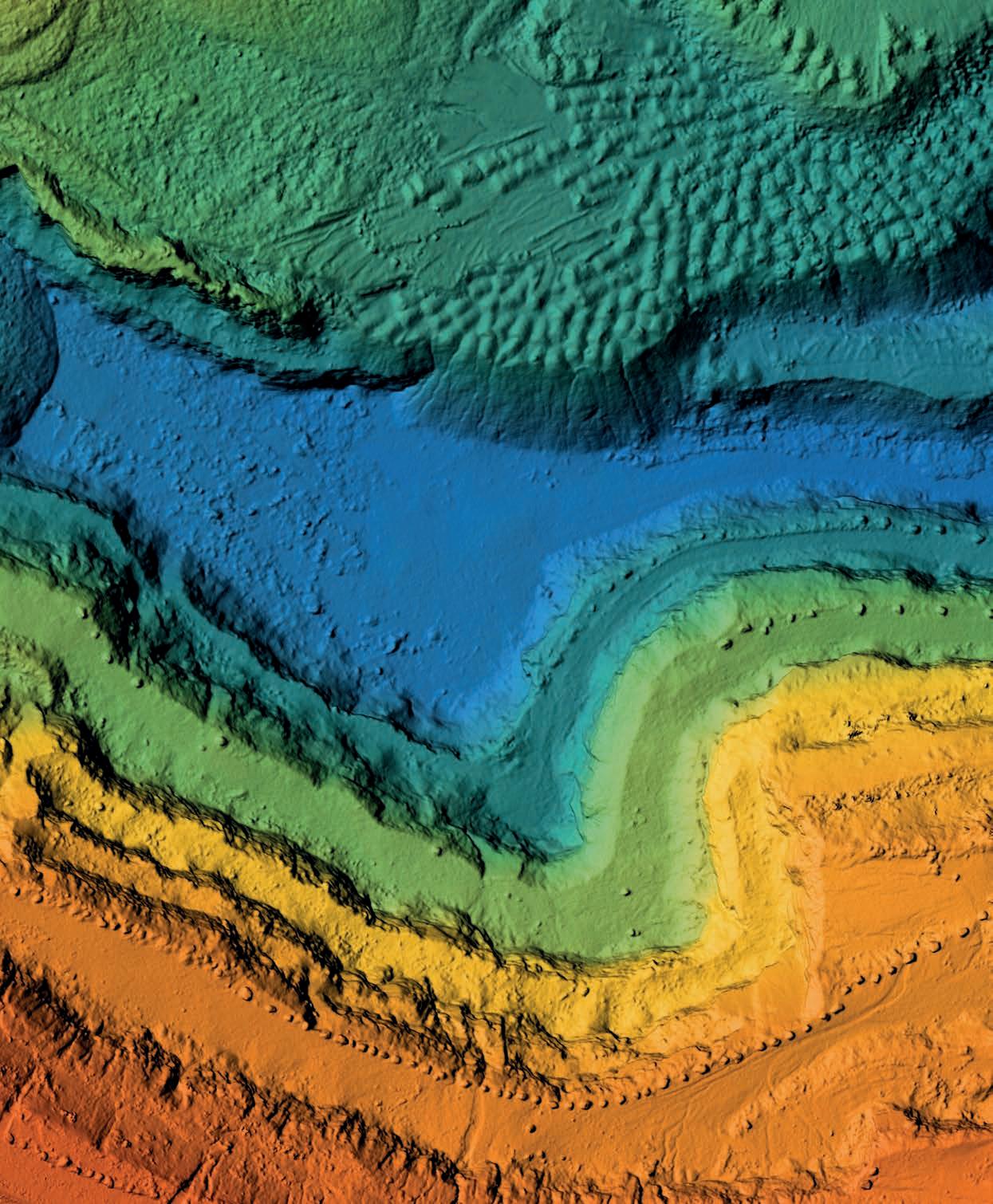

Mine sites offer an opportunity at their end-of-life to be repurposed into low-cost pumped hydro energy storage systems, providing reliable firm power for the electricity grids of the future.

Recognising this, a team of researchers from the Australian National University (ANU) created a series of atlases that highlights former mining sites that have the potential to host pumped hydro storage.

Around the world, solar and wind made up approximately 84 per cent of new generation capacity added to electricity grids in 2023. Annual solar installations are doubling every three years, and solar and wind are now the cheapest form of new electricity.

Any other low-carbon technology, including nuclear and carbon capture and storage, would require extraordinary growth rates to become competitive with solar and wind to meet decarbonisation targets.

Figure 1 utilises IRENA, IEA, World Nuclear Association and Global Energy Monitor data to display annual installations of electricity generation technologies globally.

In the Australian National Electricity Market, about 40 per cent of electricity is currently generated from renewable sources. The Federal Government has set a target of 82 per cent renewables by 2030 and established the Capacity Investment Scheme to secure 32GW of renewable capacity to meet this target. Almost all of this renewable generation will come from solar and wind, as this is almost all that is being built at the moment.

According to the Australian Energy Market Operator (AEMO), electrification of transport, heating, cooling and industry could double electricity demand, and a large hydrogen industry could double it again. Australia is in the middle of the fastest energy change in history.

Rapidly rising electricity demand coupled with the low cost of solar and wind generation means that most of Australia’s electricity supply will be variable. This means that when the sun does not shine or the wind does not blow, many of these generators will not be able to produce new electricity. It is essential to integrate energy storage systems into the grid to fill the gaps in electricity supply.

According to various analyses from ANU, AEMO, and the Commonwealth Scientific and Industrial Research Organisation (CSIRO), Australia may require between 480–1050GWh of energy storage by 2050. The actual amount will depend on the level of grid

interconnection and the size of Australia’s hydrogen production economy.

Pumped hydro energy storage is currently the cheapest form of overnight storage. It is a mature technology that constitutes about 95 per cent of all existing electrical energy storage around the world. These pumped hydro systems are complementary with batteries, which excel at short-duration storage on the scale of seconds-to-hours. A future electricity grid would benefit from hybrid storage configurations, where pumped hydro can trickle-charge high-power batteries, allowing them to meet peak demand at a low cost during the day.

Most possible pumped hydro sites are located off-river. They are formed using a pair of reservoirs with a large elevation difference (called the ’head’) connected by a high-pressure tunnel. When there is excess generation in the grid, water can be pumped from the lower to the upper reservoir. Later, the water stored in the upper reservoir can be released through a turbine to fill the gaps in electricity supply. Since these systems are off-river, they form a closed loop that recycles the water up and down for up to 100 years. Off-river pumped hydro systems do not involve any new dams on rivers. This unlocks an enormous number of options for sites far away from rivers with very large head and small dam walls. Doubling the head, in turn, doubles the energy storage, dramatically reducing the cost per unit of energy storage. Off-river sites generally have a low environmental footprint compared to on-river systems.

Due to the lack of cooling towers and fuel processing, a 100 per cent renewable energy system mostly consisting of solar, wind and pumped hydro also requires far less water than a comparable fossil fuel-based energy system.

The 100% Renewable Energy Group at ANU has been developing Global Pumped Hydro Energy Storage Atlases that locate possible sites for off-river systems outside large urban areas. These atlases account for over one million unique options around the world. The recently developed Brownfield Atlas focuses on mining pits, pit lakes and tailings pods that have the potential to be paired with a nearby upper reservoir, forming a cheap and convenient pumped hydro system.

Mine sites have the benefit of existing infrastructure that can be repurposed for a ‘brownfield’ pumped hydro energy storage system; one of the reservoirs has already been cleared and dug through the original mining operations. Mines also require electricity transmission, major road access, nearby accommodation for developers and operators and water sources and licences for their operation, all of which can be rolled into the development and operation of a pumped hydro system.

Building new transmission is one of the main bottlenecks for Australia’s renewable energy transition due to the need to negotiate with large numbers of private landholders. Therefore, existing

onsite transmission infrastructure can greatly streamline the development of brownfield pumped hydro compared to other types of reservoirs.

Just having a large mining pit, however, is not enough for a pumped hydro system.

A nearby location with a higher elevation must also be found for the upper reservoir. The ANU group used a global dataset of terrain elevation to model reservoirs and pair them with nearby mining pits. The sites with large head, large reservoir volumes relative to the dam wall size (water-to-rock ratio) and small separation distances are all recorded in the Brownfield Atlas. Each site is assigned a ‘cost class’ from AAA to E, with a class E site costing roughly six times more than a class AAA site.

Although mining sites have a lot of great features that help to simplify the development of a pumped hydro system, they are not without their own unique challenges. One such challenge is that mining pits are often in possession of steep conical sides. Additionally, rapidly changing the water level can strain the walls of the mining pit and put pressure on the turbines, limiting the water volume that can be practically used for energy storage. Contaminants within the mining site, such as sulphides, could corrode pumped hydro components or contaminate freshwater ecosystems if they seep into the environment. These technical challenges may require designs that incorporate reinforcement

84 per cent of Australian brownfield pumped hydro options (red) are within 10km of existing transmission lines.

of unstable slopes and reservoir linings to prevent water seepage.

There is also the risk of the land surrounding active mining sites containing additional mineral reserves, making mineral rights an essential consideration for the impact of future mining on the pumped hydro system. Mining pits are also typically smaller and more geographically constrained compared to new greenfield pumped hydro systems where both reservoirs are built on undeveloped land. This smaller size makes them ideal for providing overnight storage of solar generation but limits their ability to provide seasonal storage during the winter.

Some combination of pumped hydro systems consisting of brownfield, greenfield and sites that repurpose existing lakes and reservoirs (bluefield) will be necessary to support a transition to 100 per cent renewable generation.

The last pumped hydro system completed in Australia was Wivenhoe Power Station in 1984. Recently, the development pipeline has exploded with new pumped hydro projects as solar and wind generators have rapidly connected to the grid.

In Australia, there are at least 23 pumped hydro projects with 21,000MW/ 660GWh of storage at various stages of investigation and development that have been publicly announced. Snowy 2.0 makes up almost half of this prospective energy storage, with completion expected by 2028.

One of the earliest examples of a brownfield pumped hydro system is Dinorwig Power Station, completed in 1984 in northern Wales, repurposing an old slate quarry. In Queensland, the Kidston Pumped Storage Hydro Project (250MW/ 2GWh), which repurposes two adjacent mining pits, is due to be completed at the end of 2024. Muswellbrook Pumped Hydro (500MW/ 4GWh) and Mt Rawdon Pumped Hydro (2000MW/ 20GWh) are other brownfield sites that are also undergoing feasibility studies.

The Brownfield Atlas produced by ANU located 904 mining sites in 77 countries which could be repurposed as pumped hydro systems at their end-of-life. Of these sites, 37 were in Australia with a total energy storage potential of about 540GWh.

It is unlikely, however, that all 23 pumped hydro projects in Australia’s pipeline will be determined to be feasible. Thankfully, the potential sites on the Global Pumped Hydro Energy Storage Atlases, including the Brownfield Atlas, provide 100 times more energy storage than what would be required for Australia to support a 100 per cent renewable energy system. This means that developers can afford to be picky – if one site is deemed infeasible, then there are thousands of other good-quality options available to choose from.

Renewable generation and energy storage are a solved problem. Off-theshelf technologies such as solar, wind, pumped hydro and batteries are the backbone of the energy transition. There is no need to wait for dramatic improvements in technology; this means Australia can just focus on getting the job done.

For more information, visit re100.eng. anu.edu.au or scan the QR code.

As Australia continues its path to net zero, there are increasing calls for the mining industry to utilise equipment that reduces its environmental footprint.

Mining plays a key role in the clean energy transition, with a variety of critical minerals vital to renewable technologies such as solar panels, batteries and magnets.

Though the output is imperative to Australia’s renewable future, implementing sustainable practices can minimise the environmental impact of mining operations on a day-to-day basis.

Although finding ways to electrify and decarbonise the large machinery associated with the sector can make an impact on reducing emissions, an oftenoverlooked area is the smaller equipment that powers the industry.

Valves are essential components in a mining operation and can contribute to its overall sustainability.

Many valves in the mining industry rely on pneumatic actuation, in which compressed air is used to enact a mechanical motion. The production of compressed air is an energy-intensive process and, as such, these types of valves have high overall energy consumption.

Pneumatic actuator valves require a stable and continuous supply of air or gas, meaning their performance can be affected by fluctuations in air supply. Leaking can further exacerbate energy

consumption and lead to environmental hazards. Additionally, pneumatic actuator valves require more maintenance and have shorter lifespans than other types of actuators, resulting in negative environmental outcomes.

Whilst pneumatic actuated valves are the norm in the industry, utilising alternatives can boost a mining operation’s sustainability.

Bürkert’s fluid control systems provide unparalleled valve solutions that are customisable to fit every mining application. With high flexibility thanks to modular designs, a diverse choice of materials, longevity, high-reliability and low environmental impact, Bürkert valves stand the test of time.

When it comes to sustainable alternatives for pneumatic actuated valves in the mining industry, electromotive and solenoid valves are often a better replacement, with applications ranging from dosing to dust suppression.

Electromotive valves offer accuracy, ease of control and, importantly, low energy consumption. Bürkert range of electromotive valves include angle seat, diaphragm, globe, ball, butterfly and disc types, all of which come in multiple configurations to suit the needs of the operation.

Solenoid valves are electromechanically operated and allow fluids or gases to be shut off, released, dosed, distributed or mixed. Valves with kick and drop technology have coils with double winding that is initially excited by a high electric current before switching to an energy-saving holding power consumption. Bürkert’s solenoid valves with kick and drop coil technology are not only durable and silent, but they allow for energy savings of up to 80 per cent.

In addition to optimising onsite efficiency, Bürkert’s range of electromotive and solenoid valves offer an opportunity for mining operations to minimise their environmental footprint from the inside out.

Bürkert’s valves enable more efficient resource extraction, reducing energy consumption and waste generation. The company prioritises eco-friendly practices and adheres to stringent quality standards from design and manufacturing to installation and maintenance.

Bürkert’s range of solenoid and kick and drop valves will be on display at Booth 13 in the German Pavilion at the International Mining and Resources Conference.

To learn more, visit burkert.com.au

Enhance your operations with sustainable solutions

Meet us at the show 29-31 OCT 2024

German Pavilion

Booth 13

We make ideas flow.

We make ideas flow.

Solutions in the mining industry must serve the dual purpose of being advanced enough to withstand the harsh conditions of mine sites, while also supporting sustainable mining practices.

With so much change occurring across Australian industries, including mining, it’s important for the suppliers and manufacturers that provide solutions to these sectors to also adapt and grow to better serve the industry.

complete Hayward Gordon range of products locally.

for feed, these mixers enhance the efficiency of the flotation process, leading to higher recovery rates and improved performance.

Hayward Gordon mixers are designed to handle the most challenging and demanding conditions in the mining and mineral processing industry.

To achieve this goal, EBARA CORPORATION acquired Hayward Gordon ULC in October 2022. The integration allowed EBARA to expand its product range and manufacturing capabilities, as well as enhancing its global sales and financial stability.

Founded in Japan in 1912, EBARA began as a pump manufacturer and was the first company to manufacture centrifugal pumps in Japan. Today, it boasts a global presence with over 100 companies across five continents and a workforce exceeding 19,000 people.

Hayward Gordon was established in Ontario, Canada in 1952, and was originally a regional supplier to the North and South American regions. Hayward Gordon has emerged as a global leader in heavyduty pumps and mixers, particularly within the minerals industry.

EBARA PUMPS AUSTRALIA has been serving the local market since 2000. The company’s pump success has prompted its expansion into Australia’s minerals industry. To facilitate this, EBARA PUMPS AUSTRALIA forged a closer partnership with Hayward Gordon in early 2024. As a result, it now offers the

Hayward Gordon’s gold leach CIL mixers are among the most efficient in the world, crucial for the gold leaching process. These mixers ensure uniform mixing of slurry, maximising contact between the ore and leaching solution, which enhances gold recovery rates. The highefficiency of these mixers significantly improves the extraction process, making them a vital component in gold mining operations.

The storage tank agitators from Hayward Gordon are crucial for maintaining slurry homogeneity, preventing sedimentation and ensuring a consistent feed to downstream processes. Built to handle high solids concentrations and abrasive solids, they provide reliable performance, ensuring process stability in mineral processing operations.

Hayward Gordon’s conditioning mixers are essential to the flotation process, ensuring proper blending of additives and thorough mixing of the slurry before flotation. By creating the ideal conditions

Every mining operation is unique, and Hayward Gordon mixers can be customised to meet specific requirements. Whether it’s handling slurry with varying viscosities or operating in extreme conditions, these mixers are engineered to deliver optimal performance and durability. Customisation ensures that each solution is tailored to the specific needs of the operation, maximising efficiency and effectiveness.

The mixers offered are designed to be energy-efficient and environmentally friendly, aligning with the global push towards sustainable mining practices. This focus on sustainability ensures that solutions not only meet current regulatory requirements but also contribute to long-term environmental stewardship.

With an experienced local presence at EBARA PUMPS AUSTRALIA, customers can expect enhanced support and service. From timely maintenance to technical assistance, EBARA is dedicated to ensuring that clients receive the best possible service for their equipment, minimising downtime while maximising operational efficiency. The local support infrastructure means faster response times and more personalised service, ensuring all operations run smoothly.

By Alex Gore, Senior Communications Officer, Department of Biodiversity, Conservation and Attractions

Although output and production remain a key focus area for mining companies’ reporting, information on an organisation’s environmental, social and governance credentials are increasingly sought-after.

Australia is home to a broad, diverse range of terrain, with everything from snow-capped mountains to large deserts, and tropical forests to bushlands. These landscapes are home to an abundance of unique flora and fauna, and the protection and preservation of it is especially significant.

With the rapid growth of Australia’s industries pushing infrastructure out of urban locations and further into the remote areas of the country, these landscapes and their flora and fauna are increasingly being impacted.

Most of the work in the mining industry is conducted in rural locations, and often on previously untouched areas. Mining organisations that take action to reduce the impacts of their operations and look after the areas they mine on showcase a commitment to safeguarding the environment for future generations.

The iron ore-rich Pilbara is one of the undisputed powerhouses of the Australian economy. Beyond the mines, the Pilbara has high species richness and many endemic plants and animals. Within its landscape are also vast spinifex-covered plains, rugged hills and spectacular gorges that host elusive wildlife, like northern quolls, and one of the richest reptile collections in the world.

Protecting the Pilbara’s unique biodiversity has been a priority for some time and these efforts were bolstered in June 2024 through a new strategic partnership between the Western Australian Government and Rio Tinto.

The Rio Tinto-funded Pilbara Conservation Project is a four-year, $8 million effort to further integrate Traditional Owner knowledge into the work of the Department of Biodiversity, Conservation and Attractions (DBCA) at high-conservation value areas and tourism hotspots like Karijini National Park, which receives over 300,000 visitors annually, as well as Millstream Chichester National Park, and other sites across the region.

The funding will also help support DBCA’s delivery of bushfire management, weed management and feral animal control at Karijini National Park.

Western Australia’s Minister for Energy; Environment; Climate Action, Reece

Whitby, described the partnership as a win for the environment.

“It’s also a win for the community, it’s a win for conservation, it’s a win for economic development and sustainability, with Traditional Owners being supported and ranger programs being engaged.

“Conservation is a shared responsibility, and this new partnership demonstrates how government, industry and Traditional Owners can work together to manage biodiversity values through practical, on-ground actions.”

The mining industry is not entirely alone in its efforts, and in many sectors, industry is responding to the Western Australian Government’s commitment to a longterm integrated vision and strategy for a sustainable future.

Rio Tinto Iron Ore Managing Director of Port, Rail and Core Services, Richard Cohen, said the environment, the community and industry alike would benefit from voluntary naturepositive reforms such as the Pilbara Conservation Project.

“Maintaining Pilbara biodiversity is critical not only for our business today but also for future generations within the region and we recognise our responsibility to understand and effectively mitigate our impacts on nature through collaborative partnerships.

“Partnerships like the Pilbara Conservation Project are crucial to delivering nature-positive outcomes, with collaboration, resource sharing, innovation, local engagement and collective effort needed to address the complex challenges with environmental conservation and restoration.

“Most importantly, this project will enable DBCA and Traditional Owners to continue to care for Country, placing Traditional Owner knowledge at the heart of conservation management.”

The partnership also includes significant resources for research and monitoring projects to improve evidencebased land management, something that was highlighted at the project’s launch in Karratha by DBCA Director General, Stuart Smith.

“The Pilbara region has enormous biodiversity and conservation value. The great thing about this partnership is it brings together some of the key players to really protect that biodiversity and conservation,” Mr Smith said.

“You’ve got DBCA working with Traditional Owners and Rio Tinto, all bringing their expertise to protect the environment. And that partnership is going to deliver great things for improving the biodiversity and conservation in the Pilbara.”

Full-time ranger positions within DBCA, as well as training and fee-for-service work for Aboriginal ranger groups, are central to the project’s design. Management planning for all fire, weed and feral herbivore management will be carried out alongside Traditional Owners including Nyamal, Yindjibarndi, Ngarluma, Yinhawangka, Nyiyaparli, Banjima and Eastern Guruma.

Scientific studies supported by the project will focus on fire-sensitive Pilbara landscapes, including the development of a long-term fauna monitoring program to inform adaptive conservation management actions. Aboriginal ranger groups will contribute cultural fire knowledge and help co-design the fire program and monitoring in national parks.

An important component of the project will be the development of fine-scale vegetation maps produced through remote sensing and field surveys. These maps will inform the continued

creation of a prescribed fire mosaic within the landscape that will better protect biodiversity, cultural and infrastructure values and provide an invaluable tool to limit the size and impact of bushfires.

The project’s focus on the effective management of priority weeds will aim to improve vegetation and habitat quality within the region’s national parks. Collaboration with a broad range of stakeholder groups will also be improved as part of the project and accessible information on weed control methods will be developed to ensure land managers can prioritise weed control to the most important species.

Weed mapping with Yindjibarndi rangers along sections of the Fortescue River within Millstream Chichester National Park has commenced. The initial focus is on mapping and controlling the invasive plant Parkinsonia and date palms.

At Karijini National Park control of the Agave cactus and date palms has commenced with strategic weed mapping being undertaken in important tourist destinations at Kalamina and Dales Gorge.

Feral camels and donkeys are widespread through the Pilbara and can have significant negative impacts on the environment, including fouling water

courses, degrading native vegetation and competing with native wildlife for food, water and shelter.

The funding from Rio Tinto will increase collaboration and engagement on landscape scale programs for large feral herbivores and allow management to extend outside of national park boundaries in partnership with other key stakeholders in the Pilbara, including Recognised Biosecurity Groups, pastoralists and Aboriginal ranger groups.

A key priority that is shared and echoed by the parties involved in the partnership is the importance of safeguarding areas like the Pilbara for years to come.

Yindjibarndi Senior Ranger, Simon Lockyer, acknowledged that there is a need to care for Country and safeguard culture and heritage.

“Culturally we need to protect it, sustain it and look after it for future generations. We need to follow our ancestors and their footprints; what they've left behind. We do cultural mapping, looking after heritage, prescribed burning, quoll trapping.

“Just being on Country, it gives you a different world and a feeling. It lifts your spirit. It really soothes your soul.”

At the conservation project’s launch in Karratha, Mr Cohen spoke about the company’s values and its commitment to the region.

“The Pilbara is such an important part of Australia – both in its Traditional Owner heritage and its amazing landscape, flora and fauna. It’s also very important for our business.

“We recognise we have got a really important part to play in ensuring that we maintain and minimise our impact on this lovely and beautiful environment.”

With more mines expected to be built and developed to stay abreast of global

demand for Australia’s minerals and commodities, more land is expected to be impacted by the industry across Australia. Conservation partnerships like the Pilbara Conservation Project are a way for the industry to demonstrate its commitment to minimising environmental impacts and take steps to preserve the country’s unique landscapes for future generations.

We produce Linear Motion Screens (HLS) and Circular Motion Screen (HKS) with a maximum length of 10,000mm and a maximum width of 4,000mm. We also deliver Banana Screens, Dewatering Screens and Hot Screens for material up to 1,000 °C.

With a working moment of up to 15,000kgcm, our drive system exciters are also compatible with other brands. We are searching for a professional partner in Australia for sales and service.

Call +49 (0) 6157 402 9982 or email info@hoppeschwingtechnik.de

To learn more about Hoppe Schwingtechnik GmbH and its products, please visit www.hoppeschwingtechnik.de

A mining substation as part of APE’s refurbished and repurposed equipment range.

In an era where sustainability and reliability are paramount, customers are in search of power equipment solutions that combine innovation with dependability.

Established with a vision to provide robust power solutions while championing environmental stewardship, Australian Power Equipment (APE) has secured a place for itself as a provider of choice for a diverse clientele.

Founded and operated by Co-Directors, Abby Crawford and Andrew Cockbain, APE prides itself on its 100 per cent Australian ownership and dedication to serving businesses worldwide.

Specialising in a wide array of power solutions, the company represents renowned global brands such as Üntel, B&D, Leistung Energie, WE Walters, and CAB. These strategic partnerships ensure APE delivers high-quality power equipment tailored to meet the varied needs of its clientele.

APE not only offers brand-new products but also champions a circular economy through its extensive range of refurbished and like-new equipment. This approach supports environmental conservation by reducing waste and provides cost-effective solutions to clients with urgent equipment needs.

Ms Crawford said, “Our circular economy approach allows us to repurpose stranded assets quickly, saving both time and valuable resources that would otherwise be lost to landfill or scrap.”

The concept of a circular economy is central to APE’s business model.

By refurbishing and repurposing equipment from sites across Australia

and internationally, APE provides agile solutions to clients facing critical equipment shortages or failures. This capability is particularly crucial in industries like mining and renewables, where operational continuity hinges on the availability of reliable power equipment.

An example of APE’s circular economy practices is the acquisition of transformers from decommissioned coal mining operations, refurbished to meet the exacting standards required for renewable energy projects. This supports the transition to sustainable energy sources, as well as extending the lifespan of equipment that might otherwise be discarded prematurely.

Beyond product offerings, APE integrates sustainability into its organisational ethos through a three-fold approach encompassing safety, environmental stewardship and community contribution.

Ms Crawford said, "Our commitment to sustainability is ingrained in everything we do – from complying with stringent environmental regulations to actively supporting local communities and wildlife conservation efforts."

The company’s operational agility is another key strength. With just two directors overseeing operations, APE leverages its extensive network of industry contacts and specialised service providers to deliver tailored solutions efficiently and transparently.

This approach not only ensures flexibility and responsiveness, but also underscores APE’s commitment to delivering excellence in every aspect of its service delivery.

APE’s ability to navigate industry challenges is exemplified by its critical sourcing services, renowned for swiftly resolving urgent equipment needs.

Mr Cockbain said, "Our critical sourcing capabilities are pivotal in keeping industries operational during crises such as equipment failures or supply chain disruptions."

By sourcing and delivering essential equipment with minimal lead time, APE mitigates downtime for clients, thereby supporting productivity and operational continuity.

Moreover, APE’s dedication to quality assurance is uncompromising: all sourced equipment undergoes rigorous testing and certification by thirdparty entities to ensure compliance with industry standards and client specifications. This commitment not only safeguards operational safety but also reinforces APE’s reputation as a trusted partner in the power equipment sector.

Through its dedication to excellence, sustainability and community stewardship, APE is not just shaping the future of power solutions – it’s powering a sustainable tomorrow.

For more information, visit australianpowerequipment.com.au

Australian Power Equipment is a leading provider of low, medium and high-voltage power equipment across the Power Generation, Infrastructure, Renewable Energy and Resources sectors.

As the agents for Üntel cables, B&D transformers, Leistung Energie switchgear, CAB cable systems and WE Walter substations, they can supply new equipment to specification.

With a strong commitment to sustainability, the company also provides repurposed and refurbished equipment including substations, transformers and switchrooms.

They can provide immediate solutions to unplanned outages with their in-stock equipment or their critical sourcing solutions.

Australian Power Equipment is dedicated to delivering exceptional customer service and electrical engineering support, ensuring businesses can make best-practice decisions for their operations.

By Ian Scrimgour, Senior Executive Director, Northern Territory Geological Survey

The Northern Territory is increasingly being recognised as one of the world’s most prospective destinations for critical minerals exploration and mining.

Western Australia is widely acknowledged as the powerhouse of Australia’s resources industry, but recent investment and analysis has uncovered the potential emergence of another frontrunner.

Recent months have seen an uptick in investment and project activity in the Northern Territory, helping the Territory establish a place for itself in Australia’s resources landscape.

In the Fraser Institute Annual Survey of Mining Companies, the Northern Territory has ranked in the top three jurisdictions globally for its mineral potential in the past two surveys, and is also sitting in the top ten globally for investment attractiveness. This recognition of the Territory’s exploration potential has been accompanied by a boom in exploration expenditure in the Territory, as well as a doubling of the land area under granted exploration licences since 2018.

The Australian Bureau of Statistics’ (ABS) figures show that in 2023, more than $228 million was spent on private sector mineral exploration in the Territory, equalling the record figure that was set in 2011. A record March 2024 quarter in

the Northern Territory has rolling annual expenditure now sitting above $230 million for the first time.

The figures show growth in exploration is particularly driven by critical minerals, with exploration for other commodities as defined by the ABS – which includes all critical minerals except nickel, cobalt and mineral sands – hitting a record $106 million in 2023.

Critical minerals exploration was substantially higher in the Northern Territory than in any state except Western Australia, driven largely by booming lithium and rare earths exploration.

The resources sector is already a key contributor to the Northern Territory’s economy, especially through world-class mines such as McArthur River, Tanami, Gove and GEMCO. But it is demand for the critical minerals needed for the energy transition that is driving most of the current boom.

The Territory is already home to one of the world’s largest manganese mines, has a world class rare earths mining and separation project approaching development, and has Australia’s

only lithium resources outside of Western Australia.

Furthermore, thanks to recent exploration successes, the Territory now has Australia’s largest known resource of graphite and a rapidly expanding pipeline of critical minerals projects.

The Territory has defined resources of 17 critical minerals (minerals on the Australian Critical Minerals or Strategic Materials lists), with demonstrated geological potential for a further 12.

In the past year, graphite and gallium have been added to the Territory’s critical minerals list. This follows the announcement of Australia’s first gallium resource at the Transition Minerals’ Barkly rare earths vanadium project, and the discovery of Australia’s largest graphite resource at Kingsland Minerals’ Leliyn project near Pine Creek.

Graphite is a critical material for battery anodes, and given recent graphite export restrictions imposed by China, this expands the Territory’s potential to be a reliable supplier of materials to the global battery industry. Gallium is critical for LED screens and semi-conductors and is subject to recent Chinese export restrictions.

Importantly, the Territory’s known mineral endowment is only a fraction of what is likely to be found, as a significant part of the Territory’s land mass of around 1.4 million square kilometres has not been systematically explored.

With its high geological prospectivity, the opportunity for further resource discoveries and development in the Territory is immense.

The Territory Government has been backing exploration through the $9.5 million per year Resourcing the Territory program, which funds new pre-competitive geoscience by the Northern Territory Geological Survey (NTGS) to attract and de-risk exploration investment and provides grants to co-fund exploration.

A recent outcome evaluation report by Deloitte1 has shown that the Resourcing the Territory initiative – first introduced by the Northern Territory Government in 2018 – has helped significantly boost investment in resources exploration in the Territory.

The report covered the first four years of the program and documented

multiple case studies that demonstrate that pre-competitive geoscience, legacy data capture and exploration grants led to substantial new investments in the Northern Territory, including investments from major mining companies through joint ventures and partnerships.

An example of the impact of these programs is collaborative work undertaken by Geoscience Australia and NTGS in the previously poorly-explored Barkly Tableland region east of Tennant Creek. This included a diverse range of pre-competitive geoscience programs and substantial upgrades of geophysical data to support exploration targeting in the area. This directly led to more than 100 new exploration licence applications by the industry since 2018, spanning more than 50,000km2, largely targeting copper-gold and sedimentary copper deposits.

A number of majors are now active in the areas, including South32, who have farm-in agreements worth $25 million with Encounter Resources’ tenements in the eastern Barkly Tableland.

Deloitte found that “investment into pre-competitive geoscience is one of the most significant things the Territory

Government can be doing to de-risk investment and increase the possibility of successful resource projects contributing to the Northern Territory economy” and that Resourcing the Territory has delivered on that aim.

The report comes as the recently released Fraser Institute Survey of Mining Companies2 showed the Territory ranking near the top both in Australia and globally for how its geological database encourages investment.

In July 2022, funding for the Resourcing the Territory program increased from $6.5 million to $9.5 million per year, and was made ongoing, signalling the Territory Government’s long-term support for the sector. The Northern Territory has now joined Western Australia as one of the only two jurisdictions in Australia to commit ongoing high levels of funding to support the exploration sector.

An important component of the Resourcing the Territory program is the Geophysics and Drilling Collaborations Grants Program, which is now funded to at least $3 million per year and provides co-funding for selected exploration programs, including greenfields and brownfields drilling, regional

The Territory has a rapidly expanding pipeline of critical minerals projects. Image: electra/shutterstock.com

geophysical surveys and innovative exploration targeting.

In June 2024, the Territory Government announced that a record 41 projects from 29 companies had been awarded a total of $4 million in grants as part of the 2024/25 of the grants program.

This year’s program includes a new ‘Advancing Critical Minerals’ category, which will see the Territory Government co-fund selected projects to re-analyse existing datasets for critical minerals, or to undertake early-stage test work on the metallurgical recovery of critical minerals.

The strength of exploration is underpinning an impressive pipeline of mining developments, with 18 mining projects in various stages of the development process.

Territory project pipeline snapshot

Combined, these projects represent a combined capital expenditure of $8.7 billion with the potential to create up to 4,250 jobs in construction and up to 3,100 jobs in operations.

The Tennant Creek region is seeing a revitalisation in activity, with two projects currently in construction, including the new gold plant at the Nobles Nob mine site that is expected to underpin the recommencement of a significant gold and copper mining industry in the field.

A flagship critical minerals project for the Territory is Arafura Rare Earths’ Nolans project, which is steadily moving towards final investment decision. Arafura is now fully permitted to establish Australia’s only integrated mine and rare earth separation plant, which is set to be located north of Alice Springs.

The Federal Government has recently committed concessional debt finance of $840 million to help deliver the project, with further support for debt funding from export credit agencies in Germany, Korea and Canada.

The Nolans project represents a major step in the Territory’s transition from a ‘dig-and-ship’ mining jurisdiction to having domestic downstream processing of critical minerals.

It is not just Arafura that is looking at downstream processing in the Territory. Castile Resources has commenced approvals to produce high-purity copper metal, cobalt and gold from the Rover 1 project near Tennant Creek.

Avenira is progressing a feasibility study on a lithium iron phosphate cathode

production facility at the Middle Arm Sustainable Development Precinct near Darwin, sourcing phosphate that is to be mined at its Wonarah site. In addition to this, Tivan is also investigating production of vanadium electrolyte at Middle Arm, from product initially sourced from its Speewah project in Western Australia.