23 minute read

2021 Endeavour Awards

ENDEAVOUR AWARDS 2021

2021 Endeavour Awards winners announced

Moving forward from the COVID-19 pandemic, Manufacturers’ Monthly was thrilled to celebrate Australian innovation and excellence at the 2021 Endeavour Awards.

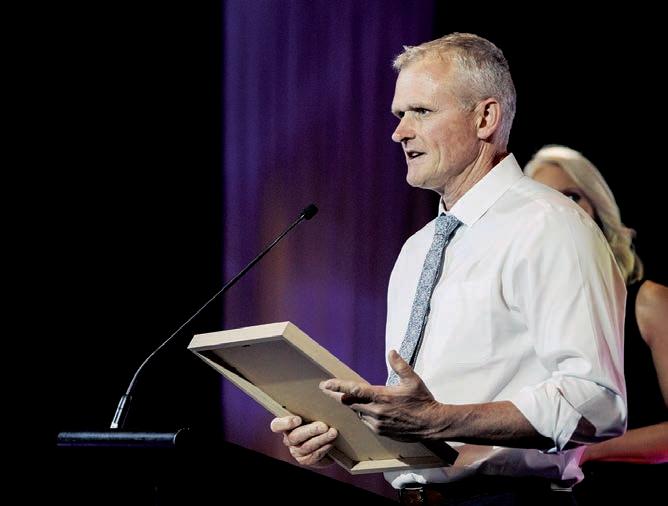

AFTER a frustrating wait from COVID-19 postponements, the 2021 Endeavour Awards were held in Melbourne last month. Key industry faces had the chance to reflect on the last couple of years – and the resounding atmosphere reflected a gratitude to be able to celebrate Australian manufacturing with each other, instead of over the internet. As always, the awards featured a high calibre set of companies with innovative ideas, technologies and products.

It’s no secret that Australian manufacturing has been challenged by the economic climate brought about by COVID-19, so the event was dedicated to the entrants, finalists and winners who embraced change and hard work to advance the industry. There was a jump in the number of quality nominations in individual categories this year, despite any anticipated flow-on effect from the economic downturn. Manufacturers’ Monthly congratulates all the winners and finalists and was so pleased by the large turnout to the prestigious event.

Takeaways from the judges

Peter Canavan, senior policy officer at AI Group said the Endeavour Awards provide a great opportunity to showcase the exciting ways that Australian manufacturing companies are dealing with a rapidly changing world.

“Not for many years has Australian manufacturing shown itself to be so vital for our country’s prosperity and security, and the Endeavour Awards highlight just what our industry can achieve,” he said. “What stood out for me this year was the innovations that address some of the key issues facing the world: our need to develop products friendlier to the environment; our need to engage more deeply with digitisation and the Internet of Things; and our need to find innovative ways to skill up our workers. To me this demonstrates that our manufacturers might be working locally but they are coming up with global solutions.”

Scott Martin, group leader of applied physics at CSIRO concurred saying that every year there are impressive examples of inward and outward innovation – inward innovation bringing new technology form around the world into Australian markets and manufacturing processes; and outward innovation developing Australian-grown technology for local and export markets.

“I think it’s wonderful when I see companies getting recognition for some of the really innovative stuff happening here in Australia,” he said. “But the awards also show that innovation need to be cutting edge technology to be really impactful. If it’s something that drives more adoption of what’s already available, this can be equally or if not more valuable.”

“There were a couple nominations which were extremely difficult to judge between this year. These were scalable and very easy ways for manufacturing companies to implement industry 4.0, without a huge amount of investment in equipment and automation, there were some really nice ways to collect data on existing manufacturing lines.”

“Companies are applying a lot of machine learning algorithms to put on top of data. We really need the Australian industry to adopt industry 4.0 and automation more strongly, and I thought this was a really strong step in the right direction.”

Matthew Young, manufacturing innovation manager Innovative Manufacturing CRC said he was surprised about the variety of applications for different sectors in the nominations.

“It’s important to encourage Australian manufacturers not to fly under the radar,” he said “We definitely need to showcase Australia. Some still think that there’s not much going on here but there’s a lot of innovation, as evidenced by the nominations. The innovation in manufacturing is an enable for broader Australian industry.”

Industry gathered to celebrate Australian manufacturing at the 2021 Endeavour Awards.

ENDEAVOUR AWARDS 2021

MANUFACTURER OF THE YEAR - COOLON LED LIGHTING

MOST INNOVATIVE MANUFACTURING COMPANY - COOLON LED LIGHTING

BEST IIOT APPLICATION - COOLON LED LIGHTING

Sponsor:

Coolon’s connected lights clean sweep

DIGITISATION is the ultimate goal of the rapidly evolving and sometimes seemingly limitless world of Internet of Things (IoT). With this in mind, Coolon LED Lighting puts smart networking nodes inside the industry’s best, most robust lights, enabling digitisation in any mining, industrial, manufacturing, chemical, defence, food and beverage, commercial or other industry facilities.

Andrew Orkin, business development manager for Coolon LED Lighting said while digitalisation of industrial processing plants is worthwhile, it can be extremely challenging because of the complex and hazardous environment of industrial settings.

Running cables and setting up Wi-Fi coverage is challenging, costly, and disruptive to operations, while radio signal propagation is often impossible due to the presence of massive steel and concrete infrastructures, as well as constant electromagnetic noise from various types of equipment.

“Coolon’s lights now come fitted with smart wireless mesh networking nodes inside,” he said. “The new technology acts almost like a network of satellites which can achieve a variety of things which traditionally hasn’t been done before. Lighting is naturally positioned to provide the best radio coverage, by being mounted in elevated positions, constantly powered, located throughout the site, routinely inspected and essential to any facility.”

Coolon smart lights contain nodes inside the fittings, which enables almost “plug-and-play” capability, offering immediate and effortless digitisation for mining and industrial sites, regardless of the size or complexity of the infrastructure. Once installed, the lights can automatically create a wireless mesh network that covers the whole site, solving connectivity challenges: one node only needs to service a limited area around itself and pass the data onto its neighbour for retransmission.

The lights hold many capabilities, for instance the mesh network offers the ideal backbone for asset tracking service providers to roll out their services with high accuracy and low latency. Gaining real-time site-wide visibility enables site management to instantly locate any tagged item anywhere on site, including indoors and underground, with relative precision, maximising asset utilisation efficiency and productivity.

Orkin explained Coolon Brilliant Connected Lights do not only represent disruptive innovation but provide a backbone for thousands of emerging IoT-dependent services and technologies.

“We spend a lot of time and most of our money on research and development,” he said. “And we will continue to update our product range with new technology. It’s about the technology revolutionising what people do from day-to-day.”

Andrew Orkin and Ekaterina Borisova from Coolon LED Lighting.

ENDEAVOUR AWARDS 2021

ENVIRONMENTAL SOLUTION OF THE YEAR - AWMA WATER CONTROL SOLUTIONS

AWMA design, manufacture and install water control infrastructure and water management systems. The Australian company has gate-specific design expertise, a dedicated design team, manufacturing facility and installation capacity all in-house. All of AWMA’s innovative solutions are customised to meet site specifications, utilising proven designs with a variety of local and remote control and management systems.

Brett Kelly, managing director said the regional manufacturer in Victoria’s north has a sense of community.

“A benefit of being a regional manufacturer is the retention of your workforce,” he said. “We have a pretty unique set up in terms of what we’re doing not being done elsewhere.”

The company’s Fish Exclusion Screens were developed to protect Australian native fish species. Whenever water is taken out of rivers, fish and debris are taken out with it. Studies show Australia is osing nearly 100 million fish every year to water extraction systems.

“The screens are part of the jigsaw of native fish recovery,” Kelly explained. “It closes the loop to keep them in the natural waterway. And the technology that we’ve been able to develop is able to do that in a way that doesn’t impact on water delivery at all.”

In 2016 AWMA was approached by renowned fish ecologist Martin Mallen-Cooper along with the North Central Catchment Management Authority (NCCMA), to provide feedback on the viability of screening irrigation off-takes to protect native fish. AWMA travelled to the United States on a number of occasions to meet with screen operators, asset owners, fish scientists, university academics, water providers and screen manufacturers. The technology review has resulted in an in-depth understanding of the applications, engineering, design and operational characteristics associated with fish

Brett Kelly and Peter Ebenwaldner from AWMA Water Control Solutions.

exclusion screens. Considerable time was also spent with the NSW fisheries scientists and Charles Sturt University specialists understanding the differences between the US Salmon and our native fish to allow engineering and specification changes to the screen design to suit our native fish species.

“When you’re doing things that hasn’t been done before in Australia, it makes sense to go and have a look around the world,” he said. “A real key is ‘self-powered’ or ‘selfpropelled’ screen which uses a pumps flow velocity to clean the screen, rather than powered options. A clean screen and low flow velocities actually produces high quality water without impingement or entrapment of fish onto the screen.”

Since the first screen project in 2018, AWMA have been involved in numerous project steering committees and assisted in developing many concept designs for screen applications. To date, applications include projects for irrigation diversions, agricultural pump stations and hydropower intakes, with dam intakes also now in progress.

ENDEAVOUR AWARDS 2021

OUTSTANDING START-UP AWARD - SPACE TANK STUDIO

SAFETY SOLUTION OF THE YEAR - SPACE TANK STUDIO

Space Tank Studio – CoLab shields Australia from COVID-19

AS a start-up under the Space Tank Studio makerspace banner, CoLab set out to design an Australian made, sustainable face shield solution as COVID-19 sparked a vulnerability in health PPE and a need for a domestic manufacturing line. Having the foresight and flexibility to pivot operations during the pandemic, Space Tank founder and director, Holger Dielenberg, and CoLab business partner, Scott Anderson, launched the Rapid Shield to help improve the quality of life for Australians during this period.

To be recognised by the industry as an Outstanding Start-Up with the Safety Solution of the Year was an honour, Dielenberg said.

“For us, it’s about industry recognition. In this context, what we’re trying to achieve is to make things locally and help Australia reach its goal of sovereign manufacturing – having a local journal support us is a good way to send the message out to the community that things can be made locally,” he said. “So, from our perspective, it’s good to be recognised for those reasons.”

Rapid Shield’s simple, innovative design was completely manufactured and assembled in Melbourne with zero wastage by reusing all offcut materials and ensuring 100 per cent recyclability. Using a curved folding pattern, the solution closes the gap between the forehead and shield, providing a critical barrier against air borne viral droplets and reducing the number of parts needed. With the ability to be delivered flat packed, storage space and transport costs were reduced as well as unit costs.

Rapid Shield is a great example of how clever design, collaborative spirit and local knowledge can achieve local and sustainable mass production of critical health PPE without compromising on cost, volume or quality. Thus, it has attracted attention from Australian frontline workers, federal and state governments and the broader commercial market.

Dielenberg believes there is still work to be done to secure a more resilient manufacturing industry in Australia.

“I think COVID-19 has certainly exposed a lot of inefficiencies, gaps and weaknesses,” he said. “Larger companies tend to do well, but the middle to small players tend to struggle a lot, mainly due to high labour rates and high-cost dollar and our low population.

“It’s very, very hard to get anything off the ground or to develop anything new. So, I think there’s some huge systemic issues that continually need to be addressed.”

Space Tank Studio is currently addressing this by doing what they do best – developing strong networks and advocating collaboration in the industry.

“As a business maker space, we are constantly working with either council or state government,” Dielenberg said. “I’m constantly on various workshops, innovation workshops and precinct workshops to work with the government and help them understand what is actually needed on the ground, what are the challenges that local manufacturing are facing. We also lobby for assistance to continue our work in that area.”

As further evidence that Space Tank Studio is a deserving winner of the Outstanding Start-Up and Safety Solution of the Year Awards, they now have a new innovative safety product in the works.

“We’ve actually been working on a new medical product for the last 14 months or so – it’s a patient isolation device, which basically detoxifies the environment in a healthcare setting.”

Manufacturers’ Monthly congratulates the double award winner in their achievement and looks forward to seeing what they do next.

Space Tank Studio – Winner of the Outstanding Start-Up and Safety Solution of the Year Awards.

ENDEAVOUR AWARDS 2021

TECHNOLOGY APPLICATION AWARD - TILLIT

AUSTRALIAN INDUSTRIAL PRODUCT OF THE YEAR - TILLIT

Sponsor:

Manufacturing’s do-it-all digital platform

ANNOUNCED in July 2021 in Adelaide, South Australia, the launch of the TilliT technology business forms part of a strategic expansion for SAGE Group to deliver Software as a Service (SaaS) and associated IoT hardware solutions for customers across the broader manufacturing industry, to enhance manufacturing processes.

TilliT is a no-code, simple to set up, digital factory platform, that provides an integrated way to plan, execute and analyse manufacturing processes – in one out-of-thebox cloud application. It is a comprehensive digital platform that delivers forward-looking insights, real-time visibility and operational control to a client’s factory.

TilliT CEO James Balzary explained that only 5-10 per cent of Australian manufacturers have an industrial automation backbone or PLC-sort of infrastructure.

“Industry 4.0 demands that manufacturers have real-time visibility of their people, process and tasks in their production environment,” he said. “But the majority of manufacturers still capture tasks on paper.”

“The vast majority of manufacturers are SME without any industrial backbone in pace. For those customers, we send them a range of IoT sensors which are battery powered and last three or four years. The sensors start to record really insightful information accurately – temperature, vibration, counting products down a manufacturing line or whether a machine is running or not – and push all that data to the cloud. The new-gen approach is of course cloud-enabled and IoT enabled data capture. Our approach challenges the traditional approach to manufacturing and we’re really kicking goals as everyone scrambles around to come to the party with their own do it yourself IoT platform.”

The newly expanded TilliT platform can operate standalone between the ERP and the machine control layer to digitalise the operation or co-exist with existing tools in place because of its flexibility and ease of deployment as a cloud solution such as Amazon Web Services.

The TilliT SaaS and IoT solution is a powerful, yet simple to implement, digital factory suite that provides an integrated way to plan, execute and analyse manufacturing processes by orchestrating people, machines, material and tasks. It affords visibility of asset and manufacturing line performance, directs the execution of events and coordinates activities necessary to manufacture any type of finished good. It also handles quality checks, production scheduling and digital workflow with a focus on real time visibility.

We are seeing AI and IoT technologies such as TilliT improve manufacturing efficiency and costreduction by enabling visibility of operations and therefore smart decision making in real time. The end goal is to ultimately protect manufacturing profitability and deliver the opportunity for all manufacturers – large or small – to thrive on a global stage.

TilliT delivers flexible and powerful digital tools in one integrated platform.

ENDEAVOUR AWARDS 2021

Sponsor:

Essity – Deepening essential operational skills

ESSITY Australasia is a personal care and hygiene company known for its market-leading household brands including Sorbent, Handee Ultra, Purex, Libra, Tena, Tork and Treasures. Their Springvale site in Victoria supports 100 operational staff and 150 administration staff in manufacturing feminine care and incontinence care products for over 40 years.

By locally manufacturing such essential products, Essity has been able to thrive as the stresses of supply shortages struck the industry, Essity site and operations manager for Springvale Matthew Arblaster explained.

“I think COVID-19 has shown us the importance of local manufacturing and as a local manufacturer of critical goods – being in one of the categories of products that got hit by surge buying in the pandemic – it shows that if you’re making those essential goods locally, it really does ensure that we can react quickly and ensure that our consumers have those essential products in ample supply,” he said.

“We have proven now that local manufacturing has an absolute strong place and stable supply chains can outweigh cost reductions and mitigate that risk of short supply.”

In creating an even stronger supply chain, recently Essity’s strategy has been to grow, promote and build skills in its dedicated manufacturing and supply team. This was achieved through a Skills Development Program that was introduced in 2020 to capture, assess and share the team’s amassed knowledge. The aim was to develop a platform to train new staff, cross skill operators, create a standardised process, and build skills in using more modern equipment and creating new products.

An online induction was created to train every visitor and employee, to standardise safety messaging and expectations before anyone entered the site, which was particularly effective for casual workers and contractors.

The company developed a robust training and assessment programs for each of its machines and roles which have allowed the business to cross-train and upskill its operators. This has enabled Essity to be agile in a changing market and channel resources appropriately based on consumer demand. The training system includes an assessment of all roles on sites across 16 machine operating roles, a list of key ‘core’ skills of industry and best practice knowledge, an assessment tool that measures competency and qualifies staff to run the machine, a regular face to face feedback and coaching system with both the trainer and supervisor and a revamp of the graduate intake program to attract motivated graduates who bring innovative ideas.

“With all of the change we’ve undergone, we needed to upskill and train our staff,” Arblaster said. “The depth of knowledge we’ve had to transfer to people has been challenging, but we’ve got really good systems in place. And equally, keeping people safe is a big focus of ours – and with that comes the work we’ve been doing.”

Since the program was implemented, Essity says it has witnessed a plethora of benefits at the Springvale site. Along with a 56 per cent reduction in consumer complaints, there were less staff injuries and better flexibility in staff’s work schedules. Additionally, there has been an increase in employee satisfaction in the team and more internal promotions, as well as new apprentices hired; the training program has enabled them to upskill quickly.

Ultimately, the Skills Development Program has improved operations and driven a great return on investment, as the cost per unit has been reduced by 16 per cent. It will continue to support a legacy that will serve the Essity manufacturing site in delivering sustainable, customer-centric products to the community.

Arblaster said it was great to be recognised in the Endeavour Awards in an industry where it can be hard to balance inputs and outputs, and people and processes.

“I think it’s great to be in the company of, and measured against, really established and professional companies and to know that you’re in their league in working on best practice,” he said. “That’s a huge accomplishment.”

Essity – Winner of the Excellence in Manufacturing Skills Development Award.

ENDEAVOUR AWARDS 2021

EXCELLENCE IN GROWTH - HEALTH FOCUS MANUFACTURERS

Sponsor:

Health Focus Manufacturers – Organically growing Australian manufacturing

THE Excellence in Growth Award recognises three aspects: financial growth, people growth and market growth. These are vital in achieving sustainable and consistent growth in the long term. Health Focus Manufacturers has excelled in each of these areas.

Launched in 2011 as a contract manufacturing business, Health Focus Manufacturers has grown from humble beginnings – with only six staff, a basic warehouse and no offices – into a leader in the provision of new product development and contract manufacturing for the skin care, personal care and hair care industries. This was done by listening to their valuable customers and doing whatever possible to assist them in taking their expertly manufactured products to market in a timely manner.

As client needs and market forces have changed, Health Focus Manufacturers have modified and adapted the business to keep abreast of these needs and underpinned their product development and manufacturing services with quality systems and excellent customer service.

Health Focus Manufacturers is now an Australian cosmetic and cosmeceutical manufacturer that delivers quality skin care and cosmetics products – both certified organic and synthetic – to domestic and global markets. A decade on, the business has reached over $8 million in revenue for the 2020/21 financial year with 40 staff.

Part of this growth can be attributed to strategic partnerships with existing clients, whereby Health Focus Manufacturers will both formulate products on demand and recommend products to fill gaps in clients’ product lines, identify opportunities and anticipate client needs. And according to Health Focus Manufacturers managing director, Derelle Mitchell, the company is continuing to grow with plans for a new manufacturing facility.

“We’re looking to build a purposebuilt therapeutic goods facility in the next two to three years,” Mitchell said. “We are excited about where we’re heading – we currently manufacture high-end skincare and a lot of organic products, and this will broaden our area in the market. We’re going to build a pretty impressive manufacturing facility which will employ more people and we will definitely continue on the growth path once we build it. It’s very exciting!”

A women-led business, Health Focus Manufacturers holds a strong position in the global market by making high quality, sustainable, Australian made products and working with clients both big and small – all while committing to customer service within an experienced team comprised of great talent. The company wants to make a positive impact on the sustainability of the cosmetics supply chain.

Some of the products that the business manufactures include highend skincare, tanning products, hair care, deodorant, masks, moisturisers, serums and cleansers – even dog shampoo. Almost any cosmetic or cosmeceutical product available in a skincare clinic, chemist or supermarket (except for aerosols and sunscreens) can be produced by them. During the COVID-19 pandemic, they also upscaled the manufacture of hand sanitiser.

The manufacturer is proud to be recognised in the Endeavour Awards, especially in view of the high calibre competition for the Excellence in Growth Award.

“I’ve noticed, more so than ever since COVID-19, that manufacturing in Australia is being supported and recognised,” Mitchell said. “We’ve come from pretty humble beginnings, so for us especially to be producing Australian made products and flying the Australian flag, while employing Australian people and growing – it’s a pretty proud industry for me to be in.”

Health Focus Manufacturers won the Excellence in Growth Award.

ENDEAVOUR AWARDS 2021

GLOBAL SUPPLY CHAIN INTEGRATION OF THE YEAR - SUPASHOCK

Supashock advancing defence vehicles

SUPASHOCK is a worldclass producer of advanced mobility, logistics handling and autonomous systems that control, monitor and improve mobility of defence, autonomous, commercial, automotive and other transport vehicles.

Oscar Fiorinotto, founder and CEO at Supashock Advanced Technologies said the company is proud to be recognised for pushing Australian manufacturing forward.

“We’re seeing some of the largest demand for manufacturing in our lifetimes,” he said. “The modern push into manufacturing, moving away from offshoring and advancing intellectual property is important. The problem we face as an industry is we haven’t kept up with training over the past 20 years, but there’s been huge progress made lately in terms of bringing niche manufacturing to the fore with automation and the transition from industry 3.0 to 4.0.”

The company was recognised at this year’s Endeavour Awards for its LYNX KF41 IFV Running Gear, which is helping with the development of new military vehicles to fill the technology gap which currently exists from outdated fighting vehicles in modern warfare settings.

The running gear is a vital component of the armoured fighting vehicle, increasing the mobility aspect of the tank, resulting in improved all-terrain handling, ride

Supashock CEO Oscar Fiorinotto and ICN’s Derek Lark.

Sponsor:

quality, and the ability to be tuned to all variants of the IFV including APC, ambulance, recovery, and command and control.

“It fills a gap where advanced mobility systems are required for modernized fighting vehicles and enhances the driving capabilities for its operators in threatening situations,” he said. “We have a reputation for providing high performance mobility products and services. As well as the unique design and competitiveness, the ability to manufacture the system and sustainability of the system here in Australia is key. But first and foremost, it gives the end user a better offering.”

Supashock has had major success in international markets with the LYNX KF41 Running Gear system. So far Hungary is the first launch customer and the vehicle is built upon partnerships with suppliers across the globe. Supashock was chosen as the Running Gear supplier because of its innovation, reliability, technical compliance, quality, and years of experience in the mobility systems field for defence vehicles.