It seems like only a short time ago when range was raised as one of the biggest impediments for Australians in their slow uptake of electric vehicles.

Now that CATL has launched what they claim to be the fi rst battery with 1000km range, it will be interesting to see its impact on EV ownership.

The prospect of an uninterrupted trip all the way from Sydney to Melbourne in an EV will certainly capture the imagination of many Australians who may have teetered on the threshold of alternative powertrains but were held back by range anxiety. The milestone fi gure may even encourage more regional Australians to look to EVs, considering the distance would surpass the range of most traditional petrol-driven vehicles. It might even take the sting out of the lagging infrastructure network that has su ered from insu cient public fast chargers or their locations being too far apart.

Despite some great research and development in solid state batteries, the Chinese manufacturing giant CATL appears to have got the jump on what is a highly-coveted marketing point. While it may be some time before this Lithium-Ion Phosphate development becomes a commercial reality in everyday cars, not to mention the delay that it takes before any new technology becomes a ordable, it shows how swiftly innovation and technology can move to grapple the thorniest of problems. What these developments add up to is the seeming inevitability of the transition to alternative power sources for vehicles as impediments are overcome. Even if the slower dispersal of this technology in Australia gives a little breathing space for repairers, the pace of progress indicates it is only a matter of time before it

becomes commonplace on the fl oors of collision workshops.

There are some in the industry whose investment in training and equipment for electric vehicles is already paying o . It is only one to two per cent of the car parc that is electric but inevitably they are involved in collisions and need repairing.

There are many more repairers who are either waiting for that fl ood of electric vehicles to occur or even some simply hoping it won’t come. As such, the government’s steps in the recent budget to fi nancially assist some repairers get on board are to be commended.

One of the most signifi cant of the changes is to the Clean Energy Program that o ers $10,000 grants for apprentices working with EVs and wage subsidies for their employers. Formerly it was limited to those who worked exclusively on EVs which made it far too narrow and did not assist the many businesses and prospective new apprentices who are more likely to work across a few di erent power sources.

A transition by its nature means a gradual changeover and having technicians skilled in both ICE and electric drive trains makes sense for at least the next decade or more, as the proportion incrementally shifts.

Other wins in the federal budget include $50 million for an equipment investment fund for facility upgrades to expand clean energy training capacity and $30 million for a clean energy training workforce.

While those amounts are not likely to shift a whole workforce or industry to where it needs to be, it is welcome assistance and may be the incentive some businesses need to take the step.

It also sends another clear message to a potential workforce, as the repair industry struggles with an ongoing shortage of new recruits, that this is a career for the future. Career pathways are always going to be more attractive to young people when they promise fl exibility in skills on o er and the longevity of relevance in a fast-changing technological world.

Eugene Du y Editor The National Collision Repairer

When Axel Gernhardt joined spray equipment specialist SATA as a technician for the global markets, including the Asia / Pacific region, he discovered a ‘love brand’ that inspires incredible loyalty.

When it comes to dream jobs, it doesn’t get much better than working for SATA, according to Axel Gernhardt. As one of only two SATA export market technicians, he gets to indulge his love of travel to a wide variety of di erent countries, while showing people the finer points of exactly what SATA technology is capable of. When he was completing a spraypainting apprenticeship and working in the collision repair industry in Germany, SATA was clearly the dominant brand in the local market but that didn’t prepare Axel for the remarkable level of worship on display from fans all around the world.

“If you are a painter in Germany, you pretty much grow up with SATA. However, where SATA has a real benefit on a global scale is that it’s a ‘love brand’. For example, all around the world you can meet people who have SATA tattoos. The crazy thing is this is a spray equipment manufacturer! It means that if you are in the paint industry, you know SATA. It makes me proud to come from

being a regular painter in a body shop to being a technician at a company like this.”

At SATA, an export market is defined as the entire globe, excluding the home markets of Germany and Austria. It makes the Export Market Technician role vital because it helps to create a pipeline linking all those global markets back to SATA’s head o ce in Kornwestheim, in the suburbs of Stuttgart.

“We are basically there to support SATA importers and distributors with training and technical support whenever they need it. Rather than go in and tell people what to do with our products, we aim to make it more like an information exchange where we can give them some valuable information to improve their process. After all, some of the people I deal with have been painting for decades so they have a lot of experience, and we can also learn from that.”

Although refinish painters around the world are generally aiming to reach the same goals, Axel has found they can often have quite di erent ways of achieving it and that makes actually visiting countries the best way to learn. It also means he spends a lot of time getting to know di erent countries and cultures and he couldn’t be happier.

“For me, the most enjoyable part of the role is the travel that lets me explore the world. Australia and New Zealand are definitely two of my favourite countries – both have a really relaxed and open culture which I love. Wherever I go, because I am actually working with people who live in that country, it helps me get closer to SATA end users. It’s an important part of staying in touch with the people who are using our products, so we get feedback on how they are being used and any issues that crop up. It’s easy to just concentrate on the upsides of a product but that doesn’t help SATA to improve. We know we make great products but there can still be room for improvement which is why a key part of our role is to gather information about what is happening in the markets and what people want from our products and ensure it gets to our R&D team. This constant flow of information puts any issues in the spotlight where they can be solved and the result is better products for SATA users.”

SATA’s passion for perfection means the technologies it o ers are never going to be cheap, says Axel. However, it’s the joy of using a SATA spray gun and the clear-cut return on investment which often makes painters a SATA fan for life. “I have travelled to a lot of di erent regions and countries and that is what I get everywhere – once a painter uses SATA it’s very di cult to go back. As a premium product, SATA will never be the cheapest but we are aiming to be the best. If they are prepared to make the investment in SATA, we can show them how it makes life easier for the painter, improves processes and transfer e ciency and saves money in the long run.”

A comprehensive range of SATA spray equipment and spare parts, is available from authorised SATA distributors across Australia and New Zealand.

The end-to-end digital ecosystem bringing advanced, game-changing technologies to your collision centre

Introducing the 3D digital sprayout

This advanced, 3D digital colour visualisation tool smoothly interfaces with the next-generation PPG DigiMatch™ camera-equipped spectrophotometer to totally transform the user experience of selecting the best colour match formulation from PPG’s extensive library.

Scan the QR code to see how PPG LINQTM can benefit your business! youtu.be/t4isZfVLwzw Explore the PPG LINQ™ Digital Ecosystem. Visit PPGLINQ.com

Compact, fast, easy-to-use spectrophotometer

PPG’s high tech DigiMatch spectrophotometer features a digital colour camera to significantly boost performance. The camera’s six imaging angles combine with six reflective angles to provide additional texture information to help quickly and precisely retrieve the correct formula match.

Workplace productivity is essential for smooth operations in any workshop. Car-O-Liner’s workbenches and equipment o er an e cient and e ective solution to speeding up the repair process.

Car-O-Liner products are well known for their long-standing history and dedication of providing technical support, and consistent customer service.

Having cemented themselves as a global player on the scene, CarO-Liner is known for their longevity, reliability and quality equipment.

With an extensive selection of

approvals from various Original Equipment Manufacturers (OEM), the Car-O-Liner name is a trusted brand and influence in the automotive industry.

Car-O-Liner’s two models, Speed 3T or the longer Speed Plus 3T are designed to bring versatility, reliability and e ciency to your workshop. With two types of installation, aboveground or flush mounted, they can provide a dynamic system for light service to damage repair.

The Speed 3T and the Speed 3T Plus

are two light weight work benches, perfect for speeding up the repair process. Carrying a weight of up to 3 tons, the equipment is made to withstand any medium and cosmetic damage repair.

The bench system is an easy assemble of the convenient draw aligner, which can be rotated 180 degrees around the platform at one end and can be tilted 90 degrees horizontally.

Once the Speed 3T bench begins pulling, the draw aligner finds the correct position. For maximum pulling power, the Speed 3T Plus bench is your go to. With an attachment of two draw aligners at either end, the Speed 3T Plus bench gives you extended capability.

The Speed 3T Plus will give you the boost your workshop needs. With longer bench space and room for two draw aligners, one at either end, the bench could solve e ciency issues. There are eight features to the Speed 3T Plus that can enhance workplace performance. The life capacity can hold up to 3,000 kg (6,600 lbs). The 5-ton draw aligner has a multi-angle pulling capability, and 360-degree access. This allows for almost complete vehicle access.

The quick setup time increases workshop capacity. The Speed 3T Plus keeps a low profile, as it is easily rolled, driven under a vehicle for a swift start to repairing. The versatile nature of the bench allows the handling of most types of damage and cosmetic damage repair. The single setup means less clutter in your workshop and an entire repair job can be completed using one bench. This allows for a shortening of cycle times and increased profits.

For more information visit: car-o-liner.com.au/

To celebrate our 50-year milestone, we are offering unbelievable on all Car-O-Liner Welders, Benches and Measuring Equipment ... and you also receive our normal ‘Trade-in Deal’ which is still available. This Special Offer is 50-years in the making.

The automotive refinish industry is witnessing a transformative trend that is reshaping the way car panels are prepared.

At the forefront of this innovation is the introduction of flexible, resealable packaging for a range of products, with body filler being the most notable. This shift towards more practical packaging solutions is not just a fleeting trend but a significant advancement that enhances productivity and e ciency. U-pol, a pioneering force in the automotive refinish sector, has been instrumental in driving this change.

Products in the U-pol range currently supplied in the flexible pouches include Dolphin Glaze, Dolphin Speed Glaze, Gold Fine Filler, and Fibral (Fibre Glass reinforced filler).

When first launched, refinish professionals welcomed the introduction of flexible pouch packaging finding them more convenient, faster to use, and improved product lifespan after being opened. How often have you re-opened a can of filler to find it has dried-up or formed a solid skin?

However, suggested improvements have led to the packaging redesign which will be introduced across the range.

Revolutionary new flexible packaging

U-pol is launching a new improved range of flexible pouches incorporating significant improvements over the existing bags. The major change is the relocation of the nozzle from the top to the side of the packaging. However, there are several other significant improvements. This new design enhances usability, minimizes waste, and improves precision in dispensing the product, o ering a cleaner and more controlled experience.

Benefits of the new improved bag

• Self-standing: the current flexible pouch design doesn’t need to lie on

its side. Standing allows for less bench space and quicker to find and grab.

• Angled nozzle for easier dispensing and cleaning: The new nozzle is angled providing greater control when dispensing the product.

• Tamper proof cap and nozzle: when purchasing the product, it is nice to know the product hasn’t been open prior to your purchase.

• Made from premium high-quality foil for durability: there are cheap bags and then there are U-pol bags. The new packaging will survive to the last drop despite being manipulated and squeezed many times.

Why flexible packaging?

Flexible packaging o ers numerous advantages over traditional rigid containers:

• Enhanced E ciency: The ease of dispensing from flexible packages allows for quicker and more e cient application, saving valuable time in busy workshops.

• Reduced Waste: The ability to squeeze out the exact amount of product needed minimizes waste, making operations more cost-e ective and environmentally friendly.

• Improved Storage: Flexible packages take up less space and can be easily stored, providing better organization and inventory management.

• Increased Durability: The robust nature of flexible packaging protects the contents from external elements, ensuring the product’s integrity until it’s ready for use.

U-pol as an industry innovator U-pol has not only adopted flexible packaging but has also been a key player in its development. Their approach to packaging reflects a deep understanding of the industry’s needs, focusing on user-friendly designs that cater to the demands of professionals in the field. By o ering products in flexible,

resealable packaging, U-pol has demonstrated a commitment to enhancing the user experience. This innovative packaging allows for precise control over the amount of product used, leading to less waste and a cleaner work environment.

The future of automotive refinishing

The move towards flexible packaging is a clear indicator of the industry’s direction. As companies like U-pol continue to innovate, we can expect to see further advancements that prioritize e ciency, sustainability, and user satisfaction.

The automotive refinish industry is poised for a future where flexible packaging becomes the norm, thanks to the vision and ingenuity of companies like U-pol. Their contributions are not just improving the present—they’re shaping a more e cient and sustainable future for the entire industry.

U-pol’s embrace of flexible packaging is a testament to their role as a leader in the automotive refinish industry. Their innovative solutions are setting the stage for a new era of productivity and sustainability.

First products launched soon The new flexible packaging will be introduced with Dolphin Glaze and Dolphin Speed Glaze, U-pol’s popular premium high performance fine-fillers.

For more information contact the technical support team at U-pol on (02) 4731 2655 or visit www.u-pol.com.au

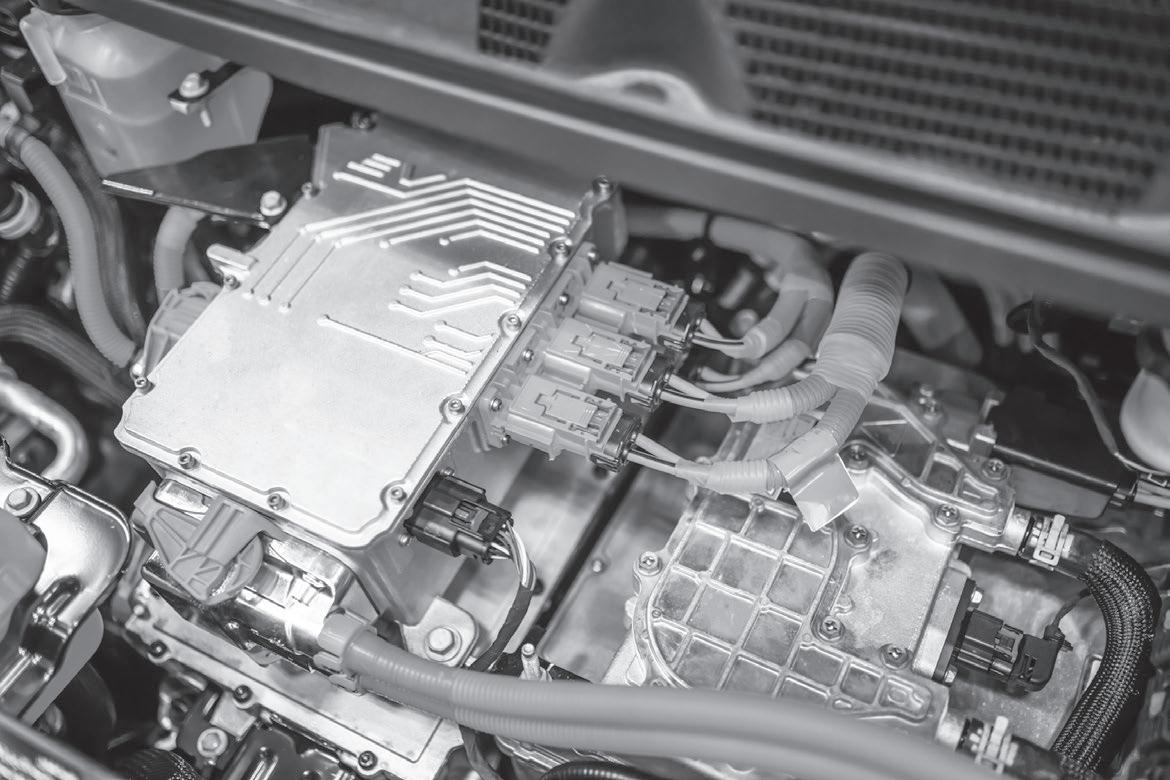

The pace of uptake of electric vehicles continues and it is only a matter of time before they become commonplace on the repair shop floor. Critical in this transition will be ensuring any workplace can deal with them safely.

There are new and inherent risks associated with the maintenance and repair of Electric Vehicles and Hybrids such as short circuits, exposed connections and the presence of high voltage cables. Obtaining additional skills, appropriate training through registered training facilities and following the car manufacturer’s guidelines will be necessary to allow technicians to work safely with these vehicles. But there is also the indispensable gear a workshop needs to tackle EVs and hybrids safely.

AS 5732:2022 “Electric Vehicle Operations- Maintenance and Repair” lists necessary personal protective equipment (PPE) depending on the task and level of risk involved.

Some of these last lines of defence measures include:

Electrical Insulating Gloves with an appropriate voltage rating, commonly these are Class 0, that o er protection up to a working voltage of 1000V AC /15000V DC. These can be worn with a cotton under glove to reduce sweating and provide comfort. Leather overgloves are worn to protect the rubber insulated gloves from mechanical harm and also to provide protection against electrical arcing.

The use of Caution signage and

Warning steering wheel covers to alert others of potential risks and temporary exclusion zones to instruct non authorised people to keep away.

Using 1000V insulated rated tools when working on energised components to lessen the risk of shorting out the high energy source.

Wearing arc rated face shields and clothing to protect the face and body against the direct force of an electric arc incident.

Having an (AED) automated external defibrillator immediately available in the event of an electrical shock.

To get more information on product solutions that help technicians mitigate risk, contact Electrical Factory Outlet. www.electricalfactory.com.au

The trolley contains the basic safety equipment and signage requirements of AS 5732:2022 “Electric Vehicle Operations Maintenance and Repair.” Designed to be portable with locking wheels the trolley can be moved to any bay the EV or Hybrid vehicle is being worked on. The technician’s personal protective equipment, emergency equipment and tooling will always be near the potential risk area.

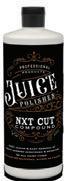

Finding solutions for repair workshops with innovative products has been at the heart of the SAPE Groups commitment to the industry and that tradition is continued with Juice Polishes and their breakthrough abrasive NXT Cut.

SAPE Group, established in Australia in 1976, has prided itself on supplying the highest quality products to the automotive industry for nearly 50 years. Juice Polishes NXT Cut is another stand out among its market leading products. The advantages it brings to the bodyshop become apparent when you consider how far paint technology has advanced. Gone are the days of running a bu at full speed slapping compound on with a brush and spraying water to cool o the panel. This was not only messy but a process that no longer achieves the results it once did.

Clears have certainly come a long way in the last couple of years and none more than the development of the air-dry clears. These new clears are designed to

cure faster and harder than ever before, albeit with the aid of higher heat coming from increased booth temperatures or infrared lighting.

The one downside of this evolution and advancement in technology is that the heat required for the curing process can also be re-produced by the bu ng/ denibbing process.

Nearly every shop in Australia has had issues with come back, dye back or whatever people are calling denibs re- appearing after a wash. This can also occur outside when the panel has had time to cool. Manufacturers have multiple reasons or explanation as to why this is happening whether it is because the paint’s not cured, the wrong hardener, poor mix ratios, booth temperature or baking times. But none of these explanations solve the problem.

Oil based polishes and compounds contain a large amount of mineral oils, which like the engine in a motor vehicle requires a warm up period to thin out enough to become viscous. This may be good for a supercar but not that great for the current batch of clears available. The heat cycle required to get these oil-based products to operating temperatures also prematurely cures the clear leading to the problems mentioned.

Juice Polishes NXT Cut compound represents the largest advancement in abrasive technology for almost two decades. For the first time in the company’s history NXT Cut contains not one but two active abrasives to not only cut faster but finish better than any of Juice Polishes previous products. The low dust waterborne substrate is perfect for use on all paint types with particularly outstanding results on air dry clears. More information at sape.com.au

When it comes to power backups, chargers and general battery organisation, including testing and charging in the repair workshop, owners and technicians want safety, reliability and flexibility.

Projecta has established itself as the name synonymous with all three and continues to pursue innovation with power accessories. Their new INTELLI-CHARGE Automatic Battery Managers extend even more flexibility to an automotive business.

Projecta’s latest range of INTELLICHARGE Automatic Battery Managers, o er an all-in-one solution for testing, charging and maintaining 12 or 24V batteries of multiple chemistries.

Perfect for the professional workshop or for DIY enthusiasts who own occasional use vehicles, Projecta’s HDBM35 and HDBM150 Battery Managers have all the features needed to e ciently keep batteries in top condition and ready for use.

Among the benefi ts of the range are customisable charge profiles that cater to di erent battery sizes and chemistry types, including Lead Acid, Wet, Calcium, AGM, Gel and Lithium. With these adjustable charge profiles, owners can be sure that their batteries are getting the exact amount of power they need for optimum performance. As well as keeping batteries at the ready – whether automotive, marine, deep cycle or Lithium – the HDBM35 and HDBM150 Battery Managers also o er testing and diagnostic capabilities, allowing users to accurately test a vehicle’s alternator for faults and starting capacity, while also monitoring voltage levels.

At 35A and 150A respectively, power supply for the HDBM35 and HDBM150 is strong and ultra-safe, ensuring stable output

during demanding diagnostics and recalibration tasks. The outputs also make the units ideal for workshops who service and maintain European vehicles which can typically have more sophisticated electrical systems.

Both Battery Managers feature heavy duty, quick release charging leads (3M 8mm² for the HDBM35 and 3m 25mm² for the HDBM150) with copper clamps, providing a secure and reliable connection with the

battery. For added performance in demanding workshop environments, the units are dust proof and also benefi t from spark-free, polarityprotected connections for added safety.

Automatic Battery Managers are available from leading automotive and transportation outlets nationwide and are backed by a generous 5-year warranty.

heavier duty

PROJECTA INTELLI-START JUMP STARTERS

DON’T GET CAUGHT OUT WITH A FLAT BATTERY THIS WINTER

A flat battery can leave you in a frustrated or even dangerous situation and cost businesses time and money. With Projecta’s patented Rapid Recharge Technology, Intelli-Start are the only jump starters in the world that replenish their charge after starting an engine, meaning they’re always ready for your next emergency. There’s a model to suit every engine and budget. Smart, compact, powerful. That’s Intelli-Start.

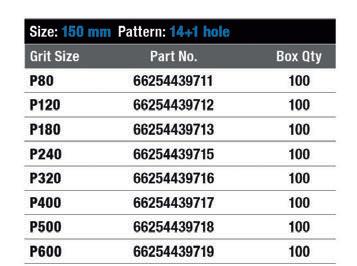

Sanding discs can be one of the high-turnover consumables in any body shop but a small investment in quality can reap huge dividends when it comes to wastage and timesaving. Norton’s new range of sanding discs reveal how it’s done and yet still achieve the best results in the workshop.

Widely trusted brand Norton, from SaintGobain, has launched two new ranges of sanding discs, the Azure Film Q216 and Amber A293 series aimed at adding to workplace e ciency and profitability, without compromising on the quality of the job.

The secret is in the quality; harder wearing with less clogging and fast cut rates equals a more reliable disc that adds up to fewer changeovers and less rework. This means fewer discs being consumed and critically, for the technician on the floor, less time on any sanding job. How these incremental time savings can translate into higher turnover and greater workshop e ciency is a fascinating insight into how quality can deliver savings to a business.

One recent study estimates that consumables make up only about nine per cent of a workshop’s cost on an average repair job and of these consumables, abrasives make up less than a tenth of that cost. By contrast,

labour could average as much as 45 per cent of the overall costs of a job, with almost a third of this time spent using abrasives. Given these estimates, any increased investment in abrasive consumables that can cut labour time has the potential to deliver at a savings ratio of more than twenty to one.

The Azure Film is Norton’s premium

product that promises a range of features and benefits to deliver on this promise.

As Saint-Gobain product manager Steven Hutchinson explains it’s about bringing together the best technology into a premium product that can deliver back to the workshop with time saved for the technician and yet still give the best results.

“Its sturdier backing allows the grain and resin to bond better and last longer,” he says.

“If you’re using conventional paper discs, generally they’re not always sanding dead flat. On the surface, they’ll have a bit of lift up on the edges or they are butting into di erent contours and di erent shapes so that the paper will wear away and you don’t have any grain left. Whereas with a film disc, it stays stronger, and you can get into those areas and keep working on those edges.”

The Azure Film is a polyester filmbacked disc utilising P-graded premium aluminium oxide with ceramic that

promises extra durability with minimum clogging and fewer changeovers for the technician. The polyester backing adds strength to the disc that resists tearing and has the flexibility to conform to the contours and uneven surfaces that are increasingly common in automotive panels.

“Having the film backing gives you a flatter surface. So that allows you to get a smoother finish compared to a regular paper disc. It also allows for better grain retention, so you get less edge wear than you do on a conventional paper.”

The abrasives, a blend of premium aluminium oxide with ceramic, means a faster cut that sands flat and gives a consistent scratch pattern further saving time and the need to rework jobs. Critically they are also designed to resist clogging up of sanded particles on the disc, a potentially wasteful and timeconsuming impediment.

With Norton’s Azure Film discs the water-based stearate coating helps minimise this clogging with a specially developed No-Fil® coating to shed particles, enhance e ciency and further prolong the life of the disc. When the time comes to change over the disc, a hook and loop Speed-grip backing means easy changeover and less time fiddling, particularly when multiple sanding steps are required.

The Azure Film discs cut consistently for maximum productivity with a uniform, precise finish and are highly flexible on a range of surfaces including primed or painted surfaces, wood, composites,

attention to their sustainability, both in the workshop and by Saint-Gobain looking at the entire supply chain of their products.

“We are improving sourcing of materials to reduce transportation in the manufacturing process,” he says.

“Also, for both products, it is our first introduction of their new packaging, which is reducing the coloured inks and providing more sustainable packaging.”

aluminium, and ferrous metals.

Next in line in Norton’s o ering for sanding solutions is the Amber series, the workhorse of any body shop.

The Amber series of discs are designed for dry sanding and have a more economical paper backing but this has been reinforced with latex to ensure they stay flexible and durable.

The Amber series also uses the special No-Fil® coatings as the Azure Film series to add to the e ciency of the sanding job by minimising interruptions necessitated by changeovers.

“We use the same anti-loading coatings, or stearates, that stop the dust balling and sticking to the disc and allows them to dissipate and get sucked away with the dust extraction.’ Hutchinson says.

Like the Azure Film, keeping them clog-free adds extra life to each disc and reduces wastage in the workshop. This becomes particularly important with those workshops with a very high disc turnover. The hook & loop Speed-grip backing ensure easy and quick disc changeover when necessary. The Amber series also employ P-graded premium aluminium oxide abrasives to produce a quick, cool cut and a more consistent surface finish. They are ideal for use on a range of primed or painted surfaces, wood, composites, aluminium, and ferrous metals.

The bigger picture Both disc series also come with new

Whether it is the top performance and durability of the Azure Film or the value proposition of the Amber series discs, Hutchinson says Norton and Saint-Gobain are dedicated to providing quality materials for the workshop to make informed choices about essential consumables.

“We are bringing products into the market that the market is after,’’ Hutchinson says.

“One of the things we really want to do is o er complete solutions to the industry with our range.

“If it’s just that little extra bit of information, which helps people to decide and say, ‘I’ll give that a go — will spend a bit more and save a bit more’.

“And if it turns out to be better for their workshop and their businesses — that produces great results for everybody.”

A four-minute drive from the crystal-clear waters of Esperance Bay, Melisa and David Rowe have set up shop in one of the most beautiful rural towns in Western Australia.

In a small, beachside community, the Rowe’s automotive repair shop, Esperance Smash Repairs has garnered a well-respected and trusted reputation in the community.

As managing director, Melisa’s primary role is to coordinate the flow within the workshop. Managing the human resources division, the OH&S requirements and apprentices, Melisa juggles many hats.

With her husband, David Rowe, they have created a trusted rural repair shop that has survived each changing, and challenging decade.

Purchasing the company in 2006, David and Melisa are passionate about providing quality customer service and workmanship.

Esperance Smash Repairs works alongside the local branch of Windscreen O’Brien, a business already owned by the Rowe’s before they acquired the complex.

Being the largest repair shop in Esperance, the business encompasses 1330 square metre workshop, and a purpose-built workspace that has the capacity for 30 vehicles.

Almost doubling their company size since 2006, Esperance Smash Repairs currently employs 15 sta with a variety of skills and backgrounds.

Their sta comprises of four apprentices, three o ce managers and 8 trades people. With knowledge ranging from automotive repair, to paint and automotive glass, the sta at Esperance Smash Repairs pride themselves on their attention to detail and quality repairs.

Business in a rural town

Strong and clear communication with clients is important in any business, but in a rural town, it can make all the di erence.

Esperance Smash Repairs strives to

keep a clear line of communication throughout the entire repair process.

“We pride ourselves on e ective communication with our clients. We ensure each client is kept up to date about their vehicle. We communicate throughout the entire process to solidify trust,” Melisa says.

“We make sure adequate ‘touch points’ occur to guarantee that we meet a client’s expectations.”

Esperance Smash Repairs has a dedicated team, with one unified approach.

“We have an amazing team of hard working and dedicated sta ,” Melisa says.

“Everyone who has completed an apprenticeship with us has continued to work with us. We encourage sta to take time away if need be, but we also encourage them to return.”

The Rowe’s pride themselves on a family friendly environment that also helps to keep and attract sta .

“We have a family friendly environment, but we also make a work life balance a priority,” Melisa says.

“Our family has grown up in our workshop and around the business. Some of our sta members have grown

up here in a sense too. We encourage our team to enjoy work, but also enjoy home life. It is all about maintaining a good balance.”

Workplace productivity

Increasing workplace e ciency and productivity is a key focus for Esperance Smash Repairs.

“We are always looking to streamline our workplace productivity,” Melisa says.

“We are currently looking to improve our management side of the business. Using the latest IBody Shop program, we are undertaking middle management training

to streamline our systems better.”

“I am always open to learning from other shop owners as well. There is so much we can learn from one another. We enjoy visiting other businesses and exchanging ideas.”

Having an honest reputation is essential in maintaining a harmonious and productive relationship with insurers. Melisa outlines how they preserve a positive relationship with insurance companies and assessors.

“Being open and honest with assessors and insurance companies is our priority,” Melisa says.

“We appreciate that insurance companies give us around 80 per cent of our work.

“As a self-assessing centre, we have a great relationship with some of the major insurers. We have been dealing with some of our insurers for over 20 years.”

“Taking the time to discuss what is best, and negotiating fairly for all parties is vital for David and I.”

Operating a business in a rural community, however, can bring multiple obstacles when it comes to training and upskilling sta .

“Sta training is a highlight this year, we are 800km away from Perth, so the

cost to send sta away is very high,” Melisa says.

“We like to encourage trainers to come to our beautiful town instead of us travelling all the time.”

Women in industry

A career in the collision repair industry has proven to be a successful and rewarding journey for Melisa and David Rowe.

Starting the Esperance Windscreens O’Brien business together at just 21 years of age, Melisa would juggle being a commercial property manager with invoicing work at night to achieve their goals. It is this dedication and commitment that made going from employee to employer a smooth transition.

Since acquiring Esperance Smash Repairs, Melisa has been acknowledged and recognised as a leader for females in the automotive industry.

In 2023, Melisa won the MTA Western Australia Business Woman of the Year Award which recognised Melisa as a ground-breaking influence in the industry.

Melisa also cites completing the Australian Rural Leadership Program in 2013 as being a career highlight.

Forging a pathway in a male dominated industry, however, hasn’t always been smooth sailing. But fostering a passion, one also shared by her husband, Melisa found that the Esperance community welcomed her in the fold.

“Being a woman in the industry has become easier over the past 5 years or so. It has been great living in a rural location, that has helped a lot,” Melisa says.

Originally from Mandurah in Western Australia, the move to Esperance was only supposed to be for one year. After loving their stay, they extended their trip and have been in Esperance for 28 years.

“We have been in the industry for a while now, since 2006. People know who we are now and are familiar with the business and how it is run,” Melisa says.

Melisa highlights the need for encouraging females to experience the automotive industry, whether that be through an apprenticeship, or work experience.

“There has always been a great need for women in the automotive industry. Women have a great eye for detail and it’s the quality in tradespeople that business owners look for,” Melisa says.

“I encourage any women that are interested in the industry to take on some form of work experience.”

our continued apprenticeship training over the past 18 years has given us 25 apprentices,” Melisa says.

“With four apprentices in their 3rd and 4th year, we feel grateful to have a loyal workforce.”

Esperance Smash Repairs encourages people from all walks of life to give the repair industry a fair shot.

“From mature age people, to females, to local high school students, we always encourage work placement for younger and mature age people wishing to have a trial to see if the automotive repair and refinish industry is for them,” Melisa says.

“We work closely with the local high schools and have often waited for someone to complete their final year at school before starting an apprenticeship with us.”

“We enjoy training our sta and creating a healthy workplace environment.”

At Esperance Smash Repairs, females are celebrated for their strengths.

“We have two women working with us on the workshop floor and two women in the o ce. Females have a great eye for detail and our team certainly has that,” Melisa says.

With the nationwide recruitment issue that has a ected the automotive industry, many workshops have resorted to sourcing sta from overseas.

For Esperance Smash Repairs, their apprentices have proved to be an integral part of their loyal workforce.

“We have been extremely lucky that

“Females are very much needed in our industry. Any female is more than capable in completing any automotive trade available. There is also the business side of collision repair that females can tap into. There is opportunity for everyone.”

Remaining true to their core values of clear communication, honesty, and quality service and repair, has allowed Esperance Smash Repairs to thrive since 2006.

“Any small business owner knows how challenging it can be to run a small business, and the automotive industry is no di erent,” Melisa says.

“For anyone starting o in this industry, I would highly recommend becoming a member of the Motor Trade Association and also to the local chamber of commerce.”

“Always o er the best service and quality to clients, even when that can mean saying no at times.”

A window on the world can reveal future trends and lessons for the Australian collision industry. Repairify Director of Innovation, Martin Brown, who has decades of automotive industry experience behind him, has kept a close eye on the development of technology and can draw some valuable insights into where we might be in the years to come. Don’t miss the opportunity to hear Martin at Symposium24 on June 19.

For an industry veteran who can recall when the most sophisticated thing in a car was the electric windows, Martin Brown is still amazed but undaunted by the ever-increasing sophistication of modern vehicles.

For the individual workshop, keeping across these developments in a diverse range of car models and makes, to deliver high quality and e cient repairs can seem almost impossible, he says. But that is where Repairify has built an international reputation, helping workshops overcome diagnostic issues through its remote services and specifically unlocking the sophisticated coding and gateways of the modern vehicle.

In the UK and Europe, Martin Brown has observed a strong and steady upsurge in demand that is principally based around the ADAS systems

incorporated in vehicles. As an indicator of how quickly this is moving, he highlights the fact in the UK all new cars since 2016 have been equipped with some form of ADAS technology and this has meant as many as 90 per cent of vehicles coming into collision workshops are ADAS equipped.

Martin says this has translated into change in the industry with about 75 to 80 per cent of the workshops being either ADAS equipped or having subsidiary businesses who can do the calibrations in partnership with the repair workshop.

“I think where Australia needs to jump forward in a big leap is in the area of autonomy and ADAS,” he says.

“Historically you’ve only got a few collision groups investing in their own equipment to be able to calibrate cars locally on site.”

“The thing we have to try and get people’s head around with ADAS and the cameras on cars, is it is not just to stop you crashing. If it’s not calibrated correctly, your car could stop when you don’t want it to and then somebody else could end up hitting you.

“For example, if your radar is pointing towards the pavement because the brackets got bent in a collision and the repairers haven’t noticed. That radar sees a pedestrian and your car is just going to stop, without you touching the brakes. The motorcyclist that could be behind is then going to hit you and it’s your fault.”

also looking for workshops that can complete the repairs in-house and can guarantee the quality of the work.

This avoids involving sub-contractors where the quality control is more di cult and increasingly part of insurers due diligence.

The investment in the expertise and equipment to be ADAS ready holds a valuable lesson for Australia where it is rapidly emerging, as an opportunity for workshops to embrace it.

wrong direction because laser and smart multibeam LEDs use the screen camera to shadow out oncoming vehicles or pedestrians.”

Looking into the future, Martin believes the shift to higher levels of ADAS including autonomous cars will be a gradual process, as the technology needs to be developed to overcome the public perception of the high risk associated with driverless cars.

Underpinning this surge are the key safety advantages ADAS brings.

For the customer, there is also the expectation that the safety features ADAS o ers will work to the expected level after a repair.

“People sometimes don’t realise how important it is,” Martin says

He says in the UK and US the responsibility and ultimately the liability of the safety of the car can come down to how meticulously it is repaired.

Insurers are also acutely aware of this liability, so the partnerships with trusted workshops can become more critical. For the workshops that are ready, it is in turn a business opportunity

“They are looking for the workshops who are qualified, equipped and can complete the work to their standards,” Martin says.

“Aggressive insurers are going to be telling the repair shops, if you had this equipment, we’re going to drive volume through to you of these types of vehicles. And if you don’t have it, we won’t.”

While the UK now has mandated training qualifications for anybody working with ADAS, insurers are

“Now’s the time to get in on this because if you’re going to invest now, then you are in a good place to take on the work, perhaps also for other collision centres around you and make sure that you recoup the device investment relatively quickly.”

While Australian automotive businesses are frequently seeing the need for calibration for windscreen mounted ADAS cameras, other technological complexities in European cars are becoming more popular and are a ecting repair workshops.

“One of the most common issues are headlights on the European cars,” he says. “Headlamps, airbag modules, steering racks and ADAS radars and calibrations they’re the fi ve key points where Repairify can help any shop.

“Because you can’t just change a headlight in modern cars without programming the headlights. Many people don’t understand if you don’t do the camera calibration correctly, your headlights can be pointing in the

“We’ve not seen new technology in ADAS apart from the single twin radar stereo camera which has been around for the last six years.

“The large roof mounted LIDAR boxes used on driverless cars are essentially only at a pilot stage and haven’t hit mainstream vehicles with the exception of Nio.”

But Martin says the company is committed to keeping across these and any other developments to ensure

Repairify o ers

repair shops can meet the need.

“The manufacturers will develop the software and once we start to see them in the cars in the collision centres then of course Repairify will be ready to have the latest technology we need to be able to get those vehicles repaired to the manufacturer’s standards.”

This delay in next level ADAS and autonomous cars provides some breathing space for Australian workshops but also an opportunity.

“It is a chance for them to actually catch up in Australia and get themselves into a more comfortable position with ADAS and where it is at the moment.”

Part of what Repairify has been able to o er to repair businesses around the world is the expertise to diagnose modern vehicles, aid technicians with repairs and get them back on the road quicker, enhancing the e ciency and profitability of a repair business.

“Reducing the key-to-key times is absolutely critical for bodyshops and insurers,” he says.

“For a smaller shop to be able to perform the task that the main dealer once had to do. Rather than waiting for the dealer to perform a calibration for a headlamp or whatever they’re doing is critical.

“In Australia, the last time I was there, there was about two to three weeks lead time on some of these

jobs, where we can do that the same day.”

The increasing complexity of the cars and the importance of these relationships with crash customers means in the UK there is a gradual steady shift toward specialisation due in part to the e ciency the repairer can o er the customer in more rapid repairs with better and more complete diagnostics.

“For most makes the specialist repair shop will actually amount to a shorter repair period because they know what’s wrong with it first time rather than having to go back three times.”

This is not only better for the

Europe has shown ADAS calibrations will continue to grow as a key part of the repair process.

Technology and recruitment. Two of the biggest daily challenges of repair businesses will be the focus of the special forum Symposium24 this month.

customer but adds e ciency right through the repair chain.

“In the UK, a lot of the repairers also have to give out (courtesy) hire vehicles as part of their insured costs. So, the quicker they are repaired the quicker they get the hire car back and the less that’s costing them on the loan vehicle.”

At a global level one of Repairify’s great advantages is the relationship it maintains with multiple OEMS. This enables them to provide an integrated solution for repairers resolving issues on vehicles with the latest technology including secure gateways,

In the US and Europe, Repairify have developed a reputation for providing not only market leading technology and solutions, but also as a result of their understanding of the requirements of the vehicle repair market have been able to tailor services to meet specific needs. In addition, Martin says, the qualified, trained and focussed technicians recognise that much of their work takes place at the end of the repair process so the importance of supporting customers to program, calibrate or scan the vehicle and resolve any issues is critical.

“These are some of the driving factors in the UK and why people use Repairify.”

Martin Brown will be the keynote speaker at Symposium24 on June 19. More details at ncrsymposium.com.au

Take a day out of your busy schedule to learn where the industry is heading and how it can find solutions to these and more of its critical challenges in the years ahead.

The idea-packed Symposium24, to be held on June 19, hosted by the National Collision Repairer magazine, will bring together thought leaders and industry veterans.

The key themes to be explored across the stimulating day will be the challenges facing the industry, including technology, recruitment and processes that a ect the industry’s operation.

But the one-day event will also be firmly future focussed and help turn the changes to come into opportunities.

A combination of expert panels and interactive Q&A’s will focus on the future of the repair industry in Australia and what are the best solutions to help it to thrive.

Symposium24 will take an in-depth

look at future technology, specifically the need to adapt to the uptake of ADAS systems, the transition to EVs and the opportunities posed by AI.

It will also explore the crucial issue of getting the right people for your business to thrive and discuss the recruitment challenge and how the industry can reframe its image to be more relevant to a new generation of talent.

For anyone who wants to learn more and prepare for the future of the repair industry, the event will be an important opportunity to learn, discuss and take away your own solutions. It will also prove a valuable opportunity for the industry to network.

Supporting Symposium24 are some of the biggest names within the Australian automotive industry including cuttingedge automotive tech services company

Repairify, along with high profile industry names like Capricorn, AMA Group and PPG.

Repairify Australia general manager Tristan Sender says they are thrilled to be a sponsor of Symposium24.

“Events like the Symposium provide an opportunity for us to listen and learn from our colleagues in the Industry as well as talk about the innovative advancements we are making at Repairify.”

“The Symposium is shaping up to be the premier event for the collision repair industry this year, with a number of impressive speakers on the cards. It is looking like a great program, and encourage everyone to come along”.

Australia’s largest automotive

co- operative; Capricorn, its largest repair group AMA Group and leading global coatings giant PPG will all support and be featured as sponsors.

“Capricorn are proud to be a sponsor of the National Collision Repairer Symposium again in 2024,” Capricorn Group CEO David Fraser said.

“Events like these are so important as they allow people to get together, learn about the latest information and meet others working in the collision industry.

“NCR always put on a really interesting and engaging event, and we’re excited to be involved.”

The event will be held at the Novotel at Sydney Olympic Park on Wednesday June 19.

Tickets are still available for $150(ex. GST). Don’t miss out.

Scan here for tickets

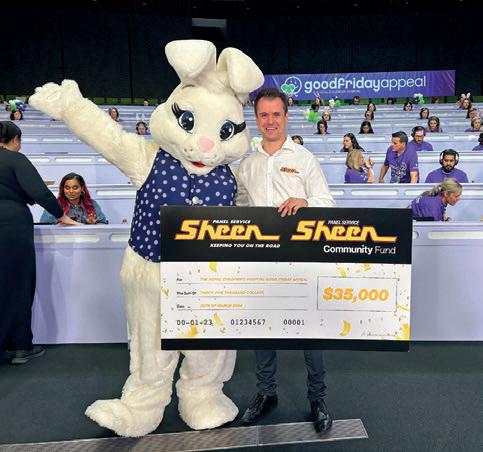

The Sheen Group’s outstanding e orts in the field of community giving have continued, ensuring the generosity flows onto some of Victoria’s favourite charities but also generating a community spirit throughout the organisation.

The Sheen Group’s prominent history in philanthropy is more than 30 years old and, in that time, they have developed a culture of giving that extends from the company founders, though management, to building a sense of community at the individual workshop level.

Part of this is developed through encouragement to actively engage in Sheen Community Fund causes but it is also manifested in the scale of the generosity, with donations expected to be more than $300,000 in 2024. Whichever causes are the beneficiaries, the fund’s principle remains the same; a conscious determination to change people’s lives for the better.

The flexibility and largesse of the Sheen Community Fund was again on display in April when with a swift turnaround it managed to increase its donation by 40 per cent in a single year to the ever-popular Good Friday Appeal.

This year the fund, supported by Sheen Panel Service, donated $35,000 to the Royal Children’s Hospital - Good Friday Appeal. Partnering with 3AW, the Sheen Group team joined Climb for The Kids event where they committed the event’s largest contribution, a big step up from last year’s $25,000 and part of a long history pf the repair group supporting the cause. Funds raised during this fundraiser go towards research and equipment for the Royal Children’s Hospital to treat critically sick kids. The fund’s contribution helped the Good Friday Appeal raise an incredible $20 million in 2024.

Manager of the Sheen Community Fund David Whitehead says while the Royal Children’s Hospital was a clear good cause, the work also had the benefit of raising their profile through their partnership with radio station 3AW.

“There are two sides to this,” he says. “We spend a lot of money on 3AW. We know it’s a good audience for us and that the word Sheen and repair resonates with their audience.

“And we know certainly from a hospital point of view what we’re raising money for. They had specific needs to be met. And that’s why we decided that that amount of money was going to vastly accelerate that process.

“That’s an example of what the community fund does; they’re the net receiver of our good work.”

Part of the success of the Sheen Community Fund and its capacity to generate strong funding ability lies in its partnerships and sharing the culture of giving with other business partners.

“We leverage who we know and who we spend money with and if we put commercial deals in place, then part of that commercial inclusion is if they want to come on board that’s good if they fit in. But it comes at a price and part of that entry to the room is to support us with our fundraising. We don’t put a dollar figure on it, but we try and grow them into it, get them involved and then it builds year on year.”

The strong pool of funds gives the flexibility to meet the urgent needs of a high-profile cause like the Royal Children’s Hospital but also smaller needs where they can apply the same principles of maximum a ect.

“We know that helping a kid helps their family. We’re not just targeting the kid who’s in the hospital and ensuring they’re getting the best treatment. We are potentially helping the family who can’t a ord that treatment, or who needs somewhere to stay or someone needs to pay the parking ticket they get while their kid is at the hospital.

It’s a bit like what we do with the assistance dogs, it has a ripple e ect, and we like that. It doesn’t just impact one family, but a wider community.”

These positive results and the feelgood e ect of making a di erence then flow onto every one of the 27 Sheen Group workshops that contribute to the community fund.

“Organically, the shops contribute to the fund every year on a corporate level, so all our businesses pay their way and contribute to the community fund. That’s built into the way our business operates.”

Next up for the fund will be several bike-building days involving schools and not-for-profit organisations that make the requests for donated bikes. This project allows Sheen Group to involve their workshops and hold an inclusive charity day.

“We’ll get our guys using their

skills and their tools to put the bikes together. And then we hand over those bikes for recipients on the day. We’ll invite the charity, the benefactors, their family and put on a barbecue.

“We’ve addressed a specific need, everyone gets a bike, we bring the family in under the Sheen banner, and everyone’s had the best day of their life.”

For more info or to donate go to; lmcf.org.au/ways-to-give/sheencommunity-fund

If you’re a Manager who is looking to join a supportive, award

family-owned smash repair business with over 50 years of experience, enquire now by emailing: anthony.demeca@sheengroup.com.au

NCR sat down with the Senior Policy Manager at the Electric Vehicle Council, Natalie Thompson, to discuss the changing car parc and how it is within Australia’s grasp to achieve a circular economy.

With a curious nature and a fascination for technology, Natalie Thompson is a part of the system that is supporting and advocating for the biggest change in Australia’s automotive industry since it began.

Natalie entered the world of electric vehicles at the Electric Vehicle Council 18 months ago, and since then, she has witnessed its rapid uptake across the automotive industry.

As a Senior Manager in the EVC policy team, Natalie’s responsibilities include identifying obstacles to electric vehicle adoption and finding solutions to overcome them, exploring opportunities within the electric vehicle value chain, and promoting sustainable practices.

Natalie’s role requires extensive coordination across di erent jurisdictions and industries. This

involves close collaboration with policymakers, industry representatives, and consumers to support the electric vehicle transition.

Launching in May 2017, the Electric Vehicle Council (EVC) is one of Australia’s largest advocates for a greener future through the uptake of electric vehicles.

With a large network of varying industries and collaborations, the EVC works across the entire EV ecosystem.

Creating a relationship with industries in each Australian state and territory has been essential for the EVC to ensure Australia moves forward as one nation.

“We engage with government bodies, industry groups, and industry stakeholders in every Australian state and territory,” Natalie says.

“We aim to develop nationally consistent approaches to support the EV transition across all segments of transport.”

The uptake in electric vehicles in Australia has been an uphill battle. With logistical and infrastructural issues, to a lack of consumer trust in the vehicles, the uptake of electric vehicles has not been a linear pathway. Rates of purchase and acceptance of electric vehicles has taken an upward trajectory post pandemic. According to the EVC, new electric vehicle purchases in Australia have more than doubled in 2023, compared to 2022.

The total number of EVs on Australian roads now exceeds 180,000.

Natalie outlines the primary issue of the adoption of electric vehicles.

“It’s definitely improved, but there has been a historic lack of policy ambition at the level required for a large-scale transition. Consistent support is essential to provide a signal to investors, industry and consumers that Australia is ready for the change.”

Natalie says.

In recent years, policy support has improved, with multiple standards, incentives, and strategies to encourage the acceptance and use of electric vehicles.

“This situation is improving,” she says. “It is great that more measures are being adopted by various states and territories. There have been significant steps by the Federal Government in the last 12 months in the form of a National EV Strategy and commitment to a New Vehicle E ciency Standard.”

The EVC are aware of the scope of the transition ahead and the areas that are still in need of development and improvement.

“We need greater focus on the electrification of commercial vehicles including trucks and buses,” Natalie says.

“There needs to be significant investment in expanding charging infrastructure, and alleviating barriers in apartment complexes, commercial developments and out on major freight routes.”

Supply chain sustainability is

essential in promoting electric vehicles as the green and environmentally friendly future.

Even though the life of an electric vehicle creates significantly lower emissions across its lifecycle in comparison with a petrol vehicle, Natalie emphasises the need and potential for improvement.

“It is particularly clear when you look at the production phase of a vehicle. The energy intensive processes involved in mining and manufacturing o er significant opportunities to decarbonise this part of the vehicle’s life,” Natalie says.

“Over time we will see more recycled content involved in vehicle and battery manufacturing which will play a big role in this.”

“The scaling up of battery recycling as we reach higher volumes of EVs in coming decades presents enormous opportunities to reduce demand for raw materials.”

“Addressing these issues is crucial for enhancing the overall sustainability of the EV lifecycle and ensuring the environmental benefits of EVs are

maximised from production through to end-of-life.”

For the EVC, the infrastructural and logistical challenges of electric vehicles do not fall to the wayside. The heightened demand on the electrical grid is one source of confusion and worry for consumers.

The EVC identify the issue and are advocating for a strategic and planned approach to ensure the strain on the electrical grid is minimised.

“If every car on Australia’s roads today were to switch to electric, it is estimated that there would be around a 15 per cent increase in overall electricity demand,” Natalie says.

“Considering that the transition to electric vehicles is projected to occur gradually over the next 25 years (aligned with achieving with net-zero targets by 2050), there is ample time to scale up the deployment of renewable energy to meet this increased demand.”

Creating a resilient electricity grid

will be crucial in consumer trust in the new electric future.

“A key part of ensuring this will involve incentivising EV owners to charge their vehicles during periods of high solar penetration and overnight,” Natalie says.

“This will minimise demand for electricity during peak periods.”

“Fortunately, we are seeing that existing EV owners do tend to operate this way. We are seeing the proliferation of electricity retail o ers that cater directly to this as well.”

Natalie and the EVC are optimistic that the high emission production of an electric vehicle will not only balance out, but will continue to develop and advance.

“Unlike petrol or diesel vehicles, which maintain a consistent rate of emissions throughout their lifecycle while burning fuel, the emissions associated with an EV are expected to fall progressively as the electricity grid continues to get cleaner,” Natalie says.

“Over time, it is also expected that the supply chain emissions for EV batteries will reduce as the industrial

processes involved in battery production are decarbonised globally.”

“This presents a significant opportunity for improving the lifecycle emissions of EVs even further.”

So far, the Australian Capital Territory is leading the way for electric vehicle uptake, with 21.9 per cent of all light vehicles sold in 2023 being electric vehicles.

The automotive repair industry has had to prepare for an electrical future, whether that is gaining an I-CAR Gold Class Collision Status or investing in the latest equipment, or upskilling sta

The EVC represents several organisations, including businesses involved in the servicing and aftermarket sectors of the automotive industry.

“As the EV market grows, our role includes supporting these sectors as they adapt to the changing fleet. And what’s exciting is that many of these companies are leading the way in developing diagnostic tools to help ensure proper vehicle maintenance,” Natalie says.

The EVC acknowledges the progress the automotive industry has made in initiating upskilling and training. The EVC supports and encourages the repair industry to continue with the future led approach, while recognising that the transition will not change the fleet overnight.

“The maintenance and collision repair sectors are in a phase of transition, with ongoing e orts to upskill and prepare for a future

dominated by electric vehicles,” Natalie says.

“While the current proportion of EV-trained mechanics is small, it is steadily increasing as the number of EVs on Australian roads grows, driving demand for EV repair services.”

“To support the transition to electric vehicles, consistent policy signals and strategic government investment is needed.

This includes the areas of skills development and training to equip the workforce with the necessary capacity to support a growing EV market. For example, the provision of fee-free or subsidised upskilling programs and the availability of targeted EV apprenticeships.”

Recycling of EV batteries

As electric vehicles are still in the early stages of production and repair, the automotive industry is still getting to know the boundaries and limitations of the technology. Natalie highlights the premature writing o of electric vehicles as being a minor setback.

“There is some concern that electric vehicles are being prematurely written o due to minor damages like superficial scratches to battery packs,” Natalie says.

“This is expected to change as the insurance, repair and maintenance industries develop more robust evaluation criteria and gains confidence in handling EV-specific issues.”

“As training and experience in EV repair improves along with clarity around di erent state regulatory

approaches, we anticipate a reduction in unnecessary write-o s and an increase in the repairability of EVs.”

The progress towards making an electric vehicle completely ‘green’, includes the afterlife of the battery. The EVC welcomes the progress made, both in Australia and internationally.

“Companies in Australia, such as Envirostream and InfinitEV, focus on recycling and reusing EV battery cells,” Natalie says.

“Overseas there have been significant developments in EV battery recycling, including Redwood Materials which has achieved a 95 per cent material recovery rate, which is great to see.”

“A huge advancement we saw in the last decade was the evolution of battery management systems (BMS) and software to regulate temperature and usage patterns and optimise performance.”

“Ongoing research and development in battery chemistries is also expected to enhance the longevity and e ciency of EV batteries.”

According to the EVC, a current limitation is the low volume of end of life batteries available for reprocessing. However, there will be significant growth in the recycling sector once the batteries reach the end-of-life cycle in the 2030’s and onwards.

“There is promising progress in the recycling and reuse of electric vehicle batteries. This will be crucial for minimising the environmental impact associated with the extraction and processing of raw materials,” Natalie says.

“It all helps to develop the circular economy.”

While Natalie acknowledged that Australia is not at the forefront of the EV transition, she highlighted how that gives us a unique position.

“We have the advantage and opportunity to adopt successful strategies to avoid potential pitfalls. This will allow us to streamline our own transition,” Natalie says.

Keep a lookout for EVC’s upcoming State of EVs report for 2024.

As the world edges towards a greener future, the risk of EV fires and thermal runaways from lithium-ion batteries will increase and experts want safety standards regulated.

According to Australian firm EV FireSafe, from 2010 to 2023, Australia had six electric vehicle fires, of which none started in the batteries.

However, lithium-ion batteries are getting some bad press that includes more than a thousand reported lithiumion fires caused this year alone in Australia by batteries in all applications, including e-scooters and small electronic devices.

Earlier this year, Fire and Rescue New South Wales also recorded the first deaths in a fire caused by a malfunctioning lithium-ion battery. Fire Service Commissioner, Jeremy Fewtrell highlighted the first deaths from thermal runaways as a warning to the community.

“This appears to be what we have been fearing for a while now: a person or persons dying due to a lithiumion battery-related fire in this state,” Fewtrell says.household

“We continue to warn the community about the potential for these batteries to explode in flames.”

The accident was an indication of the dangers posed by the kind of rechargeable batteries that power everything from the phone in your pocket to electric cars. Lithium-ion batteries can be found in e-scooters, forklifts, power tools, laptops and tablets, camping and gardening equipment, and a host of other home, o ce and industrial items.

The Australian Competition and Consumer Commission (ACCC) says that by 2026 households will have on average 33 devices powered by such batteries.

The growing fire risk has government, fire services and the insurance industry paying close attention.

The batteries’ strongest attribute is also what makes them potentially dangerous. Lithium ions allow for the storage of large amounts of energy in a relatively small area, but the liquid electrolyte in which they are held is highly volatile and flammable, and in producing power the batteries also generate heat.

Energy Systems Research Group at the University of NSW School of Electrical Engineering and Telecommunications, Matthew Priestley, says an overheating lithium-ion battery can succumb to a phenomenon known as thermal runaway.

“In this process, the excessive heat promotes the chemical reaction that makes the battery work, thus creating even more heat and ever more chemical reactions in a disastrous spiral,” Priestley says.

Batteries that are not stored properly, or are overcharged due to misuse or faults can explode into self-sustaining fires that burn up to 400 degrees within seconds and are hard to extinguish. The batteries can also release toxic fumes.

“These fires are extremely intense and volatile,” Fewtrell says.

“Even our firefighters find putting them out challenging because they burn so hot.”

“The Government needs to step in to regulate this area and develop a safety standard to which e-mobility devices should be constructed, but there has been slow progress on this. This is part of the reason why there have been so many e-mobility fires in Australia to date,” Priestley says.

In October the ACC released a report noting that the fires were increasing but existing data was incomplete and often unspecific to the breadth of the problem. But it did note that between April 2017 and March 2023, the ACCC received 231 product safety reports relating to Li-ion batteries.

The ACCC also identified a sixfold increase in media reports relating to lithium-ion battery incidents between February 2021 and February 2023 and 23 recalls between 1 January 2017 and 31 December 2022 a ecting an estimated 89,000 products on the market.

The ACCC provides a list of recommendations for consumers to follow to help protect their safety including monitoring charging times and disconnecting products once they are fully charged and not using batteries or devices if products are overheating or showing signs swelling or leaking.

Extra insight and ability in welding basics can be the pathway to advanced welding skills. Blake Baker and Ed Valle explain how.

A lot is changing in welding equipment, materials, and techniques; but even if you are up to speed on these trends, you will be at a disadvantage if you haven’t mastered the simple basics. These are the fundamentals that have guided generations of welders, going back to the day of traditional MIG welding equipment. Yet, we see these well-established basics being overlooked by many of the structural technicians we work with.

We often see opportunities for experienced technicians to enhance their skills by improving their knowledge of welding fundamentals. Our objective in writing this is to take you back to the basics - the building blocks for skills development - so you can reach your highest possible potential as a welder.

There is an underlying science in every phase of the collision repair process, from the physics of energy transfer occurring in a collision to electrical theory as it applies to modern collision

Ohm’s Law Formula Explained:

Ohm’s law is a mathematical equation that defines the relationship of voltage, current, and resistance. Voltage is one of the three parts in Ohm’s Law. When voltage is used in an Ohm’s Law equation, it is represented by the symbol V. Current or amps is another one of the three parts in Ohm’s Law. When it is used in an Ohm’s Law equation, it is represented by the symbol I. Resistance is another one of the three parts in Ohm’s Law. When resistance is used in an Ohm’s Law equation, it is represented by the symbol R.

repair welding processes. Welding is a precise process, and it is the mark of a professional to understand Ohm’s Law, which is simply the relationship between voltage, current, and resistance.

Practical knowledge gained from hands-on training and experience with operating welding equipment is invaluable, but theory knowledge helps reduce ine cient trial-and-error learning. Understanding electrical theory will help you expertly adjust machine settings, troubleshoot problems quickly, and consistently produce high-quality results. Knowing electrical terminology also will help you interpret equipment manufacturers’ operating instructions.

More often than not, technicians we work with have an incomplete understanding of electrical theory. As a result, a number of issues can arise.

The most common ones we see in the field are di culties identifying proper machine settings and adjustments, wasted time and materials, and poorquality results.

We recommend these I-CAR courses

to build your theory knowledge:

• Steel GMA Welding Theory

• Explain GMA/MIG/MAG Steel Welding

• Explain GMA/MIG/MAG Aluminium Welding

It Should Be Clear You Need Good Vision

It should go without saying that good vision is necessary for the precise work of welding; but unfortunately, it’s not uncommon for us to encounter technicians who have problems seeing clearly. It’s a sure tip-o when they struggle to follow a welding joint. If the problem is a dirty or worn outer cover lens on the helmet, it’s an easy fix. The solution may be as simple as cleaning or polishing the lens, but often it needs replacement. Worn or damaged outer cover lenses can hinder a technician’s performance during an I-CAR Welding Training and Certification event, and most importantly, may negatively impact the quality of vehicle repairs. Replacement cover lenses (inner and outer) are consumable items and are readily available from welding equipment

Source: I-CAR

suppliers. Keep a few inner and outer cover lenses on hand and replace them before their condition adversely a ects your weld quality.

Other problems commonly faced are environmental. When welding overhead or underneath vehicles, auxiliary lighting may be required. As a simple fix, welding helmets are now available with built-in lighting, alternatively a light can be added to your existing helmet. Like everything else, welding helmet technology has been evolving. Advancements in auto-darkening lens technology such as enhanced optical clarity, a broader colour spectrum, and increased number of arc sensors all contribute to the best view possible when welding.

We are always surprised by how many technicians are unaware of their need for prescription glasses or contacts. If you already wear glasses, follow your ophthalmologist’s recommendations for how often to schedule eye exams. Even if you’ve always had 20/20 vision, recognize that you will need to get your eyes checked more often as you age.

Today’s welders have sophisticated user interfaces that o er synergic programs specific to each wire alloy and diameter, as well as advanced features such as pulse, double pulse, 4T trigger modes, in addition to hot start and crater fill timers. A thorough understanding of welding equipment has always been a basic principle of welding, but the learning curve to utilise all the advanced features on today’s sophisticated machines can overwhelm technicians.

Our advice: Get to know your welder. Understand how synergic programs function and are adjusted according to material thickness. Perform test welds prior to welding on vehicles. The time you invest learning about your welder will minimize user errors and ultimately decrease the amount of time needed to identify optimal weld settings. Many equipment manufacturers have websites o ering a variety of resources. Their model-specific operator manuals

can typically be viewed online and downloaded when paper manuals are unavailable. This is a vastly underused resource. If you want to prioritize what to read first in these manuals, we suggest looking up information on the location of all machine adjustments and reading all information on synergic programming. It’s also worthwhile checking out the o cial social media platforms of equipment manufacturers which may lead you to training videos and other resources. Finally, do not overlook your equipment vendors and suppliers as potential sources for technical support.

I-CAR instructors also are a resource to help you set up, safely operate, and maintain your equipment. There are a wealth of resources here to assist before, during, and after any welding training. In addition, I-CAR also o ers equipment manufacturer-specific courses, including:

• GYS Autopulse 220-M3 - GMA Welder Operation and Tuning

• Pro Spot SP-5 - GMA Welder Operation and Tuning

• Car-O-Liner CMI300 Pulse Trio - GMA Welder Operation and Tuning

• Car-O-Liner CTR9 - Spot Welder Setup and Operation

• Pro Spot i4s - Spot Welder Setup and Operation

Back to the Basics

Something that will never change about welding is that before you pull the trigger on your welding gun, you have to pay attention to these simple, but essential basics:

• Understand electrical theory to help you identify the proper welder settings to consistently perform complete, safe, and quality repairs.

• Make sure you can see well with adequate lighting, a clean cover lens, and, if needed, glasses or contact lenses with an up-to-date prescription.