ACKNOWLEDGED BY THE

ACKNOWLEDGED BY THE

One of the things we love to The National Collision Repairer magazine is tell stories.

There is always plenty of news to focus on and endless issues which are constantly changing in an automotive industry that is undergoing almost unprecedented change but there is always time as well to stop and tell stories from the industry.

Some of these stories come from industry veterans and some from those who are just beginning their journey. What we know is there are plenty of quiet achievers in this industry who often spend a lifetime knuckling down and getting the job done, without the recognition they sometimes deserve. Part of the reasoning behind NCR ’s Lifetime Achievement Awards is to make sure those, who are often the backbone of the industry, are celebrated with fitting pomp and circumstance. But that award is only once a year and we feel there are so many more opportunities to tell great stories about the industry, whether it is a thriving and innovative business or a young player showing the characteristics that highlight what a great future the industry has.

In this issue we were lucky enough to speak to Shawn Buie from Drive Group in Kingston, Brisbane. Like so many young people Shawn has a passion for cars, so much so that he has even set up a sideline pursuit to further focus his interests and skills. All this is commendable enough, but it is the obstacles he has had to overcome which make his story inspiring and a worthy subject for our Future Leaders section. These are always great stories to tell.

And on the subject of inspiring stories, Capricorn’s Rising Stars award unearths some wonderful industry case studies

whose details are always worth taking the time to tell. The WA cooperative, that is enjoying its 50th year and fast approaching 30,0000 members, is a model in how to keep serving its members. But it is also an organisation that is acutely conscious of the industry it serves and the way the automotive industry perceives itself. Part of helping to shape that perception is celebrating people within the industry. With this award it highlights the young people who have the qualities and enthusiasm that make the industry great.

The worthy winner of this year’s Rising Stars award is Megan Toia, who although she is not directly involved in collision repair, is an apprentice in the automotive trade whose story is too good to pass over. Megan’s commitment at the start of her career to overcoming obstacles is exemplary, as is her passion for learning. But another element in her story that is worth promoting to the whole repair industry is just how ready these young people are to thrive when they have a supportive workplace and family. In many ways, this is also an award for her family and for Badgingarra Motors. Having this backup is about a lot more than luck. It is a story of patience and generosity. These are the qualities that are the key foundations for growth, both for Megan as an individual and for any business which wishes to thrive. We believe in these qualities at NCR and look forward to continue celebrating them wherever they come from in the industry.

Which leads me to an invitation, if you know someone in the collision repair industry who is particularly deserving of attention or has a great story to tell, then we are always happy to listen. This may be that opportunity to give these people or businesses the attention they deserve. And that is good for the industry.

Feel free to email me at eugne.duffy@primecreative.com.au

Eugene Duffy Editor

The National Collision Repairer

Global coatings giant BASF has used one of the highest profile auto events in the world to launch its latest innovations in recycling and sustainable products.

BASF has announced its first ChemCycling® products that utilise recycled waste tyres at the world’s leading international trade fair for the automotive aftermarket, Automechanika 2024, held in Frankfurt, Germany in September.

The product lines, manufactured using recycled materials will be marketed under BASF’s premium brands Glasurit and R-M and aim to boost body shop efficiency and productivity, contribute to the circular economy and reduce CO2 emissions.

The advent of a smaller footprint and greater efficiency will be exciting news for workshops determined to incorporate sustainability into their long-term business plans.

BASF Senior Vice President, Global Automotive Refinish Coatings Chris Titmarsh says one of the substantial

pushing what’s possible, empowering body shops to lead the change with sustainable technologies that are unique to the market,” Titmarsh says.

“With our exclusive ChemCycling, our vision is to support a circular economy by reducing the use of fossil raw materials, minimising waste and cutting CO2 emissions in the value chain.

“We’re making a difference with our new products, replacing a share

BASF Coatings’ Glasurit AraClass A-C-24 Eco Balance and R-M Race Finish-R eSense clearcoats are the first automotive refinish products that utilise this technology, delivering benefits to both body shops and the environment, BASF notes.

For the workshop, the clearcoats’ drying speed allows for fast processing, with the coating drying in just 20 minutes at 40ºC.

By reducing drying time, energy consumption is significantly lowered, resulting in improved efficiency and reduced environmental impact.

This feature is particularly advantageous for electric vehicles, as it minimises their exposure to excessive heat.

BASF will also expand its range of Biomass Balance products. New mixing clears based on BASF’s biomass balance approach have been added to the waterborne basecoat series of Glasurit 100 Line and R-M AGILIS, both of which already offer the lowest VOC content below 250 g/L in the industry.

The new mixing clears now reduce CO2 emissions by up to 50 per cent.

For more information go to glasurit.com/en-int/sustainability

Creating positive change for your business and the environment.

Taking sustainable action can make a real difference to your bodyshop. In fact, those who’ve already chosen our sustainable products are now using less materials, conserving resources, saving money and more importantly, protecting the environment. Contact us and find out how you can switch your bodyshop to eco-friendly products today.

A well-established name in the industry, Car-O-Liner products are known for being reliable, dynamic and efficient.

Car-O-Liner offers many workshop solutions that ensures a broad range of equipment to suit a diverse scope of workshop requirements and needs.

Car-O-Liner’s services don’t stop at the equipment, they also provide customer support services for any issues that may arise.

The CDR1 Workstation, the CR200, and the Speed 3T are three pieces of equipment that will boost your workshop’s functionality and pace.

The relatively compact size and small footprint of the CDR1 workstation is ideal for all workshops doing cosmetic

The CDR™1 is a value-packed repair cart that allows technicians to quickly and efficiently provide professional repairs of small to medium autobody damage.

These quick cosmetic collision repairs generate good margins, faster cycle times and a decreased need for investments in expensive, heavy equipment.

Colour-coded tools are neatly arranged in the workstation which can be rolled around the workshop as needed.

There are also three versions of the CDR1 to adapt to a workshop’s needs with the basic unit including the workstation, the CR235 Combi Spotter and two drawers for steel and aluminium.

The advanced kit adds a drawer for glue, while the Master Kit adds a drawer for Holding and another for Push-Pull, to make up an all-inone workstation to cover almost all cosmetic jobs in the workshop.

The CR™200 spotter uses a unique short cycle welding process that is an effective for both aluminium and steel automotive bodywork. The process is especially designed for welding screws, pins and accessories such as washers and keys.

The CR™200 boosts efficiency for quick dent repairs and allows vehicles to move quickly through the repair process. The CR™200 can increase shop productivity and profitability.

3T are designed to bring versatility, reliability and efficiency to your workshop. With two types of installation, aboveground or flush mounted, they can provide a dynamic system for light service to damage repair.

The Speed 3T and the Speed 3T Plus are two light weight work benches, perfect for speeding up the repair process. Carrying a weight of up to 3 tons, the equipment is made to withstand any medium and cosmetic damage repair.

The bench system is an easy assemble of the convenient draw aligner, which can be rotated 180 degrees around the platform at one end and can be tilted 90 degrees horizontally.

The Speed 3T Plus will give you the boost your workshop needs. With longer bench space and room for two draw aligners, one at either end, the bench could solve efficiency issues.

To learn more, visit www.car-o-liner.com.au.

pays special homage to the global movement with a beautifully crafted, precision engineered body covered in sophisticated street art motifs and offset with black accented nozzle and gun controls.

This strictly limited-edition spray gun combines the energy and creativity of street art with the outstanding quality that has made SATA a global industry leader.

What’s beneath the surface

Best of all, behind the standout graphics you will find all the high value features that have made the regular SATAjet X 5500 a market favourite, including the unique X-Nozzle System.

This innovative range of nozzle options makes it easy to perfectly tune this spray gun to suit a painter’s personal spraying preferences, the paint brand being used and application conditions that can range from a cold, dry Melbourne to a hot, humid North Queensland.

A spray gun with street cred and then some….

Featuring creative and expressive street art images, SATA’s latest special edition spray gun makes an eye-catching statement in the paint shop or on display in a collector’s display cabinet. These days, you can find impressive examples of uber cool street art pretty much everywhere around the world, including on the latest SATA limited edition spray gun, the SATAjet X 5500 Street Art.

Originally created in the urban landscapes of large cities, many artists have turned street art into a legitimate worldwide art movement that has become famous for sending and immortalising social and political messages in the form of extraordinary murals.

The SATAjet X 5500 Street Art

The SATAjet X 5500 Street Art is available in your choice of RP or HVLP technology, as well as selected nozzle sizes, and the popular digital version with an extremely handy air pressure readout integrated into the gun handle.

Being a special edition also means it is a time-limited promotion available from your SATA distributor while stocks last.

Whether you plan to enjoy it every day in the spray booth or add it to your gun collection display cabinet as a piece of awesome artwork, SATA recommends spray technicians get in quickly and place orders ASAP to reserve a SATAjet X 5500 Street Art and avoid disappointment.

For more information go to sata.com or speak to a SATA distributor.

U-pol’s High #5 is a 1K high-performance primer designed for compatibility with most solvent and waterborne paint systems, making it ideal for spot and small component priming applications. Available in Grey and White, High #5 meets VOC compliance and adheres to safety guidelines for use outside the spray booth.

Its performance rivals that of a 2K primer applied with an HVLP spray gun, but without the associated hassle.

Efficiency and Convenience: High #5 is faster, requires less masking, has no pot life, and significantly reduces material waste and cleanup. Its exceptional build and outstanding adhesion set it apart from industry competitors, making it the perfect product for SMART repair applications.

Versatile Bonding: High #5 bonds directly

to bare steel, aluminium, galvanized steel, and most plastics, including flexible bumper components.

It comes with two spray nozzles to maximize performance:

• High output round tip: Generates approximately 2 mm depth per coat.

• Flat tip: Produces a 4-inch-wide fan pattern with 1.1 mm per coat, offering finer atomization for better control over larger areas.

Rapid Drying: The fast-drying resin system reduces shrinkage and easily fills 180 grit and finer sand scratches in just one to two coats.

With a flash time of just 5 minutes, rapid recoating is possible. After drying, you can wet sand with 600-800 grit sandpaper or dry sand with 400-600 grit sandpaper.

High #5 is simply one of the highest-

The High #5 sets new standards for high-performance primers.

performing high-build primers available, making it an essential part of any SMART repair toolkit. Its superior performance and ease of use ensure that it supports spot repairs effectively and efficiently.

For further information and to locate your nearest stockist contact U-pol’s technical customer support team on (02) 4731 2655 or email sales@u-pol.com.au

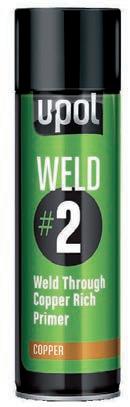

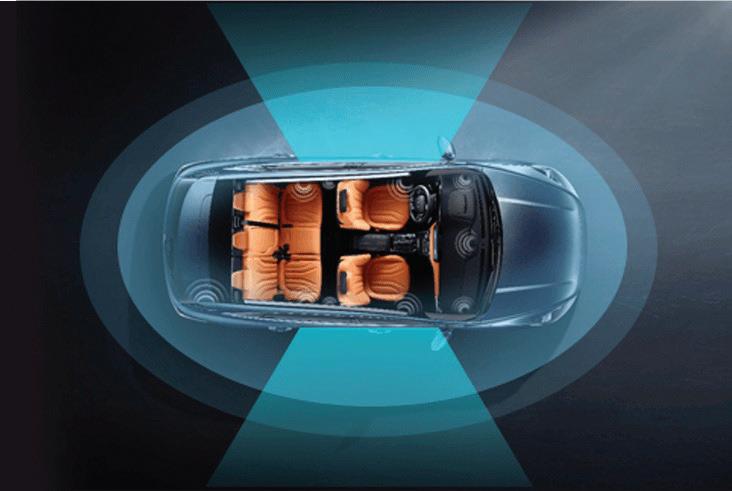

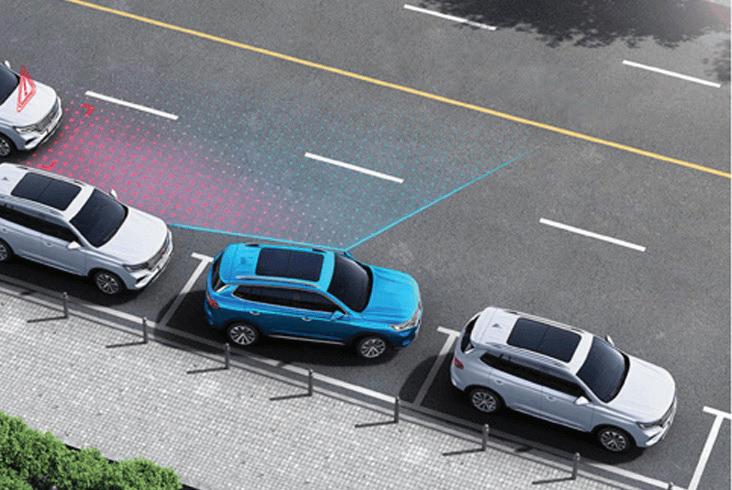

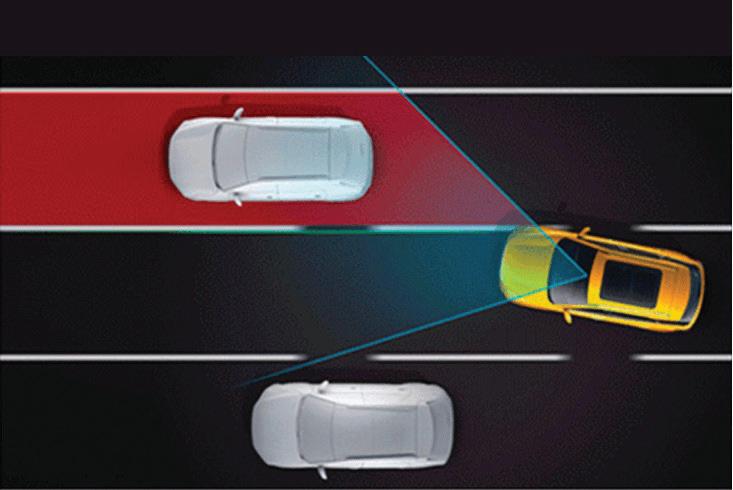

Safety and comfort are driving innovation in cars at an unprecedented rate. But where ADAS systems were once the domain of luxury or European cars, repairers can expect them on almost any new car that comes into the workshop. This means businesses need to be ready for calibration as a regular part of the workflow. Logicar has a workshop solution that may be the very thing businesses are looking for.

repair workshop, but Logicar’s Thinkcar ADAS calibration kit has focused on functionality to ensure it meets the demands of modern technology but is also easy to use.

Logicar has taken the best of new automotive technology and adapted it into a calibration system that is flexible, accurate and easy to install.

Safety first Collision repairers have a growing

calibrations of cameras, radars and sensors on a modern vehicle are an essential part of the repair process. These ensure the onboard devices continue to collect the precise data and provide exact warnings to the braking and steering functions of ADAS systems.

The Thinkcar ADAS calibration kit aims to give repair workshops this capability and continue to serve customers with a level of expertise that develops trust and client satisfaction.

The Thinkcar kit is designed for workshops to be able to calibrate a wide range of safety systems that are becoming prevalent on modern vehicles including Lane Departure Warning, Adaptive Cruise Control, 360 Panoramic Monitoring, Rear Collision Warning and Blind Spot Monitoring. In order to ensure the ongoing safety of these systems on the road after repairs Thinkcar has also paid close attention to the accuracy of its system. It uses five-line laser and cross

at the front of the vehicle, leaving the technician with the help of the software to begin the calibration.

The Thinkcar ADAS Calibration kit is a fully portable device that can be folded up for storage or transportation, freeing up valuable space in the workshop when not in use.

It also features universal calibration components and has a range of different elements that can be assembled and added to calibrate different car models.

It is also compatible with the full

range of Thinktool diagnostic devices to meet the daily calibration need of auto repair shop.

Logicar also has an industry reputation for backing up their equipment with ongoing technical support and training, from certified and authorised ADAS Technicians. The support staff can work with customers through issues and diagnoses to ensure calibrations are successful.

This further adds to workshop flexibility and potential business profitability by keeping calibration services in-house. It can also avoid further delays in key-to-key times on repairs and greater enhance customer satisfaction.

The system has full software support that covers a comprehensive range of vehicles covering 98 per cent of the modern fleet including popular makes such as Toyota, Ford, Holden Mazda, Nissan and Subaru, right through to luxury manufacturers such as Ferrari, Rolls Royce, Aston Martin and Mercedes Benz.

It is also up to date with a range of new Asian vehicles appearing on the market including Proton, Tata, Mahindra, Maruti, Ssangyong, Perodua, Geely.

For more information go to logicar. com.au or watch the full demonstration video on Youtube

Panels know how to successfully break new ground.

The Iacobuccis define success as continuous growth, learning, and improvement as a team, and it is safe to say, that so far, it has worked in

it’s a collective effort. Every member of our team plays a role in our success, and as they grow and develop, so does the business,” Clarissa says.

“We wouldn’t be where we are today without the incredible team we have. Their dedication and progress is what truly defines our success.”

David Iacobucci’s parents, Don and Silvana, started DSI Panels over 40 years ago with a workshop in Box Hill North. In 1998, DSI Panels moved to its current location in Blackburn.

Wanting to follow in his family’s footsteps, David began his panel beating career in 1999 at his parent’s workshop. David moved quickly through the ranks, and by 2006, he had purchased half the business from

In 2014, David and Clarissa bought the remaining half of the business from Don

to four factories in Blackburn, a large purpose-built factory in Croydon South, and most recently, the acquisition of four adjoining factories in Lilydale, making us the largest panel shop in the Yarra Valley,” Clarissa says.

“It’s been quite a journey, and we’re grateful for all the support we’ve received along the way. That says, we never stop looking— the next expansion could be just around the corner!”

Working as a family unit has meant that David and Clarissa can openly communicate and get straight to the source of the challenge or issue. United by the same goal, the discussions surrounding improvement and growth are underpinned by openness and candidness.

“While we might not always have a filter in our discussions, honesty has shaped the personality and culture we’ve built across the DSI Panels locations,” Clarissa says.

David takes care of the front-end responsibilities, working with insurance companies and suppliers to get the best deals. David also steps in to help with quotes, parts, and answering day-to-day questions from the team.

“Together, we do our best to keep things running smoothly for both staff and customers,” Clarissa says.

Until marrying David, Clarissa had zero experience in the collision repair industry. Like many, Clarissa had preconceived ideas about the industry, but when she began her work in the

“I was able to bring in experience from my previous work which added more structure to the way we operate,” Clarissa says.

After a decade with the thriving Blackburn workshop, DSI Panels were faced with a difficult choice in an uncertain economy. Their choice was to either expand or plateau.

“We are driven by our core values and a desire to keep moving forward. So, we chose growth,” Clarissa says.

The expansion process was a time

end result even more satisfying.”

The Croydon workshop opened in 2018, and it has been a highlight in the Iacobuccis’ journey so far.

“The opening of our Croydon branch stands out as one of the most memorable moments for us. It was our second location and really marked the beginning of our major growth,” Clarissa says.

“Watching that shop grow into what it is today, with multiple awards and a strong, dedicated team, has been incredibly rewarding. We couldn’t be happier with how far it has come.”

The Iacobuccis lead DSI Panels with an innovative eye that is strengthened by the ability to adapt and grow.

“We’re committed to discussing, formalising, and continuously finetuning our processes. We gather input from everyone involved to ensure that our practices are as streamlined as possible,” Clarissa says.

Having a consistent approach throughout all levels and areas of the office and workshop has allowed DSI Panels to continue its growth and expansion.

“For instance, we have a standardised list of photos needed at various stages—

quotes, drop-offs, progress updates, and hand-overs. This simple yet effective practice helps minimise potential issues and keeps everyone on the same page,” Clarissa says.

“It’s a great example of how small, consistent improvements can make a big difference, and it’s something that everyone contributes to.”

All repair shops are facing numerous

changing contracts, there’s been added pressure on our operations. However, we’ve focused on understanding our limits and setting clear boundaries regarding the number of cars we can handle at any given time. Learning to say ‘no’ when necessary has been crucial.”

At DSI Panels, keeping a happy and cohesive workplace is an expectation that they constantly work to uphold.

who align with our values. We focus on finding the right fit for our team rather than just filling positions,” Clarissa says.

DSI Panels recognises the shift in attittudes towards the work/llife balance, particulary after the pandemic.

“We offer flexible working arrangements, including options for 4 or 5-day weeks, part-time or casual roles, and the ability to make up time for personal appointments. This flexibility helps our staff balance work and personal commitments,” Clarissa says.

Having an open and honest community of staff, however, hasn’t come without its challenges.

“Maintaining this positive environment sometimes means having difficult conversations when things don’t work out or when someone doesn’t fit well with the existing team. Managing this for a team of over 50 staff across three locations can be challenging, but it’s an essential part of ensuring a harmonious workplace,” Clarissa says.

As soon as a new employee begins, there is full transparency to the level of training that is required.

“We actively promote a strong training culture when advertising for new staff, and this commitment has been embraced enthusiastically by our current team,” Clarissa says.

The Iacobuccis also foster the next generation of talent at their workshops.

They currently have four apprentices, two of which are on track to be signed off in the next month.

“Having apprentices is really rewarding for us. We’re always on the lookout for more apprentices and plan to focus on this area moving forward,” Clarissa says.

Every DSI Panel shop is I-CAR Gold Class accredited, which is in alignment with the Iacobuccis’ belief to keep moving forward.

“Our staff understand that this accreditation not only benefits the business but also supports their own professional development and progression in their trades,” Clarissa says.”We are strong believers in the need to constantly learn – if you stay still, you fall behind!”

The training isn’t just for the staff, as the Iacobuccis believe it also benefits current and potential customers.

“Our customers can rest easy knowing that our technicians are up-to-date with the latest industry training, which provides them with a sense of security. For us, it means we can be confident that we’ve done everything possible

The collision repair industry is rapidly evolving, with new technological advancements like EVs and hydrogen batteries, and new OEMs entering the market. In an environment where some people might become overwhelmed, the Iacobuccis see opportunity.

“This period of change presents exciting opportunities for the industry. It’s a great time for young, driven individuals to join the field and contribute to its growth and innovation,” Clarissa says.

With a motto like ‘to remain the

have one eye on planning for the future. The Iacobuccis have recently received council approval for a redevelopment of their original site in Blackburn. This redevelopment will include adding an adjoining factory that DSI Panels has just secured.

“Even with this project underway, our plans don’t stop there. We’re always looking ahead and thinking about future opportunities, but we approach them one step at a time,” Clarissa says.

“It’s important to us that while we evolve and improve, the core values of DSI Panels remain unchanged. We want to grow and innovate without losing sight of who we are.”

Whether it is building a business from scratch or growing an established enterprise, industry relationships are vital. When it comes to sophisticated workshop equipment, the support they offer can make the difference between failure and thriving. A major installation demonstrates how a partnership between Sandersons Prestige Accident Repair Centre and the SAPE Group has yielded results.

For Lincoln Cridland the abrupt shift to Queensland in the middle of COVID brought a raft of challenges and opportunities. It was while looking for work in the industry that he was offered the opportunity to takeover an established repair business.

“As far as owning an actual panel shop, now it was the first time I’d done it, but I’ve been around the industry,” he says after decades working in the collision repair sector.

“I was named after a car, my grandfather was a coach builder and same with my dad, We were forever building motorbikes and hot rods at home. As a kid, I pretty much grew up in the shed, welding things and building things and doing all sorts of stuff. Owning a business was just a natural progression.”

If the step to ownership on the Gold Coast was something of a leap of faith for Cridland, he brought with him this generational passion for repairs and a dedication to doing things better.

“It was just familiar territory, because I’d run some pretty big shops in Melbourne successfully. But I guess the hardest part was I didn’t know anyone on the Gold Coast. I had no contacts whatsoever.”

The value of relationships really came to the fore in this period, both with those he took over from the former owner of Sandersons and the industry contacts he retained from past roles. One of the most important of these was a developing relationship with the SAPE Group.

SAPE became particularly important when Cridland began to consider investing in the business to give it

adjoining space and equipping it with the lifting and measuring equipment that would enable them to do structural repairs and a wider range of vehicles.

it involved some trial and error with benches that Cridland describes as “not cutting the mustard”. But it was the support of SAPE and their Group

that it utilises, it is actually a smaller unit. But at the same time we can put much larger vehicles on it. The arm is detachable, and you can put the pulling arm in all different positions around the bench. That was a win for me.”

He says this flexibility is enhanced by the equipment that works with the Spanesi 106 bench.

“SAPE really came to the party with a lot of accessories. We ended up with 4WD clamps, the Euro clamps; it’s got everything.”

This has given Sandersons Prestige Accident Repair Centre as a business the confidence to take on a wider variety of repair work.

“We’re fully equipped to do anything they throw at us now,” Cridland says.

“If a job presents itself, you’re confident to know that you can tackle a specific job. If a job needs aligning or a fair amount of pulling power, we have the capacity to do it.”

The investment at Sandersons Prestige Accident Repair Centre extends to a new booth to cater for bigger vehicles, measuring eight and a half meters long and three meters high. This has enabled them to take on repairs ranging from larger utes and US style ‘pick-up’ trucks’ as they become more popular in Australia.

capability is spreading, as customers see and hear what the workshop is capable of.

“it just opens up other avenues,” he says. “When a job presents itself in the driveway out front or over a phone call or photos from an insurance company or whatever it may be, we can do it with what we’ve got, and we don’t have to second guess anymore.”

Another part of the satisfaction from the installation is how it makes Cridland feel about having an up-to date, fully equipped workshop that looks professional and modern.

“We’re really big on presentation here. I absolutely hate it when I see dust and parts and bits of tape stuck to the floor. Having this set up, it is reassuring.”

Cridland says during this investment, the back-up support of SAPE was critical; particularly the relationships he developed with SAPE’s Beau Knowles.

“You need reliable people that are going to give you the right information,” Cridland says.

“We hummed and agh’ed over certain machines, and I even looked at the bigger machine, but it wasn’t really necessary.

“All this time, Beau was honest in his opinions and his approach. He went over and above my expectations of what

For Cridland and his partner Carmen, the installation and the Spanesi 106 bench were also a cumulative investment in the business to ensure they were set up for future growth.

“I stopped recently, and I said, we have to give ourselves a pat on the back here. We came to Queensland with no jobs, and we took on a shop unexpectedly and now we’ve got triple the staff. We took on two staff members when we bought the shop and there’s 10 of us here now. We have got the business set up to where we want it.

“We’re quite happy with the size that we are at; It’s very manageable. It’s profitable, and we finally ticked off that last piece of the puzzle in the last of the big-ticket equipment items we needed.”

Cridland says while they will continue to refine details and address any issues, it was a credit to the hard work and all the support of relationships like that they enjoy with SAPE that had brought them to this point in their business journey.

“Now the processes and procedures are in place to make it all tick along smoothly. We need to give ourselves a pat on the back, because hopefully within the next few months, we’ll be able to just turn up and actually just get the work done.”

Everyone loves watching a master at work. The passion for perfection is contagious and can bring new insights into spray jobs in the workshop. A special partnership between legendary custom vehicle builder Howard Astill and PPG is providing a YouTube experience that informs, educates and entertains.

Anyone who has taken a deep dive into the YouTube video sharing platform will tell you that it’s littered with virtual rabbit holes that can quickly make huge chunks of time simply disappear. However, at the same time, it’s a medium that has the power to reach vast numbers of people across the region and, indeed, the planet, and that is exactly what the Astill Design / PPG partnership has been tapping into.

As a revered elder statesman of the Australian custom car scene, Howard Astill has amassed a treasure-trove of experience and knowledge which he is keen to make available to others. At the same time, he admits that, even after a career spanning over four decades, he is still eager to learn more.

In the second half of 2023 the opportunity came up to expand on the 25-year partnership Astill has had with PPG by documenting the stages of a ‘Muscle Car Respray’ project on the Astill Design YouTube channel. Brought to you by PPG and MIRKA, the fascinating 14-episode series follows the step-by-

While it drew in viewers from all quarters, it was targeted at a certain sector, says Astill. “We were primarily aiming for the small custom / restoration businesses, along with DIY people who have the enthusiasm and basic skills but are looking for some expert guidance.”

Thanks to the success of the original format, the partnership has rolled on into a new series in 2024, where Astill hosts a series of videos that delve into a whole range of interesting subject matter, including correct polishing, removing stone chips, selecting the right spray gun

so he is able to ask questions and get detailed answers on why things are done a certain way or why certain products and tools are used at certain times.

“I am really pleased to be able to do these series in conjunction with PPG and MIRKA. I have had a lot of positive feedback from viewers about being able to learn from the PPG professionals.”

“We have been able to call on guest PPG experts, such as Terry Noble (PPG Customer Support Specialist), Casey Calis (PPG MSO Technical Support) and Trevor Duke (PPG Refinish National

Training Manager ANZ), to help us understand why particular tasks are done at particular times.

“Although we are covering quite technical subjects, we get answers that are explained in layman’s terminology as much as possible. For example, there are a variety of different primers we use and the PPG guys are able to explain when we use each one and why, along with how to get the best from each one. We are also able to introduce viewers to the latest MIRKA electric and battery tool range, as well as products like the new MIRKA Galaxy self-sharpening abrasive range.”

After more than 40 years in the industry, Astill could be forgiven for just sticking to ‘the way things have always been done’ but he actually prides himself on continually keeping up with the latest in products and processes. In fact, he is happy to think outside the square.

“One thing I have recognised over the years is that products and processes are constantly changing so one of the aims of these series is to provide people with the latest information, as well as tips, techniques and hacks that can be used to make the job more efficient and produce a better end result, “ Astill says.

“For instance, we have looked at opportunities to take advantage of some of the latest PPG refinish technologies in the custom car space in order to let us eliminate certain steps or shorten the process without impacting on the quality of the end result.

“A good example is to use a WetOn-Wet primer to eliminate a whole sanding step and this is where PPG has quite a few different product options. One of them is F4949 CT Protective Chassis Primer Binder from PPG’s DELFLEET® Evolution commercial transport range which is perfect for chassis and engine bays. And to finish off those parts you can also use a

satin black from the Delfleet range.”

The latest MIRKA electric tools, abrasives and polishes have also taken centre stage in many episodes.

“I have use a MIRKA dustless sanding system for over 10 years – I don’t do any wet rubbing. I have upgraded to the latest MIRKA Galaxy self-sharpening abrasives range and I trialled the MIRKA DEROS electric sanding block. It’s a nice tool to use because it takes away some of the wear and tear on the body so I have added that to my process.”

Judging by the statistics, the PPG / MIRKA partnership on the Astill Youtube channel has been an outstanding success with terrific viewing numbers and a growing audience coming from all over the world. What is also interesting is how people are choosing to consume the content.

“People will watch our videos on the phone, PC or tablet but perhaps the biggest surprise was how many view it on their smart TV. Statistics show that almost 50 per cent of the viewing is being done on a TV. That is why we tend to do long format videos (over half an hour) because people will sit down in the evening and watch Astill Design rather than traditional TV channels.”

One unexpected consequence of hosting a popular YouTube channel is that Astill has become more well known.

“I was walking through Los Angeles airport on the way to SEMA when a guy yells out ‘hey Howard’. It was an Aussie guy who just wanted to say how much he loved the show. Then an American guy did the same thing at a convenience store on the way to Las Vegas. Even back home in Wollongong, people will stop me in the street to tell me they love the show!”

Over a 25-year partnership, Howard credits PPG with helping him produce some of the best paint finishes in the country and that continues today. As well as PPG products featuring on the Muscle Car Respray, they are also being used on Astill’s current XC Falcon Panel Van build project.

You can follow that build by tuning into the Astill Design YouTube channel (www.youtube.com/@AstillDesign), as well as see coverage of various custom vehicle shows and events. Fresh content appears regularly and, if that is not enough, there is a vast back catalogue of videos to pick over.

This is one YouTube rabbit hole definitely worth going down.

A small country town and hours of commuting time are no barrier to one of the automotive industry’s best and brightest future stars.

Small communities in rural towns are often faced with unique challenges. The town of Badgingarra in Western Australia is no exception.

With a population of 173 people and being 200 kilometres north of Perth, Badgingarra has been put on the automotive map by supporting Capricorn’s latest recipient of the Rising Stars Award, second year apprentice, Megan Toia.

The Capricorn Rising Stars Award recognises and rewards outstanding apprentices in the automotive aftermarket industry.

Travelling 60km from her hometown of Moora to her work at Badgingarra (Badgy) Motors, Megan is nothing short of dedicated.

Megan also regularly makes the 200km trip to South Perth for her TAFE studies in three-month blocks throughout the year. Megan starts her

2.5-hour drive to TAFE the night before classes begin and is then up at 5:30am to beat the traffic.

Megan’s life is centred around her love of the automotive industry.

Capricorn noted Megan’s passion for the industry, her love of learning and her constant pursuit of excellence. These qualities impressed the multiple rounds of judging from among 300 nominations.

Megan’s boss, Harry Burgess nominated her for the award last year, but time restraints meant she was unable to complete the application in time.

“This year I had some time off when the original entry was due, and my boss was encouraging me to complete the questions and submit my responses,” Megan says.

“I’m so glad I took the time this year to follow through with the questions.”

Megan has always had a passion for cars and practical learning, so working in the automotive industry was a perfect fit.

“As I have always loved cars and learning about how they worked, while also loving problem solving and getting my hands dirty, this apprenticeship has proven to be perfect for me.”

Capricorn Group CEO Designate Brad Gannon says he was inspired by many of the nominees and particularly Megan’s dedication.

“It’s an amazing story,” he says.

“The passion and dedication that Megan’s got for not only the industry, but for her job itself, and the personal commitment that she makes each and every day with travel. I think that’s what the industry is all about.

“The industry is about passion, passion for people, passion for cars and Megan’s an absolute worthy winner, because she shows both passion for

the team she works for, passion for her customers, passion for that problem solving.

“That’s the automotive industry in a nutshell.”

But Brad also wanted to highlight the outstanding talent of the finalists and the calibre of more than 300 Capricorn Members who nominated their talented apprentices from all over Australia and New Zealand, showing the breadth of talent across the industry.

“Megan was a worthy winner, but there were so many worthy nominees and that’s really exciting for the industry, because this passion is an amazing thing, and these people are passionate about what they do each and every day.

“If you’re passionate about what you do every day, you’re really not working a day in your life. To find a job and an industry where you can have that genuine passion, is truly special.

“When you see these nominees, lots of them have had challenges in getting to their career, that’s not uncommon, but to be able to overcome those challenges is a hallmark of many of them and it’s inspiring.”

Megan’s boss at Badgingarra Motors, Harry Burgess, was also glowing in his praise for her motivation and enthusiasm.

“Megan is a great asset to my business,” Burgess says.

He highlighted her detail orientated approach and positive attitude in being an asset to the business.

“She applies pressure to herself to complete her tasks to the highest standards and she is very thorough. She is a fast learner who follows instructions, can work independently and takes constructive advice well.”

Megan was quick to thank her boss for showing her the ropes as she continues to study at TAFE.

“Harry has been very patient, he has walked me though all of the mistakes that I have made and has been incredibly supportive throughout my exciting automotive apprenticeship journey,” Megan says.

Megan’s partner has also been an integral part of her journey.

“He has been there for me on days where I question whether I keep going. He’s been there financially and emotionally, and I cannot thank him enough,” Megan says.

Brad Gannon stressed that the workplace was a powerful contributor to the success of young people.

“We could see from both the nomination and the comments made in the nominations, that support came through so clearly from Megan’s boss, Harry,” Brad says.

“This is key for all industries and all organisations, but particularly when you’re starting out; to have that support around you, that imparting of knowledge, that comfort to learn new things. No doubt when you’re learning new things, there’ll be challenges along the way, but having that support network around you makes such a difference.”

Throughout Megan’s journey in the industry, she has encountered few females in her courses, and at her workplaces. Despite this, Megan has made a community for herself in the industry that is based on mutual respect and merit.

“There were two other girls who started in my TAFE class, but they both ended up dropping out for different

reasons after a few months,” Megan says. “I’m lucky to have met two great guys who have turned into good mates at TAFE,” .

At her workplace, Megan highlighted how her gender has no influence over how she is treated.

“At work there has never been an issue with being the only female apprentice. There is a female receptionist who is lovely, and Harry’s partner Sharon has also been a great support,” Megan says.

“My gender has never been an issue; they will make fun of me no matter what.”

Behind every worker

In another sign of her support, Megan’s family have been behind her every step of the way. She praised her parents for their continued encouragement.

“My mum was always my biggest inspiration for being a strong woman. She was in the army in the 80’s and 90’s, and she constantly had to prove herself,” Megan says.

Megan has found herself in a similar experience to her mother’s, having to double down on her work and prove she is worthy of being in the industry.

“I have had people at TAFE and customers look down on me because I am female. But because I have such a great boss and coworker I feel really supported. Whenever someone tries

to talk down to me, I know they always have my back,” Megan says.

“I have such a strong support system around me.”

Brad Gannon says Megan’s story not only shows the importance of support but the critical role that families play in helping young people choose and sustain an automotive career.

“The reality is the automotive industry is one of the best kept secrets for people looking for a new career, and so we do need to step up and start promoting it, particularly to families. Let the mums and dads out there know that it is exciting and innovative, because they do have a significant influence on where the next generation look for their career.

“The message as an industry we want to get out is there are more and more diverse new skill sets required all the time. And I think Megan puts it best when she says, it’s a great industry to be in.

“We absolutely need to get that message out there and influence, parents, teachers and career counsellors that this industry is going places.”

For people thinking about entering the industry, Megan encourages them to have patience and belief that the pathway will lead to endless opportunities.

“It can be daunting going into a trade, especially if you don’t have the support network. The pay and the motivation to get started can be difficult,” Megan says.

Despite the initial barriers, Megan highlighted that, “It gets better, it gets way better.”

“As soon as you are qualified, the world is your oyster. There is so much you can do with your qualifications.”

Brad highlights Capricorn’s continued commitment to the Rising Star Awards was not only to celebrate role models like Megan and her supportive workplace but to show the wider automotive industry at its best.

“That’s part of the reason why Capricorn runs the Rising Stars, because we want to give that opportunity for people to recognize great apprentices,” Brad says. “And not only apprentices, but we also know that celebrating staff at any level, is great for staff, team engagement and morale.

“We want to celebrate the heroes and heroines we have in our industry that every day are doing an amazing job and fundamentally keeping people safe and that is what they do by having a properly serviced, repaired and maintained vehicle.

“I think the other aspect of this rolemodelling is it really allows people to thrive. This is an industry that inspires massive passion. It really changes people’s lives. That sense of purpose in what you do every day is really a hallmark of this industry.

“There’s many jobs out there, but not so many jobs that really give you that sense of purpose and belief and skills that means that you’ve got your own trade, and ultimately can own and operate your own business off the back of that trade.”

“They are things that are truly unique, something that we should

be proud of, and something that as industry, we should continue to celebrate.”

For Megan her automotive journey is just beginning and if her skills offer her this flexibility, she is also a person already with plans to give back to the industry.

Megan aims to become fully qualified at Badgingarra Motors and after a couple of years she plans to gain a heavy diesel trade qualification, a qualification that will allow her to work in the mining industry.

But Megan’s ultimate ambition is to open her own automotive service and repair business. Her goal is to employ people that typically aren’t well represented in the industry, creating a safe space for them to thrive, as she has found at Badgingarra Motors.

The Capricorn Rising Stars Award is made possible thanks to its sponsors, Castrol, Repco and The Workshop

It has been years in the process, but a milestone point has been reached. The collision repair industry can shortly expect a rewritten MVIRI Code of Conduct to guide future relations between repairers and insurers.

Earlier this year the MVIRI Code Administrative Committee (CAC) commissioned MST lawyers to complete one of the key recommendations of the 2022 Schaper review into the code, to make it clearer and more accessible.

This new draft version will shortly be released for industry consultation and new CAC chairman George Manos has given an idea of what repairers can expect.

“The new code will be clearer about the responsibilities of both repairers and insurers. It will be written in plain English, making it easier to understand and improving awareness,” Manos says.

A key part of this will be addressing the specific areas highlighted as needing change by the Schaper review.

“The implementation of the recommendations from the Schaper review will require the establishment of a new and improved website to make it easier to navigate and more useful in educating people about what is and isn’t considered a dispute under the Code.”

While some automotive bodies have pushed for a mandatory and federally regulated national code, and cite NSW and South Australia as precedents, this is not the first priority for the committee.

Manos notes that the question of

whether to mandate the Code was not in the Review’s terms of reference and that education will play a stronger part in building repairer confidence and encouraging more signatories.

“A new Code will require significant initial and ongoing communication, education and training not only for insurers and repairers, but also other stakeholders like state and federal government regulators,” he says.

“Better education and awareness raising about the existence of the Code – what it’s there for and how dispute resolution works – will be crucial. The Schaper review highlighted this, and it is a key focus of our efforts. Clearer communication about the Code, along with promoting its benefits, will naturally encourage greater engagement and participation.”

Another contentious issue surrounding the code is the question of enforcement and sanctions and it is another focus for the committee.

“Discussions amongst the CAC are ongoing, so it’s too early to give specifics. However, this is something we are actively looking into, along the lines of Dr Schaper’s recommendations,” he says.

“We recognise that enhanced enforcement, including the introduction

of sanctions, is crucial for ensuring confidence that when a complaint is lodged, it is taken seriously and dealt with appropriately.”

The CAC will also look to refining how it deals with unresolved issues between repairers and insurers and is actively discussing further independence in the dispute process.

“Under the current Code, Small Business Commissioners and the Resolution Institute play a role in mediation or external determination,” Manos says.

“The CAC has also agreed to governance changes to bring more independence and professionalism to how the Code is managed.”

In line with Dr Schaper’s review, a new website for the code will also enable the committee to properly manage the data arising from the usage of the website.

“We will continue collecting data on disputes and further improve this process by upgrading the website, as well as working closely with industry participants and regulators. This will help us track not only the number of complaints and disputes but also their nature, allowing us to identify trends and emerging industrywide issues.”

For more information go to www.abrcode.com.au

WorldSkills is a highlight of the trade skills sector every year and displays a wealth of future spray-painting talent from across the globe, including Australia. The Australian repair and skills industries even had a hand in helping along the world’s best.

One of the star spray painters from WorldSkills 2024 held in September in Lyon, France conducted some of his competition preparations in Melbourne.

Yuto Hoshino, 22-year-old participant from the Aichi Province in Japan, won the Gold medal at the international ‘Olympics’ of trade skills, with a score of 758 points.

Hoshino was also one of six international competitors who took part in a special competition training preparation week at Kangan TAFE in Melbourne in May with the support of Glasurit.

Hoshino told NCR this year the competition was all about honing his skills.

He has worked for Toyota in Japan and it was here he discovered his talent for car painting, and from there joining the WorldSkills Competition has been a continual development.

“I had no experience in painting before working in the automotive industry, but I am really enjoying it so far,” Hoshino said.

Apart from the winter cold he experienced in Melbourne, Hoshino was glowing about the support of his team, the WorldSkills support and the facilities he trained on in Australia at the Kangan Institute.

“It is a great institute (Kangan) with the spray painting and drying booths, it is well equipped for what we do.”

BASF’s Coatings division was also the exclusive global industry partner for the Car Painting skills section in France and supported the young talents and experts from around the world with its Glasurit 100 Line.

Part of this is an extensive training program, including the Australian events, where Glasurit experts train the finalists

via a series of exclusive digital webinars, online training courses and select training courses held at the Refinish Competence Centres.

The Car Painting category required participants to restore damaged vehicles to pristine condition, with an emphasis on precision in matching colours, textures, and finishes all in a race against the clock.

The testing and advice of the experts has paid off for Hoshino, beating a host of talented competition from 23 different countries.

Lara Kaufmann from Switzerland, Jason Scherer from Germany and Ronan Le Tutour from France won the Silver medal in Lyon and all scored silver medal scores of 728 and 727.

Australia’s outstanding young painter, Kynan Bonanno from NSW scored 680 points but missed out on a medal.

For the third-year apprentice spray painter who was also an MTA NSW representative, Bonanno says it has

up to the rigours of competition after his impressive performance in the Automotive Refinishing category at the WorldSkills National Championships in Melbourne, where he secured first place at a regional level and fourth place at the national level.

In July he was also chosen as a finalist in the Apprentice of the Year category in NSW and has since undergone months of training to qualify him for the 2024 Skillaroos Training Squad.

Like the true artisan, Bonanno told NCR in May that his motivation came from the finished product and pursuing the perfect job.

“Some panel repairers talk about the feeling of a finished job but for a painter it’s even better, once you see a that shiny paint, it is something else,” he said while competing in Melbourne.

Bonanno works at Boxalls Automotive Industries in Pendle Hill and says he has inherited a passion for automotive from his father who owns and runs Boxalls.

MTA NSW CEO Stavros Yallouridis says the industry body was excited to see its former student represent MTA on the world stage.

“Kynan’s journey to WorldSkills Lyon 2024 is an example of how top-tier training is an asset to the future of the automotive industry. We are incredibly proud of his accomplishments and excited to see him represent Australia on an international stage.”

MTA NSW ensured Bonanno was equipped at the highest level and covered his costs to France.

The competition in France uses the Glasurit 100 Line, Refinity and paintrelated material from SATA and 3M and the car painters are encouraged to be mindful of using the precise amount of paint materials to achieve the highest quality results, thereby enhancing ecoeffectiveness for both the environment and the business.

Among the 23 competitors, Glasurit and SATA awarded first place for their most eco-effective preparation of process to Yuto Hushino from Japan. Second

place went to Vikash from India, and third place went to Hui-Shan Chen from Chinese Taipei.

BASF Senior Vice President, Global Automotive Refinish Coatings Chris Titmarsh described the event as inspiring and ‘spectacular in every way’.

“The passion and excellence shown by the high calibre of talent in the Car Painting skill competition has been phenomenal,” he says.

“We have raised the bar with Glasurit 100 Line and we’re setting new standards for sustainable skill development required by the industry. With WorldSkills, and our vocational training partners, we’re committed to delivering an even more diverse and highly skilled workforce to lead the future of collision repair.”

WorldSkills International CEO David Hoey thanked Glasurit for its support and continuing to lead the way with innovative processes and solutions.

“We know that skills development is a key driver of sustainability especially when it is at the heart of government, industry, and education strategies,” Hoey says. “Along with our partners, we have placed extra effort to develop

tangible objectives for the responsible management of the event and its impact, particularly regarding the environment.”

US coating giant PPG was an official gold sponsor of the event, offering support to the finalists with the theme ‘Let’s Paint Your Future’, aiming to showcase the company’s focus on skills improvement, innovation, sustainability, community engagement, and diversity.

PPG Vice President, Government Affairs, Europe, Middle East and Africa Pascal Tisseyre says the company’s support follows a proud tradition of fostering future talent.

“We are proud to partner with WorldSkills Lyon 2024 and emphasise PPG’s dedication to supporting skilled professions,” Tisseyre says.

PPG says their sponsorship is part of its global commitment to support education and workforce development initiatives that prepare students for careers in the skilled trades.

In other events Japan also took out the top position in the Autobody Repair section, Takaya Koishi scored 738 and a Gold medal. He was followed by Junfeng Zhu from China on 736 points and David McKeown the United Kingdom.

Australia did not have a representative in this skills section but Harrison Field from Australia did take out a bronze medal in the welding competition with a score of 727.

The global vocational skills event gives more than 1,500 young professionals the opportunity to come together to compete in 64 different skills categories across a range of industries.

The world’s first WorldSkills Museum was inaugurated in Shanghai, China, in 2023 and the 48th WorldSkills Competition will be held there in 2026.

Shawn Buie’s story is a model in resilience. Breaking through numerous barriers and paving the way for others with a disability is only a fraction of his contribution to the automotive industry.

There aren’t many people in the industry like Shawn Buie. Not only does he raise awareness for the deaf community in the industry, but he has a strong will and desire to push through any obstacles that are in his way.

Overcoming the challenges of deafness has led Shawn towards a career he loves. He has impressive plans for his future and is constantly developing ways to best navigate his disability in the automotive repair industry.

Shawn is employed as a full-time panel technician, and is currently working with Drive Group in Kingston, Brisbane. Shawn also has a side passion project, his own business – Buie’s Garage.

Shawn began his passion for restoring and repairing old cars on the Central Coast in New South Wales ten years ago. He moved up to Brisbane, Queensland, five years ago to explore new opportunities and pursue his career.

Most teenagers are unsure of which direction they want to take after leaving school. Luckily for Shawn, his older brother was a guiding figure that nudged him in the right direction. After listening to his brother, who was studying to be a mechanic, Shawn decided to enrol in a tertiary course.

“My brother encouraged me to give a pre-vocational course in panel and paint a go,” Shawn says.

“Once I started, I immediately enjoyed panel beating. It all just went from there.”

Shawn’s passion for panel beating started in his pre-vocational courses, and

his love of repairing vehicles, especially old cars, has kept him in the industry, despite a few challenges along the way.

Shawn has successfully integrated his deafness into a career in the automotive industry. The industry is becoming increasingly aware of the issues of access and acceptance, as the profile of the industry is changing to expand and grow into a diverse sector of the workforce.

After Shawn’s experiences in the industry over the past decade, he wants

Having a disability has not barred Shawn from doing his job, but the day-today communication with team members has sometimes been an issue.

NCR recognises the ongoing support of IAG for the Future Leader’s series and their continued support in developing industry skills.

“Another issue was that some staff find the extra effort to communicate with me frustrating and that caused some tensions,” Shawn says.

Advocating for himself and sharing his experiences with his workplace has been a strategy that has worked in Shawn’s favour.

“I have overcome most of the barriers by communicating my needs and feelings. I have been met with some very patient and understanding people and they have made the workplace so much more enjoyable,” Shawn says.

“That is also another reason why I have set up my own business. I want to have other deaf employees and make them feel comfortable at a workplace without communication barriers.”

Shawn also faced multiple setbacks at the beginning of his career. Shawn underwent additional training after realising he still had more to learn before becoming a full qualified panel technician.

“I thought and felt as though I was

technician has been a highlight of his career. Back in 2019, Shawn was interviewed by NCR, and he spoke about his dream to one day set up and own his own business. Now, five years later in 2024, his dreams are finally coming to fruition.

Shawn’s ultimate goal is to grow his business to a point where he owns a repair shop and can be his own boss.

“Becoming fully qualified was a great moment. Also making the first step in setting up my own business has been a proud achievement,” Shawn says.

“The whole process of setting up a business is exciting and it’s finally happening. It’s an amazing feeling.”

For anyone wanting to join the industry, but especially those who face adversity, Shawn encourages them to give collision repair a second thought.

“One of the key things I learnt is, to be efficient with your time,” he says. “Ensure you check that all parts are ordered and delivered prior to starting the job. Second thing would be buying tools as you go, it is crucial.”

“You can achieve anything you put your mind to if you have a true passion for the career.”

Australia’s key automotive bodies have teamed up to solve one of the industry’s biggest problems; how to deal with almost a million dead cars each year that have been written off or reached their end of life.

About 850,000 motor vehicles reach this point every year in Australia, generating around 1.36 million tonnes of waste, much of which goes into costly and potentially environmentallydamaging landfill.

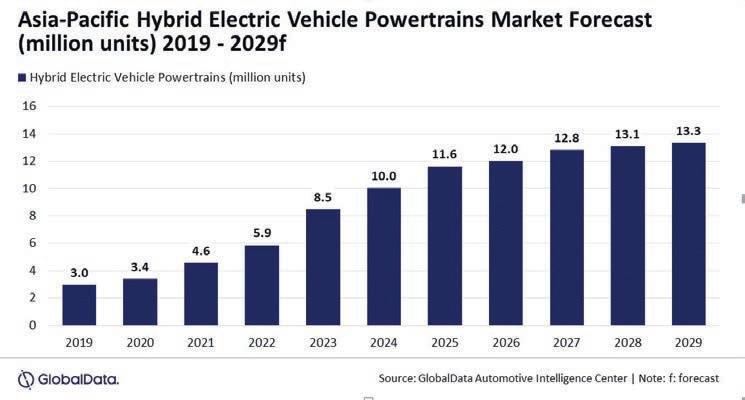

Currently 70 per cent of the material is recycled or reused but the aim of the new End-of-Life Vehicle (ELV) strategy is to get this rate much higher and closer to the international standards set in Japan and the EU where at least 95 per cent is reusable or recoverable.

The Federal Chamber of Automotive Industries (FCAI) and the Motor Trades Association of Australia (MTAA) along with the state-based motoring associations have united to develop the strategic pathway for boosting automotive recycling through a product stewardship scheme. This would achieve higher material-recovery rates, avoid interstate leakage of the vehicles and reduce landfill.

The plan would oversee all passenger vehicles and light commercial vehicles under 3.5 tonnes that make up the bulk of the Australian car parc. It also wants a future pathway to include all vehicle powertrain technologies and new materials, such as from EVs.

The extensive study has identified a fragmented recycling sector, a diverse vehicle fleet and insufficient processing options for non-metal materials as some of the key barriers preventing reducing the problem for end-of-life vehicles .

More to deal with FCAI CEO Tony Weber says getting an ELV scheme operational may take some time but the sheer number of ELV

vehicles amassing in Australia meant acting on its advice was critical now.

‘“The study presents a way forward for the sector and clearly shows the need for cooperation between the automotive, dismantling, recycling and waste management sectors and the different levels of government,” Weber says.

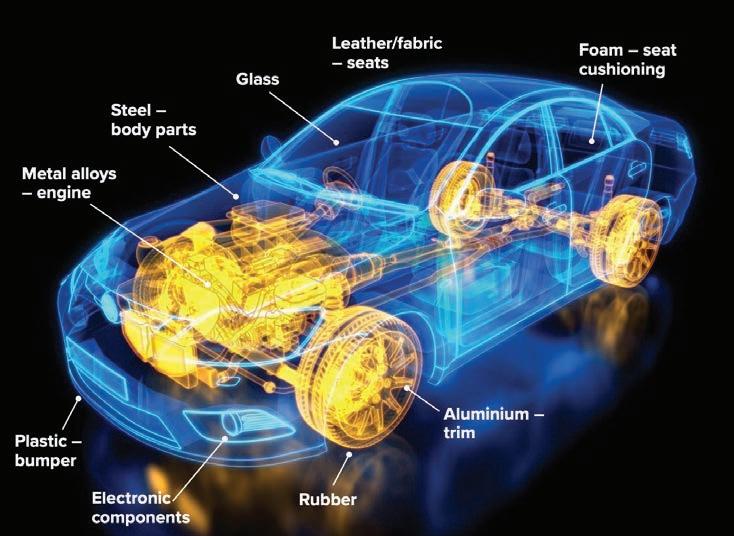

While the report recognised the substantial part played by the recovery industry in sourcing useable parts that are often a cheaper and more viable option for the collision repair industry, and the recyclable metals industry, the problem lies with numerous other materials that make up a normal motor vehicle.

These include plastics, glass, rubber and textiles that do not have the same organised recovery rates and often went to landfill.

The strategy makes a comprehensive

study of overseas models, including manufacturers like Japan and South Korea and EU nations such as the Netherlands, Ireland, German and the UK.

It distinguished several key factors that will be critical in ensuring the success of any scheme, including establishing a nationally consistent scheme that overcomes complex and diverse state regulations.

But it also maintains the scheme must be compulsory and co-regulation was needed between industry and government.

However, the complexity of the solutions and the transitional time meant Australia needed a customised model for an ELV plan to take the best of international examples, such as the potential adoption of an Extended Producer Responsibility to increase whole-of- life ‘ownership’ for products.

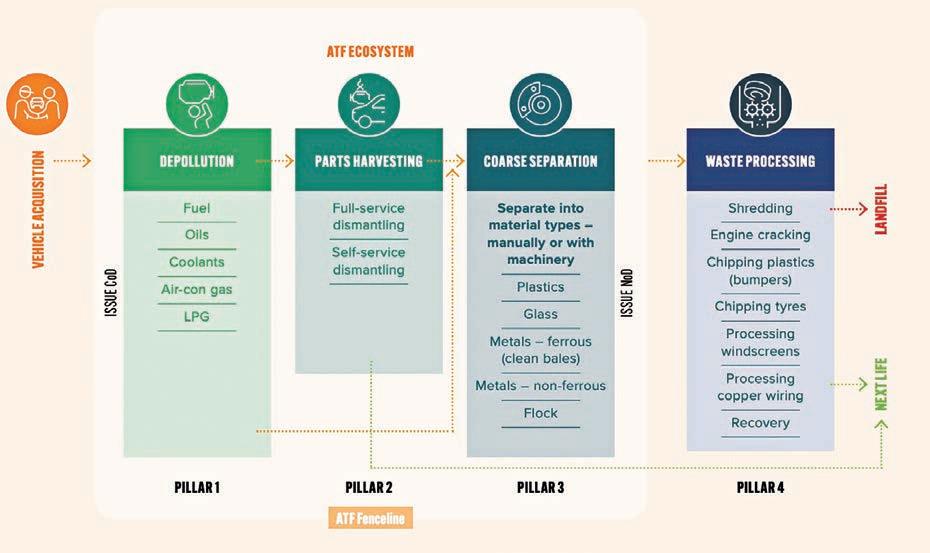

The report has detailed the complex waste journey of a vehicle at an Authorised Treatment Facility with this graphic.

The strategy also identifies new and emerging technologies as key to the scheme’s success, including developing better ‘cradle to grave’ tracking of vehicles and viable recycling solutions for the non-metal parts of a car.

VACC CEO Geoff Gwilym says the proposed stewardship scheme would be a “significant step” towards upgrading vehicle recycling infrastructure.

“Our industry needs to improve recovery rates and adopt more effective practices in automotive recycling, but we need support to achieve this,” Gwilym says.

“We are eager to assist our members through this transition and assist them to capitalise on the opportunities that an end-of-life vehicle program will create for small to medium sized businesses in particular.”

The report notes there is currently little capacity to track the three key stages following a car’s deregistration; the depollution of fluids like batteries and other dangerous materials, the dismantling and then its crushing and shredding.

The parts reuse market and the recycling industry were also cost dependent and victim to market value volatility.

The strategy calls for better processing of vehicles at a preshredding stage including better sorting and triaging when they are dismantled to reduce shredder residue.

“One clear commonality was that the achievement of high standards, consumer accessibility and strong environmental performance typically aligned with the use of Authorised Treatment Facilities,” the report notes.

“Authorised Collection Facilities (ACF) and Authorised Treatment Facilities (ATF) would need standardised operating and environmental standards along with Certificates of Destruction (CoD) to reach the higher standards and guarantee the success of any initiative in Australia.”

MTAA CEO Matt Hobbs says the substantial work put into the report gives a clear pathway forward.

“This is a pivotal moment for us to enhance recovery efforts and reduce environmental impact as the industry moves towards a more sustainable future,” Hobbs says.

“Our research reveals the necessity of modernising Australia’s vehicle dismantling and recycling processes. The proposed stewardship scheme will not only streamline operations across

the industry but also address the unique challenges we face.”

Following on from further publicity for the scheme and feedback from the various parts of the industry, the next steps for the scheme are to establish how a co-regulatory scheme would work, its governance structure and study potential funding sources, including levies on manufacturers and consumers when cars are registered.

The plan hopes by 2025, in an estimated timeline, to establish the foundational prerequisites of ELV Certificate of Destruction and accreditation of ELV dismantlers.

Then by 2026, it hopes to legally establish this framework including a Product Stewardship Organisation that would administer and oversee it.

It would then become an ongoing operating scheme, regulated and monitored by the federal government, with cooperation from state governments and their motor registries.

The report was released at the Auto Parts Recyclers Association of Australia conference at the Gold Coast from the $1 million grant received from the federal government’s Project Stewardship Innovation Fund.

The Outlook for End-Of-Life Vehicles in Australia report can be found at mtaa.com.au

with Yarrah Muneer

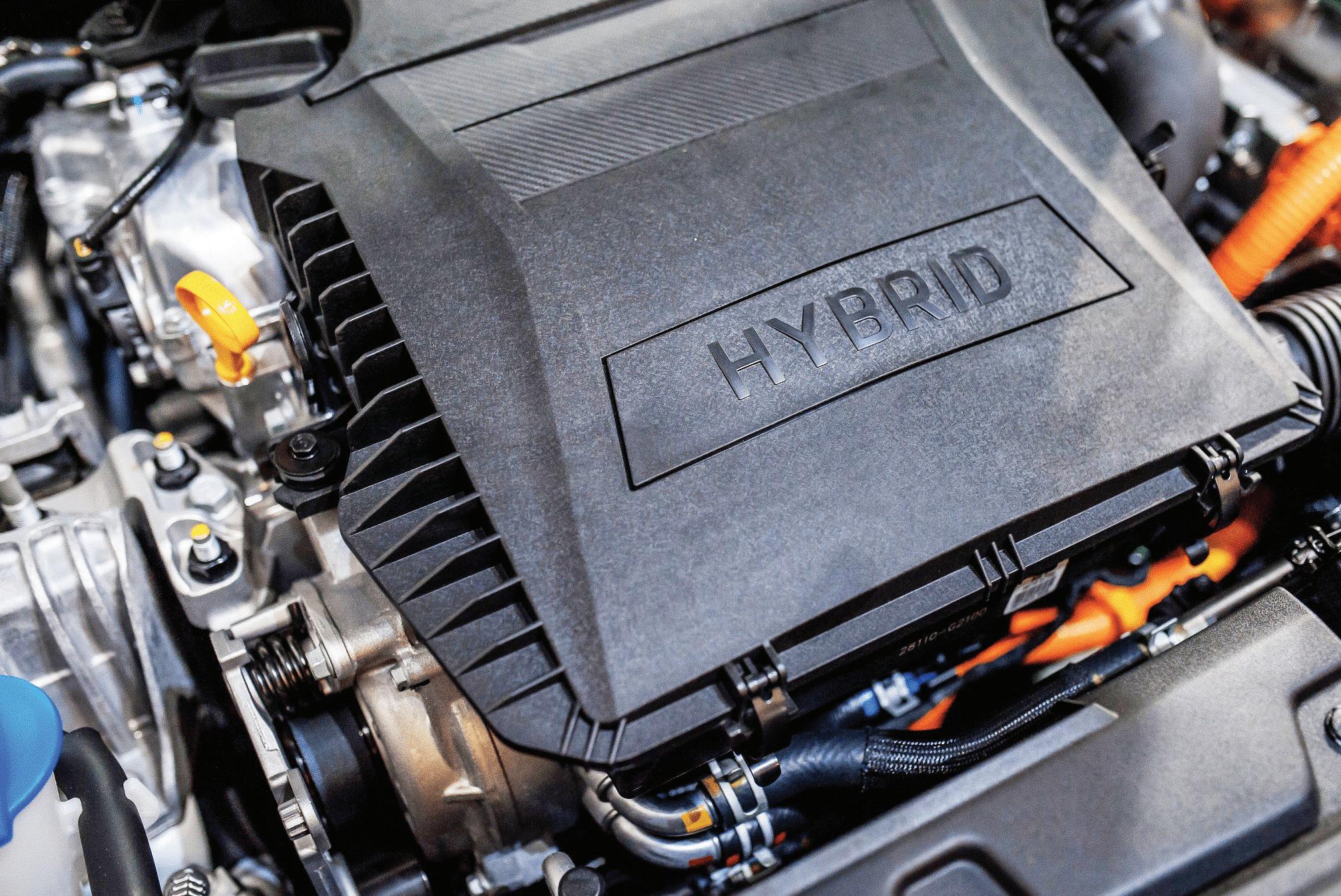

Lithium-ion batteries have been hitting the headlines for all the wrong reasons. Fire authorities report seeing over 10,000 fires caused by these batteries each year across Australia. But what does this mean for electric vehicles, and the people who repair them? NCR looks at the risks and what can be done about them.

With sales more than doubling in the last year, EVs are slowly becoming more popular in Australia. But even with their rising popularity, doubts remain about their safety.

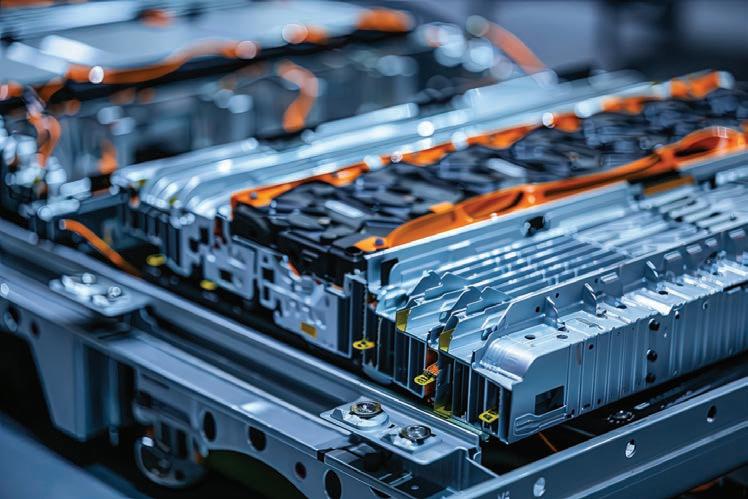

Lithium-ion batteries are small, rechargeable batteries that can store large amounts of energy in a small space. This battery can also be found in households, in items such as phones, laptops, and vapes, but also in numerous battery powered tools in the workshop. A normal EV battery is powered by hundreds of these in a bank.

While the news about fires have heightened safety concerns, authorities agree it is training and knowledge about the risks associated with lithium-ion batteries that can best lower the risks.

One area of concern that is causing many of the fires, more often with the general use of smaller lithium-ion batteries, is incorrect disposal or improper care. All batteries are susceptible to exothermic chain reactions. When scores of these reactions occur, it is called ‘thermal runaways’. This is a chemical reaction causing a sharp increase in the internal battery temperature. When a battery generates more heat than it can dissipate, it results in a fire.

Chemical Engineering Lecturer at Edith Cowan University Dr Muhammad Rizwan Azhar explains the science behind these reactions.

“To create any fire, you need three things; fuel, oxygen, and a high temperature,” he says. “Fuel exists in the plastics of a battery, and oxygen is also preexisting in every battery, meaning when the temperature of the battery

rises, all three components of a fire are present, instantly igniting the battery. This is why the importance of temperature regulation must be prevalent and prominent.”

The reasons for the fires can be traced to multiple factors including, but not limited to improper charging of the battery, manufacturing defects, or even physical damage. Dr Azhar believes mechanical compromise as an external factor is the main reason for the fires. When the battery is cracked, the physical and chemical properties exude a larger outward reaction, which if it isn’t a fire, can result in one quickly. Even though they can be dangerous, the chances of one of these fires occurring in an EV are very rare.

Low chances

EV FireSafe is an organisation endorsed by the Australian Department of

Defence, who research EV battery fires and emergency responses. They have established the only detailed incident database for fires in EVs. Their database shows 18 percent of fires occur when vehicles were charging and two percent were within an hour of disconnecting from the charger. EV FireSafe found from 2010 to June 2023, only 4 fires happened to EVs in Australia. Globally, there were approximately 30 million EVs on the road, and 393 fires occurred.

Australian Automotive Aftermarket Association (AAAA) Marketing Coordinator Jos Roder says now that there is more demand for EVs in the market, workplaces need to be further trained on how to work with them.

“A lot of workers have been servicing hybrid cars for a while, so the concept isn’t totally new, but it’s just another level

Training in correct handling of lithium-ion batteries is the first step in keeping workers and the car safe.

should be a crucial part of the New Vehicle Efficiency System. This will ensure not only that workshops and repairers are safe but that the repair experience for owners will improve.

They suggest that all repairers who will be working on EVs undertake basic safety and training courses on depowering, such as the AURETH101, and safely maintaining those vehicles when handling lithium-ion batteries.

Working on EVs can pose additional risks to repairers, with hazards including stored electrical energy, and battery electrolytes. SafeWork NSW say repairers have a chance of receiving electric shock if they do not take safety precautions when working on an EV, so depowering them before beginning work on their engines or bodies is critical. Safety steps include using the correct PPE and depowering the EV correctly.

Depowering, or disabling an EV is the process of isolating and disconnecting the battery from the vehicle. This is done to ensure the components of the battery cannot be energised, and then repairers have a safe platform to work on the EV without the chance of electric shock. It notes EVs can also generate electricity when the wheels rotate, so electric shock could be caused by physically pushing the vehicle in the workshop.

Experts say repairers should also get to know any model of vehicle well, and familiarise themselves with all its safety features, thermal management systems, and any sensors that could

can significantly increase the risk of it overheating, which is the first step of combustion reactions.

Leading industry-trainer I-CAR Australia also highly recommends courses for general technicians in the automotive repair industry to get better acquainted with depowering and working safely on EVs, including damage analysis and general handling of the parts.

I-CAR Australia recommends damaged EVs are isolated 15 metres, if possible, away from all other vehicles, until they can be assessed. This could prevent potential fire spread and ensures the battery is well ventilated to eliminate any hazardous gases if there is any damage. Ideally, this monitoring would take place for the first 48-hour period following an accident until assessment. Batteries should also be kept out of the weather to protect them from rain and moisture.

These precautions bring us back to the risk of fire, which however rare, is still worth taking precautions over for any workshop working on EVs.

“These fires are not like normal fires,” Dr Azhar says.

“There is research being undertaken to find the best way to stop these fires, but at this point, there are no specific techniques on putting out the flames apart from adding water, saline water being the best option.”

Experts stress that plenty of water is needed, because using a minimal

could potentially fuel the fire and cause it to intensify, instead of shutting it down. This is because of two things. One being the reaction between water and lithium, which produces flammable hydrogen gas, and the second being that water conducts electricity, which means spraying it on a battery powering an electric vehicle can lead to short-circuits or electric shocks.

“It is important to be aware that putting water on the fire will not stop it, only suppress it to ensure that it is not expanding. Keeping the fire burning, at as low a flame as possible is the best and safest way to regulate the fire.”

Other forms of fire suppression include Class D fire extinguishers, or dry chemical fire extinguishers which contain sodium chloride powder that combats the fire by melting to form an oxygen-excluding crust over the fire, not allowing it to grow. After the fire is out, it is common to need to deal with the toxic fumes it leaves behind. The fire releases a combination of smoke, carbon monoxide, hydrogen fluoride, and hydrogen chloride. All these gases can be hazardous to health when inhaled in significant quantities.

EV FireSafe offers free training resources on their websites (section 05.6) for education on EVs.

More information on courses is available through I-CAR Australia, and the automotive trade organisations (MTA’s) in each state, and nationwide (MTAA).

Dreaming of the weekend? Now the work you do on a weekday could help give those leisure hours an extra bit of grunt with a dream machine on offer.

The SAPE Group have teamed up with major supplier 3M to offer workshops that extra bit of incentive in the form of a Harley Davidson over the next two months.

The Harley Davidson 2024 Street Bob 114 is valued at $25,500 with $1500 in accessories to compliment the budding easy rider.

SAPE Group Trade Customers will need to make a minimum purchase of $500 on 3M products within a single invoice during the months of October and November 2024.

Each qualifying purchase will grant one entry into the draw and multiple entries can be obtained through additional purchases.

The lucky winner will learn if they are free to fly on 29th November 2024.

Full Terms and Conditions on the SAPE Group website.

Navigating the uncertainties and risks associated with using non-genuine parts is one of the daily concerns for many collision repairers and the leading motor trades association is hoping a new guide will shed light on this key part of the supply chain.

The Motor Trades Association of Australia guide aims to give legal guidance on how repairers can make the most informed and best decisions, and how to communicate this with both the vehicle owners and the insurance companies.

The MTAA partnered with the Australian Motor Body Repairers Association (AMBRA) and HWLE Lawyers to address the critical issue.