ACKNOWLEDGED BY THE INDUSTRY AS THE LEADING MAGAZINE

ACKNOWLEDGED BY THE INDUSTRY AS THE LEADING MAGAZINE

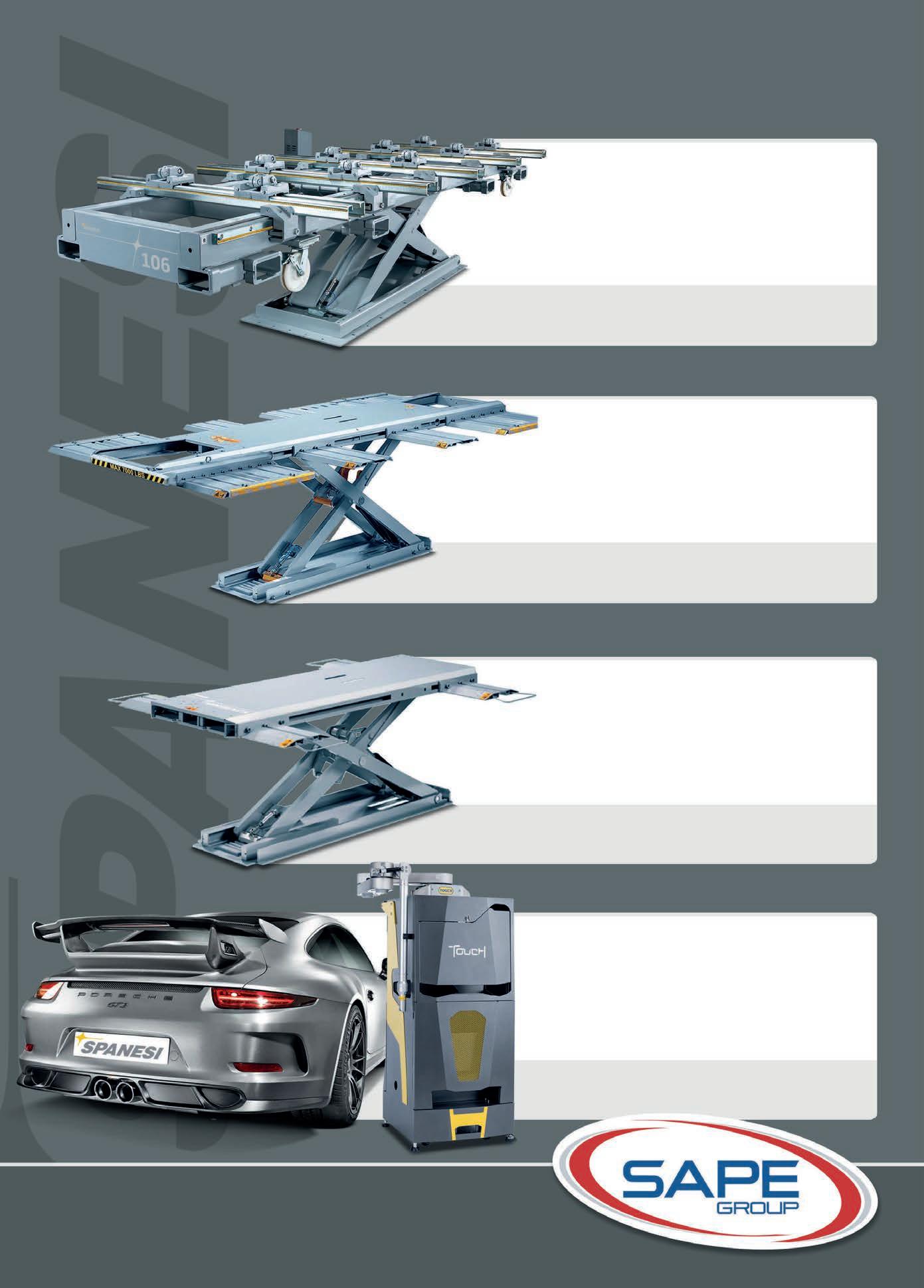

The 106 series straightening bench is the world’s most advanced workstation that meet OEM repair standards for small, medium and large vehicles.

• LOAD CAPACITY:

• LENGTH:

• LIFTING HEIGHT:

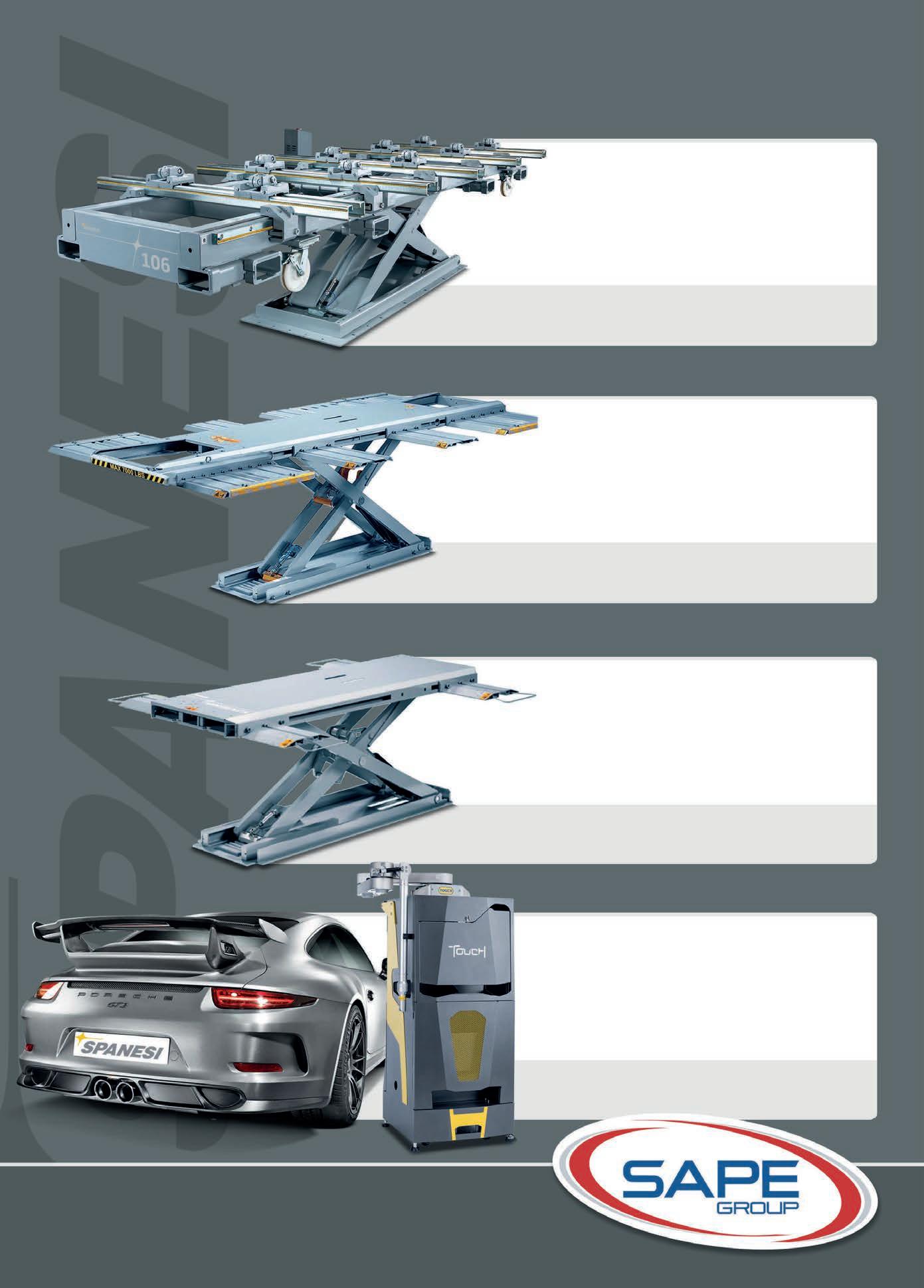

The Multibench is a which employs an electro-hydraulic lift suitable for lifting most vehicles. The platforms sit flat on the ground to enable vehicles with limited ground clearance to easily drive onto the lift.

• LOAD CAPACITY:

• LENGTH:

• LIFTING HEIGHT:

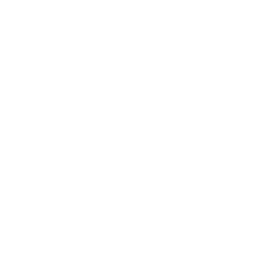

The Minibench is designed to medium damage ease. It can be used as a lift or straightening bench, with a 6 ton pull column capable of delivering 360° pulls around the entire vehicle.

• LOAD CAPACITY:

• LENGTH:

• LIFTING HEIGHT:

The Touch provides the ability to measure a vehicle on any lift, bench or surface. Detailed pre-repair and post-repair reports ensure the return of the vehicle to OEM specifications.

• FAST AND

• MEASURE IN

• REAL-TIME

One of the great traditions developed by the National Collision Repairer magazine and its supporters, is the annual Lifetime Achievement Awards. It gives me great pleasure to announce that this tradition will continue in 2025 and again celebrate the best there are in a great industry. There are many industry awards, and each have their place in celebrating business success or people who are making a difference. Many awards are also valuable ways to spotlight what has happened over the last year and those who might otherwise miss that valuable pat on the back. The Lifetime Achievement Award is all this and more.

’s Lifetime Achievement Awards unique is in the title. This is an award shaped specially for those whose lifetime has been dedicated to the collision repair industry.

The criteria are both demanding and strict, but they too are what make it special. To begin with there is the parameter that any candidate must have a minimum of 20 years in the collision repair industry. Then the judges review the candidates’ contributions, not just to their own business, but to the wider industry and this entails those contributions beyond the scope of their employment. This element of the award is seeking that ‘above and beyond’ factor which makes the winners so special. It also taps into the lifelong passion for collision repair these nominees have, not only for their businesses, but the wider industry and a desire to see it grow and thrive.

In the 17 years since the Lifetime Achievement Awards were

started it has become a very exclusive club. This group not only demonstrates these qualities, but also reflects well on an industry that has such extraordinary people at its core; people generous with their time and efforts, people with a collaborative spirit who keep their eye on the greater good.

But there is also another quality to these awards that makes them so worthwhile. They are an opportunity for key players to have their time in the sun in an industry that is loaded with humble operatives who toil away for decades, often under the radar.

As always, NCR applauds winners like 2024’s recipient Craig Carey, who embodies these values, but all the recipients of the Life Achievement Awards. The list on page 33 of this edition is a lot more than a ‘who’s who’ of the collision repair industry in Australia. It is a celebration of dedication and invaluable contributions the winners have played in shaping the vital and modern field it is today. It is a ‘brains-trust’ of enormous experience that should make the industry feel proud.

And on the subject of unsung heroes, it seems appropriate that we should include in this edition of NCR a special profile dedicated to women in the industry. Not only are they an emerging force as more and more take the reins at repair workshops, they too have often played an unsung but vital part in many businesses and parts of the industry.

Stay tuned for the exciting information on the venue and time of the 2025 Lifetime Achievement Awards which will be confirmed shortly. Once again we can play our part in celebrating the industry. In the meantime, perhaps it is a good time to consider who you think might be appropriate for the awards.

Eugene Duffy Editor

The National Collision Repairer

Unite

In a little over a year since its launch in Australia, Repairify has brought its global reputation at providing efficient solutions for sophisticated automotive technology to a multitude of repair workshops.

The rise and rise of ADAS is no exception, and now that repairers are finding the systems in almost every modern vehicle, it is another opportunity to tap into Repairify’s expertise and cutting-edge technology to complete calibrations quickly and safely.

Repairify offers its unique and worldleading services in remote diagnostics and ADAS solutions by providing the specialist expertise many workshops are looking for. Coupled with their cuttingedge calibration equipment, they make tackling ADAS systems an asset rather than a challenge to a repair business.

Repairify’s solutions remove the need for repair workshops to take vehicles back to the original manufacturer, call in contractors or outsource calibrations. Its renowned Remote Services bring the expertise into the workshop at the time and any time it is needed.

Complex systems made easy

Repairify has complex ADAS calibrations covered with its Digital ADAS Calibration Unit, a three-metrewide tool that includes a 65-inch TV screen that sits in front of the vehicle and mirrors that reflect under the vehicle, allowing for a range of ADAS calibrations to be performed.

The calibration unit aims to change the way a workshop does business by offering the full suite of equipment and skills needed for efficient, accurate and safe calibrations from targets and tools to expert support.

Repairify’s system is designed to be easy to use and has the ability to add efficiency to the workshop by cutting ADAS calibration set up times to around

Its comprehensive digital system has the major advantage of keeping pace as OEMs change and eliminates the need to purchase new physical target

boards by downloading new targets as they are released.

The objective for a workshop is to reduce key-to-key times and increase workshop revenue by keeping vehicles in house and Repairify’s solution helps with delivering just that.

The capacity to have a same day turnaround on some jobs by keeping vehicles in-house, not only leads to greater business profitability but to more satisfied customers.

As with all Repairify solutions, they come with comprehensive training and support, and are installed by qualified technicians.

Repairify solutions also include the back-up of integration with their Remote Services, through the All-In-On Diagnostic Tool, where on-hand experts have access to the secure gateways of the most modern vehicles.

For more information and to see how Repairify can help provide your ADAS solutions contact Repairify at repairify.com.au

With Remote Services, you can access expert diagnostics and support whenever you need it, with a wide range of OEM tools available to complete the most complex of repairs. You will be working faster with more accuracy on every job, making your customers happier and boosting your bottom line. Scan the QR and bring your workshop into the future.

Launch/SmartSafe’s ADAS equipment helps the repair workshop keep up to speed with the latest technology updates across the automotive industry.

Whether a workshop is transitioning to repairing on vehicles with ADAS features, or looking to upgrade existing equipment, Launch Tech Australia offers a variety of products aimed at ensuring the work they do on ADAS equipped vehicles, is efficient, accurate and reliable.

Launch Tech Australia (also T/A SmartSafe Australia) is the major distributor of LAUNCH & SMARTSAFE products in Australia and New Zealand. Launch Tech Australia provides a range of automotive workshop equipment including diagnostic scan tools, ADAS calibration equipment, vehicle hoists, wheel aligners, tyre changers, wheel balancers, battery testers and flushing machines.

With a changing car parc, Launch Tech Australia ensures the workshop is up to date and well equipped with the ADAS Mobile and the ADAS Radar 3-IN-1 Kit.

ADAS Mobile is a portable ADAS calibration tool for calibrating ADAS system. The ADAS Mobile is ideal for repair businesses that want to target new revenue stream. The unique fully foldable design can minimise the transporting risk, speed up the setup procedure and calibrate in various places.

Features with 23-style manufacturer standard targets and advanced ADAS software, the ADAS Mobile Standard Package offers a one-stop calibration service.

Features

• Start to calibrate in seconds, no more tedious work of disassembly and installation

• Fully foldable design

• Multi-functional base integrates 360° rotating wheels and height-adjustment

• Equilateral triangle design of the base ensures a stable frame

• Digital distance laser shows the crossbar height

• Five-line laser and fine-tuning switch help to centre the device

• Special small target design makes it convenient to carry and store

provide one-stop calibration service

• Compatible with AVM/ RCW/ BSD Targets of AUSCAN ADAS PRO

• Quick access to ADAS calibration with tutorial graphics on LAUNCH X-431 diagnostic tools

• Three optional packages of ADAS Mobile are available

ADAS RADAR 3-IN-1 Kit is a ADAS radar system calibration kit for passenger vehicles. The Kit can meet the calibration requirements of adaptive cruise system, blind spot monitoring system, lane change assist system and front corner radar system.

Features

• Supports calibration for multiple radar systems

• Providers detailed visual tutorials

• Pre-and-post calibration reports

• Functions:

• ACC (Adaptive Cruise Control), BSM (Blind Spot Monitoring), LCA (Lane Change Assist), FCR (Front Corner Radar) For more information, visit https://www.

For many business owners in the repair industry, ADAS calibrations are already a reality appearing in the workshop every day. The rate of innovation shows little sign of abating. A recent data analysis showed 90 per cent of new 2023 vehicles are equipped with at least six ADAS systems. So, it makes sense for any workshop to take advantage of this business opportunity and invest in the technology to safely and efficiently work on them.

While some workshops are still hesitant about the technology, the right investment can efficiently set a workshop up for ADAS readiness and help build their future.

Premium Diagnostics is a specialised service provider intent on giving repair businesses a competitive edge that enables them to position themselves as a cutting-edge business in automotive services. They aim to equip workshops to meet the growing demand for ADAS services whether it is windscreen replacements, bumper repairs, and general maintenance on systems like cameras and radars.

This investment in equipment and skills leads to increased revenue opportunities and the potential to complete calibrations on in-house repairs along with the lucrative work from insurance companies and even other repair shops.

Premium Diagnostics sells and recommends Topdon, one of the most

cost-effective calibration systems on the market, that can have a workshop equipped for ADAS calibration for as little as $14,500.

Premium Diagnostics offers three levels of package aimed at giving workshops the maximum flexibility and ‘bang for their buck’, from the Basic kit to the complete Max Package that will set a business up for an ADAS-driven future.

All Topdon kits are designed to maximise mobility and flexibility and deliver precision results. The foldable PX1000 calibration frame means set-up can be completed almost anywhere and can be completed in the workshop or on the road for in-demand mobile calibrations. Trained staff can complete the set up in less than 30 minutes.

Topdon PX1000 ADAS kits and Topdon scan tools, like the Phoenix Scanner feature a clear, intuitive interface with step-by-step guidance that minimise technician error and reduce training time, allowing workshops to

quickly integrate the tool into their daily operations.

The Topdon kits cover a wide range of ADAS systems, including cameras, radars, LiDAR, and night vision and even the basic kit covers a wide range of popular OEM brands. It is also built with ever advancing technology in mind, with regular software updates on new vehicle models and ADAS technologies.

Premium Diagnostics also prides itself on in house training and full technical support to ensure staff adapt to the equipment efficiently and boost workshop productivity.

For a starting point for any workshop seeking precise and intricate calibrations, the Phoenix ADAS Mobile

Laser; a Cross Laser; a Laser Reflector; an Auxiliary Mirror; an L-Type Positioning Bracket; Plumb Bob; a Targets Storage Bracket; two Targets Extension Rods along with multiple targets.

The Deluxe Package extends calibration capacity with 17 additional 360-degree surround view targets for a wide range of Asian, European, and American vehicles, covering almost every car brand on the road today. It also includes a doppler simulator, radar cone target and ACC reflector.

The Max Package gives its users robust calibration coverage, including all targets from the deluxe package, and an additional 14 targets. This package also includes targets for night vision systems, rear camera warnings, around view monitoring, and lane departure warnings. The ADAS Max

The Topdon PX1000 fame is foldable and designed for maximum flexibility.

Package aims to give workshops that make the investment now, the ability to work without limits for years to come.

For more information go to premium-diagnostics.com.au or phone 07 3180 6771

Are you hesitant about investing in ADAS calibration technology? With the Topdon Phoenix PX1000, you can easily turn ADAS calibration into a profitable service without breaking the bank!

Topdon is one of the most affordable ADAS solutions on the market, designed for workshops just like yours and our team is here to support you every step of the way.

Boost your revenue by offering ADAS calibration services.

Simple setup and operation – perfect for those new to the technology. Covering all major vehicle brands with reliable accuracy. Backed by industry-leading technical support

The PX1000 is portable for mobile calibrations Don’t miss out on this income opportunity! Equip your workshop with the Topdon PX1000 today for as little as $14,599! Stay ahead in the evolving collision repair industry.

Call us now to find out more about Topdons ADAS Solutions!

sales@premiumdiagnostics.com.au

www.premium-diagnostics.com.au

07 3180 6771

As collision repair shops across Australia strive to improve their operations and profitability, Axalta Coating Systems is leading the charge with its latest innovation: Axalta Irus Mix.

This fully automated, hands-free paint mixing machine is set to revolutionise the paint-room when it launches locally in early 2025, offering unprecedented benefits in speed, accuracy, and sustainability.

The introduction of Axalta Irus Mix marks a significant advancement in the automation of paint mixing. Following on from its global release in 2023 and now making its way into markets worldwide, including Australia, the Axalta Irus Mix machine is designed to simplify and streamline the paint mixing process. Traditionally, mixing paint has been a time-consuming task that required manual labour and precision. With Axalta Irus Mix, Axalta has eliminated the need for manual intervention, allowing collision repair shops to operate more efficiently than ever before.

The machine’s fully automated process seamlessly integrates with Axalta’s proven bottle system, eliminating the need for technicians to refill or decant products into separate containers. This not only saves time but also reduces the potential for human error, ensuring that each colour selected is mixed to perfection. Based on Axalta’s trials, the machine significantly reduces labour time associated with mixing, freeing up technicians to focus on other critical tasks in the repair process.

Moreover, Axalta Irus Mix is simple to operate, requiring minimal training for technicians. This ease-of-use further

contributes to labour optimisation, as staff can quickly learn to operate the machine and get back to their core responsibilities.

In an industry increasingly focused on sustainability, Axalta Irus Mix has been designed as a technology that aligns with these goals. The machine’s integration with Axalta’s innovative packaging, made from 50% recycled plastic, underscores the company’s commitment to reducing environmental impact. The precise dosing lids on the bottles ensure accurate colour mixing without waste, further minimising the environmental footprint of each job. For its launch into Australia, the Axalta Irus Mix system will be used in conjunction with Standox Standoblue and Spies Hecker Permahyd Hi-TEC waterborne paint systems.

success and global recognition

The success of Axalta Irus Mix is already evident on the global stage. The machine

was recently installed at Bodyshop Carenove in France, marking the 100th installation of Axalta Irus Mix worldwide. This milestone is a testament to the machine’s effectiveness and the value it brings to collision repair shops.

Axalta Irus Mix’s innovation has not gone unnoticed in the broader industry either. The machine was recently honoured with a 2024 Edison Award™ for Innovation in the Environmental and Industrial Solutions category, further cementing its reputation as a groundbreaking technology.

Axalta’s commitment to innovation and sustainability, as demonstrated by the Axalta Irus Mix, sets a new standard for the industry. For collision repair shops across Australia, embracing this technology is not just an opportunity—it’s a necessity for staying ahead in a rapidly changing landscape.

Axalta Irus Mix will be available in Australia in 2025, and for more information visit axalta.au/Axalta-Irus-Mix

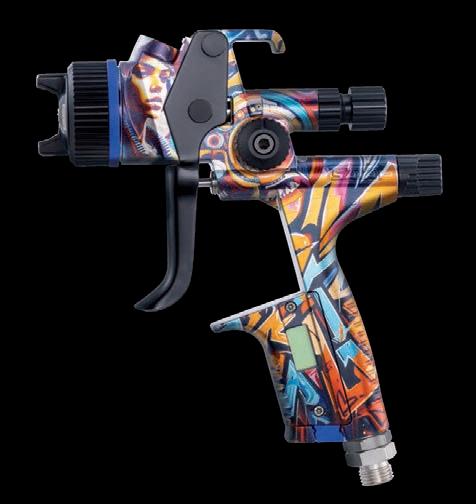

Axalta Coating Systems, the local importer for Sagola, has announced the Australian launch of the all-new Sagola 4600 DFT series spray gun.

While retaining the signature design of the original 4600 Xtreme model, the new Sagola 4600 DFT spray gun represents a significant leap forward in spray gun efficiency, comfort, and performance.

At the core of the Sagola 4600 DFT is the groundbreaking Dynamic Flow Technology (DFT™). This advanced technology optimises ambient air around the aircap, delivering a flawless finish even at lower working pressures. This results in superior performance, with enhanced fan stability, finer atomisation, and a consistent fan pattern from top to bottom. Whether tackling challenging base colours like metallics, silvers, or pearls, the Sagola 4600 ensures uniform paint distribution, eliminating defects such as shadowing, mottling and striping.

Painters will also benefit from the reduced bounce-back and overspray, making it easier to achieve precise application with smoother overlapping.

These enhancements not only elevate the quality of your work, but also streamline the entire painting process.

Another notable feature of the 4600 DFT is Sagola’s renowned Metal to Metal Technology (M2M™). With fewer joints and wear parts, this technology minimises ongoing maintenance costs, ensuring the spray gun remains reliable and cost-effective over time.

Locally released models will include

• SAGOLA 4600 BASE: The ultimate gun basecoat spray gun for colours, metallics and silvers.

• SAGOLA 4600 HVLP: Designed for high air volume, low pressure applications.

• SAGOLA 4600 CLEAR: Ideal for clearcoats, single-stage paints and OEM-quality finishes.

• SAGOLA 4600 CLEAR PRO: Perfect for newer technology clearcoats, such as fast drying, low energy clears with lower viscosities.

Sagola spray guns offer exceptional value, backed by a 3-year warranty. These guns are competitively priced,

with spare parts providing outstanding value as well.

Connect. Automate. Digitise. The end-to-end digital ecosystem bringing advanced, game-changing technologies to your collision centre

Sagola offers the flexibility to purchase replacement needles and nozzles sets or air caps individually, resulting in significant cost savings and underscoring Sagola’s commitment to customer satisfaction.

Introducing the 3D digital sprayout

Compact, fast, easy-to-use spectrophotometer

Axalta’s Cromax, has launched the new 1K aerosol primer-surfacer in grey (VS4), PS1504A Quickfill Primer-Surfacer designed for fast working processes to make bodyshops more productive, profitable and sustainable.

It aims to reduce process steps with a simple universal application and quick drying performance. Cromax PS1504A can be used directly on bare metal and the most common plastic substrates during a collision repair and can be re-coated after sanding with both waterborne basecoats as well as solvent-borne basecoats and topcoats.

It is suitable for both small area repairs and small rub-throughs.

PS1504A Quickfill Primer-Surfacer employs SprayMax technology to ensure sprayability and flow.

Axalta Product and Technical Manager for Axalta in Australia and New Zealand, Jim Iliopolous says the concept was about offering greater efficiency to workshops

The new Sagola 4600 DFT Series spray gun is now available. Secure yours today from your nearest Axalta Distributor. For more information, visit axalta.au/sagola or call Axalta on 1800 292 582. through innovative products.

“In our efforts to help our bodyshops boost their productivity, it is vital we offer them innovative products that not only promote shorter process times, but also reduce material consumption.

PS1504A Quickfill Primer-Surfacer does just that.

“It is part of our ValueShade® concept that delivers the optimal undercoat for every topcoat colour, for faster coverage and reduced basecoat consumption, which enables bodyshops to speed up processes and increase profitability.”

PS1504A Quickfill Primer-Surfacer Aerosol in grey is available now from your local Cromax distributor, with white and black soon to come.

Aerosol convenience can be a perfect way to save time and boost productivity in the modern repair process. SEM is now offering four high-quality, locally made solutions. As well as providing highly effective options for various steps of the repair process, these four SEM aerosols are manufactured in Australia to ensure they are perfectly tuned to the needs of repairers in this region.

SEM aerosol products cover four key areas that can help enhance workshop processes.

SEM Universal Gun Cleaner. Featuring a 100 per cent virgin solvent formulation, this heavy-duty cleaner quickly removes both solventbased and waterborne coatings and overspray. By cleaning just as well as dedicated solvent or waterborne cleaners, SEM’s versatile 2-in-1 solution eliminates the need to keep multiple products on the shelf, while also reducing mistakes from choosing the wrong or faulty cleaners. This makes SEM Universal Gun Cleaner perfect for cleaning things like spray equipment, glass, metal, etc. or even blocked up aerosol can spray nozzles. Fitting the handy straw nozzle to the spray tip can also be used to help reach hard to get at areas.

This virgin solvent blend is specifically designed for the cleaning of panels (bare metal, primed or painted) prior to refinish or repair. It’s easy to use, leaves no residue and quickly and effectively removes contaminants, such as wax, grease, road tar, oil, silicone, adhesive residue, paint overspray and bug remnants.

SEM Guide-Coat Black gives you all of the performance you need but with none of the frustrating downsides. Thanks to its super convenient aerosol application, it’s easy to target just the required surface area which not only avoids mess, it also minimises wastage because you only use as much as you need for each job. Simply give the can a thorough shake and apply a number of light mist coats to achieve the required coverage. If there is any overspray, it simply wipes off. SEM Guide-Coat Black dries instantly and is ready to sand immediately. The fine spray is perfect for effectively identifying low spots, pinholes and other surface defects when sanding primer, yet it will not clog the abrasives.

When it comes to returning vulnerable areas, such as inner body panels,

body cavities and body channels, to original factory condition after a repair, SEM Rust Preventer Cavity Wax is the easy and effective way to achieve the special protection required. The semi-transparent black internal panel compound restores OEM levels of corrosion protection and comes with a variety of special features that deliver excellent performance and ease of use. Even in tight, out of the way places, the 360° application wand provides a spray pattern that achieves a true 100 per cent coverage with no patchy areas or missed places. In addition, the non-hardening SEM Rust Preventer Cavity Wax formulation ensures that it flows quickly over surfaces to fill any seams and provides superior wicking performance and adhesion.

You can find a range of innovative SEM products at PPG distributors and PPG Paint Powerhouse stores.

Gladiators of old were revered for being ultra tough and resourceful and now PPG is offering a next level protective coatings solution that invokes the spirit of these elite warriors. Developed by SEM Products, the all-new Gladiator XC Matte Extreme coating is a premium, matte finish, 2K urethane, textured protective coating that is perfect for a vast range of application, from automotive and light industrial to marine (above the waterline) and off-road. At the same time, it’s also incredibly easy to mix, apply and work with in general. While this makes it an excellent solution for DIY situations, it also opens up an abundance of opportunities for automotive businesses by providing a cost-effective way to help customers with a product tailored to jobs that require extreme protection.

Gladiator XC can be used across a wide range of different substrates and surfaces so the breadth of applications it opens up is really only limited by your imagination. The most obvious application is on ute trays and truck beds where it offers a superb alternative to plastic liners or mats. And it’s not just for new vehicles – it can be a quick and cost-effective way to rejuvenate the tray in an older ute and give it an enhance level of protection and appearance. With the ongoing popularity of 4WD and off-road vehicles, Gladiator XC’s protection can be applied to lots of potential problem areas, including underside components, bumpers, bull bars, running boards, etc. When it comes to caravan and recreational vehicle manufacture, Gladiator XC can be a weight saving alternative to checker plate and other shielding materials while achieving high level protection from stone chipping and other damage. Other suggested uses include trailers (both inside and out), agricultural, industrial and

commercial vehicles and equipment and much, much more. No matter which application you are tackling, Gladiator XC comes with PPG’s full package of support and training to ensure you get the best possible results.

Gladiator XC comes conveniently packed in super simple, ‘shake and spray’ kits, in either 1 litre or 4 litre sizes. Each 1 litre kit consists of a short filled 1 litre can of material, along with a 250ml can of hardener – the 4 litre kit is effectively four 1 litre kits in one package. Mixing Gladiator XC could not be simpler – just pour the 250ml of hardener into the 1 litre can of material, give it a shake and it’s ready to apply. Gladiator XC can be used in a variety of application modes to suit the job. As well as using the SEM Products applicator gun (sold separately), this versatile product can be rolled on, brushed on or applied with a recommended HVLP spray gun setup. The ability to purchase Gladiator XC in 1

litre kits makes it a convenient, costeffective solution for smaller jobs, touch ups or for adding to a 4 litre kit in order to extend its coverage for larger jobs. Gladiator XC is available in a pretinted black or there is the ability to tint it to a wide range of colours to suit the application. Existing PPG customers can do this using PPG 2K / DG tinter systems, such as Deltron DG, Paraglaze, Delfleet or Selemix. For anyone else, simply speak to your local PPG distributor or PPG Territory Manager about colour possibilities. Along with easy application, Gladiator XC delivers excellent adhesion and a rapid curing time, as well as incredible toughness and superior fade resistance.

While it was formulated using PPG’s latest global coatings technology, Gladiator XC is being manufactured in Australia using high quality raw materials. Gladiator XC range has been fine tuned for conditions in this region which include some of the highest UV readings on the planet.

Celebrating 20 years of Flagstaff Autobody, but even longer in the industry, John Barry has been a leading figure in the Melbourne collision repair scene. Known for efficient business operations, he is also the embodiment of what it means to run an independent workshop.

Opening in 2004, Flagstaff Autobody has gone through different workshop locations, survived the changing climate of the industry and economy, and has embraced new technologies to best benefit the business. The desire to succeed has outweighed the challenges and has created a momentum in the workshop that thrives on getting the job done ‘once, and right’.

John Barry is the managing director of Flagstaff Autobody. Over the past twenty years, John has built Flagstaff Autobody to what it is today – a successful workshop that has a trusted reputation and independent streak that is driven by the core values of independence and quality.

Flagstaff Autobody is currently situated in Kensington, a suburb on the fringes of Melbourne’s CBD. The convenient location serves both clients residing in Melbourne and in regional Victoria.

The almost one-hectare Kensington site is a state of the art workshop, with

a trusted reputation for quality repairs and a high standard of service. Flagstaff Autobody has 25 team members and the capacity to repair between 35 and 40 vehicles per week.

Throughout Flagstaff Autobody’s time on the collision repair scene, they have worked with some of Australia’s largest and most recognisable automotive companies, insurance companies, and fleet management companies.

The team at Flagstaff Autobody pride themselves on providing a corporate level of service with a personal feel, that is tailored to each client’s needs and requirements.

After working and managing multiple workshops before owning his own, John was ready to expand his capabilities and take on a new

challenge. In 2004, John acquired Flagstaff Autobody, when it was still situated in West Melbourne. The location suited the clientele at the time, with many customers in the fleet and corporate fields.

Not one to wait and see what happens, John was determined to make the business a thriving and successful workshop. He focussed his efforts on levelling up the existing business.

“My direction with the business was about providing a service that was above and beyond what was being offered elsewhere,” John says.

“I specifically targeted the needs and requirement of large fleets and corporates. The business grew quickly and over the years we had a customer base spread across Melbourne and well into regional Victoria.”

With the business expanding as the

years went by, so did the workshop size. After adjoining the neighbouring properties to the workshop, it was clear that the workshop had to relocate in order to continue growing and living up to its full potential.

“We were nearing the limit of space in West Melbourne when we received a notice from the landlord that our property/s were marked for redevelopment in the coming years,” John says.

With all signs pointing towards moving locations, John inspected a building in Kensington and moved quickly to secure it.

“I jumped on the opportunity with the intention to operate across the two locations until time run out at the West Melbourne address,” John says.

Fast forward to late 2009, and a destructive hailstorm hit Melbourne, causing large scale damage across the city. Both the Flagstaff Autobody worksites were badly damaged, but John saw the silver lining and with strategic thinking, pushed forward with his vision.

“We quickly realised this was actually very good news and secured a team of PDR (Paintless Dent Repair) technicians and commenced repairing what turned out to be thousands of vehicles,” John says.

After some quick thinking and a reignited passion for the industry, expansion was on the cards once more.

“I was reinvigorated with the industry after moving to the Kensington workshop, and moving out of West Melbourne,” John says.

“When an adjacent property to the Kensington workshop became available, I jumped on the opportunity but it wasn’t in any state to operate a business, it was in a state of disarray.”

Unfazed by the challenge and ready to take anything in his stride, John funnelled his newly found enthusiasm and energy into expansion.

“I started building what I had always wanted in a bodyshop. I left behind everything I didn’t like about the industry and changed and adapted every aspect of the business,” John says.

proper spaces for parts storage, processes for receiving new parts and worked with my team to refine our workshop standard.”

United by a shared goal and a positive momentum, John and his team at Flagstaff Autobody transformed how they approached everyday tasks.

“Acceptable was no longer enough and my team’s input was pivotal in setting the company standard moving forward,” John says.

“This is also when the company motto of ‘Do It Right, Do It Once’ grew to become part of everything we were doing as the tired old building started to shine into a modern, large and very well-equipped facility.”

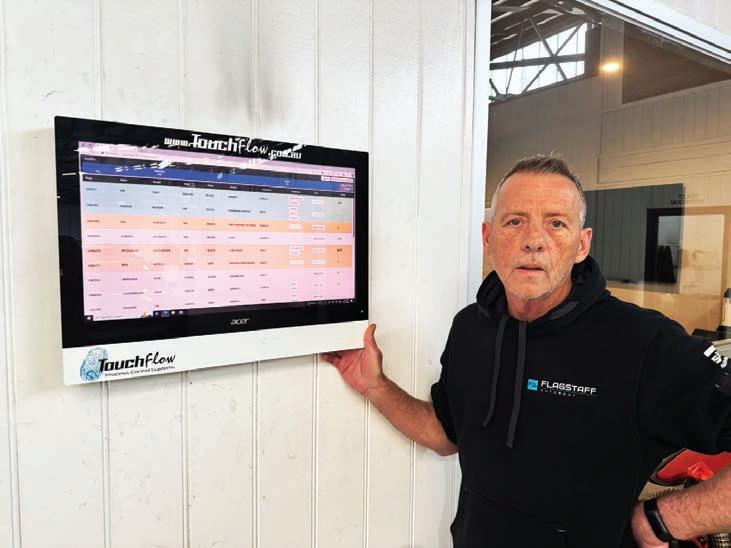

With a large-scale workshop and a physical separation between the repair building and the refinish building, the old-school system of using a whiteboard to coordinate the day to day operations was becoming increasingly challenging. Creating a new, online system called Touchflow allowed the workshop to thrive.

“I had the idea of creating an electronic whiteboard that would display the daily tasks independently for each working area,” John says.

“We engaged a website developer around 2012 to develop an electronic representation of the age-old workshop whiteboard.”

The Touchflow system was an instant

was very modern for the time using touchscreen terminals and designed with minimal interaction or button presses required to move the jobs around the system.”

John designed Touchflow to be a continuously evolving tool that allowed for processes and functions to be

“All of a sudden, we were managing hundreds and thousands of parts movements each month with zero lost, missing or other issues,” John says.

“Parts control doesn’t even get a second thought now, it just happens. It is because this was exactly what the team needed not something forced upon them.”

There are plenty of memorable moments over twenty years of a workshop’s life. Yet, it is often the small moments that are the most memorable and can reap the most rewards, and in John’s case, this sentiment rings true.

“I was observing the workshop shortly after introducing Touchflow, when I noticed a staff member as he was finishing a job,” John says.

“I watched as he stopped, stood

The careful and considered response

and embodied the ethos behind Touchflow.

“It was proof to me that Touchflow and all the encouragement I was providing my team to be their best was paying off,” John says.

“We often joke that we would be blind without Touchflow, but it’s not really a joke. Touchflow has since evolved further and encompasses just about every step, stage or process in our workshop.”

Going from strength to strength and implementing smart systems is part of Flagstaff Autobody’s ability to dynamically analyse, adapt and change ‘on the fly’.

“We monitor every aspect of the business, not to criticise or call out someone, but to find areas we can improve or reason for a change. If you don’t monitor it, you can’t manage it!”

John says.

The landscape of the collision repair industry is changing, but John remains certain that Flagstaff Autobody will be a proudly independent workshop for decades to come.

“As an independent, the challenges for the future are remaining relevant as the waves of consolidators, corporates and MSOs gain a hold of the industry,” John says.

“That is why we have joined the Car Craft group which is a group of like minded and fiercely independent business facing the same issue. I am also a member of the Car-Craft Victoria board and aim to drive the effort towards a thriving industry.”

Discussing solutions to industry problems all boils down to networking and sharing ideas.

“The industry in Melbourne is very closed, and although we all repair damaged cars, I can only assume how other workshops operate,” John says.

“In the relatively short time that I have been part of Car-Craft, I have met, discussed and learned from business owners about their businesses where we are happy to discuss details that are usually held tightly.”

“I encourage other independent workshops to think about their approach to this growing concern for the livelihood of independent operators in this industry.”

After twenty years at the helm of the business, John has taken a sidestep

“I am responsible to ensure everyone is rowing in the same direction. I’m not directly involved in the tasks anymore, but through encouragement and building trust I empower my team to do their best every day,” John says.

“My focus is now about how we, as an independent workshop, can tackle the challenges presented by corporate entities and MSO’s gaining market share and getting a strong hold on the industry,” John says.

John’s sons, Chris and Daniel Barry

“It has been great to include my family and watch as they grow, develop and learn new skills and gain knowledge to make well thought out decisions,” John says.

“They have also given the business a stronger position for the future with new and fresh ideas.”

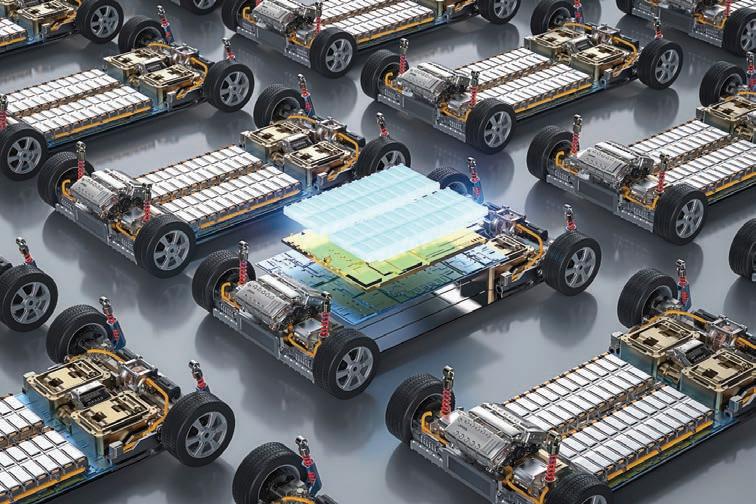

There is no doubt that electric vehicles are changing the collision repair game. With new technology and additional training required, the investment in learning about electric vehicles is on a lot of workshop’s minds.

“New thinking and ideas from Chris and Daniel are keeping us in the game with electric vehicles. As our customer base has changed over the years, so too has the way we deliver our service,” John says.

Watching his two sons take over the operations side of the business has been an inspiring time for John.

“Watching my sons and the team achieve success month after month and the rapport they are building with customers, and suppliers is inspirational,” John says.

“We have a great team of amazing people driving the success of Flagstaff Autobody and I am proud of everyone.”

It may seem simple but how to get out of a workshop can be one of the most important plans you ever devise for a business. Especially when it comes to protecting staff and customers.

The peace of mind of having an emergency evacuation plan has made it one of the most popular services delivered by PPG’s MVP Business Solutions team. Despite this, many collision centres are still dragging their feet, says Greg Tunks, MVP Business Solutions Manager ANZ.

Without an emergency evacuation plan, where does that leave your staff and visitors should a crisis situation occurring at your collision repair centre? In these pivotal moments, this crucial document can literally make the difference between life and death. Given that having an emergency evacuation plan is an absolute no-brainer, you have to wonder why many collision centres still don’t have one. Perhaps people think it will never happen to them and with a little luck and good management, you may never need to actually put an emergency evacuation plan into action – until you do! Crisis events are often accompanied by chaos so it’s very easy to lose track of where staff members or visitors are, particularly in a smoke-filled workshop. When the emergency services arrive, their first question is often, is there anyone left inside? Are you confident that you will have the correct answer?

Fortunately, the mindset across the industry seems to be changing because requests for help to develop a tailored evacuation plan for individual repairers has seen it become one of the most popular services being delivered by the PPG MVP Business Solutions team. Operating right across Australia and New Zealand, the MVP Business Solutions program is, perhaps, better known for working one-on-one with collision repair

businesses to implement productivity and profitability boosting strategies but we can also help with the essentials, such as an emergency evacuation plan or a traffic management plan. For a collision centre owner / manager, taking advantage of the service can be as easy as contacting your local PPG MVP Business Solutions Manager or mvp.anz@ppg.com to put the process into action. It starts with a shop visit to measure up the facility and then we use a special electronic drawing program to map out critical features, such as exit pathways, fire extinguisher locations, etc. From there, we can create a detailed blueprint that helps everyone exit your business safely and smoothly.

also crucial to ensure these exit points are not locked or blocked with clutter, such as equipment, old or new parts, etc. After exiting the facility, people should be directed to assemble at a suitable point a safe distance from the building. At this point, it’s particularly handy to have a check list of exactly who was onsite.

This is why every collision centre should operate a sign-in book or process. During an evacuation, someone should be assigned to collect it and bring it to the assembly point where it can be used to check off names and determine if anyone is missing. Establishing the exact number of people who are unaccounted for and where they might be is a crucial way to help emergency services staff target their efforts in saving lives.

In the event of a fire, access to the appropriate firefighting equipment – fire extinguishers or a hose reel – can make the difference between a minor event and a major catastrophe. However, this is dependent on the right type of fire extinguishers being located at easily accessible points and for staff to be trained on how and when to use them. It’s important to note that different types of fire extinguishers are designed to fight different types of fires. This crucial equipment also needs to be regularly serviced – generally every six months – to ensure it’s ready for action when required. This is where it’s sensible to contract a specialist company to regularly perform any servicing required.

Having an emergency evacuation plan is crucial but it can really only be effective if everyone understands it. As a result, it should be part of the shop induction process for new staff, as well as external

contractors who might be working on site. The document prepared by your PPG MVP Business Solutions Manager will include an emergency evacuation schematic plan which is designed to be printed in A3 size and displayed in prominent places around the facility.

To reinforce the message, a morning ‘toolbox meeting’ can be a great time for a short refresher session on the details of the emergency evacuation plan or how to use each fire extinguisher.

The chaos of an emergency situation

is where good preparation should really pay off.

PPG’s MVP Business Solutions program is available as part of PPG’s comprehensive support package and its aim is to help customers improve performance across the full spectrum of business activities, in order to enhance profitability. Enquire at mvp.anz@ppg. com or contact your PPG Representative or PPG’s Customer Service Hotline 13 24 24 (Aust) or 0800 320 320 (NZ).

The bi-annual gathering of Fix Network in Australia was a celebration of growth and collaboration but underlying it all was the spirit of community.

The recent Fix Network Australia National Conference was the first time both the Fix Auto and Novus brands were brought together and united more than 120 attendees representing over fifty franchise businesses from across Australia at the Novotel Sunshine Coast in September.

The conference was themed, “stronger together,” and this idea of collaboration reverberated throughout the event, highlighting the shared commitment across the global and local corporate teams, franchisees, and industry partners.

Special guest Fix Network World president Steve Leal, who had travelled to Australia to support the event, was one of the keynote speakers and shared his impressive business journey and personal aspirations with the network.

Leal inspired attendees with his commitment to Fix Network Australia’s future growth and he reinforced his belief that the strength of Fix Network lies in its franchisees.

Fix Network Head of Business Scott Croaker, addressing the gathering, said 2024 had been a pivotal year for Fix Network Australia, following substantial expansion and restructuring.

The company has been strategically

focused on sustainability and growth throughout this period, he said.

The integration of Novus Glass WA & NT into Fix Network Australia was also significant milestone worth celebrating.

“This integration has further strengthened the network’s national market presence, marking another achievement in the networks ongoing success,” Croaker said. “As Fix Network Australia continues its expansion, the spirit of #strongertogether propels the network forward, promising innovation, growth, and a shared journey ahead.”

The conference also highlighted the incredible strength and unity within the network, consisting of over sixty

franchisees across the region, setting the stage for an exciting future.

In keeping with the conference’s purpose to inspire, excite, and unite members of the network, moderator David Lingham said the range of speakers and events offered valuable insights and fostered a sense of optimism for the future.

Brett Wallace from Suncorp Group gave an insightful presentation, highlighting the future of auto glass and the advancements in ADAS technology, while offering Suncorp’s vision for the industry’s trajectory.

Conference keynote speaker Mark Mathews, the renowned big wave surfer,

also captivated the audience with his life journey where his story of triumph over adversity deeply aligned with the conference theme of strength and unity

The Fix Network Australia National Conference concluded with an elegant Gala Dinner and awards ceremony, where Fix Network Australia honoured

the outstanding contributions of their committed franchisees who are fostering success and innovation within the industry.

The evening culminated in a charity auction that raised nearly $20,000 to support several charities across Australia and New Zealand, highlighting Fix

Network Australia’s steadfast dedication to community and philanthropy.

The Fix Network National Conference was also supported by Fix Network Australia’s industry partners and sponsors, ADAS Solutions, Axalta, BASF, National Auto Glass Supplies, ALP Oz Auto Moulds, 3M, and Auto Parts Group.

• • Business Growth Award 2024: Fix Auto Darwin

• Service Excellence Award 2024: Fix Auto Sunshine

• Operational Excellence Award 2024: Fix Auto Northern Beaches

• Overall Business Excellence Award 2024: Fix Auto Rockhampton

• Overall Business Excellence Award 2024: Novus Glass Gold Coast

A people first approach, mixed with a desire to see the industry succeed, Hiliary Bradbury from the ACIA is one name behind a team of industry veterans aiming to uplift the collision repair industry.

Hiliary Bradbury ensures that her work is centred around one element: people. With a strong focus and a genuine care for the industry, Hiliary’s investment is geared towards long-term success.

Wearing many different hats and managing multiple different roles, Hiliary thrives on jumping in at the deep end and embracing the challenges in the repair industry.

Hiliary’s keen interest in creating and supporting the collision repair industry has manifested in a few different ways. Whether it’s being part of the Australian Collision Industry Alliance, attending career events and trade expos, or her role at the Auto Glass Association, to mastering virtual reality spray painting systems, her commitment is always evident.

Hiliary’s involvement in the repair industry

Based in Brisbane, Hiliary is the executive administrator for the ACIA and Secretariat for the AGA.

Her role with ACIA is to look after the administration side of things, which

includes managing the memberships, databases and working closely with the ACIA board, ensuring good governance and function.

Hiliary is also involved in numerous action groups within the Alliance, where her role is to assist with the action groups activities, whether it be communications and marketing, financial and audits or events and expos.

Hiliary highlights how the main goal of the ACIA is to change the perception of the industry through generating interest for people to take a second look.

“I get to attend a lot of fun events and meet a broad range of people,” Hiliary says.

“At these career events we are always looking for a way to maximise the exposure of the industry and get as many people on board as possible.”

The broadness of her multiple roles keeps her engaged in the industry, and up to date with the latest challenges and changes.

Hiliary acknowledged how her roles

aren’t necessarily hours based, but are rooted in a passion for the ACIA’s cause - to uplift the industry from the grass roots level.

“We try and get others to share the vision and passion for the industry too,” Hiliary says.

As well as being an advocate with the ACIA, Hiliary and her partner also own auto glazing businesses.

“There is a synergy between the glass industry and collision repair. Through my associations with the auto glass industry, I was introduced to the ACIA to work with them,” Hiliary says.

‘The two industries complement each other well.”

A significant part of Hiliary’s work is promoting the industry in alignment with the vision of the ACIA.

“It’s all about educating young people and their parents that the industry has changed,” Hiliary says.

“We aim to give them the view that collision repair isn’t what it used to be. It is a highly technical trade. It’s a

very attractive career pathway with opportunities.”

For Hiliary, helping people to see the reality of the industry is her main focus while she is at industry events.

“I love to help develop people,” Hiliary says.

“When we speak to the parents at the career days we try to open their eyes to careers in the collision industry.”

“Most people only know about the mechanic side of the automotive industry, so it’s great to explain and share the possibilities available in the repair industry specifically.”

Female representation in the industry has been one of the many focuses for the ACIA, and Hiliary actively encourages females to rethink a career in the industry.

“There is an artistic side to the industry that not many people know about,” Hiliary says.

“When we speak to young girls, the artistic side to spray painting is often of interest to them because a lot of them enjoy being creative, and a career in spray painting is just another way of

for people to consider a career in collision repair.”

Networking and connecting with other females in the industry has identified the multiple roles females can explore if they give the industry a chance.

“I met some inspiring young ladies at a women’s event last year. They were all spray painters and have now gone into parts, estimating and the quoting sides of the business,” Hiliary says.

Changing the perception of the industry, and creating a culture among workshops to embrace change, is at the forefront of Hiliary’s ethos.

“The ACIA is a great tool for the industry. Everyone knows there are issues with the ageing workforce, retaining staff and attracting people in the industry,” Hiliary says.

“The industry is on a huge curve, and the technological updates and advancements are constant. There are so many new skills that need to be learned.”

Hiliary believes the industry needs to pivot towards focussing on learning,

industry that is excited by change and technology.

“We are trying to encourage a new mindset. It’s all about a long-term goal,” she says. “We have to be prepared to move forward and adapt to the changes. At the ACIA we have great support from the suppliers, we now just have to convince the smaller operators that there is a long-term benefit to investing in the future.”

In her role with the AGA Hiliary is currently preparing for the Auto Glass Trade Show, which will be held in Melbourne on the 9th of November. (See

Forecasting into 2025, the ACIA will be at Summernats in January, chatting to motor vehicle enthusiasts. Hiliary will also be representing ACIA at multiple Career Events when the calendar

“We meet a lot of people who have a passion for vehicles, and we love to spotlight our industry and let them know they can turn their passions into a

Her continued motivation all boils down to one central element: the people. Whether that is other industry members, students at a careers day or general members of the public, Hiliary is passionate for the growth of the industry.

“The ACIA aims to be the united front for the collision industry, backed by a strong and trusted guidance,” Hiliary

“It is a great industry to be in, and we want more people to know how

Careers in the automotive industry are often overlooked by young people, but Kynan Bonanno has found his stride and passion for spray painting vehicles, and is embracing every opportunity the industry has to offer.

Swapping the outer suburbs of Sydney for Lyon, France, third year spray painting apprentice, Kynan Bonanno represented Australia in September at the WorldSkills International Competition.

Bonanno currently works at his father’s business, Boxalls Automotive Industries in Pendle Hill, New South Wales. He says he inherited a passion for automotive and spray painting from his father, and was inspired to follow in his footsteps.

“He helped me restore my first car at the age of 15,” Bonanno says.

significant feats in his career.

“Being the WorldSkills National Winner, a WorldSkills Skillaroo and being nominated for Apprentice of the Year for NSW have all been highlights so far,” Bonanno says.

The Olympics of trade skills, the WorldSkills International Competition

France was meeting all kinds of people from Australia and from all around the world,” Bonanno says.

“Seeing how different people work, even though we are in the same industry was awesome to watch.”

The Car Painting category at the WorldSkills Competition requires participants to restore damaged vehicles to pristine condition, with an

NCR recognises the ongoing support of IAG for the Future Leader’s series and their continued support in developing industry skills.

emphasis on precision in matching colours, textures, and finishes.

Participants need to present their finish products in a flawless, showroom-quality finish under stringent competition standards.

Outside of the Competition, the Skillaroos were able to experience all that Lyon had to offer.

“We went to a local school to learn about French culture and meet young students from the school,” Bonanno says.

“The Car Painting competitors were all taken to a Car Museum in Lyon to see the history of old European cars, which was a cool experience.”

Representing the MTA NSW, Bonanno finished 12th at the 47th WorldSkills Competition and was proud of his time spent in Lyon.

“There is always room for improvement, and I always strive to be better. I am proud of what I have accomplished,” Bonanno says.

Before travelling to Lyon, Bonanno already proved his skills at his impressive performance at the Automotive Refinishing category at the WorldSkills National Championships in Melbourne. Bonanno secured first place at the regional level, and then won fourth place at a national level.

Before travelling to Lyon and being chosen to represent Australia on the

world stage, Bonanno was chosen as a finalist in the Apprentice of the Year category by the MTA New South Wales in July.

In preparation for the International Competition, Bonanno underwent months of training to qualify him for the 2024 Skillaroos Training Squad.

“The training I received prior to the competition from 3M and Glasurit was eye opening,” Bonanno says.

“Learning how to use water-based paints was really interesting as it is not a system I had used before,” Bonanno says.

Bonanno told NCR in May that his motivation came from the finished product and pursuing the perfect job.

“Some panel repairers talk about the feeling of a finished job but for a painter it’s even better, once you see that shiny

paint, it is something else,” he said while competing in Melbourne.

Preparing for the international competition, Bonanno learned how to navigate the strict standards of the Competition.

“The preparation for WorldSkills Lyon has given me the opportunity to train with products that I haven’t used before, and allowed me to build connections in the industry,” Bonanno says.

MTA NSW ensured Bonanno was equipped to compete at the highest level and covered the costs of his flights, accommodation, and additional training leading up to the competition.

MTA NSW Stavros Yallouridis, CEO says the industry body was excited to see its former student represent MTA on the world stage.

“Kynan’s journey to WorldSkills Lyon 2024 is an example of how top-tier training is an asset to the future of the automotive industry. We are incredibly proud of his accomplishments and excited to see him represent Australia on an international stage.”

After returning from the WorldSkills Competition, Bonanno is back working with his father in the family business.

“The Competition was great, but now I am working towards finishing my apprenticeship,” Bonanno says.

“Beyond that I want to play a larger role in the family business which I am really looking forward to.”

New EV sales appear to have stalled, and one report shows myths and misconceptions may be standing in the way of people’s purchasing choice.

While EVs make up only 1.5 per cent of the current car fleet in Australia, a leading insurer expects this to reach nine per cent by 2030 but before then it is critical to understand the barriers standing in the way of people’s choices

The NRMA Insurance research report Changing Gears: The road ahead for EV adoption in Australia found only one in five Australians is planning to buy an EV in the next five years. However, this rate is more than 50 per cent higher, and closer to a third of all buyers, with those already familiar with them.

The report highlights despite 78 per cent of drivers travelling 50km a day or less on average, range anxiety and charging speed remained the strongest objections to their adoption.

“Many Australians feel that EVs remain out of reach or impractical due to a combination of upfront cost, affordable model availability, charging infrastructure and low awareness,” the report notes.

The survey highlights four key areas in objections to EVs, led by 82 per cent who cite vehicle attributes such as range and time to charge. 64 per cent cite infrastructure such as lack of charging stations and an inability to charge at home as barriers while 63 per cent cite cost as the main restriction. But more than half also cite safety, including the risk of fire, as a barrier to purchase.

The NRMA report also coincides with another drop in monthly sales, with FCAI figures showing uptake is EV lower in 2024 than last year.

The Australian trepidation toward zero emission technology is not isolated and has been reflected in sales slowing in other key markets.

The EU has experienced four consecutive months of EV sales drops, with 2024 sales now a third lower than the same time last year. But these figures do come off the back of exceptional growth in 2021 and 2022.

In August 2024, registrations of battery-electric cars dropped by 43.9 per cent to 92,627 units (compared to 165,204 in the same period last year), with their total market share slipping to 14.4 per cent from 21 per cent a year before.

EU manufacturing peak body, the ACEA is calling on urgent government help to boost the transition and meet the Paris emissions targets mandated in the EU by 2025, including reinstating purchase incentives, subsidies and investment in infrastructure.

Mario Draghi in his Competitiveness

Report says, “the automotive sector is a key example of lack of EU planning, applying a climate policy without an industrial policy” and said the ambitious transition could not be done alone.

The US is also seeing a slow done in EV uptake, with sales expected to reach just nine per cent of the auto market this year according to consulting firm J.D. Power, after it lowered its previous forecast of 12 per cent.

Despite the near-term slowdown, the consulting firm said it expects EV sales to reach 36 per cent of the total US retail market by 2030 and 58 per cent by 2035.

While hybrid technology has also stagnated in the EU, plug in hybrids and Extended Range EVs that utilise a petrol engine to recharge the battery, may be filling the gap.

Back home it has been the rise and rise of hybrids that has been the standout trend in new vehicles for 2024.

The Federal Chamber of Automotive Industries September figures show hybrid

Plug-in hybrids are also seeing a surge in popularity with numbers doubling from last year off a low bas, as OEMs seek to fill the gap left by buyer concerns over range and charging.

The NRMA commissioned the market research company Ipsos to study attitudes to EVs and argues boosting familiarity with electric vehicles could be the game-changer needed to speed up their adoption.

Its Changing Gears report shows that as Australians become more informed about EVs, their likelihood of considering them for their next car purchase rises.

The report highlights a normal EV on a home charger would cover the daily journey for more than three quarters of Australians, negating prevalent range anxiety fears.

It also notes 44 per cent of nonconsiderers cite worries about battery fires, even though research shows road registered EVs do not present a greater risk of fire than internal combustion vehicles.

Similarly, a survey in regional Victoria conducted by the RACV’s in June of 7000 drivers found that 36 per cent of participants have considered buying an EV but only 0.7 per cent were current EV owners.

Of those who did not purchase, a third said they were too expensive , while 21 per cent cited the limited battery range and 11 per cent says there were not enough charging stations.

NRMA Insurance CEO Julie Batch says the report highlights the work needed to bust the myths about range anxiety, safety and cost.

“Even with the progress made to date, there are a significant number of Australians still hesitant about purchasing an EV due to worries about driving range and cost. To tackle these issues, more investment and effort are needed to encourage adoption,” Batch says.

The NRMA wants governments to address EV education gaps about safety and range anxiety and fund education campaigns to increase familiarity, knowledge and confidence in EVs. This extends to clearer information on where and how to charge EVs.

Echoing a case made by the AAAA, it also wants investment in creating repair capacity and an established network to make the aftermarket experience better for owners. This includes investing in upskilling repairers and modernising repair supply chains.

Unsurprisingly, the NRMA report also found the surge in EV adoption is most pronounced among drivers with household incomes over $200,000, families with children, and residents of capital cities with many citing lower running costs and sustainability as the key reason for their purchase.

High cost is another barrier, with only three models under $40,000 and a limited second-hand market making

The report notes an average car driving 13,700 km per year could save $1,000 annually in fuel, or $1,200 with overnight off-peak charging.

For those unfamiliar with EVs, cost doubts remain strong, with only 30 per cent viewing EVs as the most costeffective option, and just 42 per cent see them as the most environmentally friendly choice.

At present, only 26 per cent of Australians feel knowledgeable about EVs, but nearly half (47 per cent) are eager to learn more.

“We need policies and incentives to support the second-hand EV market, which will help make these vehicles more accessible, especially among some buyers who may be deterred by the upfront cost.” Batch says.

“The good news is that more affordable models are now becoming available,” Batch says.

“This expansion will boost the used car market and make EVs more accessible to a broader audience. The research shows that 58 per cent of Australians interested in EVs are open to buying a used car, so this will be a practical option for many drivers”.

“Additionally, standardising battery health testing, similar to an odometer test, will be a positive step to building consumer confidence in the longevity and safety of these cars.”

The full report is available at nrma.com.au

The repair industry’s most prestigious award returns in 2025.

Join us for the annual National Collision Repairer Lifetime Achievement Awards in April 2025.

Held each year, the recipients of The National Collision Repairer’s Lifetime Achievement Awards are inducted and honoured for their outstanding service to the collision repair industry.

The awards evening also sees further prestigious awards presented on the night: The Future Leader of the Year Award; and The Woman in Automotive Award.

The National Collision Repairer Lifetime Achievement Awards began in 2007 and was created to acknowledge

the dedication and commitment of the men and women who have contributed to the collision repair industry over and above their “day job”.

The criteria for induction are a minimum of 20 years in the collision repair industry, contributions to the industry beyond the scope of their local area, contributions to the industry beyond the scope of their direct employment and nomination from within the industry.

The gathering each year represents a who’s who of the repair industry, including sponsors, collision repairers, suppliers, insurers, and previous inductees who gather to celebrate the people that make the industry strong, innovative and supportive.

The honour roll includes those who have not only contributed to the development of the but also left an indelible mark on the Australian collision repair landscape.

A fun and glamourous night that “honours the past” and now, recognises the industry’s bright future.

Details of the venue to come shortly.

Importantly, we continue to attract sponsors that are the leaders in the collision repair industry, many of whom have been with us since the inaugural awards.

To get involved and support the Lifetime Achievement Awards visit ncrlifetimeawards.com.au or contact Michael Ingram at michael.ingram@primecreative.com.au

Richard Nathan 2007

David Weatherall 2007 Terry Flanagan OAM 2008

Jeff Hendler (Int) 2008 Max Chanter 2009 John Howes 2009

Robert Renwick (Int) 2009

David Newton-Ross 2009

Wayne Phipps 2010

Richard Pratt 2010

Bob Rees 2010

Lance Weiss 2011

Mark Brady 2011

Don Wait OAM 2011

Tony Farrugia 2012

Bob Christie 2012

John Zulian 2012

Tom Vukelic 2013 Robin

The team at Western General Bodyworks Group are convinced the future of automotive repair holds plenty of change in store and striving towards high training standards is an important way of meeting it.

Western General Bodyworks Group is a collective of ten collision repair shops across the eastern states of Australia with their sights firmly set on the future. Training is a big part of that future and this year they have clocked up all ten of the shops meeting I-CAR Gold Class Collision training accreditation. The Gold Class status is the highest level of accreditation within the I-CAR Professional Development Program.

WGB group business director, Danny Buzadzic celebrated the awards, acknowledging that the Road to Gold program and cemented the group’s

standards in providing top-notch service to customers.

“Achieving Gold Class status signifies our commitment to excellence and differentiates us in the collision repair industry,” Buzadzic says.

“I wanted our team to benefit from the latest training and knowledge to stay ahead in this fast-changing field. By participating, we aim to ensure our repairs meet the highest industry standards, enhancing customer confidence and satisfaction.”

“The program offers a thorough framework that improves our skills, knowledge, and overall performance. This combined with the continuous learning aspect ensures that we

stay updated with the latest industry standards and technologies,” he says.

“Our team across Western General Bodyworks has become more skilled, confident, and tech-savvy, which has significantly improved our service quality, making it a worthwhile investment for any collision repair shop.”

WGB director Nathan Thai says the efforts by all the workshops have helped cement their reputations as trusted industry leaders in quality and service.

“Becoming an accredited OEM repairer such as Tesla, Porsche and

highest standards set by I-CAR for safety, quality and service,” he says. “This ensures our team stays on top with the industry and our staff is proud to be a part of a trusted name in this industry.”

Thai says another recipient of the recognition, Belmont Smash Repairs in New South Wales showed how valuable the Gold Class training can be for any collision repair business.

“The program is a game-changer,” Thai says. “It not only hones technical skills but also instils a proactive learning culture.”

“The most rewarding aspect of achieving Gold Class at Belmont Smash Repairs was the profound impact on our team’s cohesion and skill advancement.

“The collective journey toward this shared goal strengthened our collaboration and elevated our

beyond being a certification, has transformed us into a more unified, capable, and tech-savvy team, positioning Belmont Smash Repairs for sustained success in the ever-changing automotive industry.

“This training isn’t just about meeting industry standards; it’s a strategic investment in staying ahead. So, without a doubt, I’d encourage any colleague or business to dive into Gold Class for a transformative boost in skills, confidence, and overall shop performance.”

Thai outlined how the training didn’t come without its challenges. He highlighted how the training often required careful planning to ensure everyone could actively participate.

“The hands-on certification, while immensely valuable, demanded a delicate balance between daily

operations and dedicated certification time. It was a juggling act, but the commitment of the team made it possible,” Thai says.

“The versatility of the training delivery options proved highly advantageous for Belmont Smash Repairs. Afternoon virtual classrooms emerged as a preferred method. This adaptability facilitated a smooth learning experience.”

The Gordon Avenue Accident Repair Centre was another workshop to achieve the Gold Class Collision status showing the benefits and challenges of adding an intensive training schedule into the already busy workload.

“Achieving Gold Class at Gordon Avenue Accident Repair Centre was both challenging and rewarding, managing the daily operations alongside the time needed for online quizzes, virtual classes, and hands-on certifications required careful planning, but our valued team’s commitment made it possible,” Buzadzic says.

“This experience has improved our ability to tackle similar challenges in the future and highlighted the importance of investing in top-quality training.”

“I wanted to invest in our team’s skills and provide them with the best tools and knowledge,” he says.

Buzadzic outlined how the various training delivery options made the training accessible to work schedules of staff.

“The online quizzes provided flexibility, allowing our team to complete them at their convenience

their regular duties,” Buzadzic says.

“The hands-on certification was valuable for applying what we learned and for validating our skills. Overall, the combination of online, virtual, and practical training methods was wellbalanced and suited our needs.”

“We’ll include renewal training as a consistent part of our professional development schedule which will enable us to keep our skills sharp, our knowledge current, and our service quality exceptional. This ongoing dedication will help us maintain our Gold Class status and continue to provide outstanding repair services to our customers”

building endeavour Buzadzic says.

“For Werribee Accident Repair Centre, working together towards this goal significantly strengthened our teamwork and collaboration, creating a more cohesive unit,” Buzadzic says.

“The feedback from our staff has been very positive. They appreciate the practical nature of the Gold Class training and how it directly applies to their day-to-day work.”

He skills, knowledge, and overall performance says the training notably boosted their confidence and skills, particularly in modern repair techniques and new technology.

“This newfound expertise has not

and teamwork, making the staff feel more competent and motivated. Gold Class training has enhanced the teams’ technical abilities and job performance, benefiting both the business and our customers.”

For Buzadzic the training is part of an ongoing plan of personal and professional development for the group.

“By joining the Road to Gold program, we aimed to stand out from competitors, enhance our repair capabilities, and boost customer satisfaction. Incorporating Gold Class renewal training is a key part of this strategy.”

NSW’s leading automotive industry body has highlighted its commitment to training the next generation of repair workers with a newly opened and refurbished training centre in Sydney.

The Motor Traders’ Association of NSW purchased MyTradeStart and the centre in September 2023 and has opened the revamped training facility to develop industry-ready training. The centre will offer automotive body repair, among its courses, and have a new dedicated EV training hub, the MTA hopes will ensure apprentices gain future-focused skills for the industry.

MTA NSW CEO Stavros Yallouridis says the refurbished MyTradeStart facility complements the organisation’s existing onsite training model.

“With the opening of these training facilities, we can tailor our training even further to meet the individual needs of each student, whether that be through hands-on, onsite experience or in a classroom setting,” Yallouridis says.

MyTradeStart offers six accredited courses, including certificates in

Automotive Body Repair Technology, Heavy Commercial Vehicle Mechanical Technology, Light Vehicle Mechanical Technology, Automotive Electrical Technology, and Automotive Air Conditioning Technology.

MTA NSW has implemented its training standards across all the courses, offering apprentices the opportunity

industry knowledge and passion to the training experience.

With smaller class sizes, students also benefit from personalised mentorship and one-on-one time with trainers, fostering a collaborative learning environment where they can build valuable connections with their peers and industry leaders.

The rise of EVs and particularly hybrid technology has™ demanded repair skills to match, and Victoria’s leading automotive body has completed its latest round of specialised training courses.

The VACC recently held intense three-day courses in specialised EV training led by industry expert Neil Speetjens from Automotive Certified Training Academy, to equip participants with advanced skills to meet industry demand.

The VACC said those who completed the program are already recommending it to others eager to stay at the forefront of this evolving landscape.

The course began with the IMI Level 3 Qualification in Electric/Hybrid Vehicle

System Repair and Replacement of the High Voltage Certification Training program that gains technicians an internationally recognised certificate from the Institute of the Motor Industry.

The training offered comprehensive knowledge on key topics such as electrical circuits, the role of components in high-voltage systems, and the application of Ohm’s law.

It covered transformer and rectifier operations, relays and transistors, vehicle intake safety, HV battery diagnostics, four-wire measurement, insulation testing, EV diagnostic techniques, and safe disconnection procedures.

Following the Level 3 training, staff could then progress to the IMI Level 4