In transport there’s no one size fits all. That’s why we have a wide range of sleeper cabs locally engineered to maximise the living quarters of your most important asset, your drivers. When it comes to comfort and well-being, size matters.

When it’s your business you need to feel confident.

Trust Continental. With 150 years’ experience, we know what you need to keep you on the road.

Normal service was resumed in Alice Springs in August when a new batch of inductees were added to the Shell Rimula Wall of Fame

The giants of the trucking world are fast tracking their way to a future where fossil fuels could extinct … and spearheading the charge is the biggest of them all, Daimler Truck

provide

and entertainment 24/7 for long-haul

OwnerDriver tracks down a few of younger truckies who explain the motivations and disincentives of a career in trucking

Martin Rieck has always enjoyed working with cattle, a vocation that he has embraced further with his move to southern Queensland as an owner-driver

A new spruced-up Kenworth T909 has proved to be the shining light for Jeff and Lori Turner’s small fleet under the banner of Method Earthworks

The streets of Lowood in Queensland’s Somerset Region were chock full with the biggest rigs when its annual truck show made a triumphant return

The IAA Transportation event in Hanover, Germany showcased the low emissions future of the commercial vehicle industry attracting exhibitors from 42 countries

74 THE HIGH AND LOW OF HINO With the best model range in its Australian history and a red hot sales truck market, these should be bumper days for Hino’s Australian operation

MAN’s recent launch of its allnew truck generation was a wellexecuted event, attracting media from all parts of the country

TYRE LIFE up to 35%+

SAVE TIME. No more hassles getting wheels balanced

THELARGEST CAPACITY to suit even super single tyres

BALANCES your wheels while you drive

EXTENDED suspension life. REDUCED vibration. SMOOTHER ride.

AVAILABLE FOR US, European and large Japanese trucks

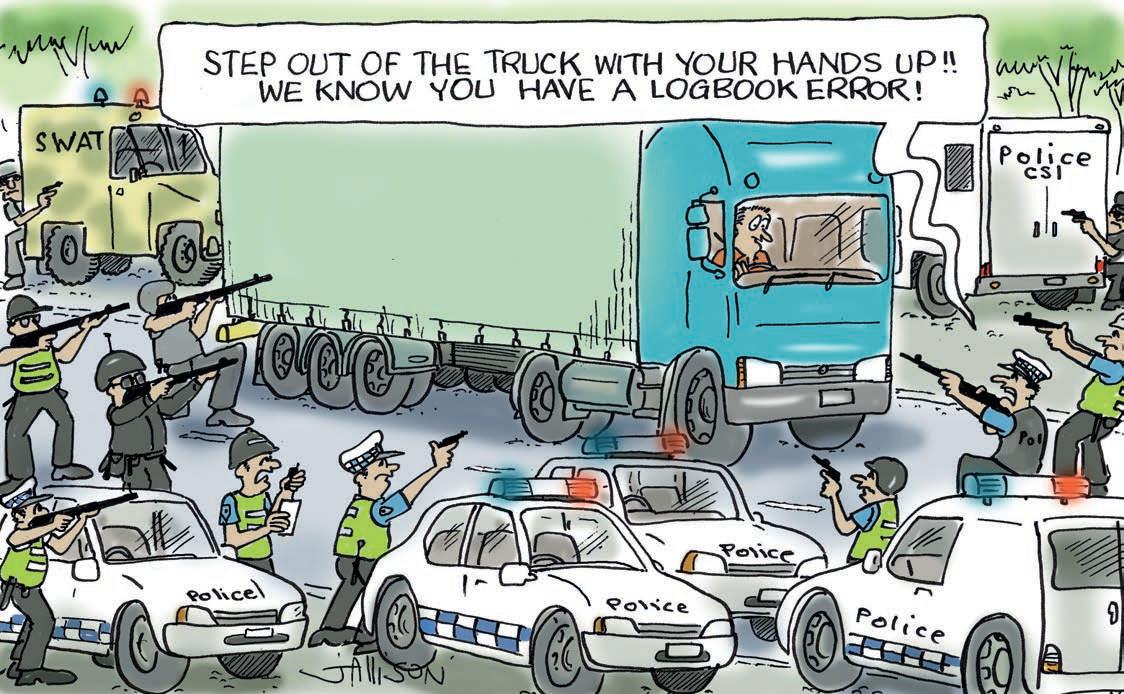

“The rules and regulations and fines put a lot of people off.”

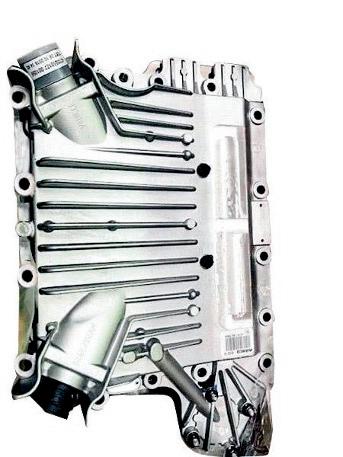

To keep your truck performing at its best, only trust Isuzu-backed parts, which include Isuzu Genuine Parts, Isuzu Best

& Isuzu

Last month OwnerDriver magazine quietly clocked up 30 years in existence. Originally presented in a newspaper format, OwnerDriver was first published in midSeptember 1992 (pictured right) under the Publishing Services Australia banner.

OwnerDriver ’s founding editor Andrew Stewart wanted his new publication to give its readership important information on how to go about their business, present professional owner-drivers in a positive light and therefore setting an example to the entire road transport industry.

“It’s all designed to help owner-drivers know the facts affecting their industry, pick up a few tips to save a dollar or make life easier, and to feel pride in the tough job they do,” Andrew said at the time.

Back then truck drivers and owner-drivers were frustrated by the general public’s perception that the road transport industry was loaded with “big rig-driving loudmouths”. While that image may still exist in some quarters, mainly thanks to sensationalist mainstream media (notably commercial TV networks), truck driving has raised its profile through state-of-the-art trucks, a more professional attitude and the removal of most ‘cowboy’ operators from the landscape.

One of OwnerDriver ’s long-term opinion columnists, Ken Wilkie, penned his first piece in the publication’s first issue. A veteran of many decades in road transport, Ken is still a contributor and, while his comments may go against the grain of some associations and officialdom, he has firsthand knowledge of the industry’s issues. And he’s still behind the wheel today.

John Allison, with his witty cartoons, was another to add his personal touch to OwnerDriver, continuing his artistic endeavours throughout the years. Another regular columnist, Rod Hannifey, signed up in 2001 to report on a variety of concerns, including road enforcement irregularities, poorly maintained truck routes and substandard rest stops, all among the many bugbears of truckies. He continues in his attempts to boost the industry’s profile.

While contributing writers have come and gone,

OwnerDriver currently has the best and most experienced in the business, including the likes of Steve Brooks and Warren Aitken.

Over the past 30 years, some long-standing truck publications have shone brightly and later vanished into oblivion.

However, since 1992, OwnerDriver magazine has continued on its trajectory through the ownership of various high-profile media companies who recognised the value in this unique publication.

OwnerDriver plans to continue to set the standard for Australia’s trucking media for another 30 years … and well beyond.

As for the future?

The Victorian Transport Association (VTA) has welcomed the reinstatement of the fuel excise tax credit by federal transport and infrastructure minister Catherine King following months of advocacy by the transport industry for its reinstatement to offset higher diesel costs.

The previous government’s temporary reduction in the fuel excise ended at midnight on September 28, however the VTA says it is important that operators continue to resist absorbing higher business costs so as not to put any unnecessary pressure on their ability to trade.

The credit increased by 1 cent to

18.8 cents per litre on September 29, although the higher amount intended to offset an increase to the heavy vehicle road user charge of 0.8 cents per litre, which took effect at the same time.

Earlier in September, Minister King announced that the new Road User Charge would be 27.2 cents per litre and the fuel excise 46 cents a litre.

NatRoad CEO Warren Clark says the increase in the road user charge from 26.4 cents per litre is consistent with the National Transport Commission’s recommendations earlier this year.

“While we acknowledge that the

3 per cent rise is less than half the inflation rate for 2021-22, it will still make life tough for truck operators,” Clark says.

However, the VTA says consumers are growing accustomed to the impacts of inflation in our economy so it will come as little surprise that increases in fuel, registration and charges must be factored into transport costs.

The VTA says it gratefully acknowledges and sincerely thanks the minister for listening to the

legitimate concerns of industry, which is reflected in the higher fuel excise tax credit afforded to road transport operators.

In its deliberations with state and federal governments, the VTA says it has consistently advocated for any increase to the road user charge to be kept to a minimum, in consideration of the significant increase in diesel costs due to inflationary and supply chain pressures, as well as ongoing conflict in Eastern Europe.

The VTA has welcomed the reinstatement of fuel tax credits but NatRoad warns of tough times ahead for operators due to road user charge increase

Shell Card is the culmination of all we’ve learned about Australia’s truck drivers since we first started working together in 1901.

It’s your passport to our Australian Truck Network, giving you access to discounted fuel a wide range of driver amenities, a national network of strategically located Shell service stations, and a whole lot more.

Talk to us about Shell’s Australian Truck Network, and how Shell Card can help drive your road transport business towards a better future.

shell.com.au

rucknetwork

Modern technology and the internet deliver the opportunity for listenerfocussed broadcaster Australian Truck Radio to be ideally positioned for the captive niche market of Australian trucking. Founder and manager Simon Smith recognises the need for a connection to trucking community, and also the responsibilities which come with it.

“They’re a huge mobile community and they are looking for their own station, and now we have to technology and resources to provide that nationally 24/7. The mobile phone is today’s radio transmitter and receiver,” says Simon, a veteran of radio broadcasting who initiated the successful ‘truckers’ radio’ format at several stations in southern NSW during the late 1980s, mostly on the midnight to dawn shift.

An unexpected bonus after the original show had been on air for a time was an anecdotal reduction in fatigue-related accidents involving heavy vehicles in the areas where the broadcasts were being received.

The consolidation of commercial radio networks in Australia during the past few decades has led to focus shifting from categories such as trucking as more stations chose to concentrate on specific consumer groups such as young homeowners or even attempt to be all things to all listeners while ultimately only satisfying the overall listening needs of a few.

Australian trucking is a huge mobile community looking for industry specific news and information and the drivers are at the same time looking for a radio

station they can lock on and leave on while they are occupying their cabs and listening to the information and entertainment which apply to their own work activities as well as their often unique lifestyles.

“If you’ve got a radio station and you’re trying to be everything to everybody it’s not going to work,” says Simon. “We provide something that people want with a music-driven format, and in between the songs we can have a bit of a laugh and a bit of variety including regular on-air conversations with industry people.”

“The trucking industry has changed,” Simon points out. “It’s mostly dual carriageway between capital cities such as Melbourne, Sydney and Brisbane.

“In the past, drivers would pull up at a roadhouse and sit around and have a meal together, but now with the dual carriageways, that opportunity for camaraderie is no longer there.

“We want to provide a radio

station that’s like a truckies’ campfire where they can sit around and talk and listen.”

Simon says Australian Truck Radio, dubbed the ‘voice of Australian trucking’, can be heard simply by downloading the designated Radio Station app (or scan the bar code below) or on a

computer via the station’s website: www.truckradio.au.

“The mobile phone is today’s radio transmitter. You can download the app straight onto your mobile plus you can of course listen online from our Australian Truck Radio website,” he adds.

“The Australian Truck Radio program format is designed to be a radio station truckies around Australia can lock onto 24/7.

“There’s loads of trucking classics every hour with heaps of handy industry news and information plus lots more all day every day.”

Music can range from anywhere between Slim Dusty and Lee Kernaghan to Jimmy Barnes, Midnight Oil, INX and Bruce Springsteen.

“It’s a jukebox for truckies that goes everywhere you do,” says Simon.

“The trucking industry is the biggest niche market in Australian radio and this huge mobile community deserves to have their own 24/7 radio station – now they do.”

“We want to provide a radio station that’s like a truckies’ campfire.”

The 11L Quon just got even better with its latest enhancements improving its already outstanding performance. 11-litre Quon’s new driveline features an improved ‘GH11 Engine’ with increased horsepower and torque, and the legendary ESCOT 12-speed automated manual transmission is now even better with new software enhancements that have to be tried to be believed.

These upgraded features also have the added bonus of delivering an even smoother ride for comfortable driving with minimal fatigue. For over 85 years, UD Trucks have delivered ultimate dependability. No wonder this is the truck Australia trusts.

To find out more, contact your UD Trucks dealer on 1300 BUY A UD or visit udtrucks.com/australia

Heavy vehicle safety services in New South Wales has a new home following the official opening of the National Heavy Vehicle Regulator’s (NHVR) Parramatta headquarters.

Minister for Regional Transport and Roads Sam Farraway opened the new office on September 23 as part of the transition of state-based heavy vehicle services to the NHVR.

“Over the last six months, the NSW Government and Transport for New South Wales have been working closely with the NHVR to make the transition as smooth as possible while ensuring the heavy vehicle industry continues to operate safely and productively,” Minister Farraway says.

“On 1 August, we saw the transition of roadside heavy vehicle inspections, investigations and prosecutions and administration services

to the NHVR, and I’m pleased to officially open the new Parramatta headquarters.

“Nationally consistent compliance is essential for the safety and productivity of heavy vehicle operators, and I look forward to continuing to work with the NHVR to keep NSW roads safe and our economy growing.”

NHVR chair Duncan Gay says the transition would reduce the impact of state borders on the movement of freight across Australia.

“With staff now based in NSW, we can continue to work towards a national approach to heavy vehicle safety and compliance and improve consistency for operators,” Gay says.

“While drivers will see a new logo on our vehicles and uniforms, they will continue to receive the same services and support, and will need meet the

same safety requirements as they have in the past.

“The transition is part of an ongoing journey towards becoming a single national regulator, and I’d particularly like to thank the heavy vehicle industry across NSW for their time and feedback throughout the process.”

who will continue to deliver services from more than 200 existing Heavy Vehicle Inspection Stations, safety stations and on-road enforcement sites across NSW.

NSW is the fifth state or territory – after South Australia, Tasmania, ACT and Victoria – where the NHVR is directly delivering heavy vehicle regulatory services.

should never stain

hands. Even at

change. If it does

have engine sludge & power loss.

“My T650 Kenworth lost power, was smoking badly and using oil. Cummins said it needed a $32,000 rebuild! I tried FTC Decarbonizer and Flushing Oil Concentrate. I was absolutely amazed how much rubbish came out on the flush. Now the power’s great! No smoke! No oil use!”

Hugh Maslin

Hugh Maslin

The Victorian Transport Association (VTA) says heavy vehicle drivers should prepare to see monitoring cameras and new road signage communicating important information about restrictions.

The VTA says it has been working closely with Freight Victoria and the Department of Transport to ensure a sensible balance is maintained between operator productivity and community amenity with respect to heavy vehicle movement in the inner west Port of Melbourne precinct.

New cameras and road signage were put in place on September 19 and the VTA is keen to update operators about curfews and restrictions in the inner west which has caused recent confusion.

The VTA says curfews have been in place on many roads in the inner west for nearly 20 years, with the re-defining of these curfews having taken access one step closer to the completion of the West Gate Tunnel.

The VTA says operators should note that a 24/7 curfew exists for heavy vehicles at all times on Hyde

St, north of Francis St to Napier St.

Partial curfews for heavy vehicles from 8pm to 6am weeknights and from 1pm Saturday to 6am Monday along Somerville Rd, Francis St, Moore St, Whitehall St (Francis to Somerville Rd, Hyde St (south of Francis St.

Heavy vehicles are prohibited from 8pm-6am weeknights and from 1pm Saturday to 6am Monday on Somerville Rd, Francis St, Moore St, Whitehall St (Francis to Somerville Rd) and Hyde St (south of Francis Street).

High productivity freight vehicles may operate on permit conditions along Williamstown Rd.

There are no curfews along Footscray Rd, Napier St, Buckley St, Whitehall St (Somerville Rd to Napier St), Sunshine Rd, Geelong Rd and the Westgate Freeway.

The VTA also says the bridge height clearances in Napier Street of four metres must be observed. It advises that operators unsure on these restrictions should contact its office.

After 30 years in business, Bernie Hilder, managing director of Hilder Transport, has sold the company’s entire fleet as he winds down operations.

Ritchie Bros handled the dispersal fleet of the prime movers and trailers through a national unreserved auction on October 12 and 13.

The trucks auctioned off included eight Kenworths of various year models, including recent T610 6x4s.

Other trucks included a 2003 UD MKB215, 2007 Volvo FH13 and two Hino 4x2s. There are also a variety of Freighter, Kreuger and Barker trailers, as well as forklifts and crane trucks.

Based in Rowville in Victoria, Bernie’ Hilder’s father George established Hilder Transport in 1972. The younger Hilder has continued his father’s legacy by growing the company, offering specialised Australia wide freight services.

“In the early years, my father worked with the sawmills buying and selling timber into Melbourne, then the produce market, before transitioning into the transport business,” HIlder explains.

“I just love trucks and the industry. However, it’s gotten to the stage where we can’t attract drivers and staff. We have some great customers, the journey has been awesome, but it’s time.

“After months of consideration and numerous discussions, I have made the tough and heartbreaking decision to cease the transport services of George Hilder and Co Pty Ltd,” he stated on the company’s site.

“I would also like to take this opportunity to thank our staff and customers who we have never taken for granted.”

More commentators are voicing their concerns over the situation around port fees in the transport industry. On September 9 a story on The Financial Review echoed the sentiment of many, including OwnerDriver readers, that port fees should be placed on shipping companies and not individual truck drivers.

The Transport Workers Union (TWU) national secretary Michael Kaine says more mainstream calls for port reform is a step in the right direction.

“This a positive step towards ending the stevedores monopoly gouging scandal which has gone on for years. Exorbitant fees have imposed major burdens on transport companies and owner drivers already operating on razor-thin margins.

“For over five years, the TWU along with companies like ACFS and transport associations have been calling for wealthy heads in maritime supply chains to pay their fair

share rather than pushing transport operators to the brink.

“The proposition of ‘flexible fees’ to create ‘efficient incentives’ undermines safety in Australia’s deadliest industry and should be abandoned. When profits are squeezed, operators and drivers are pressured to delay maintenance, speed, skip rest breaks and drive fatigued. Imposing fees to make transport operators work faster will only result in more deaths on our roads. In the last year alone, 188 people have been killed in truck crashes, including 54 truck drivers.

Kaine says a recent transport industry roundtable of workers, clients, employers, industry groups and gig companies called for enforceable standards to ease pressures on the industry.

“We’re pleased that the Federal Government acted on this consensus, announcing its intention to empower the Fair Work Commission to set standards in transport.”

The VTA is warning heavy vehicle drivers that new monitoring cameras and signage are being placed in the Port of Melbourne area to track curfews

“New cameras and road signage were put in place on September 19.”

Trust

Acommon consensus across the truck industry is that there are way too many disincentives deterring young Australians from considering a career driving trucks. On the flip side, there are many drivers that have chosen trucking and say the freedom of life on the road makes up for the negatives.

OwnerDriver reached out to working young people in the transport industry to hear about their stories and find out what they believe needs to change.

Each respondent explained that they were either born into a family of transport workers or had a deep passion for trucks and transport that made them want to put up with the many sacrifices the industry demands.

Twenty-nine-year-old Cameron Byrom from Perth told us what attracted him to truck driving.

“It’s something I’ve wanted to do ever since I was a kid watching dad drive trucks,” he says. “I’ve met a lot of good people throughout my childhood that made a good living on the road and had some unreal stories to tell.

“At 25 I got my truck licence and moved out of the office and into one of the trucks full-time. It was an itch I needed to scratch and I’m glad I did it,” Byrom says.

Despite the drawbacks, he says there’s a lot he still enjoys about the profession.

“Watching the scenery change as you move across the state, looking up at the countless stars when you’re camped up overnight in the middle of nowhere, the time and space you get for deep thinking, and meeting great people all over the place.

The Australian road transport industry continues to suffer from a shortage of young drivers while its existing workforce continues to age and approach retirement. Julian Daw tracks down a few of the younger brigade who explain the motivations and disincentives of a career in trucking

“I also just love trucks, so I get to see a lot of really nice rigs out and about, often with top-notch operators behind the wheel,” Byrom says.

Twenty-seven-year-old William De Maio of Melbourne says it was an interest in vehicles that got him started.

“I have a passion for anything with wheels and an engine. I also love driving and being out on the road so to me it was a no-brainer.

“It’s an industry that’s always on the go – it never stops. And when you’re living in uncertain times like we are currently, having that job security is a big weight off the shoulders. Transport never stops.”

De Maio says there are other parts of the job he appreciates.

“I enjoy being out on the road; every day is different with plenty of variety. You get to meet some really cool people out there as well.”

For many younger drivers and owner-drivers however, the downsides to a career in transport are many and should create pause for anyone considering getting stared in the industry.

Laurie Frederikson of Queensland is 30 years-old and

points to over-regulation as the number one disincentive for young people entering the transport industry.

“We are one of the most over regulated industries in Australia. I invite anyone to give me an example of a different industry where the worker can be given an on-the-spot fine or given a court date for just doing their job,” Frederikson exclaims.

“The logbook alone can cost a driver anywhere from half to well over his weekly wage just for going 15 minutes or half an hour over their legal working hours.

“In any other industry that would be called overtime and would be reflected in the pay packet at the end of the week.

“The logbook has been designed to catch people out, so they make mistakes as far as I’m concerned.

“We’re truck drivers not rocket scientists so why make the logbook so intricate that it’s harder to make it right than it is to get it wrong?” Frederikson says.

However, he still considers truck driving a long-term career and one of the best industries to be involved in.

“Being a truck driver becomes not only a job, but a way of life.”

However, Cameron Byrom says the strain on relationships is another factor that would deter many people from becoming a long-haul driver.

“The unpredictable nature of long-distance transport is really hard on relationships. I’m often having to cancel plans because of a delay somewhere or a last-minute job coming up, which puts a strain on things at times.

“It’s also tricky maintaining physical and mental health on the road,” Byrom adds.

Warren Clark, CEO of the National Road Transport Association (NatRoad) says the industry doesn’t just have to be for those born into it or with a strong enough passion to accept the drawbacks. Clark says there can be a real place for transport workers in Australia.

“The simple fact of it is, is that not everyone’s going to go to university, not everyone’s going to go to TAFE. Not everyone’s going to be a doctor or a lawyer. So, truck driving itself can appeal to younger people.

“This industry is full of opportunities, but it has a lot of perceived negativity about it. For young people looking for a career in transport, there needs to be a career path established. There needs to be flexibility, and there needs to be adequate training.

“At the present time the only thing that these guys get training on is the licensing process and that’s where it’s completely wrong,” Clark says.

Will De Maio says that without going through a proper apprenticeship program, learning about the industry, and gaining experience, was unnecessarily difficult.

“At first it was tough because no one wants to help – it’s like everything is a big secret.

“A lot of my knowledge come from talking to older seasoned drivers I met while at [my previous job]

Bridgestone and watching Australian trucker Rod on YouTube, and that’s 100 per cent the truth,” De Maio says.

“I had very few people who were willing to help me, and even the ones that did wouldn’t say much. For someone just starting out they need all the help they can get.

“While I love trucks, I also love other things. A life in transport often doesn’t leave a lot of spare time to raise kids, play social sport, hang out with mates and family,” he says.

“We are one of the most over regulated industries in Australia.”

“Finding time to do even the simplest things like mowing the lawn or maintaining the car can be hard at times.”

The penalties in the truck driving industry was another issue that quickly came up for many of the younger owner-drivers we heard from. While generally understood that fatigue and safety standards need to be met there is a still a feeling that many of these fines are unfair and actively discourage new drivers from entering the industry.

De Maio believes the penalty systems have instilled a culture of guilt and fear into owner-drivers.

“We understand having rules and regulations to create a safer industry for everyone; I don’t think anyone has a problem with that. What I do think people have a problem

with is getting fine after fine for paperwork errors.

“We all know that feeling of pulling into a weighbridge, even if you’ve done nothing wrong you start to sweat! Most of the time they aren’t even worried about walking around the truck. They just want to see logbooks and certificates!”

Warren Clark calls it a ludicrous system that deters people from the freedom the industry can offer young people.

“These days you have people that don’t want to work five or seven days a week. But you can get in a truck, and you can work for just two or three days, you can do it at night, or in the day.

“There’s plenty of flexibility in our industry but people just don’t see it.

“So then when we get these people into the industry, how do we keep them? We keep them through adequate training, proper pay and flexibility.

Clark says the penalty system and the prescriptive fines imposed on drivers is ludicrous.

“That is a massive deterrent to people staying in the industry. So many people get their licences, but why would they if they get fined $600 for a logbook breach or because they haven’t spelled a town right?”

For Cameron Byrom the changes in the industry that will make the biggest difference to how many young people consider it a viable career come down to an adequate training program.

“The school system pushes kids to either go to university or get a trade, neither of which leads to a career in transport, so truck driving isn’t seen as a respectable or skilled job.

“Creating an industry apprenticeship program and making heavy vehicle operations a trade qualification is a good start, but this is much more than an image problem.

“Despite what the older generation like to claim, young people these days aren’t generally scared of hard work or long hours, they just don’t want to do it forever. And given the option, they’ll almost always choose to work smarter rather than harder,” Byrom says.

“The next generation places a greater value on worklife balance, physical and mental health, life experiences and relationships than previous generations did.”

However, Byrom has a word of caution for would-be truckies.

“If there’s no passion for trucks and you’re just looking for a job to pay the bills, I’d say look elsewhere.”

OwnerDriver would like to hear from other young truckies or those aspiring to enter the road transport industry. Email julian.daw@primecreative.com.au

Normal service was resumed in Alice Springs in August when a new batch of inductees were added to the Shell Rimula Wall of Fame as part of the Australian Festival of Transport

More than 55 new inductees were added to the Shell Rimula Wall of Fame at Alice Springs on August 27. The induction ceremony was a major part of the Australian Festival of Transport at the National Road Transport Hall of Fame Reunion, that took place on the last weekend in August.

It was return to normality following two years of the pandemic, marking the dedication and commitment of individuals withing Australia’s transport industry.

Inductees from 2020 and 2021 who missed the opportunity

to attend due to COVID restrictions were also recognised this year.

“We’re proud to be able to celebrate the achievements of the industry once again at the National Road Transport Hall of Fame and to welcome another group of deserving inductees into the Shell Rimula Wall of Fame,” says Nick Lubransky, transport marketing manager at Viva Energy, the Shell brand licensee in Australia.

One of the 2022 inductees, Laszlo Bruzsa, was recognised as being instrumental in the implementation of innovative and more freight-efficient heavy vehicle combinations like B-doubles

Maxwell Andrews Peter Annett Raymond Arty Leonard Barty Byron Bonney Laszlo Bruzsa Barbara Byrnes Ronald Byrnes Larry Charles Edward Cockburn Jeffrey Cutter Sidney Cutter William Cutter John Deane Joe Dickerson

John Dow Ross Dow Keith Fowler Larry Gill Brian Hailes Noel Halliwell David Hayter Gerard Hicks Stanley Hiscock Kenneth Hopper Colin Johns Adrian Johnson Leo Kelly Barry Knee Kathleen Knee Peter Knee

Terence Lamprell James Leahy Kevin McAuliffe Primo Martignago Sydney Matthews John Molloy Raymond Mullane Beverley Newland Brian Norton John Norton Barry Pfeiffer Robert Picone Geoffrey Purtill Keith Purtill Ian Purtill

John Molloy Brian Norton John Norton Peter Redding Lesley Schrapel Peter Shiells Edward Smith Ivor Stewart Donald Stewart Denis Taylor Douglas Tory Lionel Ward Denis Wheare Hazel Whitmore Steve Woodward

and AB-triples, which now represent the norm in terms of productivity and road safety in the Australian road transport industry.

Brisbane-based Bruzsa is an internationally renowned authority on heavy vehicle technology, road safety and the complex interplay of heavy vehicles and roadways, and has received many awards and accolades for his achievements.

“We’re excited to acknowledge the achievements of people like Laslo and celebrate their outstanding commitment to the road transport community,” Lubransky adds.

paving the way for their family legacy to continue well into the future.

Above: After two years of COVID restrictions, John and Ross Dow’s plaque was added to the Shell Rimula Wall of Fame following their 2021 induction

Below: Lionel Ward (centre) from Geraldton in Western Australia made the trip to Alice Springs to be officially added to the Shell Rimula Wall of Fame

Hi-Trans Express managing directors and brothers Ross Dow and John Dow followed their father George Dow who retired in 1998 and was inducted in 2004, by having their names added to the Shell Rimula Wall of Fame.

The Adelaide-based Dows are credited with ensuring their business is an industry leading force with proactive technology, safety and sustainability commitments.

The brothers now have their sights set on operating a carbon neutral fleet by 2025. They have also inspired and enlisted the next generation of Dows in the Hi-Trans Express business,

Barry Knee, from northern Victoria, is known for offering his services to help primary producers in need and giving back to the community, was among a number of owner-operators to be inducted this year. Working in the transport industry since the age of 19, Knee started working for his father full-time in the family business Barry Knee Haulage. He was joined by family members Kathleen Knee and Peter Knee.

Lionel Ward, from Geraldton in WA, was another among the list of 55 inductees named for 2022. Starting in the road transport industry in 1973 at the age of 16, Ward has gained a solid reputation as a very safe driver with an accident-free record despite driving a triple road train millions of kilometres across some of the roughest roads on the planet.

Hailing from the Sydney suburb of Horsley Park, Primo Martignago is still working in the industry at almost 77 years of age, a testament to his deep commitment.

With a wealth of experience, Martignago has hauled a range of products behind the wheel of various truck makes and models. However, despite now relying on his sons for jobs that require greater physical activity, Martignago says he has no plans to retire.

Also from NSW, Steven Woodward of Kiama was added to the Wall of Fame on August 27 after a long career which commenced in the 1980s. Involved in some of the biggest heavy haulage moves in the country, Woodward is known for becoming a master of multiple truck and ‘push-pull’ operations, developing a unique and highly specialised skillset.

Aways keen to share his knowledge, Woodward is known for frequently mentoring young people in the industry, including his own son who assisted in moving the largest mobile crane in the country, at the time, in a dual truck operation.

As well as the induction ceremony, other highlights of the Australian Festival of Transport included the Transport Women’s Association welcome breakfast, the Cummins Cup Truckies Day at the Alice Springs Turf Club, and the Territory formal gala dinner and live music inside the Kenworth Pavilion.

For Shell Rimula, this year marked another in the long partnership with the National Road Transport Hall of Fame which has so far tallied more than 1,700 transport industry identities to the Shell Rimula Wall of Fame.

The National Heavy Vehicle Regulator (NHVR) is committed to always looking at what we do, to find opportunities to better our approach and deliver fit for purpose and improved efficiencies for the heavy vehicle industry and in turn, our communities.

As the sector continues to address the challenges involved in managing the impacts of COVID, including the ongoing effects of driver shortages and the forever growing freight task, it is critical that we do what we can to improve accessibility to safer and more productive heavy vehicles. This is focused on operators moving more freight in a safe way with fewer truck movements – and is a key principle underpinning the NHVR Performance Based Standards (PBS) Scheme.

The PBS scheme has been considered one of the most sophisticated in the world and since its introduction in 2007, has played a significant role in transforming the movement of freight in Australia by putting safer, more productive vehicles on our roads and encouraging innovative approaches to the significant transport task. There are now more than 14,500 of these smarter, safer PBS combinations operating across the country.

Over the next couple of months we’ll be delivering a range of initiatives to continue evolving the scheme and removing barriers to operator participation. This approach is focused on modernising PBS so that it reflects the improved safety performance of the industry over the last 10 years as well as recognising technology and innovation advancements.

This month, we will be delivering a new notice – the National Class 3 20m Long 3-axle Truck and 4-axle Dog Trailer Mass and Dimension Exemption Notice – that provides operators of longer 3-axle truck

and 4-axle dog combinations up to 20 metres in length with the option to operate these combinations outside of the PBS scheme in the ACT, New South Wales, Queensland, South Australia and Victoria.

These combinations have only been able to operate under the PBS scheme, with access restricted to PBS networks, or by permit. Now that the PBS scheme has been in operation for more than 15 years, we know enough about this particular combination to move it out of the PBS regime. So, operators can enjoy the benefits to be gained from one of these combinations without the expense and time needed to get a PBS Vehicle Approval (VA).

This notice is the important first step in moving ‘mature’ combinations out of the PBS scheme and into the less complex and less costly ‘normal’ regulatory framework – and we will continue to identify other well-known combinations that can also be transitioned out of the scheme. This move allows the scheme to focus on the next iteration of innovative vehicles, further enhancing productivity and safety.

This is just an option though, and operators can continue to operate, or apply for approval for, these vehicles within the PBS scheme.

We’re also putting changes in place to simplify and reduce turnaround times for the PBS VA process. Firstly, we’ll be removing the operator’s name from the VA, so that it becomes an authorisation to the vehicles listed on the VA, regardless of who owns or operates them. This means there will be no need to transfer the VA when a vehicle is sold or when it’s being used by a subcontractor. All existing VAs will be unaffected, although we will remove operators’ names on request.

Secondly, we’ll be replacing the specification tables with a simpler table that only contains key vehicle information like VINs, number of axles, and vehicle make and model. This will eliminate duplicated

SAL PETROCCITTO became CEO of the NHVR in May 2014, bringing extensive knowledge of heavy vehicle policy, strategy and regulation to the role. He has broad experience across state and local government, having held senior leadership roles in transport and logistics, land use, transport and strategic planning, and has worked closely with industry and stakeholders to deliver an efficient and effective transport system and improved supply chain outcomes. Over the past seven years, Sal has led a significant program of reform across Australia’s heavy vehicle industry, including transitioning functions from participating jurisdictions to deliver a single national heavy vehicle regulator, harmonising heavy vehicle regulations across more than 400 road managers, and modernising safety and productivity laws for heavy vehicle operators and the supply chain.

information and reduce the size of a VA application by about 30 per cent.

We’ve also progressed the implementation of the generic tyre approach for PBS assessments endorsed by Ministers in 2021. This will move away from the prescriptive nomination of tyres on PBS VAs to an approach that will allow industry to use any tyre of the specified size and rated load.

Since we first announced our intention to adopt this approach, we have undertaken extensive technical evaluations to ensure that the safety of PBS vehicles won’t be compromised by using generic tyres. The results have clearly shown PBS vehicles deliver excellent safety, regardless of tyre performance.

We hope to introduce this approach before the end of October 2022. From commencement, all existing vehicles will be deemed to comply with the new approach and, importantly, operators of existing PBS combinations won’t be required to amend their VAs to reflect this change.

Looking to the future, we have been undertaking work to deliver a revamped scheme – PBS 2.0 – which will, among other things, enable the scheme to focus on innovation.

Of course – one of the key barriers we need to tackle is opening up increased access for PBS vehicles so they can operate on the same networks as their conventional equivalents. PBS 2.0 has as a strong focus on working with road managers to provide certainty of access for these vehicles as well as eliminating the need for permits.

Critical to this outcome will be the ability to display all the PBS networks across states and local government areas in one single national map through the NHVR’s National Spatial platform. This will provide increased efficiencies and certainty by removing the need for operators to access multiple statebased maps when planning cross border journeys. The single map as it develops will also deliver dynamic network outcomes based on an operator’s fleet and increased national information on movements will reduce the need for permits, supporting the move to increased gazetted network outcomes.

A Discussion Paper outlining our proposed approach will be available on our website shortly, and I encourage everyone in the industry to review it and provide feedback.

The PBS scheme is something the NHVR takes great pride in. As it continues to mature, we are seeing more and more how it has fundamentally changed the way we move freight in this country while delivering significant safety and productivity benefits.

I look forward to continuing to work with the industry to improve and grow the scheme, for the benefit of all road users and our broader economy.

For more about the PBS scheme, visit www.nhvr.gov.au/pbs

“This move allows the scheme to focus on the next iteration of innovative vehicles.”

Road transport workers around the country are closer than ever to safer roads and a more prosperous industry – and it’s thanks to an industry that has never been more united.

In September I joined representatives from right around road transport for an industry roundtable ahead of the Federal Government’s Jobs and Skills Summit. It is a testament to the industry that there was unanimous agreement on what we need to make road transport more viable, fair, safe and sustainable.

We emerged from the roundtable with a set of principles to reform our industry, backed by stakeholders from every corner of the industry including the Transport Workers Union (TWU), the Australian Road Transport Industrial Organisation (ARTIO), NatRoad, the National Road Freighters Association (NRFA), state transport associations, transport operators like Toll, Linfox, ACFS and FBT Transwest, and even supply chain clients Woolworths and Coles, and gig giants Uber and DoorDash.

These groups have not always been allies, but the ‘wild west’ of the gig economy spreading rapidly through transport has only heightened our need to stand shoulder to shoulder. Even the gig companies themselves have joined calls for a level playing field, feeling the threat of being undercut out of business in a lawless society like the gig economy is today.

In what is Australia’s deadliest industry, this set of industry principles form a powerful blueprint for how we can achieve life-saving reform in road transport, and they are groundbreaking.

The consensus between the representatives at the roundtable was so absolute that Workplace Relations Minister Tony Burke has announced the Federal Government’s intention to empower the Fair Work Commission (FWC) to set fair standards for the entire transport industry.

Under this proposal, the FWC would be tasked with making transport a more sustainable industry for all.

Unanimity and accord across a whole industry does not come from nowhere. One of the driving forces of this reform was Senator Glenn Sterle’s two-year inquiry into road transport, which heard from dozens of representatives and earned trust from all corners of the industry. Thanks to the tireless efforts of these advocates, the commitments from the Federal Government are built around the findings of Senator Sterle’s inquiry and give life to a number of its key recommendations.

This is a significant breakthrough to lift standards in the industry and protect all participants from the existential crisis brought by the gig tsunami.

We must band together and do everything we possibly can to back the Federal Government’s commitment. The stakes are too high for inaction.

For owner-drivers it would mean

MICHAEL KAINE is the national secretary of the Transport Workers Union of Australia. Contact Michael at: NSW Transport Workers Union, Transport House, 188-390 Sussex Street, Sydney, NSW 2000. twu@twu.com.au

greater economic strength and fair payment terms, including for cost recovery, increasingly crucial with skyrocketing fuel prices.

It would mean access to real dispute resolution, so drivers’ voices can be heard, no matter their label.

It would mean transport workers get a seat at the table when decisions are being made about the industry and be able to provide advice and recommendations.

But the most crucial element is that it will apply to all transport workers, including employees and gig workers. Having minimum standards for all workers means that the industry as a whole can prosper from a safe and fair starting point.

It would mean all workers have the regulatory backing they need to make a decent living. We would have a system of fair competition that allows all participants to thrive.

With companies like AmazonFlex destroying good jobs through its exploitative app-style model, this commitment from the Federal Government could not come at a more urgent time.

We’ve already seen FedEx fall to the Amazon Effect, with its proposal to bring in owner-drivers on shocking piece rates on a take it or leave it basis. If FedEx does it, soon others would be forced to do the same to stay competitive.

If passed through parliament, this would close the loophole that companies like Amazon have been able to take advantage of for far too long.

The benefits of this system for ownerdrivers are numerous. Supply chain accountability would increase the size of the pie so drivers aren’t fighting for scraps. Cost recovery would be easier but so too would negotiating take-home pay on top.

We have worked together for years for a solution that will create a fairer and safer industry. Only two months ago, hundreds of employee and owner truck drivers, couriers, rideshare and food delivery workers joined

nationwide convoys alongside industry representatives in support of reform.

That moment – real, industry-led, positive change – is on the horizon. It’s a reminder of what we can achieve when we stand together – we need to keep up the strength and unity to get this done.

We’re not at the finish line yet. The industry has never been more united, but we need to continue to work together over the next weeks and months to make this a reality.

We know that if passed, this will save trucking businesses, jobs and lives. Our tenacity and unity as an industry has got us this far, and the prospect of a more prosperous industry is something every single person in road transport must get behind to make it happen.

“For owner-drivers it would mean greater economic strength and fair payment terms.”

Heavy vehicle legislation is becoming increasingly complex. Remember when they said the Heavy Vehicle National Law (HVNL) would make things easy to understand? We see the whole range of offences and enforcement across the country here at Highway Advocates, and they have us scratching our heads on more than one occasion. This month’s column will detail a few that might have you scratching yours.

Does calling a law national make it so? If Queensland had a law called the National Parks Act (QLD), could that law apply to all National Parks across Australia? Western Australia and Northern Territory have yet to sign on the dotted line for the HVNL. The NT originally signed, but they must have their toes crossed. They reneged soon after. Could that be something to do with the fact that the NT is a Federal Territory, not a State?

A Federal Territory, even one with a self-government act like the NT, would have problems enforcing another State law. Hence, no HVNL in the NT.

Western Australia has always wanted to do its own thing and the HVNL is not its thing at this point in time. However, drivers from participating States still have to comply with the HVNL for up to seven days while operating in WA. Think of it this way, if you will. While in WA you must comply with Queensland legislation in a State that does not apply that legislation. Does your head hurt yet?

A driver (or subject of The King) who is a resident in another State, is then treated differently to a resident of WA while in that State. That starts to take the shape of the number 117. To make matters worse, cameras have been installed in WA that monitor interstate driver movements while in WA. How does this happen? Because we let it!

Turning now to the eastern states, in particular NSW. Here comes another head-scratcher. The Safe-T-Cam system came about because of reforms implemented after the tragic Grafton and Kempsey bus and truck crashes. They are used as surveillance devices, not unlike CCTV. ‘Outsourced’, like almost everything in NSW, they are now used for a whole raft of offences.

Many operators around the country will relate to receiving notices to

produce purporting to force operators to disclose drivers’ names and addresses under the threat of heavy fines. The wording on the notice goes a little bit something like this:

“Your vehicle was detected travelling between Safe-T-Cams faster than the allowable travel time. Therefore it is alleged you have committed an offence under the HVNL.”

OK, so what is the allowable travel time? What is the offence?

Frequent enquiries draw a blank, with a typical response being “it is a policy” breach. An unknown policy –and then you are accused of breaking the law! How and why does this happen? We know it happens because we let it. However, we do know it faces some possible legal hurdles.

Without a specific reason for doing so, these notices requiring the production of work diary records may be described as a ‘fishing exhibition’. A term used in law, a ‘fishing exhibition’ may be a process that seeks to ‘cast a wide net’ to catch something. It has been widely held in common law that when it is necessary to require production, the process must identify expressly and precisely the legitimate forensic purpose for which access to the documents is sought. The process may be creature of statute, however the reason for initiating that process may not enjoy that protection. Furthermore, a ‘fishing exhibition’ is

ROBERT BELL a former truck driver and current law undergraduate and practising paralegal, is the CEO and a director of Highway Advocates Pty Ltd. Contact Highway Advocates Pty Ltd on robert.bell@ highwayadvocates.com.au or phone 0488 010 101 or see the website at www.highwayadvocates. com.au

not a legitimate forensic purpose and should not occur in this manner.

We think this is a case of just dropping a line and seeing what you catch. It would be interesting to see the statistics on how many notices are issued compared to detected breaches. The data would confirm it one way or another. The allowable travel time answer seems to be floating around space, out of reach for mere mortals. Safe-T-Cams are not approved speed or average speed cameras under the HVNL or any other legislation. Shall we go on?

While we are on the subject of SafeT-Cams, I’ll shout a drink to anyone who can find a reference to them in the HVNL or any other legislation prescribed for fatigue-related heavy vehicles. Yet inexplicably they are used to provide evidence of making false or misleading entries in your work diary. Let’s draw this one out for a big finish, shall we?

A non-prescribed, gazetted, or authorised camera takes a picture that initiates a prosecution. The Prosecution avers that you made a false or misleading entry according to the said camera and the ‘fishing exhibition’ that follows.

That prosecution is then treated as a strict, or even absolute, liability offence. The HVNL has stripped away most defences over time, including a mistake in fact. Yet the wording of the offence appears to include the mental element of mens rea, or guilty mind (intent). For those nerds among us, actus reus non facit reum nisi mens sit rea, “the act is not culpable unless the mind is guilty”.

This is just about enough things to make you go ‘hmmm’ for one session. There’s plenty more where these come from, though.

Remember, a policy is not law, quickly becoming a feature of our legal landscape. For answers to some of these questions or others not yet asked, contact the team at Highway Advocates Pty Ltd. It’s the link between your world and the law world.

From his early years in South Australia, Martin Rieck has always enjoyed working with cattle, a vocation that he has embraced further with his move to southern Queensland as an ownerdriver. Greg Bush writes

Anyone regularly travelling Queensland’s Warrego Highway will, at some point over the past six months, caught a glimpse of Martin Rieck’s new Mack Super-Liner hauling B-double livestock trailers. However, Martin has been on the road for much longer than that, while his association with trucks goes back to his family’s property in north-east South Australia which he says was ”nearly one million acres in the desert”.

The property, south of Innamincka and west of Cameron’s Corner, ran cattle. Out of necessity Martin bought his first livestock truck. More trucks were upgraded over the years.

“Dad always had trucks, not livestock trucks, but he had an earthmoving business, so we always had trucks to shift around and supply the fuel,” Martin explains.

“Working with the stock was first and foremost, so I was bought up more machinery to start with before trucks. My father didn’t really like trucks,” he adds.

The Riecks’ home state of South Australia was the obvious choice for sending cattle to sales yards and abattoirs. However, in the early to mid-1990s they soon realised that southern Queensland provided more opportunity.

“Earlier on South Australia was always the place to go with the cattle,” Martin recalls. “We started coming this way (Queensland) because there was a lot more competition with the buyers and the feedlots, a lot more places to go with your cattle. South Australia was limited to only a few buyers back in them days.

“It was a little bit further, 300km or something, but it was still going to be better to come this way. Better weather and, when we did move, there were more opportunities with the truck.”

Earlier, the Rieck family had sold the property to Australian oil and gas exploration and production giant Santos, leasing the same land back for around 12 years. That lasted until Santos began selling its properties following the oil price crash.

Champion shearer Martin, wife Kate and children Mason and Taylor, made the permanent move to southern Queensland close on five years ago. Sadly, Martin’s father Ted Rieck had passed away in 1990, but not before leaving behind a major personal achievement.

“He was a champion shearer, he was the first one to break Jackie Howe’s shearing record,” Martin proudly exclaims.

“My father was the first one to break it with mechanical shears. He sheared 327 sheep in seven hours, 39 minutes and ran out of sheep before the end of the cut. That was up near Brinard Station, Julia Creek.”

Martin’s relocation across the Queensland border came after selling almost all the gear from the South Australian property. He brought his family along, as well as his Western Star prime mover, one of two he’d owned over a 16-year period.

However, running a small owner-driver business means the less downtime, the better. The six-year-old Western Star, with around 480,000km on the clock, wasn’t cooperating. While Martin enjoyed his long history with the brand, a series of engine issues, namely the Cummins EGR, forced him to look for an alternative.

He began turning his attention towards the Mack brand. “I knew people who had Macks and they had a good run out of them.”

Placing an order for the Mack Super-Liner in October 2021, he received delivery of it in April this year and then sold the Western

Star, admitting that he “should have put more on it”.

The Mack came with an MP10 685hp engine and mDrive automated manual ’box. After years of operating an 18-speed Roadranger, Martin became an auto convert, especially as his runs take him through regional townships as well as trips to Brisbane. “That’s one thing you don’t worry about, changing gears,” he remarks.

However, he often switches to manual override, especially on roads such as the Toowoomba range. Putting it into 7th gear, he says holds it all the way down with the engine break on.

He’s also pleased with the Mack’s engine and its fuel economy, believing that if he’d had stuck with the Western Star it would have worked out around an $30,000 a year. “The way things are going with fuel at the moment, the old truck would have broken me.”

As for the Mack’s safety features, including lane departure warning and automated cruise control, he opted out.

“I could have got all that, but they deleted it for me. Being it’s a bush truck, I really didn’t want it,” he says.

Martin’s only regret is the Super-Liner’s single bed. His old Star had a double bunk and he would have preferred a 64-inch in the Mack but he says that spec wasn’t available. At any rate, he still has enough space for a TV and microwave, handy for the three or four nights a week he spends away from home.

The majority of Martin’s subcontracting work is around Roma where the saleyards are situated, and south to Surat and east to the feedlots around Dalby, with only the occasional run further west.

“Nine times out of 10 you always do a load in Roma on Monday before the sale, the rest of the week you might take cattle to a feedlot or a meat works down in Brisbane,” Martin says.

The Brisbane run takes him to the Beenleigh meat works, his most easterly destination. That brings Martin to the issue of effluent and hauling cattle through suburban streets.

“There’s a big argument with the effluent side of things as a truck driver. Because I’ve owned cattle myself, even coming 1200km, we’d curfew them for 12 hours before we load them. The simple fact is that they travel better,” he explains.

He says others will load the cattle full of water to keep the weight on.

“But as soon as you put them on the truck full of water they start emptying out, and that causes another problem. You need to wash them out and that’s a cost that’s getting higher and higher.”

He says he can be up for around $300 to wash his crates out.

Then there’s the ever-changing regulations and the inconsistency between meat works.

“Some are very good, some are very ordinary,” he says. “Because my crates are sort of set up more for road train work, they haven’t got the sliding doors on the back.

“It makes it harder in some of the meat works because you’ve got to back in. I still do it, no worries at all, but the rules and regulations are getting tighter and tighter from dropping through your three load doors at the back.

“As far as unloading, Roma’s good, nice wide dumps, you can pull up and open all three doors sideways.

“A lot of feedlots haven’t got ideal unload facilities, you’ve still got to unload down a ramp which is a lot narrow, so you can’t open all your doors. That way there’s a smaller gap to try and get out.”

Martin runs either three, four or five decks on cattle, with five

“I knew people who had Macks and they had a good run out of them.”

the ideal combination as he can get a permit to go into Dalby from St George. “With six decks you can’t get the permit anymore,” he says.

Nevertheless, Martin enjoys the job, travelling along the wide open spaces and working with livestock. However, he has words of warning for young would-be drivers and owner-drivers.

“Money is the big thing these days,” he says. “There must be easier jobs they look for, and the rules and regulations and fines put a lot of people off.”

Martin says going through Brisbane’s suburbs on the way to Beenleigh can get tricky with red light cameras put in a position where it’s difficult for trucks, especially those loaded up with cattle, to pull up safely.

“There’s some cameras going to Beenleigh where you can be right on them and they’re green, then they’ll change and if you roll through, you can then get a fine.

“The amount of points you lose, you only have to lose them three or four times and you’ve lost your licence.”

Still, Martin has managed to cut costs in a couple of areas. Five years ago he gave up the dreaded ‘nicotine sticks’, which he says cost him $200 a week. “I don’t know how people can afford to smoke,” he adds.

Other cost-saving areas include doing 50 per cent of his own maintenance, especially on his trailers, while Kate covers most of the billing and banking.

“At this stage between the fuel, insurance and registration, the future is a bit of a mystery at the moment,” Martin says.

“Something’s going to have to change, especially for the small operator.”

The Federal Government’s budget will be a sight for sore eyes in one vital area for road transport

By the time you read this, preparations will be well underway for the Albanese Government’s first budget on October 25. Those of you familiar with the events of Budget Night will know that the speech that becomes public the instant the Treasurer rises to his feet to deliver it often provides a “make you or break you” moment.

Unfortunately, the last time we made our way to Parliament House for this red-letter event, all our industry got was a collective black eye.

Even some members of the thengovernment were blindsided by suspension of the Fuel Tax Credit for heavy vehicles.

To paraphrase an old song, we can see clearly now and it was anything but a bright shiny day for those operators forced out of the industry by yet another unfair financial impost.

Bear in mind that this was an idea cooked up by Treasury to offset the cost of halving fuel excise for cardriving families of voting age.

Ironically, the extra burden it placed on truckies ended up costing mum and dad more at the supermarket … and there was no dividend at the ballot box.

Word on the street this time around is that the new Government’s budget

will be sharply focussed on delivering promises it made from Opposition.

One we understand will be met in full is the pledge for an additional $80 million for heavy vehicle rest areas.

NatRoad praised this mid-election campaign announcement.

Promises from both sides of politics were admittedly thin on the ground at the time, but this one seemed like common sense, and it was surprising that it went unmatched.

NatRoad thinks that building a national network of rest areas, strategically located and informed by evidence about fatigue, will go a long way to making our industry much safer and much more efficient.

It’s important that rest areas are more than rudimentary driveways with a cold running water tap and a lean-to added as after-thoughts.

Safe and secure toilets and change areas for men and women should be a minimum requirement.

Hot and cold water, power that isn’t dependent on the grid, well designed entries and exits and ample truck parking are not luxuries, they are mandatories.

WARREN CLARK is CEO of the National Road Transport Association

“I want the truckies to tell us where they want the trucks bays and what they expect in the bays,” said WA Labor Senator Glenn Sterle, who at the time was the Shadow Assistant Minister for Road Safety.

Form an orderly queue, here.

We all know that $80m won’t go a long way but it’s good progress.

What’s more, it is expected to be delivered in one budget year.

It should be enough to build 16 wellequipped rest areas. Locate them strategically and you will make a difference.

The Federal Government already commits up to $65m a year through its Heavy Vehicle Safety and Productivity Program, some of which finds its way into rest areas. There are also joint funding programs with states and territories.

The National Heavy Vehicle Regulator receives $5.5 million per year from the Australian Government to deliver the Heavy Vehicle Safety Initiative (HVSI), which funds industry-led safety projects.

NatRoad believes the Federal Government can go further and can make road funding grants to the states and territories at least in part conditional on matching cash for rest stops that are of a nationally uniform standard.

It might take a lot of heavy lifting but only then will we see safety and productivity baked into infrastructure.

NatRoad communications are intended to provide commentary and general information. They should not be relied upon as legal advice. Our advisers are available to clarify any questions you have and provide the right advice for your business and workforce. Contact our advice line at advice@natroad.com.au, or on (02) 6295 3000.

“The extra burden it placed on truckies ended up costing mum and dad more at the supermarket.”

The road transport industry is starting to see some progress in trying to attract new blood to our industry. Above award wages, sign-on bonuses, paid training, and the nationally recognised apprenticeship schemes are popping up in job advertisements.

Australia isn’t unique with having driver shortages, there are similar issues across the world. Maybe the time has come where we need to grasp the reality that the old school drivers are a dying breed and that the industry must start to focus more on driver retention.

There is no point enticing new blood into the industry, only to poison them after a short period of time and leave that driver totally disenchanted.

There are still many truck drivers who love this industry and will have diesel in their veins until they die, but will new drivers accept or endure what the industry throws at them?

The wages are one thing, but workplace conditions and expectations by management are another.

Monash University recently conducted a study on driver health and wellbeing, only to conclude the solution lies within management and what we expect of our drivers. The transport industry reform must start at the managerial level.

Expecting drivers to sell their souls to the company just doesn’t cut it with the new breed of driver. Scheduling must take into account the real-world impacts of delays and sleep quality, which has a real impact on fatigue. From what we are witnessing, the new breed of driver is looking for a work/life balance and to have a reasonably predictable schedule.

Expecting drivers to push the boundaries of work diaries, human endurance and to complete work, which is essentially unpaid, is a significant reason to seek work outside of truck driving.

What we have witnessed in Australia, Canada and the US is the focus on fit-forpurpose vehicles and a re-evaluation of remuneration. One company in Canada is now offering name brand vehicles with large sleeper berths like the 84-inch Paccar Driver’s Studio. Wages are based on distance travelled plus non-driving wages such as for on-call time and waiting onsite/detention time.

This company also pays $50 per day for ‘compliance allowance’ and $200 per day for ‘holdover money’, as opposed to zero dollars for this work under the Long Distance Operations (LDO) award

in Australia.

Australia, in general, seems to think that truck drivers will continue to accept ‘if the wheels ain’t turning you ain’t earning model. The modern award for ‘Long Distance Operations’ has been fiercely attacked to ensure long distance truck drivers are not paid like most other modern awards.

The affordability of a proper remuneration when broken down to dollars per kg is a negligible cost.

Truck drivers sitting on loading docks for zero wages breaks down to less than one cent per kg or $300 for 30,000kg load of bananas. One cent a kg is not going to impact anyone … but this industry will vehemently oppose any Fair Work Commission intervention on this and then complain, “there are no good drivers”.

Some companies have claimed the cost of employing a new driver ranges from between $20k to $30k, taking into account training time, loss of productivity and damage to equipment.

Companies have been on this merrygo-round for decades and we have now reached a point where the pool of experienced drivers is dwindling fast. As the freight task grows, the industry needs to act quickly.

The quickest course of action would be to reduce the drivers leaving your business. Quite often they don’t leave the industry, they just go to another workplace.

Where will you be in a few years time? The race is now on to be an “employer of choice”, not one of “last resort”.

Small business and owner-operators are also in a similar position, where the prime contractor is bleeding them to death as well. So, when I say become an “employer of choice”, this also flows on to be a “contractor of choice”. We have all heard the stories – or should I say warnings –about “don’t work for that mob” or “so and so must owe money to every truck owner in the city”.

TREVOR WARNER is an interstate driver along the eastern seaboard with 20 years’ experience. He is the current vice president of the National Road Freighters Association, having been involved with the NRFA for nearly 10 years.

Big business knows the costings down to the last cent where it is very clear that truck owners struggle in this department. If this was not the case, we wouldn’t see freight rates to the level we see now.

When fuel is $1 a km and wages are 65 cents a km, how can you operate when you invoice $1.85per km? That’s how low our rates have gotten.

I priced a potential job recently and the rate on offer was about 66 per cent of what my calculated costs. Somebody out there is doing this work now; somebody out there is slowly going broke and may not even realise it.

If the contractor is also employing drivers to do this work, then I would be surprised if the wages are correct. So the merry-go-round continues.

The larger companies are slowly becoming part of what is known as ‘ESG’. Their business models will now be addressing the impacts in environmental, social and governance.

One would think the ‘social’ part of this business model would include ‘do not exploit your workers or contractors’. Paying workers and contractors as little as what you can get away with surely must fundamentally fail the bit on ‘social’.

Our economy works on consumerism and if the consumers haven’t got the money to spend on your product, then this impact will flow all the way from the consumer through to the primary producer. Everyone in the relevant supply chain will suffer and consequently, society suffers.

Surely being socially responsible must have the primary goal of the prevention of suffering.

Some economists call this ‘Tapeworm Economics’ because eventually the host or source of sustenance (revenues) no longer exists.

However, this isn’t all about drivers’ wages. We understand the risk of running a business must also be priced into the equation. In fact, insurance companies would be the experts on this, as pricing risk is their business.

Freight contracts must be seen as socially responsible – allow all businesses to operate sustainably and must include the pricing of risk. Some may agree that the

pricing of risk could also be known as net profit.

Road transport isn’t going away any time soon, so the industry as a whole must get off life support and back to enjoying a healthy and vibrant supply chain that can attract people who will be proud truck drivers and proud contractors. I am fairly sure 10 cents/kg extra for bananas, potatoes or a box of Coke won’t faze the consumer or supermarket shareholders, but it will make a world of difference for the transport operator to maintain a safe, sustainable and essential road transport operation.

“Somebody out there is slowly going broke and may not even realise it.”

As you will know, the National Heavy Vehicle Regulator (NHVR) took over the enforcement of the Heavy Vehicle National Law (HVNL) in NSW in August. Throughout the transition the NHVR has said it wants to take a more collaborative approach with the industry.

Recently I attended an information evening hosed by the NHVR prosecution department. One of the main messages was a goal to help prevent breaches through education and training. Of course, this doesn’t mean they’re abandoning prosecuting cases through court, but it does mean that they’re open to consider alternatives to court in the right cases.

It’s still early days and we’re all still learning what practical differences it will make having NHVR as the prosecutor. But early signs suggest there might be chances to be a bit more creative with how court prosecutions are resolved.

One of the tools that NHVR is promoting is the use of Enforceable Undertakings. This is a way to have a prosecution discontinued in return for taking steps to prevent future breaches and educate the industry.

The option of an Enforceable Undertaking is available to people or companies who have received a Court

Attendance Notice for an HVNL offence.

The person submits a proposal to NHVR setting out what steps they will take.

NHVR reviews the proposal and decides whether they think it is enough to warrant withdrawing the charge.

Some examples of promises that have been accepted in the past include:

• Retraining all employees with courses from accredited providers

• Implementing Chain of Responsibility policies and procedures

• Providing promotional and educational campaigns to educate other members of the industry

• Donations to not for profits that focus on heavy vehicle transport safety or funding research into transport safety.

The benefits of an Enforceable Undertaking is that the case is discontinued entirely. This means that you can keep a clear record and you avoid the fines imposed by the court.

It’s important to know that Enforceable Undertakings aren’t an easy way out.

The promises need to be substantial.

They often cost more than the fine that a court would likely have imposed for the offence.

However, the investment can be

SARAH MARINOVIC is a principal solicitor at Ainsley Law – a firm dedicated to traffic and heavy vehicle law. She has focused on this expertise for over a decade, having started her career prosecuting for the RMS, and then using that experience as a defence lawyer helping professional drivers and truck owners. For more information email Sarah at sarah@ainsleylaw. com.au or phone 0416 224 601

worthwhile because it will help to avoid future breaches and having to come back to court again where fines are likely to increases substantially. That’s in addition to the benefit of not having the original offence on your record.

We also find that many people are already implementing new training and policies in response to being charged with an offence. If you’re going to take these steps anyway then it can be worth seeking the full benefit by getting the court case discontinued.

It’s also important to understand what will happen if the Enforceable Undertaking is not complied with. Not complying with the undertaking is an offence with a maximum fine of more than $10,000. NHVR can also apply to the court for an order directing the person to comply with the undertaking or cancelling the undertaking. The court can also make orders that the person pay for the cost of the case and the cost of NHVR to monitor that they’re complying with the undertaking in the future. So it’s important to be sure that the promises are achievable.

If you are considering the Enforceable Undertaking option the NHVR website is an excellent starting point. They have published a very helpful Guideline document that explains how to make the application and the criteria. The website also has examples of previous Enforceable Undertakings that give a good idea of what’s involved and the types of promises that may be accepted.

As always, if you have any questions my team at Ainsley Law is always happy to speak with OwnerDriver readers.

“They often cost more than the fine that a court would likely have imposed.”

As of September, OwnerDriver has been around for 30 years. Congratulations to all who have made the publication a success. “Dedicated to the success of the person behind the wheel!” What an admiral determination. For the 30 years I have been contributing, my ambition has been to highlight issues that have played against the wellbeing of those behind the professional wheel. In doing so, my forthright comments have got some offside. Sorry, but where criticism is deserved, it must be brought to the public’s attention.

There is and has been no malice intended – but problems and deficiency of outcome must be addressed. From comments received, it appears that some in bureaucracy have taken exception to my forthright comments. In fairness, I have used a fair bit of sarcasm when raising concerns – sorry.

However, regulations applying to Australian truck drivers are a disgrace – in some cases verging on inhumanity. And the degree of application of these regulations by some enforcement leaves much to be desired from the point of view of enforcement’s morality.

Take the recent issue of the Roe boys, father and son. Dan inadvertently missed ticking the basic fatigue management box in his so-called work diary. That is

an incorrect name for the book. It would be more appropriate to call it a revenue raiser or better still a system for the denigration of this industry.