DAF.COM.AU

DAF.COM.AU

8 ROAD UPDATES

24 KEEPING IT KLEEN

Samantha Ruggeri has gone from dance teacher to expert truck cleaner in the space of a decade

28 FORMING A LEGEND

Inside Michael Bransgrove’s fun owner-driver journey

32 SPECIAL CELEBRATION

VE Group paid tribute to Kenworth in a unique way

44 RISING STAR

Inside the latest funding and safety upgrades for Australian roads

18 TOP OF THE TREE

Warren Aitken hops behind the wheel of the new Volvo 780

Chatting with the NatRoad Young Driver of the Year

62 LOCK IN THOSE SHOW DATES

Find out what’s on for the end of this year

66 GROWING THE NEXT GEN

Goldstar Transport invests in its youth

You don’t need to use a general transport system, courier system or plant hire system to issue your Tipper dockets. It’s not too late to change.

Use TipTraxx - the only system developed for Tippers. TipTraxx allows you issue Tipper Dockets on Job Completion & Manage your Tipper Operations.

Easy & Convenient to Use - designed for Drivers

Allocation System - ongoing or future jobs

Dynamic Pre-Start & Safety Equipment Checklist

Load Tracking - Truck travelling loaded/empty?

Downtime & Wait Time Notification

Capture Signature - Job sign-off, load verification

Record Tolls/Fuel/Speedo

Set Job or Daily Cartage targets

Accommodates Pre-Loads/Split Loads

Attach Load Documents to Dockets

Set Load Rates - Totals Calculated

Accounting system integration

The ONLY paperless docket system developed specifically for TIPPERS

Innovation that puts people first

The UD Quon may be our greatest modern achievement.

From its 2004 introduction with the world’s first ‘Selective Catalytic Reduction System’. To its reinvigoration in 2017, with Euro 6 compliant technology. To today, with the reimagined Enhanced Quon, that continues to break boundaries with greater safety, productivity, comfort and sustainability. We continue to go the Extra Mile to ensure our flagship Quon is better for business, better for people, and better for the planet.

There’s a reason the UD Quon is the truck Australia trusts

Going the Extra Mile

To find out more, contact your UD Trucks dealer on 1300 BUY A UD or visit udtrucks.com/australia

EDITORIAL

Editor Geoff Crockett

E-mail Geoff.Crockett@primecreative.com.au

Journalist Alex Catalano

E-mail Alex.Catalano@primecreative.com.au

Contributors Warren Aitken, Frank Black, Warren Clark, Daniel Woods, Tiarna Condren, Tiane Gavillucci, Rod Hannifey, Michael Kaine

Cartoonist John Allison

PRODUCTION

Art Director Bea Barthelson

Print IVE Print

ADVERTISING

Business Development Manager

Hollie Tinker Ph 0466 466 945

E-mail Hollie.Tinker@primecreative.com.au

SUBSCRIPTIONS

www.ownerdriver.com.au/subscribe

Phone +61 (0)3 9690 8766

Mon-Fri 8am-4.30pm (EST)

Email subscriptions@primecreative.com.au

Mail 379 Docklands Drive, Docklands, VIC 3008 Australia

EXECUTIVE GROUP

CEO John Murphy

COO Christine Clancy

Operations Manager Regina Fellner

Trader Group Sales Director

Asanka Gurusinha

VIC 3008

Telephone: (+61) 03 9690 8766

www.primecreative.com.au

ISSN 1321-6279

OwnerDriver magazine is owned by Prime Creative Media. All material in OwnerDriver is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published.

Opinions expressed in OwnerDriver are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

Proof-reading this month’s edition of OwnerDriver, getting it ready for the printer, the distribution team, and ultimately you, the reader, I was reminded just what this life is all about.

While we all love to read about amazing machinery and marvel at the pictures of the glorious trucks that play their part in the transport industry, the real heroes are the people.

Each month at OwnerDriver we have a dedicated team of columnists who find time in their busy schedules, away from work and family, to share their thoughts or advice with our readers and try their hardest to push the industry a little further down the road to becoming the best it can be.

An industry where people share their knowledge freely, where earning a living doesn’t have to be a race to the bottom. Where safety is a priority. And where fairness reigns supreme, both in the contracts between transporters and their hirers, but also in the policing of the boundaries of behaviour agreed upon by all those participating in the transport game.

It’s these sorts of ideals that Ken Wilkie has championed in OwnerDriver for more than 30 years. While Ken’s battling a few health issues right now, and has hung up the pen, his decades’ long quest continues to offer a guiding light for his friends, fellow columnists, and the OwnerDriver team, and we wish him a speedy return to good health.

Rolling through the feature stories in this edition, it’s a reminder of just how much passion the transport industry inspires.

Warren Aitken’s interview with Samantha Ruggeri, who went from teaching and dancing to helping to lead a family truck washing business in

Western Australia, captures perfectly the power of this community to draw people in and engage their imagination.

And his Truck of the Month tale about VE Group not only offers some stunning photography of a classy Kenworth, but also highlights the power of family, of the willingness to take a risk, and the desire to succeed.

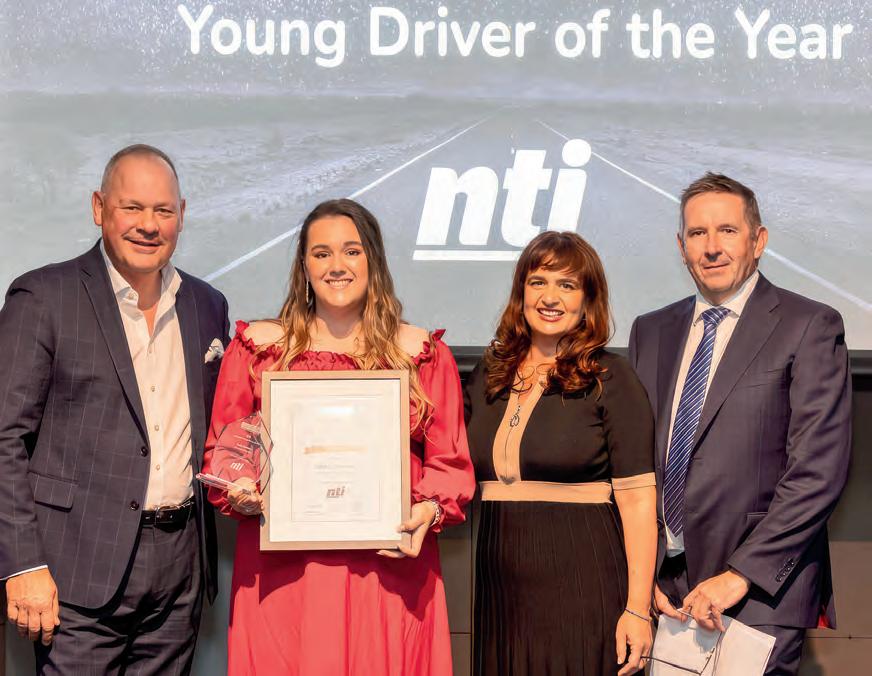

Long time owner driver Michael Bransgrove shares the tale of his classy ride, along with some great tips on how to keep a small transport business alive in today’s world and we celebrate the champions chosen by NatRoad members this year to take home their coveted transport industry awards — including Young Driver of the Year Jade Harney — who started out learning on a forklift and moved on to driving trucks.

There are top tips for staying on top of fatigue management, the latest in lighting technology, and even a review of Volvo’s biggest truck yet, the monster D17 780hp model.

I hope you enjoy this month’s read and would love to hear your stories or ideas for the magazine at geoff.crockett@primecreative.com.au.

Funding and safety upgrades have been rolled out across Australia’s key freight routes over the past month

There’s been significant funding put towards the completion of several major road upgrades across Australia, particularly in New South Wales.

The $700 million Singleton Bypass project is set to get truckies home quicker and safer, with major construction commencing on the long-awaited connection in New South Wales.

The project will deliver Singleton’s biggest infrastructure project to date, with plans to remove one of the Hunter region’s most notorious bottlenecks and around 15,000 vehicles from the Singleton CBD daily.

NSW minister for Hunter Yasmin Catley says this project will make travel safer, faster, and more efficient for all road users.

“Starting construction on the bypass is one of the ways the NSW government is delivering top-quality services to regional areas, making sure that our communities have access to the best infrastructure possible,” she says.

“There’s never been a better time to live in the Hunter. With this new bypass, we’re connecting people across NSW and getting people from A to B quicker and safer than ever before.”

Motorists will avoid five sets of traffic lights and benefit from improved road safety and reduced travel times.

Six bridges will also be built including four across the Hunter River floodplain as well as a northbound climbing lane, allowing heavy vehicles to climb the hill without slowing other traffic, between Gowrie Gates and the northern connection.

West of Sydney near Orange, a section of the Mitchell Highway has been re-opened for public use, following the completion of works to widen the highway near the intersection with Pretty Plains Road.

A dedicated left turn lane off the highway into Pretty Plains Road was also installed.

“This is a very busy intersection on the Mitchell Highway and Bathurst and Orange, and for years motorists have been asking for something to be done to make it safer for all road users,” says Transport for NSW Regional Director West Alistair Lunn.

“The problem has always been that motorists wanting to turn from the highway into Pretty Plains Road have had to rapidly decelerate from 100 km/h, running the risk of vehicles behind them not reacting quickly enough and creating further hazards.”

likely to see the biggest benefits.

“The trial is a win-win for our city and our freight industry,” Minister for Roads and Road Safety Melissa Horne says.

“By taking livestock trucks off inner-city streets and into the tunnels we’re improving road safety while also keeping our freight sector moving.”

The Queensland Department of Transport and Main Roads (TMR) has

work is done reinstating the bridge to a safe condition.

The department will continue monitoring, assessing and reviewing the roads in the region while encouraging operators to drive through the region.

SAFETY WORKS IN SA

Meanwhile in South Australia, the state government has allocated

“By taking livestock trucks off inner-city streets and into the tunnels we’re improving road safety while also keeping our freight sector moving.”

A 12-month trial will commence in Melbourne in 2025 to remove livestock trucks from some of the city’s busiest streets.

The Victorian government is partnering with Transurban and the freight industry to allow the heavy vehicles to enter Citylink tunnels.

Livestock trucks had previously been banned from the Burnley and Domain tunnels due to low-clearance infrastructure, but recent upgrades to raise it to a safe height mean the trucks can enter the tunnels with no risk to animals on-board.

The trial is expected to remove 600 trucks from city streets each week, with City Road, Power Street, Olympic Boulevard and Hoddle Street

announced that heavy vehicles can now travel through Developmental Road.

The Springton Creek Bridge along Developmental Road in central Queensland was originally closed in June due to an ongoing grassfire, with heavy vehicle restrictions now changed on a temporary side-track around the bridge.

All vehicles operating under OSOM guidelines and permits are now allowed to travel on the side-track centreline at a maximum speed of 10kph, gaining access through the region and onto Developmental Road.

The Queensland TMR department says conditions may change in the event of wet weather, with the side-track to remain in place until

$10 million over four years to undertake safety treatments on key regional roads across the state.

Southern Ports Highway and Southend Access Road junction, Spencer Highway (Wallaroo to Moonta), Flinders Highway (south of Wangary to the junction of Western Approach Road), Goolwa Road (Mount Compass to Goolwa) and Gorge Road (Amber Gully to Corkscrew Road) will all be beneficiaries of the funding.

The $10 million investment is part of the state government’s larger $98 million road safety package, which is one of three being delivered under a combined $346.1 million partnership with the federal government.

Royans Transmech based in Wingfield, is one of Australia’s leading manufacturers of car carriers. Supplying some of the industry’s most soughtafter vehicle transporters ranging from four car carriers through to fourteen car RTV2 Road Train configurations.

Transmech provides customers with the complete customised package from design, engineering, manufacture, trailer servicing and repairs. Additional capabilities also extend to other specialised transportation equipment, including specialist rig moving equipment for the mining industry.

Regulations setting mass limits under the Heavy Vehicle National Law (HVNL) have been amended to allow Australia’s heavy vehicles to meet the latest international standards, according to federal transport minister Catherine King.

From November 1, 2024, general access mass limits will increase by

500kg for trucks in Australia that comply with Euro VI or equivalent noxious emissions standards.

“This will improve safety and emissions reduction outcomes in our heavy vehicle fleet and follows the government’s recent announcement of tighter noxious emissions standards for new

trucks and buses,” King says.

“The increase in heavy vehicle mass limits is an important step towards improving productivity and safety in the heavy vehicle sector, while reducing emissions.”

It follows the government’s recent announcement of the introduction of tighter noxious emissions standards for new trucks and buses, which must also be met from November 1, 2024.

The mass limit amendments have been made under the HVNL, which is based in Queensland and adopted by participating states and territories.

The Euro VI standards will be phased into effect across the 12 months following the commencement in November.

King said that new emissions standards for new trucks and buses will reduce a significant pollutant in Australia when the new standards were first announced.

“These new standards will improve air quality and health

outcomes and bring safer and more efficient trucks into Australia,” she said.

“We are committed to continuing to work with industry and state and territory governments to ensure the smooth introduction of these standards.

“Australia has been lagging in our vehicle noxious emissions standards for years now, and this move will help bring our vehicle market into the 21st century — and into line with overseas vehicle markets.”

Euro 6 standards have already been in place in the European Union and United Kingdom for years, and equivalent standards also apply in most developed countries, including the United States and Japan.

Introducing Euro 6 will mean manufacturers must add the advanced safety and fuel-saving technologies to Australian models that other countries already have – notwithstanding the leadership of many manufacturers who have brought compliant powertrains and safety technologies to market.

• CLIPLOCK features a TWO-STAGE locking mechanism. The industry standard and the Optional innovative GP LOCKING CLIP & LOCKING GROOVE (PATENT PENDING).

• Prevents incomplete coupling connections of Trailer Airline Couplings.

• A dangling Locking Clip will alert the driver that the Coupling Connection may not be securely connected. Ensures positive and secure connection of the Trailer Airline Couplings.

Industry association NatRoad recognised excellence in the transport industry on the last day of its annual conference on September 13, crowning the winners of its three major awards.

It says these awards “highlight the dedication, professionalism, and commitment of individuals who have set new standards of excellence in road transport”.

The Professional Driver of the Year was won by James Ellison of Ditton Bulk Haulage, recognising his impeccable safety record and dedication to mentoring and uplifting those around him.

“James has been driving over 200,000 kilometres annually without a single incident to date,” NatRoad says.

“His professionalism and

willingness to mentor his colleagues have set a high standard in the industry.”

PowerTorque editor Tim Giles was awarded the Ted Pickering Memorial Award, recognising his 50-year career in the trucking industry both on the road in Europe and Australia, and more recently in journalism.

NatRoad recognised Tim’s “dedication to informing and uplifting the industry, as well as his ongoing passion for technology and preparing the industry for the future”.

Jade Harney from Followmont Transport was awarded the Sam Sali National Young Driver of the Year, named in honour of the late industry veteran.

“Earning multiple licenses and certifications at just 24 years old,

Jade’s dedication to safety and proactive approach to problem-solving have made her a standout in the i ndustry,” NatRoad says.

NatRoad CEO Warren Clark congratulated all the winners from the night.

“These awards reflect the hard work and passion of individuals who have excelled in their roles and gone above and beyond to have a significant positive impact on the

broader industry,” he says.

“This year’s award winners have all made outstanding contributions to the sector. They have truly set the standard in our industry and exemplify the kind of commitment, professionalism, and passion that drives the road transport sector forward.”

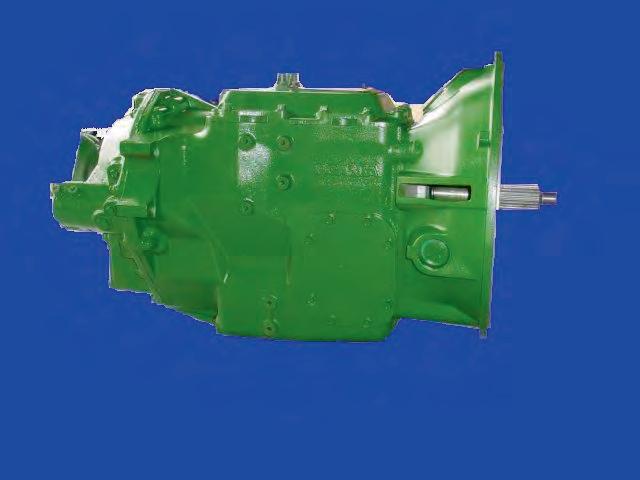

Specialists in CAT and Cummins Engines also carrying parts for all American Truck Brands and Road Ranger Gearboxes. Rebuilt and Second Hand Options Available. Warranty with all second hand and rebuilt engines.

CAT C-15 Rebuild (6NZ or 9NZ Prefix) $48,000 + GST exchange on Special Until EOFY or While Stocks Last. (Block Work, Pistons/Sleeves, Cyl Head, Injectors, Turbo, Camshaft, Rocker Gear, Water Pump, Oil Pump). 12 Months Parts Warranty, 6 Months Return to Base Labour. 550 HP Spec.

CAT C13 Engine (KCB Prefix) $25,000 + GST exchange. Second hand engine with 600,000km on it. Runs good with good oil pressure. 60 Days Return to Base Warranty. 470 HP Spec.

CAT C15 Acert Engine (NXS Prefix) $26,000 + GST exchange. Second hand engine. Has had a bearing roll (mains and big ends). 60 Days Return to Base Warranty. 550 HP Spec.

Cummins Signature Gen 2 Rebuilt Engine $48,000 + GST exchange on Special until EOFY or Stocks Last. Block Work, Pistons & Sleeves, Cylinder Head, Turbo, Camshafts, Injectors, Water Pump, Oil Pump all done. 12 Months Parts Warranty and 6 Months Labour.

Cummins ISX 475 Engine Second Hand Engine. $22,000 + GST exchange on Special Until EOFY. Good Oil Pressure, Ran Good. 60 Days Return to Base Warranty.

Cummins Signature Gen 2 Second Hand Engine

$25,000 + GST exchange. Good Oil Pressure, Ran Good. 60 Days Return to Base Warranty.

Cummins ISX Signature EGR Engine. $52,000 + GST Exchange on special until EOFY or Stocks Last. Blockwork, Pistons & Sleeves, Cylinder Head, Turbo, Camshafts, Water Pump, Oil Pump.

Road Ranger Gearboxes Reconditioned and Second Hand. All genuine Eaton Parts in reconditioned boxes. Various models available including 16718B, 16918B, 18918B, 20918B, 22918B. Call for pricing and availability of your preference.

While there is a clear need for a freight hub in Melbourne’s west, another project hasn’t been able to get off the ground

Locals of the Little River area have made their voices heard in opposition to a proposed freight hub that was supposed to commence construction soon.

Located west of Melbourne, in the growing Wyndham region, the freight hub was proposed as a logistics precinct, led by rail freight operator Pacific National.

It was to be a mixed-mode facility, incorporating both rail and road freight to unlock what is becoming a transport and logistics hotspot in Melbourne.

But after the response from the Little River community, raising concerns over the environmental impact of increased freight activity in the region, Pacific National has confirmed it will withdraw from the project.

“Pacific National has commenced notifying relevant statutory authorities and decisionmakers of its decision to withdraw its environmental referrals and applications for planning and environmental approvals for the Little River Logistics Precinct Project,” it said in a statement.

“All work on the Environment Effects Statement (EES), including technical investigations and technical design for the project, will shortly cease.

“Pacific National has made this decision given the changed timelines for associated freight and infrastructure projects and economic factors which have impacted on the project business case.

“Pacific National will continue to consider potential alternative terminal site options as they emerge to support efficient freight transport connectivity.

“Thank you to the many stakeholders, project partners and community members who engaged with the project team to discuss the project and have their say.”

The Wyndham City Council had previously rejected the proposal from Pacific National for the removal of vegetation in the area to start the process of laying out the foundation for the freight hub.

Permits had been voted down by the councillors by a vote of eight to three.

The Victorian government had also made them aware that the Minister for Planning decided in December last year that an environment effects statement (EES) was needed for the Little River Logistics Precinct project to proceed.

“In February 2024, Wyndham City Council considered two applications for vegetation removal — one to allow for archaeological excavations and the other for geotechnical assessments — as part of preconstruction works at the 500ha site on Old Melbourne Road, Little River,” a Wyndham City spokesperson told OwnerDriver.

“Both applications were refused.

“The permit to remove native vegetation for the purposes of geotechnical testing was refused on the grounds that the proposal did not sufficiently minimise the impacts of the removal of the native vegetation and land and water degradation within the site.”

As a part of the technical studies informing the initial proposal, Pacific National had identified a number of key reasons for a hub to be built in the area.

It can considered that rail freight needed to be able to easily access the regions west of Port Melbourne, supported by road freight.

The precinct would have accommodated a rail freight terminal, internal rail sidings and access roads, maintenance facilities and warehouses, and aimed to support more than 3,600 ongoing jobs at capacity.

A Victorian government backed-freight hub project was also scrapped earlier this year in favour of a federal project north of Melbourne’s CBD.

There’s some good news for truckies on the quest

Six new projects have been announced under the Heavy Vehicle Rest Area (HVRA) project, just days after confirmation the project’s Steering Committee of industry professionals had been extended to 2025 to continue to inform the initiative.

The more than $6.85 million committed to the six new projects has been funded through the third tranche of the HVRA, with $5.48 million of the latest round of funding being provided by the federal government while the remainder will come from state, territory and local governments.

Overall, the value of the HVRA is $140 million over 10 years. The newly funded projects, which include the construction of new rest areas with facilities including toilets, resurfacing, line-marking and bitumen sealing are:

• Wollondilly Shire Council –Ted ‘Greendog’ Steven’s truck parking bay renewal (NSW).

• Walcha Council – New Pindari Tops rest area on Thunderbolts Way (NSW).

• Bourke Shire Council – new heavy vehicle rest area on the Bourke to Milparinka Road at Goonary (NSW).

• Shire of Mukinbudin –Mukinbudin heavy vehicle rest area (WA).

• Shire of Coolgardie – Asphalt surfacing of road train/truck stop area at intersection of Bayley Street/Great Eastern Highway and Ladyloch Road in Coolgardie (WA).

• Northern Territory – five heavy vehicle rest areas on Buntine Highway to be upgraded.

HVRA Steering Committee Chair, Senator Glenn Sterle, says the upgrades will continue to improve road safety and outcomes for Australia’s truckies.

“These projects are another example of the federal government’s Heavy Vehicle Rest Area initiative boosting heavy vehicle user safety and productivity through new and upgraded rest areas,” Sterle says.

“We are steadfast in our commitment to keeping our freight operators and communities safe.

“These new and upgraded rest stops will help drivers reduce

Roughly $11.5 million will upgrade a critical stretch of the rural NSW route

The New South Wales government has announced that it is investing $11.5 million into upgrading a six kilometre stretch of the Oxley Highway, approximately 50km west of Gunnedah.

Works got underway on Monday, September 16, with crews working to widen and rehabilitate the pavement, widen nine culverts and seal the 6km stretch of road. Changed traffic conditions,

including single lane closures and lowered speed limits to 40kmh, will apply while works are underway.

“This pavement improvement work will deliver a stronger and more resilient road surface, safer turning at the Oxley Highway intersection with Goolhi Road and reduced ongoing maintenance costs,” NSW transport and roads minister Jenny Aitchison says.

“These improvements will benefit all road users, including drivers of heavy vehicles who regularly use this route hauling freight across NSW.

“Crews were relocated from this job in 2021 to provide support to the urgent flood repair work required at various locations across the state.

“Rehabilitating the road surface to make it more resilient will reduce the need for ongoing pavement maintenance and improve the experience for road users, as well as reducing

truckie fatigue as they work hard keeping our country moving.”

Federal assistant minister for regional development, Senator Anthony Chisholm, says the $5.48 million federal investment is part of the government’s commitments towards achieving zero deaths on Australian roads by 2050.

“By investing in much-needed rest stops, we will ensure that truckies spend less time on the roads and get home safely to their loved ones,” Chisholm says.

“I would like to thank the HVRA Steering Committee for their work in identifying these strategic projects, which are essential for the safety of all road users.”

disruptions due to roadworks.”

Works will take approximately eight months, taking place on weekdays between 7am and 6pm, and on Saturdays between 8am and 1pm.

“In recent years, the Oxley Highway has proven to be particularly prone to floods. This work will help improve the road’s ability to resist future flood events and remain open,” member for Barwon Roy Butler says.

“As I have often said, it is important not just to rebuild roads after natural disasters, but also to build them back better than they were. This work will continue the process of making our regional road network safer and less likely to be cut off during heavy rains.”

NSW Labor spokesperson for Barwon Stephen Lawrence says regional NSW makes up a third of the NSW population, but two thirds of deaths on the state’s roads happen in the country.

“This investment will improve safety on the Oxley Highway and will work towards achieving the goal of ensuring everyone gets home safely every time to their loved ones,” Lawrence says.

Tickford Racing trusts Castrol fluids in its supercars and transporters. When performance matters, trust Castrol in your trucks.

25 Main Roads WA inspectors will now use a NHVR app to carry out heavy vehicle intercepts throughout the state

The National Heavy Vehicle Regulator (NHVR) has announced that Main Roads Western Australia’s 25 transport inspectors will now carry real-time heavy vehicle analytics on site that use national technology.

This means that heavy vehicle inspections in the state will connect with the national enforcement database through the NHVR’s Regulatory Compliance Mobility Solution (RCMS) app.

The app allows Main Roads WA to target high risk offenders by giving inspectors access to a central database with driver and vehicle information so that they can administer digital notices during a heavy vehicle intercept.

WA transport minister Rita Saffioti says the RCMS WA app will help improve road safety across the state.

“We know the majority of the heavy vehicle industry are safe and compliant and it’s only a small cohort of high-risk operators and drivers that put themselves and the community at risk,” Saffioti says.

“By leveraging heavy vehicle

“We know the majority of the heavy vehicle industry are safe and compliant and it’s only a small cohort of high-risk operators and drivers that put themselves and the community at risk.”

compliance and enforcement data, Main Roads WA can target recidivist offenders to keep road users safe and prevent damage to the state’s infrastructure.”

NHVR CEO Sal Petroccitto says the app provides a single central system that stores and analyses compliance and enforcement data in real time.

“Camera sightings from over 115 fixed cameras across Australia alerts RCMS users if an approaching heavy vehicle is unregistered, has current defect notices, compliance breaches or recently failed to enter an inspection station,” Petroccitto says.

“The NHVR and Main Roads WA are addressing key safety risks quickly and accurately to deliver an efficient and borderless regulatory approach.”

The NHVR first introduced the RCMS app in Victoria in October 2020 before expanding it to the ACT, South Australia and Tasmania in June 2021, with NSW receiving the app in August 2022.

The app is also now live in Queensland following the state’s transition of heavy vehicle regulatory services to the NHVR in April this year.

Main Roads Western Australia chief operating officer Des Snook says the RCMS will transform its

approach to roadside inspections, with the end-to-end technology removing the need for paper-based forms.

“We expect a 60 per cent reduction in the time spent per heavy vehicle intercept,” he says.

“This targeted enforcement approach rewards safe operators with quick roadside intercepts, as our transport inspectors prioritise unsafe drivers, operators and vehicles.

“We can now collaborate with the NHVR in real time and be alerted to unsafe, high-risk operators travelling between WA and the eastern states, and vice versa.”

Volvo Trucks recently unveiled its new D17 780hp model, boasting a larger internal combustion engine that provides extra grunt. Warren Aitken hopped behind the wheel to discover the power that comes with Volvo’s latest addition

reckon the best way to start off this commentary on my recent experience with the new Volvo D17 780hp is to share part of one of the many interactions I had with Matt Wood, Public Relations and Media Manager for Volvo Group Australia. This conversation took part with Matt in the passenger seat while I was behind the wheel, pulling out onto Geraldton Mt Magnet Road in the 780hp Volvo with a Western Australian C-train in tow.

“Have you actually put anything in these trailers mate?” I said.

“Yeah, 106.8 tonnes,” Matt replied.

“You’re telling me I’m pulling 106 tonnes behind me?”

“106.8.”

“I call BS, no way.”

“I loaded it myself mate. Bang on 106.8 tonnes.”

That’s where I’ll cut the chat off, for the next couple of comments contained multiple expletives as I accused Volvo’s Media Manager of waxing lyrical and pulling the old weekend fisherman’s trick of ‘I swear it was this big bro’. However, when you put yourself in my shoes, I had just flown 4500km across

the country to test drive Volvo’s latest evolutionary engine. I was being told by a PR professional that it was 106.8 tonnes, yet under my feet I had a road train pulling up the highway feeling quieter, smoother and less hindered than my car with a heavily packed lunchbox. How could I not question the validity?

It turns out that Matt was right — it was 106.8 tonnes and Volvo’s new D17 engine, with 3800nm of torque, was eating it up like Patrick Bertoletti at Nathan’s Famous Hot Dog Eating Contest.

I had been invited over to Geraldton, Western Australia to be impressed, and it took all of about three minutes on the road for that task to be achieved. The rest of the ride out to Mt Magnet was used to solidify my first impressions of this top torque engine and quiz Volvo guru Matt on exactly what was impressing me under the floorboards.

Be warned, 95 per cent of this writeup on Volvo’s latest iteration of the popular FH line is going to be under the drivers’ feet rather than what was wrapped around me. The test truck I had my happy hands on was the newest version of the long

“The moment you put your foot down, the truck gets into the job. Peak range is from 950-1450rpm and the smarter-than-me G-series I-shift does a fantastic job of working the torque curve.”

running Volvo workhorse, but very little has changed. According to Matt, there are several aerodynamic adjustments added for efficiency, however those were hidden by the far less aerodynamic cowcatcher bolted to the front. Inside the Volvo I found all the creature comforts that have made this series of truck so popular — ergonomics aimed at drivers who appreciate comfort, practicality and a bass booming stereo system.

All of the stuff that you take for granted with the Swedish truck maker was on hand and in action. What I went to experience was their new D17 engine and G-series I-shift transmission — a product designed with the future in mind. As many are aware, at the start of 2025, Australia will have a whole lot of new safety and compliance requirements rolling into law. One at the top of the food chain is the necessity for new heavy vehicles to meet the Euro 6 standards.

Volvo has had a Euro 5 and a Euro 6 version of its 16-litre engine available for quite some time and it could’ve quite happily rested on its laurels. However, as Matt explains, it’s just not in the brand’s DNA.

“The motivation behind the 17-litre and 780 is all about sustainability and efficiency,” he says.

“Volvo has made the D17 engine ‘slipperier’, with less friction and drag. It’s more powerful and has a lower drag transmission, which means better economy and efficiency.”

The D17 continues Volvo’s strive for market leading efficiency and world leading technology.

When you look at the stats for the new D17, it is pretty impressive. It features the same crank and block as the previous D16, however the white coats in the Volvo engineering laboratory have made some major changes. The extra displacement comes from a 5mm larger cylinder bore diameter and the added efficiency comes from the low friction cylinder liners, the Volvo patented wave-top pistons and the new fuel injector design. Couple all of that with the updated G-series I-shift and you have a winning formula.

Another big difference between the Euro 6 D16 engine and the Euro 6 D17 is the turbo system. The D16 came equipped with a twin turbo system and found its sweet spot in the 500-600hp market. Although there are several 700hp variants working the tough gigs over here, we never got to see the big 750hp that some countries got, mainly because of the truck breaking conditions we have here in the land of hot and heavy loads. The new D17, however, is fitted with a whole new VGT Turbocharger system, which means it is more than capable of handling the toughest of Australian conditions, with the biggest loads we can throw at it. It also means we finally get to appreciate the biggest torque output the big Swedish scientists

can pack into a 17-litre internal combustion engine.

As I mentioned before, the D17 tops out at 780hp and 3800Nm of torque. You can also get the D17 at 600hp and 700hp, putting out 3000Nm and 3400Nm respectively. It is definitely the torque numbers that deserve all the attention because that is what you can feel when you get behind the wheel of the big 780 Volvo. The moment you put your foot down, the truck gets into the job. Peak range is from 950-1450rpm and the smarter-than-me G-series I-shift does a fantastic job of working the torque curve. You can feel the I-shift changing gears, but in the same way an old school trucker would change gears, doing it smoothly and timed perfectly so there is no break in momentum. It’s almost therapeutic. If you want to take a bit more control or let the big motor rev out a bit more, you still have that option available, but truth be told, the Volvo doesn’t really need any gear changing tips.

The Volvo 780 will garner a lot of attention for the fact it’s made it to the highest horsepower number to date. While being able to wave that Everest size flag is important, for the drivers and for the owners there are going to be two very different

For the owners it will be about the numbers, specifically the fuel numbers. It is a bigger, more powerful engine than Volvo has had before, but the technology and efficiency inside it has been designed to make the latest Volvos even more fuel efficient than we’ve seen before. Obviously, I can’t quote numbers, as every application is going to be different, but across the board, the D17 is delivering on its design goal of improving fuel efficiency and that’s the important thing for owners and companies.

For the driver’s litmus test, the verdict all comes back to chasing that hot damn hill feeling. That feeling of having a fully laden truck dropping gears as it reaches the pinnacle of whatever legendary jump up you travel, watching the revs drop down and down, waiting to feel another gear, and then noticing that instead of dropping, the engine has just dug in, holding on and hooking into the hill like it’s stolen your lunch and you’re not letting go. There is something in that feeling that all drivers know and the 3800Nm of torque oozing from the new 780hp Volvo will ensure you get that feeling on every hill you hit. 106.8 tonnes. I believe it now, colour me impressed.

The ability to access the Fair Work Commission thanks to recent transport law reforms presents an unprecedented opportunity to set fairer standards

There are over 500,000 transport workers in Australia. But we are all intrinsically and deeply connected to the transport industry. When lives are lost on our roads, they affect countless families and communities. This year and every year we have lost far too many from truckrelated crashes — 140 just in 2024, 35 of them truck drivers.

Recently transport reform laws came into effect that will allow us to improve this industry for all participants. Not only that, it will allow us to save lives. That’s pretty big. It’s so big that to mark the occasion we had guests in Sydney from international transport unions, coordinated by the International Transport Workers Federation which represents over 18 million transport workers — guests from across Europe, Africa and Asia. It’s not just a huge moment for Australian transport, it’s a big global moment.

Other countries are looking on, and last year 67 other unions around the world signed up to a global campaign to secure similar systems. For decades we’ve talked about what these laws would mean to this industry. Now it’s time to use them to actually start fixing things. We’re wasting no time.

Two days after new transport laws came into effect, we made our first applications to the Fair Work Commission to begin making road transport a better industry. These have been informed by discussions with industry over the last few months after we won the laws.

The applications are in three areas — three areas that require critical action.

The first is unfair terms in trucking contracts. We need to ensure that maximum 30-day payment terms are standard, and get rid of terms that force transport operators to dangerously cut costs in their operations.

We’ve seen scores of transport businesses go under because of unsustainable contracts — even leaders in their industry, like Scott’s Refrigerated Logistics last year. Drivers and operators shouldn’t have to wait months just to be paid. This application will seek to lift some of

those critical pressures on workers and operators.

The second is food delivery, where the standards are not just rock-bottom, they’re non-existent. We need to stop the horrific exploitation of gig workers and we need to make sure it doesn’t spread by raising standards to a decent level.

On the day we made the applications we were joined with gig workers like Rosalina, who’d come to the Fair Work Commission seven years previously trying to get justice, and being turned away. Gig workers until now have been excluded entirely from the workplace system, and that needs to change.

The third is the last mile sector, which is exploding in Australia, but with entrants like Amazon Flex, standards are plummeting.

Amazon recently announced it was recruiting hundreds of seasonal workers, “no experience required.”

We’ve seen how it will recruit drivers with their own cars, dangerously overloaded, rushing to fulfill a set amount of orders. If they don’t complete them in the allotted time frame, supposedly they can bring the undelivered parcels back to the depot—but in doing so risk being deactivated.

twu@twu.com.au

This model is a threat to couriers, to owner drivers, to transport operators, to the Amazon Flex workers themselves. We need to ensure drivers can access fair cost recovery, dispute resolution and consultation. This will stop the Amazon effect that is crushing this sector of the industry.

Rome wasn’t built in a day, and after decades of neglect, there’s a lot of work to do.

The applications we’ve made using the new laws are just the beginning — an immediate safety net to stop the dangerous downward spiral, while we work on more involved issues with the rest of the industry. So how will we achieve all this?

This is where industry consultation, the heart of the system, comes in.

There are three main parts to this. First there’s the Expert Panel which will establish and maintain standards.

Second, this will be guided by the Road Transport Advisory Group.

Recently Richard Olsen, TWU NSW Secretary, and Peter Anderson, ARTIO National Secretary, were appointed to that group. Both have decades of experience in the transport industry.

The third part are subcommittees which can be formed of other industry stakeholders, so that those who will be affected will have a say.

It’s industry unity that got us here and it is industry unity that will allow us to start reshaping road transport with this powerful tool.

The brilliance of this system is its ability to overcome threats to that unity in the likes of Amazon and Aldi who refuse to get on board.

Aldi is the only major supermarket that hasn’t signed a charter with the TWU on supply chain safety. Aldi and Amazon continue to stick their heads in the sand. But we’ll carry on with or without them, because we’ve already shown that when we join together as an industry there is nothing that can stand in our way.

When it comes to fully automatic transmissions, Allison Transmission is the choice of the transport industry. Fleet owners and operators understand that in terms of reliability, productivity and ease of operation, no-one comes close. What’s more, our national distribution and dealer network is here to provide all the support and maintenance you’ll need. That’s why Allison is Australia’s number one choice for fully automatic transmissions in medium duty and light heavy duty truck sales.

Just a decade ago, Samantha Ruggeri was a dance teacher studying for a diploma. Now, she’s the queen of the Kleening Zone in WA, where she helped keep Warren Aitken’s big rig shiny

This month’s ‘Woman in Trucking’ feature is going to be focused away from the driver’s seat, as our central character doesn’t even hold a heavy vehicle license, yet. However, she plays a pivotal role in an area very dear to the heart of most truck drivers — the ‘looking sharp and shiny’ arena.

I am focusing on Samantha Ruggeri, a young lady who, up until 10 years ago, admitted she had no idea what the bonneted and cabover terminology meant in reference to truck and wasn’t able to point out an A-double Mack unit or know what a Kenworth road train was. Growing

up, Sam’s expertise lay in teaching and dancing, a far cry from the dirt and detailing that now encompasses her life. However, before Sam hit her 20s, she got introduced to the world of trucks and transport and the addiction took hold. Ten years later, she is eying up the idea of getting her license while running one of Perth’s busiest truck washing operations and being a Zen-like master of all things soap. She is the go-to lady when it comes to making a showpiece shine.

In order to introduce the lovely Samantha Ruggeri into this tale, I need to set the scene a little. I had just arrived in Perth, having driven from Brisbane. The first 90 per cent of the 4500km trip had been great weather, meaning I retained the shiny wheels and pristinely polished paint and had only the inconvenience of surfeit of suicidal bugs to contend with. That’s fine, I had my bottle of Bowden’s Bugger Off and Jax Wax Body shine, so I had been able to keep my truck looking pretty damn good. However, the final 10 per cent of the trip involved rain, inappropriately located rain, to be exact. By that I mean it only rained around the same sections of road that the big WA quad tippers all entered the highway from their stockpiles

and quarries, leaving kilometres of dirt, which turned into kilometres of dirty brown road spray. This resulted in my road train looking like it had spent a week bush bashing in the Pilbara. I did not have enough micro-fibres to rescue the shine hidden under a layer of WA dirt, so while I was waiting to reload in Perth, I popped into the Kleening Zone and booked the big rig in for a little TLC, which is where I met Sam.

What convinced me to sit Sam down and learn a little more about her was when I discovered she wasn’t just the smiley face that answers the phones and books the trucks in. She was the person that created the deep dive questionnaire you need to pass just to get a booking, a questionnaire that rivals any onsite induction course. It’s a questionnaire that shows how committed to cleanliness the Kleening Zone team are, and it reflects the depth to which Sam’s passion for the transport industry has hit.

Sam is a truck washing guru. What started as a parttime job has now become a Certificate in Shine for the young lady running one of Perth’s largest and busiest truck washes. She is also someone that, up until a decade ago, was teaching a classroom of five-year-olds how to

Above: Sam credits her dad with a lot of her accomplishments, particularly her work ethic and her addiction to ensuring the highest quality service possible. She grew up watching her dad work round the clock and with utmost professionalism, now she carries the same standards as she oversees the family business.

“I definitely have my favourite trucks now, but most of all, with doing a lot of the cleaning, I really appreciate how important the trucks are to the drivers and how it’s our role to ensure we clean them with the care they need.”

dance while gaining her teaching diploma. Now she has been bitten by the transport bug and has become the sovereign supreme of soap.

“I started working here about 10 years ago,” Sam says.

By ‘here’ she is referring to the business her father bought around 2009 in ‘The Kleening Zone’.

“I was only here part-time to start — I had another part-time job and was at uni, so I would just work doing the invoices. I wasn’t even helping with the booking because I didn’t know one thing about trucks.”

While Sam may not have had a deep background in transport, one thing she had picked up from her dad Jamie was a very strong work ethic. The part-time element of her job quickly became all-encompassing and soon enough her passion for the transport industry saw the idea of becoming a teacher shelved as Sam ended up full-time at The Kleening Zone.

“I started taking on more and more responsibilities,” she says.

“Dad was teaching me and introducing me to all the different trucking configurations, as well as a lot of the drivers that came in. They were great — they’d get me out to show me the setups and types of truck they drive. At the start I didn’t even realise there were different makes of trucks.”

It wasn’t just managing the business that appealed to Sam.

“I really love getting out and cleaning — even now when I am running everything in here, I will still get out and help the team to clean as often as I can,” Sam says.

“Back at the start I had someone teach me how to wash a truck. From starting at the top, to ensuring the truck stayed wet and had nothing baked onto it, to which parts you could use brushes and which parts you had to use sponges on, I really began to appreciate the importance of what we do, and I am thankful for those lessons.”

Sam credits a lot of the regular customers for fanning the flames of her trucking passion.

“I definitely have my favourite trucks now, but most of all, with doing a lot of the cleaning, I really appreciate how important the trucks are to the drivers and how it’s our role to ensure we clean them with the care they need.”

It’s that level of attention and comprehension that saw Sam throw herself into the seriousness of her role.

“I have become extremely well informed about soaps,” she says.

“I have investigated a lot of different soaps, working out which ones work best in our conditions, which ones work best on the red dirt trucks, all that sort of stuff. There’s a lot more to it than just ‘a truck wash’. When I’m booking the trucks in, I ask a lot of questions, finding out where the trucks have come from and what they cart is important. I like to know if there’s particular areas of the trucks that need attention so I can factor that into the schedule, finding out if they want a wax as well. All that sort of stuff is important.”

While Sam’s love for the transport industry has evolved as her years behind the gurney have compounded, her pre-

existing skills have continued to flourish in her new role. Ingenuity and personal management are two skills that have played a huge role in the success of both herself and the family business.

“Co-ordinating the books and timing the bookings I find second nature now,” Sam says, a task made easier by actually knowing the different combinations.

“I also know which staff members work better together and in what areas, so I know I can put certain ones together and they’ll push out a particular truck in a certain time. We have a great crew working for us and they make it easier.”

It’s not just soap and staff that Sam has mastered in her new role.

“I also have a huge whiteboard of ideas I am slowly convincing my dad to implement,” she says.

Those ideas are seeping through, such as the idea for the movable gantries that Sam designed, and her dad and brother built.

“I wanted something that would make it easier for our team to clean safer and more efficiently. I came up with a design, and dad can build anything, so he and my brother just knocked them up for me.”

Adding a wash and wax option to the truck wash services was also well received by Kleening Zone clients as an extra level of protection for the recently shined up rigs. Another outside the box idea was lining the interior shed with white panelling, the premise being that not only would it tidy up the wash bays and make it easier to clean, but it would also add more light to the sides of vehicles, ensuring less missed spots and a better overall job done.

Sam’s formative years may not have included any thoughts of getting into the transport industry, however it is now a major part of her life and indeed her future.

“I think the transport game is a great place, especially for female workers. People have an idea of what ‘the transport industry’ is like but I have found it great. It can be a really big family, once you are in there are so many people that are keen to teach you and help you,” Sam says.

Sam also points out that in her line of work she is not

Top: Sam’s original motivation for the family-built gantries may have been influenced by her diminutive size, but they make life easier for all the team, allowing for easy access to the harder to reach areas of the trucks

Above: Managing and helping her staff is a huge part of Sam’s role, the fact she understands the roles they have makes it easier to problem solve and keep the system working effectively

Opposite: Sam’s familiar smile is a welcome greeting to all those coming in for a bit of a tidy up in Perth’s Kleening Zone truck wash. Take note of the huge stack of micro fibres drying behind Sam, the tools of the trade are on high was rotation; It’s not all office work for Sam, she enjoys being able to get out and help the Kleening Zone team to get the trucks shined up

the only female keen to pick up the sponges and tyre shine

“We’ve had a few females working here and they were great. The guys are also great when it comes to working alongside them,” she says.

“There are areas that just need a bit more elbow grease and the guys will pitch in and help on those spots, it’s teamwork. It isn’t easy work, but it doesn’t matter if you are male or female, you get the job done.”

I shall wrap up my homage to truck washers by once again just trumpeting the fantastic appeal and diversity of our industry and the opportunities for ‘Woman in Trucking’ to get in and master every aspect. Samantha is a shining example of the alure of our industry. At 20 years old, a truck was just an annoying moving roadblock getting in her way on the journey home. Now, a decade later, she is looking to add a heavy vehicle license to her repertoire. And as for those moving roadblocks, now Sam can’t travel anywhere without noticing and admiring them, albeit with a critiquing view. Welcome to the club Sam.

Owner-driver Michael Bransgrove has taken the lessons of the past forward when it comes to his own journey as Alex Catalano found out

Being able to confidently and securely own a truck can be a challenging experience in the current trucking landscape — just ask owner-driver Michael Bransgrove. He’s been in the game for as long as he could sit behind the wheel, getting his first taste of driving with his father, also an owner-driver.

“I didn’t have a lot of hope!” he tells OwnerDriver.

“I spent a lot of weekends growing up washing dad’s truck, greasing it. It was pretty much inevitable that I ended up in it.”

Michael’s first job was in his dad’s truck, carting paper and bricks from their native Gippsland to Melbourne and back.

One became two as he got more involved in the business, with the pair driving Scanias on shorter local journeys most of the time.

As work expanded, Michael found himself driving interstate, going as far as Newcastle in a truck that was only meant for local work at most.

“I did that for about 17 years. Dad ended up with about half a dozen trucks across that time,” he says.

“The Scanias weren’t quite right for driving interstate though. The bed wasn’t big enough and they were underpowered.

“We got into Freightliners after that, which dad had a few of over the years. They were a lot better to live in than the Scanias with their set up.

“It was hard on the family though, you sacrifice a lot being away at that time when your kids are growing up.”

With more considerations to make for the family, Michael dialled it back to local work for the last 18 months of working with his dad. As many ownerdrivers would know, when work comes calling, it can be hard to refuse.

“We ended up with another job which I said to dad, ‘you should get a new truck for this one’,” he says.

“He was pretty convinced he’d bought his last truck,

and suggested I buy my own. That’s pretty much how I got into owner-driving, with help from him.

“I don’t know how anyone starts off as an owner-driver these days without help from someone. I’ve been working for myself now for 12 or 13 years.”

While it was a daunting task to take the next step into being a fully solo owner-driver, Michael was taking plenty of lessons learned from the start of his career into it.

Making the leap

Following in his father’s footsteps, Michael went out and bought his first truck – a brand-new Freightliner Argosy.

After enjoying the Freightliners he’d been driving previously, it was a no-brainer. He says a number of factors came into account, as he had to look closely at the reliability and productivity of his truck.

Any downtime or potential loss of revenue would be a killer, as he had discovered from his dad’s work.

“The Argosy came with extended warranty on the motor and driveline,” Michael says.

“That gave me peace of mind, I didn’t have too many concerns. I knew the costs were going to be covered by it.

“The biggest thing I noticed that was different going out on my own was that concern of costing.

“When you’re working for someone and something’s gone wrong, the motor’s blown up or I’ve done a diff, your only concern is how you’re going to get home. When it’s your truck, you’re thinking how am I going to pay for this?”

Michael managed to stay mostly in Victoria across his time in the Argosy, about 600,000km in total, but still did some interstate work.

He stuck with Freightliner for his next purchase, jumping behind the wheel of a Coronado next, which he had for four and a half years.

That was when his love of customising trucks really started to come out. It’s another benefit of being an owner, Michael says, being able to change and shape your truck to your heart’s content.

“I like to customise trucks, and I went to town on the Coronado,” he laughs.

“I really enjoyed it. It was a nice truck to live in, drove well and was comfortable.

“Dad was normally pretty good when I wanted to customise his trucks, but sometimes I could see him looking sideways thinking ‘what’s going on here’!”

Michael’s most recent purchase, and his current truck, is a Kenworth T900 Legend – the stuff of dreams.

Beautifully painted and finished in a combination of black, tan and brown, it’s certainly a sight to behold, both on the road and off it.

He bought it in 2017 and has already put a cool 1.2 million kilometres on the odometer.

There’s almost a childlike wonder in Michael’s voice when he speaks about the Legend — it goes to show his passion not only for the job, but the truck itself.

“We did all the customising on it at home in about 30 days and then sent it away to get painted,” he says.

“That’s one of the main reasons I’m an owner-driver. I could make more money and have a different lifestyle doing something else, but I love the machinery.

“If I could keep my truck sit in the shed and not have to work it, I’d do it every day of the week. I just love the trucks.”

Words of wisdom

With now more than a decade of experience as an owner-driver under his belt, Michael has taken plenty of learnings out of his career on the road.

One of the things that he’s strived for is a ‘point of difference’ — particularly important when you’re competing for contracts constantly as a part of the job.

“You have to be doing something different from everyone else,” Michael says.

“If you want to buy a truck and cart 24 tonnes and make a reasonable living, it’s not going to happen. You have to be proactive and find the most productivity out of your truck.

“I specced my truck up really light so I can get a 29-ton payload. I went down a different path, doing investigations on diff ratios to try and save on fuel.

“Every .1 of litre of fuel you save can save you $700 or $800 a month. These are the little things.”

As much as being an owner-driver can be hard, lonely work, Michael says building business relationships in areas you may not be as proficient in is vital.

“It’s easy to work hard and make no money.

“You do a lot of hours, doing maintenance and bookwork along with the driving. You want to put as many things going in your favour.

“It’s important if you’re not proficient in certain areas that you get help with it, whether it be insurance, maintenance or the business side.”

Adding to that, being familiar both with your customers, both their products and business, as well as your own responsibilities on the road, will go a long way.

“One of the biggest problems is the chain of responsibility,” Michael says.

“The responsibility on you as an owner is quite extreme. You have to take the risk into account. You need to be making more out of that, in case something does happen. You’re the front line.

“A lot of people get into the truck without realising that, and then it’s too late if something does happen.

“As an owner-driver you have to realise the customer is king. Not necessarily your contractor, but where your product is going. It’s important to understand their business, their product and how they’re using it and how you can make them happy.

“I remember dad going through tough times as an ownerdriver, and he always depended on whether he had good work or bad work. It’s all about relationships.”

October’s big in the trucking world for an abundance of truck shows, it’s also home to Halloween, but what about the music world?

Here are some notable events and anniversaries related to Australian rock music history that took place in the month of October: from The Australian Truck Radio Rock’ N Roll Diary!

OCTOBER 1

1980: INXS released their self-titled debut album INXS. This marked the beginning of the band’s rise to international stardom, blending new wave and rock sounds that would become iconic in the 1980s.

OCTOBER 4

1976: AC/DC released their album Dirty Deeds Done Dirt Cheap internationally (though it had been released earlier in Australia in 1976). This album became one of their classic records, featuring the title track as a signature anthem.

OCTOBER 6

1997: Silverchair released their second studio album Freak Show, which solidified their position as leading figures in the post-grunge scene. The album debuted at No. 1 in Australia.

OCTOBER 8

1987: Midnight Oil released their influential album Diesel and Dust in the U.S. This album featured their massive hit “Beds Are Burning,” which raised awareness about Indigenous rights and environmental issues in Australia.

OCTOBER 13

1986: Divinyls released their album What a Life!. It included the popular single “Pleasure and Pain,” showcasing lead singer Chrissy Amphlett’s raw vocals and the band’s unique mix of rock and pop.

OCTOBER 18

1975: Skyhooks released their second album Ego is Not a Dirty Word, which topped the Australian charts and became an essential part of the Australian glam rock scene in the 1970s.

OCTOBER 19

1973: AC/DC played their first gig in Sydney at the Chequers Nightclub. This performance was a crucial moment in the band’s early years, eventually leading to their iconic status in rock music worldwide.

OCTOBER 23

1990: Cold Chisel reformed for a brief tour after their initial breakup in 1983. Their reunion, known as the “Last Stand Tour,” reignited interest in their music, particularly songs like “Khe Sanh” and “Flame Trees.”

OCTOBER 30

1984: Hoodoo Gurus released their debut album Stoneage Romeos. This album gained critical acclaim for its energetic mix of garage rock and new wave, influencing many Australian bands that followed.

“AC/DC played their first gig in Sydney at the Chequers Nightclub”

SIMON SMITH is the manager and producer of Australian Truck Radio. He has been in the radio game for 44 years and has been customising playlists for truckies for at least 20 of those. For great tunes 24 hours a day, 7 days a week, download the digital app for your phone at www. australiantruckradio. com.au

1981: Men at Work released their debut album Business as Usual in Australia. The album would later top the charts globally, fuelled by hits like “Down Under” and “Who Can It Be Now?” It became one of the best-selling Australian albums of all time.

October 28, 1956: Jimmy BarnesScottish-born Australian rock singer, known for his work with Cold Chisel and a successful solo career.

October 16, 1953: Peter Garrett - Lead singer of Midnight Oil and former Australian politician.

October 27, 1959: Andrew Farriss (born October 27, 1959) - member of INXS, key songwriter and multiinstrumentalist for the band.

ABOVE RIGHT: Get on board with Australian Truck Radio

BELOW: Celebrate the great musical milestones of October

These events highlight the influence of Australian rock on both the local and international stages, particularly with bands like AC/DC, INXS, and Midnight Oil shaping global music trends. October is full of anniversaries that mark key moments in the Australian rock evolution that powers Australian Truck Radio 24/7 around the Nation.

An Australian operator recently paid tribute to Kenworth’s centenary celebrations with a unique configuration. While checking out the truck, Warren Aitken soon found that the family company at the helm of the vehicle has its own intriguing story

Heads or tails? That’s the 2000-word question today. The reason I am fl ipping a metaphorical, and behind the scenes, literal, coin is because what started out as a single lane story quickly diverged into a two-lane tale. Allow me to explain before I fl ip the coin.

I was recently asked by Rocklea Truck Electrical to track down Nathan Howell from VE Group in order to snap some photos of the Kenworth 100-year anniversary truck – a model that Rocklea Truck Electrical had a hand in creating. Having personally seen one of the American 100-year releases myself, I had several questions. Like what? Ah? Are you serious? And of course, when can I shoot it?

The idea of an Australian 100-year tribute truck instantly triggered my ‘I need to make a

story out of these’ senses. The single lane story I was aiming for would focus on Kenworth’s century long history, the special 2023 releases over in America and exactly how there is an Australian built truck waving the Kenworth 100-year flag.

The second lane of my story manifested itself when I met Nathan Howell and his wonderful wife Bronwen. This humble couple have built one of Australia’s leading earthmoving and civil construction companies, all while holding onto the work ethic and country culture that’s entrenched in their small-town roots. The story was meant to be purely about the truck, but then I met the force behind the machine and suddenly I have two avenues to cover. Do we start with the mechanical or start with the familial? Let’s flip.

prying into the lives of Nathan Howell, his wife Bronwen and the VE Group.

“I grew up around trucks, my dad had a truck and pig trailer with a loader doing local work for the council – their industrial lot was adjacent to the Moura Wheat Board which was also a hype of transport activity,” Nathan says.

Tails it is, and that means we get to start by

“Moura Bulk Grain & General Haulage was owned by my uncle and aunty, Tony and Marlene Seccombe. They lived next to mum and dad’s depot, which, in years to come, became our own Moura depot. Next door to that was Absolon Transport.

“Absolon had a few R-model Macks, and it was big gear back in those days – I was just truck mad. If I wasn’t sitting beside dad in the truck, I was sitting beside my uncle Butch or next door helping uncle Tony or up in Absolon’s yard, I was always doing something truck related.”

Listening to Nathan recall his childhood in the small Queensland town of Moura brought out the jealous side of me – no internet, no Wi-Fi and probably only three channels on the TV you never used, but an outdoor playground that consisted of trucks, trucks and more trucks. It really was inevitable that decades later Nathan would find himself working under the shadow of a gluttony of gorgeous trucks and life size tonka toys.

“Dad also had yellow gear as well,” Nathan says, referring to the distinct CAT yellow earthmoving gear.

“My passion shifted to include that stuff. Because us kids didn’t have any licenses, we would just use his little digger to mix dirt for Dad or dig sand out, stuff like that so dad could go deliver it.”

Through Nathan’s school years, the distinct lack of earthmoving and transport activities in the government set curriculum meant Nathan’s attention was often focused more on the school bell and getting home to undertake some manual labour. This meant that once Nathan was old enough, he said goodbye to school lunches and hello to a country apprenticeship.

“I went and worked in Absolon’s shed, completing a lot of general maintenance such as re-bearing trailers and doing brake linings the old school way with having to do the rivets manually – we didn’t get to just buy them off the shelf like you can today,” Nathan says.

It wasn’t your standard official apprenticeship that many get. Instead, it was the country apprenticeship that has nourished so many of this country’s greatest bush mechanics.

Seeing as Nathan was still in his late teens when he left school, he had the skills and desire to drive trucks and earthmoving equipment. However, that good old-fashioned issue of ‘not legally old enough’ kept rearing its head. That period of waiting was filled in for Nathan by getting some work on a local farm, then moving into work in a local Moura engineering workshop that would lead to work with an earthmoving outfit where Nathan found himself out west building dams and doing property work, ‘bush ticketed’ of course.

“I never actually thought about having my own business back then,” Nathan says.

“I was wanting to get officially ticketed and get into the coal mines, which I did. I was about 20 when I got a job in the mines and was there operating the big excavators and such. I moved up the chain, supervising people, running a crew. After a few years I remember coming home to Bron one night saying, ‘this isn’t for me, I think I want to start our own business’.”

Bronwen Howell, or Bron as she will be referred to, is Nathan’s wife and mother to the couple’s three children. Nathan and Bron have been a couple and team since they first met way back in high school.

“Behind every successful business is a successful team,” Nathan says, adding in that without Bron, none of what the couple has achieved would’ve been possible. Bron is a story on her own with her amazing charity work on top of the day-to-day VE Group work she takes care of. She also recently picked up the prestigious 2023 Queensland Trucking Association (QTA) Trucking Woman of the Year award.

Hence back in 2006 when Nathan finished his night shift and sat down with his wife to tell her he wanted to start his own business with her. Bron was right there to assist. That business would eventually become VE Group and began with a small little skid steer loader –no truck, no transporter, just the skid steer. With a laugh, Nathan recalls the company’s humble beginnings.

“I had a mate building Cavalier Homes and he couldn’t get anyone to do his pads, so I bought a little skid steer and I’d park it at home,” Nathan says.

“On my days off, and sometimes after night shifts, I’d just order the product from the quarries to site, then drive the little skid steer

around town to the site, do the job and drive it home. Eventually some plumbers wanted work done, which needed a little digger, so I bought my first truck in an Ex-K&S 4864 Western Star. I took the sleeper off it and bought an old Shephards bin off Croydons in Sarina, had it brought down and fitted at Shephard Transport Equipment in Brisbane.

“I then got a single axle tag trailer to haul the digger around on. As that work picked up, I was finding I’d have reliability issues with getting the product to do the jobs I had, so I bought another truck and dog tipper combo, a full tipping setup. It just kept growing from there.” Now we jump ahead a little to the VE Group story. The trajectory that VE Group took was the picture-perfect representation of ‘hard work pays off’. That first truck became two, then four and, with positive word of mouth growing, the company kept expanding and taking on more and more jobs. The company’s workload shifted from council jobs in small town Moura to large scale projects in the greater Queensland area. Next thing, the VE Group started undertaking more work interstate, with Nathan and Bron

“I was just truck mad. If I wasn’t sitting beside dad in the truck, I was sitting beside my uncle Butch or next door helping uncle Tony or up in Absolon’s yard, I was always doing something truck related.”

currently setting up a new head office in Brisbane.

“But we’ve found if you say family culture then people don’t want to call each other out and have some of those hard conversations that need to be had sometimes.”

Having the ability to undertake tough business conversations, and fostering an environment that cultivates and encourages them, means you are held to a higher standard and thus the work you produce is of a higher standard. It is an aspect of life that has paid dividends for the company.

Above, L to R: Another exclusive American addition is the dash mounted badging; Straight out of America, Kenworth Australia managed to also get Nathan the custom bedding set that came with each of the America special releases.

The reason I am not using all my words to track the course that VE Group took to get from a single skid steer to their current collection of around 60 trucks, a similar number of trailers and almost as many pieces of yellow gear is because I want to focus on the couple and the culture at VE Group. It will segue perfectly into the second half of this story where we shine the light on the big 909 on the pages before you.

Spending time with Nathan and Bronwen, the one thing you do pick up is the old-school, small-town values that are the essence of many grassroot companies. It’s not just about hard work, honesty and loyalty, although those three attributes are extremely important, it’s also about building relationships and treating everyone, from suppliers to staff and customers to contractors, with respect.

“We don’t label ourselves a family business, even though we are,” Nathan says.

One particular example of this is the very low staff turnover within the company. It is a very competitive job market out there and, in order to hold onto your staff, you need a culture that people want to be part of, which VE Group prides itself on.

“Our core values are integrity, endurance and relationships,” Nathan says.

“We want to build a culture that people want to be part of. To make something like that, you just have to go that extra mile.”

While practicing those values is important to VE Group, finding reciprocal values in the people VE Group deal with is also vitally important and that is what brings us to the second lane of our two-lane story today in Kenworth.

“My first truck was a Western Star and it did us well. When we started buying more trucks, we tried another manufacturer and we just had such a bad run. It almost sent us broke, to be honest,” Nathan says.

When you choose Ryco, you’re not just buying a part. You’re buying round-the-clock technical support, market-leading innovation, and unparalleled filtration expertise. Ryco’s Commercial Filter Range includes oil, fuel, air, coolant, crankcase, cabin air, AdBlue urea filters, transmission and Service Kits for a large range of popular North American, European and Japanese Trucks. So when your customers need superior protection, be Ryco Ready.

“Then we got onto Kenworth and the product just spoke for itself. The support throughout the Brown and Hurley Network is awesome, the resale value is there and we haven’t had any issues.”

The VE Group truck role call sees the everpopular T610 model as a favourite for the truck and dog tipper combinations. When it comes to the away work and the float work, that’s when Nathan starts rolling out the bigger gear, with several T659s in the fleet and, of course, the favourite child of the Kenworth family in the Aussie-built T909. All of this leads us towards our star pupil for today.

LANE TWO

In 2023, when Nathan first went looking for a new truck to add to his expanding fleet, he chose to add another T909 to the stable. However, this time he wanted to try and do

something a little different. He wanted to shine a light on a brand that has been the backbone of his company for many years by celebrating and acknowledging the 100-year anniversary of Kenworth.

Australia has been a card-carrying Kenworth country since 1960, when George Blomfield and Ed Cameron imported the first Kenworths from the United States. A decade later, the huge Bayswater plant in Victoria was built and, in 1971, the first Australian-built truck, a K125CR, rolled off the production line. That was the origins of Kenworth in Australia, but the American trucking icon had a history nearly 50 years older than our first locally built ‘Grey Ghost’.

Kenworth Motor Company was incorporated in 1923, with the name coming from the two guys that owned the company, Harry Kent and Edgar Worthington. Hence the original Kenworth logo was just a round badge, with Kenworth written through the middle and a K and W above and below to represent the company’s founders. The two men were aiming to build trucks tough enough to help out the local loggers who were struggling to get the felled trees up the slippery winding mountain track.

Since its beginnings, Kenworth has become a household name, both within the transport circus and the general Joe public. In 2023 it celebrated its 100-year anniversary by offering a limited release of 900 commemorative W900L and T680 tractor units. Now 900 may seem far from ‘limited release’, but keep in mind Kenworth sold nearly 40,000 class 8 trucks in 2023, so 900 is very limited in that scale. These

limited editions came with special badging, numbering, interiors and a few other goodies.

‘Why didn’t we get them over here?’ you ask.

‘We’re Kenworth fans, what about us?’. To start with, the T680s would laugh at our width laws, and the W900L would positively crack up at our length laws.