18 minute read

Final Mile

Isuzu has brought additional factory dual controlled solutions to market.

ACQUIRED WASTE

With a view to boosting its presence in the vital refuse and recycling KERBside collection sector, Isuzu has launched a raft of dual-control models it hopes will clean up in this segment ofthe industry.

Waste collection and processing never has and never will be the golden-haired child among the various essential services industries upon which developed societies depend. When problems arise, as they have recently with changes in the international landscape and the muchpublicised failings of significant local providers in the waste and recycling space, it grabs our attention quickly. According to official government figures, in 2014-15 Australia produced around 64 million tonnes of waste, which is equivalent to 2.7 tonnes of waste per capita. This is roughly inline with population growth at an average increase of 1.2 per cent per year, but it nonetheless presents the enduring challenge of continuing to refine our waste mitigation and processing operations. For its part, Isuzu Australia Limited (IAL) – Australia’s overall truck market leader for the past 31 years straight – understands that the waste industry is particularly demanding at every step of the process, and none more so than at the first step – kerbside collection. With this in mind, the company has stepped up to the plate to offer what it believes the market is demanding – low tare weight dual control trucks with gross vehicle mass (GVM) ratings ranging from 12 to 24 tonnes in a variety of wheelbase lengths. The existing dual-rated (available in 12 and 14 tonne GVM guises) FSR dual control model has now been joined by the FVD 165-300 with a 16.5 tonne

GVM, along with the FVY 240-300 and FVZ 240-300, both sporting 24 tonne GVMs. The latter two can also be ordered with two distinct wheelbase lengths. The FSR features robust Isuzu axles, multi-leaf rear suspension, ABS equipped drum brakes, an Allison 2500 Series automatic transmission and ISRI 6860 air suspended seats on both sides, complete with integrated belts. Stepping up, the FVD and FVY incorporate Hendrickson HAS 230 airbag rear suspension – a feature Isuzu claims gives these units a tare weight advantage over competitor units. Meanwhile, the FVZ uses Isuzu’s bulletproof six-rod and trunnion axle location with taper-leaf rear suspension that’s said to offer excellent axle articulation over uneven ground conditions often present at waste processing facilities. The FVD, FVZ and FVY all feature Meritor tandem drives, with the latter two sporting the heavy-duty MT44-144 unit which includes driver-controlled inter-axle lock and cross locks on both axles. Braking is by way of Meritor Q-Plus S-cam drums with ABS on all axles. The FVD is fitted with an Allison 3000 Series while the heavier two sport Allison’s 3500 Series automatic. Powering each of the variants is Isuzu’s venerable 6HK1 six-cylinder engine that in FSR guise produces 191kW at 2,400rpm and 761Nm of torque between 1,450 and 2,400rpm. The three larger trucks share ratings of 221kW at 2,400rpm and 981Nm at 1,450rpm. Commenting on the new dual control models, IAL National Sales Manager, Les Spaltman, said the factory developed range has been carefully designed for Australian conditions and considerations. “We are extremely pleased to be able to bring additional factory dual control solutions to market,” he says. “Many would be aware of the discontinuation of some of the more traditional go-to

trucks in this sector. In response, we have a highly competitive, low tare weight solution on offer – one which ticks some key boxes for Australian operators.” Speaking of boxes – steering boxes, that is – common features across all Isuzu dual control models include high precision cross shafts linking both leftand right-hand steering columns to provide a consistent driving experience from both sides. For ease of operation, the instrument panel has been duplicated on the left-hand side and both sides feature pneumatic adjustment of the steering wheel enabling complete driver customisation and control. The design also retains standard wiring harnesses with the additional harnesses incorporated on a ‘plug and play’ basis. Fresh safety elements include interlocks for control change overs, safety yellow grab handles and steps, along with a right-hand side driver’s airbag and automatic cornering lamps for urban laneway safety. “What we’ve worked really hard to develop with these new models is a compelling total cost of ownership argument for Isuzu,” Les says. “Lower tare weights bring improved productivity and payload and when you add the commonality of parts we’ve developed with our F Series range, the equation really adds up in favour of our customers.” The trucks have been designed specifically for Australian conditions and industry need according to Isuzu, which has incorporated proven efficiencies across its engines, drivelines, chassis componentry, wheelbase options and in-cab appointments, with the aim of making the dual-control line-up extremely competitive on a number of fronts. “We know that when it comes to the waste and refuse industry, reliability, economy and durability are non-negotiables,” Les says. “We believe these new models have these qualities in spades.”

BRAKE CLEAN

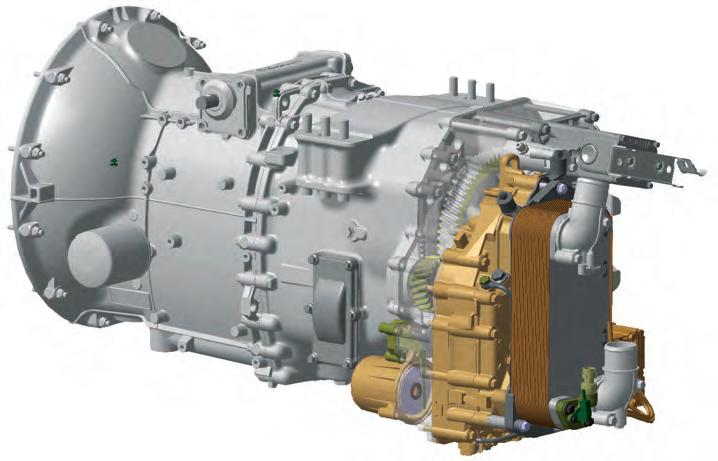

The Retarder is a hydraulic auxiliary braking system that has been fitted as standard to practically every Scania truck equipped with Opticruise automated gearchanging since the early 1990s. It provides a significant amount of retardation, which not only lengthens the working life of brake pads but ensures that the service brakes remain cold and in peak conditions for use in an emergency, even when descending the steepest of hills. By not regularly overheating the discs on downhill runs, rotor life is also increased. In fact, the Scania Retarder is so powerful it outperforms a traditional exhaust brake by delivering up to three times the power. A further benefit is that with such fadefree and reliable braking performance available, trucks are able to descend steep hills at higher speeds, where safe, to enhance journey times. The latest generation of Scania retarders puts a maximum braking torque of up to 4100 Nm into the driver’s right hand, via the five-stage stepped-travel lever attached For Scania, driving down operating costs for Australian transport and logistics companies, remains a matter of precedence and the Scania Retarder is considered one of the secrets to the ongoing success of the pioneering Swedish truck manufacturer.

to the steering column cowling. By simply pulling the lever back towards the driver through the five steps offering increasing retardation, the truck is able to be decelerated smoothly and safely or when integrated with the Downhill Speed Control, held at a constant safe speed all the way to the flat. “The Scania Retarder is easy to use, extremely efficient and a valuable safety feature,” says Benjamin Nye, Scania Australia’s Product Manager, Trucks. “Once our customers have been introduced to the correct way to use the system and benefit from it, they are quickly converted. The Retarder is the driver’s best friend in everyday driving as well as in emergency conditions. It can be activated either by use of the lever on the steering column, or when in ‘auto’ mode, by a light touch of the brake pedal. It couldn’t be simpler.” By being integrated with the transmission, it means that the system can trigger downshifts to make the most of the available engine braking as possible. “The Scania Retarder is one of the most frequently used and appreciated technical features on a Scania truck. Once drivers have become familiar with the Retarder, they will not switch back to a truck that does not have one,” Ben explains. “It very quickly becomes an indispensable tool assisting them to drive safely and efficiently whether it is in stop-start traffic at generally low speeds or driving interstate at freeway speeds.” In service, the Retarder preserves brake linings like no other system. Customers regularly marvel at the lack of wear of their brake pads, with 800,000 km common and one customer, NAD Transport, based in Melbourne, achieving more than 1.25 million km on a set of brake linings fitted to an R 560 V8 prime mover, and they are still going strong. “The Scania Retarder is capable of dealing with 90 percent of all braking on long haul work, so it substantially increases the service life of the wheel brakes,” says Tomas Selling, a control system

The Retarder can generate a braking force up to 500 KW on the propeller shaft.

development engineer at Scania. The saved costs of downtime, materials and work for changing the linings and brake pads on a tractor and semi-trailer mean that a Scania Retarder is a very costeffective feature for companies focused on their total operating economy. “The Scania Retarder distributes the braking power in a vehicle to as many different systems as possible, keeping the brake pads as cool as possible. In an emergency, the pads can then deliver as much braking as possible,” Tomas says. The Scania Retarder is integrated into the output end of the truck’s gearbox and uses high-pressure oil as a braking medium. Via a gear transmission, the Retarder acts on the output shaft of the gearbox and thus directly on the propeller shaft. Once the Retarder is applied, it generates a braking force on the propeller shaft of up to 500 kW, depending on the propeller shaft speed and the applied braking torque. Depending on the position of the automatic exhaust brake switch, the automatic exhaust brake is also activated with increasing brake power to achieve the highest possible retardation. “Reducing fuel consumption” says Örjan Åslund, who is responsible for Product Affairs at Scania Trucks in Sweden, “is Scania’s main priority,”

MORE THAN A CENTURY OF TRANSPORT INNOVATION

In the 30 years since establishing its brand here, ZF has played a major part in the development and introduction of innovative technologies.

Sachs shock absorbers.

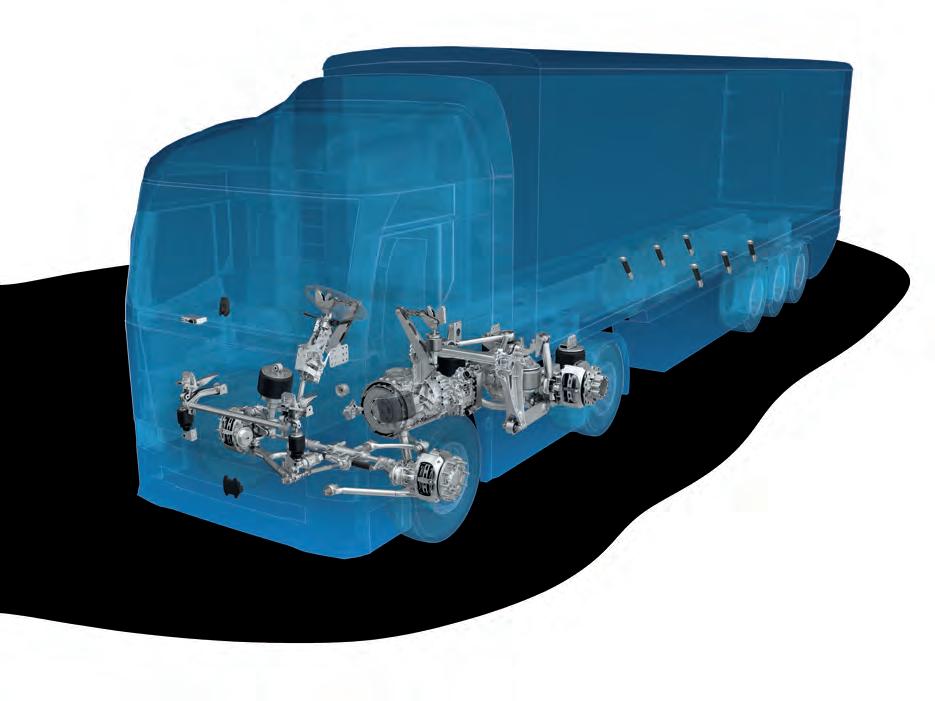

Australia’s road transport industry has long been an early adopter of technology to enhance the efficiency, reliability and safety of its fleet operations. Such forward thinking has real-world measurable benefits right across the industry, for all road users. For the last three decades global German technology specialist, ZF, has been a leader in the Australian market. But the company can trace its roots significantly longer than that, to the original airship building business known as the Zeppelin Foundation (ZF) of 1908 and the official founding of the company as a vehicle transmission gear manufacturer in 1915. One hundred and five years later, ZF is now one of the world’s leading automotive technology companies, providing original equipment and aftermarket componetry to the car, truck, bus, aircraft, marine, mining and rail sectors. Its innovative approach manifests itself in the product performance of its varied heavy vehicle original equipment and

aftermarket componentry. It’s also reflected in the easy accessibility of part information available to fleet operators and repairers, either via the ZF website and its online part finder, or by the free-to-download ZF Part Finder app, available via app stores. Users simply need to set Australia as the default country, and the ZF Part Finder app will allow them to search for components by various means from the part number to the vehicle’s VIN or vehicle manufacturer. ZF has rich aftermarket legacy. From its Lemförder, Sachs and TRW brands, ZF offers shock absorbers, steering and suspension componentry and clutches, all developed to maximise service life and minimise downtime. The Lemförder brand has long been considered one of the market leaders in suspension and steering technology for commercial vehicles, with a comprehensive range of products and spare parts. The chassis and steering spare parts range includes torque rods, v-links and 4-point links, stabiliser rods and repair kits, as well as drag links and tie rods, angle joints and ball joints. Through its Sachs brand, ZF offers replacement shocks and dampers, as well as clutches and clutch components. All Sachs components are manufactured to OE standards and designed to both maximise the efficiency in power delivery and durability. From TRW, ZF has available a comprehensive range of steering and suspension products, including linkages and steering gear systems, with flexible fitments to suit the wide range of heavy vehicles operating in the Australian market. A global leader in spare parts and components, all TRW branded commercial vehicle parts are tested in the laboratory, on the track and on the road to ensure that in the real world they work first time, every time.

ZF offers a range of clutch componentry.

ZF. For parts you can trust.

Innovative solution. OE quality. German technology.

With a comprehensive range of products for commercial vehicles, our reliable product brands LEMFÖRDER, SACHS and TRW represent the best quality and dependable service. Visit aftermarket.zf.com/au

Telematics Unit Shock Absorbers

Brake Components

Clutch Components

Steering and Suspension Components

For enquiries on any of our brands and products:

1800 93 72537

Drive Axle

Transmissions

SHINE SHOE

Weather events can arrive suddenly with little warning in Australia where drivers are no stranger to the heightened experience of flash floods, dust storms, cyclonic rainfall and extremes of heat. Having top quality, certified brake systems like those made by TRP Truck and Trailer parts, provides confidence for the end-user for whom safest practice is not only best practice, but a non-negotiable. Inferior linings on brake shoes can result in premature wear and ruinous overheating to which brake fading, costly repairs and damage to brake components are the hidden costs of poor quality. With its range of products all independently tested to meet and exceed internationally recognised standards, TRP partners with some of the world’s largest and most respected brake manufacturers to ensure it has a quality and safe product. TRP offers a comprehensive range of aftermarket solutions including brake shoe and S Cam hardware parts to suit truck and trailer applications. But it doesn’t end there. The company has an expansive portfolio that also encompasses air systems, brake hardware and hardware kits, disc brake pads and disc brake rotors. Backed by a 12-month unlimited kilometre warranty against manufacturing defects, TRP brake shoes have been specifically designed to remain stable throughout a wide operating temperature, provide safe and secure heavy vehicle braking and stand up against any aftermarket brake shoe when it comes to quality, durability and performance. With brake shoes available in either standard (21K Gross Axle Weight Rating) or premium (23K GAWR) and manufactured to OE specifications, TRP brake shoes are all independently tested to Federal Motor Vehicle Safety Standard 121 or FMVSS 121. The main difference between a standard and premium brake shoe according to Marcus Dunn, PACCAR Parts Senior Product Manager is the lining formula and application. “As a rule of thumb, most on-highway truck and trailer applications can use a standard lining, whilst more heavy duty linehaul and vocational applications such as construction, refuse and heavy-haul should use a premium lining,” he says. TRP brake shoes, where applicable, are also certified to ECE R90, reportedly making it the only supplier of brake shoes to be awarded with both standards. As Australian vehicle standards only cover the fully dressed axle it’s vital that TRP conducts its own independent testing. “FMVSS 121 and ECE R90 certifications are both globally recognised and we are very proud of the performance on both the standard and premium linings,” he says. “There are a lot of brake shoes in the market that are inferior quality and drivers should really consider such testing when weighting up aftermarket brake products for their truck or trailer. I would encourage all drivers to ask their service departments if the brake shoes have been independently tested.” As a rotor must have what is called sufficient heat dissipation characteristics to pass the set test requirements this is achieved through the FMVSS 121. As linings get hotter, more force from the air chamber is needed to create enough friction in order to stop. The test results confirm TRP linings are able to maintain sufficient friction as the temperature of the lining increases while creating sufficient friction through all of the air chamber pressure ranges in the test parameters in FMVSS 121 certification under retardation force evaluation. Moreover, tests in which TRP was put alongside the OEM equivalent to see how the TRP brake shoe lining compared yielded interesting results, explains Marcus. “The testing showed that the TRP lining performed very similar to the OEM across each of the three tests. When you compare the recovery performance on the premium lining you can see that the TRP shoe is comparable to the OEM performance on PSI recovery and even stays cooler than the OEM during the recovery period,” he says. “A cooler lining means less fade and better braking performance. The test results prove that the TRP lining is comparable to OEM performance and can stand up against any aftermarket shoe.” Drivers who are unsure which lining type to use should speak to their local service department to help identify the best lining for the respective application. All TRP products come with a 12-month hassle-free warranty and are available at four dedicated TRP stores and across 53 PACCAR Parts dealerships nationwide. To see how TRP brake shoes performed in the tests, visit the website: www.trpparts.com.au/range Rigorously tested to the highest industry standards, TRP Parts is committed to delivering to market warranty-backed brake systems for all makes of trucks and trailers.

STANDARD TRP LINING 21K

The TRP Standard brake shoe linings are designed to remain stable throughout wide operating temperatures and provide safe and secure heavy vehicle braking. TRP Standard lining is ideally suited for truck and trailer medium-duty, on-highway and dry freight applications. TRP Standard 21K linings can be easily identified by the green edge coloured lining.

PREMIUM TRP LINING 23K

The TRP Premium brake shoe linings have been developed for original equipment/first fit applications on heavy vehicle brakes. The material, with its medium to high friction coefficient, has excellent density and heat stability and is ideal for heavy duty line-haul and vocational applications such as construction, refuse and heavy-haul. Engineered for superior performance in 23K axle applications. TRP Premium 23K linings can be easily identified by the gold edge coloured lining.

NOT ALL AFTERMARKET BRAKES ARE CREATED EQUAL…

At TRP, we stand by our products 100%.

That’s why when we developed the latest generation brake shoes, we wanted to make sure that they could stand up against any aftermarket shoe on the market. To do this we commissioned a number of tests on aftermarket and OEM shoes to see how the TRP brake shoes compared. The standard that we tested to was FMVSS 121, an industry recognised standard that tests whether a friction material has sufficient frictional characteristics to be safe on a given application.

TRP brake shoes only use the best quality materials available and manufacture to OE specifications. All of the brake shoes in the TRP Range meet or exceed ^ Federal Motor Vehicle Safety Standard (FMVSS121) for air brake systems and comply to ECE R90 regulation where relevant, a standard that is recognised by Australian and New Zealand design rules.

^ For more information about the test results, visit trpparts.com.au/productguides and refer to the Product Guide “TRP Brake Shoes – What’s Stopping You?” or speak to your local dealer

BRAKE SYSTEMS AIR SYSTEMS BRAKE DRUMS BRAKE HARDWARE BRAKE SHOES & HARDWARE KITS DISC BRAKE PADS DISC BRAKE ROTORS

FREECALL * 1800 TRPART (877 278) ONE PHONE NUMBER TO CONNECT WITH 57 DEALERS AUSTRALIA WIDE

* Calls from Australian landlines are generally free of charge whilst calls from mobile phones are typically charged based on the rate determined by the caller’s mobile service provider. Please check with your mobile service provider for call rates.

DRIVE INTO THE FUTURE

MEGATRANS.COM.AU

PROUD PARTNER SUPPORTING SPONSORS CONFERENCE SPONSORS

1ST - 3RD APRIL 2020 MELBOURNE CONVENTION & EXHIBITION CENTRE

ACCREDITATION PARTNER

ASSOCIATION PARTNERS