13 minute read

Moving with the Beat

by Prime Group

MOV

WITH THE

Isuzu FVD 165-300 with 1.9 tonne excavator.

ING

B E AT

Utilising highly specialised water jetting and vacuum pumping equipment mounted on a pair of Isuzu FVD 165-300 trucks, Dynamic Excavations performs non-destructive digging operations to assist councils with maintenance and repair work on essential services.

Dynamic Excavations was founded on the Gold Coast in 2003 with a view to resolving a long-standing issue that was endemic in the building and civil construction industries. For many years the company’s director, Andy Smith, saw contractors struggle – and often fail with disastrous consequences – to accurately locate delicate and expensive underground services while delivering their works. Andy knew there was an easier, safer and far more accurate way, so he launched Dynamic Excavations and pioneered the groundbreaking hydro-excavation solution in the Gold Coast region. From that day forward the business has been characterised by continual change and progress, typified by diversification of its repertoire to include specialised technical services such as CCTV inspections and recording, truck and asset monitoring, underground services location and mapping, in addition to non-destructive digging. The company has since significantly expanded its footprint on the east coast of Australia, having established additional facilities in Melbourne, Brisbane, Sydney and the Sunshine Coast. By way of explanation, hydro-excavation is a two-part process using highly pressurised water jetting to penetrate and break up the earth and a highvolume vacuum pump to suck up the dirt and water slurry that is then collected in the truck-mounted tank and subsequently disposed of at a specialised waste management site. This method is widely acknowledged as the safest for excavating around delicate underground services including mains power, sewer, telecommunication and fibre optic cables. Isuzu trucks have been a mainstay of the operation’s fleet over the last 17 years and the latest pair of FVD 165-300 4x2 units have been purpose-built with an extra-long wheelbase to accommodate the hydro-vac equipment and tank at the rear and a compact excavator and fold down ramps at the front. As a result, the unit is fully equipped to perform both the hydro-excavation and

On a job for the Gold Coast City Council.

other tasks requiring an excavator such as backfilling and lifting valves or other heavy items required for the jobs. “The airbag rear suspension and the longer wheelbase were two essential requirements for us,” said Dynamic Excavations’ Chief Financial Officer, Brad Allen, in reference to the two

new Isuzus. “While the majority of our fleet of vacuum trucks are the standard format, these two each carry a 1.9-tonne excavator. To accommodate this, we used a shorter 3,000-litre tank and installed a cradle setup to carry the excavator and its attachments. There are also two large rectangular fresh water tanks, mounted each side of the main tank, to supply water for the jetting guns.” The new units are kept busy, according to Brad, doing emergency callouts and scheduled maintenance work right across the vast region managed by Gold Coast City Council. “They are the busiest trucks in our fleet due to their versatility,” he says. “They work non-stop on council callouts and planned maintenance jobs all over the place.” The trucks were supplied by Gold Coast Isuzu while the tanks and pumping equipment were supplied and fitted by STG Global at Yatala on Brisbane’s southside. Brad says the company has supplied this type of equipment for the bulk of the vacuum truck fleet. “Ideally, we’d like to build another two of these trucks for our southern states branches to service the council work,” he says. “Because they do such a great job they are always in demand.” Brad has glowing praise for the Isuzu trucks, saying they have been totally reliable and capable in handling the busy and often heavy workload. “Most of the fleet is Isuzu and we find running the same brand across the board is the best solution for our needs,” he says. “We have roadside assistance plans for changing flat tyres and that works well. Gold Coast Isuzu does all the scheduled maintenance and are good to deal with. We also buy the trucks for our other branches from them and have the bodies fitted by STG Global.” Having the right operator for this type of specialised equipment is paramount. According to Brad, Lee Gray is one of the company’s longest serving and most experienced operators who takes immense pride in both his work and the appearance of the truck. Lee has been employed by Dynamic Excavations for the last seven years and has worked his way up through the ranks. “I’m now doing primarily Gold Coast City Council work with the excavator and hydro-vac truck,” Lee says. “It’s a tidy bit of kit and it works really well.” He explains the Isuzu FVD 165-300 has plenty of power and is the right size for most of the jobs he does, although the

long wheelbase means negotiating tight turns and narrow streets, which does require extra care. “The previous truck I drove was a bit shorter but that meant all the equipment wasn’t laid out as well as this one,” he says. “The extra storage boxes are great – everything is where I need it to be. “The only issues I’ve had with the truck were the radio and the chrome on the grille which bubbled in one small area. But Isuzu were straight onto it and had it fixed in no time. Apart from that, it’s been trouble free.” Having previously only driven manuals, Lee admits to initially being less than enthusiastic about the prospect of driving an automatic. However, he was pleasantly surprised at the responsiveness of the six-speed Allison automatic coupled with the 300hp engine. “It has a power mode so when you push the button it really gets up and goes,” he

Brad Allen Dynamic Excavations’ Chief Financial Officer

says. “It’s proved itself in every way.” The 4x2 is more suited to negotiating the tight streets where a 6x2 or 6x4 would struggle. A lot of the bounce common to the application has been offset by the rear air suspension. “It really is a comfortable truck to drive,” he says. “The interior is easy to keep clean and the cab is a very pleasant environment when driving between jobs.” Isuzu has a strong reputation for manufacturing robust and reliable medium-duty trucks in a range of sizes to suit most applications and for Dynamic Excavations, the Isuzu FVD 165-300 is just the ticket for its hydroexcavation operations.

ADVANCED PERFORMANCE & LEADING TECHNOLOGY.

DISC PADS

• Improved surface technology • Quieter braking performance • Dependable and reliable performance • Comprehensive range across most applications

BRAKE SHOES

• Reduced wear rates • Easy to install with no fuss • Resistance to high operating temperatures • Comprehensive range across most applications

BRAKE LININGS

• Protects other brake components from wear • Reduced replacement cycles • Cleaner technology • Comprehensive range across most applications

FIFTH THE

ELEMENT

The ELI-te fifth wheel assistant from SAF-Holland offers increased productivity through better safety practice. Dyers Transport has been one of the first formidable freight operations to put it to use across the entirety of its fleet.

Dyers runs a range of DAF commercial vehicles equipped with ELI-te.

Efficiency and ease of operation remain primary considerations for heavy vehicle operators whose tasks are many and enduring in a society so currently reliant on their safe arrivals and departures. While the exceeding prioritisation of best practice management in road transport operations has been greatly beneficial to driver health it has also brought with it fleet efficiencies thanks to reductions in disruptive events like the unsuccessful coupling of trailers. Dropped loads can cost thousands of dollars and as commercial vehicle equipment specialist, SAF-Holland, recognises, there’s no room for failure. With better safety also comes a healthier bottom line. To help promote consistent and thorough driver coupling inspections, it offers a fifth wheel coupling assistant it calls ELI-te, an abbreviation for electronic lock indicator — technology enhanced. It offers a significant advantage to fleets looking to provide their drivers with user friendly assistance that enhances coupling efficiency, driver confidence and safety. The optional system, offered on the popular FW35 series of Holland fifth wheels, is highly versatile. At present it can be supplied as factory fit on the new FW351. The FW331 fifth wheels are also part of a retrofit kit that includes instruction manual, drilling template, drill bits and ELI-te system components. Dyers first trialled the technology on a couple of units in 2018. Soon welcomed by the drivers it was initially foisted upon, ELI-te later became a mandatory tool to augment driver safety protocols according to Dyers Workshop Manager Troy Malcholm. “It was originally adopted by us here for the drivers so that if there was a safety issue they’d soon know about it,” he says. “Once they all got used to it they started bringing it up in conversation and they certainly noticed, during the initial introductory phase, its absence.” Based in the Gippsland region of Victoria, Dyers has installed the ELI-te across its entire operation. Since 1997 the company has increased its contract distribution fleet to 150 dedicated trucks across three states. A preferred carrier for the likes of IGA and Foodland, its Bairnsdale-based operations run primarily DAF commercial vehicles fulfilling demanding cold chain orders for supermarkets as a direct result of the forced closure of many restaurants, bistros and pub dining rooms under social distancing regulations. Like most transport companies currently operating on the surging grocery supply chain, Dyers has never been busier. No Christmas peak, at least in recent memory, can rival the sheer scale of pressures derived from the COVID-19 pandemic, which has many freight specialists stretched thin. Under these circumstances the entire supply chain is put under additional pressure. Even more reason then, at this sustained pace, for safety procedures to be adhered to closely including trailer coupling, a routine which must be completed daily, often multiple times. “The ELI-te provides an extra situational awareness that is always welcome in

For Dyers the ELI-te forms part of a threecheck system required of all drivers at the point of departure.

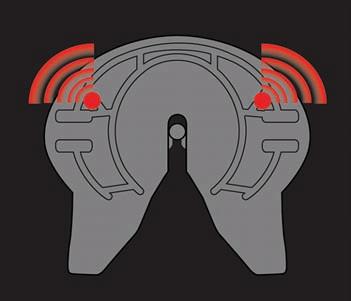

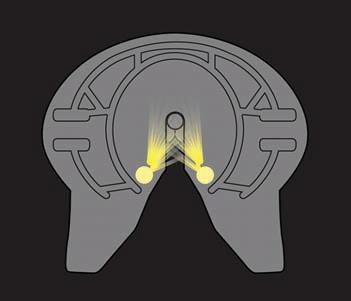

this line of work where everyone is so pressed for time. Especially given how busy things have gotten in recent weeks with the current situation,” says Troy. Gone are the days with which a driver points a flashlight to validate the coupling. When the kingpin is properly seeded in the fifth wheels lock jaws, ELIte shines four glowing white LED lights into the lock. This assists the driver in confirming the connection is solid and secure. These high-intensity LED lights are strategically aimed at the kingpin and lock for enhanced visibility during the inspection process, especially in poor weather and low-light conditions. Red lights, however, flash on the side of the coupling to assist the driver in quickly recognising what might be a potentially costly mistake before attempting a tug test or driving away. As it helps prevent potential mistakes before they happen, the ELI-te system also increases confidence levels of drivers who are often required do to much more than just drive busy schedules. For Dyers the ELI-te forms part of a three-check system required of all drivers at the point of departure. “It serves as one of the preventative measures we have put in place and invested in,” says Troy. “The more backups and risk mitigation we can introduce to our trailer coupling the better. If it’s better for our drivers then its better, in all likelihood, for the business.”

Dyers has not shirked on their investment either having decided last month to install ELI-te on it’s A-trailers going forward. “The first two of these are now in operation and we’re working through some design elements with regard to power and exhaust for the moment,” Troy says. “ELI-te functions as part of our overarching goal to create further awareness among staff and drivers across the organisation in accident prevention. It’s another simple-to-use safety aspect for the driver in his pretrips.” Just as the LED lights and sensors are strategically positioned under the top plate for maximum function, reliability and protection, all of the electronics are mounted on the fifth wheel itself. The sealed one-piece harness connects the LED lamps, cables, sensors and logic module and the entire system is joined to the prime mover through a simple one cable connection. Dyers favours DAF commercial vehicles

Red lights flash to alert drivers of a failed coupling attempt.

in its refrigeration applications. Reduced repair costs remain one of the key factors for Troy who confirms the business has recently ordered nine of the new Euro 6 DAF trucks from the Gippsland Truck Centre. Their arrival is imminent. “We’ve always gone with DAF. From a costing side we like their value proposition and new generation offering is replete with the latest safety features which we highly value.” The ELI-te option for the FW35 series requires minimal maintenance and is backed, according to SAF-Holland by a 2-year warranty. With scalable connectivity for local or remote performance monitoring, SAF-Holland’s fifth wheel assistant, what’s more, permits the user to expand the system capabilities and includes the likes of audible alerts and GPS, dash cam or telematics integration. Trend analyses also offers actionable data for informed fleets such as Dyers. Built to withstand real world environments so that the circuitry and components are not impacted by the grease contamination that affect common sensors, ELI-te is a robust system according to Troy. “We’ve found it extremely reliable,” he says. “All of our trucks have it fitted now regardless.” Rare incidents of a failed coupling have dropped in step with its use across the fleet. Troy says it has assisted in making operations more productive. “Less accidents naturally mean less costs,” he says.

White LEDs illuminate to confirm a successful coupling has been made.

NOW ON TWITTER

Follow us on