30 minute read

Prime Mover News

by Prime Group

PRIME NEWS

> AJM Transport prepares for 22 incoming Kenworths

A newly delivered Kenworth K200.

Overnight express specialist, AJM Transport, has taken delivery of the first Kenworth K200 of an order of 21. A second K200 is reportedly in the workshop nearing handover. Delivery of the order is expected to be completed by the end of 2022 when the last truck is slated to roll off the production line and will include a new Kenworth T909. The lion’s share of the order is set for deployment as shuttle trucks operating on the busy Melbourne to Brisbane road freight corridor. For the interstate drivers the newest K200s will have fridges and microwaves and some extra bells and whistles according to Dennis Roohan, AJM Transport Group General Manager. “We want to look after the guys who are away five nights of the week and also attract a better calibre of driver,” he said. The Kenworth K200 is a tried and proven product in the AJM Transport fleet which, in terms of sheer numbers, sits around 80 prime movers, with a mix of Kenworth, Volvo and the outgoing Freightliner Argosy which some of these new trucks are expected to eventually replace. Of the strategic benefits often realised from investment in the Kenworth K200 its ability to have multiple lives is singled out by Roohan. “We love the fact that it can do a job for a number of years and then be redeployed in a whole new role,” he said. “It can easily do a million kilometres on the long haul journeys and then be reassigned to Sydney to Brisbane or Sydney to Newcastle for another million kilometres.” Operations also favour, in the majority, a 26-metre specified Vawdrey super drop deck, a requirement the dogged K200, which is powered by an ultra-reliable Euro 5 rated 600hp Cummins X15, has no issues with. “We know every nut bolt on them, how they brake, what they require at certain intervals,” said Roohan. “That kind of familiarity means we can fix them really quick,” he said. Transmissions on the new K200s are an 18-speed Eaton manual 22918B through a Meritor RT 46-160 tandem rear drive axle. Roohan said he is looking forward to the new Kenworth K220 which has only been teased so far by the Melbournebased OEM. He has been promised one in the not-too-distant future. Now nearing the midpoint of 2022, the business, according to Roohan, has never been busier hence the necessity for additional mobile assets. He said having planned a good forward order in the bank has paid dividends in terms of possessing reliable new equipment to meet the contractual demands of the moment. “I can’t see myself having to trade a lot of gear given how busy things are at the minute,” he said.

PRIME NEWS

> Followmont celebrates delivery of 200th UD truck

Queensland-based carrier and logistics company, Followmont Transport, have taken delivery of their latest UD Truck, the 200th from the Japanese marque. The bright red UD Croner 6×2 comes with a set of curtains to match with a gradient fade. At an event held at Volvo Group Australia (VGA) corporate headquarters in Wacol, key leaders from the two companies gathered together to talk about the past, present and future. Followmont Transport CEO Mark Tobin, VGA President and CEO Martin Merrick along with UD Trucks Vice President, Lauren Downs and Mack Vice President, Tom Chapman, held a discussion panel airing views on the transport industry, its evolution and what it might look like in the future. A Volvo FHXXL was also on display, marking another milestone — that of 300 truck sales made by VGA to Followmont. The event, according to Tobin, as well as the two trucks symbolised an incredible partnership between the brands. “It started off as a supply and demand need to one which has flourished over the decades to become one which is built off of trust and transparent communication,” he said. “Both organisations know each other’s businesses and we work together to not only contribute but to strengthen the transport industry as a whole,” continued Tobin. “Whilst our values are aligned, the frequent and open communication has assisted to remove the anxiety out of the curveballs our industry has faced whether it be natural disasters, the pandemic or the current recruitment strain.” Staffing struggles, at present, impacting the industry were occasion for Followmont to reiterate the vast opportunities the evolving industry still can provide workers. “Whatever your background, age or ethnicity, there is a place for you within transport and we are an industry which cares and accepts you as one of the family,” said Tobin. Merrick, who also spoke during the panel, said celebrating customer success was a key part of who Volvo Group Australia is. “Marking milestones such as this with such a valued customer makes us very proud to have played a part in that success,“ he said. “We don’t just sell trucks, we forge meaningful partnerships that are ultimately based on trust and integrity and I’m delighted to see a family business like Followmont Transport continue to flourish”

Volvo Group Australia members with Mark Tobin [middle].

PRIME NEWS

> WA announces program to improve heavy vehicle rest areas

> Qube begins world’s first outback electric truck trial

Important upgrades to rest area facilities for heavy vehicle industry operators are now underway across 13 locations in Western Australia. The program is part of the $50 million Freight Vehicle Productivity Improvement Program across more than a dozen locations recently announced that covers sites across the Pilbara, Mid-West Gascoyne, Wheatbelt, Goldfields Esperance and South-West. The $50 million program, jointly funded by the Commonwealth and State Government, includes improvements that will allow for safer turning movements, improvements to parking and breakdown areas for combination vehicles reducing noise and dust, and the construction of ablution blocks at some locations. Work recently commenced at the heavy vehicle rest area in Munjina adjacent to the Auski-Munjina Roadhouse and Accommodation and includes the sealing of the rest of the area and improved access for heavy vehicles. Work will progressively commence on each of the 13 locations over the next six months, with all improvements due for completion in late 2022. The 202223 program is also being developed through consultation with industry and will continue to be developed to

A heavy haulage vehicle negotiates a rest area outside of Perth.

ensure the appropriate priority areas for drivers are identified for forward works planning. These priority projects, according to the State Government were identified through extensive consultation with peak industry groups, including Transport Workers Union (WA Branch), Livestock and Rural Transport Association of WA and Western Roads Federation. “Our freight drivers in WA provide an essential service and are key for delivering critical supplies across the country,” said Transport Minister Rita Saffioti. “Our engagement with the transport industry has helped WA achieve outcomes that are often the envy of our eastern state counterparts and providing these much-needed amenities and facilities in regional WA will only make it that much easier for our freight drivers. “The Heavy Vehicle Industry has advocated for all needs to be addressed in one place creating a ‘one stop’ approach, and we are delivering these improvements to support road safety and provide greater opportunities for heavy vehicle operators to utilise as part of their fatigue management.”

Leading logistics and bulk carrier, Qube, has embarked on a trial of batterypowered trucks for heavy haulage in Western Australia. Qube in partnership with OZ Minerals is working on what it calls a world first in which battery electric heavy vehicles are tested across long distances in the rugged terrain of the Australian outback. Known as the Vision Electric project, it focuses on tackling the challenge of emissions footprint reduction in the heavy transport and resources industries. This self-funded trial is at an early stage and will be phased over 12 months, beginning in the latter part of 2022. “Qube is constantly evolving and that building a strategy that ensures a resilient and robust approach to sustainability is key for Qube’s long-term success,” said Todd Emmert, Qube Bulk Director. “Vision Electric is a collaboration of technology and service for a challenging environment with currently limited alternate fuel solutions,” he said. “The vision is to elevate current technology to meet the demand of a dynamic remote export supply chain and advance our respective pathways to decarbonisation. Vision Electric is an exciting element to the next chapter of our pathway with OZ Minerals.” As part of this trial, a battery recharging and replacement station will be set up in South Australia at Port Augusta, approximately 300 km from Adelaide. Construction of this station is estimated to start in May 2022 and be completed by early August 2022. Once ready, the station will be used as a battery change over pit stop for the battery-electric truck. It is expected that the battery change over can be completed in the same time it takes for traditional refuelling.

PRIME NEWS

> Isuzu reveals new F Series Range

The 2022 F Series range of trucks from Isuzu have been unveiled on the back of an all-new audio-visual unit and industry-leading, new vehicle six-year warranty and roadside package. A 10.1-inch touchscreen audio visual and multimedia unit, the MyIsuzu Co-Pilot, is being marketed as an all-in-one smart partner out on the road by the OEM who has complemented many of the high-volume models in the range with advanced safety features. The 4×2 models powered by the hightech and efficient four-cylinder N-4HK1 engine come equipped with Advanced Emergency Braking (AEB), Forward Collision Warning (FCW), Distance Warning System (DWS) and Lane Departure Warning (LDW). These models and the larger FTR and FV models have, as an additional benefit, received Electronic Stability Control (ESC), while the Electronic Braking System is introduced to the four-cylinder FSR and FTR and FV models. New LED headlamps for all FRR/D, FSR/D, FTR and FV models have been installed for improved nighttime operation while cab-tilt warning has been introduced across the entire range. In the cab, the four-cylinder 4×2 models also have a new instrument panel with 4.2-inch colour multi-info display and steering wheel controls. Further highlights of the 2022 release include an upgraded GCM of 21,000 kg for FSR, FTR and FTS models with the 6HK1 260PS engine. Isuzu’s highly regarded aftermarket support is bolstered with warranty upgrades across the range, featuring a six-year standard warranty with much higher distance and engine hour limits than previous models, as well as a sixyear roadside assist package. “The Isuzu F Series has enjoyed excellent customer acceptance over the years, and the 2022 model year release offers even more for mediumduty truck operators, from improved owner and driver experience to even greater application suitability,” said Isuzu Australia Limited (IAL) National Sales Manager, Les Spaltman. “In planning this model release, we’ve looked at how our customers are using their medium-duty trucks and we’ve targeted our updates at the key market requirements,” he said. “We’ve introduced active safety with ADAS to the volume 12 to 14 tonne GVM segment and in doing so, we’ve got features that match the operating environment. “In the heavier end of our offering, again the introduction of electronic stability control and electronic braking system brings the features that operators of these models, namely fleets, are looking for. “And our 6-year warranty and roadside upgrades for all models further underlines our confidence in the reliability and performance over time, of our specification for this range,” concluded Spaltman. The brand-new AV unit was developed in partnership with Blaupunkt Asia Pacific with a design and user interface exclusive to Isuzu according to IAL Chief Engineer, Product Strategy, Simon Humphries. “We’ve also introduced a new navigation system from HERE Navigation with smart updates for maps, live traffic with a mobile phone wifi connection and the requisite truck specific data and routing,” he said. “Drivers will appreciate the array of features from this major in-cab upgrade — this really is the latest in automotive AV technology,” said Humphries. “The inclusion as standard of a new, digital low-light capable reversing camera furthers the smarts and safety of these models.” The heavy-duty Isuzu FX and FY Series model ranges also receive a select series of updates, including the MyIsuzu Co-Pilot AV unit. In common with the FV models, FX and FY ranges are upgraded with the new headlamp assembly, with low beam and position LED lamps, and halogen high beam and fog lamps. “The technology used in these new lights provides performance that is superior to the most premium HID globes, and these aren’t even available for Isuzu models in Australia,” said Humphries. “This and other inclusions such as the fast USB charger and CAN connector for fleet management systems add to the improved driver and operational amenity of these models.”

New FSR from Isuzu with LED main beam and halogen high beam headlamps.

PRIME NEWS

> Don Watson Transport partners with Primary Connect on A-double first for Sydney

Primary Connect has partnered with Don Watson Transport to trial the first approved 35-metre A-double combination operating in the Sydney region. Transport NSW approved the trial in February to help businesses create more efficient ways to move goods for their customers during the pandemic. Two 35-metre A-Double combinations, pulled by Kenworth K200s, travel between Sydney and Melbourne daily, passing each other along the Hume Highway. Their final destination is at Primary Connect’s consolidation sites in Truganina VIC and Wetherill Park NSW. A permit for the use of 35-metre A-Double combinations in Victoria had previously been granted by the Victorian Government. Over the past few years, Don Watson Transport has partnered with Primary Connect to operate A-double combinations between Melbourne and Brisbane. Lyndon Watson, CEO Don Watson Transport, said he was excited to be part of the trial into Sydney. “The trial in partnership with Primary Connect has been a great experience,” said Watson. “These high performance vehicles are so advanced. They are designed with a fixed drawbar which improves braking performance,” he said. “They hum along by themselves and are typically contained on the highway and industrial estates while east of the Newell Highway. The general public don’t even know they are there.” With each trailer having the capacity to hold 22 pallets, a 35-metre A-double combination will help reduce truck movements according to Primary Connect. The logistics specialist for the Woolworths Group anticipates a 29 per cent productivity improvement with it equating to a total of 44 pallets. A standard B-double load would typically hold 34 pallets. The trial is expected to continue until the end of June.

> Daimler Trucks announces Dealer of the Year

A Queensland-based dealership has been awarded the Daimler Trucks prestigious Dealer of the Year. At a gala event in Melbourne representing Mercedes-Benz Trucks, Freightliner and Fuso brands in Australia and New Zealand, Daimler Trucks Sunshine Coast was named as the Daimler Truck Dealer of the Year for 2021. Daimler Trucks Sunshine Coast Dealer Principal, Chris Spence was on hand to receive the award in person. Daimler Trucks Sunshine Coast was also announced as the Fuso Regional Dealer of the Year for 2021 and staff member Victor Dos Santos took out the Service Manager of Year award for both Freightliner and Mercedes-Benz. “Daimler Trucks Sunshine Coast provides a shining example of customer service and the team has well and truly earned this award with sheer hard work,” said Daniel Whitehead Daimler Truck and Bus Australia Pacific President and CEO. “Remarkable customer satisfaction and strong sales across all three brands means Daimler Trucks Sunshine Coast is a worthy winner of the Daimler Truck Dealer of the Year award.” While Daimler Trucks Sunshine Coast won the Fuso Regional Dealer of the Year award, it was the Whitehorse Truck Centre in Dandenong that was announced as the Fuso Metro Dealer of the Year for 2021. Mercedes-Benz Trucks announced that Mavin Truck Centre was the 2021 Mercedes-Benz Trucks Regional Dealer of the Year, while Daimler Trucks Huntingwood was recognised as the 2021 Mercedes-Benz Trucks Metro

Dealer of the Year. Daimler Trucks Huntingwood was also recognised by Freightliner as its 2021 Metro Dealer of the Year, while Daimler Trucks Albury was announced the 2021 Freightliner Regional Dealer of the Year after another strong performance. Daimler Trucks Adelaide was announced as the Daimler Truck Financial Guild Dealer of the Year for Light and Medium Duty Trucks, while Daimler Trucks Laverton was announced as the Daimler Trucks Sunshine Coast Dealer Daimler Truck Financial Guild Principal, Chris Spence accepts an award. Dealer of the Year for Heavy Duty Trucks. “The multitude of awards taken home by the Daimler Trucks Sunshine Coast team highlights the depth of its customer commitment,” said Greg Lovrich, Daimler Truck and Bus Australia Pacific Director Aftersales and Network Operations. “Whether it be the person out the front helping a customer select the right truck for the job, or the person behind the service counter or under the truck in one of the service bays, the whole Sunshine Coast team is working hard to serve the customer.”

PRIME NEWS

> CS Asset reveals monster B-triple

Rising interstate carrier, CS Asset, has taken delivery of a new Freightliner Cascadia B-triple. The combination, which features a Cascadia 60 inch cab, the roomiest on the market, is spec’d for gruelling long haul journeys such as Adelaide to Perth, return, as well as Adelaide to Darwin, transporting general freight. Owner Chamkaur Sodhi established the Adelaide-based company in 2013 following five years behind the wheel as a driver having graduated from a heavy rigid licence to B-doubles and later roadtrains. His current operations feature 35 prime movers, a majority of which are Mercedes-Benz Actros units, with some Kenworths, Volvos and Western Stars. CS Asset also runs 52 B-double sets in addition to roadtrains. Melbourne and Sydney are also on the B-double legs the business caters to overnight. The fit-for-purpose Cascadia 126 is rated up to 98 tonnes gross weight and is already accumulating an estimated 6000 kilometres a week. Powered by a Detroit DD16 600hp engine with a peak of 447kw and 2,708 Nm of torque, the prime mover comes loaded with the latest safety systems including Antilock Braking System, Vehicle Stability Control, Adaptive Cruise Control, Auto Head Lights and Wipers, Lane Departure Warning and Side Object Detection. The truck is also fitted out with Guardian driver monitoring technology and forward facing and side view cameras which are alway live into the dispatch office located in Green Fields where the business runs its sizeable warehousing and distribution operations. A 60-inch XT Sleeper Cab incorporating overhead storage with doors, premium cab lighting and between seat storage ensures the driver, who is reportedly thrilled by the new vehicle, with plenty of working space on his long journeys. “I’m super impressed. There’s a lot more space in the cab which is important for the distances it covers,” said Sodhi. Sodhi spends the majority of his time these days in the office, helping coordinate transport operations which have rapidly expanded over the last nine years. “Road transport is never slow especially over the last year. It’s been anything but predictable,” he said, acknowledging supply chain challenges including flood disruptions earlier in the year that befell, many interstate trucking companies that rely on the Nullarbor and Central Australia transport corridors. “It’s rarely the same day to day. There’s only so much you can control at the moment and upgrading our trucks is certainly one way of managing that as best we can.” The new Cascadia is the fifth new prime mover to enter the CS Asset stable this year. “The truck is going great and the driver very much is liking it,” said Sodhi. “It pulls the weight behind it like you would expect from a new American prime mover. It’s got the guts of a North American truck but the comfort of a European vehicle,” he said. “For the driver it’s the best of both worlds.” Sales Executive Ghautum Dhillon, courtesy of Daimler Trucks Melbourne, helped facilitate the delivery.

> Silk Contract Logistics appoints new COO

Wharf cartage and distribution firm, Silk Contract Logistics, has announced the appointment of a new Chief Operating Officer. Dani Aquilina was appointed to the role after 14 years as COO of the Reject Shop. She joined Silk officially in April. “I am excited to take my experience and passion for supply chain and the customer into this new role,” Aquilina said via a LinkedIn post. “It has been great to meet and connect with Brendan Boyd, John Sood, Nicole Sullivan, Brendon Pentland, Matt Hannah,” she said. “I look forward to working with all of you and the team as we continue the Silk journey and make it easy for customers to do business.” At The Reject Shop, Aquilina was accountable for all operating functions including store operations, supply chain, new store development and space optimisation. She also helped oversee business optimisation, in which operational costs were a focus along with support for business growth requirements. Silk Contract Logistics had been enjoying a steep upwards trajectory with several high profile acquisitions and the opening of a new facility in Brisbane prior to the arrival of the COVID crisis. At present the company operates 21 sites nationally and billed for over 283, 300 containers according to FY 2021 results. In that same period Silk reported revenue of $323.3 million, a 28.6 per cent increase year-on-year.

CS Asset’s new Freightliner Cascadia 126.

> VTA urges Govt to lift mandatory vaccination requirement for workers

The Victorian Transport Association (VTA) is calling for the vaccination mandate for transport workers to be lifted, bringing it in line with other jurisdictions around Australia. While the VTA welcomed the further easing of COVID restrictions in Victoria announced by Health Minister Martin Foley, it questioned why the state was now one of only three jurisdictions to retain vaccine mandates for workers. “With transport being a truly national industry, we need consistency in the rules between the states and territories,” said Peter Anderson, VTA CEO. “Since mandates were introduced last year, we estimate around seven to ten per cent of drivers have left the transport industry, which is significant for an industry already facing driver shortages and challenges attracting new drivers to the industry,” he said. “We need to make it easier for drivers to enter the transport industry, not harder.” Anderson said the mandates had been a factor in supply chain disruptions that have led to delivery delays and chronic shortages at supermarkets and other retail stores. Removing the mandates, according to Anderson, would ease the labour pressures operators have been dealing with for months. “The sooner vaccination mandates in Victoria are removed, the sooner drivers can get back to doing the work they love, and operators can re-employ workers they desperately need,” he said. Anderson also pointed out that the transport industry has worked harder than ever during the pandemic under some of the toughest rules and restrictions, and that having maintained its social licence to operate the time had come to start to responsibly ease rules in the workplace. “From having to get swabbed up to ten times a month, isolating from family and friends in order to continue working, and observing strict hygiene practices, the transport industry hasn’t skipped a beat keeping Australia moving,” he said. “As we start to move into the next phase of COVID, and with vaccination rates as high as they are, we need a consistent set of rules to start to get our supply chains back to normal.”

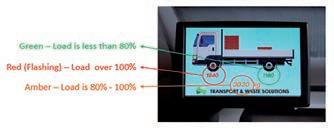

CHAIN OF RESPONSIBILITY LEGISLATION GOT YOU WORRIED? RELAX!

With TWS and Axtec there is no longer any reason or excuse for your vehicles to be overloaded

ONBOARD AXLE LOAD INDICATOR

DISPLAYS AXLE AND GROSS WEIGHTS SIMPLE COLOURCODED DISPLAY

Visual and audible warnings alert drivers to load errors Side and rear cameras Single touch-screen displays all functions - less driver distraction

WITH AXTEC ONBOARD

You can: • Load vehicle to capacity every time • Avoid fi nes and threats to Operating License • Avoid excessive wear and tear to associated with overloads • Reduce environmental impact • Receive real-time notifi cations via GPS / telematics system • Connect cameras to improve safety to pedestrians and cyclists ph: 02 9623 1800 e: chris.coleman@twsaust.com.au www.twsaust.com.au

PRIME NEWS

> Hyzon to build hydrogen refuelling depot in Melbourne

Hyzon Motors Australia has announced plans to build a green hydrogen refuelling depot at their regional headquarters in Melbourne. The commercial-scale green hydrogen depot will reportedly support Hyzon’s rapidly growing manufacturing footprint in the region, to supply hydrogen to new customers, and to further demonstrate the commercial viability of what the company refers to as ‘behind the fence’ hydrogen to decarbonise fleet operations. Expectations are that the depot could be up and running by late 2023. Hyzon, in partnership with the RACV, hydrogen specialists ENGV, and other yet-to-be announced third parties, is working through the design, planning, permitting and development process for the green hydrogen depot anticipated for Noble Park. This follows Viva Energy’s announcement last month of a New Energies Service Station in Geelong which also incorporates hydrogen refuelling for heavy vehicles.

Lily D’Ambrosio speaking at the media event.

Hyzon is currently delivering an initial order of hydrogen powered vehicles for RACV-owned subsidiary Nationwide Group, the first order of such vehicles for a Towing company in Australia. These vehicles are the first customers for the planned green hydrogen depot. It is likely the green hydrogen refuelling depot will be powered, at least in part by onsite solar generation installed and operated by RACV Solar. Victorian Minister for Energy, Environment and Climate Change, Lily D ’Ambrosio, was on hand at Hyzon Motor’s Noble Park site to officially open the manufacturing facility and announce the development of the green hydrogen refuelling depot. “Green hydrogen is a key part of our plan to halve emissions by 2030,” she said. “We’re creating jobs in new industries as we lead Australia’s clean energy transition.” Hyzon Motors Global CEO, Craig Knight, said the announcement sent a strong message that Hyzon was playing a key role in Australia’s energy transition. “Our hydrogen fuel cell electric vehicles will play a key role in the decarbonisation of the transport sector and be a key component of Australia’s fuel security strategy for the future,” he said. Hydrogen availability for heavy duty vehicle refuelling is the key missing infrastructure link in Australia for the industry, according to Hyzon Motors Managing Director ANZ, John Edgley, who said investments like this one would underpin the creation of local hydrogen communities, essential to build into the promise of the hydrogen economy. “We are focused on generating new local jobs, new and sustainable local manufacturing facilities, and a fundamental transformation of fuel supply to green and local,” he said. CEO of Nationwide Group Michael Stephenson said as Australia’s largest towing and roadside assistance company, that the company was always working to be at the forefront of fleet innovation. “We are excited to explore how hydrogen can play a part of road transport in Australia,” he said. “This trial will give us an opportunity to test hydrogen vehicles in a real-world test for towing and transport and we’re thrilled to be part of this new industry leading partnership.” Business Development Manager for ENGV, Gemma Harrison said ENGV was thrilled to work with HYZON and RACV on renewable hydrogen production and refuelling infrastructure in Melbourne. “Along with our global technology partners, we are continuing our contribution to the growth of the Australian renewable hydrogen industry,” she said. “By deploying and servicing hydrogen infrastructure to support the transition to zero-emission transport and a clean energy future, ultimately reducing global emissions and providing local resources to support such projects.”

> Transport merger shakes up heavy haulage sector

Two mainstays of the Australian heavy haulage industry have announced their imminent merger. Hunter Valley-situated Hogan’s Heavy Haulage is to be acquired by Bower’s Heavy Haulage. The proposed acquisition of Hogan’s Heavy Haulage gives Bower’s Heavy Haulage a major stake in the region’s coal mining and civil industries the latter said in a statement. “The merger with Hogan’s Heavy Haulage adds to our NSW presence and national footprint and like our other business. It is an established family business with a reputation for great service to its customers and an excellent safety record,” said Daniel Bower, Bower’s Heavy Haulage Managing Director. “Hogan’s Heavy Haulage has led the way for many privately held transport companies in NSW since they began trading over 25 years ago. They are a highly respected company and have always demonstrated their appreciation of all individual roles within the transport and heavy haulage industry and their involvement will be heavily missed,” he said in the statement. “We have had an incredible relationship with Hogan’s Heavy Haulage for almost 15 years with the working relationship between the companies going back even further for my father and grandfather. We are saddened to lose this working partnership, but we are excited for the Hogan’s family to be moving towards their well-earned retirement from the industry.” Settlement was targeted for the end of May. The purchase for Bower’s Heavy Haulage follows two major acquisitions in the Hunter Valley over the past seven years with the acquisition of the Boom Logistics’s Hunter Valley transport fleet in 2015 followed by Tutt Bryant Heavy Lift and Shift in 2018. As specialists in transport for both large and small freight, Hogan’s Heavy Haulage offers a dedicated service 24 hours a day, seven days a week. Its clientele range within New South Wales, Victoria and North Queensland for whom it can offer a variety of low loaders, tilt trays and other trailers towed, in the main part, by Mack and Volvo prime movers.Hogan’s Heavy Haulage specialises in transporting mining machinery and associated equipment, earthmoving and farming machinery and heavy industrial components. “We want to take this opportunity to say thank you and express our gratitude to Gary, Yvonne, Tanya, Jason, Sonya and their families for trusting us to take forward one of your life’s greatest achievements,” said Bower. “We are very grateful for the relationship we have had in the past, and the opportunity to continue this into the future. We are confident we will continue Hogan’s Heavy Haulage at the level you did and aim to make you proud of what you created when you see your legacy still on the road.”

RENAULT MASTER

it’s my business it’s my van

“I have a fleet of Renault Masters. I started my business in 2002 with 5 Renault Masters. I now have more than 40 across Australia. They look great on the road and they are great for business. There’s loads of storage throughout and tech keeps us connected. Both rear doors open and you can load a pallet straight in. We love the way our signage looks on the van. You can’t miss us on the road!” Peter, Cowan Restoration Services

GLOBAL NEWS

> Daimler subsidiary launches Autonomous Advisory Council

Torc Robotics in partnership with major US logistics companies, has launched an Autonomous Advisory Council in North America. An independent subsidiary of Daimler Truck, Torc is cooperating with the likes of Schneider, Covenant Logistics, Penske Truck Leasing, Ryder System, Inc, CH Robinson and Baton to further develop the real-world applications for autonomous trucking. To that end, Torc has established the Torc Autonomous Advisory Council (TAAC) with these key freight industry players to incorporate deep industry insights into its development process. Daimler Truck North America as OEM partner will provide strategic guidance to Torc as they integrate with the freight network and tackle challenges beyond highway driving. With customer co-creation, Torc enters what is considered the next stage of development, focusing even more sharply on specific customer requirements and concrete business models. Daimler Truck and Torc are reportedly committed to making autonomous trucking a reality and commercialising the technology within the decade. Daimler Truck CEO, Martin Daum, foresees an opportunity to increase its service revenue, in addition to promoting significant market and growth potential. “We are fully committed to autonomous trucking as it can benefit everyone. It will increase safety, because systems do not get tired and do not lose attention,” he said in a statement. “It will boost logistics performance by enabling trucks to run more. It will help society cope with the growing volume of freight, particularly in times of severe driver shortages.” Daimler Truck and Torc claim to have the longest autonomous driver technology and truck OEM partnership in the industry and have been testing a fleet of autonomous trucks on public roads in the US on a daily basis. Since acquiring a majority stake in Torc three years ago, Daimler Truck has made significant progress in turning autonomous trucks from an idea into reality. Typical driving scenarios such as lane changes and complex merges have been tested intensively and have proven that Torc’s autonomous driving software can safely navigate on highways. More recently, Torc expanded its testing and is now demonstrating L4 autonomous trucks with enhanced capabilities in more complex scenarios. Autonomous truck testing in the US has expanded to include surface streets, ramps and turns at controlled intersections through state-of-the-art LiDAR, radar and camera technology. These capabilities are essential for the planned deployment in the hub-to-hub use case. In this application, drivers deliver goods in conventional trucks over the first mile to transfer hubs along highways in key US freight corridors. From there, the trailer is coupled with a purpose built L4 autonomous truck that safely navigates long stretches of highways by driving autonomously from hub-to-hub. Once the L4 truck reaches the destination hub, the last-mile distribution will continue via manually driven trucks. Factors such as long, open stretches of highway, increasing demand for freight movement, large fleets and forward-looking regulators make the US the ideal proving ground to deploy this new technology first. As a next step, Torc is now involving leading logistic companies to specifically develop the real-world use case of the autonomous logistic system of the future. In the past few years, engineers at Daimler Truck North America have successfully developed the first scalable autonomous truck platform with critical safety systems. Based on Freightliner’s industry-leading flagship truck, the Class 8 autonomousready Cascadia with redundant functions enables the deployment of autonomous trucking. This truck has been designed and developed with a second set of critical systems, such as steering and braking to meet Daimler Truck’s uncompromising safety standards. The vehicle continuously monitors and assesses the health of these systems. In case of interruption or errors, the newly developed redundant systems will be able to safely control the truck. Given its redundancy of systems, the autonomous truck can contribute to enhancing safety in traffic and brings Daimler Truck that much closer to its vision of what it refers to as accident-free driving. “With Torc’s experience in commercialising autonomous vehicle solutions and Daimler Truck’s strong customer relationships in the freight industry, we’ve formed a powerhouse team to develop Level 4 technology for long-haul applications,” said Michael Fleming, Torc Founder and CEO. “The cooperation with our partners from the logistics industry creates numerous opportunities to co-develop concepts and facilities, and conduct research and development for Class 8 autonomous trucks, hub-to-hub operations, fleet operations, and fleet maintenance services.”

L4 autonomous-ready Freightliner Cascadia.