INTELLIGENT WASTEWATER POWERTRAIN SOLUTIONS

Purposefully designed gear motors from Bauer for fully submersible applications in wastewater treatment and other water or sludge type applications.

• German Engineered IP68 gearmotors that incorporate the latest in epoxy coatings, seal design, electrical connection and stainless-steel shafting

• Power classes from 0.37 to 11kW

• Submersible to 5m

• Application specific seals available

• Epoxy Coating to 400um

Epoxy Coated to 400um and Stainless Steel shafting to ensure complete corrosion protection, even when fully submerged

Pump Industry Australia Incorporated

PO Box 527

YARRAWONGA VIC 3730

Phone: +61 493 975 931 secretary@pumps.org.au www.pumps.org.au

PIA Executive Council 2024

Joel Neideck – Acting President TDA Pumps

Tracey Guida – Treasurer/Secretary

Alan Rowan – Councillor Executive Officer – Publications and Training, Life Member

Ken Kugler Executive Officer – Standards, Life Member

Steve Bosnar – Councillor Franklin Electric/Pioneer Pumps

Mat Arnett – Councillor Ebara Pumps

Michael Woolley – Councillor Tsurumi Pumps

Luke Biermann – Councillor Mechanical Seal Engineering

Tim Yakup – Councillor Regent Pumps

Alex Calodoukas – Councillor Pump Strategy

Keith Bowen – Councillor Xtron Pumps Australia

Acting President’s welcome

As the season of renewal arrives, it is my pleasure as the Acting President of Pump Industry Australia to welcome you to the spring edition of Pump Industry. Spring is a time of growth and opportunity, and this year, our industry is well-positioned to embrace the challenges and advancements ahead.

I’d like to take this opportunity to highlight a crucial resource available to all readers – the 6th Australian Pump Technical Handbook. This handbook is an essential piece of literature for anyone involved in our industry, providing comprehensive guidance on everything from pump design and selection to installation and maintenance. It is a must-have for staying informed and ensuring that you are following the best practices that underpin our industry’s success. This can be found at www.pumps.org.au

While you’re exploring the handbook, I also encourage you to take some time to browse our website. If you’re not already a member, consider joining our community to gain full access to a wealth of resources designed to support your work in the pump industry. From technical guides to industry news, our website is a hub of information that can help you stay ahead in a rapidly evolving field.

Our Councillors at PIA have been working diligently this year to give you the best direct link in our industry. Their efforts are focused on advocating for our members, driving innovation, and ensuring that we remain at the forefront of industry

developments. Their dedication to these goals is shaping a more robust and sustainable future for all of us, and I encourage you to stay engaged with the association’s initiatives.

Looking ahead, I’m excited to announce that our Annual General Meeting (AGM) will be held in Melbourne. This event is a cornerstone of our calendar, providing an invaluable opportunity for members to come together, review the past year, and set the agenda for the future. It’s also a chance to connect with fellow professionals, exchange ideas, and collaborate on key issues facing our industry. Keep an eye out for further announcements regarding the specific dates and details, and I hope to see many of you there. New faces are always welcome to attend.

As we move through this season, let’s continue to work together to foster innovation, resilience, and excellence across our industry. The PIA is here to support you, and we are committed to providing the resources and opportunities you need to succeed. Thank you for your ongoing support and dedication to Pump Industry Australia. I look forward to seeing many of you at the AGM and Annual Dinner in Melbourne, which this year will be held at Crown Casino on Tuesday, November 19. You will receive an email about this shortly.

Joel Neideck Acting President

Pump Industry Australia

Scan to subscribe to Pump Industry Magazine’s weekly newsletter –delivered to your inbox every Thursday afternoon.

Cover image: New South Wales

Reconstruction Authority

Published by

Prime Creative Media

ABN: 51 127 239 212

379 Docklands Drive

Melbourne VIC 3008 Australia P: (03) 9690 8766

www.primecreativemedia.com.au enquiries@primecreative.com.au

Editor: Chris Edwards

Journalists: Kody Cook, Tess Macallan

Business Development Manager: Rima Munafo

Art Director: Alejandro Molano

Designer: Jacqueline Buckmaster

Marketing Manager: Radhika Sud

Marketing Associate: Bella Predika

Digital Marketing Assistant: Emily Gray

Publisher: Sarah Baker

Managing Editor: Laura Pearsall

ISSN: 2201-0270

Contents

6COVER STORY

Resilient stormwater pump stations

10 PIA MEMBER NEWS

Moving to the next stage

Technology driving results

A legacy of innovation

16 ENERGY EFFICIENCY

Investigating energy savings

No wasted energy

Regulars

3PIA WELCOME

Acting President’s welcome

26 ASK AN EXPERT

No more waste in brewing beer

20 MOTORS, DRIVES AND PUMPS

Pumping into the future

Pump excellence anywhere, anytime

Gearing up

35 INDUSTRY INSIGHT

More paperwork for pump engineers

This document has been produced to international environmental management standard ISO14001 by a certified green printing company.

39 EVENTS

Heading west for WAME

41 INDUSTRY CAPABILITY GUIDE

28 PUMP SCHOOL

Operation of centrifugal pumps at reduced flows

30 PUMP TECHNICAL HANDBOOK

Pump Testing

This magazine is published by Prime Creative Media in cooperation with the Pump Industry Australia Inc. (PIA). The views contained herein are not necessarily the views of either the publisher or the PIA. Neither the publisher nor the PIA takes responsibility for any claims made by advertisers. All communication should be directed to the publisher.

The publisher welcomes contributions to the magazine. All contributions must comply with the publisher’s editorial policy which follows. By providing content to the publisher, you authorise the publisher to reproduce that content either in its original form, or edited, or combined with other content in any of its publications and in any format at the publisher's discretion.

Pumps Industry Magazine acknowledges Aboriginal Traditional Owners of Country throughout Australia and pays respect to their cultures and Elders past, present and emerging.

Robust,

Engines that keep running even in the toughest conditions. Easy to install, operate and maintain. A powerful partnership you can trust all the way from the drawing board throughout the operational life of your engine. Competitively priced complete power-pack units ready for delivery Australia wide with a local support team on hand 24/7. To find your nearest dealer visit volvopenta.com/industrial

Resilient stormwater pump stations

How communities and governments work together after a natural disaster is critical to building resilience.

With populations growing and climate change becoming an ever-present issue, governments are looking to take a proactive approach to reducing the impact of future disasters. These departments seek to help communities recover faster and minimise the future shock on these vulnerable populations.

The New South Wales Reconstruction Authority (RA) is one example of such a department. It works with communities, businesses and all levels of government to complete essential planning and preparation work, reducing the impact of extreme weather events on cities and towns across New South Wales.

Staff work closely with emergency services and community leaders to understand what is needed to help affected communities recover. RA will also lead recovery efforts once the immediate threat has passed, in conjunction with community leaders and other partners.

It’s people like Geoff Waterhouse, the Program Director for the Northern Rivers Recovery & Resilience Program at RA, who are helping communities

recover from extreme weather events. He’s an electrical engineer by trade who found himself in hydrology works. The creation of a new stormwater pump station in Murwillumbah was the first major pump works program he worked on, and it provided him with significant learnings.

The need for investment

The new stormwater pump station was located on the corner of Dorothy and Williams Street in Murwillumbah.

Murwillumbah is a town in the Northern Rivers of New South Wales and associated with the Tweed Valley region. Tweed Shire Council undertook this project in partnership with the National Emergency Management Agency (NEMA), RA, and the New South Wales Department of Climate Change, Energy, the Environment and Water (DCCEEW).

“One of the biggest reasons for building this flood pump station was to assist in removing stormwater and excessive water,” Mr Waterhouse said.

“We get that within low-lying areas from storm fronts that come through the region. They usually provide a lot of rain,

so the pump station will help remove that excess stormwater.”

Murwillumbah has dealt with significant floods over the years, with the town being inundated at least seven times in the last 70 years. In the last 20 years alone, the people of Murwillumbah have had to deal with significant disruptions from floodwaters that cut off the town from the north and south.

“The Dorothy Williams area desperately needs this upgrade. The biggest impact of flooding has been on residents and the football club. The Murwillumbah Brothers Leagues Club exists for the community and has been a centre for rugby league for many years now.”

Another benefit of installing the new stormwater pump station is to improve evacuation times for people wanting to leave the area. It provides a path for people to leave safely – particularly the case when it comes to flood events that could breach the levees throughout the central business district.

“2022 was the most recent time Murwillumbah was flooded,” Mr Waterhouse said. “It didn’t breach the

It is important to keep worksites safe during periods of extreme weather. Image: New South Wales Reconstruction Authority

in the past. With climate change, our wet season seems to be especially wet.”

The stormwater pump station

The stormwater pump station was part of a broader strategy to mitigate and build resilience to natural disasters and the impact of climate change. It is located behind the Dorothy Street levee, which runs in an east-west direction.

During the 2017 flood, the Dorothy Street levee was overtopped by about 300mm at the peak of the event. This overtopping and significant local catchment flooding around Brothers Leagues Club filled the basin. This water impacted the Leagues Club and several homes around William Street. Peak water levels from this section of the Rous River appear to have exceeded one per cent of the annual exceedance probability (AEP) levels in this event.

“Williams is a brand new greenfield site,” Mr Williams said. “The pumps will sit in a manufactured concrete well that sits at about the five-metre

by the pump sets. This will allow us to control more water flow when required, particularly in an extreme weather event. An additional benefit is the option to control the velocity of each pump. It allows for better control and water flow throughout the system.”

The team has installed two vertical in-shaft submersible pumps from Flygt, part of the Xylem group. One of the issues facing the RA during the installation was ensuring product continuity across the approximately 100 pump stations within the Tweed region. The Flygt pump set manufacturer supports every pump.

“The idea is to keep everything in that commonality, which makes maintenance nice and easy,” said Mr Williams. “It also means that if we need spare parts, we can source them locally and very quickly.”

Project challenges

Any project of this magnitude is subject to risks and challenges, and this project was no different. Like any government

ground while looking at everything that needs to be done from a mitigation point of view,” Mr Williams said. “The goal is to try to lower that risk, so we worked with the principal contractor to ensure they had the capabilities and resources to undertake this work. We also needed to ensure that any work done would create higher risks through the design development process.”

As part of the product selection phase, the RA team undertook a rigorous design and development process before selecting the type and category of pumps. There was also considerable work put into the hydrology report.

“We needed to know how much water was going to stay in the area that we would need to remove under pressure,” said Mr Williams. “We measured that and compared it against the natural water flow. Once we looked at it relative to rainfall records and collection data, we could predict and forecast what a one per cent AEP event would look like in the

area. We can measure that in litres per second or cubic metres.”

In a water-soaked environment that can be subject to extreme conditions, it is vital to ensure that the pumps are durable for long-term use. The Flygt range of pumps is designed for these situations, which is one advantage. Mr Williams also looked to reduce risk in this situation.

“Durability, performance and capability were the three biggest requirements that we looked for,” he said. “That’s particularly the case when we are looking at an area subject to extreme stress and pressure during flooding events. As a general rule, we try to match product types where possible. That makes life significantly easier when it comes to maintenance, while also accounting for those rare situations where something might need an urgent replacement. With renowned manufacturers and distributors in the local area, we could ensure that they could support us in times of need.”

Benefits for community

It’s often the case that people do not appreciate the benefits of proper stormwater management until they are impacted by poor stormwater management.

“The major benefit or outcome for the community is seen when excess water is removed from an area that is usually prone to flooding,” Mr Williams said. “While an individual flood pump station will never stop all the flooding forever, it helps remove large amounts of water quickly, particularly as part of a larger stormwater management system.”

Keeping homes and businesses as dry as possible during extreme weather events is key to keeping the community happy. Looking at what he

has experienced, Mr Williams pointed to the Murwillumbah Brothers Leagues Club operating as an important business for the community.

“We’re always trying to help businesses and organisations like that open their doors every day that they can,” he said. “If we are doing that, it’s a huge outcome for the community and for us.”

Tri-partisan support

During an emergency and the subsequent recovery, all levels of government need to work together to help the community. The creation of the Northern Rivers Recovery and Resilience Program (NRRRP) came from

Street in East Murwillumbah as well as on Wharf Street by the council chambers. We also have one of the largest pump stations under installation at Lavender Creek. There are also two civil projects that will help with the entry and exit points to the bridge across the Tweed Valley River.”

All the pump stations and civil works started in 2024, with the pump stations due for completion in the middle of 2025. The last two projects should be finished by the end of 2025.

“It’s important to note that most of the hydrology works for improving flood assets and pump stations is happening across the Northern Rivers, including

The RA’s Geoff Waterhouse discusses flood pumps improvements in Murwillumbah with Richmond MP Justine Elliot, NSW Parliamentary Secretary Janelle Saffin and representatives of the Brothers football club. Image: New South Wales Reconstruction Authority

Getting the right infrastructure in place is essential. Image: New South Wales Reconstruction Authority

Working together is essential when recovering from emergency situations. Image: New South Wales Reconstruction Authority

Flowrox™ pumps for transferring, dosing and metering

Unmatched pumping reliability

The world’s toughest pumps are all about ensuring your productivity and profitability even in the most demanding applications and conditions.

Flowrox industrial pumps serve a wide range of industries, performing especially well in processes involving abrasive, corrosive, highly viscous or crystallizing media with high solid content, up to 80%.

We provide solid performance around the world for the most heavy-duty pumping applications.

Moving on to the next stage

“Technology. Passion. Support Our Globe” is the philosophy driving this manufacturer forward.

Ebara Pumps Australia has opened its newest location, a brand-new facility in Bayswater North, Victoria.

For over 40 years, Ebara Pumps have been sold and used in Australia to support a sustainable society and a growing economy. A subsidiary company of the Ebara Group, Ebara Pumps Australia was established in 2000 to better service the market with an increasing range of high-quality products. A strong network of nationwide dealers has been developed to support the sales and service of our extensive range of products.

The new location will enable Ebara to enlarge its stock capacity, expand its production capability and enhance its corporate organisation to provide a greater level of services to customers. This will meet growing business demands in Australia and allow Ebara to move on to the next stage.

Ebara will continue to generate the innovation our world needs as the pace of change accelerates, driven by our core passion for benefiting people and society.

1.Innovative hydraulic design technology

With over 120 years of experience in the pump industry and as the first centrifugal pump manufacturer in Japan, Ebara’s most remarkable capability is hydraulic design technology.

1-1. 3D inverse design method

Ebara produces high-efficiency and high-performance pumps that meet required operating conditions by using optimisation technology, combining the computational analysis of water flow inside the pump with the unique design methodology of the internal geometry of pumps through simulations under prescribed ideal flow conditions so-called 3D inverse design method. This unique design method has been applied

to the extensive range of Ebara Pumps to meet customer requirements of high pump efficiency and performance.

1-2. Low axial thrust

impeller, Shurricane™

The static pressure imbalance between an impeller’s front and back shroud causes an axial thrust load on the pump, which reduces the motor’s bearing life. Ebara’s patented impeller design, “Shurricane™,” is applied to Ebara Vertical Multistage Pumps (EVMS Series). Shurricane™ maintains high efficiencies and significantly reduces the axial thrust load, meaning that any standard IEC motors can be used, and bearing life is ensured.

2. High quality hydroformed one piece volute casing

Hydroformed pump casing.

Ebara also developed the unique production process of pump casing, called hydroforming. This innovative production method uses a highpressure fluid (up to 1200 bar) to form the metal perfectly smooth, highly flowing, and without welding points. This innovative production method enables the one-piece volute casing to obtain high pump efficiency and reliable quality. This unique design method has been applied to the extensive range of Ebara Stamped Stainless Steel Pumps, such as the 3 Series.

3. One million cycles endurance test

Ebara Pumps are manufactured to the highest quality standard and achieve reliable operating performance through rigorous technical evaluation criteria and control programs that involve the whole manufacturing process.

The endurance test, which involves one million cycles of pressure pulsations, is applied to the product development stage of Ebara Pumps to ensure the highest reliability in the pump industry.

For more information, visit ebara.com.au

Low axial thrust impeller, the Shurricane™.

3D inverse design method. Images: EBARA PUMPS

Technology driving results

WEG is expanding its product range to offer complete monitoring and data analysis capabilities.

WEG has already introduced two wireless smart sensors that can be used with a simple smartphone interface or a gateway. It is well known that by monitoring the performance of critical equipment through condition monitoring, it’s possible to detect early changes in equipment, providing end-users with enough time to take the necessary steps to avoid unexpected downtime.

But what has changed significantly in recent times is the development of smaller, smarter, cheaper sensors and inexpensive support systems that can provide more practical visibility to the number of machine data points with comparably little investment.

Top factors for real outcomes

WEG has considerable experience in understanding how to achieve real outcomes for maintenance and reliability teams. It ultimately comes down to several essential factors.

Condition monitoring must be easy to install and set up, reducing set-up time and labour costs. The systems need to integrate with a range of existing assets and follow site practices, further minimising onboarding and maintenance problems. Data loggers must be robust and account for dust and water ingress with a suitable IP rating.

The data itself must be secure, and end-users must have strict controls over it. The reports that come out of the collected information need to be understood, from basic monitoring to highly complex diagnostics. That data needs to be broken down into its constituent parts to ensure maximum visibility.

It’s also essential to understand the financial aspect of such a program. Companies may baulk at the initial upfront cost, but such assessments

need to take on board the benefits of improving safety, productivity, and finances.

How WEG plays a role

Considering these factors, WEG is introducing an additional patented technology to its wireless condition monitoring suite for use with the WEGscan.

In a system where the sensors are already performing periodic measurements of vibration, temperature, power consumption, motor efficiency, bearing health and running hours, WEGsync technology combines the synchronous vibration measurement of multiple sensors for the asset’s phase and structural deformation analysis.

Simply put, the data from multiple sensors is synchronised and analysed, allowing the specialist to concentrate on the immediate outcomes rather than the measurements themselves. This saves time, and the overall monitoring process becomes less expensive.

Smart technology is revolutionising maintenance and scheduled downtime for pump users.

Flexibility in data capture

The sensors can be easily fitted to a great variety of machines and fixed locations if necessary, becoming a strategic resource for any maintenance or engineering team measuring temperature, vibration, functional hours and real-time operations, as well as for machine health trending or operational deflection shape information as required.

In addition, the WEG Motion Fleet Management (MFM) platform offers access to modules such as “motor specialist” and “exchange”, which provide access to advanced algorithms for more complex failure and energy consumption analysis and any data integration with the customer’s systems.

Plant productivity, efficiency, planning, and profitability are the intended outcomes. From the basics of alarms and data viewing from a smartphone app to analysis and data sharing through the WEG MFM platform, WEGscan can be adapted to any site’s needs and practices.

For more information, visit weg.net/au

The WEG ODS system ensures that pumps are maintained at the best possible level, with problems identified early. Images: WEG

A legacy of innovation

Franklin Electric evolved from its WWII roots to become a global

the first electrical engineer. Since its humble beginnings as a small motor manufacturing company, Franklin Electric has grown into a global leader in the water and fuel systems industry.

Early beginnings

Franklin Electric’s journey began with the production of a backpack generator designed to power radio equipment

fuelling applications.

In 1962, Franklin Electric established its presence in Australia to support the local water industry. This began a long-standing commitment to providing water systems solutions to the Australian market.

Global consolidation

In 2020, Franklin Electric took a significant step towards global

Electric Australia and Pioneer Pump Holdings Australia merged to form Franklin Electric Australia New Zealand. This new entity operates two critical facilities: a warehouse and assembly facility in Dandenong South, Victoria, and a fabrication assembly and test facility in Sunshine West, Victoria. A logistics warehouse in Ravenhall, Victoria, also supports operations.

Expertise and product range

One of Franklin Electric’s most significant assets is its wealth of experience. With hundreds of years of combined expertise, the company’s staff is well-equipped to assist customers with a wide range of pumping applications. This extensive knowledge base ensures that Franklin Electric can provide tailored solutions to meet the unique needs of each client.

Today, Franklin Electric offers an expansive range of products, including:

• Surface mount pumps: ISO, split case, multi-stage, small and large centrifugal motor pumps

• Progressive cavity pumps: mono and self-priming ranges

• Solar pumps and equipment: catering to the growing demand for sustainable energy solutions

• B elow ground pumps: submersible turbine, line shaft, bore hole and dewatering pumps

These products are designed to handle everything from small volume, low head applications to extremely high volumes (up to 2500 LPS) and discharge heads exceeding 300 meters. This comprehensive product range makes Franklin Electric one of the largest

suppliers of pumping and associated products globally.

Commitment to innovation

Franklin Electric’s commitment to innovation is evident in its continuous efforts to improve and expand its product offerings. The company’s relocation in 2013 from its original headquarters in Bluffton, Indiana, to a new global headquarters and Centre of Design Excellence in Fort Wayne, Indiana, underscores this dedication. This state-of-the-art facility serves as a hub for research and development, ensuring that Franklin Electric remains at the forefront of technological advancements in the industry.

Global reach

Franklin Electric’s global footprint is extensive, with manufacturing and distribution facilities in numerous countries, including Australia, Brazil, Canada, China, Czech Republic, Germany, India, Italy, Japan, Korea, Mexico, New Zealand, Singapore, South Africa, Turkey, the UK, and the United States. This widespread presence enables the company to serve clients worldwide, providing

reliable and efficient water and fuelling systems solutions.

The company’s primary markets include water transfer and grey water systems, clean water systems and fuelling systems. Franklin Electric has the expertise and products to meet diverse needs, whether it’s a submersible pump for a clean well water system or an industrial water pump for a larger application.

Franklin Electric’s journey from a small motor manufacturing company to a global leader in water and fuelling systems is a testament to its commitment to innovation, quality, and customer satisfaction. Franklin Electric continues to set the standard for excellence in the industry with a rich history, extensive product range and a global presence.

As the company moves forward, it remains dedicated to providing cutting-edge solutions that meet the evolving needs of its customers, ensuring that “Moving Water is Our Business” is more than just a slogan –it’s a promise.

For more information, visit franklinelectric.com.au

Leading fluid

path solutions provider expands Australian presence with new Perth office

Watson-Marlow Fluid Technology Solutions (WMFTS) is celebrating the opening of its new Perth office, the company’s second in Australia.

Previously operating solely out of its Sydney office, WMFTS has been a leading provider of fluid path solutions for the past 13 years. This new Perth office brings the Watson-Marlow team closer to its Western Australia-based customers so that it can further enhance its quality of service.

This new Perth base is located in Belmont, and is focused on directly supporting, selling, servicing and repairing WMFTS solutions.

Elie Elazar, Country Manager at Watson-Marlow Australia, said, “We’re delighted to strengthen our presence in the market with the opening of our second office in Perth. We put the customer at the heart of everything we do and with our Perth site, we are making sure that we can truly partner with them on their fluid path challenges.”

How validated carbon reduction targets can safeguard your business

Grundfos is the first water solutions company to receive validation of its long-term 2050 net-zero target and near-term 2030 emission reduction targets from the Science-Based Targets initiative (SBTi). As your trusted partner you

Get immediate savings from lower energy consumption and optimised processes

Achieve emissions reduction without compromising reliability an essential requirement in many sensitive factory processes

Benefit with a partner who helps developing energy-efficient solutions for the future

Optimise processes at the factory with a recognised partner offering a range of energy optimisation tools and service

Let's work together towards decarbonising industry!

Sustainability is a vital component of wastewater management, and is increasing in importance.

Image: Poh Smith/stock.adobe.com

No wasted energy

Given wastewater management is a challenging and highly dynamic industry, improving environmental outcomes is a key focus for facility managers.

In the dynamic landscape of pump and wastewater management, efficiency isn’t just desirable — it’s imperative.

SEW-EURODRIVE’s DR2C synchronous motors represent a pinnacle of energysaving innovation designed to set a new operational benchmark within the sector. Engineered for pure inverter operation and boasting the ultra-high efficiency class IE5, these motors set their own standard when it comes to sustainable technology.

Efficiency and cost savings

At the core of SEW-EURODRIVE’s DR2C motors lies a dedication to efficiency. The DR2C series slashes energy losses by up to 40 per cent, translating directly into end-user benefits of substantial operating cost savings. One of the key features is low inherent mass inertia. This reduces energy usage during acceleration while benefitting net energy usage over extended operation periods.

With tonnes of water processed at most plants and multiple stages

of purification, essential equipment like motors and geared motors are an important consideration. SEWEURODRIVE has facilitated many water treatment operations, a standout example being a treatment plant in North East Victoria. Since water quality in this region was ever-changing, the plant system required the flexibility to adjust the motor speed in response to the varying conditions.

Versatility and easy integration

Compatibility with SEW-EURODRIVE’s modular systems enhances the versatility of DR2C motors. These motors seamlessly adapt to diverse mounting topologies, whether paired with central MOVITRAC® advanced inverters or decentralised MOVIMOT® advanced units from the MOVI-C® automation system.

Adaptability to dynamic load requirements

Pump and wastewater systems often face fluctuating load demands. The DR2C motors, with their dynamic

capabilities and high power density, adjust seamlessly to varying operational conditions. This adaptability ensures optimal performance and energy efficiency across a wide range of applications, including full or partial load operations.

Space and installation flexibility

In facilities where space is at a premium, the compact design of DR2C motors proves invaluable. These motors offer a smaller footprint than traditional counterparts, facilitating easier installation and retrofitting into existing infrastructure without compromising performance. The DR2C motors can have a frame size up to two times smaller than comparable power IE3 asynchronous motors!

Regulatory compliance and sustainability

Efficiency isn’t solely about financial benefits; it’s about reducing environmental impact and meeting stringent energy efficiency regulations.

By curbing energy consumption and minimising carbon footprints, these motors help organisations navigate regulatory landscapes while promoting a cleaner, greener future.

Reliability and reduced downtime

Unscheduled downtime is a costly occurrence in any industrial setting. With robust quality features, the DR2C motors ensure reliable and continuous operation while minimising maintenance needs and optimising uptime. This reliability is crucial for maintaining seamless operations in critical pump and wastewater applications.

The DR2C represents the continued effort in futureproofing the processes, systems and operations of SEWEURODRIVE’s customers.

Extended warranty offerings, local service and support SEW-EURODRIVE confidently stands behind its products.

The DR2C motors are supported by extended warranty options, which signifies SEW-EURODRIVE’s confidence in their performance and longevity. This offer aims to provide peace of mind and safeguard investments in critical infrastructure for future users.

Beyond innovative technology, SEW-EURODRIVE prioritises customer support. With a robust network of local sales and service teams, including engineering specialists and maintenance experts, prompt assistance is always within reach.

For more information, visit sew-eurodrive.com.au

Driving the world

The range of DR2C synchronous motors ensures that it can be utilised in a range of industries.

When quality and innovation combine

How can we help you achieve your KPIs?

At SEW-EURODRIVE, we understand the operational needs and demands that pump a pplications require. We provide efficient and sustainable solutions using the latest in drive system technology from our vast range of products.

Worrying about failure rates and operational costs is a thing of the past; it’s time to shift your focus to exceeding productivity and sustainability.

Want to learn more about how we can support you? Get in touch today! Scan QR code to view our website

Image: SEW-EURODRIVE

Pumping into the future

Pump Systems was established in 1984 and has been based in Canterbury, New Zealand. Quickly moving from its roots to expand its market to Australia, Pump Systems has become a noted supplier of wastewater pumps and processing equipment, specialising in chopper pumps, digester mixing systems, rotary drum screens and sludge heat exchangers. More recently, Pump Systems has recognised and services growing demands from the agriculture and biogas waste-toenergy sectors.

“We started as a small industrial pump supplier and service agent,” said Jarrod Marsden, Director of Pump Systems. “Since then, we’ve grown and streamlined our operations to focus on the industrial and municipal markets. Through these efforts, Pump Systems has been key in establishing a wide range of pump and wastewater process equipment brands in Australia and New Zealand.”

Entering the chopper pump industry

In 1993, Pump Systems formed a relationship with the manufacturers of the first chopper pump at Vaughan Company. These pumps were developed in 1960 to avoid the historical problem of clogging in manure pumps.

“We sold our first chopper pump in New Zealand in 1993, followed by Australia in 1994,” Mr Marsden said. “We

have been supporting the Australian and New Zealand markets ever since with our highly experienced and factorytrained sales and projects team.”

More than 25,000 Vaughan chopper pumps have been installed worldwide, a testament to the company’s innovative approach over the decades.

Chopper pumps work by chopping all incoming solids before they pass through the pump. Since handling solids-laden wastewater and sludge can be challenging at times, chopper pumps do the job that conventional cutter and grinder pumps cannot.

“These pumps provide trouble-free operation in the most challenging environments that an operator might experience,” Mr Marsden said. “We often find those environments in wastewater treatment plants and other industrial waste processes. The Vaughan pumps ensure that any solids in suspension do not cause any clogging or blockage problems. That protects the pump and ensures that downstream processes and components can continue operating at high efficiency.”

Representing top brands

Pump Systems is the authorised representative for Vaughan Chopper Pumps and supplies the Rotamix Process Mixing Systems in New Zealand and Australia. It also provides products for municipal wastewater

treatment plants, food processors, abattoirs, fishing vessels, and pulp and paper mills.

“We are well-known for providing high-end pumping and mixing systems that exceed performance requirements,” Mr Marsden said. “These machines are energy-efficient, offer long-term reliability and are easy to operate and maintain.”

Pump Systems also works with Lackeby Sludge/Water Heat Exchangers. Lackeby Products is a division of the Lackeby Water Group in Sweden and is known for its sludge heat exchangers.

“The unique design is based on a modular principle with large circular sludge channels,” Mr Marsden said. “The channels provide a large throughput area that keeps pressure losses low and minimises the risk of clogging.”

This commitment to providing highquality machines sees Pump Systems continue to operate at the cutting edge of the industry. Working with world-class suppliers, Pump Systems remains at the forefront of advancing wastewater management solutions across Australia and New Zealand, ensuring sustainable development and operational excellence for its valued clientele.

For more information, visit pumpsystems.co.nz and chopperpumps.com.au

Leachate pumps installed on the Gold Coast are making a significant difference.

Pump excellence anywhere, anytime

Pumps are an integral part of modern life, and end-users choose to purchase solutions from experts who are committed to customer satisfaction.

There’s a famous saying: ‘A jack of all trades is a master of none.’ This expression can be applied to companies that stretch themselves too thin by trying to supply many products across varying industries. The pump industry is not immune to this, but Roto Pumps stands out as one company that maintains a laser focus on its core focus as a manufacturer of high quality pumps. With a reputation for reliability and innovation, Roto Pumps is dedicated to advancing pumping technology and delivering exceptional value to industries that depend on precision and durability in their fluid handling systems.

Indian expertise

Established in 1968, Roto Pumps is India’s pioneer manufacturer of progressive cavity pumps. It has more than 50 years of experience providing high-quality, efficient and reliable pumping solutions to a wide variety of industries. Roto Pumps has been pivotal in the evolution of manufacturing in the subcontinent, with the vast majority of global pump manufacturers now partnering or owning plants in India and China.

The willingness to embrace cuttingedge technologies has significantly increased the precision and efficiency of their products. Roto Pumps has

incorporated advanced engineering techniques and state-of-the-art machinery into its manufacturing processes. Adopting high-tech solutions has enabled Roto Pumps to produce components with tighter tolerances, higher reliability, and improved performance.

Similarly, research and development (R&D) investment has fuelled innovation within the Indian pump industry. Prioritising R&D to drive the development of new technologies and solutions has resulted in highly efficient, durable, and customised pumping solutions that cater to diverse industrial needs.

Roto Pumps has exported its pumping solutions to more than 50 countries worldwide, demonstrating its dependability as a manufacturer and supplier of high-quality equipment.

Roto Pumps has been supplying directly to Australia since 2001 – its first warehouse outside of India. With its head office in Dandenong, Victoria, and satellite sales managers in Sydney, Brisbane and Perth, Roto Pumps’ reach is steadily growing as end-users recognise its high-quality products and expertise.

A focus on satisfaction

Sacrificing expertise is not a concern for Roto Pumps. Its focus on pumps

has enabled it to hone its industry knowledge and establish itself as a pumping expert prioritising customer satisfaction.

Roto Pumps’ world-class research and development have enabled it to develop customised, state-of-the-art pumping solutions. With its singular focus on pumps, Roto Pumps has helped cement itself as a market leader. Roto Pumps is so committed to customer satisfaction that at its Dandenong head office, the team takes worn or damaged pumps from customers and completely rebuilds them like new.

Roto Pumps has also adopted a customer-centric approach, focusing on tailoring solutions to meet specific client requirements. It exemplifies this by offering customised pumping solutions and responsive after-sales support. An extensive network of distributors and channel partners pairs seamlessly with its optimum levels of spare parts across the country.

With its extensive knowledge of pumps, Roto Pumps understands industry needs and is committed to delivering high-quality pumping solutions to the global market.

For more information, visit rotopumps.com.au

Image: ROTO Pumps

ROTO MINE DE WATERING PUMP SERIES

E mpowering your mine operations with Roto’s high pressure flexible shaft series pumps. Unleash the solution that challenges excess water, ensuring safe and efficient operations ; the Underground Maintena n ce Engineers’ Choice for ground water control.

Features:

•Robust construction for prolonged life and reliable performance

• Adaptable for challenging underground environments, available in fixed station configurations for single lift or staging along with portable packaged solutions

• Forge a direct connection with the manufacturer, ensuring personalised support, reliable service, and unparalleled product knowledge

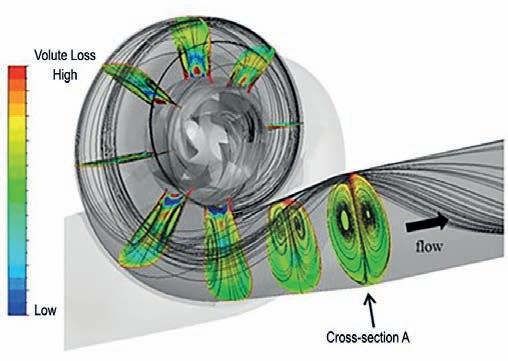

It’s critical to have the right pump infrastructure in place, particularly within a wastewater facility. Image: Regal Rexnord

Gearing up

When looking to improve the performance of wastewater facilities, it’s critical to understand the products that can achieve this goal.

Regal Rexnord seeks to create a better tomorrow with sustainable solutions that power, transmit and control motion. For the people who work for Regal Rexnord, that means creating innovative solutions while focusing on customer needs. Regal Rexnord employees like Greg Josephson, the Marketing and Distributor Manager, and Rex Sinclair, the National Product Manager, drive positive outcomes internally and externally.

“We got involved collectively with Regal Rexnord through the power transmission and industrial power train industry, and we are now part of the company,” said Mr Josephson. “We can offer full end-to-end powertrain solutions with the company’s size now.”

Supporting wastewater

Regal Rexnord’s product range is exhaustive, with over 60 brands supplied. Regal Rexnord can provide

a full range of intermediate power transmission products.

“It doesn’t matter what the job is,” Mr Josephson said. “We can support massive pumps pulling water out of a river, a slurry pump on a mine site or a submersible unit that needs a constructed gearbox within a wastewater plant.”

The last example is particularly noteworthy. Bauer Gear Motors is a brand under the broad Regal Rexnord corporate umbrella. Bauer’s wide product range includes helical geared motors and shaft-mounted geared motors, among other products.

The BX series includes unparalleled standard features, including hollow shafts in the smallest sizes. The IP68 design geared motors are most suitable where conveying or transporting grey water, waste, river or rainwater and all types of sludge-containing water in communal or industrial areas is required.

The BK series is frequently used in agitators, extremely wet areas, or completely submerged underwater.

Customised solutions

Regal Rexnord’s business involves providing customised solutions to its clients. It’s a fundamental part of the company’s work. Mr Josephson sees the world as one of entrepreneurial expansion. Society has moved past when everyone bought the same product and is now looking at how to get the most from their processes.

“Regal Rexnord seeks to provide solutions for its clients by looking at the entire product catalogue,” Mr Josephson said. “We need to work with our clients to understand their processes and provide the component parts that they need. By doing that, we create an effective solution that achieves the client’s goals.”

He pointed out that they can

communicate with partner brands across the globe to obtain the individual parts needed for a solution.

“It would not be unusual to have German engineers on one phone, US engineers on a second phone and Chinese staff on a third phone. It’s an opportunity for us to work across multiple brands to provide solutions for our clients.”

The future for Regal Rexnord Businesses, big and small, want to streamline their processes. It is products like the BK Series of submersible bevel geared motors from Bauer Gear Motors, working in conjunction with other products from the Regal Rexnord umbrella, that provide customised solutions, both now and into the future.

“There’s no need to go to multiple suppliers to get a complete system,” said Mr. Josephson. Companies can come to us, and we can provide solutions specific to an application or its objectives. That’s how we can make a difference for customers.”

For more information, visit regalrexnord.com

MINE DEWATERING EXPERTS

Bauer Gear Motors has produced the BK Series of submersible bevel geared motors, ideal for wastewater applications. Image: Regal Rexnord

No more waste in brewing beer

In this edition of Ask an Expert, we look at the benefits of a groundbreaking system solution for spent grain transfer for breweries.

Q: Can you explain what this system is and how it benefits breweries?

A: The Smart Air Injection (SAI) system of a renowned pump manufacturer is an advanced solution designed to enhance the efficiency of transporting brewing by-products, particularly spent grain. This system significantly reduces the consumption of compressed air, a major energy expense in conventional methods. By combining an open hopper progressive cavity (PC) pump with pneumatic dense phase conveying, the SAI system efficiently transfers spent grain over long distances with controlled air pulses. This leads to considerable energy savings and contributes to breweries’ sustainability goals.

Q: How does the SAI system compare to traditional methods of handling spent grain?

A: Traditional pneumatic systems for handling spent grain are energy-intensive as they use continuous compressed air. These systems are prone to blockages and require a lot of energy to move the by-products over long distances. The SAI system, on the other hand, uses a discontinuous method where spent grain is moved in plugs with intermittent air pulses. Additionally, it minimises pipeline wear due to lower flow velocities, further enhancing system efficiency and longevity.

Q: Can you discuss the environmental impact of using the SAI system in breweries?

A: The SAI system’s reduced air consumption directly translates to lower electricity usage, which helps breweries reduce their carbon footprint. The SAI system aligns well with sustainability initiatives by halving the time required for spent grain transfer and cutting air usage by more than half.

It reduces energy costs and supports breweries in achieving their carbon reduction targets, making the brewing process more eco-friendly.

Q: How does the SAI system handle variations in the moisture content of spent grain?

A: One of the key advantages of the SAI system is its flexibility in handling media with varying moisture content, ranging from 60 to 85 per cent. This adaptability ensures that the system maintains high efficiency regardless of the moisture levels in the spent grain.

Q: Can you elaborate on the integration capabilities of the SAI system with existing brewery operations?

A: The SAI system is designed for easy integration in breweries. Its advanced control technology can seamlessly fit into current processes without requiring major overhauls. This ease of integration makes it a versatile and practical solution for breweries looking to modernise their spent grain handling operations while maintaining operational continuity.

Q: What feedback have you received from breweries that have implemented the SAI system?

A: Feedback from breweries has been overwhelmingly positive. They appreciate the significant reduction in energy consumption and the associated cost savings. The improved efficiency and reduced transfer times have also been highlighted as major benefits. Breweries and operators have noted the system’s reliability and reduced maintenance needs due to lower pipeline wear. Overall, the SAI system has proven to be a valuable investment for breweries aiming to enhance sustainability and operational efficiency.

Vila, Managing Director of SEEPEX Australia, is a progressive cavity pump expert. He has been involved with pumps for over 40 years. Peter spent the first five years repairing pumps and the following 35 years in technical sales, 20 of which have been with SEEPEX progressive cavity pumps. For more information on progressive cavity pumps, please contact SEEPEX Australia on 02 4355 4500 or at info.au@seepex.com

Air consumption reduced up to 80%

SEEPEX’s Smart Air Injection (SAI) is the cost saving solution that energy-efficiently transports spent grain with a variable wetness content of 60-85% and at distances of up to several hundred meters. SAI offers numerous benefits for your brewery and distillery.

YOUR BENEFITS WITH SAI

y Air consumption reduced by up to 80%

y Minimal operating expenses due to fewer energy costs

y Optimal conveying process increases overall process reliability

y Long distance transport of up to several hundred meters

y Flexible operating point to easily transport media with varying wetness-content

y Increased process efficiency due to reduced throughput times

y Simple integration into existing automation and control systems

Operation of centrifugal pumps at reduced flows

Centrifugal pumps can operate over a wide range of capacities, from near zero flow to well beyond the rated capacity. However, there are certain minimum operating flows which must be imposed on centrifugal pumps for either hydraulic or mechanical reasons. Four limiting factors must be considered: radial thrust, temperature rise, internal recirculation, and shape of the power curve.

For sustained operation, it is important to adhere to the minimum flow limits recommended by the pump manufacturer.

The thermodynamic problem that arises when a centrifugal pump is

An ITT Goulds process pump, built by Kelair Pumps. Image: Kelair Pumps

operated at extremely reduced flows is caused by the heating up of the liquid handled.

The difference between the power consumed and the waterpower developed represents the power losses in the pump, except for a small amount lost in the pump bearings. These power losses are converted to heat and transferred to the liquid passing through the pump.

If the pump were to operate against a completely closed valve, the power losses would be equal to the shutoff power. Since there would be no flow through the pump, all this power would go into heating the small quantity of liquid contained in the pump casing. The pump casing would heat up, and a certain amount of heat would be dissipated by radiation and convection to the atmosphere.

However, because the temperature rise in the liquid pumped could be quite

rapid, it is generally safer to ignore the dissipation of heat through radiation and the absorption of heat by the casing. Calculations for determining the temperature rise in the liquid are available from Kelair.

The maximum permissible temperature rise in a centrifugal pump varies over a wide range, depending on the type of service and installation. The minimum capacity based on thermodynamic considerations is then established as that capacity at which the temperature rise is the maximum permitted.

There are also hydraulic considerations which may affect the minimum flow at which a centrifugal pump can operate. In recent years, correlation has been developed between operation at low flows and the appearance of hydraulic pulsations both in the suction and in the discharge of centrifugal impellers.

It has been proven that these pulsations are caused by the development of an internal recirculation at the inlet and discharge of an impeller at certain flows below the best efficiency capacity. The pump manufacturer’s recommendations on minimum flows dictated by these considerations should always be followed.

The NPSHR curve becomes increasingly unstable at low flows. As a rule of thumb, do not operate pumps at flowrates lower than that equivalent to the left-hand end of the NPSHR curve. This rule must be considered in conjunction with other issues detailed in this section.

Ensuring you have the right pump for the right application involves a thorough set of considerations.

Consult a knowledgeable pump supplier like Kelair Pumps to discuss your pumping requirements.

Article courtesy of Kelair Pumps Australia “When Pump Knowledge Matters” Phone 1300 789 466 or visit kelairpumps.com.au

PUMP TECHNICAL HANDBOOK Pump testing

Our ongoing series from the PIA’s Australian Pump Technical Handbook investigates why and how pump testing is used.

FACTORY PERFORMANCE TESTS

Pumps are tested for a variety of reasons, not all of which are solely to meet the customer’s test requirements.

The final user’s interest in the machine is generally confined to the following:

a. T he total head at the duty flow.

b. T he power consumption at the duty flow and head directly indicates the pump efficiency.

c. Suction performance, defined by NPSH.

d. Th e mechanical integrity of the machine.

The customer may also be interested in the following:

e. T he level of noise emitted by the machine.

f. T he vibration level of the machine.

g. A f unctional check on auxiliary equipment.

h. Th e starting capability under simulated site conditions.

i. To verify the curve shape and rise to zero flow.

AS/ISO9906:2018 covers the Australian Standard for pump

performance testing and is a direct adoption of ISO9906:2012, Rotodynamic pumps – Hydraulic performance acceptance tests – Grades 1, 2 and 3.

It should be noted that the ANSI/HI 14.6-2016 standard is harmonised with the ISO standard, so testing under either standard will enable a similar test result.

Where required and specified, ISO and HI/ANSI standards are available to provide guidelines for acceptable test levels for pump noise and vibration testing. BS EN ISO 20361 provides guidelines on noise tests, and Europump has also published Pump vibration standard guidelines.

The centrifugal pump test standard applies to water or liquids with similar viscosity. Since a centrifugal pump may eventually be pumping viscous liquid, ISO 17766 provides conversion factors to predict its actual site performance.

PUMP TEST TOLERANCES

The allowable tolerances and error limits are clearly defined in the separate testing grades allowed in the standard.

For information about selecting suitable acceptance grades, refer to section 10.3 of the Australian Pump Technical Handbook.

Every measurement is inevitably subject to inaccuracies, even if the measuring procedure, the instruments used and the analysis directives fully comply with prevailing acceptance rules. The test standards consider these inaccuracies (errors of measurement) when determining an allowable tolerance.

The test code expresses the rules for deciding whether a pump meets the guaranteed conditions of a contract. These rules vary greatly for Grade 1, 2, and 3 tests, and the allowable errors in the measuring equipment used for Grade 1 tests are more stringent than those required for Grades 2 and 3.

The verification of each guarantee shall be accomplished by comparing the results obtained from the tests with the values guaranteed in the contract, including their associated tolerances.

All tolerances are percentages of the values guaranteed.

While the test standard nominates default acceptance grades for various industries and pump kilowatt ratings, the most common test is Acceptance Grade 2B.

For a pump performance test, the guarantee point (duty point) must specify a guaranteed flow Q G and a guaranteed head H G . Unless specified in a contract, the power or efficiency is an optional guarantee value. Power is directly measured, while efficiency is a derived value.

In verifying if a guaranteed Grade 1B, 1E, 2B or 3B condition is met a tolerance cross with the horizontal line ±tQ × Q G and the vertical line ±t H x H G is drawn through the guarantee point. Similarly, Grades 1U and 2U guaranteed conditions are met by an L with the horizontal line +tQ x Q G and the vertical line +t H× H G drawn from the guarantee point.

The guarantee on the head and flow rate has been met if the H–Q (measured head and flow) curve cuts or at least touches the vertical and/or horizontal line (see Fig.2 for Grade 2B acceptance).

The efficiency shall be derived from the measured H–Q curve, which is intersected by the straight line passing through the specified flow rate guarantee, head guarantee, and the zero of the Q-H axes, and where a vertical line intersects the efficiency curve.

The guarantee condition on efficiency (n G) is within tolerance if the efficiency value at this point of intersection is higher than or at least equal to n G x (1t n), as per Fig 2.

When it is contracted to be tested, a measured NPSHR value shall not exceed the guaranteed NPSHR value.

To determine the complete hydraulic performance of a pump, it is necessary to measure the following:

a. Rate of Flow: This can be done using classical venturi flow meters, orifice plates, volumetric measuring tanks, weirs, electromagnetic meters, or velocity measuring devices used in

a known cross-sectional area of the pipe. A throttle valve on the pump discharge controls the flow rate.

b. Suction and Discharge Pressure: Pressure gauges, transmitters and transducers are the most common devices for direct pressure measurement. Often, gauges in factory test facilities read directly in metres of water, deleting the need to convert a kPa pressure reading into metres of water head. Pressure tappings should be placed in a parallel section of pipe located at a distance of two diameters from the pump flanges. Grade 1 requires four tapping points around the pipe, whilst grades 2 and 3 only need one tapping on the horizontal centreline. The height of the gauges above or below the pump datum must be included in the head calculation. Most factory pump tests eliminate this by positioning the suction and discharge gauges at the same height (via flexible tubing), whereby the correction becomes zero. The pump datum is the shaft centreline for horizontal pumps. As the total pressure in the suction and discharge pipes includes a velocity head component, these must be calculated and included in the total head.

c. Power Measurement: The majority of pumps are driven by electric motors. The normal method for determining the pump input power is to measure the motor input kW using a suitable power analyser. The pump input power is then calculated using motor efficiency figures corresponding to the actual load. Where the pump is not directly coupled, e.g., belt or gearbox drive, consideration needs to be made for additional drive losses.

d. Speed of Rotation: Optical frequency response tachometers are the most common method for measuring the pump input speed (r/min). Reflective tape is attached to the pump shaft to trigger the optical response device. If a speed-changing device, such as a belt drive or gearbox, is used between

the driver and pump, the loss of this device must be known to arrive at the pump’s input power. Modern variablespeed devices, such as frequency inverters, have electrical losses that need to be considered to arrive at the total input power.

It should be noted that the rotation speed is not usually a guaranteed performance value. However, it is a significant value to know, especially for performance diagnostic evaluation either while testing or later on site. Whenever possible, a manufacturer’s test on an engineered pump should be at the specified rated speed and power. Under these conditions, NPSHR tests can clearly determine the zone of suction instability or onset of cavitation. This is particularly important where low NPSHA conditions exist at the site.

Where pumps cannot be tested at the rated speed, e.g., high-head pumps such as boiler feed units or units with variable speed drives, problems may be encountered where testing facilities require performance testing. In many such cases, reduced speed tests are conducted, and the affinity laws, as described in Section 6.4 of the Australian Pump Technical Handbook, are used to translate the test data to reflect the performance at the actual site operational speed. When it is agreed between the purchaser and supplier, the test standard allows test speeds to be within 50 to 120 per cent of the specified rotation speed (actual site operational speed).

In most instances, the pump is installed on the test bed coupled to its own driver, and both are mounted on a combined baseplate. Thus, the behaviour of the entire unit can be monitored during factory tests. Manufacturers outlay considerable capital to provide and maintain an adequate test facility. While testing costs are relatively expensive, the potential improvement in plant/station reliability outweighs and justifies these additional costs. If the reliability of operations is improved and there is a reduction in standby equipment results, then the cost will be justified. Specifying a factory test provides baseline data that will be available for all future analyses of a pumping system.

SITE TESTS

Many clients specify testing of pumps after initial installation at the site to prove the guaranteed performance.

If a pump has been factory tested and further tests are required after installation, reproducing the factory test results can often be difficult. Often, instrumentation and the layout are such that accuracy of measurement is not possible, and the results can differ greatly from those obtained in the factory test facility. Actual site testing should be regarded more as part of the unit’s commissioning. This means ensuring

that the unit operates satisfactorily both mechanically and hydraulically. The commissioning personnel should also ensure that the driver is not overloaded. Most often, site tests are performed using pressure gauge readings in kPa or bar, so it is important to convert these readings into metres of head and include the velocity head in the suction and discharge pipes and the height of the gauges relative to the pump datum.

PUMP TEST LAYOUT, REPORT AND CALCULATIONS

Typical Pump Performance Test Layout

• Figure 1 shows typical pump performance test report.

• Calculations have been included for point 1 of the test sheet.

• Figure 2 shows a typical performance curve and verification of a Grade 2B guarantee on flow rate, head and efficiency.

• Figure 3 shows a typical test rig layout.

Fig 1 – Typical Test Performance Test Report

Fig. 2 Typical Test Performance Curve

Figure 1. A typical pump performance test report. Images: Pump Technical Handbook

Figure 3. A typical test rig layout.

Figure 2. A typical test performance curve.

Notation

����&'()* Inlet Head, m absolute

����+*,-. Barometric Pressure, millibar

p/ =p01234 5!"#$% ×/7.9 : m gauge

p9 Outlet Head, m gauge

e3 Drive Efficiency (decimal), determined by percentage load on the motor

e5 Pump Efficiency (decimal)

e5 = ;< ⁄ ×$ >?×/79

e@ Overall Efficiency (Pump and driver total Efficiency) (decimal)

e@ =e5 ×e3

EkW Motor input power kW

H Total Head m

Metres H=p9 −p/ +Z+ v9 9 −v/9 2g

Pump Input Power (KilowaNs) =EkW×e3

L/sec Flow rate reading = L/s

v/ Fluid Velocity at inlet gauge point p/ (m/s)

Inlet Velocity v/ = 1273×L/s d/ 9

v9 Fluid Velocity at outlet gauge point p9 (m/s)

Outlet Velocity v9 = 1273×L/s d9 9

Velocity (DifferenKal) head (m) = A&&BA' & 9C

g AcceleraKon due to Gravity (9.80 m/s2 refers to local gravity at the locaKon of test)

ρ Density, Water at 19°C = 998.4kg/m3

NPSH NeN PosiKve SucKon Head at Pump Datum (m) v/9 2g +z/

NPSHA =Barometric pressure(m) +p/ Vap.press+

kWh/1000 litres KilowaN hours per 1000 Litres EkW kWh⁄kL= 3.6×L/s

SUMMARY

This chapter details how the Australian Pump Test Standard operates, how to select the correct test grade for your requirements, and how to translate the test results recorded to determine if these results meet the

Test conditions

d1 Inlet (Pipe) Diameter (mm)

d2 . Outlet (Pipe) Diameter (mm)

z 1 Inlet gauge height from pump datum (m)

z2 Outlet gauge height from pump datum (m)

Z Corrections for gauge height to pump reference plane (m) =Z1- Z2

°C Water Temperature (°C)

Driver details

Motor efficiency Efficiency at rated loads (as decimal)

V Rated Motor Voltage (Volts)

Rated Amps Rated Full Load Motor Amps

Rpm Speed of rotation, Pump Revolutions per Minute

Refer to Chapter 15 of the Australian Pump Technical Handbook for a sample calculation.

requirements of your test grade chosen, ensuring that a successful pump test is undertaken. It also provides comprehensive guidance on pump test tolerances. It outlines the acceptable deviations in pump performance from stated specifications. By correctly

AIMEX PROVIDES AN UNMATCHED OPPORTUNITY TO CONNECT AND DO BUSINESS WITH LEADING MINING SUPPLIERS FROM AROUND THE WORLD.

More paperwork for pump engineers

Ron Anstall from United Pumps is examining new regulations across the east coast, advocating for all PIA members.

Engineers can find themselves working in multiple jurisdictions just by the nature of their work. An engineer in Albury might be called upon to work on a project in Wodonga, or similarly, an engineer in Tweed Heads might be offered a contract in Coolangatta.

However, under existing regulations in Queensland and Victoria, someone providing professional engineering advice could be in trouble if they are not registered in each state.

“I’ve been working for a long time as an engineer, and I’d like to think that my peers respect me,” said Mr Ron Astall, former PIA President and United Pumps Senior Engineer. “The need to register in those states initially felt like a slap in the face. However, it could mean the cowboys and pretenders could get weeded out of the industry.”

This registration extends to any engineer working professionally in relevant states, and the fee is around $300. The engineer does not need to work or reside in the state to be affected.

“Consider a well-credentialled engineering consultant based in and operating wholly from the US,” said Mr Astall. “Should they design a pumping station in Victoria, they must be registered appropriately in Victoria.”

Engineers must be registered if they provide professional engineering services for Victoria under these new regulations. ‘For Victoria’ is defined as a project or purpose in Victoria, specifically related to or connected to Victoria in some way.

“I spoke to some of our suppliers and asked if they were aware of this regulation,” Mr Astall said. “They were not aware, but it did not worry them because their engineering work was being done in Los Angeles. They were shocked to realise that since the work was for Victoria, they would need one of their engineers in Los Angeles to be registered or have someone in their Victorian office registered to sign off on the work.”

Ron Astall in United’s test bay with a custom engineered 985 kW pump, recently designed and manufactured by United in Melbourne. Images: United Pumps

of assessing people’s qualifications and putting them on the National Engineering Register.”

The requirement that mechanical engineers adhere to these regulations will be of particular interest to the pump industry. Mechanical engineers need to be registered in their field and have their registration endorsed to work in the building industry if necessary. The guidelines state that mechanical engineers in the building industry can work with mechanical systems. That includes vertical transport, heating, ventilation, air conditioning, refrigeration (HVAC-R), smoke control, thermal and environmental systems, and systems to aid people with disabilities.

Do I really need to do this?

Engineers can be exempt from registration in two situations. They can be exempt if they provide professional engineering services under a registered professional engineer’s direct supervision or only per a prescriptive standard.

A prescriptive standard is defined as a document that states procedures

or criteria for carrying out a design, or a construction or production activity, relating to engineering and the application of which to the carrying out of the design, or the construction or production activity, does not require advanced scientifically based calculations.

“There are many prescriptive standards out there,” Mr Astall said. “The pressure vessel code (AS 1210-2010 Pressure Vessels) could be followed step by step. Similarly, some calculation methods have been set up within my area of expertise to calculate various facets of pump design. You can get the answer if you follow them step by step.”

There are four criteria for determining whether a standard is a prescriptive one. It requires the prescriptive standard to be a document that states procedures or criteria for carrying out the design, construction, or production activity to which it relates. It also needs to require little or no engineering judgment to apply the stated procedures or criteria and not require advanced scientifically

based calculations to use the stated procedures or criteria.

“The big question is whether an engineer has the technical training to understand the concept of garbage in, garbage out,” said Mr Astall. “They need to recognise that the outcomes do not match what is expected. All our engineers are degree-qualified, so they know what they are doing. Having now gone through the assessment and registration process, there is nevertheless a high degree of satisfaction and a feeling of achievement ”

In Mr Astall’s opinion, a national register of engineers could be a better solution to this situation.

“I’m worried about the spectre of having to apply for registration individually in each state and territory,” he said. “If you are on the National Engineering Register, that should cover the whole country. It seems unfair to have to separately register in each jurisdiction and go through a separate police check for each one. I think there should be one point of registration for Australia.”

Keynote speakers and panels are regularly among the highlights of WA Mining Conference and Exhibition. Images: Prime Creative Media

Heading west for WAME

The WA Mining Conference and Exhibition is back – here’s what’s happening at the show in 2024.

Perth has long been the centre of mining in Western Australia, with tens of thousands of people directly employed by the industry. With significant resources within Western Australian soils, events like the WA Mining Conference and Exhibition provide numerous opportunities to present products and services to key decision-makers.

The WA Mining Conference and Exhibition will integrate the innovation and research ecosystem while addressing the social and environmental standards driving a more sustainably conscious industry. The expanded exhibition will showcase technical and digital innovation across every aspect of the mining value chain while illustrating the economic importance of mining to Western Australia and its contribution to the resource technology sector.

Show Director Siobhan Rocks said the 2024 event is designed to connect mining industry businesses.

“Western Australia is an important market for the mining industry, and we’re focusing on connecting buyers to that market. We’re making it so they don’t have to come all the way over to the eastern seaboard to talk to people within mining communities.”

It is the ultimate event for mining and engineering professionals,

showcasing the technical and digital evolution transforming the mining industry in Western Australia. WA Mining gives attendees a blueprint to solve operational pain points while listening to industry-leading experts in this highly targeted conference.

“Understanding the needs of the Western Australian mining industry, we are excited to expand the show’s offering,” Ms Rocks said. “Attendees will be able to find a whole range of solutions for mining, including advanced technology and equipment on display.”

Conference highlights

WA Mining Conference will provide engineers, mine managers, site superintendents, HSE managers, exploration managers and operations managers with the technological insights that will shape the future of the mining industry in Western Australia.

Of note is the expansion of digitalisation and automation in the sector, which will continue to push the industry into new frontiers. The WA Mining Conference will examine these new technologies and applications and draw insights from digital experts across a variety of sectors that will have applications in mining. Cyber security managers, technology heads, and chief technology officers will be in

attendance as they look to discover the technological changes that will have a positive impact on the sector.

“This year’s event will welcome leaders from mining companies, government and all the key bodies in Western Australia as part of our speaker lineup,” Ms Rocks said.

Industry and stakeholder engagement is paramount to the success of the mining industry. The WA Mining Conference will investigate social license to operate for projects and explore the most effective ways to limit the environmental impact of mining in Western Australia. Environmental managers, stakeholders, and community engagement managers will hear from industry and government experts.

It will also allow mining equipment, technology, and services (METS) suppliers to engage with a highquality audience of mining industry professionals.

There are many opportunities to get involved in the WA Mining Conference and Exhibition. The conference allows companies to showcase their business as technical leaders in the Western Australian mining industry, and attendees will engage with a high-quality audience of professionals looking to evolve, adapt, and improve their mining operations.

Prospect Awards

The Prospect Awards will be a major highlight of WA Mining Conference and Exhibition. They are amongst the most esteemed and prestigious awards for the Australian mining and minerals processing industry. For more than a decade, the Australian Mining Prospect Awards have been one of the few national awards programs to stop, look at what the mining industry is doing, and reward those who are excelling and going above and beyond, recognising and rewarding innovation.

The categories are:

• I ndigenous and Community Engagement Award

• E xcellence in IIOT Application

• E xcellence in Environmental Management & Sustainability

• E xcellence in Mine Safety, OH&S

• Project Lead of the Year

• Safety Advocate of the Year

• I nnovative Mining Solution

• M ine Project Success of the Year

• O utstanding Mine Performance

• D iscovery of the Year

For more information, visit waminingexpo.com.au and prospectawards.com.au

The exhibition will be packed again with new technology and services to support the mining industry.

PUMP INDUSTRY CAPABILITY GUIDE 2025

Welcome

Celebrating its tenth year, the Pump Industry Capability Guide welcomes me as its new editor at a time when the industry must rise to meet new challenges and seize the chance to explore fresh opportunities.