A NEW AGE SOURCING SOLUTION

How machinery works in harmony on a mine site

THE GOLD STANDARD

Ensuring gold miners access the right equipment

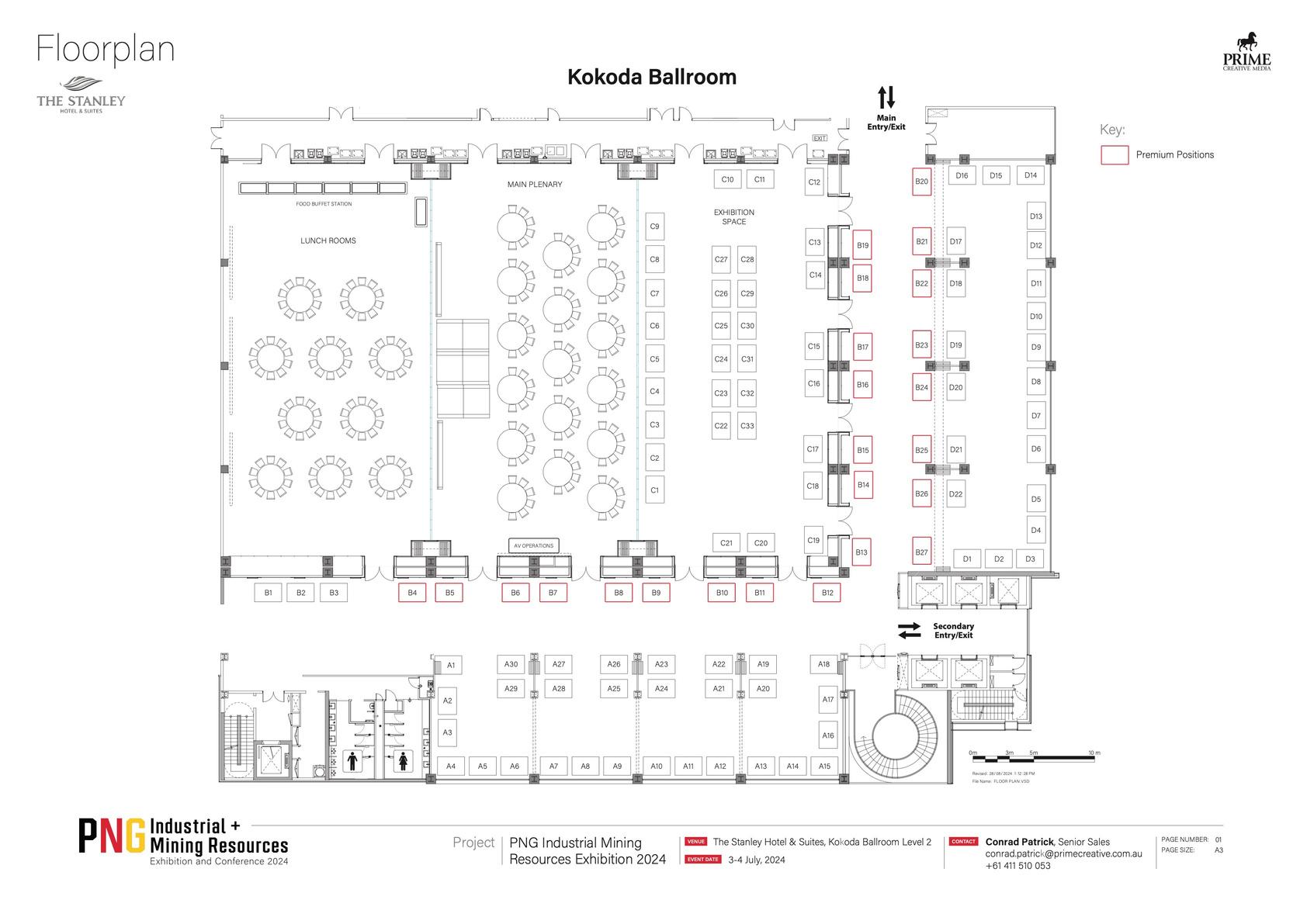

PREVIEW THE 2024 PNG MINING EXPO

The premier industry marketplace showguide edition

A NEW AGE SOURCING SOLUTION

How machinery works in harmony on a mine site

THE GOLD STANDARD

Ensuring gold miners access the right equipment

PREVIEW THE 2024 PNG MINING EXPO

The premier industry marketplace showguide edition

How companies give back to their communities

We are now better equipped than ever to help you to optimise your comminution and material handling operations for maximum performance, safety and efficiency.

Combining the industry leading screening, feeding and loading expertise of Schenck Process Mining with our mastery of crushing and wear protection, allows us to bring you an unrivalled equipment line-up. We underpin this unique offering with our expert process knowledge, full range of digital tools, high quality OEM spare parts, consumables and life-cycle services.

Scan the QR code to discover why we are the industry’s partner in eco-efficient mineral processing.

COO

Christine Clancy

GROUP MANAGING EDITOR

Paul Hayes

T: +61 3 9690 8766

E: paul.hayes@primecreative.com.a

EDITOR

Alexandra Eastwood

T: +61 3 9690 8766

E: alexandra.eastwood@primecreative.com.au

JOURNALIST

Kelsie Tibben

T: +61 3 9690 8766

E: kelsie.tibben@primecreative.com.au

CLIENT SUCCESS MANAGER

Janine Clements

T: +61 2 9439 7227

E: janine.clements@primecreative.com.au

RESOURCES GROUP LEAD

Jonathan Duckett

M: +61 498 091 027

equipment for each site.

E: jonathan.duckett@primecreative.com.au

BUSINESS DEVELOPMENT MANAGER

KahChi Liew

M: +61 421 474 407

E: kahchi.liew@primecreative.com.au

ART DIRECTOR

Michelle Weston

SUBSCRIPTION RATES

Australia (surface mail) $140.00 (incl GST)

New Zealand A$148.00

Overseas A$156.00

For subscriptions enquiries please call +61 3 9690 8766

PRIME CREATIVE MEDIA

379 Docklands Drive

Docklands, VIC 3008 Australia www.primecreative.com.au

landscape that is the PNG resources sector.

WELCOME to the inaugural edition of PNG Mining.

I am thrilled to be joining you on this journey as we discover the many intricacies of the Papua New Guinea (PNG) resources industry and celebrate the work of a growing sector.

Our first issue puts the focus squarely on the companies that go above and beyond to help the country run.

From Hastings Deering’s 75-year legacy in PNG to Islands Petroleum’s focus on being an oil provider of choice, the Pacific nation is filled with opportunities for the resource sector to thrive.

Our first edition also coincides with the PNG Industrial and Mining Resources Exhibition and Conference (PNG Expo). Held from July 3–4 at the Stanley Hotel in Port Moresby, the PNG Expo is a true marketplace for networking, learning and sharing ideas.

PNG Mining caught up with a number of exhibitors ahead of the event to chat about their offerings and what they’re looking forward to seeing at the PNG Expo.

Personal protective equipment supplier JB’s wear discussed how critical a strong supply chain is to PNG, while cable manufacturing expert TriCab showcased the importance of choosing the best

Elsewhere in this edition, we shine a spotlight on the growing nature of the PNG resources industry, focusing on the PNG Government’s mission to attract international investment to the sector. In true community spirit, the PNG Government is also focusing heavily on ensuring the land in and around projects can be used for years to come, with the country’s people benefitting from the flourishing sector.

And given this is the first issue of PNG Mining, we also take a look at some of the industry’s key players, with the likes of Boss Attachments, Industree Group and Lincom sharing their stories.

Industree Group in particular has exploded onto the PNG scene, bringing with it a drive to keep the mining industry as safe and productive as possible, while Boss Attachments is keen to foster more community partnerships through funding and sponsorships.

It truly is an exciting time to be a part of the PNG resources sector, and PNG Mining is humbled to be a part of this journey.

Happy reading.

Alexandra Eastwood Editor

Alexandra Eastwood Editor

6 Industry insight

Power to PNG

What does the PNG Mining Minister’s new priorities mean for the nation’s growing sector?

16 Equipment

The gold standard

When a gold mine in PNG needed new equipment, Lincom Group was an obvious choice.

22 Equipment

Beyond belting Fenner Conveyors is working to deliver a onestop-shop conveyor belt and roller offering.

26 Equipment

A new sourcing solution

Blackwoods has over 35 years’ experience supporting Papua New Guinea’s mining and resources industry.

30 Education

Investing in the future Apprenticeship programs have become vital recruitment tools for major companies across PNG.

32 Community

A Boss on the ground

As an equipment supplier for Tier 1 clients, Boss Attachments knows a thing or two about the needs of the industry.

36 Equipment

Building quality connections

TriCab has big plans to bring its decades of cabling knowledge to Papua New Guinea.

38 Energy

Fuelling Papua New Guinea Islands Petroleum might be a fuel-focused company by name, but its joy comes from giving back to its communities.

42 Technology

Scanning the horizon

A paperless future is on the horizon with BizPrint’s Scan Bureau.

44 PNG Expo

What’s on the cards for the 2024 PNG Expo?

A packed conference schedule will be awaiting attendees at the 2024 PNG Expo.

What do the PNG Mining Minister’s new priorities mean for the nation’s growing sector?

PAPUA NEW GUINEA (PNG) is taking its position on the world stage as a resources powerhouse.

Mining accounts for more than 80 per cent of PNG’s export revenue every year and plays a significant role in supporting skills development, employment opportunities, and community projects across the country.

The PNG Government has long been a vocal supporter of the sector, showing it is keen to bolster the nation’s resources industry through a number of investments and funding packages.

Perhaps the biggest testament to this is the PNG Government’s investment in the recently reopened Porgera gold mine in Porgera Enga Province.

Operated by Barrick Gold, PNG shareholders stand to gain $11 billion over Porgera’s 20-year life through a highly negotiated compensation agreement.

PNG Prime Minister James Marape has been a vocal supporter of mining projects in the Pacific nation but has been firm on ensuring the economic and social benefits be fairly redistributed within the country.

In a recent address to mine operators in PNG, Marape emphasised the need for governments and businesses to work together to reap mutual benefits from the nation’s resources.

“By 2025 PNG will be going into a new regime as far as resource laws are concerned, without harming your rate of return,” he said. “Your profit margins will be maintained. However, Papua New Guinea too must get its fair share.”

The 2019 ‘PNG Extractive Industry Transparency Initiative’ report found of the K32 billion ($12.5 billion) in contributions from the extractive industries in 2019, only 18.5 per cent was received by PNG entities, and only 3.7 per cent went to the PNG Government.

As operations across the Pacific nation ramp up, eyes are turning to how the PNG Government will support the country’s transition to a formidable global player while ensuring the nation continues to benefit.

In January, PNG welcomed a new Minister for Mining, Muguwa Dilu, during a cabinet reshuffle.

As he was sworn in, Dilu emphasised his commitment to growing PNG with the help of its expanding mining sector.

“The mining sector (is) an important sector to the PNG Government as it contributes 70 per cent of the total gross domestic product annually, brings in foreign exchange, creates job opportunities for citizens and brings benefits for project landowners,” he said.

“It (is) critical that all stakeholders of the mining sector work together for everyone’s interest and benefit.”

Dilu has since announced a set of priorities the PNG Government will focus on based on a key question he poses: “Are we being responsible to the people of Papua New Guinea in comparison to other jurisdictions throughout the world?”

The PNG Government is looking to boost its relationship with major players in the country’s mining industry. Dilu recently outlined three critical projects central to that mission.

The Porgera compensation agreement aims to ensure 53 per cent of the wealth generated from the mine is reinvested in Papua New Guineans.

Under the Mining (New Porgera) (Amendment) Act 2023, the rights of landowners in the area to be properly and appropriately compensated have been protected.

The conclusion of project negotiations should see the Wafi-Golpu project up and running by the end of 2024.

Wafi-Golpu will operate under a special mining lease between its joint venture owners Newmont and Harmony Gold, as well as the PNG Government.

The PNG Government is advancing the Frieda River project license application through to project negotiations.

The project aims to build stronger and more viable communities by establishing necessary public infrastructure, generating skilled employment, and creating business opportunities for local people.

These projects have inspired a host of legislative and policy priorities for Dilu, which he plans to carry out under the Department of Mineral Policy and Geohazards.

“The mining sector contributes significantly to the nation through the generation of foreign exchange, dividends, income tax and other financial streams, creating employment opportunities for citizens and delivering benefits to project landowners,” Dilu said.

“The importance of collaboration among all stakeholders within the mining sector is vital in this industry. As the Minister responsible, I stand committed to supporting policy initiatives that benefit the interests of all parties involved.”

Dilu’s priorities may be ambitious, but such is the brand the new Minister is becoming known for. If successful, Dilu’s legacy could set PNG up to prosper for years to come.

As well as seeing through current policy projects like reviewing the Mining Act 1992 and the Mining (Safety) Act 1977, Dilu has developed a host of new policy initiatives aiming to boost PNG’s mining sector.

The Offshore Mining Policy aims to support the exploration and extraction of deep-sea mineral deposits both in PNG and on international waters.

Boosting relationships is key for the PNG Government.

To protect PNG’s environment and safeguard it into the future, the Mining Project Rehabilitation and Closure Policy aims to ensure miners have rehabilitation at the forefront of their operations across the full scope of the mining cycle.

Working in tandem with the Rehabilitation Policy, Dilu’s Sustainable Mining Development Policy aims to ensure mining operations improve the quality of life for neighbouring communities.

Similarly, the Mining Involuntary Resettlement Policy seeks to see communities in need of resettlement due to mining activities duly compensated. The policy will enshrine the fair treatment of resettled communities in law and set Papua New Guineans up for a brighter future.

Dilu will also strive to establish a Downstream Mineral Processing Policy, which will keep the mineral processing chain on PNG shores, where the economic benefits have been touted to triple.

PNG currently hosts four world-class large mines, three medium-scale and three small-scale mines, and several alluvial gold fields across the country.

Mines like Newmont’s Lihir, Barrick Gold’s Porgera, MRDC’s Ramu, and OMTL’s Ok Tedi have and will continue to provide massive benefits for PNG.

These projects are continuing to ramp up, and new projects are filling up the pipeline as the world realises the potential PNG has as a leader in critical resources. With Dilu and the Government firmly committed to seeing the Pacific nation’s mining sector flourish, there has never been a better time to invest in PNG. PNG

While mining in Papua New Guinea can come with its challenges, Cummins has maintained a strong presence in the country for more than 50 years.

CUMMINS, a global power technology leader, has been a proud partner of the Papua New Guinea (PNG) mining industry for over five decades.

Initially represented in PNG by Blackwood Hodge, the year 1984 saw the Cummins Diesel Sales and Service franchise sold to Cummins Engine Co (Cummins Inc.).

Today, Cummins employs 45 nationals in PNG who work out of two locations: Port Moresby and Lae. Most employees are involved in workshop and field service technical roles.

“It’s probably the most challenging assignment I’ve ever taken on but it’s also the most rewarding in terms of employee development,” Cummins PNG general manager David Leach told PNG Mining.

“Currently, I’m the only expat in Cummins PNG. For a long time, all key roles within the PNG business were in the hands of expats. I can see one day that our work in building skills, loyalty and dedication within our workforce will see a PNG national as general manager.

“We already have two nationals managing our Port Moresby and Lae branches.”

Leach has worked for Cummins for over 27 years, starting in the UK at the International Training School in Daventry where he led training on Cummins’ high horsepower engines – QSK45, QSK60 and QSK78.

He was also involved in establishing an engine and power generation distributorship in Ghana before taking on the role of senior application engineering manager for Cummins’ power generation business in Europe.

Leach moved to Australia in 2018 to become branch manager of Cummins Emerald in Queensland, a business with a strong mining focus.

“One of the key reasons our customers prefer using our product is because they’re dealing directly with Cummins, not through a dealership,” Leach said.

Cummins sees developing apprentices is another key to building a sustainable business, and Cummins PNG currently has six apprentices.

“We have a lot of applications for our apprenticeships because Cummins is recognised in the community as being a good employer and good trainer,” Leach said.

And it’s not just technical training that’s important at Cummins PNG. Training in corporate values is vital.

“We want Cummins’ values of integrity, teamwork, diversity and inclusion, caring, and excellence to be ever-present in the minds of our team,” Leach said.

“Safety training is also crucial to the success of our business. Our ‘safety first’ culture is reflected in our record of zero incidents over the last two years.

“It’s all about creating the right work environment.”

Cummins PNG’s business procedures have seen a dramatic transformation in recent years with support from Cummins Asia Pacific maintaining the company’s competitive edge in a volatile, diverse market.

PNG is a resource-rich country which sees a number of high horsepower Cummins engines involved in its diverse mining operations.

Indeed, Cummins has had a presence at the iconic Ok Tedi copper-gold mine for over 30 years thanks to its product reliability and service support.

Today, six Cat excavators, each with dual Cummins KTTA38 engines, are the backbone of the operation and are supported with parts and service from Cummins Lae.

The first of 21 new haul trucks from Chinese manufacturer XCMG, powered by Tier 2 Cummins QSK60 MCRS engines, will go into service at OK Tedi in September. Elsewhere, K92 Mining, a Canadabased gold producer, has 21 Cummins Powerboxes at its Kainantu gold mine in Eastern Highlands Province.

These Powerboxes provide a fully integrated power system with the generator installed in a standard 20-foot ISO container. The 1250 kilo-volt-amperes gensets are powered by Cummins’ long established KTA50 engine.

Currently, two Cummins technicians are dedicated to onsite support at the K92 mine.

Cummins also supports Lihir gold mine with its fleet of QSK23 and KTA38 engines, while the Porgera joint venture and Wafi-Golpu joint venture also use Cummins power in their gold exploration and mining operations.

A new focus for Cummins PNG is the 20 Cummins X15 Euro 5 engines, powering T659 Kenworths, which have recently gone into service with Mapai Transport, Traisa Transport, Zenag Island Products and IPI Transport, all involved in logistics haulage for the mining sector. PNG

Proudly supporting customers in Papua New Guinea for over 35 years.

As Australia’s foremost supplier of industrial, safety, and Maintenance Repair Operations (MRO) products, Blackwoods has been at the forefront of supply excellence for over 145 years. We cater to a diverse clientele, including over 200,000 customers in construction, manufacturing, government, and defence, across 77,000 sites with a vast catalogue of more than 300,000 products. Our expertise shines in delivering endto-end solutions for substantial industrial, mining and oil & gas operations, affirming our status as the trusted provider for all industrial supply requisites.

At Blackwoods, we understand the challenges and complexities of sourcing the right products in a timely manner – Having what you need, when you need it, is critical in managing your inventory levels, project deadlines, keeping costs down, and most importantly keeping your people safe.

Our focus is helping you reduce product lead-times from Australia via faster cargo clearances and mutual recognition arrangements with key trading partners to ensure we deliver what you need, when you need it.

Contact Blackwoods export specialists today! brisbane.export@blackwoods.com.au

Stage 1 Consult

Review project scope and product requirements, engage dedicated export team and centralised contact points to support all stages of the export process.

Stage 2 Source

Leverage a global supplier network and our own distribution network to source products. Our technical specialist team provide selection advice for approved products that meet strict quality, compliance and safety standards.

Stage 3 Coordinate

Manage transportation and logistics, including local and international stakeholders and freight forwarders.

Stage 4 Deliver

Dedicated product packaging team consolidate stock and pack in accordance with your specific requirements, and complete necessary documentation.

Combining a Putzmeister pump with the support and knowledge of Beasley’s Hydraulic Services ensures everyone walks away a winner.

A TAILINGS dam is a crucial piece of the puzzle for any mining operation. Used to store by-products and waste left over from separating ore, tailings dam technology has come a long way from the mines of old – but that doesn’t mean they’re fool-proof.

One of the best ways to ensure a tailings dam remains up to code is to employ strong and reliable pumps that go the distance – and that’s where Putzmeister and Beasley’s Hydraulic Services work their magic.

“The mining industry has come a long way in improving safety for mine workers and the communities living nearby,” Beasley’s business development manager Peter Beasley told PNG Mining.

“The challenge for all stakeholders is to embrace new standards while developing creative and innovative solutions.”

With so many variables on the line when it comes to tailings dams, Putzmeister takes precision seriously. The company custom-designs each pump to meet the standards of the individual site or project.

“Each unit is designed to suit the explicit conditions of your site and demands,” Beasley said.

“If you need to overcome site-specific challenges and your standards require zero tolerance for error, then a customdesigned, precisely built pump from Putzmeister is your best solution.”

Beasley’s previously supplied a Putzmeister paste pump and regular

maintenance services at one of the largest gold mines in Papua New Guinea (PNG). Ensuring the right pump was applied to the solution has meant that the mine continues to use Putzmeister and the services of Beasley’s.

“The pump itself is not the end goal, nor is it the whole story,” Beasley said. “The work that goes into both the before- and after-sales service is just as important.

“Putzmeister pumps are built to work under the harshest conditions. From consultancy through to commissioning, every detail is checked and rechecked,

every component minutely analysed, every finished unit rigorously tested to its specification.

“Nothing is left to chance.”

This level of detail has left Beasley’s customers coming back time and again. The company’s PNG client was especially thrilled at the high level of

“

professional support and technical competency.

“The company said that our support and service significantly contributed to the exceptionally high availability and utilisation status achieved with the Putzmeister pump,” Beasley said.

The challenge for all stakeholders is to embrace new standards while developing creative and innovative solutions.

Peter BeasleyAlso highlighted was Beasley’s attention to detail and ongoing commitment to clients.

“The mine was able to achieve valuable increases in production,” Beasley said.

“The goal of managing tailings for zero harm to people and the environment and zero tolerance for human tragedy is what this all comes down to – it’s the broader goal we’re working toward.

“We have made significant steps in the right direction and Putzmeister pumps have been a big part of that because they never leave the factory until they have been proven beyond specification.” PNG

Telescopic Cable Mast Conveyor

• Versatile, affordable conveyor solution

• Quick and cost-effective installation

• It can be lowered to the ground to provide easy access for maintenance

• No head or tail undercarriage provides greater clearance under the conveyor

Images: Beasley’s Hydraulic ServicesTutt Bryant Equipment prides itself on offering its customers premier mining equipment across the entire value chain.

NESTLED IN far-away foothills or hard-to-access valleys, isolation can be a cruel mistress for Papua New Guinea’s (PNG) mines.

Mining is known for its massive equipment, which can present significant problems for isolated miners when it comes time to upgrade machinery or expand operations.

And even after equipment is implemented, it’s no small feat for suppliers to simply pop in and check how things are running.

That’s why PNG miners need suppliers who are experienced with the demands of the region and have a plan to ensure not only the delivery of quality equipment, but also timely ongoing support should they need it.

Tutt Bryant Equipment has been supplying heavy machinery to some of the most remote parts of Australia since 1938, and in recent years has been putting its expertise to the test in PNG.

Tutt Bryant Equipment national business manager –crushing and screening Paul Doran told PNG Mining the company supports its customers by providing technical support, whole-of-life maintenance programs, and breakdown repairs.

“We have been supporting the area out of our Brisbane branch for a while thanks to its prime location near PNG,” Doran said. “Particularly when it comes to PNG, we spend a lot of time with our customers to learn about the area and what kind of critical parts and ongoing support they might need.

“Having engaged with our customers early on in the process, we can save them time and money down the track by taking a range of possibilities into consideration and providing them with preemptive solutions.”

As a national multi-franchised distributor, Tutt Bryant Equipment exclusively represents a number of industry leading global brands in Australia.

The company’s range of equipment includes Sumitomo and Yanmar excavators, Metso mobile

crushing and screening equipment, Gehl wheeled and tracked skid steer loaders, Yanmar wheel loaders, and Weiler motor graders.

Tutt Bryant Equipment is well known for its longterm relationships with its manufacturers, some of which have spanned nearly 40 years.

“There’s not a lot of long-term relationships like that in the equipment market,” Doran said. “Our customers need reliable, high-quality equipment and we’re able to provide that thanks to our partnerships with the best in the business.”

Doran emphasised that having access to a wide range of high-quality manufacturers allows Tutt Bryant Equipment to offer a one-stop-shop to its customers for all their equipment needs.

“It’s a huge advantage for our customers to save on downtime by choosing a complete solution from one source,” Doran said. “Our warehouses across Australia stock over one million parts and carry over 30,000 lines of inventory.

“It really speaks to how easy it is to work with Tutt Bryant; we can lean on our extensive offering to come up with a solution for any challenge and have it delivered and implemented quickly.”

Looking to the future of PNG’s rapidly growing mining sector, Doran is confident Tutt Bryant Equipment has the Pacific nation’s needs in hand.

“We understand the challenges PNG is facing,” he said. “At Tutt Bryant, we’re keen to meet those challenges head-on and continue to grow with the region.” PNG

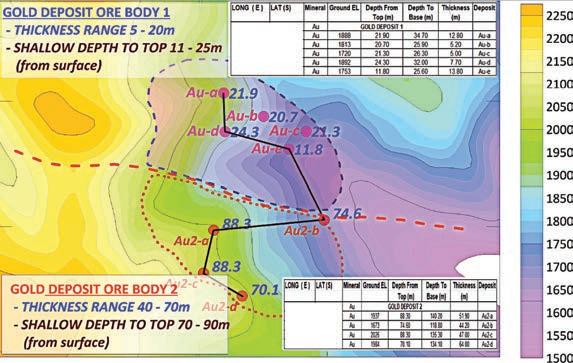

Geo Scan Australia Pacific recently hit a digital mining milestone by using satellite technology to define significant subsurface mineralisation zones in Papua New Guinea.

THE EXPLORATION phase is an exciting time for miners, but the flush of discovery can be tainted when terrain is too rough or hard to access.

One of the greatest challenges facing miners in Papua New Guinea (PNG) is its deep jungles and mountainous regions, which can slow the mining chain and hinder progress.

Therefore, having a clearly defined mineralisation target prior to on-the-ground exploration means more time can be spent getting to the heart of what the industry is all about: mining.

That’s exactly what Geo Scan Australia Pacific (GSAP) aims to do.

GSAP is a tech start-up in the resources, energy and water sectors. The company has only been in PNG for 18 months, but its technology has been used globally for decades.

And GSAP has certainly not wasted any time while in PNG, with the successful completion of its first project in December 2023.

After a raft of interest from the PNG market, GSAP has since established its Pacific HQ in Port Moresby and partnered with PNG-owned resource companies to drive its new technology throughout the country and broader region.

But what is this technology?

By using state-of-the-art resonance-frequency satellite technology, GSAP is able to successfully define the depths and lateral extents of mineralisation at prospective sites.

The satellite survey employs advanced nonphotographic resonance-frequency imagery to identify and quantify any mineral concentrations, with a particular focus on gold and copper deposits in a recent case study.

This method involves analysing the electromagnetic spectrum to detect specific frequency patterns corresponding to different minerals.

It has proven to be a highly effective technique in delineating areas of potential mineralisation, allowing for a detailed and non-invasive assessment of the subsurface.

Data recorded by the satellite is relayed back to Earth where it is analysed and processed by GSAP

specialists, including geoscientists and artificial intelligence (AI) data processing engineers in the US.

After the raw data is processed, GSAP delivers a detailed report to its clients, giving them precise geographical locations on the surface of the earth, as well as the precise depth of occurrence.

GSAP recently used this technology on a 2.5 square kilometre area to create its ‘PNG Mineral Case Study’ report, which encapsulated a succinct geophysical exploration analysis of the prospect, confirming two significant gold and copper deposits.

The results were later validated independently by historical diamond drill hole samples, demonstrating an extremely high-depth correlation match of 95–99 per cent.

The entire project, from the initiation of data acquisition to the delivery of the report, was completed in just 12 days.

GSAP Pacific general manager Clinton French said even though the technology stands to change the way mining is done, traditional mining methods are still a vital part of the process.

“Mineral exploration and development are inherently highly speculative and involve a significant amount of data collection and time from the traditional methods,” French told PNG Mining.

“The technology does, however, have the potential to disrupt the traditional ways of exploration.

“Our rapid turn-around time and precise information relating to the presence or absence of targets presents an alternative method that would see projects eliminating many phases of exploration to identify, delineate and mature drilling targets in an unprecedented short span of time.”

French said had GSAP’s technology been used before the historical drilling at its recent project, the client would have saved approximately $3 million in drilling costs, as three drill holes were outside of GSAP’s findings and had no mineralisation in their core samples.

“Mining companies that embrace this new technology will be better equipped to identify potential mineral deposits, reducing costs and environmental impacts and dramatically expediting project timeframes when compared to traditional exploration methods,” he said.

Now GSAP is working with the client to map out its future prospects around the country and build on the initial project.

GSAP also has a number of minerals projects in the pipeline which aim to put PNG in the spotlight.

By working with the PNG Government and academic experts, GSAP has plans to significantly reduce the exploration process by moving from a prospect target to a qualified reserve in only a few short years.

French said it’s all part of GSAP’s mission to redefine the mining process, which would see

Geo Scan identifies mineralisation using state-of-the-art satellite technology.

exploration shortened to a maximum of two years from start to finish.

“Our team at Geo Scan Australia Pacific and GeoScan PNG are committed to pushing the boundaries of exploration technology,” French said.

“The unprecedented depth match accuracy, reliable data, and reduced target acquisition timeframes reinforce the effectiveness of the satellite’s resonance-frequency technology.

“It surpasses conventional methods and elevates additional challenges companies face like terrain land access, and social or environmental concerns.”

French expects a significant transition within the PNG mining sector, with the satellite technology heralding a new era of remote imagery-based mineral prospecting.

“The implications of this project are undeniably game-changing, and we are seeing that through the engagement from the local sector and with the relevant government departments,” he said.

“Our aim is to assist those companies just starting or currently operating in PNG to rapidly expedite their exploration programs at a fraction of the cost.”

Data

The technology not only holds the potential to rapidly uncover much-needed critical minerals for the green transition, but also assists nations like PNG in unlocking the value of its in-ground assets.

In such a rapidly expanding industry, it’s technologies like these that will give PNG an edge as it expands on the global stage.

French said this technology is a tool to source and secure deposits that can become bankable assets bringing prosperity to the region, while also helping achieve netzero targets.

“Governments and organisations can now source and secure minerals with zero carbon footprint and zero environmental impact at a fraction of the cost and time compared to traditional methods,” French said.

“That’s the true human value this technology offers.” PNG

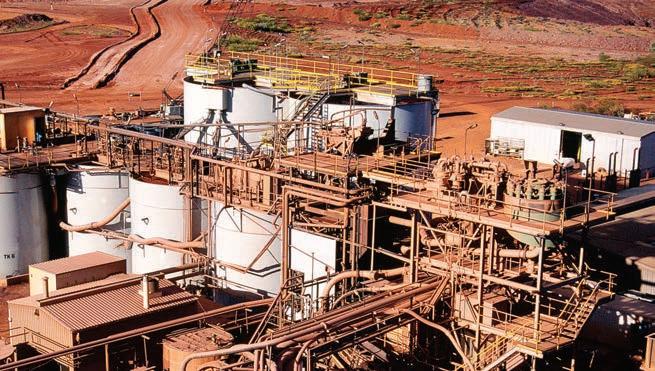

When a major gold mine in Papua New Guinea needed new equipment, Lincom Group was an obvious choice.

THERE’S NOTHING quite like a repeat customer in the business world, and that holds especially true when it comes to mining.

“At the heart of it is the Automax cone crusher, providing excellent capacity and high reduction.

“With cone overload protection, a heavy-duty chassis and track frame and an economical operation, it was the perfect choice.”

Equipment supplier and after-sales support aficionado Lincom is no stranger to repeat customers. With the company’s reputation for great results and reliability, customers keep coming back for more.

Such was the case when a major gold miner in Papua New Guinea (PNG) contacted Lincom to purchase more equipment for a different location.

“The major miner had previously used the equipment elsewhere with great results and reliability,” Lincom area sales manager Erwin Koch told PNG Mining. “Our reputation in PNG also helped us secure the deal.”

In no time at all, a Powerscreen Premiertrak 330 jaw crusher, a 1000 Maxtrak cone crusher and a Chieftain 1700 screen three deck had been delivered to the customer – and the mine has been reaping the rewards ever since.

“The Powerscreen Premiertrak, Maxtrak and Chieftain are all high-performance machines,” Koch said.

“The Premiertrak in particular has aggressive crushing action with its high-swing jaw, encouraging material entry into the crushing chamber.”

The mine will be using the equipment to make products like road base and blast stemming, both of which consist of crushed rock.

The road base and stemming will be used in the mine itself, creating more employment for local workers and a revenue stream for operators.

“The mines in PNG can be very remote, and those working there need people they can trust to give them help and support,” Koch said.

“Whether that’s getting spare parts for their machines or helping to choose the machinery that works for their site, a strong support system is invaluable.”

And it was with Lincom’s support that the gold miner chose the three pieces of equipment that now do so much for the site.

“The Powerscreen Maxtrak in particular has been a key piece of equipment for the mine,” Koch said.

And when it comes to the Powerscreen Chieftain?

“It’s the perfect piece of equipment for mines requiring a large volume of high-specification product,” Koch said.

“Quick set-up times and maximum mobility means the operator can have the unit operational in minutes, and the hydraulic auxiliary conveyer can easily feed the oversize ore into another unit for further crushing or screening.”

Given even the strongest pieces of equipment need servicing from time to time, Lincom has that covered, too. In the case of the major gold miner, Lincom worked with the company to establish a recommended spare parts list to keep on-hand in case it was ever needed.

“It can be tricky to get parts to PNG in a short timeframe,” Koch said. “But a mine doesn’t have the luxury of waiting; if a machine stops, so can production.

“To combat this, the gold miner in PNG invested heavily in spare parts so they wouldn’t have to face that problem.

“Of course, if something goes wrong, we can get parts airfreighted over from our head office in Brisbane. But we try to encourage our PNG customers to keep as much stock on hand as possible to minimise their downtime.”

But Lincom’s expertise doesn’t stop at supplying the equipment and its parts. The company is especially proud of its after-sales support.

“Our key objective is customer service and support,” Koch said.

“Selling the machines might be the first step, but our job isn’t complete until we know our customer has been supported right throughout the life of the equipment.”

JB’s wear has been proudly Australian-owned and run for 30 years, and the workwear company is now looking to expand across the Pacific.

WHEN PEOPLE think of personal protective equipment (PPE) on a mine site, they might conjure up images of bright yellow jackets, hard hats and bulky glasses.

But there’s one company that knows how much more goes into this crucial part of safety in the resource industry: JB’s wear.

From humble beginnings at entertainment and sporting events, JB’s wear has grown into a nationally recognised brand across Australia, renowned for its high-quality workwear and footwear.

This recognition has spanned more than just decades. JB’s wear is now a globally celebrated company, renowned for its ability to quickly get stock where it needs to be – including in Papua New Guinea (PNG).

JB’s wear general manager Gary Malcolm has been liaising with JB’s PNG resellers for over 30 years.

“We have people who have worked here at JB’s wear for over 20 years, and they stay that long because they like the people they work with,” he told PNG Mining. “And that’s both the people inside our buildings and the customers that we work with around the country and in PNG.”

JB’s wear director Andrew Smith told PNG Mining about the company’s beginnings with his dad in the early 1990s.

“My old man ordered 6000 polo shirts for the first run,” Smith said. “He went and visited the factory and, when he got back, he was so nervous that he cut the order down to 3000.

“All 3000 shirts sold before they arrived, and we still work with that same factory.”

This anecdote would go on to be a running theme for JB’s wear, a company that prides itself on long term relationships.

“We know what our customers want because we have active relationships with them,” Smith said. “Our money goes back into making and carrying the stock that our customers need.”

And while PPE is undoubtedly a vital aspect of on-site safety, there are many aspects of a mining operation that don’t require the high-vis typically worn by people at the proverbial coalface. Luckily, JB’s wear has a solution for that, too.

“Mines employ support staff, corporate staff, chefs, admin … the list goes on,” Malcolm said.

The JB’s wear warehouse in Altona North, Melbourne.

He described the relationships he has formed as career highlights.

“And we know that it can be challenging to get uniforms from 10 or 20 different suppliers to PNG. That’s why we do it all – we’re a one-stop shop.

Image:

JB's wear

Image:

JB's wear

“We have the high-vis and boots for those on the ground, but we also have the trousers and shirts for those in the office, and the hats and aprons for the chefs at the camps.”

Smith is particularly proud of the company’s ability to remain consistent and capable throughout its history.

“Even after all that time, we’re still privately-owned and family-operated and we have a long-term commitment to the industry,” he said.

“When you buy a uniform from JB’s wear, you know it will be in stock and will remain in stock year after year.”

Malcolm said JB’s wear is looking forward to exhibiting its offerings at the PNG Industrial and Mining Resources Exhibition and Conference in Port Moresby on July 3–4.

“We really want to emphasise that we are a one-stop shop, because we know it can be hard to get everything a mine needs across the ocean,” he said.

“If you want footwear, we have it. If you want safety gloves or eyewear or respiratory equipment, we have that, too.

“We can support the PNG mining industry the best way we know how: by providing capable, honest and enthusiastic service.”

Following its acquisition of the Schenck Process mining-related business in November 2022, Sandvik has been working hard behind the scenes to bring its new offerings to market.

IN OCTOBER last year, Sandvik reached a key milestone in the integration of Schenck Process Mining (SP Mining) into its rock processing solutions business area, when the company changed the names of the legal entities that came with the Schenck Process acquisition.

The newly acquired entities provide Sandvik Rock Processing with a wider global reach, particularly in geographies where it previously had little presence.

This is especially true in Australia, where Sandvik Rock Processing only had a small team, while SP Mining had the majority of its engineering and research and development (R&D) teams as well as production and service facilities in Australia.

Schenck Process Australia, which employed over 400, people became Sandvik Rock Processing Australia, which is now a major hub for Sandvik’s global Screening Solutions Division.

Since the renaming of the legal entities, the integration of the SP Mining business around the world has been a key focus area for the company.

Part of this work includes the rebranding of all aspects of the business. In parallel, the SP Mining and Kwatani equipment offerings have been united under the Sandvik brand.

Sandvik said the result is an unparalleled range of vibrating screens, feeders, screening media and train loaders.

In early May, the company achieved another key integration milestone, shipping out the first Sandvik branded SP Mining screen from its Jandakot production facility in Western Australia.

Sandvik underpins its new offering with its team’s expert process knowledge and suite of digital tools.

Sandvik global head of marketing – screening solutions Peter Newfield, who was previously SP Mining APAC head of marketing, was pleased with the result.

“Apart from the change to the look, branding and Sandvik nomenclature, nothing else has changed,” Newfield said. “Our legendary reliability, technology and aftermarket support remains as our customers have come to expect.

“We are now better equipped to help our customers optimise their comminution and material handling operations for maximum performance, safety and efficiency.”

Newfield said combining the screening, feeding, and loading expertise of SP Mining and Kwatani with Sandvik’s mastery of crushing and wear protection

Images: Sandvik

Images: Sandvik

allows the company to bring an unrivalled equipment line-up to market.

“This unique offering is underpinned by the expert process knowledge of our teams, a full range of digital tools, high-quality original equipment manufacturer spare parts, consumables, and lifecycle services,” he said.

But the integration isn’t just limited to equipment. Newfield said it has been a major project that involves every part of the business.

“Of course, a big part of the integration is making sure our key stakeholders understand the benefits of us becoming a fully integrated part of Sandvik,” he said.

As part of the integration process, SP Mining staff

had to embrace the Sandvik culture and learn the company’s systems and ways of working.

“It takes time for people to adjust to change, and they need to know what is happening throughout the process,” Newfield said. “We have worked hard to communicate the changes to all our key stakeholders including our customers and employees.

“We are now changing the branding of all our Australian facilities, our motor vehicles, and the work clothes that our people wear on the job every day.

“Our website and other marketing collateral is also being changed to showcase our new product offerings and brand.”

Newfield said he expects the rebranding projects to be complete by the end of June, which is the final step in the integration process.

“Our new offering, along with the advances that our combined R&D teams are making, allow us to partner with our customers to address our industry’s biggest challenge – making mineral processing more eco-efficient,” he said.

Expect more at

every stage of tyre life

Making tyre management safer and more productive. Reducing total cost of ownership and putting ESG at the core of our offering.

By delivering more than what is expected, we help make a difference every day.

Preparing to ship the first Sandvik-branded SP Mining screen from Jandakot.

Preparing to ship the first Sandvik-branded SP Mining screen from Jandakot.

Fenner Conveyors and Conveyor Products and Solutions are working to deliver a one-stop-shop conveyor belt and roller offering.

PAPUA NEW GUINEA (PNG) has been making strides in a mission to take its place on the world stage as a major supplier of essential resources.

But there’s only one way those critical metals and minerals will travel the mines of PNG to the rest of the world: conveyors.

Luckily, Fenner Conveyors has a curated team with the knowledge and experience to keep the Pacific nation rolling.

Having acquired Conveyor Products and Solutions (CPS), an Australian conveyor component design and engineering expert, in 2022, Fenner Conveyors is now well-positioned to deliver enhanced conveyor solutions to the region.

Over the years, Fenner Conveyors has established itself as a key player in PNG’s mining sector, supplying conveyor belts and services to various mining operations.

A PNG gold and copper mine commissioned with a Fenner Conveyors belt and CPS rollers.

National sales manager Travis Lewis said CPS has also had a long history of supplying high quality conveyor rollers, idlers and pulleys to PNG.

“We’ve been providing support to the region for years and working with some of the biggest mines in PNG,” Lewis told PNG Mining. “As part of the Fenner Conveyors Group, we can now provide a full turnkey solution for conveyor systems.

“It sets us apart as we’re now the only company in the market that can deliver that full conveyor engineering expertise, service and product supply.”

Equipped with ultra-modern industrial means, automation, digital, and robotic production tools, Lewis said CPS and Fenner Conveyors have the solution to an issue many mine operators face.

“Traditionally, mining clients would have to go to various companies for each conveyor component or service required, which can be tricky because components might not be optimised to work together, effecting how the overall conveyor operation will run,” he said.

“But the joint position we’re in as Fenner Conveyors means we can leverage the experience and knowledge of all companies within the Fenner

Conveyors Group to offer our clients a one-stop-shop for equipment engineered to work together.

“It’s a quantum leap in our ability to provide quality belts and rollers to PNG.”

Where CPS’ conveyor products were previously sold through various suppliers in PNG, Fenner Conveyors account manager Andrew Morgan said taking a ‘One Fenner’ approach can offer customers an added layer of care.

“We have engineering expertise and support onhand every step of the way to combat any challenge,” Morgan said.

“We have experts in pulleys, experts in rollers, experts in belting – experts for every part of a conveyor system.”

This expertise is enhanced by Fenner Conveyors’ parent company, global manufacturing powerhouse Michelin.

Fenner Conveyors is able to tap into Michelin’s research and development capabilities to constantly re-optimise and enhance the performance of its conveyor products.

“PNG can be a very harsh mining environment with uneven terrain and extreme rain and humidity,” Morgan said. “If you leave things lying around for too long, the landscape will reclaim it very quickly.

“With the support of our parent company, Michelin, we’re able to expedite our research and development

and get solutions on the market that thrive in such a harsh environment. This improves productivity, reduces costs, and minimises downtime.”

With mining operations nestled in hills hundreds of metres above sea level, product often has large drops between conveyors, the shock of which can quickly wear out the belt if it’s not engineered for the conditions.

Fenner Conveyors’ cover protection for cut and gouge resistance, ArmorShield, is demonstrating outstanding results for mining operations in PNG.

“ArmorShield is proving to more than double the life of the belt,” Morgan said. “It’s a great solution for the PNG market, where belts can wear out much faster than they do in other environments.”

When the belt and rollers are engineered to work together, significant progress can be made towards optimising conveyor operations.

the right culture, the right collaborations, and the right engineering skill set and of course, the right conveyor products.

“In all, we’ve generated a very holistic approach as one Fenner Conveyors team to support our customers in PNG.”

Drawing on our vast experience and integrated network of key technical professionals, Kramer Ausenco delivers projects with insight and expertise. Seamless coordination of professional services ensures smooth delivery of projects from concept to completion.

• Building Services Engineering • Architectural Design

• Master Planning

• Feasibility Studies

• Concept Tanks

• Fluid Management Solutions

Concept Tanks knows that when two companies come together in a joint venture, it creates a powerhouse of knowledge, connections and skills.

AS ONE OF Australia’s leading providers of large-scale fluid storage, Concept Tanks offers environmentally sensitive solutions to the energy, resources, waste and water sectors.

And with more than a decade of hands-on experience, Concept Tanks wasn’t after just anyone when it was looking for a joint venture partner. The company needed to find someone with as much skill, knowledge and passion as it had.

Enter Kramer Ausenco.

“The relationship between Kramer Ausenco and Concept Tanks was formed over a number of years and developed into a shared understanding and mutual respect for each other’s unique offerings,”

Kramer Ausenco managing director Adam Kramer told PNG Mining

“Kramer Ausenco has identified that there is a huge demand for innovative products and are thrilled to be partnering with Concept Tanks to offer solutions to our valued clients.”

Engineering giant Kramer offers services throughout a project’s entire lifecycle, from initial concept and design through to construction and commission across a range of industries.

With Kramer’s background in engineering and Concept Tanks’ fluid storage expertise, the stars aligned when the two entered into their partnership.

Concept Tanks is now looking forward to venturing into PNG with Kramer’s support.

“PNG is our newest endeavour after entering the US

and Canadian markets in 2023,” Concept Tanks chief executive officer Phil Hollywood told PNG Mining.

“This expansion reflects our commitment to providing innovative fluid-management solutions on a global scale. We see PNG as a promising market with unique needs, similar to our successful ventures in other regions.”

Tanks are used in almost all areas of a mine and with so many new and planned operations making a home in PNG, there will be no shortage of work for the joint venture partners.

Concept Tanks’ solutions can fit seamlessly into any project.

Concept Tanks is one of Australia’s leading providers of large-scale fluid storage.

Images: Concept Tanks

“Kramer Ausenco acknowledges Concept Tank's innovative and versatile product and believes it is an answer to many water and containment issues for medium to large scale projects in various industries,” Kramer said.

“As an engineering consultancy servicing PNG for over 45 years, Kramer Ausenco can see strong potential for the partnership between these companies to offer end-to-end solutions to the various issues our clients commonly face.”

But the two companies aren’t about to lose sight of their goal to provide customers with the best possible support.

“Our mission is to help our clients and partners achieve their business and environmental objectives through the provision of innovative fluidmanagement solutions,” Hollywood said.

“Since 2009 our focus has been on creating a sustainable and cost-effective way to manage fluids. We have achieved this through our patented and unique modular prefabricated concrete tank design.

“And in 2023, Entacon was established as our parent company to further combine a rich legacy of expertise with a vision for future growth.”

Sustainability is also a key focus for Concept Tanks. The company fosters relationships with local communities in Australia to help drive down transport

“

emissions and keeps its goal of reducing greenhouse gas emissions at the core of its operation.

“Rather than just supplying a tank, our focus is to supply fluid-management solutions that really benefit our clients, the communities and environment,” Hollywood said.

“We want to work closely with these stakeholders to provide the best possible sustainable solution.”

Hollywood counts these relationships as the key to Concept Tanks’ success and is ready to welcome more as the Kramer-Concept partnership gets off the ground.

We see PNG as a promising market with unique needs, similar to our successful ventures in other regions.

Adam Kramer

Concept Tanks is looking forward to expanding into PNG.

“One of the biggest advantages of our solution is that we can utilise a local supply chain to rapidly supply secure and flexible storage solutions for liquids ranging from potable water to heavily contaminated fluids, providing containment certainty to our clients,” he said.

Kramer echoed similar sentiments.

“As a PNG based company, Kramer Ausenco has an unbeatable understanding of the country’s unique landscape,” he said.

“As such, in partnership with Concept Tanks, we are ideally positioned to understand the issues companies and communities face and can offer solutions that are fit for purpose.” PNG

Blackwoods has over 35 years’ experience supporting PNG’s mining and resources industry.

THE MINUTIAE of a mine site can be a difficult thing to quantify. From PPE (personal protective equipment) to power tools to machinery, all equipment must work in harmony to make a mine site tick.

But where do they come from? There’s no ‘mining shop’ operators can pop into.

That’s where Blackwoods come in. With over 145 years of experience in industrial procurement, Blackwoods knows what it takes to keep a mine site running smoothly.

“Having what you need, when you need it, is critical in managing your inventory levels, project deadlines, keeping costs down, and most importantly keeping your people safe,” the company told PNG Mining.

“Our expertise lies in our ability to provide a one-stop sourcing solution for major mining operations.

“Our position within the Wesfarmers Group allows us to leverage the expertise of other group companies while offering peace of mind when it comes to supply chain security and financial stability.”

Working with more than 4700 suppliers, Blackwoods boasts over 300,000 catalogued products.

Blackwoods partners with some of Australia’s largest companies to seamlessly mobilise their assets and deliver the right products for the right applications.

“Backed by unmatched expertise and an industryleading product range, Blackwoods will make the procurement and supply process as seamless as possible,” the company said. “Our dedicated team offer a single point of management for every stage of the process, from project scope through to delivery.”

Blackwoods has been a trusted supplier to some of Papua New Guinea’s (PNG) largest mines for over 35 years. For Blackwoods, success comes from a commitment to ensuring its customers are supported at every step.

“Our goal is to remove the headache out of the procurement process so customers can focus on more critical operational areas, by leveraging

our dedicated export team and our product and technical experts based in our Brisbane warehouse,” the company said.

Blackwoods begins every partnership the same way: with a detailed consultation process to review a project’s scope and requirements.

From there, the company sets about leveraging its global supplier network and its own distribution network to source the highest quality products.

Blackwoods’ procurement process is defined by commitment to detail when it comes to managing transportation and logistics. This includes balancing local and international stakeholders and freight forwarders.

And when it comes to getting its products delivered, Blackwoods’ dedicated product packaging team consolidate stock and pack in accordance with the specific requirements of its customers, as well as completing any necessary documentation.

“Blackwoods utilises cutting-edge technology and the support of qualified professionals to help you better manage inventory, reduce cost, free-up capital and improve productivity,” the company said.

As a trusted supplier to PNG, Blackwoods is confident in its ability to keep the Pacific nation’s mining industry covered for another 145 years.

trusted supplier to some of PNG’s largest mines for over 35 years.

“Blackwoods has earned its reputation as a trusted and reliable partner when it comes to supplying quality products, reflecting our strong supply chain network,” the company said.

“We are truly committed to being the chosen partner for the supply of industrial and safety products and solutions. It’s our promise.” PNG

With a reputation as a go-to specialist valve company, Winnellie Valve & Process is no stranger to hard work and perseverance.

A large-diameter butterfly valve for process applications.

WINNELLIE VALVE & Process’ products have been helping to regulate the flow of fluids and gas across the energy and mining sectors for more than 40 years.

Since 1983, the company has sourced, sold and maintained equipment that works hard so its customers don’t have to.

And Winnellie Valve & Process is now looking to expand in Papua New Guinea (PNG).

“We see PNG as a massive potential growth market for us,” Winnellie Valve & Process manager Iain Garvin told PNG Mining.

“What makes us different is our technical expertise; we’re not just selling products, we’re providing the technical support, too.”

Garvin highlighted the continuous replacement and maintaining of valves as a common concern that Winnellie Valve & Process can help solve, and he’s looking forward to helping operations in PNG with similar issues.

“If an operator is continuously replacing or maintaining their plant valves, they need to be looking at correct severe service valve selection,” he said.

Correctly selected severe service valves take into account temperature, pressure, pressure drop, erosion and corrosion to ensure the best valve for the application.

Winnellie Valve & Process takes into account why valves might be failing at the plant and will then work with its customers to ensure new valves can provide better reliability.

“If you’re constantly getting leaks, the costs of those leaks start to become clear really quickly,” Garvin said.

“So by spending some money on better quality valves that won’t leak, you’re saving far more money in the long term.”

According to Winnellie Valve & Process, valve gland leaks can account for up to 60 per cent of emissions in refineries and chemical plants. When combined with the higher costs incurred when a valve leaks, this can put a real damper on a business.

Luckily, Winnellie Valve & Process has a solution.

“Bellows sealed valves are something you don’t often come across because they tend to be very niche as far as applications go,” Garvin said.

“The idea behind a bellows sealed valve is that it has welded bellows inside it that keep any of the medium contained within the valve itself.”

Should the bellows fail, the valve also has a standard glad sealing arrangement to contain the medium until it can be replaced

Garvin explained that bellows sealed valves are particularly useful in plants that deal with chemicals like hydrogen sulphide, chlorine and other gases or liquids that can be poisonous in the event of a leak.

“Obviously plants want to ensure their employees and anyone around the plant is kept safe and healthy, so a bellows sealed valve is the best option,” he said.

“And if a plant wants to reach net-zero and really drive down their emissions, cutting those leaks is going to be a top priority. A bellows sealed valve can help with that, too.”

Garvin, who carries decades of technical knowledge, is looking forward to seeing how Winnellie Valve & Process can help more customers in PNG.

“From our perspective, we see ourselves as being able to provide that technical expertise that we are so known for,” he said.

“I have 30 years of experience, another of our team members has 25. It’s this kind of knowledge that means we are able to help our customers in the best way.

“That’s what we pride ourselves on; the fact that we can give you the right valve at the right time and back it all up with exceptional technical support.” PNG

Images: Winnellie Valve & Process

Images: Winnellie Valve & Process

Apprenticeships provide vital handson learning for those looking for a career in the resources industry.

Education and apprenticeship programs have become vital recruitment tools for major companies across Papua New Guinea. PNG Mining takes a look at some of the initiatives.

IT’S AN AGE-OLD question in the resources sector: how do we hire, train and retain enough staff to keep the industry running?

Papua New Guinea (PNG) is not immune to the sector’s recruitment challenges. To combat this, companies across the country have ramped up recruitment, education and apprenticeship drives in an effort to bring in skilled workers looking for a fulfilling career.

Ok Tedi

Ok Tedi Mining Limited (OTML) could perhaps be dubbed the bedrock of education and training drives in Papua New Guinea.

The major miner regularly welcomes swathes of new graduates to its ranks while training groups of apprentices and investing heavily in university students.

OTML runs several different training programs throughout the year, combining its scholarship scheme with different employee intake periods.

Training and development manager Ian Strachan said OTML’s programs are a unique opportunity for students to bridge the gap between theory and practice.

“We aim to provide them with an environment where they can apply their knowledge in real-world scenarios,” he said.

The apprenticeship selection often begins at a university level, with OTML supporting students at the University of PNG and the PNG University of Technology with scholarships.

“The Undergraduate Scholarship Award Scheme is an initiative of OTML to help support high performing students attending tertiary institutions in PNG that offer disciplines relevant to OTML work areas,” OTML said.

Since 2007, OTML has invested K830,000 ($329,753) in the scheme, covering student costs such as tuition, boarding, textbooks, travel and stipends for over 60 students.

From there, scholarship recipients are given the opportunity to work for OTML in trainee or apprenticeship positions.

The highly successful program has launched the careers of some of OTML’s best and brightest, including its managing director and chief executive officer Kedi Ilimbit.

“Our current managing director and chief executive officer is a product of the program, as well as other managers and general managers, so it’s a great program to be a part of,” OTML said.

Those looking to make waves in the energy sector can rely on Kumul Petroleum’s training entity to provide

coaching and employment capabilities.

The Kumul Petroleum Academy (KPA) was established in 2015 and has been creating an industry skill pool for technicians, supervisors and engineers ever since.

With a 100 per cent pass rate, there is perhaps no better place to be for someone looking to begin a career in the energy or oil and gas spaces.

“We are passionate about investing in programs and projects that will up-skill and develop our young Papua New Guineans so that they are ready for the projects that are coming online now,” Kumul Petroleum managing director Wapu Sonk said.

In January this year, Kumul Petroleum announced that it would build a new facility for the KPA to expand its coaching and employment capabilities.

Built next to its fabrication facility near the PNG LNG (liquified natural gas) project plant site at Caution Bay, the training facility is expected to open within two years with the capacity to train 350–400 trainees.

The resources companies of Papua New Guinea have a long history of providing comprehensive education and traineeship opportunities to the sector, and with so many opportunities available, the thriving energy and mining sectors will remain ones to watch.

As a preferred equipment supplier for Tier 1 clients, Boss Attachments knows a thing or two about the needs of the mining industry – and about helping the community.

WHEN BOSS Attachments general manager Ricky Kirby sat down with PNG Mining, his passion for the communities and companies of Papua New Guinea (PNG) was evident.

“I love seeing people succeed,” Kirby said. “There’s something special about watching people who put in the effort succeed because of that effort.”

Kirby has been a vocal supporter of Boss Attachments’ recent moves into PNG, seeing it as a natural progression for a company that is always looking to grow.

“PNG is moving forward, and as Australia’s closest neighbour it seems natural to want to help that happen,” he said.

“We’re looking to start a dealership in PNG over the next couple of years because the country is really getting into the high-end mining equipment that we use in Australia.”

Boss Attachments is leveraging its reputation for supplying world-class machinery attachments to the construction, mining and civil industries of Australia to equip PNG with the same level of safety and productivity in their equipment.

The company selects its range of brands for their design innovation and performance, so its customers can rely on them to work longer, harder and faster without compromising on safety.

“Safety is key for us at Boss Attachments,” Kirby said. “We would like to take what we’ve learned on the ground here and help apply that to projects in PNG.

“People in PNG are big believers in a strong educational foundation, and we can help with that by passing on our knowledge.”

This ethos translates to environmentally friendly work, too.

“If a customer wants to move forward with their site, we can help with that,” Kirby said. “If there’s scrap salvage laying around, we can offer solutions to help clean that up and get the site running with a more environmentally conscious outlook.

“People on the ground have responded really well to our help, and we’re seeing an ongoing effect where they will then pass on that knowledge to other sites.”

Boss Attachments has structured its service delivery to leave nothing to chance, meaning customers can be assured its friendly team and world-class warehouse and logistics centre will always be there for them.

The company understands professionalism, success and what its customers want.

But, as Kirby explained, it’s not just about sales.

“We get customers for life by investing in them, not the other way around,” he said. “It’s not all about the sale.

“If a potential customer comes to us and wants our help, we’re happy to brainstorm different ideas about how we can get their site to run more efficiently or safely. And if we get a sale out of that, then that’s just a bonus.”

With new products coming in almost every day, it’s hard to imagine that the Boss Attachments team can find the time to help so many in the PNG community, but Kirby explained that it’s just part of the job.

“Being able to help with the right solution is the most important part of my role at the end of the day,” he said. “If something is more cost-effective or better for the environment or the people, then that’s what we go with.

“It’s never just about the sale. It’s about helping people move forward.” PNG

Boss Attachments is a preferred equipment supplier for Tier 1 clients.

A proud family run business for over 30 years, JB’s wear is your trusted source for Industry leading workwear. With millions of garments in stock at our warehouses, we are confident that we can deliver what you want, when you want it.

With Hastings Deering recently celebrating 75 years of operation in Papua New Guinea, the equipment supplier sat down with PNG Mining to discuss its accomplishments.

LEGACIES ARE built on persistence, trust and endurance, something Hastings Deering knows well.

Having worked in Papua New Guinea (PNG) since 1949, the Cat equipment supplier remains dedicated to the country’s future through its community work and mine site services.

Hastings Deering PNG continuous improvement manager Phil Beinke has worked with the company since 2007 and, in that time, he has seen the company go from strength to strength.

“Certainly one of the biggest accomplishments for me was the delivery of the single largest fleet of Cat 793F dump trucks at the time,” Beinke told PNG Mining.

“We commissioned, assembled and delivered those to a remote mine site in the Western Province of Papua New Guinea. We had to create the capability needed to deliver them and train our team in servicing the equipment in order to provide the product support required by our customer.

“As you can imagine, it was a massive challenge but one that I’m very proud to say we accomplished.”

The company operates across five PNG sites: Kimbe, capital of West New Britain province; Lae, capital of Morobe Province; Lihir Island, the largest island in the Lihir group of islands; Tabubil, in the Star

Mountains area of the North Fly District of Western Province; and the national capital of Port Moresby.

Hastings Deering employs 300 people across these five PNG operations, and the company is always looking for ways it can help its employees grow.

“Every year, we send our top apprentice to Australia for our Apprentice of the Year Competition, and we’ve had a number of our Papua New Guinean team crack the top 10,” Beinke said.

“One employee in particular was my former apprentice, and he is now the services manager for the Lae component rebuild centre, and we still work closely together.”

It’s this commitment to its team that has allowed Hastings Deering to build a successful business with so many moving parts; not only does Hastings Deering supply Cat equipment and parts to the PNG mining sector, it also services and rebuilds machinery.

By partnering with its customers to deliver tailored rebuilds, Hastings Deering allows customers to maximise asset life and performance in accordance with what they need from each machine.

And with Hastings Deering’s flexible servicing options, booking a service for a machine online is as easy as a few clicks.

Images: Hastings Deering

Images: Hastings Deering

But it’s not just its customers that Hastings Deering looks out for. The company also has its focus set on giving back to the communities in which it operates.

“We’re involved in several charities that help to rebuild or renovate classrooms at rural schools, and a lot of our team will go down and help on their days off,” Beinke said.

“And, more recently, we’ve donated classrooms to a local village in Western Province.”

Knowing a classroom is often only as good as the materials inside it, Hastings Deering has also partnered with Buk bilong Pikinini, a not-for-profit organisation helping to increase literacy rates in PNG through children’s libraries and high-quality education programs and books.

“The foundation has a series of books called When I grow up, I want to be … and they’re about growing up to be a police officer or a firefighter, but there’s now one that’s called When I grow up, I want to be a Heavy Equipment Operator,” Beinke said.

“We often run open days at our facility in Port Moresby where we’ll bring school kids in to check out the equipment and show them some future job opportunities.”

With such a strong 75 years of work in PNG behind Hastings Deering, what’s next for this iconic company?

“Technology is helping us do things faster and more efficiently, and we know the world is going digital but there’s no substitute for good oldfashioned service,” Beinke said. “So, as always, we’ll be growing our presence in the country and continuing to support our customers, employees and communities the best way we know how.” PNG

TriCab has big plans to bring its decades of cabling knowledge to PNG.

THERE’S ONE thing all sizes of mining machinery have in common: cables.

Mines are made up of millions of copper wires powering equipment so they can keep producing essential metals and minerals. But not all cables are created equally.

In such a heavily productive industry as mining, it is especially important to ensure the cables keeping operations running are of the highest possible quality.

Enter Australian owned and established electrical cable manufacturer TriCab.

Now a cornerstone of cable manufacturing, TriCab has been servicing the Australian and international markets for nearly 50 years.

The company operates manufacturing facilities across Australia, Asia and the US, aiming to respond to the needs of its customers and produce fit-forpurpose cables companies can rely on.

And TriCab has a vision to share its wealth of experience with Papua New Guinea (PNG).

“As a successful Australian electrical cable manufacturer, it was a natural step for us to move into the mining space where our expertise can save operators time and money by using quality cables from the start,” TriCab Queensland state manager Shane Plumridge told PNG Mining

“We’re excited to share our knowledge and expertise with the PNG mining sector, using our prime position in Australia to bring quality and reliability to the market.”

Plumridge has seen first-hand what can happen if companies choose a lesser quality cable. Breakdowns are just the beginning, with time spent out of action coming at a huge cost to operations.

“That’s why it’s so important to choose quality cables,” Plumridge said. “With TriCab, you know you’re getting the best.

“Our team of engineers are constantly developing the latest advancements for our cables, meaning they are able to be installed quicker and require less labour on site, saving operators time and money.”

manufacturing in Australia to meet the requirements of Australian/New Zealand wiring standards (AS/NZS).

“We’re very focused on these standards, which include PNG in their jurisdiction,” Plumridge said. “As an Australian manufacturer, ensuring our cables are in line with the AS/NZS standards means we can consistently deliver quality over time.”

Plumridge emphasised TriCab products are always up to the latest AS/NZS standards, whether they’re smaller cables for switchboard manufacture or larger cables for powering up equipment like pumps and motors.

Heavy mining machinery requires more copper in its cables in order to conduct enough electricity to keep things running reliably, but a thicker cable means less flexibility which could spell trouble for operators. Thankfully, TriCab has a solution.

“Our cables are all made from a 0.3mm copper strand,” Plumridge said. “Even our largest cables are made from bunching together fine strands.

“That makes the cables easy to bend and get in and around tight spaces, allowing labour saving and reduced downtime. Our competitors’ cables may be unable to keep up with that level of flexibility.”

Plumridge emphasised TriCab’s commitment to its customers and the company’s reliability as a leader in the cable industry.

“We’re very proud of our product and our customers are used to the high level of service we provide,” he said.

“A lot of our competitors have moved their manufacturing offshore, but TriCab has remained a strong producer in Australia thanks to our consistent quality.”

Looking ahead to the coming year and beyond, Plumridge is confident in TriCab’s ability to meet the growing needs of the PNG mining sector.

“We’re looking to expand our footprint in the PNG sector and work with like-minded companies looking for labour-saving installations,” he said.

“We’re determined to support the PNG mining sector with the best quality cables on offer.”

TriCab Queensland state manager Shane Plumridge knows the importance of choosing quality cables.

TriCab control cable.

TriCab Queensland state manager Shane Plumridge knows the importance of choosing quality cables.

TriCab control cable.

- Greenfield Mineral and Hydrocarbon Exploration

-Due diligence on Resource & Reserve estimates Agriculture, Forestry, Maritime compliance -

-Satellite Survey mines, dams and pipelines

-Archaeological Investigations - - Hydro-geological studies

-Drill support

Islands Petroleum might be a fuel-focused company by name, but its joy comes from giving back to its customers and communities.

HAVING CARRIED and distributed fuel in Papua New Guinea (PNG) for more than 40 years, Islands Petroleum is a company built on legacy.

What began as a transport company back in the 1980s has since grown into a trusted and respected distributor of fuel and Mobil lubricants in PNG.

“We are often asked what the secret is to running a successful customer-focused business,” Islands Petroleum chief executive officer (CEO) Nathan Bluett told PNG Mining.

“A family business, Islands Petroleum takes pride in going the extra mile to make its customers feel like family, too, with exceptional service a part of our culture.

“When our customer has a problem, we solve it, and we’re not opposed to being creative with our problem-solving.”