VOLUME 1 NO. 3 | OCTOBER–NOVEMBER 2024

VOLUME 1 NO. 3 | OCTOBER–NOVEMBER 2024

Transforming mineral processing in Papua New Guinea

Up-to-date technology for an essential aspect of mining

PNG’S COPPER RESOURCES

Profiling some of the biggest copper mines in the region HELPING HANDS AMID DISASTER

How companies give back to those in need PORGERA’S TIMELINE

The story of one of the most iconic gold mines in PNG

Looking at PNG’s past, present and future energy needs

At MASPRO, quality is embedded in our DNA, influencing every decision we make. Through innovative design, rigorous testing, continuous improvement, and a customer-first approach, we consistently deliver products and services that meet the highest standards, ensuring reliability our customers can trust.

COO

Christine Clancy

GROUP MANAGING EDITOR

Paul Hayes

T: +61 3 9690 8766

E: paul.hayes@primecreative.com.a

EDITOR

Alexandra Eastwood

T: +61 3 9690 8766

E: alexandra.eastwood@primecreative.com.au

JOURNALIST

Dylan Brown

T: +61 3 9690 8766

E: dylan.brown@primecreative.com.au

CLIENT SUCCESS MANAGER

Janine Clements

E: janine.clements@primecreative.com.au

RESOURCES GROUP LEAD

Jonathan Duckett

M: +61 498 091 027

excellence and a future-focused approach, from engineering to the energy transition.

E: jonathan.duckett@primecreative.com.au

BUSINESS DEVELOPMENT MANAGER

Les Ilyefalvy

M: +61 421 474 407

E: les.ilyefalvy@primecreative.com.au

ART DIRECTOR

Michelle Weston

SUBSCRIPTION RATES

Australia (surface mail) $140.00 (incl GST)

New Zealand A$148.00

Overseas A$156.00

For subscriptions enquiries please call +61 3 9690 8766

PRIME CREATIVE MEDIA

379 Docklands Drive

Docklands, VIC 3008 Australia www.primecreative.com.au

© Copyright Prime Creative Media, 2016

MINERAL PROCESSING has been touted as the beating heart of the mining sector, taking rocks and turning them, sometimes literally, into gold.

The mining industry of Papua New Guinea (PNG) has a booming mineral processing sector, and the industry is shifting more and more towards precision engineering and improving operational efficiency while driving innovation.

The October–November issue of PNG Mining takes a closer look at this important part of the mining value chain, taking a deep dive into the entire process and looking at the new technology that’s making waves in the industry.

With so many new technologies emerging, PNG has been given an opportunity to refine its processes and become a leader in the global market –but it will need future-focused companies in its corner to meet this goal.

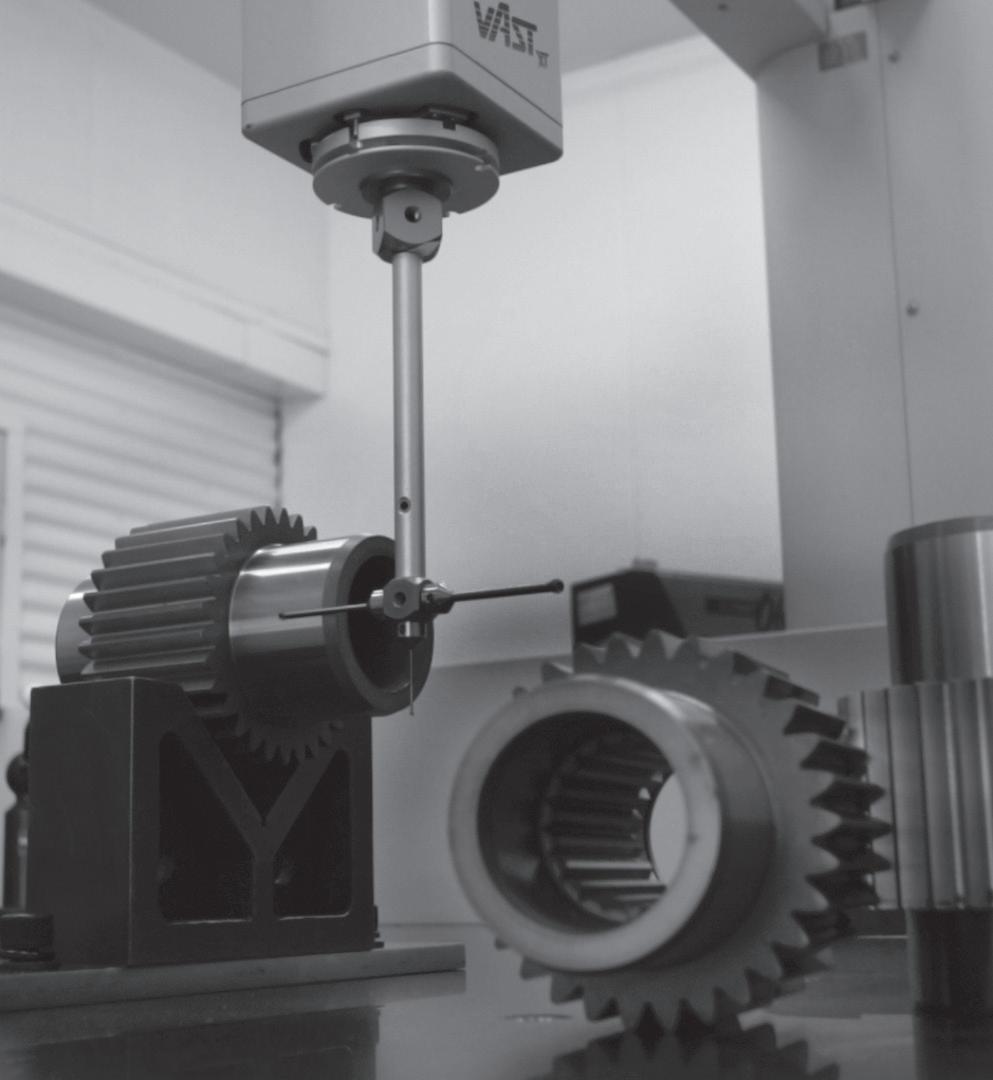

One leader in this space is MASPRO, a company known for its focus on quality engineered parts.

In this issue, MASPRO chief executive officer and founder Greg Kennard takes us on a journey from the company’s humble beginnings in 2006 to leading the

engineering and spare parts supply at some of the biggest mines around the globe.

“Quality is never an accident,” Kennard said. “It is always the result of high intention, sincere effort, intelligent direction and skilful execution.”

MASPRO also graces this issue’s cover, showing off one of its quality engineered parts.

Elsewhere in this issue, we turn the spotlight on the upcoming 2025 PNG Expo. With last year’s event setting a high bar, 2025 promises to be even more impactful, bringing together experts to showcase the latest advancements in mining and resources.

We also take a look at PNG’s rich copper mining history, profiling some of the biggest and most well-known copper mines in the country.

Renewable energy has been another focus of our October–November issue, as we profile new Energy Minister Thomas Opa, and take a look at what the future of renewable energy might look like for the country.

It truly is an exciting time to a part of the changing landscape of PNG.

Happy reading.

Alexandra Eastwood Editor

14 Mineral processing

From rocks to riches

Mineral processing is a crucial part of mining. But what is it? And what does it involve?

18 PNG Expo

A glimpse into the future

The dates have been set for the 2025 PNG Industrial and Mining Resources Exhibition and Conference.

20 Technology

Technological triumphs

The global resources sector has been quick to implement new and emerging technologies to make mining easier and safer – and PNG is no exception.

24 Engineered parts

Quality without compromise MASPRO’s focus on quality, productivity and safety has seen it become a household name in mines around the world.

30 Commodity spotlight

PNG’s copper-rich core Copper has been a mainstay on PNG’s commodity list since mining began in the country. PNG Mining takes a look at the ore’s past, present and future.

38 Gold

Porgera: A timeline Exploring the storied history of the iconic Porgera gold mine.

42 Energy

Powering PNG Renewables, oil and gas all have their place in PNG’s future.

52 Community

Helping hands amid disaster

When a landslide struck Enga Province in May, resources companies across PNG were quick to help.

56 Company profile

Leading the way

As a mining industry leader, Barrick Gold consistently helps to set the standard for operational quality.

The PNG Government remains in talks with Newmont and Harmony Gold to finalise the mine development contract (MDC) for the Wafi-Golpu coppergold mine.

The MDC is a critical step in issuing a special mining lease for the mine, something Morobe Governor Luther Wenge is hoping will happen quickly.

Prime Minister James Marape has requested that Wenge nominate a representative from the Morobe Provincial Government to be included in

the state negotiating team for the final round of negotiations with the miners.

“We are now going through exchanging notes [with Newmont and Harmony] for the MDC,” a Mineral Resources Authority statement said.

“They [Newmont and Harmony] have given us their views; we have also given them our views on the proposed MDC.

“I have instructed our team to move fast. In fact, next Tuesday, we’ll be

having a meeting on this matter so that we all have a clear view on the MDC. After that, we’ll be ready to sign off the MDC, and then we move to the special mining lease.

“We are almost there, in as far as the MDC and special mining lease are concerned.”

Once the special mining lease is issued, Newmont and Harmony will have 30 months to announce their final investment decision for the development of Wafi-Golpu. PNG

Rio Tinto is set to join forces with the Autonomous Bouganville Government (ABG) and Bougainville Copper Limited (BCL) to address the old infrastructure at the Panguna copper mine.

The ageing infrastructure was identified after an independent legacy impact assessment was conducted. The new agreement will aim to mitigate potential risks from the infrastructure and promote safety at the site.

Work will begin to modernise the Jaba pump station and Momau River bridge and will include the former mine area workshop, and concrete wall in the town.

“We are very pleased to be working with BCL with support from Rio Tinto in responding to the issues raised in the best interest of our people,” ABG Chief Secretary Kearnneth Nanei said.

“As we await the final results of the legacy impact assessment, these works represent a positive sign of cooperation by BCL and Rio Tinto.”

BCL chairman Mel Togolo said the company maintains a healthy presence in the region.

“Our local team will be working closely together with the ABG in overseeing the project works to ensure these ageing

buildings and structures don’t cause issues for the community,” he said.

Rio Tinto country director PNG Andrew Cooper said the company is looking forward to supporting ABG and BCL.

“We are pleased to support the Autonomous Bougainville Government and Bougainville Copper Limited in addressing these issues identified as a priority during the legacy impact assessment field work,” Cooper said.

“We commend the ABG and Chief Secretary Nanei for their proactive leadership in driving tangible action.”

Mineral Resources Authority (MRA) managing director Jerry Garry is pushing for more mineral exploration in PNG.

It comes as the MRA revealed there has been a decline in mineral exploration activities since 2019.

Speaking at the Geoscience, Exploration & Extraction Conference in Port Moresby, Garry said he would like to see exploration levels return to that of 2012–18.

“As a country, without exploration, there will be no mining,” Garry said.

Garry said a number of factors had contributed to the decline in exploration, including negative perception around geoscience data and the idea that the permitting of licences was a slow process.

“About 60 per cent of the country’s annual revenue comes from the mining sector,” he said.

“It is therefore important to start looking for new mines now, because the lead time from discovery to commissioning of projects is between

Stage two of wharf construction has progressed for Mayur Resources as the company looks to come to an agreement for its Central Cement and Lime (CCL) Project.

Orders have been made for key construction materials with PNG company Hi-Lift Global.

Once stage two is complete, the wharf will feature roll-on/roll-off barge operations to help generate earlystage revenue.

The PNG Government has also established a state negotiation team to finalise the terms of a project development agreement between the

11–50 years, as in the case of the Frieda River project.”

The Frieda River gold project was discovered in 1967, but is yet to be commissioned.

Garry said the MRA would be looking into ways to overcome the challenge of resource depletion, including a five-year program that tests deep-seated porphyry systems to provide quality baseline geoscience data while testing new potential geological areas. PNG

government and Mayur in the final key step towards full-scale construction.

“Dedicated wharf facilities are strategically important to Mayur”

Mayur managing director Paul Mulder said. “The proximity of the wharf is less than one kilometre from Mayur’s manufacturing facilities and quarries.

“This compares incredibly favourably over some of our Southeast Asian competitor suppliers, who have trucking distances of some 100 kilometres to the wharf that are significantly further away from customer markets in Australia and the Pacific, both of which generate a significant cost advantage for Mayur.”

Mayur is anticipating that agreement negotiation will be completed during the third quarter of 2024, covering both its Central Lime Project and the upcoming Cement and Clinker Project phase.

“Our wharf facilities create a unique, vertically integrated development with a highly efficient supply chain and direct access to Southeast Asian markets,” Mulder said.

“We look forward to completing construction in the fourth quarter of 2024 and generating early stage revenue from the sale of limestone and aggregates.”

St Barbara is ahead of schedule for its Simberi concentrate flowsheet, previously scheduled for November 2024.

The saleable concentrate flowsheet has now been selected for the Simberi sulphides expansion, with metallurgical testwork showing approximately five per cent higher overall gold recovery than previous testwork.

“We are excited by the improvements in the recoveries-to-concentrate and overall recovery being achieved in the flotation testwork we have completed to date,” St Barbara head Andrew Strelein said.

“The results have allowed us to take an early decision in favour of the saleable concentrate flowsheet, three months earlier than anticipated.”

The favourable concentrate market conditions have suggested St Barbara will have the ability to negotiate higher gold payable than previously modelled.

“The confirmation of our expectations of the consistency and competency of the Sorowar ore’s crushing and grinding characteristics with those of Simberi’s other ore zones is a breakthrough,” Strelein said.

Ok Tedi Mining Limited (OTML) has awarded a road construction contract worth K36.1 million ($14.9 million) to a local company to connect the villages of Atemkit and Kavorabip.

Located in the North Fly District in Western Province, the two villages are currently only accessible by helicopter.

Management (FEAML), which will complete the road within the next two and a half years.

The contract was made possible through the PNG Government’s Tax Credit Scheme.

“The people of Atemkit and Kavorabip are principle landowners just like the

“The demonstrated benefit of the flotation circuit design optimisation and the value we have unlocked from confirming Sorowar’s ore properties have already delivered a return on our investment in FY24’s comprehensive metallurgical drilling and testwork campaign.”

St Babara is well-funded to complete the next phases of work and beyond, including the investment in preexpansion growth capital. The company has mobilsed two trucks to the site to further accelerate its growth. PNG

too long to recognise them through such infrastructure projects.

“Today we are witnessing the signing of a road construction project that will link these very people to the rest of Western Province.”

North Fly Member of Parliament James Donald thanked OTML and the PNG

Ok Tedi Mining (OTML) is backing a new book written by its manager –business improvement Gilbert Hamambi, purchasing 100 copies to give to students at the University of Technology.

Graduate Trainees Practical Tips for Accelerated Learning in Reliability Engineering and Maintenance at Ok Tedi Mine is to be used as a tool for those in graduate positions at OTML’s mine.

Prime Minister James Marape has hailed the PNG LNG Project, calling it “transformational” for the country.

The project, located 20km northwest of Port Moresby, has brought in K26.3 billion (approximately $10.2 billion) in economic benefits to PNG since 2014.

“The PNG LNG Project is a transformational project,” Marape said

“This book is an exemplary sustainable tool to be used by trainees and graduates at Ok Tedi as well as those in the tertiary institutions in the field of reliability engineering and maintenance,” OTML managing director and chief executive officer Kedi Ilimbit said at the official launch of the book.

“While we all have our primary roles [at the copper-gold mine], every

at a dinner commemorating the 10th anniversary of the project.

“The National Alliance Government of the late former Prime Minister, Sir Michael Somare, must be commended for having the foresight in 2008 to start this project.

“As of today, after 1069 cargoes, we have received in the country K26.3 billion. The economy has grown from under K25 billion in 2008 to K79 billion in 2019 when I took office, to K113 billion now.

“This project was the impetus for the growth of the economy.”

Marape thanked project developer Exxon Mobil for its work at the site and for “having faith in PNG since 2008”.

individual human being is talented and equipped with a different skillset that he/she can use to impact those around him/her in one way or another.”

With the donation of 100 books to the University of Technology, it is hoped that graduates will be better equipped before entering the workforce, able to utilise their skills in an accelerated manner. PNG

The Prime Minister also thanked the landowners for allowing the project to proceed, acknowledging multiple leaders for their vision.

“The total value of economic benefits to the country since production started 10 years ago is K26.3 billion,” he said.

“This includes K1.3 billion for landowner royalties, K1.26 billion in development levies, two per cent equity for landowners, plus distribution to the Mineral Resources Development Company of K1.9 billion, K9.6 billion to Kumul Petroleum Holdings for 16.5 per cent equity, and a total tax amount of K12 billion.” PNG

Drilling has commenced at Great Pacific Gold’s (GPAC) Arau project, marking the first drilling by the company at one of its PNG sites.

The drilling follows the rehabilitation of the road access to Arau and the completion of nine drill pads. With exploration access now complete, GPAC has been able to mobile a reverse circulation drill rig at the site.

The Arau project consists of two exploration licenses and is located in the Kainantu region in the Eastern Highlands. Drilling will target coppergold porphyry mineralisation.

While drilling is underway at Arau, GPAC will be readying its Kesar Creek project in the New Guinea Mobile Belt.

The phase two soil program at Kesar Creek is expected to be completed before the end of the month, further defining drilling targets at the site.

GPAC is also working on road rehabilitation at its Wild Dog project in East New Britain Province as it prepares to commence exploration there.

“As part of the Arau project, in the southern exploration licence, an initial extensive soil sampling program of 377 samples has recently been completed,” GPAC said. “The area is underlain by the highly prospective Elandora porphyry

unit, which is known to host copper porphyry.

“Assays for this program will be received in the coming weeks.”

GPAC will continue work at Wild Dog in the meantime. PNG

An Interplast surgical team sponsored by PanAust completed a five day visit to East Sepik Province in August where they performed 17 surgeries.

The aim of the visit, announced in July, was to provide life-changing surgeries at no cost to disadvantaged communities and is part of PanAust subsidiary Frieda River’s commitment to improving healthcare.

Over the five days, the Interplast team worked alongside PNG medical and nursing staff to perform 17 surgeries, 50 consultations and provide clinical training to 18 surgeons, nurse and anaesthetic support staff.

Surgeries included burn reconstruction, upper limb surgery, scar revision and

correcting a complex congenital condition in a 17-month-old.

“Whether it’s providing helicopter and fixed-wing medivacs or offering support during natural disasters, we want the people of Sepik to know we are here for them and will continue to be a good neighbour,” Frieda River project director Phil McCormack said.

“We know that people in remote communities such as the East Sepik have limited access to healthcare and may not have the means to pay for consultations let alone surgeries. This partnership with Interplast is designed to address this critical healthcare gap, providing lifechanging surgeries that can significantly

enhance the quality of life for individuals and their families.”

PanAust is now planning for future Interplast visits.

“The Interplast team was so pleased to be able to return to Wewak after several years thanks to the funding and logistical support from PanAust, and to the terrific support of our local clinical partners in Papua New Guinea,” Interplast director of international programs Jess Hill said.

“We look forward to continuing to deliver this important work in Papua New Guinea, and in doing so, building the capacity of the excellent Papua New Guinea clinicians to deliver these services independently.”

The Autonomous Bougainville Government (ABG) has signed a memorandum of understanding with UK-based green energy company Stellae Energy.

The partnership marks an achievement for ABG in its journey toward energy independence and economic sustainability. It will see Stellae and the ABG work with the Department of Mining and Petroleum and the Bouganville Power and Water Corporation to identify geothermal energy sites in the island.

“It is the Bougainville energy policy strategic view that green energy investment and development is encouraged by the government,” Bougainville President and Minister for Mineral and Energy Resources Ishmael Toroama said.

“This partnership is a testament to Bougainville’s commitment to sustainable development and can provide the basis for an industrial revolution in Bougainville in the near future.

“By tapping into solar energy and now our geothermal resources, we not only aim to secure a reliable and clean energy source for our people but also aim to reduce our dependency on imported fossil fuels, paving the way for a greener and more self-sufficient Bougainville.”

A 5000L water tank has been donated to the Wombun Community Health Post in Chambri Lakes, East Sepik Province, courtesy of Frieda River Limited.

The tank will be used to ensure the safe water supply for patients and medical staff affected by natural disasters.

Villagers and local ward councillor Jimmy Manguan attended a special ceremony where the tank was presented.

“Patients with illnesses and those undergoing treatment need clean water to prevent dehydration and other complications,” Manguan said.

Frieda River project director Phil McCormack said the tank donation was just one way the company is showing its commitment to invest in the local community and its healthcare, education and infrastructure.

“We’re invested in meeting the demand for resources in a socially responsible way and looking after the diverse needs of local communities,” McCormack said.

“From supporting infrastructure projects to providing fresh water, we remain deeply committed to helping communities in need, especially during times of crisis.

“We know this water tank will make a huge difference to a community that has been affected by two natural disasters in one year and we are proud to be a part of the community’s rebuilding efforts.”

Wombun experienced an earthquake in April 2023, and a second 6.9 magnitude earthquake in 2024. PNG

Stellae Energy is set to lead the exploration efforts in collaboration with local stakeholders. The project will be rolled out in phases and will begin with an exploration screening study to assess the viability of geothermal sites.

“The ABG is committed to ensuring that the development of geothermal resources is carried out with the utmost respect for the environment and the rights of local landowners,” ABG Secretary for Mining and Petroleum Peter Kolotein said.

“The government will work closely with Stellae Energy to engage with communities throughout the exploration and development process, ensuring that their voices are heard and their interests protected.” PNG

Kumul Petroleum, in a joint venture with the Fly River Provincial Government, has opened a new health centre near the village of Teapopo.

The centre was constructed in an effort to make accessing healthcare easier for residents in the nearby villages, who previously had to travel for hours to seek basic medical care.

Kumul Petroleum external affairs executive general manager Luke Liria officiated the opening of the health centre at a ceremony attended by other senior provincial and government ministers.

“Investing in health care facilities such as the Teapopo Health Centre improves the livelihoods of community members and also contributes the development and prosperity of the nation,” Liria said.

“Kumul Petroleum Holdings is always ready to support the healthcare system in Papua New Guinea.”

The Teapopo Health Centre includes staff housing, six in-patient wards, an antenatal clinic and a month’s supply of medication.

“The facility is solar powered, has rainwater collection and storage as well as a septic system – so it is self sufficient with regard to support services, very necessary in this location,” Liria said.

The opening of the facility will support the healthcare needs of people in eight nearby villages who now no longer need to take a boat to the larger areas of Daru and Balimo to access care.

”Our support for the construction of this health facility is a total of K4 million ($1.5 million), and is consistent with our support of major health infrastructure in Port Moresby and elsewhere in the country,” Liria said. PNG

The Kesar gold project in Eastern Highlands province will become more of a focus for Great Pacific Gold (GPAC), with the second role of soil sampling completed.

The project is contiguous with K92 Mining’s tenements, with several highpriority targets at Kesar near the K92 property boundary.

Multiple veins at Kesar remain on strike, with the same orientation as key K92 deposits.

“The results of the two phases of geochemistry highlight the tremendous

potential of Kesar,” GPAC chief executive officer Greg McCunn said.

“With our recently announced plan to focus on our core projects, we intend to direct our financial and technical efforts on Kesar over the remainder of 2024.

“The high-grade nature of the nearby Kora deposit highlights the potential of Kesar and our Phase 1 drill program is designed to test our highest priority targets.”

GPAC will commit the majority of its focus to Kesar and the Wild Dog project.

“While focusing on Kesar, we will continue to evaluate and advance the other core assets in our high-quality portfolio, including recent drilling at the Arau project, from which initial results are pending, environmental baseline work at Wild Dog and consolidation of our knowledge on the Lauriston and Walhalla projects in Australia,” McCunn said.

“Longer-term, the recently acquired Tinga project also has the potential to create significant shareholder value.” PNG

Santos has welcomed Sherry Duhe to the roll of chief financial officer (CFO), replacing Anthea McKinnell as she plans for retirement.

Duhe was most recently interim chief executive officer (CEO) at Newcrest, where she worked to negotiate and complete the sale of the company to major miner Newmont.

She was also CFO at Woodside Energy until early 2022, coming off the back of a 13-year career with Shell.

Santos managing director and CEO Kevin Gallagher has thanked McKinnell

for her time at the company while welcoming Duhe into the fray.

“Anthea joined Santos more than five years ago and has steered the finance function through a period of significant inorganic and organic growth,” he said.

“Anthea has been a valued member of the Santos executive leadership team and I wish her all the very best for the future as she returns to Perth for family reasons.

“Sherry’s demonstrated financial capability, knowledge of the complex and dynamic energy and financial markets in which Santos operates, and experience in

Kumul Petroleum Academy (KPA) has celebrated the graduation of 17 new trainees from a year long full-time course, achieving City and Guilds Certification.

Eleven of the trainees received their certificate in plant process operation, with six others receiving a certification as instrument maintenance technicians.

The graduation ceremony featured words from guest speakers Breton Macdonald (ExxonMobil upstream asset manager) and Sikke Jan Wynia (Kumul Petroleum senior manager), along with trainees and the KPA manager.

“Kumul Petroleum is proud to have sponsored KPA for almost ten years, enhancing the capabilities of the petroleum industry workforce, including the seventeen graduates today from the 8th Junior Operations and Maintenance Staff Course,” Wynia said.

Kumul Petroleum is currently constructing a new training facility at Caution Bay to provide more facilities and allow for additional courses.

engaging with investors, capital markets and governments, positions her well to support the Santos management team and board of directors in delivering superior value for our shareholders into the future.”

Duhe holds a Bachelor of Science in Accounting from Louisiana State University and an International Master of Business Administration from the University of South Carolina. She is also a Certified Public Accountant.

Duhe joins the company from mid October. PNG

The graduates were the ninth cohort to go through KPA, with training involving the basic understanding of the oil and gas industry, safety training, knowledge in their destined discipline, practical on-thejob training, and coaching in workshops.

KPA first opened its doors in 2016. Since then, over 180 trainees have graduated from the facility, with the tenth cohort of ExxonMobil-sponsored trainees expected in the coming weeks. PNG

Mineral processing is a crucial part of mining. But what is it? And what does it involve?

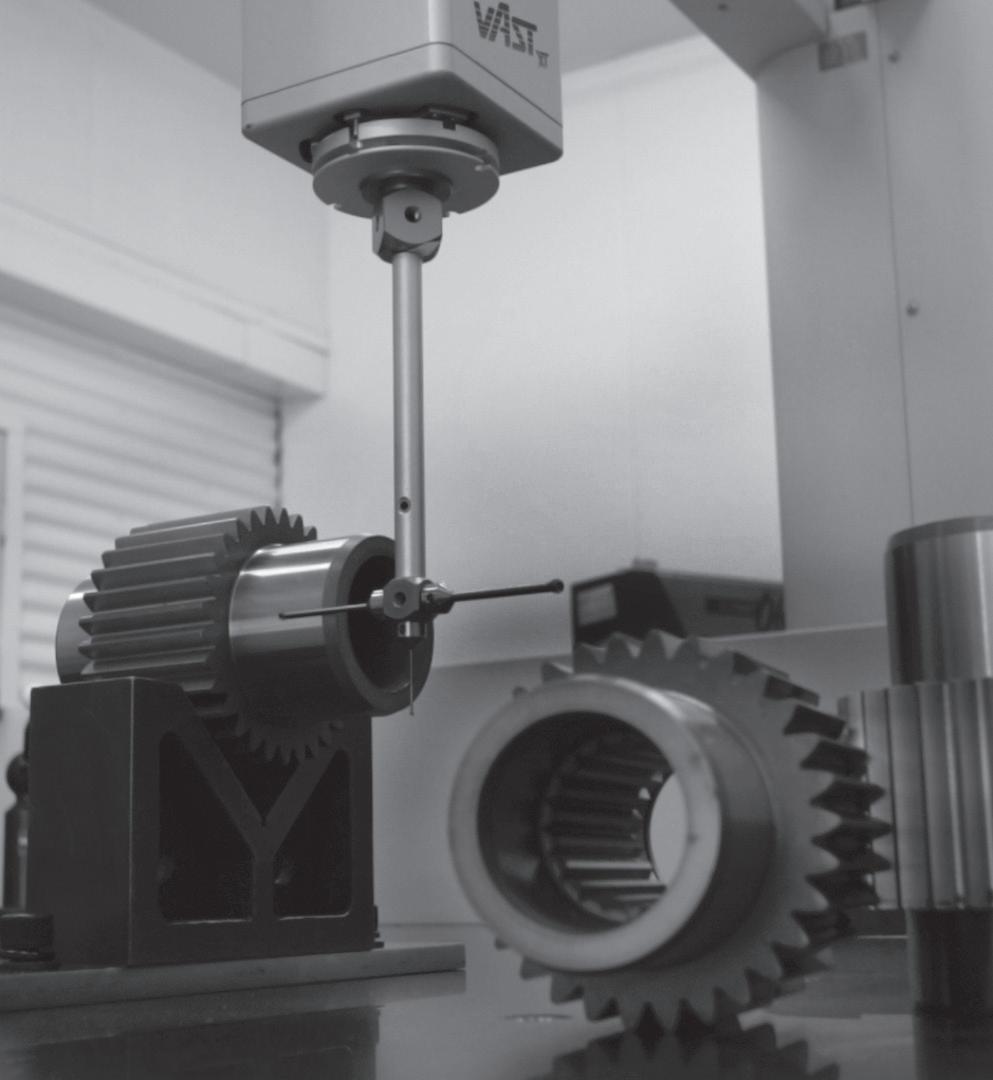

MINERAL PROCESSING is perhaps one of the most important aspects of mining.

This vital technique separates the valuable minerals from the waste ore. To put it simply, if the processing plant doesn’t do its job, there is no ore to sell.

Conducted on-site at the mine and overseen from a central control room, there is little room for error when it comes to mineral processing, as the technique is designed to yield the maximum amount of mineral concentrate to ensure the mine remains profitable.

Mineral processing consists of four stages: crushing and grinding, sizing and classification, concentration, and dewatering.

Crushing and grinding

The crushing and grinding stage starts off the ore size reduction process. In a basic sense, it is the process of reducing the particle size of large rocks to allow them to be processed further down the line.

As one of the most important parts of mineral processing, it is also the most energy-intensive.

Crushing and grinding equipment at metals mines can account for 65–70 per cent of the total plant value, with power consumption sitting at 50–60 per cent.

There are hopes that mines will ultimately make the crushing and grinding process more energy-efficient through flotation, though more research is needed.

Flotation refers to the process where fine mineral particles are added to large bubbling tanks. This allows the valuable particles to be recovered at the top of the tank in the form of a mineral froth.

According to University of Queensland associate professor Liza Forbes, while there is existing technology for flotation use in crushing and grinding, more development is needed.

“We are trying to develop and integrate technology that is able to process particles and extract value from them without having to grind them very fine,” Forbes said.

Mineral processing can be an energyintensive exercise.

Screening is a method of sizing and classification.

“Being able to process coarse particles is acknowledged as a key method for industry to improve the energy efficiency of its processing operations.

“This is all about achieving a very substantial drop in energy consumption and, in turn, reducing greenhouse gas emissions.”

Forbes said mining is a traditionally conservative industry, which means there is “little appetite” for risk. But if the industry were to move past this approach, new technology could open more doors than ever.

“We want to fully unlock all its possibilities,” she said.

“We are finding out the best way to make use of it in the industry to give mining companies enough understanding and enough comfort to be able to implement it in their operations.”

Another option for miners is the development of electrified crushing and screening equipment.

Engineering group Sandvik has been developing electrification technologies for crushing and grinding mills for a number of years. The company’s aim is to help its clients reduce their climate footprint.

“By using connected equipment … you can get a lot more out of your machines and processes,” Sandvik Rock Processing Solutions head of sustainable business Pontus Alexandersson said.

“Optimised productivity and sustainability really do go hand-in-hand.

“In general, there is an improvement potential of up to 10–15 per cent to be reached through configuration and customisation of the equipment already in use.”

The second step in mineral processing is sizing and classification – separating particles based on their size.

There are a few different classification methods –including screening, hydrocyclones, spiral classifiers, and centrifuges – but which method a mine uses comes down to what it hopes to get out of the process.

Hydrocyclones and centrifuges use centrifugal force to separate fine particles from a liquid slurry. These methods are useful for finer particle classification and are commonly used in dewatering processes.

Screening is often used for coarse particle separation. The particles pass through various mesh screens, with larger particles being retained on the screen.

Spiral classifiers use the principle of settling rates to separate the particles. Commonly used in

Mineral processing is a well-known and important part of mining.

gravity concentration processes, they consist of a spiral screw to transport settled particles up an inclined trough.

Regardless of the method of classification mines use, the importance of this step cannot be overstated. Effective classification not only ensures a consistent particle size distribution but also impacts the efficiency and sustainability of mining operations.

Sizing and classification leads to the concentration stage of mineral processing.

Concentration refers to the process of breaking down material until the mine reaches its desired concentration of crude material.

Like sizing and classification, there are several techniques a mine can employ at this stage of the process.

The most conventional method is gravity concentration which, as the name suggests, separates the minerals based on differences in gravity – this is also a popular method.

Gravity concentration equipment is easy to install thanks to a limited number of moving parts. It is also something of a “set-and-forget” method that can be used in the processing of gold, copper, coal, iron ore, and mineral sands.

Another well-known technique is froth flotation, which involves using a chemical collector and frother to form bubbles on the surface of the slurry.

Any hydrophobic materials in the slurry will bond to these bubbles, which can then be collected on the surface of the frother.

This method is primarily used to separate coal from ash-forming minerals, remove silicate minerals from iron ores, and process fine-grained ore that is not amenable to conventional gravity concentration.

The final stage of mineral processing is removing the water content of the mineral to dispose of the gangue and reach the desired concentrate levels.

After concentration, the product may still be about 50 per cent water, and this water is not needed – nor wanted – at the end of the process.

The water can also be recycled into the mine’s existing water circuits after this step, reducing the demand for fresh water and ensuring the mine stays on top of its sustainability goals.

“The goal with dewatering is to produce the driest possible solids and the cleanest possible filtrate,” mining solutions company McLanahan said.

“Removing moisture from the material has several other benefits in addition to creating dry, solid cakes and reusable process water.

“First, dewatered material is easy to handle and less expensive to transport. Second, dewatered material reduces stockpile drying time, which frees up land space on site.

“Finally, using dewatering equipment to remove moisture from a particle-laden slurry at the final stage of the wet processing plant can reduce

Mineral processing is conducted on-site at the mine.

the amount of material that is destined for the settling pond.”

Once the ore has travelled through each of these four steps, the minerals are dried off to be sent for smelting or refining, depending on the ore type.

Though mineral processing can be a complex process, it could be the most important in the mining value chain.

Grinding the ore is the first stage of mineral processing.

By investing in advanced, energy-efficient mineral processing equipment, miners can help to ensure their ores are up to standard and ready for the world. PNG

The dates have been set for the 2025 PNG Industrial and Mining Resources Exhibition and Conference.

AFTER A WHIRLWIND two-day event in July 2024, the stage has been set once again for the PNG Industrial and Mining Resources Exhibition and Conference (PNG Expo) to shine a light on the resources sector in 2025.

To again be held at the Stanley Hotel in Port Moresby from July 2–3, the 2025 PNG Expo is set to be bigger and better than ever.

“We came away from the 2024 PNG Expo with some key lessons that we can apply to our 2025 program,” show director Siobhan Rocks told PNG Mining.

“We’re looking forward to welcoming more attendees, exhibitors and speakers to the Stanley Hotel in July 2025.”

Like this year, the 2025 PNG Expo will feature a number of key networking events that attendees can use to get to know each other. These include the

The conference program was a particular highlight of the 2024 show.

Speakers included Austrade country manager PNG Titus Hela and business development manager Kembol Kaikipae speaking to Austrade’s perspective on doing business in PNG, and Green Finance Centre (Bank of PNG) director Mohinesh Prasad speaking about creating a better environment through financial institutions for green and sustainable investments.

On day two, Cherie Litwiller, International Education Agency of PNG director of education, spoke about technical education and corporate training in Port Moresby and throughout PNG from the perspective of IEA TAFE College, while Steamships general manager – corporate affairs Vele Rupa spoke to the sustainability of

The exhibition was also running as the conference

setting up shop for the two days, with gold sponsor

The networking events sold out quickly in 2024.

Silver sponsor Islands Petroleum was also onhand to speak to the future of PNG’s fuel industry.

““Supporting the PNG EXPO offers Islands Petroleum an opportunity to exhibit our brand, quality products, and dependable services while also fostering connections with key industry players,” Islands Petroleum marketing manager Kavitha Bluett told PNG Mining.

Supporting the PNG EXPO offers Islands Petroleum an opportunity to exhibit our brand, quality products, and dependable services while also fostering connections with key industry players.

Kavitta Bluett

The exhibition ran concurrently with the conference.

“Most importantly, sponsoring such an event underscores our dedication to both our community and the advancement of Papua New Guinea’s resources sector.”

As the team gears up for 2025, Rocks is excited about the future of the PNG Expo.

“Seeing the level of engagement and connections made at the 2024 PNG Expo was incredibly rewarding,” she said.

“It was a real privilege to witness the collaboration and innovation that came from this year’s event.

“As we take those learnings into 2025, I know we will only continue to grow this vital event.” PNG

AI is becoming a mainstay in PNG’s mines.

The global resources sector has been quick to implement new and emerging technologies to make mining easier and safer – and PNG is no exception.

THE NEED to improve safety, productivity and efficiency is something that has been a part of the mining industry for decades.

To help ensure sites remain as safe and profitable as possible, miners are increasingly turning to new technology like artificial intelligence (AI), autonomous vehicles, and remote sensors.

And as the industry continues to embrace these new technologies, the potential for even greater improvements is vast.

This is especially true in Papua New Guinea (PNG), where miners are keen to implement as much new technology as possible to keep the country’s most important sector functioning for decades to come.

AI

St Barbara has turned to AI to get the most out of its Simberi gold mine.

Following a successful collaboration with technology company Stratum, the major has boosted the annual gold production at Simberi to between 70,000–75,000 ounces.

The partnership saw St Barbara use Stratum’s AI-based algorithms to identify carbon in leach (CIL) treatable sulphides that would previously have been considered unsuitable.

“The work achieved with Stratum AI has been highly effective in enabling the Simberi team to delineate more ore, which can be treated with the existing CIL plant,” St Barbara managing director and chief executive officer Andrew Strelein said.

“The increased confidence built from the practical application of the AI work in the last quarter has given us the confidence to reclassify our material types under this new method and add 143,000 ounces of material that can be processed through the existing circuit.”

St Barbara has now incorporated the AI-based system into its mine plan for Simberi.

“This allows us to plan for a stable annual gold production target over the next three years of 70,000–75,000 ounces in the lead up to transition to production of gold concentrate from the sulphide ores,” Strelein said.

The specific application at Simberi was for Stratum to use its AI-based algorithms to model sulphur and other indicators of oxidation to better classify oxide and sulphide mineralisation. The primary objective was to identify additional mineralisation that would work with CIL treatment that may have previously been overlooked.

St Barbara and Stratum deployed the AI material-type classification the second quarter of the 2023–24 financial year (FY24) as part of the site grade control process – and the impact was almost instantaneous.

During the third quarter of FY24, the use of the AI material-type model identified an additional 10 per cent of CIL treatable material that was successfully fed through the process plant.

“Gold recoveries for the additional material were in line with expectation and consistent with the recovery performance of previous quarters,” St Barbara said in an announcement confirming the results.

“This AI-based system of material type classification has now been incorporated into the Simberi mine plan by using the AI material type field in the current mineral resource model.”

Environmental controls

It’s not just safety and productivity that technology can help with on a mine site.

Environmental management is just as important, and often requires specialised technology to make a difference.

Australia and PNG joined forces in a landmark 2023 trial to showcase an innovative mercuryreplacement technology, the brainchild of Australian Commonwealth Scientific and Industrial Research Organisation (CSIRO) and Clean Mining.

Mercury can be used in artisanal and small-scale gold mining to extract gold from ore as an amalgam.

Many of PNG’s gold mines have implemented new technology.

The amalgam is isolated by hand and then heated to distil the mercury and isolate the gold.

This process can be hazardous for the environment and for the people involved; inhaled mercury can lead to neurological damage, while mercury can also contaminate water and soil around the source.

This new project has been described as a “beacon of hope”, proving that more sustainable gold extraction is becoming a tangible reality.

The venture brought together PNG’s Conservation and Environment Protection Authority, Mineral Resources Authority, and key Australian government departments in the heart of Bulolo, Morobe Province.

“Acknowledging there are still some technical and social-uptake challenges to consider, as this project’s ripples spread, the potential for global application looms large, heralding a possible end to mercury’s reign in gold mining worldwide,” secretariat of the Pacific Regional Environment Programme said.

“Australia and PNG are not just making history; they’re making mercury history with every gold nugget now a symbol of a brighter, cleaner future.”

In 2019, Newcrest Mining (before it had been acquired by Newmont) implemented PNG’s first private 4G long-term evolution (LTE) mobile network at its Lihir gold mine with the support of Telstra Mining Services.

While Newmont is now the owner of Lihir, the mine is still using the network today.

The private LTE technology facilitated Lihir’s digital transformation, establishing greater levels of safety, tele-remote operation and automation across the entire site.

Every kind of Lihir production asset, including trucks, drills, excavators, dozers, shovels and barges, is connected to LTE.

The mining company also implemented new towers, data centres and redundant power systems across the site to complement the LTE technology solution.

“The Lihir mine extends 300 metres into a volcanic crater, and workers can often be exposed to elevated temperatures,” then-Newcrest Lihir general manager Chris Jordaan said.

“Teleremote and autonomous mining technologies are fundamental to working the hot work areas that will become more dominant features of Lihir’s operation in the future.”

The solution also includes ‘HetNet’ functionality that allows the site’s vehicle fleet to seamlessly switch between LTE and existing Wi-Fi networks.

“We’ve provided Newcrest with a tailored platform that will underpin its safety and digital mining ambitions and will help improve productivity and deliver new value and efficiencies to the business,” then-Telstra

Australia and PNG are not just making history; they’re making mercury

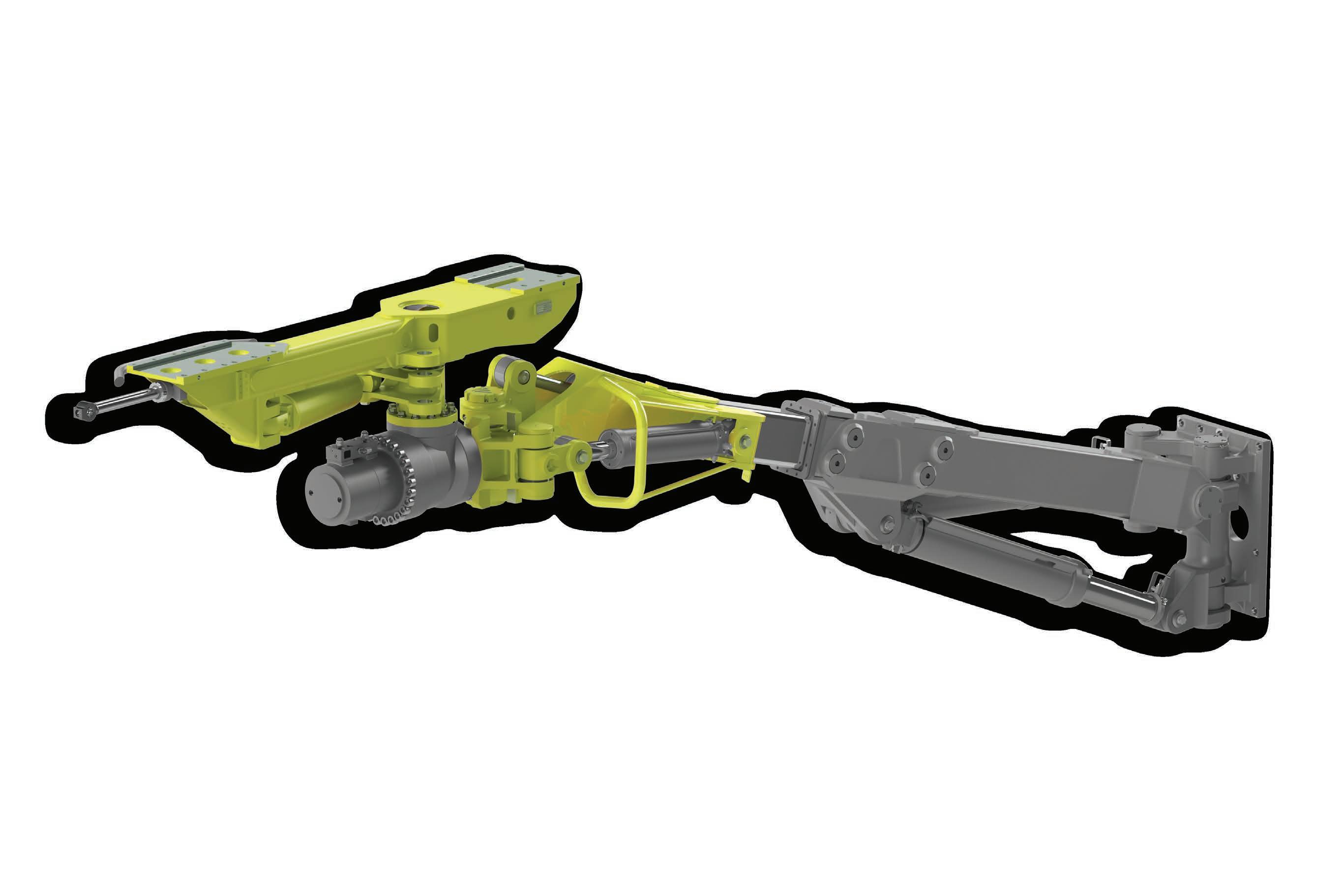

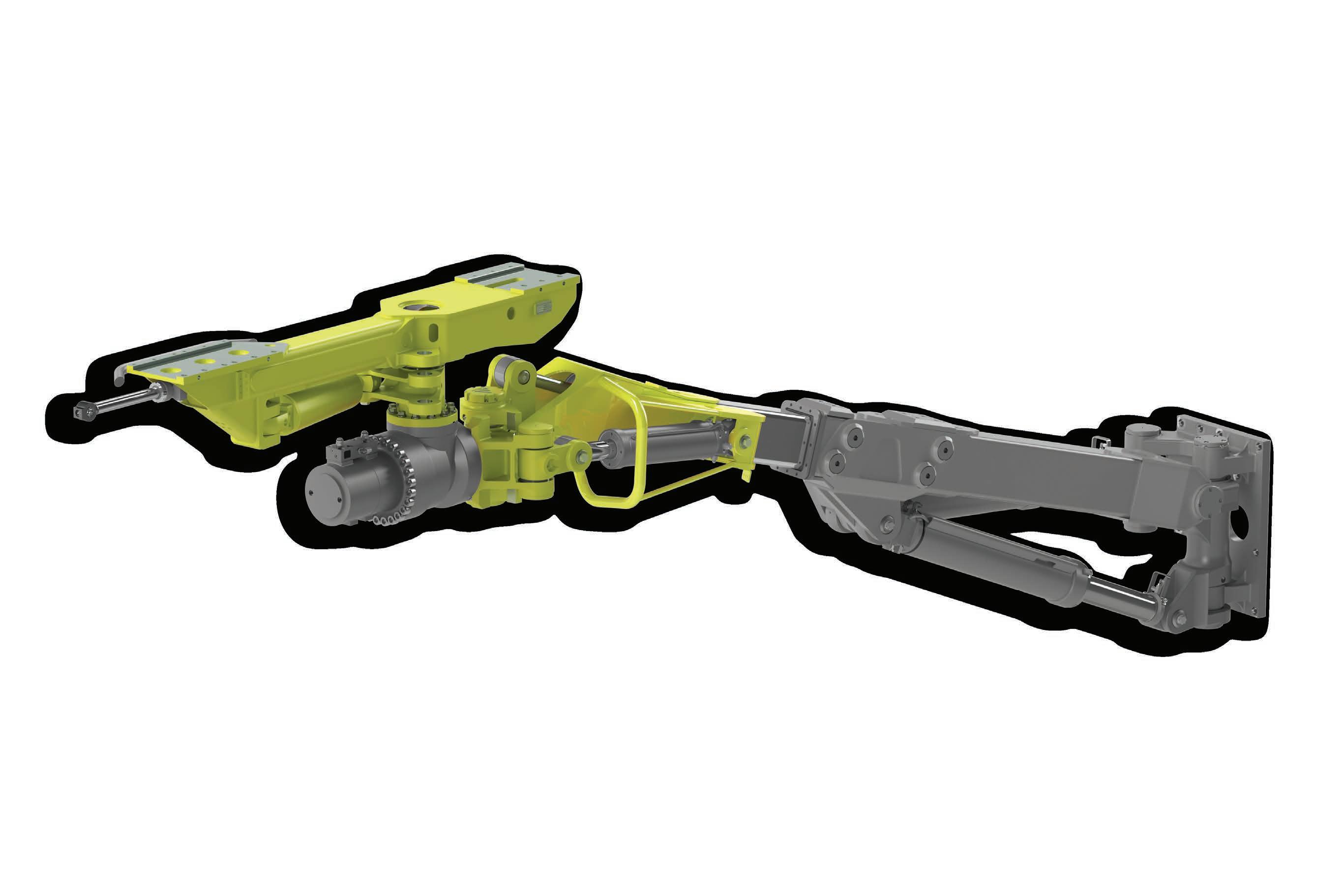

MASPRO’s commitment to quality, productivity and safety has made it a recognised name in mines all over the world.

FROM ITS HUMBLE beginnings in Condobolin, New South Wales, to leading the engineering and spare parts supply at some of the biggest mines around the globe, the name MASPRO has become synonymous with quality.

This focus on quality has seen MASPRO go from strength to strength since it opened its doors in 2006, focusing on a culture of innovation and growth.

“We try and foster a culture of quality throughout our entire business, no matter what the role is,”

MASPRO chief executive officer and founder Greg Kennard said.

“We need to be constantly asking ourselves if we’re putting in our best efforts.

“It doesn’t matter if we’re cleaning the windows, speaking to a customer, or machining a precision part.”

Kennard said this push for quality is firmly rooted in MASPRO’s DNA.

“If we step back a little to where we started as a smaller team, this focus on quality was the foundation on which we grew,” he said.

MASPRO takes pride in every product and solution it sends out the door, with each meeting a number of rigorous quality checks.

“We have processes in place to ensure that every step of the manufacturing process is meeting specifications,” Kennard said. “All this information is recorded and held in our system to ensure full traceability.”

When MASPRO performs work, part of the company’s due diligence includes regularly reviewing its quality systems to ensure compliance to its own quality standards

This commitment to transparency, coupled with its commitment to delivering quality, has seen MASPRO become a leading mining technology business.

MASPRO is investing in automation, which can significantly improve safety on a mine site.

“Being able to provide a high-quality product that’s trusted, reliable and fit for hard rock mining is important to us,” Kennard said.

Mining is an industry in which just a single mistake can be extremely costly in terms of safety and profitability, meaning MASPRO is more determined than ever to keep its customers safe and productive.

“Miners need to trust the equipment and the replacement parts they’re using,” Kennard said. “They can’t afford the downtime that occurs when a machine is out of action.

“If we see that a machine is being pushed to its limit, we go away and redesign the products that are failing so we can give that machine new limits.

“We do that with our three strategic pillars in mind: safety, reliability and productivity.”

Safety is a particularly important aspect of MASPRO’s business, as the company wants to make sure every miner goes home at the end of their shift.

“If we can come up with a better design or way of doing something that will keep people off the

All of MASPRO’s design, fabrication and manufacturing is done in Australia.

more hazardous equipment, that’s important,” Kennard said.

And this focus on safety doesn’t stop at the mine. All of MASPRO’s design, fabrication and manufacturing is done in Australia with an

MASPRO is able to complete work efficiently and to the highest standards.

in-house engineering team focused on working at the highest standards.

MASPRO is also investing in automation, which can significantly improve safety on a mine site. The company will often incorporate automation into its manufacturing processes to support loading, lifting

and carrying to reduce harm and repetitive stress injuries in the production team.

Coupling safety with technology seems to be a recipe for success. According to Kennard, the ability to improve a product beyond its benchmark in a safe and efficient way is at the core of MASPRO’s business.

“There may be an industry expectation for a product or assembly to last a specific service life,” he said.

“We recognise that reaching this service life carries the risk of failure, which could potentially cause injury.

“Therefore, we focus on enhancing the quality of the product through design and other improvements, aiming to develop a solution better suited to its application.”

Kennard pointed to a situation where MASPRO’s insistence on quality and reliability was able to save the day at a major iron ore mine in Western Australia.

“The mine had some gearboxes that were only getting a runtime of 500 to 1000 hours before failing,” he said. “We were able to bring the boxes back to our research and design centre, where we did some testing.”

Because MASPRO is a smaller operation that many large original equipment manufacturers

(OEMs), it was able to complete the work quickly for the major miner. This agility meant the company was able to make some key changes and send the gearboxes back so the mine could minimise lost production time.

“We made some changes to the boxes and sent them back,” Kennard said. “Now, they’re consistently hitting 6000 hours and above.

“The miner was churning through around five units each month before we fixed the problem. But since we’ve been working with their team and they have implemented our improved solution, they’ve only replaced the head twice in two months –saving over $20,000 each time.”

The ability MASPRO has to solve problems quickly comes from working with its customers as genuine partners.

“We work with a mine’s reliability engineers to understand their problems, then get on site and come up with solutions,” Kennard said.

“And once we come up with a solution that is fit for purpose, we can commercialise it throughout Australia and offshore, knowing that it’s a better product.

“We know that gives our customers more reliability, safety and productivity by using that particular assembly of the solution.”

The ability to improve a product beyond its benchmark is at the core of MASPRO’s business.

MASPRO works closely with its casting and forging suppliers to make sure the company is supported in all areas of its business.

It also works closely with its heat treatment plants to ensure they follow the company’s specific process for heat treatment – all for the sake of quality.

Quality

is never an accident; it is always the result of high intention, sincere effort, intelligent direction and skilful execution.

MASPRO founder Greg Kennard “

“Understanding the whole situation from various stakeholders is important for building out a solution,” Kennard said.

“Once we partner with someone to come up with a new design, we can push it out to anyone else that’s in that same industry.

“Delivering quality consistently is what sets us apart from the competition.”

Kennard credits MASPRO’s willingness to adopt new technology as a reason for its continued success.

“There’s always a better way to do something,” he said.

“We’re not the company that thinks that just because we’ve done it a certain way for years that that’s the only way to do it. We’re always looking at ways to produce something better.”

When a landslide struck Enga Province in May, resources companies across PNG were quick to help.

AT APPROXIMATELY 3.00am local time on May 24, a landslide hit the Mulitaka district of Enga Province, Papua New Guinea (PNG).

This terrible event, which claimed lives and homes, saw the people of PNG come together in a bid to provide funding, aid and supplies to those affected. At the same time, countries around the world were gearing up to help as much as possible.

PNG Mining takes a look at how people, companies and government banded together to help when it was needed most.

Barrick Gold’s iconic Porgera gold mine is located in the same district as Mulitaka, less than 50km away.

Barrick and its joint venture partner Zijin Mining Group contributed K3.8 million ($1.5 million) in the wake of the landslide.

Senior Barrick executives spent a week in PNG during early June, visiting the landslide site and working with the provincial and national governments, as well as officials from the United Nations, the Asian Development Bank, Australia, New Zealand and the US, to coordinate relief and recovery activities.

And it wasn’t just monetary donations that Barrick and Zijin gave the area.

The employees at the Porgera gold mine also supported the Enga Provincial Government with manpower at the disaster operations centre in Wabag. A total of five New Porgera Limited (NPL) employees were seconded to advise and assist the operations centre with logistics, inventory, community relations and media.

The mine delivered relief supplies including food, medical items, tarpaulins for temporary shelter, and eight shipping containers to store supplies.

Construction personnel also scoped out the installation of additional structures and water tanks, and an excavator and bulldozer were deployed to assist with clearing operations.

Porgera personnel also looked at the viability of using radar to help with monitoring at the slip site, in the event a second slide were to occur.

Barrick president and chief executive officer (CEO) Mark Bristow said NPL would work closely with the Enga Provincial Government to continue the relief efforts.

“Porgera stands ready to provide additional relief and assistance to support impacted families and communities during this time of need,” Bristow said.

“Reacting rapidly to the disaster, our teams put into operation an air bridge and a temporary pipe across the slip to be able to supply fuel and essential goods not only to the mine but to local businesses serving the tens of thousands of residents of the Porgera valley.

“The cooperation of the Mulitaka community is essential to keeping these lifelines open until the permanent bypass road can be completed.”

As one of the most well-known miners in PNG, Ok Tedi Mining Limited (OTML) has workforces stationed across the country. So it made sense that OTML’s Engan workforce stepped in to raise muchneeded funds in the wake of the landslide.

The landslide occurred in Enga Province.

A corporate dinner and cash donations from the Engan workforce and community in the town of Tabubil raised K80,000 ($31,077) in cash donations.

The Engan workforce’s group lead Edward Maiapu said it was important for PNG-based companies to dig deep for those affected.

“Although the Mulitaka incident has garnered a lot of support from PNG and the global community, there are certain social issues in the affected three villages that the community cannot utilise the donated funds to resolve,” he said.

Much of the funding from OTML will be used to help the families of the victims come to terms with their losses.

“The Engan workforce have shown us that they are from the area, have done their due analysis of the impact and found an area that would be left unattended to, thus they took the lead in providing a solution for that,” OTML managing director and CEO Kedi Ilimbit said.

“Such an initiative is to be commended and sets a precedent for us here at OTML and also across PNG to stand up and do what we can within our means to assist in any given situation.”

OTML is set to provide more donation support to the Mulitaka Appeal in the coming months.

Kumul Mineral Holdings and Kumul Petroleum Holdings each donated K1 million ($385,956) to the Mulitaka disaster relief.

“There has been a lot of support coming from other countries, companies and the community at large but as PNG’s national gas and resources company,

we also want to assist with the relief effort.” Kumul Petroleum managing director Wapu Sonk said as he presented the donation to Enga Governor Peter Ipatas.

“The funds, approved by the KPHL board, are to assist the disaster relief committee on the ground in their efforts to bring some comfort and relief to people who have lost their loved ones and homes in this terrible landslide.”

Sonk said that he hoped the donation would help those displaced by the landslide find somewhere safe to resettle.

“On behalf of the board, management and staff of Kumul Petroleum, we extend our heartfelt sorrow to those families that have lost their loved ones and homes, but we also want to encourage them to be resilient,” he said.

Kumul Minerals managing director Sarimu Kanu echoed those sentiments.

“As PNG’s national minerals company, Kumul Minerals recognises its responsibility to support the Porgera Paiela District communities during this disaster,” he said.

The MRA donated boxes of much-needed food and supplies.

“Properties were destroyed and people were displaced due to the landslide.”

Kumul Minerals was one of the first companies to provide on-the-ground support in the way of fuel drums, transport and food worth over K50,000 ($19,406).

Kanu expressed heartfelt condolences on behalf of the chairman of Kumul Minerals, the board, management and staff.

The Mineral Resources Authority of PNG (MRA) was one of the first groups on the ground in Mulitaka after the landslide.

Working with the Enga Provincial Disaster Committee, the MRA donated K200,000 ($77,809) worth of relief supplies to the people of Yambale Village.

Supplies included 600 bags of rice, 400 cartons of tinned fish, 400 cartons of noodles, and 200 bottles of cooking oil among other basic goods. At the same time, the MRA was working with a shop in Wabag, the capital of Enga, to procure more supplies.

The MRA team was led by Porgera project coordinator Joe Kak Ryangao, who conveyed the MRA’s condolences to those affected on behalf of managing director Jerry Garry.

“To see the very village that MRA officers pass by every other week completely wiped out in such a tragic manner was devastating,” he said.

Following the first delivery, the MRA was back in the area in early June to donate the remaining relief supplies.

Enga Provincial Government officer Ben Saret thanked the MRA team upon receiving the supplies.

“Disasters like the landslide occur when we least expect them and … the supplies would go a long way in helping the people of Yambali village,” he said.

PNG Prime Minister James Marape made what was described as an emotional visit to the affected area after the landslide. He was joined by Ipatas, Defence Minister Billy Joseph and Hela Governor Philip Undialu to meet and speak with those affected.

During the visit, Marape announced that the PNG Government would provide K20 million ($7.7 million) to the Enga Provincial Government.

The Hela and Southern Highlands governments each contributed K1 million ($376,800).

“I express my heartfelt sorrow to the people of Maip-Mulitaka who lost loved ones in the disaster,” Marape said. “I thank the Enga Provincial Government of Governor Sir Peter and Provincial Administration of Sandis Tsaka, who, even if the landslide had occurred at 3.00am on Friday, responded immediately and by 8.00am disaster work was already in progress.”

Marape also thanked PNG’s sister countries for providing aid.

“I thank our partner countries including Australia, New Zealand, USA, Japan, China, United Kingdom, Indonesia, France, Israel, South Korea, Philippines, Malaysia, Singapore, India, Czech Republic and many others, United Nations, International Organisation for Migration and Pacific Islands Forum for responding very quickly to the disaster,” he said.

“I assure the people of Maip-Mulitaka, PorgeraPaiela, Enga and Papua New Guinea that you are not alone in this difficult time.

“Our focus should now be on relief, restoration, and reconstruction into the future.”

As Marape highlighted, the PNG Government was not the only government body to contribute funds.

The Australian Government committed an initial

K6.4 million ($2.5 million) in humanitarian assistance, deploying a 16-person disaster assistance response team for incident management and technical advice.

The team distributed humanitarian emergency relief kits for over 750 households, which included hygiene kits, water filtration, dignity items, shelter kits, tents, solar lights, lighting towers, tarps, blankets, and bed mats.

The Australian Government worked closely with the New Zealand Government to support the disaster response, including working with New Zealand experts to complete geohazard and drone imagery of the landslide site.

“All Australians will be thinking of Papua New Guineans at this very difficult time,” Deputy Prime Minister Richard Marles said in May.

“As a close neighbour and friend, we will be doing all we can to provide support.” PNG

Copper has been a mainstay on PNG’s commodity list since mining began in the country. PNG Mining takes a look at the ore’s past, present and future.

PAPUA NEW GUINEA (PNG) is a land of rainforests and rugged terrain, holding plenty of treasures below the surface.

And one of those treasures is among the world’s most sought-after metals: copper.

The timeline of copper mining in PNG is a story of discovery, challenges and economic makeover that has shaped the nation’s development to this day.

PNG’s history of utilising mineral resources for practical and ceremonial purposes goes back thousands of years.

It was the arrival of Europeans in the 1800s that led to the intensification of the scale of extraction, particularly after the uncovering of gold on the islands of Sudest and Misima in the late 1880s.

The story of copper in PNG begins with the exploration activities of the mid-20th century. Geologists, driven by the promise of untapped mineral wealth, conducted surveys across the country’s mountainous regions.

From 1906, copper was recovered from smaller copper-zinc-gold deposits on the Astrolabe field near Port Moresby before Australian entrepreneurs set up New Guinea Copper Mines in 1920 to create a larger operation.

It was a dream of those early entrepreneurs to establish a major industrial complex that included a mine, a smelter, and transport

Copper is widely used in the renewable energy transition.

facilities supported by a hydroelectric scheme and township.

This dream was only partly accomplished and on a condensed scale before the complex was closed in 1926 due to intractable ore and the price of copper stagnating.

It wasn’t until a small Australian company called Mandated Alluvials revived the site and worked it from 1938 to 1942 that copper took off again.

The Panguna mine, developed by Bougainville Copper Limited (BCL), a subsidiary of the global mining giant Rio Tinto, was a landmark project. Panguna began production in 1972 with the PNG Government acting as a 20 per cent shareholder

– and it quickly became one of the world’s largest copper mines.

At its peak, Panguna produced around 175,000 tonnes of copper annually, along with substantial quantities of gold and silver as by-products.

The mine not only contributed significantly to PNG’s economy but also acted as a catalyst for infrastructural development. Roads, schools, and healthcare facilities were built in the area, transforming the lives of many locals.

In 2016, Rio Tinto transferred its 53.83 per cent majority shareholding in BCL to the Autonomous Bougainville Government (ABG) and the PNG Government for no consideration, enabling the two governments to hold an equal share in BCL of 36.4 per cent each.

The Yandera project is a significant copper mining endeavour that has attracted attention due to its potential for substantial production.

The Yandera deposit is characterised by a combination of primary copper sulphides and associated secondary minerals, making it a promising target for long-term copper extraction.

Exploration efforts at Yandera have identified multiple mineralised zones with notable copper grades, highlighting the project’s potential to become a major contributor to the global copper supply.

The project is situated relatively close to ports and established mining regions, providing a logistical advantage for exporting the mined ore The development plan for Yandera includes open-pit mining methods, which are expected to provide efficient access to the copper ore bodies.

With the demand for copper continuing to rise across the planet, driven by the growth of electric vehicles and renewable energy technologies, the

Yandera project is poised to play a crucial role in meeting this demand, offering a substantial new source of high-quality copper for the market.

In the years following the closure of Panguna in May 1989, the PNG Government and international mining companies shifted their focuses to other sites.

The discovery of the copper-gold deposit at Ok Tedi River in the Star Mountains of Western Province marked a new chapter.

Ok Tedi has contributed immensely to the national economy and local community development throughout the years.

Operated by Ok Tedi Mining Limited (OTML), the mine began production in 1984 and has since become a cornerstone of PNG’s mining industry.

The Ok Tedi mine is an open pit mine located near the headwaters of the Ok Tedi River, 2000m above sea level near Mount Fubilan.

The mountain was known as the ‘copper mountain with a gold cap’ before mining operations began, with drilling beginning in the area in the 1970s.

After the gold was depleted in the area during the mid ’80s, then-owners BHP surveyed the site for larger copper deposits underneath.

At the time, the area was believed to be the largest copper deposit in the world, and the finding led to BHP entering into a partnership with the PNG Government, fuel company Amoco and Inmet Mining to mine the deposit.

Ok Tedi has contributed immensely to the national economy and local community development throughout the years, including the implementation of significant environmental management programs aiming to mitigate its impact on the nearby Fly River system.

The current landscape of mining in PNG is vibrant, with numerous ongoing and prospective copper projects.

Exploration activities continue to uncover new potential sites, with six about to progress into the

mine development state, attracting investment and technological advancements.

The development of sustainable mining practices is at the forefront of discussions, aiming to balance economic growth with environmental stewardship and social responsibility.

PNG’s history of copper mining is a microcosm of the broader challenges and opportunities facing the resource-rich nation.

From the transformative impact of the Panguna mine to the ongoing contributions of the Ok Tedi mine and promising new projects, copper has played a pivotal role in shaping PNG’s economic and social landscape.

As PNG moves into the future, the lessons learned from the past show the importance in sustainable and equitable mining practices.

The country’s vast mineral wealth holds the promise of a prosperous future for its people, ensuring that the legacy of copper is one of progress and positive change. PNG

The latest 2024 quarterly reports reveal strong results across the gold operations of some of PNG’s majors.

THE SECOND QUARTER OF 2024 was one of highs and lows for miners of Papua New Guinea (PNG).

Major gold mines like Lihir, Simberi and Kainantu were standouts for the quarter, with miners upping their production and ore reserves throughout the months of April, May and June.

Junior miner Geopacific has spent much of the first half of the year ramping up its Woodlark gold project, and St Barbara has been working to expand Simberi into a premier operation.

PNG Mining takes a look at the latest quarterly results of four of PNG’s most well-known miners.

A slower-than-usual start to the year has made K92 Mining hungry to launch into the second half of 2024.

While temporary suspension of underground operations affected K92’s first two quarters, the miner still produced 21,661 ounces (oz) of gold, 1.2 million pounds of copper and 26,754 oz of silver.

Strong metallurgical discoveries of 93.7 per cent gold and 95.3 per cent copper were a highlight of the second quarter, with the gold discovery representing the highest gold recovery since the fourth quarter of 2019.

Gold and copper grades remained in line with budget, with both commodities delivering a positive grade reconciliation.

K92’s major milestone for the quarter was the commencement of vertical development from two raise bore rigs.

The larger of the two rigs has focused on completing a ventilation upgrade connecting the main Kainantu gold mine to a twin incline.

to shareholders.

However, attributable gold production decreased four per cent from the prior quarter due to lower production at Cerro Negro in Argentina. Heavy rainfall at the Lihir gold mine also affected mine sequencing and, by extension, second quarter production.

The major remains on track to deliver 2024 guidance for production, costs and capital spend and is anticipating a sequential increase in production in the latter half of the year.

“Newmont delivered a solid second quarter, producing 2.1 million gold equivalent ounces and generating $594 million in free cash flow,” Newmont president and CEO Tom Palmer said.

“We continued to advance our divestiture program and, to date, have announced $527 million in proceeds this year. With this momentum, we completed $250 million in share repurchases and repaid $250 million in debt.”

Newmont is expecting to achieve at least $2 billion in gross divestiture proceeds from high-quality, non-core asset sales as the year progresses.

Full-year production is expected to be second half weighted, with a sequential increase weighted toward the fourth quarter. Improved throughput from Lihir is expected to largely drive production for the remainder of 2024.

“As we head into the second half of the year, we remain confident in our ability to continue executing on shareholder returns, meet our full year guidance and deliver on our commitments,” Palmer said.

This will be followed by the development of the ore and waste pass system to connect Kainantu to the twin incline for material transport.

“As we look forward to the second half of the year, we expect it to be significantly stronger than the first half, driven by a combination of mining sequence, higher throughput rates, more mining fronts, progressive productivity increases through the completion of infrastructure upgrades, [and] ongoing continuous improvement initiatives,” K92 chief executive officer (CEO) and director John Lewins said.

“Concurrent with improved operational performance, we are very excited about our plans for exploration in the second half of 2024.”

The Simberi gold mine emerged as St Barbara’s golden child for the second quarter of 2024, with ore reserves increasing by 0.8 million ounces (Moz) to 2.8Moz. This 40 per cent increase was attributed to the successful conversation of 1.9Moz of mineral resources from inferred to measured and indicated.

Concurrent with improved operational performance, we are very excited about our plans for exploration in the second half of 2024.

K92 CEO John Lewins

St Barbara also completed the Simberi expansion concept study with a 10-year-plus mine plan. This plan has seen the average gold production at Simberi rising to over 200,000oz per annum from FY28 to FY34.

Metallurgical test work at the site is expected to confirm flowsheet alternatives.

“Pleasingly, Simberi ore tonnes mined and processed for the fourth quarter [of 2023] were both at record highs for the year despite the interruptions to logistics due to currency and aviation fuel shortages in PNG,” St Barbara managing director and CEO Andrew Strelein said.

“With the arrival of the two trial Volvo A60H haulers at quarter end, the placement of orders for excavators, as well as for new sizer installation, we have confidence in continuing the improvement in mining and milling performance over FY25 to underpin a lift in gold production to a guidance range of 65,000–75,000oz from 55,000oz this year.”

St Barbara spent between $8–10 million in exploration at Simberi, with growth capital investment set at $30–40 million in line with the 10-year mine plan.

Gold production was also up at Simberi, hitting 14,100oz for the second quarter of 2024, and 54,705oz for the full financial year.

“The fourth quarter was an incredibly important quarter for the advancement of our plans for the

slower start to 2024 but is expecting to pick up speed as the year progresses.

Simberi 10-year-plus mine plan, increasing our ore reserves by 40 per cent to 2.8Moz and the delivery of the concept study outcomes announced in May,” Strelein said.

“St Barbara is in a strong position, with substantial mineral resources and ore reserves, a strong balance sheet and a clear development pathway for Simberi.”

Geopacific expects total gold production from Woodlark to hit 1.14Moz over a 12-year mine life, with undiscounted life-of-mine revenue of $3.3 billion.

Geopacific CEO James Fox

St Barbara’s plan for Simberi includes the mining of multiple open pits to exploit the substantial oxide and sulphide ore reserves found at the site.

The next key step to progress the Simberi expansion study work is the completion of the metallurgical test work program, which is on track for the third quarter of FY25.

St Barbara is also on track for the commencement of the early feasibility study, ahead of final flowsheet selection, including the review of the processing layout and completion of the metallurgical test work program.

This work allows a head-start on the feasibility study update anticipated to be completed in the last quarter of FY25. PNG

As the second quarter of 2024 came to a close, the Woodlark gold project stood out as a highlight for Geopacific. The 1.56Moz project is forecasted to generate strong operating margins and significant free cash flow.

Ongoing expansion at the site has included geochemical sampling, and mapping identified priority areas with a strong potential to increase the existing mineral resource.

A recent scoping study forecasted strong financial returns and a long-life operation for the site.

“These findings are underpinned by extensive technical and financial information, and are based on conservative estimates, including the assumed gold price of $2900 per ounce,” Geopacific CEO James Fox said.

“Additionally, Woodlark offers substantial upside exposure to the gold price and ongoing resource inventory growth.”

Geopacific has engaged consultants Intrepid Geophysics and SensOre to assist with improving targeting methodology in areas below surface cover, and to improve the company’s understanding of existing prospective target areas.

Field mapping will continue over the next quarter in areas with encouraging host lithology, complex magnetic responses, favourable structures, and anomalous geochemistry.

Geopacific expects total gold production from Woodlark to hit 1.14Moz over a 12-year mine life, with undiscounted life-of-

When the 2024 GEE Conference was held in Port Moresby in August, it brought together delegates from across the geoscience, exploration and extraction industries.

THE PAPUA NEW GUINEA (PNG) exploration and geoscience sectors were thrust into the spotlight at the second annual Geoscience, Exploration and Extraction (GEE) Conference in August.

Held from August 7–9 at the APEC Haus in Port Moresby and hosted by the Mineral Resources Authority (MRA), the 2024 GEE Conference served as a platform for vital discussions about the future of the industry.

In his opening address, Prime Minister James Marape said events like the GEE Conference were vital, as PNG’s economy is primarily based on revenue generated from the extractive industry.

“Our involvement in geosciences is not merely an academic exercise,” he told attendees.

“It is a calling and a mission to understand our land and also all resources on land and under the sea.

“Without geoscience data, there would be no extraction and production, which means no revenue for the country.”

PNG Mining takes a look at some of the important discussions that took place during the twoday event.

MRA managing director Jerry Garry took to the GEE stage to highlight the need for more mineral exploration throughout the country.

Garry said he would like to see exploration levels return to that of 2012–18, revealing there had been a decline in such activities since 2019.

“As a country, without exploration there will be no mining,” Garry said.

Garry said a number of factors had contributed to the exploration decline, including negative perception around geoscience data and the idea that the permitting of licences was a slow process.