Carrier: Rogers Transport

Forrestry: Elliott’s Bulk Haulage

Feature: Wörth Production Facility

Test Drive: DAF XG

Carrier: Rogers Transport

Forrestry: Elliott’s Bulk Haulage

Feature: Wörth Production Facility

Test Drive: DAF XG

Australia’s leading truck magazine, Prime Mover, continues to invest more in its products and showcases a deep pool of editorial talent with a unique mix of experience and knowledge.

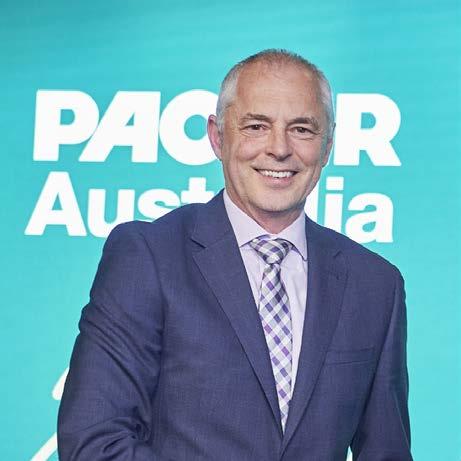

Christine Clancy | COO

With more than two decades of experience as a media professional, Christine has worked in newsrooms across Canada, Vietnam and Australia. She joined the Prime Creative Media team 12 years ago, and today oversees more than 43 titles, including a dozen print and digital transportation titles. She continues to lead a team that focuses on continuous improvement to deliver quality insights that helps the commercial road transport industry grow.

William Craske | Editor

Over the past two decades William has published widely on transport, logistics, politics, agriculture, cinema, music and sports. He has held senior positions in marketing and publicity for multinational businesses in the entertainment industry and is the author of two plays and a book on Australian lm history. Like many based in Melbourne he is in a prolonged transition of either returning or leaving.

Peter Shields | Senior Feature Writer

A seasoned transport industry professional, Peter has spent more than a decade in the media industry. Starting out as a heavy vehicle mechanic, he managed a fuel tanker eet and held a range of senior marketing and management positions in the oil and chemicals industry before becoming a nationally acclaimed transport journalist.

Peter White | Journalist

Since completing a Bachelor of Media and Communication degree at La Trobe University in 2021, Peter has obtained valuable newsroom experience, supplemented by direct industry exposure at Prime Creative Media. As the Editor of Trailer, Peter brings a fresh perspective to Prime Mover. He has a strong interest in commercial road transport and in furthering the magazine’s goal of growing the industry.

Sean Gustini | Journalist

Having completed a Bachelor of Arts majoring in Media and Communications at the University of Melbourne in 2024, Sean looks forward to bringing his passion for writing and journalism to the road freight and transport industries. He previously lived in the Philippines, Vietnam, Indonesia and Malaysia. In his downtime he enjoys playing the guitar and running.

Ashley Blachford | Business Development Manager

Handling placements for Prime Mover magazine, Ashley has a unique perspective on the world of truck building both domestically and internationally. Focused on delivering the best results for advertisers, Ashley works closely with the editorial team to ensure the best integration of brand messaging across both print and digital platforms.

CEO John Murphy john.murphy@primecreative.com.au

Editor William Craske william.craske@primecreative.com.au

Managing Editor, Luke Applebee Transport Group luke.applebee@primecreative.com.au

Senior Feature Peter Shields Writer peter.shields@primecreative.com.au

Business Ashley Blachford Development ashley.blachford@primecreative.com.au Manager 0425 699 819

Art Director Blake Storey blake.storey@primecreative.com.au

Design Blake Storey

Contributors Sean Gustini sean.gustini@primecreative.com.au

Peter White peter.white@primecreative.com.au

Client Success Salma Kennedy Manager salma.kennedy@primecreative.com.au

Head Of ce 379 Docklands Drive, Docklands VIC 3008 enquiries@primecreative.com.au

Subscriptions

03 9690 8766 subscriptions@primecreative.com.au

Prime Mover magazine is available by subscription from the publisher. The right of refusal is reserved by the publisher. Annual rates: AUS $110.00 (inc GST). For overseas subscriptions, airmail postage should be added to the subscription rate.

Articles

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

Copyright PRIME MOVER magazine is owned and published by Prime Creative Media. All material in PRIME MOVER magazine is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material.

While every effort has been made to ensure the accuracy of information Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in PRIME MOVER magazine are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

Make real savings from your fuel and maintenance costs, reduce your operating costs and more. With superior technology at work, the Hino Hybrid Electric will deliver up to 20%* reduction in both fuel use and emissions, compared to a traditional diesel

“When I was Head of Revenue I would say to the customers ‘you’re not as important as my drivers and they would say, ‘what the hell does that mean?’ and I would say, ‘well, if I didn’t have good drivers, you wouldn’t be a customer, so they have to come before you.’”

24 Moving with the Times

An entrepreneurial family vision set in motion Peter Sadler Removals & Logistics, a respected business that has risen above its niche origins to become a serious player across three industry segments.

30 Out of the Blue

Rogers Transport is a family chronicle animated by the spirit of adventure, old-fashioned entrepreneurial nous and the gifts of good timing.

34 Moving Mountains

Efficiency is a major factor in the Elliott’s Bulk Haulage operation which is based in the town of Tumut in the foothills of the NSW Snowy Mountains.

TRUCK & TECH

42 Work Horse

A new tribute truck honouring the former General Manager at Red Horse Transport reveals a story of integrity, commitment and selfless leadership.

58 No Country for Old Fleets

The latest instalment of the annual

Commercial Fleet Guide expands the categories to help provide a better overview of the movers and shakers in road transport in Australia.

66 Silent Partner

DAF’s entry into the Australian 15-litre cabover market delivers a no-compromise viable consideration for linehaul operators.

William Craske Editor

Supply chains are critical. This is not up for debate. Through famines, pandemics, civil unrest, natural disaster and war, supply chains are the unifying factor that can accommodate relief if not resolution, whether whole or in part. No military power can succeed without them. In transport and logistics there’s a common adage: “No day is the same.” Changeability is the precondition of entry. Outsourced production, a commonplace practice of international corporations to cut costs, boost quarterly pro ts, and enhance scalability, has helped increasingly centralise global networks which have been netuned to adapt to the endless cycles of this supremely indeterminate state. The socio-economic outcomes have been both profound and also dubious. Austerity measures implemented in the wake of the Global Financial Crisis have led to no end of perspectives offered on how businesses and communities can at once develop and employ a range of resilience strategies to help creatively navigate the market and exibly adapt to the long-term effects of intense and longstanding crises. In a borderless world, where international trade barriers have

been removed, the new Prometheanism of the counter enlightenment, whereby nature’s terms are rejected contra naturam, don’t quite t.

Some cargo makes this more apparent than others.

There exists between Colombia and Panama an insect border. Vigilant inspectors cover thousands of square miles by motorcycle, boat, and horseback, searching for stray screwworm infections to keep the insect out of North America. Maintenance involves dropping 14.7 million sterilised screwworms over the rainforest every week. To streamline supply a screwworm rearing plant operates 24/7 in Panama. One of Argentina’s chief exports is responsible for a prodigious supply chain expansion unrivalled by anything in shipping. You’ve probably never heard of it even as it grows right under your nose. Invasive colonies of Argentine ants have formed supercolonies across the globe. There is one with a trillion workers that stretches from San Francisco to San Diego. It’s generally understood that the colony formed over a century ago when ants were accidentally transported from Buenos Aires in the 1890s to Louisiana on steamboats and then California, likely by train. Through the use of ports, the Argentine ant has extended its dominance by exploiting sea lanes. The California colony now controls the port cities of San Diego, Los Angeles, Long Beach, Richmond,

Oakland and San Francisco.

In Japan the port of Kobe is in the grips of an ongoing con ict between three supercolonies. Meanwhile a new supercolony in Nara prefecture has reportedly mastered rafting on the river to increase their nest budding and dispersion mechanisms. Somewhere a corporate Goliath is running this all through AI analysis. But as Aristotle warned, “You Ain’t Seen Nothing Yet.” A supercolony associated with southern European dwarfs almost all others. It extends 6,000km with few pockets of resistance. These are embodied by two smaller rival colonies in Corsica and, unsurprisingly, Catalan. The scale of the main colony has led to human intervention, with the aim of playing off the supercolonies against one another. But there’s a twist.

More recently it’s been discovered that the supercolony in California and the main colonies in Japan, Europe, New Zealand, Hawaii and Australia are indeed the same colony. The workers recognise one and other and do not attack. While international trade operates under the aegis there’s no limit to growth the march of the Argentine ant might be a case study in sustainability and portend to things to come.

Followmont Transport has made changes to its leadership team. After 12 years of service as Chief Executive Officer and Managing Director, Mark Tobin will transition into the role of Managing Director.

Tobin’s transition will see Chief Operating Officer, Ross Longmire, step up as the new CEO. Longmire has an extensive and successful career in transport and is highly regarded by Tobin as one of the most skilled operational leaders he has encountered.

“Ross is the ideal choice to lead Followmont,” said Tobin. “His steady, thoughtful approach and deep care for our people will ensure we remain a company that values family and quality in everything we do.”

Longmire brings over 25 years’ industry experience, holding primarily operational management positions overseeing transport and logistics

requirements in a number of different states and business units.

As a Board Member of the Queensland Trucking Association, and previous representative for other industry councils, he is deeply committed to the success of the industry.

Longmire is passionate about driving smarter, safer operations and fostering growth alongside customers, and this includes making the transport sector a more attractive place to work with strong career opportunities.

For Longmire, the family-oriented culture at Followmont is what sets the business apart from its competitors.

“From the moment I walked through the doors, I knew this was an incredible workplace,” he said. “The sense of community and genuine care here is unmatched, and I am committed to preserving and strengthening that as CEO.”

The change in leadership marks a

pivotal moment in Followmont’s history.

“Our customers and team members remain at the heart of everything we do, and I look forward to steering Followmont as we continue to go from strength to strength,” said Tobin.

Under Tobin’s leadership, Followmont has expanded its fleet, network footprint, while building strong customer relationships, and embracing innovation. Tobin has guided the company through significant growth and key milestones, including investments in sustainability, training and development, and safety initiatives.

“Every decision I’ve made as CEO has been driven by my passion for our people and their growth,” said Tobin.

“Our strength has always been in our team, and I am committed to nurturing that as we move forward together.”

In his role as Managing Director, Tobin will continue to focus on driving Followmont’s strategic evolution.

Almost 200 people gathered to celebrate the opening of Blue Water Shipping’s new Queensland depot and distribution hub at a 5.178ha site on Fisherman Islands. The new facility has enabled the international transport and logistics provider to consolidate its port operations into one location, having occupied casual lease sites at the Port for just over two years.

The facility was delivered by PBPL with Principal Contractor, FKG. It was designed by Sparc Architects and project managed by Johnstaff.

Blue Water Shipping’s new landside transport and logistics depot comprises a 15,000m² warehouse plus a 500m² administrative building, car parking and over 30,000m² of hardstand together with a washbay and bond store.

Port of Brisbane Pty Ltd (PBPL) Chief Commercial Officer, David Keir, congratulated all involved.

“We’re very pleased to have designed

and delivered this high quality, purposebuilt facility for Blue Water Shipping in less than 12 months, providing them with a permanent home from which to operate and grow,” said Keir. “Our project teams worked hand-in-glove with Blue Water Shipping throughout the design stage, really testing their user requirements to design the most flexible depot for them and deliver the best possible outcome.”

Blue Water Shipping’s Regional Manager Operations for Oceania, Justin Bound was on hand to take possession of the purpose-built facility.

“This facility will play a huge part to our local success and will enable further growth across our targeted verticals: Mining, Renewables, Infrastructure, and Conventional Energy.

“The entire process, from design to construction, has been seamless, thanks to PBPL, Johnstaff, and FKG’s collaborative approach.”

As is standard in all new PBPL property

developments, the Blue Water Shipping depot and distribution hub was delivered to a 5-star equivalent sustainability rating. It incorporated sustainable design elements including a 99kW rooftop solar system, Enviroconcepts water treatment system, low carbon concrete in the car park and warehouse dado panels, and a highly efficient steel frame design that reduced overall steel tonnage. Construction commenced in January 2024 and was completed in November 2024.

As Australia’s largest vehicle aftermarket parts provider, we’ve built our heritage on

Late last year Viva Energy began to take delivery of key elements for its new ultra-low sulphur gasoline (ULSG) plant as Geelong Refinery began its biggest upgrade in decades. A $350 million investment in Australian manufacturing, including a $125 million contribution from the Australian Government, will allow the refinery to produce the cleanest petrol ever made in Australia said the energy company.

In a media release it issued, Viva Energy said these sulphur reductions in petrol more closely aligned Australia’s fuel

quality with international standards, allowing for more fuel-efficient vehicles to come here, and providing Australians with health, environmental and economic benefits.

The units delivered are up to 28 metres tall, with the largest weighing nearly 900 tonnes. They were delivered by ship and arrived at Lascelles Wharf. Over several days, the units were transported by barge from Lascelles Wharf to a landing ramp next to Refinery Jetty before being transported by SPMT (Self-Propelled Modular Transport)

units to their final location near the refinery flare.

The largest unit, a 900-tonne production module, was delivered in the first week of December.

Completion of the ULSG plant is planned for the second half of 2025, in time to meet the new petrol standards that take effect from 15 December.

This refinery upgrade is part of a pipeline of significant projects that Viva Energy is delivering in Geelong.

In October, Viva Energy commissioned three 30 million-litre diesel storage tanks to help deliver fuel security in Australia. Early this year it will commission a renewable hydrogen refuelling station as part of the Viva Energy Hub.

Viva Energy is also investigating processing alternative feedstocks in the refinery such as used cooking oil, canola and tallow, which could see it producing lower carbon fuels in support of the government’s Future Made in Australia program. The refinery’s critical infrastructure could also provide a circular pathway to recycle waste soft plastics which could be processed through the refinery and adjacent polypropylene plant.

These projects all form part of the Viva Energy Hub, which the company is confident will play an important role in delivering cleaner fuels, supporting the nation’s fuel security, participating in the circular economy and preserving Australia’s sovereign manufacturing capability.

The ULSG plant will produce the cleanest petrol ever manufactured in Australia, with sulphur content of less than ten parts per million claimed Viva Energy. The $350m project is part of the Fuel Security Package. Viva Energy noted that $200 million of the entire budget is going into Australian procurement and construction contracts, with the majority of that going to businesses in the Geelong region.

Up to 300 people will be employed during the peak of construction activity.

FREIGHTLINER IS SERIOUS ABOUT SAFETY.

Every Cascadia comes with a complete suite of fully integrated active safety features and connected technology that helps you get on with your work.

With Active Brake Assist, which can even detect moving pedestrians, Side Guard Assist, a driver airbag, and forward-facing camera footage that can be sent on-the-go for immediate incident reports, the Cascadia sets a new standard for practical safety.

Singapore Post Limited has entered into a sale and purchase agreement with Pacific Equity Partners (PEP) for the sale of its Australian business, Freight Management Holdings Pty Ltd (FMH). The Melbourne-based private equity firm, PEP, welcomed one of the country’s largest vehicle fleets, which includes Border Express and CouriersPlease, to its expanding portfolio. The bid is reportedly valued at $1.02 billion.

“We are thrilled to welcome FMH Group to our portfolio. FMH Group has a stellar track record of growth, a passionate team and a clear and compelling trajectory,” said Pacific Equity Partners Managing Director, David Brown. “We look forward to supporting them to build on their success and facilitate further opportunities.”

The news comes less than 12 months after FMH Group acquired Border Express. Last December PEP acquired a majority stake in Australian electric vehicle charging solutions provider EVSE for $250 million. The company provides DC fast charging

solutions for larger commercial vehicles and fleets, with the commercial offerings including end-to-end solutions that bundle hardware, software and installation services.

In a statement released by Border Express it was called a new chapter for the business.

“This new partnership reflects the strength of the Group and its businesses, including ours, and sets the stage for continued growth and success,” the company said. “We’re optimistic about the potential to further build on our strong foundation and deliver even greater value to our customers and employees.”

Simon Slagter, CEO of FMH Group said it was an exciting milestone for FMH Group.

“We have built a foundation of trust with our customers, achieved significant growth, and led the way in providing excellent logistics services,” he said.

“The investment of Pacific Equity Partners will help us take the next leap forward, empowering us to further enhance our technology platform,

turbocharge our business development function and pursue strategic acquisition opportunities, strengthening our position as industry leader and unlocking even greater value for our customers.”

The proposed divestment is subject to regulatory approvals such as approvals from the Foreign Investment Review Board of Australia, and SingPost obtaining the requisite approval from shareholders in an extraordinary general meeting of SingPost to be convened.

“Since our initial investment in FMH Group in 2020, we have witnessed the group achieve extraordinary growth,” said Singapore Post Chairman, Simon Israel. “Now, with its strong market position and growth pathway the Board has decided it is time to realise the substantial shareholder value created. The transition of FMH Group ownership to PEP will support its continued upward trajectory.”

Mark Luff, son of founder Max Luff and the last family member to depart Border Express after 36 years, finished up last November.

Freight specialist Sadleirs has taken delivery of four new Euro 6-compliant MAN TGS 26.510s. Each vehicle

Thomas McAulay, Sadleirs National Assets and Facilities Manager.

is equipped with advanced safety features, enhanced fuel efficiency, and a comfortable, reinforced cab.

Features such as active roll stabilisation, lane change assistance, and emergency braking were key factors in the decision.

Providing multimodal solutions across rail, road, sea and air, Sadleirs, which was founded in 1829, remains a privately owned family business today. Described as a perfect fit for Sadleirs, the MAN TGS prime movers were delivered by Chris Thompson and the team from Penske Australia’s Perth dealership. The new vehicles are expected to enhance Sadleirs’ national network and have been warmly received at depots in Perth, Adelaide, Melbourne, and Brisbane.

“The MAN trucks are very modern

trucks that have the driver’s needs and safety at the forefront,” said Thomas McAulay, National Assets and Facilities Manager. “The performance and reliability of the equipment have exceeded our expectations, and we couldn’t be happier with the overall quality.

“The trucks have seamlessly integrated into our fleet, delivering the efficiency and durability we require to maintain smooth operations.”

McAulay added that it had been a pleasure working with Penske.

“We couldn’t hope for a better result. Chris from Penske provided exceptional support throughout the whole process,” he said. “His professionalism and dedication have made the experience remarkably easy, ensuring that all our needs were promptly addressed.”

Cold chain specialist, SLR Trans, has taken delivery of five new Volvo FH16 prime movers. The Euro 5 trucks are rated to 600hp and will be deployed initially as B-doubles in refrigerated transport with the option for being upgraded for roadtrain activity. These latest trucks, which are expected to cover 1,000 kilometres daily interstate, bring the Volvos in the SLR Trans fleet to 24 units.

Volvo’s reputation for heavy vehicle safety and integrating advanced technologies with their vehicles fits with SLR’s commitment to safety. The company opted for preventive safety features like collision warning with emergency brake as it uses radar and cameras to detect vehicles or obstacles in the truck’s path, warning the driver and applying brakes automatically if necessary.

The Volvo FH16s also feature lane keeping support, driver alert support, adaptive cruise control and electronic stability control.

Intelligent technologies such as Volvo Dynamic Steering (VDS) aims

to reduce driver strain by providing precise steering with minimal effort, enhancing safety and reducing fatigue.

Earlier this year, SLR Trans opened a new state-of-the-art facility in Archerfield and celebrated its tenth anniversary.

The 5,600m² cold store and freezer distribution centre provides distinct advantages to the expanding refrigerated transport logistics business, namely the capacity to store 8,000-pallet spaces over six areas providing specific temperature and ripening capabilities.

SLR Trans has become a valued customer of Volvo Commercial Vehicles, recently purchasing several trucks to meet their operational needs.

“Their continued business and trust in our products demonstrate the strong relationship we’ve built together,” said Nicholas Singh, VCV Sales Representative. “We deeply appreciate their loyalty and are proud to support them with reliable vehicles

and excellent service.

“They are a great bunch of people at every level, that has been received so well by all of our departments. If I could say what an ideal customer would be, it would be SLR Trans.”

The drivers are big fans of the Volvos, which are deployed mainly from the company’s Brisbane headquarters along the eastern seaboard to Sydney and Melbourne or north to Cairns.

SLR Trans Chief Operating Officer

Aumar Moosa said Volvo Trucks had been a fantastic partner.

“The service levels from Volvo have been, by far, one of the best experiences in this affair and the vehicles are most reliable,” he told Prime Mover. “The overnight servicing is incredibly helpful. Having all our trucks under the Volvo Gold Contract servicing plan has given us peace of mind —it goes beyond just repairs and maintenance.”

Moosa adds, “The Volvo Connect telematics system also provides us with valuable information to optimise efficiencies across our Volvos.”

The future of internal combustion truck engines in Australia is renewable fuels according to Volvo Group Australia.

From December 2024, all Volvo and Mack trucks built at the group’s Wacol factory in Queensland will be filled with Hydro Treated Vegetable Oil (HVO) instead of diesel fuel.

Volvo Group Australia said the recent recognition of HVO100 as a fuel on the Australian market had allowed it to speed up its adoption of the renewable fuel as a part of the local manufacturing process.

“While HVO is not strictly a zero emissions fuel, it is a fossil free alternative that reduces well to wheel emissions by up to 90 per cent, which makes a significant step forward in reducing our environmental impact,” said Martin Merrick, President and CEO, Volvo Group Australia. “We will continue to take steps to cut our emissions and meet our decarbonisation targets by

thinking globally whilst acting locally.”

Volvo Trucks first adopted the HVO first fill program at its Tuve, Sweden factory in 2022, however, this Australian announcement represents the first time a multi-branded Volvo Group manufacturing facility has implemented this approach with fossil free fuels.

HVO100 is a renewable and sustainable synthetic fuel made from vetted waste vegetable oils and animal fats.

It has low carbon footprint, zero sulphur, and can be used in Volvo Group engines without any modifications.

HVO100 can be used as a standalone fuel or blended with diesel without impacting service intervals or engine components.

Volvo Group has adopted what it calls “science-based emissions targets”, as a result the group is targeting net zero value chain emissions by 2040 to allow it to meet net-zero targets by 2050. Volvo Group recently signed a

Butler Freight has acquired Coynes Freight Management, a third-generation, family-owned transport company based in Melbourne. Established in 1950 by Neville Coyne and his father, WR (Bob) Coyne, Coynes began as a newspaper delivery business and has grown into an independent transport company specialising in wharf container cartage. The 74-year old Coynes operates a modern fleet of over 70 vehicles— including Super B combinations, B-doubles, and sideloaders. Coynes offers services in container cartage, warehousing, unpacking/ packing, and goods distribution.

The Coynes Freight Management brand will continue to operate under the ownership of Butler Freight, ensuring continuity for its customers.

All members of the Coynes team will remain employed, according to the business management consultancy EP Advisors who said Butler Freight had sought to preserve the “expertise and

dedication that have been hallmarks of the Coynes operation.”

The acquisition marks a new chapter for both Butler Freight and Coynes Freight Management, as it brings together two industry leaders to better serve Australia’s transport and logistics needs.

Butler Freight Services (BFS Extra) is a privately owned Australian company with deep roots in Melbourne’s wharf transport industry.

In February 2017, Butler Freight Services expanded its operations by acquiring Extra Transport, positioning BFS Extra as one of the larger wharf transport operators in Australia.

The company’s operational facilities include a highly efficient West Melbourne wharf facility, located just 300 metres from the wharf, handling over 110,000 TEUs yearly. BFS Extra operates a diverse fleet of approximately 140 prime movers daily, comprising Super B-doubles, B-doubles, sideloaders, retractable skels, Tautliners, and other trailer combinations.

12-month agreement with Ampol to supply HVO100 to its fleet of trucks built at the Wacol QLD factory.

“Incorporating HVO100 into our manufacturing process is just one part of our multi-pronged approach to decarbonisation,” said Merrick.

“We’ve been very clear that the future of fossil free transport here in Australia will still utilise the internal combustion engine, however the fuel that the engine consumes will no doubt continue to evolve as we move to a fossil free future.”

BFS Extra utilises its proprietary wharf management IT solution, which offers web-based booking and scheduling, EDI capabilities, online visibility of scanned PODs, and extensive automated reporting.

EP Advisors issued a statement in which it said it had been honoured to act as sell-side advisors to facilitate the sale of Coynes Freight Management.

“As the family prepared for retirement, they entrusted EP Advisors with a clear mandate: to secure a strategic industry buyer who would uphold the legacy of the business,” the company said.

“The selection of Butler Freight as the acquirer ensures that the Coynes brand, team, and values will remain intact while benefiting from the resources and vision needed to drive future growth. We congratulate both the Coynes family and Butler Freight on this exceptional partnership and are proud to have played a role in this significant transition.”

It’s the same trusty workhorse, but not as you know it. Pairing a fresh new design with the features that have made it Australia’s hardest-working light-duty truck. The new look Fuso Canter is now bringing even more to the job site – including brighter LED headlights, a sleek new exterior, and enhanced 8” multimedia touch screen with wireless mobile connectivity. Plus, class-leading payload across most models, active safety systems*, and impressive 30,000km service intervals to take your business further.

CMV Truck & Bus has unveiled its redeveloped Dandenong dealership, a facility designed with the future in mind. This state-of-the-art transformation goes beyond meeting current customer and staff needs, and has been built to create enhanced efficiencies, safer working environments and an unparalleled customer experience.

Positioned in a prime industrial location at 77-79 Princes Highway, Dandenong South, the dealership has proudly served Eastern Melbourne since 2006. Specialising in the sales of Mack and UD Trucks, with parts and service of Mack, Volvo and UD trucks, CMV Truck & Bus Dandenong has become a trusted transport partner in the area.

The redevelopment of CMV Truck & Bus Dandenong was completed following more than 18 months of intensive construction.

Strategic planning helped keep the dealership operational throughout the process, ensuring uninterrupted service for customers. A key priority for the business was to create a future-ready facility designed to support business growth and keep up with demand in the region.

“This transformation reiterates CMV Truck & Bus’ dedication to investing in its facilities and delivering industryleading solutions to our growing customer base. Additionally, the expansion includes modern and increased office space to support this continued growth,” said CMV Truck & Bus General Manager Eastern Victoria, Anthony Russell.

With the addition of a new 20,000m² Tech Centre at the rear of the facility, the dealership now has 55 truck bays and generous space for trailers, both inside and under the fullweather canopy.

This assures the long-term viability of CMV Truck & Bus Dandenong to meet the future requirements of customers.

“Our spacious workshops are equipped with the latest diagnostic tools and state-of-the-art equipment, enabling us to reduce turnaround times and enhance efficiency, ensuring drivers can get back on the road quickly to keep their businesses moving,” said Russell.

The refurbishment involved an upgrade and expansion of the parts warehouse, ensuring rapid availability of genuine

components, minimising customer downtime.

This year CMV Truck & Bus Dandenong appointed a new Branch Manager, Adam Steenbuck, a highly respected individual who has been with the business for over 17 years and started his career as an apprentice.

“I am privileged to take the reins of this innovative dealership, which not only provides the highest level of service but puts the safety of our team and customers first. Safety is at the heart of everything we do and is a core business value, and this new facility is a true reflection of that commitment,” said Steenbuck.

Part of the investment has resulted in four 25-tonne inground knuckle lifts, which allow technicians to raise vehicles safely, ensuring they can perform their tasks with ease and precision. Additionally, industry-leading pit covers have been installed, further enhancing pit safety standards for staff during a service.

Another key addition is the separate Dangerous Goods Workshop, providing a designated area for safe servicing and repairs on customers specific vehicles.

Unlike a standard wash bay, We are able to setup a temporary washbay onsite! This cuts costs and time down considerably by eliminating lengthy trips to offsite washbays. We also utilise a road legal Yard Tug, This allows our team to move trailers around your yard without setting foot on the ground!

With multiple collection methods to suit most situations, We are able to collect and remove all truck wash water from the premise to be disposed of safely. All of this is done at no additional cost!

As Australia’s leading mobile washing supplier, We are in position to service fleets sizes from 15 to 15,000! Wash It Australia is proudly the preffered supplier for Australia’s largest transport company & Australia’s largest supply chain solutions

Dana Incorporated has announced the appointment of R Bruce McDonald, a member of the Dana Board of Directors, as Chairman and Chief Executive Officer, effective immediately.

McDonald’s appointment follows the retirement of James Kamsickas as Chief Executive Officer and his departure from the Board.

Kamsickas will remain as an advisor to the company through March 2025 to support the transition. The Board has retained a leading executive search firm to identify Dana’s next permanent CEO.

“Jim is an exceptional leader with more than 18 years as a CEO in the industry. He led Dana through one of the industry’s most challenging periods while successfully building a high-performance culture, enabling a world-class manufacturing company and assembling a portfolio of leading products and technologies,” Keith Wandell, Dana’s Lead Independent Director, said in a statement. “The Board and Jim agreed that now is the right time to transition the leadership of Dana, and we thank Jim for his many contributions over his nine years leading the Company and wish him all the best.”

Kamsickas said he was proud of the work the Dana team has done over the past decade to grow revenues and successfully enhance the technology to serve all mobility markets.

“It has been an honour to lead this talented global team during that time and I am confident the company is well positioned for the future,” he said. While there was confidence in the long-term opportunity in the mobility industry, Wandell said it was undergoing a significant transformation, including protracted cost pressures and demand uncertainty.

“To address these challenges and deliver more value to customers and shareholders, Dana is taking action to streamline the business, unlock the value of its Off-Highway business and further reduce costs,” he said. “Bruce is an experienced public company CEO in our

industry with significant M&A expertise, and we are confident that he is the right person to oversee this transformation while the Board conducts a search for a permanent successor.”

Dana also announced it had engaged financial advisors Goldman Sachs & Co LLC and Morgan Stanley & Co LLC to sell its Off-Highway business, as it looks to unlock substantial value for shareholders. The Off-Highway business provides drive and motion systems for heavy-duty vehicles in markets such as agriculture, materials handling, mining, construction and forestry.

A sale will position Dana with a streamlined go-to-market approach focused on serving its light and commercial vehicle customers, with traditional and electrified products that are largely shared across the remaining portfolio. Proceeds from a potential sale will enable Dana to strengthen its balance sheet through substantially reduced leverage, and to return capital to shareholders.

While the company and its advisors believe there is strong interest in the Off-Highway business, there can be no assurance that the sale process for OffHighway will result in a transaction. There is no timeframe for the conclusion of the process. As Dana continues to improve its profitability in a challenging operating environment, the company

announced further actions to support sustained long-term profitability and enhanced cash flow generation. This includes substantial reductions in selling, general and administrative costs across all the company’s businesses and engineering expenses to match current industry dynamics, including the ongoing delay in the adoption of electric vehicles.

The company expects to deliver annualised savings of approximately $200 million by 2026. Furthermore, the company plans to reduce capital spending to reflect the revised market demand for electric vehicles.

“Dana is committed to a strategy that accelerates value creation and has taken action to flex its cost structure and generate efficiencies by leveraging its core strengths through current market conditions,” said Bruce McDonald, Chief Executive Officer. “It is clear that further actions are needed, and I am confident that the new incremental cost reductions, paired with the benefits of a potential Off-Highway sale, will enhance shareholder value.

“Following the Off-Highway business sale, we believe Dana will have an adjusted EBITDA margin and free cash flow margin in excess of current levels.” Dana, according to McDonald, is differentiated by leading technology innovation and a track record of continuous improvement.

“My conviction in our businesses, the team and the opportunities to capitalise on the EV transition over the longterm remain strong. I look forward to stepping into my new role as CEO at such an important time for Dana and will work diligently alongside the Board and management team to deliver on these actions and drive value for Dana shareholders.”

Prior to his appointment as Chairman of the Board, Mr. McDonald served on Dana’s Audit Committee and as chair of the Nominating and Corporate Governance Committee.

He has been a member of the Dana Board of Directors since 2014.

North American transport powerhouse

Schneider National has announced the company, through certain wholly owned subsidiaries, has entered into a definitive agreement to acquire Cowan Systems, LLC and affiliated entities.

The agreed upon cash purchase price of approximately $USD390 million is subject to certain adjustments.

The sale includes separate agreements to purchase certain real estate assets

relating to Cowan Systems’ business for approximately $USD31 million in cash.

Based in Baltimore, MD, Cowan Systems is primarily a dedicated contract carrier with a portfolio of complementary services including brokerage, drayage and warehousing.

Cowan Systems’ Dedicated customers include leading producers of retail and consumer goods, food and beverage products, industrials, and building

The 24th edition of Brazilian transportation fair, FENATRAN, has made history. It again proved itself the largest fair for road freight transport and logistics in Latin America, by attracting 74,000 attendees.

That was not the only record smashed. The event also achieved nearly $AUD4 billion in commercial transactions.

According to a survey carried out by RX do Brasil, the event’s organisers, the result well exceeded the $2.5 billion in revenues recorded in 2022. More than 2,000 people from 53 countries passed through the pavilions of Sao Paulo Expo, most of them from Mercosur, such as Argentina, Uruguay, Chile and Peru.

For Thiago Braga Ferreira, executive manager of FENATRAN, both the number of participants and the volume of negotiations exceeded the expectation of the organisation.

“The results achieved this year bring us a great challenge: in 2026, we want to be even better,” he said.

“We will dare, innovate and seek the best to attract exhibitors and visitors. And we have already started working on this.”

The next edition is confirmed and scheduled for the period of 09 to 13 November, 2026.

Truckmakers and other OEMs took advantage of the event to present new technologies aimed at reducing emissions and supporting industry

materials. The company operates approximately 1,800 trucks and 7,500 trailers across more than 40 locations throughout the Eastern and Mid-Atlantic regions of the United States.

The acquisition will further complement Schneider’s Dedicated organic growth success. Including Cowan Systems, Schneider will operate over 8,400 Dedicated prime movers – approximately 70 per cent of Schneider’s Truckload fleet – cementing its place as one of the largest dedicated providers in the transportation industry.

“This acquisition aligns with Schneider’s long-term vision to have customercentric dedicated solutions as the cornerstone of its Truckload segment,” said Schneider President and CEO Mark Rourke. “By complementing our organic dedicated growth success with transactions like this, we are broadening our presence to provide greater value to our customers and stakeholders.”

decarbonisation, in addition to their latest launches in terms of services, leasing, among others. Volvo, to name one OEM, achieved over $794 million in business generated by early afternoon on Friday, 8 November.

The amount includes the sale of trucks, service plans, insurance, consortium, in addition to the rental of vehicles.

Scania later announced the sale of 2,000 vehicles at FENATRAN.

WITH THE TIMES

An

entrepreneurial family vision set in motion

Peter Sadler Removals & Logistics, a respected business that has risen above its niche origins to become a serious player across three industry segments.

Afamily business in origin, evolution and current incarnation, Peter Sadler Removals & Logistics, is a success story predicated on persistence and hard work. Conceived on the run in a pre-millennium environment, very different from today, the company commenced trading around 1997 with two 3-tonne Fuso Canters owned by a father and son team both of whom were named Peter Sadler. After some initial trial and error in several different vocational pursuits, local furniture removals, something Peter senior was already familiar with, began in earnest. Not soon after, the son secured ongoing work from Beacon Transport, a subsidiary of Linfox. Beacon’s head of ce was in Rayhur Street in Clayton.

It was also where the Fox family kept many of their antique cars. Peter, the younger, then began doing personal moves to Portsea for the Fox family. The work was ongoing. Meanwhile, the son’s brother David Sadler, who was enrolled in a tertiary education but undertaking a gap year purchased a van in 1999. Over the summer period he delivered product for either Schweppes or Coca Cola. By 2000 the company was on its way to re ning its operations with David’s brother having “taken the bit between his teeth” to make it a success.

Two key discoveries were made during this period on short haul tasks in which the curtains were, to simplify it, opened and closed at delivery point. The rst was the trucks were entirely not suited; the second, soon became clear, that it would descend into a race to the bottom. In response, Peter set about curating a niche in areas where the complexity of the work made the barrier-to-entry too great for Johnny Come Lately. Aside from moving MRI machines, which are more of an anomaly, there isn’t work with a greater degree of dif culty in the fastmoving consumer goods domain. David eventually left Melbourne University with a double degree and went to work in the corporate sphere for a few years.

“I enjoyed corporate, but I came to the realisation that I wasn’t going to have any real impact any time quickly and my brother rang me and asked if I wanted to have a crack for a while,” recalls David. “I said, ‘yeah, why not?’

We’ve had mountains of ups and downs since then.”

In 2007 he of cially joined the business where he still remains as the General Manager.

“Beverage deliveries require you to go out with 30 drops for 500 cartons and you’ve got to collect cash at the same time,” says David. “Some are at service stations and convenience stores in the middle of nowhere that are still dealing in cash. The other part of the equation is the inherent dif culty of furniture removals.”

Given the bookends of the business — moving people’s houses and contract beverage transportation — in order to achieve success in those elds it became less about the truck and more about the people behind the steering wheel. The business is now modelled on what David refers to as a reverse pyramid, an idea, quite radical in its implications, that amounts to him and his brother being the least important people within the business, and the people who are out there driving and lifting all day long the most important.

“Because without them we can’t put food on the table,” says David. “When I was Head of Revenue I would say to the customers ‘you’re not as important as my drivers and they would say, ‘what the hell does that mean?’ and I would say, ‘well, if I didn’t have good drivers, you wouldn’t be a customer, so they have to come before you’. Once that sinks in, they realise that it’s pretty true.”

While the rst trucks were well suited to small furniture removals, they were not so well adapted to large furniture removals and certainly incompatible to beverage drops. Wave picks that group

orders into batches for simultaneous ful llment are problematic when there are 30 drops to do.

“Any pallet might have the stock that you want,” says David. “So, you’re clambering over pallets all day in a Pantech.”

Nowadays to nish that nal mile, Peter Sadler Removals & Logistics enjoys the bene ts of having palletised product on curtainsiders for the superior access it affords.

The two-tonne light-duty trucks are nominally operated by subcontractors these days.

“What used to be great about the twotonners that we previously owned is going out and doing 35 drops of 600 cartons of beverage or 35 drops for microbrewers where you’re handling kegs which are 63.5 kilos,” says David. “But it takes a fair bit of time to develop through the grades to get to that intensive work.”

The once traditional model for nding people and upskilling them is no longer what it was. David quotes a Sean Connery line from The Untouchables: “If you’re afraid of getting a rotten apple,

don’t go to the barrel. Get it off the tree.” Young people straight out of school or rst year of university now make the best recruits as they haven’t been indoctrinated into a particular way of doing things. The reasonable standards of what should be done in the world have diminished according to David.

“There’s a little bit of entitlement creeping into our everyday life as the generations unfold,” he says. “‘I don’t deserve to do that’ type of attitude. When we rst kicked off, we did what the business required. No matter how hard it was.”

The smaller vans helped provide a breeding ground with a steady ow of drivers progressing up to a rigid. David acknowledges that the pool to draw from isn’t as big as it was previously.

“Long story short we got rid of those vans, as it wasn’t the breeding ground it once was,” he says. “Now we take a slightly different path that takes a bit longer but eventually gets us the result we’re after.”

Typically, the eet is aligned with Isuzu through Westar Trucks in Derrimut. They have close to 40 vehicles with the lion’s

share badged by Isuzu. The eet contains Isuzu NRR 3-tonnes Pantechs, Isuzu FRRs for the 8-pallet application, the Isuzu FSD for 10- and 12-pallet vehicles, and Isuzu FVL Series for 12and 14-pallet vehicles. There are three different verticals within the business. Furniture, including residential and commercial services, a space they entered in recent years, that involves construction, joinery, high end furniture, represents approximately 20 per cent of revenue. The other segments are evenly shared between 3PL services comprising the beverage task with the exception of one signi cant customer and contract cartage which is aligned to a few select major clients whereby the eet provides a set number of vehicles a day. This will uctuate.

“We’re currently in a season where the people become more important than the truck,” David says. “We do work with a major soft drink brand where we might run 12 route loads a day through winter. That’s now upwards of 20 a day over summer and the highest point will see it get to 26 or 27 loads. With a set number of equipment, it’s really about jockey capability.”

This refers to having personnel capable of performing a double run entailing they pick up a load of up to 10-tonnes in the morning and then return for another load.

“Having a jockey with them is making sure that they are going to stand the best chance of being injury-free and stand the best chance of being fatigue free because it’s quite physical work,” says David. “It’s a unique business because

there’s nothing particularly similar about the verticals with the exception of some contract cartage and 3PL services. There’s a need for highly skilled people to be undertaking the work in each of those verticals.”

That can mean complex project management on a commercial furniture task, delivering a keg down a cellar, taking couches upstairs or picking the keg on overnight pick or delivering on contract cartage when multiple drops are the order of the day.

The current headquarters in Laverton North have recently been refurbished to increase onsite capacity. Peter’s original truck, which sits out front, will get a makeover next to further celebrate the company heritage. It’s certainly come a long way as it now employs 175 staff.

Employees like Phil Payne have been with the business nearly as long as it has existed. This year will be his 22nd. He joined in 2003. His utility to the business is widely regarded both internally and externally, having worked as a removalist, a multi-drop route driver, within the warehouse, “exactly whatever the business needed,” as David describes it.

“Phil tted in straight away. Nothing was too hard,” says David. “He’s as loyal as the day is long. He’s one of a kind.”

The organisation recently launched a new set of internal values. These are Community, Grit, Leadership, Partnership and Adventure.

“These are values we have always abided by in terms of our behaviour and our actions,” says David. “Recently, the executive leadership team made the

decision to formalise these values.”

In addition, the senior leadership is set to report on its return on investment (ROI) analysis for going green. Initially the transition will target very speci c verticals in the business. The most obvious one is in the furniture space says David.

“Why? Because the consumer is probably a little bit more inclined to say that’s something I want to be involved with,” he explains. “In tough economic times these priorities can also be delayed if the cost for the customer proves prohibitive in the short-term. But there’s not many providers that are truly ready to have an 8-, 10- or 12-pallet vehicle carrying 6, 8 or 10-tonne for a sustainable period of time via an alternative fuel service. Rarely does your household contents get above 1.5 or 2-tonnes. Rarely are you doing more than

one or two stops. It’s not a multi-drop task moving homes.”

Being as lean as possible is an imperative for the business at the moment. Hazard Analysis Critical Control Point (HACCP) and ISO accreditations are next on the agenda with a possible move into New South Wales.

“That would be the point of which it would be very logical for us to get into some linehaul work,” says David. “We’d start looking at prime movers and we’d start looking at running return on investment type of analysis. That’s not to say we can’t do it with our current con guration. It just hasn’t been the highest priority, so we’ve chosen to use different carriers, whether it be interstate, whether it be local, whether it be regional.”

Gary subcontracted initially for NQX and then a smaller company based out of Rocklea. It had a small eet of ve trucks. They eventually went bust but not before Gary purchased the eet, bringing into existence the company that now bears his name.

A second major turning point for Rogers Transport occurred when it landed a contract with global paint supplier PPG. That partnership has lasted for 32 years. Reliability springs eternal. As a testament to the company’s levels of commitment, some of its initial customers are still being serviced today. Gary and Val’s three adult kids now all work within the business. Chantelle

Rogers serves as Warehouse & Finance General

“He’s always had a philosophy or growing organically,” she says of her father. “He was mindful of not wanting to grow too big, too

As Gary secured more work he added to the eet. Presently, there are 45 Kenworth prime movers supported by eight Isuzu FVL Series 240-300

A tyre import business, sold many years ago, may have been the forerunner as to how they got into port cartage according to Brad Rogers, General

“A sideloader was purchased at one point to shift imported containers full of tyres,” recalls Brad. “The container distribution portion of the business right now accounts for about 25 per cent.”

The warehousing segment represents roughly another 30 per cent of revenue while linehaul achieves approximately 35 per cent due in part to accelerated ROI.

The Kenworth trucks in their linehaul and container cartage operations range across the board with a W900SAR LEGEND, T610SAR, T410SAR, T408SAR, T409SAR, T409, T610s, T410, K200s, K220, T909s, K104B, T350 and T388.

The Brown and Hurley dealership at Darra and

salesman Scott Coleman have delivered every prime mover in the contemporary eet undergirding the long-term solidarity of the partnership.

“The majority of the Kenworths come in a manual transmission,” Brad explains.

“You get a better calibre of driver with a manual transmission, but they are getting harder to nd.”

Each Kenworth is spec’d for roadtrain detail. While none of the trucks currently in operation perform this kind of work it enhances their resale value while also providing Rogers Transport an option, should they need it, in future.

“You never know what work will pop up,” says Chantelle. “We’re in the business where we won’t say no to any opportunity if it’s something we can make work we’ll be willing to consider it.”

The other ten per cent of the business is local distribution.

Five of the rigids are on contract wet hire arrangements with the same two customers they have serviced for the last 30 years.

The linehaul eet consists of 22 units and though primarily dedicated to the east coast regularly ventures inland.

“The eet travels all over Australia depending on what our customer needs are,” says Chantelle. “We try not to pigeonhole ourselves on just the main routes. We do a lot out in rural

Australia. We also have contract work where we hire out our drivers who complete the customer requirements on a contract basis.”

Effecting a functional one stop shop model, incorporating wharf cartage to customers and back to base, in addition to unpacking and storage in the warehouse both racked or bulk, cross-dock and redeliver have been greatly optimised since the company relocated to its new facility at the Port of Brisbane last March. Prior to the move they were in Rocklea and Lytton with some off site storage at the Port. The whole site is 55,000m2 – just under double the size of all three depots combined previously – with 18,000m2 under cover. They also have their own workshop and truck wash facilities on site. Consolidation, according to Chantelle, provides useful synergies.

“Obviously with the three different sites, we lost a lot of man hours moving drivers between them. With the one depot, if you’ve got a driver who has become free in your container division you can easily shift them across to your local division,” she says. “You’re not having to run people across to different sites meaning those hours are used to service our customers instead. With the two different warehouses, sometimes you’d end up with some product at one warehouse and some at the other. In order to consolidate

a load, you would have to drive from one to the other.”

The new setup greatly advantages the workshop as it no longer needs to cart parts and equipment between the sites for servicing.

“To be fair, we probably outgrew the previous sites years ago,” says Brad. “There was probably not really any opportunity for growth. That’s the biggest advantage — we’ve now got the opportunity to grow.”

The new facility enables Rogers Transport to expand its offering in both 3PL and carrier divisions.

“Medium-term, we have goals to not only grow the business but also work towards being the best business we can offer through enhancing safety measures, improving our operational ef ciency and boosting our customer satisfaction as we continue to offer the same personalised service that our customers have grown to love, no matter our size,” says Chantelle.

Longer term, however, the expectation is the baton will be passed onto the next generation of the company while shining a light on Gary and Val, who have worked tirelessly to build the company. Investments in IT and green technology are anticipated. Their younger brother Troy also works at the business in an of ce role.

Growing up around the business, with Brad often sweeping the yard on

weekends and Chantelle handling administrative tasks like ling, their parents encouraged them to seek experience elsewhere as part of their development.

“It was strongly suggested to both of us that we do something else,” Brad notes with a laugh. And he did. That resulted in construction management studies which subsequently saw him posted in that industry for the better part of ten years before Gary asked him if he was ready to join the family business.

Chantelle, who had persisted six months at university knowing it wasn’t for her, began delivering automotive parts for Chrysler, Jeep and Dodge in a Triton ute. She loved it. While she was on holiday in New Zealand, the replacement driver rolled the vehicle which was substituted with a “hideous” parts ute with body cage that hadn’t been used in several years.

“The doors wouldn’t open, and they wouldn’t shut. That’s when I was complaining to dad one day and he offered me a job here,” she recalls. “I think it was inevitable anyway, but I think it helped move up the timeline.”

That was 16 years ago. More than enough time to develop a standard by which to compare present circumstances with the past. Rates and driver shortages will, in her view, continue to vex the

industry for the foreseeable future. The overarching issue is the disconnect existing between operational realities and consumer demands, which are becoming increasingly unrealistic under the “now society” as she describes it.

“Without any background into how many cogs are turning in the supply chain to meet these consumer demands, coupled with issues surrounding driver shortages, declining rates and a more heavily regulated industry to ensure the safety of our drivers, it’s

Rogers Transport also runs regional B-doubles.

certainly becoming a challenge to meet both customer demands while also maintaining the pro tability of the company,” she says. “Viability has always been important in this industry however we have seen rates on a downward trend while costs continue to rise. This means viability is now becoming more important than ever – every kilometre the truck covers needs to be running in the most optimised and ef cient way possible in order to hold our share in the industry and continue to thrive.”

E ciency is a major factor in the Elliott’s Bulk Haulage operation which is based in the town of Tumut in the foothills of the NSW Snowy Mountains.

Achange in career away from his trade as a panel beater and spray painter saw Graham Elliott buy his rst truck in 1962 which was a tipper he drove for various organisations in the Tumut region such as Tumut Council and the Forestry Corporation. Graham also established a small landscape products supply service for materials such as sand and gravel. Graham’s business grew quickly after he began doing transport work for local sawmills hauling wood chips with semi-trailers between mill sites located in Tumut. This area of operation grew to include four trucks working from the mill sites and Graham also ventured into the pine bark business. Graham purchased the raw bark material, which until then was

mostly considered a waste product, from the mills, built a bark grading plant in Tumut, which sorted it into different sizes, before it was delivered to mainly Sydney based customers.

An industrial accident laid Graham up for many months and his son Grant, the “Son” in Elliott and Son Bulk Haulage quickly took over the running of the operation.

“I was just a young truck driver which back then was all I ever wanted to do,” recalls Grant. “I didn’t want to come into the of ce but didn’t really have a choice.”

With four trucks then on the mill work and another running to Sydney daily, Elliott’s was also supplying a lot of graded pine bark to various Sydney landscaping suppliers who would arrange their own transport to pick up eight to ten loads each day.

The Elliott’s entrepreneurial minds sought to expand the business without affecting ef ciency.

“I thought there was a better way, so I got the Sydney Yellow Pages and started to ring every single landscape yard in the book,” says Grant. “Within 12 months we grew to four trucks running

daily to Sydney, expanding eventually to 19 trucks and 68 employees with a 24-hour workshop staffed by six diesel mechanics.”

Grant was managing both the burgeoning landscape yard and the growing transport business and by 2017 was stretching himself too much so the decision was made to sell the pine bark business to Martin’s Fertilisers in Yass. Later that same year devastating bush res saw all of the sawmills in the region go from 24-hour operation to ten hours on just four day weeks. The forestry industry lost half of its timber resources and for the next 12 months Elliott’s dealt with burnt pine bark as loggers attempted to salvage what they could.

“It changed the landscape up here forever,” says Grant. “It takes 22 years to grow a ‘saw log’ so it’s not going to change up here for another 15 years or so.”

Elliott’s currently has six prime movers with two more on order. Two Freightliner Cascadia 116 day cab prime movers have joined the predominantly Kenworth eet at Elliott’s and the move came about mainly due to Grant’s longterm relationship with Dave Warren who became the Dealer Principal of the Daimler Trucks dealership in Wagga Wagga. The Fuso Canter tipper which delivers material from the landscape products yard also came via Dave Warren.

“Dave’s been a friend for years and he was our Kenworth salesman, and I’ve bought many trucks from him over the years,” says Grant. “I normally keep trucks for ve years and I’d never really looked at Freightliner, but back then there was a long wait for Kenworths, so I ordered the two Freightliners.”

The Cascadia’s are performing mostly local work, hauling wood chip ten to 12 hours per day from Tumut sawmills to the VISY plant, then the afternoon shift hauling ungraded pine bark to Yass, then going to Canberra to pick up loads of woodchip which is in turn delivered to the VISY papermill back in Tumut. Working about 20 hours a day,

each day, the Cascadia’s have travelled around 170,000 kilometres over 12 months. The Freightliners are powered by DD13 Detroit Diesel engines rated at 505hp and 1850lbs/ft of torque and are equipped with DT12 overdrive automated transmissions and Meritor diffs riding on Airliner rear suspension. The bespoke liveries are not wraps but are actual paint and were designed back in 1988 by Graham Elliott who rst applied them to his then brand-new Ford LTL 9000. The standout paint schemes have won Elliott’s the prestigious PPG Fleet of the Year award twice.

The Cascadias are connected to fouraxle Barker moving oor trailers which feature self-steering rear axles and have a capacity of 100 cubic metres. Operating on the Higher Mass Limit of 50.5 tonnes the combinations deliver a 30-tonne payload.

To give each truck its individual identity they are named for AC/DC songs, an idea

Grant’s wife Tanya came up with.

“The fuel consumption from the Freightliners is exceptional,” says Grant. “Bear in mind they’re doing local work and unloading up to ten loads per day with the moving oor, sitting there at idle pumping the trailer out. The trucks the Cascadias replaced averaged 1.67km/ litre and the Cascadias are delivering 1.84 km/litre. That’s a big saving.”

The strategic downsizing of the Elliott’s business in 2017 subsequently led to a compact and more ef cient operation according to Grant.

“We can’t downsize any further than what we are now. At the moment we’ve got a very ef cient, very easy business,” he says. “Gone are the days of trying to organise 68 people and trying to nd loads all over the place. Our drivers now basically have a roster three months in advance and very rarely do we have to vary anything. We’ve got long-term drivers — some have been here over 20

years. We’ve been very mindful of being in the situation over the next few years when those drivers retire, they’re going to be very hard to replace. Today, we’re not looking for drivers, we don’t currently have a driver issue and haven’t for years, but as these drivers retire that’s going to be a challenge replacing them with good drivers.”

Re ecting on the continued success of the business Grant praises his father Graham’s vision.

“My father saw a market for pine bark many years ago when it was considered a waste product and over the years we’ve managed to get everything tied in to work together even though there are separate contracts for pine bark and wood chips,” he says. “We also haul Tumut’s local household waste to Jugiong every day. Everything that we do ts in with the other pieces of the puzzle to make it a very ef cient and pro table business.”

The eet at JOPA Queensland has grown to 20 trucks in its twentieth year. It’s a successful operation built on the back of strong relationships with both customers and suppliers.

In the highly competitive world of bulk construction supplies, service and innovation are two of the crucial factors required for a successful business not only to survive but thrive. JOPA Queensland is celebrating its twentieth year of operation with the delivery of its twentieth Hino truck, which is itself a signi cant milestone in the company’s journey. The company name JOPA Queensland is inspired by the owners’ names JOdy and PAul Curtis.

JOPA doesn’t operate from a typical retail landscaping supplies yard, instead the company uses a bulk holding yard in a strategic location adjacent to the Logan Motorway, providing easy access to not only the Gold Coast, but also the northern suburbs of Brisbane as far as Caboolture, and west to areas around Mount Marrow and Fernvale.

A feature found on most of the JOPA trucks is the centre tailgate tted to the tipping bodies which accommodates the transporting of two different bulk products at the same time, delivering an obvious ef ciency bonus as well as a reduction in JOPA’s carbon footprint by signi cantly reducing the number of truck movements required to deliver their customers’ needs. The loaders at the yard have special buckets to suit the two compartment tipper bins. Most of the trucks initially leave the yard in the morning fully loaded from material stocks held there, and then after that rst delivery is achieved, they often reload at various suppliers’ facilities throughout the rest of the day, reducing the need to return several times to home base and delivering a more ef cient service to the now more than 350 regular customers.

“I explain to people that, just like Uber, the material is our passenger and we work our way around and can be in and out

of different quarries throughout the day,” says Paul. “We’re not married to one supplier, as much as the suppliers may want us to be. Theoretically, we’re a transport company and instead of transporting parcels or freight or bricks, we deliver the sand, gravel, road bases and similar bulk products for the construction industry.”

The inspiration for the divided tipping bodies came to Paul back before 2010 when he was driving behind a small landscape supplies truck which had a divider tted and had bagged cement at the rear and some bulk product at the front. Paul immediately realised the better option this offered, as distinct from the established method of using a tarp to separate different products being carried in the one tipper body. Paul experimented with a number of different con gurations to determine where to put the additional centre tailgate before arriving at what has since proved to be the optimum design.

“The majority of our clients, such as drainers, would buy six metres of one type of material and two to three metres

of another material,” says Paul. “Hence we had to put the biggest sector on the back so we can legally carry six metres of material in the back compartment and, depending upon the product, carry up to four cubic metres in the front. We had a few smaller trucks in the early days which could carry around seven cubic metres and we had a different con guration of split but it wasn’t safe, so we came up with the idea that a small truck can’t carry big loads, but a big truck can carry small loads.”

The smaller trucks were progressively changed over to Hino FM500 models which have since become the standard units in the JOPA eet.

The bespoke tipping bodies, on the other hand, are manufactured by MiniBody Engineering at Acacia Ridge, and Auzprint in the Brisbane suburb of Hillcrest take care of the graphics, including a special twentieth anniversary livery for the latest Hino 500 Series FM2628 auto which also becomes JOPA’s twentieth Hino. The JOPA livery has evolved over time and still retains the JOPA logo in yellow with the entire tipping bin now wrapped in

black vinyl which can be easily removed when the trucks are on-sold, leaving the aluminium looking like new.

Prior to establishing JOPA, Paul’s background was in the parcel freight industry and the JOPA Queensland business commenced in 2005 with a modest $15,000 start-up investment. This included a little Daihatsu Delta tipper which was traded less than a year later.

Paul admits he didn’t know a lot about the market when he started out but armed with an honest approach to customer service and the promise of ontime deliveries provided customers with an option and a reason to change the way their businesses were serviced. Initially he was intent on buying a truck that could carry ve cubic metres tantamount to around 6.25 tonnes in payload.

“Hino at Coopers Plains had a factory tipper called a Hino FC Dump which could carry 6.4 tonnes,” recalls Paul. “I thought we’d halve our workload because we had a truck twice as big, but in actual fact it doubled our workload because the business grew.”

On the advice of Brad Elliot at Sci-Fleet Hino, JOPA purchased its rst tandem drive Hino FM500 in 2007.

“Sci-Fleet were just so helpful and the following year we bought another one, so within three years we had the two tandems and still had the little Hino FC Dump which we hung onto for ages,” Paul adds.

Prior to the pandemic Paul would order a new Hino from Sci-Fleet when the JOPA eet’s oldest truck reached 300,000 kilometres and by the time 350,000 came around the latest truck was available and ready to replace it.

“When COVID came in it was hard to get trucks so we’re running trucks now up to the 400,000 kilometre mark, which in the lifespan of those trucks is actually nothing,” says Paul. “Now we’ve reached a stage with the twentieth truck — the oldest one we’ll keep as a spare.”

The Hinos are not on a service contract and visit the dealership every 20,000

kilometres, taking advantage of SciFleet’s night servicing and the use of a courtesy ute for the driver.

“We’re not mechanics so we let SciFleet’s mechanics do the mechanicing, the same as we let our accountants do the account stuff,” Paul says.

Demand for JOPA’s products has recently proved so strong that JOPA has co-opted a truck and dog owned by Aaron McKenzie’s Queensland Bulk Landscape and Civil Supplies (QBLCS) to deliver some of the larger bulk loads.

Supporting Jody and Paul in meeting JOPA’s “You ring, we bring” service commitment, is son Matthew and his wife Olivia, along with an enthusiastic and experienced team of drivers and of ce support staff.

“Matthew has been here for 15 years and basically runs the operation with assistance from Zane Ellison,” says Paul. “These young blokes are amazing and are moving about 1,200 cubic metres

a day around the greater Brisbane area. People have to have places to live, and the housing industry continues to grow, and our data base of customers continually grows.”

Twenty years ago, JOPA’s rst customer was Ownit Homes, an award winning building rm which remains a valued client to this day.

An online presence has been developed and existing and potential clients can obtain a quote by using the JOPA Queensland website.

JOPA has built a strong foundation by providing exceptional service to existing customers utilising some innovative equipment and continues to show strong growth despite never having to advertise.

“It’s all just word-of-mouth,” says Paul. “I just couldn’t say ‘no’ to people. To be honest I had no idea that it was going to be like this. I’m humbled by it and I pinch myself every day.”

A new tribute truck honouring the former General Manager at Red Horse Transport reveals a story of integrity, commitment and sel ess leadership.

Fledgling freight carrier Red Horse Transport in a little under a quarter century has diligently carved out a respectable reputation, initially in southeast Queensland and now as an interstate player. Determined to become a national presence, the company, it’s fair to say, has appraised the wider Australian transportation and logistics sectors and likes what it sees. While market share capture is not one of its stated aims, the business is having an industrious period of growth all the same.

Shortly after it opened a 5000m² warehouse in Stapylton, strategically located between Brisbane and the Gold Coast, Red Horse Transport commenced plans to establish a new

site in South Australia. Widely regarded as a key growth corridor for logistics and freight carriers, South Australia is still largely untapped on the national network for companies looking to offer advanced storage solutions downstream from their transport services. That facility opened late last year. It marks another milestone in the organisation’s recent ascent.

Internally, the investment is viewed as an opportunity for Red Horse Transport to deliver leadership in the logistics sector by better equipping itself to serve clients with greater ef ciency and care, one of the hallmarks of the business according to the company, which was founded in 2001. The mandate has drastically diversi ed since it rst began as a metro

last mile provider de ned by its use of commercial vans. The opportunity to evolve alongside the country’s growing logistics demands prompted the company to steadily expand to the national bulk freight transportation specialist it is today. The eet has grown to nearly 150 mobile assets including prime movers, rigids, LCVs and trailers. Heavy cargo in its oversized load management is handled by Kenworth and Volvo prime movers. Smaller freight tasks are allocated to rigids including new Hyundai trucks. The Toyota HiAce is the van of choice.

Two areas Red Horse Transport likes to pride itself on are innovation and customer service. Indeed, the three core values celebrated at Red Horse Transport

— family, teamwork, and safety — were embodied by the late General Manager Patrick Glassborow, whose sad passing in 2024 has been commemorated on a new Kenworth K220 dedicated to his memory.