PUBLISHED BY Prime Creative Media Pty Ltd

ABN 51 127 239 212 379 Docklands Drive, Docklands VIC 3008 Australia

Recent developments in the fast changing world of truck making, as they race to develop zero emission technologies for the road transport industry, has led to a drastic reduction into the number of alternative suppliers.

The facts are quite simple, developing a completely new set of technologies to provide the motive power for trucks into the future is a very expensive business. ven the biggest truck manufacturers in the world are daunted by the prospect of the billions of dollars they will have to spend in order to bring the trucking industry into line with the zero emission goals set by governments in the developed countries.

Not only is all of the new technology difficult to develop, we also don’t know which technologies will be the most successful. his means that our ma or truck manufacturers are pursuing a three pronged strategy, moving forward.

They are developing battery electric vehicles, fuel cell electric vehicles and hydrogen powered internal combustion engine vehicles. ow, those massive global groups are coming up with oint ventures to mitigate the costs of developing the new technology.

ellcentric, owned ointly by the olvo group and the aimler truck group, is expected to make fuel cells for both sets of brands. ore recently, the coming together of Fuso and Hino as a merged company sees the number of Japanese truck manufacturers in the Australian market basically getting halved in the last few years. is now owned by su u and uso and ino will be part of a single entity in the future.

This is a very different picture than the one with which truck buyers were presented with ust over years ago. hen, you could go to several of the ma or truck manufacturers and have a choice of at least three engines from three different manufacturers. he choice will not be between a ummins, a aterpillar or a etroit, it will be between battery electric, a fuel cell or .

We can’t be sure of the economic implications of these developments, but the absence of competition is always an issue for prices in any industry. owever, there is also an elephant in the room.

China has been able to grow market share in many industries around the world purely on the fact that it can bring its cost base down far enough to make it competitive against any competition. e can expect the same process to happen over the coming years, as the technology picture becomes clearer, and trucking works out what it needs.

Telephone: 03 9690 8766

Fax: 03 9682 0044

Email: enquiries@primecreative.com.au

Chief Executive Officer: John Murphy

Managing Editor: Luke Applebee

Editor: Tim Giles

Contributors: Bob Woodward and Paul Matthei

Correspondent: Will Shiers (UK)

Advertising Manager: Trevor Herkess: 0411 411 352, trevor.herkess@primecreative.com.au

Client Success Manager: Salma Kennedy, salma.kennedy@primecreative.com.au

Production Manager: Michelle Weston

Circulation & Subscriptions Manager: Bobby Yung

Head of Design: Blake Storey

Designers: Caterina Zappia, Kerry Pert

Official Media Partners: REGISTERED BY Australia Post - ISSN 1445-1158

SUBSCRIPTION

03 9690 8766 subscriptions@primecreative.com.au

PowerTorque Magazine is available by subscription from the publisher. The right of refusal is reserved by the publisher.

Annual rates: AUS $60.00 (inc GST). For overseas subscriptions, airmail postage should be added to the subscription rate.

DISCLAIMER

PowerTorque Magazine is owned and published by Prime Creative Media.

All material in PowerTorque Magazine is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher.

The Editor welcomes contributions but reserves the right to accept or reject any material.

While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published.

The opinions expressed in PowerTorque Magazine are not necessarily the opinions of, or endorsed by the publisher unlessotherwisestated.

With Caltex Delo’s ISOSYN Technology, fleet owners and drivers can rely on extended service protection, maximised engine durability and minimised operating costs.

Talk to your local distributor or find out more about Caltex fuels and lubricants. www.caltex.com/au/business-solutions

In recent years the number of trucking operators looking for fuel savings has multiplied and truck manufacturers have come to the party with new offerings which take fuel consumption down to levels never seen before.

14 THE K220 WINS THE FIRST TOYA

An all-time Australasian trucking classic was celebrated.

24 VALE: PAUL KEAST

The trucking fraternity has farewelled one of its long-term members.

26 THE MAN FROM MAN

Tim Giles talks to the man from MAN, Alexander Vlaskamp.

38 GENUINE B-DOUBLE PRIME MOVER

A B-double prime mover with no compromises involved.

44 REDUCE EMISSIONS NOW

You can make a start by using a hybrid electric truck.

48

FIRST FORAY WITH A FOTON

We take one of the new electric trucks out on the roads of Sydney

52 NEXT GENERATION OBM

PowerTorque talks to Airtec about the next generation OBM.

56 INCREASING SOPHISTICATION IN BRAKING SYSTEMS

PowerTorque talks to Micahel McLellan from Knorr Bremse about a fast changing technology.

60 TIMES THEY ARE A-CHANGIN’

Mathew Munro is stepping away from ALRTA to become CEO of the Australian Trucking Association (ATA).

61 PBS LIVESTOCK CONCEPTS

Transport for NSW has developed some PBS livestock concepts which it hopes will improve the state’s productivity and safety.

66 STRONG PARTNERSHIPS, STRONG ENGAGEMENT

At BTS NHVR displays saw l community engagement with extensive conversations across an array of topics.

72 UK’S MOST AUTOMATED PORT

$3.78bn has been invested in London Gateway, the UK’s most automated port.

78 ISSUES AROUND COUPLINGS AND B-TRIPLES

Reporting back from technical meetings held at the BTS.

72

This year’s Brisbane Truck Show was the biggest show ever for the Heavy Vehicle Industry Association. At the end of the show a record turnout of 40,000 showgoers was announced, and those in attendance can attest to this fact after having to ght their way through the crowds in the narrower areas at the Brisbane Convention Centre.

thebrand behind the brands

• Supporting drivers for more than 50 years

• Seating – on ahigher level

One of the dominant players in the Australian truck market is making a change at the top with Andrew Hadjikakou moving on and a new Paccar boss announced.

The new Managing Director, Damian Smethurst, will officially take charge on Monday May 8. Damian has been with Paccar Australia for 25 years and has held leadership positions of increasing responsibility including Director of Operations, Chief Engineer, and most recently General Manager Paccar Parts Australia, where he has led the parts organisation to consecutive years of record levels of customer support and parts availability.

over the past two years and is sad to see him go, and he says he’s looking forward to a smooth transition.

“Mat will bring so much experience to the role and will build on Michael’s great work,” said David. “I look forward to joining forces with Mat as we tackle industry issues together.”

Trailer maker, MaxiTRANS, announced that international OEM and the European market leader in the trailer industry Schmitz Cargobull, has become an investor in the business. Schmitz Cargobull has become

focus has been on supporting Australian manufacturing, its people and delivering a highquality product for its customers.

“We are extremely thrilled to have Schmitz Cargobull onboard with MaxiTRANS as a partner,”

The trucking industry and its stakeholders are being asked to have input to the trucking industry code review of the Master Code of Practice. The Master Code is a registered industry code of

Heavy Vehicle National Law..

The review of the code will consist of six phases, requiring input from stakeholders in multiple phases. The review will commence in June 2023 and will use a variety

Fuso and Hino will merge on an equal footing and collaborate in the areas of commercial vehicle development, procurement, and production. They will build a globally competitive Japanese commercial vehicle manufacturer.

In the deal, Daimler Truck, Fuso, Hino, and Toyota will collaborate toward achieving carbon neutrality and strengthening the commercial vehicle business on a global

holding company of the merged entity. They will collaborate on the development of hydrogen and other alt-power technologies to support the competitiveness of the new company.

“This collaboration among our four companies is a partnership for creating the future of commercial vehicles in Japan and the future of mobility society,” said Koji Sato, CEO of Toyota Motor Corporation. “Our four companies will work

NatRoad says it looks forward to working with the new Minns Government in New South Wales, especially on the vexed question of tolls. NatRoad CEO, Warren Clark said his NSW Members regard tolls on the state’s privately-operated motorways as a major drag on their viability.

“The Minns Opposition promised to cut tolls for heavy vehicles on the M5 East and M8 and we look forward to those commitments being delivered once it is sworn in,” said Warren. “The pledge that heavy vehicle drivers will pay a third less in tolls for two years is welcome news. So is the appointment of former Australian Competition and Consumer Commission chairman Allan Fels as Tolls Commissioner, which NatRoad sees this as the first step in untying the messy knot that is Transurban’s monopoly on the State’s tollways.”

Rivet Mining Services, which hauls for iron ore and gold miners in Western Australia, went into receivership this week citing labour shortages and cost pressures. Difficulties in sourcing skilled drivers is quoted as being one of the factors in the collapse of an operation with 450 employees.

“Based on a preliminary assessment, it appears Rivet has been deeply affected by a number of adverse economic factors including extreme weather events, project delays, labour shortages, and cost pressures,” said FTI Consulting,

An increase in the Road User Charge (RUC) by six percent annually over the next three years. Next financial year, the RUC will increase from 27.2c a litre to 28.8c in 2023-24, jumping to 30.5c and 32.4c in the years after. Registration costs for a 6-axle articulated truck will go from the current the $6,530 (2022-23) to $6,872 (2023-24), and then to $7,236 and $7,621.

After 32 years in the business, Nicholson and Page Transport’s founders, Graeme Nicholson and Meredith Page have made the decision to sell half of their fleet through Ritchie Bros, although not retiring just yet, they plan to scale back the fleet and slowly transition towards retirement. They founded the company in 1991 with just one truck, a Ford LTS, and have since grown it into a successful business.

“Right now is a great time to be in the transportation industry,” said Graeme. “If I was younger, I’d be buying more trucks.”

He noted that finding good drivers is becoming increasingly challenging, which makes it difficult to maintain the company’s reputation and service his loyal customers to the high standard Graeme prides himself on. After 42 years of driving including 32 years of self-employment it’s time to slow down.

A new industry-led data sharing initiative between Transport Certification Australia (TCA) and the National Bulk Tanker Association (NBTA) aims to provide better understanding of the movement of vehicles transporting dangerous goods and bulk liquids on the road network.

TCA’s General Manager of Strategy and Delivery Gavin Hill

TCA and the NBTA, which involved transport operators in the dangerous goods sector.

“What we found from the previous study was that many dangerous goods transport operators had not necessarily seen a macro view of their vehicles’ footprint across the network. So, instead of leaving that as a one-off study, we’ve decided to launch an evergreen study, where

The National Heavy Vehicle Regulator (NHVR) has prosecuted a logging company and its Director based in Tasmania, following pleas of guilty to serious offences under the Heavy Vehicle National Law (HVNL).

An extensive investigation by the NHVR revealed ongoing fatigue breaches by the company. Over a 12-month period, the company had 251 fatigue-related breaches which were undetected by the company

and Director. Due to the management of these practices, charges were laid under sections 26G and 26H of the HVNL.

As a result of the serious offences the Tasmanian Local Court issued two Supervisory Intervention Orders (SIOs) worth $100,000 to the company and Director, requiring them to address their faults in fatigue management. The court also ordered a fine of $80,000 and issued the Director a fine of $8,000.

The electric truck industry and the trucking industry are stressing that Australia needs a clear zero emissions strategy, as the Australian Trucking Association join the Electric

around width and axle mass limits to increase electric truck supply to Australia

Signing the global MOU on zero emission trucks to make sure Australia is committed to a

At the Trucking Australia 23 event on the Sunshine Coast, the Australian Trucking Association presented the National Trucking Industry Awards, celebrating trucking people and the good work they do.

The Outstanding Contribution to the Australian Trucking Industry award went to Jacquelene Brotherton of Transport Women Australia

Meanwhile, the National Professional Driver of the Year went to Steve Broadbent, who works as a driver for Freestones Transport, and who has as been driving trucks since he was 21, driving around 6 million kilometres. He’s transported everything from livestock through to Formula 1 cars.

Alina Hawkins from the Livestock and Rural Transporters Association of Victoria was named as the National Trucking Industry Woman of the Year as someone who is known throughout the trucking industry as a passionate advocate for the livestock transport sector.

The National Training Excellence Award was awarded to. CMV Truck & Bus, while the TruckSafe John Kelly Memorial Award went to SeaRoad Logistics.

Integrity Systems Company’s (ISC) new electronic National Vendor Declaration (eNVD)

Livestock Consignments app is accelerating the digitalisation of the red meat industry by enabling consignment details to be transferred from creator to transporter, even while offline.

The eNVD app is a completely offline solution and uses QR codes to transfer consignment data from producer to transporter, saleyard, feedlot and processor. If a transfer takes place where there is no internet, the data will sync with the eNVD database when the receiver is back in a service area.

The eNVD app was released in November 2022 and since then has been downloaded more than 3,000 times with 69,000 head moved using the app.

Developed in collaboration with the red meat industry, ISC has been onboarding processors, transporters, agents, feedlots and saleyards since the app was made available on the Google Play and App stores.

ZF’s all-new AxTrax 2 electric axle platform is an integrated and modular e-powertrain system for light, medium and heavy-duty vehicles. It is ZF’s latest e-mobility solution to help support the industry’s transformation toward a more sustainable future.

AxTrax 2 is an axle-based, fully integrated system, featuring a compact design to help maximise the available space for batteries and enhance manufacturer’s design flexibility for future vehicle concepts. Series production of AxTrax 2 is planned to begin in Europe in late 2024, and in the U.S. in 2025, with Oceania region to

be confirmed.

“Customers are under tremendous pressure to implement zero emission technology, and our e-mobility kit allows them to electrify existing platforms, and develop purpose-built platforms, delivering superior total cost of ownership,” said Julien Plenchette, senior vice president, Americas, Commercial Vehicle Solutions, roup.

Iveco Trucks Australia has recognised its highest achieving dealers at its awards dinner event in Melbourne, held in conjunction with the internal launch of the company’s new heavy-duty S-Way range.

The Dealer of the Year winner was announced as STM Trucks & Machinery, led by Dealer Principal, Michael Gerace. Dealer of the Year – Light was taken out

by Iveco Sydney, who had Dealer Principal, Daniel Glynn accept the award, while Dealer of the Year for the Medium and Heavy category was received by General Manager, Michelle Papalia, who accepted the award on behalf of Adelaide Iveco. Newcastle Iveco, was announced as Dealer of the Year – Regional, an accolade that was received by Dealer Principal, Sean Lynch.

At the ACT Expo in the US, the Daimler Truck group announced the launch of a line of electric trucks in the US market under the new brand name Rizon. The three model

variants, sold elsewhere in the world under the Fuso name, are the e18L, e16L, and the e16M, will be the first trucks available under the Rizon brand.

Hyzon announced an agreement to trial its first heavy rigid fuel cell electric (FCEV) waste collection truck with REMONDIS Australia, one of the world’s largest recycling, service, and water companies. The collection truck is scheduled for trial in the middle of 2023, initially to operate out of the

company’s Wollongong facility in New South Wales.

Hyzon has developed this truck locally as a global platform, adaptable for international markets with a multitude of vehicle use cases, such as garbage compactors, tilt trays and flatbed trucks.

Once-off funding to support the development and delivery of Chain of Responsibility (CoR) training and education projects is now available, with $1.7 million being invested to help boost safety across the supply chain.

The funding will support businesses who use heavy vehicle transport to deliver tailored training programs focused on the CoR. Grants will be awarded to projects aimed at educating

safety of heavy vehicle transport activities.

Priority will be given to projects that focus on ‘off-road’ parties in the CoR, particularly for industries where there is a lack of existing training resources. Additionally, preference will be given to proposals that also guide executives to use due diligence to ensure that a business discharges its primary duty. Successful applicants will be able to access

NHVR Safety Survey measures improvements in key areas of industry safety management

The NHVR has released the Heavy Vehicle Industry Safety Survey 2022 report, which measures how the heavy vehicle industry manages its safety responsibilities.

“The results indicate there have been incremental improvements to safety across the industry, which in turn informs our forward-thinking work program,” said NHVR Chief Regulatory, Policy and Standards officer David Hourigan.

“One area the NHVR has worked tirelessly to deliver on since 2020 is greater awareness and uptake of Safety Management Systems and we’re encouraged to see an increase in implementation by businesses of this important safety tool.

To view the survey visit nhvr.gov.au/safety-survey

An all-time Australasian trucking classic was celebrated, as the Kenworth K220 was awarded the inaugural Truck of the Year Australasia.

On a balmy night at Archer eld Air eld in Brisbane, a group of trucks was unveiled, driving in line, out of the dark and into the doorway of a massive hangar, lled with the Kenworth faithful.

he excitement was palpable and the expectations were realised as the line of shiny new Kenworth K220 trucks nosed into the lights in the hangar, and the shadowy shapes became the new range of cabovers.

Less than 12 months later, on the opening morning of the Brisbane ruck how, the award for the ruck of the Year Australasia (ToYA) winner was being presented to amian methurst, recently appointed anaging irector of Paccar Australia.

am proud to accept the inaugural

ruck of the ear Australasia award on behalf of A A Australia, said amian. his award also belongs to our valued customers who, as a result of close collaboration with our roduct lanners and ngineering teams, represent such an integral part of our product development pro ects.

ased on the nternational ruck of the ear o rules, the annual award will be presented annually to the truck introduced into the Australasian market in the previous year, which has made the most significant contribution to road transport safety and efficiency. his udgement relies on several critical criteria, including technological innovation, comfort, safety, driveability, fuel economy, environmental ‘footprint,’ and otal ost of wnership.

“The Kenworth K220 is a massive

step change for the enworth brand here in Australasia, said im iles, ditor of PowerTorque aga ine and chair of the o A ury. he Series has been with us for a long time, evolving time after time, but both the K and definitely the , have seen complete transformations of a classic truck design. here are a load of new innovations in this truck, too many to list here but multiplex wiring, sophisticated electronics and the aton ndurant A stood out for the ury.

The launch of any Kenworth truck model is something special, so many of the trucks the brand produces have become iconic in the Australasian truck industry. he arrival of the had been widely anticipated, and there had been broad speculation about what was coming and some

dodgy leaked material on video and posted to acebook. othing this big can arrive without some seepage onto social media.

This is a truck which uses the same basic cab concept as the first Kenworths built in Bayswater in Victoria back in 1971, but with a cabin interior layout much improved, even when compared to the .

There’s also a large amount of new technology in the driveline. t s still the ummins , but the adoption of the A concept, where the engine and the aton A transmission communicate at a high level, is a significant advance.

There is even more sophistication on tap with the latest A from aton, the ndurant , which brings this orth American transmission into the same ballpark, previously only occupied by the uropean A transmissions.

Therefore it was with some excitement that im iles recently climbed up the steep metal ladder into the cabin of the new for a two day test drive hauling a double set from the KW HQ at Bayswater to Tamworth in rural New South Wales.

n this brave new world, where oadranger skills are no longer a given in the trucking industry, the aton ndurant , which is an all new box, developed as an A from the ground up, is a massive leap forward. his is the kind of A enworth need to enable their customers to help them cope with the skill levels at the younger end of the workforce. f course, there is still a manual option available in the Kenworth range.

he ummins fficiency Series is available from 550 to 580 hp k , while developing 2800Nm (2050 ft lb) of torque. These engines also include something called Hill Climb Assist, which uses an inclinometer to detect when the truck is heading up a grade and changes the shifting strategy on the A to suit the conditions and maximise the power available.

eanwhile, the erformance eries is much more like the traditional with power outputs from 525hp to hp k and with tor ue ratings from to m 2050 ft lb).

he big difference between the

At the end of the show a record turnout of 40,000 showgoers was announced, and those in attendance can attest to this fact after having to ght their way through the crowds in the narrower areas at the Brisbane

Apart from the, Truck of the Year Australasia winner, the Kenworth K220, the big surprise on the Paccar stand was the all-new DAF XG+, scheduled for release in 2024. This project is the biggest undertaking in DAF Trucks Australia’s history and involves combining the latest and greatest from Europe, with the power of the X15D, the next generation from Cummins.

This is what the heavier end of the DAF range has been looking for in Australia, more power. Rated at 660hp, it will be a DAF solution for the growing A-double, B-triple, and high-utilisation B-double linehaul segments. The final version will also be fitted with Airglide suspension and Meritor axles to achieve a 97t GCM.

Convention Centre.

“This is the first time we have had over 40,000 people through the doors over the four days of the event, said

that happening at its very best. ero emissions was clearly the overall theme and innovation in the halls, with Volvo having all of the

This year’s Brisbane Truck Show was the biggest show ever for the Heavy Vehicle Industry Association.

Hot off the press after its unveiling in Japan, the Isuzu N Series EV (electric vehicle), where it was launched alongside a complete renewal of the N series and F Series just a couple of months before, the Isuzu electric N Series took pride of place on the Isuzu stand in Brisbane.

The new electric models will range from standard cab models under 3.5t GVW to wide-cab models of up to 7.5t GVW. Battery storage comes in a variety of sizes, there’s 40kWh capacity, and the larger 60kWh capacity, and the wide-cab gets up to 100kWh capacity.

The show was the Iveco S-Way (a ToYA contender) model’s first official public appearance with two models, an AS (Active Space) 550 and AT (Active Time) 460. With Euro6 (Step E) engines, Hi-Tronix AMTs and a full suite of active safety equipment, these models bring the Iveco offering bang up to date.

Iveco also presented its latest off-road model, the T-Way, which replaces the Trakker range. Available in 4x4, 6x6 and 8x4 configurations and sharing innovations and technology with the S-Way.

Volvo released a complete electric range at the show. The 4x2 FL can store 375kWh, with three or four batteries, and achieve a range up to 400km, and puts out 177hp. Available as a 4x2 or 6x2, the FE can also store 375kWh but with a smaller range claimed to be up to 300km, with 306hp on tap.

The electric FM comes as a 6x2 or 6x4 and the maximum capacity from six batteries is 540kWh, offering up to 300km in range. The more rugged FMX offers similar performance to the FM, and both can put out 666hp.

Top of the range is the FH Electric, also either 6x2 or 6x4, and with the same driveline available as fitted to the FM, and therefore with the same performance levels available.

The all-new MAN TG3 range (a ToYA contender) is the first newly-developed truck generation for Australia from MAN in two decades The TGL, TGM, TGS, and TGX ranges introduce a wide range of efficiency and economy features.

The Fuso stand had a 510 Tipper, prepared by Daimler Trucks Gold Coast, alongside the regular 510 prime mover (a ToYA contender). The Shogun 510 uses a 13-litre OM471 engine from the Daimler Truck family, creating 510hp

fully Automated Manual Transmission (AMT).

“The Shogun 510 Tipper has been embraced enthusiastically by Australian customers

Brisbane Truck Show was the first public appearance of the Iveco eDaily, the first electric vehicle from the brand in ANZ markets. Iveco will be using its local engineering department in validating the new range using facilities within its Customer and Innovation Centre (CIC).

In other markets, the eDaily range is available in several van and cab chassis variants and with one, two or three batteries depending on configuration, with combined battery capacities of up to 111kWh producing power and torque of loaded drive range for local eDaily will be

and dog with more than 500hp as well as the aftersales support that comes with every Fuso,” said Alex Müller, Fuso Truck and Bus Australia Director.

Celebrating six decades of Australian manufacturing , Mack displayed a Super-Liner featuring a new fully integrated walk through 70” sleeper, and an optimised spec Mack Anthem 36” fully integrated sleeper.

“Our display at the show this year tells our best news to date,” said Tom Chapman, Vice President Mack Trucks Australia. “The addition of a 70-inch integrated sleeper really bolsters the Super-Liner’s credentials as a heavy haulage and road train hauler.”

“As part of our renewed focus, the Hybrid Electric light-duty truck has moved from a niche offering 15 years ago to a genuine purchase option for many fleets as it is the only Hybrid Electric product available in the market,” said Richard Emery, Hino Australia Vice President of Brand and Franchise Development. “It provides operators with a unique combination of lower operational costs, fuel savings, and emission reductions, while also meeting Euro 6 emissions compliance.”

Hino Australia’s customers will soon have even more choice with a range of new Alloy Tray and TradeAce Hybrid Electric Built to Go products available in Hino dealerships from July 2023.

Mercedes-Benz presented an all-electric duo. The electric eActros is focused on heavy-duty short radius distribution and development trucks have been working in select fleets in Europe since 2018.

The electric eEconic adds to the positives of the diesel Econic, which was developed from the ground-up to work in densely populated areas and is known for its excellent visibility, practicality and active safety features.

The next-generation eCanter’s new features include greater range, additional safety and a fresh interior and exterior design. The eCanter line-up has grown with a variety of different wheelbases, weight ratings and a choice of City Cab or Wide Cab.

The new design also features an eAxle, for the next generation eCanter, engineers have built the electric motor into the rear axle itself, so there is no need for a driveshaft, saving weight and reducing energy losses. A new eMotor has a maximum output of 129kW and 430Nm.

The new Scania 660hp V8 engine presents operators with two pieces of a puzzle, perfectly matched. Where 3300Nm (2433 lb-ft) of power and performance is combined with an all new Opticruise gearbox to deliver over 6% in fuel savings. Outstanding power, performance and driveability coupled with amazing fuel efficiency. The new Scania 660hp V8 is where emotion meets logic.

To find out more go to scania.com.au

continues to grow, including this locally engineered solution, based on the eight litre 360hp Quon, available with either an Allison automatic or ESCOT AMT.

The 11 litre UD engine now has increased torque and horsepower up to400 and 430hp. A redesigned turbocharger, low drag pistons and cylinder liners improve fuel efficiency for the Quon without compromising on driveability.

Hyzon Motors showed its Heavy Rigid truck platform at the show, it’s an Australian locally designed and built Hydrogen Fuel Cell Electric truck.

“We are building our zero emission heavy vehicles right here in Australia, using local skills, employing local people, and collaborating effectively with our colleagues across the globe”, said John Edgley, Hyzon President of International Operations. “Our vehicle development process is following a path of design, build and validation to make use of resources that are available in Australia and provide an opportunity to train new engineers and technicians.

Well-known industry face, Bill Gillespie reappeared as the General Manager-Light Vehicles for Foton Mobility. TheChinese truck maker is making progress bringing in a range of electric trucks to Australia.

The T5 Electric Truck comes with a five year/200,000kms warranty and can be driven with a car licence or light rigid licence. The D11 van has a 105kwh battery with a claimed 300km driving range and a 1480kg payload.

Road Train stood out on the Daimler. It features a 60-inch cab, a factorydeveloped bullbar designed to protect operation of the front radar unit used by

600hp and 2050lb-ft of torque. It can be paired with a 12-speed Automated Manual Transmission (AMT) with GPS

coasting and correct gear selection for the terrain. There is also an old-school 18-speed Eaton manual if preferred.

Western Star displayed the all new X Series , with the 47X, 48X, and 49X models on display for the first time at the show.

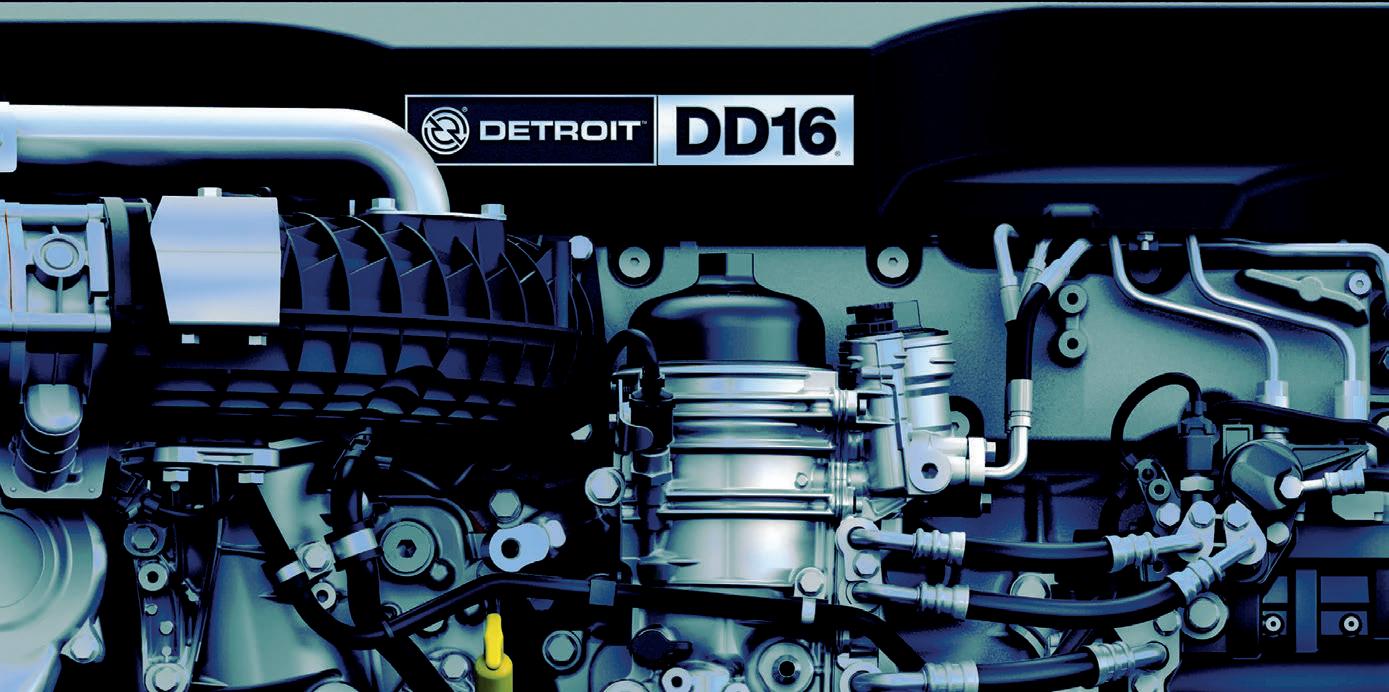

The 47X has a short, sloped bonnet, a set-back front axle, up to 72.5 tonnes GCM, and comes in either a 6x4 or 8x4 configuration and with the choice of Cummins or Detroit power under the hood. The 48X is powered by the Detroit DD13 Gen 5 or DD16 engine, is available to over 130 tonnes GCM, features a set-forward front axle, has a BBC of 113 inches, and a choice of four sleeper cabins. At the top of the range, the 49X is powered by the Detroit DD16, has 200 plus tonnes GCM capability, and is available with multiple cabin options.

At Mack, we’re proud of our long history of manufacturing trucks in Australia. Since 1963, we’ve been designing and building tough and smart trucks like the Mack Trident, the ultimate in versatility for line-haul and heavy construction assignments. Its axle forward configuration is perfect for tipper and tipper, dog set ups, and its Mack MP8 500hp or 535hp engine delivers up to an impressive 1,920 lb-ft of torque. On the road, Trident is the ideal combination of power and productivity. It’s capable of hauling up to 131 tonnes, and its intelligent design means it leads the way in fuel efficiency and driver comfort.

Make your own history with Mack, and talk to your dealer today, or visit MackTrucks.com.au/Trucks/Trident/

The Australian trucking fraternity has farewelled one of its long-term members with the passing of Paul Keast in January 2023, aged 68. Paul Matthei spoke with with Paul’s wife Helen and son Bradley.

Paul Keast is widely and fondly remembered as one of the industry’s true gentlemen, having dedicated his life to his beloved family and the Australian trucking industry to which he actively contributed with undivided loyalty right up to his dying day.

He began his truck driving career at the tender age of 17 and continued with it, unabated, for the following 51 years.

Paul’s first job involved driving trucks for his mother and stepfather, carting grain during the harvest season in western New South Wales. His father, also a truck driver, passed away when Paul was 17.

Around 1975 he decided to strike out on his own, buying a truck and starting a family business called P R & H M Keast that continues today, now run by his wife Helen, son Bradley, daughters Jodi and Tina and son-in-law Scott.

Being a quintessential family business, Bradley and Scott, both qualified diesel mechanics, take care of the truck and trailer maintenance in addition to driving, while Helen and Jodi are kept on their toes managing the dayto-day operations and administration.

“Paul was a very family-oriented man, a beautiful husband to me, and a wonderful father of our children and grandfather of their children,” his wife, Helen, fondly relates, stating that they had been together for over 50 years.

While in the earlier part of his career Paul owned and operated mainly North American prime mover brands including Freightliner, Western Star and Kenworth, his son Bradley helped convert him some years back to Scania and he remained loyal to the Swedish brand from that day forward.

Bradley explains that completing a diesel mechanic apprenticeship and subsequently working as a qualified tradesman for a number of years at a local truck dealership gave him significant insight into the different brands of trucks available in Australia and specifically enabled him to understand and appreciate the benefits of the European prime movers.

He says that while it took quite a while to convince his father to try a Scania, after his first drive he was sold on the brand.

“I organised a demo prime mover through Scania Coffs Harbour and we

did a trip to Melbourne; Dad drove his truck and I drove the Scania to Marulan and then we swapped trucks,” Bradley says. “After that I literally couldn’t get him out of it, so upon arriving in Melbourne, we swapped our bed gear over and he stayed in the Scania for the rest of the trip.”

Over the next few years, the North American trucks were replaced with four V8 powered Scanias, including the flagship of the fleet, an R770, which Paul proudly drove all over the eastern states of the country.

After his Dad’s passing, Bradley took the reins of the big Scania and the business, and, with the able assistance of his mother, sister’s, brother-in-law and loyal drivers and subbies, has been successfully running it ever since.

“Since Dad’s been gone I’ve been told by a lot of our customers that we’re doing a really good job and to keep up the good work, so I think everyone is pretty happy with how we’re doing things now,” Bradley says. “We’ve also picked up some more work, but we’ve had to sell one of the Scanias which had done over one million kilometres

because the high cost of fuel lately has been a real killer.”

Bradley also opens up on how life has changed for him over the last year or so now that his father is no longer around.

“Every time I go on holidays, I have to take the mobile phone with me because no one else wants to answer it 24/7,” he says, adding, “My brotherin-law Scotty is a brilliant help to me

with the maintenance of the equipment which is quite intense now that the Scanias are no longer on the Scania Maintenance Plan.”

Bradley also talks about the close relationship he had with his father and how hard it’s been for him to adjust to the ‘new normal’ following his sudden departure.

“I still wake up every day missing the old fella,” he confides earnestly. “As well as my father, he was my best friend and while we certainly had our disagreements, it was all over in 10 minutes or so and we’d be talking to each other again like nothing had happened. We never held grudges on each other and he would call me about 10 times each day just to check up and make sure everything was okay.”

While the heartache of suddenly losing Paul at a relatively young age continues, the Keast family is forging ahead with his beloved business, in the process carrying forward the legacy Paul left behind and doing their best to emulate the pride he held in everything he accomplished.

It’s not very often that the Australian trucking media get a chance to have a one-on-one interview with the global CEO of one of the leading truck manufacturers, but recently Tim Giles sat down with the man from MAN, Alexander Vlaskamp.

On a recent trip to Australia, MAN CEO, Alexander Vlaskamp, took time out to sit down and speak to PowerTorque about the MAN and Traton Group view of the trucking world. He was spending some time here meeting up with the team from Penske ANZ, who distribute the MAN brand here.

He also came to have a look at the Rhieinmetall facility in Redbank on the outskirts of Brisbane, where the large MAN-based military vehicles used by the Australian defence Forces are assembled.

After a career in several countries around Europe and Brazil with Scania, Alexander moved across to, fellow Traton Group brand operation, MAN, a couple of years ago. Although a relatively small player in the Australian truck market, in Europe MAN is one of the big six truck brands, all of which control between 15 and 16 percent of the total medium and heavy duty truck market.

“We always want to understand our customers and be be very close to where the marketplace is, and understand what the demands are short term but also of course, mid and long term,” says Alexander. “Our team here, Thomas Hemmerich covering Asia, together with Penske, we have

“We can lift our market position and we are making sure that we bring more of our MAN products to Australia. It really kicked off with the launch last year. It was really successful and now we’re delivering the first vehicles and getting a good customer reception.”

One of Alexander’s priorities is to work with the team from Penske, meeting with customers and the dealers as well as others on the front line to keep up momentum behind the launch of the TG3 models, which are starting to appear on our roads. Work is going into building up the network and getting it up to speed on the new technology and design elements in the new range.

“In Australia, every different segment, every different branch, what our customers are into, what they transport, you have to have the right vehicle for that, and have customisation too,” says Alexander.

think that has been worked through very well. Actually we do have the right fit, and are bringing it on board and combining it well with the service network.

“It’s about product and the right services, it is around the right financial services, also having the offer like Penske Rental. We have that in place for our customers so that we can focus on supporting them in their business

The strength, as Alexander sees it, of the MAN product is concentrated in the heavy duty segment. This is the sector where the brand has made headway in the past, interstate and intrastate, as well as urban distribution.

He also points out the MAN product on the medium duty side. However, as a truck manufacturer MAN has little experience slugging it out with the Japanese truck makers which dominate our medium duty segment.

“We have fantastic vehicles for distribution, and also for garbage collection, etc,” says Alexander. “That is where I think where we have the right product line. I would say it’s nice to compete with the Japanese. I think, for the drivers, it’s a real good feeling to be in a TGM or TGL and enjoy the comfort of a European cab. Basically, to have the space around you and be able to bring your food and other things for the day and not have to worry where to place it in the cab.

“When I spoke to some customers they said that getting drivers is not easy. In the distribution segment, there is also a good argument that you can get and retain drivers, if they have a comfortable working environment. I think that’s the name of the game in the coming years, to make sure that the product fits, that service fits, but

operating the trucks, the drivers.

“I think that we are hitting that well with our TG3. That’s where you see our TG3 design also goes into the medium duty trucks, where we don’t compromise, unlike other brands that in medium duty offer a ‘plain’ dashboard.”

The Penske organisation is working hard on training their staff and also recruiting additional staff. Potential customers and prospects can expect higher levels of engagement with the Penske team, with regards to the A offering.

“Penske has vast experience in operating in Australia, in various services businesses, with a very strong service mindset,” says Alexander. “Not only bringing through the product but also making sure we take care of the product over its lifetime, and taking care of the distribution network as well.

“I think that that gives us a lot of stability, and it’s good that we have a stable partner here, with their own retail units out there, being, not only an importer with sub dealers, but really being themselves with their direct interaction with the customers, and I think that is what Randall Seymore and

With up to 600 horsepower and 2,050 lb-ft of torque, the big bore workhorse provides efficient and dependable power and performance without compromise. Detroit’s advanced technology also means GHG17 requirements are met through innovative fuel efficiency resulting in lower emissions.

This power, performance and efficiency prowess is backed by our industry-leading warranty and extended coverage packages that ensures the highest level of support for our customers.

Combined with superior fuel economy and the absence of a midlife change out, the DD16 delivers an enviably low total cost of ownership and maximum uptime.

This is all backed by our well-established and extensive national service and support network which, together with our highly skilled factory-trained technicians, means you can count on getting the right advice when you need it.

With Detroit, there’s no compromise.

the Penske team are demonstrating,

“That’s really what makes this partnership unique, for us to operate in this world effectively. It is also good that we really worked out our plan to move forward, where we are also bringing in our outside team through the Australasian cluster, supporting them in the same time zone. Thomas Hemmerich is bringing a team of people here to work in the Penske network to actually be a support, with parts support and direct support, when it comes to training or when it comes to operating and connecting to our head uarters.

The expertise from around the Asian region on the MAN product will be bringing in experienced people to support the growing organisation here.

The development of the military trucks for the defence forces is also a partnership, in this case with Rheinmetall. The vehicles are delivered through Rheinmetall Military Vehicles, which is a joint venture between MAN and the truck builder. The process also involves a joint partnership, including Penske,

providing the network of service locations, where those Penske locations close to local military bases can look after the vehicles.

“We need to have a connection to the dealer, so that we can support the military in every area in Australia,” says Alexander. “We touched base here as well to make sure that this will work well for the years to come. The number of military vehicles gives us a good base for our network to be properly utilised and ensures our service locations are trained on MAN products because it’s an MAN drive line.

“This is supporting the experience of our service network. As a customer, if you have a breakdown, there’s somebody who knows how to fix it. We’re looking forward to actually getting to work on the commercial side and to be as successful on the civil side, as we are on the military side. On the military side, we have very high market share, in that sense.”

The number of MAN drivelines in Australia has risen steeply in recent years as over 3,400 Rheinmetall trucks have been handed over to the military. All of these need regular servicing and will mean more

personnel in the Penske workforce have hands on experience with the A product.

Those Penske dealers around the country will have seen the slow shift across from a preference for American trucks to a European brand and some regional branches and dealerships may not have seen many MAN trucks, but will have seen the military vehicles and started to get their head around the philosophy behind European truck engineering.

The Rheinmetall relationship has seen Penske develop strongly in areas like Toowoomba, parts of regional Victoria, Townsville, Cairns and Darwin, because of the large numbers of military vehicles based in those areas.

In the all wheel drive off highway market, MAN has historically been very strong all around the world. They have been less so in the conventional semi/B double segment. The new product will still mean include MAN all wheel drive, six by six, eight by eight or eight by four with high clearance will continue to sell.

The visibility of the large number of military vehicles around will be a testament to the utility of those trucks. Demand is forecast to increase in the B-double/A-double and to certain extent in the semi market. MAN expects it’s going to be playing in that space in that 400 to 600 hp sector.

When looking at where serious growth is going to come from, the brand is planning on aggressively targeting medium and large fleets, which are running East Coast Australia overnight. The improvements in the TG3 product should get the level of driver acceptance and therefore fleet acceptance, alongside the kinds of total cost of ownership fleets are looking for.

Penske has been increasing the reach of its Penske Rental outlets and working on a mix of company owned dealerships and privately held independent dealers, helped by the Rheinmetall relationship. There is now a new dealer development team inside the business, identifying black spots and addressing issues with the network.

tt erthe driverorthejob , theEnd ur ant Series fr omEa ton Cummins has the automated transmission for your fleet. Each product reflects our commitment to best-in-class fuel efficiency, performance, and uptime.

In recent years the number of trucking operators looking for fuel savings has multiplied and truck manufacturers have come to the party with new offerings which take fuel consumption down to levels never seen before. Scania has entered the market with the Super models and Tim Giles took a couple of examples out on the road to see how the magic happens.

The European truck makers have been leading the charge in the race to bring fuel consumption down for Australian operators. Mercedes Benz got the ball rolling with the new Actros in 2016, Volvo developed the iSave concept, then Freightliner used the Daimler driveline to bring the idea to the US truck sector. Now Scania have taken the idea to the next stage, developing a new engine and transmission to further reduce fuel consumption.

Over the years, Australian truck operators have paid lip service to the idea of saving fuel, without putting fuel use top of the list when it comes to the criteria for buying a truck. However, with the level of savings now available with these modern frugal trucks, the rationality of prioritising fuel burn has taken hold and is yielding tangible results.

In this truck test, PowerTorque took two Scania Super models out for a quick run. There was a Scania 460P Super pulling a single trailer and a Scania 560R Super pulling a fully loaded B-double set. For some reason the Swedish truck maker has swapped the cab classification from before to after the horsepower number, but only

on the 13 litre engines and below, not for the trucks with V8 engines, why?

The return of the Super name is a logical choice, it has been used historically by the brand when new engines were introduced and was often written somewhere on the front of the truck, in the past. The 13 litre engine in the two trucks tested is an all-new engine for Scania. This test drive included the 460hp version and the 560hp version, which is taking the 13 litre into unknown territory.

“This is a new engine and it has changed from the bottom end to the top,” says Benjamin Nye, Director of Truck Sales at Scania Australia. “With a 23 to one compression ratio, this reduces inefficiencies in combustion from a gas exchange perspective. An interesting fact about this engine is that it has cracked 50 per cent brake thermal efficiency.

“That’s how far we’ve had to push diesel to get to this level. Double overhead cams is a big departure for Scania. Normally, we have used pushrods in the individual heads in the past. Everything’s had to be strengthened to cope with the new compression ratio. Hence the all new engine.”

Scania has stuck with tried and tested technology, There’s no VGT or turbo compounding, the designers have simply put together a stronger design with conventional components which can cope with a higher compression ratio.

There’s no EGR, but a two-stage SCR, the main dose is injected just after the turbocharger exhaust outlet near the exhaust brake flap where the exhaust gas is hot and turbulent. This better atomises the AdBlue for a more efficient clean up of NOx.

High compression engines tend towards higher ignition temperatures, in cylinder, leading to higher NOx and lower PM in the exhaust flow. Therefore a more efficient SCR system is needed and PM levels are more easily controlled.

Maximum torque on the 460 engine is available from 900 rpm at 2500Nm (1850ft lb) and that is available up to 1280rpm. 1300rpm is the point at which the power curve flattens out before rising slowly to maximum power

between 1700 and 1800rpm.

On the 560hp version of this engine the torque maxes out at 2800Nm (2065ft lb) which is up there, in terms of torque, with many of the 15 and 16 litre engine available.

“To put it in perspective ,at 2800Nm it matches a 2658 16 litre Benz,” says Ben. “It matches an FH 16 litre Volvo and it out-torques an X15 at its top horsepower rating. So it’s huge torque.”

PowerTorque asks Ben whether asking for 2800Nm out of a 13 litre engine is pushing the 13 litre engine too far. His answer is an emphatic no.

“That is the first horsepower rating for that engine, that was the first one that got developed,” says Ben. “The engine is designed to do it, we’ve done that through smart engine design, not seeing how much boost and fuel that we can jam down its throat. It’s been done from a fundamental engine design.

“Plus, we still offer a 16 litre in the V8. So people have that opportunity, if they want capacity. We do find in certain applications, the old adage ‘there is no replacement for displacement’ comes into it. I strongly believe when you start getting into the heavier weights, that is the realm of the 590hp 16 litre. Scania work with our customer base to make sure that we’ve put the right truck in the right job.”

That right job for the 13 litre is expected to be interstate, intrastate and local B-double, plus some A-double work and probably road train in WA. Testing and studying fuel use data on

these heavy duty cycles is helping to find the point where the V8 engine becomes more economical, because it’s doing it that bit easier.

In a change which took many by surprise Scania have broken with a very long tradition and developed an AMT without any synchros. Opticruise has been though many iterations, always with synchros, but this new box is a revolutionary and not evolutionary step-up.

The reduction of 75kg in the engine weight is complemented by going over to a basic crash box which means the simplifying of the AMT design, so now it’s also 75kg lighter on the 460R. The casing is no longer steel, but cast aluminium not cast iron plate.

The higher rated AMT fitted to the 560hp 13 litre engine, and also to the higher horsepower V8 engines from Scania, is 60kg lighter than the previous gearbox. This is still a considerable weight reduction.

Another change in the AMT design sees Scania going away from its old reverse gear design and instead the AMT locks the planetary gear in the back of the box for reverse and the driver has, theoretically as many reverse as forward gears. In actual fact the system limits the driver to just four reverse gears. However, for certain tasks Scania can make eight available.

Front axle weight has always been Scania’s achilles heel in the Australian truck market and this new engine and

gearbox tare weight gives the brand more leeway in chassis layout design, as a result.

As part of the fuel saving design the AMT will only go up to 12th gear in hilly country, keeping it in direct drive. When the topography is a little smoother, it will revert to the overdrive 13th top gear. In that top gear, at 100km/h, the engine is running at 1180rpm, very low level historically, but Scania reckon this engine can handle it.

On the 460P test drive from Melbourne along the Calder Highway towards Bendigo and back, the truck held its 100km/h cruising speed quite well, dealing with the small rises using changes in strategy to maintain speed, and remain frugal on fuel.

Coming into a steeper grade at 100km’h the speed started drifting down, holding onto overdrive at 1000rpm. Then it grabbed a gear to drop to the direct drive 12th gear. As the incline steepens the rpm levels got down to 1100, before the next change. As it was getting steeper the truck held well at 70km/h.

Even on the tougher gradient, the AMT still let rpm dip below 1200 before making the change down a cog. As it dropped into 10th gear, it settled at around 1450rpm and felt it would be able to hold onto that all of the way to the top. The engine and AMT got themselves into its sweet spot when doing about 56km/h in a fully loaded semi, on quite a steep grade.

In terms of the the programming

for this gearbox and the engine management etc, there are three levels to choose from: economy, normal and performance. Unlike in the smaller engines, Scania has found that the calibrations of these programs from Europe also work well in Australian conditions.

Back on the flatter sections the truck settles back down to cruising speed sitting between 1100 and 1200rpm. For me, as as a driver, who started driving in the seventies, this sounds like the engine is not working but that’s just in my head. In fact, it is quite hard to hear the engine at all, this new engine is clearly quieter than its, already quiet, predecessor.

Later that day, hauling the B-double up the same grade with the 560R, the engine hit its straps at 50km/h at just over 1400 rpm. The variations in the grade brought the speed down to 45km/h, but there was no need to change down a cog. It was a smooth uneventful climb with a loaded B-double.

The new engine and transmission are not the only thing which has changed on the Super, there’s also a new fuel delivery system from the diesel tank. The new fuel system is claimed to pull 97 per cent of the fuel from the tanks compared to the 85 per cent which could be practically used in the past.

There is a fuel optimisation unit fitted to the main fuel tank. It contains a fuel filter, a lift pump, and 27 litres of diesel and the engine is always pulling from that 27 litres of diesel. This

enables the system to pull more diesel out of the tanks without overheating the fuel or sucking in air. It works as a kind of holding tank and it enables operators to maximise the capacity of fuel they can use.

This new engine sees Scania going away from the modular engine concept, where, whether you had eight cylinders or six, they were all the same cylinders, pistons etc. The new design’s twin cam heads cannot be fitted to the V8 engines as it would make them too big dimensionally.

The move across to overhead cam in this engine came because Scania found efficiencies within overhead cams in getting air and fuel into the engine and the exhaust gases out. Also, running an engine brake creates too much complexity and overloads components within the engine, it’s much simpler with an overhead cam..

The fuel savings available with these engines is claimed by Scania globally to be around the eight per cent mark. Some will get more and some may get less. There will also be a corresponding increase in AdBlue consumption, probably around three per cent. How this plays out will vary with driver behaviour and freight task, but if Scania are saying eight per cent, then that level of saving, and more, should be possible.

This engine is the one which Scania’s owners, the Traton Group, are putting into the International trucks in the US truck market where low fuel consumption is the only way to sell an engine. The kind of numbers achievable there mean there are going to be plenty of these engines in truck on highways around the world.

Questions are going to be asked by potential buyers of this truck about the high compression ratio, which might make them wonder about the durability. It might be compromised, time will tell. However, it would be very unlike Scania to go out on a limb on such an important development for the brand. With the kind of fuel and mass saving available with these trucks, the calculations are going to be relatively easy, as to how effective it may be in a freight task.

ith the speci cation of the Freightliner ascadia the rand ha e rought a truck hich is a genuine dou le prime mo er ith no compromises in ol ed Tim Giles takes one for a spin to see ho it performs

In the speci cation driven for this truck test, the reightliner ascadia is tted with the sleeper cab and, correctly coupled, this prime mover can pull pallet double curtainsider set and stay inside the metre envelope. ver since the double allowance was extended from to metres, the makers of conventional trucks have spent a lot of time and research dollars trying to shoehorn their typical conventional prime movers, based on original design concepts from orth America where length

is never an issue , into the space in front of a palleter.

he denomination is the inches between the bumper and back of cab and ust to make sure you remember this, the number is written in letters a metre high down the side of the cab. he wheelbase is , mm and has a factory fitted bullbar that keeps the dimensions inside the envelope.

ften this kind of exercise has led to compromises with cab interiors feeling cramped or ust difficult to move around in, and for a driver trying to rest in the bunk. ome have been

more successful than others, but none have come up with a truly suitable solution. hat being said, this design of the ascadia does get reightliner uite a bit further down the road to the perfect solution and there is plenty to commend this ascadia.

he arguments for a conventional double prime mover have always been the same. ith the driver sitting further back from the front wheels there is less of a tendency for the prime mover to nod out on the highway when its under power and working hard. onventional prime

movers feel more stable, especially on rough road surfaces, and we have plenty of them in Australia.

Alongside precise dimensions, the other deciding factor in the choice of double prime mover is the power and tor ue available to the truck. auling up to tonnes does put a strain on a driveline. Also, for many operators, many tasks are moving cross to the use of A doubles, occasionally or more regularly, this puts more pressure on the driveline at tonnes .

he engine at the heart of that driveline is the etroit rated at hp and at ft lb of tor ue, right in the sweet spot many look for in this kind of application. hoices range down to hp and ft lb, but reightliner are finding that the specification at hp and ft lb of tor ue is suiting many of the operators running these trucks in double applications. he hp versions are chosen by operations where the trucks are up on their weights most of the time.

ehind this is the etroit A , but there is still an option for traditionalists of an aton speed oadranger. owever the predominates, with the oadranger chosen often in rural locations or for heavy haulage.

n the back end there s the eritor rear axles with a final drive ratio of . , a common choice for a orth American truck in Australia with the A , whereas the oadranger is normally coupled with the . ratio.

ut on the highway in the s top gear, km h sees the engine running at ust over rpm. At rpm the engine reaches peak tor ue and maintains that tor ue up to rpm. his means that the engine is producing maximum tor ue most of the time while out on the road.

his driveline uses the eco roll function when it realises there is an opportunity to disengage the clutch and coast, dropping the revs down to . he driver has control of the sensitivity and can ad ust the speeds

driver thinks it s coasting too often, they can reduce it.

he etroit used with the litre is now the option which includes an off road mode. n this mode, on the bottom six gears there is extra tor ue launch available, plus a rock free mode which enables the driver to put power on and off to rock the truck out of a hole, with a power on and then clutch off action.

here is also adaptive cruise control available and it s relatively simple to ad ust the following distances as you drive along. f course there s now the obligatory, and soon to be mandatory, automatic emergency braking, and this along with the adaptive cruise control are standard. All of the other add ons remain optional, including lane keeping assist and sideguard assist.

rom the point of view of this driver, would be happy if all of them were available all of the time. es, you do get some false positives sometimes, but you never get false negatives.

or someone without much familiarity with the ascadia, a driver simply has to fold down the sun visor and take a shot with their phone of the code placed there, this sends them to a series of instructional videos on all of the control systems in the truck. verything from connecting to bluetooth, to using the gear control stalks, to ad usting the seat, and more is covered. A simple solution for a driver who is unfamiliar with the way the truck works.

his may well be needed when trying to drive the in cab display unit directly in front of the driver. he screen is set in the middle of the dash. here are plenty of menus to scroll through and a number of options as to what is displayed when driving.

his version of the ascadia is fitted with the all digital dash. asically, it looks like two large i ads, one directly in front of the driver and the other on the central binnacle. All of the essentials sit in front of the

driver, with an information screen in the middle, where optional read outs can be selected, like average fuel consumption, digital road speed or radio station selection. he overall look of these screens is very functional with a hint of tar rek.

he central binnacle screen gives you a read out of the less essential data, with a navigation and entertainment system included. All of the early models of the ascadia came into the country with the old fashioned analog dash, which still included the information screen in front of the driver. ow, the less conservative early adopters are starting to option the screens, but analog still predominates.

f course, they are all digital, but it s a matter of perception, for many.

ven with all of this technology and sci fi screens, it s still an old fashioned layout. aving the key right down by the right knee and the old style lights switch. Although the light switch now has an A on it, so automatic lights activation is fitted. he wipers can also be set to auto.

he steering wheel has the obligatory array of buttons and it does take time to get which one does what and when. owever, after a while the hands tend to remember where to go for the cruise control etc. hese buttons also control what you can see on the screen directly in front of the driver, while the entertainment screen is a touch screen.

ne for the traditionalists, is the maxi brake set up, the is not going to stop re uiring them any time soon and reightliner are not heading down the electronic parking brake road at this point. here may be legislation in the pipeline in the , so if this eventuates, reightliner will probably include it, as it will simply be another component to come across from the current en product.

As with any multiplexed truck all of the main switches are configurable and can be placed in the operator s preferred positions. here is a mix of modern switching linked to the A bus and more traditional separately wired options like beacons. nder this inch bunk, the roll out fridge is an option. here s also a set of controls in the bunk area, for air

We deliver confidence. We deliver it by the truckload, because we know companies can’t thrive without it. Penske is built around helping your day-to-day operations run as smoothly and efficiently as possible. Our commercial rental solutions will help you carry the load so you can focus on your core business.

conditioning, lights etc. uyers can customise the cabin interiors, if they so wish, with wood grain paneling and when you get up into the bigger and inch cabins, raised roofs and a number of cupboard and storage options come into play.

own the track there s going to be iterations of the ascadia which embrace more technology and models developed to suit market niches. t will pick up a lot more from the aimler family, e uipment now available from the ercedes en range. he American conservatism will see reightliner running behind. reightliner should be able to pick and choose from the array of new technology and if sentiment is moving towards hi tech, the truck maker will already have it available on the components shelf.

ne of those technologies which will probably finally arrive will be mirror cam. his has had limited

the en option, as the sloping A pillar does make it more difficult to fit, than on the more upright A pillars elsewhere in the the aimler product range. he fact that they will improve fuel efficiency means there will come a point when fitting them will certainly come into play.

he is not a big seller for reightliner elsewhere in the world, and this means the and litre etroits are being developed faster, as the top sellers on the market. he is on en , while the two smaller engines are already on en . anada and Australia are the biggest users of the litres, so there is a large enough sales volume to ensure further development down the track. o, there will be a more fuel efficient generation coming along for the litre.

here have been ma or updates on the transmission already this year, further refining the system. etween seventh to th, the A no longer uses the clutch, leading to

his is one of those models brought into the Australian truck market where the truck maker has looked at the task the trucking operator needs to perform and honed the design down to what is needed, at the same time as fitting it into the dimensions it needs to be to remain legal.

he ascadia does tap into a long held preference for a conventional truck in Australia, but the uropeans have been going forward with great strides meeting the needs of the double operator. he one thing the cabover struggles with in terms of driver acceptance is the si e of the cabin and the bunk.

his ascadia does fit the bill for a prime mover in front of a pallet double set, but in getting into the envelope it does end up with a bunk of similar si e to the uropean competition. f it has one advantage over the growing number of uropean prime movers

The 126 denomination is the 126” BBC and just to make sure you remember this, the number is written in letters a metre high down the side of the cab.

With undisputable road presence and trusted reliability, there’s no place you’d rather be than behind the wheel of a Kenworth.

Keen observers may have noticed that the truck formerly known as a ‘hybrid’ is now to be known as a ‘hybrid electric’. This is because Hino is promoting the range as a rst step on the road to zero emissions. As something an operation can do now to reduce its carbon footprint before the, in development, zero emission solutions start to appear in numbers and become cost effective.

Late last year Hino decided to reemphasise the advantages of the hybrid platform and promote the technology as a first step solution for those looking to decarbonise their fleets.

“We’ve gone from an average of 50 sales a year, that’s the most successful low or zero type emissions vehicle

to be sold in the commercial market over the past 15 years,” says Daniel Petrovski, Department Manager, Product Strategy for Hino Australia. “We’ve got over 700 of them already on the road. We’ve got orders coming in this year and have exceeded 300 vehicles already. We’re expecting that we’re going to see a massive shift and will be hitting 500 plus orders by the end of the year.

The objective of this truck test was a simple one. Tim Giles would drive a hybrid electric truck around a typical urban delivery route in Sydney followed by an identical truck powered only by diesel. Measuring the amount of diesel burnt over the journey for both trucks would give the amount of difference in overall fuel consumption and also the reduction of

CO2 going into the atmosphere.

Driving style can effect fuel consumption on any kind of propulsion, but we were looking for a best case scenario and drove to try and minimise fuel burn, both on the hybrid and diesel truck.

For the trip around Sydney, in traffic most of the day, the trucks covered 82km, over roughly three or four hours of driving. The diesel 300 Series used 13 litres, while the hybrid used about 10 litres.

More precise measurement from the onboard electronics brings the result to 6.329km/L for the diesel versus 8.265km/L for the hybrid. This is a reduction in fuel burn of 30.58 per cent. Of course, this also equates to a reduction of 30.58 per cent in carbon emissions.

There is a lot of buzz and speculation going on around zero emissions vehicles, but you can make a start on the process and reduce emissions now by using a hybrid electric truck. PowerTorque took to the road to quantify just how much it is possible to save.

Over the 82km, which is probably half a shift for a truck like this. Calculating from this relatively small experiment, it is possible to calculate the kind of savings available over a year for a hybrid compared to a conventional diesel.

Of course, Hino won’t give precise figures for lease payments on the two different technologies, but we know there is a premium on a hybrid truck over the diesel, and that commonly works out at around a 25 per cent price premium for the hybrid version.

The test run would probably, in practice, equate to a truck doing just over 41,000km a year in a similar application. The hybrid should be able to save around 1500 litres of diesel a year at that rate. If you are counting, that’s a reduction in carbon emissions of well over 300kg. Going on current fuel prices, that’s up to $3000 less spent on fuel and that will be clawing back that hybrid premium, from the first month.

Daniel suggests the maintenance costs on the hybrid will be $60 a month less than for the diesel. The engine is working less hard and the

electric power component needs less maintenance. Brakes should last longer, when the battery regeneration helps retard the vehicle when slowing down. The calculation will come to break even territory between four and five years into the truck’s life.

The average Hino buyers tend to get a truck with a five year finance package, and then keep the truck for seven to ten years. In that scenario, a hybrid has probably saved the buyer most of the initial hybrid premium by the end of the finance agreement, and will definitely be either level pegging or better off over the whole period of ownership with a hybrid.

This is the kind of detail the Hino team are going into with clients now, telling them there is an advantage in buying hybrid over a diesel now, with the added benefit of being seen to be trying to do something about global warming. Plus, if the price of diesel looks set to climb higher then the logic behind a hybrid purchase. just gets stronger.

Hino is the only truck maker active in Australia with a hybrid option, and their competitors will be pushing the jump straight to battery electric

vehicles (BEV), missing out on this first step. The fact is that the hybrid is available now, and can start to offer real fuel and carbon savings now, but the BEV is still an expensive item, with limited infrastructure for recharging and with no clear picture of pricing or possible subsidies.

As a driver the experience of taking this truck around the city is a relaxed one. The response from the truck is smooth and comfortable with the fact that there is an electric motor and batteries involved in the driveline, simply making the whole process of speeding up and slowing down much less stressed, The bonus is the engine shutting off as soon as the truck is stationary, it’s the serenity.

Out on the road the AMT will make precise gear changes when the truck is setting off. Sometimes, there’s something a bit ponderous about it. As the driver takes their foot off the brake, the AMT has to be in neutral, engage the clutch, start the engine, disengage the clutch, select the gear, then move off.

There is a cure for this on the part of the driver, if they take the foot off the brake, as the car in front’s brake lights go off, then the truck will set off at the right time and keep the queue moving. This is because, if the engine’s running when the car immediately in front sets off, it’s good to go.

These are the sorts of things the driver will have to do to make the

is probably both the hybrid’s strength and weakness.

This technology makes it possible for a motivated driver to put in some effort and probably get a better saving than this PowerTorque test achieved. However, give it to a driver with a heavy right foot and no incentive to save fuel, then the premium on the hybrid price is going to take a lot longer to be paid down.

Looking ahead into the trucking crystal ball becomes difficult, as the fast changing technology emerges, gets developed and is finally released to the market.

That kind of calculation became all the more difficult after the recent announcement of a merger between Fuso and Hino, where Toyota and Daimler will form a single entity to bring the next generation of technology forward for both brands.

“Fuso and Hino will merge on an equal footing and collaborate in the areas of commercial vehicle development, procurement, and production,” said a statement from Daimler and Toyota. “They will build a globally competitive Japanese commercial vehicle manufacturer.

Daimler Truck and Toyota will equally invest in the (listed) holding

company of the merged Fuso and Hino. They will collaborate on the development of hydrogen and other CASE (Connected/Autonomous and Automated/Shared/Electric) technologies to support the competitiveness of the new company. Until those solutions eventuate, the Australian truck buyer can make a start down the lower carbon track with a hybrid option, and wait until the

The Australian-exclusive 48X is the perfect partner. Featuring a set-forward front axle, powered by a Detroit DD13 Gen 5 or DD16 engine, with a fuel tank volume of up to 1,500 L, over 130 tonnes GCM, and a BBC of 113", the 48X boasts up to 600 hp and 2,050 lb-ft. Available with a choice of four sleepers and in a 6×4 wheel configuration, the 48X is just right for any B-double application.