Future proofing irrigation with water recycling

Rewriting

the

code for HVAC pump selection

How to get the most out of your centrifugal motor

For 80 years Warman has been at the forefront of pump technology. The second generation WGR® is no exception. We’ve listened to what you need and innovated to create a pump that works harder than ever. The replaceable impeller and liners are manufactured using Linatex ® premium rubber, a proven performer in the sand and aggregate market. Plus the streamlined slurry flow path reduces recirculation and energy consumption, making this the best pump we’ve ever designed for sand and aggregate sites. Visit www.warman.weir to learn more.

Pump Industry Australia Incorporated PO Box 55, Stuarts Point

NSW 2441 Australia

Ph/Fax: (02) 6569 0160

pumpsaustralia@bigpond.com

PIA Executive Council 2018

Dave Alexander - President KSB Australia

John Inkster - Vice President Brown Brothers Engineers

Kevin Wilson - Treasurer/Secretary Executive Officer

Keith Sanders - Councillor Executive Officer - Marketing & Statistics Life Member

Alan Rowan - Councillor Executive Officer - Publications & Training Life Member

Ken Kugler Executive OfficerStandards Life Member

Ron Astall - Councillor Astech Technology

Mike Bauer - Councillor Dynapumps

Andrew Black - Councillor Envirotech Water

Malcolm Eyre -Councillor Franklin Electric

Ashley White - Councillor Davey Products

President’s welcome

We are well and truly into 2018. One moment I am enjoying camping at Byron Bay with the family over Christmas, and the next, Easter is here.

It is good to see your Pump Industry Australia team already working on technical meetings, seminars, installation commissioning courses and more. These take a lot of work, and I am sure you appreciate the effort the PIA committee put in to ‘make it happen’.

I had the opportunity to attend the first PIA Technical Meeting 2018 in February. This was held at Kelair Pumps.

Kelair’s Jeff Greely gave an update on Kelair and Brown Bros activities, and a tour through the workshop. Great to see the passion Jeff exudes for the work he does.

Paul Bannister and Alex Zeller from Energy Action Group, gave a very interesting presentation on changes to the NCC 2019, with considerable discussion on compliance, among attendees.

We appreciate both gentleman making the effort to travel up from Canberra to present and update PIA members.

Keith Sanders took the opportunity to update members on the changes to AS2417 – 2001 from a 9906-2012.

Keith focused on the key changes, and once again, another interesting presentation.

The PIA wishes to ensure there is industry awareness for the changes to the standard.

After the meeting, it was great to network with PIA members, having a drink and some food.

As I write this, it has been raining most of the night, with more rain on its way. This coming after several weeks of an intense heat wave through Southeast Queensland.

Listening to talk-back radio coming into work this morning, you realise how big of a country we live in.

The presenter had a lady ring in from Far North West Queensland, and talk about how bad the drought was where she lived and the impact it was having.

It’s the same predicament in parts of rural NSW where they need rain.

But there are parts of Southeast Queensland where it is forecast to receive more than 200mm of rainfall over the weekend.

For our farmers and anyone working in rain-dependent industries, I am sure it is a challenge.

I certainly know it is for my brothers who have farms in different locations (1600km apart) on the east coast of Australia.

But these weather challenges also give opportunities for the Australian pump industry, to get water from one place to another with the focus on doing it the most efficient way possible.

The PIA team has already had several conference calls and meetings this year. And we have a packed calendar ahead of us.

We are positive that you and the companies you work for will benefit directly from these PIA activities.

As such, I encourage you to regularly visit the PIA website, pumps.asn.au, to keep up with PIA events and happenings in your area.

Here’s to pumping, Dave Alexander

Many options, quick choice.

ERV-BR : Rubber Expansion Joint for abrasive Media

ELAFLEX PACIFIC, a daughter company of ELAFLEX Hamburg in Germany, is the supplier of the Elaflex product range: ZVA nozzles, rubber hoses, couplings and ERV expansion joints along with MannTek Dry Disconnect Couplings in the Pacific region, including Australia, New Zealand and the Pacific Islands.

The ELAFLEX ERV-BR, rubber expansion joint has been created specifically for abrasive media and is perfectly suited to the aggressive nature of sludge dewatering, mineral processing and the transfer of many types of slurries. Our online configurator is the perfect tool to get a fast and efficient overview of the product you require. Try it at

http://ervconfigurator.elaflex.com.au/

pumpindustry

Cover image highlights the feature on water infrastructure upgrades being undertaken by Parkes Shire Council to future proof irrigation and water supply.

proofing irrigation with water recycling 4,358

Published by Monkey Media Enterprises

ABN: 36 426 734 954

PO Box 1763

Preston South VIC 3072

P: (03) 9988 4950

F: (03) 8456 6720

monkeymedia.com.au

info@monkeymedia.com.au

pumpindustry.com.au

magazine@pumpindustry.com.au

Publisher: Chris Bland

Editor: Lauren Cella

Senior Associate Editor: Jessica Dickers

Journalists: Elisa Iannunzio, Nicole Valicek, Kirsty Hutton

Marketing Director: Amanda Kennedy

Marketing Associate: Sam Penny

Marketing Consultants: Rima Munafo, Katie Chancellor, Helena Brace

Production and Customer Service:

Titian Bartlau

Senior Designer: Alejandro Molano

Designer: Jacqui Abela

ISSN: 2201-0270

PIA MEMBER NEWS

This magazine is published by Monkey Media in cooperation with the Pump Industry Australia Inc. (PIA). The views contained herein are not necessarily the views of either the publisher or the PIA. Neither the publisher nor the PIA takes responsibility for any claims made by advertisers. All communication should be directed to the publisher.

The publisher welcomes contributions to the magazine. All contributions must comply with the publisher’s editorial policy which follows. By providing content to the publisher, you authorise the publisher to reproduce that content either in its original form, or edited, or combined with other content in any of its publications and in any format at the publisher's discretion.

MOTORS AND DRIVES

Construction will soon begin on a new $52 million wastewater facility in Murray Bridge, South Australia. John Holland has been contracted to carry out the work which includes the construction of a new underground pipeline connecting the plant to the township, new pumping stations along the pipeline route, and the gradual decommissioning of the existing treatment plant adjacent to the Murray Bridge Marina.

The site is located around 10km south of the township, set back from Pfeiffer Road opposite the Brinkley Waste and Recycling Facility.

SA Water’s Senior Manager of Community Engagement, Matthew Bonnett, said a new treatment plant for the regional centre will provide numerous benefits for the local community, environment and SA Water.

“Since the existing treatment plant began operating in the 1970s, the population and needs of Murray Bridge residents and businesses have changed significantly. We are updating

our operations to align with community growth and activity,” Mr Bonnett said.

“The plant currently treats around 2.6 million litres of sewage a day, with 100 per cent of it recycled for irrigation use at a Department of Defence training area and a nearby pastoral property.

“The new plant will have a daily capacity of around 5.6 million litres to continue these operations and accommodate expected future growth in the area.

“Enhanced treatment processes and odour control facilities will also help minimise odour from the new plant.

“Moving the plant away from the River Murray floodplain and residential areas will improve its environmental performance by eliminating the current source of odour and the potential for discharge into the river during high flood events.”

Construction is expected to start in August 2018 with the facility expected to begin operating in early 2020.

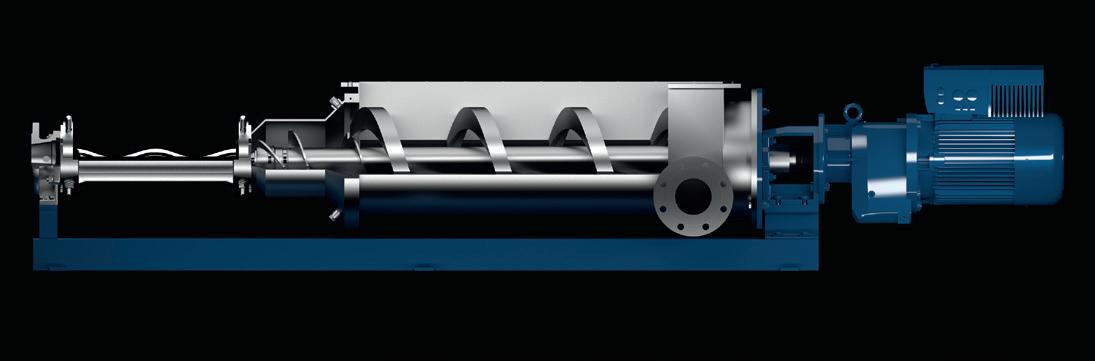

MORE EFFICIENCY. SMART CONVEYING TECHNOLOGY.

Pressure: up to 8 bar

Downtime: drastically reduced

Maintenance: simple and quick

Energy use: significantly reduced

Rotor and stator life:

Australia’s first seawater pumped hydro plant reaches next stage

The Australian Renewable Energy Agency (ARENA) has announced it will provide an additional $500,000 in funding to EnergyAustralia for the next stage of the 225MW Cultana seawater pumped hydro plant in South Australia.

The $8 million feasibility study will help advance the project to a final investment decision, and will involve the completion of project design including geotechnical investigations and equipment specifications, environmental impact studies and grid connection works.

ARENA previously provided $453,000 for the initial feasibility study which found the proposed Spencer Gulf plant was technically viable and could generate 225MW of electricity with 1770 MWh of storage equivalent using seawater as the storage medium.

If built, the Cultana facility would be the largest seawater pumped hydro facility ever constructed in the world, and the first in Australia.

A 30MW plant was built in Okinawa in Japan in 1999, and operated for 17 years.

The South Australian Government has also commited $500,000 to the feasibility study.

ARENA CEO, Ivor Frischknecht, said the next stage was an important step in building Australia’s first seawater pumped hydro plant.

“This pioneering project aims to build Australia’s first ever pumped hydro using seawater and could open up the potential for future seawater pumped hydro around Australia. Pumped hydro is the most common and mature form of energy storage which has been traditionally used in rivers, but seawater has the benefit of having no impact on rivers and no need to construct lower reservoirs,” Mr Frischknecht said.

Mark Collette, EnergyAustralia Executive – Energy, said Cultana would be a great achievement for pumped hydro in Australia.

“Pumped hydro is really a way of storing energy so it can be used when it’s needed, like a giant battery. Finding ways to store energy will be critical to Australia’s transition to cleaner energy so it’s great to have ARENA get behind the project with funding toward the next stage of its development.

“We’ve got a lot of work ahead of us this year with detailed design and engineering, community engagement, environmental assessments and approvals, but we’re excited about the potential for seawater pumped hydro to play an important role in Australia’s future energy mix.”

prosecution proceedings

WaterNSW has commenced several prosecution proceedings against Barwon-Darling irrigators following extensive investigations.

These prosecutions are the result of comprehensive investigations into allegations of water management rule breaches in the Barwon-Darling unregulated water source in north western NSW.

The prosecutions include some cases concerning a property that has been the subject of media coverage, as well as another property that WaterNSW has investigated as part of its compliance activity.

In the Land and Environment Court action against Peter Harris and Jane Harris, WaterNSW alleges that the defendants took water when the flow conditions did not permit it, and breached licence and approval conditions. The maximum penalty for each of these offences is $247,500.

In the Land and Environment Court action against Anthony Barlow, Frederick Barlow and Margaret Barlow, WaterNSW alleges that the defendants were pumping during an embargo and pumping while metering equipment was not working. The

maximum penalty for each of these offences is $247,500.

In 2017 and 2018 WaterNSW carried out detailed investigations concerning activities in the Barwon-Darling region and an assessment of the factors relevant to whether it is appropriate to commence prosecution proceedings.

In determining whether to commence a prosecution for alleged illegal water activities, WaterNSW must have regard to the criminal standard of beyond reasonable doubt and it must act impartially, in the public interest and without influence from external pressures.

Completing the necessary investigations and determining the appropriate regulatory response within these parameters takes time.

As these matters are now before the court, further details will not be released.

WaterNSW is also completing investigations of other alleged illegal water activities in the Barwon-Darling and other water sources, and expects to provide further updates regarding enforcement action shortly.

cool with quality, affordable

Research, price, buy at: w w w.direc tautomation.com.au

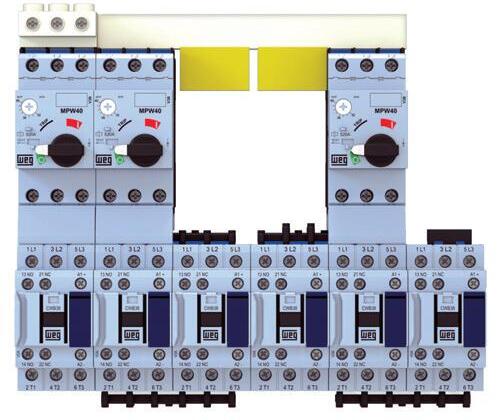

Contac tors - CWB Series

• Built-in 1NO + 1NC

Up to 80A / 37 kW (AC-3)

• Low Consumption DC Coils

• Wide range of accessories

•

• Type 1 / Type 2 coordination

Our ever yday prices star t at $32.00* for a 9 amp Contac tor * (CWB9-11-30D25)

Motor Protec tion Circuit Breakers

Up to 100A / 55kW

• Adjustable Thermal Protection

• Fixed Magnetic Protection

• 13 x Iu Shor t-Circuit Release

•

• Type 1 / Type 2 coordination

Our ever yday prices star t at $49.00* for a 4-6.3 amp Breaker *(MPW18-3-D063)

For over 20 years we’ve been saving our customers time and money on industrial automation produc ts including PLCs and HMIs, pneumatics, sensors, VS drives and switchgear. We have a huge inventor y that is constantly growing in order to provide you with the quality components you need to keep your projec ts moving. We have also invested heavily in new infrastruc ture that will allow us to continue offering the ser vice and suppor t you deser ve So don’t put that projec t of any longer...buy direc t today and save with Direc tAutomation.

Contract awarded for sewer pump station in Victoria

The contract to complete detailed engineering designs for Gippsland Water’s new outfall sewer pump station near the Port of Sale in Victoria has been awarded.

WSP was awarded the contract and design work has started.

Work is also underway at the site with demolition of a derelict building completed to make way for the new piece of infrastructure, which will be built on Foster Street, opposite the Police Station.

Gippsland Water’s General Manager Customer and Community, Paul Clark, said the new pump station will be a major improvement to Sale’s sewer network.

“This project will cater for population growth in Sale, Wurruk, and Fulham for the next 50 years. It will also allow us to demolish the existing outfall sewer pump station on Park Street,” Mr Clark said.

“The new pump station will feature industry-standard odour mitigation technology and reduce the likelihood of spills into Flooding Creek.

“We’re proud to support growth and

liveability in our region by investing in projects that improve the capacity of our network and protect the environment.”

Construction is expected to be complete by April 2021.

SA Water has awarded the contract to upgrade the sewer network in Adelaide’s north-west to support future growth in the area and improve odour management.

Fulton Hogan has been contracted to undertake the work, which is scheduled to begin in April 2018.

The $12 million project involves a refurbishment of the Largs North Wastewater Pump Station and the installation of a new 4.5km sewer main from the Largs North site to the Ethelton Wastewater Pump Station.

“The existing facilities, while currently

CONTRACT AWARDED FOR SEWER UPGRADE IN ADELAIDE

fit for purpose, won’t be able to meet an expected increase in demand on our sewer network brought on by growing urban developments such as Newport Quays and new industry in the northern parts of the Le Fevre Peninsula,” SA Water’s General Manager of Asset Operations and Delivery, Mark Gobbie said.

“Our Largs North Wastewater Pump Station currently has the capacity to transport around 75 litres of sewage per second. The upgrade will allow this to increase by around 40 per cent to 106 litres per second.

“By upgrading the local network, we are reducing the likelihood of odour and overflow issues that new connections can cause, through improving the network’s reliability and environmental performance. We are ensuring we continue to support good public health outcomes through appropriate sewage management.”

The new sewer pipeline is being installed using a construction method known as directional boring, which requires less excavation and therefore results in a reduced impact on nearby residents and road users.

Better water for regional towns in Tasmania

The North Eastern Tasmanian towns of Gladstone and Herrick have received new custombuilt modular water treatment plants, delivered from the factory floor in Launceston.

The plants are part of TasWater’s multi-million dollar project to remove all public health alerts on drinking water systems in regional towns of Tasmania.

Gladstone will start receiving treated drinking water in the coming weeks with nearby Herrick soon to follow.

TasWater will undertake a program of testing to ensure the treated water from the new plants meets Australian

Drinking Water Guidelines, before the Department of Health and Human Services can lift the Boil Water Alerts that currently affect those towns.

TasWater contractor TRILITY, with its partner Hydramet, have completed the construction of three of the seven plants to come out of the factory.

The plants were crane lifted onto low loader trucks in the Launceston factory before being escorted to the sites.

An 85 tonne crane on the Gladstone site lifted the new water treatment plant in late February 2018, with plumbing and installation taking place before it can begin producing water.

Construction continues in the factory on the water treatment plants for Cornwall, Mathinna, Rossarden and Bronte Park which will be delivered in the coming months.

TasWater CEO, Mike Brewster, is pleased the first three plants will have been delivered to site by the beginning of March 2018.

“Wayatinah, Gladstone and Herrick have now received water treatment plants made in the factory in Launceston with the rest of the plants to be rolled out in the coming months,” Mr Brewster said.

Production continues in a Stornoway facility in Glenorchy on the water treatment plants set to supply Fentonbury/Westerway, Maydena and National Park.

New water infrastructure, including extended mains pipelines, is also under construction in the regional towns statewide.

“The plants manufactured in the Prospect facility as well as the other infrastructure in the towns, once completed, will treat the drinking supply for over 600 TasWater customers,” Mr Brewster said.

“We are on track to delivering this safe, treated drinking water to the tap in the regional towns by the end of August this year.”

The ASM C Series sump pump is built tough for reliable uninterrupted operation in the most demanding conditions.

What makes the ‘C’ Series so robust is what it doesn’t have; a submerged motor, bearings or mechanical seals, the primary causes of failure in conventional sump pumps. The heavy duty shaft and bearing assembly is above the mounting plate, clear of the sump environment. This feature allows the pump to run dry indefinitely without damage, pump extreme temperature liquids and have a high tolerance to abrasive fluids.

Additional to these benefits is the fact that the pump is always

primed and ready to work. The C Series is available with material and design options for clean liquids, solids handling, chemicals and extreme temperatures.

This is the pump you need when you want peace of mind. For more information contact ASM Pumps on (03) 9793 7577 or visit asmpumps.com.au

Works start on stage two of Gippsland water project

Work has started on the second stage of Gippsland Water’s new pipeline and pump station.

The $15 million Moe to Warragul interconnector will allow the transfer of up to eight million litres of water per day between the two previously unconnected water grids.

The second stage of the project involves construction of a pipeline from Darnum to the Warragul South basin on Korumburra-Warragul Road, along with new booster pumps at Darnum and a new pump station at Trafalgar West.

Gippsland Water currently takes water from the Tarago Reservoir to supply Warragul and Drouin, but entitlements are limited as the reservoir also supplies Westernport and the Mornington Peninsula.

The interconnector will allow the transfer of water in either direction, offering improved operational security and making the region more resilient to changes in supply and demand, such as climate change and population growth.

Gippsland Water’s General Manager Customer and Community, Paul Clark, said that the new pipe is a key piece of infrastructure.

“We’re proud to support the economy and liveability of our region by investing in the water grid. Ultimately, we’re ensuring that Gippslanders are able to benefit from our valuable water resources, and enabling water to be accessed from a wider range of sources,” Mr Clark said.

The first stage of the project, a pipe between Yarragon and Darnum, was completed in 2012.

Construction of stage two is expected to be complete by mid-2018, and the pipe is expected to be operational by 2019.

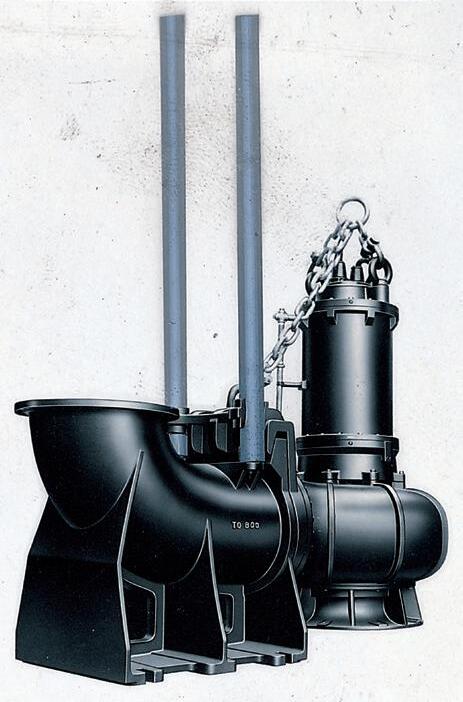

RELIABLE. EFFICIENT. KSB AUSTRALIA’S NEW GENERATION OF WASTEWATER PUMPS

The new generation of wastewater pumps: impellers capable of handling long fibres and solids, and high-efficiency KSB motors – the Amarex KRT and Sewatec type series offer even better overall efficiency.

Energy-efficient wastewater pumps and motors for optimum efficiencies

Municipal, domestic or industrial wastewater: the submersible motor pumps of the Amarex KRT type series are the perfect match for all wastewater transport requirements.

Not least because KSB’s wastewater pumps combined with high-efficiency motors enable significant energy savings.

Reliable and efficient: the new non-clogging impeller

Maximum efficiency and minimum clogging risk for KSB wastewater pumps are provided by the F-max free-flow impeller. With the asymmetric arrangement of its vanes, F-max offers a large, free passage that allows solids of different sizes to pass without difficulty.

The slightly convex profile of the hub in the middle of the impeller reliably prevents all risk of clogging

from long fibrous materials such as flushable wipes.

The F-max free-flow impeller is available for the submersible wastewater pumps in the Amarex KRT series and the dry-installed wastewater pumps from KSB’s Sewatec series.

The F-max vortex impeller by KSB Australia

Energy-efficient motors for optimum efficiency

The combination of KSB wastewater pumps with high-efficiency motors enables considerable energy savings. The economical motors are integrated

in the pumpsets as standard. The pumpsets can be supplied with or without explosion protection.

The dry-installed pumps of the Sewatec type series are fitted with the variable-speed, magnetless KSB SuPremE® IE4 motor. The efficient pump set, consisting of a wastewater pump and motor, promises maximum savings from low energy and maintenance costs, optimum operating reliability and constant performance data.

Customised pumps for every requirement

Team with specifically adapted impellers and energy-efficient motors. KSB offers a wide range of installation types as well as a large choice of materials for wastewater pumps. KSB tailors the best solution for each wastewater application – for optimum efficiency and operating reliability.

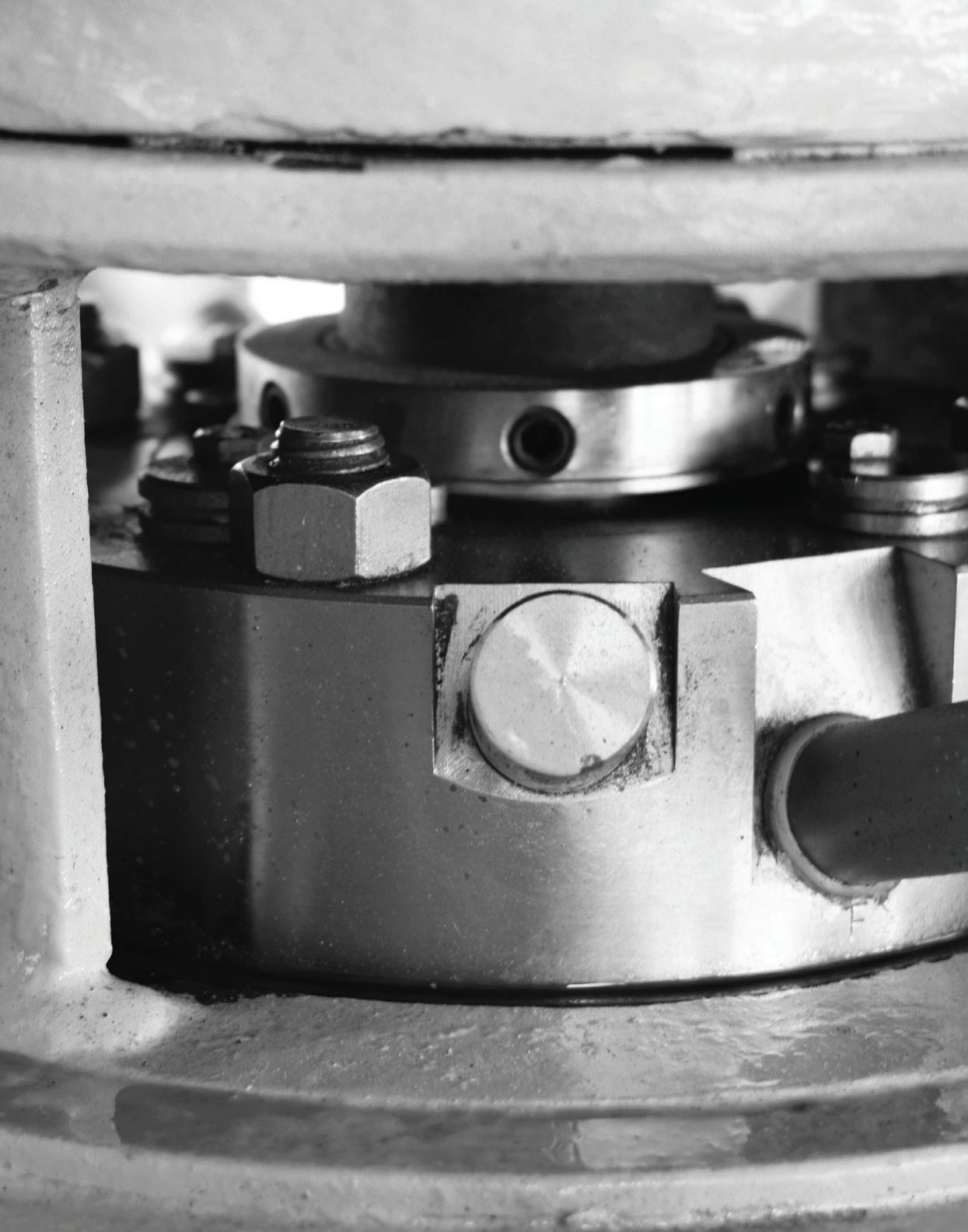

REMOTE WITNESS TESTING: A FIRST BY KSB

When purchasing large pumps, hydraulic acceptance tests and a final inspection are an essential proof of compliance with the guaranteed values.

In the past, customers had to travel to the test facility to witness their purchased pump being tested. As testing usually takes place at the KSB manufacturing plant overseas, this is a time-consuming and costly trip to make from Australia.

Online acceptance testing is KSB Australia’s answer, developed as a process enabling reliable and standardcompliant pump acceptance testing. The tests conducted are transmitted live via a secure internet connection. In an online meeting between pump manufacturer and customer, the customer can see the live camera view of the pump in the test facility, as well as the characteristic curve measurement during testing.

In addition to pressure and flow data, the test software records all further performance data required for a measurement to inspection/testing standard DIN EN ISO 9906, enabling

the derivation and assessment of the pump’s efficiency. Measurements can also include the sound level and vibrations. Prior to the acceptance test, KSB provides the customer’s test engineer with organisation information, order data sheets and a precise description of the acceptance testing.

This comprises details on the measuring instruments used, including the corresponding calibration certificates. After the acceptance test, KSB emails the test engineer the certificates to be signed. This tried and tested process is implemented in compliance with the acceptance test standards.

Online acceptance testing is available from KSB’s Halle site, specialised in water and wastewater pumps, as well as at some of

the pump manufacturer’s other sites. The test facilities can accommodate pumpsets with a drive rating of up to 10MW and a flow rate of up to 21,000 m3/h.

String tests with the customer’s original motors, transformers and frequency inverters can also be performed.

At KSB Australia’s stand at OzWater, a 360-degree presentation will give interested parties a good impression of the test facilities for online acceptance testing at the KSB site in Halle, Germany.

SAVING A FORTUNE FORTUNATELY DOESN‘T COST ONE.

Efficient, reliable and fail-safe pumps pay off in the long run.

www.ksb.com.au

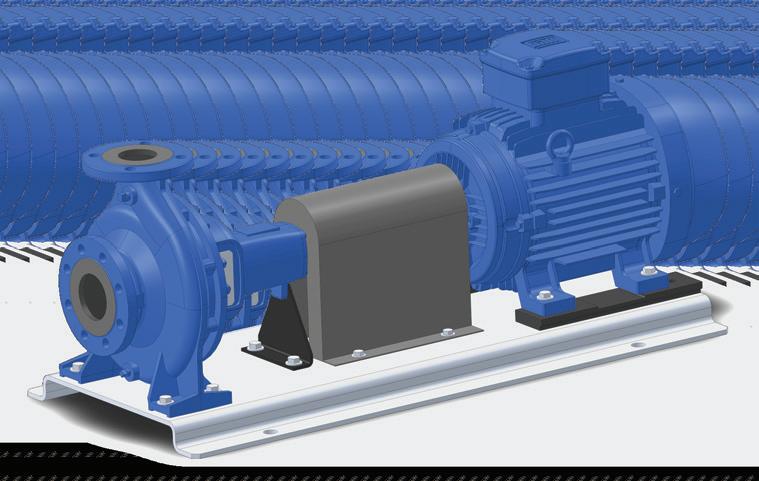

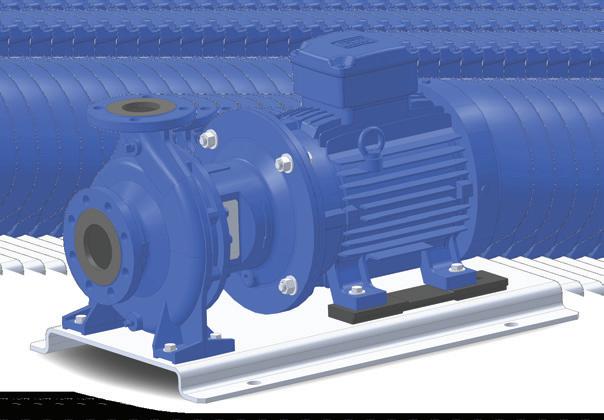

New range of EN733 pumps: WORLD LEADING PERFORMANCE

As a major manufacturer of industrial pumps to JIS and API610 standards, Ebara Corporation has embarked on a globalisation of its range of pumps for the world market. This includes the introduction of a range of industrial pumps to European EN733 standards and a new range of vertical multistage pumps.

Ebara Corporation (Japan) has recently released its new global range of EN733 standard end suction centrifugal pumps.

Utilising the most advanced hydraulic computer design software available, Ebara engineers in Japan have been able to improve and increase the pump efficiencies of the new GS range above most other available pumps of similar design and standard on the global market.

The new Ebara GS range of EN733 standard pumps are manufactured in component form at Ebara Corporation Japan owned and managed factories in the Asia Pacific region with final assembly of market range models undertaken by skilled tradesmen at Ebara Pumps Australia’s Melbourne facility.

A 16 bar rated pump – the new GS –will be available in both long coupled and close coupled versions (GSD) and will be available for release in Australia in the second half of 2018.

About Ebara Corporation

Ebara Corporation was founded in Japan in 1912 as a manufacturer of pumps. Today, as a group, it consists of more than 70 companies in six continents with a workforce of more than 11,000 people and with company owned and Japanese managed factories in eight countries covering four continents.

The huge scale of production and distribution is matched by a constant commitment to research, development and design of new products and the

modern technologies for manufacturing them. Ebara products have gained a worldwide reputation for their technology and quality.

Contact your local Ebara dealer or Ebara Pumps Australia for more information.

Two of the more popular models that are stocked in Australia are both solids handling pumps. For more details contact us at Ebara Pumps Australia or visit our website.

Stamped stainless steel pumps with open impeller

Maximum 19mm passage size

MODEL DWO MODEL DVS

50mm discharge

1.1 to 1.5kW - 1 phase

1.1 to 3.0kW - 3 phase

Cast iron submersible pumps with semi vortex impeller 32 to 56mm passage size (Depending on model)

50 and 80mm discharge

0.4 to 0.75kW - 1 phase

0.75 to 3.7kW - 3 phase

Manual or automatic

New hydraulic design - World leading performance

Combining over 100 years of experience with the latest computer aided design, EBARA has developed the new GS series of pumps that offer world leading performance and efficiencies.

End suction single stage centrifugal pumps

Pumps to EN733 dimensions

16 Bar rated. PN16 flanges (24 Bar hydrostatic test pressure)

High efficiencies. MEI ³0.6 (Minimum Efficiency Index)

Mechanical seals to EN12756

Protectors to ISO13852

O’ Ring seal for casing

Cast iron components ED painted (Electro deposition painting)

GS range - 41 pump sizes from 32-125 to 200-500

GSD motor pump versions available from 1.1 kW up to 75 kW (4 pole) and 110 kW (2 pole)

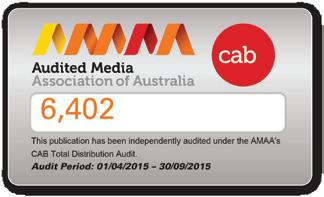

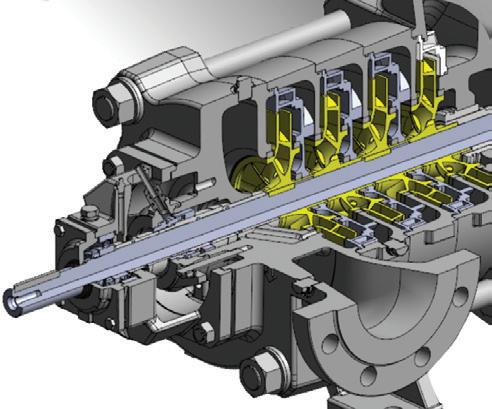

Performance, robustness and reliability: PMXT ENDURANCE

Caprari has launched the new range of high pressure multistage surface horizontal pump series PMXT ENDURANCE completely made of precision-cast stainless steel.

Very thick components, the choice of high performing materials, the innovative technical solutions and the smooth surface of hydraulic profiles make the PMXT ENDURANCE pumps unique on the market for their performance, robustness and reliability.

The pumps are:

• Able to reach performance values up to 100 bar pressure with top-level efficiency ratings

• Made of AISI 316 stainless steel precision-castings suitable for harsh operating conditions

Also available are full duplex and full super duplex versions, which are suitable for extreme industrial applications (i.e. reverse osmosis, seawater fire prevention, seawater injection, etc).

The balanced mechanical seals have been specifically selected for industrial applications.

The Caprari axial thrust compensation system is present on the whole range, minimising the loads that persist on the bearings of the machine, giving the product a long life.

The wear rings are replaceable and made in duplex with anti-seizing properties and self-lubricated. At the same time, this solution makes it possible to minimise the gap between the impeller and the wear ring, improving hydraulic efficiency and avoiding seizure problems.

Optional PT100 probes are useful for monitoring bearing temperatures. Together with the vibration probes, which are also optional, it is easy to monitor the wear level of the bearings, thus preventing costly downtime.

Caprari surface groups made with high-pressure multistage pumps are a benchmark for the market. The product's wide range makes it possible to always find the best solution for the customer's duty point at the highest efficiency level.

With the ENDURANCE series in stainless steel and duplex, Caprari satisfies the most demanding industrial market applications.

YOUR RELIABLE PARTNER IN INDUSTRIAL APPLICATIONS EXPERIENCE SINCE 1945

Designing the future with highly appreciated and advanced solutions for Industrial Applications

Pumps and electric pumps able to raise primary process water and waste water.

ENERGY | METAL INDUSTRY | PAPER INDUSTRY | FOOD & BEVERAGE

www.caprari.com |

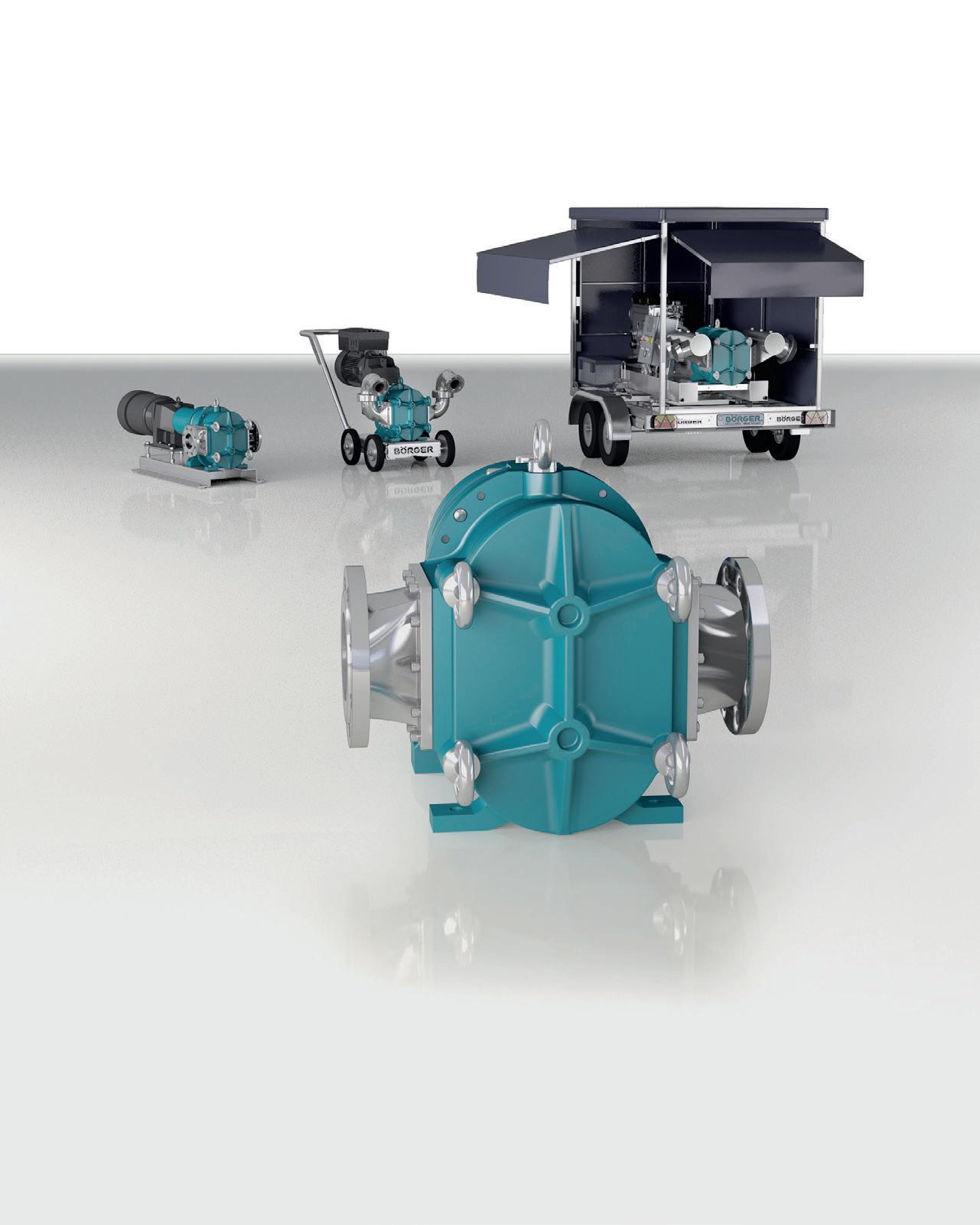

Each mobile pump is unique

The rotary lobe pumps from Börger, a pump manufacturer from Germany, are built in line with the individual requirements of the customer. The demand for Börger mobile pumps has increased in recent years.

Börger GmbH from Germany has manufactured rotary lobe pumps for more than 30 years. The self-priming, valveless positive displacement pumps are used in the environmental and municipal technology sectors, and in almost all industrial sectors. The solids-resistant Börger pumps are available in the BLUEline and ONIXline series. The pumps convey highly viscous, chemically aggressive media or media containing solids without any effort.

The correct pump size for every single application is selected from a portfolio of 25 pump sizes with flow rates of 1 to 1500 m³/h. All pump components are selected individually according to the requirements of the pumped medium and the customer. Rotors in different geometric

designs and made of a wide range of different materials; pump casings made of gray cast iron, steel casting, stainless steel or Hastelloy; and different sealing systems only give an idea of the wide variety of Börger rotary lobe pumps.

Börger mobile pumps have the same individual character. The demand for mobile pump units has increased in recent years. There are hardly any limits when installing a mobile pump. Whether as a pump on a trailer, a portable pump or as a hand cart pump which can be used flexibly. The mobile units are supplied from a single source. Börger produces the chassis, the pump technology and the control technology themselves. This way, we will be able to provide a customised solution to our customers’ requirements.

MOST EFFICIENT WAY OF PUMPING

POWERFUL.

Börger configures and builds each rotary lobe pump in line with your requirements. The solidsresistant pumps ensure the best efficiency even with pressures of up to 16 bar. The correct pump size for every single application is selected from a portfolio of 25 pump sizes with flow rates of 1 to 1,500 m³/h. Börger rotary lobe pumps are especially suitable for mobile use due to their

compact design. The mobile units are supplied from a single source. Börger produces the chassis, the pump technology and the control technology themselves. This way, your individual requirements and wishes can be considered.

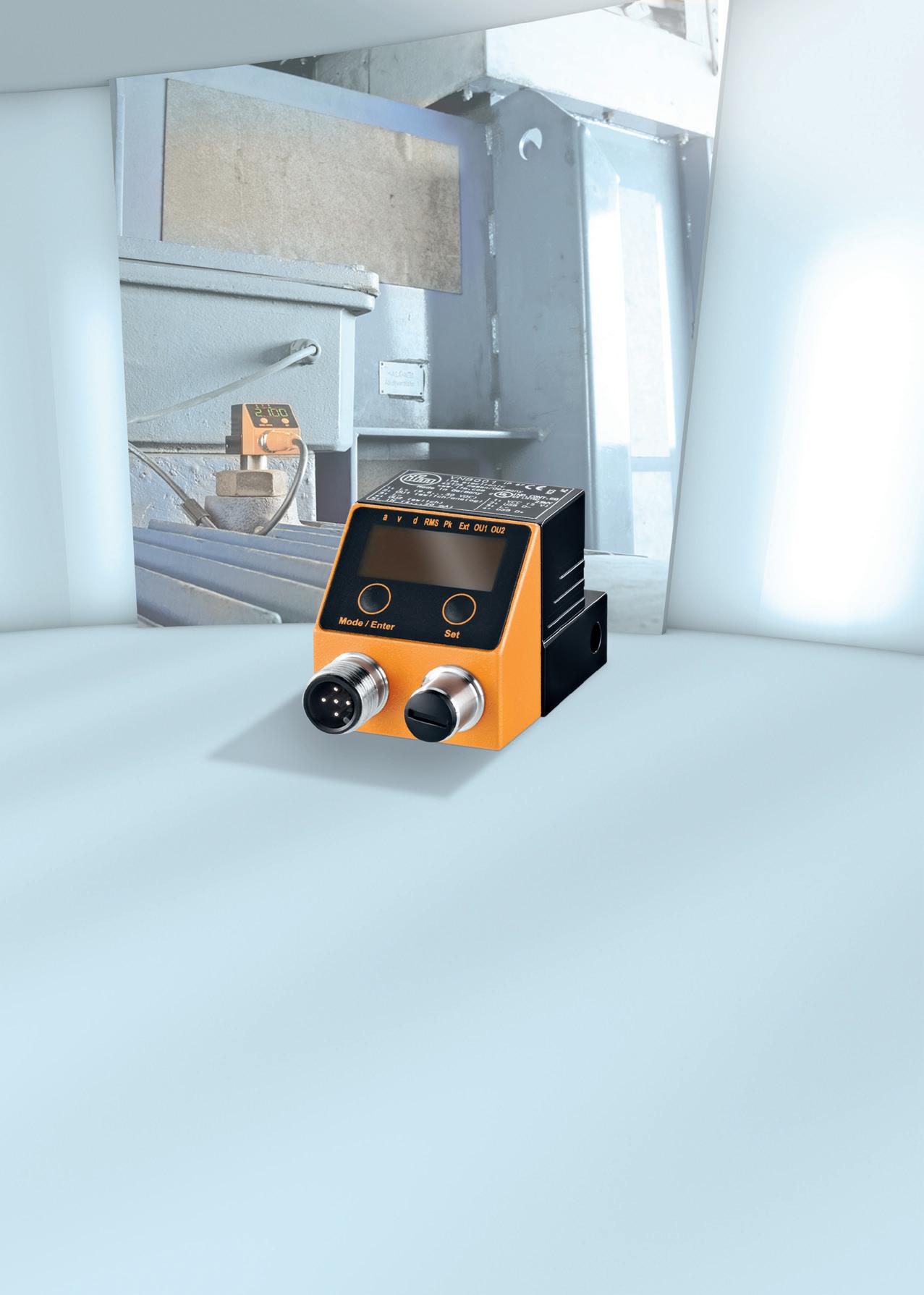

MONITORING VIBRATIONS with new powerful compact sensor

ifm has now added another intelligent vibration monitoring sensor to our already comprehensive range. This sensor has been developed to protect machinery to a high standard without spending a huge sum of money and still affording a great deal of protection.

This unit looks almost identical to its brother the pre-existing VNB001 with its local displays, but this is where the resemblance ends.

This small unassuming unit now has a huge array of functions available in its portfolio.

The VNB211 is a standalone monitor that has the following algorithms: V-RMS to ISO10816 or it can be set to peak if desired.

This generation also has A-RMS (Acceleration RMS) which sensors of this size normally do not have. This acceleration algorithm is normally used for bearing damage detection and whilst it is not band specific, good protection can still be afforded by its use.

In addition to these desirable functions, a small ‘Y’ cable can be added to the M12 port so an external 4-20mA device - e.g. a temperature transmitter, which was also possible in the VNB001 - can be included, or excitingly, another accelerometer (VNA001) which turns the unit into quite a powerful twin accelerometer system. This means that it is possible to monitor DE and NDE ends of a large fan for example. Once programmed, either by the on-board push buttons or by the software, the sensor will run totally autonomously, giving an analogue output or set-points as required.

It doesn’t stop there either. The VES004 programming software enables full setup of the above algorithms with full control of set-points, time delays and histories. The history function alone is a very powerful tool. Log rate is as low as one second intervals for around 90 days. The default is set as five

minutes and thus will log for three years without overwriting. This is perfect for monitoring trends over long periods of time.

Such is the power of this system that Spectra and Time Waveform can also be monitored when connected to the VES004 software. These files can be trended and saved as desired then played back at any time for analysis or comparison. No matter what you have connected to the VNB211, whether it be an accelerometer, pressure or temperature transmitter it can all be logged internally and then saved to a file when the programming cable is connected.

Agitator pumps for all applications

Australian Pump Industries, Tsurumi’s Australian distributors, is proactive in developing applications for slurry pumps. Tsurumi is now regarded as a leading submersible slurry pump manufacturer, with a wide range of pumps suitable for handling everything from sandy, salty water, to heavy duty slurry found in the quarry, mining or the concrete industry.

Tsurumi, claimed to be the biggest manufacturer of electro submersible drainage pumps in the world, developed dewatering pumps during the land reclamation program of the 50’s and 60’s in Japan. Used by the piling and concrete industry, products were designed for these aggressive and abrasive applications.

Today the company is highly specialised, making slurry pumps from 2-pole all the way to 6-pole, capable of handling sandy liquids in quarries and concrete plants.

The secret of their success is the design of high chrome, cast iron agitators that ensure the smooth suction of the settled matter. This same philosophy is used in single and 3-phase pumps alike, providing the ability to move solids in suspension that conventional pumps can’t handle.

The ultimate extension of the product range is 4 and 6-pole pumps with huge flows, capable of pumping thick slurry. Tsurumi’s 4-pole GSZ Series will handle flows of up to 18,000 LPM, and heads of up to 54m.

The impeller, agitator and suction plate are made of high chrome cast iron to resist abrasion. Even if the impeller and suction plate wear down to the point of diminishing pump performance, the plate can be easily replaced or its gap from the impeller adjusted, giving users an easy, inexpensive means of extending use.

Tsurumi’s GSD series, a new range of heavy duty, high powered agitator pumps, feature horsepower ratings of up to 75kW. They feature high heads and volumes and are set to change the way the international market thinks about mine, quarry and heavy mineral movement.

Big GSZ slurry pumps have an inbuilt agitator impeller to make sure the liquid is moving before it comes into the main pump chamber. That’s Tsurumi’s advantage.

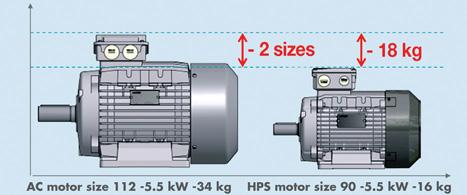

The High Performance (HP) range from Lafert is a generation of PM (Permanent Magnet) Synchronous Motors, achieving IE4 and IE5 Super Premium Efficiency level, that offer improved electrical efficiency at stable & reduced production costs without applying rare earth magnets.

This uniquely engineered product combines the electrical design of Brushless Servomotors with the mechanical design of AC Induction Motors. The result is a compact motor primarily targeted toward HVAC applications in pumps, fans, compressors, and blowers, where there is emphasis on reducing the operating cost and weight and size of the motors.

The complete range 0.37 kW to 30 kW are supplied as stand-alone motors (HPS) to be controlled by a separate drive or as motor/drive integrated units (HPI), specifically designed for their energy saving potential.

RECHARGING PERTH’S

The south west corner of Western Australia continues to dry, and hotter summers combined with lower rainfall have led to Water Corporation seeking new ways to secure climate-resilient water sources. To help secure more water, the utility has embarked on an expansion of its $262 million Groundwater Replenishment Scheme — the first full-scale scheme in Australia — which will see 28 billion litres of water per year pumped back into Perth’s aquifers for reuse.

PERTH’S GROUNDWATER

The process of groundwater replenishment is an innovative concept that involves treated wastewater being further treated so that it’s good enough to drink, before being recharged into groundwater supplies. This water is then stored or ‘banked’ in the aquifers, and taken out later for further treatment and supplied to a drinking water system.

As the process doesn’t rely on rainfall and has the potential to recycle large volumes of water, it is sustainable and drought-proof.

Planning on water forever

For this reason, Water Corporation has prioritised groundwater replenishment in its Water Forever plan — a long-term plan to further secure water supplies in response to climate change and an increasing population.

The Water Forever plan is based on a three-pronged approach, which includes working with the community to reduce water use, increasing the amount of water recycled and developing new water sources.

A Water Corporation spokesperson said the Groundwater Replenishment Scheme, taking place at the Beenyup Advanced Water Recycling Plant in Craigie, ticks two of these boxes as it increases water recycling and is developing a new source.

By 2060, groundwater replenishment could provide up to 20 per cent of Perth’s water supply.

For the water to be recycled for reuse, wastewater is first rigorously treated at the Beenyup Wastewater Treatment Plant. It then undergoes further treatment at the onsite Advanced Water Recycling Plant where all trace levels of microorganisms and chemicals are removed so that it meets drinking water standards.

To achieve this, it is processed through three water treatment methods:

1. Ultrafiltration filters out suspended materials that are larger than 0.1 of a micron

2. Reverse osmosis removes any remaining dissolved materials by passing the water through tightly wound membranes

3. Ultraviolet light is used to destroy any trace levels of microorganisms that may remain

Once water has passed through the three stages, it is of drinking water quality and is recharged into the aquifer where it mixes with the existing groundwater. The water will remain in the aquifer before it is drawn out at another location, treated at a groundwater treatment plant and added to the water supply scheme.

Over time, the difference between the recycled water and existing groundwater is indistinguishable.

A work in progress

Stage one of the Groundwater Replenishment Scheme was completed and began operation last year and has the capacity to recharge up to 14 billion litres of water into Perth’s groundwater supply each year.

Work on the stage two expansion of the scheme is underway, which will double the capacity to 28 billion litres of water per year.

Stage two includes the duplication of the 14 billion litre Advanced Water Recycling Plant, and the construction of a 13km recharge pipeline extending to the north-east of the plant, connecting the plant in Craigie to the two new offsite recharge bore sites in Wanneroo and Neerabup.

The location of the new Advanced Water Recycling Plant has meant careful planning and delivery continues to be important.

The site is located in the Perth suburb of Craigie, on Water Corporation-owned land that houses the original Advanced Water Recycling Plant and associated infrastructure from stage one of the Groundwater Replenishment Scheme. This stage continues to recharge water while stage two is under construction.

The proposed route for the pipeline was selected with a number of considerations in mind, including impacts to the community, environment, safety (of people constructing and maintaining the pipeline), constructability and cost.

At each recharge site, Water Corporation will be installing a total of four bores, including two recharge bores and two monitoring bores. Work to install these bores will involve drilling and construction of above-ground infrastructure. The work will be delivered in stages.

Work to install the bores at both the Wanneroo and Neerabup sites has begun and is expected to finish later this year. Work on the associated above-ground infrastructure will begin after the bores are completed and are expected to be completed early next year.

Pumping water back into Perth’s aquifers

The Clough-Suez Water Partners joint venture was awarded the contract to construct the Advanced Water Recycling Plant in October last year, and is also responsible for procuring the pumping equipment for the project. A spokesperson for Water Corporation said there were a number of pumps being used through the treatment process at different stages. These include:

• Digital dosing pumps and pneumatic diaphragm pumps for chemical transfer and dosing

• End suction centrifugal pumps for CIP, UV feed, UF feed, UF backwash

• Progressive cavity pumps for analyser panels

• Axially-split case centrifugal pumps for RO feed

• Transfer and recharge pumps

• Vertical multistage centrifugal pumps for service water

• Wet well submersible pumps for the feedwater pumps and sump pumps

“With all pumps, material compatibility with the pumped liquid is the principal concern.

"Generally speaking, for larger pumps energy efficiency is an important factor,” the spokesperson said.

“For smaller pumps, the most important factor is the initial cost as it forms a large proportion of the whole-of- life cost.”

When complete in 2019, the scheme will have the capacity to recycle enough water to supply up to 100,000 households per year, providing Perth with a new climate independent water source to boost much needed drinking water supplies.

Inside the Advanced Water Recycling PlantPumps involved in the Groundwater Replenishment Scheme include:

• Feedwater pump station – feeding water from the wastewater treatment plant and through the 1mm coarse screens

• Ultrafiltration (UF) feed – pumping through the 200um fine screens and the UF skids

• Reverse Osmosis (RO) feed – pumping through the Reverse Osmosis skids and the degassing towers

• UV Feed – pumping through the Ultraviolet process

• Transfer pumps – for pumping to the remote recharge sites

• Recharge pumps – for recharging the aquifers

• Monitoring bore pumps – for groundwater monitoring

• Development bore pumps – for re/development (cleaning) of the bore

• RO flush pumps – for flushing of the RO skids on skid shutdown

• UF backwash pumps – used during the cleaning of the UF skids

• Service Water – supplying the various cleaning systems

• UF and RO Clean in Place (CIP) systems – for chemical cleans of the process equipment, and subsequent neutralisation of chemical

• Analyser panels – pumps to online analysers of process water

• Chemical dosing and transfer panels – for transfer and dosing of chemicals for the CIP system and process

Brands

Kelair stock a wide range of high quality pump brands. Find the Brand you’re looking for.

Industries

From mining to pharmaceutical, Kelair has an extensive range for applications across all industries.

Type

Whether you need Positive Displacement Pumps or Centrifugal Pumps, we’ve got one that will hit the target.

Service

All our pumps are supported by our highly skilled service division for all your service needs.

When pump knowledge matters, turn to Kelair Pumps Australia. Visit us at www.kelairpumps.com.au

Sydney’s new aquatic centre set to make a splash

The Gunyama Park Aquatic and Recreation Centre sits within the 278-hectare Green Square development area, which includes the suburbs of Beaconsfield and Zetland, and parts of Rosebery, Alexandria and Waterloo.

On completion the Gunyama Park Aquatic Centre will feature a 50m outdoor pool as a centrepiece within a larger, irregular shaped beach pool. A 25m heated indoor pool for swimming lessons and a hydrotherapy pool will also be constructed.

A cogeneration scheme will heat the pools and supply electricity throughout the complex.

Key highlights of the complex include:

• 50m heated outdoor pool set within a larger, irregular shaped beach pool

• 25m indoor heated program pool

• Indoor leisure pool

• Heated hydrotherapy pool

• A crèche with indoor play areas

• A health and fitness centre

• A multipurpose synthetic sports field suitable for use by community sporting teams

• Sports field change rooms, public toilets and storage facilities

• New landscaping, lighting and a new public artwork by acclaimed Aboriginal artist Jonathan Jones

Work is underway on the $84 million Gunyama Park Aquatic and Recreation Centre in the City of Sydney’s Green Square precinct, and is the largest pool complex to be built in the city since the Sydney 2000 Olympic Games.

Inspired by the beach

In 2014, the City of Sydney held an open architecture competition to find the most beautiful, functional and sustainable design, with 144 architects submitting designs which were exhibited for public feedback that was used in the jury’s deliberations.

Andrew Burges Architects in association with Grimshaw and TCL created the winning design – an urban beach pool concept seamlessly integrating into a park inspired by beach pools at Bondi, Bronte, South Curl Curl and Malabar.

The design will be brought to life by CPB Contractors, who were awarded the construction contract in January 2018.

CPB Contractors Managing Director, Juan Santamaria, said they were pleased to be selected to build the new aquatic and recreation centre following an extensive competitive tender process.

“Our team has both the local and international expertise and project experience to deliver significant value for the City of Sydney,” Mr Santamaria said.

“Our flexible, multipurpose design will ensure that Gunyama Park is able to host a variety of activities, welcome locals and visitors from across Sydney, and remain adaptable to the city’s future growth requirements and sustainability expectations.”

The heart of the aquatic centre

Pumps are the heart of a swimming pool and are used to circulate the water through the filter to remove large and small organic matter to keep pools clean and safe. As the pump moves the water around to help filter it, it also circulates water through the heater or heat pump, any water features, massage jets and plumbing, as well as circulates the sanitiser and balancing chemicals throughout the pool.

Heat pumps are also commonly used for swimming pools to ensure comfortable swimming temperatures all year round. These pumps work by transferring the heat from the outside air to the pool.

The most commonly used pumps for swimming pools are:

• Single speed

• Dual speed

• Multi speed

• Variable speed

Powered by cogeneration

The electricity and pool heating needs for the Gunyama Park Aquatic and Recreation Centre will be powered by a cogeneration plant.

Cogeneration – also known as combined heat and power (CHP) – is the production of two useful forms of energy, such as high-temperature heat and electricity, from the same process.

It offers major economic and environmental benefits because it turns otherwise wasted heat into a useful energy source. This greater efficiency means carbon dioxide emissions are cut by up to two-thirds when compared with conventional coal-fired power stations.

Cogeneration involves burning fuel – usually natural gas (or renewable gas) – in an engine, typically a turbine or reciprocating engine, which in turn spins a generator to create electricity.

Heat from this process is then recovered through the exhaust, water jacket and cooling circuits instead of being released into the atmosphere and being wasted. This heat is then distributed to meet the energy needs of a site.

Pumps are used throughout the cogeneration process to push waste heat through the system and then send the energy back to the site.

Cogeneration involves four steps:

• Electricity generation

• Electricity distribution to site

• Heat recovery

• Heat distribution to site

A pavilion housing a gymnasium and fitness studios overlooks the pools

Revitalising the inner city

The construction of the Gunyama Park Aquatic and Recreation Centre will be completed in two stages, as the city does not currently own all portions of the land on which the complex is planned.

The full aquatic centre, multipurpose sports field and landscaped areas will be completed by early 2020, with an expanded sports field, playground and further landscaping to be completed as the remaining land becomes available.

The project will target a five-star design and as-built rating from the Green Building Council of Australia.

The city is spending $540 million over the next ten years on extensive infrastructure and streetscaping works throughout the area, as well as new community facilities that also include a library and plaza, creative centre, childcare centre, and more than 15 parks and open spaces.

Sydney’s Lord Mayor, Clover Moore, said the new pool was an important addition for Green Square.

“Green Square is one of the fastest growing precincts in Australia, and we’re doing everything we can to make sure it is a wonderful urban neighbourhood with the services and facilities its residents and workers need,” Mr Moore said.

“I’m looking forward to seeing this exciting project take shape in the coming months and know the Green Square community will be pleased to see work begin on their new aquatic centre very soon.”

When fully developed, Green Square will accommodate close to 61,000 people living in 30,500 new homes, and provide around 21,000 permanent jobs.

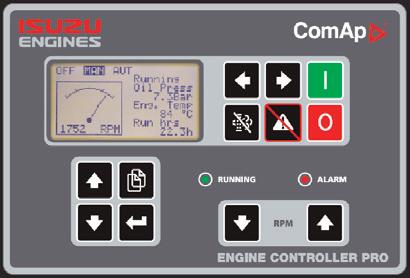

LEGENDARY RELIABILITY. UNRIVALLED SUPPORT. CUSTOM ENGINEERED.

When the time comes to install a new irrigation system, or repower an existing one, insist on the legendary reliability of Isuzu engines. With a range spanning 18 models from 13HP to 284HP and a nationwide support network, we have you covered. Visit engines.isuzu.com.au

ISUZU ENGINE CONTROLLER PRO.

A cost effective, user friendly, customisable Engine and Irrigation Pump control, monitoring and protection system.

Available options:

• Pressure transducers

• Low coolant alarm/shutdown

• 160W Solar panel kit

• 3G/4G remote communication*

Visit our stand at the 2018 Irrigation Australia Conference and Exhibition June 13th to 15th, 2018.

• LINAK automated throttle actuators

• ComAp WebSupervisor application software

INVESTING IN WATER TO FUTURE PROOF WATER

With water security a top concern, Parkes Shire Council in New South Wales is planning ahead to future proof the community’s water supply by expanding infrastructure to draw water from diversified sources - including from dam, river and groundwater sources — replacing aging infrastructure, and increasing recycled water use. Here, we take a look at two projects that have been undertaken as part of a major water infrastructure project, a new water treatment plant and advanced water recycling facility.

Parkes Shire Council’s Integrated Water Infrastructure Renewal Project (IWIRP) is a multi-award winning project, having won top Water Management honours in the Local Government NSW Excellence in the Environment Awards, and the Sustainable Systems Award at the Blue Star Awards in 2017.

The IWIRP comprises multiple projects which will allow for more effective and extensive use of recycled water, and decrease demand on scarce water resources.

Meeting needs with a new water treatment plant

The new $45 million water treatment plant will provide a safe, secure water supply and ensures the community can continue to grow and attract new business and residents.

The project has completed the commissioning and proving phases and once fully operational in early 2018 it will take over from the existing water treatment plant at Albert Street. The existing plant was built in 1958 and is no longer able to cope and meet current and future water supply demands as it is too small. Technology has also improved since it was first built, so a new plant was required to continue meeting strict compliance standards on a consistent basis, as well as provide a more sophisticated system to blend and treat water from different sources.

The new water treatment plant is state-of-the-art, is fully automated with minimal operator supervision required, and uses the latest technologies for water production and water quality monitoring.

Parkes Shire Council’s Director of Infrastructure, Andrew Francis, said the main process train configuration underpinning the water treatment plant involves Flocculation, Dissolved Air Flotation-Filtration (DAFF), Chlorine Disinfection and Fluoridation.

Dissolved Air Floatation-Filtration (DAFF) is used for the clarification process to ensure smaller particles, such as algae from raw water, are effectively removed, and to reduce the amount of chemical dosing and eliminate the need for recurrent backwash.

As the plant is a ‘zero discharge’ process, the local waterways are not affected by wastewater released from the plant. The utilisation of gravity filters, the construction of a High Level Reservoir, and the installation of a 100MW PV system (solar panels) also means it has minimal power requirements.

An innovative procurement process

To maximise the value of the construction of the water treatment plant – as well as a sewage treatment plant – Parkes Shire Council adopted unique and progressive tendering strategy not usually undertaken by local government. Council used an Early Contractor Involvement process, and developed a framework in line with NSW Government procurement policy; incorporating Expression of Interest, Requests for Tender and Intensive Workshops as part of the selection process. This process gave Council confidence in

the cost of the projects and delivered a saving of $8 million, as project risks were mitigated.

Through the project procurement process, John Holland (JH) undertook its own procurement to inform its own tender submission.

“John Holland invited specialist pump vendors with proven track records to tender for the pumping packages comprising a mix of horizontal end suction pumps as well as submersible wet well pumps across the sewer treatment plant and water treatment plant,” John Holland Engineering manager Jim Livas said.

“The main factors that were considered when selecting the pumps were pumping efficiency, level of compliance to specification requirements, delivery time, availability of local support (service and maintenance), and vendor track record.”

The new water treatment plant is not only more efficient, it is also more productive. Most importantly, the new plant has double the capacity of the old plant, with the capacity to treat 16ML of water daily, ensuring the supply of quality water during peak seasons, and accommodating for projected growth.

The project was not without its challenges but Jim Livas said an extensive collaboration was key to overcoming these.

“The main challenge to the project was time related which was overcome with extensive collaboration between all stakeholders all focused on the same outcomes.”

INFRASTRUCTURE WATER SUPPLY

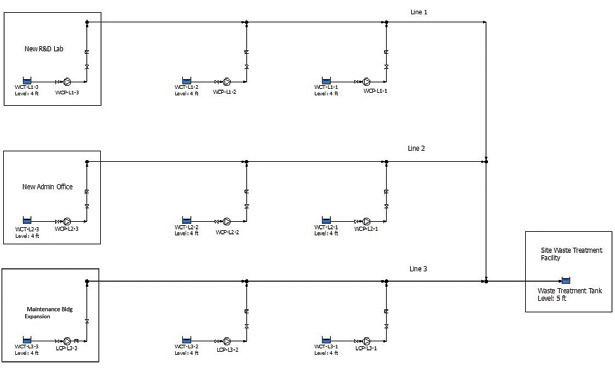

Improving security with recycled water

The Advanced Water Recycling Facility (AWRF) will underpin a new $21 million Recycled Water Scheme, strengthening water security and bringing recycling activities up to current regulatory and industry best practice standards.

The idea behind the scheme goes back to 2005, when recycled water was suggested as a potential solution to Parkes water security issues during community consultation.

The scheme will provide advanced disinfection of the high grade effluent from the new sewage treatment plant next door, to supply vastly superior water quality to customers on the existing effluent reuse scheme, and also allow recycled water to be used for irrigation purposes.

It is projected to result in water savings of up to 200ML and $20,000 per annum upon completion.

The Recycled Water Scheme replaces the existing Effluent Reuse Scheme; a long-running scheme that supplied low-quality recycled water for irrigation purposes.

The scheme is being rolled out in three phases:

Phase 1 was completed in December last year with completion of the construction of the new AWRF.

Phase 2 involves the construction of a specialised Recycled Water Rising Main to extend the delivery of recycled water to Parkes Shire Council's parks and greenspaces.

Phase 3 involves the potential expansion of the Recycled Water Rising Main to include additional third party commercial customers.

Building the Advanced Water Recycling Facility

The Advanced Water Recycling Facility has been constructed alongside a new sewage treatment plant, and uses state-of-the-art treatment processes to purify the wastewater to the highest standard.

Parkes Shire Council's Director of Infrastructure, Andrew Francis, said, "The AWRF creates a new, local and completely drought-proof water supply that will keep our parks and sporting fields green – even during water restrictions.

“Our Recycled Water Scheme will achieve incredibly high treatment standards, to be solely used for irrigating our community greenspaces.

“This will reduce the demands on treated drinking water and lower Council’s operational costs.”

John Holland’s Engineering Manager, Jim Livas, said the heart of the state-of-the-art Advanced Water Recycling Facility comprises UV and Chlorine Disinfection.

“Tenders were invited for specialist equipment mostly related to pumps, screening, and UV. Prevalidated equipment was specified and vendors with proven track records were a significant consideration.

“Pumping efficiency, level of compliance to specification requirements and delivery time were important considerations when selecting equipment.”

The maintenance and repair schedule and costs also played a significant part of the overall TOTEX evaluation undertaken by the project team for both the Advanced Water Recycling Facility and water treatment plant.

There were no significant challenges during construction as the Advanced Water Recycling Facility was a greenfield add-on to the new sewage treatment plant, and allowances for integration had been made during the delivery of the sewage treatment plant which facilitated a seamless transition.

Bringing it all together

Along with the construction of the water treatment plant and the Recycled Water Scheme, other works have been undertaken to compliment these facilities and ensure they are efficient.

Lake Endeavour Dam upgrade

Construction works have been completed at the Lake Endeavour Dam on a $12.2 million project to strengthen the embankment and spillway to ensure long-term stability and integrity, and widening/deepening the existing spillway and raising the embankment crest to increase flood security.

Urban Water Mains Augmentation

As part of the new water treatment plant, several sections of raw and treated water pipelines were replaced as they were nearing the end of their useful life and their integrity was compromised, resulting in water loss due to cracks and breaks.

These pipes needed to be replaced to ensure water is delivered efficiently to the new treatment plant.

Lachlan River Pump Station and Bore 8 upgrades

$3 million in upgrades and refurbishment works have been undertaken at the Lachlan River Pump Station and Bore 8 to improve the capacity for water extraction, enabling the spread of water extraction across a number of sources, and reducing the impacts on individual water bodies.

KEY LEARNINGS

The works make the Lachlan River Intake a permanent water source, increasing the security of the raw water supply, and maintaining the community’s newest water source.

The refurbishment of Bore 8 on the Lachlan River in Forbes will optimise sustainable extraction from the borefield by spreading the drawdown of water over eight sites, minimising impact on the aquifer, allowing increased capacity.

• Early contact with authorities is beneficial to ensure timely approvals

• Open, clear, and direct lines of communication should be implemented to ensure that work interfaces are understood and agreed by all parties

• It is advised to include 'hold points' in contract documentation for environmental and sustainability outcomes to prevent incidents from occurring Contractor and client monitoring are best synchronised

• Create and use a central database for all monitoring data

• Ensure selected vendors can adequately support their equipment locally and respond in a timely manner.

SOLAR PUMPING: economic and environmental rewards

The installation of a solar diesel hybrid irrigation bore pump on a Central West NSW farm has led to big cuts in fuel costs, greater irrigation efficiencies and a massive reduction in greenhouse gas emissions.

Attracted by the drop in the price of solar panels in recent years and the prospect of the system paying for itself in less than four years, Andrew Gill and his family decided to install a solar diesel hybrid system at one of the pump sites on their Narromine farm.

The move has led to a cut in pumping costs from $76/ML to $41/ML, and slashed diesel use by between 45,000 and 55,000 litres a year. Over 25 years, that equates to a saving of more than 1 million litres of fuel and a reduction of over 3000 tonnes in carbon emissions.

CottonInfo Technical Lead Jon Welsh and Research Economist Janine Powell worked through project economics costings and carbon emissions profiling with the Gill family during feasibility.

“If potential productivity gains and environmental benefits exist, we need to share this technology and information with industry,” Mr Welsh said.

Mr Gill said while the environmental achievements were important, the clincher was the economic viability of the project which promised a quick return on investment.

“Diesel prices are the lowest they have been in 12 to 13 years, but it is not going to be cheap for the next 20 years, it is only going to go one way, and that’s up,” Mr Gill said.

“Solar is a way for us to have a better handle on what our input costs are going to be throughout the next 20 years of production. It is not often you can get that.

“For people who can use solar energy every day it is just mad not to do it.”

The Gills run sheep and cattle, and grow summer and winter dryland and irrigation crops, including 300 hectares of cotton each year.

They have no access to river water, only bore water. Their irrigation pumping system has traditionally been run exclusively by diesel pumps.

“For the past few years we have been trying to get better fuel efficiency out of

our diesel turbine pumps,” Mr Gill said.

“We found our turbines were at their highest efficiency point already. We couldn’t really achieve much more efficiency, so we looked at cheaper ways to get the water out of the ground.”

They decided to install the solar diesel hybrid system at one of their bore sites that provides year-round pumping into a large irrigation reservoir.

The new installation consists of 400 solar panels on four banks, producing 100 kilowatts of power to run a 55kW submersible pump that is being driven by a 70kW variable frequency drive.

Being a hybrid system, the pump is run on solar energy when there is sufficient irradiance from the sun, then switches to a diesel generator when the irradiance falls away.

“The diesel is more than just a backup. It allows the pump to run 24 hours a day in the peak pumping time,” Mr Gill said.

“The generator runs for about 14 hours a day when 24 hour pumping is required, but it also allows us to pump in a more cost effective way during the shoulder periods when the solar is not at maximum capacity, like first thing in the morning and in the early evenings.

“It is during these shoulder periods that we are able to blend the partial solar power with the diesel generator to pump water at a fraction of the diesel cost per megalitre.”

Mr Gill said he was continuing to look into ways to fine tune the system and improve its efficiency.

“We are planning to pump with solar over the winter but also using the generator to capture the shoulder periods to have our reservoir full for the start of the summer watering period. We might be more inclined to irrigate wheat (in the winter) if the water is on-hand and a bit cheaper. With real

time monitoring data through the 3G network we can watch our groundwater levels, troubleshoot remotely and quantify our diesel inputs far more accurately. It gives a lot more options.”

Likewise, he is weighing up the option of adding full battery storage to the system.

“It is a bit too expensive at the moment for what we are doing,” Mr Gill said.

“With the leftover energy we can produce through the day we can only really power about four extra hours a night of pumping production. With current storage prices that would be

somewhere between an eight and 10-year payback which is too far out for us at the moment.

“But battery storage prices are coming down. We are looking to see if there is a way of incorporating some battery storage into our system to stop the solar fluctuations through the day.”

Convinced that solar is the way of the future, Mr Gill plans to introduce more solar pump stations throughout the farm.

This project has been supported by funding from the Australian Government.

Reducing irrigation energy costs with variable speed drives

Variable speed drives (VSDs) offer energy savings for irrigators. In the past, operational needs informed pump selection decisions to use VSDs. Now as energy prices continue to rise, the opportunity to save costs is driving adoption of the technology. NSW Department of Primary Industries - Agriculture, Water and Irrigation Unit explains how VSDs can reduce operating head and energy usage in pumping plants.

Costs of irrigation

Three main factors adding to pumping costs and energy usage:

1. More water than necessary is being pumped and applied to a crop

2. The pump is operating away from its best efficiency point (BEP)

3. The pumping pressure, or operating head produced, is greater than necessary

Each of these issues can potentially be solved with the installation of a VSD system.

High and low demand pumping

Single speed pumps may be installed for a range of duties — usually sized to meet the greatest output demand. For lower demand use, these pumps will be oversized and operate inefficiently. Energy cost savings can be delivered by using variable speed to regulate the power needed to drive the pump, according to the duty. VSDs allow the pump to be over-designed to meet extreme requirements, without having continuous energy wasted during low demand.

VSDs allow small, rapid and regular variations in pump speed. VSD systems are often a viable option for pumps in highly variable demand situations, such as sequentially delivering water to irrigation units of variable sizes and elevation, and more frequent operations such as filter backflushing. VSDs offer convenience and great potential for energy cost savings if flow adjustments are required during irrigation.

The most popular and cost-effective

type of irrigation VSD is the variable frequency drive (VFD), which controls electric motors by varying the frequency and voltage supplied. Other options include multi-pump VSD systems, which can cater for very small to large flow rates.

Potential energy savings realised

As soft-start devices, VFDs have ramp-time adjustments for slow start and stop, can eliminate the problems of water hammer and excess power draw on start-up, and reduce or avoid flow or pressure surges. Reductions in speed can also reduce pump wear, particularly on bearings and seals.

Hydraulic optimisation, such as installing low pressure filters or driplines, can also lower the operating head, but unless the pump has the ability to respond to this lower head, energy savings will not be achievable. VFDs can respond and deliver potential energy savings.

Agronomic benefits

A VFD allows managers to adjust pumps to automatically suit conditions, eliminating unnecessary water delivery to irrigation patches. This improves irrigation scheduling, avoids rootzone waterlogging and water wastage, and increases the potential for high production, while keeping energy costs down.

Taking advantage of positive suction head

Some communal irrigation supply districts (e.g. Coomealla and Curlwaa in

the Sunraysia, and Leeton and Griffith in the Murrumbidgee Irrigation Areas) have a level of positive suction head delivered through a pressurised supply main.

When re-pumping is required to achieve a particular pressure and flow (duty point), a VFD makes best use of the supply pressure available. The level of supply pressure is often variable between and within irrigation events, making more permanent options such as fixed changes to pump speed (RPM), unattractive alternatives.

In a study conducted in Coomealla in 2011, it was found that if reasonable supply pressures are available at an outlet (100 kPa or greater), it was worth considering installing a VSD to take advantage of this supply pressure and reduce energy costs.

The study found VSDs reduced power consumption with increased inlet supply pressure had no effect on pumping efficiency or power consumption of fixed single speed pumps.

Although a fixed single speed pump requires less power when operating at low flow rates, power consumption was found to still be considerably higher than that of a variable speed driven pump at the same flow rates.

What to know before installing VSDs

Water supply

VFDs make it possible to achieve the very low flow rates that some irrigation systems might require. However, it is important to be aware that water meter accuracy can sometimes be

compromised at very low flows (e.g. 150mm propeller meters are inaccurate below 9 L/s) and approval from water supply authorities for diverting such low flows might be required.

Cooling

Cooling has been a particularly important consideration in the past, but new VSD technology now proves simple ventilation and insulation adequate in most cases. In some situations, the pumping unit is deliberately oversized to ensure less heat is generated. Some manufacturers now produce a ventilation attachment to electric motors to provide necessary cooling.

Hydraulic

To fully allow for the variable pressure requirements that can exist in an irrigation system, there should be at least two transducer set points. This is particularly the case for drip irrigation where a certain pressure is needed to operate the irrigation system, and higher pressure is required when backflushing filters and operating the system simultaneously.

One transducer set point located upstream of the filter bank, synchronised with timed backflushing, is required to increase the pump speed to meet backflushing requirements. Another transducer set point is located at a representative point in the field to ensure enough pressure is produced to operate the system. Further transducer points can be an advantage in irrigation systems where large elevation or spatial variations occur.

Pump efficiency

It is important to note that a VFD does not improve the pump efficiency. It simply reduces input energy requirements by producing the flow and pressure combination required at a particular operating time. Replacing worn pumps or impellers, trimming impellers and replacing mismatched pumps can improve pump efficiency.

When a VFD slows a pump down, the reduced flow rate can actually result in the pump operating less efficiently. However, energy use is still reduced, resulting in an energy cost saving. If the irrigation system requires significant flow rate variations or experiences frequently variable supply pressures, then using a VSD to slow

down and speed up the pump regularly in response will usually result in the greatest energy savings.

Managing the installation

VFDs can be retro-fitted to existing systems or installed with new systems. No two irrigation systems are alike, and no two VSD requirements are the same. The unique hydraulics of the system must be correctly merged with the unique electrical requirements for every situation. Specific issues for each situation involve identifying the appropriate location and setting of transducer set points.

There are instances of VFD equipment installation where the installer hasn’t realised the intricacies of the hydraulics and pump performance, resulting in a system that is energy inefficient. It is highly recommended that a professional pumping hydraulic design service evaluates your irrigation system before VFD equipment is purchased. It is also important that VFDs are commissioned correctly and all the safety cut-outs are set and tested. These are often overlooked, causing major issues over time.

VSD benefits NSW drip irrigation system

Andy Murdoch owns an 18 hectare vineyard, irrigated in four sections, in Coomealla NSW. With each section a different size, it required constant manual pump adjustment as the irrigation system did not allow for automated changeovers. The installation of a variable speed drive allowed this adjustment to occur automatically between different vineyard sections.