pumpindustry

Top reasons for SEAL FAILURE and how to avoid them

Redeveloping Reef HQ Aquarium’s plant infrastructure

Top reasons for SEAL FAILURE and how to avoid them

Redeveloping Reef HQ Aquarium’s plant infrastructure

REVITALISE HINCHINBROOK WATER TREATMENT PLANT

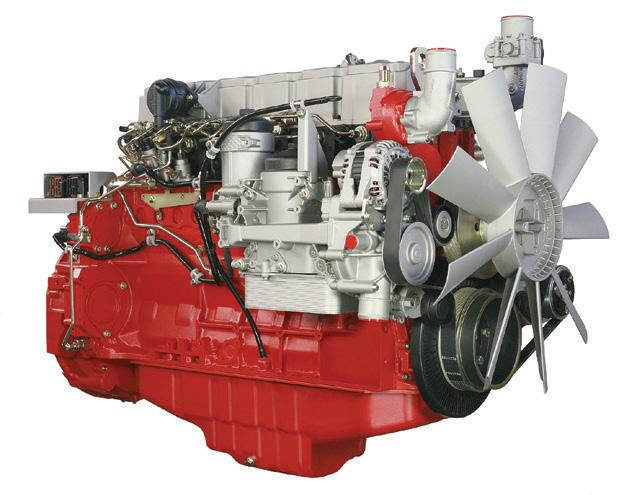

Volvo Penta. Robust, fuel efficient industrial diesel engines that keep running even in the toughest conditions. Easy to install, operate and maintain. A powerful partnership you can trust all the way from the drawing board throughout the operational life of your engine. Competitively priced complete power-pack units ready for delivery Australia wide with a local support team on hand 24/7. To find your nearest dealer visit www.volvopenta.com

Sense and Process

With this solution the following issues can be detected:

■ Ragging

■ Blockage by foreign objects

■ Faulty or damaged bearings

■ Faulty or damaged seals

■ Wear issues and rub issues

■ Imbalance

■ Cavitation

■ Looseness

■ Unusually high signatures in grinders and macerators

■ Excess Current

■ Sewage Level and Control

■ Flow and Temperature

Submersible pumps do the essential – but dirty work – of transporting sewage to treatment plants. Prone to blockages, ragging, and general wear and tear, pumps need to be monitored to avoid events such as overflow and environmental contamination of public and residential areas.

Optionally, the system can also monitor:

Direct Comms to PLC via front end dedicated ports is also available for:

■ Ethernet Ip

■ Modbus TCP/IP

■ Ethercat

■ Profinet

Hello all and welcome to the Autumn Edition of Pump Industry magazine. Much has happened since the last edition, as the world has changed significantly in more ways than one in recent months. I look at 2020 as being the year of the pandemic, 2021 the year of the variants and 2022 as the year where the welfare of many businesses is severely challenged as we see a continued wave of companies being liquidated, particularly in construction, as cost increases, supply chain issues and availability of staff exact a growing toll. Fortunately our industry, whilst certainly not immune, is better positioned to “weather the storm”.

with the Electrical Equipment Safety Scheme (EESS). For electrical safety, in-scope electrical equipment cannot be sold unless the item is marked with the RCM in compliance with AS/NZS 4417.1 & 2 and the EESS. Suppliers must be registered with the EESS Registration Database.

Pump Industry Australia Incorporated C/-340, Stuarts Point Road

Yarrahapinni NSW 2441 Australia Ph/Fax: (02) 6569 0160 pumpsaustralia@bigpond.com www.pumps.org.au

PIA Executive Council 2022

John Inkster – President Brown Brothers Engineers

James Blannin – Vice President Stevco Pumps & Seals

Kevin Wilson – Treasurer/Secretary Executive Officer

Alan Rowan – Councillor Executive Officer – Publications and Training, Life Member

Ken Kugler Executive Officer – Standards, Life Member

Michael Woolley – Councillor Tsurumi Australia

Geoff Harvey – Councillor Irrigation Australia Limited

Billie Tan – Councillor Regent Pumps

Steve Bosner – Councillor Pioneer Pumps

Joel Neideck – Councillor TDA Pumps

Mat Arnett – Councillor Ebara Pumps Australia

Jamie Oliver – Councillor Grundfos Pumps

And as if this wasn’t enough to contend with, an unprecedented weather event over a ten day period in February/March saw eastern Australia hit by unrelenting rain and flooding that affected approx. 1,000km of the Eastern Seaboard stretching from South East QLD to Southern NSW, causing destruction in its path and sadly the loss of 22 lives, followed by the massive clean up and thousands of insurance claims.

By contrast, parts of Australia are still suffering drought and low rainfall as La Nina and climate change create weather extremes. Sydney has recorded the wettest start to a year ever. The BOM has said that the Warragamba Dam was spilling the equivalent of Sydney Harbour each day; that is 500GL a day.

In terms of rare events, we already know several records were broken. Looking at the 676mm of rain that fell in Brisbane in 72 hours, statistically it is only expected to occur once every 200 to 500 years.

As the masks and social distancing regime of the last two years is gradually disappearing, PIA is hopeful of having more face-to-face meetings and in fact has received offers to host them; but in the meantime we are still planning more online seminars, the first of which was a seminar on Pump Performance Monitoring presented by Malcolm Robertson of Robertson Technology in March.

After the success of Rob Welke’s seminar on Energy Efficiency of Pipelines in November it is planned to have Rob run another seminar on Flow metering for on-site Pump Tests.

We are also trying to find a spokesperson to conduct a seminar on he Regulatory Compliance Mark (RCM), the scope of which has caused some confusion in the marketplace. The RCM is a trademark owned by the electrical regulator that represents compliance

In March, I received a call from a Senior Adviser in the Plumbing Drainage and Special Projects Division within the Department of Energy and Public Works, advising the Service Trades Council (STC) had acknowledged PIA’s request to have suitably qualified Members undertaking repairs and servicing of pumps installed as part of a plumbing or drainage system, and that our request was under review. Specifically, I was asked about training within the industry, and advised there were a number of private practitioners who offered courses, and that many of the larger companies had their own in-house training and professional development. I advised that IAA was the only training provider who was a recognised Registered Training Organisation (RTO) with a nationallyrecognised certification.

It was acknowledged that the PD Act was tightly regulated but there might be avenues they could investigate to facilitate the experience and capability 0f many of PIA’s Members in service and repair. The next meeting of the STC was scheduled for late March. This is a tentative but positive step in attempting to gain recognition for PIA Members based on their vast experience and knowledge. As more information comes to light, this will be shared with you all.

As I alluded earlier, the world has changed, not just with the challenges of factoring in price increases and the uncertainty of supply chains, but also with the Russian invasion in February of Ukraine, a European democratic country of 45 million people. Whilst Ukraine is a long way from Australia, the television and news media are able to show the terrifying and horrific scenes of a fullscale Russian invasion into our homes. This will have enormous humanitarian consequences for a long time to come. It is appropriate that Western nations, including Australia, have imposed severe sanctions on Russia and its political leaders. We all express our sympathy for the Ukrainian people; this is a very challenging time for them and we all hope that a cease fire has been reached by the time you read this editorial.

As always, I wish you all a COVID-safe, flu safe and prosperous year.

John Inkster - President

ABN: 36 426 734 954

C/- The Commons, 36-38 Gipps St, Collingwood VIC 3066 P: (03) 9988 4950 F: (03) 8456 6720 monkeymedia.com.au info@monkeymedia.com.au pumpindustry.com.au magazine@pumpindustry.com.au

Editor: Lauren Cella

Journalists: Annabelle Powell, Christopher Allan, Lauren DeLorenzo, Mikayla Bridge

Business Development Managers: Rima Munafo, Jacob Trad

Design Manager: Alejandro Molano

Designers: Luke Martin, Danielle Harris, Jacqueline Buckmaster

Marketing Manager: Radhika Sud

Digital Marketing Assistants: Andie James, James Holgate

Publisher: Chris Bland

Managing Editor: Laura Harvey

ISSN: 2201-0270

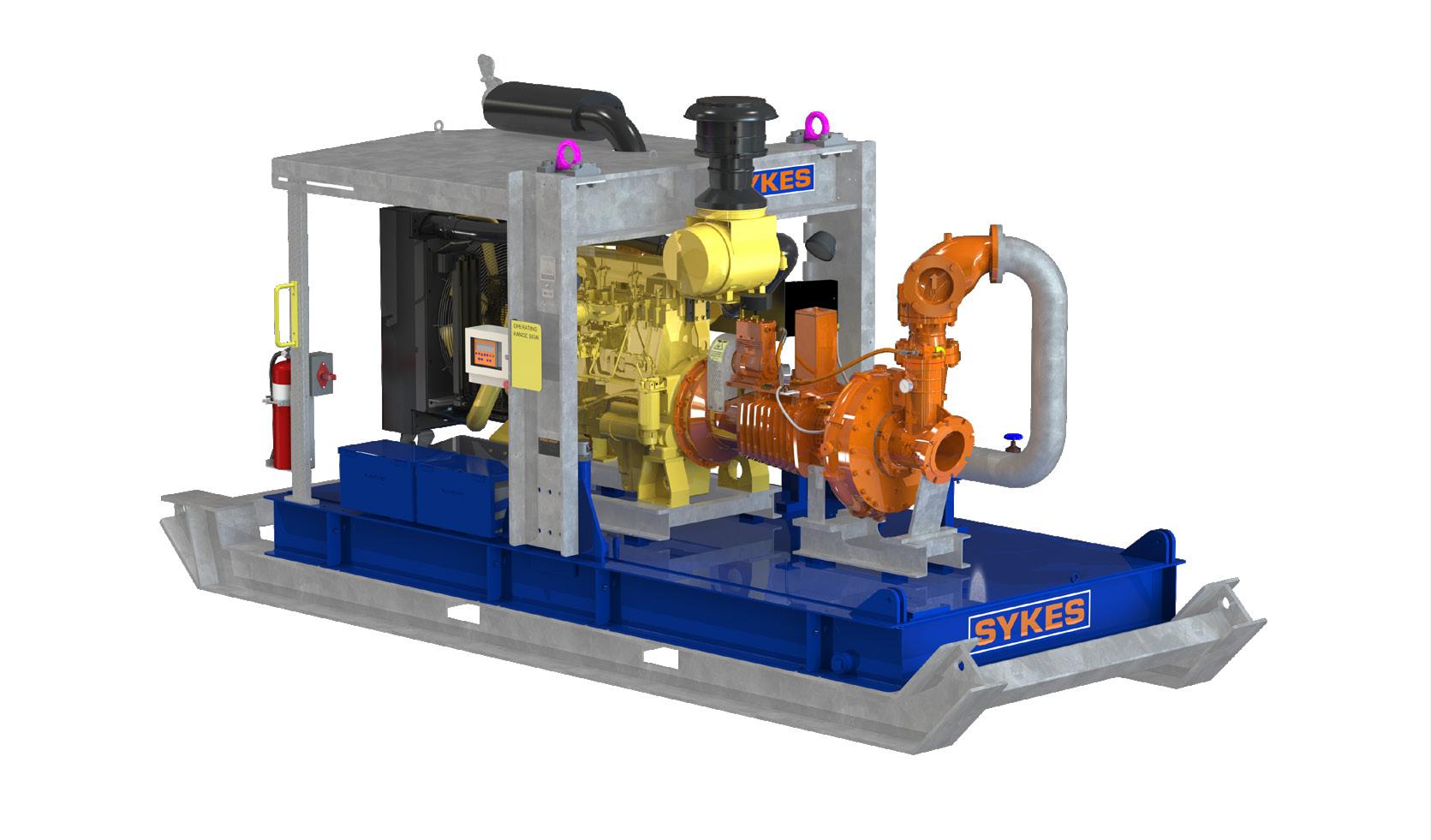

$34 million of sewer upgrades for Melbourne’s northern suburbs are now complete, with project outcomes including a new high-flow pump station and almost 10km of new sewer pipes.

Yarra Valley Water undertook the Doreen to Diamond Creek Sewerage Project over two years, investing in a robust sewer network for a growth corridor in Melbourne’s north.

The project involved building almost 10km of new sewer pipe under parks and roads, as well as supporting infrastructure like a new high -low pump station.

Yarra Valley Water’s General Manager Growth Futures, Chris Brace, said the project, which ran around the busy Yan Yean and Ironbark roads, would service properties in the rapidly expanding Mernda and Doreen areas.

“It will ensure the reliability of the sewerage system and reduce the likelihood of sewage spilling into the environment during heavy rain,” Mr Brace said.

“We’ve worked with our delivery partners, MFJ Constructions and Jaydo, to deliver the project, which is among the top ten projects we’ve committed to complete for our customers.”

Mr Brace said special care had been taken throughout construction to save trees and avoid disrupting areas of cultural sensitivity, including a large stone tool artefact identified near the Plenty River.

This included the use of trenchless drilling technology to reduce excavation, protect more vegetation, and minimise disruption to the community.

“Design partner Jacobs also salvaged almost 400 artefacts at the start of construction and we worked in partnership with the Wurundjeri Woi Wurrung Cultural Heritage Corporation to sensitively repatriate them,” Mr Brace said.

“Our approach to this project is a great example of our commitment to care for customers, the community and environment while providing vital sewerage infrastructure where it’s needed.”

The team also adapted to COVID-19 restrictions to ensure the project was delivered on-time and under budget.

The project included resurfacing of Murray Road to reduce dust, as well as construction of a 2km shared-use path, to improve public access in the Plenty Gorge parklands.

The 24,500ML Tamar Irrigation Scheme has reached a new milestone, with the launch of the Preferred Option Design, which includes five pump stations and 240km of pipeline.

The $288 million scheme covers an area of 89,000ha, and will support agricultural diversity and new jobs in the Tamar Valley.

This design centres on harvesting water sustainably from the Trevallyn Dam and delivering this high-surety irrigation water via 240km of pipeline and five pump stations to landowners located on the East Tamar in areas like Lilydale, Hillwood, Pipers River and Pipers Brooks, and on the West Tamar at Rowella, Beaconsfield, Legana and Westwood.

Once operational in 2025-26, it is forecast that the Tamar Irrigation Scheme will create more than 600 direct and indirect jobs.

Additional on-farm investment is already being planned, with some farmers planning to double the area planted to berries and expand operations across the dairy, fruit, vineyard, livestock and cropping sectors in the region.

This project is one of the many Tranche Three irrigation schemes being developed by Tasmanian Irrigation that play a vital role in assisting the Tasmanian Government reach its target of increasing the farm gate value of the state’s agricultural sector to $10 billion a year by 2050.

The Tasmanian Government continues to work with the Federal

Government and local farming communities to deliver irrigation projects across the state, rolling out Tranche Three projects including: the Don, Northern Midlands, Sassafras Wesley Vale and the estimated $370 million South East scheme.

The South East scheme will be the biggest irrigation project in Tasmania’s history, expected to deliver more than 40,000ML annually, supporting a further estimated $150 million in on-farm investment, with the potential to create more than 2,000 local jobs.

The Tasmanian Government is also progressing the development of a business case for an estimated $300 million Southern Midlands Irrigation scheme, which will deliver a similar economic benefit to the heart of Tasmania.

Standards Australia has shown its support for international efforts to pressure Russia to withdraw from Ukraine, encouraging ISO and IEC to take stronger action.

Standards Australia considers the invasion of Ukraine by the Russian Federation to be unprovoked, unjust and illegal. Russia’s war on Ukraine is exacting a catastrophic humanitarian toll and many organisations have suspended activities in Russia to show support.

In a statement to stakeholders, Head of International, Karen Batt, said that Standards Australia strongly supports Ukraine’s sovereignty and global calls upon Russia to cease its attacks on Ukraine.

Ms Batt believes that ISO and IEC should take a stronger position condemning the violence and supporting global efforts to pressure Russia to cease its invasion of Ukraine.

Regarding the situation, ISO and IEC have shared in communications that:

• The IEC has suspended technical committee activities where Russia is leading the work

• ISO has postponed any meetings of Technical Committees under the leadership of Russian ISO members

• ISO and IEC have also highlighted that they are international organisations that provide an open and neutral platform for collaboration on technical matters which results in consensus-driven solutions Standards Australia has made both organisations aware of its views on the conflict.

In any case, and until such time any other provisions are put in place by ISO and IEC, Standards Australia will support its stakeholders in continuing to contribute to international standards development that supports the multilateral rules-based international

order. Equally, it respects the decisions of any contributors who choose not to participate in technical committee activities involving Russian institutions. Standards Australia recommends that stakeholders contact their Mirror Committee Project Manager or Standards Australia’s international team (intsect@standards.org.au) if they would like to discuss in more detail. VERTICAL TURBINE PUMPS

Layne Bowler vertical turbine pumps have a proven record under the most demanding and toughest of conditions.

• Flows to 7,500 L/Sec

• Heads to 500 m

• Power to 1000+ kW

• Temperatures to 150°C

• Bowls Diameter up to 45 inch

WELCOME TO THE

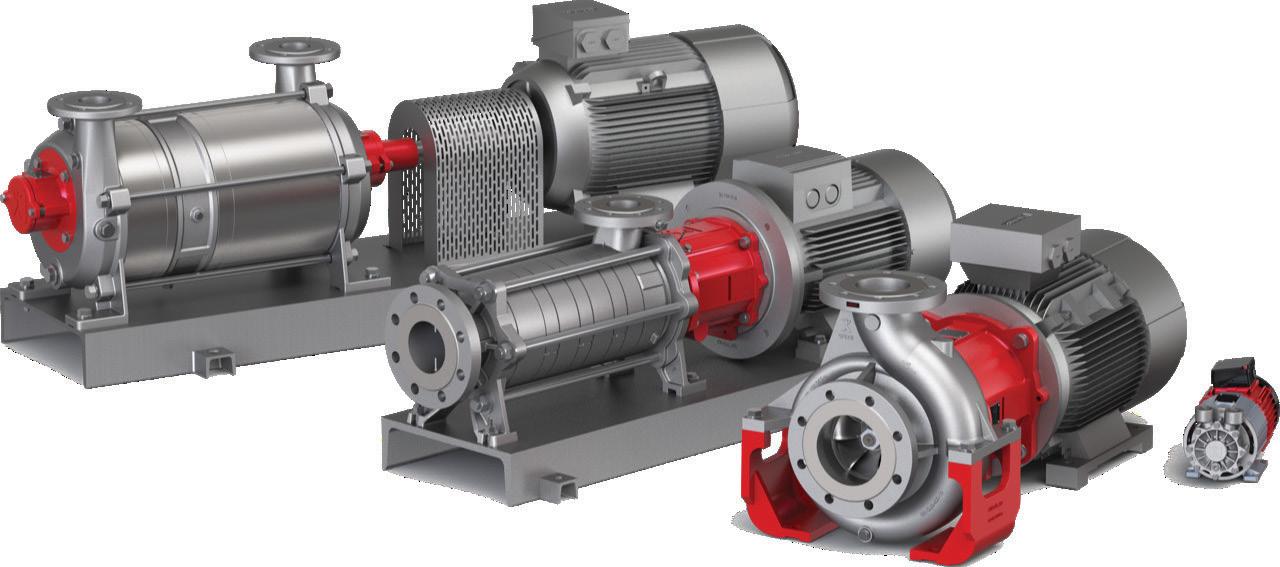

When high head and high flows are required look no further than this quality Italian made range.

• Flows to 5000m³/h

• Head to 220m

• Pumps that exceed EN733 (DIN 24255 standard)

New geotechnical drilling and ground investigations are underway at Borumba Dam near Imbil, Queensland, to help determine its suitability for a landmark clean energy project.

The findings of the ground investigations this year will help determine if a proposed pumped hydro energy storage project could help power two million Queensland homes.

Pumped hydro stores energy by using two reservoirs at different elevations, circulating and reusing the same water.

Its ability to store significant amounts of energy would allow more renewable solar and wind power to enter the market in Queensland.

For pumped hydro at Borumba, a new dam would be required upstream of the existing Borumba Dam to create the upper reservoir and be filled from future rain events.

Headrace and tailrace tunnels, and an underground power station would link the two dams to enable water to be pumped from the lower reservoir to the upper reservoir, and for water released from the upper reservoir to drive turbines to generate renewable electricity.

Queensland Minister for Energy, Renewables and Hydrogen, Mick de Brenni, said the Queensland Government and Powerlink were collaborating to undertake the necessary site research.

“Pumped hydro at Borumba could deliver more clean energy to Queensland, and support 2,000 jobs during construction,” Mr de Brenni said.

“Borumba’s existing dam infrastructure and location in the electricity network shows its potential to support development of more renewables in the Southern Queensland Renewable Energy Zones.

“But there is more work to be done to ensure high levels of environmental protections, and community consultation will play a critical role to ensure that.

“We’re investing $22 million into this, so the process will be thorough and well-considered.

“Over the coming months, our investigations will include detailed hydrological modelling, design of environmental protections, local community and economic opportunities, engineering design and financial modelling.

“This early geotechnical work involves small-scale drilling to investigate geological aspects of the area as part of those wider studies.”

Geotechnical drilling and testing will primarily focus on three main areas around Borumba Dam, including the proposed location of any new dam wall, upper reservoir and underground power station.

The Federal and Tasmanian Governments are partnering to deliver a $18 million Shellfish Lease Water Quality Improvement Program, upgrading 84 sewerage pump stations across the state.

Tasmanian Assistant Minister for Forestry and Fisheries and Senator for Tasmania, Jonno Duniam, said the funding would upgrade TasWater infrastructure, automation, monitoring and control systems for pump stations, close to the shellfish lease areas, across the state.

The project is made possible through the Federal Government’s National Water Grid Fund, with four projects in Tasmania receiving a grant of $5 million each, including the Shellfish Lease Water Quality Improvement Program.

Tasmanian Minister for Primary Industries and Water, Guy Barnett, said the upgrades will improve TasWater’s facilities while reducing spills and protecting the local oyster farms, the community and jobs in regional Tasmania.

“Tasmania’s $30 million shellfish industry is spread across more than 100 shellfish farms, providing around 300 jobs,

however, a key threat to the industry is sewage spills from TasWater facilities due to rain events or asset failure which can close leases for 21 days.’’

The Federal and Tasmanian Governments state that these upgrades are vital and will provide national-standard infrastructure for future generations.

“Tasmania produces some of the best shellfish in the world, and it is important that we continue to protect local oyster farms and the community from spills,” Mr Duniam said.

“This project will improve TasWater’s facilities in order to reduce spills, delivering better outcomes for both producers and the environment.

“This is a great example of the Commonwealth and Tasmanian Governments working together to deliver for our shellfish operators, and I look forward to working with the Tasmanian Government further in this area.”

The National Water Grid Fund has supported $52.1 million in new and upgraded infrastructure in Tasmania, which will create 53 jobs during construction and 70 ongoing jobs.

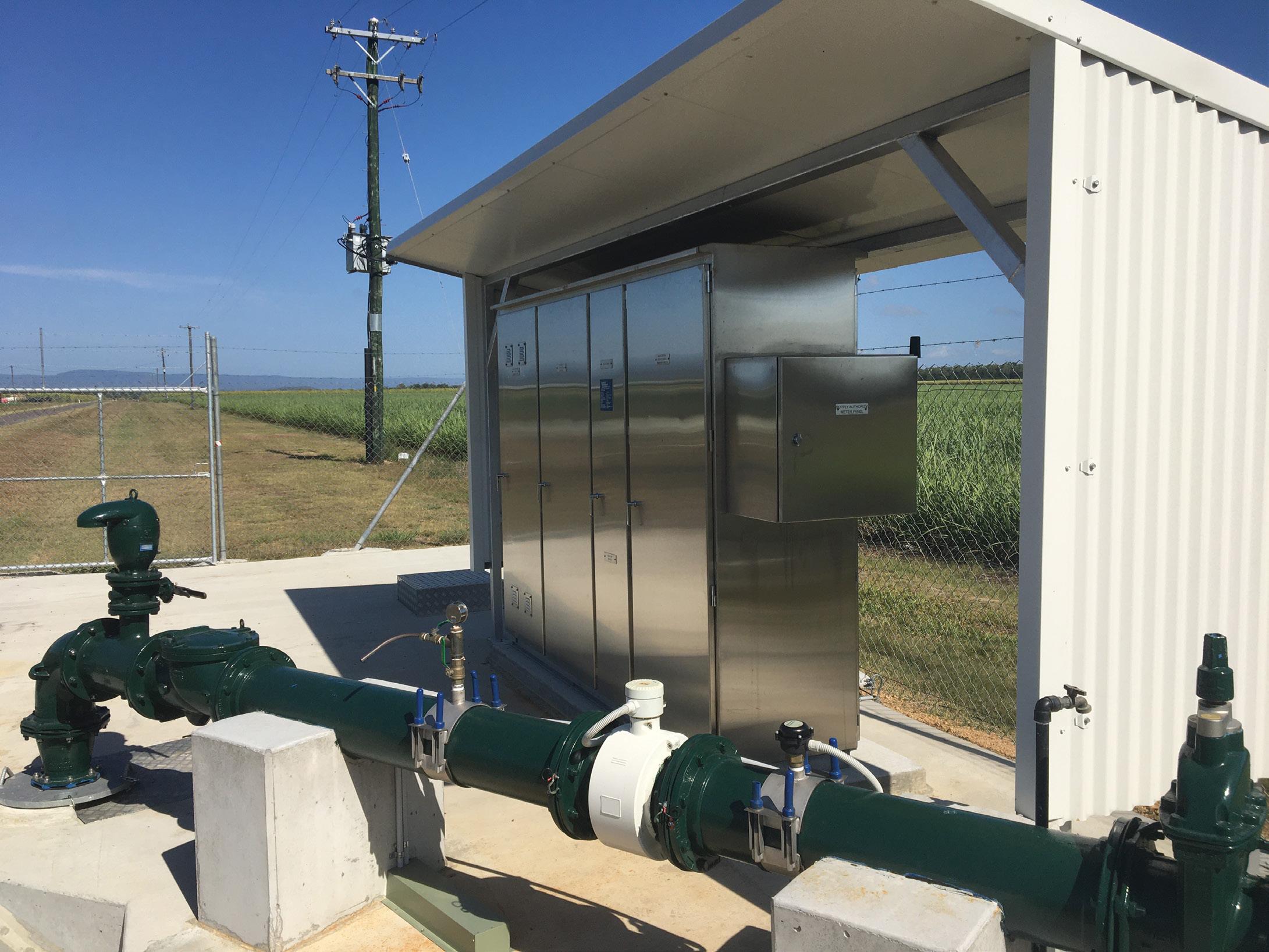

Anew recycled water scheme will strengthen water security for Wamuran farmers, providing year-round supply for one of the country’s fastest growing regions.

Unitywater is building the Wamuran Irrigation Scheme (WIS), which will take Class A recycled wastewater from the Caboolture South Sewage Treatment Plant (STP) to a number of farms for irrigation.

This project ensures a sustainable future for the growing regional population and reduces the nutrient discharge into the Caboolture River.

In Stage 1 alone, eleven tonnes of nitrogen and 1.8 tonnes of phosphorus will be diverted away from the river.

Unitywater Chairman, Michael Arnett, said the pipeline was an important investment to support population growth in the region and reinforced Unitywater’s approach to sustainable development.

“This is an exciting opportunity for Unitywater and the community, and we’re proud to be contributing to the sustainability of this region,” Mr Arnett said.

“Higher wastewater volumes due to the increasing population in the Moreton Bay region was the catalyst for the scheme.

“In its first stage, it will deliver about 2.6GL of recycled water per year to a number of farms in the region that were selected to demonstrate the feasibility of the scheme.

“That’s the equivalent of 1,051 olympic swimming pools.”

Mr Arnett said the scheme was being built by the Wamuran Irrigation Scheme Joint Venture – made up of contractor Pensar and two local growers, Twin View Turf and Pinata Farms.

The joint venture was awarded the design and construction contract in October 2019, following an openmarket tender process.

“The design has now been completed and Unitywater is thrilled that this exciting project is coming to fruition,” Mr Arnett said.

Pensar Managing Director, Karl Yunker, said the project provided local growers with climate-independent irrigation, while reducing demand on dams and creeks, and diverting discharge into local river systems.

In turn, the scheme provides Unitywater with an efficient solution for water reuse and sustainable irrigation.

“We formed a joint venture with two of the main irrigators in the region so we could tailor a solution with the end user in mind – making sure that what we’re proposing, designing and delivering meets the needs of growers, and ultimately, Unitywater,” Mr Yunker said.

Moreton Bay Regional Council Mayor, Peter Flannery, said Council was excited to have the innovative environmental project in the region.

“Moreton Bay is the third largest council in the country, and we have one of the fastest growth rates in Australia,” Mr Flannery said.

“This project helps address our expanding population and aligns with our environmental initiatives.

“It will create more jobs in the agricultural and downstream industries, and have positive flow on effects for the local community.”

Pinata Farms Managing Director and third generation business owner, Gavin Scurr, said the scheme would significantly benefit the region.

“The Wamuran Irrigation Scheme provides water security, potential for greater crop production, and creates employment within the local region. The whole community benefits,” Mr Scurr said.

Twin View Turf General Manager, Lawrence Stephenson, said the Wamuran Irrigation Scheme was critical for water security in the region.

“It will allow growers to build strong businesses that aren’t vulnerable to changes in weather events and patterns, building a solid foundation for the future,” Mr Stephenson said.

“The region has a number of longterm agribusinesses including avocado, pineapple, berry and turf producers planning sustainable futures that span the next 30 years.

“The Wamuran Irrigation Scheme brings significant confidence to this local industry.”

Construction was anticipated to begin in February 2022, with the scheme expected to be operational in mid-2024.

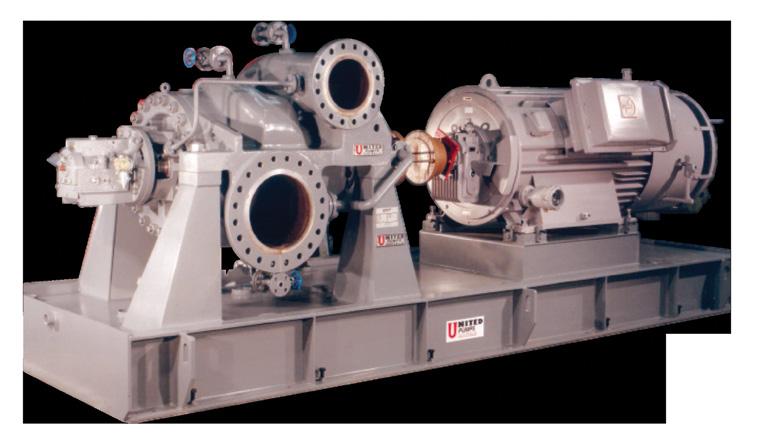

United Pumps designs and manufactures pumps, our extensive Melbourne testing facility is utilized for product development, new pump test and customer pump testing. 2.5Mw capacity with NPSHr capability.

United have made a commitment to API610 pump manufacture in Australia. With decades of experience, we can provide you with the finest engineered equipment and support

Our extensive range of process and water pumps are available in materials to suit your application. With all design and manufacture carried out in Australia we can offer a true Sovereign solution.

Proven track record in municipal water applications over a wide range of the highest quality pumping equipment. Horizontal Split Case, Vertical Turbine, End Suction and Sewage.

EnergyAustralia has commenced construction of Tallawarra B, Australia’s first net zero emissions hydrogen and gas capable power plant, that’s due to be completed by the summer of 2023/24.

Tallawarra B will be located on the shores of Lake Illawarra at EnergyAustralia’s existing Tallawarra Power Station, near Wollongong.

Tallawarra B is one of several projects the business is developing that contribute to the clean energy transition.

The 316MW power station, being built with the support of the New South Wales Government, will sit alongside the existing Tallawarra A power station on the shores of Lake Illawarra in New South Wales, and pave the way for more renewables to enter the system.

EnergyAustralia’s Chief Operating Officer, Liz Westcott, said the start of construction is great news for the local area.

“It’s an exciting time for the Illawarra, with the construction phase creating about 250 jobs and expected to deliver a boost to the economy in the hundreds of millions,” Ms Westcott said.

“The cranes, backhoes and concrete pumps helping build Tallawarra B are local, and so are the people that operate them.

“And where we can, we’re sourcing the plant’s components from local suppliers. It’s a real win for the region.

“Tallawarra B will be stepping in just as Liddell Power Station retires. It will provide quickly dispatchable power for around 150,000 homes when they need it most.

“The new power station will be a first of its kind in Australia –capable of utilising a mix of green hydrogen and natural gas.

“And the plant’s direct greenhouse gas emissions will be fully offset over its operational life.”

During the current stage of construction, major excavations are taking place ahead of the forming and pouring of the main foundations. In May 2022, the gas turbine will be craned into place on top of the foundation.

Once the plant is up and running, EnergyAustralia will offer to buy 200,000kg of green hydrogen per year from 2025.

“What’s particularly exciting is that we will be conducting engineering studies to see if the amount of green hydrogen can increase,” Ms Westcott said.

“We’ve made a commitment to be net zero (scope one, two and three) by 2050, to be out of coal by 2040, and to reduce our direct emissions by 60 per cent by 2028/29 relative to 2019-20.

“And the construction of Tallawarra B is just one of the ways we’re making our promises a reality,” Ms Westcott said.

Around 50 people are currently working at the construction site, which will increase to 250 towards the end of 2022. Ms Westcott has said that keeping workers and the community safe during the current COVID-19 pandemic is a priority during the works.

Northern Australia Infrastructure Facility (NAIF) is set to invest $255 million in upgrades to common-user infrastructure, including a $95 million loan to Water Corporation for the expansion of the Burrup seawater supply and brine disposal scheme.

The Water Corporation investment will support the proposed $4.3 billion Perdaman Urea Project, which is located 20km north-west of Karratha. The project will convert Western Australian liquefied natural gas into about two million tonnes of urea per year (urea is a widely used form of fertiliser for food production).

The Burrup seawater supply and brine disposal scheme will connect to the Perdaman Urea Plant once built.

The two loans are the first NAIF investments into Western Australian Government entities, and include:

• $160 million to the Pilbara Ports Authority for a new multiuser wharf and facilities at the Port of Dampier

• $95 million to Water Corporation for the expansion of the Burrup seawater supply and brine disposal

Western Australian Water Minister, Dave Kelly, said, “The Western Australian Government has committed to upgrading the common-user infrastructure needed to support the Perdaman Urea Project.”

The NAIF loans build on Western Australian Government support for the project, which has provided $47.6 million for road relocation costs, the detailed design of a new Dampier Cargo Wharf and upgrades to seawater supply infrastructure.

Western Australian Regional Development Minister, Alannah MacTiernan, said that the government has also supported this project because it develops manufacturing capabilities and because of its commitment to working closely with Murujuga Aboriginal Corporation.

It is estimated the Perdaman project will create around 2,500 jobs during construction and 200 operational jobs.

Western Australian State Development, Jobs and Trade Minister, Roger Cook, said, “Recent international supply chain issues have highlighted just how important urea is to industry sectors such as agriculture and transport.

“Western Australia has the potential to supply these sectors with the urea they need.

“As the first new gas manufacturing project in the Pilbara for more than a decade, the Perdaman Urea Project will play a role in helping diversify Western Australia’s economy and create local jobs.”

Any WA Government financial contribution is subject to a number of conditions, including the project reaching financial close and all statutory and regulatory approvals being met.

Kelair Pumps Building & Fire Division is one of the most technically-competent suppliers in Australia. We can provide a complete range of fire sprinkler pumpsets for all applications, fully compliant to technical specificiations.

- Purpose built to individual requirements

- Compact, pre-fabricated, complete packaged solutions

- Fully tested to AS2941/ISO9906 and pre-commissioned

- Turnkey installation saves time and labour costs

- Simple to mobilise and transport

- Routine maintenance packages also available

We know the importance of choosing the right equipment to match your process. With our extensive range of pumps, first class customer service and ongoing comprehensive support, Kelair Pumps are second to none when it comes to your pumping requirements.

South Australia is one step closer to delivering its major Northern Water Supply project following a $15 million commitment from both the Australian and South Australian Governments for a business supply case.

Among the options being considered is a desalination plant located in the Upper Spencer Gulf, which would reduce water reliance on the Great Artesian Basin and the River Murray.

If construction proceeds, the project could support up to 8,000 construction jobs and up to 6,000 ongoing jobs once operating.

Deputy Prime Minister, Barnaby Joyce, said delivering a secure and sustainable water source in the region would drive the growth of regional communities and industries.

“Our $5 million investment builds on the state’s $10 million commitment to progress a business case that will inform the future direction of this much-needed project,” Mr Joyce said.

“A safe, reliable and sustainable water source will improve water security, create jobs and help unlock the economic potential of new and expanded opportunities for businesses in the state’s north.

“Since 2015, the Australian Government has committed more than $75 million from the National Water Grid Fund towards projects in South Australia.

“This includes projects supporting premium grape production in McLaren Vale, water security for farmers on the Coolanie Plains, and new water for agribusinesses through the Northern Adelaide Irrigation Scheme.”

Mines in northern South Australia rely on these sources for their groundwater, which can be expensive to extract and can be affected by salinity and other water quality issues.

Previous attempts to provide a sustainable water supply to this vast region have not been successful because they have lacked a strong customer base.

To support the business case, the South Australian Government entered into a Memorandum of Understanding (MOU) with SA Water, BHP and Oz Minerals to progress the projects and address the region’s water needs.

Former South Australian Premier, Steven Marshall, said this was why it has been important for the government to play a coordinating role to bring together a range of potential customers to make this project possible.

He said the Northern Water Supply project has the potential to create thousands of jobs throughout South Australia.

“This project is a once-in-a-lifetime opportunity to secure a brighter future for South Australia and create jobs in an environmentally sustainable way,” Mr Marshall said.

“We are always looking for ways to ensure we are using water efficiently because ongoing and secure access to water is integral to economic growth and regional communities rely on industry for jobs, community strength and resilience.

“A desalination plant is an option we will investigate to provide a sustainable and sufficient water supply to support many industries, including the burgeoning hydrogen industry, mining, horticulture, pastoral, agriculture sectors and the transition to green steel.

“To be able to partner with some of South Australia’s biggest companies to decrease reliance on our finite water resources and future-proof our state in a changing climate is really pleasing.”

Federal Member for Grey, Rowan Ramsey, said the expansion of the resources industry in the north of the state was a reality and not some dream in the far-off future.

“South Australia already relies heavily on the resources industry and water is an essential ingredient to mine, concentrate and process our product,” Mr Ramsey said.

“Currently, this water is sourced from either the Great Artesian Basin or the Murray River, and trying to extract more from these sources is not environmentally sound.

“We are well aware of the long-term issues with the Murray, and the Great Artesian Basin is a national treasure which is vital to our traditional grazing industries and small communities that continue to thrive in our harsh environment.

“While we know the basin replenishes, it is an incredibly slow process and maintaining the pressure in the basin is of paramount importance. Simply, we cannot continue to grow the resources industry without finding a new source of water.

“It is encouraging that our two biggest players in the industry, BHP and OZ Minerals, recognise the need and are part of the MOU.

“Desalination would seem the obvious answer, but there will be a whole lot of community concerns which will need to be addressed along the way. This project will do that.”

Infrastructure Australia has recognised the importance of a new sustainable water source to improve water resilience and increase water supply to the northern parts of South Australia.

Polymaster’s unique Enclosed IBC Bund solves many of the problems associated with IBC storage and chemical/fluid decanting in a weather resistant, purpose-built enclosure.

Æ Full weather protection – stops rain entering the enclosure

Æ Easy forklift loading with wide forklift access from both side and back

Æ 250ltr day tank

Æ Lockable cabinet to keep system secure

Æ Venting by two sides

Æ Viewing windows incorporated into the doors

Æ 110% bund capacity complies with AS3780

Æ Sight tube and low-level alarm available

Æ Chemical resistant – high grade polyethylene construction

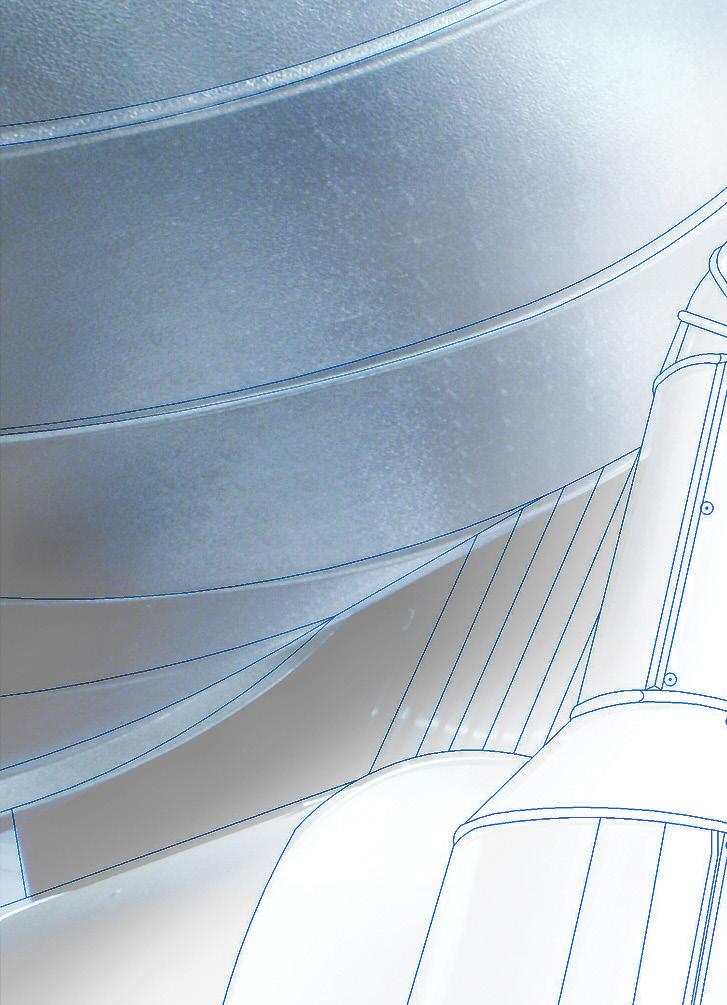

The iconic Fitzroy swimming pool, operated by the Yarra City Council and Yarra Leisure, has recently installed three new Ebara GSD 100-250/11kW close coupled EN733 motor pumps as part of its filtration pump upgrade.

The Ebara GSD motor pump was chosen by mechanical services contractor, Mechanical Plumbing Services (MPS), due to its quality, proven hydraulic design and competitive pricing. The GS/GSD pumps come as standard with a high-quality electro deposition corrosion-resistant coating to the ferrous static components, both internal and external, making them ideally suited to harsh swimming pool environments.

The GS/GSD range is the Ebara Corporation (Japan) new global range of EN733 water pumps and utilises the most advanced hydraulic computer software available. Ebara Engineers in Japan have been able to improve and increase the pump efficiencies of the new GS/GSD range above most other available pumps of similar design and standard on the global market. The majority of the GS/GSD pump range are MEI>0.7 efficiency index with the balance MEI>0.6, an indication of the high-quality design and manufacture by Ebara.

The Ebara GSD range of close coupled motor pumps and the GS range of bare shaft EN733 end suction pumps are both manufactured in component form at Ebara Corporation (Japan)-owned and managed factories in South East Asia.

After being assembled from these components by skilled tradesmen at the Ebara Pumps Australia facility in Melbourne, the pumps are then hydrostatically tested and inspected to our Japanese parent’s strict QA policies and procedures.

The Ebara GS/GSD range of EN733 pumps are a true 16 bar working pressure with a high grade SiC/Carbon/EPDM Burgmann mechanical seal fitted as standard. Galvanised steel baseplates that have been fully engineered by Ebara Japan engineers are also available as an optional extra for the GSD motor pumps.

About Ebara Corporation

Ebara Corporation was founded in Japan in 1912 as a manufacturer of industrial pumps. Today, as a group it consists of more than 70 companies in six continents with a workforce of more than 12,000 and with company-owned and Japanese-managed factories covering nine countries and four continents.

The huge scale of production and distribution is matched by a constant commitment to research, development and design of new products and the modern technologies for the manufacturing of them. Ebara products have gained a worldwide reputation for their technology and quality.

Combining over 100 years of experience with the latest computer aided design, EBARA has developed the new GS series of pumps that offer world leading performance and efficiencies.

Pumps to EN733 dimensions

16 Bar rated. PN16 flanges (24 Bar hydrostatic test pressure)

High efficiencies. MEI ³0.6 (Minimum Efficiency Index)

Mechanical seals to EN12756

Protectors to ISO13852

O’ Ring seal for casing

Cast iron components ED painted (Electro deposition painting)

When we started to think about Esybox Max, we asked ourselves how to manage the evolution of the Esybox range. It was clear from the very beginning, it could not just be something bigger. We felt we had to bring forward the path of evolution, completely changing the rules of the game for booster sets in residential and commercial buildings. Esybox Max is the outcome of listening to and communicating with many different people who will be in direct contact with the product.

Introducing a new concept and industry first in the booster set industry, Esybox Max is an integrated pumping system for pressurisation in commercial building services. Available in two power sizes, it consists of modular elements that allow different configurations to cover the needs of medium/large apartment blocks and high buildings (even over 14 floors). Each unit consists of the single, double or triple connection base and the pumping units – a four-pump system is available with the additional kit to connect two double bases.

Large energy savings are achieved with the DAB inverter combined with a brand new permanent magnet motor. DAB also designed completely new hydraulics, making it leaps ahead in terms of energy efficiency. But it is not just energy efficiency that is at the forefront of this new technology.

Esybox Max will improve the storage efficiency in the warehouse. Where there was once one booster occupying space, you can now fit three twin pump booster sets in its place. This allows people to store the full range on one pallet, meaning a customer can pick up an off-the-shelf booster solution of up to four pumps on the same day. Keeping it flexible, DAB has the on-site assembly concept. So if you have difficulties getting to the pump's location, due to narrow stairways and corridors etc., you can choose to assemble your booster on-site which will only require moving smaller, lighter boxes into the location then carrying out a quick and easy assembly.

DConnect

The Esybox Max also offers full connectivity and control using DAB’s

DConnect technology which is built into the pump and offers many more advantages than typical BMS systems. Performance, data storage and remote monitoring support users, and facility managers can control their pumps from anywhere, making sure that the running parameters of the pumps follow project specifications exactly and avoiding any possible site issues for complete peace of mind.

(1) Display (2) Inverter

(3) Module Wifi/Bluetooth

(4) Pressure sensor (delivery side)

(5) Pressure sensor (suction side)

(6) Non-return valve

(7) Two Litre expansion tank

(8) Impellers

(9) Hydraulic connections

(10) Fast connection tool

(11) Water cooled permanent magnet motor

(12) Handles

The DAB inverter has been combined with a brand new permanent magnet motor. We also designed completely new hydraulics, making it leaps ahead in terms of energy efficiency.

The most compact and integrated booster set on the market. Connect 1, 2, 3 or 4 Esybox MAX units.

Easy to maintain

Connect and control from anywhere with DConnect.

Easy to move & install

Quick On-Site Assembly.

Affordable web based remote control for your installation

With DConnect you can use your smartphone to connect directly with the pump using the simple interface. All adjustments are possible remotely, allowing total control with no unwanted surprises.

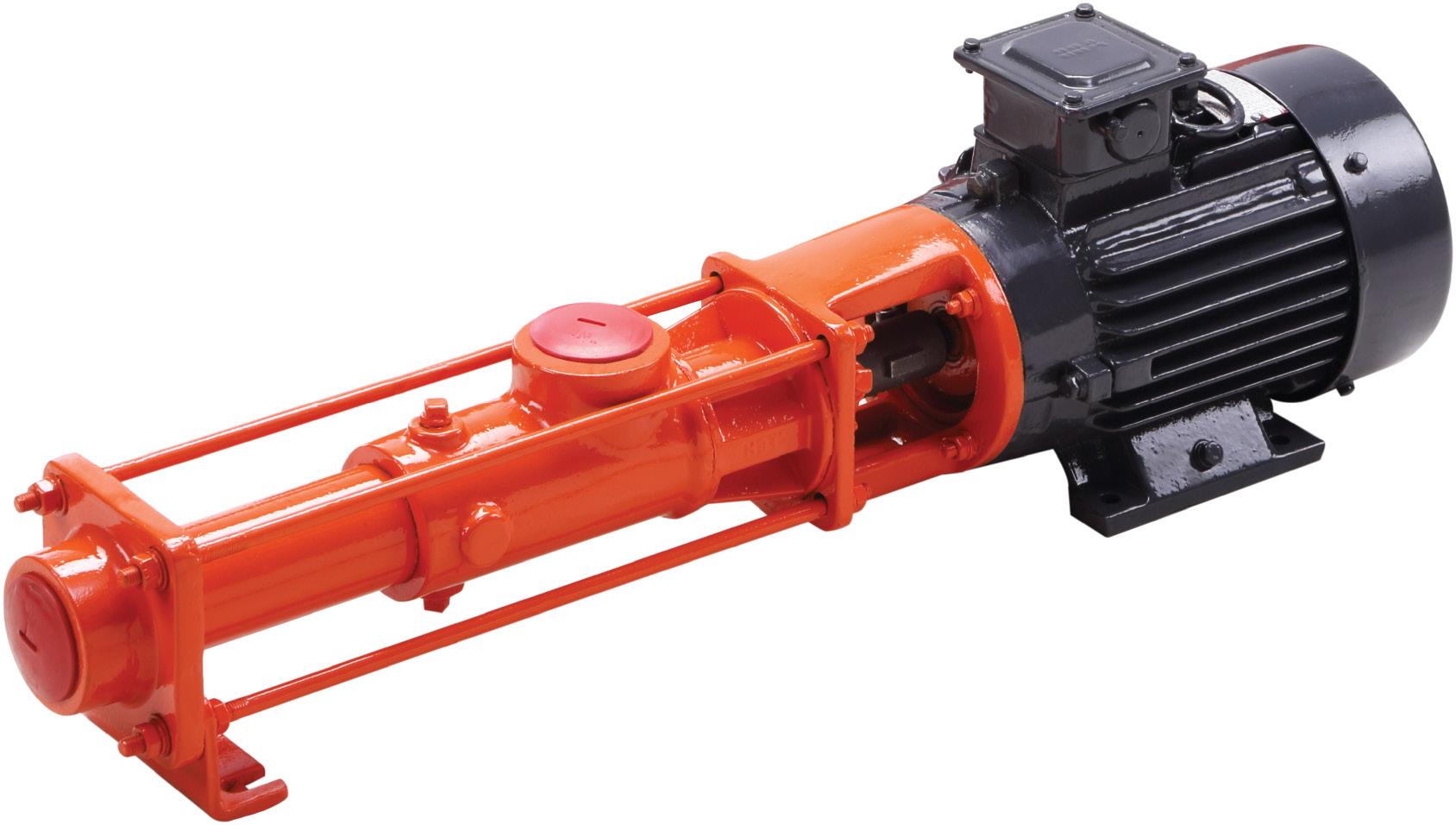

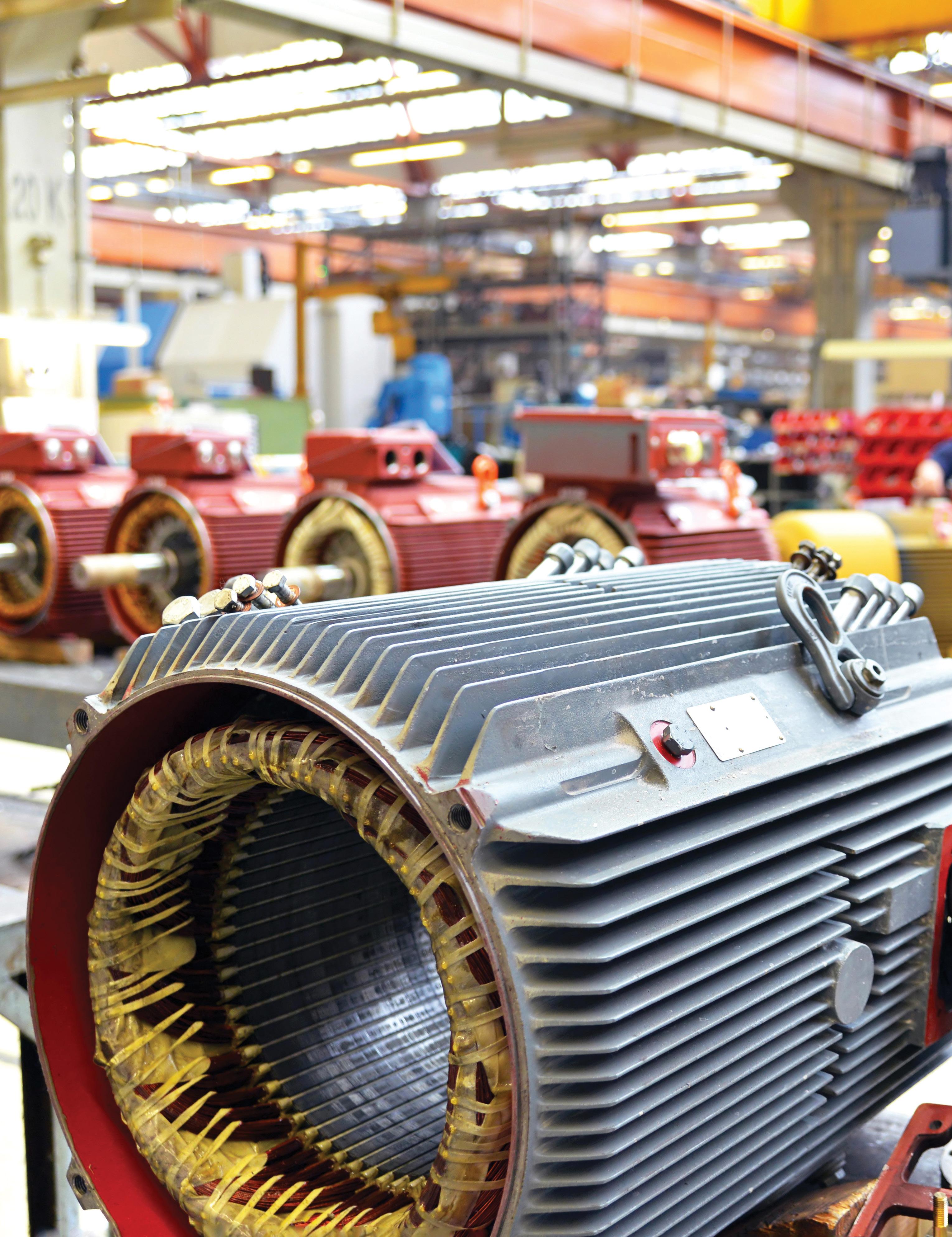

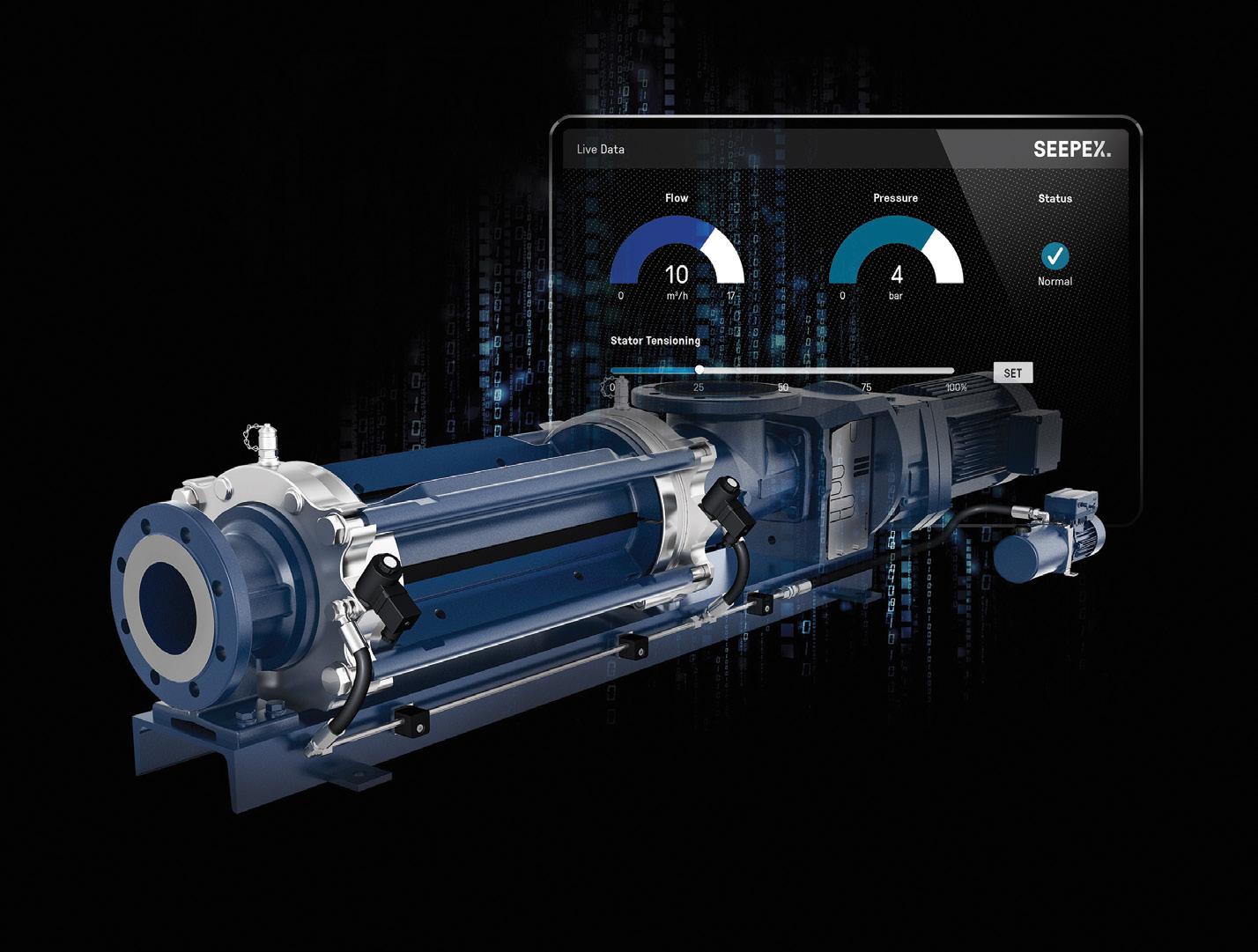

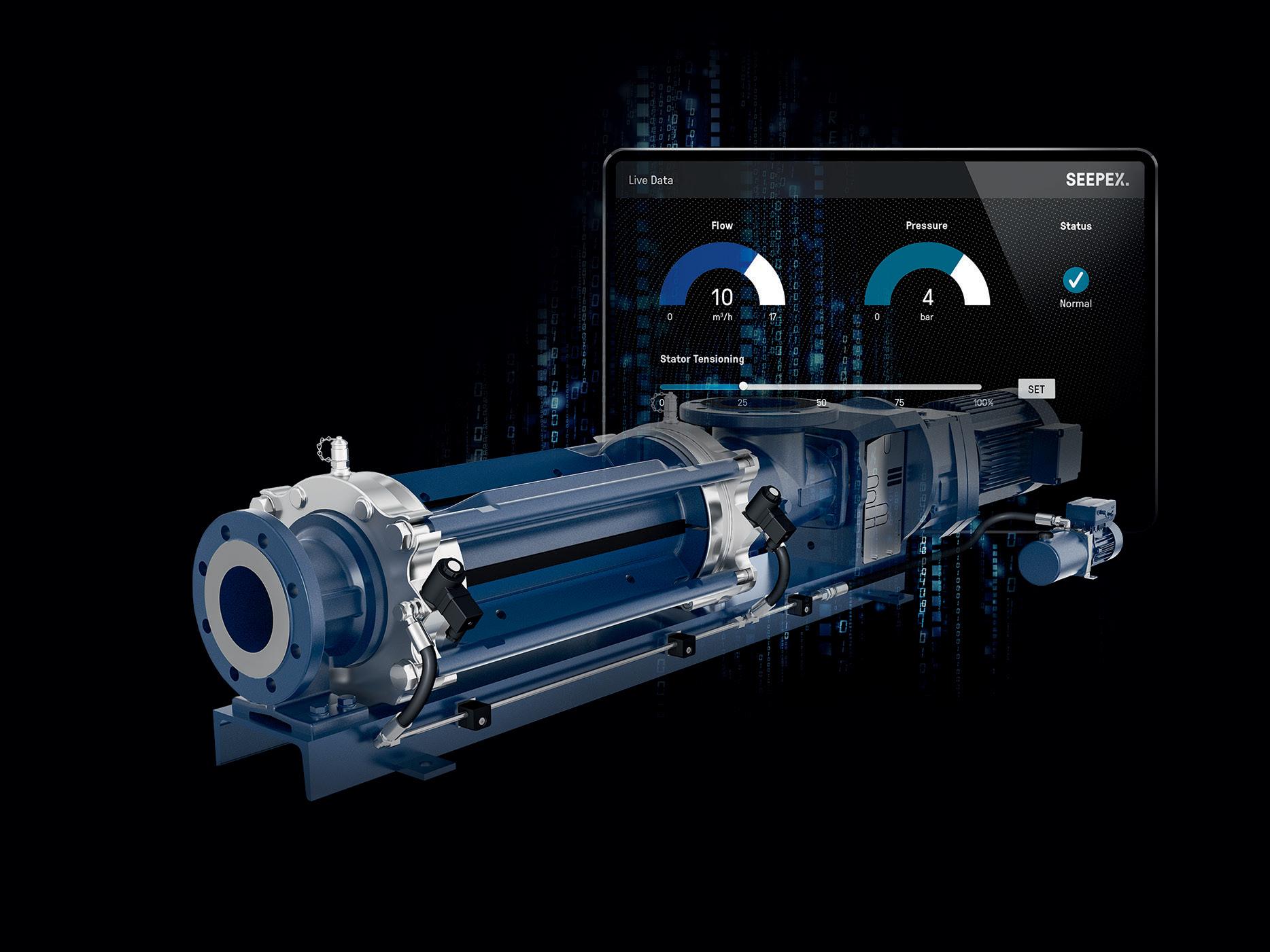

We at Roto Pumps started our journey by supplying our very first pumps to the mining industry. As a user-turned manufacturer, we have always understood the major challenges faced by the mining industry. This led us to carefully design and develop advanced helical rotor pumping technology to meet the challenging demands of the industry.

Roto has provided helical rotor pumps to all types of mines i.e. underground, open surface, placer and in-situ mines for the last 53+ years. In modern times, the major challenges that are faced by mining companies are:

• High wear and tear in elastomeric stators and rotors

• Reduced pump performance due to the use of rechromed rotors

• Low lifecycle of pumps and spares

• Reducing recurring pump, spare and operation costs

• Need for prompt service and support

• Regular requirement of readily available pumps and spares

Since it has been associated with mining from its early days, Roto has evolved and invested in its manufacturing practices to stay ahead of the competition while meeting the global mining industry demands. Roto Pumps has developed a complete range of helical rotor pumps for the mining industry, solving critical media pumping challenges and successfully handling all the major applications in mining and explosive industry such as:

• Cement grout/grout mix

• Clay and mineral slurries

• Coal water mixtures

• Dirty water

• Explosive mix transfer and filling

• High pressure wash

• Gland service

• Mine dewatering

• Mineral processing

• Mortar with fine oily water

• Oily water transfer

• Rock dust slurry

• Water spray for dust suppression

• Gace dewatering and high head dewatering

Built for a long lifecycle

Roto has an advanced manufacturing plant for developing a wide range of

helical rotor pumps and spares. It has six strategic overseas establishments with large assembly and warehouse infrastructures. These establishments are backed by strong localised sales teams to provide readily available pumps and spares, and prompt service support.

Roto has developed a unique rotorstator geometry that ensures low rubbing velocities between rotor and stator; eventually leading to an increased rotor and stator lifecycle. This also helps in providing consistent flow at varying pressures.

Roto’s specially designed two-pin joint (Cardan universal joint) provides flexibility in operating the pump in both directions. These joints are designed to have more angular movement which reduces the overall footprint of the pump; thus making it more compact. Also, these two pin joints can easily withstand loads caused by pumping at high discharge pressures.

Roto ensures strict in-house process control and stringent quality checks for designing and manufacturing of the high-quality energy efficient pumps and spares (including spares for other brands) having a long lifecycle and less operational costs.

Over the years, Roto has mastered the art of providing highly efficient elastomeric stators in a wide range of materials having high dimensional accuracies. These stators remain highly abrasion-resistant for a longer period of life compared to other stators available in the market. This is achieved by continuously focusing on in-house compound formulation and preparation, and mould design and manufacturing of elastomeric stators. We also have an in-house polymer test lab where it runs various tests on stators.

The rotor is the lifeline of helical rotor pumps. In mining, rotors are subjected to very high abrasion; thus most mining companies prefer hard chrome plated metallic rotors for longer life. Over a period, the high abrasion leads to faster wear out of the rotor, thus affecting the life of the pump.

Presently, many mining companies send these worn out rotors to local hard chrome plate companies to remove the chrome, rebuild and re-chrome the rotor. If they fail to ensure the correct dimensional accuracies (on major and minor diameters) between rotor and stator as per the original design, this eventually results in faster wear turnout of both parts, and finally damaging the whole pump and reducing the overall pump lifecycle. So in many cases it is better advised to order a new hard chrome plated rotor knowing it will be to correct dimensional tolerances. Roto can provide rotors in a varied range of materials, including exotic materials, to ensure optimal life of the component.

Mining is one industry Roto knows well and it will continue to strive to develop technically superior products resulting in smooth and reliable pumping operation in order to provide peace of mind to our mining customers.

High-performing helical rotor pumps with exceptional suction capabilities for varying pressure applications.

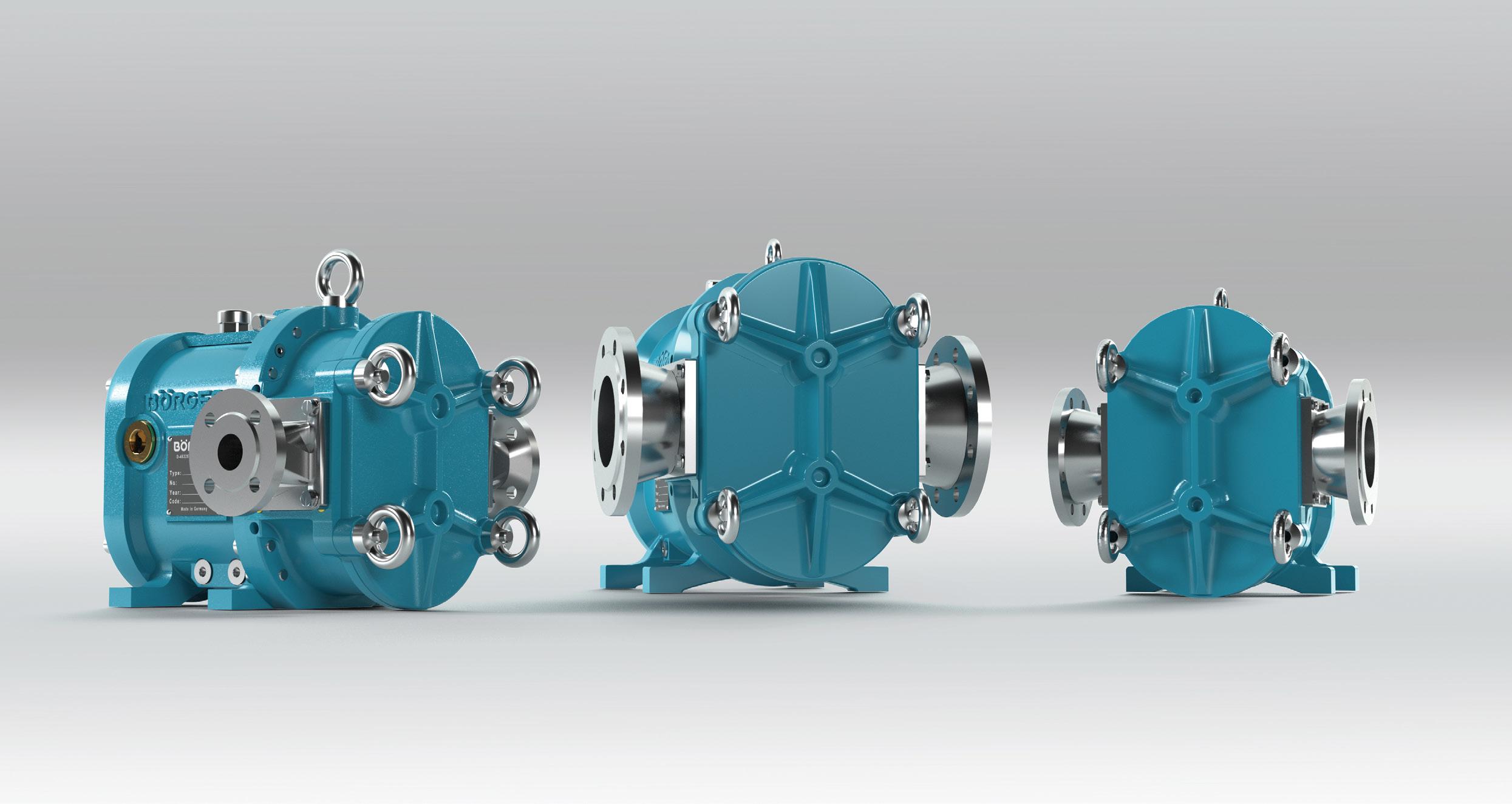

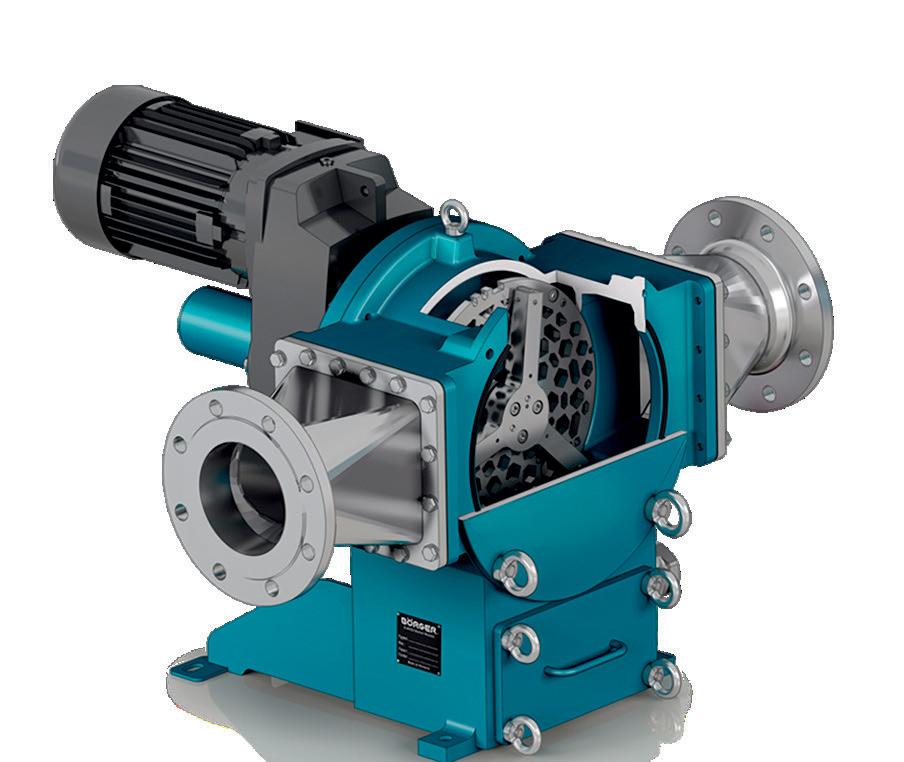

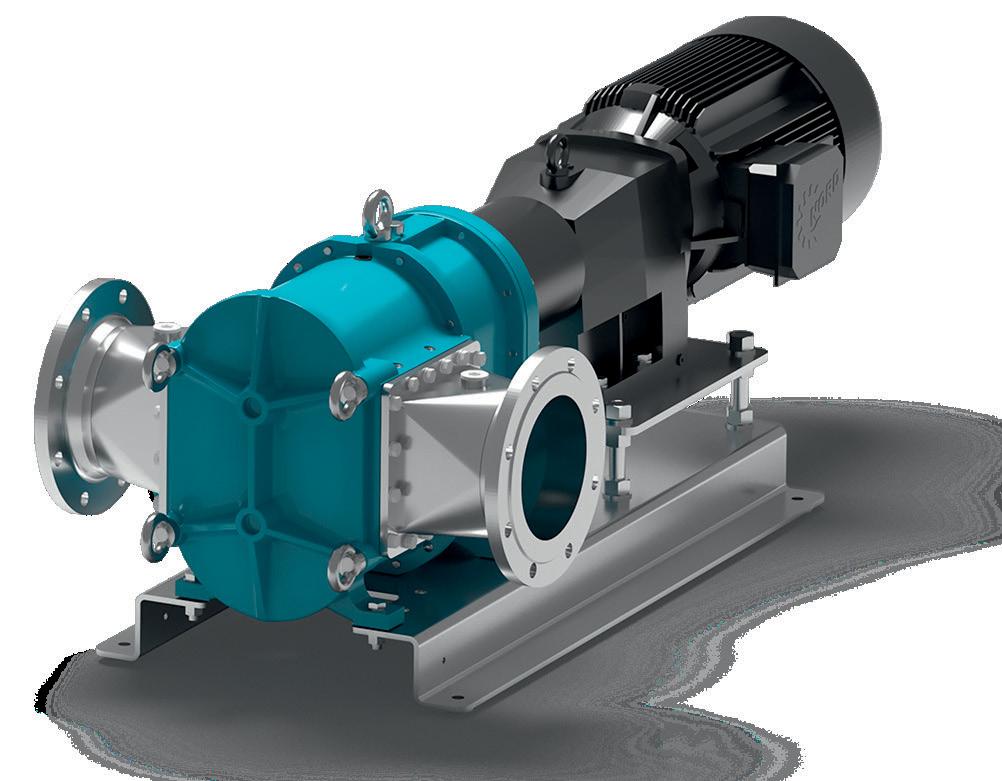

Boerger has surprised the world of pumps with a new generation of its BLUEline rotary lobe pumps, the BLUEline Nova, with the high-tech pump available in six sizes and with flow rates of up to 110m³/h. The German manufacturer promises not only excellent volumetric efficiency but also maximum choice of sealing systems.

Boerger is well-known for its highquality rotary lobe pumps with flow rates of up to 1,450m³/h. Presenting the new generation of its BLUEline rotary lobe pumps, Alois Börger, Managing Director of Boerger, said, “The development of the BLUEline Nova has benefited from our 30 years of experience in pump manufacturing. With the help of computer flow simulations and physical test bench hours, we were able to improve the pumps even further.”

Mr Börger said the rotors and casing were made for one another. This newly developed one-piece DIUS rotor ensures an almost pulsation-free pumping at pressures of up to 12 bar, while the wide sealing surfaces of the screw-profile rotor prevents backflow of the medium.

“Boerger has also modified the pump chamber to utilise the dual-lobe rotor to its full potential. The geometry of the inlets and outlets, as well as the wrap angle of the casing, were

particularly optimised. We were able to considerably improve the volumetric efficiency of the pump. To this end, we have adjusted the pump chamber to the rotor geometry in a flow-optimised design,” Mr Börger said.

The BLUEline Nova comes in two variants: with or without protection plates and liners. In its clean version, protection plates and liners are not required. The pump with minimum dead space can be cleaned according to the hygiene procedures, CIP (Cleaning-InPlace) and SIP (Sterilisation-In-Place).

In its tough version, the pump is equipped with protection plates and liners for pumping abrasive media containing solids. With a new innovative fastening system, the ‘tough’ version of the Nova pump ensures the best volumetric efficiency ever achieved in a rotary lobe pump. In case of wear, the protection plates and liners will be replaced quickly and easily due to its MIP® design (Maintenance in Place).

The large seal chamber of the BLUEline Nova provides space for different sealing systems, therefore ensuring connection of external supply systems is possible, and without issues. Different motors can also be selected for driving the BLUEline Nova rotary lobe pump. Upon request, the drive can be directly flanged to the pump and, due to the elimination of the coupling, the unit is now even more compact. In addition, this version does not require a base frame.

Like all Boerger pumps, the BLUEline Nova rotary lobe pumps can be manufactured according to the European ATEX guidelines for use in potentially explosive atmospheres. An API-676-compliant design, production according to the FDA regulations, or a technically tight pump design according to the German TA Luft requirements, round off the various options for versatile applications.

Mobile, stationary or submerged – Börger configures and builds each rotary lobe pump in line with the requirements of the specific application.

The application options of Börger pumps have expanded with the new B BLUEline Nova rotary lobe pump. The BLUEline Nova pump ensures the best efficiency even with high pressures. Börger pumps are available in 25 pump sizes with flow rates between 1 – 1,440 m³/h.

Further to this, Börger also offers three different macerators - providing efficient chopping operations and capabilities, ensuring downstream machines and pumps to perform smoothly.

Australian layflat hose manufacturer Crusader Hose has an excellent working relationship with leading pump companies. When a new thermal springs and spa resort needed to install some bore pumps, they turned to Franklin Electric, who then recommended Flexibore®, the flexible riser from Crusader Hose.

Crusader Hose has been manufacturing layflat hose for over 35 years and, during that time, has forged strong relationships with leading pump companies. Combining world-class submersible pumps and innovative layflat hose is the perfect solution for efficient groundwater extraction.

A layflat hose solution for water management

Alba Thermal Springs and Spa is being developed on the Mornington Peninsula in Victoria to meet the high demands of the luxury spa and wellness market. The property will offer guests the opportunity to enjoy geothermal springs in over 30 pools.

The brief for the project was clear; to establish a water system to manage the water cycle and treatment, ensuring that the full health benefits for patrons are achieved. The water infrastructure includes numerous holding tanks, pumps and pipelines. Therapeutic natural hot spring waters from the underground source need to be extracted with reliable pumps while risers lead the water to the network of pipes. The mineral-rich clean hot water is then piped into tanks from 60100m down, then fed into selected bathing areas.

Matt Bevil, Services Manager for Alba, has worked with these water management systems for many years and used his contacts to secure the best products for the project. His first contact was David Strang from Franklin Electric, a highly respected company that manufactures submersible pumps with corrosion-resistant and high-quality motors.

Franklin Electric has worked with Crusader Hose on other bore water pumping projects in the past and is familiar with the ease of installing Flexibore®, the flexible riser.

“Flexibore® is a reliable product and can be easily installed without too much fuss, saving time and money for the end user,” said David.

Superior construction and easy to install

Flexibore® is not only easy to use, but its superior construction enables it to handle temperatures of bore water, sometimes exceeding 80°C. For new installers, it’s always helpful to have an expert on hand for tips and guidance; Francois Steverlynck, Managing Director, was happy to accommodate.

With plenty of room to lay out the hose, two workers attended to the snaking of the electric cable and their attachment to the hose. A guernsey was used to lift and insert the pump and later the bore cap. Flexibore® accessories such as lifting clamps and an installation roller made the work relatively straightforward. A 4x4 truck was all that was needed to install the 60m Flexibore® hose.

“Working with our customers is always a pleasure. We know Flexibore® makes bore installations so much quicker. To receive the positive feedback from Matt and his team reaffirms our commitment to developing the most efficient water systems in Australia,” said Francois.

Alba will open later this year so that discerning bathers can enjoy the reinvigorating effects of thermal water. Enjoy!

Contact us today on +61 3 9720 1100 or email sales@crusaderhose.com.au to learn more or request a quote! Flexibore® it with hydrolysis-resistant polyurethane.

Proudly manufactured in Australia by Crusader Hose, Flexibore® 250 is made to suit most bore water pumping applications and is manufactured in a large range of diameters from 40 mm to 152 mm, in continuous lengths of up to 250 m.

With a high burst pressure for deep bore water pumping, the Flexibore® 250 can handle the weight of the pump plus water up to 250 m without a safety cable.

Quality you can trust

Deep ground water pumping up to 250 m

Ultra-high tensile strength for large submersible pumps

Flexible, so easy to install & retrieve

Swells up to 15%, avoiding internal build-up

Rigorously tested

Secure couplings

Lower pumping costs and friction loss

Aquarists corralling the barramundi ready for relocation within Reef HQ Aquarium.

Reef HQ Aquarium in Townsville is the world’s largest living coral reef aquarium and was originally designed to make experiencing the wonders of the Great Barrier Reef accessible and affordable, while also spreading the Reef conservation message and gaining public support for the protection of the ‘real thing’. However, since its opening in 1987, the aggressive tropical environment of the region and the stress of holding in excess of four million litres of saltwater have impacted the facility, resulting in the need for a major refurbishment and upgrade of aging infrastructure to ensure optimal operation. Pump Industry spoke to Sasha Thyer an expert at Reef HQ Aquarium about the redevelopment and upgrades, including those undertaken to the plant room, fire systems, life support systems, and hydraulic systems.

Since the transformation of Reef HQ Aquarium began in 2019, the Australian Government has committed $80.1 million to develop a global centre of excellence in tropical coral reef education. The works are occurring in stages with early works undertaken to improve aquatic life support systems.

The early works program focused on a number of projects that primarily aimed to resolve critical safety issues, as well as other works required to relocate and upgrade connected systems at the same time.

“The early works program was necessary to address the most urgent rectification requirements of aging critical systems at Reef HQ Aquarium affecting safety, function and animal life support systems,” Ms Thyer said.

“Fundamental building services required replacing or upgrading, including the building’s electrical network, elements

of the Heating, Ventilation, Air Conditioning, Chilling and Refrigeration (HVAC&R), building structural elements, and animal life support systems.

“The Aquarium is 35 years old, and located in a hot, humid seawater environment in North Queensland, which requires highly durable equipment and systems. It is also unique in its function – being home to the largest living coral reef aquarium, with a total of four million litres of seawater being integrated into the building structures. The Coral Reef Exhibit (CRE) requires 24/7 uninterrupted power and stability for key water quality parameters, thus system failures can become critical quite quickly.”

Careful and highly detailed programming and contingency planning began more than 18 months before the site was handed over to a Principal Contractor to manage the remaining scope of works, including likely latent issues that may be exposed during the construction phase.

“Space in the building is limited, so efficient use of space was also important. Due to the severe weather season in North Queensland, careful scheduling had to occur and there were many dependencies relying upon government permissions and other permitting authorities (such as the electrical network provider),” Ms Thyer said.

“A core limitation and complexity for the project was that continuity of basic building services such as power, chilling systems and pumping systems had to be maintained to ensure animal life support systems were not interrupted for more than two hours. Backup systems were required to guarantee the two hour window was not exceeded, and major construction activities had to be avoided where possible during the severe weather season.”

New plant rooms were built on level one directly above an exiting substation to house electrical and mechanical services, including the thermal energy storage unit, life support systems, electrical battery storage and the main switchboard. Some of these services required relocation due to works and changes in their existing locations, and others were new to Reef HQ's operating systems, but were implemented to improve energy efficiency.

One of the main projects was the replacement of the Aquarium’s main electrical switchboard (MSB), originally installed in 1986, and associated distribution switchboards. As the existing plant room had been subject to subsidence and was potentially exposed to flooding, it was relocated from the ground floor to the first floor. Due to the requirement for no power interruption, and to allow a smooth changeover and minimal power interruptions, the existing MSB had to remain in place until the new MSB was operational. At the same time, an old substation containing 35-year-old transformers owned by Ergon Energy had to be replaced and relocated to a padmount transformer in a different location.

Ms Thyer said that this had knock-on effects, requiring other major systems to be relocated.

“The coral reef exhibit heater and animal life support systems had to be relocated to make way for the padmount transformer. The solution to all these challenges was to construct a new plant room directly above the substation to contain the new MSB, heater, thermal storage and life support systems,” Ms Thyer said.

“This occurred whilst all the existing systems stayed operational. New foundation piles had to be installed to accommodate the new structure, and other systems required protection from the construction works. Meticulous planning, scheduling, risk management and communication was required to ensure all scenarios were planned for and all phases ran smoothly.”

the plant room

A fundamental corporate principle for the Great Barrier Reef Marine Park Authority is sustainability and energy efficiency in the delivery of its services. The upgrades provided an opportunity for sustainability improvements to be made, such as the use of high efficiency pumps and locating life support systems to minimise pumping power.

“Major retrofit actions rarely occur in the life of most buildings so it is important to seize the opportunity for improvements across all levels of service. Every project involved greater efficiency through a range of mechanisms including guiding principles of the circular economy,” Ms Thyer said.

“Materials and equipment were reused where possible or recycled. Design of every system was reviewed, even if the

requirements had not changed. The integration of system efficiencies was considered overall, reviewing elements such as cable and pipe distances, location of supporting equipment and structures, maintenance requirements, system lifecycle costs and energy use, and smart building management systems.

“High efficiency pumps were chosen, and life support systems were located in order to minimise pumping power and requirements. The new pump room services included the main electrical system (MSB), solar power inverters, and associated electrical battery storage system, communications equipment, a new thermal storage system (ice), animal life support systems and heat exchangers.”

The relocation of the Predator Exhibit life support system resulted in no additional energy use for filtration pumping, but has provided greater efficiency for cooling/heating (heat exchanger) due to its closer proximity to the Aquarium exhibit.

Ms Thyer said the relocation of the Coral Reef Exhibit life support system resulted in significantly greater efficiencies, as the design was changed to reduce pipe distances (horizontally and vertically), and pumping requirements were reduced by utilising more circulation pumps inside the tank and less sand filtration, which was previously used excessively.

Furthermore, recycled glass was used in the sand filters to improve flow and reduce compacting.

The wave machine, which supports the coral reef exhibit, was also refurbished for longevity and greater efficiency. One of the most important improvements to efficiency was to optimise the location of equipment to minimise friction losses through pipework and pumping heights.

“The Coral Reef Exhibit foam fractionator and ozone system were also redesigned to minimise pumping head height, and we were able to take advantage of low-head pico-hydro turbines to recover energy returning to the main exhibit tank. The pico-hydro generators (which are a turbine-style generator) are capable of recovering 10,000kWh per year, which is fed straight back to the building’s electric network via inverters,” Ms Thyer said.

“We were also able to use rejected heat from the chilling system (the new thermal storage system) to heat the Coral Reef Exhibit in winter – this created significant efficiency for energy and space.

“New system controls on the Coral Reef Exhibit wave machine allowed more control to finely tune the system for greatest efficiency, to find the optimum wave height and frequency.”

The Aquarium was already utilising a 20kL chilled water thermal storage system to minimise stop/start of the HVAC main chillers and shave the facility’s peak power load. While this system was working well – and was relocated to the new plant room above the old substation – the 216kW solar power system was generating a surplus during the highest solar radiation periods. As the electrical network provider did not require power export back to the grid, the surplus power was being wasted.

A solution to this issue came with an invitation to partner with Glaciem Technologies under the Advancing Renewable Program co-funded by the Australian Renewable Energy Agency (ARENA).

“Our commitment involved working through complexities in a real-world setting to refine the technology. The project included the installation of a new thermal storage system using phase change materials (ice), a carbon neutral refrigerant (CO2) and 50kW of additional solar panels for the existing solar power system,” Ms Thyer said.

“As the existing Coral Reef Exhibit filtration system had to be moved to make way for the new padmount transformer, on request by the Reef Authority, the design of the new thermal storage system also incorporated energy recovery by utilising the system pumps to redirect waste heat to the Coral Reef Exhibit in winter.

“This may seem counterintuitive, however the Aquarium building requires space cooling for all but two to three weeks of the year, whereas heating is required for the Coral Reef Exhibit for three to four months.”

Energy efficiency results

The Aquarium is still collecting data and tweaking and refining the systems as there has been a drop in power requirements due to COVID-19, and some systems have been decommissioned as Reef HQ was closed to enable major works to occur.

While this has made it difficult to precisely determine the overall savings, Ms Thyer said significant savings are evident through the design and relocation of the animal life support pumping systems.

Furthermore, 50kW of new solar power was added to the solar system, bringing it to a total of 260kW, and the new thermal storage and heating system, which uses heat generated by the chilling system to heat the Coral Reef Exhibit in winter, has eliminated the need for a dedicated heater (48kWr heating capacity). The pico-hydro generators will recover 10,000kWh per year from the Coral Reef Exhibit life support system, which represents ten percent of the pumping power required for the system.

Fire system upgrades

Both wet and dry fire systems were upgraded to meet current standards, and were triggered by works associated with the relocation of the main switchboard. The wet fire hydrant system included a connection manifold to the Townsville City Council mains water system and involved the installation of a fire hydrant booster pump.

Ms Thyer said the fire hydrant booster pump project was a huge challenge, particularly when it came to the space and correct location for the fire hydrant booster pump and space for the reticulation pipework.

“To bring the building's emergency systems up to the modern standards, the booster pump and associated pipe network were required. Reticulating the large pipes around an existing building that contains four million litres central to its main structure was an enormous design challenge,” Ms Thyer said.

“Locating the fire booster pump to comply with proximity requirements adjacent to the new padmount transformer and other building structures seemed like mission impossible and required an underground stormwater drain to be relocated to accommodate it.

“A major setback for this project was that the final test of the mains water pressures resulted in inadequate mains pressures. This was due to the mains water system pressures changing during the construction period. Resolution of this issue was pushed forward into the major works.”

Upgrading mechanical and hydraulic services

A number of mechanical services required replacement as they had come to the end of their life, including other upgrades to the wave machine’s air delivery system, motors and pneumatic equipment, and new blower motors.

Ms Thyer said the wave machine was originally installed by Boes Technology in 1986 and was functioning remarkably well, delivering a wave every eleven seconds, 24 hours a day, 365 days a year for 35 years.

“It is a beautifully simple, effective and energy efficient system. It delivers a huge volume of laminar flow through the entire exhibit, and this is supplemented by turbulent flow which is directed by low voltage, carbon fibre circulation pumps inside the exhibit,” Ms Thyer said.

“Laminar flow is important to the coral colonies as it pushes water through the coral heads, and this allows gaseous exchange and the removal of waste. It also allows waste to be blown out of the rocky substrate and keeps all areas oxygenated.

“The original blower motors were 75kW which could deliver a massive wave, much larger than required. The blower motors were at the end of their life, so they were replaced with a 40kW high efficiency motor, with a new variable speed drive and upgraded control system.

“In 2016, the other parts of the system (the compressors, receiver, air dryer and ducting) were replaced and thus in 202021 were still in good working condition. The system design was found to be still relevant and efficient, so only modernisation of the control system was required.

“Commonwealth procurement processes were followed for this work which was relatively low value and, in this case, involved quotes from numerous local suppliers and installation by a local technician.”

Some hydraulic services were modified, replaced or repaired as part of the retrofit actions in other works, including an overhaul of the creekwater intake system to mitigate the risks

of failure. Some preliminary works were required to address failed valves, pipework and pump seals, and the larger upgrade will include a complete review of the creekwater intake system, to mitigate risks and maximise efficiencies.

Upgrading life support systems

In May 2020, the Aquarium received $2.6 million in funding from the COVID-19 Relief and Recovery Fund to assist Great Barrier Reef Tourism and the North Queensland regional economy. This investment was used to upgrade the crucial animal life support systems that were at the end of their life, and some systems that had already partly failed or become inadequate to meet modern standards. One system had to be relocated to enable some building structural repairs.

The animal life support systems maintain critical parameters for inhabitants of the Aquarium to thrive, such as oxygen, low nutrients, low pathogen levels, optimum salinity, temperature, pH and calcium levels.

These systems also enable the intake of new seawater from the adjacent Ross Creek. During the severe weather season, the system can remove freshwater via reverse osmosis to maintain salinity within critical parameters.

Ms Thyer said meticulous planning was fundamental to the success of the early works as scheduling had to take into account the severe weather season, long lead times on equipment, government permissions, and crucially, the requirement to maintain the operation of most of the systems throughout the construction phase.

“There were many interfaces between projects and where building structural work was involved, latent issues associated with an old building were likely. Contingency planning was very important with room in the schedule and budget to accommodate any issues that may arise,” Ms Thyer said.

“The projects involved a lot of highly specialised equipment, so the right expertise was critical to smooth implementation and also good communication between the Reef Authority team, Project Manager and the contractor’s Project Manager.”

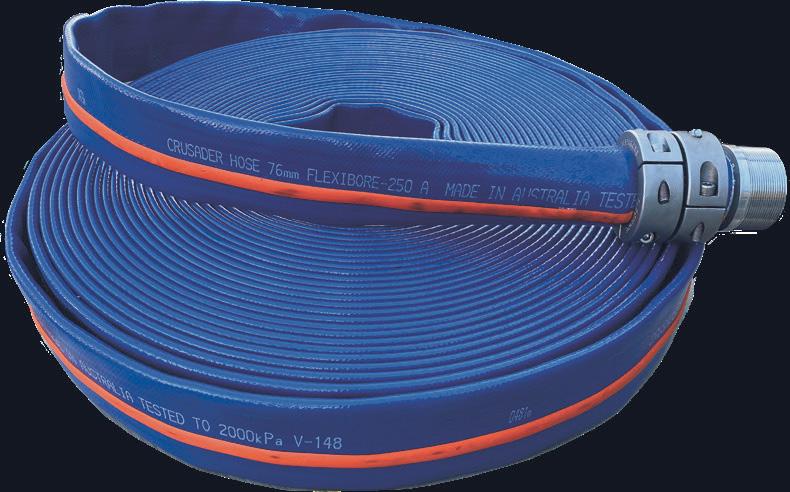

Upgrading the reverse osmosis machines

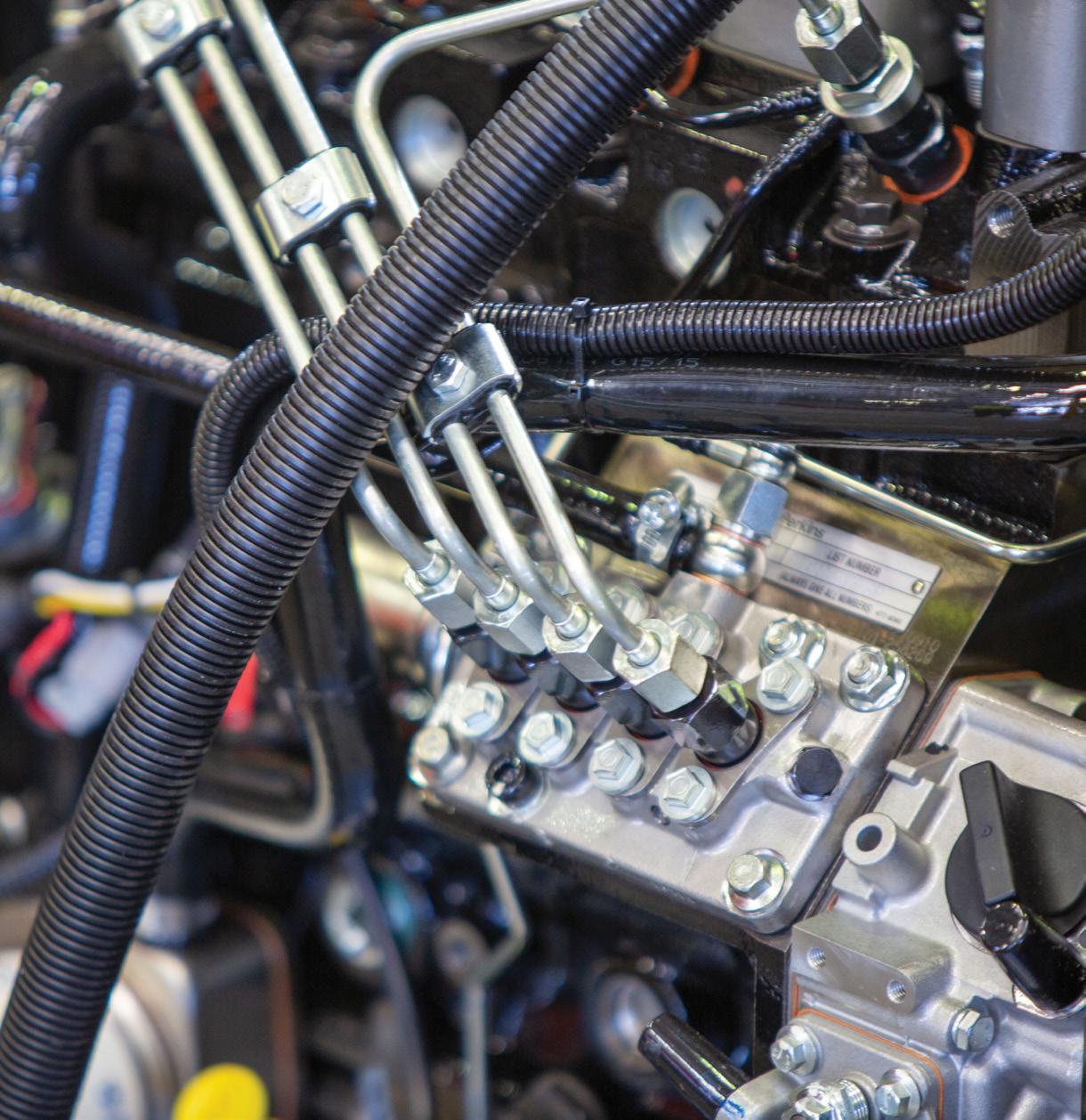

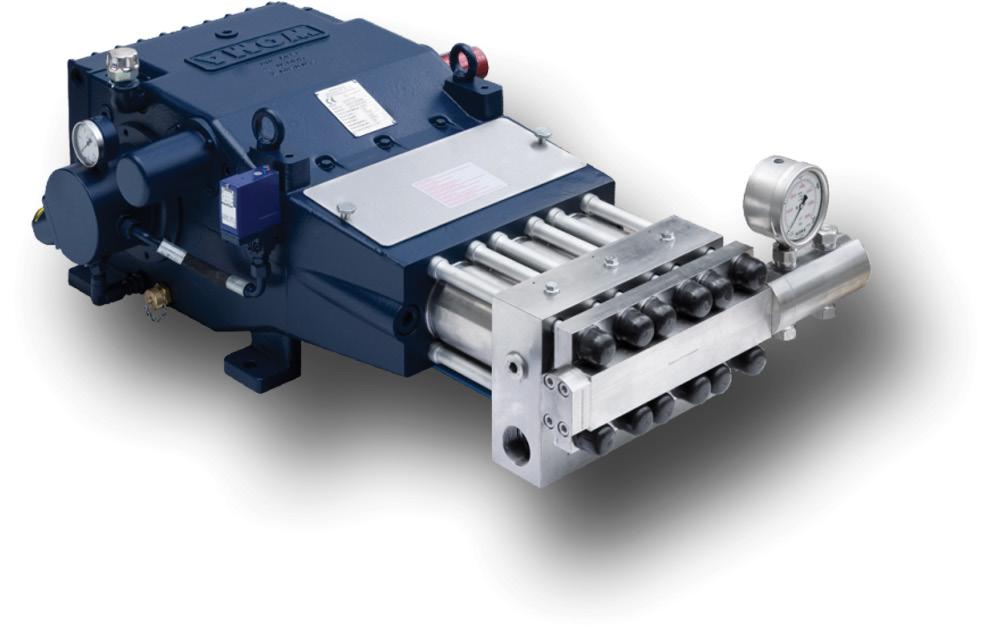

The reverse osmosis (RO) system uses very high pressure pumps to push seawater into a membrane where the freshwater can travel through (the ‘permeate’) and the concentrated saltwater (the ‘concentrate’) is left behind. In other settings, RO is usually used to create drinking water from seawater or contaminated water, but at the Aquarium it is used to remove rainwater from the large open topped aquariums to maintain the correct amount of saltiness (salinity). It can

also correct the salinity of new seawater water taken from the adjacent the Ross Creek.

The reef tank inhabitants are very sensitive to changes and the salinity needs to be maintained at 33-35ppt. During severe weather seasons, huge rainfall can occur – in 2019 the region copped 381mm rain in 24hrs and 277mm in just three hours – and the salinity can only be adjusted by RO or the addition of salt. Ms Thyer said RO is preferred as it can be activated automatically when staff are not on-site and does not involve manual handling of salt.

The Aquarium's old RO system was at the end of its life and had failed completely during the 2019 wet season which saw a once in 100-year flooding event. This meant that 40 tonnes of artificial salt had to be added by hand (20kg bag at a time) by staff over a four day period.

The old system could remove 27,000L of freshwater per day while the new system can remove 45,000L per day.

Ms Thyer said the new system provides resilience and redundancy in the overall system, mitigates risks associated with flooding, and also helps to manage the variety of events that can occur.

“The new systems are better protected from the elements (some outside systems were moved into the new plant room) and moved out of areas that could possibly be exposed to flooding. The new foam fractionator system includes a degassing reservoir to ensure that no residual ozone can enter the Aquarium tanks,” Ms Thyer said.

The ozone configuration and dosing was improved to allow for optimal removal of waste products, and the systems were made safer for staff to operate and more energy efficient. The energy efficiency improvements mean the emergency power system is able to service more equipment for longer.

“RO systems are specialised, however, there are quite a few options available in the marketplace. In this case, the Aquarium requires a medium sized system (not a domestic sized system and not a municipal water sized system), so the number of options for size and other requirements – such as short lead time and specific technical requirements and local support –narrowed the field,” Ms Thyer said.

“The Commonwealth Government has mandatory procurement processes that must be followed. In this case, a number of suppliers were approached to quote on the new system and the urgency of the project was an element in the procurement method chosen.”

Commencing back in 1962 in Dandenong, Victoria, close-by its present site, Franklin Electric began importing and distributing 4” submersible products. Soon after, local manufacturing commenced with specialised imported parts to offer the Australian water industry Franklin’s world-leading 4” submersible motors.

Over the decades, Franklin Electric motor products were designed and evolved to provide the industry with the highest quality 4”, 6”, 8”, 10” and 12” submersible motor products available.

The main benefit that the Australian industry has come to rely on from Franklin is its quality, reliability and performance. Franklin demonstrates these every day to its customers through its Five Key Factors for Success: quality, availability, service, innovation and cost.

Franklin submersible motor products became Australia’s leading submersible motor and indeed the world’s most installed submersible electric motors.

Franklin had been partnering with pump manufacturers for decades and had developed a deep understanding of the market. When the industry started to consolidate around the world in the late 1990s and early 2000s, Franklin had some serious decisions to make.

automatic self-priming pumps, as well as solids handling selfpriming pumps.

Outside of the US, Pioneer Pump has factories for fabrication, and assembly and warehousing facilities operational in South Africa, England and Australia.

In 2011, Franklin Electric agreed to purchase the remaining 65 per cent of Pioneer. In 2020, Franklin Electric decided to consolidate its water business group globally under one Franklin Electric company.

In 2004, Franklin Electric announced the purchase of JBD (the former Jacuzzi industrial range), and that it was entering the pumping industry by launching Franklin Pumping Systems, now known as FPS. Starting from a very low share, FPS is now leading the US market.

As the pumping industry is global, similar issues applied in Australia. In late 2007, Franklin Electric Australia, after three years of evaluating the market, entered the main water pump industry by launching and distributing its FPS range of submersible pumps and above ground pumps, motors, drives and controls direct to its own Australian dealer network.

In 2005, Franklin Electric purchased a 35 per cent stake of Pioneer Pump Inc, situated in Canby, Portland, Oregon. Pioneer manufactures a large range of centrifugal pumps and

Today, Franklin Electric Australia and Pioneer Pump Holdings Australia are one company, Franklin Electric Australia New Zealand Pty Ltd, with two facilities operating: the warehouse and assembly facility in Dandenong South, Victoria; and the fabrication assembly and test facility in Sunshine West, Victoria, which includes a logistic warehouse in Ravenhall, Victoria.

Along with the consolidation of the businesses comes the staff and the years of pump experience, the company has hundreds of years of experience to assist every person who needs help with a pump or application.

An expanding range

Today, the range of products have expanded to:

• A full range of surface mount pumps, ISO, split case, multistage, small and large centrifugal motor pumps, progressive cavity (MONO TYPE) and self-priming ranges, small volume low head, to extreme high volumes (2500 LPS) and discharge heads exceeding 300m

• Solar pumps and pumping equipment

• A huge range of belowground pumps: submersible turbine, line shaft, bore hole and dewatering

Truly one of the largest and most comprehensive ranges of pumping and associated products supplied by a single company globally.

“Moving Water Moving Forward”

Maxijet is driven to be the industries most trusted source in customer service, technical, aftermarket support and industry solutions for the conservation of our most important global resource. We pride ourselves on being the industry people who care.

Custom made rain water re-use, hot water circulator, and water boosting systems. Maxijet Australia is committed to manufacturing the best pump systems for water conservation.

Available in many configurations to suit your flow requirements or any project specifications. All manufactured locally in our Melbourne factory.

For more information on Hyjet and Pedrollo products and expert advice to help you choose the right solution for your project, contact us today!

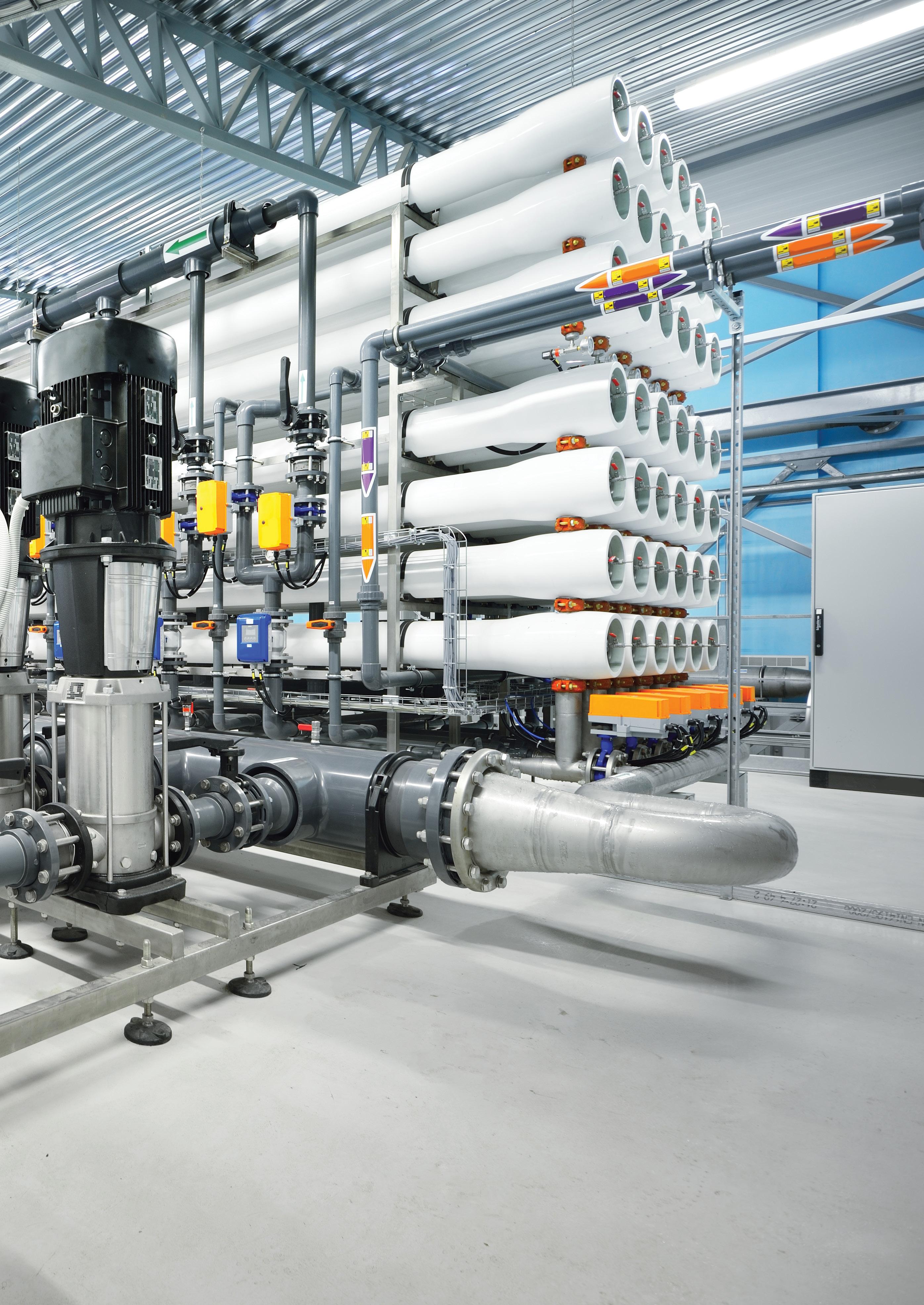

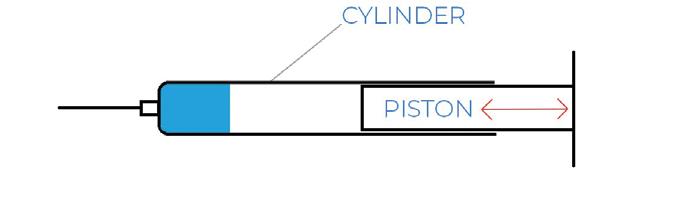

Reverse osmosis (RO) is a filtration process where pressurised water is passed through a membrane to produce purified water, used across countless industrial applications including desalination and industrial wastewater treatment. In the context of minimising global energy consumption, water utilities and asset managers are now measuring their water treatment systems against both sustainability and cost outcomes, with new insights for RO pump selection. Here we explore how RO works, the types of pumps involved in different industrial applications, and how the right pump selection can meet both sustainability and cost reduction outcomes.

Reverse osmosis (RO) is a water treatment process where a raw water source, such as seawater, is separated into purified water and a concentrated waste of dissolved salts, minerals, bacteria, and other matter.