New screw pumps increase wastewater treatment CAPACITY IN BALLARAT

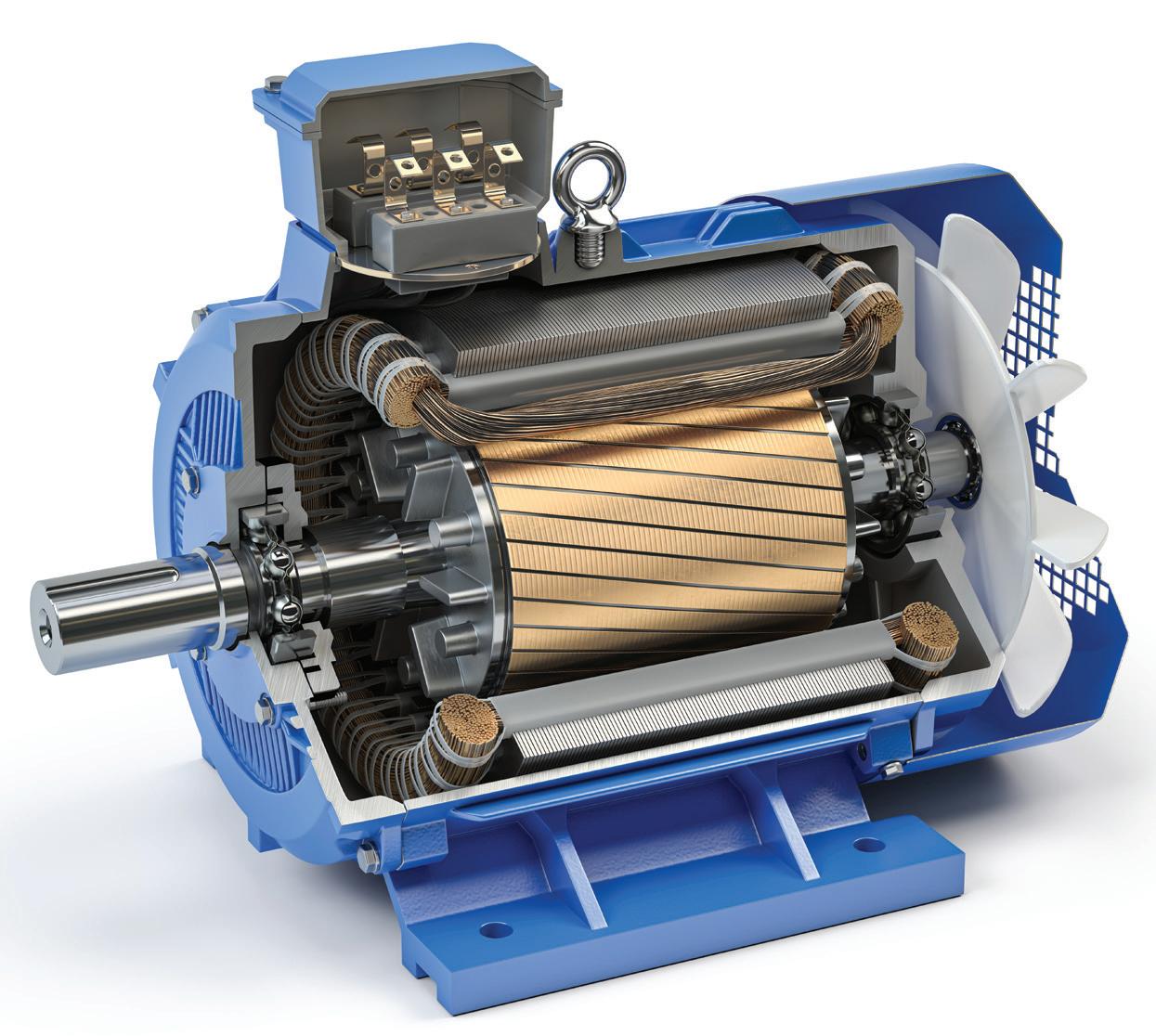

Top five ways to reduce motor running costs

Electric pump system keeps threatened bats cool

Electric pump system keeps threatened bats cool

In everything we do, we never lose sight of what is more important to our customers: to work economically with a technology that is modern, innovative and reliable.

In everything we do, we never lose sight of what is more important to our customers: to work economically with a technology that is modern, innovative and reliable.

As the inventor of the elastomer-coated rotary lobe pump and innovation driver in the field of pumping, grinding and disintegration technology, Vogelsang has been one of the world’s leading mechanical engineering companies for decades. With progressive concepts and sophisticated technology, such as the RotaCut macerator or the wastewater twinshaft grinder XRipper, we work daily on efficient solutions for the individual applications of our customers.

As the inventor of the elastomer-coated rotary lobe pump and innovation driver in the field of pumping, grinding and disintegration technology, Vogelsang has been one of the world’s leading mechanical engineering companies for decades. With progressive concepts and sophisticated technology, such as the RotaCut macerator or the wastewater twinshaft grinder XRipper, we work daily on efficient solutions for the individual applications of our customers.

We use our extensive know-how, the continuous further development of our technical solutions and our many years of experience in the field of environmental technology to support our customers as a competent partner. Among other things, with powerful and service-friendly technology. You can rely on competent and personal advice and reliable service.

We use our extensive know-how, the continuous further development of our technical solutions and our many years of experience in the field of environmental technology to support our customers as a competent partner. Among other things, with powerful and service-friendly technology. You can rely on competent and personal advice and reliable service.

VOGELSANG – LEADING IN TECHNOLOGY

VOGELSANG – LEADING

Unit 2/7 Dunn Road | Smeaton Grange NSW 2567 | Australia

Unit 2/7 Dunn Road | Smeaton Grange NSW 2567 | Australia

Phone: +61 2 4647 8511 | E-mail: sales.au@vogelsang.info vogelsang.info

Phone: +61 2 4647 8511 | E-mail: sales.au@vogelsang.info vogelsang.info

Hello all and welcome to the Autumn edition of Pump Industry Magazine and our second for 2023.

After enduring the very high summer temperatures across the nation I am sure you are all welcoming the cooler temperatures of Autumn.

As we head into April we may well wonder what the year ahead looks like with both global and domestic markets at play. Sadly, the war in Ukraine continues now into a second year with no end in sight, impacting on energy costs around the globe. I was in the Netherlands in December and was surprised to experience power cuts in the middle of the night which were considered normal.

The aim is having a Breakfast Meeting in each of the states so if you or your company would like to host a Meeting, please get in touch with our Secretary, Kevin Wilson, at pumpsaustralia@ bigpond.com.

An ongoing topic of the utmost importance to PIA Members and pump companies at large is the continuing dialogue with the Services Trade Council (STC) who govern the QBCC’s licensing of plumbing and drainage tradespeople.

Pump Industry Australia Incorporated C/-340, Stuarts Point Road Yarrahapinni NSW 2441 Australia Ph/Fax: (02) 6569 0160 pumpsaustralia@bigpond.com www.pumps.org.au

PIA Executive Council 2023

John Inkster – President Brown Brothers Engineers

James Blannin – Vice President De.mem – Stevco

Kevin Wilson – Treasury/Secretary Executive Officer

Alan Rowan – Councillor Executive Officer – Publications and Training, Life Member

Ken Kugler Executive Officer – Standards, Life Member

Steve Bosnar – Councillor Franklin Electric/Pioneer Pumps

Geoff Harvey – Councillor Irrigation Australia

Joel Neideck – Councillor TDA Pumps

Jamie Oliver – Councillor Grundfos Pumps

Mat Arnett – Councillor Ebara Pumps

Michael Wooley – Councillor Tsurumi Pumps

Billie Tan – Councillor Regent Pumps

The recent collapse and fall out of the three banks in the US will have a ripple effect around the globe but we are told should have minimal effect in Australia. Time will tell if there is any spill over into the Australian economy.

On the domestic front, we continue to see the RBA increase the cash rate in an endeavour to address inflation. At the time of writing, the RBA was signalling it might pause a further rate rise in April. Meanwhile the continued robustness of the Australian economy is reflected in the low unemployment rate of 3.5 per cent.

When I speak with industry colleagues I hear that there is still a strong demand for pumps and services with many indicating they have a full pipeline of work for the next six plus months; this pipeline of work ranges across the entire spectrum of our industry from mining to building services, agriculture, industrial, municipal and energy sectors.

This is good to hear and augurs well for the industry, because we all know there may well be a slow down in the economy in the coming months. It also demonstrates that our industry provides an essential service to Australian businesses whether in the private sector or in the municipal and public health arena.

For those involved in the $90 billion (predicted for 2023) agriculture market the BoM advises that the third consecutive La Nina weather pattern that brought wet conditions and devastating floods on the eastern seaboard is declared over, with a 50 per cent chance of El Nino occurring mid year bringing with it warmer, drier weather.

On 8 March, we had our first Breakfast Meeting, kindly sponsored by Cummins South Pacific in Scoresby who provided a warm welcome with breakfast, coffee and tea, and attended by about 24 Members.

On our behalf, the QBCC has petitioned the STC to consider recognising pump industry practitioners to lawfully perform work on pumps installed as part of a plumbing or drainage system as defined by the PD Act 2018

We understand to achieve this we may have to meet certain criteria as set out by the STC, and the outcome may well be some form of concession, regulatory change, new legislation, or the creation of a new Pump Service Licence.

Our last communication with QBCC was on 20 February where we were advised that our request for more information had been passed on to the Chair of the STC. We understand the STC is preparing a report to go to the Minister of Energy and Public Works; we are seeking clarification of the STC’s position.

Ken Kugler, our standards officer, has been busy in recent months engaged in the review of numerous ISO standards. These reviews relate to the question as to whether to confirm, review or withdraw a standard that is now aged. Of particular interest was ISO 9906:2012, the pump test standard that Australia accepted to be known as AS ISO 9906:2018. As the standard is now some ten plus years old, PIA has recommended its review.

Also under consideration is the most common pump standard ISO2858:1975 for 16 bar end suction pump designation, duty point and dimensions as pumps to this standard are still being manufactured in Australia today. There was a mixed response with the majority in favour of reconfirming.

And just another reminder to you all that the Pipe Friction Handbook has been updated and that the 6th Edition of the Pump Technical Handbook was released in September with 40 per cent more content – a must have on your desk or library.

Thank you for your continued support of Pump Industry Australia.

John Inkster – President

Scan to subscribe to Pump Industry Magazine’s weekly newsletter – delivered to your inbox every Thursday afternoon.

ABN: 36 426 734 954

C/- The Commons, 36–38 Gipps St, Collingwood VIC 3066 P: (03) 9988 4950 monkeymedia.com.au info@monkeymedia.com.au pumpindustry.com.au magazine@pumpindustry.com.au

Managing Editor: Lauren Cella

Assistant Editors: Rebecca Todesco, Stephanie Nestor

Journalists: Tess Macallan, Tayla Oates

National Media and Events Executives: Rima Munafo, Brett Thompson

Design Manager: Alejandro Molano

Senior Designer: Luke Martin

Designers: Ozlem Munur, Danielle Harris

Marketing Manager: Radhika Sud

Marketing Associates: James Holgate, Jackson Barnes

Digital Marketing Assistants: Natalie Ta, Bella Predika, Rhys Dawes

Publisher: Chris Bland

GM Growth and Strategy: Laura Harvey

ISSN: 2201-0270

This document has been produced to international environmental management standard ISO14001 by a certified green printing company.

This magazine is published by Monkey Media in cooperation with the Pump Industry Australia Inc. (PIA). The views contained herein are not necessarily the views of either the publisher or the PIA. Neither the publisher nor the PIA takes responsibility for any claims made by advertisers. All communication should be directed to the publisher. The publisher welcomes contributions to the magazine. All contributions must comply with the publisher’s editorial policy which follows. By providing content to the publisher, you authorise the publisher to reproduce that content either in its original form, or edited, or combined with other content in any of its publications and in any format at the publisher's discretion.

The first projects being funded under the Federal Government’s $150 million commitment to improve the disaster resilience of the Northern Rivers region have been announced, including over $18 million for new and upgraded pumps and pump stations.

As part of Phase 1 of the Northern Rivers Resilience Initiative, 16 projects were recommended by CSIRO following extensive community consultation, and agreed by the Federal and New South Wales Governments. They deliver on 41 individual project proposals put forward to CSIRO through their review process, with the scope of some proposals expanded to provide benefits across the entire Northern Rivers Region.

The announcement enables work to commence in the first tranche of projects while the New South Wales Government continues a due diligence review of the remaining recommended projects. All projects to be funded from the $150 million will be confirmed within the next six months.

The Tranche 1 projects, totalling $50 million, include $17.2 million for seven combined upgrades to pumps and pump stations in Lismore, $1.1 million for a new pump system to assist in draining East Murwillumbah, and $470,000 to install box culverts through a river bank levee to improve local drainage in Grafton.

Region-wide programs to increase flood risk awareness will benefit all seven regions, delivering floor level surveys, assessing evacuation routes and options for infrastructure upgrades and establishing community-led resilience teams.

Many of the projects align with recommendations from the NSW Flood Inquiry, and with local floodplain risk mitigation programs. All seven local government areas of the Northern Rivers region – Ballina, Byron, Clarence Valley, Kyogle, Lismore, Richmond Valley and Tweed – will benefit.

Federal Minister for Emergency Management, Murray Watt, said the recovery of the Northern Rivers region following

“The Albanese Government remains with the people of the Northern Rivers on this recovery and today’s announcement of projects funded under the Northern Rivers Resilience Initiative builds on the billions of dollars in assistance dedicated to the region.

“As previously announced, $150 million has been set aside for projects that local communities told us are a solid first step in improving the region’s resilience to future disasters.

“This money will be signed over to the NSW Government to manage the agreed projects and I’ve asked that this first tranche of projects commence implementation as soon as feasible.”

New South Wales Deputy Premier and Minister for Regional NSW, Paul Toole, said the State Government welcomes the Federal Government’s announcement of funding for these important projects.

“The successful projects align with the recommendations from the Independent NSW Flood Inquiry and play an important role in improving flood preparedness and flood resilience across Northern Rivers communities.

“With the funding secured, we look forward to work starting. The NSW Reconstruction Authority will manage the program administration and governance, and the Northern Rivers Reconstruction Corporation (NRRC) will be responsible for coordination and delivery of on-ground works.”

The NSW Reconstruction Authority and Northern Rivers Reconstruction Corporation (NRRC) will continue to undertake due diligence for the remaining $100 million of projects, including larger infrastructure projects requiring further engineering assessment to determine feasibility.

The CSIRO study that informed the allocation of the funding, and details of the first tranche of projects, are available at Northern Rivers Resilience Initiative | National Emergency Management Agency (nema.gov.au)

CSIRO is now preparing to undertake the second phase of

More than 100 million litres of water was pumped out of Blackwattle Bay to allow major structural works to begin on the new Sydney Fish Market site.

Pumping water out of the Bay created a dry working space within the cofferdam, which was constructed using more than 1,000 interconnected sheet and tubular piles and has been drained to about four metres below sea level.

New South Wales Minister for Infrastructure, Rob Stokes, said the draining of the cofferdam was a major engineering feat and created a dry working space so building can commence safely on the main structure.

“Infrastructure creates opportunity, and the relocation of the Sydney Fish Market to the head of Blackwattle Bay has been the catalyst to transform a patchwork of industrial uses to a stunning new precinct on the harbour foreshore,” Mr Stokes said.

“This is an engineering feat that has enabled the creation of a new public

boardwalk along the foreshore four football fields in length and 15 metres wide where people can walk, ride and linger after a long lunch at the Sydney Fish Market.

“This project will employ more than 700 people and their work to drain the cofferdam is a significant milestone in the construction of what will be one of Sydney’s great attractions for locals and visitors alike.”

Multiplex Regional Director, Daniel Murphy, said the draining of the cofferdam was an exciting milestone for the delivery team.

“For the first time, the dewatering of the cofferdam has given us dry ground on which to start building the main structure. It has been a unique and complex challenge, and we can’t wait to see the new Sydney Fish Market continue to take shape,” Mr Murphy said.

The new Sydney Fish Market is on track to be completed in 2024.

Dubbo Regional Council (DRC) quickly responded to the failure of the Fluoride Dosing System at Wellington’s Water Treatment Plant in January 2023, installing a new fluoride pump to allow fluoride dosing to recommence.

As a result, fluoride treated water could continue being supplied to all areas including Wellington township, Montefiores, Nanima Village, Wellington Caves, Wellington Correctional Centre and Macquarie Correctional Centre.

At the time of the system failure, there was an expected timeframe of mid-March 2023 for delivery of a new system, which remained on order.

However, Council staff were able to modify the fluoride pump not being used at Dubbo’s John Gilbert Water Treatment Plant.

Acting Director of Infrastructure, Chris Godfrey, said, “This is a fantastic outcome for the Wellington community and those who use Wellington’s potable water supply.

“Operational staff advised us earlier [in January] the pump could not be repaired and needed to be replaced, with a pump having to be sourced from Germany.

“Staff have worked hard to secure a new fluoride dosing pump within a much shorter than anticipated timeframe, allowing the fluoride system to be re-established.”

The fluoride treatment at the Dubbo facility requires a complete rebuild of fluoridation infrastructure with the tender process for a contractor undertaken.

The water produced at the Wellington Water Treatment Plant has always been maintained to the highest level and has met the required control points for provision of safe drinking water during the process.

Construction of Sydney Water’s $4.3 million state-of-theart Leura Water Pumping Station (WPS) in the Blue Mountains is almost complete, and will be crucial in mitigating the risk of water supply loss for up to 60,000 people during low rainfall events and drought conditions.

Operating at full capacity, the Leura WPS will transfer the equivalent of 16

olympic-sized swimming pools of water to the Blue Mountains region each week.

The Leura Water Pumping Station is due to be operational by July 2023, with the construction of the facility beginning in late 2021 and final preparations currently taking place.

Sydney Water Principal Project Manager, Trevor Mondon, said the plant is an important piece of infrastructure for the region and will leave a positive legacy for the Blue Mountains community.

“The Leura WPS upgrade works are part of an overall Strategic Drought Planning action. The network upgrades will increase and improve

reliability of supply within the Cascade Water Delivery System (WDS),”

Mr Mondon said.

Sydney Water Senior Project Manager, Ben Samcou, said he believes the new facility will be a game changer for the people of the Blue Mountains when it comes to accessing reliable water supply, especially during drought conditions or bushfires.

“When in operation, the Leura WPS allows potable water to be transferred from lower parts of the Cascade water delivery system up to Katoomba Reservoir which is currently only fed from Cascades Water Treatment Plant,”

Mr Samcou said.

Comet Ridge has partnered with Denison Gas to transport gas from Mahalo North via the nearby Denison compression and dehydration plant and pipeline infrastructure, with the contract for the Front-End Engineering Design (FEED) study – including equipment selection –now awarded.

Verbrec Infrastructure Services has been nominated to undertake the FEED study which is being jointly funded by Comet Ridge and Denison.

The intent of the FEED study is to undertake process design, equipment selection, develop plant layout, project scope, schedule and budget for the Denison Infrastructure upgrade to accommodate the supply of 10TJ/d of gas production from the Mahalo North Early Production Scheme (EPS) within ATP 2048.

Once the results of the FEED study are finalised, Comet Ridge and Denison will finalise the commercial arrangements under which Denison

will compress, dehydrate and transport Mahalo North gas production, enabling Comet Ridge to move the project very quickly from recent appraisal and reserves certification activities, through development, and onto gas sales.

Comet Ridge Managing Director, Tor McCaul, said, “We are very pleased with the considerable progress we have made with the team at Denison, our near neighbours in the Denison/Mahalo gas province.

“Whilst Comet Ridge will have a path to market for Mahalo North gas, there are other potential opportunities for this partnership to benefit both parties, such as the sharing of technical resources and data, operating efficiencies, and reducing drilling and other field related costs by rig sharing and gas blending arrangements.

“The investment in engineering studies for this project comes at a modest cost, which is appropriate at a time of uncertainty for the gas production industry.

“We remain hopeful that the Australian Government will listen to industry concerns about the negative impact its current domestic gas policy will have on future gas supplies and make necessary changes that will allow companies like Comet Ridge to invest with confidence in the development of the new sources of gas that are urgently needed for Australian consumers and manufacturers.”

Denison Chief Executive Officer, Benson Wong, said, “Denison is pleased to be working with Comet Ridge and assisting them in getting their gas to market more quickly. This is an excellent example of two companies working together to help satisfy the needs of the East Coast energy market.

“In addition to expanding our processing and transportation capacity in our established, integrated processing facilities, Denison is also focused on expanding our supply of gas to market from our conventional gas reserves and CSG resources.”

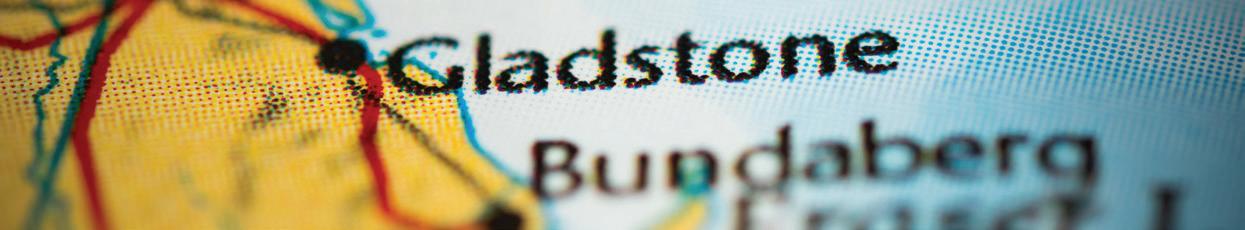

The Queensland Government has approved the $983 million Fitzroy to Gladstone pipeline project, which is expected to provide water security to the Gladstone region.

The 117km pipeline will run from the Lower Fitzroy River in Rockhampton and connect to Gladstone Area Water Board’s existing water network at Yarwun.

The project is crucial for supporting the existing industries that generate $6 billion in gross regional product every year and these activities depend on significant quantities of water now and into the future.

400 local jobs will be supported during the project’s construction and it is due to be completed in 2026.

Queensland Premier, Annastacia Palaszczuk, said the Government is committed to building the infrastructure Queensland needs to support good jobs in new industries during the clean energy industrial revolution.

“Nearly $1 billion has been committed to this important project, which guarantees water security and sends a powerful signal to the hydrogen sector that Queensland is the place to be for clean energy,” Ms Palaszczuk said.

“Gladstone will be the engine room when it comes to delivering our landmark Queensland Energy and Jobs Plan – that means good secure jobs now, and into the future.”

The infrastructure approval also aligns with recommendations made in the Bradfield Report, commissioned by the State Government and prepared by the expert Bradfield Regional Assessment and Development Panel.

Hydrogen proponents under development with future water requirements include:

• Fortescue Future Industries hydrogen electrolyser manufacturing facility

• Mitsubishi Gas’s proposal for a hydrogen to green methanol plant

• Stanwell/Iwatani Central Queensland Hydrogen Project

• Orica and H2U’s proposed green ammonia plant

• Rio Tinto and Sumitomo’s proposed hydrogen plant

Queensland Treasurer and Minister for Trade and Investment, Cameron Dick, said, “The Government’s contribution towards this vital infrastructure for Central Queensland is the first investment from our new progressive coal royalty tiers.

“This revenue was generated in Central Queensland and as we promised, it will be invested in regional Queensland.”

Queensland Water Minister and Member for Gladstone, Glenn Butcher, said the Gladstone pipeline project will support the emerging hydrogen and renewables sector that is set to expand in Gladstone, with several companies expressing interest in coming to the region.

“The Bradfield panel recommended investing in the use of water closer to where it falls as well as developing Regional Water Grids, and this is exactly what we are doing,” Mr Butcher said.

“The Fitzroy to Gladstone Pipeline is clear evidence the Palaszczuk Government is serious about listening to experts and taking action to ensure water security in Queensland.

“This pipeline will also allow Gladstone to access their water allocation from Rookwood Weir, which we know means security in good jobs and the delivery of safe and reliable water services to enhance the liveability of our region.”

Gladstone Area Water Board was appointed by the State Government in August 2021 to deliver pre-construction activities for the pipeline, which included undertaking procurement activities, addressing land access arrangements and determining long lead time items to ensure construction readiness for the pipeline.

Gladstone Area Water Board CEO, Darren Barlow, said the project is pivotal in securing water for Gladstone’s industry and will support the hydrogen and renewables industry, as well as help sustain the Queensland economy and provide jobs.

“As the Delivery Authority for the project, we look forward to partnering with local suppliers to deliver tangible benefits to the Gladstone region such as jobs, supply contracts and local capability raising,” Mr Barlow said.

On 8 March, the PIA held its first Breakfast Meeting of 2023, with Cummins South Pacific hosting the event at its head office in Scoresby, Melbourne. Over 20 people attended, hearing presentations from Cummins about its Australian branch and support network, as well as its main product groups in Australia and their applications and ratings.

James Blannin, PIA Vice President and Director De.mem – Stevco, opened the meeting, talking about the PIA Council members for 2023 and providing attendees with an overview of the PIA AGM held in November 2022. He also provided an update on ongoing discussions with the Queensland Building and Construction Commission (QBCC)

about who can complete works being undertaken that are covered by the Plumbing and Drainage Act 2018. Attendees were also reminded about the current version of the Pipe Friction Handbook and the newly updated Pump Technical Handbook, which are available with custom covers and can be ordered online at https://pumps.org.au/publications.

Running an optimised and sustainable mining and mineral processing operation has never been so important with pressures on water availability, rising costs and environmental regulations becoming stricter.

Water conservation is vital in countries such as Australia, the driest inhabited continent in the world, and good water management reduces disruption to mining operations as well as damage to the environment.

Using reliable and efficient peristaltic pump technology from Watson-Marlow Fluid Technology Solutions (WMFTS) for mining procedures can produce water savings of 71% in comparison with typical centrifugal pumps.

Bredel hose pumps from WMFTS can be considered water-saving devices in their capabilities, such as being able to handle undiluted tailings and thickener underflow with up to 80% solids. Since Bredel hose

pumps do not have seals, it eliminates the requirement of water for flushing, to treat process wastewater and provide pump service water.

A reduction in water usage also delivers associated benefits through lower chemical usage and energy required for the treatment of process wastewater. Pumps must be capable of high operating pressures and flow rates to ensure a smooth liquid passage and deny the opportunity for the product to settle. Bredel hose pumps are self-priming to 9 metres, can run dry safely and can meter accurately to ±1%.Reducing water usage is better for the environment too, as less storage is needed for tailings and the number of basins can be minimised.

The wear-free performance of clog-free peristaltic pumps also means the need for routine maintenance and spare parts is reduced greatly.

Bredel hose pumps have a corrosionresistant enclosure which suits arduous mining environments

MORE INFORMATION

For more information on how peristaltic pump technology can deliver significant water savings for mining and water treatment companies, go here: wmfts.com/en/mining/ Find out more today +61 2 8787 1400

Following the opening presentation, attendees heard from Michael Hicking, Manager - Construction and Agriculture Business for Cummins Asia Pacific.

Mr Hicking spoke about Cummins’ global manufacturing and distribution footprint as well as its five operating segments: engines, power systems, components, distribution and new power.

The key takeaway for attendees was that Cummins is looking ahead to keep up with changes happening in its industries and regions so that it can bring customers the right technology at the right time. In particular, there is a focus on innovating and investing in helping customers, and the world, on the path to net zero emissions.

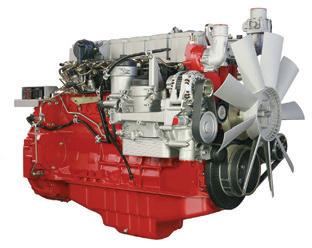

Then Vince Sessano - Victorian Sales Rep for Cummins, spoke about the three main product groups in Australia – the CustomPak, ComPak and FirePak – and outlined their applications and ratings.

Following the presentations, attendees were given a tour of part of the Cummins South Pacific facility by Dwayne Brito - Project Manager Off Highway, and had the opportunity to further mingle with others to discuss all things pump related.

Welling & Crossley can now supply a range of self-priming & mixed-flow China Pumps.

Ranging from 100ml (4”x 4”) to 300ml (12”x 12”). (larger sizes to come).

Mixed-flow pumps feature:

• Table D flanges

• Oil bath / Mechanical seals

• Stainless steel shaft Can be

Ebara Pumps' new GSD close-coupled EN733 motor pump has been selected as one of the primary water pumps for the new billion-dollar Festival Plaza upgrade in the heart of the Adelaide Arts and Culture precinct. The Ebara GSD range of ED coated pumps will be used on chlorinated water for the Festival Plaza's new water feature.

The Festival Plaza Water Feature is one of the many new highlights and attractions that have been incorporated in this new development of public realm that connects Adelaide CBD and the riverbank.

The specialist contractor who supplied the pumps and water treatment equipment for the new water feature – Total Water Resources chose the Ebara GSD pump due to its quality, proven hydraulic design and competitive pricing.

The GS/GSD pumps come as standard with a high-quality electro deposition corrosion resistant coating to the ferrous static components, both internal and external making them ideally suited to treated fresh water environments.

The GS/GSD range is the Ebara Corporation (Japan) new global range of EN733 water pumps and utilising the most advanced hydraulic computer software available, Ebara Engineers in Japan have been able to improve and increase the pump efficiencies of the new GS/GSD range above most other available pumps of similar design and standard on the global market. The majority of the GS/GSD pump range are MEI>0.7 efficiency index with the balance MEI>0.6, an indication of the high-quality design and manufacture by Ebara.

The Ebara GSD range of close-coupled motor pumps and the GS range of bare shaft EN733 end suction pumps are both manufactured in component form at Ebara Corporation (Japan) owned and managed factories in South East Asia.

After being assembled from these components by skilled tradesmen at the Ebara Pumps Australia facility in Melbourne, the pumps are then hydrostatically tested and inspected to our Japanese parent’s strict QA policies and procedures.

The Ebara GS/GSD range of EN733 pumps are a true 16 bar working pressure with a high grade SiC/Carbon/EPDM Burgmann mechanical seal fitted as standard. Galvanised steel baseplates that have been fully engineered by Ebara Japan engineers are also available as an optional extra for the GSD motor pumps.

In addition to the GS/GSD range of pumps Ebara Pumps has also recently introduced the GSO range of semi-open impeller ISO 2858/5199 process pumps, which are also available in 304,316L and Duplex stainless steel. The GSO range of pumps have been designed by Ebara Japan with a unique reverse open impeller reducing axial thrust and creating a low seal/stuffing box pressure. The pumps can be fitted with a vast range of single/double mechanical seal options and piping plans. They are also available with the option of oil lubricated bearings and ANSI drilled flanges.

Ebara Corporation was founded in Japan in 1912 as a manufacturer of industrial pumps. Today, as a group it consists of more than 70 companies in six continents with a workforce of more than 12,000 and with company-owned and Japanese-managed factories covering nine countries and four continents.

The huge scale of production and distribution is matched by a constant commitment to research, development and design of new products and the modern technologies for the manufacturing of them. Ebara products have gained a worldwide reputation for their technology and quality.

Combining over 100 years of experience with the latest computer aided design, EBARA has developed the new GS series of pumps that offer world leading performance and efficiencies.

Pumps to EN733 dimensions

16 Bar rated. PN16 flanges (24 Bar hydrostatic test pressure)

High efficiencies. MEI ³0.6 (Minimum Efficiency Index)

Mechanical seals to EN12756

Protectors to ISO13852

O’ Ring seal for casing

Cast iron components ED painted (Electro deposition painting)

Water hammer is a destructive phenomenon, best described as hydraulic shock. Its cause is from a sudden change in fluid motion as the liquid travelling through a pipe system has momentum. Changing that momentum, by closing a valve suddenly, results in the build up of kinetic energy and, if left untreated, causes a shockwave to propagate through the pipe system. The result can be as low key as an audible bang or pipe shudder, however there is potential for more catastrophic results such as pipeline blowouts.

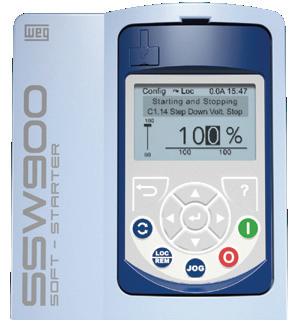

One cost-effective solution to water hammer is to avoid sudden changes in fluid motion. This can be achieved by reducing the flow of fluid prior to closing a valve and is where WEG’s SSW900 soft starter comes into its element. The modern soft starter controls motor torque to gently start a motor, however it’s capable of much more than a controlled start. The technology used to gently start a pump can also be used to decelerate the pump. The SSW900 includes an algorithm, called Pump Control, which was purposefully designed to maintain a level of torque output during deceleration. This maintained torque output prolongs the deceleration and provides time for valves to be slowly activated and thus avoiding water hammer.

Combining convenience and innovation, WEG’s SSW900 is a highperformance device with integrated PLC functionality, providing fully programmable algorithms for regulating induction motors as well as fully flexible torque control. It offers a complete solution for motor start/stop control and protection. Developed for industrial

or professional use, the new line of soft starters adds unfounded ease of use and application flexibility.

Featuring a full text and graphical interface, user interaction has never been more intuitive allowing simple access to configuration settings and data. Oriented Start-up provides guided step-by-step parameter configuration. On the occasion that help is required, simply pressing the ‘Help’ button will bring up a complete description of the parameter function removing the dependence of referring to a manual.

The inclusion of a Real Time Clock allows time and date stamping of alarms

and events. Being a full text display, the alarm code is followed by a fault description and critical diagnostics data captured at the time of fault, aiding in troubleshooting and reducing production downtime.

Extending the benefit of the Real Time Clock is the SoftPLC. Custom code can be written to control inputs and outputs, control process requirements, and extend the protection capabilities by creating industry specific protection features. Whether you want a pump to start at a particular time of the day, run for a specified time, control a jacking pump or even create a dry run protection algorithm all is within the SoftPLC’s capability providing the user the ultimate in application flexibility while reducing component count and circuit complexity.

The SSW900 design includes a builtin bypass which optimises space and reduces heat dissipation in electrical panels. This leads to better efficiency of both cabinet space and electrical efficiency leading to longer term energy savings and a longer lasting product.

The SSW900 from WEG offers the ultimate solution in pump control.

icropump has announced a new distribution partnership with Kelair Pumps Australia, a leading source of pumping systems and fluids handling expert in Australia.

Micropump, established in 1960, is the originator of magnetic drive gear pump technology. Today, Micropump is a part of IDEX Corporation and the market leader in low-flow gear pumps offering standard models, configure-to-order options, and custom solutions.

Founded in 1975, Kelair Pumps is one of Australia’s largest pump distributors with an established sales footprint in all Australian states. Kelair Pumps, a member of The AxFlow Group, has been working with IDEX Corporation for the last 23 years of which it has been the sole importer of several IDEX brands in Australia (including Sandpiper, Viking and Pulsafeeder).

After 12 years absence of a dedicated distributor in the Australian market, Micropump will work with Kelair Pumps to solve challenging fluid handling applications as well as provide local availability of Micropump products and services that are critical to keeping plant operations running.

Fabian Stiegler, European Sales Manager for Micropump, said, “Micropump could not be happier to have Kelair Pumps join the distribution family. Kelair Pumps strong reputation

with end users and leadership position in Australia make them the ideal partner to drive long-term growth for Micropump in this region.”

Myro Bratkovic, General Manager of Kelair Pumps, stated that he was extremely enthusiastic about the new relationship while noting that Micropump has such a high standard of performance in their positive displacement and dynamic pump products, and their lead in design and innovation, and technology is second to none.

“The entire Micropump range has a high reputation for reliable performance and long product life, which is essential for precise, low flow applications,” Mr Bratkovic said.

“The addition of Micropump to our wide range of pumps, drives and controllers, along with our extensive knowledge and expertise means we can package their products with other IDEX family products for complete fluid assemblies.

“Micropump complement our current product offering and ensure we are continuously meeting the needs of our customers.”

For more information about Micropump, visit https://micropump.com/ or for more information about Kelair Pumps Australia, phone 1300 789 466 or visit https://kelairpumps.com.au/.

Kelair Pumps Building & Fire Division is one of the most technically-competent suppliers in Australia. We can provide a complete range of fire pumpsets for all applications, fully compliant to technical specifications.

- Purpose built to individual requirements

- Compact, pre-fabricated, complete packaged solutions

- Fully tested to AS2941-2013 and AS/ISO9906-2018 Grade 1U

- Turnkey installation saves time and labour costs

- Simple to mobilise and transport

- Routine maintenance packages also available

We know the importance of choosing the right equipment to match your process. With our extensive range of pumps, first class customer service and ongoing comprehensive support, Kelair Pumps are second to none when it comes to your pumping requirements.

ump Industry’s Managing Editor, Lauren Cella, is leaving the publication after seven years in the role. Lauren has been the magazine’s longest serving editor, shaping the conversation and being instrumental in making Pump Industry the number one trusted source for pump news in Australia.

An experienced journalist and editor with a wide variety of news and B2B publishing experience across print, online and radio, Lauren quickly became interested in pumps and their different applications when she joined the team as a journalist in 2016, which led her to taking on the role of Editor.

It’s an understatement to say that Lauren has been the heart and soul of the magazine and she has provided high-quality technical content issue after issue, allowing readers to learn about the latest developments and sparking new ideas they can implement in their jobs. Lauren spearheaded some of Pump Industry’s most beneficial features including the Industry Capability Guide and annual State of the Industry survey.

Managing director of Pump Industry and its publisher, Monkey Media, Chris Bland, said Lauren will be greatly missed as she has been the backbone of Monkey Media for seven out of the company's ten years.

“Monkey Media wouldn't be the same company without Lauren – she will always be a vital and much loved part of the Monkey Media and Pump Industry story,” Chris said.

“She was the person we relied on to create client content when we knew it had to be the best, and her work on Pump Industry and relationships she had with the PIA and pump users around Australia has made the magazine the important resource it is today.

“However, we’re extremely happy for Lauren to be pursuing her dream job with the Department of Defence and wish her all the best for the future.”

While this edition of the magazine is Lauren’s last, we’re excited to welcome the new Pump Industry Editor, Katie Livingston, and look forward to seeing the direction Katie takes the magazine.

MAIRS Technology uses traditional technologies and innovative engineered solutions to service a range of industries and customers to help manage their environmental needs and systems, whilst meeting environmental and health safe regulations, and health of nearby communities.

Our capabilities:

• Project Management Services

• Engineering Service Support

• Equipment Spares Supply

• Construction services and supervision

• Sub-contract management

• Commissioning and training

• Asset inspections and reports

• Asset maintenance and management planning

• Optimisation and system improvements

03 9028 8080 sales@mairstech.com www.mairstech.com

While traditional trade publications have quality audiences and high levels of trust, they can lack the full range of services to guarantee a return on your investment. And while traditional marketing agencies offer the latest marketing techniques, they don’t have the audience or the industry understanding the B2B sector needs.

Monkey Media is the missing link that brings together a trusted brand and powerful audience, with a complete agency offering.

TO FIND OUT MORE SCAN THE QR CODE NOW

Pumps can be used as turbines to generate low-cost electricity from existing pipe systems with no associated environmental impact.

Hydropower energy recovery is an effective response to rising energy prices. SAER has an extensive product range that can be used as pump as turbine (PAT): small and medium-scale modular hydropower generating sets suitable for sites up to 500+ kilowatts of nominal power.

Pumps used as turbines can transform the surplus hydraulic energy of water into electricity and the newly generated electricity can be selfconsumed or exported to the grid. With low investment and maintenance costs, pumps as turbines (PAT) allow the recovery of the energy from existing pipe networks and achieve considerable energy savings.

Instead of a specifically designed conventional turbine, SAER proposes a standard water pump designed for reverse operations, which is easy to maintain and offers a low lifecycle cost. This technology allows water-intensive organisations (e.g. water, irrigation, mining companies) to conveniently exploit an untapped energy source in a costeffective way. Due to the use of existing infrastructure, all of this can be done with negligible environmental impact. How?

Competitive advantages

• Short investment return time, especially in the presence of high energy prices

• The turbine is optimised to operate in a reliable and fail-safe way

• Easy maintenance, with spare parts readily available

• Real-time information: a complete telemetry system can be supplied for real time monitoring

• SAER’s PATs are made in Italy with a quick lead time with a wide choice of performances and design configurations to fit your system

Due to the different materials available in the SAER range, from cast iron to super duplex, several kinds of liquids may be handled.

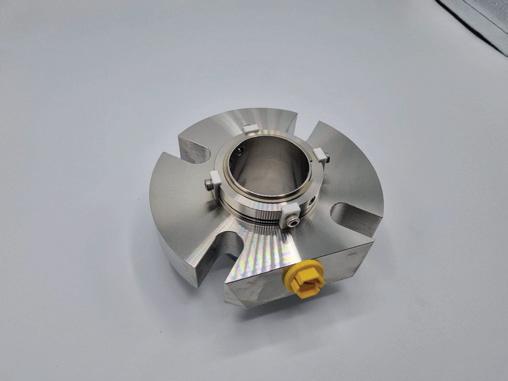

Case study: pilot energy recovery installation at a mine site

Pictured is a successful installation recently designed by SAER partner Easy Hydro.

Head: 210m

Flow: 22L/s

Maximum output: 30kW

Annual generation: 200MWh

The PAT has been installed in parallel to an existing pressure reducing station

PATs are suitable for applications in existing pipe systems where water pressure needs to be reduced or where water flows by gravity into a reservoir.

PATs can be installed on either manmade water networks (e.g. drinking water or irrigation networks) and natural ones (rivers, lakes); next to the water supply of underground mines; or at the outfall of wastewater treatment plants or in pressurised irrigation pipelines, etc.

on a DN 150 pipeline carrying cooling water from the surface into the depths of the mine. The turbine location is 300m underground. Instead of just dissipating the water pressure as heat and noise via the pressure reducing valves, the E-TMZ multistage turbine is generating power, which helps the mine operator to reduce the electricity import from the grid.

For more information about the project, visit https://easyhydrosolutions.com/en/energy-recovery-from-the-water-supply-of-tara-mines/.

With climate change causing an increase in extreme weather events – including floods, fires and drought – organisations and councils around Australia are repairing and upgrading pre-existing infrastructure to futureproof their communities. To help Southern Downs Regional Council (SDRC) improve drought resilience, the Queensland Government has invested $19.34 million to extend local water supplies, providing much-needed water security to more than 24,000 residents in the region. The latest works completed under this funding are upgrades to the SDRC owned Leslie Dam Pump Station, including the replacement of three 55-year-old pumps.

In January 2020, Warwick was projected to run out of water by the end of the year with Leslie Dam down to less than 4.6 per cent capacity, creating a difficult and challenging time for the region. However, feasible solutions that could be delivered quickly were limited as water carting to a town the size of Warwick – which has a population of about 15,000 – is not viable.

While recent rain has bolstered short-term water supplies by filling both Leslie and Storm King Dams, historical data shows rain cannot always be relied on at the time of need, with this funding vital to providing drought resilience for Southern Downs’ drinking water supply.

The funding for the Queensland Government’s drought resilience package includes the following activities:

• Connection of a new bore at Warwick to the Warwick water supply system

• Recommission of the Allora bores, and in the longer term to the Toowoomba to Warwick Pipeline for treatment at the Warwick Water Treatment Plant

• Investigation into the potential use of Connolly Dam as a supplementary supply for Warwick without impacting Stanthorpe’s water security

• Upgrades to the Warwick Water Treatment Plant to treat blended water from various sources of supply

• Infrastructure to access remaining Leslie Dam dead storage by Sunwater

• Investigation into potential new local groundwater sources around Warwick, Stanthorpe and Yangan

• Investigation into the potential availability of water allocations in Leslie Dam for urban use has been completed by Sunwater

One of the activities being undertaken as part of the drought resilience package is installing the infrastructure needed to access a portion of the water from Leslie Dam that was previously below the level of the pumps, and couldn’t be reached (dead storage).

Leslie Dam holds around 1,700 megalitres in its dead storage. By funding new capital works to access that water, the drought resilience package makes the best use of the Southern Downs’ locally available supplies and ensures as little water as possible is inaccessible, but allowing for some water to be left in the dam as per the Upper Condamine Water Supply Scheme Resource Operations Licence.

Works to access the dead storage – including upgrades to the Leslie Dam Pump Station – are being carried out by SDRC who is responsible for reticulated supply to its service areas, and Sunwater who owns Leslie Dam. The $4.54 million upgrade to the Leslie Dam Pump Station was completed in December 2022 and in conjunction with a low level pumping station currently under investigation and in planning by Sunwater, it will enable SDRC to utilise the dead storage.

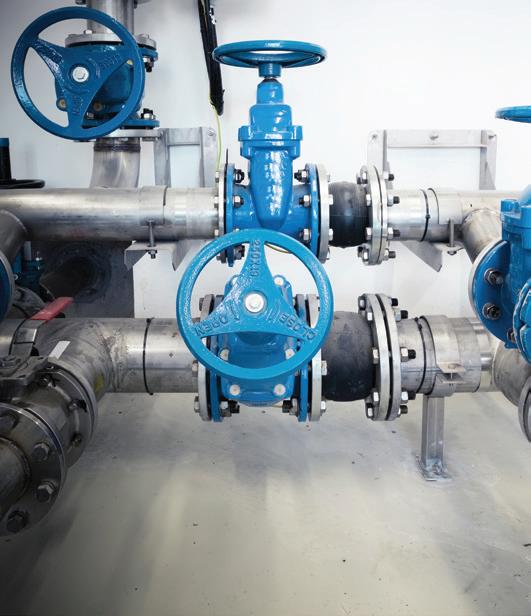

The upgrade consisted of the replacement of three 55-year-old pumps, pipework and the electrical switchboard, with Vosloo Consulting Engineers (VCE) undertaking the design work.

The Leslie Dam Pump Station was originally constructed in 1966 and employed three single stage horizontal split case centrifugal pumps (Pump Class EC) by Thompsons (Castlemaine). The 125HP pumps were installed in a parallel arrangement and operated in a duty/assist/standby mode.

The existing raw water transfer scheme involves pumping approximately 1,946m through a DN525 rising main from the Leslie Dam wall to a 118.39kL balance tank, before water flows under gravity head for approximately 7,427m to the water treatment plant in Warwick.

The original system resistance curves indicated nominal duty points of 67.82L/s at 80.77m head for a single pump operating, or 126.18L/s at 83.82m head for two pumps operating simultaneously. The pumps are controlled by the water level in the balance tank via level sensors, control and SCADA systems.

One of the original pumps failed in June 2018, which impacted on the ability of the remaining pumps to supply the water treatment plant. The failed pump was removed and a temporary diesel backup pump installed in its place. The remaining two pumps delivered approximately 66L/s when a single pump was operating and 119L/s when both pumps were operating simultaneously.

SDRC indicated that winter demand in 2020 was approximately 120L/s, and summer demand approximately 160L/s. To keep up with current water demands the two remaining original pumps were both running as duty pumps, with the temporary diesel pump serving as a standby pump and to assist the existing pumps when demand was high.

Due to the age of the pumps and considering future demand, SDRC decided to upgrade the existing pumps and switchboard to ensure that the raw water supply to the water treatment plant is uninterrupted. SDRC appointed VCE to undertake the design required to upgrade the existing Leslie Dam Pumping Station.

VCE’s scope of services included the following:

• Undertaking hydraulic analysis and review of the existing pumping system to assess its hydraulic capacity to cater for current and future demands

• Estimating future demand flow rates to be used in the sizing and pump selection for the replacement pumps

• Do a pump selection for the replacement pumps

• Undertake hydraulic modelling and make recommendations regarding the suitability of the existing rising main and balance tank with regards to future demands

• Assess the existing power supply’s suitability for the proposed pump upgrade

• Prepare detailed design for the replacement of the existing pumps, control system and replacement of the existing Dall Tube (Venturi) type flow meter with an electromagnetic flow meter, including upgrade of the power supply

VCE appointed ECG Engineering (ECG) to undertake the electrical design, SafeGroup Automation (SGA) for the control and telemetry designs, and Minstaff Survey for the detail survey and 3D laser scan of the internal of the pump house.

Preliminary pump selections were undertaken with the aim of designing a pumping system that can deliver a nominal pump rate of 243L/s, which is the 50-year (2070) Mean Day Maximum Month (MDMM) flow rate over 20 hours. Two pumping options were considered, option one being a duty/ standby arrangement and option two being a duty/assist/ standby arrangement.

System resistance curves were developed for each of the two options, which included increased pipework sizes inside the pumping station, suitable to ensure flow velocities and friction head losses are acceptable and in accordance with

adopted standards. The pipe upgrades included increasing 5.83m of DN200 DICL suction pipework to DN450 DICL and DN375 DICL for options one and two respectively. The 1.56m length of DN200 DICL discharge pipework required upgrading to DN375 DICL and DN300 DICL for options one and two respectively.

VCE undertook a Net Present Value (NPV) analysis to quantify the most economical pump selection of the two options considered. The NPV analysis was undertaken for a 50-year period. The duty/assist/standby arrangement (option two) with 160kW pumps proved to be the most economical pump selection according to the NPV analysis results and energy cost estimates. It was anticipated that the construction cost for option two would be higher than for option one, but the pumps will operate closer to the best efficiency point (BEP), resulting in lower operating cost over the life of the asset.

Option two can also supply a wider flow range than option one, starting from approximately 70L/s at 80.36m head (at 47Hz) with one pump being operational, to approximately 247L/s at 88.36m head (at 50Hz) with two pumps being operational simultaneously, for the dam mean water level (MWL) scenario. The duty/standby 315kW pump selection (option one) can deliver a flow range in the order of 165L/s at 83.20m head (at approximate frequency 47.9Hz) to 243L/s at 86.87m head (50Hz) for one pump being operational and dam MWL. SDRC approved VCE’s proposal to proceed with the detailed design of the duty/assist/standby arrangement and the horizontal split case centrifugal pumps with 160kW motors.

Three Grundfos type LS horizontal split case centrifugal pumps (Model LS200-150-508B) with 485.2mm diameter impellers and 160kW motors were selected for a duty/assist/ standby arrangement, to operate at a nominal duty point of 153L/s at 83.23m head with 82.6 per cent pump efficiency, for the dam MWL scenario and single pump operation at full speed (50Hz). Two pumps operating simultaneously in a parallel arrangement were estimated to have a nominal duty point of 247L/s at 88.36m head with 81.9 per cent pump efficiency, for the dam MWL scenario and full pump speed. The pumps will be controlled with Schneider Electric’s model floor-standing model Altivar Process ATV650C20N4F Variable Speed Drives (VSD).

The electrical mains cables between the existing 500kVA transformer and the main switchboards needed to be upgraded to prevent overloading during pumping above the nominal pump duty point. The 500kVA transformer and mains cable, as well as the main switchboards were replaced as part of the pump station upgrade.

The pump selection was undertaken with the intent of delivering the nominal pump rate of 243L/s at dam MWL and two pumps operating simultaneously, not for the worst case – dam bottom water level (BWL) scenario. This was done to reduce the power loading on the existing 500kVA transformer and avoid the need for upgrading the same. The disadvantage of this approach is that for the dam BWL scenario, the proposed pumping system will be limited to deliver a maximum flow rate of approximately 106L/s for dual pump operation at full speed (50Hz).

SDRC is currently working with Sunwater and the Queensland Government to design a low level pumping station that will enable it to utilise water below the pumps’ BWL, the remainder of the ‘dead storage’. The low level pump station will be additional to the existing Leslie Dam Pump Station, and will enable the new 160kW pumps to deliver the full 50-year planning horizon flow rate of 243L/s at dam BWL and lower water levels. This investigation and planning work into a ‘dead storage pumping station’ are currently being undertaken by Sunwater as part of the Queensland Government’s drought resilience package.

VCE’s analysis of the pumping system confirmed that the balance tank storage volume is sufficient for the existing and proposed pumping systems if it is setup and operated in accordance with its original design intent, which is not to provide raw water storage, but only as a small holding facility to utilise the available gravity head between the balance tank and the water treatment plant.

The purpose of the balance tank is to limit pumping to it, and thereby minimise pumping costs.

Adjustment to the pump stop and start level within the balance tank was proposed to reduce the number of pump starts and minimise pumping time (and power costs).

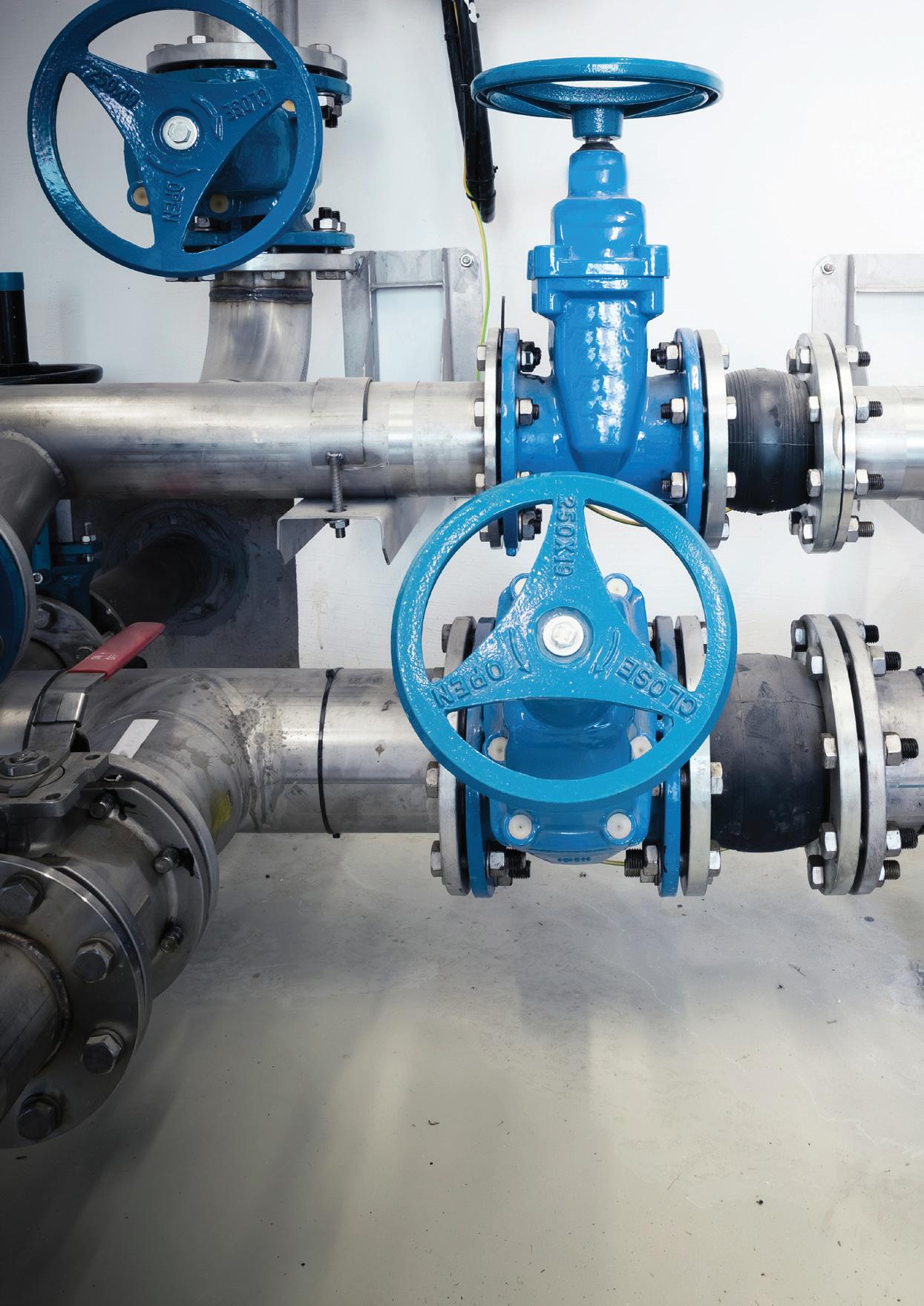

SDRC appointed Repump for the replacement pumps, VSDs and switchboard, including pipework, valves and fittings inside the pump house, and installation of a DN500 flowmeter and isolation valves in the existing DN525 MS pressure main outside the pump house.

Repump was also responsible for design and installation of a bypass pumping system that would maintain pumping operations while replacing the civil, electrical and control equipment. Ergon Energy was responsible for installation of a new 500kVA pole-mounted transformer adjacent to the pump house. Repump also installed a new hoist and hoist beam inside the pump house as part of their contract with SDRC.

Works are continuing on other projects to secure the region’s water supply funded by the Queensland Government, including the construction of a pipeline to connect a new bore near Warwick to augment its water supply network, and recommissioning its Allora bores for supply to Council’s construction purposes in the short term and connection to the Toowoomba to Warwick Pipeline in the long term.

The Queensland Government has invested more than $380 million for the construction of the Toowoomba to Warwick

Pipeline project, which forms part of its wider commitment to providing longterm water security for the region.

With an expected completion date of early 2027, the Toowoomba to Warwick Pipeline pipeline will transfer water from Wivenhoe Dam when needed, to ensure a drought contingency water supply to 24,000 Southern Downs residents (which includes contingency supply for water carting to Stanthorpe when required), and a permanent water supply to 3,400 residents in the Toowoomba Regional Council towns of Cambooya, Greenmount, Nobby and Clifton along the Pipeline route.

The drought resilience package funding also allows SDRC to upgrade the Warwick Water Treatment Plant so that it can effectively blend, treat and distribute all of the new (and existing) water sources available to Council.

Getting the best use from its locally available water sources not only gives the Council more water – it also contributes to reducing Council’s demand on the Toowoomba to Warwick Pipeline, and hence the costs for operating the pipeline.

The Queensland Government will continue working closely with Seqwater and the Southern Downs and Toowoomba Regional Councils to optimise the operation of

the Toowoomba to Warwick Pipeline, keeping costs low for the Southern Downs without impacting Toowoomba’s water security.

The Southern Downs drought resilience package and the Toowoomba to Warwick Pipeline will create 460 local jobs, and deliver on the Queensland Premier’s November 2019 commitment that Queensland families will not run out of drinking water.

Since the construction of the Ballarat South Wastewater Treatment Plant (BSWWTP) in 1925, the population of Ballarat has grown, compliance requirements have changed, and technologies have advanced. To keep up with these changes and to mitigate challenges associated with storm events, Central Highlands Water undertook a major upgrade of the plant, which involved the installation of new Archimedes screw pumps, and new coarse and fine screens.

BSWWTP is the primary wastewater treatment plant for the City of Ballarat, treating approximately 70 per cent of the Ballarat catchment – currently the equivalent population of 85,000 – with the other 30 per cent treated at Ballarat North Wastewater Treatment Plant. Ballarat has been experiencing significant development and growth – primarily in the western corridor which is treated at BSWWTP – and the population is expected to continue to grow, with the BSWWTP expected to be servicing an equivalent population of 110,000 by 2035.

Furthermore, wet weather inflows to the plant have been historically challenging to manage.

With storm events predicted to increase, combined with population growth, Central Highlands Water decided to upgrade BSWWTP to increase its capacity to allow it to better deal with wet weather events, and to ensure the plant’s ongoing sustainability.

The key aims of the upgrades were:

• Contribute to the sustainable treatment of wastewater, for the benefit of the environment and local community, and treat wet weather inflows to meet Environmental Protection Agency (EPA) licence conditions and General Environmental Duty (GED) obligations

• Increase the capacity of the inlet pumping station and inlet works to manage wet weather inflows

• Reduce potable water usage by constructing a new plant service water system for the inlet works and a new pipeline for the distribution of Class A equivalent recycled water

• Improve automation and decrease reliance on manual intervention when transitioning from normal dry weather to wet weather control modes

The wastewater treatment plant’s new screw pumps

The upgrade focused on inlet works, which was estimated to cost $9.2 million and came in under budget, at $7.5 million. This allowed for other complementary site improvement works to be funded, to further improve the efficiency and safety of the operations. By maximising the capacity of the existing inlet works structure, Central Highlands Water was able to avoid building a replacement inlet works, as originally planned.

The inlet works design, done by Jacobs Group, was able to increase the hydraulic capacity of the inlet works to provide a coarse screening capacity

of 2,000L/s (up from 700L/s) and a minimum fine screening capacity of 1,200L/s. It improved solids capture performance of the coarse and fine screens to approximately 70 per cent (up from approximately 30 per cent).

The project involved the installation of new Archimedes screw pumps and new coarse and fine screens to help filter out unwanted material from the wastewater, as it arrives at the treatment plant first before it makes its way through several additional treatment process steps.

“The screw pump is a technology more than 2,000 years old and is probably the most efficient technology for low head pumping,” a spokesperson for Central Highlands Water said.

“The last upgrade of the inlet works was in the early 1990s, which included the installation of two smaller capacity epoxy coated mild steel Archimedes screws. Over the last 30 years the screws had been periodically removed, one at a time, for maintenance and recoating and were at the end of asset life.

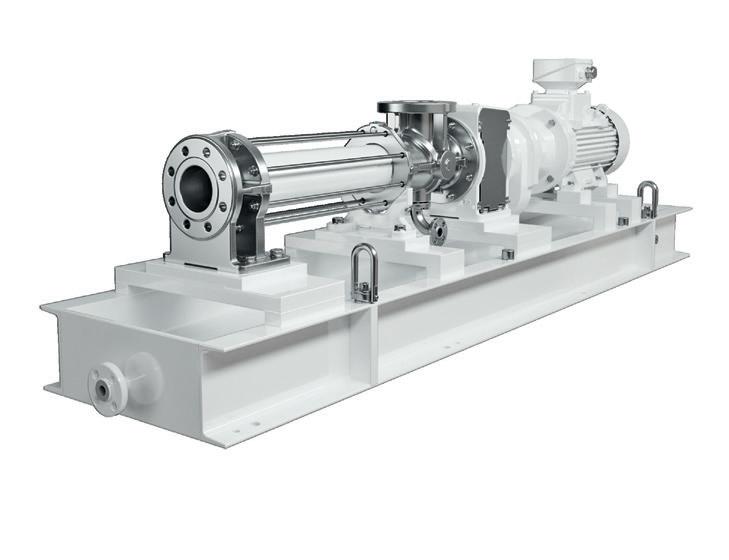

“The two new STM1400 316 stainless steel Archimedes screw pumps were manufactured in the Netherlands by Spaans Babcock. They are a selfsupporting unit supported on top and bottom bearings, inclined at 33 degrees, 1,400mm diameter, approximately 8m in length, and rotate at 42 rpm.

“These pumps lift the influent 3.52m to provide hydraulic grade through the treatment process so that pumping in the downstream processes is minimised.

“The drive motors are 37kW, and the fabricated self-supporting trough ensures a perfect fit of the screw with a small tolerance between the screw and trough, which maximises the efficiency.”

The screw pumps also have VSD inverter drives, with the speed varying to maintain a level setpoint in the inlet pump station.

“Central Highlands Water engaged Bureau Veritas to perform an inspection of the equipment once it was fabricated and tested before shipping from the Netherlands. This included all facets of the manufacture from compliance with drawings and tolerances, material composition, electrical certification, and welding,” a Central Highlands Water spokesperson said.

“Once the units arrived on-site they were inspected and treated for minor rust defects prior to installation, and full wet-commissioning was undertaken with recycled water prior to putting in service.”

The ongoing maintenance of the screw pumps involves inspection and maintenance of the screw pump body, the drive unit, and the upper and lower bearings.

“The gap between the spiral blade and the trough is key to maintaining the pumping efficiency, so this is inspected quarterly. The drive unit inspection and maintenance regime is typical for a motor and gearbox (noise, oil level, leakage, grease lines, etc.). The bearings are inspected for wear and tear, and alignment,” a Central Highlands Water spokesperson said.

Mitigating challenges

The inlet works were offline for approximately nine months, which required the project team to consider flow management and impact of providing no screening or grit removal on downstream processes.

“The northern and western sewers both discharge to the inlet works but fortunately a bypass channel around the inlet works already existed for the northern sewer. A new diversion structure was built over the western sewer to divert flows around the inlet works directly to the primary sediment tanks

(PSTs). Bypass pumping was entirely avoided during construction, by building the pit over the sewer and cutting out a pipe section using a wire saw,” a Central Highlands Water spokesperson said.

“An automatic 30mm coarse screen was installed in the common channel to the PSTs. This reduced handling and safety associated with manually raking the two existing trash screens during the upgrade works. Despite the reduced screening capacity, no significant downstream equipment issues were experienced while the inlet works were offline.”

3D point cloud and models were also prepared for all new works by designers, who were based interstate. The use of the 3D models significantly improved operator engagement and the elimination of OH&S risks through visual representation.

Great consideration was also needed to reduce the risk of delays.

“The tender for the project was released in December 2019, prior to the outbreak of COVID-19 later that month. With the progression of transmission, and subsequent travel restrictions imposed, there was a great deal of

consideration put into managing the risks for delays and likely impositions before awarding the contract to head contractor Guidera O’Connor in June 2020,” a Central Highlands Water spokesperson said.

“As there was a long lead time involved with procurement of the screw pumps and screening equipment, the design inputs for these were essential to obtain quickly. The use of 3D surveying and video conferencing enabled the contractor’s design team to engage with the operators and quickly and efficiently resolve the design and place orders. This then reduced the time risk for the period between the equipment landing on-site and the mobilisation of the work team to site.

New pump station and pipeline to transfer water

A new pumping station and pipeline were also constructed as part of the upgrade to transfer recycled water to the inlet works. This is used as service water to clean screens within the wastewater treatment plant, and enhances water recycling efficiency to the operations by reducing the demand on potable water use at the plant.

These works involved replacing existing recycled water pumps

and installing a new pipeline to transfer recycled water to the solids dewatering process.

“Potable water usage at the site has been reduced with service water demand being met by Class B recycled water and filtered tertiary lagoon water which is supplied to the inlet works, saving approximately 400kL of potable water use per day,” a Central Highlands Water spokesperson said.

“A new pipeline was constructed from the Class B booster pumps to the dewatering, digester and primary sedimentation with a new pump skid installed with three CRNE 20-6 Grundfos pumps running in parallel. The pumps are configured to operate in a duty/duty/assist configuration, depending on the water demand required, and the overall capacity of the system is 25L/s.

“A new service water pipeline has also been constructed, taking secondary clarified effluent from the lagoon system and pumping it to the inlet works. Effluent is filtered to remove particulates using a 100μm AMIAD filter to comply with the inlet works screening equipment manufacturer’s water quality requirements in order to prevent the spray nozzles on the band screens and washer/compactors from blocking.”

Upcoming projects at BSWWTP include upgrading and refurbishment of critical process units such as the primary sedimentation tanks and mechanisms, the dewatering process facility, and augmenting aeration capacity.

Continuing to improve services to the region

The inlet works are part of Central Highlands Water’s top ten priority projects for the 2018 to 2023 period. Additional ongoing and/or planned capital works project being undertaken, include:

• Ballarat Sewer Growth Project –Ballarat West

• Ballarat Sewer Build – Ballarat East Trunk Sewer (Stage 2)

• White Swan Dam Safety Improvement

• Digital Water Metering

• Ballarat North Growth Project –Northern Growth Area

• Ballarat Sewer Build – Ballarat South Outfall Project

• Regional Recycled Water Scheme Upgrades

• Daylesford Water Treatment Upgrade

• Daylesford Raw Water Pipeline

• Ballarat Sewer Growth Project –Northern Growth Area

Access to clean water is a fundamental right of humans as well as animals. Today, we are deploying multiple pumping technologies to get drinkable water including building wastewater treatment plants and saline water desalination plants; drawing water from rivers, wells and creeks; filtering water; etc. Apart from this, multiple industries deploy effluent treatment plants at their manufacturing facilities to process their end effluent and reuse clean water in their processes.

With our 22 years of experience, we have supplied numerous pumps for these applications and solved various critical pumping challenges. Today, we have developed a comprehensive range of helical rotor positive displacement pumps for water, wastewater, agriculture and many other industrial applications. Also, we are hugely trusted for designing customised fluid engineering solutions for our customers.

Agriculture and water-based pumps

Tirrana Agricultural Pumps

Built on a heavy-duty and proven platform, the Tirrana range of helical rotor pumps offers peace of mind and the best solutions to all types of surface water transfer duties.

Capacity: up to 360LPM

Head: up to 120m

Applications:

• Ideal for tank filling or stock watering from dams, creeks, wells, and rivers

• Can handle clean water, brown water, dirty water with sand, silt, or algae

• High suction lift applications

• Viscous, abrasive and solid laden media

• High/varying discharge pressure applications

• Dirty/salty water

Multipurpose pump range

Wastewater pump range Industrial pumps

Capacity: up to 500m3/hr

Pressure: up to 48 bar

Roto’s industrial pumps are designed for continuous or intermittent transfer duties in innumerable applications for varying viscosities, abrasiveness and even fluids with high solid content across every industry. These pumps are also used to handle all the wastewater application from the preliminary treatment process to final sludge dewatering.

Applications:

• Primary/secondary/tertiary sludge

• Thickened and stabilised sludge

• Digested/undigested sludge

• Bio sludge

• Secondary activated sludge

• Floating/settled sludge

• Secondary excess sludge

• Dewatered sludge and sludge cake

Dosing Pumps

Capacity: up to 500LPM

Pressure: up to 24 bar

Roto dosing pumps are developed for low flow applications that demand high accuracies and repeatability (+/- one per cent) with the unique advantage of smooth and non-pulsating flow. These dosing pumps can handle clean and clear liquids. The pump is ideal for either intermittent or continuous dosing duties. These pumps ensure proportionate dosing of media via the use of a frequency controller.

Applications:

• Milk of lime

• Polyelectrolyte

• Concentrated flocculant

• Poly-aluminium chloride solution

• Polymer solution

• Polyacrylamide flocculant

• Metallic salts

• Alum flocculant

Climate change, bushfires and extreme heat have forced many bat colonies to relocate to avoid exposure to fatally high temperatures. One innovative way to alleviate heat stress among these threatened animals is by implementing large sprinkler systems, which effectively operate as a large evaporative cooler, to mitigate the effects of heat during summer. Parks Victoria has utilised this method, installing an electric pump and generator in an internationally applauded sprinkler system designed to protect Yarra Bend Park’s grey-headed flying-fox colony.

During summer heatwaves and bushfires, these native bats have been devastated with both habitat loss and loss of life. Thousands of grey-headed flying-foxes – which are a protected species – die of heat exhaustion each summer, with climate change exacerbating the length and intensity of the season.

Yarra Bend Park, home to Victoria’s largest permanent colony of greyheaded flying-foxes, was especially impacted – over a three-day period in 2020, temperatures reached 43ºC and caused the death of more than 5,000 bats at the park.

But a new permanent sprinkler system, powered by an electric pump and generator, will protect the colony of approximately 30,000 bats at Yarra Bend Park, functioning as a giant evaporative cooler for the area.

Parks Victoria Area Chief Ranger, Brendan Sullivan, said the aim of the project is to protect and enhance grey-headed flying-fox habitat and conservation.

“The grey-headed flying-fox is a threatened species listed under the Commonwealth Environment Protection and Biodiversity Conservation Act 1999 and Victoria’s Flora and Fauna Guarantee Act 1988. Their numbers have declined due to loss of prime feeding habitat and disruptions to their campsites. They are also threatened by climate change, with increased heat-stress mortality in hotter-than-average summers,” Mr Sullivan said.

Grey-headed flying-foxes are subject to heat stress mortality when temperatures exceed 40ºC, and Yarra Bend Park experiences heat stress events most summers.

“During these events, volunteers are traditionally mobilised to prevent greyheaded flying-fox deaths by spraying them with water from a 20L backpack sprayer and taking them into care for rehydration.

“These events require substantial planning and present significant safety risks to volunteers and staff,” Mr Sullivan said.

Designing an internationally applauded, permanent sprinkler system

The custom-built, $180,000 sprinkler system was funded by the Department of Energy, Environment and Climate Action (DEECA), and delivered by Parks Victoria in partnership with Zoos Victoria, who led the design of the system. Additional partners included Melbourne Water, Yarra Bend Golf, Wildlife Victoria and passionate volunteers. This internationally recognised initiative forms part of a $5.3 million boost for wildlife from the Victorian Budget 2022/23.

Following a series of similar sprinkler system trials at the Warrnambool, Bendigo and Colac botanical gardens, the Yarra Bend Park sprinkler system is the first to be installed as a permanent fixture.

Mr Sullivan said the sprinkler system has been fully installed and commissioned as of January 2023, with the completion date extended from the expected November 2022 as a result of October 2022 storms that led to flooding of the Yarra River, making access to complete the pump installation impossible.

The system is made up of aerial sprinklers that are placed in the trees and are turned on for a few minutes each hour to rain down on the bats. Thirtytwo sprinkler heads have been installed across two sites identified as important refuges for the flying foxes.

“The main objective of the new, Victorian Government-funded sprinkler system is to prevent bats going into heat stress/heat stroke by cooling the ambient temperature using water. The system acts like a massive evaporative cooler,” Mr Sullivan said.

The sprinklers are activated on days when the colony is likely to experience heat-induced illness. This is determined by both behavioural monitoring and when temperatures rise above 38ºC. The system works to rapidly cool the environment by five to six degrees on days of extreme heat.

Since the installation of the system, the colony of approximately 30,000 have enjoyed these major temperature drops throughout February, especially on days where the mercury reached 41ºC.

“We also wanted to use off-the-shelf materials and not create a completely bespoke system that requires special orders for parts. This allows any repair to be undertaken quickly and keeps production costs down,” Mr Sullivan said. “The sprinkler mainline runs for more than 750m and reduces in diameter towards the end of the line to sustain appropriate pressure. It starts off at 125mm and reduces incrementally down to 90mm.

“Given terrain type, the mainline was winched through in sections and welded together on site.”

Mr Sullivan said that after testing numerous sprinkler heads, the Rain Bird 8005 was selected based on coverage and customisation of the spray pattern.

“Thirty-two sprinkler heads on galvanised poles extended beyond the tree canopy make up the sprinkler component of the system and when all are operating provide coverage across 3ha.”

Sprinkler system trials