ABN: 36 426 734 954

204/23–25 Gipps St

Collingwood VIC 3066

P: (03) 9988 4950

F: (03) 8456 6720 monkeymedia.com.au info@monkeymedia.com.au pumpindustry.com.au magazine@pumpindustry.com.au

ABN: 36 426 734 954

204/23–25 Gipps St

Collingwood VIC 3066

P: (03) 9988 4950

F: (03) 8456 6720 monkeymedia.com.au info@monkeymedia.com.au pumpindustry.com.au magazine@pumpindustry.com.au

TEditor Lauren Cella

Assistant Editor

Eliza Booth

Business Development Managers

Alastair Bryers

Rima Munafo

Design Manager

Alejandro Molano

Designers

Jacqueline Buckmaster

Danielle Harris

Publisher Chris Bland

Managing Editor

Laura Harvey

Operations Manager

Kirsty Hutton

ISSN: 2201-0270

he Australian pump industry is becoming increasingly competitive, with international, national, and online suppliers and manufacturers offering their products and services to end users. With this in mind, the Pump Industry Capability Guide aims to make it quick and easy for end users to find information on specific pump companies or services through detailed entries, all in one location.

Now in its fifth year, the Pump Industry Capability Guide has become a key reference tool and an important part of end users day-to-day operations.

The guide has continued to receive overwhelming support and growth over the years, making the 2020 edition bigger and more comprehensive than ever before.

Each entry includes information on the services and products a company offers, the specific industries they relate to, as well as their contact details.

The layout of the guide has been designed to be user-friendly to make finding the right service, product or company as quick and easy as possible. Readers can navigate the guide using the indices which separate companies by industry, services and products.

Along with a comprehensive list of companies, this year’s guide also features a technical article looking at pump flow rate ratings and why it shouldn’t be considered bad straightaway if it doesn’t deliver.

The guide also features content exploring the key markets in the pump industry including dewatering, irrigation, water and wastewater, minerals processing, hydrocarbon processing, food and beverage, HVAC, plastics and rubber, power generation, and more. You’ll also be able to read about the Pump Family Tree which shows how the different pump types relate to each other, and details some of the commonly available pump types and their applications.

As well as the print guide, all listings are also available online at www.pumpindustry.com.au/ directory. The fully-searchable format allows you to type in a keyword, category or product and the site generates a list of all the relevant pump companies.

I hope the Pump Industry Capability Guide continues to be a key tool in your day-to-day operations throughout 2020.

Lauren Cella Pump Industry Editor

The field of water treatment demands superior instrument performance and networkability. Our versatile systems highlight our continuous customer- oriented innovation and are developed to simplify any water treatment situation.

We are the fluid control experts. Speak to our team to find out how more than 70 years’ experience can benefit your business.

We make ideas flow.

Implementing digital, diagnostic & future-proof solutions into water treatment Phone

One of the most common misconceptions I hear is that a pump is rated for a certain flow rate and that the pump is bad if it does not deliver. While this may be true when you are discharging to a spillway and there is little resistance, most pumping systems are much more complicated. I was recently dealing with a situation where there were multiple pumps in parallel and the operators and engineers were confused as to why they were not getting the flow or pressure they thought they should. In fact, they were only operating with one of the two cooling towers available due to the lack of flow. The system had been expanded many times, and they were considering expensive repairs to the pump manifold that would total more than $100,000.

Since the system had been in operation for many years, there were not many places to collect data. There was a pressure gauge on the pump manifold. It was known that the cooling tower would overflow at 2,200 gallons per minute (gpm), so a flow rate of around 2,000 gpm was assumed. While we looked at modelling the entire system, the crux of the problem can be seen in just the model of the pump manifold which we will cover here. There were two larger pumps on the ends (Pump 4070) with three slightly smaller pumps (Pump 830) in the middle. This can be seen in Figure 1 operating at just over 82 pounds per square inch (psi). Under normal operation, all these pumps were in operation. The operators thought that something must be wrong, though, because they really could not see a difference in discharge pressure when one of the smaller pumps was turned off.

When the system was modelled with one of the smaller pumps shut down some interesting results were realised. Shutting down the middle pump resulted in a pressure drop at the gage of less than 2 psi as seen in Figure 2. This drop could easily be missed on a gage or not even noticeable depending on its accuracy. This also shows that it may not be the rest of the system at fault, or even the manifold itself, but how the pumps were interacting together.

Pump professionals will agree that it is generally not a good idea to have different sized pumps operating in parallel. This indeed is one of those scenarios. At one point during an expansion, the plant decided they needed more flow and installed the third small pump expecting to get the rated flow, however it appears the efforts were largely wasted. So why is it that the extra pump did not deliver the desired results? For the answer, we need to look at the pump curves.

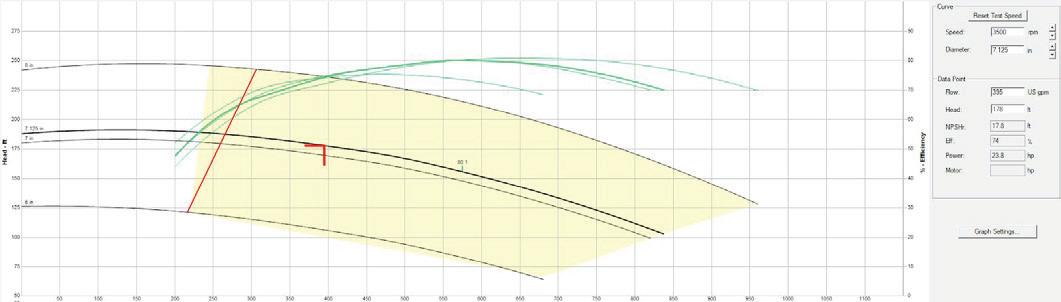

The larger pumps certainly may have been overpowering the smaller pumps, but there is another important aspect to observe. Under normal operating conditions, the smaller pumps were putting out just over 177 feet of head. This can be seen in Graph 1, where the impeller has been trimmed to 7.125 and the pump is operating far to the left of its best efficiency point (BEP). While the desired output from the pump was around 600 gpm, in reality the pump was only putting out just over half this amount. We can also see that the pump curve is very flat at this point, so we should not expect a large change in pressure with a change in flow rate.

When we investigate how the pump is operating while one of the pumps is shut down, it confirms that there is a small change in pressure due to the change in flow. While the total system flow is the same, the pressure barely drops. The small pump’s flow rate changes from around 350 gpm to almost 400 gpm. Because it is operating at an almost flat section of its curve, barely any change at the pressure gauge is observed. If we were to repeat this process with the larger 4070 pumps, we would see the exact same thing.

This scenario demonstrates exactly why more attention needs to be paid to pump curves as opposed to just ordering more pumps. To be clear, there is no issue with the specific pumps, just how they were applied. Whenever you have dissimilar pumps in parallel, they can work together or fight each other depending on the system. Here, I even ran the simulation with all five pumps the same.

Where the pump was operating at BEP on its curve shifted, but the manifold exit pressure did not change much. If all the pumps were the larger Pump 4070 model, the exit pressure would only increase by about 1 psi total to 83.5 psi. This would be a bad scenario because it would lead to an overall power increase and the pump would be so far back on its curve as to almost be outside of the manufacturers recommend operating range. Even with all five pumps changed to the smaller Pump 830 model, the pressure would only drop about 2 psi down to 80.4 psi.

While at this point it may seem that an entirely new pump is needed, there may be more inexpensive and easier items as well. Remember that the impellers were trimmed to where there is the potential of ordering new larger impellers. When modelled, this could significantly increase the pressure and flow rate, provided the motors

can handle the extra load. This is why I generally turn to a quick model of a system after doing an initial evaluation. You can get a good idea of how everything is interacting, without having to spend any money on new equipment. This in itself can avert some costly mistakes.

Dominik Fry, P.E. is Engineered Software, Inc.’s business development engineer and has nearly a decade of experience in the energy industry while working on some of the nation’s largest energy projects. Fry earned a Bachelor of Science at Montana State University. For more information, visit www.eng-software.com.

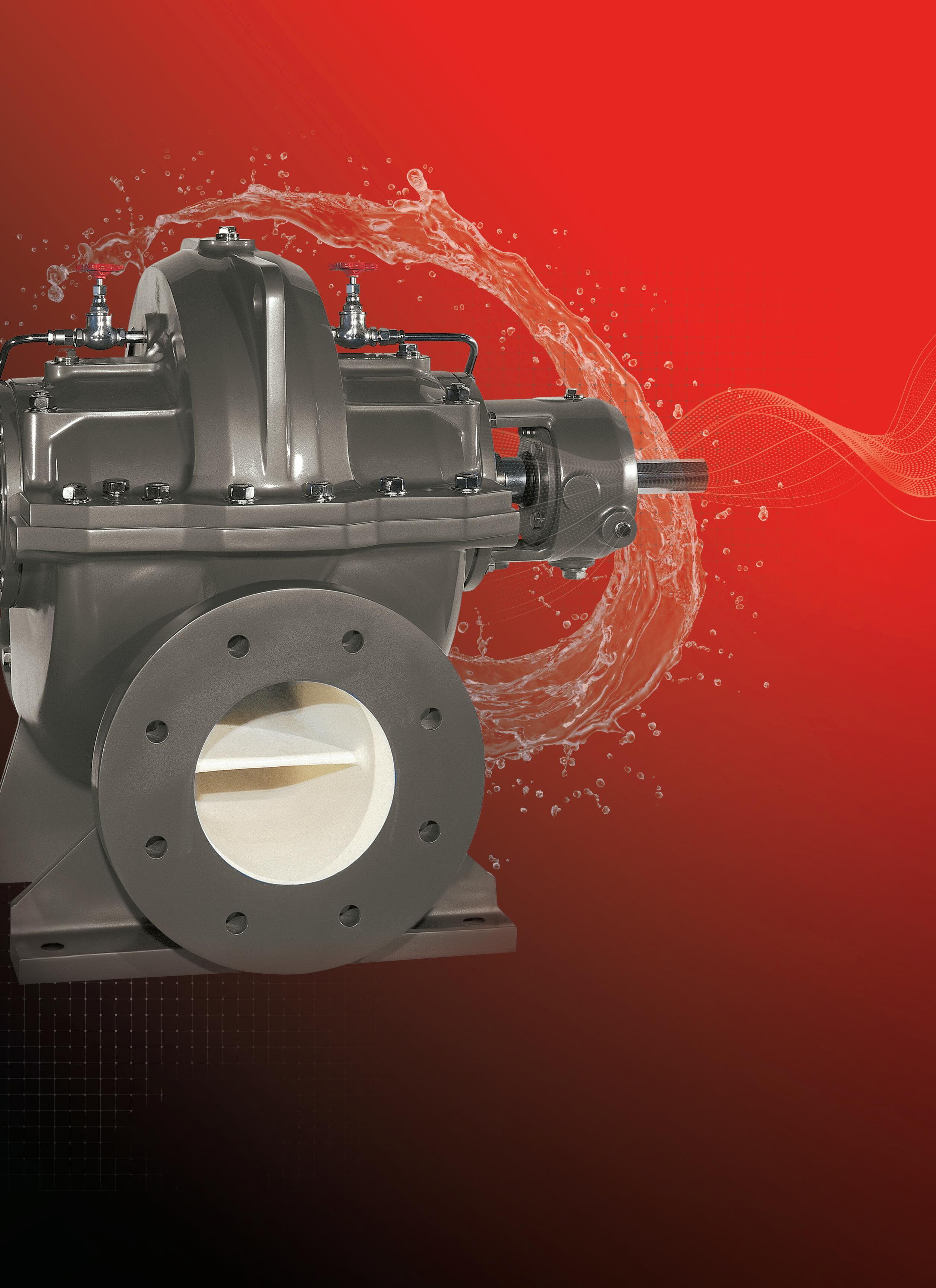

Sulzer provides a wide range of pumping solutions, related equipment, and services. Customers benefit from our extensive research and development. We supply highly efficient products that help reduce emissions and energy consumption and our state-of-the-art production and testing facilities around the globe ensure customer proximity. Our market focus is on supply, treatment, and transport of water as well as wastewater collection, fossil-fired, nuclear, and renewable power generation and specific general industries, e.g., pulp and paper, fertilizers, and other markets.

www.sulzer.com

Pumps are used around the world for a wide range of applications every day. Here we take a closer look at some of the common applications for pumps, exploring the industries they are used in and the types of pumps that are best suited for specific applications.

Filtration is required whenever there exists a need to separate solids from fluids by introducing a medium through which only the fluids can pass. Different types of filtration (including mechanical, chemical or biological processes) are suitable for different applications, and often multiple stages of filtration may be required. The properties required of the filter and filter media can be highly dependent on the application and the nature of the filtrate which passes through the filter, and the particles or solids to be removed. Filters are available to handle a wide array of liquids and gases, and filter out anything from large particles to microscopic material. Filters are used widely throughout countless industries including water and wastewater treatment, natural resources, food and beverage, chemical and pharmaceutical, and in various industrial and manufacturing processes.

The manufacturing industry uses pumps for a wide variety of applications dependent on the product being produced. Manufacturing plants producing concrete, cement, steel, clothing, textiles or plastics are a few examples of those that require pumps in their processes. Depending on the application, pumps used in the manufacturing industry may be required to cope with conditions such as high temperature and/or pressure operation, hazardous media, corrosive or flammable liquids, or low NSPH.

Different pumps are used extensively throughout the power generation industry for many applications. A typical power station will feature a wide variety of pumps including cooling water pumps, condensate extraction pumps, boiler feed pumps, booster pumps and water circulation pumps. The reliable operation of these pumps is vital in order for power to be produced safely, efficiently and cost effectively. Pumps also play vital roles in hydroelectric power production.

The water and wastewater industry relies on pumps for a broad range of water and sewage transfer applications, as well as in water and wastewater treatment processes. Sustainable industrial water and wastewater applications require pumps that can reliably deliver vital services. Pumps used to transfer sewage and wastewater must also be able to deal with its potentially corrosive qualities and the presence of potentially clogging materials. In addition to transporting water to where it is required and pumping sewage and sludge to treatment plants, pumps play other vital roles including dosing and metering the chemicals required to treat drinking water and wastewater, as well as filtration.

Dewatering is frequently required in the mining and construction industries to remove water buildup in mine shafts or construction sites, as well as applications including flood dewatering. Pumps used for dewatering applications generally need to be durable, portable and heavy duty in order to cope with tough environmental conditions and demanding applications. Centrifugal pumps, including portable submersible pumps, centrifugal slurry pumps, self-priming centrifugal trash pumps and axial flow pumps, are often used for dewatering applications, but positive displacement pumps like diaphragm pumps can also be used.

Pumps play important roles in the treatment and distribution of potable water, whether it is supplied through an extensive water network or from a smaller local source like a well. Types of pumps commonly used for potable water pumping applications include centrifugal booster pumps such as vertical turbine pumps (including well pumps), submersible turbine pumps and horizontal or vertical split case pumps. Circulator pumps may be used to circulate water through closed systems. Metering pumps, often used to deliver precise amounts of fluid for drinking water treatment applications, are often positive displacement diaphragm pumps. Reliability and energy efficiency are important considerations for potable water pumps.

Pumps play a vital role in irrigation projects for both water intake and distribution. Most irrigation applications require pumps to supply water from its source – such as a dam, bore or main – and to distribute it to where it is required. In cases where water must be treated before use, such as by adding fertilisers and/or removing elements that may be harmful to crops from groundwater via filtration, pumps are also required in the water treatment process. Generally, energy and water efficiency, maximising crop yield per unit of water used, as well as cost-effective operation are important considerations for irrigation pumps.

Pumps play a number of vital roles in the process of mining and mineral recovery. Within the mining industry, different types of pumps are utilised for a range of applications including raw water supply, mine dewatering, transporting slurry, leach and drainage solutions, chemical dosing and transporting process water to be used in the metal recovery process. The most common types of pumps used in mining are slurry pumps and dewatering pumps. These pumps often need to be durable, portable and heavy duty in order to cope with tough environmental conditions and demanding applications.

In the oil and gas industry pumps are employed for an extensive range of hydrocarbon production, transportation and refining applications both upstream and downstream. Typical roles for pumps in the industry include transporting hydrocarbons, raw water supply, produced water disposal, chemical injection, secondary recovery and dewatering. Pumps also play a key role in the recovery of unconventional oil and gas reserves, transporting the water required in the process of hydraulic fracturing. Generally, pumps used in this industry need to be able to provide reliable and safe operation in demanding applications.

The food and beverage industry utilises pumps to transfer a variety of materials from raw ingredients, flavouring and other additives, cleaning fluids and corrosive chemicals, to finished food and beverage products. Often the fluids and processes involved in the production of food and beverages will have requirements for careful handling, non-reactive components, accurate dosing and metering, and high levels of hygiene. Positive displacement and centrifugal pumps are among the types of pump commonly used for food and beverage applications.

Pumps are an essential component of HVAC systems, supporting the operations of cooling towers, chillers, boilers, water systems, fire systems and other equipment by providing the energy required to move water and other fluids through piping, fittings and other HVAC system components. The roles of pumps in the building services and HVAC industry include the supply and distribution of water for cooling processes and pumping away condensate by-products. Pumps used in this industry include centrifugal pumps, condensate pumps, heat pumps and vacuum pumps.

Pumps play many roles within the chemicals and pharmaceuticals industries. They are frequently used in bulk transfer, degassing, vacuum distillation, crystallisation, sterilisation, drying, freeze-drying, packaging, extraction and purification processes, as well as fulfilling a variety of other functions depending on the particular product being produced. The chemicals and pharmaceuticals industries often have very particular requirements for pumps and the materials from which they are made, dependent on the characteristics of the substance being pumped (e.g. whether it is corrosive or reactive) and various standards of sterility, hygiene, precision and control required by the application.

of different properties. Efficiency and reliability are also frequently vital requirements for pumps in the plastics or rubber industry.

The pulp and paper industry is a water intensive industry that requires the continuous, reliable operation of equipment. This industry employs a huge variety of different types and sizes of pumps for supply, mixing and transfer processes. Pumped fluids can range from highly corrosive chemicals, to abrasive sludges, to solvents and oils, to clean water. Some common roles for pumps in the pulp and paper industry include those involved in paper stock preparation, water handling, chemical processing, power generation and pollution control. These pumps are often highly specialised for the specific applications and process fluid, and to help meet various safety standards in operations, and quality criteria for the produced product.

From heavy-duty mine dewatering to precise chemical metering and dosing, the vast range of different pumps available on the market means there’s a pump configured to suit any application. There are many job specific factors that will determine the right pump for you, including the design of the pump and mechanics of how it operates. Here, we take a look at some of the commonly available pump types, and where they fit in the pump family tree.

Most pumps fit into one of two main groups. These are:

• Rotodynamic pumps

• Positive displacement pumps

Rotodynamic pumps

Rotodynamic pumps transfer energy to the pumped fluid via a rotating element, such as an impeller, propeller or rotor.

There are many different types of rotodynamic pump suited to varying applications.

Centrifugal pumps

Centrifugal pumps are one of the most commonly used pump types in the world. These pumps use a shaft-mounted impeller which rotates unidirectionally within the pump casing. They can be classed in one of three categories depending on the type of impeller used: radial flow impeller, mixed flow impellers, and axial flow impellers.

Regardless of the impeller type, centrifugal pumps can be either single stage or multistage, self or non self-priming, and can have open, semi-open or closed impeller types.

Other types are defined by unique characteristics or functions such as sump pumps, sewage pumps, slurry pumps and more.

Centrifugal pumps have numerous applications in various industries, including oil refineries, power plants, chemicals and process, food and beverage, mining and municipal water. They can also be found in boiler feed applications, wastewater management, flood protection, drainage, irrigation, and building applications such as booster services to homes, fire protection and HVAC.

Peripheral pumps

Peripheral pumps (also known as side channel or regenerative turbine pumps) transfer energy to the fluid within the cells of a vane wheel impeller with a large number of radial blades.

Peripheral pumps can be single or multistage and can come in various configurations.

These pumps are suitable for applications which require pure, non-abrasive or polluted liquids to be pumped, such as car wash installations, increasing pressure in water networks, or in the chemical industry or mechanical engineering for cooling, reticulation and as small boiler feed pumps.

They can also be used for enrichment and mixing liquids and gases in applications including biofuel, dissolved air floatation, neutralisation, potable water treatment, bioreactors, and crude oil and water separation.

Other types of rotodynamic pump

Additional types of rotodynamic pumps exist and are defined by their unique functions. These include:

• Jet pumps: A high velocity jet of fluid creates a low pressure area in a mixing chamber, causing the suction fluid to lower into this chamber. Applications include seawater transfer and moving wastewater up to the sewer line

• Gas lift: A gas pressure source lifts the liquid by mixing it with gas under pressure (usually air)

• Magnetic drive pumps: A sealless pump that uses a magnetic coupling device so that the external rotating part of the coupling is separated from the internal rotor. Applications include chemical transfer for water, solvents, chemicals and acids

• Electro-magnetic pumps: A glandless pump where a magnetic field acts upon the medium (e.g. liquid metal)

Positive displacement pumps

Positive displacement pumps exert force upon movable boundaries of enclosed fluid containing volumes, resulting in a direct increase in pressure.

There are many different types of positive displacement pumps, with a wide range of applications, including:

• Sauces, confectionary, yogurt, and shortening in the food industry

• Chicken offal, meat purees, potato waste, thick non-flowing pastes

• Domestic and industrial sewage, primary and secondary sludges, dewatered sludge cake

• Shampoo, cosmetics, light creams

• Lime, bentonite and clay slurries

• Dosing of flocculants and various chemicals

• Wine must (grape juice with stalks and skins) using rectangular inlet versions

• High head mine dewatering usually containing abrasive rock particles and dust

• Shaft and submersible motor drive borehole pumps

• Low flow, high head, agricultural water pumping, particularly where long suction lines are required

Reciprocating pumps

Reciprocating pumps incorporate a piston/plunger, diaphragm inlet and outlet valves, and a means by which the piston/plunger and diaphragm can be actuated (for instance, an electric motor, diesel engine or steam turbine). Types of reciprocating pumps include piston pumps, plunger pumps and diaphragm pumps.

Reciprocating pumps can be either single acting like plunger and diaphragm pumps, where the liquid is discharged only during the forward motion of the piston, or double acting like piston pumps, where the liquid is discharged during both the forward and backward motions.

Reciprocating pumps can be further divided as: simplex, duplex, triplex or multiplex pumps.

These pumps can be used in a variety of applications, including general pressure wash, high-pressure

cleaning, heavy vehicle washing, sewer jetting, misting for temperature or humidity control, dust suppression, drilling mud, reverse osmosis, descaling, water jet cutting, chemical injection, crude oil transfer, mine dewatering and ore pipeline transport.

Controlled volume pumps (otherwise known as proportioning or metering pumps) provide precision control of very low rates with a flow rate accuracy typically within + or – one per cent. In construction, they are generally piston or plunger pumps, mechanical diaphragm pumps or hydraulically actuated diaphragm pumps.

These pumps are commonly used in the following applications: light duty such as fertilisers and nutrients in farming and commercial nurseries; medium duty such as food and additives in food manufacturing, dairies and wineries; dyes in the textile industry; chemicals in municipal water and sewage treatment; and heavy duty such as petrochemical industry, pulp and paper manufacturing, and mining and mineral treatment.

These reciprocating positive displacement pumps are sealless, self-priming and have the ability to run dry for long periods and will not over pressure.

Common applications for air-operated diaphragm pumps include chemical transfer, food transfer, tanker and drum unloading, contaminated bilge and pump pumping, clay slurries and polymer.

Rotary pumps

Rotary pumps generally consist of gears, vanes, screws or similar elements enclosed within a casing. They have no separate inlet or outlet valves and fluid flows through the pump in a uniform stream.

These pumps can be divided into either single rotor or multiple rotor types. They can then be further classified by the pumping element.

• Single rotor types include: vane pumps, piston pumps, flexible member pumps and screw (progressive cavity) pumps

• Multiple rotor types include: gear pumps (external or internal gear), lobe pumps, circumferential piston pumps and multiple screw pumps

These pumps can be used in a wide variety of applications depending on the type of pump.

Lobe and circumferential piston pumps are commonly found in clean industries such as beverage, pharmaceutical and personal care products, as well as industrial applications like polymers, paper coatings, soaps and surfactant, paints and dyes, and rubber and adhesives.

On the other hand, twin and triple screw pumps are more commonly used for hydrocarbons, ranging from crude oil to bitumens and lubricating oils, vegetable oils and water. Applications include tanker unloading, fluid transfer, fuel feed, hydraulic power, heavy machinery lube oil supply, and multi-phase oil and gas flow in oil well production pumping.

16 George Bellew Road

Yaldhurst Christchurch 8042 +64 03 349 1350 orders@43South.co.nz www.43south.co.nz

ABB

601 Blackburn Road Notting Hill VIC 3168 1800 222 435 contact.centre@au.abb.com www.abbaustralia.com.au

Adelaide Control Engineering

10 Peekarra Street

Regency Park SA 5010 08 8118 6460 ace@adlcontrol.com.au www.adelaidecontrolengineering.com

14 Nicole Way

Dandenong South VIC 3175 03 9793 7577 sales@asmpumps.com.au www.asmpumps.com.au

15 Activity Crescent Molendinar QLD 4214 1300 780 430 info@austworld.com.au www.austworld.com.au

Products: Hoses, Valves Austworld is the largest family owned wholesaler and manufacturer of plumbing systems and fittings for water, gas and solar in Australia. Established in 1984, Austworld continues to be an independently family owned business that prides itself on the robustness and quality of its locally engineered products. All of Austworld’s products are designed, tested and quality controlled by a team of local engineers in

its own research facility to ensure each valve or fitting can specifically meet the demands of an Australian environment.

With six distribution warehouses servicing Australia nationally from Western Australia, South Australia, Victoria, New South Wales, Queensland and Tasmania, the company is able to respond to customer demand in an efficient and timely manner.

This unique and integrated distribution model, plus its extensive range of high-end valves, tapware and fittings are all aimed at providing its customers with a high level of customer service, and the plumbers they supply, with efficient, time saving and future-proofed products enabling them to stay competitive across the water, gas and solar industry.

Australian Fluid Handling (AFH)

Factory 1, 25-27 Burns Road

Altona VIC 3019 03 9369 6200 salesvic@afhpl.com.au www.afhpl.com.au

Australian Industrial Marketing

10 Crest Drive Rosebud VIC 3939 03 5981 2680 keith@sandersoz.com

Unit 1, 156 Bonds Road

Riverwood NSW 2210 02 9153 0233 brian@blinepumps.com.au www.blinepumps.com.au

Batescrew Pumps & Valves Australia

189 Newell Highway Tocumwal NSW 2714 03 5874 2101 sales@batescrew.com www.batescrew.com

Brown Brothers Engineers Australia

7 Damian Court Dandenong VIC 3175 1300 4 BBENG info@brownbros.com.au www.brownbros.com.au

Industries serviced: Building Services/HVAC, Food and Beverage, Irrigation, Manufacturing, Mining, Oil and Gas, Power Generation, Wastewater

Products: Axial Flow Pumps, Borehole Pumps, Chopper Pumps, Couplings, Dewatering Pumps, Engineering, Hoses, Motors, Drives and Engines, Pressure Pumps, Rotodynamic Pumps, Seals, Slurry Pumps, Submersible Pumps, Transfer Pumps, Valves From small domestic pressure systems to large industrial process pumps, Brown Brothers Engineers provides a full range of pumps and pumping solutions to meet your needs.

Brown Brothers Engineers is the distributor for some of the world’s leading brand pumps, including Lowara, Goulds Water Technology and HYDROVAR in QLD, NSW, ACT, VIC and TAS, and nationally for Layne Bowler, SAER and Sakuragawa.

As one of Australia and New Zealand’s leading pump suppliers for almost a century, we have gained a wealth of experience. We can guarantee that you will get the best pumping solutions the world has to offer because we only supply the world’s leading pump brands. Our Australian operation not only includes the importation of a wide range of pumping equipment, but also the assembly, distribution, testing and custom-building of pump sets and pumping systems. Our qualified engineers work closely with you and engineering consultants to select exactly the right pump or pumping system for your project. We also give superior after sales service, backed up by our dedicated service and testing facilities.

15 Columbia Way

Baulkham Hills NSW 2153 1300 888 868 sales.au@burkert.com burkert.com.au

Industries serviced: Chemicals and Pharmaceuticals, Filtration, Manufacturing, Mining, Oil and Gas

Products: Actuators, Compressors, Dosing and Metering Equipment, Engineering, Pressure Pumps, Sensors and Instrumentation, Valves

At Bürkert, we love a good challenge. That is because we are simply fascinated by everything that flows. No matter the task faced by our customers – we pride ourselves on finding ways to deliver solutions specific to your individual needs. Whether it is about flow, level, pressure, dosing, analysis, filtration, temperature, mixing or the automation of processes –liquids and gases have to be measured and controlled. These are the fundamental fluidic variations upon which industrial process technology is based.

At Bürkert we’re unique in our approach. We begin with your fluidic challenge and draw on the basic physical principles, fluidic relationships and our experience with physics; duplicating them across the most diverse applications and industries to solve your

challenges, and in turn provide an exclusive solution that works for you.

Locally, since 1980, Bürkert has shown its commitment to bringing the highest level of quality and service to Australia and New Zealand. Bürkert provide specialists who understand you and your requirements, always on hand to answer technical needs – from one-off basic solenoid valves, to comprehensive networked systems.

In partnering with Bürkert, you benefit from our deep pool of expertise, superior service, and gain access to our reliable and sustainable product range.

Our Australian operation not only includes the importation of a wide range of pumping equipment, but also the assembly, distribution, testing and custom-building of pump sets and pumping systems. Our qualified engineers work closely with you and engineering consultants to select exactly the right pump or pumping system for your project. We also give superior after sales service, backed up by our dedicated service and testing facilities.

For more information about our services and solutions please contact us.

Melbourne: 7 Damian Court, Dandenong VIC

Sydney: 211-215 Walters Road, Arndell Park NSW Brisbane: 50 Nestor Drive, Meadowbrook QLD

1 Opala Street Regency Park SA 5010 08 8268 8880 sales@calpeda.com.au au.calpeda.com

Industries serviced: Building Services/HVAC, Irrigation, Wastewater Products: Borehole Pumps, Pressure Pumps, Pressure Sewer Systems, Submersible Pumps, Transfer Pumps

The Calpeda Group is celebrating a landmark anniversary this year; our 60th year in business. For over half a century, Calpeda has been supplying a highquality and reliable product for the pumping industry. Our commitment to the market today is stronger than ever and finds its foundations in a solid tradition and the utmost attention to every detail of our products. Calpeda has been building its achievements on the values of fairness, precision, tenacity and altruism, and these are still deeply embedded in the Calpeda style. Calpeda pumps, pumping systems and drives' undisputed reliability and durability are the most effective demonstration of the passion we put forward.

3 Jeanes Street

Beverley SA 5009 08 8244 4442 sales@caprari.com.au www.caprari.com.au

22 Industry Place

Bayswater VIC 3153 03 9720 1100 sales@crusaderhose.com.au www.crusaderhose.com.au

Industries serviced:

Irrigation, Mining, Oil and Gas, Wastewater Products: Borehole Pumps, Hoses

Vision:

World-leading Australian manufacturers of the most

efficient systems for water delivery using flexible layflat hose.

Mission:

We manufacture layflat hose and reel systems for a wide range of applications. Our products are used for firefighting, groundwater pumping, mine dewatering and farm irrigation as well as fuel transfer.

Purpose:

By manufacturing locally, we believe that the Australian market for layflat hose can be better serviced, particularly due to our experience, stocking and willingness to customise.

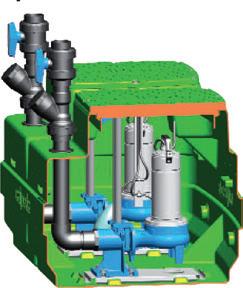

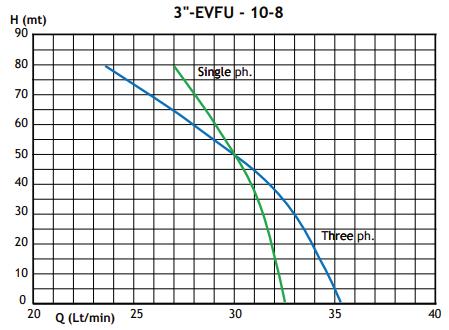

Calpeda’s new 3”-EVFU borehole pump is intended for pumping bore water (Ideal Windmill replacement) , stock , and domestic up to temperature of 35°C (using the speci ed motors).

Practical application of the pump is namely for deep-well water pumping with maximum depth of 80 m and minimum borehole diameter of 80 mm (3”). Availible in single and three phase options.

Now looking for Distributors in Key Locations

The New 3” EV Progresssive Cavity Borehole Pumps

www.calpeda.com.au sales@calpeda.com.au

Cummins South Pacific

191 Boundary Road

Laverton North VIC 3026 1800 931 181 1300cummins@cummins.com www.cummins.com.au

Industries serviced: Filtration, Irrigation, Mining, Power Generation Products: Dewatering Pumps,

Fire Pumps, Motors, Drives and Engines, Natural Gas Engines

Cummins South Pacific is a wholly-owned subsidiary of Cummins Inc., a global power leader. Cummins is the world’s largest independent designer and manufacturer of diesel engines and has an unmatched service support network in the South Pacific which includes 35 branches, 150+ authorised dealers and the 24/7 Cummins Support Centre.

To support our customers across a broad range of pumping applications, Cummins offers powerpacks which are a complete turnkey solution designed and built in Australia for demanding Australian conditions with ratings from 40 to 2000 hp. When you need power, the pump industry relies on Cummins.

Cummins Brisbane: 39–53 Ron Boyle Crescent, Carole Park, QLD 4300

Cummins Sydney: 492–494 Victoria Street, Wetherill Park, NSW 2164

Cummins Laverton: 191–195 Boundary Rd, Laverton North, VIC 3026

6 Lakeview Drive

Scoresby VIC 3179 1300 232 839 sales@davey.com.au www.davey.com.au

Delta International Sales

PO Box 240

Braeside VIC 3195 03 9723 8600 sales@dis.com.au www.greasemax.com.au

Deutz Australia

Unit 4, 13-15 Brough Street

Springvale VIC 3171 03 9549 8400 deutzoz@deutz.com www.deutz.com.au

8/32 Melverton Drive Hallam VIC 3803 03 9796 4800 info@drivesystems.com.au www.drivesystems.com.au

Industries serviced: Food and Beverage, Irrigation, Mining, Oil and Gas, Power Generation, Pulp and Paper Products: Couplings, Gearboxes, Motors, Drives and Engines

Drive Systems is a 100 per cent private Australian company and is a leading supplier of mechanical power transmission products AND services. We are proud to represent long and established manufactures predominately from Europe.

MAYR, ESCO, CMD Winflex, REXNORD, FALK, NORD, SEW EURODRIVE,OPTIBELT, JWIS, EASY-LASER

We value quality products that are engineered to be reliable and add value to our customers business. Drive Systems is committed to providing our customers with quality mechanical power transmission equipment and services, along with high levels of technical support from our suppliers and through our local in-house technical support based on our industry experience, product and application knowledge. This is available to our customers 24 hours, 7 days a week.

Drive Systems' strong relationship with our suppliers allows us to select and supply the right product for our customers application. Our comprehensive scope of supply covers the complete mechanical power transmission drive system. Product range:

• Esco & CMD Winflex Grid and Gear Couplings

• Esco API 610, API 671 and Non Sparking Disc Couplings

• Rexnord Omega and Falk Wrapflex Couplings

• Mayr Disc and Jaw Couplings

• Poona SAE Flywheel Couplings

• Mayr Torque Limiting Couplings, Brakes and Clutches

• Electric motors

• Variable Speed Drives and soft starters

• Gear motors and gear reducer

• Gearbox overhaul and repair services

• Vee Belts, HTD and timing belts

• Pulleys and shaft locking devices

• Chain and sprockets

• Laser alignment equipment

International Pumping

41 Industrial Drive

Braeside VIC 3195

1300 302 330 sales@dtbpumps.com www.dtbpumps.com.au

88 Belgravia Street

Belmont WA 6104 1300 788 579

sales@dynapumps.com.au

www.dynapumps.com.au

Industries serviced: Food and Beverage, Mining, Oil and Gas, Power Generation, Wastewater

Products: Submersible Pumps, Vacuum Pumps

Since Dynapumps commenced operations in 1981, we have supplied an extensive range of pump products servicing all major markets including mining, oil and gas, power, general industry, water and wastewater, and the food industry. With branches in Perth, Melbourne, Sydney and Brisbane, we have the capabilities to service both national and international clients.

In 2001, we commenced manufacture of our Australian designed FloMax Submersible and Turbine pumps range. We have an extensive team of engineers to offer technical backup from all offices, as well as a large manufacturing and service base for pumps, pump systems and vacuum systems.

7 Holloway Drive

Bayswater VIC 3153 03 9761 3033

sales@ebara.com.au www.ebara.com.au

Industries serviced: Building Services/HVAC, Food and Beverage, Irrigation, Wastewater

Ebara Pumps Australia is a subsidiary of Ebara Corporation Japan, one of the world’s largest manufacturers of custom and standard pumps for industry.

Ebara Pumps Australia distributes its standard range of pumps via an Australia wide network of authorised dealers and OEM’s.

Ebara manufactures pumps for use in food and beverage, wastewater, building services, industrial, domestic water supply and irrigation. The Ebara standard product ranges are considered the best in these industries due to their quality and competitive pricing.

Ebara Corporation was founded in Japan in 1912 as a manufacturer of pumps. Today as a group, it consists of more than 70 companies in six continents with a work force of more than 11,000

people and with company owned and Japanese managed production facilities in eight counties covering four continents.

The huge scale of production and distribution is matched by a constant commitment to research, development and design of new products and modern technologies for manufacturing them. Ebara products have gained a worldwide reputation for their technology and quality.

16 Stennett Road

Ingleburn NSW 2565 02 9605 0600

info@au.eagleburgmann.com

www.eagleburgmann.com.au

Electric Motor Power

10 Newcastle Road

Bayswater VIC 3153

03 9720 6366

sales@emppl.com.au www.emppl.com.au

Products: Engineering, Motors, Drives and Engines, Solar Pumps

DC motors powered to your needs.

Electric Motor Power Pty Ltd is your one-stop shop for DC motors, controllers and associated components, working with you from the original design concept through to custom manufacturing your product

with quality components and ensuring the best possible efficiency.

Australian-owned with 30 years’ experience, we take pride in our product knowledge and development capabilities for both brushed and brushless motor systems. We have the local presence to meet your service standards, and the global capabilities to match any production requirements. Contact us today to discuss your pump motor requirements.

Emtivac Engineering

170-174 Discovery Road

Dandenong South VIC 3175 03 9768 3240

sales@emtivac.com www.emtivac.com/contact-us

Envirotech Water Solutions

17 Kareela Street

Mordialloc VIC 3195 03 9587 3099

sales@envirotechwater.com.au envirotechwater.com.au

ETM Pacific

Suite 6, 273 Alfred Street

North Sydney NSW 2060 02 9956 7377

sales@etmiot.com.au www.etmiot.com.au

FITT Resources

27 Awaba Street

Lisarow NSW 2250 1300 653 229

contact@fittresources.com.au www.fittresources.com.au

Fluid Engineering

42 Bridge Road Griffith NSW 2680 0438 284 007 pumps@floodlifter.com www.floodlifter.co

Flowserve Corporation

5 Parker Street

Castlemaine VIC 3450 1300Flowserve (356 973) Spare_FPD_Australia@flowserve.com www.flowserve.com

Industries serviced: Chemicals and Pharmaceuticals, Mining, Power Generation Products: Axial Flow Pumps, Borehole Pumps, Dewatering Pumps, Pressure Pumps, Reciprocating Pumps, Repair/ Aftermarket, Seals, Slurry Pumps, Submersible Pumps

Flowserve [NYSE: FLS] is the world’s premier provider of industrial flow management services. The world headquarters is located in Texas, US. The company produces engineered and industrial pumps, precision mechanical seals, automated and manual quarter-turn valves, control valves and actuators, and provides a range of related flow management services, serving for oil and gas, chemical, petrochemical, water, mining and other general industries. Flowserve has also been investing with customers to develop solutions for alternative and renewable sources of power generation like clean coal, solar, geothermal and wind power. With annual sales of more than US$4 billion, Flowserve has about 18,000 employees

and operates in over 55 countries. Flowserve provides customers worldwide with an unprecedented level of rotating equipment and related products, services and support. It is one of the world’s largest suppliers of industrial, engineered, and special purpose pump and systems and a world-leading designer and manufacturer of mechanical seals and other engineered fluid sealing systems, and a leading global manufacturer of flow control products including control valves, quarterturn valves, actuators, and complete valve automation systems. In Australia and New Zealand, Flowserve has a wide footprint including manufacturing facilities and Quick Response Centers (QRCs) in Victoria, New South Wales, Queensland, South Australia, Western Australia, Northern Territory, Christchurch and Auckland.

Flowserve is continuously expanding the service network and enhancing its capability to serve customers in Asia Pacific and worldwide.

Franklin Electric

106-110 Micro Circuit

Dandenong South VIC 3175 03 9799 5000

meyre@fele.com www.franklin-electric.com.au

GG Pumps & Electrical

4 Beaver Street

Geraldton WA 6530

1300 443 532

ggpe@westnet.com.au www.ggpumpsandelectrical.net.au

Hatz Diesel 7 Hume Rd

Smithfield NSW 4878 1300 796 900 sales@hatz.com.au www.hatz.com.au

H.E Brehaut (Hebco)

19-25 Trade Place

Vermont VIC 3133 03 9874 4299 sales@hebco.com.au www.hebco.com.au

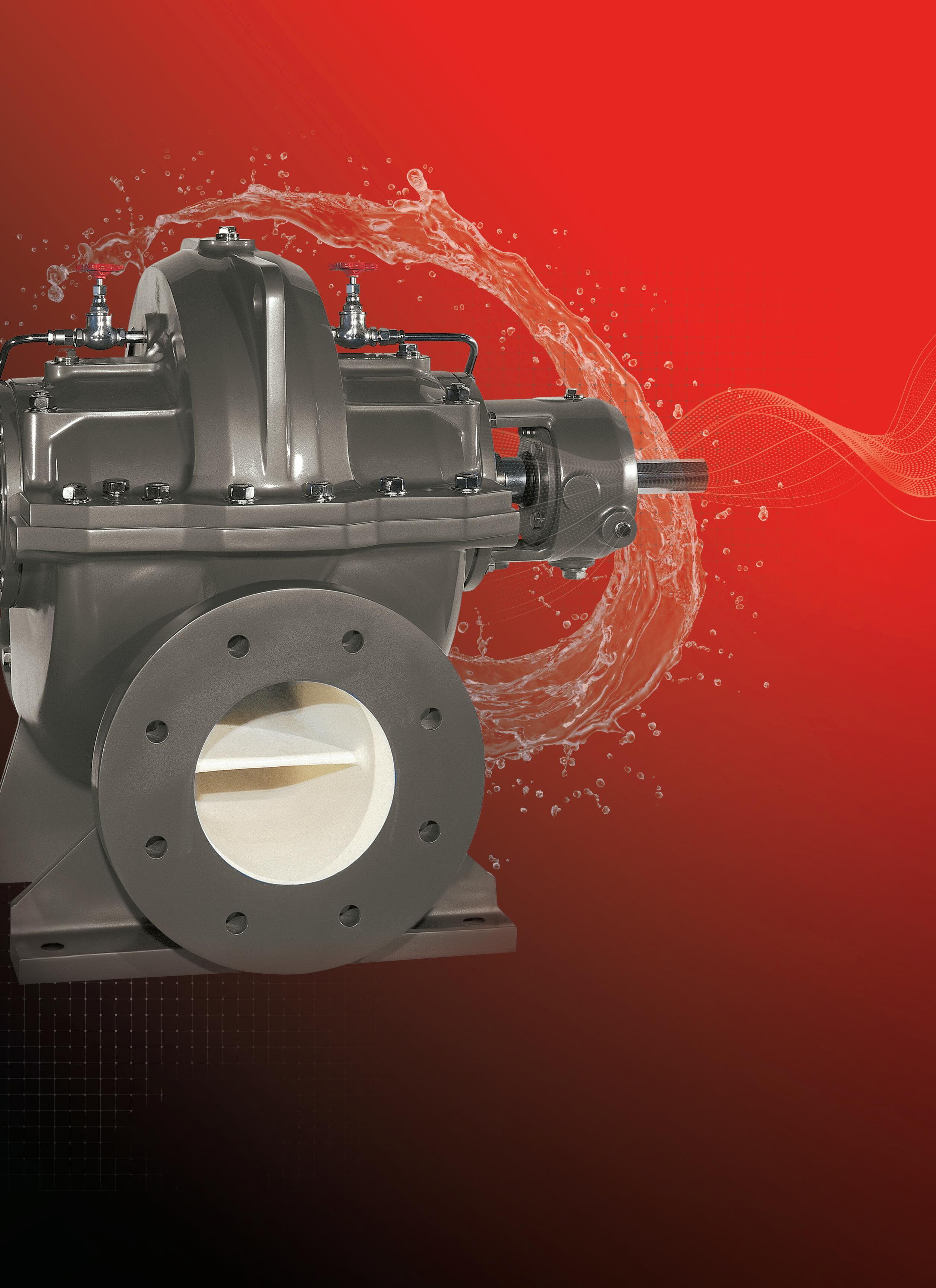

Flowserve LNN pumps provide broad hydraulic coverage to optimize power usage for the biggest water jobs.

From irrigation to desalination plants, and pipelines to cooling towers, Flowserve LNN double-suction axially split pumps take on some of the largest water applications. With more than 200 possible impeller and volute combinations, you can configure LNN pumps for virtually any job. Benefits continue because they’re designed for easy maintenance, quieter operation and maximum efficiency, making your job easier too.

Contact Us to Learn More

Email: Spare_FPD_Australia@flowserve.com

Telephone: 1300 Flowserve (356 973)

Address: 5 Parker Street Castlemaine, VIC 3450 Australia

Hidrostal Australia

Unit 3, 10 Maiella Street

Stapylton QLD 4207 07 3801 8110

sales@hidrostal.com.au www.hidrostal.com

Industries serviced: Food and Beverage, Irrigation, Mining, Oil and Gas, Power Generation, Pulp and Paper, Wastewater

Products: Dewatering Pumps, Repair/Aftermarket, Submersible Pumps, Transfer Pumps

Hidrostal Australia is a solely owned subsidiary company of Hidrostal Holding AG Switzerland.

Hidrostal is also the inventor and manufacturer of the "original" screw impeller pump which has been field proven for 60 years.

Due to their outstanding characteristics, Hidrostal pumps are used in numerous municipal and industrial sectors. They pump the most diverse fluids and materials gently and with low pulsation.

Hidrostal pumps are successful in difficult applications and achieve the best results with respect to performance, energy efficiency, non-clog capabilities and low lifecycle costs.

FreeFlow-Technology is the latest innovation from HIDROSTAL to prevent clogging in wastewater containing large amounts of fibrous material.

The innovative FreeFlow-Technology increases the benefits of the Hidrostal hydraulic characteristics and decreases unscheduled maintenance.

The SharkFin and JetDisk are interchangeable with existing installations.

Suction Sizes: 65 - 700 mm (2.5 - 28") Head: 0.5 - 90 m (2 - 300 ft)

Flow: 0.5 - 3000 l/s (7 - 47500 gpm)

Power: 0.1 - 650 kW (0.1 HP - 870 HP)

Frequencies: 50 Hz, 60 Hz, VFD

Materials: Cast Iron, Ductile Iron, Hi-Chrome, Stainless Steel, Duplex SharkFin

The SharkFin directs the incoming solids and fibrous material toward the center of the impeller.

The JetDisk directs a portion of the recirculating flow to flush between the impeller and backplate.

Available Designs

Immersible

Submersible

Bearing Frame

Vertical or Horizontal

Self Priming

Trailer Mounted

Hidrostal Australia Pty Limited Unit 3 / 10 Maiella Street, Stapylton, QLD 4207 Email: sales@hidrostal.com.au Phone: 07 3801 8110

Hydro Australia

8 Minchington Road

Morwell VIC 3840 03 5165 0390 sales@hydroaustralia.com.au www.hydroaustralia.com.au

Products: Engineering, Repair/ Aftermarket

Hydro Australia, which was opened in October 1998, is a pump aftermarket service centre in Hydro’s worldwide pump service organisation. Hydro Australia provides quality engineering, pump rebuilding and on-site field services to pump users in

Australia, New Zealand, Vietnam and South East Asia.

Hydro Australia has its own in-house engineering group which is further supported by the engineering teams in the US based service centres.

Its workforce is skilled in and specialises in pump work, and continually invests in its workforce and provides ongoing training to keep abreast in the ever-evolving area of pump engineering.

Hydro Innovations

21-23 Clyde Street

Rydalmere NSW 2116 02 9898 1800 ggrant@hydroinnovations.com.au www.hydroinnovations.com.au

ifm efector

Suite 3, 745 Springvale Road

Mulgrave VIC 3170 1300 365 088 sales.au@ifm.com www.ifm.com/au/en

43 Newton Road

Wetherill Park NSW 2164 1300 556 601

customerservice@ipd.com.au www.ipdgroup.com.au

Products: Motors, Drives and Engines

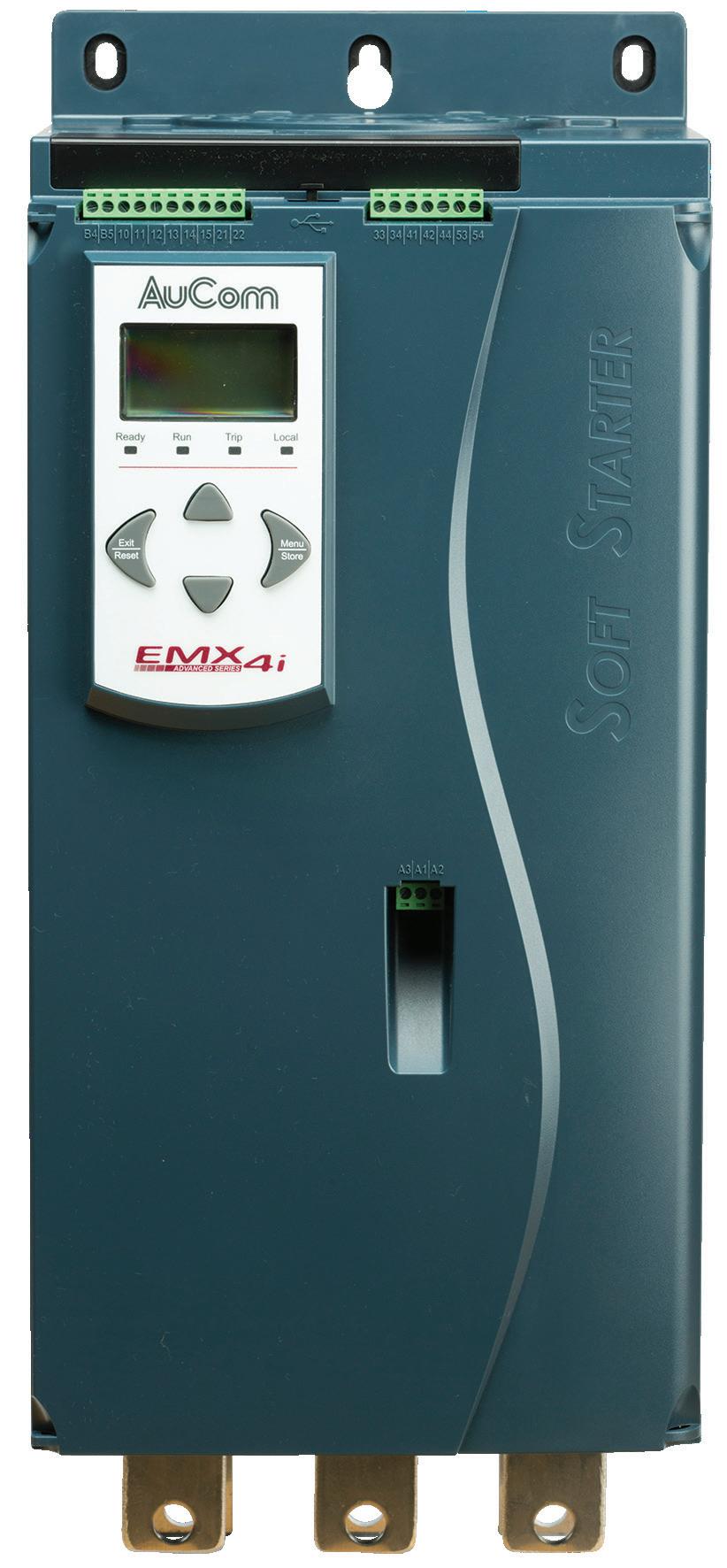

IPD is a privately-owned Australian company with a national footprint servicing the electrical industry. We have been providing quality global brands such as GE, Hensel, Socomec, DEHN and Elsteel to the Australian market for over 60 years. We are proud to employ over 160 professional people in areas such as engineering, sales and logistics. We have an innovative and extensive range of products. The range consists of power distribution, power protection, control, energy management and renewables. We have extended our product portfolio over the last few years. Now we are offering Santerno VSD and Aucom

soft starters for motor controls. IPD has an extensive technical sales network of more than 70 employees nationally, backed by a national customer service centre. We provide added value to our customers through in-house design, estimating and local manufacturing. These services are further supported by a flexible inhouse and onsite training program to better utilise our products.

29 Paramount Drive Wangara WA 6025 08 9302 1855 www.ittblakers.com

24 Enterprise Drive Tomago NSW 2322 02 4964 9777

20-22 Macquarie Drive

Thomastown VIC 3074 03 9463 0888 info@jacmor.com.au www.jacmor.com.au

549 Somerville Road

Sunshine VIC 3020 03 9289 4777 www.johncrane.com

Fully featured motor control solutions

New EMX4i range

24 – 580A with internal bypass

Features

• XLR-8 control to prevent water hammer

• Emergency run mode

• Real time metering & monitoring

• Automated pump clean function

• Extended motor protection functionality

• Clock & calendar scheduling

Gateway Estate 211-215 Walters Road

Arndell Park NSW 2148 1300 789 466

kelair@kelairpumps.com.au www.kelairpumps.com.au

Industries serviced: Building Services/HVAC, Chemicals and Pharmaceuticals, Food and Beverage, Irrigation, Manufacturing, Mining, Oil and Gas, Plastics and Rubber, Power Generation, Pulp and Paper, Wastewater Products: Axial Flow Pumps, Bearings, Borehole Pumps, Chemicals Pumps, Chopper Pumps, Consulting, Couplings,

Dewatering Pumps, Engineering, Hoses, Motors, Drives and Engines, Positive Displacement Pumps, Pressure Pumps, Repair/ Aftermarket, Rotodynamic Pumps, Seals, Slurry Pumps, Submersible Pumps, Transfer Pumps, Valves

Kelair Pumps is a privately-owned pump company that commenced operations in 1975. Our mission is to provide our clients with a range of world renowned highquality products supported by knowledgeable staff.

We take pride in our pump knowledge and ‘When Pump Knowledge Matters’, our staff is second to none.

Kelair Pumps has an extensive range of both positive displacement pumps and centrifugal pumps for applications across all industries such as mining & mineral, oil & gas, chemical, pharmaceutical, paint, power, and water & wastewater. Our range of pumps includes

Kelair stock a wide range of

diaphragm pumps, air operated diaphragm pumps, gear pumps, peristaltic pumps, screw pumps, progressive cavity pumps, vane pumps and lobe pumps. We also offer water pumps, magnetic drive pumps, solids handling pumps and chemical pumps.

Kelair Pumps is also a leading supplier of fire pumps to the construction and plumbing industries for fire protection and building hydraulics.

As well as our comprehensive range of industrial pumps and fire pumps, Kelair Pumps has a range of sewage treatment plants and wastewater treatment plants primarily applied to human waste. The products we supply are supported by our service division where a team of highly skilled service technicians can provide services for troubleshooting, repair and commissioning both in-house and on site.

13 Hawkins Crescent Bundamba QLD 4304 1300 073 887 enquiries@ksb.com.au www.ksb.com.au

Industries serviced: Building Services/HVAC, Chemicals and Pharmaceuticals, Food and Beverage, Irrigation, Manufacturing, Mining, Oil and Gas, Power Generation, Pulp and Paper, Wastewater Products: Axial Flow Pumps, Borehole Pumps, Dewatering Pumps, Hydraulic Equipment, Repair/Aftermarket, Slurry Pumps, Submersible Pumps, Transfer Pumps

KSB Australia specialises in the supply and service of

pumps, valves and systems across a range of industries. As a global company with a local focus, we offer engineered fluid transport solutions across every market.

With a commitment to first-class customer service, comprehensive support and consultancy throughout the entire product lifecycle, our engineers and technicians draw on many years of experience with all KSB products as well as products from other manufacturers. In order to further improve our services offered to customers at a regional level, KSB Australia maintains business relations with trusted and selected dealers. KSB Australia is part of the

globally operating KSB Group with more than 12,000 employees and 140 years of experience as an industry leader in pumps.

For more information about our locations, please visit our website.

Link Pumps

4 Ponting Street

North Williamstown VIC 3025

03 9391 9600

enquiries@linkpumps.com.au www.linkpumps.com.au

LK Diesel

52 Woodlands Drive Braeside VIC 3195

03 9588 6900

info@lkdiesel.com.au www.lkdiesel.com.au

Malcolm Thompson Pumps

31 Powers Road

Seven Hills NSW 2147

1800 733 687

sales@mtp.com.au

www.mtp.com.au

Industries serviced: Building Services/HVAC, Chemicals and Pharmaceuticals, Food and Beverage, Irrigation, Manufacturing, Mining, Oil and Gas, Power Generation, Wastewater Products: Borehole Pumps, Chemicals Pumps, Dewatering Pumps, Dosing and Metering Equipment, Hoses, Hydraulic Equipment, Positive Displacement Pumps, Reciprocating Pumps, Repair/ Aftermarket, Seals, Slurry Pumps, Submersible Pumps, Transfer Pumps

Since 1967, Malcolm Thompson Pumps has been one of Australia’s leading pump companies. We pride ourselves on providing a complete range of pump solutions to a diverse range of clients across Australia. We have completed a diverse range of projects, big and small, across a variety of industries including mining, industrial, agriculture, construction and mobile dust suppression. This has given us the confidence and expertise to provide our customers with the products and services they require to keep their pumps in optimum condition. We are proud to offer a diverse range of quality pumps from leading brands such as Aquaplus, Stalker Pumps, CDR, ProMinent, Flux, Wernert and Indeng.

Due to the size and reputation of our business, we are also able to source all major pump brands both locally and internationally. Based in Perth, WA, Australian-owned, designed and engineered Stalker Pumps has proudly been operating and manufacturing pumps since 1923. Now a division of MTP, Stalker Pumps is one of the last remaining pump suppliers in Australia with an onsite foundry, providing complete flexibility.

Our team of engineers work closely with consultants and end users to design and manufacture custom pump packages. This includes consultation, system design, fabrication, assembly and performance testing.

We have fully equipped, modern workshops in Sydney, Perth and Kalgoorlie. Our state-ofthe-art facilities contain advanced machinery applications including assembly, CNC machinery, pump assessment and rebuilds, spray painting and pump testing facilities.

Our team is always on hand to offer our complete pump service and repair expertise, providing a 24/7 emergency pump repair service. Our service vehicle fleet and pump service centres are designed and equipped to ensure the fastest turnaround times possible, with our technicians always identifying ways to maximise your pump’s performance and minimise downtime.

You can trust MTP for all your pumping needs.

Mawpump

8 Toupein Rd Yarrawonga NT 0830 08 8931 2511

sales@mawpump.com.au

www.mawpump.com.au

N2, 391 Park Road Regents Park NSW 2143 02 9669 0208

marketing.australia@nch.com.au www.nchasia.com/en-au

Industries serviced: Building Services/HVAC, Chemicals and Pharmaceuticals, Filtration, Food and Beverage, Manufacturing, Mining, Wastewater NCH exists because of its customers. With the latest technology, industry expertise and quality solutions, we have the tools to best understand our customer requirements. NCH has a presence in 50 countries and a network of over 8,500 sales staff.

NCH Australia is part of the Asia division of NCH Corporation.

We clean and conserve water, save energy and deliver best-in-class maintenance solutions, with a focus on industrial and commercial businesses in Asia.

At NCH Asia, we believe in "people doing business with people". We have developed and continue to grow a direct sales team to build customer connections, enhance our customer understanding, and drive market penetration. Customers value our

You’d be smiling too if you partnered with MTP. Quality sales and service, including the Aquaplus brand and the iconic Stalker Pumps, one of the last remaining pump suppliers with an in-house foundry.

offering based on:

• Reliable, close and personal relationships

• Expertise in understanding their operations

• Our technology delivering demonstrable benefits

It is with this mission firmly in our mind that we have developed a business strategy that is our roadmap in maintaining excellence in everything we do.

Solutions:

In pursuing its strategy, NCH Asia focuses efforts and investments on developing unparalleled knowledge, technical competency, and competitive differentiation on six platforms:

• Maintenance

• Chem-Aqua (Water Treatment) NEMO® Progressing Cavity Pump

• Lubricants

• Wastewater

• Food Safety

• Agriculture

Unit 3, 21 Binney Road

Kings Park Sydney NSW 2148 02 9641 2840

nas@netzsch.com www.netzsch.com.au

Industries serviced: Chemicals and Pharmaceuticals, Food and Beverage, Oil and Gas, Power Generation Products: Chemicals Pumps, Dewatering Pumps, Positive Displacement Pumps, Slurry Pumps, Transfer Pumps

NETZSCH is a German company based in Australia for over six years and has offices strategically located in NSW, QLD, VIC and WA.

NETZSCH pumps are designed specifically for the most demanding pumping applications in all industries and our technical sales team is well trained to offer you a reliable solution, which will secure and maintain production with long-term cost efficiency. In order to provide suitable high-level service and after sales support our Service Centre was established in 2013. We keep local stock of pumps and spare parts for prompt delivery to the Australian, New Zealand and Oceania markets.

Service Centre: 2/54 Westgate Street Wacol QLD 4076

TORNADO® Rotary Lobe Pump

NOTOS® Multiple Screw Pump

NEMO® Barrel Emptying System

N.Mac® Twin Shaft Grinder

M.Ovas® Macerator

NETZSCH Australia Pty

NOV

75 Frankston Gardens Drive Carrum Downs VIC 3201 1800 333 138 Ozsales@nov.com www.nov.com

Industries serviced: Chemicals and Pharmaceuticals, Food and Beverage, Irrigation, Mining, Pulp and Paper, Wastewater Products: Positive Displacement Pumps, Pressure Sewer Systems, Solar Pumps

National Oilwell Varco is a leading provider of integrated production and process solutions to a variety of industrial markets. We combine our expertise of engineering with quality products, a global footprint

and aftermarket support delivering solutions that meet our customer’s requirements. Our history of providing progressing cavity pumps dates back to being issued one of the original licenses to manufacture Mono pumps. With in-house industryspecific expertise, we understand the needs of our customers in many different industry sectors including water and wastewater, food and beverage, agriculture and solar, chemical and pharmaceutical, oil and gas, minerals, mining plus paper and pulp.

Northern Diesel and Hydraulic Service

32 Beach Street

Kippa Ring QLD 4021 07 3883 3833

info@ndhs.com.au www.ndhs.com.au

National Oilwell Varco is a leading provider of integrated production and process solutions to a variety of industrial markets. We combine our expertise of engineering with quality products, a global footprint and aftermarket support delivering solutions that meet our customer’s requirements.

Our history of providing progressing cavity pumps dates back to being issued one of the original licenses to manufacture MonoTM pumps. With in-house industry-specific expertise we understand the needs of our customers in many different industry sectors including water and wastewater, food and beveridge, agriculture and solar, chemical and pharmaceutical, oil and gas, minerals, mining plus paper and pulp.

Ovivo Water

Building A, 99-103 Cowpasture Road, Wetherill Park NSW 2164 02 9542 2366

info.AU@ovivowater.com www.ovivowater.com.au

Industries serviced: Chemicals and Pharmaceuticals, Oil and Gas, Power Generation, Wastewater

Products: Chemicals Pumps, Dosing and Metering Equipment, Pressure Pumps, Submersible Pumps, Transfer Pumps

Ovivo is a global provider of equipment, technology and systems, producing the purest water and treating the most challenging wastewater in the industry. We are

extremely competitive in the marketplace for dosing and pumping solutions including brands like Grundfos, Dosatron, Lowara and Prominent. Ovivo is a powerful global brand with renowned trademarks, advanced technologies and extensive system integration know-how. Ovivo delivers conventional to highly technological water treatment solutions for the commercial, industrial and municipal markets. Ovivo is dedicated to innovation in an industry that is in constant evolution and offers water treatment solutions that are cost effective, energy efficient and environmentally sustainable.

info.au@ovivowater.com / www.ovivowater.com.au

Pioneer Pump

67 Proximity Drive

Sunshine West VIC 3020 03 9988 1650

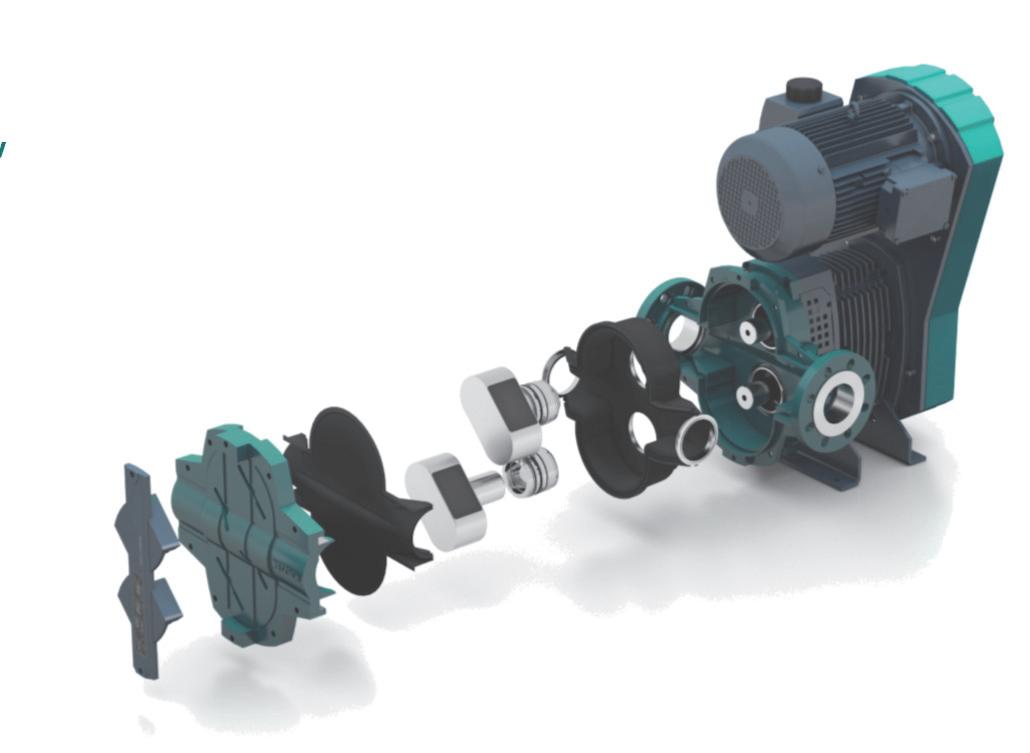

ppausales@pioneerpump.com www.pioneerpump.com

Industries serviced: Chemicals and Pharmaceuticals, Food and Beverage, Irrigation, Manufacturing, Mining, Oil and Gas, Pulp and Paper, Wastewater Products: Dewatering Pumps, Engineering, Slurry Pumps, Transfer Pumps Pioneer Pump is performance through innovation.

Leading-edge hydraulic engineering makes our centrifugal pumps the highest performing pumps on the market. Our pumps provide better flow, higher head, greater efficiency, and unparalleled service designed to meet your unique challenges. At Pioneer Pump, we don’t just design, we deliver.

The engineering leadership of Pioneer Pump

Pioneer Pump was founded on the idea that pumps should be better. Thanks to our engineering leadership, all Pioneer pumps are built using an innovative impeller design that’s now the industry’s best. It moves more pumpage, more efficiently, size-for-size. You get extreme performance while using less energy, giving you the best lifetime value in an environmentally and budget-conscious world. The large eye area and low NPSHr provide better suction lift and vapour handling. And the enclosed design handles solids more efficiently for improved performance, less maintenance and longer life, compared to traditional impellers.

Pioneer Pump Australia offers products designed to meet the requirements of the local market as well as the entire Pacific Rim. By integrating the superior performance of the Pioneer hydraulic designs into application specific packages, we deliver on the Pioneer Pump promise to provide the best quality and highest performance.

Pentair

1-21 Monash Drive

Dandenong South VIC 3175

1300 137 344

au.sales@pentair.com www.onga.com.au

14 Jesmond Road

Croydon VIC 3136

03 9722 8888

sales@pomonapumps.com.au

www.pomonapumps.com.au

11-13 Kennaugh Street

Oakleigh East VIC 3166 03 9543 2011

www.pumpengineers.com.au

PUMPNSEAL

Australia

5 Innovation Circuit Wangara WA 6065 08 9302 8444 www.pumpnseal.com.au

Australia

9 Export Drive

Brooklyn VIC 3012

03 9933 7400

www.pumppower.com.au

6/3 Marina Close

Mount Kuring-Gai NSW 2080 02 9457 8622

sales@pumpserv.com www.pumpserv.com

Regal BeloitAustralia

19 Corporate Avenue

Rowville VIC 3178 1300 888 853

SEAP.ITAdmin@RegalBeloit.com www.regalaustralia.com.au

Industries serviced: Building Services/HVAC, Food and Beverage, Mining, Manufacturing, Oil and Gas, Wastewater

Products: Axial Flow Pumps, Blowers, Gearboxes, Motors, Drives and Engines, Repair/ Aftermarket

Regal Beloit Corporation (NYSE: RBC) is a leading manufacturer of electric motors, electrical motion controls, power generation and power transmission products serving markets throughout the world.

The company is comprised of three business segments: commercial and industrial systems, climate solutions and power transmission solutions. Regal is headquartered in Beloit, Wisconsin, and has manufacturing, sales and service facilities throughout the United States, Canada, Latin America, Europe and Asia.

Our Australian division offers a national presence with offices Australia wide, including three modifications centers: VIC, NSW, QLD. Our product support and engineering team and R&D support teams offer local expertise, support and product customisation.

Our products can be found in industries such as HVACR, mining, oil and gas, water and wastewater, cement, food and beverage, and steel. We have a wide range of electric motors, motor controls and drives, couplings, gearboxes, electrical insulation, fan systems, generators, cables and varnishes, and air systems products.

We are proud to offer a one-stop-shop for complete electro mechanical, power transmission, air movement and speed control systems. Our brands include established names such as Marathon Motors & Generators, Torin, OBA, Fasco and Genteq, to name a few.

1-7 Redwood Drive

Dingley VIC 3172 03 9551 5111

esales@regentpumps.com.au www.regentpumps.com.au

Rexnord Australia

18 Statham Street

Bennetts Green NSW 2290 02 4962 8000 www.rexnord.com

Robertson Technology

9 Gleneagles Close Connolly WA 6027 08 9300 0844

info@robertson.technology www.robertson.technology

4 Muir Place Wetherill Park NSW 2164 02 4258 8790 sales@rotechaustralia.com.au

67 Henderson Road Rowville VIC 3178 03 9763 3221 info@rps-group.net rps-group.net

Seal Innovations

18 Malduf Street, Chinchilla QLD 4413 07 4665 5355

chinchilla@sealinnovations.com.au sealinnovations.com.au

Industries serviced: Food and Beverage, Manufacturing, Mining

Products: Chemicals Pumps, Engineering, Repair/Aftermarket, Seals, Slurry Pumps

Seal Innovations evolved by combining the expertise of Seal Imports, Alliance Sealing, Sealcom, Interseal and Specialised Gaskets, making the combined ANZ’s premium supplier of seal and gasket products.

Seal Innovations provides customers with access to products and technical support across four key sealing technologies: static sealing (gaskets), rotary sealing (oil seals), reciprocating sealing (hydraulic and pneumatic seals), and process sealing (mechanical seals).

SiL workshops provide professional pump repairs, refurbishment, and overhaul by recognised pump specialists.

Available at our workshops these services deliver longevity of industrial pumping equipment. Our experienced and skilled technicians save time and money with our comprehensive precision machining, servicing, modification and rebuild services that include:

• Repair to all makes of pumps including; centrifugal pumps, vacuum pumps, PD pumps, submersible, blowers

• Rotating equipment repair

On site servicing of seals, machinery & pumps

• Site Surveys

Seal Innovation's expertise, product mix, in-house manufacturing, equipment refurbishment and product design capabilities help customers reduce product supply lead times for situations with unpredictable demand as well as delaying equipment obsolescence and performance improvement for plant maintenance segments.

Seal Innovations leads its markets in both New Zealand and Australia.

• Supply and repair to all types of mechanical seals to suit any application

• Pump base fabrication

Steam turbine repairs

• On site monitoring

• Trouble shooting Reliability improvement

• Laser alignments sealinnovations.com.au

Unit 3, 4 Bounty Close Tuggerah NSW 2259 02 4355 4500 info.au@seepex.com www.seepex.com

Industries serviced: Chemicals and Pharmaceuticals, Oil and Gas, Power Generation, Pulp and Paper, Wastewater Products: Positive Displacement Pumps, Slurry Pumps, Transfer Pumps

SEEPEX is one of the leading worldwide specialists in the field of pump technology. Our portfolio comprises progressive cavity pumps, macerators, control systems and extensive services. Research, innovation and more than 700 committed employees around the world form the basis of our success.

With major technologies, such as the patented Smart Conveying Technology, we create complete solutions for use in the most important branches of industry. As a result, our customers profit from lower lifecycle costs, higher productivity and optimised energy efficiency.

The modular design principle utilised by SEEPEX makes it possible to supply custom progressive cavity pumps for virtually any pumped media. Whether thin to highly viscous, with or without solids, abrasive or gaseous –our progressive cavity pumps dose and convey media gently and with minimal pulsation.

We are utilising our developments in the field of digitalisation in a targeted manner and across all market segments, in order to optimise production facilities and processes for our customers. In the process, our focus is on reducing operating costs, increasing productivity and ensuring environmentally friendly work procedures and processes.

We support our customers with a global distribution network and assist them with personal advisory services and professional project management.

No 5, Sin-Jhan Road, Chian-Jhen District, Kaohsiung City, 80672, Taiwan +886 7811 1359 www.scenic-seals.com scenic@scenic-seals.com

17-21 Stamford Rd

Oakleigh VIC 3166 03 9269 0800 www.skf.com/au

SGF

Unit 15, 191-195 Greens Road, Dandenong South VIC 3175 03 9791 9393 sales@sgfasiapac.com www.sgf.de

Industries serviced: Food and Beverage, Irrigation, Mining, Power Generation, Pulp and Paper Products: Couplings SGF, the leading manufacturer and supplier of flexible drive solutions for torque transmission and vibration control to the automotive industry, is now gaining worldwide success with new innovative dampening solutions for the industrial market.

SGF coupling solutions are increasingly specified by

equipment and machinery manufacturers in industries including irrigation, food processing, paper, mining, marine, rail, agricultural equipment, power generation and more.

SGF offers complete and easily adaptable solutions including flange or flywheel connections and its new customised SGFlex-3FDCONNECT shaft assemblies to suit almost any pump or industrial application. For further information please visit www.sgf.de or email sales@sgfasiapac.com

Skyline Pumps

11 Monique Court

Raceview QLD 4305 07 3812 2121

info@skylinepumps.com.au www.skylinepumps.com.au

Sterling Pumps 14 Sharnet Circuit Pakenham VIC 3810 03 5941 3400 sales@sterlingpumps.com.au www.sterlingpumps.com.au

Stevco Seals and Pumps Victoria

Unit 8, Epping Business Park 53 Gateway Boulevard Epping VIC 3076 03 9408 3975 vicsales@stevco.com.au www.stevcovic.com.au

Strategic Achievement

PO Box 429

Scarborough WA 6922 0418 908 555 info@pumptraining.com.au www.pumptraining.com.au

Submersible Motor Engineering

9 Ryelane Street Maddington WA 6109 08 9452 2922 jayson@smeng.com.au www.smeng.com.au

Sulzer Australia

33 Enterprise Circuit Carrum Downs VIC 3201 03 9775 0522

water.australia@sulzer.com www.sulzer.com

Industries serviced: Chemicals and Pharmaceuticals, Food and Beverage, Irrigation, Mining, Pulp and Paper, Wastewater Products: Axial Flow Pumps, Blowers, Chemicals Pumps, Chopper Pumps, Dewatering Pumps, Pressure Pumps, Repair/ Aftermarket, Slurry Pumps, Submersible Pumps, Transfer Pumps

Sulzer is a preferred supplier for clean water, wastewater, pulp, paper, board and other selected industrial process applications in the municipal water and general industry segments, offering a full range of innovative standard and configured pumping, mixing, and agitation solutions. Sulzer adds value to the customers' processes through best-inclass solutions, products, and services.

The product and application expertise has been accumulated through committed long-term research and development in fluid dynamics, processoriented products and special materials, as well as through mergers and acquisitions, the most recent being Ahlström Pumps in 2000, Scanpump and ABS Group in 2011, and Ensival Moret in 2017.

Superior Pump Technologies Unit 23

31 Governor Macquarie Drive

Chipping Norton NSW 2170 02 9727 0525

www.sptaust.com.au

Techtop Australia

33-35 Gaine Road

Dandenong South VIC 3175 03 9753 2222

sales@techtop.com.au www.techtop.com.au

Teco Australia

335-337 Woodpark Road Smithfield NSW 2164 02 9765 8118

sales@teco.com.au www.teco.com.au

31 Western Avenue

Sunshine VIC 3020 03 9464 9500 unitedpumps@unitedpumps.com.au www.unitedpumps.com.au

Industries serviced: Oil and Gas, Power Generation Products: Engineering, Repair/ Aftermarket, Rotodynamic Pumps, Transfer Pumps Specialist designer and manufacturer of heavy duty, engineered centrifugal pumps for the process industries.

3 Carl Court Hallam VIC 3803 03 9796 4098 robert@vesco.com.au www.vesco.com.au

102/8 Century Circuit Baulkham Hills NSW 2153 02 8858 2600 support@viega.com.au www.viega.com.au

Volvo Penta

3/17 Alexandra Place Murarrie QLD 4172 07 3890 7615 www.volvopenta.com

Water Pumps Now

5/12 Simpson Street Kirra QLD 4225 1300 411 366 www.waterpumpsnow.com.au

Waterdos Australasia

Fiveways Business Park

23/31 Keysborough Close Keysborough VIC 3173 1300 980 513 info@waterdos.com.au www.waterdos.com.au

Specialising in custom design, manufacture, repair and service of centrifugal pumps for over 30 years

• Complete range of API 610 (ISO13709)

• Hydraulic and mechanical design

• Custom engineering, retro-fit, redesign

• Performance testing

• Service and repair

www.unitedpumps.com.au

T: +61 3 9464 9500

31 Western Avenue, Sunshine Victoria 3020, Australia

E: unitedpumps@unitedpumps.com.au

14 Lakeview Drive

Scoresby VIC 3179 03 9765 4600

info-au@weg.net www.weg.net/institutional/AU/en Industries serviced: Building Services/HVAC, Chemicals and Pharmaceuticals, Filtration, Food and Beverage, Irrigation, Manufacturing, Mining, Oil and Gas, Plastics and Rubber, Power Generation, Pulp and Paper, Wastewater Products: Motors, Drives and Engines

WEG offers a wide range of industrial products including low and high voltage electric motors, L.V. and H.V. variable speed drives, L.V. and H.V. soft starters, power and kiosk transformers, and low voltage switchgear, which sees them well established throughout various market segments including the mining, oil and gas, sugar, and utility sectors etc.

We do this through our world-wide network of manufacturing facilities, and in combination with our local branches and service providers.

1 Marden Street

Artarmon NSW 2064 1300 927 626

au.info@weirminerals.com

www.weirminerals.com

Industries serviced: Manufacturing, Mining, Oil and Gas, Plastics and Rubber, Power Generation, Pulp and Paper, Wastewater Products: Couplings, Dewatering Pumps, Hoses, Pressure Pumps, Repair/Aftermarket, Slurry Pumps, Submersible Pumps, Valves

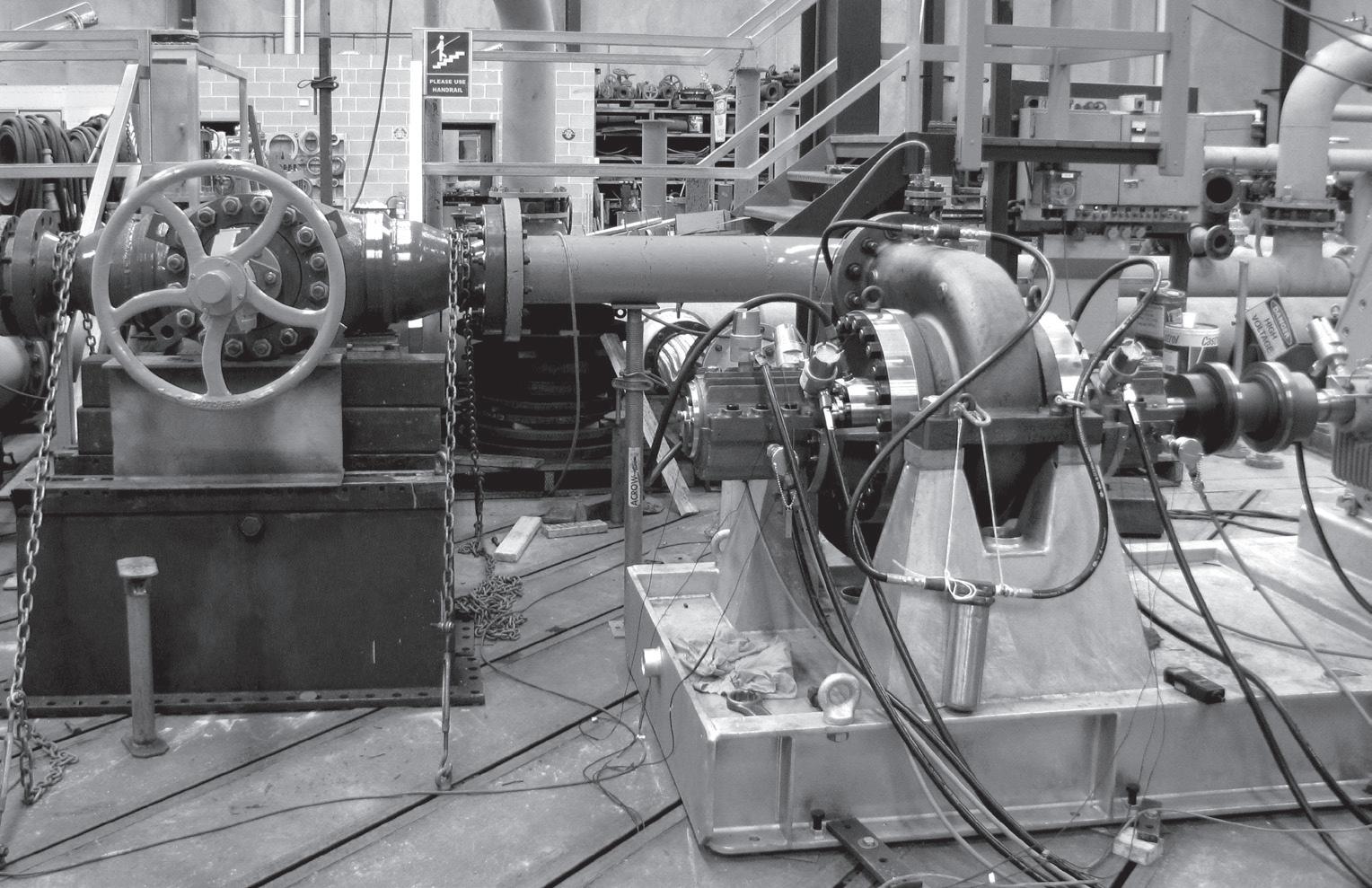

Weir Minerals is the global leader in the provision of slurry handling equipment and associated spare parts for abrasive high-wear applications used in mining, transportation, milling and processing, and waste management activities in some of the world’s most demanding environments. We are specialists in delivering and supporting mill circuit solutions including pumps, hydrocyclones, valves, hose, screens and screen media, cone crushers, centrifuges and baskets, rubber, wear resistant linings, mill systems and mine dewatering solutions for global mining and mineral processing and general industry.

At Weir Minerals we are specialists in delivering total solutions for comminution,

slurry transportation, minerals processing, tailings and dewatering applications. We are market leaders in providing trusted technology and unrivalled service to enhance our customers’ operations in more than 70 countries across the globe. Our comprehensive portfolio of high-performance pumps and superior minerals processing equipment is designed and manufactured to meet the highest specifications – for robust and reliable use in the world’s most demanding environments.

And all this is backed by an exceptional service network of more than 125 service centres around the world – all located close to our customers. At our service facilities in the Asia Pacific region, we are able to provide tailored local solutions, engineering support and aftermarket service, while being backed by global design and industry best practice.

Our strong competitive position is underpinned by core competencies in materials technology and engineered hydraulics. These naturally align with aggressive wear applications and enable us to bring our expertise to bear on both original equipment and the aftermarket, ensuring strong ongoing customer relationships.

Welling & Crossley

59 Export Drive

Brooklyn VIC 3012 1300 656 276

sales@wellcross.com.au www.wellcross.com.au