PUMP INDUSTRY CAPABILITY GUIDE Welcome to the

ABN: 36 426 734 954

204/23–25 Gipps St Collingwood VIC 3066

P: (03) 9988 4950

F: (03) 8456 6720 monkeymedia.com.au info@monkeymedia.com.au pumpindustry.com.au magazine@pumpindustry.com.au

AEditor Lauren Cella

Assistant Editor

Eliza Booth

Business Development Manager

Rima Munafo

Design Manager

Alejandro Molano

Designer Jacqueline Buckmaster

Publisher Chris Bland

Managing Editor

Laura Harvey ISSN: 2201-0270

s I sit and write this welcome to the 2021 Pump Industry Capability Guide, it’s under very different circumstances to the 2020 iteration – COVID-19 has changed the way we live and work, borders nationally and internationally are closed, and Melbourne (where I am based) is in the midst of stage 4 lockdown, and no one knows what the next 12 months will look like. But while there have been and continue to be challenges for pump and associated equipment suppliers and manufacturers, as an industry we can be confident that we remain vital – and will remain operating – to ensure essential services can be provided and economy-driving industries can continue to operate.

With industry events cancelled or with reduced attendance, people unable to travel, and more people working from home, now more than ever, the Pump Industry Capability Guide will be a key reference tool for end users to find information on specific pump companies or services through detailed entries, all in one location, at the tips of their fingers, without having to leave their homes.

Now in its sixth year, the guide remains and is now an even more important part of end users’ day-to-day operations. Each entry includes information on the services and products a company offers, the specific industries they relate to, as well as their contact details.

The continued overwhelming support over the years has seen the guide grow and become more comprehensive, and the 2021 guide – despite the uncertainty of the current situation – has continued that trend.

The layout of the guide has been designed to be user-friendly to make finding the right service, product or company as quick and easy as possible. Readers can navigate the guide using the indices which separate companies by industry, services and products.

Along with a comprehensive list of companies, the guide also includes content exploring the key markets in the pump industry including dewatering, irrigation, water and wastewater, minerals processing, hydrocarbon processing, food and beverage, HVAC, plastics and rubber, power generation, and more. You’ll also be able to read about the Pump Family Tree, which shows how the different pump types relate to each other, and details some of the commonly available pump types and their applications.

As well as the print guide, all listings are also available online at www.pumpindustry.com.au/ directory. The fully-searchable format allows you to type in a keyword, category or product and the site generates a list of all the relevant pump companies. We have made the product list more comprehensive, allowing you to search for more specific types of pump.

I hope the best for you, your families and businesses for the year ahead, and that the Pump Industry Capability Guide continues to be a key tool in your day-to-day operations throughout 2021.

Lauren Cella Pump Industry EditorINDUSTRY INDEX

BUILDING SERVICES/HVAC

Brown Brothers Engineers Australia 24

Ebara Pumps Australia 29 Franklin Electric 31 Fuseco�����������������������������������������������������32

Kelair Pumps Australia 38

KSB Australia 40

Pump Systems Group 42

WEG Australia �����������������������������������������50

CHEMICALS AND PHARMACEUTICALS

Bürkert Fluid Control Systems 25

EagleBurgmann Australasia 28

Hammelmann �����������������������������������������33

John Crane 37

John Valves 38

Kelair Pumps Australia 38

KSB Australia 40

NETZSCH Australia .....................................41 Pump Systems 42

SEEPEX Australia 46

Sulzer Australia ���������������������������������������48 WEG Australia �����������������������������������������50 Xylem 52

FILTRATION

Bürkert Fluid Control Systems ����������������25

Cummins South Pacific 26

John Crane 37

Triangle Waterquip 48

WEG Australia �����������������������������������������50

Weir Minerals Australia ���������������������������50

Xylem 52

FOOD AND BEVERAGE

Brown Brothers Engineers Australia ��������24

Dynapumps 27

Ebara Pumps Australia 29 Fuseco 32 GRAPHALLOY 33

Hammelmann �����������������������������������������33

Hidrostal Australia 34

John Valves 38

Kelair Pumps Australia 38

KSB Australia 40

NETZSCH Australia 41 Pump Systems Group 42

Pump Systems 42

Sulzer Australia ���������������������������������������48

WEG Australia �����������������������������������������50 IRRIGATION

Angus Flexible Pipelines Australia �����������22

Brown Brothers Engineers Australia ��������24 Crusader Hose

Cummins South Pacific 26

Ebara Pumps Australia ����������������������������29 Fuseco�����������������������������������������������������32

MANUFACTURING

Brown

PRODUCT INDEX

PRODUCT INDEX

FLEXIBORE FLEXIBORE

PUMP APPLICATIONS

BUILDING SERVICES AND HVAC

Pumps are an essential component of HVAC systems, supporting the operations of cooling towers, chillers, boilers, water systems, fire systems and other equipment by providing the energy required to move water and other fluids through piping, fittings and other HVAC system components. The roles of pumps in the building services and HVAC industry include the supply and distribution of water for cooling processes, and pumping away condensate by-products. Pumps used in this industry include centrifugal pumps, condensate pumps, heat pumps and vacuum pumps.

CHEMICALS AND PHARMACEUTICALS

Pumps play many roles within the chemicals and pharmaceuticals industries. They are frequently used in bulk transfer, degassing, vacuum distillation, crystallisation, sterilisation, drying, freeze-drying, packaging, extraction and purification processes, as well as fulfilling a variety of other functions depending on the particular product being produced. The chemicals and pharmaceuticals industries often have very particular requirements for pumps and the materials from which they are made, dependent on the characteristics of the substance being pumped (e.g. whether it is corrosive or reactive) and various standards of sterility, hygiene, precision and control required by the application.

DEWATERING

Dewatering is frequently required in the mining and construction industries to remove water buildup in mine shafts or construction sites, as well as applications including flood dewatering. Pumps used for dewatering applications generally need to be durable, portable and heavy duty in order to cope with tough environmental conditions and demanding applications. Centrifugal pumps, including portable submersible pumps, centrifugal slurry pumps, self-priming centrifugal trash pumps and axial flow pumps, are often used for dewatering applications, but positive displacement pumps like diaphragm pumps can also be used.

FILTRATION

Filtration is required whenever there exists a need to separate solids from fluids by introducing a medium through which only the fluids can pass. Different types of filtration (including mechanical, chemical or biological processes) are suitable for different applications, and often multiple stages of filtration may be required. The properties required of the filter and filter media can be

FOOD AND BEVERAGE

The food and beverage industry utilises pumps to transfer a variety of materials from raw ingredients, flavouring and other additives, cleaning fluids and corrosive chemicals, to finished food and beverage products. Often the fluids and processes involved in the production of food and beverages will have requirements for careful handling, non-reactive components, accurate dosing and metering, and high levels of hygiene. Positive displacement and centrifugal pumps are among the types of pump commonly used for food and beverage applications.

IRRIGATION

Pumps play a vital role in irrigation projects for both water intake and distribution. Most irrigation applications require pumps to supply water from its source – such as a dam, bore or main – and to distribute it to where it is required. In cases where water must be treated before use, such as by adding fertilisers and/or removing elements that may be harmful to crops from groundwater via filtration, pumps are also required in the water treatment process. Generally, energy and water efficiency, maximising crop yield per unit of water used, as well as cost-effective operation are important considerations for irrigation pumps.

MANUFACTURING

The manufacturing industry uses pumps for a wide variety of applications dependent on the product being produced. Manufacturing plants producing concrete, cement, steel, clothing, textiles or plastics are a few examples of those that require pumps in their processes. Depending on the application, pumps used in the manufacturing industry may be required to cope with conditions such as high temperature and/or pressure operation, hazardous media, corrosive or flammable liquids, or low NSPH.

MINING

Pumps play a number of vital roles in the process of mining and mineral recovery. Within the mining industry, different types of pumps are utilised for a range of applications including raw water supply, mine dewatering, transporting slurry, leach and drainage solutions, chemical dosing and transporting process water to be used in the metal recovery process. The most common types of pumps used in mining are slurry pumps and dewatering pumps. These pumps often need to be durable, portable and heavy duty in order to cope with tough environmental conditions and demanding applications.

OIL AND GAS

In the oil and gas industry pumps are employed for an extensive range of hydrocarbon production, transportation and refining applications both upstream and downstream. Typical roles for pumps in the industry include transporting hydrocarbons, raw water supply, produced water disposal, chemical injection, secondary recovery and dewatering. Pumps also play a key role in the recovery of unconventional oil and gas reserves, transporting the water required in the process of hydraulic fracturing. Generally, pumps used in this industry need to be able to provide reliable and safe operation in demanding applications.

PLASTICS AND RUBBER

A variety of different pumps are involved in the processes undertaken to produce and treat plastics and rubber for various uses. Pumps are required throughout the production process, including polymer processing, compounding, product manufacturing and recycling. Often, pumps are required to gently handle shear sensitive materials or transfer additives with a wide range of different properties. Efficiency and reliability are also frequently vital requirements for pumps in the plastics or rubber industry.

POTABLE WATER

Pumps play important roles in the treatment and distribution of potable water, whether it is supplied through an extensive water network or from a smaller local source like a well. Types of pumps commonly used for potable water pumping applications include centrifugal booster pumps such as vertical turbine pumps (including well pumps), submersible turbine pumps and horizontal or vertical split case pumps. Circulator pumps may be used to circulate water through closed systems. Metering pumps, often used to deliver precise amounts of fluid for drinking water treatment applications, are often positive displacement diaphragm pumps. Reliability and energy efficiency are important considerations for potable water pumps.

POWER GENERATION

Different pumps are used extensively throughout the power generation industry for many applications. A typical power station will feature a wide variety of pumps including cooling water pumps, condensate extraction pumps, boiler feed pumps, booster pumps and water circulation pumps. The reliable operation of these pumps is vital in order for power to be produced safely, efficiently and cost effectively. Pumps also play vital roles in hydroelectric power production.

PULP AND PAPER

The pulp and paper industry is a water intensive industry that requires the continuous, reliable operation of equipment. This industry employs a huge variety of different types and sizes of pumps for supply, mixing and transfer processes. Pumped fluids can range from highly corrosive chemicals, to abrasive sludges, to solvents and oils, to clean water. Some common roles for pumps in the pulp and paper industry include those involved in paper stock preparation, water handling, chemical processing, power generation and pollution control. These pumps are often highly specialised for the specific applications and process fluid, and to help meet various safety standards in operations, and quality criteria for the produced product.

WASTEWATER

The water and wastewater industry relies on pumps for a broad range of water and sewage transfer applications, as well as in water and wastewater treatment processes. Sustainable industrial water and wastewater applications require pumps that can reliably deliver vital services. Pumps used to transfer sewage and wastewater must also be able to deal with its potentially corrosive qualities and the presence of potentially clogging materials. In addition to transporting water to where it is required and pumping sewage and sludge to treatment plants, pumps play other vital roles including dosing and metering the chemicals required to treat drinking water and wastewater, as well as filtration.

THE PUMP FAMILY TREE

From heavy-duty mine dewatering to precise chemical metering and dosing, the vast range of different pumps available on the market means there’s a pump configured to suit any application. There are many job-specific factors that will determine the right pump for you, including the design of the pump and mechanics of how it operates. Here, we take a look at some of the commonly available pump types, and where they fit in the pump family tree.

Pumps

Most pumps fit into one of two main groups.

These are:

• Rotodynamic pumps

• Positive displacement pumps

Rotodynamic pumps

These types of pumps are kinetic machines where energy is transferred to the pumped fluid via a rotating element, such as an impeller, propeller or rotor. The mechanical energy is transferred to the fluid primarily by increasing fluid kinetic energy, which is then converted into potential energy in the discharge collector.

The most common type of rotodynamic pumps are centrifugal (radial flow), axial flow and mixed flow pumps. These pumps are used in near-countless applications in an array of different industries.

Types of rotodynamic pumps

Centrifugal pumps

Centrifugal pumps are the most common type of pump due to their simple and effective design and operation. This also makes them cheaper than other types of pump.

These pumps use one or more impellers that rotate unidirectionally within the pump casing. A vacuum is created to draw the fluid to the impeller by suction, with the impeller then producing liquid velocity before the casing forces the liquid to discharge, converting velocity to pressure. By forcing the liquid through without cupping it, very high flow rates can be achieved.

These pumps can be subdivided depending on the type of impeller used:

• Radial flow impellers

The liquid enters the impeller axially and discharges radially, changing the direction of the flow 90°. These impellers can be single suction (where the fluid enters the impeller from one side) or double suction (where fluid enters from both sides). These are charactarised by providing high pressure and low flow

• Mixed flow impellers

The liquid enters the impeller axially and discharges in both radial and axial directions. Can be single or double suction

• Axial flow impellers

The liquid both enters and discharges from the impeller axially (i.e. the flow does not change direction). Single suction only. These are charactarised by providing high flow and low pressure. These are typically charactarised by providing medium flow and medium pressure

Regardless of the impeller type, centrifugal pumps can be either single stage, where the total head is the result of one impeller, or multistage, with a series of impellers aligned in one casing.

Depending on requirements, these pumps can be either self or non self-priming and can have open, semiopen or closed impeller types.

Centrifugal pumps can also be identified by their basic mechanical configuration or characteristics. For example:

• Overhung impeller type

The impeller is mounted on the end of the shaft that is cantilevered from its bearing supports

• Impeller between bearings type

The impeller is mounted on a shaft between bearings situated at both ends

• Turbine type

Usually refers to vertical multistage deep well type pumps with diffuser casings attached to one another

Other types defined by unique characteristics or functions include sump pumps, sewage pumps, slurry pumps and more.

Peripheral pumps

Peripheral pumps (also known as side channel or regenerative pumps) are a niche pump type that sit somewhere between centrifugal and positive displacement type pumps as they are able to produce the high discharge pressures of positive displacement pumps, with the flexible operation of centrifugal pumps but with a less variable flow rate.

They work on the same kinetic principle as centrifugal pumps, but instead of using an impeller with vanes, they use turbine-like impellers with radially orientated teeth to move fluid. As the impeller rotates, fluid velocity is increased and moved in a circular path through the teeth. This circular path through the teeth provides the diffusion to convert the velocity to pressure.

These pumps are more compact and have tighter internal clearances than traditional centrifugal pumps so they also tend to be noisier. The shape of the pump-head capacity curve is also different, with it being steeper for peripheral pumps, and the horsepower versus capacity is reversed from centrifugal pumps, with the highest horsepower being towards zero flow.

They generally have a flow rate range between 1-200gpm, a total pressure (head) range between 50-1,200ft, and a horsepower range between 0.5-75hp.

These pumps are most commonly end suction or single stage, but there are multistage versions also available.

They are ideal for applications which require high head, low flow, flexible operation and a compact design such as clean liquid applications like deep well pumping. They’re also used in industrial applications as cooling water circulators for lasers and other machines, and in small boiler services in bakeries, dry cleaners, breweries and other commercial plants.

Speciality pumps

Traditional reciprocating pump designs are not always optimal for every pumps application, this has resulted in the design and manufacture of a number of specialty pumps to fill these gaps. These include:

• Jet pumps

A high velocity jet of fluid is used to create a low pressure area in a mixing chamber, causing the suction fluid to lower into this chamber. While they are most commonly inserted vertically into the fluid, they can be mounted horizontally as well. They are typically less efficient than a standard centrifugal pump due to factors such as friction loss, but may be more efficient in applications where it is dealing with combined media including gases, and in variable well conditions where surface characteristics involve turbulence. Generally these pumps have a flow rate between 1-70gpm, total head (pressure) range between 20-200ft, and horsepower ranges from 0.5-5hp. They are commonly used in well applications with shallow well versions where the ejector is mounted on the pump used for wells to a depth of 25ft and deep well versions with the ejector located in the well where the depth is up to 120ft. Deeper well will generally require the use of a submersible pump. They are also often used in home applications for wastewater, and applications where the fluid being pumped helps to create the motive force needed to move through the pump such as marine applications to transfer seawater.

• Gas lift

A gas pressure source (usually compressed air) is used to lift the fluid being handled by mixing it with gas under pressure. This process occurs downhole, with the compressed gas injected down a casing tubing annulus, entering the well at numerous entry points called gas lift valves. These pumps tend to have lower maintenance and installation costs than other pumps in the same application, and are generally easier to service. These pumps are typically used in the oil and gas industry to increase pressure within the reservoir and encourage the medium to the surface. They’re also useful in contexts where sand might clog or damage other types of lifts, particularly when a well is deviated, and the wear on rods may be a concern.

• Magnetic drive pumps

A sealless type pump that uses a magnetic coupling device so that the external rotating part of the coupling is separated from the internal

rotor. These pumps normally use magnetic coupling devices manufactured from samarium cobalt and neodymium iron boride. These are rare earth magnets that don’t allow slip between the inner and out magnet rings, which allow the pump to achieve high torques and for pumps as large as 200hp to be designed and manufactured in this type.

They are energy efficient, but like most other sealless pumps, have a higher capital cost than comparable centrifugal pumps. These capital costs are often offset though their lower operating costs due to lack of seal replacement, cleanup, waste and downtime.

Magnetic drive pumps are primarily designed for clear fluid applications such as in industrial, municipal or agricultural settings that require pumping of clear, low viscous fluids and where there are no solids present as solids will cause quick failure of the sleeve bearings and thrust surfaces inside the pump. Some are able to move heavier or more viscous fluids, but this is not common. They are also used in applications to transmit acids or other fluids that cannot leak into the environment or where mechanical seals would be too expensive to buy and maintain such as in chemical plants, and in chemical services in pulp mills, power plants, water and wastewater treatment plants, etc.

• Electro-magnetic pumps

A glandless pump where a magnetic field acts upon the medium (e.g. liquid metal). As there are no moving parts within the pumped liquid there is no need for seals and bearings which are found in conventional mechanical pumps, thus minimising leaks, maintenance and repairs, and improving reliability.

There are three types of electromagnetic pumps: conduction, induction and thermoelectric. These pumps are primarily designed for use with liquid metals, such as NaK, sodium and lithium, at temperatures up to around 1500°F (approximately 800°C). They can also be used with other metallic and nonmetallic fluids that have a sufficient level of electrical conductivity such as mercury, lead and bismuth. There are two main applications for these pumps: in nuclear plants to cool the reactor, and in foundry for pouring and transporting high temperature metals.

A POWERFUL PARTNERSHIP

Volvo Penta. Robust, fuel efficient industrial diesel engines that keep running even in the toughest conditions. Easy to install, operate and maintain. A powerful partnership you can trust all the way from the drawing board throughout the operational life of your engine. Competitively priced complete power-pack units ready for delivery Australia wide with a local support team on hand 24/7. To find your nearest dealer visit www.volvopenta.com

Positive displacement pumps

Positive displacements pumps is a broad category of pump, consisting of rotary and reciprocating type pumps, and is the second most popular type of pump after centrifugal pumps.

These pumps move fluid at a steady rate and pressurise it to allow it to pass through a system by drawing the fluid into a chamber, and then contracting the chamber to force the fluid out at the pressure needed to move it through the piping system.

These pumps use rotating or reciprocating parts, rather than impellers, to push the liquid in an enclosed moveable volume until enough pressure has built up to move it to the discharge. Unlike centrifugal pumps which rely on raising the velocity of the fluid by moving it through an impeller, the fluid velocity inside positive displacement pumps is much lower.

Positive displacement pumps generally work within the following ranges:

• Flow rate ranges between 0.1-15,000gpm

• Total head (pressure) ranges between 10-100,000psi

• Horsepower ranges between 0.5-5,000hp

• Viscosity limits vary with pump type, but some types can handle millions of SSU viscosity

Due to their lower fluid velocity, these pumps are ideal for applications where fragile solids need to be moved. They are also ideal for applications where constant flow

is needed, and are generally used for pumping oils and viscous fluids, and other application niches.

Where low flow rates are adequate and preferred, positive displacement pumps are a better option than other dynamic pumps

These pumps are self-priming and sealless types are available.

There are many different types of positive displacement pumps, with a wide range of applications, including:

• Sauces, confectionery, yogurt, and shortening in the food industry

• Chicken offal, meat purees, potato waste, thick non-flowing pastes

• Domestic and industrial sewage, primary and secondary sludges, dewatered sludge cake

• Shampoo, cosmetics, light creams

• Lime, bentonite and clay slurries

• Dosing of flocculants and various chemicals

• Wine must (grape juice with stalks and skins) using rectangular inlet versions

• High head mine dewatering usually containing abrasive rock particles and dust

• Shaft and submersible motor drive borehole pumps

• Low flow, high head, agricultural water pumping, particularly where long suction lines are required

VSD Earth Leakage Protection

Arc-Flash Protection

Motor and Pump Protection

Robust Protection for Critical Infrastructure

Trust your motor and pump protection to the experts. Littelfuse protection relays stand up to the harshest conditions and safeguard the most critical parts of your operation. Our field application experts will help you update your protection to extend the life of your equipment, mitigate arc-flash hazards, and reduce the risk of electric shock.

Fuseco 1300 651 460

relays@fuseco.com.au www.fuseco.com.au

Types of positive displacement pumps

There are two main types of positive displacement pumps: rotary and reciprocating.

Rotary pumps

Rotary pumps are a type of positive displacement pump where for each revolution, a fixed volume of fluid is moved. These pumps are self-priming and provide near constant delivered capacity no matter the pressure.

These pumps are designed with very small clearances between the rotating and stationary parts in order to minimise leakage from the discharge side to the suction side. As they are designed to operate at relatively slow speeds to maintain these clearances, when operated at higher speeds they are susceptible to erosion and excessive wear, which results in larger clearances and decreased pumping capacity.

These pumps can be divided into either single rotor or multiple rotor types. They can then be further classified by the pumping element.

• Single rotor types include: vane pumps, piston pumps, flexible member pumps and screw (progressive cavity) pumps

• Multiple rotor types include: gear pumps (external or internal gear), lobe pumps, circumferential piston pumps and multiple screw pumps

These pumps can be used in a wide variety of applications depending on the type of pump, but are commonly used for pumping high viscosity liquids such as oil including in handling lube oil and fuel oil in engine rooms.

Lobe and circumferential piston pumps are commonly found in clean industries such as beverage, pharmaceutical and personal care products, as well as industrial applications like polymers, paper coatings, soaps and surfactant, paints and dyes, and rubber and adhesives.

On the other hand, twin and triple screw pumps are more commonly used for hydrocarbons, ranging from crude oil to bitumens and lubricating oils, vegetable oils and water. Applications include tanker unloading, fluid transfer, fuel feed, hydraulic power, heavy machinery lube oil supply, and multi-phase oil and gas flow in oil well production pumping.

Reciprocating pumps

These pumps use alternating force and suction – using a piston or diaphragm – to create a steady, pulsing flow, with one or more check valves to regulate and direct flow through the system. The pump chamber is repeatedly expanded and contracted to draw the fluid through an intake valve and force it out through the other end. They are able to generate high pressures.

Reciprocating pumps can be either single acting like plunger and diaphragm pumps, where the liquid is discharged only during the forward motion of the piston, or double acting like piston pumps, where the liquid is discharged during both the forward and backward motions.

They can be further divided as: simplex, duplex, triplex or multiplex pumps.

These pumps range from small, hand-powered pumps, to big pumping systems. Due to the broad range of pumps that are classed as reciprocating pumps, they play an integral role in a number of sectors including private, public and commercial/industrial sectors in applications such as general pressure wash, high-pressure cleaning, heavy vehicle washing, sewer jetting, misting for temperature or humidity control, dust suppression, drilling mud, reverse osmosis, descaling, water jet cutting, chemical injection, crude oil transfer, mine dewatering and ore pipeline transport.

Common types of reciprocating pumps include: single acting, double acting pumps, mechanical diaphragm, piston, plunger, hydraulically actuated diaphragm, bladder, and well-point piston pumps.

Cosmetic

Pharmaceutical

16 George Bellew Road

Yaldhurst Christchurch 8042

+64 03 349 1350

www.43south.co.nz

AllightSykes

12 Hoskins Rd

Landsdale WA 6065 08 9302 7000 allightsykes.com

ABB Australia

601 Blackburn Road Notting Hill VIC 3168 1800 222 435 www.abbaustralia.com.au

Adelaide Control Engineering

10 Peekarra Street

Regency Park SA 5010 08 8118 6460 www.adelaidecontrolengineering.com

Industries serviced: Mining, Power Generation, Wastewater Products: Dewatering Pumps, Motors, Drives and Engines, Repair and Aftermarket

A wholly-owned division of Seven Group Holdings with a global presence, AllightSykes is a market leader in the design, manufacturing and distribution of lighting, dewatering and power solutions, and the driving force behind Perkins engines and FG Wilson generators in Australia and New Zealand. Thanks to our international presence, we have clear insight into the local issues faced by our regions and unparalleled knowledge of our industry.

With an active history stretching back 30 years as a

well-known brand, building reliable, quality products, AllightSykes is the preferred equipment supplier for the largest resource and hire companies in the world. We are committed to delivering equipment with built-in features that make ownership and operations safe, simple and costeffective for you.

As the Original Equipment Manufacturer (OEM) of Allight towers and Sykes Pumps in Australia, we work with clients throughout the entire product lifecycle, from concept to aftermarket care.

We have all our own employees on the ground dedicated to our customers, whose pioneering attitude distinguishes us from our competitors. We understand that you need to be able to rely on fast, fuss-free services, genuine parts and warranty backup after your equipment has started doing its job.

Angus Flexible Pipelines Australia

Unit 5/48 Business Street

Yatala Queensland 4207 07 3382 0434

sales.australia@angusfire.com angusflexiblepipelines.com.au

Industries serviced: Irrigation, Mining, Oil and Gas

Products: Couplings, Hoses Angus Flexible Pipelines Australia manufactures layflat hose from high tensile synthetic yarns, which are circular woven and then totally encapsulated in a tough elastomeric cover and lining. Different yarns and covers are used for different applications, but what they all have in common is exceptional strength, superior hydraulic performance, ease of storage and transport, rapid installation and retrieval, cost-effective set up and operation, and long service life.

Wellmaster is the industry standard flexible rising main for all types of groundwater borehole extraction. Wellmaster offers major cost savings and performance advantages over conventional rigid polyethylene, PVC, glass fibre and galvanised pipe.

Wellmaster has: worldwide potable water approval, including AS4020 approval in Australia and New Zealand; high safety margins in both tensile and hydraulic performance; total corrosion, microbial and internal scaling resistance; compatibility with all types of submersible pumps; and a long operational life with a five year full replacement warranty. With over 100,000 installations of Wellmaster product around the world, it is the flexible rising main of choice.

Angus is an ISO9001:2008 certified company.

14 Nicole Way

Dandenong South VIC 3175

03 9793 7577

www.asmpumps.com.au

Australian Fluid Handling (AFH)

Factory 1, 25-27 Burns Road

Altona VIC 3019

03 9369 6200 www.afhpl.com.au

Austworld

15 Activity Crescent

Molendinar QLD 4214

1300 780 430

info@austworld.com.au

www.austworld.com.au

Industries serviced: Oil and Gas

Products: Hoses, Valves Austworld is the largest family-owned wholesaler and manufacturer of plumbing systems and fittings for water, gas and solar in Australia. Established in 1984, Austworld continues to be an independently familyowned business that prides itself on the robustness and quality of its locally engineered products.

All of Austworld’s products are designed, tested and quality controlled by a team of local engineers in its own research facility to ensure each valve or fitting can specifically meet the demands of an Australian environment.

With six distribution warehouses servicing Australia nationally from Western Australia, South Australia, Victoria, New South Wales, Queensland and Tasmania, the company is able to respond to customer demand in an efficient and timely manner.

This unique and integrated distribution model, plus its extensive range of high-end valves, tapware and fittings, are all aimed at providing its

customers with a high level of customer service, and the plumbers they supply, with efficient, time saving and future-proofed products enabling them to stay competitive across the water, gas and solar industry.

Line Pumps Unit 1, 156 Bonds Road Riverwood NSW 2210 02 9153 0233

www.blinepumps.com.au

Batescrew Pumps & Valves Australia

189 Newell Highway Tocumwal NSW 2714

03 5874 2101

www.batescrew.com

Brown Brothers Engineers Australia

7 Damian Court Dandenong VIC 3175 1300 4 BBENG info@brownbros.com.au www.brownbros.com.au

Industries serviced: Building Services/HVAC, Food and Beverage, Irrigation, Manufacturing, Mining, Oil and Gas, Power Generation, Wastewater Products: Axial Flow Pumps, Borehole Pumps, Chopper Pumps, Couplings, Dewatering Pumps, Engineering, Hoses,

Motors, Drives and Engines, Pressure Pumps, Rotodynamic Pumps, Seals, Slurry Pumps, Submersible Pumps, Transfer Pumps, Valves From small domestic pressure systems to large industrial process pumps, Brown Brothers Engineers provides a full range of pumps and pumping solutions to meet your needs.

Brown Brothers Engineers is the distributor for some of the world’s leading brand pumps, including Lowara, Goulds Water Technology and HYDROVAR in QLD, NSW, ACT, VIC and TAS, and nationally for Layne Bowler, SAER and Sakuragawa. As one of Australia and New Zealand’s leading pump suppliers for almost a century, we have gained a wealth of experience. We can guarantee that you will get the best pumping solutions the world has to offer because we only supply the world’s leading pump brands.

Our Australian operation not only includes the importation of a wide range of pumping equipment, but also the assembly, distribution, testing and custom building of pump sets and pumping systems. Our qualified engineers work closely with you and engineering consultants to select exactly the right pump or pumping system for your project. We also give superior after sales service, backed up by our dedicated service and testing facilities.

For more information about our services and solutions please contact us.

Melbourne: 7 Damian Court, Dandenong, VIC

Sydney: 211-215 Walters Road, Arndell Park, NSW Brisbane: 50 Nestor Drive, Meadowbrook, QLD

Bürkert Fluid Control Systems

15 Columbia Way

Baulkham Hills NSW 2153 1300 888 868 sales.au@burkert.com burkert.com.au

Industries serviced: Chemicals and Pharmaceuticals, Filtration, Manufacturing, Mining, Oil and Gas Products: Actuators, Compressors, Dosing and Metering Equipment, Engineering, Pressure Pumps, Instrumentation, Control and Monitoring, Valves

At Bürkert, we love a good challenge. That is because we are simply fascinated by everything that flows. No matter the task faced by our customers – we pride ourselves on finding ways to deliver solutions specific to your individual needs.

Whether it is about flow, level, pressure, dosing, analysis, filtration, temperature, mixing or the automation of processes –liquids and gases have to be measured and controlled. These are the fundamental fluidic variations upon which industrial process technology is based.

At Bürkert, we’re unique in our approach. We begin with your fluidic challenge and draw on the basic physical principles, fluidic relationships and our experience with physics; duplicating them across the

most diverse applications and industries to solve your challenges, and in turn provide an exclusive solution that works for you.

Locally, since 1980, Bürkert has shown its commitment to bringing the highest level of quality and service to Australia and New Zealand. Bürkert provide specialists who understand you and your requirements, always on hand to answer technical needs – from one-off basic solenoid valves, to comprehensive networked systems.

In partnering with Bürkert, you benefit from our deep pool of expertise, superior service, and gain access to our reliable and sustainable product range.

www.burkert.com.au/en/ more-about/Welcome-tothe-Buerkert-eShop

Calpeda Pumps

1 Opala Street Regency Park SA 5010 08 8268 8880 au.calpeda.com

Caprari Pumps Australia

3 Jeanes Street Beverley SA 5009 08 8244 4442 www.caprari.com.au

Crusader Hose

22 Industry Place

Bayswater VIC 3153 03 9720 1100

sales@crusaderhose.com.au www.crusaderhose.com.au

Industries serviced: Irrigation, Mining, Oil and Gas, Wastewater Products: Borehole Pumps, Dewatering Pumps, Hoses

Vision:

World-leading Australian manufacturers of the most efficient systems for water delivery using flexible layflat hose.

Mission:

We manufacture layflat hose and reel systems for a wide range of applications. Our products are used for firefighting, groundwater pumping, mine dewatering and farm irrigation as well as fuel transfer.

Purpose:

By manufacturing locally, we believe that the Australian market for layflat hose can be better serviced, particularly due to our experience, stocking and willingness to customise.

Cummins South Pacific

191 Boundary Road

Laverton North VIC 3026 1800 931 181 1300cummins@cummins.com www.cummins.com.au

Industries serviced: Filtration, Irrigation, Mining, Power Generation

Products: Dewatering Pumps, Fire Pumps, Motors, Drives and Engines

Cummins South Pacific is a wholly-owned subsidiary of Cummins Inc., a global power leader. Cummins is the world’s largest independent designer and manufacturer of diesel engines, and has an unmatched service support network in the South Pacific which includes 35 branches,

150+ authorised dealers and the 24/7 Cummins Support Centre.

To support our customers across a broad range of pumping applications, Cummins offers powerpacks which are a complete turnkey solution designed and built in Australia for demanding Australian conditions with ratings from 40 to 2,000 hp. When you need power, the pump industry relies on Cummins.

Cummins Brisbane: 39–53 Ron Boyle Crescent, Carole Park, QLD 4300

Cummins Sydney: 492–494 Victoria Street, Wetherill Park, NSW 2164

Cummins Laverton: 191–195 Boundary Rd, Laverton North, VIC 3026

Water Products

6 Lakeview Drive

Scoresby VIC 3179

1300 232 839

www.davey.com.au

Deutz Australia

Unit 4, 13-15 Brough Street

Springvale VIC 3171

03 9549 8400

www.deutz.com.au

Drive Systems

8/32 Melverton Drive

Hallam VIC 3803

03 9796 4800

www.drivesystems.com.au

DTB International Pumping

41 Industrial Drive

Braeside VIC 3195

1300 302 330 www.dtbpumps.com.au

Dynapumps

88 Belgravia Street

Belmont WA 6104

1300 788 579

sales@dynapumps.com.au www.dynapumps.com.au

Industries serviced: Food and Beverage, Mining, Oil and Gas, Power Generation, Wastewater

Products: Submersible Pumps, Vacuum Pumps

More Than Just Pumps!

Dynapumps have provided superior pump and vacuum solutions since 1981 with our extensive product range, project management, design engineering and site service capabilities.

Dynapumps offer responsive support both on-site and from our many offices in Perth, Melbourne, Sydney, Brisbane and Chile to service our clients across Australia and worldwide.

Our experienced team of engineers are ready to provide technical back up as well as a large manufacturing base for pump and vacuum systems. Dynapumps are proficient in supplying clients with highquality pump products as packaged equipment to their specifications with excellent aftersales service and spare parts.

Perth – Head Office: 88 Belgravia Street, Belmont, WA, 6104

Sales and service: Unit 3, 94 Belgravia Street, Belmont, WA, 6104

Melbourne: Unit 5, 39 Heyington Avenue, Thomastown, VIC, 3074

Brisbane: Unit 7, 14 Hopper Avenue, Ormeau, QLD, 4208

Sydney: Unit 5, 6 Stanton Road, Seven Hills, NSW, 2147

For 20 years FLO-MAX

Manufactured and developed by Dynapumps in Australia since 2000, FLO-MAX has become the premium brand in Turbine and Submersible Pump technology!

Our FLO-MAX pump range includes Single-Stage Split Case, End Suction and the Heavy-Duty Multistage Turbine Pump designed for deep well applications available in cast iron and alternative materials.

At Dynapumps we are ‘More Than Just Pumps’! We have an extensive team of engineers to provide technical back up across Australia and have a large manufacturing base for pump products and vacuum systems. We strive to supply our clients with on-time, high quality, recognised pump products as packaged equipment to their specifications with excellent after-sales service and spares.

Contact Dynapumps for more information on our FLO-MAX range and to see how we can deliver your next pump solution!

EagleBurgmann Australasia

16 Stennett Road

Ingleburn NSW 2565 02 9605 0600 info@au.eagleburgmann.com www.eagleburgmann.com.au

venture of the German Freudenberg Group and the Japanese EKK Group, is one of the internationally leading companies for industrial sealing technology.

Our products are used everywhere where safety and reliability are important: in the oil and gas industry, refining technology, the petrochemical, chemical and pharmaceutical industries, food processing, power, water, mining, pulp and paper, and many other spheres.

Our modular TotalSealCare

service underlines our strong customer orientation and offers tailor-made services for every application. In 2019, the company generated sales of around €858 million and employed more than 5,800 people at more than 60 subsidiaries.

RELY ON EXCELLENCE

More than 25,000 applications running with EagleBurgmann Diamond Face

DiamondFace is an innovative MicroCrystalline

Diamond coating for mechanical seals.

It is characterized by extreme hardness, excellent wear resistance, maximum chemical resistance, excellent heat conductivity, superb resistance to electrochemical corrosion and minimum friction.

Diamond technology improves seal performance significantly Maximum operating performance due to minimum wear extends the maintenance intervals.

Many applications demand maximum hardness.

DiamondFace mechanical seals are especially for:

• Poor lubrication

• Temporary dry running

• Multiphase media

• Abrasive media (suspensions)

• Electrochemical corrosion

• Contact mode

EagleBurgmann Australasia Pty. Ltd

16 Stennett Road, Ingleburn, 2565, NSW, Australia

www.eagleburgmann.com.au sales@au.eagleburgmann.com

Ebara Pumps Australia

7 Holloway Drive

Bayswater VIC 3153

03 9761 3033

sales@ebara.com.au www.ebara.com.au

Products: Submersible pumps

Industries serviced: Building Services/HVAC, Food and Beverage, Irrigation, Wastewater

Ebara Pumps Australia is a subsidiary of Ebara Corporation Japan, one of the world’s largest manufacturers of custom and standard pumps for industry.

Ebara Pumps Australia

distributes its standard range of pumps via an Australiawide network of authorised dealers and OEMs.

Ebara manufactures pumps for use in food and beverage, wastewater, building services, industrial, domestic water supply and irrigation. The Ebara standard product ranges are considered the best in these industries due to their quality and competitive pricing.

Ebara Corporation was founded in Japan in 1912 as a manufacturer of pumps. Today as a group, it consists of more than 70 companies in six continents with a work force of more than 11,000 people and with companyowned and Japanesemanaged production facilities in eight counties covering four continents.

The huge scale of production and distribution is matched by a constant commitment to research, development and design of new products and modern technologies for manufacturing them. Ebara products have gained a worldwide reputation for their technology and quality.

Electric Motor Power

10 Newcastle Road

Bayswater VIC 3153

03 9720 6366

sales@emppl.com.au www.emppl.com.au

Products: Engineering, Motors, Drives and Engines, Solar Pumps

DC motors powered to your needs.

Electric Motor Power Pty Ltd is your one-stop shop for DC motors, controllers and associated components, working with you from the original design concept through to custom

manufacturing your product with quality components and ensuring the best possible efficiency.

Australian-owned with 30 years’ experience, we take pride in our product knowledge and development capabilities for both brushed and brushless motor systems. We have the local presence to meet your service standards, and the global capabilities to match any production requirements. Contact us today to discuss your pump motor requirements.

Emtivac Engineering

170-174 Discovery Road

Dandenong South VIC 3175

03 9768 3240

www.emtivac.com/contact-us

17 Kareela Street

Mordialloc VIC 3195

03 9587 3099

envirotechwater.com.au

FITT Resources

27 Awaba Street Lisarow NSW 2250 1300 653 229 www.fittresources.com.au

Flowserve Corporation

5 Parker Street Castlemaine VIC 3450 1300Flowserve (356 973) www.flowserve.com

Fluid Engineering

42 Bridge Road Griffith NSW 2680 0438 284 007 www.fluidengineering.com.au

FPT Industrial

31-53 Kurrjong Road St Marys NSW 2760 02 9673 7547 www.fptindustrial.com

Franklin Electric

106-110 Micro Circuit

Dandenong South VIC 3175 03 9799 5000 meyre@fele.com www.franklin-electric.com.au

Industries serviced: Building Services/HVAC, Irrigation, Manufacturing, Mining, Oil and Gas Products: Borehole Pumps, Motors, Drives and Engines, Solar Pumps, Submersible Pumps

Franklin Electric was established in Australia in 1962 to support the water industry.

Franklin Electric offers an extensive range of water pumps, submersible electric motors, VSD, controls and protective devices. It has earned the reputation as a technical leader in all of its specialties, with products being used in residential, industrial, agricultural, mining, municipal, commercial and fuelling applications.

No matter the project, Franklin Electric has a solution to meet your requirements – MOVING WATER - MOVING FORWARD.

Franklin ElectricPioneer Pump: 67 Proximity Drive, Sunshine West, VIC, 3020

Fuseco

4/1-7 Friars Road

Moorabbin VIC 3189 1300 651 460

Industries serviced: Building Services/HVAC, Food and Beverage, Irrigation, Manufacturing, Mining, Oil and gas Products: Centrifugal Pumps, Dewatering Pumps, Fire Pumps, Instrumentation, Control and Monitoring, Motors, Drives and Engines, Pressure Sewer Sytems,

Slurry Pumps, Specialty Pumps, Transfer Pumps

Fuseco is a leading supplier in fuses, power quality, test equipment and protection relays!

relays@fuseco.com.au www.fuseco.com.au GG Pumps & Electrical

Protection relays minimise electrical safety hazards, limit equipment damage, improve productivity, and safeguard personnel from injury due to electrical faults.

Engineers in construction, manufacturing, mining, oil and gas, solar, and many more industries have learned to rely on Littelfuse for lasting protection in their designs and critical applications.

The Littelfuse range includes line motor and pump protection relays, arc-flash relays, ground fault relays, feeder protection and more!

Call or email today to speak to our friendly team about your requirements!

4 Beaver Street

Geraldton WA 6530 1300 443 532

www.ggpumpsandelectrical.net.au

GRAPHALLOY

1050 Nepperhan Avenue

Yonkers NY 10703 USA

+1 914 968 8400

sales@graphalloy.com graphalloy.com

Industries serviced: Food and Beverage, Oil and Gas, Power Generation, Pulp and Paper, Wastewater Products: Bearings, Engineering

GRAPHALLOY® bushings and case wear rings can improve the reliability and efficiency of your API and non-API pumps. In horizontal and vertical pumps, selflubricating, non-galling GRAPHALLOY won’t seize or gall if run dry or with marginal lubrication.

GRAPHALLOY fitted pumps are able to survive upsets, dry running, loss of suction, slow roll on standby and other transient conditions that can occur when pumping low lubricity fluids and liquid gases.

Using GRAPHALLOY allows closer clearances often gaining efficiency improvements, reduced vibration and reduced NPSH requirements. NSF® and WRAS certified grades are available. GRAPHALLOY materials work in temperatures from -450°F (-240°C) to 1000°F (538°C).

H.E Brehaut (Hebco)

19-25 Trade Place

Vermont VIC 3133

03 9874 4299

www.hebco.com.au

Hammelmann

8 Law Court

Sunshine VIC 3020 1300 816 483

mail@hammelmann.com.au www.hammelmann.com.au

Industries serviced: Chemicals and Pharmaceuticals, Food and Beverage, Manufacturing, Mining, Oil and Gas, Pulp and paper Products: Centrifugal Pumps, Chemicals Pumps, Dosing and Metering Equipment, Hoses, Positive Displacement Pumps, Reciprocating Pumps, Repair and Aftermarket, Speciality Pumps, Transfer Pumps Founded in Germany in 1949, Hammelmann has over 70 years' industry experience and an international reputation for innovation, quality and reliability. Our primary focus is on developing customer-specific solutions for pumping high pressure media in diverse applications and industries. Our integrated high pressure pumps are extremely specialised and varied, and are available in a range of different performances.

Hammelmann has an extensive range of positive displacement high pressure process pumps used for chemical injection, seawater reinjection, flowline services, and dosing.

Hammelmann Australia is Australia’s largest supplier of ultra high and high pressure water pumps, hoses, and state-of-the-art specialised robotic equipment suitable for industrial cleaning and

water blasting industries. Hammelmann equipment is used in offshore platform applications, HPUs and FPSOs, mining and minerals (coal, iron ore, alumina, nickel, uranium), and chemical, petrochemical, road/bridge/tunnel rectification and ship cleaning industries.

Our ongoing commitment to high-quality standards and continuous investment in state-of-the-art manufacturing ensures we continue to offer quality Hammelmann positive displacement piston pumps “made in Germany, assembled in Australia”.

Our range also includes Inoxpa’s stainless steel, sanitary centrifugal, rotary lobe and progressive cavity pumps, and a complete range of hygenic agitators and mixers for dairy, food processing, chemical, cosmetic, and pharmaceutical industries.

QLD: 1/41 Paringa Road, Murarrie, QLD, 4172

QLD: 3 Roseanna Street, Gladstone, QLD, 4680

VIC: 8 Law Court, Sunshine, VIC, 3020

WA: 1/29 Haydock Street, Forrestdale, WA, 6112

Hiblow Australia

6/3 Marina Close

Mount Kuring-gai NSW 2080

02 9457 8622

www.hiblow.com.au

Hidrostal Australia

52 Commerce Circuit

Yatala QLD 4207 07 3801 8110

au.sales@hidrostal.com

www.hidrostal.com

Industries serviced: Food and Beverage, Irrigation, Mining, Oil and Gas, Power Generation, Pulp and Paper, Wastewater

Products: Dewatering Pumps, Repair and Aftermarket, Submersible Pumps, Transfer Pumps

Hidrostal Australia is a solely owned subsidiary company of Hidrostal Holding AG Switzerland.

Hidrostal is also the inventor and manufacturer of the "original" screw impeller pump, which has been field proven for 60 years.

Due to their outstanding characteristics, Hidrostal pumps are used in numerous municipal and industrial sectors. They pump the most diverse fluids and materials gently and with low pulsation.

Hidrostal pumps are successful in difficult applications and achieve the best results with respect to performance, energy efficiency, nonclog capabilities and low lifecycle costs.

Hidrostal

Tuma Motor Line

The new Hidrostal Tuma motors are available with drive power from 15 to 60 kW.

The motor pumps can be used in permanently ooded opera�on, or in dry installa�ons.

Cooling is provided by a patented, internal energy‐efficient cooling circuit.

Equivalent to IE3 Efficiency Levels

Standard Tuma Motor Specica ons

→ Performance: 15 ‐ 60 kW

→ Protec�on class: IP68

→ Insula�on class: F and H

→ IECEx, ATEX and FMu Cer�ed

→ Con�nuous opera�on (S1)

→ Decouple cables from motor for service purposes

→ Op�onal monitoring sensors : Windings, Seal Leakage, Bearing temperature, and Vibra�on.

Hydro Australia

8 Minchington Road

Morwell VIC 3840

03 5165 0390 www.hydroaustralia.com.au

Hydro Innovations

21-23 Clyde Street

Rydalmere NSW 2116

02 9898 1800

www.hydroinnovations.com.au

Pump Specica ons

Discharge Sizes: 50 ‐ 700 mm

Suc�on Sizes: 65 ‐ 700 mm

Head: 0.5 ‐ 90 m

Flow: 0.5 ‐ 3000 l/s

Power: 0.1 ‐ 650 kW

Frequencies: 50 Hz, 60 Hz, VFD

Materials: Cast Iron, Duc�le Iron,

Available Designs

Immersible

Submersible

Bearing Frame

Ver�cal or Horizontal

Self Priming

Trailer Mounted

Hidrostal Australia Pty Limited

52 Commerce Circuit, Yatala, QLD, 4207

Email: au.sales@hidrostal.com

Phone: 07 3801 8110

ABOUT US

IndustriTech specialises in rotating equipment, process equipment, sealing technology and technical service for power, mining, chemical process, refining, oil and gas, water and waste water applications. With our workshop and head office in Gladstone QLD and an on-site service team based in Brisbane, we are well equipped to service our customers throughout Queensland and the rest of Australia.

www.industritech.com.au

PHONE

07 4972 2015 0481 383 019

APPLICATIONS

• Additives

• Bitumen

• Boiler water

• Chemicals

• Crude oil

• Diesel

• Ethanol

• Hot oil

• Lubricant

• Motor spirit

• Slurries

• Waste water

OEM BRANDS

• Ajax

• Allweiler

• Durco

• Ebsray

• Flex-A-Seal

• Flowserve

• Goulds

• Graco

• Hermetic

• KSB

• Mono

• Netzsch

• Ruhrpumpen

• Sandpiper

• Schroeder

• Seepex

• Sihi

• Southern Cross

• Speck

• SPX

• Sulzer

• TKL

• Viking

• Warman

• Wilden

• Worthington

WORKSHOP & HEAD OFFICE

Shed E, 16-18 Chapple Street Gladstone Q 4680

EMAIL sales@industritech.com.au

GET THE SUPPORT YOU NEED FROM INDUSTRITECH IN 3 WAYS:

1. Technical Advice: Our account managers have mechanical and engineering backgrounds. They offer technical solutions for projects and reliability challenges.

2. Reliability and Repair Services: Minimise downtime and long-term spend on repairs and maintenance.

3. Distribution Services: Fast transactions for hundreds of fluid handling products all available from the one place.

ROTATING EQUIPMENT

• Industrial Pumps

• Transmissions and Drives

• Compressors

• Fans and Blowers

• Electric Motors and Controls

SEALING TECHNOLOGY

• Mechanical Seals and Supply Systems

• Bearing Isolators

• Static Seals – Gaskets and PTFE Products

• Gland Packing and O-Rings

• Industrial Coatings

PROCESS EQUIPMENT

• Engineered Valves

• Piping Products

• Filters

• Heat Exchangers

• Flexible Expansion Joints

TECHNICAL SERVICES

• Engineering and Design

• Field Service

• Laser Shaft and Pulley Alignments

• Vibration Analysis

• Rotor Balancing

• Non-Destructive Testing

• Installation and Commissioning

• Root Cause Analysis

IndustriTech

Shed E, 16-18 Chapple Street Gladstone QLD 4680 07 4972 2015 sales@industritech.com.au www.industritech.com.au

Products: Axial Flow Pumps, Bearings, Blowers, Borehole Pumps, Centrifugal Pumps, Chemicals Pumps, Compressors, Couplings, Dewatering Pumps, Dosing and Metering Equipment, Expansion Joints, Fire Pumps, Instrumentation, Control and Monitoring, Motors, Drives and Engines, Peristaltic Pumps, Positive Displacement Pumps, Pressure Pumps, Reciprocating Pumps, Repair and Aftermarket, Rotary Pumps, Seals, Slurry Pumps, Speciality Pumps, Submersible Pumps, Transfer Pumps, Vacuum Pumps, Valves IndustriTech specialises in rotating equipment, process equipment, sealing technology and technical service for power, mining, chemical process, refining, oil and gas, water, and wastewater applications.

Get the support you need from IndustriTech in three ways:

• Technical Advice – Our service professionals come from mechanical and factory-trained backgrounds. We offer technical solutions for projects and reliability challenges

• Reliability and Repair Services – Partner with us to significantly reduce unplanned repairs and put the savings into projects that further your reliability goals

• Distribution Services – Quick sourcing and fast transactions for hundreds of fluidhandling products, reducing the number of different vendors you need to deal with IndustriTech provides an experience focused on you. We invest in technology and people to meet the demands of our customers, helping you stay in control and streamlining your operations.

Our core products and services:

Rotating equipment

• Industrial pumps

• Transmissions and drives

• Compressors

• Fans and blowers

• Electric motors and controls

Sealing technology

• Mechanical seals and supply systems

• Bearing isolators

• Static seals – saskets and PTFE products

• Gland packing and O-rings

• Industrial coatings Process equipment

• Engineered valves

• Piping products

• Filters

• Heat exchangers

• Flexible expansion joints

Technical services

• Engineering and design

• Field service

• Laser shaft and pulley alignments

• Vibration analysis

• Rotor balancing

• Non-destructive testing

• Installation and commissioning

• Root cause analysis

ITT Blakers

29 Paramount Drive Wangara WA 6025 1300 333 488 www.ittblakers.com

JAC Pump Services

24 Enterprise Drive Tomago NSW 2322 02 4964 9777 www.jacpumps.com

Jacmor Engineering

20-22 Macquarie Drive

Thomastown VIC 3074

03 9463 0888 www.jacmor.com.au

John Crane Australia

549 Somerville Road

Sunshine VIC 3020

03 9289 4777

www.johncrane.com

Industries serviced:

Chemicals and Pharmaceuticals, Filtration, Mining, Oil and Gas, Pulp and Paper

Products: Couplings, Engineering, Gearboxes, Seals, Slurry pumps

John Crane is a global leader in rotating equipment solutions, supplying engineered technologies and services to process industries. The company designs and manufactures a variety of products including mechanical seals and systems, couplings, filtration systems and predictive digital monitoring technologies. John Crane customer service is accessed through a global network of more than 200 sales and service facilities in over 50 countries. Fiscal year 2019 revenue was greater than US$1.2 billion (£945 million).

In Oceania, John Crane has an extensive network including manufacturing, sales and service centres in Victoria, New South Wales, Queensland, South Australia, Western Australia and New Zealand.

YOUR NAME IS HOW WE MAKE OURS.

For more than 100 years, John Crane’s experience and technical expertise has helped keep global process industries ready to meet the ever-changing needs they face.

Our customers depend on John Crane to ensure their operations run efficiently and effectively. Our team of experts use the latest technologies to maximize reliability, provide rapid response and develop innovations needed for mission-critical rotating equipment and challenging environments. Today. Tomorrow. Together.

Metastream Couplings Mechanical Seals Filtration

John Valves

19 Martin Drive

Delacombe VIC 3356 03 5336 2113

sales@johnvalves.com.au www.johnvalves.com.au

Industries serviced: Chemicals and Pharmaceuticals, Food and Beverage, Mining, Power Generation, Wastewater Products: Actuators, Couplings, Expansion Joints, Valves Since humble beginnings in 1896, John Valves has grown into a well-known and reputable Australian valve supplier and manufacturer that meet the constantly changing needs of industry as technology changes,

develops and improves. John Valves take pride in their reputation for high-quality products, reliable team and customer service.

John Valves products include an extensive range of gate, globe, check, butterfly, level control, air release and parallel slide products with many of these products always in stock. John Valves also make specialty products to-order for your convenience.

Pumps

Gateway Estate 211-215 Walters Road

Arndell Park NSW 2148 1300 789 466

kelair@kelairpumps.com.au www.kelairpumps.com.au

Industries serviced: Building Services/HVAC, Chemicals and Pharmaceuticals, Food and Beverage, Irrigation, Manufacturing, Mining, Oil and Gas, Plastics and Rubber, Power Generation, Pulp and Paper, Wastewater

Products: Axial Flow Pumps, Bearings, Borehole Pumps, Chemicals Pumps, Chopper Pumps, Consulting, Couplings, Dewatering Pumps, Engineering, Hoses, Motors, Drives and Engines, Positive Displacement Pumps, Pressure Pumps, Repair and Aftermarket, Rotodynamic Pumps, Seals, Slurry Pumps, Submersible Pumps, Transfer Pumps, Valves Kelair Pumps is a privatelyowned pump company that commenced operations in 1975. Our mission is to provide our clients with a range of world renowned high-quality products supported by knowledgeable staff.

We take pride in our pump knowledge and ‘When Pump Knowledge Matters’, our staff is second to none. Kelair Pumps has an extensive range of both

positive displacement pumps and centrifugal pumps for applications across all industries such as mining & mineral, oil & gas, chemical, pharmaceutical, paint, power, and water & wastewater.

Our range of pumps includes diaphragm pumps, air operated diaphragm pumps, gear pumps, peristaltic pumps, screw pumps, progressive cavity pumps, vane pumps and lobe pumps. We also offer water pumps, magnetic drive pumps, solids handling pumps and chemical pumps. Kelair Pumps is also a leading supplier of fire pumps to the construction and plumbing industries for fire protection and building hydraulics.

As well as our comprehensive range of industrial pumps and fire pumps, Kelair Pumps has a range of sewage treatment

Kelair stock a wide range of high quality pump brands. Find the Brand you’re looking for. Industries

plants and wastewater treatment plants primarily applied to human waste.

The products we supply are supported by our service division where a team of highly skilled service technicians can provide services for troubleshooting, repair and commissioning both in-house and on-site.

Head Office NSW: Gateway Estate, 211-215 Walters Road, Arndell Park, NSW, 2148

VIC/SA: 7 Damian Court, Dandenong, VIC, 3175

TAS: 1/12 South Street, Invermay, TAS, 7248

QLD/NT: 50 Nestor Drive, Meadowbrook, QLD, 4131

WA: Unit 1, 14 Crocker Drive, Malaga, WA, 6090

Mackay: 19-21 Titanium Drive Paget, Mackay, QLD, 4740

From mining to pharmaceutical, Kelair has an extensive range for applications across all industries. Type

Whether you need Positive Displacement Pumps or Centrifugal Pumps, we’ve got one that will hit the target.

KSB Australia

13 Hawkins Crescent Bundamba QLD 4304 1300 073 887

enquiries@ksb.com.au www.ksb.com.au

Industries serviced: Building Services/HVAC, Chemicals and Pharmaceuticals, Food and Beverage, Irrigation, Manufacturing, Mining, Oil and Gas, Power Generation, Pulp and Paper, Wastewater

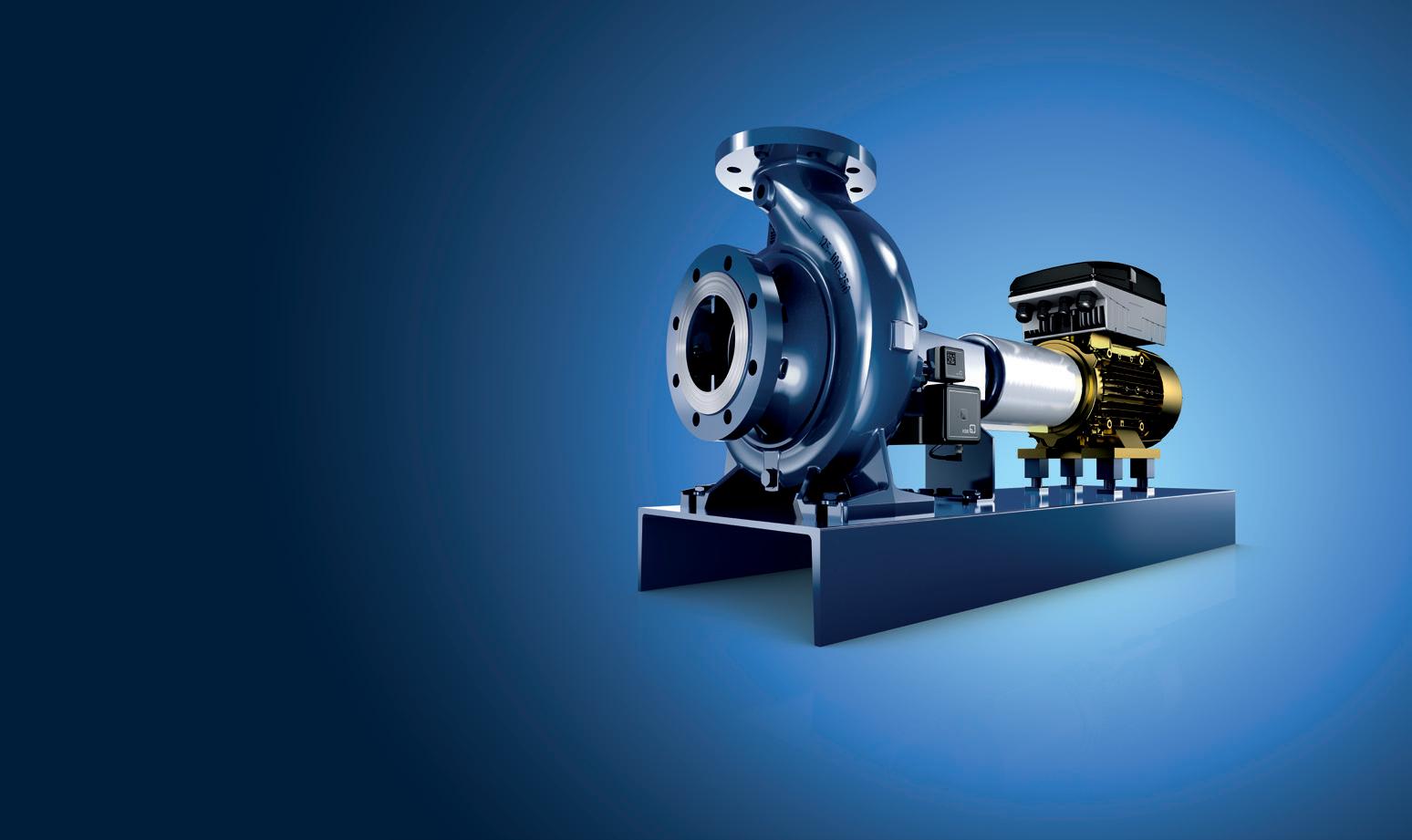

KSB Australia specialises in the supply and service of pumps, valves and systems across a range of industries. As a global company with a local focus, we offer engineered fluid transport solutions across every market.

With a commitment to first-class customer service, comprehensive support and consultancy throughout the entire product lifecycle, our engineers and technicians draw on many years of experience with all KSB products as well as products from other manufacturers. In order to further improve our services offered to customers at a regional level, KSB Australia maintains business relations with trusted and selected dealers.

KSB Australia is part of the globally operating KSB Group with more than 12,000 employees and 140 years of experience as an industry leader in pumps.

For more information about our locations, please visit our website.

Link Pumps

4 Ponting Street

North Williamstown VIC 3025

03 9391 9600 www.linkpumps.com.au

Mawpump

8 Toupein Rd

Yarrawonga NT 0830

08 8931 2511

www.mawpump.com.au

Midwest Valves & Controls

133 Mayne Street Gulgong NSW 2852

02 6374 2808 midwestvalves.com.au

NETZSCH Australia

10A/24-32 Lexington Drive

Bella Vista NSW 2153 02 9641 2840

nas@netzsch.com pumps.netzsch.com.au/au

Industries serviced: Chemicals and Pharmaceuticals, Food and Beverage, Mining, Oil and Gas, Wastewater Products: Chemicals Pumps, Dewatering Pumps, Positive Displacement Pumps, Slurry Pumps, Transfer Pumps

NETZSCH is a German company based in Australia for over six years and has offices strategically located in NSW, QLD, VIC and WA.

NETZSCH pumps are designed specifically for the most demanding pumping applications in all industries,

and our technical sales team is well trained to offer you a reliable solution, which will secure and maintain production with long-term cost efficiency.

In order to provide suitable high-level service and after sales support, our Service Centre was established in 2013. We keep local stock of pumps and spare parts for prompt delivery to the Australian, New Zealand and Oceania markets.

Service Centre:

2/54 Westgate Street Wacol QLD 4076

Northern Diesel and Hydraulic Service

32 Beach Street

Kippa Ring QLD 4021 07 3883 3833 www.ndhs.com.au

NOV

75 Frankston Gardens Drive

Carrum Downs VIC 3201 1800 333 138

www.nov.com

Pentair

1-21 Monash Drive

Dandenong South VIC 3175

1300 137 344

www.onga.com.au

Polymaster

161 Karinie Street

Swan Hill VIC 3585 1300 062 064 www.polymaster.com.au

The right pump solution for your application

Australia Pty Ltd 02 9641 2840 07 3488 8183

nas@netzsch.com www.netzsch.com.au

Pomona Pumps

14 Jesmond Road

Croydon VIC 3136 03 9722 8888

www.pomonapumps.com.au

Pump Engineers

11-13 Kennaugh Street

Oakleigh East VIC 3166 03 9543 2011 www.pumpengineers.com.au

Pump Power Australia

9 Export Drive

Brooklyn VIC 3012 03 9933 7400 www.pumppower.com.au

PUMPNSEAL

Australia

5 Innovation Circuit Wangara WA 6065 08 9302 8444 www.pumpnseal.com.au

Pump Systems Group

2/21 London Drive

Bayswater VIC 3153 03 9762 3100

sales@pumpsystemsgroup.com www.pumpsystemsgroup.com Industries serviced: Building Services/HVAC, Food and Beverage, Power Generation

Pump Systems

70 Yarra Street

Heidelberg VIC 3084 1800 121 452

sales@chopperpumps.com.au www.chopperpumps.com.au Industries serviced: Chemicals and Pharmaceuticals, Food and Beverage, Manufacturing, Oil and Gas, Pulp and Paper, Wastewater Products: Centrifugal Pumps, Chemicals Pumps, Chopper Pumps, Speciality Pumps, Submersible Pumps, Transfer Pumps

Established in 1984, Pump Systems is a specialist supplier of wastewater processing technology. We are exclusive Australasian agents for:

• Vaughan Chopper Pumps and Rotamix Systems – Designed and built in America since 1960, chopper pumps are severe duty, guaranteed non-clogging pumps designed to chop all incoming solids. Resilient to fibrous solids, Vaughan chopper pumps are often used where other pumps clog and block. This eliminates ongoing expenses associated

with call outs to clear pump station blockages. Vaughan Rotamix is a tank mixing system that uses chopper pumps to feed in-tank directional mixing nozzles. This system offers guaranteed mixing rates to keep solids in suspension within the tank, as well as conditioning tank fluids which prevents pipe and nozzle blockages while increasing biogas production. Vaughan’s chopper pumps Rotamix systems are used extensively across Australia and NZ.

• Lackeby Products –Swedish manufacturer of high-quality, stainless steel waste processing equipment including drum screens, various channel screen types, sludge heat exchangers, grit clarifiers and washers, shaftless screw conveyors and waste receiving stations.

We combine Vaughan’s nonclogging chopper pumps and Rotamix systems with Lackeby’s waste processing equipment, such as sludge heat exchangers and screening equipment, to offer high performance and reliable waste processing solutions.

Head office/warehouse: 1 McKechnie Street, Geraldine, 7930, New Zealand

PUMPNSEAL

Australia

5 Innovation Circuit Wangara WA 6065 08 9302 8400 www.pumpnseal.com.au

Pumpserv

6/3 Marina Close Mount Kuring-Gai NSW 2080 02 9457 8622

www.pumpserv.com

Rexnord Australia Unit 3, 8-10 Anderson Road

Smeaton Grange NSW 2567 02 4677 6000 www.rexnord.com

Rotech Australia

4 Muir Place

Wetherill Park NSW 2164 02 4258 8790

rotechaustralia.com.au

Regal BeloitAustralia

19 Corporate Avenue Rowville VIC 3178 1300 888 853

www.regalaustralia.com.au

Regent Pumps

1-7 Redwood Drive Dingley VIC 3172 03 9551 5111

www.regentpumps.com.au

Roto Pumps

26 Deans Court Dandenong South VIC 3175 03 9794 5200

www.rotopumps.com.au

RPS Australia Group

9B/77 Bayfield Road East Bayswater North VIC 3153 03 9763 3221

www.rps-group.net

Scenic Precision Element

No 5, Sin-Jhan Road

Chian-Jhen District

Kaohsiung City80672 Taiwan +886 7811 1359

www.scenic-seals.com scenic@scenic-seals.com

SEEPEX Australia

Unit 1, 47 Lake Road

Tuggerah NSW 2259 02 4355 4500 info.au@seepex.com www.seepex.com

Industries serviced: Chemicals and Pharmaceuticals, Oil and Gas, Power Generation, Pulp and Paper, Wastewater Products: Centrifugal Pumps

Chemicals Pumps, Chopper Pumps, Dewatering Pumps, Dosing and Metering Equipment, Peripheral Pumps, Positive Displacement Pumps, Repair and Aftermarket, Rotary Pumps, Slurry Pumps, Speciality Pumps, Transfer Pumps

SEEPEX is one of the leading worldwide specialists in the field of pump technology. Our portfolio comprises progressive cavity pumps, macerators, control systems and extensive services. Research, innovation and more than 700 committed employees around the world form the basis of our success.

With major technologies, such as the patented Smart Conveying Technology, we create complete solutions for use in the most important branches of industry. As a

result, our customers profit from lower lifecycle costs, higher productivity and optimised energy efficiency.

The modular design principle utilised by SEEPEX makes it possible to supply custom progressive cavity pumps for virtually any pumped media. Whether thin to highly viscous, with or without solids, abrasive or gaseous – our progressive cavity pumps dose and convey media gently and with minimal pulsation.

We are utilising our developments in the field of digitalisation in a targeted manner and across all market segments, in order to optimise production facilities and processes for our customers. In the process, our focus is on reducing operating costs, increasing productivity and ensuring environmentally friendly work procedures and processes.

We support our customers with a global distribution network and assist them with personal advisory services and professional project management.

SKF Australia

17-21 Stamford Rd

Oakleigh VIC 3166 03 9269 0800 www.skf.com/au

Skyline Pumps

11 Monique Court

Raceview QLD 4305

07 3812 2121

www.skylinepumps.com.au

Sterling Pumps

14 Sharnet Circuit

Pakenham VIC 3810

03 5941 3400

www.sterlingpumps.com.au

Stevco Seals and Pumps Victoria

Unit 10, Epping Business Park

53 Gateway Boulevard

Epping VIC 3076

03 9408 3975

www.stevcovic.com.au

Strategic Achievement

PO Box 429

Scarborough WA 6922

0418 908 555

www.pumptraining.com.au

Submersible

Motor Engineering

9 Ryelane Street

Maddington WA 6109

08 9452 2922

www.smeng.com.au

Best-in-class pumping excellence

Sulzer provides a wide range of pumping solutions, related equipment, and services. Customers benefit from our extensive research and development. We supply highly efficient products that help reduce emissions and energy consumption and our state-of-the-art production and testing facilities around the globe ensure customer proximity. Our market focus is on supply, treatment, and transport of water as well as wastewater collection, fossil-fired, nuclear, and renewable power generation and specific general industries, e.g., pulp and paper, fertilizers, and other markets.

www.sulzer.com

Sulzer Australia

33 Enterprise Circuit

Carrum Downs VIC 3201 03 9775 0522

info.water.au@sulzer.com www.sulzer.com

Industries serviced: Chemicals and Pharmaceuticals, Food and Beverage, Irrigation, Mining, Pulp and Paper, Wastewater Products: Axial Flow Pumps, Blowers, Chemicals Pumps, Chopper Pumps, Dewatering Pumps, Pressure Pumps, Repair and Aftermarket, Slurry Pumps, Submersible Pumps, Transfer Pumps

The Pumps Equipment division specialises in pumping solutions specifically engineered for the processes of customers.

Sulzer provides pumps, agitators, compressors, grinders and screens developed through intensive research and development in fluid dynamics and advanced materials. Sulzer is a market leader in pumping solutions for water, oil and gas, power, chemicals and most industrial segments.

Superior Pump Technologies Unit 23

31 Governor Macquarie Drive

Chipping Norton NSW 2170 02 9727 0525 www.sptaust.com.au

Tallemenco

6/16-18 Cookes Road

Windsor Gardens SA 5087 0414 492 256 www.talle.biz

Techtop Australia

33-35 Gaine Road

Dandenong South VIC 3175 03 9753 2222

techtop.com.au

Teco Australia

335-337 Woodpark Road

Smithfield NSW 2164 02 9765 8118 www.teco.com.au

Triangle Waterquip

13 Hinkler Road

Mordialloc VIC 3195 03 9580 2122

gary.horton@trianglewaterquip.com.au www.trianglewaterquip.com.au

Industries serviced: Filtration, Irrigation, Mining

Products: Dosing and metering equipment, Valves