SPRING 2019 pumpindustry PLUS the Industry Capability Guide The industry’s key reference guide to Australia’s leading providers OIL & GAS MINING IRRIGATION C WATER i OIL & IRRIG CAHV STEWAW CTURING i PUMP INDUSTRY CAPABILITY GUIDE 2020 Using data and AI for smart pumping Operations training opens new doors for WIOA winner ISSUE 29

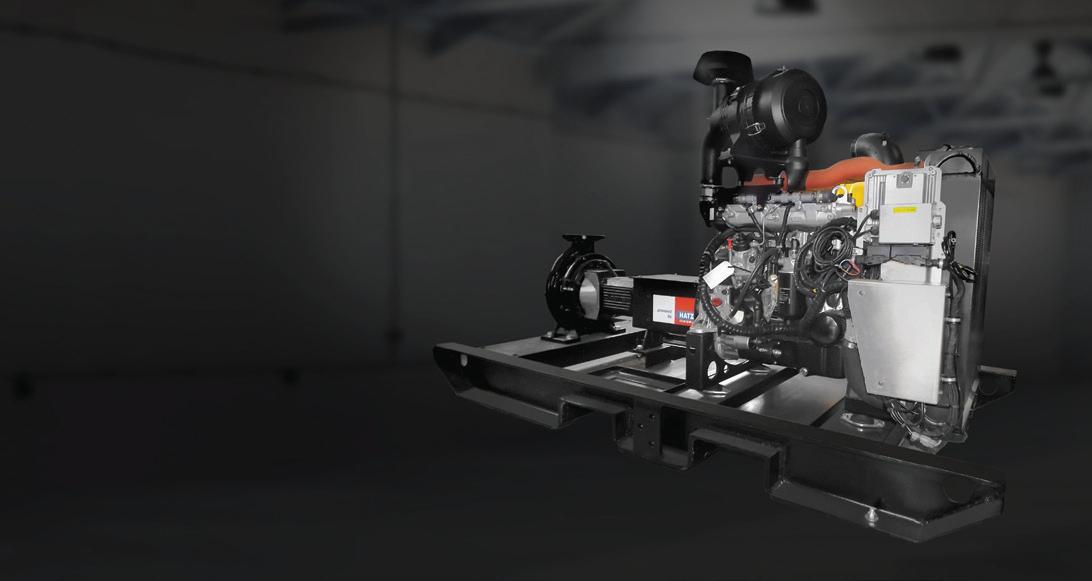

our new heavy-duty Power Generators designed specifically to suit our region’s unique business and farm environment. They all feature the trademark DEUTZ world-class quality, performance and reliability, and they are more fuel-efficient than other products in the market.

canopy is made of galvanised sheet metal and can withstand exposure to the elements. Best of all, the sound proof system exceeds industry requirements. Discover more -

or contact your local Dealer. Stay powered with DEUTZ DEUTZ Australia | www.deutz.com.au | deutzoz@deutz.com The engine company.

Introducing

The

www.deutz.com.au/gensets

Pump Industry Australia Incorporated

PO Box 55, Stuarts Point

NSW 2441 Australia Ph/Fax: (02) 6569 0160 pumpsaustralia@bigpond.com

PIA Executive Council 2019

John Inkster – President Brown Brothers Engineers

James Blannin – Vice President Stevco Pumps & Seals

Kevin Wilson – Treasurer/Secretary Executive Officer

Alan Rowan – Councillor Executive Officer – Publications and Training, Life Member

Ken Kugler Executive Officer – Standards, Life Member

Louise Black – Marketing and Statistics Executive Officer

David Alexander – Councillor KSB Australia

Andrew Black – Councillor Envirotech Water Solutions

Mike Bauer – Councillor DynaPumps

Jim Athanas – Councillor Xylem Water Solutions

Hem Prakash – Councillor Davey Water Products

Anant Yuvarajah – Councillor ASC Water Tanks

President’s welcome

Hello all and welcome to this Spring Edition of Pump Industry Magazine.

At the time of writing three events were planned with Breakfast Meetings in Sydney and Melbourne, and an Installation and Commissioning Course in Melbourne all scheduled for September. In July, we held a very successful Technical Meeting in Brisbane in conjunction with Irrigation Australia (IAL) at its premises in Murarrie. The topic was ‘Training Towards a Sustainable Pumping and Irrigation Future’, and was attended by 30 members and non-members alike.

The purpose was to find out what IAL and its stakeholders are doing to ensure that they have enough qualified and certified people to cope with the increasing demand in the irrigation industry; Geoff Harvey of IAL did a presentation on its two-day Irrigation Pumps and Systems Training Course and Path to Certification.

Further to this, IAL has extended an invitation to PIA members the opportunity to send suitable persons to its next two-day course titled ‘Irrigation Pumps and Systems’, to be held in Brisbane on 15 and 16 October, where PIA members would pay the same fee as IAL members through our MOU.

This leads me to the question: Why can’t our industry have similar training courses as a Path to Certification?

Imagine if we were able to offer a Certificate III in Pumping covering different competencies including selecting pumps, reading friction loss charts, installation, troubleshooting, commissioning – the list goes on.

IAL has done its very successfully but it has taken a few years to get there. IAL as the peak national organisation for the entire irrigation industry is a Registered Training Organisation (RTO 91313) under the name Irrigation Training Australia, providing the industry with nationally accredited training and qualifications.

This question was put to the attendees at Murarrie and the answer was a unanimous YES, with a number coming up to me after saying they would support it. To follow up on this thought, Council at our last Hot Air Meeting held on 30 July agreed to ask IAL to scope a PIA competency-based training program specifically for the pump industry.

IAL is willing to do so and it is hoped that in the future we might also be able to offer an Accredited Pump Training Course leading to a recognised Australiawide certification/qualification under the umbrella of IAL as an existing RTO.

IAL is working on this for us and it is hoped we will have something for Council to consider in the coming weeks and maybe even to present at the AGM in November.

The benefits to PIA members would be enormous, bearing in mind that part of our mantra is that PIA endeavours to encourage the ongoing development of our industry.

In recent editions I have commented on the shortcomings of the selfregulation and certification processes in the building industry.

Well if you watched the excellent Four Corners program on Monday 19 August entitled ‘Cracking Up', it is clear to see where this self-regulation has got us.

Just three days into his job as NSW Building Commissioner, David Chandler stated some of the units he investigated were “of the most poorly built he had seen”. It appears that the problem does not just lie with the privatisation of the Building Certifiers; it seems the whole system is flawed from the planning stage through to the engineering design to the construction of and finally certification.

Fortunately not all designers, engineers, building companies and certifiers fail in their responsibilities, but there are enough to give the industry and legislators serious problems.

Those in the fire industry need to ensure they don’t fall into the same category.

This was highlighted at the recent FPAA seminars co-sponsored by PIA in Melbourne (100 attendees) and Sydney (169 attendees) in July titled ‘Fire Pumpsets: Selection, Installation, Commissioning and Servicing’. Both were well patronised, demonstrating the huge interest in this area. Ken Kugler, our Executive Officer for Standards, was one of the presenters.

FPAA is planning a repeat of the seminars because of the high interest shown and will likely run in other states.

As you know, we continually seek to increase our membership, so I ask that if you know someone who would benefit or be able to contribute to PIA, please extend an invitation for them to join; the more members we have, the more relevance we have and more importantly it extends our knowledge and skills base. Any ideas or thoughts you have to improve PIA please make yourself heard; we need and welcome your input.

John Inkster President

2 pump industry | Spring 2019 | Issue 29 www.pumpindustry.com.au PUMP INDUSTRY

HAVE AN

WE ALSO OFFER A COMPLETE MANUFACTURE TO DESIGN SERVICE

We provide collaborative, quality design and development services ranging from concept to high volume manufacturing. As a leading wholesale plumbing business, we carry various brands and use innovative technologies such as 3D printing to bring concepts to life. In addition, our team of engineers can ensure products hold current industry specific standards and licenses.

So, if you have a great idea for a product, we’re here to help. We can assist you from inspiration to reality with collaborative design, engineering and manufacturing resources. Beyond that we can distribute your product nationwide and present it to significant players in the Australian plumbing industry.

At Austworld, we may be one of Australia’s largest suppliers and manufacturers of quality plumbing and drainage solutions, but when it comes down to it we’re a family that’s here to help you achieve the best for your family.

AUSTRALIA

1300 780 430

PIA MEMBER NEWS

INDUSTRY

CONTENTS Cover image highlights our article on the 2018 WIOA SA Operator of the Year. pumpindustry PLUS the Industry Capability Guide The industry’s key reference tool to Australia’s leading providers PUMP INDUSTRY GUIDE 2020 Using data and AI for smart pumping Operations training opens new doors for WIOA winner ISSUE 28 SPRING 2019 pu mp indu s tr Pump 3,153 This publication has been independently audited under the AMAA’s CAB Total Distribution Audit. Audit Period: 1 October 2018 to 31 March 2019 Published by Monkey Media Enterprises

204/23–25

Collingwood

monkeymedia.com.au info@monkeymedia.com.au

magazine@pumpindustry.com.au

Editor:

Booth

Development Managers:

Bryers, Rima Munafo Design Manager: Alejandro Molano Designers: Jacqueline Buckmaster, Danielle Harris Publisher: Chris Bland Managing Editor: Laura Harvey Operations Manager: Kirsty Hutton ISSN: 2201-0270 NEWS Jail sentence for solar heat pump installation fraud .................. 6 ‘Flushability’ trials to help inform national standard .................. 7 Sydney Water’s new procurement strategy looks to partner for success ........................................................ 8 Australia’s largest sewage storage facility completed ............. 10 New booster pump station improves Leeman water supply .... 12 New wave energy converter to be trialled in Tasmania ............ 14

ABN: 36 426 734 954

Gipps St

VIC 3066 P: (03) 9988 4950 F: (03) 8456 6720

pumpindustry.com.au

Editor: Lauren Cella Assistant

Eliza

Business

Alastair

HT thrust bearing: The exclusive Caprari patent 16 How to maximise the lifecycle cost of your pump ................... 18 Here comes the story of the Shurricane .................................. 20

NEWS The pioneering technology cutting cleaning time in half ........ 22 Viega’s Propress system provides the perfect alternative to traditional plumbing solutions .............................................. 24 Practicality and functionality: Providing superb motor management .............................................................................. 26 Flexibore chosen for Adelaide irrigation project ...................... 28 Volvo Penta: The heart that never stops .................................. 30 Motor starting for optimum performance ............................... 32 Drive Systems opens in WA with stocking of genuine Rexnord Omega Couplings........................................................ 34 Monitoring remote pump infrastructure: Better, easier and cheaper using 4G ......................................... 36 This magazine is published by Monkey Media in cooperation with the Pump Industry Australia Inc. (PIA). The views contained herein are not necessarily the views of either the publisher or the PIA. Neither the publisher nor the PIA takes responsibility for any claims made by advertisers. All communication should be directed to the publisher. The publisher welcomes contributions to the magazine. All contributions must comply with the publisher’s editorial policy which follows. By providing content to the publisher, you authorise the publisher to reproduce that content either in its original form, or edited, or combined with other content in any of its publications and in any format at the publisher's discretion.

The Australian manufacturing industry is at a crossroads. Transforming the materials we dig up or grow into the products we use every day requires enormous amounts of heat, and rising electricity costs and inefficient processes means many businesses have seen their gas and electricity bills double over the last two years. A report from Beyond Zero Emissions shows there are opportunities for manufacturers to reduce costs by generating heat through the smart use of renewable electricity, with heat pumps one technology that they can take advantage of.

SMART PUMPS

5 pumpindustry ENERGY EFFICIENCY Electrifying industry – new opportunities for improving energy efficiency ............................ 38

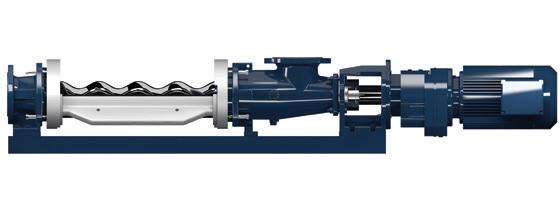

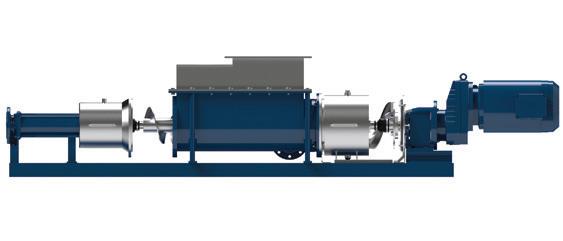

Artificial intelligence improves pump efficiency at Melbourne Water treatment plant.................... 41 WIOA Career change opens opportunities for Leigh Creek local ............................................. 44 PUMP HANDBOOK Efficient operations of pump systems (Part 1) ............. 50 REGULARS President’s welcome .................. 2 Ask an expert: Technological advances for progressive cavity pumps with quick and easy maintenance solutions. ............... 48 Pump school: Impeller trimming – changes in performance (Part 1) 54 Editorial schedule .................... 56 Advertisers’ index ................... 56 www.pumpindustry.com.au pump industry | Spring 2019 | Issue 29

Jail sentence for solar heat pump INSTALLATION FRAUD

The Brisbane District Court sentenced a plumber to four and a half years of jail time for fraud and production of false and misleading documents claimed he had installed more than 400 solar heat pumps.

The sentence, handed down on 5 August 2019, is the result of an investigation by the Clean Energy Regulator (CER) relating to the Small-Scale Renewable Energy under the Renewable Energy Target.

Brett Stephen Muldoon, who will serve a minimum term of 15 months before being eligible for parole, obtained just under $400,000 by producing false and misleading documentation claiming that non-existent solar air-source heat pumps had been installed at more than 400 properties throughout Queensland.

This enabled him to improperly create 11,180 small-scale technology certificates between 2013 and 2014.

In sentencing, Judge William Everson stated this was a sophisticated fraud, noting the length of time of the conduct and the amount of money taken.

Judge Everson said “a deterrent sentence is called for fraud of this magnitude” and that Mr Muldoon’s conduct was “extremely selfish and reprehensible”.

Mr Muldoon’s conviction was under s408C of the Queensland Criminal Code. The one charge accounted for 415 acts of fraudulent behaviour committed by Mr Muldoon.

The CER requires a high level of compliance with scheme obligations, and has a range of monitoring and enforcement powers under legislation.

Fraudulent activity, such as providing false information to create small-scale technology certificates, is a threat to the integrity of the schemes administered by the CER.

The CER warns that individuals and companies who participate in the schemes and wilfully commit an act of fraud or non-compliance, such as falsely creating certificates, will be subject to enforcement action which may lead to criminal conviction and jail, as in this case.

pump industry | Spring 2019 | Issue 29 www.pumpindustry.com.au 6 NEWS DiamondFace

Unbeatable performance for mechanical seals EagleBurgmann Australasia Pty. Ltd. 16 Stennett Road, Ingleburn, NSW 2565 Sydney, Australia Phone: +61 2 9605 0600, info@au.eag eburgmann.com http://eagleburgmann.com.au DiamondFace by EagleBurgmann is the solution for difficult mechanical seals applications. Wherever poor lubrication, partial dry running, abrasive media or electrochemical corrosion leads to high wear, DiamondFace offers the most robust solution. ANZ_DF-SA_185x125_1017_END.indd 1 04.10.17 14:27

technology:

‘Flushability’ trials to help inform national standard

Queensland Urban Utilities is undertaking a new trial to test the ‘flushability’ of products like wipes, cotton buds and paper towels, in a bid to help create Australia’s first national standard for products that want to claim the label of ‘flushable’.

Testing has started in Australia’s largest replica sewer at Queensland Urban Utilities’ Innovation Centre at the Luggage Point Resource Recovery Centre.

Queensland Urban Utilities spokesperson Michelle Cull said scientists were using the one-of-a-kind facility to study how wipes break down in the sewer network.

“Wipes don’t disintegrate quickly like toilet paper and can cause blockages not only in your household plumbing but our sewer network,” Ms Cull said.

“Creating a new national standard will lead to clearer labelling and give consumers confidence that they’re only flushing products which will break down after they’re flushed.

“Until then, the best advice is to only flush the Three Ps – pee, poo and (toilet) paper.”

In 2018, Queensland Urban Utilities removed around 120 tonnes of wet wipes – which is the equivalent of 34 hippos – from the sewer network.

Queensland Urban Utilities sits on the Water Services Association of Australia (WSAA) Standards Committee, which is hoping to have the new national standard finalised by the end of 2019 to replace industry self-regulation.

The national standard will cover the ‘flushability’ of not just wipes, but other disposable products such as tampons, cotton buds, kitty litter, paper towels and single-use toothbrushes.

NEWS www.pumpindustry.com.au pump industry | Spring 2019 | Issue 29 7

Sydney Water’s new procurement strategy looks to partner for success

Sydney Water has developed a new procurement strategy, called ‘Partnering for Success’, which will see a new Regional Delivery Consortia appointed to manage design, construction and maintenance and facilities management in each of its three regions (North, South and West) for the next ten years.

The strategy also includes Shared Purchasing, which will simplify how Sydney Water and its partners will procure specialised goods and services that can’t be self-performed.

Sydney Water’s area of operation will be divided into north, south and west, and the consortia will be responsible for operations in these areas for the next ten years. Further to this new procurement approach, Sydney Water has also entered into a long-term partnership with Aurecon and ARUP who will work with the Integrated Systems Planning team to form a truly integrated planning function, bringing the right mix of capability to co-create projects and deliver plans successfully.

The integrated team will also perform technical assurance and project engineering. This will ensure that planned benefits are realised through delivery and maintenance.

Aurecon’s Global Head of Water, Kevin Werksman, said water utilities were increasingly seeing the benefits of the partnership model as being able to much better leverage value in a collaborative, non-transactional environment.

“As well as additional technical engineering smarts, Aurecon and ARUP will provide additional advisory services such as asset management and community consultation,” Mr Werksman said.

The integrated team will also perform technical assurance and project engineering. This will ensure that planned benefits are realised through delivery and maintenance.

Shared Purchasing is a new approach adopted by Sydney Water to simplify its procurement of specialised goods and services.

Some day all motors will be this efficient. But why wait?

The idea is beautifully simple. Combine conventional stator technology and a magnet-free rotor design, take a top-of-the-line industrial drive and software, and optimize the whole package for variable speed pump and fan applications. What you get is the performance of a permanent magnet motor at IE4 efficiency and the simplicity and ease of service of a regular induction motor.

Stop waiting and take a closer look on www.abbaustralia.com.au

ABB Australia Pty Limited Contact Centre: 1800 222 435

pump industry | Spring 2019 | Issue 29 www.pumpindustry.com.au 8 NEWS

—

First requests for tender have been sought for pipes and fittings, and valves and actuators.

Additional RFTs will be issued on eTender for:

• Pump supply and servicing

• Plant equipment and hire

• Waste management services

• Electrical goods and services

• Network support

• Industrial cleaning

Head of Supply Chain and Property at Sydney Water, Xavier Decomps, said, “Shared Purchasing simplifies how we and our partners will procure specialised goods and services that can’t be self-performed.

“By pooling our purchasing in this manner, we’ll achieve economies of scale, increase our buying power and develop deeper relationships with preferred suppliers throughout the entire asset lifecycle.”

Under its new Partnering for Success model, Sydney Water and its partners will use a series of NEC4 contracts to procure these and other specialised goods and services.

Sydney Water has been an early adopter of the NEC4 suite of contracts to support the rollout of its new procurement strategy.

Head of Delivery Management at Sydney Water, Mark Simister, said Sydney Water is the first major infrastructure company in Australia to use the NEC4 contract approach to deliver new works.

“The contract will help simplify our supply chain and deliver significant benefits to Sydney Water as an organisation, to our customers and to our partners, through increased efficiency, cost savings, continuity of work, resource availability and partner capability by incentivising high performance and increasing productivity.

“By doing this, we’ll give our partners more certainty, and drive better decision-making across the whole lifecycle of our assets, improving our productivity and delivering value for our customers.”

NEC4 Chairman, Peter Higgins, said, “Our contracts have already been used to great success on water projects across the world, and we’re confident that Sydney Water will achieve the same results as our other partners.

“NEC’s fundamental principles of risk management, alliance and transparency align perfectly with the New South Wales Government’s recent ten-point plan for infrastructure delivery, and the alignment in economy, government and language makes Australia a key growth market for us.”

Sydney Water is looking to not just change the way it procures services, but to transform the way that it does business.

In March 2019, Sydney Water was recognised by the UK’s Institute of Civil Engineers (ICE) for becoming the first international organisation to adopt the principles of ‘Project 13’ for the rollout of P4S.

Project 13 is an industry-led movement to improve infrastructure delivery, so it provides better outcomes for customers, whilst moving to a more sustainable and collaborative business method.

ICE’s Director General and Chair of the Project 13 Board, Nick Baveystock, congratulated Sydney Water for being the first international adopter of Project 13. Mr Baveystock said he was delighted to see Sydney Water embed the Project 13 principles into its work on P4S and help the delivery of infrastructure move from a transactional business model to a more collaborative and sustainable one.

Mr Simister said, “The appointment of the three Regional Delivery Consortia in our north, south and west operational areas will see the need for organisational transformation to support, enable and integrate the Regional Delivery Consortia.

“Given the decade-long term of these contracts, this is a once in a generation change which will have a lasting impact on Sydney Water, the industry, and its customers.

“The scale, complexity and impact of this change cannot be underestimated and, done right, will create an enduring legacy.

“This approach will help the delivery of infrastructure move from a transactional business model to a more collaborative and sustainable one, which will focus on customer outcomes, bring together skills and technologies in a collaborative environment, properly integrate teams across projects, and foster long-term relationships.

“Regional Delivery Consortia Contracts will be awarded to the three successful consortia at the end of the year with a ‘go-live’ date of July 2020.”

Specialising in custom design, manufacture, repair and service of centrifugal pumps for over 30 years

• Complete range of API 610 (ISO13709)

• Hydraulic and mechanical design

• Custom engineering, retro-fit, redesign

• Performance testing

• Service and repair

UNITED PUMPS

www.unitedpumps.com.au

T: +61 3 9464 9500

31 Western Avenue, Sunshine Victoria 3020, Australia

E: unitedpumps@unitedpumps.com.au

NEWS www.pumpindustry.com.au pump industry | Spring 2019 | Issue 29 9

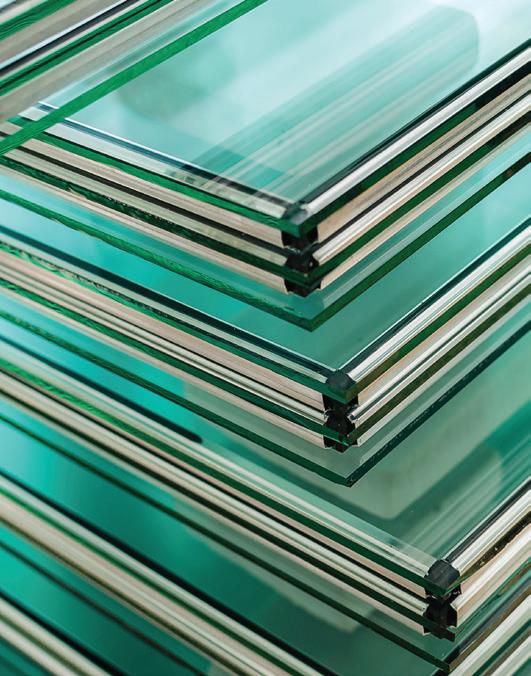

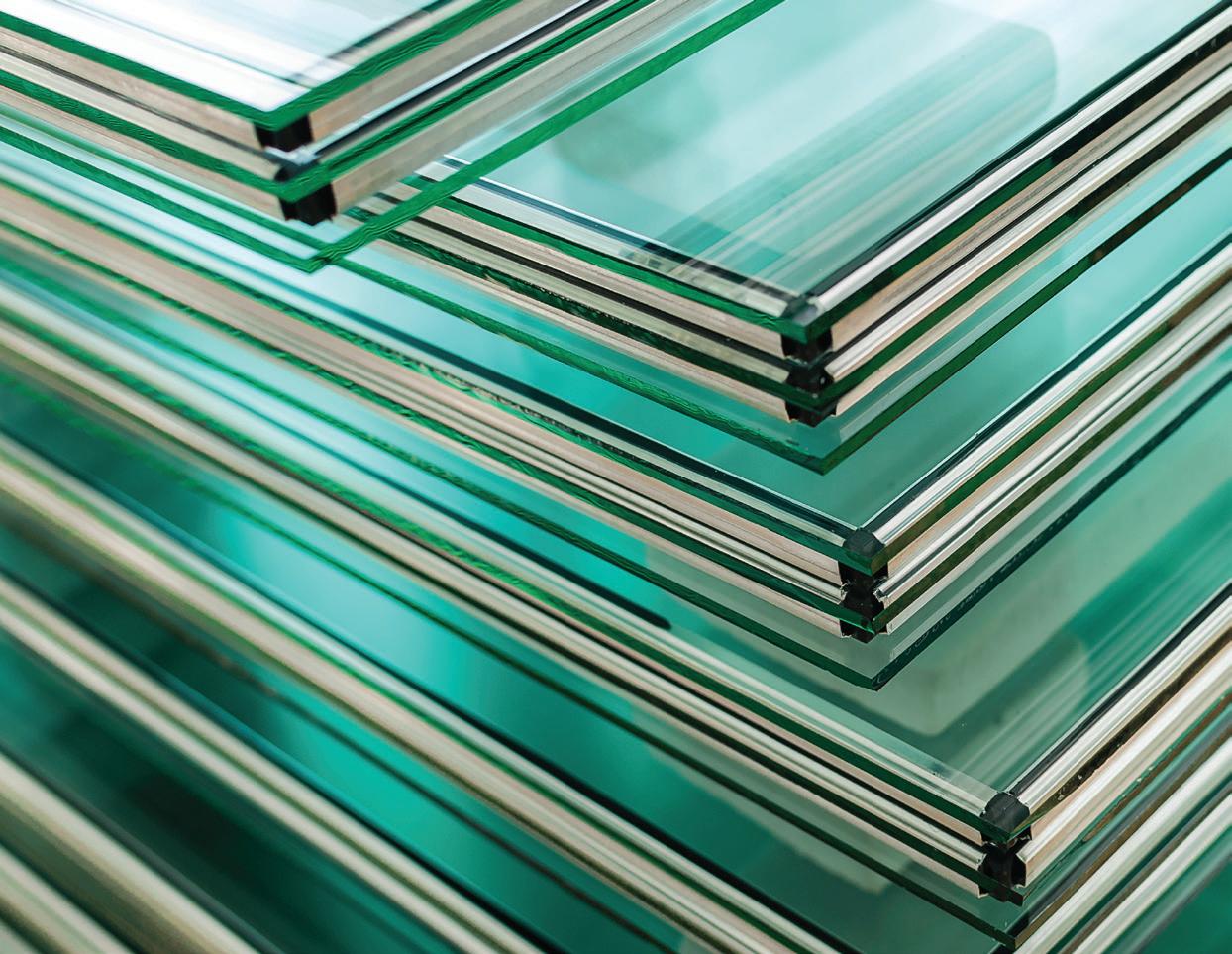

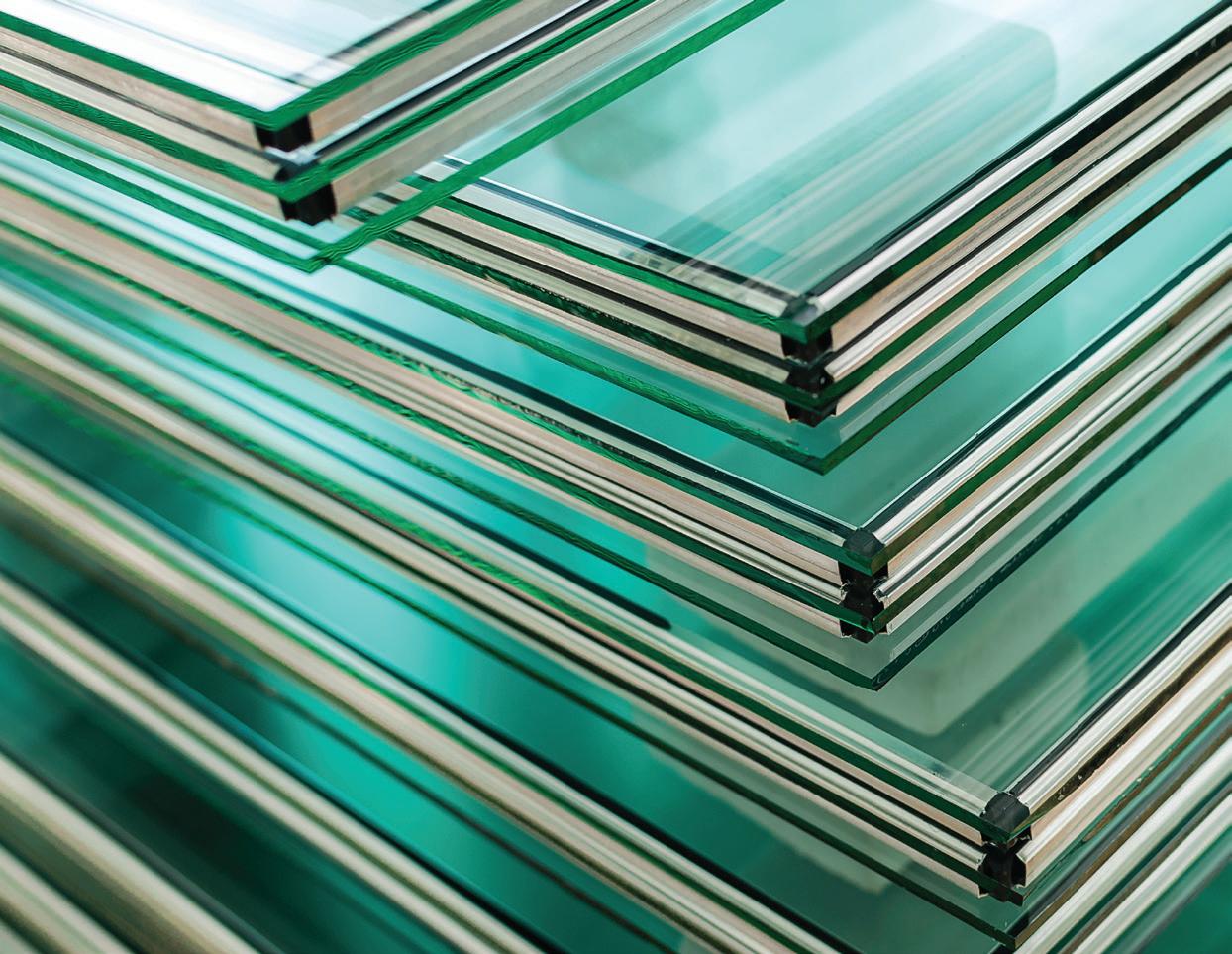

Australia’s largest sewage storage facility completed

Yarra Valley Water has completed construction on Melbourne’s new Craigieburn Sewage Transfer Hub, a critical piece of infrastructure which will service up to 420,000 people in Melbourne’s north.

The $69 million project will service developments between Craigieburn and Wallan, allowing Yarra Valley Water to collect, store and transfer sewage to the metropolitan sewerage network for treatment.

The Hub comprises two 15 million litre glass-coated steel tanks which are both the size of six olympic-size swimming pools and are the largest tanks of their kind in the southern hemisphere.

More tanks with a total capacity of 210 million litres will be added as the population of the area continues to grow.

Yarra Valley Water Managing Director, Pat McCafferty, said the Hub is innovative because it can be expanded to keep up with growth in the region.

“The Hub is an adaptive piece of infrastructure which will expand with development in the area. It’s also a much more cost-effective solution than building a large sewer at twice the cost.

“Building flexible infrastructure which can grow with the community allows us to invest money where it’s needed most, while still ensuring we’re able to service the community for years to come,” Mr McCafferty said.

The enormous project provided 15,000 hours of employment and experience for apprentices, trainees and engineering cadets.

Melbourne’s northern growth corridor is one of the fastest growing areas in Australia and the Craigieburn Sewage Transfer Hub is just one example of the vital projects that Yarra Valley Water is undertaking in the region.

Mr McCafferty said that Yarra Valley Water is working hard to deliver the infrastructure that Melbourne’s northern growth corridor needs.

“It wasn’t long ago that there was virtually no existing water and sewerage infrastructure in Melbourne’s outer north. It’s staggering to think of how far the area has come and how much further it will go in the next few years.”

pump industry | Spring 2019 | Issue 29 www.pumpindustry.com.au 10 NEWS

Zetco has all the options Australian ingenuity with Italian quality you can trust

Don’t risk being non-compliant with the new Queensland Building & Construction Commission regulations. Manufactured to Zetco’s high standards in Italy, our extensive range of WaterMarked valves passes rigorous design and testing processes to ensure that every valve is of premium quality. Ask for Zetco WaterMarked valves at major plumbing retailers. Zetco Valves. Best range. Best quality. Best brand.

1300 659 639 www.zetco.com.au IAPMO WM-000110 AS 5830.1

New booster pump station improves Leeman water supply

A$2.7 million project to improve the reliability of the water supply in the Western Australian town of Leeman has been completed, with the replacement of an old elevated water tank with a new booster pump station.

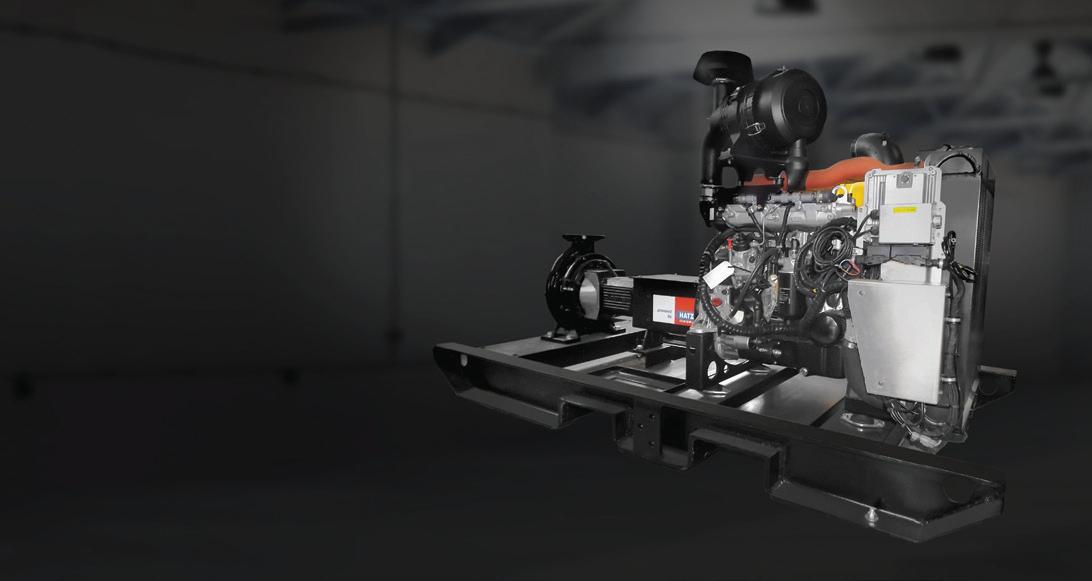

Irrigation equipment works hard, so it needs a hard-working engine. Meet Hatz Diesel’s compact and all new H-50 Series. You know irrigation, we know diesel engines

• Up to 90 kg lighter than other engines in the power range

• Long engine life and premium components

• 500-hour maintenance interval

• 18.4 kW to 64 kW*

• Unsurpassed fuel efficiency

*(intermittent loading / ISO 3046-1)

POWER

pump industry | Spring 2019 | Issue 29 www.pumpindustry.com.au 12 NEWS

Find out more today hatz.com.au 1300 796 900

CREATING

SOLUTIONS.

The project is part of the Western Australian Government’s $35.2 million investment in 2019-20 for water projects in the Mid West region.

Work began in September 2018 to replace an aging elevated water tank, built around five decades ago, with a modern booster pump station.

The new booster pump station was constructed at the existing tank site north of Vivian Street on Indian Ocean Drive, and pumps water directly from the Mount Peron ground level tank to the local community.

The new pump station has provided the dual benefit of improved water pressure and reliability of water supply to the town.

Leeman is supplied water as part of the Leeman-Greenhead Scheme, which provides water to around 900 households and businesses in Leeman and surrounding areas.

The project was completed on time, with the pump station successfully

connected to the town’s water supply and the old tank taken offline in June 2019.

Work was completed by Guidera O’Connor, with three Western Australian subcontractors and suppliers also involved, including K&K Electrical, D & Z Constructions and SANDERS Demolition.

Western Australian Water Minister, Dave Kelly, said that Leeman is just one of the many towns across regional Western Australia which will benefit from the development and upgrade of essential water and wastewater infrastructure in 2019-20.

“Last financial year, the McGowan Government, through the Water Corporation, invested $25.9 million in water projects in the Mid-West region and that number will jump to $35.2 million this financial year,” Mr Kelly said.

“I would like to thank the local Leeman community for their cooperation during this important work.”

NEWS www.pumpindustry.com.au pump industry | Spring 2019 | Issue 29 13

59 Export Dr, Brooklyn VIC 3012 Email: sales@wellcross.com.au wellcross.com.au 656 276 AUSTRALIA’S TRUSTED DIESEL POWER AUSTRALIA’S TRUSTED DIESEL POWER Adelaide | Brisbane | Melbourne | Perth | Sydney | Townsville ARE YOU RUNNING YOUR PUMPS WITH GENERATORS? We can custom design generators to suit your pumping and irrigation needs, soft start, VFD or DOL.

NEW WAVE ENERGY CONVERTER TO BE TRIALLED IN TASMANIA

The Australian Renewable Energy Agency (ARENA) has announced $4 million in funding to install a pilotscale wave energy converter off the coast of King Island, Tasmania.

The $12.3 million project by Wave Swell Energy will involve the design, construction, installation and operation of the UniWave 200, a 200 kW wave energy device off the coast of King Island.

The project will also be integrated with the King Island microgrid operated by Hydro Tasmania, which received $6 million in ARENA funding in 2011 to demonstrate the integration of several renewable resources and energy management technologies.

The device will be partially submerged as it sits on the seabed and has an opening on one side to allow the movement of the waves in and out of the chamber.

Water rises and falls inside the chamber, causing the pressure of the air trapped above to change between negative and positive pressure. The pressure fluctuations force the air to pass through the turbine at the top of the chamber, generating electricity.

ARENA CEO, Darren Miller, said the project will offer additional insights into combining wind, solar and wave energy.

“Wave energy has the potential to be integrated into microgrids, particularly on island locations with limited space, to reduce the need for significant battery storage due to the relative predictability and consistency of wave energy,” Mr Miller said.

“The tidal and wave sector in Australia is still in the early demonstration phase. Wave Swell’s unique approach to wave energy will gain valuable knowledge and help to see whether this is a viable option for generating renewable energy.”

Wave Swell Energy CEO, Dr Tom Denniss, said Wave Swell Energy is extremely pleased to have such a substantial component of the UniWave 200 King Island Project funded by ARENA.

“The project, aimed at demonstrating the commercial viability of the technology, is expected to be the first of many wave energy projects utilising this unique worldleading intellectual property. ARENA’s role in the King Island project represents a vital component of the ultimate commercialisation of the technology,” Dr Denniss said.

14 pump industry | Spring 2019 | Issue 29 www.pumpindustry.com.au NEWS

We Lead. Others Follow.

You want a trusted name when it comes to providing engineered power transmission products that improve productivity and efficiency. Rexnord provides superior products for your industrial applications world wide. We work closely with you to reduce maintenance costs, eliminate redundant inventories and prevent equipment downtime.

Rexnord® Falk® Steelflex® Grid Couplings — known for durability in critical applications, proven performance and versatile design. With replace-in-place design, Falk Steelflex Grid Couplings offer a low-maintenance solution for any application in the pump industry.

Rexnord Falk Lifelign® Gear Couplings — triple-crowned teeth are crowned on the root, tip and face to articulate freely and minimize wear caused by misalignment. By eliminating tip-loading while reducing backlash and radial clearances, Lifelign’s triple-crown teeth can help protect equipment from damaging loads.

Contact Rexnord today to see which coupling is right for your application. Tel 02 4677 6000

www.rexnord.com

HT THRUST BEARING:

The exclusive Caprari patent

Maximum resistance and extreme reliability for the MAC6, MAC8 and MAC10 submersible motors.

Innovating to discover increasingly efficient solutions for water management is a fundamental part of Caprari's core business.

Thanks to its internal research and development division and production capabilities, the Modena-based industrial group is able to offer highly efficient and reliable products.

Each new solution is designed to meet a specific market demand in the most effective and technologically advanced way.

With this objective in mind, Caprari internally develops exclusive patents aimed at improving the performance of its products.

Starting from the design stage, the company pays the utmost attention to all the measures that can improve the life of the product and has patented several devices like Defender®, Easy Check, Sand-Out system, Smart-Fix

system, ConnectoFlex, HT coupling and HT-High thrust bearing that protect the pump and extend the product lifecycle, reducing its environmental impact and overall costs for the end user.

The MAC series submersible motors have significantly increased performance thanks to the innovative HT-High thrust bearing, patented exclusively by Caprari (Caprari International Patent), with margins of tolerance that make the device extremely reliable in all conditions of use.

Today, the HT-High thrust bearing is present in MAC6 submersible motors, as well as in the MAC8 and MAC10 largersized motors, both in cast iron and stainless steel versions.

This special patent allows obtaining a more durable product and improved axial load resistance.

Its performance provides the motor with a structural oversizing with respect to the actual thrust that

the wet end generates, even during operation transients.

To achieve this result, the cage, supports and skids have been completely redesigned on new concepts.

With the same dimensions, the HT thrust bearing withstands at least three times the load of a traditional Mitchell bearing.

Thanks to its exclusive and diversified know-how, Caprari provides complete solutions for every major water requirement, including collection from deep wells, wastewater and drain water lifting, water supply and distribution for residential, industrial and agricultural purposes and various water treatment applications. Innovation and reliability of exclusive products, and services dedicated to the customer; these are the strategic assets that have always distinguished Caprari.

16 pump industry | Spring 2019 | Issue 29 www.pumpindustry.com.au

PIA MEMBER NEWS | PARTNER SOLUTIONS

For more information on our motors and patents, visit www.caprari.it.

Designing the future with highly appreciated and advanced solutions for Industrial Applications. Pumps and electric pumps able to raise primary process water and waste water. ENERGY | METAL INDUSTRY | PAPER INDUSTRY | FOOD & BEVERAGE YOUR RELIABLE PARTNER IN INDUSTRIAL APPLICATIONS EXPERIENCE SINCE 1945 www.caprari.com |

How to

THE LIFECYCLE COST OF YOUR PUMP MAXIMISE

When procuring a pump, upfront cost is often a major consideration in the decision-making process. However, according to a report issued by the Victorian Government, the initial cost accounts for less than ten per cent of the lifecycle cost, with energy and maintenance making up the bulk of these costs at between 50 and 95 per cent. Therefore, it is important to consider the long-term costs when selecting a pump to get the most cost-effective solution. Here, we look at what factors can influence and maximise the lifecycle cost of your pump.

While there are inevitable costs that are hard to control such as environmental, disposal and installation costs, end users can realise long-term savings with reduced maintenance, energy costs and downtime.

Selecting a pump: quality over cost

One important choice when selecting a pump that will influence its lifecycle costs is the quality of the equipment. A quality, reliable, well-built pump will likely have a lower lifecycle cost than a cheaper, lightweight pump.

Going for a cheaper option may result in a lesser quality product, especially if the materials selected are not suitable for the application. If this is the case, lifecycle costs can quickly increase as there is a higher chance of premature failure or unexpected servicing and replacement costs.

Along with materials, a high-quality product will have gone through rigorous testing to ensure it will run reliably and will be defect-free at the time of purchase.

Another area where quality can be realised is through the level of customer service you receive from the manufacturer. A manufacturer with top quality service will be able to provide prompt technical support to help troubleshoot any problems so that minimal downtime is experienced and that the pump is back to operating efficiently as soon as possible.

Companies with quality customer service will also be able to provide an expert opinion when selecting a pump to ensure it will be the best fit for your application so you can realise longterm cost savings.

Getting the right size pump

Selecting a correctly sized pump is imperative to reduce lifecycle costs. While it might be tempting to get a smaller pump to reduce costs or a larger pump to account for possible higher pumping requirements, these will ultimately result in higher costs in the long term.

An undersized pump will result in reduced water efficiency, while an oversized pump will have a higher installation cost, as well as higher energy usage and wear rate, so more frequent maintenance will be required.

Therefore, selecting a pump that is correctly sized to meet your exact needs will ensure the best energy efficiency and least energy wastage, and will have optimal lifespan and reliability.

Maximising energy efficiency

For applications such as irrigation where variable speed and flow rates may be needed, investing in a pump with a variable frequency drive (VFD) will help reduce lifecycle costs.

VFDs can be programmed to run the pumps at a certain speed and flow rate for different connected zones so that it is always running to its best efficiency point (BEP).

While a VFD will increase the initial cost of the pump, if the pump is not running to its BEP, it will experience increased wear and require more frequent maintenance and parts replacement, and have high energy consumption.

Quality and reliability at the heart of Franklin Electric

Malcolm Eyre, Managing Director at Franklin Electric, said the company understands its customers need for products that are durable and long lasting to ensure optimal lifecycle costs.

“Nothing less than having the highest quality products and service are acceptable for our customers, because anything else is too costly.

“That is why we are committed to the manufacture of highquality, reliable products in our facilities in the US, Germany and Italy. With solid engineering, our products are designed to stand the test of time.

“We also have a rigorous testing program. In our laboratories, we test the products for performance and endurance before they leave the manufacturing facility.”

Franklin Electric also places a high value on customer service and is committed to finding customers the best solution for their application, and providing prompt customer support to troubleshoot any problems.

“We value our customers and will go out of our way to make sure their pumps remain running at their best so the greatest value for lifecycle costs can be realised.”

18 pump industry | Spring 2019 | Issue 29 www.pumpindustry.com.au PIA MEMBER NEWS | PARTNER SOLUTIONS

Reliable irrigation solutions

Franklin Electric has over 75 years of experience providing industry-leading technical service to the irrigation industry, providing support and advice to keep you pumping in even the most rural areas.

Leading the industry in service standards

www.franklin-electric.com.au 1300 670 060

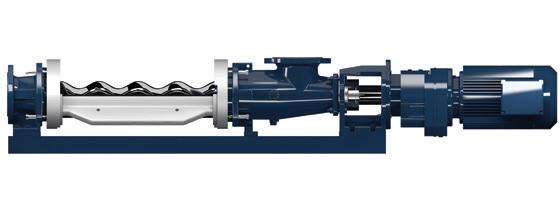

HERE COMES THE STORY OF THE SHURRICANE

Ebara has rethought the hydraulic design used in multistage pumps. Utilising the latest in computational fluid dynamics and design, followed by rigorous testing, Ebara has developed a unique impeller design that offers solutions and value to the customer – the Shurricane.

The imbalance of forces acting on the front and rear shrouds of a conventional impeller results in axial thrust. This thrust load is compounding in multistage pumps, and has to be allowed for in the pump design.

For pumps with conventional impellers, the existing solutions include having a thrust bearing built in the pump, or to use a special motor fitted with a larger thrust bearing. Both are costly and can be complicated. Another solution has been to simply have a smaller diameter back shroud to reduce the thrust.

Ebara has rethought the hydraulic design used in multistage pumps. Utilising the latest in computational fluid dynamics and design, followed by rigorous testing, Ebara has developed a unique impeller design that offers solutions and value to the customer.

The optimised shape of the Shurricane maintains high efficiencies and very significantly reduces the axial thrust –meaning that any standard IEC motor can be used and bearing life is improved.

Built like a Katana

A Katana is a traditional Japanese product manufactured with care and precision. Only years of experience can give the necessary capacity to build a masterpiece.

This is what Ebara does with its pumps. The result of over 100 years of Japanese experience in pump design and manufacturing, their pumps offer high-quality performance, reliability, and cutting-edge technology.

Ebara’s vertical multistage pumps are manufactured in Italy to the highest standards of quality, and achieve reliable operating performance by means of

strict technical evaluation criteria and control programs that involve the whole manufacturing process.

Suitable for a range of applications

The range of Ebara vertical multistage pumps are suitable for a wide range of applications, in the industrial, commercial and agricultural fields. They can be used at water treatment plants (for reverse osmosis and filtration), for the pumping of hot or cold water for HVAC systems, for the pumping or boosting of water in general, and in boiler feed, irrigation and fire fighting systems.

The pumps can be coupled with any motor, anywhere. Optional materials are part of the unique hydraulic design, and there are optional connections for customers to consider.

Product features

Innovative hydraulic solutions

• Commercial motors can be fitted to all of the pump models without any modifications thanks to low pump axial thrust load

• Long life of the motor bearing

• Patent Application

Energy saving

• High pump efficiency with MEI (minimum efficiency index) > 0.7

• Fitted with high efficiency motors

• Suitable for use with Variable Frequency Drives for further energy savings

Piping connection options

• Various types of connections are available to best suit different installation requirements

• The external dimensions are to the industry standard, and are interchangeable with most other brands.

Easy maintenance

• The cartridge type shaft seal is able to be replaced without disassembling the motor bracket

• The spacer coupling allows easy maintenance without having to remove heavy motors 5.5 kW & above.

Smart plug solutions

• Air ventilation plug

• Water filling and sensor plug

• Commercial sensor fitting

• Tappings for suction and discharge pressure, and/or drain

20 pump industry | Spring 2019 | Issue 29 www.pumpindustry.com.au PIA MEMBER NEWS | PARTNER SOLUTIONS

NEW VERTICAL MULTISTAGE PUMPS FROM

The optimised shape of the new Shurricane impeller maintains high efficiencies and very significantly reduces the axial thrust – meaning that any standard IEC motor can be used, and bearing life is improved.

EBARA

™ www.ebara.com.au EBARA PUMPS AUSTRALIA PTY. LTD. 7 Holloway Drive Bayswater, VIC. 3153

sales@ebara.com.au Looking ahead, going beyond expectations

Ph: 03 9761 3033

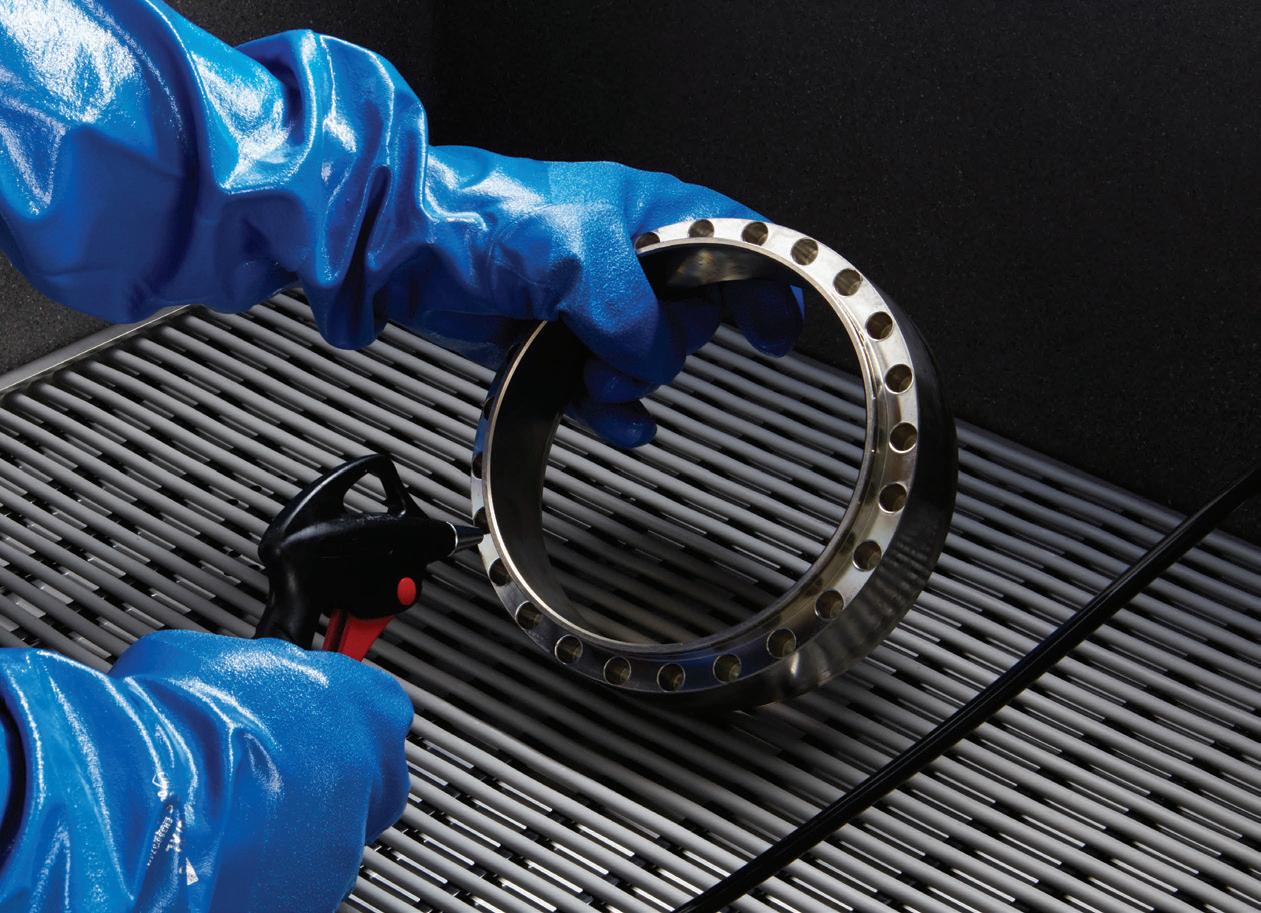

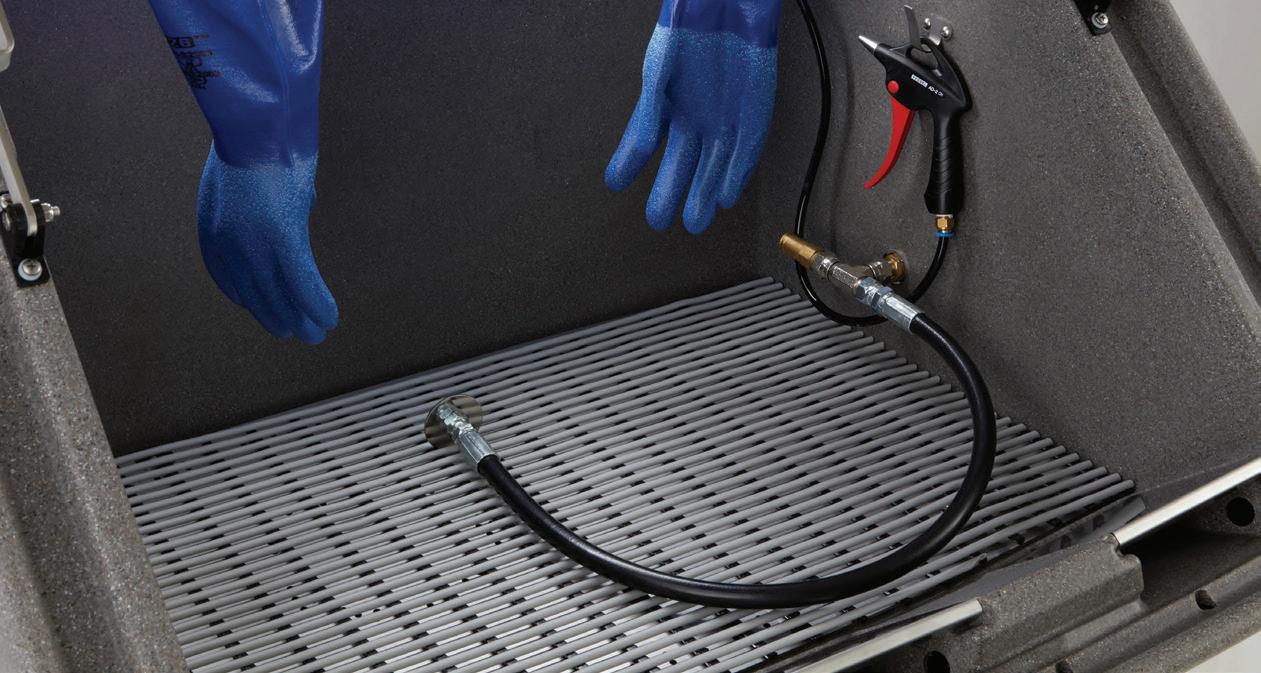

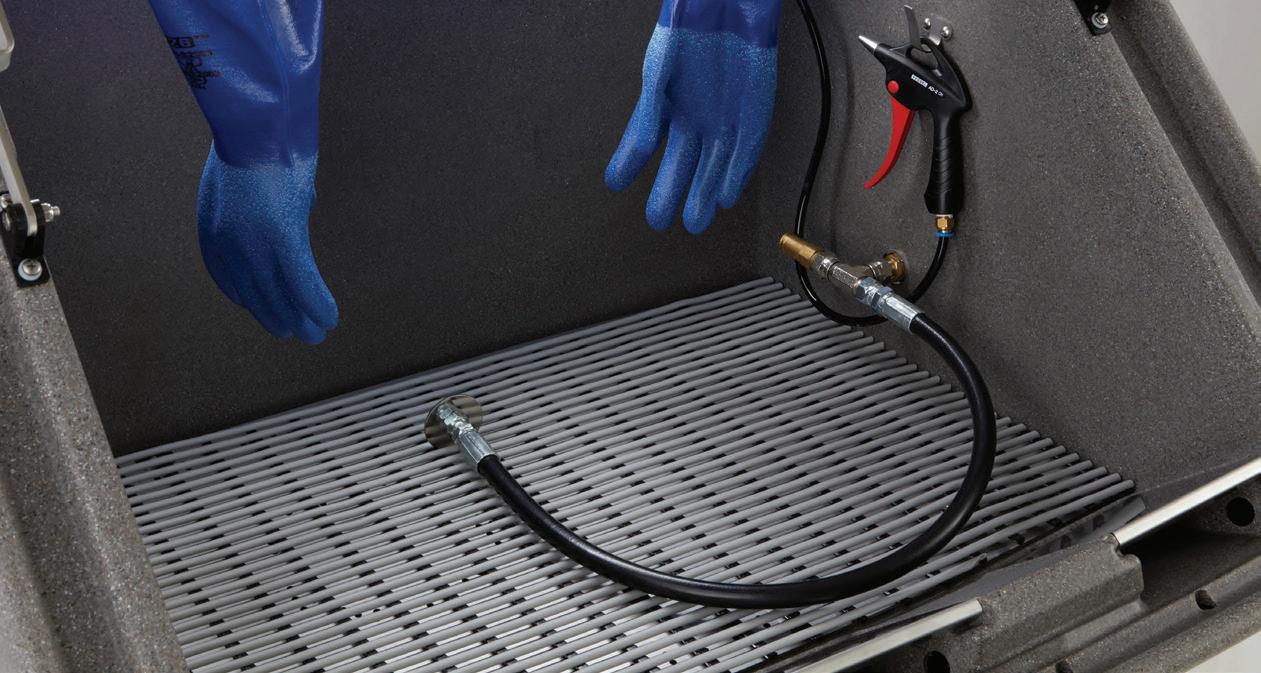

THE PIONEERING TECHNOLOGY

CUTTING CLEANING TIME IN HALF

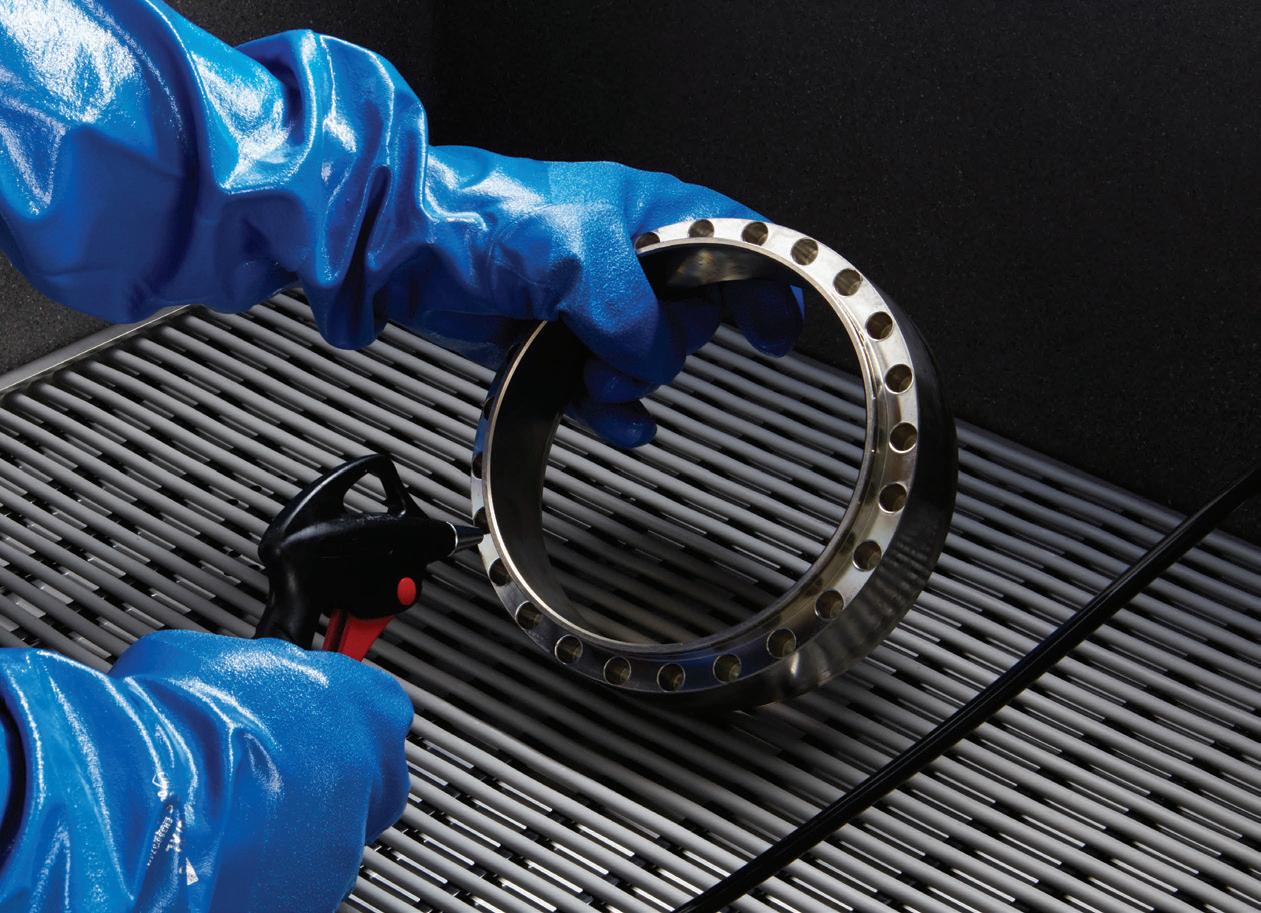

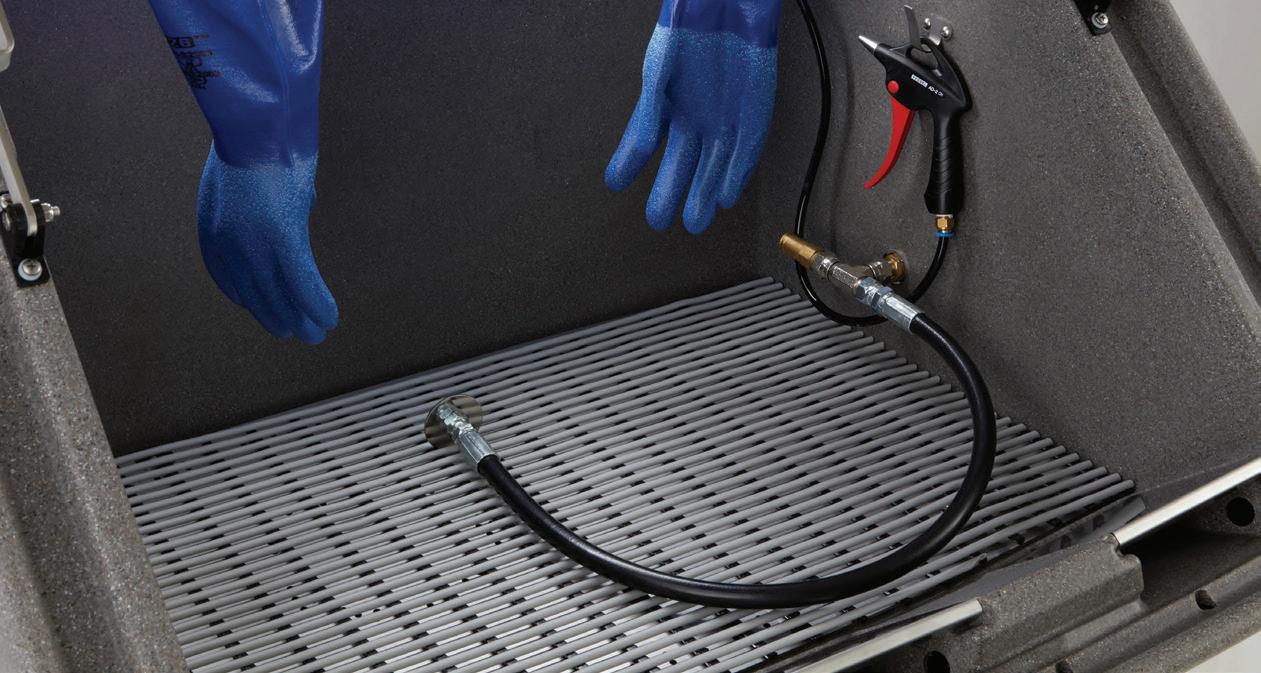

Parts Cleaning Technology is cutting the cleaning time in half for various industries including automotive, marine, manufacturing, aviation and more.

In any industry, the faster you can move projects through to completion, the better. Having said that, safety is always the priority. Celebrating its centennial year this year, NCH knows more than anyone that safety comes first.

By adopting the R&D best practice for any given product, NCH Torrent 500 Parts Cleaner technology, cuts service time by up to half, minimising safety hazards at the same time. This has resulted in reduced labour costs and delighted customers.

The Torrent system is a high pressure, waterbased, parts washing solution that not only improves efficiency, and maintains workplace safety, it reduces the environmental impact. In addition to workshops and manufacturers, the technology benefits service centres, construction, transportation and mining industries to

achieve the same results. No matter the application, they all need a solution that is quick, easy to use and safe.

Because of the unique combination of pressure, temperature and chemistry, the system cleans most parts in just one minute, five times faster than automatic machines. While the technology is nothing short of revolutionary, each industry agrees that Torrent is a game-changer.

“We calibrate the cleaning solution for the specific needs of every client,” said Reno Mythillos of NCH.

“We’re proud to have brought this system to the various industries that makes a noticeable difference in their workplace,” said Reno. “On our regular service visits to maintain equipment and fluids, we get to see how they are using the Torrent, and it is always a perfect fit for their needs.”

While traditional machines use oil-based chemicals that are great at separating grease from parts, the solvents are hazardous in the workplace and on employees. NCH said the Torrent uses a combination of heat, water, a powerful detergent and pressure to achieve better results. The equipment’s detergent has a combination of corrosion inhibitors that result in a much more effective clean.

22 INDUSTRY NEWS | PARTNER SOLUTIONS pump industry | Spring 2019 | Issue 29 www.pumpindustry.com.au

www.nchtorrent.com For more info. CALL US TODAY 1800 753 143 REVOLUTIONARY PARTS CLEANING www.nchtorrent.com For more info. CALL US TODAY 1800 753 143 Water based - no solvents! Reduce parts washing time!

Viega’s Propress System

PROVIDES THE PERFECT ALTERNATIVE TO TRADITIONAL PLUMBING SOLUTIONS

Situated in one of Perth’s most sought-after locations, Mirvac Latitude Leighton Beach is a unique seaside development offering 249 one, two and three-bedroom oceanfront apartments.

Ideally positioned adjacent to North Fremantle’s famous Leighton Beach, the prized real estate addition is only 15 kilometres from the Perth CBD and just 5.5 kilometres from the heart of cosmopolitan Fremantle.

Viega Propress was used for hot and cold water distribution to service all 249 apartments in sizes varying from DN15100mm. Hot water delivery was supplied from two central energy plants located on the roof of the new buildings. Viega Propress Gas was also used on the copper installation for gas supply to each of the luxury apartments.

Pipeline Hydraulics was tasked with carrying out all plumbing works associated with the development’s sewage, stormwater, water supply and gas supply.

The company’s Operations Manager, Mark Sadler, said that the Viega Propress system provided the perfect alternative to traditional plumbing solutions.

“Originally the tender docs called for all copper work to be welded or brazed, but we tried to steer clear of that so we wouldn’t have to organise hot works permits,” he explained.

“So, we looked for an alternative and Viega was there to help. Using their products meant we didn’t have to drag a big oxy set around and then spend time actually welding each individual fitting. It saved so much time. I reckon we got the job done three times faster than had we welded. It’s the first time we’ve used Viega. We’ll definitely use it down the track on other projects.”

PROJECT FACTS

Object Latitude Leighton Beach

Location Perth, WA, Australia

Year 2017

Object Type New building

Area of use Residential

Product Viega Propress and Propress Gas

Installation Pipeline Hydraulics

Architect Woods Bagot

24 pump industry | Spring 2019 | Issue 29 www.pumpindustry.com.au

INDUSTRY NEWS | PARTNER SOLUTIONS

SYDNEY’S VIBRANT NEW FINANCIAL HUB.

Containing thousands of Viega copper pipe fittings to ensure drinking water hygiene for the future.

Viega. Connected in quality. viega.com.au

International Towers Sydney, Sydney, Australia

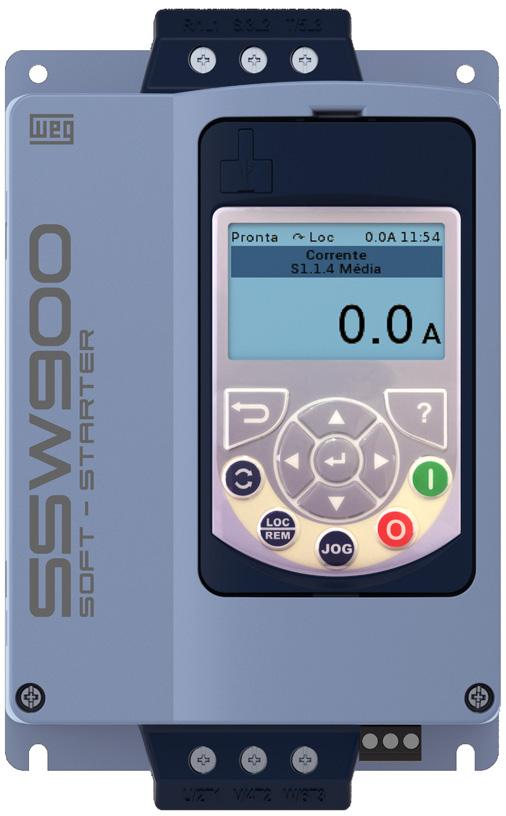

PRACTICALITY AND FUNCTIONALITY

Providing superb motor management

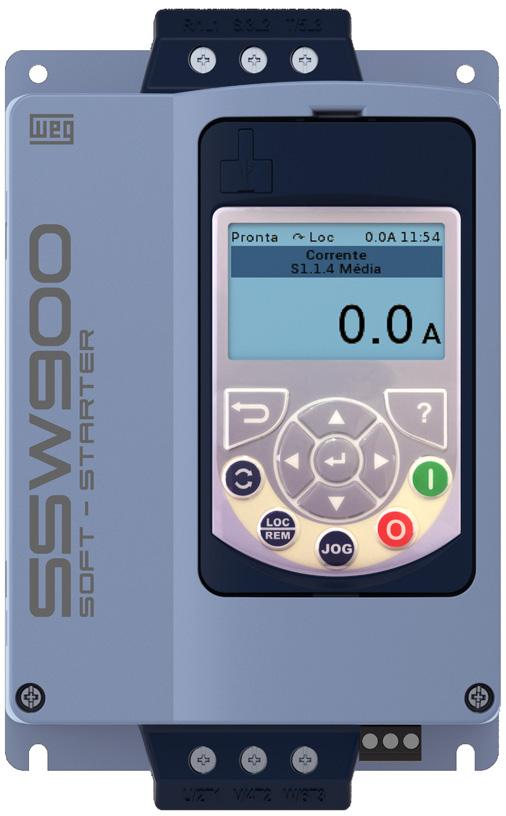

The introduction of our new SSW900, low voltage soft starter series continues to build on our broad motor starter range offered in Australia.

Torque control through the starting, processing and stopping functions remains the core to any good plant operation(s), and the product features and functionality of all WEG variable speed drives (VSD) and soft starters are designed to deliver just that.

A risk of any product diversity is complexity in programming with the subsequent difficulties for those providing general support services, but we have that covered.

Every VSD and soft starter from WEG is designed and manufactured in-house, and comes with a common and universal approach to parameters, setup and complex programming functions.

Low and high voltage soft starters covering outputs from 2.2 to 5740kW ultimately share the same manual. Similarly our VSD range covers drives from smallest single phase units up to state of the art 11kV systems, which share a majority of parameters and logic.

Maximising the investment in the training of operators and technicians is made profoundly easier by this strategic approach to product design.

Speed in commissioning and during the fine tuning of processes underpins an overall lower cost to the customer, and having a consistent platform across all our motor controllers makes this a reality.

The new SSW900 low voltage soft starter is the latest addition to our range. While keeping with the consistent approach, the SSW900 comes with additional functionality and contemporary features and will be taking over from the SSW06 series, which has been a product of choice for over 12 years.

This product fits seamlessly into our portfolio, with no disruption to our customers, distributors or service network, bringing functionality and practicality to the idea of "thinking globally, acting locally".

26

INDUSTRY NEWS | PARTNER SOLUTIONS

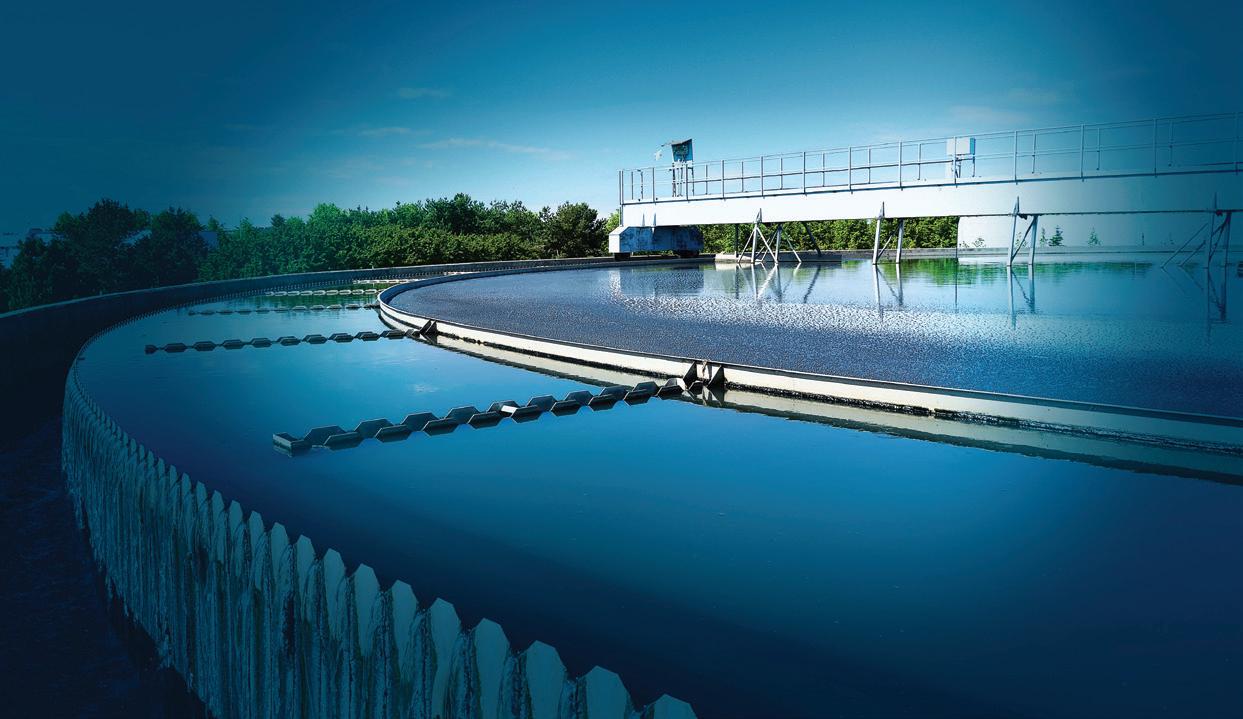

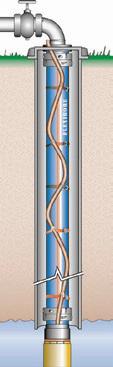

FLEXIBORE CHOSEN FOR ADELAIDE IRRIGATION PROJECT

In addition to adding 12 gigalitres of reclaimed water to the Northern Adelaide Plains, the Northern Adelaide Irrigation Scheme (NAIS), with a combined $155.6 million in funds contributed from the State and Federal Governments, will create 3,700 jobs and add a projected $500 million per year to South Australia’s economy.

With operations at Holden’s Elizabeth motor plant ceased, the people of North Adelaide who were hit the hardest will benefit most from jobs created during the construction of NAIS. This scheme will see new water treatment facilities built to increase the production of recycled irrigation water by 60 per cent, which will be suitable for food production. The benefits, once the project is completed, will be far-reaching.

NAIS has paved a clear path to get really high value crops from the fertile Northern Adelaide Plains to overseas markets. Demand in countries such as China, Japan and Korea – where Australian produce is appreciated for its freshness and quality – has been growing. Furthermore, some water will also be unlocked for the Barossa, where premium food and wine harvesting is one of South Australia’s economic pillars.

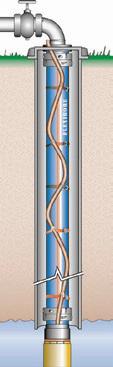

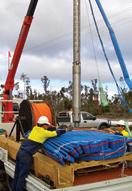

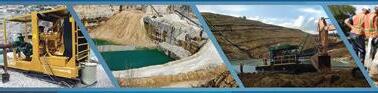

The water will be pumped into large storage dams from ten bores located around the Bolivar precinct, all using submersible pumps and Australian made Flexibore.

Providing a technical solution

Francois Steverlynck, the Managing Director of Crusader Hose, the manufacturers of Flexibore, said, “This is a flagship project for our company. We have worked closely with Leed Valoriza, the major contractor, to deliver a very technical solution in rapid time.”

Sam Doolette, project engineer at Leed Valoriza, was particularly impressed with the service and support he received from Crusader Hose.

“We had Francois come over from Melbourne to assist with the submersible bore pump installation,” said Mr Doolette.

“We were very pleased to see how easy the pumps could be installed using Flexibore and after completing the first one, we scheduled the rest to be installed at two per day. Final commissioning is planned for the end of September, and by ramping up, we will be able to supply consistent water flow that is completely independent of how much rain we get, or how full the Murray River is. This will provide certainty, as well as higher quality water at the same time.”

Supporting local industry

Business SA has long been proponents of supporting local industry, including Australian manufacturers.

Mr Doolette was well aware of the benefits of keeping jobs local.

“When we buy Australian made flexible risers, we not only increase local capabilities, but we also keep funds within the country. The multiplier benefit can be more than five times the benefits to local industry,” Mr Doolette said.

Flexibore was developed in Australia in 1991 in order to meet the market needs for a riser pipe that could be corrosion-free, never clog up due to iron bacteria, and also be easy to install. Through continuous improvement and innovation, Crusader Hose has grown to become the supplier of choice for mining, irrigation and government projects needing to pump groundwater.

“Australia has a clean and green image, cultivated over years of managing our resources responsibly. We also have a capable manufacturing industry, brought about by hard work and investments in education. It is wonderful when we all work smartly together to deliver projects such as NAIS as this will continue to benefit generations of Australians,” Mr Steverlynck said.

28 INDUSTRY NEWS | PARTNER SOLUTIONS pump industry | Spring 2019 | Issue 29 www.pumpindustry.com.au

CRANE ON TRUCK ON CRANE OVER A ROLLER WALK IN FLEXIBORE FLEXIBORE THE SYSTEM OF CHOICE FOR GROUND WATER PUMPING THE SYSTEM OF CHOICE FOR GROUND WATER PUMPING INSTALL YOUR BORE-PUMP WITH EASE Flexibore Coupling Flexibore Hose Power Cable Power Cable Strap Borehole Pump PUMPING EFFICIENCY & COST SAVING EASY STORAGE, HANDLING & TRANSPORT QUICK AND EASY INSTALLATION & RETRIEVAL Customised Layflat Hose Systems Crusader Hose Pty Ltd 22 Industry Place, Bayswater, VIC 3153 Australia Telephone: +61 3 9720 1100 www.crusaderhose.com.au For any enquiries, email sales@crusaderhose.com.au AUSTRALIAN MADE NO CORROSION NO IRON BACTERIA BUILD UP

VOLVO PENTA: THE HEART THAT NEVER STOPS

Volvo Penta’s engine range is characterised by high performance, reliability, fuel efficiency and low emission levels. Built to be versatile, their low weight, compact designs, easy installation and optional equipment packages make them perfect for numerous machine and equipment applications in a variety of industries.

As part of the Volvo Group, Volvo Penta is a premium supplier for engines for the pumping industry.

“We continuously work towards sustainable solutions and provide both OEMs and operators with stateof-the-art engines and technology based on over 100 years of engineering experience. Our engines power agricultural applications all over the world – contributing to the overall productivity of the operations through excellent performance and fuel efficiency,” Bjorn Saljo, Head of Volvo Penta Oceania said.

Aside from various pump applications (fire, irrigation, dewatering), Volvo Penta engines can be found in a wide variety of industrial applications including power generation, materials handling, rock crushing, underground mining equipment, ventilation machines, tractors, forestry machines, and tomato and cane harvesters, just to name a few. Some of the world’s largest equipment manufacturers turn to Volvo Penta for their engine requirements.

“Our industrial engines are all engineered to be part of a common platform. This means a future-proof engine range with engine interfaces and range architecture that match the different emission stages. The platform commonality also facilitates service and parts availability,” Bjorn said.

Cost of ownership

As part of the Volvo Group, Volvo Penta is at the forefront of the engine industry and is always looking for ways to reduce total cost of ownership while maintaining the reliability and the longevity of its engines.

To maximise uptime, most Volvo Penta Industrial engines can operate for 1,000 hours between service intervals. Productivity can be increased and uptime maximised by using the corresponding service protocol, an approved Volvo Penta Oil Analysis and genuine Volvo Penta oil filters with the appropriate oil and fuel quality.

The old and the new

With 30-year-old pump engines still in operation on farms throughout the country with well over 30,000 hours on the meter, it’s easy to see why farmers still look to Volvo Penta for their pumping requirements.

Ben Watson is from Allabah Pastoral Company, a large farm that produces cotton and raises livestock. Every day, Volvo Penta engines deliver indispensable work horses to Allabah’s pumps, running water with high reliability and uptime.

“We rely heavily on Volvo Penta to harvest water when it’s available,” he said.

“If you head down there some four or five kilometres in the pouring rain and are not able to hit the start button, it can be detrimental. With Volvo Penta on board, it’s just been awesome. It’s really changed the reliability and fuel efficiency too.”

David Phelps at Havana Farming also depends on diesel power to guarantee water is pumped to his vast plantation fields. The extended service intervals of Volvo Penta engines mean Havana Farming is cost efficient and always dependable.

“Volvo Penta is where we went 20-25 years ago. They’ve been very reliable motors, and now that we’re in an upgrading situation, we are just sticking with Volvo; I don’t see any reason to change. They were ahead of their time 20 years ago, as the new ones are now; they’re at the forefront too. Like any business, you’ve got to keep it humming, otherwise things can go backwards pretty quick,” he said.

Reliable engine, reliable network

With over 100 Volvo Penta dealers located around Australia committed to providing a first class service around the clock, you can depend on Volvo Penta for all your pumping requirements.

Engines ranging from 125HP through to 750HP configured for various pumping applications are in stock and ready for delivery nationwide. With over 100 years of state-of-the-art engine technology and engineering experience, Volvo Penta is here for generations to come, for the generations to come.

For more information or to find your nearest dealer head to volvopenta.com

A few months ago Volvo Penta spent time with a film crew capturing footage around northern NSW to promote the brand and tell the story of cotton irrigation in Australia.

“We recently had a great opportunity to show our commitment to the cotton irrigation industry here in Australia by shooting a series of videos showcasing the product and the people involved. We are really proud of what we produced and look forward to supporting the cotton industry for the years to come,” Gavin Rooney, Sales Manager for Volvo Penta Oceania, said.

Watch the videos below:

https://www.youtube.com/watch?v=ePjBFhpe9lA https://www.youtube.com/watch?v=wzSVTCFrysc https://www.youtube.com/watch?v=YedyYthRqzs https://www.youtube.com/watch?v=ASJ_7xUeqzY

30 INDUSTRY NEWS | PARTNER SOLUTIONS pump industry | Spring 2019 | Issue 29 www.pumpindustry.com.au

A POWERFUL PARTNERSHIP

Volvo Penta. Robust, fuel efficient industrial diesel engines that keep running even in the toughest conditions. Easy to install, operate and maintain. A powerful partnership you can trust all the way from the drawing board throughout the operational life of your engine. Competitively priced complete power-pack units ready for delivery Australia wide with a local support team on hand 24/7. To find your nearest dealer visit www.volvopenta.com

105-515 KW

MOTOR STARTING for optimum performance

It is often believed that the start current of a motor under full voltage conditions depends on the driven load, but this is incorrect.

The start current of the motor depends on the motor design, rotor speed and stator voltage from zero speed until full speed is reached. The load only influences the time taken for the motor to reach full speed. The current/ speed curve of the motor is independent of all external influences other than stator voltage.

Full voltage starting: DOL starters

The DOL starter causes a current transition from zero to locked rotor current (LRC) at the instant of contactor closure. It also causes a torque transient from zero to locked rotor torque (LRT) at the instant of contactor closure, resulting in a severe mechanical shock to the motor drive system and the machine.

Reduced voltage starters

The following four starter types are examples of reduced voltage starting which are used extensively and, in many areas, is mandatory. However, many installations would suffer fewer disturbances if a full voltage starter replaced a poorly applied reduced voltage starting system. The reduced voltage starter must be able to accelerate the motor to almost full speed before stepping to full voltage, or it risks a current step that can be very close to LRC. Therefore, start time and start voltage must be correctly set.

1. Primary resistance starters

Using resistors, connected in series with each phase, between the isolation contactor and the motor, limits the start current and torque. If the resistors are too high for the start voltage, there will be insufficient torque to accelerate the motor to full speed. In this case, the step to full voltage will result in a high current and high torque step. Several stages of resistance can be used to control the current and torque more accurately, minimising the magnitude of the current and torque steps.

2. Autotransformer starters

An autotransformer reduces the voltage during the start period. If the start voltage is too low, or the start time incorrectly set, the transition to full voltage will occur with the motor at less than full speed, resulting in a high current and high torque step. Autotransformer starters are usually rated for infrequent starting duties.

3. Star-delta starters

The star-delta starter is the most common reduced voltage starter used in industry because of its low cost. The motor is initially connected in star configuration and then, after a pre-set time, the motor is disconnected from the supply and reconnected in delta configuration. If there is insufficient torque available in star configuration to accelerate the load to full speed, a high starting torque motor such as a double cage motor should be used. If the motor does not reach full speed in star, the transition from star to delta configuration will result in a high current and high torque step, defeating the purpose of reduced voltage starting.

4. Solid-state soft starters

The solid-state soft starter controls the voltage applied to the motor through impedance in series with each phase connected to the motor. It uses solid-state AC switches with a very low power dissipation compared to traditional primary resistors, and is controllable to give a motor voltage from zero to full line voltage without any steps or transients.

It is possible to correctly apply and engineer electromechanical reduced voltage starters so the torque and current magnitudes and transients are reduced to acceptable levels. Reduced voltage starting reduces the electrical interference caused by motor starting and reduces mechanical damage caused by torque transients and steps. To achieve these objectives, the motor and starter must be correctly selected and commissioned for optimum performance.

32 INDUSTRY NEWS | PARTNER SOLUTIONS pump industry | Spring 2019 | Issue 29 www.pumpindustry.com.au

Soft Starters

Fully featured motor control solutions

New EMX4i range

24 – 580A with internal bypass

Features

• XLR-8 control to prevent water hammer

• Emergency run mode

• Real time metering & monitoring

• Automated pump clean function

• Extended motor protection functionality

• Clock & calendar scheduling

Power Distribution | Power Monitoring | Industrial Control | Photovoltaic | Installation & Accessories | Test & Measurement | Services National Customer Support Centre 43 Newton Road | Wetherill Park | NSW 2164 Tel: 1300 556 601 | Fax: 1300 550 187 Email: customerservice@ipd.com.au | www.ipd.com.au End to End Service Capabilities Custom DB Manufacturing Facility National Customer Support Dedicated Training Facility

DRIVE SYSTEMS OPENS IN WA

with stocking of genuine Rexnord Omega Couplings

Drive Systems is proud to announce the opening of its office/warehouse in Perth, Western Australia.

Drive Systems will carry a comprehensive range of mechanical power transmission products and a wide range of shaft couplings for the pump industry. Drive Systems is the Australian distributor of ESCO gear and disc couplings, Mayr couplings, torque limiters, clutches and Brakes.

CMD Winflex grid and gear couplings, Rexnord Omega and Falk Wrapflex elastomeric couplings.

One of its most popular couplings is the Rexnord Omega coupling. Often copied by cheap inferior manufacturers or mixed with non-genuine parts, Drive Systems only selects, stocks and supplies 100 per cent genuine Rexnord Omega Couplings.

Rexnord Omega Elastomeric Couplings are non-lubricated, material-flexing split-in-half tire couplings used in a variety of demanding applications in many industries. This all-purpose coupling has excellent vibration dampening capability, helping to provide extended life to connected equipment.

Omega couplings offer easy installation and replace-in-situ design, while accommodating a wide range of shaft gaps.

Higher material strength

Omega’s specially formulated polyurethane provides significantly higher peak torque capabilities than competitive

Polyurethane-to-Metal Bond minimises coupling components and eliminates potential slippage associated with mechanically clamped designs.

Radial Bolting provides easier access than axially bolted couplings in confined areas. Hardware available in carbon steel or stainless steel.

High-misalignment Capacity accommodates unavoidable misalignment with reduced reactionary forces on connected equipment.

rubber-based solutions, allowing for a smaller size coupling at a lighter weight and ultimately a lower Total Cost of Ownership (TCO).

Weight balanced

Omega elements are tightly weight matched to ensure standard weight balance conforms with ISO G16 and AGMA Class 8, helping to prevent premature wearing of connected equipment due to an unbalanced coupling.

Variety of sizes and options

In addition to being available in 15 metric sizes, Omega is offered as a general purpose Orange, in a Heavy Duty Yellow option that provides 25 per cent more torque capacity, and a Hydrolytically Stable Green option that is ideal for hot and humid environments. Anticorrosive coated steel shoes and stainless steel hardware or hubs are also available upon request.

Proven

and trusted performance

Omega couplings have been used for over 40 years in a wide assortment of demanding applications and recognised in the industry as the benchmark for elastomeric split-in-half tire couplings.

Torsionally Soft Flex Element cushions shock loads and vibration to protect and extend connected equipment life.

Split-in-Half Design for easy assembly and replacement without having to remove the hubs. No need to move hubs or realign equipment when replacing the coupling element.

Weight Balanced Elements for higher speed ratings and prevention of premature wearing due to an unbalanced coupling.

Rexnord Omega Spacer Orange Couplings

Omega Spacer elastomeric coupling consists of the unique split-in-half flex element and reversible hubs.

• Available in 13 sizes from ES2-M to ES80-M metric

• Hubs offered in rough, custom or tape bush designs

• Accommodates shaft diameters up to 155mm

• Continuous torque loads up to 4,463Nm

Rexnord Omega Close-Coupled Orange Couplings

Omega close-coupled elastomeric coupling consists of the unique split-in-half flex element and reversible hubs.

• Available in 15 metric sizes

• Hubs offered in rough, custom or taper bushed designs

• Accommodates shaft diameters up to 229mm

• Continuous torque loads up to 38,442Nm

• Peak torque loads up to 96,093Nm

• Peak torque loads up to 11,157Nm

• Features optional hole mounting positions and reversible hubs to accommodate most shaft spacing requirements

34 INDUSTRY NEWS | PARTNER SOLUTIONS pump industry | Spring 2019 | Issue 29 www.pumpindustry.com.au

Premium Couplings from Global Leaders

CMD Winex

Winex DG Grid Couplings

Bore capacity 360mm

Torque range 52Nm > 186,000Nm

Chrome

Replaceable tooth rings from size DG15(1150T10)

Winex T & S Series Grid Couplings

Bore capacity up to 390mm

High torque range 90Nm > 800,000Nm

Chrome vanadium, heat treated & shot peened grids

Replaceable Tooth Rings T series from size 28 and the complete range in S Series

+61 (0) 3 9796 4800 Melbourne Perth info@drivesystems com au 8/32 Melverton Dve, Hallam, VIC 3803 drivesystems.com.au TECHNICAL EXCELLENCE & INDUSTRY EXPERIENCE

Rexnord

vanadium, heat treated & shot peened grids

+61 (0) 455 320 552 2/64 Baile Rd, Canning Vale, WA 6155

Better, easier and cheaper using 4G

Improvements in 3G and 4G mobile network coverage, advancements in battery technology, low power electronics and cloud services have enabled the development of a new generation of devices that can be used to remotely monitor, control and log data from pumps and associated infrastructure.

ETM, one of Sweden’s leading manufacturers of Industrial IoT cellular edge solutions, has released two products that exploit these new technologies, with the new family of cellular remote monitoring, alarming and logging solutions for analog and digital signals:

• DeltaBlack optimised for industrial environments. DIN rail mount, wide DC operating voltage and flexible I/O configuration

• DeltaBlue designed for outdoor remote deployment. Battery-powered, IP66 enclosure, GPS, vibration/ movement detection and flexible I/O configuration ETM ensured that simplicity and cost effectiveness were two key criteria in designing its new range. Recognising that deploying cellular or mobile network devices have often been a frustrating exercise for engineers having to deal with procurement, IT departments and having to select antenna, power supplies etc., these units come bundled with active Telstra

SIM cards and are preconfigured for specific inputs such as temperature, current and vibration.

DeltaBlack and DeltaBlue connect to ETM’s IoT Cloud Dashboard (EWO) for real-time and historical data display. In addition, pre-set customised alarms can be simultaneously sent to multiple recipients as simple user-friendly SMS text messages direct from the device.

For more information about DeltaBlack and DeltaBlue call (02) 9956 7377 www.etmiot.com.au.

36 pump industry | Spring 2019 | Issue 29 www.pumpindustry.com.au C M Y CM MY CY CMY K INDUSTRY NEWS | PARTNER SOLUTIONS

INFRASTRUCTURE:

MONITORING REMOTE PUMP

DeltaBlue

DeltaBlack

ENERGY ELECTRIFYING INDUSTRY – NEW

The Australian manufacturing industry is at a crossroads.

Transforming the materials we dig up or grow into the products we use every day requires enormous amounts of heat, and rising electricity costs and inefficient processes means many businesses have seen their gas and electricity bills double over the last two years. A report from Beyond Zero Emissions shows there are opportunities for manufacturers to reduce costs by generating heat through the smart use of renewable electricity, with heat pumps one technology that they can take advantage of.

From fossil fuels to electricity

Every year in Australia, burning fossil fuels for industrial heat processes produces 42 million tonnes of carbon dioxide, or eight per cent of the country’s greenhouse gas emissions –as much as Australia’s entire car fleet and more than the state of South Australia. If we look at these numbers globally, the contribution of process heat is higher – about 12 per cent of all emissions.

While fossil fuels have powered industry since the industrial revolution, a new low-carbon industrial transformation is possible and could transform existing industries.

The report, Electrifying Industry, shows how electrification, powered by renewable energy, could not only eliminate eight per cent of Australia’s emissions and revive the entire manufacturing sector, but also reduce greenhouse gas emissions.

Electricity is remarkably versatile and has no practical temperature limit, meaning it can power any industrial heat process, from cooking a can of beans to melting 100 tonnes of iron.

By adopting a range of heat technologies – both old and new – industry can make things in a smarter way and can double the efficiency of many industrial processes, saving money in the process.

Australia’s renewable advantage

With Australia’s abundant renewable resources, there is the additional opportunity to develop a clean, efficient manufacturing sector, adapted to the needs of the 21st century. It is an affordable and reliable source of energy, with some manufacturers already taking hold of this opportunity, paying 20-50 per cent less for electricity. They have done this by either building their own renewable installations or agreeing to contracts for renewable energy supply.

By electrifying all industrial processes, six to eight per cent of Australia’s greenhouse gas emissions can be reduced.

It also creates an opportunity to use electrical heating technology such as heat pumps, opening the industry up to more efficient technologies to save money.

Electrifying industry – where are the opportunities?

• Beer

• Prepared meals

• Powdered milk

• Recycled paper

• Aluminum casing

• Bricks

• Plastic

• Glass

• Steel

• Ammonia

• And others

pump industry | Spring 2019 | Issue 29 www.pumpindustry.com.au 38

ENERGY EFFICIENCY

EFFICIENCY OPPORTUNITIES FOR IMPROVING

An opportunity for heat pumps

Heat pumps use electricity to make hot water, air or steam. They are able to produce three to seven times more thermal energy compared to the amount of electricity they use, leading to efficiency of 300-700 per cent. They also provide an opportunity for manufacturers to reuse sources of energy that would otherwise be wasted, such as heat expelled by refrigeration systems.

The past decade has seen high temperature industrial heat pump technology develop rapidly and there are options available now that are able to reach temperatures up to 140160°C – hot enough for many industrial processes, including for food, chemical and paper applications.

In particular, there is great potential for heat pumps to be used as an alternative to inefficient centralised gas boiler systems that are found in most factories.

The report found that while heat pumps have a high upfront cost, overall, the energy efficiencies provided by heat pumps means that their installation costs can often be paid back within two years.

It will cost around $500-1000 per kilowatt of heating capacity for a heat pump system where the pumps are below 500kW, with 1+MW systems costing around $275500 per kilowatt. Depending on various site specific factors,

installation cost can add an additional 25-100 per cent onto the purchase price. This makes the upfront costs of a heat pump system two to three times more expensive than that of an equivalent gas boiler.

However, heat pumps have lower running costs, so it will pay itself off in only a few years. This is because the heating capacity of these pumps is lower as distribution loss is minimised. There are further cost savings if the pumps are replacing costly steam distribution systems as well as the central gas boiler; and if installed in a modular fashion, plant owners only need to replace the most inefficient parts of the boiler system, rather than shutting down and replacing the entire system at once.

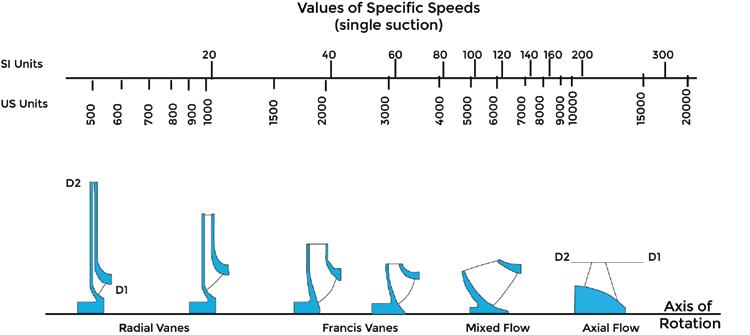

A high coefficient of performance (COP)