GWS is proud to announce the launch of our new line of ASME-certified pressure vessels in the Australia market.

Supplied with an ASME U-stamp, these vessels can be verified and registered to AS1210 for use in heavy industries like mining and oil & gas, as well as power generation and marine installations.

We design, manufacture and test each vessel in our own ASME-accredited facility, ensuring the safety, reliability and peace of mind that our customers demand for their most challenging applications.

Each vessel comes with a unique and permanent Manufacturer’s Data Report (MDR) to ensure a lifetime of traceability and strict regulatory compliance.

Our standard range covers vessels from 60L up to 3000L with 10, 16 and 25-bar pressure ratings, all certified to ASME Boiler and Pressure Section VIII Division 1 Code.

Contact our local dealer Southern Pumping Specialists to learn more!

In everything we do, we never lose sight of what is more important to our customers: to work economically with a technology that is modern, innovative and reliable.

In everything we do, we never lose sight of what is more important to our customers: to work economically with a technology that is modern, innovative and reliable.

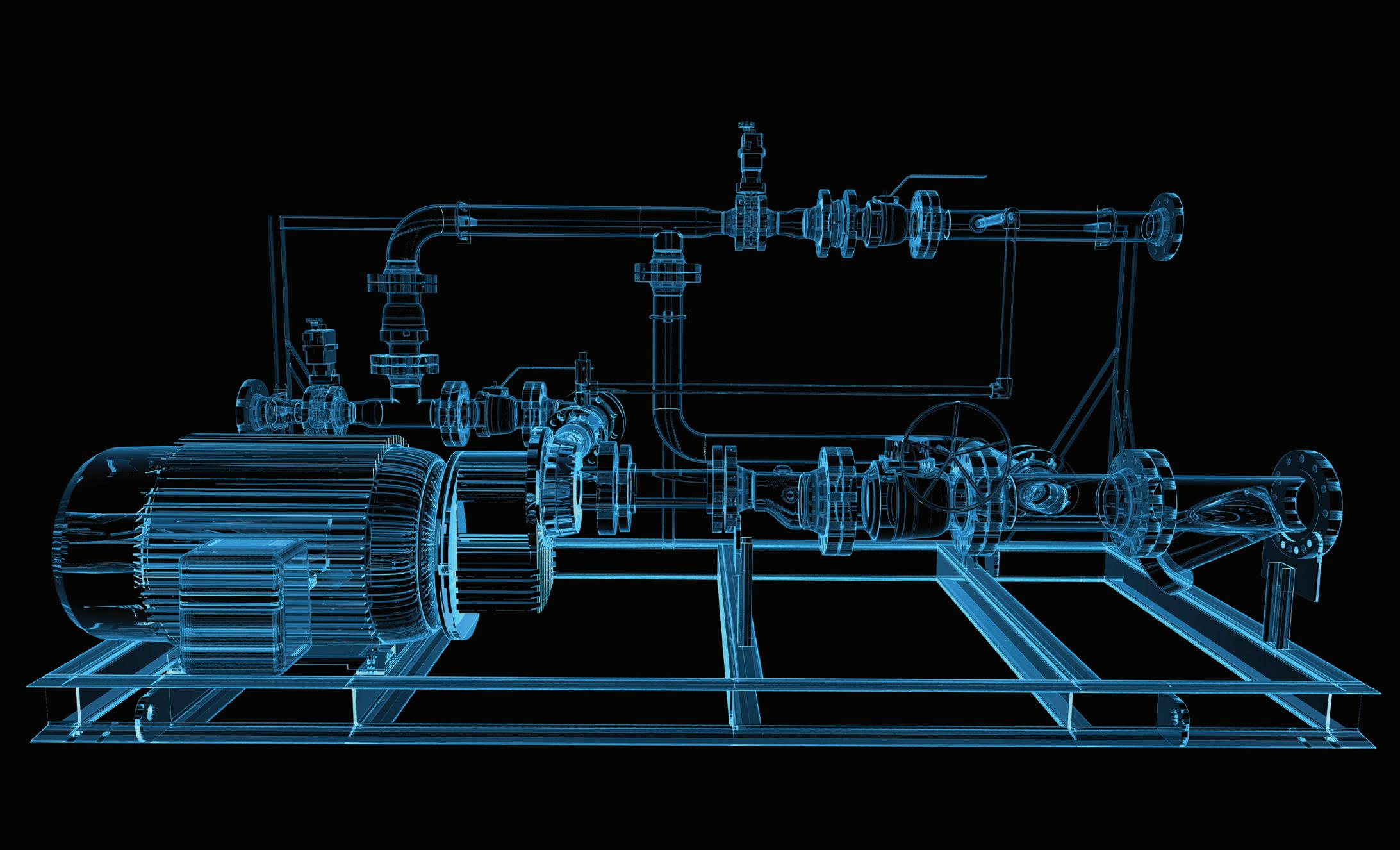

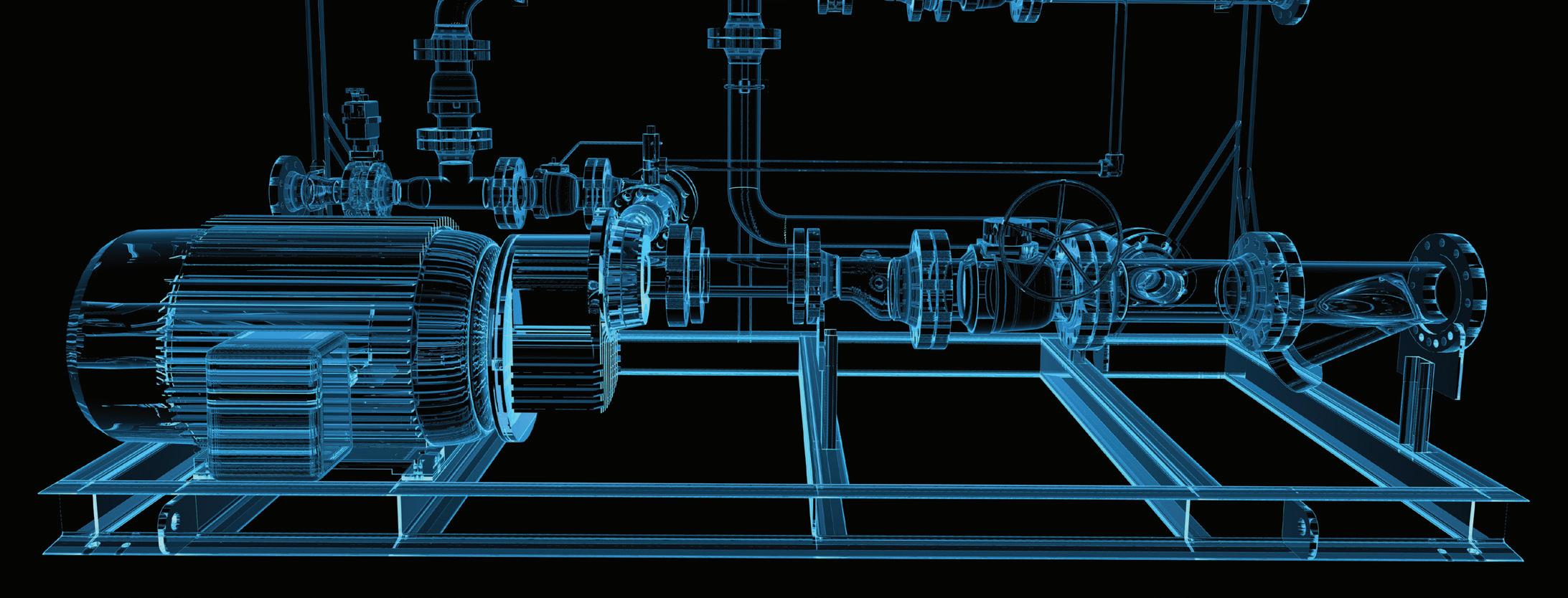

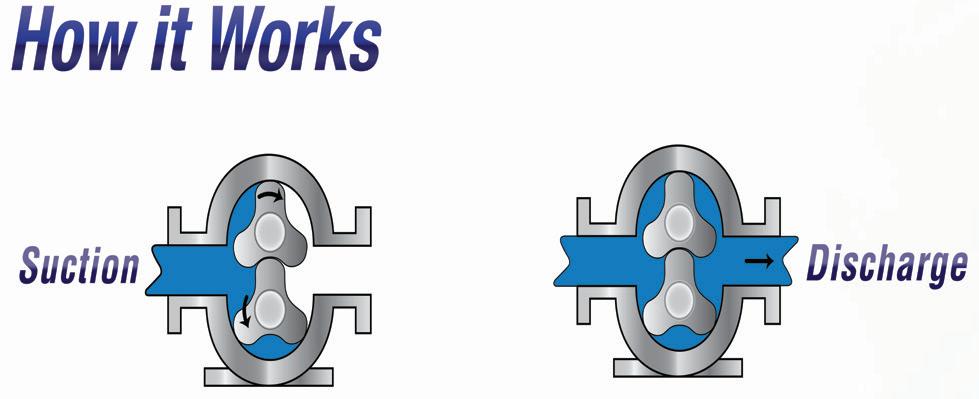

As the inventor of the elastomer-coated rotary lobe pump and innovation driver in the field of pumping, grinding and disintegration technology, Vogelsang has been one of the world’s leading mechanical engineering companies for decades. With progressive concepts and sophisticated technology, such as the RotaCut macerator or the wastewater twinshaft grinder XRipper, we work daily on efficient solutions for the individual applications of our customers.

As the inventor of the elastomer-coated rotary lobe pump and innovation driver in the field of pumping, grinding and disintegration technology, Vogelsang has been one of the world’s leading mechanical engineering companies for decades. With progressive concepts and sophisticated technology, such as the RotaCut macerator or the wastewater twinshaft grinder XRipper, we work daily on efficient solutions for the individual applications of our customers.

We use our extensive know-how, the continuous further development of our technical solutions and our many years of experience in the field of environmental technology to support our customers as a competent partner. Among other things, with powerful and service-friendly technology. You can rely on competent and personal advice and reliable service.

We use our extensive know-how, the continuous further development of our technical solutions and our many years of experience in the field of environmental technology to support our customers as a competent partner. Among other things, with powerful and service-friendly technology. You can rely on competent and personal advice and reliable service.

VOGELSANG – LEADING IN TECHNOLOGY

VOGELSANG – LEADING

Unit 2/7 Dunn Road | Smeaton Grange NSW 2567 | Australia

Unit 2/7 Dunn Road | Smeaton Grange NSW 2567 | Australia

Phone: +61 2 4647 8511 | E-mail: sales.au@vogelsang.info vogelsang.info

Phone: +61 2 4647 8511 | E-mail: sales.au@vogelsang.info vogelsang.info

Hello all and welcome to the Spring Edition of Pump Industry Magazine.

I must say I am looking forward to spring as I have found this winter to be particularly cold, maybe it’s just me, or maybe it’s the slow moving high pressure systems moving across the eastern seaboard that kept us cold and allowed very low snow levels across the SE and Tasmania.

no class of licence or restricted licence that allows a person to exclusively service, repair and maintain pumps without a Plumbers Licence; in my last communication on 8 August to the Department of Energy and Public Works, I asked if representatives of PIA could meet with their Executive Director who has extensive experience and knowledge in Public Policy Law, Legislation and Practice. I await a response.

Pump Industry Australia Incorporated C/-340, Stuarts Point Road

Yarrahapinni NSW 2441 Australia Ph/Fax: (02) 6569 0160 pumpsaustralia@bigpond.com www.pumps.org.au

PIA Executive Council 2022

John Inkster – President Brown Brothers Engineers

James Blannin – Vice President Stevco Pumps & Seals

Kevin Wilson – Treasurer/Secretary Executive Officer

Alan Rowan – Councillor Executive Officer – Publications and Training, Life Member

Ken Kugler Executive Officer – Standards, Life Member

Michael Woolley – Councillor Tsurumi Australia

Geoff Harvey – Councillor Irrigation Australia Limited

Billie Tan – Councillor Regent Pumps

Steve Bosnar – Councillor Pioneer Pumps

Joel Neideck – Councillor TDA Pumps

Mat Arnett – Councillor Ebara Pumps Australia

Jamie Oliver – Councillor Grundfos Pumps

Now we hear from the BoM that there is a 50/50 chance the Australian East Coast could be hit by a third La Nina, bringing an increased probability of rainfall and cooler temperatures for the third summer in a row. The last time this occurred was from 1998 until 2001.

Those affected and still recovering from widespread flooding this year must be dreading the thought of yet another wet year, with many not yet fully recovered from the last floods. Another La Nina year also creates difficulties for the farming community, particularly cropping whether it be planting or harvesting.

Upcoming events were to include an Online Seminar on 22 September on Flow Meters, but as that date is now a public holiday this is postponed to a later date. The Seminar is being presented by ABB and being hosted by Brown Brothers Engineers in Keysborough so attendees will have the option of attending in person or via Zoom.

As the end of the year approaches so does our AGM; this year we are looking at holding a face-to-face meeting supported by a Zoom Meeting for those outside Melbourne wishing to attend. The AGM will be held at the Commonwealth Golf Club in South Oakleigh on Monday 14 November.

In the Winter Edition I reported on Council’s submission to the Services Trades Council (STC) regarding our request for suitably qualified Members to undertake repairs and service under the PD Act 2018. This request remains in front of the STC and is still under consideration. Under the PD Act there is

Also in the last edition I made mention of the Regulatory Compliance Mark (RCM). From the action of one of our Member companies, we have received a response from the Secretariat of the Standing Committee of Officials (SCO) the Administrators of the EESS (Electrical Equipment Safety System). Hopefully we may be able to get a spokesperson to attend a meeting, possibly our AGM, to elaborate on the scope of the RCM and to address any questions, which I am sure there would be many.

Just a reminder to all that the latest edition of the Pump Technical Handbook and Pipe Friction Handbook will be released in September. Both books remain the industry standard and continue to be very popular within the pump industry and to consultants, specifiers, educators, end users and the like.

In recent months a few pump related ISO standards came up for their cyclic review as to whether they should be confirmed, reviewed, amended or withdrawn. Whilst some are of little interest to the market others such as ISO2858 – the 16 bar dimensional end suction pump standard is important, and PIA advised on this to Standards Australia. At present ISO9906 pump performance testing is also up for review; we await comments from our local industry.

As always, I wish you all a COVID-19 and flu-safe year and business prosperity.

John Inkster - President

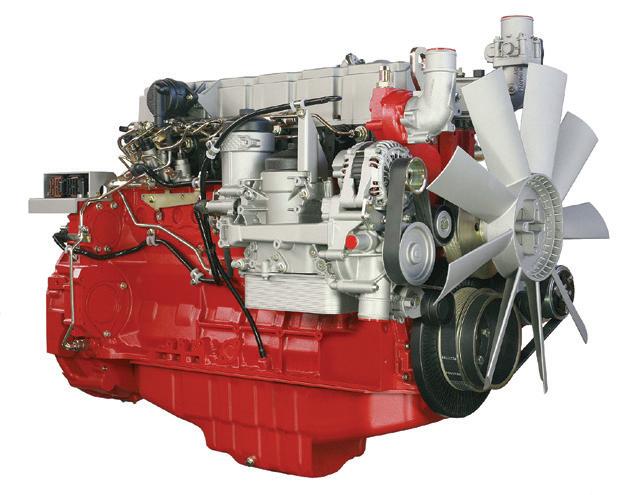

Volvo Penta. Robust, fuel efficient industrial diesel engines that keep running even in the toughest conditions. Easy to install, operate and maintain. A powerful partnership you can trust all the way from the drawing board throughout the operational life of your engine. Competitively priced complete power-pack units ready for delivery Australia wide with a local support team on hand 24/7. To find your nearest dealer visit www.volvopenta.com

Published by Monkey Media Enterprises

ABN: 36 426 734 954

C/- The Commons, 36-38 Gipps St, Collingwood VIC 3066

P: (03) 9988 4950

F: (03) 8456 6720 monkeymedia.com.au info@monkeymedia.com.au pumpindustry.com.au magazine@pumpindustry.com.au

Managing

Designers: Luke Martin, Danielle Harris, Ozlem Munur

Marketing Manager: Radhika Sud

Marketing Associate: Andie James

Digital Marketing Assistants: James Holgate, Jackson Barnes, Natalie Ta

Publisher: Chris Bland

GM

Long-time industry professional Heinz P. Bloch passed away on 20 August after a brief illness.

Heinz was a stalwart of the industry, having published over 800 pieces of work including 24 comprehensive books on practical machinery management, failure analysis, failure avoidance, compressors, steam turbines, and pumps. Over the years he has also contributed numerous technical and informative articles to Pump Industry Magazine.

Heinz commenced his professional career in 1962 which included long-term assignments as Exxon Chemical’s Regional Machinery Specialist for the United States. He held B.S. and M.S. degrees (cum laude) in Mechanical Engineering and is an ASME Life Fellow with lifetime registration as a Professional Engineer in New Jersey.

His passion for his trade and generosity for sharing his knowledge and experience means he will be long remembered by many.

The New South Wales Government has announced that it will invest $22 million in the Parkes/Peak Hill Water Supply Project to “future proof” the region’s water supply, with the project including new and upgraded pump stations and treatment plants.

New South Wales Deputy Premier and Minister for Regional New South Wales, Paul Toole, said the $61.7 million infrastructure project will strengthen water security for the region and bolster its drought resilience by creating a new raw water supply network for residents and businesses.

“I am thrilled the New South Wales Nationals in Government are providing the last piece of the funding puzzle, putting in the $22 million needed to enable this critical water supply project to go ahead,” Mr Toole said.

The project will deliver:

• 39km of new pipelines to link new and existing infrastructure

• Two new pump stations

• An upgraded Lachlan River pump station

• Two new pre-treatment plants at Eugowra Road and Akuna Road

• A new raw water dam at Parkes water treatment plant

New South Wales Minister for Lands and Water, Kevin Anderson, said the pipelines will link new and existing infrastructure to support the water needs of residents and businesses.

“While there is currently an abundance of water, we cannot become complacent because dry times are always just around the corner,” Mr Anderson said.

“Parkes was only months away from draining all its water sources before drought breaking rains fell in early 2020.

“This is why we need to invest in long-term water infrastructure now, so Parkes has a more reliable water supply when the next drought strikes.

“This project is one of the largest and most significant investments in water infrastructure in regional New South Wales.

“It will help overhaul the town’s water supply by more than doubling the transfer capacity from the Lachlan River to Parkes.”

Parkes Shire Mayor, Ken Keith, welcomed the State Government’s support and said the new infrastructure will be crucial for the region’s continued development.

“Water is the lifeblood of all regional communities, so ensuring we have secure access to safe drinking water is what will drive our future prosperity,” Mr Keith said.

“Parkes has already been identified as a Special Activation Precinct, so we need this project to deliver the necessary water infrastructure that will support our population and economic growth.

“The New South Wales Government’s contribution is a huge win for the community because it is the final stage of funding that we needed to green light this project and help secure our water future.”

The project is being funded in partnership with the New South Wales Government, the Federal Government and Parkes Shire Council.

Construction is expected to begin in late 2022.

An update to the National Construction Code (NCC) will see minimum energy efficiency requirements for new houses and apartments increase, and a new annual energy use budget will include hot water systems, and swimming pool and spa pumps.

The update comes after federal, state and territory Building Ministers agreed to raise the minimum energy efficiency standards for new houses and apartments, increasing the minimum energy efficiency requirements from the Nationwide House Energy Rating Scheme (NatHERS) equivalent of six to seven stars.

A new Whole of Home annual energy use budget –applicable to the home’s heating and cooling equipment, hot water systems, lighting, swimming pool and spa pumps, and on-site renewable energy systems – will also be introduced.

This budget intends to make homes more comfortable, help households with cost-of-living pressures, and support Australia’s transition to net zero.

In making this decision Building Ministers took advice from the Australian Building Codes Board, based on its extensive regulatory impact analysis and consultation over the last year.

Federal Assistant Minister for Climate Change and Energy, Jenny McAllister, said the new home minimum energy efficiency requirements will mean new homes are more comfortable and more affordable to heat and cool.

“These measures have clear benefits for households. Energy efficient houses are more comfortable to live in, cheaper to heat in winter and cool in summer,” Ms McAllister said.

“The new energy efficiency standards also support Australia’s transition to net-zero emission by 2050 by reducing the costs associated with new generation infrastructure.”

To ensure industry is adequately prepared, the energy efficiency changes to the NCC will come into effect on 1 October 2023 but may vary by state and territory.

Central Queensland’s Livingstone Shire Council will commit $6.6 million of its 2022/23 budget toward nine water infrastructure projects to be completed within the next 12 months, including valve upgrades, pump replacements and a new booster pump station.

The total spend will supplement funding already received for several of the projects, which has been sourced from State and Federal Government grants.

Funded projects include:

• $2.4 million for the construction of a new water reservoir at Emu Park West, improving storage capacity by 4ML

• $1.4 million to fund the replacement of filter media at the Woodbury Water Treatment Plant, and installing new air distribution grids, pipework, valves and process controls

• An additional $1.2 million to fulfil repairs at the now 97-yearold Mt Charlton water reservoir, which is expected to begin operating in September 2022

• $747,000 for the ongoing replacement of critical pumps and pipelines

• $853,000 to fund the finalisation of rectification works at Kelly’s Dam and the installation of a new booster pump station in Inverness

Livingstone Shire Council Mayor, Andy Ireland, said access to safe and reliable potable water is critical not only to residents, but also to economic growth and environmental outcomes.

“I’d like to sincerely thank the support of the Queensland and Australian Governments for their contribution towards these important projects,” Mr Ireland said.

The BNA pump from SEEPEX ensures compliance with API 676 and 682 while reducing overall costs in petrochemical applications.

y First-class API compliance along with heavy-duty design

y Pressure rating 300# and duplex stainless steel as standard

y Non-welded, cast casing reduces documentation and inspections

y High allowable nozzle loads and design pressure improve operational safety

The Queensland Government has announced a new $40.4 million allocation for new critical water infrastructure, including a new pipeline and pump station upgrades, in Mount Morgan to provide stronger water security to the town.

The funding for Mount Morgan’s No. 7 dam is part of the Queensland Government’s state budget and was announced by Queensland Minister for Water, Glenn Butcher. The Federal Government also committed $3.5 million to the project, which is expected to start in early 2023.

The critical infrastructure includes a new potable water pipeline, upgrades to the pump station and reservoir at Gracemere.

“This Queensland Labor Government is committed to building a pipeline from Gracemere to Mount Morgan, so that the Rockhampton Council will never need to cart water to this community again.

“We know how critical water security is to regional Queensland and that’s why we’ve invested this money, to make this project happen,” Mr Butcher said.

“Not only will this project create jobs during construction but a secure water supply bolsters jobs growth for existing businesses in the region and brings more businesses and families to the area.”

Rockhampton Regional Council Mayor, Tony Williams, thanked the Water Minister for advocating for the pipeline project.

“The proposed potable water pipeline from Gracemere to Mount Morgan would be approximately 28.7km in length. The project will also include upgrades to the pump station and reservoir at Gracemere,” Mr Williams said.

“Minister Butcher’s support is an incredible legacy for current and future generations of Mount Morgan, who will now enjoy a permanent, secure water supply of liquid gold.”

Member for Rockhampton Barry O’Rourke congratulated the Queensland Government on shoring up the funds for the region.

“This is a game-changer for this region and one of a number of highlights from this year’s Queensland budget,” Mr O’Rourke said.

The budget commitment means the funds can be released quickly, once the project’s Detailed Business Case has been thoroughly assessed.

“I want to really thank Rockhampton Regional Council for their hard work in preparing the business case and working collaboratively with my department,” Mr Butcher said.

“We’re all working toward a better Queensland and we do that best when we work together.”

Lynas Rare Earths has announced that it will deliver a $500 million expansion of its Western Australian Mt Weld mine, using a range of upscaled processing equipment.

The expansion project aims to meet accelerating market demand for rare earth materials and NdFeB magnets, which is forecast to grow from 130,000 tonnes of NdFeB magnets consumed in 2020 to 265,000 tonnes in 2030.

Using known technology, the project is set to deliver efficiency improvements, enhanced sustainability and a platform for further capacity increases.

Key elements of the expansion include:

• Crushing and grinding infrastructure

• Additional flotation circuits

• Apatite leach circuit

• Concentrate dewatering circuit

• Concentrate drying and load out facilities

• Reagent facilities

• A state-of-the-art high recovery water recycling circuit from the tailings dam

• Additional bore water desalination plant

• Additional tailings storage facilities, with segregated storage of process streams to enable potential future reprocessing

The initial expansion to 12,000 tonnes per annum NdPr equivalent has been fully scoped and the approximately $500 million investment is fully funded from cash flow.

Lynas CEO and Managing Director, Amanda Lacaze, said the project will assist Australia’s transition towards new energy technologies such as wind energy and electric vehicles.

“The rare earths market is growing at pace as the world transitions to new energy technologies such as wind energy and electric vehicles. Lynas has a decade-long track record in responsible rare earths production and the $500 million Mt Weld expansion project we are announcing today is designed to ensure we continue to grow with the market as a supplier of choice,” Ms Lacaze said.

“This investment is supported by our high grade, long life and reliable source of feedstock, the remarkable Mt Weld ore body. Having a long life resource is an essential foundation for success in the rare earths market and the recent 1km deep drilling has demonstrated Mt Weld’s potential to supply feedstock for many years into the future. The Mt Weld capacity expansion project aims to unlock its true value in the most efficient and sustainable way to 2025 and beyond.”

In addition to this initial expansion project, Lynas plans to implement further sustainability and circular economy activities on the Mt Weld site, including:

• A staged transition from diesel-fuelled power generation to gas and then hybrid renewable power generation

• A larger mine and waste rock landforms designed to be progressively rehabilitated

• Surface water management to capture seasonal rain events and divert into managed aquifer/groundwater recharge that also forms flood protection infrastructure for climate change resilience

Procurement of long lead equipment items has commenced and the Mt Weld expansion project is expected to create up to 300 jobs during the construction phase, and over 100 ongoing operational jobs in the Goldfields region of Western Australia. The project also supports the Federal Government’s Critical Minerals Strategy and the Western Australian Government’s Battery and Critical Minerals Strategy.

Comprehensive environmental flora and fauna and cultural heritage surveys have already been completed on the Mt Weld site and will support the environmental approval process.

Subject to relevant regulatory and stakeholder approvals, construction activities are expected to commence in early 2023, with full operation planned for 2024. Some infrastructure will be brought online in stages to accelerate production growth prior to the completion date.

New agreements for Westgold Resources are set to turn its diesel-fired power stations into gas-fired stations with renewables options across its Bryah and Murchison Operations to reduce carbon emissions and operational costs.

Westgold Resources has signed an Electricity Purchase Agreement with independent power provider Pacific Energy, and its new LNG Supply Agreement will see the company partner with Clean Energy Fuels Australia (CEFA).

These agreements will deliver substantial operating cost savings to Westgold in financial year 2023-24 onwards of ≈$100/oz at the current diesel price and will support its commitment to environmental, social and governance (ESG) initiatives that will reduce Westgold’s long-term greenhouse gas emissions.

Under this build-own-operate agreement with Pacific Energy, Westgold will materially reduce diesel consumption by replacing six diesel-fired power stations with four new, highly efficient gas-fired power stations which will incorporate renewable energy options and utilise solar power and battery storage across the Bryah and Murchison Operations.

Critically for Westgold, this transition to a mixed generation platform includes renewables and gas and is expected to reduce carbon emissions from diesel-powered generators by over 57 per cent, due to the higher integration of renewables (34 per cent solar) and cleaner fuel (gas versus diesel).

Westgold’s first new Pacific Energy power station will be commissioned in July 2023 at the Tuckabianna processing hub, with the three additional new power plants scheduled for commissioning from September 2023.

Westgold has concurrently signed a bulk LNG supply agreement with CEFA. CEFA will supply Westgold from its expanded LNG Plant located at Mt Magnet, 80km south of Cue.

This plant is currently providing LNG to another Pacific Energy power plant in the Murchison region and provides a substantial advantage due to its close proximity to Westgold’s operations. CEFA will fund and construct satellite LNG facilities (primarily comprising LNG storage and regasification equipment) at Westgold’s project sites, with the LNG trucked direct from its plant at Mt Magnet.

The new gas and solar power station to be commissioned at Westgold’s Meekatharra operations will also serve to simplify power generation by removing smaller diesel-fired power stations at Paddy’s Flat and Bluebird underground mines and providing power from a larger gas-fired power station via overhead powerlines.

Westgold’s Managing Director, Wayne Bramwell, said the transition to a cleaner, more efficient energy platform that utilises renewables and gas in FY22-23 is strategic for the company.

“It is an important step in meeting our ESG targets but is pivotal to reducing the operating cost of our business.

Westgold has selected two industry leaders in Pacific Energy and CEFA to work with us in this transition and we look forward to seeing the benefits that integrating renewable power and cleaner energy alternatives can deliver to our business and the communities within which we work.”

The New South Wales Government has awarded $45 million in funding to five pumped hydro projects, which will deliver a combined capacity of almost 1.75GW of energy storage to the state.

New South Wales Treasurer and Minister for Energy, Matt Kean, said the state’s Pumped Hydro Recoverable Grants Program will assist pumped hydro developers to cover upfront costs and lower investment barriers for the private sector.

“Funding agreements are already in place with five applicants who have received a total of $44.8 million to support pre-investment activities, establish project feasibility and develop a strategic business case,” Mr Kean said.

“If these pumped hydro projects proceed to construction, they are expected to create more than 2,300 jobs and attract $4.4 billion of private investment, which will help grow the economy and support the regions.”

Pumped hydro acts like a giant battery for the electricity system, using surplus renewable energy to pump water up a hill when it is sunny and windy, and releasing the water back down

New South Wales has a target to build at least 2GW of new long duration storage by 2030, and the Government has committed $97.5 million to accelerate pumped hydro projects that could meet this target. This includes funding for private projects as well as funding to undertake site investigations for pumped hydro potential on existing WaterNSW dams.

“New South Wales has the most ambitious renewable energy policy in the nation, which is needed to replace aging coal-fired power stations and build a clean energy future for the state,” Mr Kean said.

Mr Kean said pumped hydro is a key component of the state’s renewable energy plans, providing clean, reliable power and creating infrastructure jobs right across regional New South Wales.

“This is a win for New South Wales as these grants will be repaid to the Government if a project reaches financial close, meaning that these same funds could be used to support even more projects in future,” Mr Kean said.

The City of Yarra has announced the development of a new stormwater harvesting system, including a pump station, to supply a local park with sustainable water.

The stormwater harvesting system will be developed in Carlton North, supplying Curtain Square with an alternative water source.

The City of Yarra said this will ensure the sustainable and long-term health of this green space for the local community.

The project includes the building of an underground storage tank, treatment system and pump station which will distribute water to Curtain Square.

• API 610 Manufacturer

• In house service, repair & overhaul

• OEM Australian made spare parts

• Melbourne 2.5MW test facility

T: 03 9464 9500 www.unitedpumps.com.au

The implementation of the stormwater harvesting system will also mitigate and reduce flood risks to the local area.

This initiative supports the environmental and climate objectives outlined in the City of Yarra’s Council Plan 20212025 through sustainable consumption and preservation of its natural resources.

The project is supported by the Victorian Government’s Integrated Water Management Program.

Works are scheduled to commence mid-2023.

• Deep well submersible pumps to 1000kW

• Vertical turbines 6”to 48”

• Australian Made

03 5941 3400

Water Corporation will oversee a $320 million expansion to its Groundwater Replenishment Scheme (GRS), promising to double capacity for a total output of 28 billion litres per year.

Construction of the second stage began in late 2017 and has since been fully commissioned by the Western Australian Government, following additional testing of the off-site bores.

New infrastructure constructed as part of the $320 million Stage 2 expansion will include:

• A second Advanced Water Recycling Plant next to the first at Water Corporation’s Beenyup facility in Craigie

• Four recharge bores and four monitoring bores across two recharge sites in Neerabup and Wanneroo

• A 13km recharge pipeline to transfer the treated drinkingquality water from the plant to the new bores

Operating since 2017, the GRS remains the first full-scale project of its type in Australia, and has since recharged more than 54 billion litres of water.

The innovative scheme sees highly treated wastewater from the Beenyup Water Resource Recovery Facility purified at the Advanced Water Recycling Plant to a level that exceeds drinking water standards.

Fifty per cent of this purified recycled water will be used to recharge the Leederville and Yarragadee aquifers on-site, with the remaining water used to recharge aquifers at bore sites in Neerabup and Wanneroo, via a 13km long pipeline.

This innovative water source forms part of Water Corporation’s three-stream approach to develop new water sources, reduce water use and increase water recycling. By 2035, Water Corporation aims to recycle more than a third (35 per cent) of treated wastewater.

State Water Minister, Dave Kelly, said the project would lessen the impact of global climate change on Western Australia’s water resources.

“Due to the impacts of climate change, reduced rainfall and increased abstraction, our groundwater resources are under pressure,” Mr Kelly said.

“Water Corporation’s Groundwater Replenishment Scheme is an innovative and sustainable way to recycle large volumes of water.

“By recharging our precious groundwater supplies through the scheme, we are able to abstract equivalent groundwater in later years, adding to Perth’s drinking water supply, while reducing impacts to the environment and other water users.

“Along with the State Government’s commitment to build a renewably-powered desalination plant at Alkimos by 2028, this major $320 million investment will help secure Perth’s water supplies and manage the impacts of climate change.”

At Brown Brothers Engineers we have the most comprehensive range of quality pumps and innovative pumping solutions. We are the distributor for some of the world’s leading brands including:

WELCOME TO THE BIG END OF TOWN.

Layne Bowler vertical turbine pumps have a proven record under the most demanding and toughest of conditions.

• Flows to 2,300 L/Sec

• Heads to 350 m

• Power to 1000+ kW

• Temperatures to 150°C

• Bowls Diameter up to 45 inch

When high head and high flows are required look no further than this quality Italian made range.

• Flows to 5000m³/h

• Head to 220m

• Pumps that exceed EN733 (DIN 24255 standard)

Call us today to see how we can deliver your pumping solution.

Why efficiencyenergymatters

Fire protection at the front line Storage the key to new hydro project Dr Pump’s top tips for reliability

By Lauren Cella, Managing Editor, Pump Industry Magazine

The idea of launching a pump magazine first came about sometime before 2012 when Publisher, Chris Bland, noticed that pumps were the common theme that he kept coming across in the various titles he had worked on in industries like water, oil and gas, energy, and infrastructure. Whatever the industry, people needed pumps and used pumps. However, he also noticed there was a communication gap in the industry as there was no single channel that people could use to get information about the pump industry or to connect with pump end users. Thus the idea for a dedicated magazine about Australia’s pump industry was born.

With an idea now in mind, Chris started researching the industry and soon came across the PIA, and reaching out to them was one of the first steps he made to bring the magazine to fruition. While the PIA were wary and uncertain at first about whether the partnership could work, when Chris explained the concept and that there was no charge to them, they became pretty enthusiastic about it. Since then, Pump Industry Magazine has been the official media partner of the PIA, the only association established to support and promote pump businesses operating in Australia.

Once the PIA was on board, Chris got in touch with its members, and over the course of a month in July 2012, he tried to call pretty much all of them to pick their brains. A lot were uncertain at the start about whether the concept would work, but the key message that kept coming up that would be required for the magazine's success, was to ensure that the magazine was sent to and was read by the end users and specifiers of pumps across all industries.

The PIA membership itself consists mainly of pump manufacturers and suppliers, so Chris had to look more broadly to build the audience. Armed with the advice of the members – who told him that he needed reliability engineers, rotating equipment engineers, hydraulic systems engineers, hydraulic consultants, building managers and maintenance supervisors reading the magazine – he started researching every mine, oil and gas plant, power plant, council, wastewater treatment plant, major building and even every irrigation store in the country. At these places, he found the relevant people that should be reading the magazine, and built the audience from there.

Chris worked on not just getting the magazine to the right people, but also on ensuring they actually read it by investing in creating content that was relevant to them. He spoke to a representative sample of these people to find the key issues they were interested in and made sure that the content of the magazine was based around their interests – not just the interests of the pump suppliers.

One of the common themes that came up in these conversations was the fact these people had often studied pumps a long time ago, and now dealt with pumps along with a wide variety of other pieces of equipment in their daily lives. As a result, they were keen to see content centred around technical basics and other primers, to help refresh their knowledge. From day one, this has always been a key theme of the magazine, and the daily tracking and research we conduct into reader behaviour shows that this content has always been, and continues to be, among the most popular featured content in our magazine and website.

The first issue went out to an audience of over 2,600 and has continued to climb since then to a print readership of over 8,500.

The digital magazine also launched in 2012, building a strong audience with the newsletter and website from day one. Now, in 2022, we reach at least 48,100 people each quarter across our print, digital and social channels.

In 2014 the PIA celebrated 50 years and Chris thought it a joy to be able to publish a supplement in the magazine covering its history. After its publication, he was surprised and pleased to hear from Bob Pullen, who let Chris know that he had actually published his own Pump Journal in 1968. He was kind enough to share some original editions and Chris was amazed by the quality of the production, particularly given the lack of technological resources that we take for granted today in the world of magazine production.

As the business grew, Laura Harvey was brought on board in 2014 and took over the reins as Managing Editor of Pump Industry Magazine. Laura continued to foster and expand upon the strong relationships Chris had built, solidifying the magazine as the go-to source of news for the Australian pump industry. Over the time Laura was editing the magazine, the range of features for the magazine grew, including the launch of the annual State of the Industry survey and the Industry Capability Guide.

The annual State of the Industry survey and article provides the industry insights into what has affected the industry over the previous 12 months and what the industry expects to have an impact over the coming 12 months based on the experiences of pump businesses. It also looks at the opportunities and challenges ahead, and gives those working in the industry a view of how the industry is changing.

In 2015 the first Pump Industry Capability Guide was published; an annual publication and integrated website to help better inform pump end users about the offerings of Australia’s many innovative pump suppliers. It has continued to grow, with the digital version of the guide becoming increasingly integrated with the Pump Industry website, solidifying it as the key reference tool for end users.

We’ve also expanded our offerings and now act as a full marketing agency for a number of companies in the industry, helping manage their marketing and create unique content, custom newsletters, social campaigns, websites and more.

I joined the Pump Industry team in 2016 and took over from Laura as Editor in 2017, continuing to build the brand.

In recognition of the PIA and the industry’s long history, we created a feature called ‘Pump Pioneer’ that appeared in a number of editions. Over the years we’ve spoken to life members and other industry stalwarts about their life and their career in pumps. We’ve had the pleasure of interviewing and writing about industry legends like Bob Moore and Antony Grage in our early editions – both of whom have sadly since passed away – as well as many others.

We’ve also done interviews with younger pump professionals under a feature titled ‘Industry Voices’, showing their career path and discussing challenges facing the industry.

The last few years have been particularly challenging for the industry with the COVID-19 pandemic and supply chain issues, amongst other challenges, but as an essential service and with a focus by state and federal governments to spend on infrastructure, the industry has worked to overcome these. The PIA in particular did a lot of work during the early days of the pandemic to have the industry recognised as an essential service to allow it to work even during the most strict lockdowns.

Over the past ten years, Monkey Media has launched a number of new magazines in areas like utilities, infrastructure, energy, council and mining, but as our first publication, Pump Industry always holds a special place in our hearts.

I want to thank all of the PIA members and executives for their support over the past ten years, in particular Keith Sanders, Ron Astall, John Inkster and Kevin Wilson.

Here’s to another ten and many more beyond!

In consideration of environmental relief and energy saving, Franklin Electric has developed High Efficiency 4”, 6” and 8” Submersible Electric Motor Borehole Systems, consisting of synchronous submersible NEMA electric motors, associated variable frequency drives and output filters.

Advantages of the system:

• One-stop shop – perfectly matching components guarantee first-class performance.

• Up to 20 per cent energy saving* = system payback< 2 years

• Up to 13 per cent improved motor efficiency (system up to eleven per cent) with excellent partial load behavior

• Significantly lower motor heat rise = increased lifetime

• Higher power density* = lightweight

• Easy setup due to tailored pre-setting, user interface and Franklin Electric’s own software

• Speed control = optimum aggregate operation-pump matches system all the time

• Incorporated soft start and protection features = increased lifetime = no additional investment

• Reduced amps = reduced drop cable size

• First-class protection with electronics in IP66/54 = easy retrofit – no additional cabinet cost

• Power factor corrected input = no power compensation needed

• Communication Modbus (RS485, Ethernet and optional Profibus)

*In comparison to current asynchronous technology System Technical Specification:

• Rating: 4” 1.1-7.5kW 6” 4-37kW 8” 75-150kW

• System Power Supply: Voltage 400V +/- 10% Frequency 50Hz +/- 6%

Solar systems:

The High Efficiency Systems are ideal for larger solar pumping systems due to their superior efficiency, which in most cases results in less solar panels being required. The system can be standalone solar or incorporated into a blended system utilising solar, mains power or diesel generated power.

Flow - Up to 300 m3/hr Pressure - Up to 24 bar

Brown Brothers Engineers Australia celebrated the official opening of its new purposebuilt facility in Melbourne on Wednesday 15 June 2022.

Approximately 120 were in attendance, including over 70 customers and suppliers as well as international guest Ole Weiner, CEO of AxFlow Holding AB making the trip from Sweden.

The new facility was officially opened by John Inkster, Managing Director of the AxFlow Oceania Group, and Ole Weiner.

The site, located at 228 Atlantic Drive in Keysborough, provides a much larger and improved space that is around triple the size of its previous Melbourne facility. At over 5,500m², the additional space will hold some of the latest technology,

enabling Brown Brothers Engineers to design, build and test pumps and equipment to recognised standards.

Some of the key capabilities of the new site include:

• 22m-deep pump test well interconnected to a 2.6m-deep test tank holding approximately 34,000 litres of water capable of testing pumps in excess of 250kW and flows to 300L/s

• Dedicated diesel driven test bay

• Overhead crane with five tonne lifting capacity

With business continuing to expand, the larger size and additional space of this

for the continued support and commitment, saying, “without them this facility would not have been possible”.

Joining Brown Brothers Engineers on the new Keysborough site, are fellow AxFlow Group members Kelair Pumps Australia (Victoria division), and GT Water Technologies.

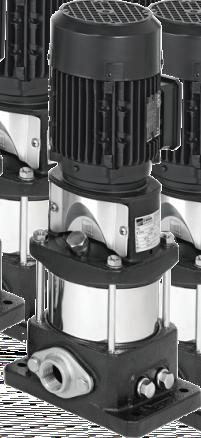

Lowara’s Smart Pump range is all about the right combination of motor, variable speed drive and pump.

Maxijet has a diverse range of market leading and innovative irrigation pumps suitable for all agricultural and non-agricultural applications.

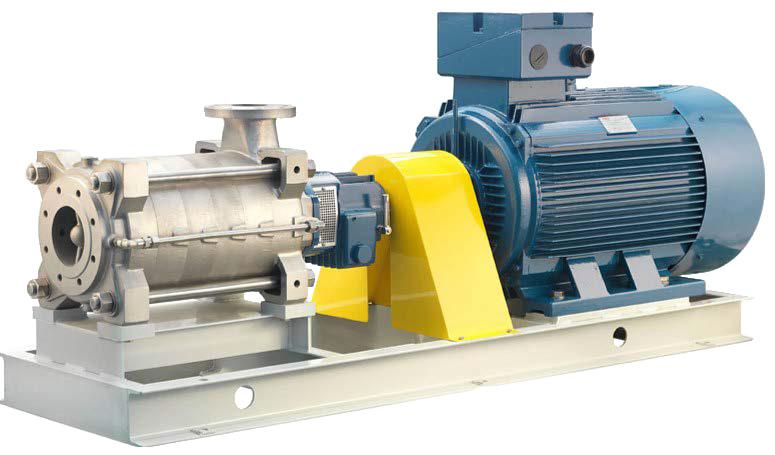

• Horizontal Multistage Pumps

• Vertical Multistage Pumps

• Heavy Duty Centrifugal Pumps

• Bore Pumps

Maxijet is driven to be the industries most trusted source in customer service, technical, aftermarket support and industry solutions for the conservation of our most important global resource. We pride ourselves on being the industry people who care.

For more information on Hyjet and Pedrollo products and expert advice to help you choose the right solution for your project, contact us today!

DAB Pumps is introducing commercial building services to a new concept and industryfirst product that is supercharging the booster set industry – the EsyBox Max, an integrated pumping system for pressurisation. Available in two power sizes, it consists of modular elements that allow different configurations to cover the needs of medium and large apartment blocks and high buildings, even over 14 floors.

Each unit consists of the single, double or triple connection base and the pumping units – a four-pump system is available with the additional kit to connect two double bases.

Large energy savings are achieved with the DAB inverter combined with a brand new permanent magnet motor. DAB also designed completely new hydraulics, making it leaps ahead in terms of energy efficiency. But it is not just energy efficiency that is at the forefront of this new technology.

Esybox Max will improve the storage efficiency in the warehouse. Where there was once one booster occupying space, you can now fit three twin pump booster sets in its place. This allows people to store the full range on one pallet, meaning a customer can pick up an off-the-shelf booster solution of up to four pumps the same day.

“When we started to think about Esybox Max, we asked ourselves how to manage

the evolution of the Esybox range. It was clear from the very beginning, it could not just be something bigger. We felt we had to bring forward the path of evolution, completely changing the rules of the game for booster sets in residential and commercial buildings. Esybox Max is the outcome of listening to and communicating with many different people who will be in direct contact with the product.”

Keeping it flexible, DAB has the on-site assembly concept. So if you have difficulties getting to the pump's location, due to narrow stairways and corridors etc., you can choose to assemble your booster on-site which will only require moving smaller, lighter boxes into the location then carrying out a quick and easy assembly.

The Esybox Max also offers full connectivity and control using DAB’s DConnect technology which is built into the pump and offers many more advantages than typical BMS systems. Performance, data storage and remote monitoring support users, and facility managers can control their pumps from anywhere, making sure that the running parameters of the pumps follow project specifications exactly and avoiding any possible site issues for complete peace of mind.

The DAB inverter has been combined with a brand new permanent magnet motor. We also designed completely new hydraulics, making it leaps ahead in terms of energy efficiency.

The most compact and integrated booster set on the market. Connect 1, 2, 3 or 4 Esybox MAX units.

Easy to maintain

Connect and control from anywhere with DConnect.

Easy to move & install

Quick On-Site Assembly.

Affordable web based remote control for your installation

With DConnect you can use your smartphone to connect directly with the pump using the simple interface. All adjustments are possible remotely, allowing total control with no unwanted surprises.

LEARN MORE

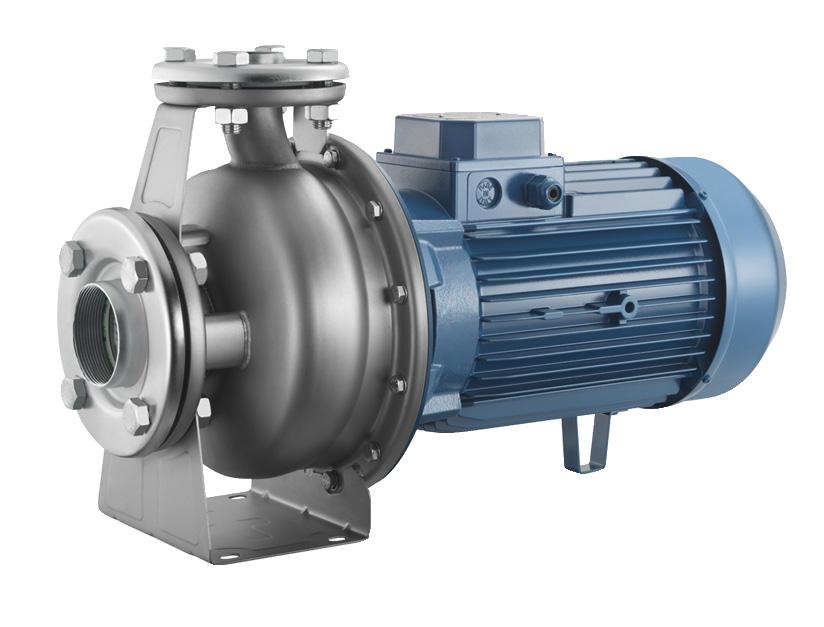

Ebara is known worldwide as one of the largest and most diverse manufacturers of custom, industrial and general purpose pumps. Since its beginnings in Japan over 100 years ago, the Ebara Corporation has been a major supplier of pumping equipment to Japanese industry, and over the last 50 years has expanded to all industrial markets worldwide.

Ebara has factories and sales offices in six continents and has recently undertaken a major globalisation of its standard industrial product range. This includes the introduction of a new range of EN733 end suction pumps, and a redesigned and economical vertical multistage pump.

In Australia, the Ebara name has been renowned for its quality and reliability. The Ebara Pumps Australia standard product line has been sold and supported in Australia for over 30 years.

Ebara continues to supply world-leading pumps.

Two recent examples are shown below:

Ebara has supplied some of the world’s largest boiler feed pumps to supercritical power plants in China. These were the first single pumps capable of supplying boiler feed water to an entire 1,000MW power plant.

Discharge:

Duty: 3,200t/hr @ 3,800m.hd.

Many Ebara custom pumps have also been installed in Australian and New Zealand power stations and in industry for over 40 years with trouble free operation.

The new products have been designed to global standards to suit the world market, and are manufactured at Ebara owned and managed factories in Europe and South East Asia. This is building on the 100 years of Japanese technology and engineering expertise obtained in the manufacturing of high-end custom pumps.

Ebara has recently manufactured its largest submersible pump in terms of length and motor power. This will be installed at Lake Mead to supply water to Las Vegas, US.

Diameter: 900mm Motor Power: 2,500kW

Duty: 79m3/min @ 132m.hd. Length*: 130m

Length*: The pump is assembled with 24 x 5.2m column pipes

Ebara have been supplying pumps into Australia for over 30 years and have gained a reputation for their quality and reliability.

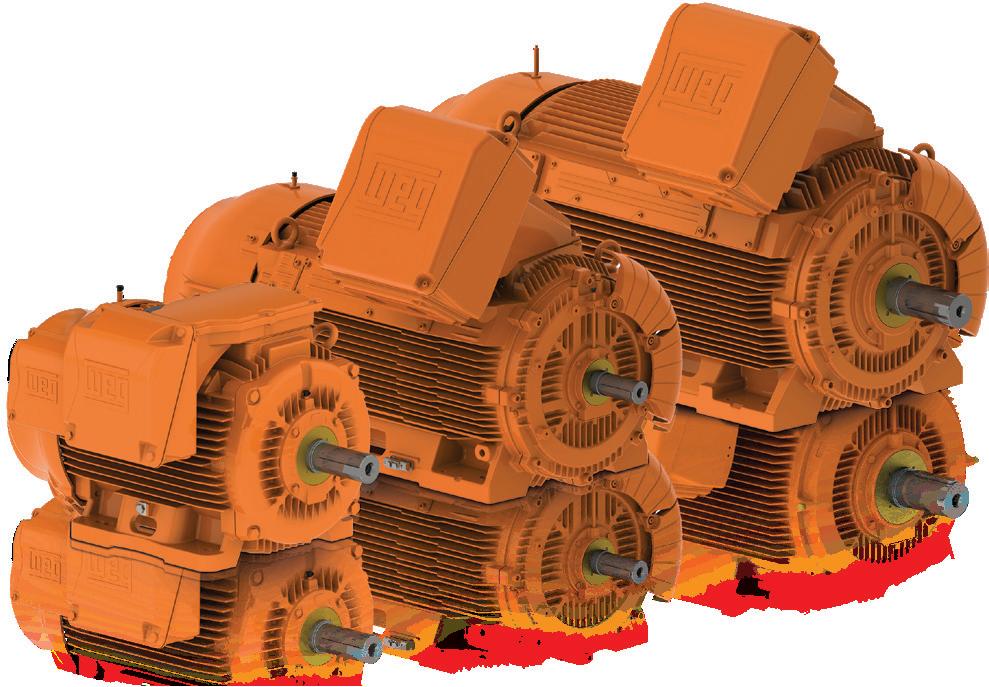

The WEG Mining Motor was first launched in 1985 after an extensive review of electric motor specifications from the major mining companies and industrial sites throughout Australia.

Highly efficient and featuring outstanding mechanical capabilities, the WEG Mining Motor established an identity and reputation as a high-quality, rugged, reliable product for belt and direct drive pumping applications.

The WEG Mining Motor has been relied upon by end users and leaders of the pumping segment for use in their missioncritical solutions.

For over 37 years and through changes in Australian industry standards, the WEG Mining Motor has continued to evolve to meet industry demands. It remains the benchmark for electric motors in technological features, efficiency, reliability, and performance, making it the ideal component for your pumping solution.

Speck in Roth is a family-run business spanning over four generations, with a tradition that stretches back to 1909. Today, we are a partner to OEM and plant manufacturers in more than 43 countries. Our extensive range of products, with a focus on liquid and gas delivery, is adapted to the specific needs of our customers.

Innovative and successful products for a wide variety of applications are the result of hard work and close cooperation with our customers. We listen to the market requirements, and with the use of our brilliant research and development facility provide our customers with the right solution to meet their exacting demands.

Precision, top quality and service set us apart. We passionately manufacture pumps and drives responsibly for the demands of today and tomorrow with our high vertical range of manufacture, an enthusiasm for technology as well as our unique know-how. Our objective is to create lasting values for both our customers and ourselves. In this way we open up new markets and prepare ourselves for the future.

Speck manufactures products to EN ISO 9001. This system describes the methods and provides the employees with the tools to ensure the quality of each individual process.

Bespoke products can be manufactured to meet our customer’s requirements using the ‘One-PieceFlow’ method where a single employee accompanies each product throughout the whole assembly process. This means that variations in product can be changed from piece to piece; benefiting our customers with shorter deliveries and optimising quality.

Baking processes with heat transfer media

30,000 bread rolls per hour at 250°C; in order to achieve consistent results during baking, ultramodern baking ovens are operated with heat transfer oils at temperature ranges of up to more than 300°C. Speck supplies a clean solution for this challenge with reliable, sealless pumps – maintenance-free and safe.

Speck supplies pumps for applications in the beverage and food processing industry, which calls for particular hygienic, clean and reliable processes. Top-quality pumps for bespoke and technical perfection.

Speck pumps can be found wherever the highest demands on hygiene, reliability and safety for end users are a must. For example, we produce liquid ring vacuum pumps for steam sterilisation equipment in doctors‘ surgeries, clinics and hospitals, or sealless pumps for cooling on X-ray, laser devices as well as in computer tomography. In addition, Speck offers customised packages with a variety of accessories such as separators, heat exchangers etc. These system solutions do away with extensive assembly times and purchases from several suppliers.

Plastic, the all-rounder material, is omnipresent and indispensable. Saving energy in profile extrusion, degassing during plastic recycling or the control of temperature during the injection moulding process; Speck is the problem solver for the OEM and the processing industry.

Our specialised products are principally used in medical technology, the chemical and pharmaceutical industries, cooling and tempering appliances and in the plastics industry. Speck is very export-oriented and employs over 575 staff members worldwide.

Products from Speck are characterised by a wide range of available variants which is specially tailored to the customer’s needs. Our staff in the Technical Department are constantly working on new solutions and further developments to our existing products that help our customers move forward – day in, day out.

Over time, pumps and associated components are subject to wear, corrosion and cavitation damage in service, resulting in downtime, reduced efficiency and service life, increased costs, and in some applications, safety hazards. As this deterioration occurs on the surfaces of the components, having a high-quality protective coating installed by an experienced company can preserve assets, extend their service life, and improve safety.

The Belzona Polymeric range of metal, rubber and concrete repair and protection materials – distributed in Australia solely by Rezitech – allow the rebuilding and protection of damaged machinery and equipment, ensuring they will stand up to chemical attack, constant immersion in liquids and other industrial environments.

The Belzona range reduces labour time and costs by eliminating the need for disassembly, welding, and postweld heat treatment; decreases costs by increasing asset availability; and enhances safety by allowing in-situ cold work with solvent-free materials.

Belzona fixes common problems associated with industrial equipment by:

• Extending service life and delaying replacement – the products provide a superior layer of protection for damaged equipment

• Simplifying maintenance procedures and reducing costs – the polymers are resistant to abrasion, erosion, chemical attack, corrosion, and are relatively easier to clean than bare surfaces

• Improving operational efficiency – polymer surfaces are easier to work on compared to bare surfaces, resulting in less to worry about during operations

• Minimising downtime – damaged industrial equipment can disrupt operations. Polymeric solutions minimise downtime and don’t get in the way of production

Belzona protective coatings feature:

• WRAS approval

• AS/NZS 4020 approval for drinking water use

• High adhesion

• Low surface tension

• High mechanical strength

• No shrinkage

• Electrical insulator

• Smooth surface

• Long working life

• Chemical and impact resistance

• Safe for constant immersion

• Safe for cold application

• Environmentally friendly

In 2010, a major Australian water utility was undertaking scheduled routine maintenance on a pump and was extremely happy to find that the Belzona coatings that had been applied 19 years previous were still intact and evident, and there was no additional repair or coating of the internal casing/cover required. Furthermore, an independent test by the water authority confirmed efficiency gains in flow capacity were accomplished between 4-7 per cent.

Extending the life of cyclone cones

In 2012, Belzona was installed on cones in a cyclone wash infiltration plant

in a limestone quarry in England. As the cones were suffering heavy levels of abrasion, the mean time between failure was unacceptable, with unprotected clones failing within one month and rubber-coated cones only lasting for six months. The downtime and replacement costs were costly for the client.

Belzona was used for a trial application to increase the working life of the cones, and resulted in the cones lasting 18 months – a lifespan increase of 12 months. As well as reducing the cost of replacement, the largest cost saving for the plant was the reduced downtime. After the successful trial, Belzona was made the standard solution for all abrasion areas within the plant.

Your trusted and experienced Australian distributor for Belzona Rezitech is an 100 per cent Australian-owned company and the sole distributor of Belzona in Australia. It has been involved with major plant upgrades and expansions projects for many major companies servicing a wide range of industries. Its team of experienced industry professionals are able to diagnose a problem and recommend a solution, as well as apply Belzona coatings either on-site or at its dedicated workshop.

Rezitech can also provide on-site supervision, NACE qualified coating inspectors, and in-plant seminars and on-site training.

Rezitech combines the wide range of Belzona materials with its application expertise to provide high-quality, longlasting repairs for all types of equipment and structures.

Belzona 1341 (Supermetalglide) improves pump efficiency by using hydrophobic technology to repel process fluids and reduce turbulent flow.

Efficiency increases of up to 7% have been recorded on new equipment and up to 20% on refurbished equipment.

Belzona 1341 is used to improve efficiency on both existing pumps as well as coating new pumps prior to being installed for use.

A 2-part epoxy coating designed to improve efficiency of pumps, pipes, valves and other fluid handling equipment while protecting them from the effects of erosion and corrosion. This high performance product is proven to reduce energy consumption, provide excellent chemical resistance and lower maintenance costs.

Key Benefits of Belzona 1341:

• Enhancing efficiency performance of various pumps including:

» Centrifugal Pumps

» Positive Displacement Pumps

» End Suction Pumps

» Split Case Pumps

• Long-term erosion and corrosion protection

• Excellent chemical resistance against a wide range of chemicals

• Suitable for contact with potable water (AS/NZ 4020 standard)

• Reduced health and safety risks as it is solvent-free

• Excellent bonding to metals including stainless steel, duplex steels, carbon steel, aluminium, cast iron and bronze as well as specialist alloys and other materials

Climate change, demographic growth and water scarcity are creating new challenges, and desalination is becoming a crucial alternative to traditional fresh water resources. SAER is ready to face these new scenarios with a strong and effective response; a full range available in duplex and super duplex.

n the last decade, SAER heavily invested in the research and development of optimal solutions for water treatment, increasing the flexibility of the pumps range, and widening the offering through highly personalised products in order to meet customers’ needs.

A range of end suction pumps, close coupled, high pressure pumps, split casing pumps and submersible pumps and motors, are now available in duplex and super duplex. The knowledge acquired from over 70 years of experience in the pump business has enabled the creation of pumps that can withstand harsh and corrosive environments, for a troublefree experience.

In desalination there is an extensive use of centrifugal pumps, both for the extraction phase and for water transfer.

It is crucial to select the right pump on the basis of performances and materials.

The importance of looking for the right material is sometimes underestimated; cheaper materials could lead to problems (costs of maintenance or replacing), while selecting a well-built, reliable pump will have lower lifecycle costs.

The SAER team can follow customers step by step in the process of product selection according to their specific needs.

The super duplex range of SAER features flow up to 5,000m³/h and head up to 60 bars for surface pumps; while for submersible pumps, the available sizes range from 6” to 14” up to 300kW, with incredible delivery times, thanks to their Italian production.

Laboratory tests can be performed, as well as third party certifications when needed.

• NCB NCBK end suction pumps exceeding EN 733 norm

• IR extensive closed couple range

• TM high pressure multistage pumps available in hundred configurations

• SKD split casing pump for big flow

• S and NR submersible pump range

• MS submersible motors completely rewindable

For more information, visit the SAER website: www.saerelettropompe.com.

If you want to receive the complete hard copy documentation related to super duplex SAER pumps, contact info@saer.it Subscribe to the SAER newsletter, and follow on LinkedIn @saerelettropompe

Sense and Process

With this solution the following issues can be detected:

■ Ragging

■ Blockage by foreign objects

■ Faulty or damaged bearings

■ Faulty or damaged seals

■ Wear issues and rub issues

■ Imbalance

■ Cavitation

■ Looseness

■ Unusually high signatures in grinders and macerators

Submersible pumps do the essential – but dirty work – of transporting sewage to treatment plants. Prone to blockages, ragging, and general wear and tear, pumps need to be monitored to avoid events such as overflow and environmental contamination of public and residential areas.

Optionally, the system can also monitor:

■ Excess Current

■ Sewage Level and Control

■ Flow and Temperature

Direct Comms to PLC via front end dedicated ports is also available for:

■ Ethernet Ip

■ Modbus TCP/IP

■ Ethercat

■ Profinet

As proactive environmental leaders, SA Water continues to integrate sustainable and innovative practices into its large-scale water and wastewater pumping operations, as it strives to achieve net-zero carbon emissions by 2030.

With approximately 1.7 million customers across all corners of the state, the utility has made a continued shift towards using renewable energy generation and storage at some of South Australia’s most remote locations, such as the Anangu Pitjantjatjara Yankunytjatjara (APY) Lands and Far West coast.

Together with a combination of efficient pumping operations and innovative solar scheduling technologies at two new remote desalination facilities, SA Water is already achieving significant reductions in power consumption.

SA Water manages water supplies and/or wastewater disposal systems in 13 Aboriginal communities and government facilities in the APY Lands – Indulkana, Mimili, Kaltjiti (Fregon), Umuwa, Pukatja (Ernabella), Yunyarinyi (Kenmore Park), Amata, Pipalyatjara, Kalka, Kanpi, Nyapari, Murputja and Watinuma.

Included in these operations are 62 bores – 15 of which are solar-powered – five desalination plants and one wastewater treatment plant.

SA Water’s General Manager of Operations, Chris Young, said, “Having worked closely with communities across the APY Lands for many years, we understand the important role that a sustainable water service plays in maintaining public health and hydration, as well as facilitating future growth and development.

“Solar generation is a particularly useful renewable energy source, and its availability and scalability enables it to be integrated swiftly within our existing energy management portfolio across the state, achieving the greatest impact on our environmental performance.

“Given the abundance of warm and sunny weather across the Lands, it makes sense for us to use renewable energy where possible on the construction of new treatment facilities, without compromising on their performance.”

This focus on innovation was most recently demonstrated in the remote Aboriginal community of Kaltjiti, near the South Australia-Northern Territory border – with a new energy efficient desalination facility now up and running.

Replacing the previous facility constructed in 2005, the small-scale reverse osmosis plant can produce up to 120,000 litres of water each day.

“With the previous plant reaching the end of its useful life, Kaltjiti’s new desalination plant will help us to continue providing sustainable water services to the local community well into the future,” Mr Young said.

“Using the process of reverse osmosis, the plant removes any naturally-occurring impurities like high levels of salinity, which are found in many of Australia’s inland groundwater sources.

“It also manages levels of naturally-occurring fluoride, in line with the Australian Drinking Water Guidelines (2011), before delivering the high-quality drinking water to the community.

“As further demonstration of our path to becoming proactive environmental leaders, the plant is also fitted with 38 kilowatts of solar panels and additional battery storage, helping to harness the region’s traditionally warm and sunny weather, to reduce carbon emissions and our reliance on power from the local grid.

“Like many of our remote treatment sites, the plant is fitted with a high-tech computer system which can be remotely monitored and controlled by our people, meaning any required faults or maintenance can be identified early and repaired as needed by our team or local contractors.”

Yalata’s green energy machine achieves 400 per cent milestone

South of Kaltjiti on South Australia’s Far West Coast lies the small Aboriginal township of Yalata.

Looking to construct a new, state-of-the-art desalination facility to service local customers, SA Water turned to the use of 40 kilowatts of solar energy and back-up battery storages to capture the region’s sunshine and reduce reliance on the local power grid.

“Within a matter of months, the new desalination facility had used a fraction of the energy required to power the old plant, falling from an average of 10,000 kilowatt hours per quarter prior to the upgrade, to just over 2,000 kilowatt hours,” Mr Young said.

“Our new plant – which is capable of producing 180,000 litres of water per day – is predominantly powered by a 40-kilowatt solar array with back-up storage, and with increased throughput we are able to produce enough water while the sun is shining to meet customer demand during the day and store water for supply overnight.

“Through clever design and construction, we have increased the Yalata plant’s capacity to secure a reliable water supply for our customers, while also reducing our environmental footprint.

“The previous plant’s energy consumption got as high as 22,000 kilowatt hours per quarter last year, so it is fantastic to see the new plant harnessing more clean energy to reduce greenhouse gas emissions and operational costs.

“Importantly, upgrading our plant at Yalata ensures safe, clean drinking water into the future to support the health and wellbeing of the local Aboriginal community.”

SA Water is among South Australia’s largest electricity users, with the utility’s energy-intensive drinking water and wastewater pumping and treatment operations across the state costing approximately $86 million in 2020-21.

Driven by a desire to deliver sustainable benefits for its customers and business, the utility has enhanced its focus on renewable energy sources and storage at pump stations, pipelines, and treatment plants, headlined by its industryleading Zero Cost Energy Future initiative.

“One of the largest leaps on our ambitious path to slash operating costs and carbon emissions is our initiative to integrate around 360,000 solar panels at our locations across Australia, together with 34 megawatt hours of battery storage,” Mr Young said.

“Once progressively energised and connected to the national grid, these sites will generate 242 gigawatt hours of clean, green solar energy per year, which is around 70 per cent of our annual electricity needs in an average weather and water consumption year.

“In the same way that many Australians have harnessed the benefits of solar panels at home, we are making some of our physical assets work harder for us, taking advantage of our large buildings, roof spaces and land holdings to generate a sustainable source of energy.

“There will still be times when we draw electricity from the grid to power our pumping operations, but we’ll offset those costs by storing and selling energy we produce at other times, to bring our net external electricity expenses down.

“It is clear that one of the most significant challenges facing the water industry is climate change, and through this large-scale project and the wider implementation of renewable energy, electric vehicle integration and focus on land biodiversity, we’re proactively taking steps to help transition to a low-carbon economy over the coming decade.”

Pump monitoring technology has been around since the 1970s, but as the industry launches into the digital revolution, pumps equipped with artificial intelligence (AI) systems are expected to be the rule, not the exception.

As pump manufacturers and operators embrace these new technologies, the industry is expected to transition from a product-based industry to a service-based one.

Now, the focus is not just on ensuring a high-quality product, but partnering with original equipment manufacturers (OEMs) to envision and build more efficient, more connected pump ecosystems.

This swift shift has changed the focus for pump manufacturers. Between 50 and 60 per cent of OEMs’ revenue will come from service-related activities (real-time monitoring and reliability services) by 2025, according to a Frost & Sullivan analysis, 2025 Vision: Future of Pumps in a Connected World. Pump OEMs are looking to diversify portfolios with new services that can provide meaningful data insights.

These service areas might include cloud computing, edge analytics, smart sensor mesh networks, blockchain, predictive maintenance and other IIoT-based technologies, while leveraging AI to reduce energy consumption and control operational costs for pumps. With a new age of digital pumps on the horizon, how are AI-enabled systems expected to change the future of the industry?

With AI-enabled predictive analytics, there is an overall reduction in both operating and lifecycle costs. A Deloitte analysis found that predictive maintenance can reduce overall maintenance costs by up to 30 per cent, and reduce breakdowns by 70 per cent.

Wireless technology can connect advanced pump sensors to the cloud for analysis by AI software, offering a more comprehensive and long-term vision of equipment performance, as opposed to manual checks.

Typically, manual pump equipment assessments will be carried out periodically. This can give an indication of whether there are any potential operating issues which could cause a shutdown or disruptions in the short term.

However, during the gaps between these manual equipment checks, issues can arise without an operator’s knowledge. With innovative pump monitoring devices, operators can check on pumps daily in real time, leaving no time for potential issues to arise.

This shift from a reactive to a proactive approach to maintenance has been happening for a number of years, and is key to extending equipment life. AI, the industrial internet of things (IIoT) and other smart pumping methods are transforming not just practical operations, but also our understanding of holistic equipment management.

Data from sensors can offer early detection and diagnostic processes, troubleshooting problems before they impact plant efficiency and incur extra costs. This means that plant managers can be on top of signs of equipment failure or maintenance concerns before they result in problems that can affect the operation.

Smart sensors can operate, control and protect pumps and their associated systems, helping operators to more easily avoid common causes for equipment failure. With predictive AI systems, it is possible to anticipate when a pump is continuously running below minimum flow or dry running due to closed suction valves. These sensors can also indicate when insufficient net positive suction head available causes cavitation, or when closed discharge valves result in heat buildup and subsequent liquid vaporisation.

For example, excessive vibration is a common cause of wear and tear for pumps, and can quickly and drastically cut down on expected equipment life. With AI-enabled pumps, operators can more accurately sense too-high vibration levels. Even if this issue is overlooked, and a pump breaks down because of improper operation, managers will be able to look back at a continuous record of high vibration levels, examine why the breakdown occurred, and make an informed plan for how to prevent future issues.

This type of data analysis is also available for other common causes of poor equipment health, such as temperature, runtime hours and battery life.

Visualising trends

AI-based predictive analytics can use historical data to identify performance trends and estimate the remaining lifetime of equipment. This ability gives operators a much clearer picture of when repair and replacement actions may need to be scheduled. This is extremely useful, as it can help managers determine how to go about maintenance issues in a way which will have the least impact on operations, rather than forcing a reactive shutdown or outage.

Advanced product data management combines AI-based analytics with neural networks to compress data into visual, usable information. This can involve dashboards full of graphics and information, which users can look at to quickly survey equipment conditions and trends, leading to more informed, data-driven decisions.

Condition monitoring can involve the observation of a number of different elements, depending on the type of pump being used.

In condition monitoring-based AI, data is enhanced through pre-processing methods before it is sent through the AI system. AI has been used for automatic fault detection of centrifugal pumps to allow for remote monitoring of multiple pumps at the same time.

With cloud-based computing, operators can manage facilities halfway around the world, with pumps in different locations, but connected to the same system, learning from each other and adjusting their performance accordingly through a connected AI system.

Thanks to cloud-based computing, pumps in vastly different locations can be controlled through smart sensors, which detect changes in vibration, temperature, pressure and electrical signals. These sensors can track data in real time, and can be connected to AI systems through a complex diagnostic system.

Pumps that ‘learn’ from data

AI can also teach the equipment how it is supposed to operate, allowing it to detect anomalies and adjust its performance accordingly. Employing self-diagnostic features can also give users time to schedule and prioritise the maintenance needs of equipment, giving operators more control over the health of the system.

AI-driven machine learning can not only help operators monitor the performance of pump system components – it can also be used to optimise the output of the machinery. Compressors, turbines and drives can all be tracked with visualisation tools, which in turn can reveal and minimise any inefficiencies.

When coupled with digital twins, AI-enabled machine learning can simplify maintenance with predictive tools to boost the reliability of pumping equipment and get the most out of the assets. These tools can also identify and amplify strengths in the operating system.

More recent developments are exploring how AI can be further integrated with IIoT in other areas of machine condition monitoring.

Collated data

A common challenge is that companies can monitor hundreds, sometimes thousands of machines at one time,

making collecting, organising and analysing data extremely difficult. This can result in oversights, and limit the operator’s ability to monitor equipment in real time.

A proactive, AI-enabled system, however, can tackle this problem by converting massive volumes of data into collated patterns and trends for a more comprehensive analysis. Innovative AI algorithms, which are built from software and neural networks, can analyse advanced sensor data in multiple formats, distilling them into trends that can identify normal and abnormal operation patterns.

AI algorithms can adapt to a specific facility or system, learning from previous data to provide more valuable insights and highlight correlations between specific factors and equipment performance. These analytics can get to the true underlying cause of the issue, rather than addressing it solely at the surface level.

This approach reduces downtime and extraneous costs by giving operators more time to deploy solutions to foreseen issues.

Centrifugal pumps can be prone to hydraulic faults, including cavitation, waterhammer and turbulence. They can also fall victim to mechanical defects, such as misalignment, imbalance, bearing damages and impeller damage.

Recent research has investigated how these faults can be mitigated with the use of AI. One study examined a centrifugal pump under seven different testing conditions – normal, imbalance, misalignment, impeller damage, bearing damage, mechanical looseness and cavitation.

An accelerometer was used to collect vibration data, which was then put through pre-processing algorithms (AI system). By integrating the AI with an advanced diagnostic system, faults could be processed and classified for further machine performance analysis.

The future of AI-enabled pumps

AI system improvements aren’t just limited to motors and pumps – the entire operating system can benefit from how AI interacts with sensors, relays and optical sensing equipment.

As IIoT continues to set higher service expectations for OEMs and operators alike, the pump industry must shift towards a new business model that encompasses the support, management and maintenance of equipment, while making operations more efficient and sustainable.