Dewatering mines for safer communities

Pump Industry Australia Incorporated

PO Box 55, Stuarts Point NSW 2441 Australia

Ph/Fax: (02) 6569 0160 pumpsaustralia@bigpond.com

Ron Astall – President United Pumps Australia & Astech Consulting Services

John Inkster – Vice President Brown Brothers Engineers

Kevin Wilson – Treasurer/Secretary Executive Officer

Keith Sanders – Councillor Executive Officer – Marketing & Statistics Life Member

Alan Rowan – Councillor Executive Officer Publications & Training Life Member

Ken Kugler Executive Officer – Standards Life Member

Ashley White – Councillor Davey Pumps

Frankie Camilleri – Councillor John Crane

David Brooks – Councillor Flowserve FSD

Dave Alexander – Councillor KSB

Jamie Dixon – Councillor White International

“I

t’s really just common sense!” I was in Auckland, at an IPENZ evening meeting in front of a large group of engineers. With my PIA President’s hat on, I had just completed my somewhat controversial presentation; Are Your Pumps Running Too Slowly?

One of the organisers had kindly got up to say a few words of thanks and smiled broadly and said; “It’s really just common sense!” He was being generous and complimentary and I was grateful to have had the opportunity to attend a lively meeting. Whilst my topic was at first pass perhaps counterintuitive (higher speed pump selections being potentially more efficient and reliable), he contended that once you worked through the logic, it was indeed just common sense. I believe that this is true of most things technical. If you take the time to look at the issues and the logic, it often becomes quite simple. Unfortunately, the thought processes required to simplify things are typically not easy, do take time and we are all often guilty of intellectual laziness.

At PIA we are becoming heavily involved in pump-related energy efficiency initiatives through the Federal Emissions Reduction Fund (ERF) and

the NSW Office of Environment and Heritage. The challenge is to distill our collective experience into practical guidelines and initiatives that reflect a common sense approach that is understandable and will allow the realisation of the massive energy savings that PIA believe are possible in pumping systems. At its core, this approach must emphasise the critical role of system design as the number one priority. A badly designed system with the most efficient pumping equipment installed will still be a badly designed system.

The USA’s Hydraulic Institute and the British BPMA are at the forefront of pushing a system approach when assessing the energy efficiency of pumping systems. I have been reading the HI publications on optimising pumping systems, variable frequency drives and the BPMA’s life cycle costs. It is indeed all common sense, but if we are to reap the rewards we must embrace the intellectual rigor, understand the basic techniques, and take action if we are to reap the rewards.

Ron Astall President, Pump Industry Australia

3,404

ABN: 36 426 734 954

PO Box 1763

Preston South VIC 3072

P: (03) 9988 4950

F: (03) 8456 6720

monkeymedia.com.au

info@monkeymedia.com.au pumpindustry.com.au magazine@pumpindustry.com.au

Publisher and Editor: Chris Bland

Managing Editor: Laura Harvey

Marketing Director: Amanda Kennedy

Marketing Consultant: Aaron White

Associate Editor: Jessica Dickers

Contributing Editor: Michelle Goldsmith

Senior Designer: Alejandro Molano

Designer: Jacqueline Buckmaster

Contributing Designer: Sandy Noke

ISSN: 2201-0270

This magazine is published

All communication should be directed to the

The publisher welcomes contributions to the

’m observing with cautious optimism the signs of hope we’re starting to see in the pump industry. While new construction in the resources industry remains quiet, this has become the new normal and many have instead shifted their focus to maintenance, meanwhile many other areas of pumps, including water, irrigation, and building services continue to perform strongly.

My view is shared by a number of the leaders we interviewed in this issue for the second installment in our “Pump People” feature. While all of our interviewees have their own unique take on things, the thing they all have in common, like myself, is a belief that the industry will recover and prosper in the long run. The first tentative steps that are being taken now are positive news for the industry as a whole.

That said, there’s no denying we have a long road ahead of us. Fortunately, other industry sectors are providing bright spots of opportunity for those involved in the pump industry. Wastewater, in particular, continues to provide us with opportunities to manufacture, supply, service and maintain the pumps charged with the critical (albeit not particularly glamorous) role of transporting and treating the our wastewater.

As is often the case, this issue of Pump Industry will have additional

event distribution, in this instance at the Queensland Mining & Engineering Exhibition, being held in Mackay in July, and at the Victorian Water Industry Operations Conference and Exhibition, held in Bendigo at the end of August.

It’s timely that this issue will be distributed at these events. In the mining sector, the signs of hope will buoy those exhibiting at and attending the event. In the water sector, the ongoing challenge of managing the networks required to safely, efficiently and sustainably provide water and wastewater services will keep attendees busy, constantly on the lookout for innovative new products and services to improve operations in the sector.

I hope you enjoy this issue of Pump Industry, and I’d like to take the chance to remind you all that the next issue of the magazine will feature our second annual Pump Industry Capability Guide. We launched the first issue of the guide in November last year, and the publication was a resounding success. I know many companies were disappointed to miss out on the opportunity to have a listing in the first edition, so I encourage you all to start planning your entries in the guide now.

Chris Bland Publisher and Editor Cover image highlights our features on mine dewatering and wastewater. Published by Monkey Media Enterprises

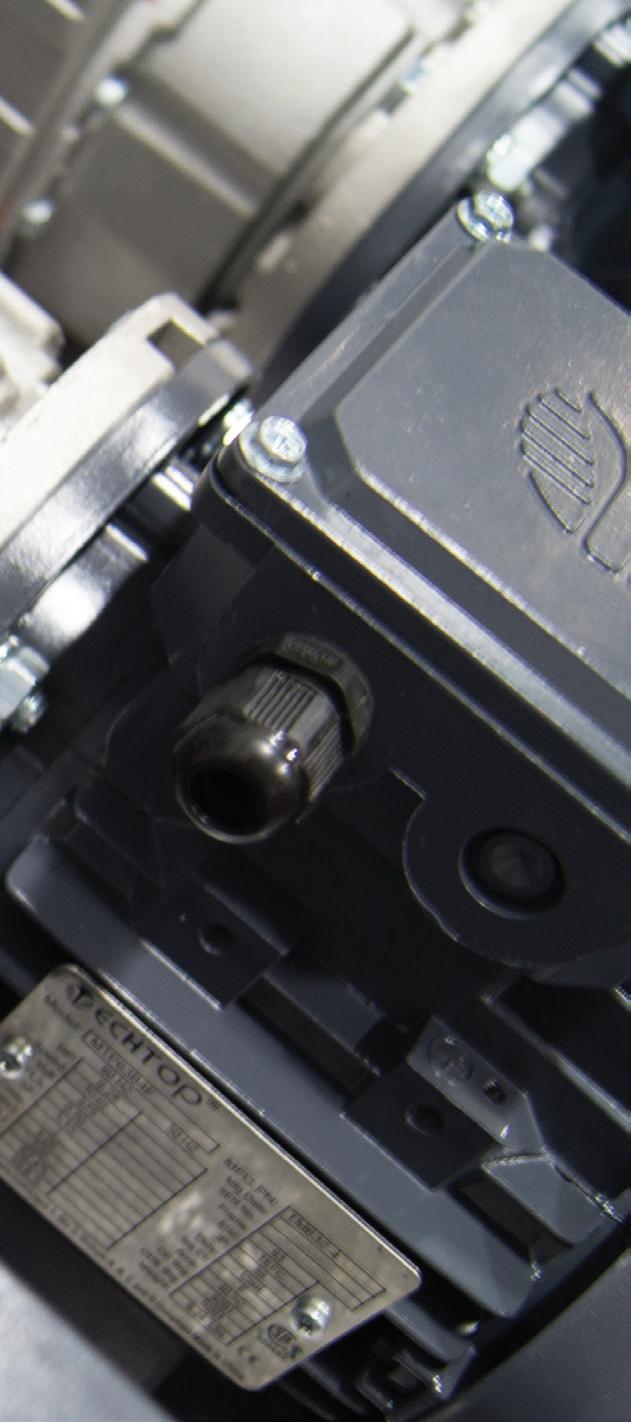

The HDP series consists of a range of heavy duty parallel helical reducers that feature advanced designs and robust build quality to ensure trouble free and quiet operation in all water treatment applications.

The nodular cast iron housing ensures robustness even in the harshest of applications, whilst the strict assembly tolerances and fully ground gears provide an extremely quiet and vibration free operation.

With over 100 years of gearbox assembly knowledge, local stock holdings, dedicated HD application engineers, 24 hour service and an extensive list of aerator application references, Bonfiglioli can provide you with a complete Heavy Duty aerator drive solution.

Series: HDP parallel helical

Size: 14 sizes available

Torque Ratings: 4,650Nm - 194,050Nm

Reduction Ratio: 7.1 - 534.5

Input Options: High Speed shaft, IEC close coupled.

Output Shaft Options: solid shaft + rigid flange, hollow keyed, shrink disc.

Options: Mechanical and motor driven forced Lubrication systems, cooling systems, oil level sensors, heavy duty output bearings, drywell, taconite seals, rigid output mounting flange.

Pump Industry magazine has taken a peek behind the scenes, gathering together some of the influencers within the industry to gain an insight into their careers in pumps. Here, we take a look beyond the technology and the issues and meet the personalities that make the pump industry Down Under tick.

PIA MEMBER NEWS

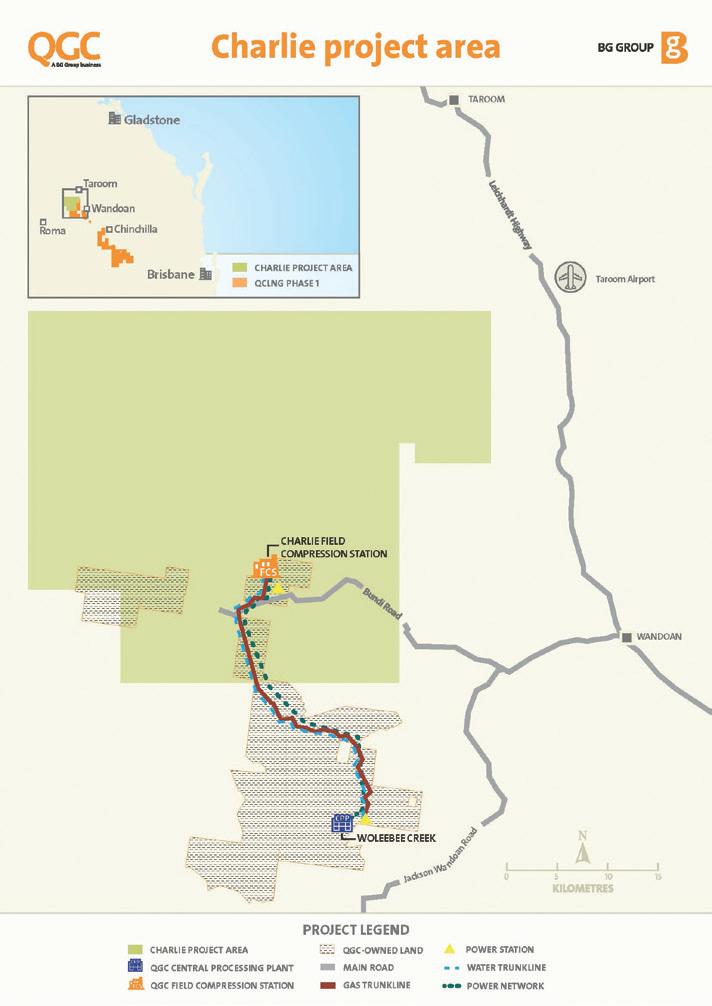

boosting Queensland’s gas

caught up with Bill Coulter to reflect on his years as a pioneer of the Australian pump industry.

The PIA will host a Technical Presentation Meeting in Adelaide in August, with member company Grundfos hosting the event.

The meeting will be held on August 2 and will kick off at 4.30pm. Refreshments will be served following the meeting.

There will be four speakers during the meeting, each presenting on a topic that will be of value and interest to people working in, supplying to or using

the pump industry. PIA President Ron Astall will be co-ordinating this event and will provide more information on the speakers and their topics as we get closer to the event.

The PIA invites our members, suppliers, customers and anybody else who has an interest in the pump industry to come along and benefit from the opportunity to learn something of the latest technologies and other issues impacting on our industry in Australia.

This will also be a unique opportunity for those based in Adelaide to network with others with similar interests in this important Industry.

Date: Tuesday 2 August 2016

Venue: Grundfos Pumps 515 South Road Regency Park SA 5010

Time: 4.30pm

Townsville City Council has reached an agreement with SunWater to pump water from the Burdekin Dam in Queensland, ensuring supply during current drought conditions.

The council now has access to 16,000ML of high priority water from SunWater and an agreement for the rights to 20,000ML of medium priority water, enough to supplement reserves in Ross River Dam through to mid-2017.

Securing the rights to the high and medium priority reserves in the Burdekin will provide the council with 223 days of water available to pump.

The Burdekin pipeline was built specifically for times of drought, and this year will be the first time the city has had to pump for a substantial period for more than 20 years.

The agreement was reached after SunWater CEO Nicole Hollows and SunWater chair Leith Boully travelled from Brisbane to discuss the issue at a special council meeting.

Townsville Mayor Jenny Hill said the water allocations from the Burdekin Dam would safeguard Townsville’s supply against another failed wet season.

“Our priority is to secure Townsville’s water supply well into next year with a contingency that will safeguard the city against another failed wet season,” Ms Hill said.

“It was pleasing to have SunWater at our meeting to confirm that water from the Burdekin was guaranteed, and they were willing to work with council on an acceptable agreement for the city.

“While the council will plan and

budget for every eventuality, if we receive decent rain in the Ross River Dam catchment and the pumps are turned off, we will only pay for what we use.

“As a result of this agreement, the purchase price and pumping costs for the entire water allocations would be $7.7 million, but significantly less if we get a wet season.

“That’s well below the amount of $12.4 million for a year’s supply of water as high priority originally proposed in November, and justifies our decision to carry over negotiations after the wet season.”

The Ross Dam is expected to fall to the 20 per cent trigger point for level three restrictions towards late July 2016, with pumping from the Burdekin likely in late August to early September 2016.

Our latest Pump Industry selfie comes from John Inkster, Chief Executive Officer of Brown Brothers Engineers Australia & New Zealand and Vice President of the PIA. John was spied reading his copy while doing the recent trade show rounds, which in our opinion is a great way to make use of the inevitable down time that happens when foot traffic quietens down at trade shows!

Production testing and fraccing operations at Strike Energy’s Southern Cooper Basin Gas Project in Queensland have been successfully completed and several pump systems have been upgraded.

Strike Energy Managing Director David Wrench said, “The productivity improvements we have seen at Klebb 3, and the fact that we have now successfully completed seven fracs in the Patchawarra coals are important milestones – they’re further confirmation of our confidence in the long term productive capacity of the field and our ability to commercialise it.

“We are looking forward to having all four Klebb wells working together to accelerate progress towards commercial gas flows.”

The performance of the wells since recommencement of testing had been consistent with previous production

ramp-ups and Strike was particularly pleased with the improved productivity of Klebb 3.

The upgraded pump systems were also operating well and had sufficient capacity to handle increased water rates.

Based on the success of the Klebb 3 workover and downhole jet pump equipment upgrade, Strike plans to implement the same modifications at Klebb 2.

The Klebb 4 fracture stimulation has also been pumped and the well is flowing back unassisted.

The electric submersible pump and control systems will be installed once the well has cleaned up with commissioning and extended testing on track to commence in early July 2016.

Anew pump station on Lake Road in Kyabram is now complete, despite several setbacks in the pump testing phase.

The project was carried out by Girdwood Constructions and involved the construction of three new pumps. All required infrastructure to monitor and control the pumps, as well as the decommissioning and removal of the original pumps.

A site cleanup was also completed to improve the appearance of the site and to allow better access to the new pump infrastructure.

We can replace up to 70% diesel consumption with gas That’s smart control

Shire of Campaspe spokesperson for Roads Ian Maddison said apart from the setbacks the project was completed well under budget.

“This has been a difficult site to develop. The basin and pumps are critical infrastructure that provide protection to the town when it rains. It was essential at all times that the basin and pumps remained operational until such time as the new pumps were constructed,” Mr Maddison said.

“Starting this work was not helped

InteliBifuel brings you a new level of control for dual fuel systems.

> Reduce OPEX

> Fuel flexibility

> Accepts a range of gas types

> Short ROI

> Minimise your environmental impact

due to rain over the first few weeks of the project as well as the discovery of a very soft layer where the new pump structure was to be built.

For a chance to win an iPad Mini, head to www.comap.com.au and visit our Bi-Fuel page

“When the new pumps were installed and the project reached testing phase, there was no water in the basin. It was essential to have as much water as possible in the basin to enable all the new pumps to be tested to their full capacity.”

Mr Maddison said this resulted in a period of several months during which the pumps couldn’t be tested, causing significant delays and pushing back the completion date.

“Thankfully we were able to test the pumps after May rains, and they have had a good test with further rain in May and June. I am confident these new pumps will serve the Kyabram community well into the future.

“We also made sure the older pumping systems were running while the works were happening in order to provide flood protection. This project had a lot of elements to it, all of which had to come together,” Mr Maddison said.

Hydro Innovations have introduced a new range of positive displacement pumps that make safety and maintenance a breeze.

The Ragazzini Rotho range of positive displacement peristaltic pumps have a “roller on bearings” design, so that the pump housing does not need to be filled with lubrication fluid. This makes them safer and easier to maintain, says Australian distributor Hydro Innovations. The pump is selfpriming, seal-less, can run dry without damage, and apart from the flanges, only one part comes in contact with the pumped fluid.

The Ragazzini range is self-priming and widely used in water and wastewater treatment, the food and beverage industry, the chemical industry, as well as in the construction, paper, ceramic, paints, inks, mining and marine industries.

Rotho pumps are available with a wide variety of hose options to suit abrasive and/or corrosive applications and are also available with food grade hoses capable of being sterilised with hot water (to 70o) and/or steam (to 120o). A leak detector is standard equipment to provide early indication of hose failure. This is a float type sensor that is located at the lowest point in the pump. Because of the speed of the leak detector, and the fact that the pump casing is not filled with lubricating fluid, contamination and product loss is greatly minimised.

Ragazzini peristaltic pumps are perfect for clean in place (CIP) or sanitise in place (SIP) applications when fitted with the optional “retractable roller”. With this system, one of the rollers can be retracted via an over-centre rapid release cam and lever system. This now enables full flow of a flushing/cleaning/ sanitising fluid through the hose. This new positioning system is essential for fully automated foodstuff handling applications that require regular cleaning

and sterilisation of all the components in contact with the product.

These pumps can deliver as little as 0.2 litres per hour and up to 180,000 litres per hour. Pressures to 15 bar can be achieved and solid particles can be passed through the pump. It can also be run in reverse, making it ideal for tank emptying and filling operations.

Ragazzini pumps do not need the casing to be filled with lubrication fluid. This reduces the chance of contamination, and makes hose changes cleaner, quicker, safer and cheaper.

Roller on bearing design minimises friction on the hose compared with the rubbing shoe method.

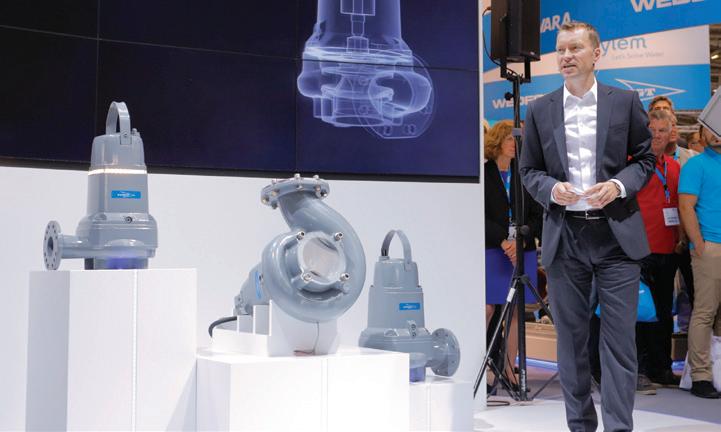

Xylem, a leading global water technology company dedicated to solving the world’s most complex water issues, has developed another breakthrough technology, launching the world’s first wastewater pumping system with integrated intelligence at the recent IFAT 2016 trade show in Munich, Germany.

Flygt Concertor, a smart, sustainable, interconnected solution, significantly advances the sustainability of the wastewater sector by offering unprecedented flexibility and reduced overall cost of ownership, while consuming considerably less energy and ensuring consistent, clogfree wastewater pumping. The system senses the operating conditions of its environment and automatically adapts to pumping conditions to deliver optimal pumping performance.

“Flygt Concertor is another example of Xylem’s commitment to developing innovative and integrated designs that can meet the current and future challenges of the industry,” said Tomas Brannemo, President of Xylem’s Transport business. “This revolutionary new solution represents a step-change in sustainable wastewater management solutions and is a real problem-solver, developed in close collaboration with our customers. Our recent report Powering the Wastewater Renaissance shows that the adoption energy efficient wastewater management technologies can dramatically slash electricity-related greenhouse gas emissions by almost half.”

There is a growing need for technology that optimises the performance and management of pumping systems. Ageing infrastructure, increased global urbanisation and rising energy costs make sustainable wastewater pumping systems an urgent priority. By 2050, 70 per cent of the global population will be living in cities – an urban wastewater challenge on a scale never experienced before. Frost & Sullivan’s report European Smart Pumps Market for the Water and Wastewater Industry notes that a sustained focus on energy efficiency and a reduction in the total cost of ownership of pumps are likely to lead to increased demand for intelligent pumping solutions. Flygt Concertor can help address these complex challenges in a sustainable manner.

Fields tests conducted around the world have validated significant benefits that Flygt Concertor delivers including:

• Energy savings of up to 70 per cent compared to a conventional pumping system by consistently operating at the lowest possible energy level.

• Reduced inventory of up to 80 per cent due to flexible performance –the system self-adjusts or can be adapted to suit different conditions, without changing the impeller or motor size. This versatility eliminates the need for pump station managers to keep large inventory stocks.

A built-in sump and pipe cleaning function – a world first for a wastewater pumping system delivering clog-free pumping and clean wet wells saving up to 80 per cent in vacuum cleaning costs.

Compact design, reducing cabinet size by up to 50 per cent compared to conventional designs.

Xylem is committed to developing technologies that advance the sustainability of wastewater management systems. For example, Xylem’s recently launched Flygt 4320 mixer with integrated speed regulation optimises operators’ control over the

mixer’s thrust, enabling consistent process results and reduced energy consumption. It is a high efficiency, low-speed, submersible wastewater mixer that can help reduce energy costs by as much as 50 per cent.

Flygt Concertor and the Flygt 4320 mixer share a rich heritage with other Flygt innovations. The brand is renowned as a market leader in the design of advanced water and wastewater solutions with a 100 year legacy of innovation in pumping, from developing the first submersible pump to designing the non-clogging N-impeller.

The name Concertor is derived from the Latin “concentare”, meaning “working together to orchestrate harmony”. Flygt Concertor combines IE4 motor efficiency, N-hydraulics, integrated power electronics and intelligent controls that work in harmony with each other, resulting in optimal pumping performance at the lowest cost of ownership.

Flygt Concertor will be available in Australia and New Zealand from early 2017. For more information, visit flygt.com/one-ultimate-system.

VISIT US AT THE WIOA VICTORIA

CONFERENCE &

EXHIBITION:

STANDS 130 & 147.

THE ULTIMATE SOLUTION TO REDUCE TOTAL COST OF OWNERSHIP

Prepare to experience a whole new level of wastewater pumping. Xylem will soon be launching a revolutionary and integrated new technology that will redefine the wastewater industry. It combines everything we know about meeting your toughest wastewater challenges to significantly lower total costs.

To find out more, visit us at www.flygt.com/one-ultimate-system

www.xylem.com/pumping

Right price, right place, right now! This may be the simple ‘scope of supply’ at any given time or in the heat of the moment, but what other responsibilities come along with a willingness to supply?

It’s apparent that historically it was easier to sell to the larger industrial sites and councils than it is today. Typically there used to be a clearly definable engineering infrastructure, usually led by an experienced engineer, where the scope of supply was articulated in a series of (consistent) specifications, procedures, and standards that challenged you to conform with and which in turn granted you eligibility to supply. Essentially, there was someone in place to ensure product performance and overall system integration into the plants needs and processes. That was a win-win, and that’s the way we all liked it!

As costs were ripped out and outsourcing became the creative accountants mode of operation, the removal of local and site engineering not only saw site specific intellectual property vanish overnight, but along with that came a massive (but not so obvious) shift in responsibilities to the original equipment manufacturer (OEM) and manufacturer. No longer was there a guardian of the site that held you to account through the compliance requirements.

What also came along with this more traditional process were obligations that didn’t need prescribing. Manuals, commissioning and maintenance training were all usually supplied willingly and freely as part of the scope of supply. Combined with that, ongoing services such as spare parts availability and technical support were unconditionally included, basically because you wouldn’t dare turn up to try and sell something else if previously supplied products

weren’t performing to site expectations. Hand in hand with this ‘localisation’ came the commercial rewards that made it possible for OEMs and manufacturers to maintain local services that brought benefits in plant design, plant performance, and plant reliability.

While specifications still abound, many scenarios today see a cut-copy-paste effect where compliance rates vary, where opportunities for genuine quality and broader based value propositions have no platform to be presented (or assessed) on, and where longer term obligations of product support, as in after sales services (spare parts etc), can easily be bypassed by cheaper ‘imitations’, at the expense – both short and long term – of the site.

The difficulties don’t only manifest themselves on the supply side. If and when things go awry, it can be extremely difficult to identify just who is in control at any given time. Invariably, managing and defending your brand reputation can become extremely difficult and expensive in times of crisis, whether the crisis be actual or perceived. Having a clearly articulated scope of supply may be the only fall-back position you have to rely on when these events occur, providing a practical line-in-the-sand which in turn provides a basis for moving forward.

Ensuring you qualify your scope of supply may just be the difference between enjoying the rewards of a nice job or facing a financial disaster.

Most of us won’t spend much time thinking about the logistics of fuel transfer and supply for the Australian Defence Forces (ADF), currently active in a number of countries around the world. But for one Australian company, this very topic has been a focus for a number of years, ultimately providing the ADF with an innovative method for fuel distribution.

Melbourne-based Crusader Hose are the manufacturers of the Petroline hose. This product has recently been used by the ADF for fuel transfer at overseas locations. For the ADF and their staff, who often move quickly between locations - yet still need a regular and consistent source of fuel - building a permanent fuel line to a set location is not a possibility, due to time and construction constraints.

The need for a temporary solution, which can be easily deployed to the battlefront, led the ADF to investigate options such as layflat hoses, so that they have the capability to transport fuels between constantly changing locations.

“The appeal of Petroline for the ADF lies in the fact that it provides a rapid and compact solution for the transportation of fuels,” said Crusader Hose Managing Director Francois Steverlynck.

“As a military deployment, the army needed the flexibility and maneuverability of the flexible layflat hose, often over rough terrain and over significant distances.

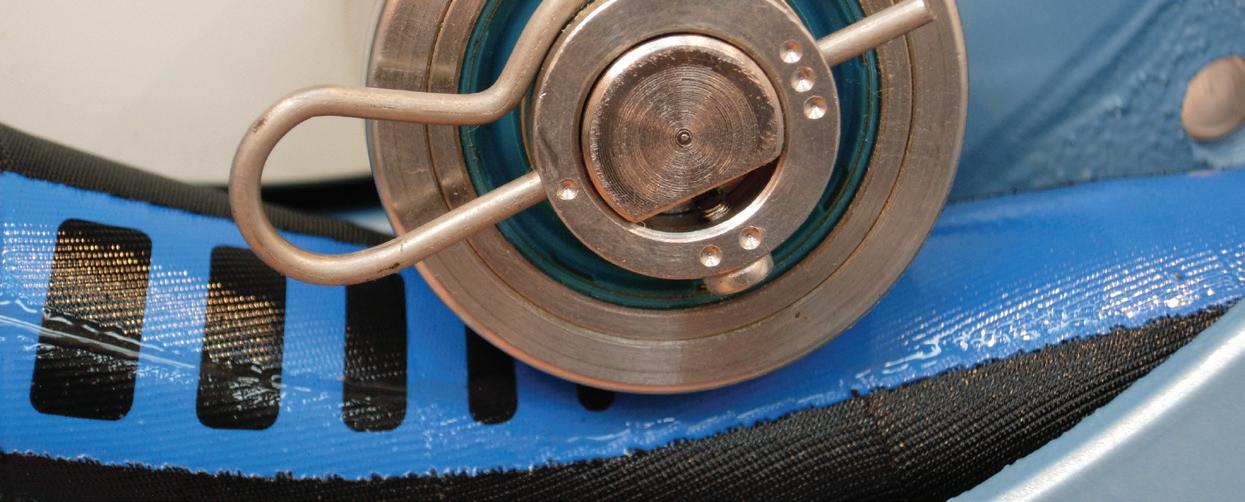

“The fuel hose reel systems were essentially modular in design, allowing for easy deployment and retrieval, at the completion of that particular mission.”

Additional factors central to the success was the fact that

Petroline is a lightweight, easily handled and stored fuel hose of high pressure rating. The polyurethane cover also provides chemical and abrasion resistance, plus UV stabilisation.

In securing the ADF contract to supply Petroline, Crusader Hose overcame stiff competition from international suppliers, to reach the demanding standards set by the ADF.

Since securing the initial supply contract, the Petroline hose has risen to the occasion and performed successfully in service. As a result, the ADF has since placed several more orders with Crusader Hose.

As well as the compact nature of the solution, the ADF was also impressed with the product’s ability to pump fuels over long distances. By using Petroline, the ADF has eliminated the need to truck fuels large distances, which has obviously provided a rapid maneuverability benefit to the front-line troops.

As part of this contract, Crusader Hose also developed a purpose built hose reel system that can be easily deployed in the field to lay the fuel transfer hose. Portable reels capable of each holding 800m of layflat Petroline were designed and built to exacting specifications.

Government investment in Tasmanian irrigation is creating economic growth and new job opportunities across the state.

Reid Fruits at Jericho is one of the local businesses benefiting from increased irrigation investment, using an investment of $1.13 million to expand its orchards and employ an additional 30 people.

Reid Fruits will soon begin planting its first cherry trees at Honeywood Orchard in the Southern Midlands, which is traditionally dry grazing land.

Tasmanian Minister for Primary Industries and Water Jeremy Rockliff said having 95 per cent reliable water available through Tasmanian Irrigation schemes was unlocking new opportunities.

“Generations before would never have believed that we could turn this grazing land into a cherry orchard, yet that’s what’s being achieved through irrigation,” Mr Rockliff said.

“Reid Fruits’ investment and expansion will create 30 full-timeequivalent positions when it’s operational and as many as 200

positions in the peak of the picking season.

“The unique elevation of the site will also extend harvest time beyond that at any other orchard, allowing Reid Fruits to tap into the lucrative Chinese New Year market unlike ever before.

“We look forward to seeing other agricultural projects expand just like Reid Fruits as we progress the five Tranche 2 Schemes, made possible

with $60 million from the Federal Liberal Government and $30 million from the Hodgman Liberal Government, and investment from farmers.

Tasmanian Federal Liberal Member for Lyons Eric Hutchinson said “It’s clear that the water provided through our investment in irrigation is transforming not just our landscape, but also our agricultural sector’s capacity to grow, invest and create jobs.”

Leading pump supplier National Pump & Energy (NPE) has signed a new deal as the exclusive Australian supply partner of a world renowned pump manufacturer.

NPE will be the exclusive supplier of BBA Pumps across Australia. With a solid history of providing pumping solutions to the Australian market, this latest development further strengthens NPE’s place as a market leader.

Under the terms of the agreement, NPE will be the sole supplier of the entire BBA range of market leading pumps and parts through their Australia-wide network of branches.

BBA Pumps Managing Director Roland Berns said that they are extremely happy with the deal and look forward to partnering with NPE.

“NPE was selected based on its commitment and dedication to providing quality products and services in each of the markets in which we operate,” he said.

“The Australian market is very important to us and partnering with a national supplier with a strong

reputation for quality, such as NPE, reflects BBA Pumps commitment to providing our customers with an exceptional experience,” he said.

Having had many years’ experience in supplying pumping equipment to the Australian market, Rod Hayes, Managing Director of National Pump & Energy, is pleased with the addition to the company’s extensive fleet of specialist equipment.

“The BBA Pumps are class leading in their design and performance” he said. “We are thrilled to be associated with BBA Pumps and look forward to providing the Australian market with these terrific pumps.”

The BBA range of contractors pumps, piston pumps and trash pumps are more often than not the professional’s first choice for a quality, reliable pumping solution.

NPE will stock the range of pumps for hire or sale from their branches throughout Australia.

Products and services now offered by the amalgamated company now range from everything from pump

hire, pipeline construction and water management, right through to generator hire and continuous power systems.

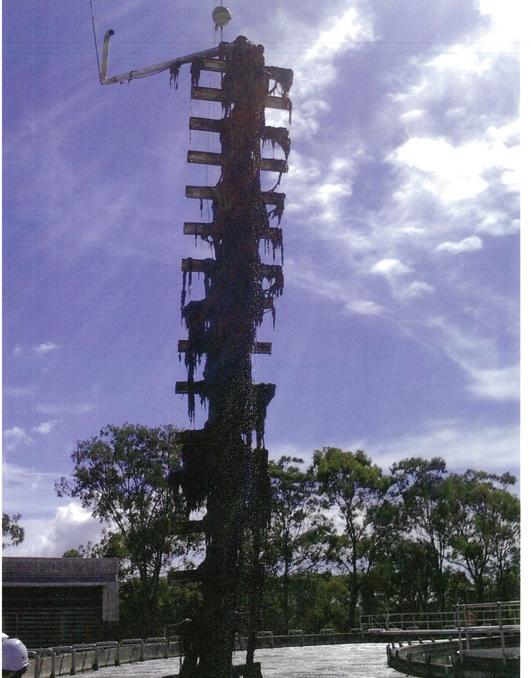

Keeping settling ponds in optimum condition without taking the sewage plant offline represents real cost savings. Dredging Solutions from Sydney NSW are now able to offer this option due to an innovative application of a Tsurumi submersible cutter pump.

While dredging ponds for Sydney Water, the company was faced with pump chokes caused by accumulated rags. Normal submersible pumps cannot cope when oversized, fibrous materials get flushed into the system. Dredging Solutions turned to Aussie Pumps for a suitable cutter pump to solve the ragging problem.

Tsurumi, the world’s leader in submersible pump development, has produced a range of cutter pumps, called the C Series, designed to handle such contaminated waste. The C series cutter pumps chop waste material, including rags, thus allowing free passage through the pump without clogging.

“Tsurumi’s breakthrough cutter impeller chops through sewage, rawhide, plastic, rags and other materials in seconds,” said Aussie Pumps Product Manager Neil Bennett. “We’ve seen various unmentionables handled by these extraordinary pumps, so they were an obvious choice for Dredging Solutions’ ragging issue,” he said.

The C Series incorporates a large

open channel impeller with a cutter mechanism. A sintered tungsten carbide alloy tip is brazed on the impeller vane. As the impeller rotates, the vane slices against the serrated edge of the suction cover, chopping fibrous matter into small fragments that won’t clog.

The three phase, heavy duty pumps range from 50mm bore to 100mm. The largest pump in the range has an enormous capacity of 2,750 litres per minute, and a max head of 26 metres.

“There is a terrific video on YouTube that shows the pump’s cutting ability. It’s amazing to watch what these unique cutters will do. You’ll never believe it until you see it,” said Bennett. “The demo even shows the pump swallowing nylon rope,” he said.

Like all Tsurumi submersible pumps, the C Series include features that extend the life and enhance reliability of the pump. Significant design details make a big difference. They include an anti-wicking cable entry that prevents water from entering the motor if the power lead is damaged or the end of the cable is accidentally submerged.

A double silicon carbide seal is

standard on all models. Both seal surfaces are submerged in an oil chamber, away from the pumped liquid. This ensures lubrication and protects ingress of foreign materials.

The oil bath features a patented “Oil Lifter” that increases mech seal longevity. The lifter ensures both the upper and lower seals are lubricated and cooled, even if the oil level in the chamber is low.

“We have created a bit of a buzz within Sydney Water with how well the new system is dealing with the rags on site. They have a lot of the ponds to dredge at one time or another, that are heavily ragged up and we now have a solution to deal with it,” said Cameron Lorimer from Dredging Solutions. “The cutter pump coupled with our dredge system will allow the cleaning of the ponds while they remain online. This is critical to the ongoing operation of the plant,” he said.

Further information on the complete range of Tsurumi

pumps is available on the Aussie Pumps website (www.aussiepumps.com.au) and from Dredging

• Direct Injected

• Air Cooled

• Indifferent to Climatic Conditions - Rugged engine suitable for any harsh climatic conditions

• Sensibly priced

FOR

Naturally occurring groundwater in Bendigo’s historic gold mines has been rising and threatening water quality and surrounding infrastructure for many years– but there are solutions. The Department of Environment, Land, Water and Planning (DELWP) recently contracted the Bendigo Trust to dewater the mines until a permanent solution is found.

In early 2015, groundwater from historic mines in Bendigo, north west of Victoria, began causing odours along Bendigo Creek, impacting local water quality and resulting in small surface discharges.

That is why Bendigo Trust, the operators of the Central Deborah Tourist Mine, have been contracted to pump the groundwater out of the mines. This mine dewatering aims to stop the levels getting too close to the ground surface and contaminating local waterways.

Due to the region’s geology, the water from the mine voids (the excavation area that remains after mine rehabilitation) contains increased salinity, arsenic, hydrogen sulphide (causing a ‘rotten egg’ smell) and other heavy metals. The poor quality of the water has the potential to impact infrastructure such as underground utilities, road and building foundations, as well as cause soil salinisation.

The immediate solution to this problem involved pumping the groundwater from the Central Deborah tourist mine to the New Chum line of workings via the Eureka shaft, but this work was stopped in late February 2016 due to the pending transfer of mining and exploration licences for the Bendigo gold fields.

Then, from early March, groundwater was pumped to the Garden Gully line to ensure the Bendigo Trust could continue their business without disruption.

In May, the Victorian Government approved the transfer of mining licences in Bendigo from Unity Mining to Kralcopic. The transfer of the mining licences enabled DELWP to enter into negotiations with Kralcopic to resume pumping the groundwater from the Central Deborah shaft to the New Chum line via the Eureka shaft, and pumping resumed in June 2016

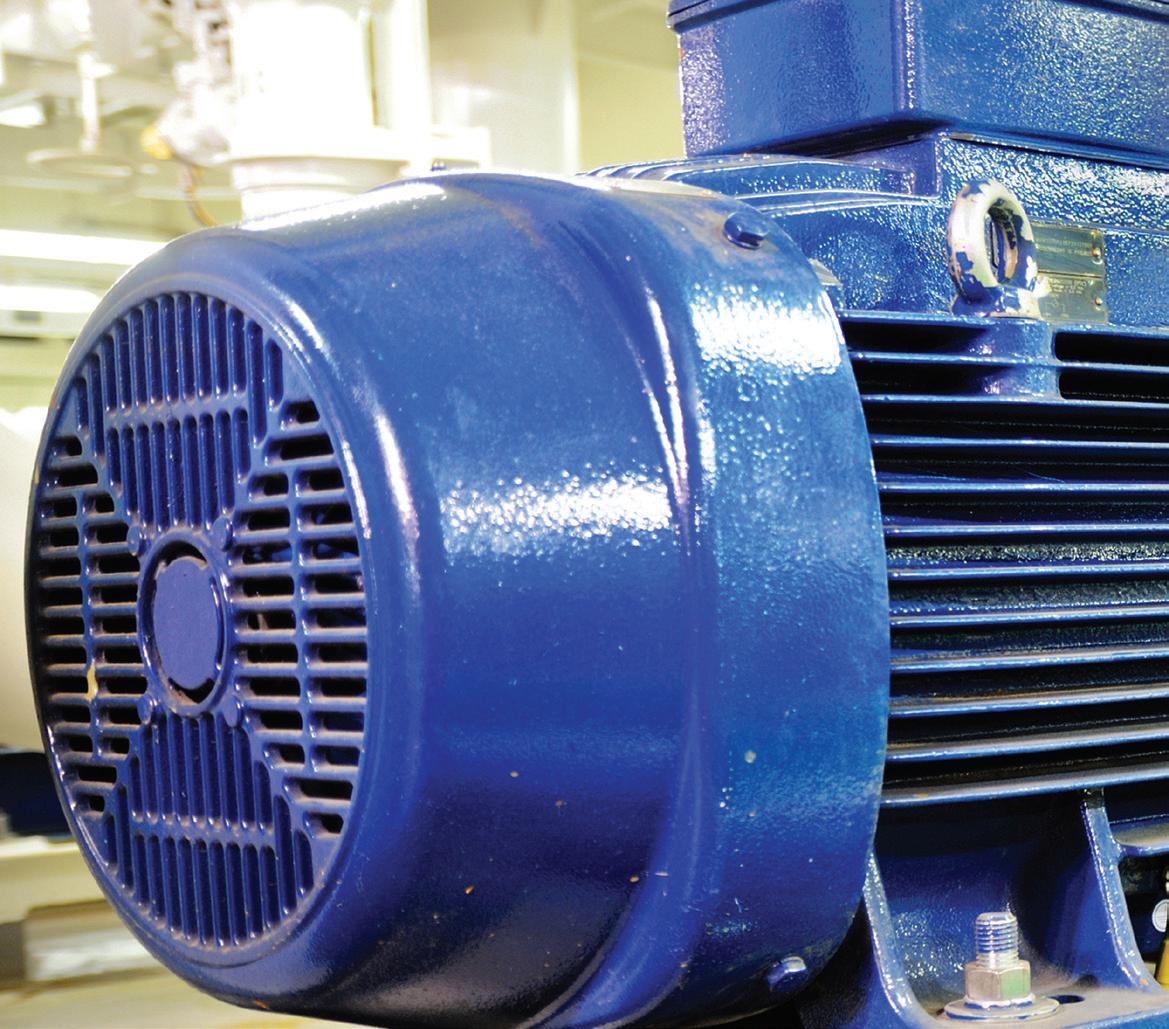

Contractors Bendigo Trust pumped the groundwater using Grundfos SP 95-20 pumps. Two pumps were installed

to provide redundancy in the project and to allow pumping at a higher than normal rate when required. These fully submersible pumps consisted of a 95kw pump motor and 20 pump stages in the wet end.

The submersible pumps were chosen because they met the specific technical requirements of pumping the groundwater, which was a head pressure in excess of 260 metres and a required maximum volume of two M/L per day, per pump.

Besides the technical requirements, the pumps were also chosen based on the constraints of the project, which included the short lead time Bendigo Trust had to get the system installed, as well as the ease of acquiring spare pumps and parts, the cost, and the reliability of the pump units.

Even with all this in mind, there were still major challenges involved in installing these large pumps into the confines of the mine shafts.

At the Central Deborah mine, there were difficulties regarding the installation and maintenance of the pumping infrastructure so very specialised engineering solutions had to be devised to allow for installation into the timber mine shaft, which was located approximately 260 metres below the surface.

Since there was no access for heavy machinery or heavy lifting equipment, most of the preparation and installation work relied heavily on devising one-off solutions and using equipment such as hand-held jack hammers to carry out excavations in the rock and allow installation of the necessary components.

DELWP has since been searching for a backup pumping point to divert the groundwater from the mines, with one potential short-term solution involving uncapping the former Specimen Hill

mine shaft in Eaglehawk.

DELWP investigated the old shaft at Specimen Hill to see if it would be a suitable extraction point for pumping the groundwater from Bendigo’s disused mine shafts to Coliban Water’s Reclamation Plant at Epsom for treatment.

While there is no immediate threat from the contaminated water, the uncapping works of Specimen Hill mine were undertaken to identify viable options to divert the groundwater while the transition option is in place.

This transitional solution with the Epsom plant involves implementing

processes and infrastructure that could then be used within the permanent solution, once one is found.

The uncapping of Specimen Hill involved drilling a 300 millimetre diameter hole into the concrete shaft cap and assessing the shaft condition. After the assessment, Bendigo Trust submitted a report to DELWP on the mine’s suitability to be used as part of the transitional solution, but unfortunately the report showed the mine had collapsed timbers and backfill creating a ‘choke’ in the shaft. Removal of the choke would require considerable effort and cost.

Taking these factors into account, planning is now under way to see if the Suffolk and Argus mines would be more suitable sites to pump the groundwater.

The 2016-17 Victorian Budget includes a further $14 million of funding to enable implementation of this transitional plan, based on the pumping and treatment of groundwater at the Epsom Treatment Plant. DELWP is also working closely with the community and local government to develop future options for Bendigo’s rising groundwater problem.

The pump industry relies on expertise from a large and varied range of specialists, from experts in particular pump types to those with an intimate understanding of pump reliability; and from researchers who delve into the particulars of pump curves to experts in pump efficiency. To draw upon the wealth of expert knowledge the Australian pump industry has to offer, Pump Industry has established a panel of experts to answer all your pumping questions.

QUESTION: We often hear that progressive cavity pumps are extensively used in the mining industry. What are some of the common applications where these pumps are most suited?

ANSWER:

Our progressive cavity pump expert is Peter Vila, Managing Director of SEEPEX Australia. Peter has been involved with pumps for 35 years. He spent the first five years repairing them and the subsequent 30 years directly in technical sales, and for the past 15 years he has been predominately involved with SEEPEX progressive cavity pumps.

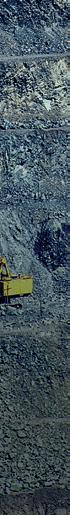

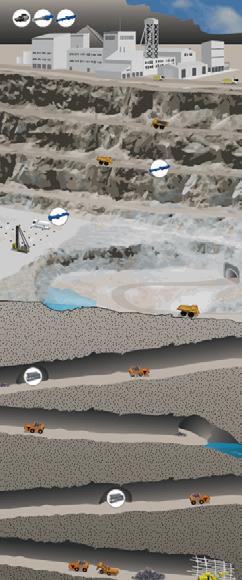

Open-cut mine.

It’s correct that progressive cavity pumps are very common on mine sites throughout Australia. In fact, this particular market sector would be on par with water/wastewater, as one of the most popular for PC pumps in Australia. To list in detail the various applications would take up this entire magazine issue, so instead I have summarised the following typical applications and the key benefits of this pump design.

Mining methods.

Mine types where progressive cavity pumps are used in Australia:

• Bauxite (also refined alumina)

• Coal

• Copper

• Gold

• Iron ore

• Mineral sands

• Nickel

• Shale oil

• Tin

• Uranium

• Vanadium

• Zinc

Also used by countless suppliers of mining equipment and chemicals for:

• Decanters and centrifuges

• Tunnel drilling equipment

• Flocculants

• Chemical dosing

• Liquid explosives

Common applications for progressive cavity pumps in mining:

• Transfer of mineral slurries

• Void back-filling applications

• Dosing of explosives

• Thickener underflow applications

• Centrifuge filling

• Chemical dosing

• Water treatment

• Cake transfer

• Leachate treatment

• Gland water supply

• Sludge feed to dewatering machines

Typical transfer liquids include: polymers, sludges, slurries, grouts, various chemicals, clean and dirty water.

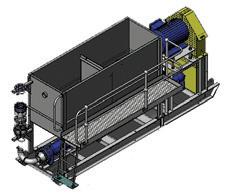

Mine dewatering applications for progressive cavity pumps:

This is probably one of the most common areas where progressive cavity pumps can be seen, usually installed on a

transportable skid with collection tanks for incoming water, and generally incorporating some kind of solids separation to partially clean the muddy, high sediment mine water. The range of progressive cavity pumps used for these applications can be quite long in length, due to the pressure generation required for pumping to the surface from several hundred metres underground. There are several companies currently who specialise specifically within this application sector and occasionally there can be new design developments which may give significant benefits to the users of this product range. Keeping oneself abreast of these developments can certainly pay significant dividends to mine operators. More detailed information on specific design developments can be requested via the contact details at the end of this article.

• Self-priming

• Non-pulsating flow

• Valveless operation and flow control

• Reversible for back-flushing

• Flow proportional to speed

• No day-to-day maintenance required

• Versatile, can be installed horizontally, vertically and virtually any position

• Minimal flow drop against changing pressures

• Ability to handle multi-phase fluids (liquid and gas)

For more information on progressive cavity pumps for the mining industry, please contact SEEPEX Australia on (02) 4355 4500

Alberto Caprari Chief Executive Officer, Caprari Pumps

Alberto Caprari is the Chief Executive Officer of the Caprari Group, headquartered in Italy and with posts around the world, including here in Australia. The Caprari Group was established 71 years ago, and has been focused on the manufacture and production of centrifugal pumps and electric pumps. The group is also focused on the creation of advanced solutions for management of the integrated water cycle, and other professional sectors including oil and

gas, power generation, mining and industry.

Caprari’s continuous research is aimed at manufacturing products that are sustainable, both in respect to the materials used and the energy that is ultimately used by their products.

Mr Caprari was recently named President of ANIMA, Confindustria’s Federation of Italian Associations of Mechanical and Engineering Industries. ANIMA is one of Europe’s most important and well-established organisations, comprising 34 associations and over one thousand member companies. Numbering over 194,000 employees and with

Last year we took a closer look at some of the people and personalities that make the Australian pump industry tick in our inaugural ‘Pump People’ feature. This year, we’ve spoken to a new crop of leaders in the industry to learn about their careers in pumps, their current roles in shaping some of the key players in the Australian pump industry, and where they see the future for the industry heading.

€40 billion revenue, the mechanical engineering industry is the backbone of Italian industry as a whole, and Mr Caprari’s appointment as President is reflective of Caprari’s significant involvement in the sector.

For Mr Caprari, the ongoing impact of globalisation is something he and the team at Caprari Pumps are constantly taking into consideration.

“We definitively believe that the globalisation process has now clearly transformed into more of a ‘global’ approach - we need to think globally but act locally.

“A successful pump company like Caprari must continue to adapt itself to the new challenges that changing markets impose, while strongly leveraging on its own precise identity.

“We are a family-owned Italian company, established by Amadio Caprari 71 years ago, and today we have more than 15 facilities, including subsidiaries and manufacturing plants, around the world. Together with our 700 employees, we are fully committed to tackling the new challenges of the global pump marketplace: system approach, total cost of ownership, the internet of things and new pump applications. In doing this, there’s always an awareness of emerging global markets, and constant changes to the geopolitical map.

“We’ve really developed our worldwide presence in order to be closer to our customers and pump end users, and we always operate with our values of loyalty, integrity and innovation at the front of mind. For Caprari, the focus is on strengthening business relationships with our partners and ‘bringing more quality-water around’.”

It’s this focus that Mr Caprari, and the Australian arm of the group, bring to their operations Down Under - which the group predicts will continue to grow in the coming years.

“We predict that Australia, in the long run, will keep growing as a country that’s attracting people both from western countries and also from China and Southeast Asia,” noted Mr Caprari. “Newcomers that are willing to make local investments and participate in the development of either the primary or tertiary sectors, such as agriculture, food and dairy, plus education, tourism, and health care, will be successful.

“This will also positively affect infrastructure networks and building services, which are the market sectors where Caprari is able to offer hightechnology pumping systems and solutions.”

For Mr Caprari, he loves the diverse nature of being involved in the pump industry in Australia.

“In my view Australia is just the world, compacted. Almost every culture is represented today Down Under,” said Mr Caprari.

“We certainly love the fact that Australian professionals involved in the water and pump industries are appreciating new technologies and quality solutions, and the fact that they look for good, solid companies to work with.

“Australian companies never take a superficial approach, they look at the broader implications of the challenges they face and together, we create new solutions that meet their pumping needs.

“It’s the quality professional

environment, and the long-term market potential, that has led us to recently to further invest in Oceania, becoming last November 2015 the full owners of Caprari Pumps Australia and Caprari Pumps New Zealand.

“As part of this move we’ve adopted a business plan for the next few years that will include consistent investments, in order to increase customer satisfaction and therefore market shares.”

David

Chief Executive Officer, Davey Water Products (Global)

David

Chief Executive Officer, Davey Water Products (Global)

David Worley is the Chief Executive Office of Davey Water Products – a multi-national manufacturing company headquartered in Melbourne, Australia and owned by the GUD Group.

Mr Worley is a relative newcomer to the pump industry, joining Davey in 2013. He is an experienced operating CEO and has significant building industry and manufacturing experience, having

spent 17 years in a range of senior leadership roles across a spectrum of manufacturing and distribution businesses.

With a number of the businesses he has joined (ranging in size from $100 million to $2 billion) performing sub-optimally, Mr Worley has applied a combination of strategy development and business fitness improvement to improve their performance – a strong theme in the last 15 years of his career in particular.

Headquartered and a market leader in Australia, Davey manufactures and distributes a range of products which transfer, conserve, treat and filter water to over 50 countries where they perform in some of the world’s toughest conditions.

With a focus on new and smarter ways to help customers solve problems and its strong engineering capability, Davey develops and markets leading water products for homes, businesses and farms, fire and flood protection, rainwater harvesting, swimming pool and community needs.

Mr Worley is particularly excited to bring his unique skill set to Davey, and the broader Australian pump industry, in the current challenging environment.

“With the market looking fairly flat and no immediate prospect of

substantial market growth, in order to thrive, companies will have to get better at doing the basics – looking after customers, setting high standards of delivery and service, and constant product improvement – at an economic cost,” said Mr Worley. “And it’s not just about looking after customers, but properly understanding their needs and helping them to grow their business by understanding what works for them in their local markets.

“In our particular market, to thrive we need to anticipate industry changes and recognise that water is becoming an increasingly important resource that is not always going to be available at the quality or cost that people prefer or have become accustomed to – even in the major metropolitans.”

Like many in the industry, Mr Worley expects that while challenging market conditions prevail, we’ll continue to see more merger and acquisition activity in the industry both locally and globally.

“I expect to see some level of industry consolidation - particularly in distribution channels and how we get products to customers,” said Mr Worley. “We will continue to see the increasing impact of the internet, which will also have a significant impact on how we get products to customers.

“I think the pump industry has

held a belief that, due to the technical complexity of what we do, our products and services don’t lend themselves to an ‘online’ or self-service environment. But people are smart and inevitably more and more of what the industry has to offer will be available on the internet directly for consumers.”

While his time in the industry has been brief, Mr Worley has already identified some of the key factors that make it a great place to work.

“It’s an industry that has operated on traditional lines which, if carefully managed, provide an opportunity for innovation with a vitally important commodity – water,” he noted. “And from a Davey Water Products perspective, it’s exciting to have the opportunity to protect and enhance people’s lives with water.”

Steve Bosnar is the Managing Director of Pioneer Pump Australia, a leading edge US pump company based out of Victoria. Mr Bosnar has been in the pump industry for over 30 years and has a deep knowledge of the current state of play.

For Mr Bosnar, challenging market conditions have provided opportunities for growth in new areas.

“The industry that we share is one that’s had its challenges, particularly over the last four years,” said Mr Bosnar. “The downturn in the mining and oil and gas sectors has had a huge influence on our local economy, and our industry has not been immune.

“For us, like most that are still in the pump industry, we had to adapt to the changes in this economic environment. We have had to diversify into other markets, introduce innovative new products, whilst continuing our aim for greater share of our traditional markets. We have also increased our footprint further into Southeast Asia and the Oceania, which has helped us find new markets and grow.”

According to Mr Bosnar, the performance of the broader Australian economy will continue to have impacts on the Australian pump industry.

“As today’s market uncertainty continues, our industry, like most, fluctuates with Australian Commodities,” said Mr Bosnar. “If the markets are taking a beating, so are we through the flow on.

“Analysts predict that certain commodities will firm and slightly strengthen by the end of 2016. The strengthening is suggested to continue throughout 2017 and more so in 2018. If this prediction is correct, I suggest that the pump industry should see the benefits mid to long term.”

Like many industries, the pump industry is a cyclical one, but for Mr

Bosnar, one thing that remains constant is his enjoyment at being involved in pumps.

“This is an industry that some of us are passionate about,” said Mr Bosnar. “I started when telex machines were the preferred method of communication with suppliers! With over 30 plus years in the pump industry, I have made an enjoyable and fulfilling career. I have made lifetime friendships worldwide because of it, and I love the fact that I’m still learning and meeting new people everyday.”

John Shanasy, the Managing Director of Pump Power, began his career in the pump industry with an apprenticeship in instrument making when he was seventeen, before going on to study electrical engineering and graduating as an electrical engineer in 1975.

In 1978 he landed his first job in the pump industry, with Link Pumps. Mr Shanasy worked there for seven years in the technical and sales areas, providing a very good foundational knowledge and experience with a wide range of pumps. After a few years Mr Shanasy became the General Manager of Link Pumps, and in 1988 he acquired the sales division of the business and renamed it Pump Power Australia. Situated in Brooklyn, the business has been wellplaced to service the industrial areas of Melbourne, as well as developing markets throughout Australia and New Zealand.

A key value for Pump Power has always been to develop good personal relationships with both suppliers and customers. This goes along with expert technical knowledge and an emphasis on prompt and professional service. According to Mr Shanasy, Pump Power has always been ready to go the extra mile to help customers out of a tight spot.

In 2015, Mr Shanasy’s son Will and his wife Belinda took over the reins of Pump Power. Mr Shanasy said they are committed to the DNA of Pump Power, and to long-term suppliers

and customers. At the same time, Mr Shanasy said it is also rewarding for him to see a new generation introducing healthy innovations and new products.

According to Mr Shanasy, while the market conditions for the pump industry as a whole are currently challenging, some sectors of the industry have remained somewhat unaffected.

“Current market conditions have not changed dramatically for high-end and specialist pump products,” noted Mr Shanasy. “The change has been in the cheaper and simpler product ranges, where it has become all about price. It will be important for specialised pump companies to keep abreast of new technologies and maintain their technical edge. This will differentiate them from the crowd and enable them to be known for appropriate pump selection in technically complex situations.

“I also think that there may be an increased demand for pump system packages rather than individual pumps. Pump companies can adapt by gearing up for this.”

Mr Shanasy also believes that the ongoing focus on energy efficiency and whole of life costs will have an impact on the industry moving forward.

“In the short to mid-term there is likely to be an increased emphasis

on pump efficiency so less energy is consumed and costs are reduced. This shift is in the context of an increasing global focus on energy efficiency.

“As larger companies, whose business involves the use of pumps, focus more and more on core products and become less inclined to be involved with peripheral equipment, they will turn more to service providers like pump companies. There is therefore an opportunity for pump companies to get more involved in servicing and monitoring pumps. For the clients

it means less employee time spent on maintenance, and with wellthought-out pump monitoring, costly environmental spills are less likely.”

After a long and varied career in the industry, the part that Mr Shanasy has always enjoyed most has been the connections he’s made with clients and colleagues.

“The aspect of my career in the pump industry I have always enjoyed the most is the people. Having been

relationships with customers, suppliers, and the people at Pump Power.

“Being a practical person, who started off as an apprentice, I have also always enjoyed the hands-on aspect of working with pump systems. Whether it was working down a mine, or in the bilges of FPSOs, I welcomed the variety and the opportunities to get my hands dirty and not always be stuck in an office. The problem-solving required for complex pump applications has always

Across Australia and the world, water utilities are witnessing an increase in faults caused by non-degradable materials entering sewer networks. Many of these issues can be largely attributed to wet wipes, which do not readily disintegrate when flushed down the toilet, despite many brands being advertised as ‘flushable’. While the role of wet wipes in the creation of ‘fatbergs’ has received substantial media attention, wet wipes can also cause significant and costly damage to vital pumping infrastructure. We spoke to a number of water utilities across the country about some of the wet wipe-related issues they’ve experienced in their networks and what they are doing to protect pumps, fight fatbergs and combat the wet wipe menace.

Wet wipes are a significant problem for Sydney Water. Keiran Smith, Manager Media and External Communications, and Charlie Kawtal, Systems Operations Officer, told Pump Industry that in the past two years alone, Sydney Water has removed over one million kilograms of wipes from its network at an annual cost of over $8 million. Nationally, water utilities are spending over $15 million annually to remove wet wipes from their networks.

“If the wipes removed from the Sydney Water network each year were placed end to end they would stretch from Sydney to Los Angeles,” said Mr Smith.

“Wet wipes pose an environmental risk from overflows resulting from pumping station and overflow blockages, causing environmental and aesthetic issues in our creeks and waterways which are costly to clean up.

“As well, there is a safety risk to maintenance technicians and treatment plant operators who are required to clear wastewater blockages and filter screens.”

However, ‘flushable’ wipes can also create problems for customers before they even enter the larger wastewater network. They can also block household plumbing, causing overflows inside the home and costly plumbing bills.

Sydney Water reports receiving an increasing number of notifications from customers and private plumbers about problems being caused by wet wipes in private sewer pipes. One plumber claims that one in three of his call outs are the

result of blockages caused by wipes, and one customer reported a plumbing bill of $16,000 to repair damage to her property’s plumbing caused by wipes.

“In many areas about 75 per cent of sewer blockages will have wet wipe materials either directly or indirectly responsible for the blockage.”

Sydney Water first identified its wet wipe problem due to an increased frequency of issues caused by non-biodegradable materials in its wastewater network.

“The problem with wet wipes was initially detected due to the increased dredging frequency of the wet wells in Sydney Water’s pumping stations, as the result of the build-up of wipes,” said Mr Kawtal.

“There was also an increasing trend in faults at sewage pumping stations across the network. The cause of these faults was again largely attributable to the increasing disposal of non-biodegradable wet wipes via the wastewater system. Further investigation revealed it was an escalating issue for water utilities around the world.”

According to Sydney Water, there are two main areas in its wastewater system where wet wipe blockages are likely to occur – small diameter reticulation pipes and pumping stations.

Small diameter reticulation pipes usually have low flow. In addition to causing blockages directly, wipes can combine with tree roots or other minor obstructions within the pipes to cause blockages.

At pumping stations, wipes can get caught in the pumps, causing

breakdowns. Wastewater settles between pump operating cycles, leading to a build-up of material that has not broken down, such as wipes. These wipes can then get picked up by the pump during its next operating cycle.

To combat wet wipe related issues, Sydney Water is deploying a combination of operational innovations, public awareness campaigns and industry collaboration.

“Traditionally, wet wipe blockages were removed manually and as the problem has increased, Sydney Water has needed to put in place protocols to manage the process.

“At the Cronulla Wastewater Treatment Plant, as an example, step screens now dump the wipes into a water sluice which conveys them to a corkscrew press where liquid is removed and the dry wipes are deposited into a sealed tanker which takes the wet wipes away. 2.5 tonnes of these materials are removed from the Cronulla Plant every week.

“Sydney Water has 679 sewage

pumping stations (SPS). Wet wipes accumulate over time in the well, causing many hazards and maintenance problems. Level sensors and instrumentation become blocked, pumps choked and odour builds up. Traditionally, maintenance crews have gone to SPS’s on a regular basis to manually clean the wet wells. Issues with this process include excessive water usage, high labour costs, confined space entry, pump chokes and ineffective cleaning. This time consuming and labour intensive process is very expensive with each SPS requiring on average five to six manual flushes per year.”

As a result, Sydney Water has introduced an automated process of self-cleaning of wet wells on SPSs. This process also optimises performance of the SPS and has significantly reduced Sydney Water’s operating costs.

“The ‘auto-flushing’ was achieved by modifying the cut out levels of pumps during peak flows for each site via the use of the SCADA system. The concept is that if you started with a clean well you could keep it clean by running the pumps down to a low level near the top of the pump intake so that the pump would skim off the surface material. If done on a daily basis there would be no extra burden on the pumps and there would be no build-up of material, leaving the well clean. This leads to no build-up of material on the measuring instruments and large lumps no longer forming to choke pumps. Without build-up of surface material odour is significantly reduced.

“The direct benefits of having an automated system was a significant reduction in cleaning costs, safety risks removed, corrections of other sewage pumping station faults during implementation, reduction in odour complaints and deferral of major capital outlay for equipment or construction.”

Knowing that an operational response was only part of optimising network performance, Sydney Water developed a multifaceted communications approach to better engage with the community to raise awareness and modify customer behaviour around flushing wipes.

Mr Smith said “Our customer research informed us that packaging claims have a direct influence on individual customer’s choice of wipes and leads to a higher prevalence of flushing these wipes down the toilet.”

Further our research found that:

• Approximately 1 in 3 wipes users flush, which equates to 1 in 4 of the total Sydney population over 15 years of age

• Intimate wipes are the key problem category and packaging claims are influential (more so for women)

• If customers perceive products as biodegradable, they twice as likely to flush them

• Males 15-44 years were the worst flushing offenders

“The survey also found 25 per cent of respondents indicated they would reduce wipes usage after knowing the cost and environmental impact, while 31 per cent would look to switch to another ‘biodegradable’ option.

“With this insight, the ‘Keep wipes out of the Pipes’ program was launched by Sydney Water in May 2015 across multiple communication platforms.

“The strategy was to engage and activate our customer base through creative social media posts that would raise awareness of the issue with a simple call to action,” said Mr Smith.

“The creative concepts, developed by HOST Sydney, aimed to bring a problem which mostly exists underground to the everyday consciousness of our customers. It was about converting an ‘out of sight, out of mind issue’ into one of everyday relevance.

“All materials produced featured a shocking statistic and the call to action to ‘Keep wipes out of the pipes’. These visuals were then able to be easily adapted for use across many channels, from social media, educational programs, right through to the Sydney Water bill.

“Building staff engagement through empowerment was an important element in the communications program. Sydney Water staff were brought along on the program through staff lunchtime sessions and given access to a ‘BBQ pack’ of key messages they are authorised to use with families and friends to build word-of-mouth networks to support the program.

“The media strategy has had a current cumulative reach of over 12 million people across print, online, radio and television. This includes Sydney Water and its spokespeople regularly being cited in the media.

“Our social media reach has exceeded one million people at an average engagement rate of 6 per cent, above the utility industry benchmark of 0.5-2 per cent.

Sydney Water’s education campaign on wipes has produced stunning results. Comparing the Sydney Water Consumer Sentiment Survey conducted for the March Quarter 2016 and those from the April/June Quarters in 2015 found that:

• There has been a 50 per cent

reduction in the proportion of customers who think it’s OK to flush wet wipes

• There has been a 57 per cent reduction in acceptability of flushing baby wipes

• The number of 20-29 year olds (one of the target demographics) who think it’s OK to flush wipes has reduced by 54 per cent

• The number of people 50+ years old who think it’s OK to flush wipes has reduced by 61 per cent

• The number of males of all age groups who think it’s OK to flush wipes has reduced by 46 per cent.

This highly effective campaign also resulted in customer advocates questioning wet wipe packaging claims, including a CHOICE magazine investigation into the packaging claims made by wipes manufacturers, which culminated in a major brand being awarded a ‘Golden Shonky’ at the 2015 Shonky Awards in Sydney. Over 5,000 people have joined CHOICE’s ‘Flushbusters’ campaign to have wipes products more appropriately labelled or removed from sale.

“Market-leading wipes manufacturer Kimberly-Clark has introduced ‘new and improved’ paper rather than plastic based Kleenex Flushable Wipes, along with a commitment to label their non-flushable products with a distinctive ‘do not flush’ symbol.”

“Sydney Water has also closely

supported WSAA’s successful approach to seek approval from Standards Australia to establish a mirror committee to the work of the international committee ISO/TC 224 WG 10 Flushable Products.

“Sydney Water is contributing technical expertise on behalf of the industry in the development of an international standard on ‘flush-ability’, which can be recognised by Australian water utilities as appropriate for local wastewater system characteristics,” said Mr Smith.

Yarra Valley Water (VIC)

Glenn Wilson, General Manager Infrastructure Services with Yarra Valley Water, said the introduction of ‘flushable’ wet wipes and other non-degradable products into Yarra Valley Water’s sewerage network causes significant operational issues.

Materials that do not break down can cause issues in a number of places throughout the network of pipes and pumps:

• Smaller diameter pipes: small numbers of wipes or non-degradable products can cause blockages at bends and fittings, or in the pipe itself (particularly when snagged by tree roots)

• Larger diameter pipes: large numbers of wipes or masses of non-degradable products can cause blockages as they can clump together, or combine with fats to

cause bigger blockages

• Sewage Pumping Stations: material that flows through the network of upstream pipes will accumulate in the wells of pumping stations. These can block the pumps, preventing the station from being able to convey flows and in the worst case, overflowing

• Sewage Treatment Plants: non-degradable products that pass through the inlet screens (these are designed to remove non-degradable materials from the flow stream) can cause damage to mechanical components and interrupt sewage treatment processes.

“Yarra Valley Water has not characterised the non-degradable material we have removed from the sewerage system, so it is not possible estimate what proportion of the material is made up of wet wipes,” said Mr Wilson.

“However, many of our Sewage Pumping Stations must be cleaned out frequently to remove the build-up of non-degradable materials that accumulate in the well. This material includes wet wipes, feminine hygiene products, and other items that have passed through the upstream network of pipes. Currently, Yarra Valley Water is forced to clean one of its larger facilities every three months. Every time, a mass of non-degradable materials between 10 and 20 cubic metres in size is removed from the well.”

If sites are not cleaned out, the build-up of non-degradable material can cause significant operational issues, including:

• Pump blockages, and inability to re-seat pumps once they are put back into the well

• Damage to pumps, and excessive wear on pump impellers

• Fouling of instrumentation and interference with float level switches.

According to Mr Wilson, Yarra Valley Water’s operational teams have noticed an increase in issues caused by non-degradable products in recent years.

“Yarra Valley Water frequently experiences blockages in pumps at Sewage Pumping Stations and Sewage Flow Control Facilities. In these instances, wet wipes and non-degradable materials pass into the well of the site from the upstream sewerage network. They tend to accumulate in the well, and clump together with other wipes and non-degradable material. The pumps at these sites are located at the bottom of the well, so when they start up, they draw the obstruction directly into the pump impeller. If a large enough obstruction remains lodged within the pump impeller preventing it from turning, the pump will stop and the level within the well will rise.

“Yarra Valley Water is alerted to the issue by a remote telemetry system and our maintenance contractor is sent out to correct the problem. We also have multiple pumps at all pumping stations

to provide a level of redundancy. The blockages need to be removed manually, which requires the lid of the well to be opened, the pump to be lifted out by a crane, and the obstruction to be removed by hand. If the well is extremely dirty, and the pumps are blocking frequently as a result, the well must be cleaned out before the pumps are returned. This requires the maintenance contractor to use a vacuum truck to remove the contents of the well. They will often need to isolate flows into the site and enter the well to ensure a thorough clean which is high-risk work.”

Mr Wilson said that Yarra Valley Water had replaced some pumps in its network order to reduce blockages. However, replacing pumps was not a suitable solution for every site.

“In recent years, pump manufacturers have been able to design pumps that are less susceptible to blockages. It is not possible for Yarra Valley Water to employ this technology at every site in its sewerage network due to the extreme cost in replacing all of the older pumps within the network, and also because pump selection must be primarily based around meeting the required duty point (being able to operate across the required flow range and lift the sewage to the discharge point).”

Yarra Valley Water has implemented

a number of measures in response to the growing volume of non-degradable material in its sewerage network. These have included:

• Changing pumps at some sites to types better able to deal with non-degradable material (e.g. chopper pumps, or pumps with impellers that are less susceptible to blockages)

• Installing macerators at inlets to sites

• Increasing the frequency of wet clean outs at sites which accumulate large quantities of non-degradable material.

“The efficacy of these measures has varied, and they have not entirely prevented pump blockages from occurring,” said Mr Wilson.

“For example, while wet wipes and other non-degradable materials may be macerated, the cut up material can reform together in pump wells over time and create an even larger blockage. Therefore, the fixes that involve the use of mechanical equipment have not removed the need for pump wells to be cleaned out.”

In addition, Yarra Valley Water is currently developing an education campaign in regards to the sanitation services it provides.

“It will cover what cannot be flushed down the toilet, as well as how to dispose of an array of items that are regularly flushed, and how the sewerage system works and is maintained,” said Mr Wilson.

The utility also employs targeted community engagement via newspaper and other media following any sewer spills determined to have been caused by large quantities of non-degradable material.

“We are also participating in the development of an international standard for flushable products. Australia’s input to this committee is being coordinated by the Water Services Association of Australia,”said Mr Wilson.

Queensland Urban Utilities (QLD)

Queensland Urban Utilities has also experienced an increase in problems due to wet wipes in recent years.

Queensland Urban Utilities Manager of Trade Waste, Col Hester, said so-called ‘flushable’ wipes contribute to increased maintenance and disposal costs.

“Our treatment plant operators have noticed blockages caused by a build–up of ‘rag’ material on inlet screens have become significantly worse,” he said.

“Call outs to blockages at pump stations and fouled impellers are also on the rise. Not all of the foreign material is ‘flushable’ wipes, but a significant

SEEPEX Smart Conveying Technology extends the life of your stator. Adjustment of the retaining segments takes just 2 minutes and restores 100% pump performance.

Tests have shown up to 3x stator life compared to conventional progressive cavity pump design Join the smart revolution and test our innovation “Smart Conveying Technology”.

SEEPEX Australia Pty. Ltd.

Tel +61.2.4355 4500 pvila@seepex.com

www.seepex.com

proportion usually is.

“It’s estimated we remove around 120 tonnes of wet wipes from our sewerage network every year, which if laid end-to-end, would stretch all the way from Brisbane to New Zealand.”

According to Mr Hester, wet wipes entering QUU’s sewer networks are a growing problem.

“Our operators are definitely reporting the problems associated with ‘flushable’ wipes are getting worse,” he said.

“We’re removing more ‘grit and screenings’ from inlet works at treatment plants and also spending more time maintaining pumps and other equipment.