pumpindustry

Thank you to all our

18 months

Pump Industry Australia Incorporated PO Box 55, Stuarts Point NSW 2441 Australia

Ph/Fax: (02) 6569 0160 pumpsaustralia@bigpond.com

PIA Executive Council 2018

Dave Alexander – President KSB Australia

John Inkster – Vice President Brown Brothers Engineers

Kevin Wilson – Treasurer/Secretary Executive Officer

Keith Sanders – Councillor Executive Officer - Marketing & Statistics Life Member

Alan Rowan – Councillor Executive Officer - Publications & Training Life Member

Ken Kugler Executive Officer –Standards Life Member

Jim Athanas – Councillor Xylem

Mike Bauer – Councillor Dynapumps

Andrew Black – Councillor Envirotech Water

Malcolm Eyre – Councillor Franklin Electric

Ashley White – Councillor Davey Products

The PIA has had a productive couple of months and are pleased to see several new members join our ranks in recent weeks. Welcome aboard.

The PIA committee have produced a new flyer to outline the features of PIA membership which is shared on our website. Please spread the word to encourage new members. It is one of our principal objectives for 2018 to increase the number and diversity of members to get the broadest possible input into initiatives that will benefit everyone.

The PIA were proud to present another seminar at Bruce County Conference Centre in May on Pump energy efficiency and reliability in operation. Our thanks to Albert Dessi for making a presentation on the Industrial Equipment Upgrade program under development by the government. This continues the work PIA has been doing with several government authorities in the past 12 months. Further seminars are planned for later this year in Brisbane and Sydney, and we invite you to participate.

Alan Rowan organised another Installation & Commissioning course in Brisbane which was well attended. These courses are based on best industry practice and we encourage all members to send their Installation Supervisors to complete this program. The next course will be in Melbourne on 14 August. Look out for the flyer for more information.

As members will know, PIA recently concluded a reciprocal agreement with Irrigation Australia. This allows both organisations to cooperate on issues of common interest and we hope to develop this relationship further over time.

The recent Irrigation Australia Expo in Sydney attracted a number of pump companies and proved to be a valuable platform for introducing new products to this important market segment. In my day job as Managing Director of KSB Australia, I was very interested to attend since irrigation is a competitive market in Australia. Many players are well established, and we were keen to get our new products in front of the experts in irrigation. Irrigation Australia did a great job and we thank them for their support.

Let me say a big thank you to Ron Astall, who recently advised us that he would be resigning as Councillor with work and travel commitments in his role with United Pumps taking the lead. We hope Ron will still find time to attend PIA functions and add some humour to meetings and events that are organised in future, as well as continuing to provide his valuable insight.

Jim Athanas of Xylem will also be joining the Council to round out the PIA representatives voted in at the last AGM. Be in touch if you have any requests or inspiration for our team and your PIA.

Here’s to pumping,

Dave Alexander President – PIA

The ASM C Series sump pump is built tough for reliable uninterrupted operation in the most demanding conditions.

What makes the ‘C’ Series so robust is what it doesn’t have; a submerged motor, bearings or mechanical seals, the primary causes of failure in conventional sump pumps. The heavy duty shaft and bearing assembly is above the mounting plate, clear of the sump environment. This feature allows the pump to run dry indefinitely without damage, pump extreme temperature liquids and have a high tolerance to abrasive fluids.

Additional to these benefits is the fact that the pump is always

primed and ready to work. The C Series is available with material and design options for clean liquids, solids handling, chemicals and extreme temperatures.

This is the pump you need when you want peace of mind. For more information contact ASM Pumps on (03) 9793 7577 or visit asmpumps.com.au

Cover image highlights the mining feature in this issue, showing the potash ponds in Western Australia.

3,583

Published by Monkey Media Enterprises

ABN: 36 426 734 954 PO Box 1763

Preston South VIC 3072

P: (03) 9988 4950

F: (03) 8456 6720

monkeymedia.com.au

info@monkeymedia.com.au

pumpindustry.com.au

magazine@pumpindustry.com.au

Publisher: Chris Bland

Editor: Lauren Cella

Senior Associate Editor: Jessica Dickers

Journalists: Elisa Iannunzio, Kirsty Hutton, Lauren Butler

Marketing Associate: Sam Penny

Business Development Manager:

Rima Munafo

Marketing Consultants: Helena Brace, Stephanie Shaw

Production and Customer Service:

Titian Bartlau

Senior Designer: Alejandro Molano

Designer: Jacqui Abela

ISSN: 2201-0270

This magazine is published by Monkey Media in cooperation with the Pump Industry Australia Inc. (PIA). The views contained herein are not necessarily the views of either the publisher or the PIA. Neither the publisher nor the PIA takes responsibility for any claims made by advertisers. All communication should be directed to the publisher.

The publisher welcomes contributions to the magazine. All contributions must comply with the publisher’s editorial policy which follows. By providing content to the publisher, you authorise the publisher to reproduce that content either in its original form, or edited, or combined with other content in any of its publications and in any format at the publisher's discretion.

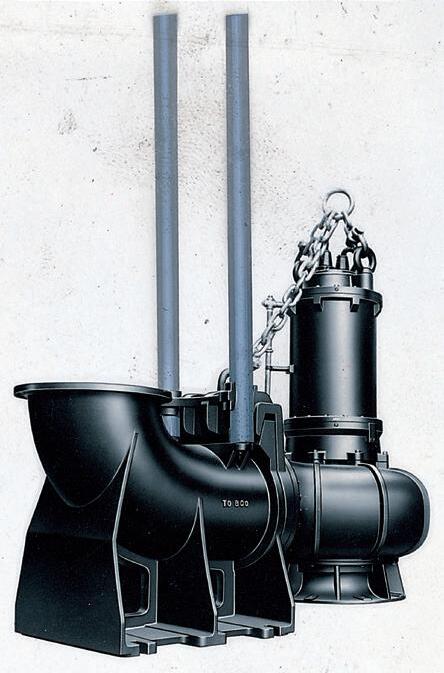

new DryWet sewage pumps set to change the market

The Senate Economic References Committee has conducted a public hearing on the future of Australia’s new submarine fleet, with the use of pump jets questioned.

Australia’s next generation of submarines will be built under the Federal Government’s Future Submarine Program, with French company DCNS designing 12 Future Submarines.

A pump jet propulsion system has been proposed as a key feature of the Shortfin Barracuda submarine, however the inquiry revealed discrepancies between expert opinion and the project team’s design.

Aidan Morrison, a physicist who compiled a report for the inquiry, noted that the pump jet is not efficient at the speeds that a conventional submarine operates in.

“Pump jets have a far lower efficiency than propellers at a low speed of travel in contrast to high speeds, where jets tend to become more efficient,” Mr Morrison said.

“The crossover does not lie near or anywhere under the probable transit speed of eight to 10 knots of a diesel-electric submarine. One world-renowned expert I discussed the matter with said it was impossible that a pump jet could be designed to be more efficient than a well-designed propeller under 18 knots.”

He claimed that no other conventional submarines used this type of system.

“There are none in service at all. I’m aware of a prototype or demonstrator that was built once on a Russian submarine, a Kilo class submarine. I’ve seen a photo of that, but as far as I can tell it was never put into much active service.”

Mr Morrison also contested claims made by French company Naval Group that pump jets meant that the Shortfin Barracuda would be able to move more quietly.

“The pump jet is only quieter when compared with an obsolete propeller. This could actually be the statement that was intended to be made, in which case it is perfectly consistent with the research that I have done and put before you today,” Mr Morrison said.

While pump jet propulsion systems are generally used in nuclear submarines, they are generally not used in conventional submarines.

Anew water treatment plant –consisting of two containerised facilities as well as several new tanks – has been craned in to place at Bronte Park in Tasmania’s Central Highlands region.

It is one of 12 new treatment plants installed by TasWater around the state to meet its commitment to end all public health alerts by the end of August 2018.

The plant has been manufactured in a factory in Launceston by TasWater contractor TRILITY and its subsidiary Hydramet. In total, eight similar modular plants have been built – the Bronte Park treatment plant is the last to roll off the production line.

It was transported by road to site and lifted into place by crane. Once installation is complete, the treatment plant will complete the integrated water supply system.

Bronte Park’s water supply was originally installed by the Hydro Electric Commission in the 1940’s with much of it replaced by a private developer from the 1960’s. TasWater took over Bronte Park’s water supply in 2016.

The water will continue to be sourced from Hydro Tasmania’s Bronte Canal which is fed from Pine Tier Lagoon. Following treatment the drinking water will be stored in both the existing and two new reservoirs before being piped to the existing reticulation network.

Now the treatment plant modules are in place, the piping, mechanical and electrical connections will be completed ahead of a stringent testing program overseen by the Department of Health and Human Services.

It is only after this that Bronte Park’s current Boil Water Alert can be lifted. TasWater is on track to meet this commitment by the end of August 2018.

The New South Wales Government has announced the expansion of Hunter Water’s sewerage network, allowing over 400 businesses and residences in Wyee to be connected, with capacity for hundreds more to be connected in the future.

Minister for Energy and Utilities, Don Harwin, said the State Government recognised the growth potential of Wyee.

“We have long acknowledged Wyee has great potential and we’re committed to helping it meet that potential by investing in the expansion of this scheme.

“Expanding the scheme now makes economic sense, ensuring the right infrastructure is delivered to provide capacity for new homes in Western Lake Macquarie, increasing the overall investment to more than $36 million.

“I’m pleased to report that Hunter Water has made significant progress in the design and environmental assessments for the new sewer system, with construction work expected to start by mid next year.

“Even with the expansion plans, the project remains on track to be delivered for connection by December 2020,” said Mr Harwin.

Member for Lake Macquarie, Greg Piper, welcomed the expansion.

“I’m delighted the NSW Government has decided to expand this important project. In addition to the 400 homes and businesses, which will be directly connected now, the system will be built for the future needs of Wyee with the capacity to service 2750 new homes.

“I genuinely believe this project lays the groundwork for a very bright future for the Wyee township.

“The residents have waited a long time for these changes and I have no doubt they are eager to see the works completed.”

AGL has announced the progression of its proposed gas import project at Crib Point in Victoria. Two agreements have been signed, the first enabling berth upgrades at the Port of Hasting as well as a leasing agreement that would be required should the AGL project go ahead.

The second, with APA Group, is for the Crib Point to Pakenham pipeline to transport imported gas to homes and businesses.

The project itself remains subject to approvals, community consultation and a final investment decision by AGL.

AGL project spokesman Kelly Parkinson said, “Although we have been consulting with community members and governments since 2017, some community members are still understandably concerned about the project and the impact it might have.

“We’re carrying out feasibility into using the Crib Point Jetty because this has been identified as the best site to minimise local impact.”

AGL Managing Director and CEO, Andy Vesey, said, “The Crib Point LNG Import Jetty project has significant potential to provide AGL with the ability to deliver a new flexible source of gas supply to the southern states of Australia. This will deliver liquidity, increasing competition to put downward pressure on wholesale prices and provide much needed capacity and long-term security of supply.

“As highlighted in the Australian Energy Market Operator (AEMO)’s Victorian Gas Planning Report released in March 2018, without additional gas supply there is a potential shortfall in the market from 2022 and a potential shortfall in meeting peak Victorian winter daily demand in 2021. Our proposed project is uniquely placed to address this challenge.

Mr Parkinson said he is aware of concerns over the environmental impact of the project.

“We are very aware that Western Port is an environmentally sensitive area and many areas within it are covered by the RAMSAR international convention on the protection of wetlands,” Mr Parkinson said.

“There is already an existing jetty that currently functions for petrol importation.

“It has an existing deep water berth that does not require deep dredging and importantly it’s a relatively short distance from the Victorian gas network.”

Selecting another location would require the construction of a new jetty and significant excavation of the bay floor.

Kelair

SANDPIPER Air Operated Double Diaphragm Pumps

• Capacity: To 59 m³/hr

• Pressure: To 8.6 bar

• Temperature: To 150°C

• Viscosities: To 25,000 cps

Applications

Chemical Processing, Mining, Paints, Food Processing, Industrial Maintenance, Electronics, Construction, Utilities

PULSAFEEDER Metering Pumps

• Capacity: To 52m³/hr

• Pressure: To 383 bar

• Temperature: To 260°C

• Viscosities: To 25,000 cps

Applications

Water and Wastewater Treatment, Chemical Processing, Hydrocarbon Processing, Food Processing

ALBIN Peristaltic / Hose Pumps

• Capacity: To 155m³/hr

• Pressure: To 15 bar

• Temperature: To 50°C

• Viscosities: To 100,000 cps

Applications

Mining, Thickener Underflow, Pulp and Paper, Filter Press, Brewery, Water Treatment, Quarry, Grout, Concrete, Waste Liquids

LOWARA Single & Multistage Centrifugal Pumps

• Capacity: To 187m³/hr

• Pressure: To 15 bar

• Temperature: To 150°C

• Viscosities: To 500,000 cps

Applications

Pressure Boosting, Industrial Washing, Water Supply, Water Conditioning, Demineralised Water, Glycol, Boiler Feed, Multi-pump, Pressure Sprinkler Systems

Visit kelairpumps.com.au for more information on our extensive range today.

Locally Engineered & Supported

End-suction or Horizontal Split case

Optimum Efficiencies

High pressure, up to 40bar

Conforms to API standards

Complies with ISO 2858, ISO 5199 & EN 733

Townsville City Council has awarded the contract to build a new sewage pump station in Cranbrook, Queensland. NQ Excavations has been awarded the contract to construct the $1.5 million sewage pumping station, including a sewage rising main and gravity sewer, and installing a new sewage pump.

Townsville Water and Waste Committee chairman, Paul Jacob, said the new pump station upgrade will improve capacity of the sewerage network in the Cranbrook area and prevent overflow occurring during heavy rain events.

“Providing high-quality infrastructure throughout our suburbs is a key priority for Council,” Mr Jacob said.

“This pump station will be built to the highest standards and is designed to be as unobtrusive as possible.”

The pump station will be installed at McConachy Park, after an extensive community consultation was undertaken.

Mr Jacob said the chosen site was the best option out of five areas examined.

“We have spoken with residents in the area and we have selected a site after reviewing all other potential locations,” Mr Jacob said.

“The final site location of this project was chosen as it is located near existing services, significantly more cost effective and accessible for Council and contractors to complete this important project.”

www.masterflow.net.au

~ over ~ 30YEARS

The Image Flat Water Treatment Plant on the Sunshine Coast hinterland is celebrating five decades of operation, having produced 365 billion litres of water for the community. Seqwater held a small ceremony at the facility to celebrate those who have worked at the plant.

The plant, which was officially opened in 1968, formed part of Maroochy Shire’s first reticulated town water scheme, until individual householders became responsible for their own water supply through rainwater tanks.

Image Flat is the main treatment facility in the Maroochy River area. It draws water from Poona Dam, Wappa Dam or the South Maroochy River which is supplemented by water from Cooloolabin Dam.

Treated water from the Image Flat Water Treatment Plant supplies numerous suburbs, including Nambour, Yandina, Eumundi and coastal urban developments north of the Maroochy River.

Also in attendance was Nambour grandmother Muriel Harrison-Peters, whose late husband Jack Harrison worked as the first Water Officer for Maroochy Shire Council from 1957 to 1984.

Ms Harrison-Peters, 88, said she was among those in attendance when the Image Flat Water Treatment Plant was officially opened in 1968 by then Maroochy Shire Council Chairman David Low.

Among those to attend the celebratory ceremony was 91-year-old Martin Schultz, who was the first Water Treatment Plant Operator to work at the Image Flat plant and worked there for more than 20 years.

“Being back inside the plant again brings back a lot of memories. It sure doesn’t feel like 50 years since it was opened,” Mr Schultz said.

“There’s been a lot of technological advancement in water treatment since I worked here which was interesting to see.

“Machines and software systems

have replaced a lot of the tasks that would previously have needed to be done by hand.”

Pressure: up to 8 bar

Downtime: drastically reduced

Maintenance: simple and quick

Energy use: significantly reduced

“I remember we all went on a tour of the plant when it was opened with council members and engineers, including Jack Mulholland who was crucial to the installation of numerous Sunshine Coast dams,” Mrs Harrison-Peters said.

“With his job, my husband would have to travel to different pump stations a few times a day to control the water supply to different tanks.”

Seqwater Acting Chief Executive Officer, Dan Spiller, said anniversaries were opportunities to look back and take stock of the past as well as plan for the future.

“It can be easy to take a safe, secure water supply for granted, but water is essential for all aspects of life, and we’re very proud of the role we play in a healthy and prosperous South East Queensland,” Mr Spiller said.

“The history of South East Queensland’s water supply is a fascinating and often dramatic story as engineers and planners work to adapt to a rapidly growing population in an ever-changing climate.

“These challenges continue as Seqwater plans for a sustainable water future that meets the needs of all South East Queenslanders.”

Productivity and efficiency: significantly

Rotor and stator life:

Life cycle costs:

Standards Australia has approved the development of a national standard that defines the criteria for material suitable for toilet flushing, along with appropriate labelling requirements.

The Water Services Association of Australia (WSAA) and the urban water industry in Australia and New Zealand have been concerned about the contribution of wet wipes products to pipe blockages and, in turn, disruption to customer services, extra costs and impacts on the environment.

“An Australian Standard would provide manufacturers with clear specifications to design products compatible with the sewerage network,” WSAA Executive Director, Adam Lovell, said.

WSAA and its members started developing the standard in May 2018 and it is anticipated that the standard will take between 12 to 24 months to complete.

Separately, the International Water Sector Flushability Group (IWFSG) published its flushability specification in June 2018, outlining the preferred requirements for flushability as developed by water industry representatives from the US, Canada, Japan, Spain, Israel, New Zealand and Australia.

The documents are in the form of three publically available specifications or PAS documents.

“This is an international issue for water utilities around the globe and while there is no standard at present, customers need clearer labelling to ensure these products do not contribute to blockages in urban wastewater systems,” Mr Lovell said.

You’ve probably heard about the innovation and progress LaserBond is achieving in surface engineering technology. We apply new surfaces to worn parts so they work literally better than new. And brand new parts can also be treated so they last a lot longer. Customers enjoy longer wear life, fewer shutdowns for component replacement, and better workplace health and safety control. Our laser-applied coatings typically at least double the life of a part.

The new ‘laser cell’ in our SA engineering facility will have the highest-power laser beam used for laser cladding in the Southern Hemisphere. We already operate the three most powerful lasers in this industry in Australia. These are supported by many other processes and technologies, such as HP HVOF, all supported by our own well-equipped metallographic laboratory and state-of-the-art workshops. If you’re looking for the best surface engineering available, look no further.

With the world of pumps continuously evolving at both an Australian and global level, the challenge is to keep all stakeholders aware of these activities, so that the latest technologies, pump standards and legislation being contemplated can be successfully introduced. To address this challenge, Pump Industry Australia (PIA) hosted the one-day Energy Efficiency and Savings in Pumping Systems seminar on the 15 May at the Bruce County Hotel in Mt Waverley, Melbourne.

The seminar provided attendees with the opportunity to hear from key stakeholders, including government representatives, pump user groups, and leading national equipment suppliers and manufacturers about the latest developments on the impacts of

pumping systems on energy and the environment, energy efficiency policies and planned legislation, and technical and commercial advances made in the application and penetration of energyefficient pumping systems.

Keith Sanders, PIA Executive Officer Marketing and Statistics, opened the seminar and introduced the day’s keynote speaker, Albert Dessi, Assistant Director at the Department of Energy and Environment.

Mr Dessi’s keynote presentation ‘Industrial equipment upgrades program under the Emissions Reduction Fund’ set out the eligibility criteria for energy efficiency upgrades in pumping systems.

The Emissions Reduction Fund (ERF) provides incentives for Australian businesses, farmers, land holders and

others to adopt new practices and technologies to reduce greenhouse gas emissions by giving people an opportunity to earn money while reducing emissions.

Under the ERF a new Industrial Equipment Upgrades method has been put forward to provide incentives for energy efficiency projects involving replacing or upgrading common industrial and related equipment such as pumps, boilers, compressed air systems, refrigeration and industrial cooling systems.

“The way the fund works is you register for the fund using an approved method, then you bid into an auction and the government pays you for your credits once you have realised them, so you measure and verifiy that you have obtained emission reductions, and then

Members of the pump industry gathered in Melbourne in May to discuss the latest in government energy policies and planned legislation, as well as advances in the application and penetration of energy-efficient pumping systems.

you are paid once you report those credits,” Mr Dessi said.

“In order to use the Emissions Reduction Fund, you need to use an approved method of calculation, you need to have a project registered, and then you need to obtain the savings in energy efficiency to prove this and verify and measure that they’ve occurred.

“Credits run for seven years, but depending on how you do the measurements under this method the credits will tend to be discounted in later years.”

In order to apply for the fund, the government requires approved

methods to be used to determine and verify that emission reduction has occurred.

“The method establishes the calculations you have to do to determine those emissions and they establish reporting requirements so that we can verify that the savings are genuine, and that they can be measured and verified,” Mr Dessi said.

One of the aims of the fund is to provide incentives for projects that would not normally have gone ahead in order to encourage emission reductions additional to what would happen in the ordinary course of business as usual.

“It calculates emission reductions by measuring your energy consumption for

a representative measurement period before you undertake a project and after you’ve made the energy efficiency improvements, and in that way we can ensure that the measurements are comparable and that you have actually achieved the intended results.”

Strict energy boundary and professional measurement and verification oversight are also in place.

“To make sure emission reductions are additional to what would normally happen, we first off require that the project be recommended through an energy audit or through another energy efficient assessment by a suitable professional. This cuts out equipment suppliers that are selling equipment just because they want to sell equipment, where there isn’t a good energy efficiency reason to replace that equipment,” Mr Dessi said.

Mr Dessi also mentioned that there is ongoing work by the Equipment Energy Efficiency program which is looking into minimum energy efficiency standards for pumps.

To learn more about the ERF, visit www.environment.gov.au/ climate-change/government/ emissions-reduction-fund.

Setting the Standards

Standards were a key focus of the seminar with several papers presented on proposed and newly implemented standard changes, as well as approaches to standards overseas.

Ken Kugler, PIA Executive OfficerStandards, talked about the new pump test code AS/ISO 9906:2018.

As a member of the Standards Australia ME-030 sub-committee, Mr Kugler provided attendees with an update on the changes to the standard.

“AS 2417 is now withdrawn and considered obsolete, and was replaced by AS/ISO 9906:2018 in February this year,” Mr Kugler said.

“Previously, acceptance grades [from AS 2417:2001] were levels 1 or 2 with

tolerance values based on specific flow and/or pressure ranges – regardless of industry or pump type.

"The new guidelines recognise that different pumps and/or industries have differing needs and established a multitude of default acceptance grades based on the application and rated power of the pump.”

For more information about changes to AS/ISO 9906:2018 see page 18.

Keith Sanders’ presentation ‘Energy auditing and certification: ISO 14414’ reviewed energy saving approaches in the UK and US, and the need for a uniform approach to auditing and certification in Australia.

“Legislation on energy consumption in Europe and in the US is more advanced than it is in Australia; they already have more standards and more procedures, and these are harmonised to ensure auditing follows consistent guidelines. The standards are already in operation, and Europump, BPMA and Hydraulic Institute offer courses for auditing of pumping equipment and certification,” Mr Sanders said.

“While there is no industry standard for commissioning of pumping equipment to determine base operating data in Australia, the PIA has developed a program to train specialists to conduct commissioning and energy evaluations.

“ISO 14414:2015 is also being considered at this time and may be recommended to Standards Australia for adoption.”

PIA also welcomed back Brett Dundules, Senior Technical Officer at the Fire Protection Association of Australia (FPAA), who has presented at a number of PIA events .

Mr Dundules’ presentation ‘The mechanics approach to the NCC by FPAA’ explored the changes in the mechanics approach to the National Construction Code (NCC). He presented the proposed changes for sprinkler systems in buildings less than 25m, how the code addresses primary and secondary referenced documents, and how these changes would impact pumpsets.

Pumpset standards for fire installations were further explored by Bala Thuraisingam from the FPAA and Ken Kugler in their presentation ‘Fire pumps and conformance to AS 2941’.

The presentation looked at what is specified in the standard, why it is needed and who is responsible for ensuring compliance.

Mr Thuraisingam and Mr Kugler also presented a number of case studies to illustrate where compliance has or has not been met.

Insights from the industry

Attendees also had the opportunity to hear from specialists, and leading national equipment suppliers and manufacturers about the technical and commercial advances made in the application and penetration of energy-efficient pumping systems in Australia and overseas.

Naren Gangaiah, Project Engineering Manager - KSB Australia delivered his presentation ‘European Extended Product Approach (ErP and EEI explained)’ which provided a manufacturer’s view on European legislation and product availability.

Warwick Stannus, Group Engineering Manager at A.G. Coombs, talked about efforts to establish guidelines and standard templates for a range of pump installations in his presentation ‘HVAC Pump Installations - An integrated approach to pump selection, installation and maintainability’.

Mr Stannus said he has seen a lot of different approaches to installation and commissioning leading to inconsistency between installations, which is a problem, especially if it’s happening within a business.

James Chalmers, Global Water Industry Manager – ABB (UK), discussed effective water utility management techniques, focusing on managing leakage, optimising pump performance and energy efficiency.

According to Mr Chalmers, business intelligence and performance metrics play a large role in the efficient

use of water and meeting the utility’s challenges, which relies on the use of digital technology to optimise operations. In particular, he discussed the use of different technologies for early detection of faults in the system in order to reduce costs, as well as customer complaints.

Malcolm Robertson, Robertson Technology, explored strategies for performance assessment and improvement using the thermodynamic method of measuring pumping performance on-site.

From Davey Water Products, Andrew Rathjen’s presentation ‘Remote data capture for power savings in Industry and Irrigation’ looked at the management of data to achieve improved pump performance.

To ensure the Australian pump industry remains up to date with the latest PIA news, changes in standards and training, the PIA runs a number of seminars, technical meetings and training courses throughout the year in various states. For more information or to see when the next event is on, visit https://pumps.asn.au/.

Pump

Industry Australia (PIA)

has continued to liaise

with industry organisations and government departments

to promote cooperation

between industries,

and improve standards. Here, we look at the most recent changes to standards relating to pumping systems that you need to know.

In late February, AS/ISO 9906:2018 Rotodynamic pumps - Hydraulic performance acceptance tests - Grades 1, 2 and 3 was officially published and is now in effect. As a result, AS2417:2001 Rotodynamic pumps - Hydraulic performance acceptance tests - Grades 1 and 2 has been superseded.

In November 2015, Standards Australia advised that AS 2417:2001 was considered an aged standard and could be subject to withdrawal.

ISO 9906:2012 had previously been adopted in Europe and member countries with an equivalent British Standard introduced the same year and other countries following suit soon after. Therefore, the AS 2417:2001 standard was out of sync with the rest of the world by five years. Additionally, the US had published ANSI/HI 14.6:2011 Rotodynamic pumps for hydraulic performance acceptance tests. This standard is “harmonized” with ISO 9906:2012 and the outcome from testing in either standard is identical.

Due to this, the PIA Council decided to initiate the procedure required for the direct adoption of ISO 9906:2012 in Australia as the direction globally is toward one worldwide standard for pump performance testing.

AS/ISO 9906:2018 specifies hydraulic performance tests for customers’ acceptance and specifies the requirements at test facilities. The tests can be applied to pumps of any size, and any pumped liquids that behave as clean, cold water. It only applies to the bare pump itself without any fittings, electric motors or any other associated equipment.

When evaluating and making pump selections, it forms part of the guidelines intended to ascertain the performance of the pump and to compare this with the manufacturer’s guarantee.

Previously, AS 2417:2001 consisted of two acceptance levels: Grade 1 and Grade 2. Both grades had bilateral tolerances for rated head or rated flow and allowed a negative

tolerance on efficiency. As an annex to the standard, it had Annex A which provided a minimum tolerance which general purpose pumps were to meet unless otherwise specified.

The new standard contains three levels of acceptance criteria for pump performance test results, with each grade broken down into further subgrades with differing tolerance bands for pump acceptance levels.

• Grades 1B, 1E and 1U with tighter tolerance (old AS2417 Grade 1)

• Grades 2B and 2U with broader tolerance (old AS2417 Grade 2)

• Grade 3B with even broader tolerance (old AS2417 Annex A)

Compared with the previous test standard, in general the level of acceptable tolerance value increases from Grade 1 to Grade 3 and can either be unilateral (one sided, designated by U) or bilateral (two sided, designated by B). Tests to U grades do not have an allowable negative tolerance for flow and head.

ISO pump standards are reviewed by the appropriate committee every three to five years and PIA is in the process of submitting a proposal to Standards Australia to have international participation. This would allow PIA to have direct input to the responsible ISO committee in Europe. It is expected that this will be finalised in the next couple of months.

Discussions with Fire Protection Association of Australia (FPAA) are ongoing regarding the adoption of a checklist to accompany AS2941 Fixed fire protection installations – pumpset systems.

In the meantime, an abridged version can be found on the PIA website for use by members who want to adopt a uniform approach for the verification of compliance to the requirements of AS2941

Reliable, powerful, robust.

For several decades, AUMA actuators have proved their reliability in automating sluice gates, butterfly valves and gates in weirs, fish ladders, locks, and hydropower plants.

AUMA’s comprehensive portfolio covers torques ranging from 10 Nm to 675,000 Nm offering homogeneous automation schemes throughout the plant: from simple OPEN-CLOSE applications to level control using an integral PID controller.

Jacmor Engineering is an authorised supplier of world-leading Thordon Self Lubricating Pump Bearings. Utilising proprietary polymers, Thordon high-performance bearing solutions have the capability to run dry, deliver high reliability and long wear life, particularly in tough abrasive operating conditions. This high level of product performance results in decreased lifecycle costs and increased mean time between failures for Thordon’s customers.

Jacmor Engineering regularly supplies fully finished bearings to leading pump companies, mining, sewage treatment plants, power generation, marine, offshore, pulp and paper, irrigation and other Industries across Australia. We also offer drinking water and FOOD grade bearings. Based out of Melbourne – Australia, Jacmor Engineering provides full technical and installation support. We carry a huge inventory and bearings can be dispatched overnight from our state of the art machining facility. To date, bearings to suit shaft diameters ranging from 25mm–1500mm have been supplied to valued clients across Australia. Thordon Bearings is the proven, cost-effective, environmentally-friendly, solution for rigorous and demanding journal bearing applications. For specific applications, feel free to contact Josh Sayed at Jacmor Engineering via email on joshs@jacmor. com.au or on 0447 546 142.

Imagine if Coke didn’t have Pepsi. If there was no PC vs Mac. If GM never came close to Ford. That’s pretty much what it’s like with Warman pumps. We have been the top of the industry for decades. We’re the only people we have to beat. And we don’t make it easy for ourselves.

Here’s to 80 years of being the best and another 80 years of being even better. It’s always been Warman, and it always will be.

To find out more visit www.alwayswarman.weir

www.minerals.weir

Ebara Pumps Europe is expanding its range of EVMS (Shurricane) vertical multistage pumps, with models of 32, 45, 64 and 90 m3/hr capacities.

Following the success of the smaller EVMS vertical multistage pump—and its unique “Shurricane” impeller design which greatly reduces axial thrust—Ebara Corporation Japan and its Italian factory have invested in research and development, and tooling to expand the design and concept for larger capacity vertical multistage pump (VMS) models.

The EVMS model VMS pump—with its Shurricane impeller design—greatly reduces axial thrust and allows the use of standard electric motors without any modifications or additional bearings up to and including 30kW. Motor bearing life is greatly increased and the overall cost is reduced as larger thrust bearings don’t need to be fitted to the motor and no additional thrust bearings need to be fitted to the pump.

Other features include a minimum efficiency index (MEI) of >0.7 and a cartridge type mechanical seal utilising standard EN 12756 mechanical seal

components. All models over 5.5kW are fitted with a spacer coupling, allowing the easy removal of the cartridge seal and if needed the standard EN 12756 mechanical seal can be sourced from your local seal supplier, as well as your local Ebara dealer or sales office.

The new larger EVMS model pumps are available in a variety of materials including CI/304SS, all 304SS and all 316SS materials, plus hard faced and standard mechanical seals (balanced and unbalanced). Other features include smart plug solutions with separate air vent plug, and water filling and sensor plug.

Ebara continues to expand the range of products they stock and supply in Australia with two recent additions. For more details contact us at Ebara Pumps Australia or visit our website.

Very economically priced cast iron end suction motor pumps to EN733. They are based on the well proven 3M using the same extended shaft motor and stainless steel impeller, but with a cast iron casing.

A range of robust submersible grinder pumps with a high torque motor & powerful grinding mechanism. Another quality product in the well regarded and proven D’ series of Ebara submersible sewage & wastewater pumps.

with powerful grinding mechanism

In mid-March, a bush fire tore through Cobrico in Victoria’s south-west, igniting the peat bog underneath. This left behind toxic levels of carbon monoxide and caused the temporary relocation of 20 per cent of residents. With no decent rainfall expected, a four kilometre layflat hose was laid to create a temporary pipeline to pump water to the site and extinguish the threat.

The recent fire that tore through Cobrico, burned over 15,000 hectares of land in a peat bog. Firefighters worked day and night using fire trucks, helicopters and bulldozers to try to contain it. However, peat fires are extremely difficult to manage as they require a significant amount of water running continuously to extinguish them.

Peat is created over time in wetlands through the build-up of partially decayed vegetation such as leaves, grass and root systems. Once ignited, it is a challenge to extinguish and can burn for months or years. It burns similarly to briquettes, emitting significant smoke as it does.

This smoke can reduce air quality, and contains fine particles, water vapour and gases including carbon monoxide and nitrogen oxides. It may also contain sulphur compounds which are odorous.

If left to burn, the Cobrico peat fire could have spread through the vegetable matter up to 10m below the surface and damaged prime farming land.

Since the traditional method of using fire trucks and the expenses of helicopter water bombing were not having the desired effect, the decision was made by the local authorities to flood the area using large volumes of water. After careful consideration of the pipeline options available to bring in this water, flexible layflat hose was decided upon as the most efficient and economical option. 200mm diameter layflat was rapidly connected to a valve in the Major Ottway Pipeline, four kilometres away, and this brought water to the peat fire in just 48 hours.

State Emergency Management Commissioner, Craig Lapsley, said that with no decent rainfall on the horizon, an above-ground temporary pipeline was deemed the only feasible way to get a constant and significant amount of water onto the peat fires in a short time.

“One of those is to put above-ground piping to bring [water] from a major reticulation main; it’s quite extensive but necessary without rain,” Mr Lapsley said.

The temporary pipeline was assembled using Crusader Hoses’ flexible layflat hose which was supplied on reels of 200m plus some shorts. This was easily and efficiently transported to the site in only three truckloads, due to its compactness, and the full four kilometres of hose was unrolled and in-situ within one and a half days. The water was soon flowing through at 50 litres per second at 10 bar pressure and this rapidly contained the fire behind an inactive edge.

The segmented hose pumps water 24 hours a day alongside roadsides and across paddocks until it reaches two dams dug at the edge of the peat fire at Lake Cobrico. There are irrigation pumps going from the dams into sprinklers which directly attacks the fire. The water is also being used to flood a trench which is acting as a fire break.

The construction of the pipeline took just 48 hours—one expert said such a feat would ordinarily take weeks—and is understood to be the first time such a method has been used to fight a peat fire in Victoria.

Francois Steverlynck, Managing Director of the Australianmade Crusader Hose, said, “We have been in the development and manufacturing of high-quality flexible layflat hose systems for over 33 years and we are happy that the benefits of this method were proven in extinguishing the Cobrico peat fire.”

Once the layflat hose and pump was installed, roads were reopened without obstacles as the hose had been placed in culverts at crossings and ran alongside. The layflat hose was deployed with minimal environmental impact and a soft footprint.

Residents were permitted to return with health risks significantly reduced.

The layflat hose will next be retrieved by rolling it up on reels or pallets. It will then be ready to move water again at whatever site it is needed at.

Founded in 1968 in Montecchio, Italy, Lowara is recognised as a world leader in stainless steel manufacturing for turbine, centrifugal and submersible pumps for use in the building services, residential, public utilities, agriculture, aquaculture and mining industries. In June, Lowara celebrated its 50th anniversary, with distributors and dealers coming together in Sydney to mark the occasion.

Lowara celebrated the occasion with a Sydney Harbour cruise, with 110 dealers and customers enjoying a great night and a spectacular view of the Vivid Sydney festival illuminations.

Lowara pumps are distributed in New Zealand, and Australia in QLD, NSW, VIC and TAS by Brown Brothers Engineers, in SA and NT by WBS Pumps, and in WA by Advanced Pump Technologies.

It’s success in Australia and New Zealand is built upon the passion of its distributors and dealer network, and the quality of the materials used for manufacture.

John Inkster, CEO at Brown Brothers Engineers Australia, was among those to attend the celebration in Sydney.

“Brown Brothers Engineers congratulates Lowara on celebrating 50 years of manufacturing, growing from a small business in Montecchio, Maggiore, to a world renowned global pump company. Quite an achievement in the space of 50 years,” Mr Inkster said.

“Brown Brothers has been a distributor for 28 of those 50 years starting in New Zealand in 1990 and in Sydney, Australia, in 1994.

“Being a Lowara distributor for such a long time very much defines who we are; it has been a rewarding journey and enabled Brown Brothers to make ‘the jump’ across the Tasman where we are now the sole distributor on the eastern seaboard with sales offices, warehousing and workshop facilities in Brisbane, Sydney and Melbourne.”

An evolving product range

Lowara continues to grow as a manufacturer, making its mark on the pump market with the introduction of new and improved models to meet the demands of end users.

“For me one of the most significant achievements by Lowara was the introduction of the Hydrovar in the mid-90s and now up to version Gen5—dubbed ‘giving a pump a brain’— which is a truly remarkable example of technology at work reducing energy costs across all sectors, from households to large industrial end users,” Mr Inkster said.

“The next generation of smart pumps is about to be released here in Australia and NZ with the Lowara Smart Pump range which incorporates a permanent magnet motor that meets IE5 standard, providing efficiencies well above a standard IE3 asynchronous motor.

“We had an e-HM model on display at the Irrigation conference in Sydney and it attracted a lot of interest.”

1968–1977

• LOWARA Spa was established in 1968 by the Ghiotto brothers

• Production started with the iconic PM16 pump, followed by the A - AZ - F - JET - DN series, Lowara SMC circulators, the 4” submersible pump and the Hydrosphere tank 1978–1987

• Earlier pump models were joined by the CV - JET inox - ROBBY - MB, and 4”, 5” and 6” submersible series

• LOWARA Spa was acquired by Goulds Pump in 1985 1988–1997

• Goulds Pump was acquired by ITT Industries in 1997

• With the introduction of stamped stainless technology, stainless steel took centre stage and new pump ranges were developed, including CE/CA - DOC

- DOMO - HM - BG - HF 1998–2007

• Stainless steel features are included in all LOWARA products, both new and old 2008 - 2018

• ITT Industries created a spin-off company, Xylem, which is active in the water movement sector through many brands, including Lowara

• Due to a new production layout some of the series produced, such as SV - LNE - LNT - NSC - HM - HVL - XL, reach maximum reliability and competitiveness levels

Today, Lowara is a leader in providing long-term economical solutions for pumping and circulating clean or dirty water.

Lowara pumps, drives and packaged solutions, such as pressure booster sets and wastewater lifting stations, are all developed with low lifecycle cost in mind, ensuring robust, efficient products that are easy to install and service, and have a long service life.

Full range of Watermarked fittings and valves to suit your every requirement

Extensive range of precision valves, already installed around the country in many commercial, agricultural and industrial projects around the country. The range includes the likes of dual approved ball valves, gate valves, gas isolation valves, non-return valves. dual check valves and more.

Made tough to endure the harsh demands of the Australian environment, the range includes everything from T Head Tapware, compression and screwed brassware.

An extension of our Logi valves into civil and other projects, these valves are designed to respond to the incredible demands of an ever changing lanscape, and includes our brass poly connector range.

Corrosive liquids on mining and construction sites are a fact of life. Pumps used for metalliferous mines are susceptible to breakdowns simply because the material of construction is not compatible with the required mid-range PH liquids. Tsurumi’s new 316 cast stainless steel high head pumps have been designed for such applications and challenges.

Australian Pump Industries is working with Tsurumi to develop a range of big electro submersible pumps designed to deal with these issues. The pumps are available in 316 stainless steel are now in a range of up to 110 kW with heads as high as 200m.

Called the Tsurumi LH series, the new pump claimed by API to change the way mines, quarries, industrial applications and even infrastructure projects think about moving inconvenient water fast.

Aussie Pumps’ Tsurumi Product Manager, Neil Bennett, said, “Tsurumi’s LH series will deliver flows of up to 6,500 lpm.

“They are loaded with features that Tsurumi has integrated as standard to maintain the highest levels of reliability.”

The big pumps, with their high flows and high head combination are designed in the unique ‘slimline’ that enables the pump to be used in bores and wells. For example, even the 110kW pump has a diameter of only 606mm.

Additionally, the pump incorporates a centred discharge flange that ensures the pump is ideally balanced for lifting in its installed position. Discharge ports are up to 200mm (8”) and are flanged.

The pumps achieve their high performance by using two 316 stainless steel impellers. Pumps over 55kW are fitted with electro type leakage sensors and protection anodes where required.

Tsurumi’s anti-wicking cable entry prevents water getting into the motor if the power lead is damaged or the end submerged. Their unique double dual silicone carbide mechanical seal system is an added feature, and seals are incorporated in an oil chamber fitted with a patented ‘oil lifter’ that provides forced lubrication into the mechanical seals thus ensuring they always stay ‘wet’.

The extension of seal life and the anti-wicking cable entry point eliminates 90 per cent of the reasons of failure in submersible motors, dramatically extending the pump’s life and ultimately its reliability on-site.

“Tsurumi’s commitment to Australian Pump and the Australian market is tremendous,” Mr Bennett said.

“The establishment of the pump banks in Singapore and Japan mean fast delivery even if Australian Pump’s huge warehouse in Sydney doesn’t have product for immediate shipment.”

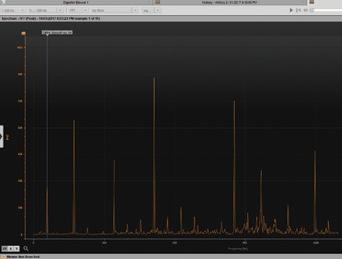

For many years, the octavis diagnostic amplifiers have been a mainstay in ifm efectors’ condition monitoring suite, and have been continuously upgraded to include more features with every generation of firmware and software.

Traditionally, the amplifiers took four MEMS accelerometers with two speed inputs into a FFT and a H-FFT environment so that raw signals could be pre-processed to offer protection from bearing faults and unbalance conditions, and to meet ISO standards.

It also had a small (by its current standards) history function where its diagnostic outputs could be monitored internally.

Like most technology, nothing stays the same, and the octavis VSE amplifiers are no exception. They have been upgraded over time to meet different needs, with recent upgrades catering for an increased demand for more information and better protection.

Some notable upgrades include:

• Faster processor

• Ability to take any accelerometer (of any IEPE rating or MEMS style) as inputs

• History memory has been upgraded to take 660,000 readings — this normally equates to around two years of on board data for every channel and diagnosis programmed at around a 30 minute interval

• Full time waveform diagnostics are now available and can be converted to a full spectral view at the click of a button. Waveform samples can be taken at 20, 50 or 100KHz samples depending on resolution requirements

• VSE15x models now have a Fieldbus Interface. This feature is model dependent for Ethernet IP, Profinet, and Modbus TCP, with Ethercat and Powerlink options available soon. While only some models have OPC UA ability, all models have OPC DA ability to talk directly to SCADA systems

• All models have the ability to take 4-20mA devices into six channels, so now the unit can be a monitor and controller for any system such as a pump controller or a compressor

• Flow, pressure, temperature, level and vibration can be monitored from

one unit, and trending and switching each point can be done without the use of a PLC

• New diagnosis objects, in addition to unbalance and bearing wear alarms, have been created making it simple to create:

» Acceleration RMS in the time domain

» Displacement RMS in the time domain

» Acceleration peak in the time domain

» A RMS in the frequency domain

» V RMS in the frequency domain

» D RMS in the frequency domain

» Specific frequency alarms in G/ mm/sec or mm

» Time waveform

• History

• Alarm display

• Spectral views

With all of these features, the system is flexible and cost effective.

As usual, all of these new features from functional VES004 programming and diagnostic software are free to download after registering on the ifm website.

The octavis diagnostic amplifiers can also be used in conjunction with the new SmartObserver Software suite.

SmartObserver is a Real-Time Maintenance system that can be implemented to expand the octavis system and assist operators to get a very good handle on asset status.

SmartObserver monitors all amplifier points continuously by reading information that has been programmed into the octavis processor. This data sent by an agent in VSE amplifier is then used to create a dashboard of the exact condition of the plant. Alarms can also be emailed or sent by SMS to any staff that need to know the machines status. There is also a cloud based version available.

With the population of Melbourne’s Northern Growth Area expected to rapidly increase in the coming decades, Yarra Valley Water was faced with the task of needing to install major water, recycled water and sewerage infrastructure to meet the increasing demand. To deliver services in the coming years, a $400 million program of works is being completed, including the construction of the Craigieburn Sewage Transfer Hub (CSTH)—an innovative facility designed to expand with the community.

The Northern Growth Area runs from Craigieburn up the Hume Highway to the Wallan area and covers roughly 20km. By 2040, the area is planned to accommodate an additional 128,000 properties and around 300,000 new residents.

At the time of the planning, there was no existing major sewerage infrastructure between Craigieburn and Wallan where most of the population growth will occur.

This presented a challenge, as the predicted growth could not occur without the construction of new infrastructure including sewage tunnels, water transfer mains, storage tanks, and new and upgraded treatment plants.

Yarra Valley Water is undertaking a $400 million program of works over the next five years to build this much needed infrastructure, which will be largely supported by the CSTH.

Once completed in late 2018, the CSTH will be the largest mid-system sewage storage facility in Australia, with the facility able to expand as development in the area continues.

It will send waste from the Amaroo Main Sewer downstream to the Western Treatment Plant, storing flows when required, allowing Yarra Valley Water to make the best use of the existing infrastructure that it has to service growth.

The facility will ensure large quantities of sewage flows associated with wet weather can be captured and managed without expensive upgrades to the downstream sewer network, reducing the risk of sewage spills.

By creating flexible infrastructure which can grow along with the community and keep up, it provides an innovative, cost-effective alternative to building a large sewer in the area at a much higher cost.

A sewage transfer facility of this scale is an unusual approach to sewage management, and traditionally Yarra Valley Water would have installed a large sewer tunnel — similar to the Amaroo Main Sewer—to transfer flows from the area at Craigieburn to the nearest downstream sewer with sufficient capacity — most likely sending it down to Melbourne Water’s main trunk sewer, the Northern Intercepting Sewer. Following an innovative planning and design process, it was decided that the CSTH would be built to locally store and distribute flows, and designed to grow as needed to match development. This approach has resulted in a saving of over $100 million through this alternative solution.

Sewage generated in the growth area will flow into the site of the existing Craigieburn Sewage Treatment Plant via the Amaroo Main Sewer, which is currently reaching the final stage of construction, and the existing Aitken Creek Branch Sewer. The existing sewerage network does not currently have the capacity to accept peak sewer flows from the area.

As a result, the CSTH is required to store flows temporarily when there is insufficient capacity in the downstream network, reducing the risk of sewage spills. The sewage will then be transferred to the Western Treatment Plant for treatment.

The CSTH is a unique sewerage flow storage and distribution facility consisting of two 16 Megalitre (ML) storage tanks making it the biggest in Australia, with plans for future on-site storage of over 200ML across 14 tanks. There will also be a built-in inlet drop structure to help regulate wet weather flows to the storages, and an emergency relief structure.

To manage the flows there will be three sewer pump stations with a total capacity of approximately 1000L/s, with provision to be upgraded to around 2000L/s if needed.

Andrew Cosham, Divisional Manager Major Projects, said

the facility will receive daily dry weather flows which will then be pumped offsite into the existing network.

“During a wet weather event when the incoming flows from the new area are greater than the capacity of the downstream network, the flows in excess of the downstream capacity will be temporarily stored at the facility and fed back into the system when capacity becomes available.”

Andrew said extensive research was undertaken in the design stage of the project on the pump and impeller options available.

“This helped to develop specific functional requirements and a list of preferred pumps. The contractor then undertook the procurement process as part of the construction phase of the project.”

Due to the high load of rags that are being encountered in newer developments, Yarra Valley Water said the key factors when selecting pumps for the CSTH were the pumps ability to handle solids—either by passing or chopping them. Other important factors that were a priority when considering pumps were energy efficiency, cost, replacement availability and lead times.

“Energy efficiency is always important in selecting pumps, however, it was not the primary selection criteria. Due to the highly varied operating points (300L/s at 2m head or 14m head) for the wet weather pumps, high efficiency was always going to be hard to achieve with a limited pump selection,” Andrew said.

“As the pumps have all been type tested, the on-site testing will be limited to checking that the design setpoints can be achieved. There will be a trial period to refine the pump cut in and out points, as well as the control programming.”

The project has pumps of varying sizes and functions:

• The main dry weather transfer pumps are Sulzer XFP 205J-CB2 PE 900/4 pumps with contrablock impellers

• The main wet weather pumps are Sulzer XFP 305M-CB2, PE 750/6 pumps with contrablock plus impeller

• Mono progressive cavity pumps were chosen for sludge transfer

• Three JWC Environmental Muffin Monster macerators were chosen to reduce ragging of the dry weather pumps

The Craigieburn Sewage Transfer Hub includes the following key elements:

• Excavation of approximately 120,000m3 of rock

• Stabilisation of cut batters and retaining wall construction

• Concrete works including manhole, sewage pumping facility, emergency relief structure and tank foundations slabs

• Site roadworks and drainage

• Sewage macerator, pumps and associated pipework valves and fittings

• Two 16ML circular storage tanks with sealed roof

• Air treatment facility

• Site electrical works

• Assorted site steelwork

The CSTH is an example of the type of innovation required to service growing cities where traditional infrastructure approaches are high cost and face significant technical challenges.

The process adopted has ultimately provided a significant direct saving to the community, maximised the use of existing infrastructure, and delivered a facility that is low risk and simple to operate and maintain, whilst still satisfying all involved stakeholders and providing an equivalent level of service to customers.

By implementing this unique strategy, Yarra Valley Water has been able to provide the community with an innovative lower cost sewerage network compared to what would have been implemented if traditional planning, servicing and design philosophies were adopted.

CPB contractors are the principal construction contractors, with Jacobs initially involved for three years from the creation of functional design through to detailed design. The project is in its final stages, with installation, testing and commissioning of equipment taking place before it is completed in mid-2018.

At Brown Brothers Engineers we have expanded our capabilities with two more quality pump manufacturers. In addition to the current world leading brands we can now offer the following range:

Layne Bowler

vertical turbine pumps have a proven record under the most demanding and toughest of conditions.

WELCOME TO THE BIG END OF TOWN.

When high head and high flows are required look no further than this quality Italian made range.

• Flows to 5000m³/h

• Head to 220m

• Pumps that exceed EN733 (DIN 24255 standard)

NCBK

In a previous issue, we reviewed the drawdown analysis portion of my pump and motor field test spreadsheet. The calculations performed by that section of the spreadsheet provided us the flow and total dynamic head produced by the pump during testing. In this issue, we will review the motor testing section.

Motor testing is important for two reasons.

First, it provides us with the information necessary to calculate horsepower at the test point. Horsepower allows for calculation of pump efficiency at the test point. We can then compare the tested head, flow, horsepower and hydraulic efficiency with those shown on the manufacturers

pump curve. Pump efficiency also allows us to monitor the cost per thousand gallons pumped each time we perform a test.

Second, motor testing provides operational data that can be used to identify unhealthy conditions that can lead to premature failure. Motor temperature, loading and the actual supply voltage are important components.

Another factor that has a major influence on submersible pump reliability is unbalanced phase voltage and current. A small voltage unbalance will give rise to a current unbalance that is six to ten times greater. Unbalanced currents increase the stator operating temperature which reduces insulation life. Phase unbalance is one of the largest causes of premature motor failure in the US.

Figure 1 is the motor test portion of the ‘Submersible Wastewater Pump and Motor Testing’ spreadsheet. As with the pump test portion, the gray cells are entered data and the yellow ones are the calculated results. The equations on the right show how certain results were calculated. The

information required includes phase voltage and current, motor nameplate efficiency and power factor (PF) and the power cost per kilowatt hour (kWh). Voltage and current are measured with a high-quality voltmeter and clamp on ammeter. The spreadsheet instructions detail the optional use of kW and PF meters.

The phase voltage and current should be measured at the beginning of the pump down cycle in order to provide an accurate horsepower calculation. They should also be measured on the motor side of the contactor. Contactor corrosion cannot be detected when voltage is measured on the line side. Before or after the pump down test, measure the phase voltage on the line side with the pump off. If any phase voltage unbalance occurs with the pump off, the supply side can be identified as the source of the unbalance. As seen in Figure 1, the calculated voltage unbalance was 1.1 per cent with the motor off. I have other articles which cover effect of voltage variation and phase unbalance in detail.

The average voltage and current are used to compute the motor horsepower at the test point. The test point horsepower and hydraulic horsepower (assumes 100 per cent pump efficiency) are used to compute the actual pump efficiency at the test point. The cost per thousand gallons pumped is calculated using the equation shown at the bottom right in Figure 1.

It is important to test submersible pumps and motors annually. Changes in system conditions can have a large impact on the pump operating point. This can result in a reduced life for several components including seals, wear rings and bearings. Off BEP operation will also increase the cost per thousand gallons pumped. Unbalanced phase voltage can occur at any time. Just because they were balanced a year ago doesn’t necessarily mean they will still be balanced this year. My Field Test spreadsheet is available on the ‘Pump Evaluation, Selection & Testing Tools’ page at PumpEd101.com.

Joe Evans has been in the pumps industry since 1986 and is passionate about the sharing of knowledge within the industry. To read more of his insights into the world of pumping,

With work health and safety (WHS) practices under increased scrutiny, there is a safer way to pump wastewater, according to engineered pump solutions provider Hydro Innovations. It has made available a white paper on ways to improve or even eliminate some of the dangers associated with working on or around wastewater pumps.

Firstly, Hydro Innovations maintains that using its Gorman-Rupp self-priming centrifugal pumps eliminates the dangers of “working over heights” and “working over water” usually associated with pumping wastewater with submersible pumps. Because the pumps are located “high and dry” above the wet well, operators do not have to be exposed to the dangers of open wet well pits when monitoring, inspection or maintenance is necessary. A correctly engineered solution will also eliminate the need for working in confined spaces.

Also, because maintenance can occur while the pump is still connected to the pipe system, and no cranes or lifting devices are needed, the dangers

of working with heavy swinging weights and cranes is eliminated.

When pump clearances need to be adjusted, Gorman-Rupp “V Series” pumps allow operators to make

adjustments externally, without removing the pump from service and without having to come in contact with the pumped fluid. To adjust submersible pump clearances, operators need to open wet well lids, use a lifting device and “manhandle” pumps that are covered in the pumped fluid, which could be corrosive, contain “sharps” or be full of bacteria.

The Gorman-Rupp Ultra V Series pump has been built with operator safety as a high priority. These pumps feature pressure relief valves, “burst disc” flap valves that can uniquely be replaced without opening the pump, and the safest “fill port cover” of any self-priming pump on the market. These features and others, separate Gorman-Rupp as the leader in self-priming pump technology.

For the complete white paper on wastewater pump operator safety, go to www.pump-stations.com.au or call Hydro Innovations on 02 9898 1800.

An $8.1 million upgrade of the Gunnedah Wastewater Treatment Plant in Gunnedah, New South Wales was completed in May, securing the town’s sewage treatment works until 2038.

The project was jointly funded, with the New South Wales Government providing $1.98 million through the Restart NSW Resources for Regions Program, and Gunnedah Shire Council allocating the remaining funds from its own budget for the works.

Member for Tamworth, Kevin Anderson, said, “The $1.98 million contribution by the NSW Government to the Gunnedah Wastewater Treatment Plant is an investment in the future of Gunnedah.

“The plant has not been upgraded since 1968 and was in need of improvement to enable additional treatment volume to support a strong and growing Gunnedah.

“This upgrade is about meeting residential and business

needs on the horizon as Gunnedah continues to expand to meet growth in both the mining and agricultural sectors.”

The project was in the planning for a number of years, with work beginning in 2017.

The Gunnedah Sewage Treatment Plant (STP) uses a trickling filter and maturation pond to treat sewage. Under normal operating conditions, all of the treated effluent from the works is transferred to the North Gunnible Cotton Farm where it is used for irrigation under a reuse agreement.

While the old plant met the water quality requirements specified by the EPA it needed to be upgraded to improve reliability and increase treatment capacity. The upgrade aimed

to extend the working life of the existing treatment assets until 2038; provide additional hydraulic capacity to service population growth and a planned expansion of the sewerage network to service an industrial estate; and improve workplace safety at the site.

Michael Ludlow, Project Manager Water Services at Gunnedah Shire Council, said Council considered both rebuilding and upgrading in the initial planning stages.

“Council looked at all options before the decision was made to upgrade. The main factors that led to this decision were being able to keep the plant operational during construction; the cost of a new plant was over $30 million compared to the cost of the upgrade at $8 million; the trickle filter process is a cost effective way of treating effluent; nutrients left in the water from the trickle filter process are good for Councils effluent reuse program to North Gunnible Cotton Farm; and Council was able to fund the project with a $1.9 million grant from the NSW State Government.”

Introducing modern processes and equipment

Various works were completed as part of the upgrade, including:

• Decommissioning the existing inlet works, lift pump station, belowground sludge digesters and digester building, and sludge drying beds

• Constructing new facilities including a septage reception facility, an inlet lift pump station, an inlet works facility with screening and grit removal, an above-ground anaerobic digester, a sludge transfer pump station, a biosolids dewatering facility and a new switchroom

• Refurbishing existing assets units including the stage one Imhoff, primary tanks and trickle filters; the stage two primary tank and trickle filter; the humus tanks; and the maturation ponds

• Site works including a new amenities building; roads; stairs and access ways and hand rails across the site; a new service water system; site services; and landscaping

Heavy duty ISO2858, End Suction Pump Design

Proven reliability in Australia’s harshest conditions over the last 20 Years.

Widely supported by over 75 Xylem service personnel, across fifteen service locations nationwide, as well as throughout our national distribution network.

For more information, call us at 13 19 14 or visit www.xylem.com/au

www.xylem.com/au

• An electrical upgrade including a new Form 3B main switchboard/MCC; local control panels and operator stations for all equipment; cabling; site lighting; lightning protection; site security and smoke detection system; and new PLC, SCADA and telemetry system.

Council’s Manager Water Services, Kevin Sheridan, said some of the equipment replaced was nearly 80 years old and the upgrade has allowed new technology to be introduced to improve the plant’s efficiency.

“The dewatering building has allowed the plant to enter the world of modern technology. It has the ability to dry treat sludge to 28 per cent dry solids, where most other technology sits at around 18 per cent. It also replaces the old drying beds which were really labour intensive and unsightly. We are really pleased with the outcome,” Mr Sheridan said.

Mr Ludlow said Council procured a number of items for the project. These included:

• Inlet works from VOR environmental, including a reception chamber, inlet screening, grit chamber and splitter chamber

• Sludge mixing equipment from Aquatec Moxon

• Sludge dewatering unit from Ishigaki - this is a screw press that is producing 25-27 per cent dry solids

• Amenities building from Austam Homes

• Fully automated ClearSCADA Telemetry system for monitoring and control from Alliance Automation

“The upgrade was on the inlet structure, new digester, dewatering building, sludge pump station, feed averaging tank and new amenities building the rest of the plant was all reused,” Mr Ludlow said.

“There was no added treatment process added to the upgrade, and all effluent that passes through the new inlet works is treated through the existing sedimentation tanks, trickle filters, humus tanks and maturation ponds.”

Mr Ludlow said the Inlet Lift Pump Station has three submersible N-series pumps installed in a duty/assist/standby configuration.

“The pumps are fitted with variable speed drives (VSDs) to assist in the balancing of flows presented to the inlet works and process streams. At full speed, lift pumps transfer 3ADWF to the inlet works with two pumps running. There are also Roto mono pumps and a Vogelsang grinder pump for sludge transfer,” Mr Ludlow said.

“Reliability, service, durability and adaptability were all important considerations for the pumping equipment.

“Energy efficiency is particularly important, so Councils design consultants added VSD’s to the inlet pumps for this very purpose of power savings and flow control.”

Mr Ludlow said there were a number of challenges that needed to be overcome including keeping the plant running during construction and maintaining water quality.

“We needed to keep the existing plant working while the upgrade was constructed with cut overs and parts of the plant needing to be isolated for periods of time. Having an experienced contractor and involving operational staff with decisions about cut overs and plant isolation was the key to overcoming this,” Mr Ludlow said.

“Keeping Councils EPA water quality requirement while under construction with all the disruptions to the plant was also a challenge. Key to overcoming this was regular monitoring of water quality and experienced operational staff that were able to adapt and overcome obstacles that arose on a daily basis while still keeping within Councils EPA Licence conditions.”

Gunnedah Shire Mayor, Jamie Chaffey, commended those that worked on the project to ensure it was delivered on time and on budget.

“Gongues Construction was contracted for the works and has put in a fantastic effort ensuring this project has come in under budget and on time. I would also like to commend Council staff for their forward-thinking and initiative shown throughout this project,” Mr Chaffey said.

“Gunnedah is in a unique position as one of few rural towns in NSW still experiencing growth and it is important we strive to see our infrastructure match this expected growth.”

The project is now in the running for the Institute of Public Works Engineering Australasia (IPWEA) Engineering Excellence Awards which will be held in the Hunter Valley later this year.

As part of the IPWEA’S State Conference, the awards recognise excellence in Local Government and Public Works Projects, as well as individual teams.

The Gunnedah Wastewater Treatment Plant upgrade is nominated in Category 3 – Innovation in Water Supply and Wastewater, which requires nominated projects to demonstrate innovations in water supply and/or wastewater, reflect efficiencies and demonstrate cost savings.

Acting Director of Infrastructure Services and IPWEA member, Daniel Noble, said, “To receive this nomination is the icing on the cake and a sweet reward for the hard work of the project managers, in particular Manager of Water Services, Kevin Sheridan, who has been the driving force behind this project since its inception.”

Caprari has launched an innovative new product with an exclusive patent, that is set to be a turning point in wastewater pump design. The new K + Energy range of pumps take reliability and efficiency to a new level, and captures Caprari’s core business to find new efficient solutions for water management.