pumpindustry

Maximising slurry pump efficiency

SA Water gets smart about pump asset maintenance

Maximising slurry pump efficiency

SA Water gets smart about pump asset maintenance

Hello all and welcome to the Autumn Edition of Pump Industry Magazine, the official voice of Pump Industry Australia. It’s some 16 months into the pandemic now and at the time of writing Melbourne was coming out of a 14 day lockdown, the number of days in lockdown now totalling 200, which demonstrates yet again there is still a lot to learn about this virus and these scenarios will continue to play out for some time to come. Globally, the death toll has now surpassed 3.5 million.

This year we note that three of our colleagues have passed away. In April, we noted with sadness the death of Bob Neale from COVID whilst he was working for Southern Cross in PNG. Bob had a long and successful career in the pump industry; he had management roles with Flowserve, Southern Cross and BCIP.

it was hard-covered in red, dated 1993 and the foreword was written by Anthony Grage who was President of the APMA at the time. It tells the story that the Australian Pump Manufacturers Association was formed in 1964, off the back of a trade export mission to South Africa attended by a group of pump manufacturers. The benefits of the mission extended beyond its immediate findings, and the companies involved and other companies voted for the formation of a viable body of pumping interests which could speak with authority for the industry.

Pump Industry Australia Incorporated C/-340, Stuarts Point Road

Yarrahapinni NSW 2441 Australia Ph/Fax: (02) 6569 0160 pumpsaustralia@bigpond.com www.pumps.org.au

PIA Executive Council 2020

John Inkster – President Brown Brothers Engineers

James Blannin – Vice President Stevco Pumps & Seals

Kevin Wilson – Treasurer/Secretary Executive Officer

Alan Rowan – Councillor Executive Officer – Publications and Training, Life Member

Ken Kugler Executive Officer – Standards, Life Member

Geoff Harvey – Councillor Irrigation Australia Limited

Anant Yuvarajah – Councillor ASC Water Tanks

Joel Neideck – Councillor TDA Pumps

Matt Arnett – Councillor Ebara Pumps Australia

Michael Woolley – Councillor Tsurumi Australia

Steve Bosnar – Councillor Pioneer Pumps

Billie Tan – Councillor Regent Pumps

It is also with sadness that we advise the recent passing of one of our initial Life Members Bill Aitken. You can read more about Bob and Bill’s careers and contributions to the industry on page 16.

Many of you might also know of Brian Pritchard who passed away in March after an illness. Brian owned B Line pumps, an industrial pump company in Sydney.

On behalf of the membership of the PIA, we express our sincere condolences to all their families and close friends.

During these unpredictable times, PIA is still committed to holding events for the benefit of Members. In March we successfully held another Pumps and Systems Training Course in Melbourne. This was our second, and to date we have had 21 people attend; we propose to hold another in the coming months. Strong interest was shown in the Course at the Perth meeting.

On 22 April, PIA held an evening in Perth sponsored by Tsurumi Australia. Our thanks to Michael Woolley and his team for putting on an excellent meeting attended by some 30 people. Michael raised the bar somewhat by having a raffle on the night for a bottle of whiskey – won by Troy Drysdale of Cummins South Pacific.

On Wednesday 21 July, it is planned to have a breakfast session sponsored by DAB Pumps Oceania, so please pencil that date in your diaries as an opportunity to meet with colleagues and to learn more about DAB.

And now for a little bit of history. When I was in Sydney recently, I found an old edition of the Pipe Friction Handbook;

On 10 March 1977, the Association was incorporated in Victoria. The administration of APMA activities was carried out by a National Council consisting of eight Members. APMA played an important role in representing the pump industry in government enquiries. In 1987, APMA prepared a major submission to an IAC Inquiry into mining, construction and agricultural equipment.

In the early 2000s, the Association changed its name to Pump Industry Australia to better meet the needs of the industry, which had greatly changed from representing manufacturers to that of importers and wholesalers, reflecting the changing nature of manufacturing as a whole in Australia. That said, there is still a degree of manufacturing taking place and local assembly.

I also found a 1980 edition of the Australian Pump Technical Handbook, this was a soft cover in red, as was the custom at the time, and was issued with the compliments of Ajax Pumps, a Member of McPhersons Group Ltd, with the foreword written by the Minister for Productivity, Parliament House, Canberra. The opening sentence was ‘The Australian pump industry is a vital supplier to any water user requiring a system for the movement of fluids’ –how little has changed!!

In closing, I can advise that I have had my first jab of AstraZeneca and suffered no ill effects, and encourage you all to do the same. We know the virus has a long way to run and we know the vaccinations significantly decrease the likelihood of catching the virus with an efficacy of around 63 per cent.

Best Regards

John Inkster President

ABN: 36 426 734 954

C/- The Commons, Office 1, 36-38 Gipps St, Collingwood VIC 3066

P: (03) 9988 4950

F: (03) 8456 6720

monkeymedia.com.au info@monkeymedia.com.au pumpindustry.com.au magazine@pumpindustry.com.au

Editor: Lauren Cella

Contributing Editor: Michelle Goldsmith

Marketing Assistant: Stephanie Di Paola

Business Development Manager: Rima Munafo

Design Manager: Alejandro Molano

Designers: Jacqueline Buckmaster, Danielle Harris

Publisher: Chris Bland

Managing Editor: Laura Harvey

ISSN: 2201-0270

Kempsey CBD was able to quickly get back in operation following flood conditions in March, thanks to Fire and Rescue, the RFS and a ‘super pump’.

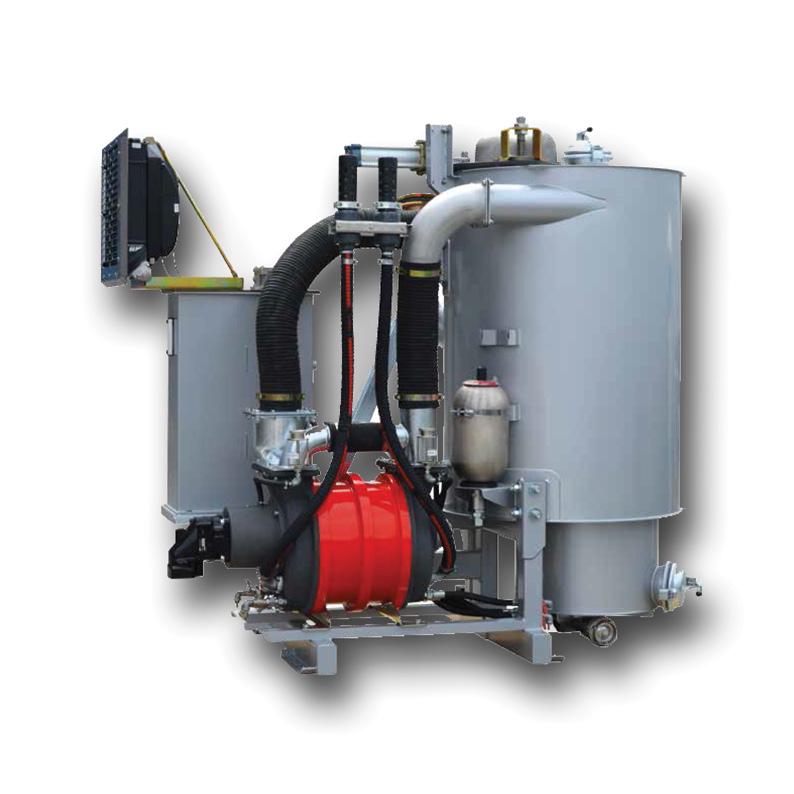

Fire and Rescue pumped out the centre of town. Various pumps were used to attempt to clear the floodwater from Belgrave Street, with no great success, so the Fire and Rescue team employed the use of the super pump: the Bulk Water Transfer System ‘Hytrans’.

The Hytrans moved roughly 6,000L of water a minute and was crewed by two specialists assisted by the local FRNSW crew, 345 Kempsey. There is only one pump of this capacity in NSW and it was brought in by Fire and Rescue and used

on Belgrave Street, with near instant, incredible impact.

When the pump was turned off in the centre of Kempsey at 3pm on Saturday

27 March, it was estimated that the total amount of water removed was ten million litres.

The HYTRANS was then moved about 1km up the road to pump out a section of water in another area of Kempsey. There they had to run 500m of 150mm hose to send the water back to the Macleay River. Another large amount of water was removed from Kempsey, almost another ten million litres.

Fire and Rescue was also busy in the outer areas. Two Rapid Damage Assessment teams were assigned to the problem areas of Stuarts Point and Maria River Road. Another crew went to Frederickton.

Central Highlands Regional Council has employed a helicopter to hoist an almost 50-year-old structure and pumps from the Blackwater Water Treatment Plant site.

As a part of the raw water pipework and pump station upgrades taking place at the Blackwater Water Treatment Plant, due to the complexity of the lift, local contractor HeliCentral was engaged to fly in to replace the pumps from within the raw water dam.

Acting General Manager Infrastructure and Utilities, Jason Hoolihan, said the project will optimise many aspects of the raw water plant process.

“Our process for providing drinking water to Blackwater will be more efficient and cost-effective going forward,” Mr Hoolihan said.

“The project also includes replacement of the raw water switchboard and pump station building structure.”

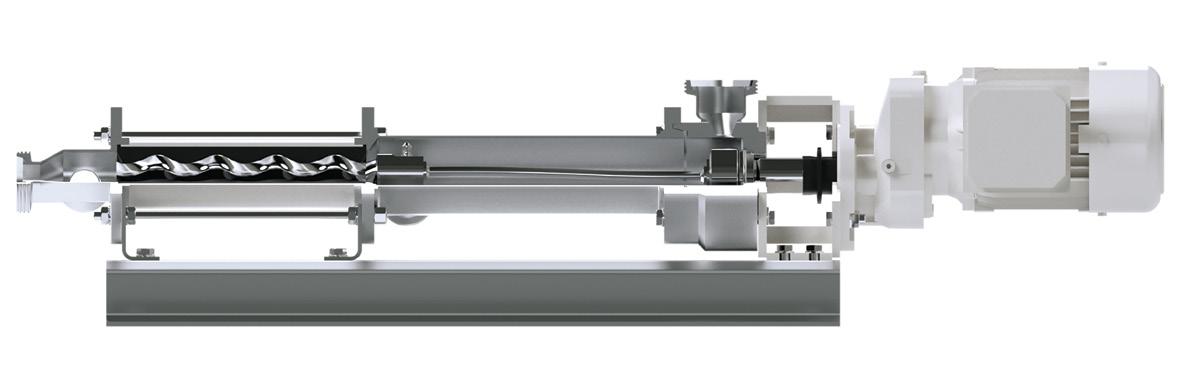

The EHEDG certified BCFH range of progressive cavity pumps handles thin to highly viscous products, including those containing soft solids with a low shear action and minimal pulsation which enables accurate flow control. BCFH pumps fulfill the stringent demands of cleanliness in the food, beverage, chemical, pharmaceutical and cosmetic industries.

EHEDG Type EL Class I and 3-A Sanitary Standards certified

Enhanced internal design ensures residue free cleaning with CIP/SIP

Equipment requires less cleaning time compared to other CIP solutions

Easy maintenance due to detachable rotor connection and split suction casing

The Federal Government has handed down its 2021-22 Budget, with funding allocated for agriculture, and water and energy infrastructure.

The 2021-22 Budget delivers substantial new investment to drive the competitiveness, growth and resilience of the Australian agriculture industry, with $850 million in funding to support the industry to reach its goal of $100 billion by 2030.

The Federal Government’s focus remains on delivering targeted measures for Australia’s farmers, fishers and foresters in the Agriculture 2030 2021-22 Budget package.

Resources

The Federal Government said it will invest in a global strategy to highlight the quality, strength and reliability of Australia as a supplier of crucial resources and energy to the world while supporting companies to diversify and develop new markets.

Supporting junior explorers is expected to help the industry make the next big discoveries. The resources sector employs more than 260,000 people, with many of these jobs in regional Australia. More than a million Australians rely on the sector indirectly.

The 2021-22 Budget includes:

• $100 million in fiscal balance terms to extend the Junior Minerals Exploration Incentive for four years from 1 July 2021, to encourage exploration and development of new deposits and to ensure a strong investment pipeline for development across regional Australia

• New funding to implement the Government’s Strategic Basin Plans, including $15.7 million to support Gas Field Trials in the North Bowen and Galilee Basins, and $2.2 million for the Northern Land Council to help provide better services to Traditional Owners in the Beetaloo Basin

The Government is investing $189.6 million over five years for the Next Five Year Plan for Northern Australia, with a focus on job creation, stronger digital connectivity, and support for businesses to scale up and diversify.

Our North, Our Future: 2021-2026 represents the next phase of the 20-year framework set out in the 2015 White Paper on Developing Northern Australia, to build on the economic potential of the north and to create jobs and opportunities to help attract people to live and do business in the north.

Measures include:

• $9.3 million over five years to pilot the targeted Regions of Growth (ROG) program in four locations: Beetaloo Basin to Darwin; Broome to Kununurra to Darwin; Cairns to Gladstone; and Mount Isa to Townsville. The program will target investment to the strengths of each region and help identify future geographical areas of economic potential

• $111.9 million over five years for a Northern Australia Development Program. The program will support northern

Australian businesses to scale up and diversify by providing co-investment funding to businesses for activities including infrastructure, assets, feasibility studies and business planning

Our North, Our Future: 2021-2026 builds on the Federal Government’s plans to drive job creation and industry growth, supporting national recovery efforts from the impacts of the COVID-19 pandemic.

In the water portfolio, Minister for Resources, Water and Northern Australia, Keith Pitt, said Budget measures are centred on three key areas to set Australia up for the future:

• Providing practical support to farmers who experienced drought to improve their on-farm water infrastructure in partnership with states

• Reforming water markets to ensure water users could have confidence in their integrity and operation

• Improving Murray-Darling Basin modelling to build the confidence of governments, water users and communities in planning for an uncertain future

“We have extended the On-farm Emergency Water Infrastructure Rebate Scheme for 12 months until June 2022, to ensure drought-affected farmers can access the $50 million in rebate funding secured through the 2020-21 Budget,” Mr Pitt said.

“We will form an expert panel to progress important reforms to Murray-Darling Basin water markets in ways that support water users while improving market efficiency, information and governance.

“Reforming our water markets will need strong collaboration between governments, as well as with communities.

“And we’re committed to developing a state-of-the-art modelling capability for the whole Basin to ensure farmers, communities and governments can make decisions confident in the data they rely on.

“These measures are on top of the $270 million MurrayDarling Communities Investment Package announced last year to put communities and jobs at the heart of Basin Plan implementation. In 2021-22, $130 million of that is committed to support our communities.

“We have also closed the Water Efficiency Program and ruled out water buybacks, diverting over $1.3 billion to focus on offfarm efficiency projects.

“Off-farm water recovery means we can actually progress our river health targets and, unlike on-farm programs, we do not reduce water availability in the consumptive pool.”

The 2021-22 Budget invests up to a further $258 million, including up to $160 million through the National Water Grid Connections pathway, from the $3.5 billion National Water Grid Fund towards the construction of new and augmented water infrastructure projects, building a more resilient and secure Australia.

The Government’s ongoing investment in water infrastructure builds on the eight construction projects already completed since the establishment of the National Water Grid Authority in late 2019 and brings the total number of construction projects in the investment pipeline to 30. The new and augmented construction projects being funded in partnership with states include:

• Eurobodalla Southern Storage (New South Wales) – $51.2 million

• Werribee Irrigation District Modernisation (Victoria) – $11 million

• Recycled Water on the Bellarine (Victoria) – $5.5 million

• Warwick Recycled Water for Agriculture – Recycled Water Treatment Upgrade (Queensland) – $0.5 million

• An additional $7.5 million for Rookwood Weir to deliver water security in North Queensland by raising the weir wall a further 700mm to deliver an additional 10,000 megalitres. This brings total Australian Government investment in the project to $183.6 million.

Gas infrastructure and emissions reduction

In total, more than $1.8 billion has been allocated in the 2021-22 Budget for the energy sector, with $58.6 million of that going towards the gas sector.

As well as a suite of electricity funding, the Budget initiatives to drive Australia’s gas-fired recovery include:

• Up to $38.7 million to support critical gas infrastructure projects to alleviate the forecast gas supply shortfalls

• $5.6 million to further strengthen the Federal Government’s gas system planning framework through delivery of the National Gas Infrastructure Plan

• $6.2 million to design, consult and implement reforms to accelerate the development of the Wallumbilla Gas Supply Hub

• $4.6 million to develop initiatives that empower gas reliant businesses to negotiate competitive outcomes in their gas supply agreements

• $3.5 million to design and implement a framework to facilitate Commonwealth support for medium to long-term gas infrastructure to secure Australia’s future gas supply

The Budget also sets out measures to further strengthen Australia’s long-term fuel security, building on the Government’s investment in the 2020-21 Budget, including:

• A refinery production payment to help maintain Australia’s refining capability

• Support to assist the refiners to conduct infrastructure upgrades, subject to consultation with industry

• $50.7 million to establish a new fuel security framework, including for the implementation and monitoring of the minimum stockholding obligation and the production payment, ensuring industry complies

• New initiatives in the Budget will support investment in new and emerging low-emissions technologies prioritised under the Government’s Technology Investment Roadmap, collaborate internationally on achieving technology breakthroughs, lower energy costs and create more than 6,000 jobs.

In total, $1.2 billion has been allocated to establish Australia at the forefront of low emissions technology innovation and commercialisation.

The response to the Budget from the energy industry has been mixed.

APPEA Chief Executive, Andrew McConville, said support for gas-related strategic basins is a big tick, as is the announcement for new hydrogen and carbon storage initiatives to help lower emissions.

“Increased funding for gas infrastructure of $173.6 million in the Northern Territory on top of the $58.6 million will mean more supply for the domestic market and that will help keep prices competitive,” Mr McConville said.

Clean Energy Council Chief Executive, Kane Thornton, said the Budget was a missed opportunity for the Federal Government to embrace Australia’s renewable energy sector and follow the lead of international, state and territory counterparts to use the clean energy transition to drive job creation and economic recovery.

“If this truly is the infrastructure budget, Infrastructure Australia has identified that there is a need for major transmission upgrades to supply network access to renewable energy zones as a high priority, particularly in light of retiring thermal generation,” Mr Thornton said.

“The lack of transmission investment is now one of the most critical challenges facing Australia’s energy industry.

“It’s disappointing that in a ‘nation-building’ infrastructure budget, upgrades that will enable the access and security of clean, low-cost power have not been prioritised.”

The most compact and integrated booster set on the market. Connect 1, 2, 3 or 4 Esybox MAX units.

Easy to maintain

Connect and control from anywhere with DConnect.

Quick On-Site Assembly.

Leaps ahead in terms of energy efficiency with the DAB inverter, brand new permanent magnet motor and new hydraulics.

The Federal Government has committed $3.5 million in the 2021/2022 Federal Budget to the Barossa New Water project in South Australia, improving access to water infrastructure and partnering with the state to breathe new life to the Barossa and Eden Valley wine region.

Estimates show additional water to the Barossa and Eden Valley could generate $292 million for the state’s economy, through securing existing vineyards, additional plantings and by creating 1,000 jobs.

Minister for Primary Industries and Regional Development, David Basham, said it was pleasing to see the Federal Government supporting such an important project – building on the State Government’s $1.5 million commitment to date.

“Barossa New Water aims to deliver safe, reliable, recycled water from the Bolivar Wastewater Treatment Plant to meet industry demand in the Barossa Valley and Eden Valley,” said Mr Basham.

“Securing funding from the Commonwealth is an important milestone for Barossa New Water and we will continue to work closely with key stakeholders as we push ahead with this project.

“The detailed business case will explore demand for water, economic viability, and supply and delivery of new, secure, climate-independent water infrastructure for the region.

“This project could be a gamechanger for the region’s wine industry to drive economic growth and support thousands of jobs.

“Earlier this year, achieving a new water supply for the Barossa Valley region was identified as a Priority Initiative by Infrastructure Australia.

“It is one of a number of projects regarded by the State Government as being potentially transformative for South Australia – supporting regional growth and jobs.

“This project supports our Growth State Plan to create additional jobs and boost the economy by building the infrastructure that matters in regional areas, supporting both agriculture and tourism.”

Member for Schubert, Stephan Knoll, said having improved access to a secure water supply is a key concern for his local community.

“We know that the Barossa is one of South Australia’s premier wine regions, producing some of the highest value wine grapes in Australia, with an average

value of $2,278/tonne in 2020, but a key constraint to agricultural productivity and growth in the region is the lack of secure water,” Mr Knoll said.

“There are 2,700 people employed in the wine and grape sector in the Barossa and the region accounts for nearly ten per cent of national wine sector jobs.

“Delivering a long-term water security solution will significantly boost productivity for the region’s agriculture sector – and importantly create local jobs.”

Layne Bowler vertical turbine and submersible pumps have a proven record under the most demanding and toughest of conditions.

• Flows to 7,500 L/Sec

• Heads to 500 m

• Power to 1000+ kW

• Temperatures to 150°C

• Bowls Diameter up to 45 inch

Applications

• Irrigation

• Water supply

• Process water

• Geothermal

• Cooling towers

• Fire protection

• Marine

• Water treatment

• Dewatering

• Flows to 140 L/Sec

• Heads to 200 m

• Power to 110 kW

• Bowls Diameter in sizes 6”, 7”, 8” and 10” Applications

• Irrigation

• Deep well water supply

• Inline booster

• Service water

• Dewatering

Brown Brothers Engineers have innovative solutions whatever your application. Contact us today about your requirements.

Construction is set to commence on the $777 million Kidston Stage 2 pumped hydro energy storage (PHES) project – following Genex Power reaching financial close on it – with pumps now being mobilised to site for initial dewatering works.

The project will be the first pumped hydro plant to be built in Australia since 1984, and the first to be used specifically to support the integration of variable renewable energy generation from solar and wind.

Located at the former Kidston Gold Mine at the Kidston Clean Energy Hub in North Queensland, the facility will produce approximately 250MW/2,000MWh of baseload power, equivalent to eight hours of energy storage.

The Australian Renewable Energy Agency (ARENA) will provide $47 million in funding towards the project. ARENA also already provided funding for feasibility and development totalling $9 million for this current pumped hydro stage, as well as initially providing $8.9 million towards Genex’s 50MW Kidston Solar Project in 2016.

The Queensland Government will invest $147 million to connect Genex’s Kidston Pumped Storage Hydro Project to Queensland households and businesses, and the project is set to create 900 construction jobs.

The project is also supported with $610 million in concessional debt finance from the Northern Australia Infrastructure Facility (NAIF).

Genex has now finalised its capital raising process to allow the project to reach financial close. EnergyAustralia is to be the project offtake partner for up to 30 years. A joint venture of John Holland and McConnell Dowell is the EPC contractor.

Two existing mining pits at the former gold mine will be utilised as the upper and lower reservoirs for the PHES to minimise construction time and costs.

Rock material sampling and testing for concrete production has been completed, and pumps are being mobilised to site to commence the initial dewatering of the Eldridge pit.

During peak power demand periods, water will be released from the upper to the lower reservoir, passing through reversible turbines.

During off-peak periods and when the sun is abundant, water will be pumped back from the lower reservoir to the upper reservoir using electricity imported from the National Electricity Market (NEM).

A 187km transmission line, supported by the Queensland Government and Genex, will be required to connect the Kidston Clean Energy Hub to the NEM.

ARENA CEO, Darren Miller, welcomed the announcement and thanked everyone involved in achieving this significant milestone.

“On behalf of ARENA, I’d like to congratulate Genex on reaching financial close on a project that has been many years in the making,” Mr Miller said.

”The Kidston PHES project will supply dispatchable, renewable energy to the grid when and where it is needed and provide a blueprint for how we store excess solar and wind energy at scale.

“Projects like this play a significant role in progressing Australia’s energy transition.

“Storage solutions such as pumped hydro and large-scale batteries are a key part in providing backup power and grid stability as highlighted in the Australian Government’s first Low Emissions Technology Statement.”

ARENA has previously supported 16 PHES projects with over $28 million including the feasibility studies for Snowy 2.0 and Tasmania’s Battery of the Nation.

Queensland Treasurer and Minister for Investment, Cameron Dick, said Genex achieving financial close confirmed the status of Queensland’s nation-leading renewable energy credentials.

“As part of our Economic Recovery Strategy to grow the renewable energy sector and the jobs that come with it, the Palaszczuk Government has played a crucial role in getting the Kidston Pumped Storage Hydro Project over the line,” Mr Dick said.

“This decision will further secure our strong renewables future in North Queensland and will unlock hundreds of renewables jobs.”

Minister for Energy, Renewables and Hydrogen, Mick de Brenni, said the 250MW project will help secure the future of North Queensland’s energy system with a reliable supply of dispatchable power.

“As Queensland charges towards its renewable energy target, storage projects like Kidston will enable the continued investment in otherwise intermittent renewables,” Mr de Brenni said.

“Our $147 million commitment will support publicly-owned Powerlink to build a 186km transmission line from Kidston to Mount Fox near Ingham, creating 400 jobs.

“Construction of the pumped hydro project will create a further 500 jobs, powering North Queensland’s economic recovery.”

The Kidston Clean Energy Hub will integrate large-scale solar and pumped storage hydro using an abandoned gold mine 270km north-west of Townsville.

Water pumped into its reservoir will store approximately 2000MWh worth of dispatchable electricity that can be delivered back to the electricity market when needed.

Genex CEO, James Harding, said the announcement marks an important step in the rollout of large-scale energy storage capability in the NEM.

“Financial close for the Kidston Pumped Storage Hydro Project is a monumental achievement and one Genex has been working towards for over five years,” Mr Harding said.

“Site preparation activities are now well progressed as we prepare for full-scale construction activities over the next few months.

“I would sincerely like to thank the Queensland Government for the significant funding support and continued commitment to the Kidston project.”

The Kidston Pumped Storage Hydro Project and its associated transmission infrastructure is expected to be completed and fed into the NEM by early 2025.

Brown Brothers Engineers Australia, part of the AxFlow Group, has announced its acquisition of INCA Control, a manufacturer of control panels for pumps in agricultural, industrial and commercial settings. With the acquisition of INCA Control, Brown Brothers Engineers will become a full-service provider for water boosting pressure systems in Australia.

INCA Control is a family-owned business with an operational history surpassing 50 years. Located in Glendenning, Sydney, the company is involved in the pumping field, supplying control systems for water sump drainage, water pressure systems including VSD (Variable Speed Drives), water booster or transfer systems and fire pump controls to AS 2941 for both diesel and electric pumps. All these highly customised systems incorporate level, pressure and all associated control measuring devices.

“INCA Control has been a reliable supplier to Kelair Pumps and Brown Brothers Engineers in both New Zealand and Australia for several years. They are very well respected in the market for their technical competence and high-quality products,” said John Inkster, Managing Director of Brown Brothers Engineers Group.

“Control panels constitute a critical part of a pump installation. Having them in our portfolio will enable us to grow the aftermarket offering for the many pump installations that we service today.”

Mark Griffith, owner and CEO of INCA Control, is equally as enthusiastic about the acquisition commenting.

“We at INCA Control are excited about the next chapter in our history. We are proud to become a part of the AxFlow, Brown Brothers Engineers Group and we look forward to working with and supporting the Group and our current customer base as we grow moving forward,” Mr Griffith said.

The City of Townsville has achieved a number of recent milestones on the second stage of its Haughton Pipeline project.

Townsville Mayor, Jenny Hill, said Council had a team managing the project, which was being funded by the Queensland Government.

Ms Hill said Council had also engaged a number of specialist external consultants to undertake front-end engineering and design principles addressing pipe alignment, materials and pump station requirements.

“Detailed capital and operational costs continue to be validated against independent cost estimates prior to making a recommendation to Council,” Ms Hill said.

“Private and commercial landowners have been consulted on the options for the pipe alignment and three landowner access agreements have already been agreed.

“The project team has also engaged with the traditional custodians of the land along the proposed pipe alignment options and entered into a Cultural Heritage Management Agreement.

“After a series of information sessions and tender briefings in Townsville and

Ayr during 2020, five local construction contractors have been appointed to participate in an interactive tender process to assist with project design and costings.

“Suppliers and manufacturers of long lead materials and equipment have also been engaged to participate in the tender process for pipes, pumps and fittings supplies.”

Member for Townsville, Scott Stewart, said providing funding for water security for the city was essential.

“The State Government has invested more than $400 million in stages one and two of the Haughton Pipeline because we know it will set Townsville

up for the future,” Mr Stewart said.

“I’m excited about the opportunities that are out there for Townsville’s economy moving forward and that’s what this government is focused on.”

Ms Hill said stage one of the Haughton Pipeline project had provided a tremendous boost to the local economy, with around 95 per cent of the construction work delivered by locallybased contractors.

“We want to repeat that with stage two. That’s why Council will package the works into smaller parcels of work to give local businesses the opportunity to tender for it,” Ms Hill said.

Respected pump professional Bob Neale passed away from COVID-19 in Papua New Guinea on 28 March 2021.

Bob was a well-known and respected figure in the industry, having started his career in 1971 as a Water Advisor for the Queensland Water Resources Commission. He then went on to work as General Manager Sales and Services at Flowserve Pump Division for over 21 years; Managing Director HydroFlo Solutions, and Director of H20 Epiphany – trading as Thinkwater Newcastle – for over 11 years; and most recently as Business Development and Trading Manager at Southern Cross Pumps since February 2019.

He was well-liked and respected by all those he came across in the industry as a mentor, friend and colleague.

Long-time pump professional and one of the first Life Members of the PIA, Bill Aitken has passed away.

Bill started his career at Harland through IEL/Indeng for over 25 years. He was a key member of the Engineering team, working on both large custom-engineered capital projects and standard pump ranges with David McLiesh and David Macpherson.

He was renowned for his creative and practical approach, often sketching design concepts on the floor and the walls for the benefit of the drafting team. Some of the bigger projects he was a part of include Arthurs Lake pumping station, Ord River verticals, and Muja Power Station cooling water pumps.

In the early 80s, moved to Ingersoll Rand as Chief Engineer of the pump division in Dandenong. He later moved to GAAM where he worked with Ken Willcock and designed fire pumps for the CFA and the MFB.

Bill was instrumental in the team that created the first edition of the APMA Pump Tech Handbook

Bill will be long remembered by many of the PIA Members from the initial APMA days.

On 22 April, for the first time in over a year, PIA held a Meeting in Perth at Tsurumi Australia, with around 30 pump professionals in attendance.

Attendees heard from PIA President, John Inkster, and Tsurumi Australia Managing Director, Michael Woolley, before hearing a presentation about Tsurumi Australia and taking a factory tour.

The successful meeting finished off with attendees enjoying drinks and paella.

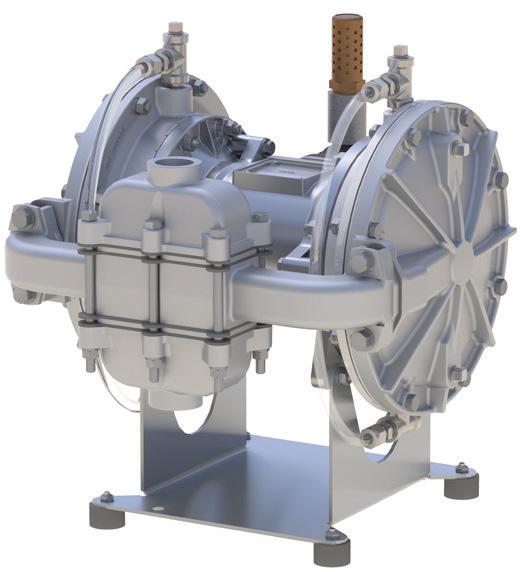

Engineered to deliver industry leading durability and performance, even for the most severe applications and environments.

Energy efficient air operated diaphragm pumps with the capability to pump abrasive and viscous liquids make these pumps great for many industries : - General industry

We know the importance of choosing the right equipment to match your process. With our extensive range of pumps, first class customer service and ongoing comprehensive support, Kelair Pumps are second to none when it comes to your pumping requirements.

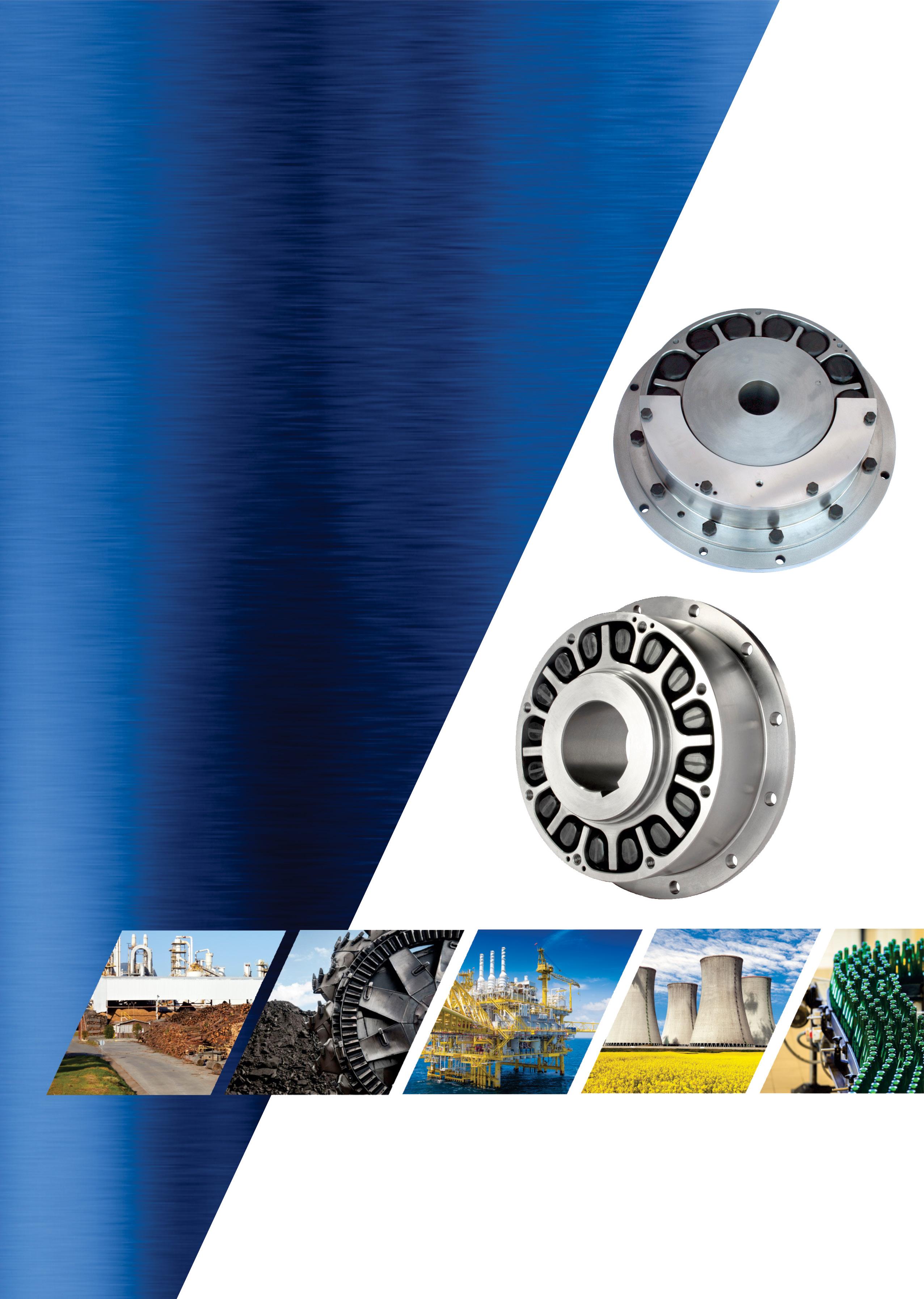

The W22 Magnet Drive System composes premium and ultra premium efficiency motors with permanent magnets driven by frequency inverters. Perfect for applications where speed variation, precise control at low speeds, low noise levels and compact design are critical.

The W22 Magnet enables a reduction of up to 55 per cent in energy consumption when used in bag filter applications.

Induction Motor IE4

Output: 30kW

Speed: 3000 rpm

Frame: 200L

Mass: 265kg

Volume: 7dm3

W22 Magnet Motor IE4

Output: 30kW

Speed: 3000 rpm

Frame: 132M/L

Mass: 76kg

Volume: 24dm3

W22 Magnet IE5

• Output: 3 to 315kW

• Frame: 132S to 315S/M

• Speed: 3000, 1500 and 1000 rpm

• Voltage: 400 V

• Degree of protection: IP55

• Bearing seal:

• V´ring (frames 132S to 200L)

• WSeal (from frame 225S/M and above

• Insulation: F (ΔT 80K)

• Service factor: 1.0

• Thermal protection: PTC

• Insulated NDE bearing hub and AEGIS shaft grounding (from frames 225S/M and above)

• Mounting: B3T

• TEFC (IC 411) per IEC 60034-6

• Possibility of operation in overspeed

• Optional characteristics on request

Voltage supply: 380 to 480V

• Power: up to 1141 A (500kW)

• Sensorless vector control: it allows the CFW11 to control the speed motor from zero up to its rated speed

• Remote Operating Interface (HMI) with backlight, soft keys, graphic display and real-time clock

• Inductors incorporated on the DC Link to improve harmonic mitigation

• Communication protocol and accessories: Profibus, DeviceNet, CANopen, Ethernet / IP, Modbus-RTU and Profinet

• IP55 available as optional item up to 211A (110kW)

• Adaptable to all kinds of load

• USB port

• FLASH memory

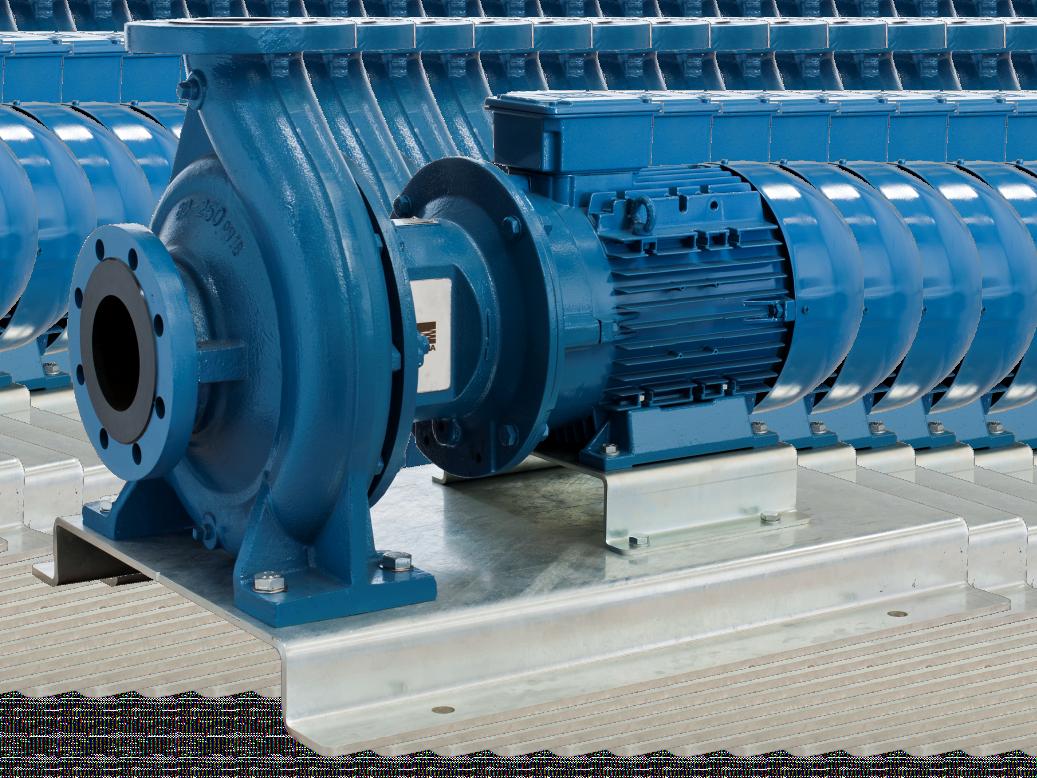

Ebara Corporation (Japan) has recently released its new global range of EN733 standard end suction centrifugal pumps.

Utilising the most advanced hydraulic computer design software available, Ebara engineers in Japan have been able to improve and increase the pump efficiencies of the new GS range above most other available pumps of similar design and standard on the global market.

As a major manufacturer of industrial pumps to JIS and API610 standards, Ebara Corporation has embarked on a globalisation of its range of pumps for the world market. This includes the introduction of a range of industrial pumps to European EN733 standards and a new range of vertical multistage pumps.

The new Ebara GS range of EN733 standard pumps are manufactured in component form at Ebara Corporation Japan owned and managed factories in the Asia Pacific region with final assembly of market range models undertaken by skilled tradesmen at Ebara Pumps Australia’s Melbourne facility.

The new GS series are 16 bar rated pumps, with a close coupled version (GSD) offered as well. Both the GS bareshaft pump and GSD are now available in Australia.

About Ebara Corporation

Ebara Corporation was founded in Japan in 1912 as a manufacturer of pumps. Today, as a group, it consists of more than 70 companies in six

continents with a workforce of more 11,000 people and with company owned and Japanese managed factories in eight countries covering four continents.

The huge scale of production and distribution is matched by a constant commitment to research, development and design of new products and the modern technologies for manufacturing them. Ebara products have gained a worldwide reputation for their technology and quality.

Contact your local Ebara dealer or Ebara Pumps Australia for more information.

Ebara continues to expand the range of products they stock and supply in Australia with two recent additions. For more details contact us at Ebara Pumps Australia or visit our website.

Very economically priced cast iron end suction motor pumps to EN733. They are based on the well proven 3M using the same extended shaft motor and stainless steel impeller, but with a cast iron casing.

A range of robust submersible grinder pumps with a high torque motor & powerful grinding mechanism. Another quality product in the well regarded and proven D’ series of Ebara submersible sewage & wastewater pumps.

with powerful grinding mech

Combining over 100 years of experience with the latest computer aided design, EBARA has developed the new GS series of pumps that offer world leading performance and efficiencies.

Pumps to EN733 dimensions

16 Bar rated. PN16 flanges (24 Bar hydrostatic test pressure)

High efficiencies. MEI ³0.6 (Minimum Efficiency Index)

Mechanical seals to EN12756

Protectors to ISO13852

O’ Ring seal for casing

Cast iron components ED painted (Electro deposition painting)

Caprari’s K+ Energy range is now being expanded, including models for both small and medium flow rates.

Caprari K+ Energy electric pump for wastewater management offers truly revolutionary features. This is thanks to its exclusive and internationally patented DryWet System: a truly unique cooling system that allows one electric pump model to be used for both submersed installations and applications in dry chambers, guaranteeing excellent reliability even when liquid levels inside the tank are unknown.

Advantages offered by the K+ Energy range include:

• Excellent energy savings: IE3 efficiency class motors guarantee premium efficiency to cut costs

• Versatility: the DryWet system means the K+ Energy range can be used for any type of application, thus allowing for considerable stock reduction

• Maximum ease of maintenance and handling: usability is greatly enhanced thanks to the standard plug (which allows the electric pump to be removed without having to disconnect the cables from the panel), the large micro-cast stainless steel handle, and the new system for disassembling the pump side mechanical seals

• Reliability and operational safety: the conductivity probe in the oil chamber (also in the Atex version), the temperature probes, and the double mechanical seal are all design solutions aimed at guaranteeing total protection for the electrical components. Moreover, the Caprari non-stop system ensures continuity of wet end operation even under the most severe operating conditions.

Browse the new website www.kenergy.caprari.com/en to find out all the features of the K+ ENERGY model.

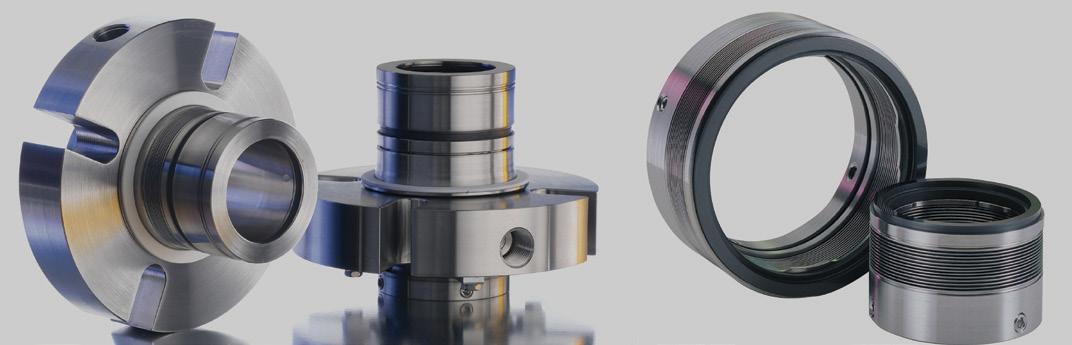

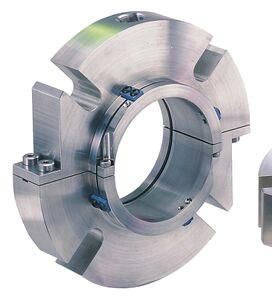

Split seals are an innovative sealing solution for environments where it may be difficult to install or replace conventional mechanical seals, such as hard to access equipment. They are also ideal for minimising costly downtime for assets critical to production by overcoming the assembly and disassembly difficulties associated with rotating equipment. Several semi and fully split mechanical seals have been designed by various manufacturers, however, with so many options available on the market how do you know what is really the best choice for your application?

While many designs may achieve the goal of reducing the amount of time required to change out a mechanical seal, they have introduced other issues.

These inherent design problems can be attributed to a few factors:

• Some component-style split seal designs have several loose parts which must be handled with extreme care

• Installation may require precise measurements or the use of various shims or special tooling to accurately align and set the mechanical seal assembly on the rotating shaft

• Some seals utilise an internal clamping method, limiting the torsional and axial holding power to positively locate the seal on the equipment

Another potential concern arises when the shaft position must be adjusted after the seal has been set. In certain designs, the set screws lock the rotary seal ring assembly to the shaft and cannot be reached after the two stationary gland assemblies have been bolted together. This means total disassembly of the seal once it has been installed, leaving the end user responsible for verifying that a complicated seal with precision lapped faces is correctly reassembled on the pump.

Flexaseal solution

Flexaseal addresses these disadvantages and limitations with the Style 85 two-piece split cartridge mechanical seal assembly.

The Style 85 split seal consists of only two unitised, selfcontained assemblies which fit together over a shaft to form a self-setting and self-aligning cartridge seal design. This fully split cartridge mechanical seal design eliminates the handling of a lot of loose, delicate, precision manufactured components and allows for a very simple, easy and time-saving installation with no measurements or guesswork. The critical primary sealing faces are held together and safely contained within the two split gland and sleeve assemblies, well protected from any mishandling, dirt or contaminants.

• The easiest installation of any split seal in the world: simply attach the two cartridge halves over the shaft and mount to the pump like any other cartridge seal

• The first split cartridge mechanical seal in the world in which just two pieces are handled: the lapped faces are secured safely in cartridge halves and cannot be cocked or chipped

• Only split cartridge mechanical seal in which the impeller can be adjusted without removing the seal: simply reinstall setting clips, release set screws and adjust impeller position then retighten set screws and remove the clips

• Only split cartridge mechanical seal that is fully assembled, and pressure tested at the factory: sealing integrity is confirmed before being sent to the field, thereby ensuring a high success rate for each installation

• No measurements, no shims, no special tools, and no glue: cartridge setting clips assures proper axial and radial alignment to make installation even easier

The design of the Style 85 is like no other on the market. While most split mechanical seals are mounted outside the stuffing box and are designed to function like an outside seal, the Style 85 was engineered as a true, fully split cartridge mechanical seal. It is a hydraulically balanced, stationary multi-spring design that is primarily mounted outside the stuffing box.

These features allow the centrifugal force to keep the solids away from the seal faces while maintaining the ability to handle higher speeds, internal pressures and misalignment. No need to worry about solids, as the springs are protected and out of the product to eliminate clogging. The static shaft sleeve “o” ring is positioned outside of the stuffing box to assure a good sealing surface, even on worn packing sleeves.

The Flexaseal Style 85 Split Cartridge Mechanical Seal… Fast, Simple and Reliable!

The Intermediate Bulk Container (IBC) is the number one container for storing and shipping chemicals worldwide. IBCs are regarded as an economical way to transport thousands of litres of chemicals to all corners of the globe. They are compact and take up no more than the footprint of a standard shipping pallet.

Despite some obvious benefits, there is a downside to this versatile container. Regulatory bodies also target IBCs because they can be mishandled, resulting in spills that can contaminate the surrounding ground, including waterways. They can also be a cause of workplace injuries through skin and eye contact when emptying the chemicals.

Organisations such as Victoria's EPA have developed and implemented liquid storage and handling guidelines to address specific issues around IBCs. These guidelines set out clear instructions on how to correctly store and handle these chemical containers for everyone's safety.

Up until now, there has been a limited range of free-standing, all-weather units that can encase an IBC and at the same time provide safe and clean dispensing options.

Designed to address the challenges of IBCs

The introduction of the Polymaster Enclosed IBC Bund addresses all concerns around the IBC.

Complete weather protection stops rain from entering the storage unit as the IBC is contained within an enclosed bund.

In the event of an IBC rupture, the unit would contain the entire contents within itself, preventing any chemical entering stormwater or the surrounding area as the design exceeds AS3780-2008: The storage and handling of corrosive substances bunding requirements of 110 per cent.

Operators have free and easy access via outward swing doors. Each door has clear viewing panels so that an operator can see inside without putting themselves at risk in the event of a spill. The unique door design acts as a splash guard, ensuring no chemicals can exit the unit.

The wide-opening doors allow an IBC to be easily forklifted into position from either side or rear. Extra clearance on all sides of the opening is advantageous to outside storage where forklifts may be operating on uneven ground.

The Enclosed IBC Bund includes a built-in vent to expel gases and a 250L day tank for continuous dosing if incorporated into an in-line process.

The day tank has safe, quick connect/

operator. A mounted audible and visual low-level alarm can be viewed through viewing panels.

The front cabinet can either accommodate a fully customised dosing system or an off-the-shelf dispensing kit suggested by Polymaster that suits chemicals.

For further information on the Enclosed IBC Bund, contact the Engineered Solutions team at Polymaster on 1800 062 064.

Polymaster’s unique Enclosed IBC Bund solves many of the problems associated with IBC storage and chemical/fluid decanting in a weather resistant, purpose-built enclosure.

Æ Full weather protection – stops rain entering the enclosure

Æ Easy forklift loading with wide forklift access from both side and back

Æ 250ltr day tank

Æ Lockable cabinet to keep system secure

Æ Venting by two sides

Æ Viewing windows incorporated into the doors

Æ 110% bund capacity complies with AS3780

Æ Sight tube and low-level alarm available

Æ Chemical resistant – high grade polyethylene construction

Mechanical seal design and manufacturing company

SPE has launched several innovative sealing products for industrial equipment applications. The nuclear, petrochemical, pharmaceutical, mining and wastewater industries in over 40 countries use SPE's products. The company's Chief Operating Officer, Yi-Chieh Huang, is a significant driver behind this success.

Huang holds an MIT Sloan MBA degree and has over 14 years of experience in the machinery manufacturing and sealing technology equipment fields. Huang combines mechanical engineering expertise and business acumen to champion sealing systems’ product development and technology commercialisation of sealing systems for energy industry applications. Furthermore, Huang has been admitted by several prominent international professional organisations such as the American Petroleum Institute, American Fluid Sealing Association, Taiwan Nuclear Grade Industry Association, Society of Manufacturing Engineers, American Society of Mechanical Engineers, and API-682 standards committee in industrial specification development. Developing technologies to meet end user needs

During her career, Huang has invented over 30 patented technologies covering over 20 advanced seal designs with comprehensive technology commercialisation. Huang developed high-performance seal products offering excellent reliability and significantly longer mechanical seal mean time between failure (MBTF) for equipment. Huang championed efforts resulting in more than US$3.5 million annual cost savings by improving equipment MTBF. Further, Huang's team implemented sealing technology upgrades for a chemical plant in China. The facility reduced maintenance costs by $3.6

million within three years, allowing the end user to achieve 40K+ tons of chemical compound production annually.

Huang's R&D team designed the APD-series products for API682 applications for hazardous, flammable and toxic processes requiring a grander scale of a mechanical seal's reliability for improving pump operating life with lower emissions and reduced end user lifecycle sealing costs. They work in various critical operating conditions with a wide temperature range of -40oF to 500oF and pressures up to 570 psi.

For lower rotating equipment electrical consumption, Huang developed CARFB, the first complete cartridge seal design with multi-segment tandem rings. CAR-FB seals are for industrial blower applications operating in temperatures up to 720oF to avoid dry running, prevent toxic gas leakage, and reduce power consumption by over ten per cent. Moreover, Huang's team lowered nitrogen consumption by upgrading a next-generation non-contacting seal with a unique spiral pattern.

For wastewater treatment, Huang's team launched the CL99SS series seals with over 35 per cent part interchangeability for five to 35 per cent of suspended particle-containing slurries, including sulfur dioxide leakage reduction and plant spare parts inventory by about 50 per cent when over 70 per cent of the pumps have the CL seal line of products installed. The CL series products handle short periods of dry running and eliminate the need for a complicated piping system, reducing water consumption. Also, CL

series seals can align shaft misalignment for up to +/-0.5mm and extend MTBF by at least 50 per cent.

In response to new government ecological policies, Huang's team reduced equipment Volatile Organic Compound (VOC) emissions below 500 ppm on average and less than 50 ppm in specific sealing technology. Typically, dual seal buffer pressure is at least 40 psi higher than the process, requiring an external resource and increasing energy consumption. Huang's LD series invention requires under 30 psi because of its automatic balancing structure with high sealing performance. This technology greatly improves the sealing heat exchange rate. It has a 15 per cent higher recirculation efficiency than the average dual cartridge seal, increasing the pump's operating reliability by at least 20 per cent, saving about 25 per cent maintenance time.

In summary, Huang contributed many extraordinary dynamic fluid sealing sector innovations, making industrial environments better.

"I am enthusiastic about providing a technical solution for various market segments according to market demands. We demonstrated SPE's technical strength by innovating and leading industrial sealing trends and thereby improving industrial environments. Our clients' needs always inspire us to create meaningful innovation," Huang said.

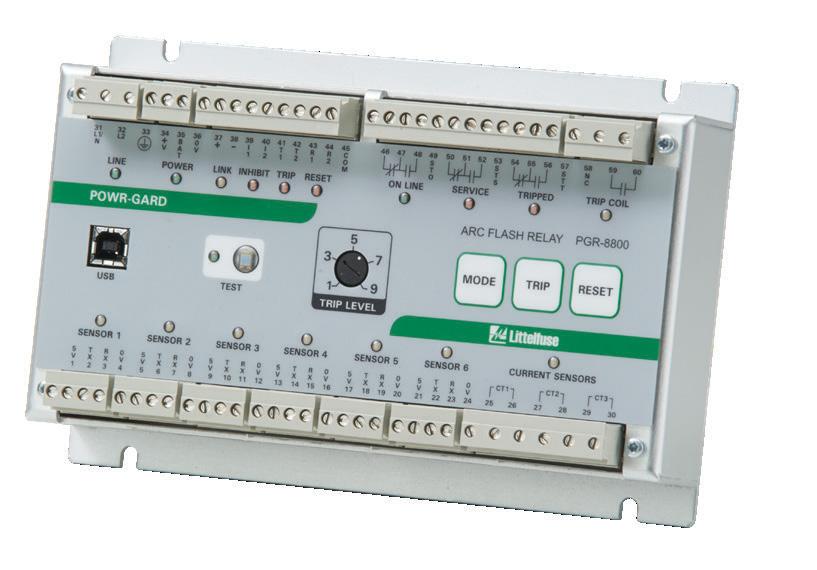

Trust your motor and pump protection to the experts. Littelfuse protection relays stand up to the harshest conditions and safeguard the most critical parts of your operation. Our field application experts will help you update your protection to extend the life of your equipment, mitigate arc-flash hazards, and reduce the risk of electric shock.

relays@fuseco.com.au

www.fuseco.com.au

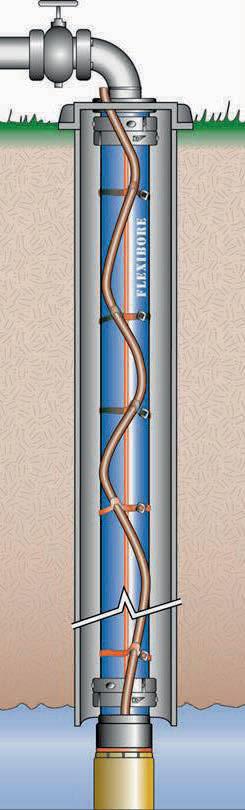

Accounting for around 98 per cent of Australia's Economic Demonstrated Resources (EDR) of iron ore (about 28 billion tonnes) and as the largest supplier to the global seaborne iron ore trade, the iron ore mines in the Pilbara region of Western Australia are a leading powerhouse for the Australian economy. These mines are at the forefront of best practice for efficiency and safety, and – along with other Australian mines as a whole – are highly rated across the world for their skilled processing and ore extraction techniques. Crusader Hose, an innovative Australian manufacturer, has produced a world-first flexible rising main for ultra-deep bores – Flexibore® 400 – to help support Australia’s mining industry remain world-class.

Crusader Hose, a Melbourne-based company with over 35 years in manufacturing layflat hose, has a strong connection with the mining, pump and drilling industries, having built relationships with players in these sectors over many years through industry networks, site visits and trade shows. As a result, Francois Steverlynck, the Managing Director for 30 years, understands the importance of water extraction in mining operations.

“Mines are extending and digging deeper, and are, therefore, reliant on water transfer systems which can handle the greater pressures at these deeper depths,” Francois said.

Manufacturing the highest pressure layflat hose in the world

A recent breakthrough by the Research and Development Team has been the development of ultra-high-pressure hose for the extraction of bore water.

Several years in the making, this breakthrough was made possible by a series of upgrades along the manufacturing chain.

Apart from loom modifications, the polyester fibre used in weaving the textile reinforcement is of a higher calibre than what is used in lower-pressure Flexibore® products; the tenacity of these higher-calibre fibres is unparalleled.

The $1 million investment in a new extruder system has brought world-class quality to this very important process. As a result, the Flexibore® 400 series hose is the highest pressure layflat hose in the world for groundwater pumping, boasting a burst pressure of 100 bar or 1000m. Groundwater now can be safely pumped from 400m below.

Committed to supporting mining operations

Crusader Hose is committed to supporting mining and the Australian economy by investing in technology to design and manufacture world-class hose systems for both vertical and horizontal dewatering.

“Flexible rising mains such as Flexibore®, have been the system of choice for many Australian mines for in-pit bores due to the simplicity with which the submersible pumps can be retrieved and installed,” said Francois.

The typical installation method uses a roller, crane or mechanised spool, as the riser pipe is one continuous length. In the most recent installation, after the 380m of hose was laid out and power cables were attached, the 160kW pump was lifted by a crane then lowered 15-25m at a time by repositioning the lifting clamps along the hose. This system has proved to be less time-consuming and arduous than using steel or fibreglass pipe.

“The Flexibore® 400 is a pioneering achievement in the history of our company, which we believe is a world first,” said Francois.

“This Australian development will hopefully be keenly adopted by more mining companies, to enable them to keep at the forefront of productivity and profitability.”

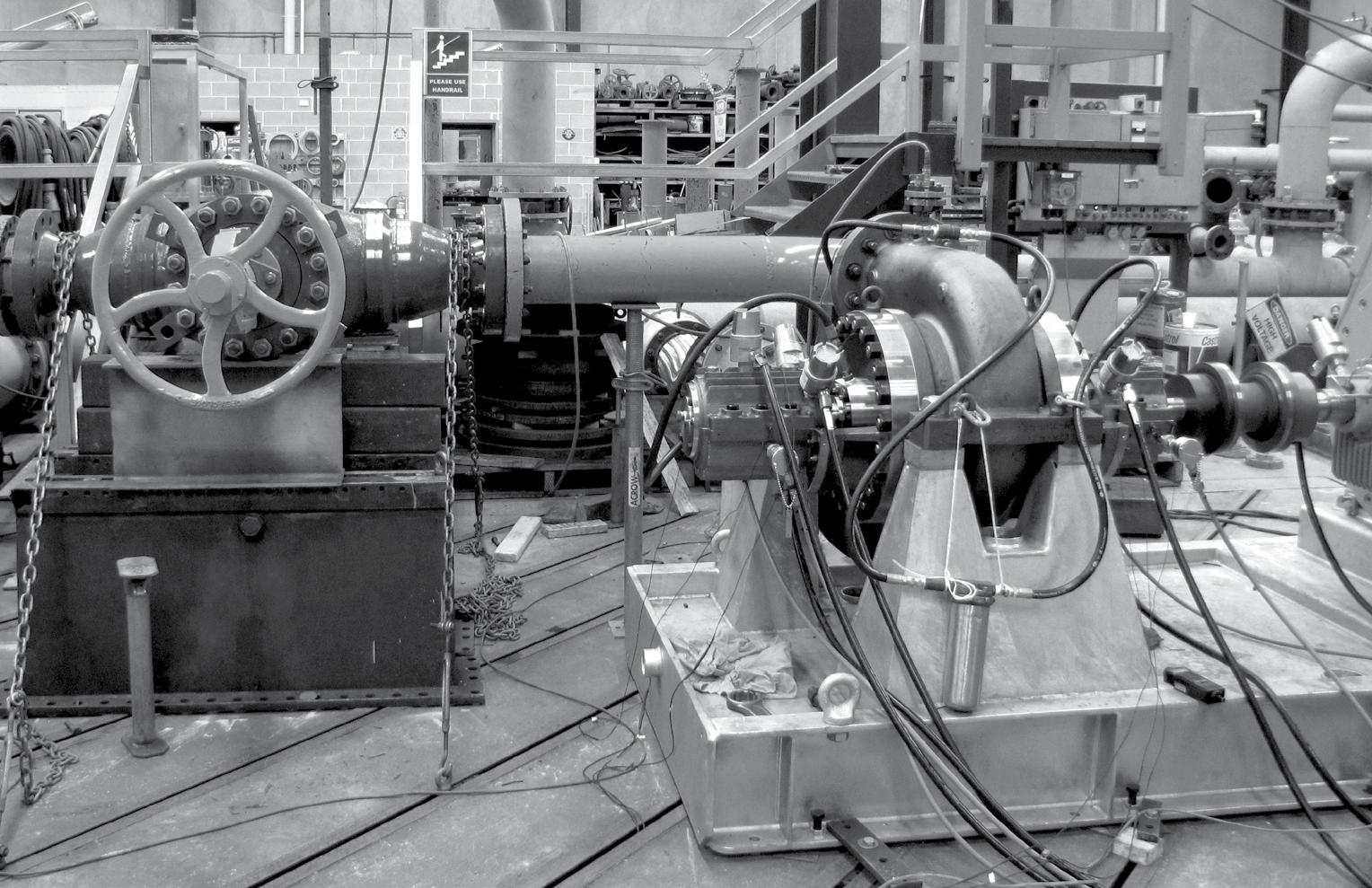

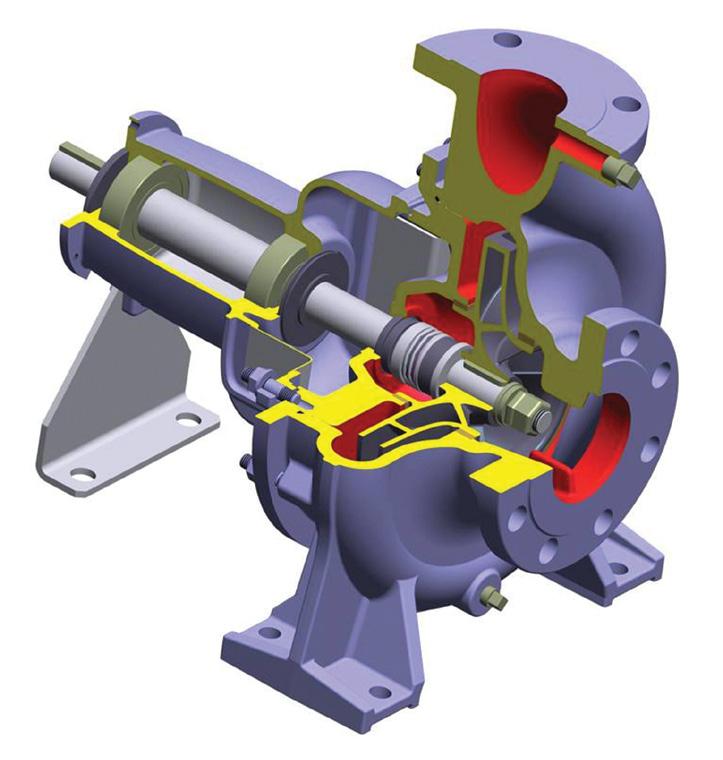

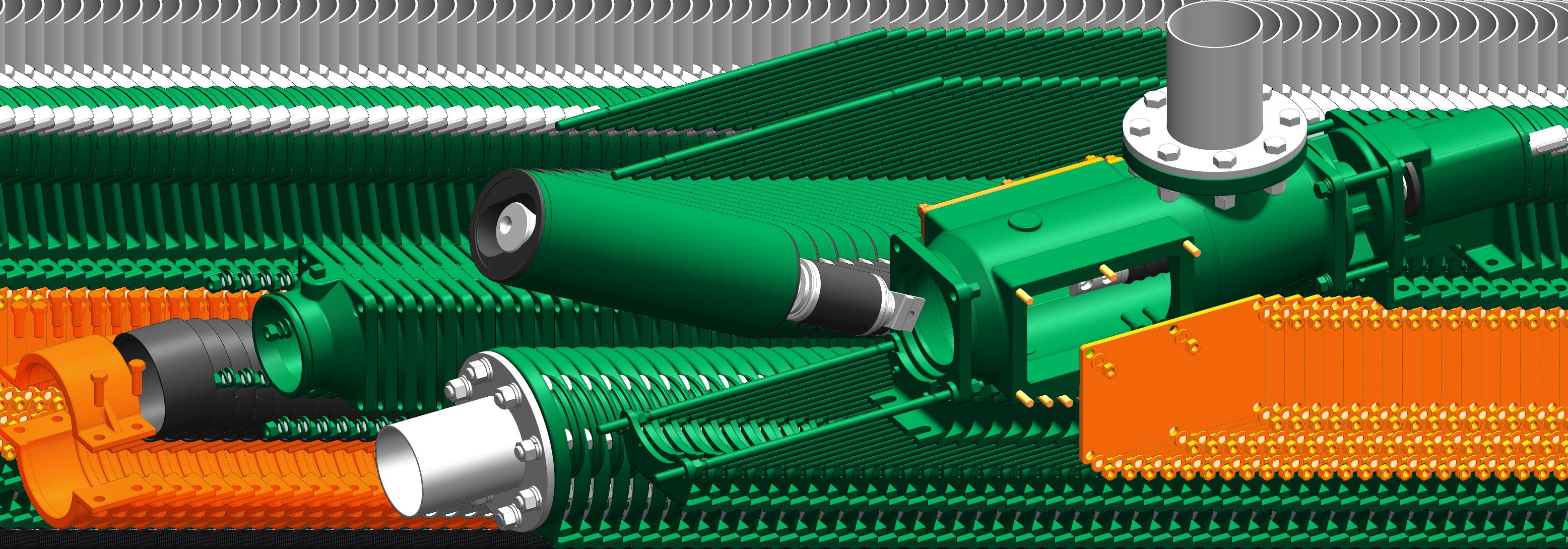

In mining and ore processing operations, slurry pumps provide a vital means of effectively transporting slurry over any distance. Their running costs also contribute a significant component of total operating costs, and any failure of this key piece of equipment can bring a mining project grinding to a halt. Therefore, improvements in the sustained efficiency and reliability of slurry pumps can result in substantial bottom-line benefits to mining operators.

Despite their importance, the highly demanding nature of the application and the complex set of factors affecting slurry pump performance in mining operations mean that it is still relatively common to find pumps being operated inefficiently, or in ways that reduce equipment lifespan, resulting in lower overall efficiency and higher costs for the project. Maximising slurry pump efficiency requires the correct specification and selection of pumps, and ensuring that they are optimally operated to deliver sustained efficiency and reliability over the longer term.

Slurry pumps are required to transport large volumes of slurry, composed of target minerals and overburden suspended in a carrier fluid, to mineral extraction process plants for separation. Therefore, they must be able to handle the abrasive solids in the slurry and, in some cases, corrosive fluids.

Due to the nature of the material being pumped and the distances involved, slurry pumps are usually large and consume significant amounts of power. This is an extremely demanding application, and slurry pumps often operate 24/7, meaning that in severe conditions the wear life of wetted components can be only two to three months. Any failure or inefficiency in slurry pumping can have significant repercussions for the entire plant and project, impacting the overall profitability of mining operations.

Optimising the efficiency of slurry pumps over their entire service life requires:

• Specifying and selecting the right pump and other equipment for the application

• Ensuring the pump is operating at its best efficiency point (BEP) flow rate

• Regular monitoring and maintenance to prevent unplanned outages and declining performance

Choosing the right pump

To deliver maximum slurry pumping efficiency, the performance characteristics of the pump or pumps employed must be well matched to the unique requirements of the particular application on a project. If wrongly specified, even a pump that appears to be operating with a high efficiency can quickly become worn down and damaged. This can result in failure or other problems, like higher power consumption and shorter pipeline equipment life, that will negate the initial efficiency and, ultimately, incur higher costs over time.

The majority of slurry pump issues are caused by a mismatch between the pump’s performance characteristics and the application requirements, either from the initial specification or due to circumstances changing since that specification.

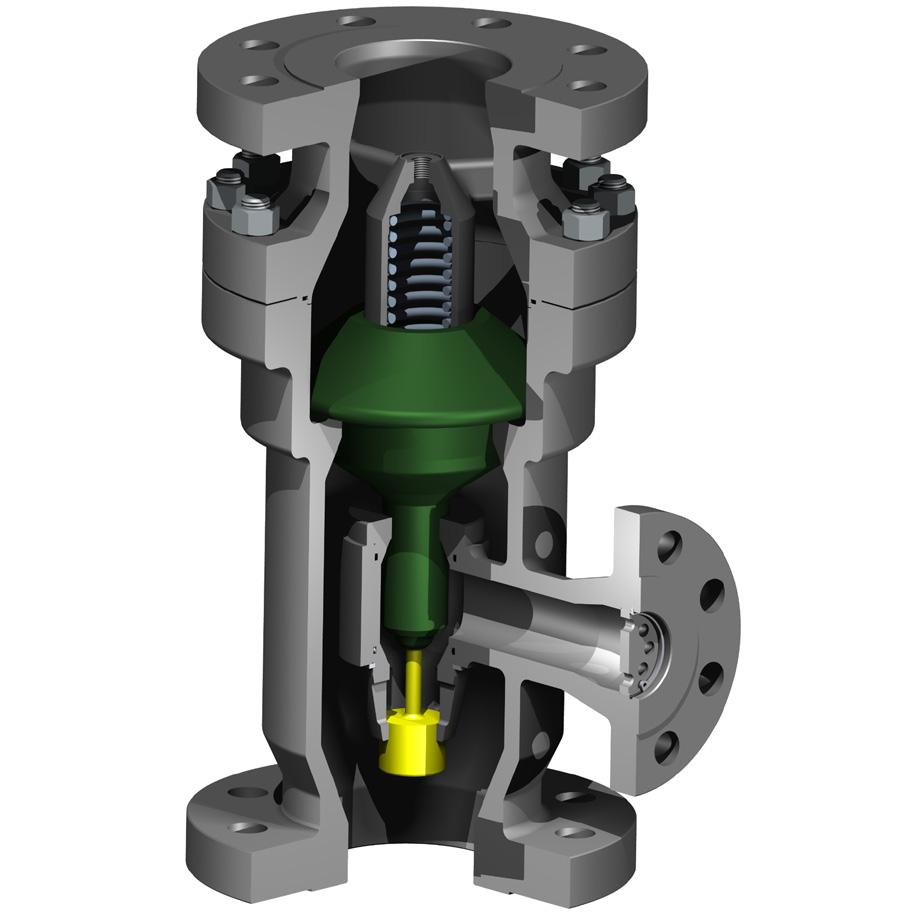

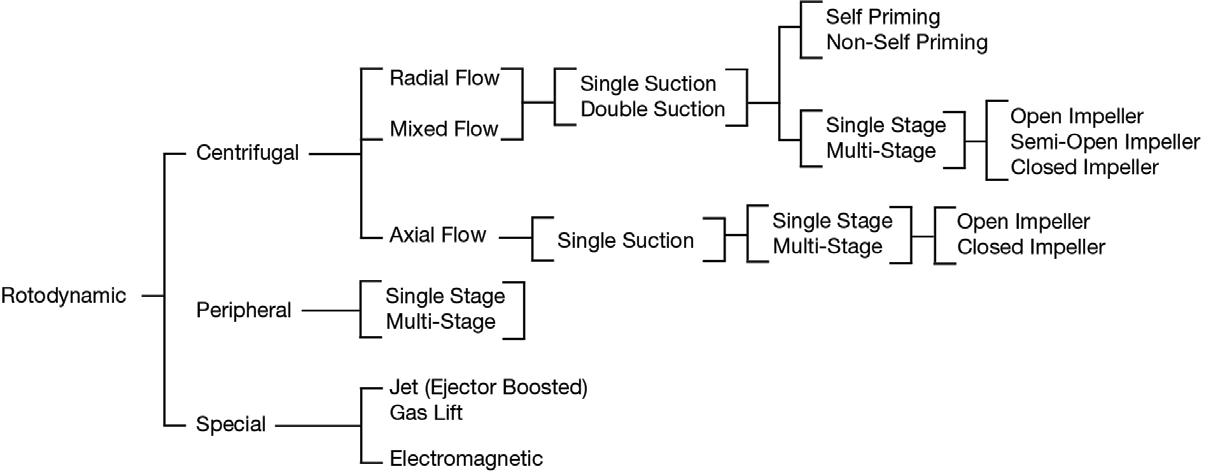

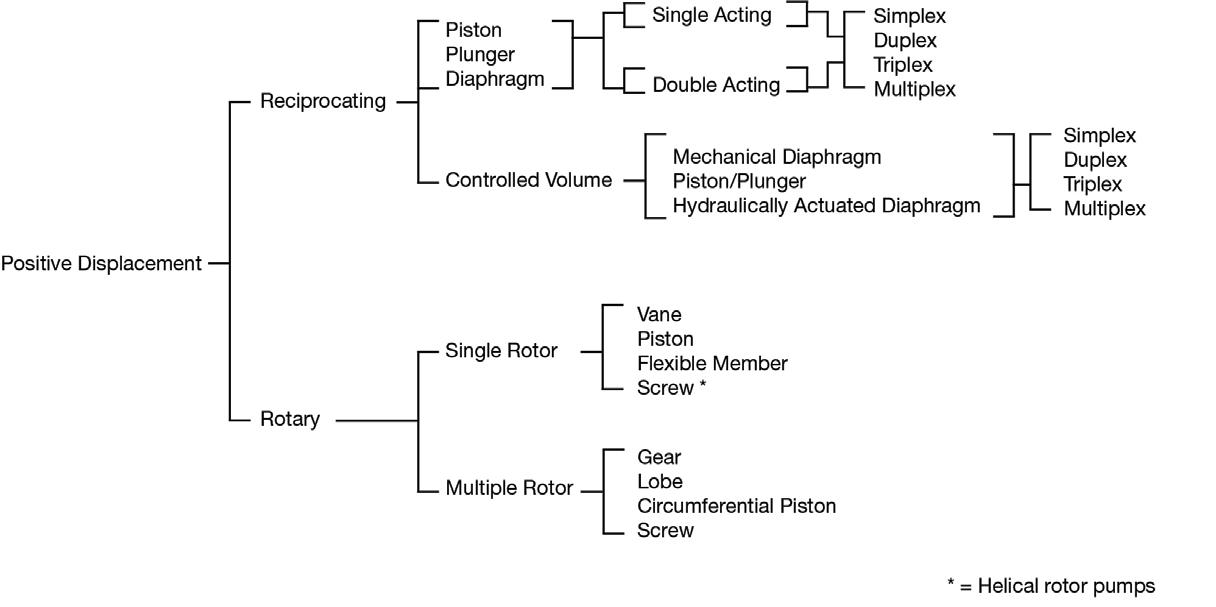

Two main types of pumps are regularly used for transporting slurries: centrifugal pumps and positive displacement pumps. Centrifugal pumps are usually employed

for flow rates from a few litres to thousands of litres per second, and can handle solid particle sizes from microscopic to large rocks up to 300mm. However, they generally can’t develop pressures higher than 7MPa even when they are arranged in series. Their casings can be unlined or lined with internal replaceable liners, composed of materials appropriate to the features of the slurry. The wearing parts are mostly impellers, volutes and side liners.

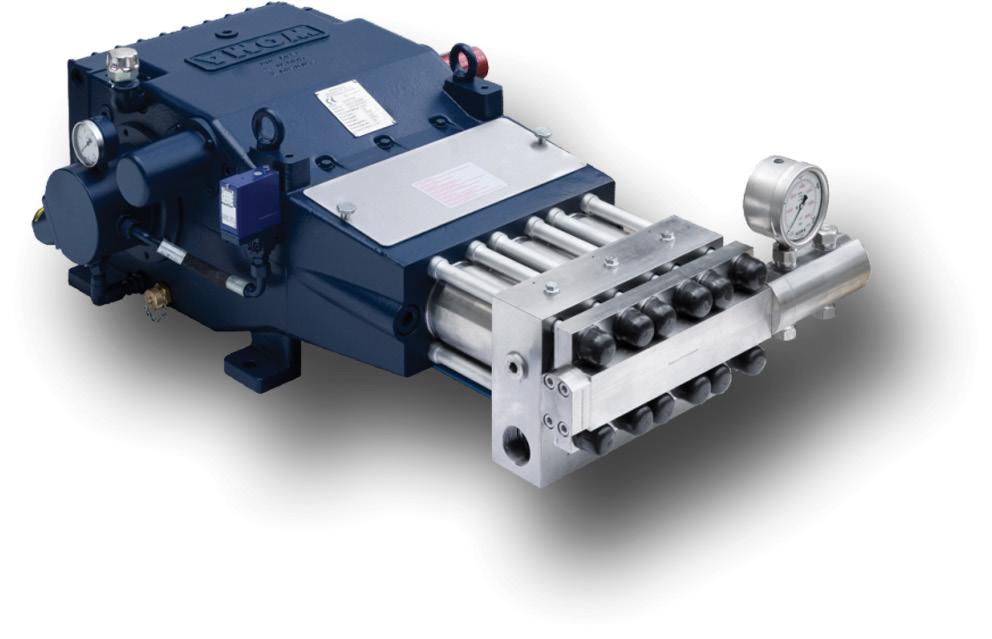

Positive displacement pumps are often employed for pumping through very long pipelines, because of their ability to generate high pressures, which are well in excess of multistage centrifugal pumps. Their design flow rate range is limited from 50 to 1000 litres per second, due mainly to their large physical sizes, both at low and high flows. They are best suited to transporting slurries with high concentrations of fine particles with a maximum size of about 6mm. The maximum particle size is dictated by the poppet valves, which can jam in semiopen position by large particles. Poppet valves are high wear components that need to be replaced frequently.

An array of different factors come into play when it comes to choosing the best pump for the job. These include the pump’s BEP, the characteristics of the slurry to be pumped, the distance the slurry must travel, and more.

Some of the most important parameters of slurries to consider when selecting a pump include:

• The particle size, shape (angular, round, long and stringy) and hardness

• Corrosiveness

• Chemical compatibility with elastomers

• Solids concentration

• Likelihood of running dry Hydraulic considerations and BEP match

A number of factors should be taken into account in order to select a centrifugal pump that matches the system and application’s hydraulic requirements. These include the system’s design, the required flow rate, the system resistance, and system curve.

System design – Oversizing or undersizing the pump for the application can result in the pump operating outside the range of its BEP or its allowable operating range. This can cause problems such as circulation issues, vibration, cavitation and loud operation.

Flow rate – The flow rate achieved in a pumping system is the result of the head created by the pump.

System resistance – The system resistance head is the head necessary to overcome the static head and the friction head in the pipeline. The duty point of the pump is the flow at which the head created by the pump is equal to the system resistance head.

Duty point (rated flow at differential head) – The key to successful pump selection is to accurately specify the required duty point.

The pump’s BEP flow rate is the optimum flow rate for the slurry to travel through the system at a particular impeller speed.

Net positive suction head available

Net positive suction head (NPSH) is the total absolute head at the pump suction minus the vapour head of the pumped fluid. To prevent cavitation, and the resulting damage, the system net positive suction head available (NPSHA) must be greater than the pump net positive suction head required (NPSHR), preferably with an appropriate safety margin.

Determining the required flow rate, total dynamic head to be generated by the pump, and the suction lift or NPSHA, enables the selection of a pump with a performance curve that satisfies these requirements.

The performance curves provided by pump manufacturers indicate pump efficiency, power use, and the suction lift or NPSH required for the pump’s flow range. The speed (rpm) and input power (kW) required can then be determined by plotting the required flow, total head and suction lift on the performance curves. However, determining the requirements for slurry pumping applications is complicated by the variable individual characteristics of a slurry. The manufacturers’ performance curves are generally based on the process fluid being clear, cold water. Therefore, pumping a comparatively heavier or lighter fluid will require comparatively more or less power, and this must be taken into account in pump selection.

Other possible features of slurry pumps that could influence final pump selection include:

• Leveling (on/off control devices)

• Self-priming

• Thermal overload protection

• Non-clog

• Plug-in

• Reversible

• Dry-running capabilities

• Ease of maintenance

In reality, final selection is often a trade-off between high capital and low maintenance costs, or low capital and high maintenance costs. Therefore, the total cost of ownership over the pump’s service life and the duration of mining operations should be taken into account and balanced.

Once an appropriate pump is selected for a mining slurry application its sustained efficient operation requires that it remain in good condition. Among the key factors that impact upon pump wear is the flow at which the pump is actually operating in relation to its BEP flow rate.

Even a large, robustly-built pump running at a slow speed can experience gouging and wear that reduces the lifespan of its components, subsequently reducing efficiency and increasing its lifetime ownership costs.

A pump operating at a high flow rate relative to its BEP often results in increased pipe friction losses, reduced efficiency, increased power, noise and vibration, high radial loads on bearings, and cavitation due to lack of NPSH available.

Meanwhile, when pumps operate at low flow rates relative to BEP, sedimentation and sanding can occur in pipes, causing blockages. Other problems that may occur include recirculation, increased noise and vibration, increased radial loads on bearings due to unbalanced volute pressures, reduced seal, bearing and impeller life, low flow cavitation, and temperature rise due to dissipated energy created by low efficiency.

Ideally, slurry pumps would be operated at 100 per cent of BEP flow, resulting in maximum efficiency and minimum wear. However, in reality this is not always possible. Nevertheless, ensuring pumps run as close as possible to BEP will improve their performance and service life, maximising efficiency and profitability.

In some cases, although a pump may be correctly specified prior to installation, changes in circumstances that result in changes to flow, such as slurry composition, can require it to operate further away from its BEP flow. Over time, even small changes can result in significant losses of efficiency and increases to wear.

As a result, to achieve optimised slurry pumping efficiency, it is important to undertake regular inspection and maintenance, and to evaluate how any changes to conditions that occur may affect the application requirements, duty point and pump BEP.

Optimising slurry pumps to maximise profitability

Slurry pumps are critical to mining and extraction operations, moving the extracted minerals and associated material to and throughout processing facilities. This demanding application can result in significant wear to pumps, which are required to be powerful and robustly built, and often require significant amounts of power. As a result, the pumps themselves and the power to run them contribute significantly to the overall costs of a mining operation, and improving slurry pumping efficiency can significantly increase profitability for operators within the industry. Maximising efficiency involves determining the requirements of a given slurry pumping application and choosing the right pump for the job (with a BEP well matched to the duty flow rates), operating it as close to its BEP as possible to increase efficiency and equipment lifespan, and undertaking smart monitoring and maintenance to sustain this efficiency over the longer term. By following these steps, operators can increase the likelihood that their slurry pumps will be performing efficiently and reliably for a long time to come, maximising return on investment, and keeping mining operations running smoothly and profitably.

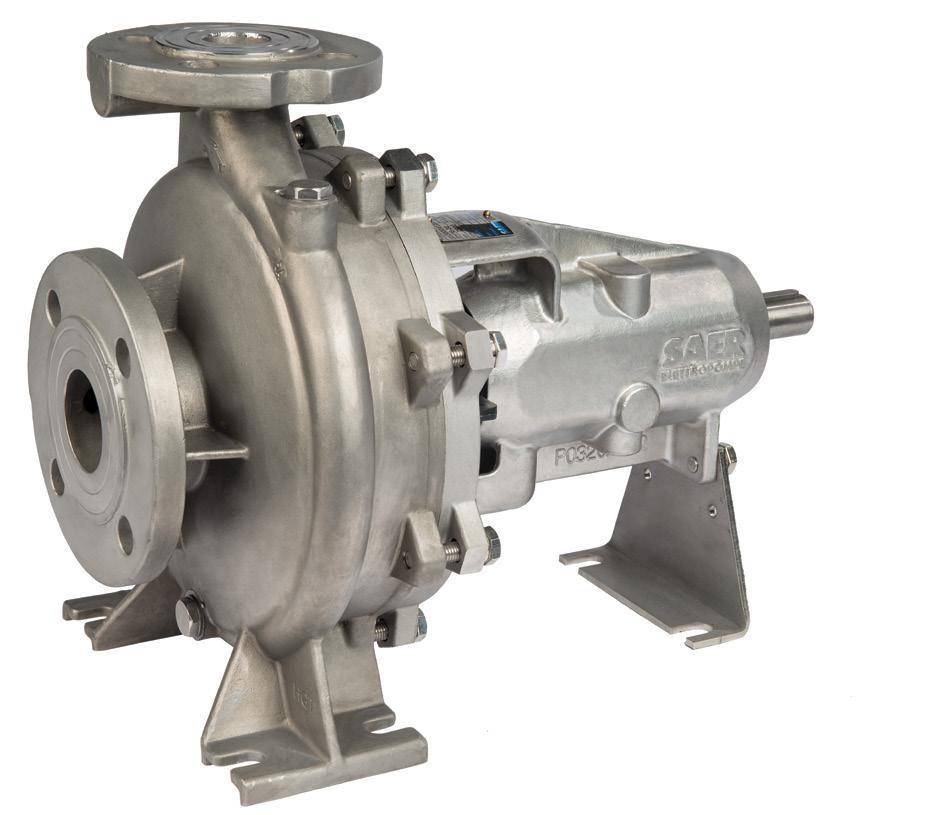

SAER, an Italian pump and motor manufacturer with over 70 years of experience and knowledge in the pumping industry, offers a wide range of products available in several different materials and configurations. Its products are suited for mining applications where reliable and robust pumping equipment is a mandatory requirement. The launch of its new supermining motor builds on its product range, providing an efficient solution engineered specially for the mining industry.

The new 4" supermining motor

SAER’s new range of 4” submersible motors designed for the mining industry – the supermining CLXV95 – addresses users’ needs, offering performance, efficiency and reliability in harsh environments. Using its experience gathered in the field, and combining it with engineers' knowledge and problem-solving skills for application-specific issues, SAER’s supermining motor is designed to be durable, portable and heavy duty in order to cope with the tough conditions and demanding environment of mining applications.

The SAER CLXV95 supermining motor, made in Italy, has a number of features to help it overcome common issues for equipment on mining sites, including:

• Reinforced structure to withstand stress

• Special cable for aggressive environments

• Thicker components

• External support in stainless steel AISI316

• Duplex shaft

• Rubber parts manufactured from FPM

• Triple seal system on the rotor shaft

• Diaphragm membrane for pressure balancing

• Oversized bearings

Built to last

Coming from SAER's knowledge in borehole pumps, its brand new VS series – high efficiency submersible borehole pumps available in sizes from 6" to 14" – is now a reality.

Designed and manufactured in Italy, the VS series is already available in various material configurations including cast iron, full stainless steel AISI316 and full Superduplex.

The new VS series features:

• Efficiency values up to 84 per cent

• Flow range from 10m3/h up to 670m3/h

• Head range from 10m up to 390m

• Motor power from 4kW up to 300kW

Thanks to precision casting of parts, long lasting performance is assured and provides an ideal solution in mining applications such as underground dewatering, dust suppression and raw water supply.

The importance of looking for the right material is indeed sometimes underestimated; cheaper materials could lead to problems such as greater costs for maintenance or replacement, while selecting a well-built, reliable pump will have lower lifecycle costs. In order to have an efficient pumping system, it is important to select the most appropriate pump for the specific application and operating conditions, so SAER’s team can help customers step by step through the product selection process to ensure it meets their specific needs.

Further to its well-known ranges of precision cast products in cast iron, AISI 316 and bronze, SAER now offers them in super duplex, featuring a flow range up to 5,000m³/h and head range up to 60 bars. These products have one of the best delivery times on the market, thanks to their production in Italy.

SAER’s NCB-NCBK end suction pumps series, SKD series split casing pumps, submersible pumps and motors, as well as its TM range of high pressure pumps are available in several configurations and able to withstand the toughest environments.

Laboratory tests can be performed, as well as third parties certifications when needed.

It is now possible to request NCB-NCBK series end suction pumps, as well as TM series multistage pumps, with bearings support in stainless steel AISI316.

Climate change, population growth, and water scarcity are creating new challenges, and desalination is becoming an important alternative to traditional freshwater resources.

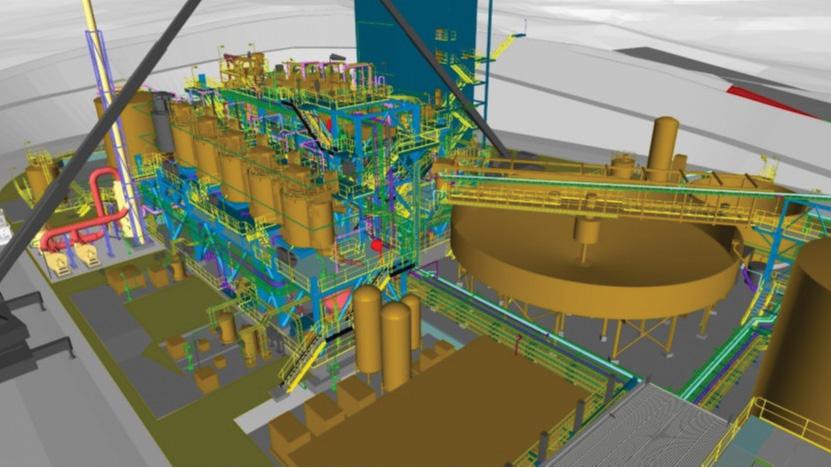

A $130 million molybdenum (moly) processing plant is being constructed at Newcrest Mining’s Cadia mine in New South Wales. The plant will extract moly from the mine’s copper concentrate stream to produce a 50 per cent moly concentrate in dry powder form, with an anticipated production of 4.1 million pounds a year. Construction began in February 2020, with commissioning starting in March 2021 and first commercial production expected in the September quarter. Here, we take a look at how the processing plant operates and the equipment used.

Moly is a silvery white metal used to enhance strength, prevent corrosion and reduce brittleness in steels and superalloys, as well as for lubricants, fertilisers and pigments. While it is sometimes mined as a primary product, it is most commonly recovered as a by-product or co-product of copper or tungsten mining.

Moly processing at Cadia

Newcrest will produce moly by extracting it from the copper concentrate stream prior to it being pumped back to Blayney.

Moly project manager, Malcolm McPhan, said, “We’re literally tapping into the pipeline that runs to Balyney.

“We divert copper concentrate from the pipeline on its way to Blayney to the moly plant where we extract the moly via floatation process, then we pump it back into that pipeline and send it on its merry way to Blayney.”

The small floatation plant is made of a series of floatation cells, thickeners, a grinding mill, dryer, scrubber, bagging plant and instrumentation to control it all. The level of control and automation provided is world-class to optimise recoveries and concentrate grades. At nameplate capacity, it is expected it will generate an additional revenue stream of about $45 million per annum.

The plant was designed using the latest intelligent 3D modelling software which provided insights throughout the design process and was expected to offer substantial benefits over conventional packages during construction and commissioning.

The project was expected to employ 140 people during construction and about 15 full-time roles when operational.

Copper and moly are often found together as sulfides, which in solution will

float or sink with the right combination of chemicals and gas bubbles (froth flotation). The sulfide ores are separated from gangue (waste) material, then from each other, by froth flotation.

This separation and concentration of copper and moly is called the coppermoly flotation circuit, and is made up of a number of steps. Various equipment is used throughout this process, depending on project needs and circuit design, but can include sludge pump skid, underflow pump skid, sand pump, diaphragm pump, rotary vacuum filter, flotation cell, SAG mill, ball mill, cyclone and spiral screen.

Grinding mills separate the ore from the gangue material, such as silica and organics, and reduce it to an optimal size for flotation. In this step a rod or ball mill is used and arranged with special non-sliming features

like a peripheral discharge or large diameter discharge trunnion opening to prevent choking and provide greater grinding flexibility. Any particles that are oversized will be caught by fine screens and transported back to the mill for regrinding, this can be done via a bucket elevator, sand pump or spitzkasten.

Once particles are fine enough, water mixes in to form slurry to help in the transportation and separation of the solids.

The flotation stage consists of multiple steps, usually running through rougher flotation cells, then cleaner column cells, and often scavenger cells which work together to give a high total yield of the bulk ore.

The regrind circuit usually consists of a closed-circuit steel head ball mill with a flotation cell and spiral classifier. The flotation cell helps remove the freed mineral coming from the mill.

The unit cell discharge is then transported to a heavy-duty spiral classifier which separates it into the fine flotation feed and the coarse regrind product.

The standard rougher tailings can then go to the scavenger cells which pull out the last trace of mineral. The product is then subjected to two or three stages of cleaner flotation to produce a final flotation concentrate.

At this stage, a high rate thickener dewaters most of the coppermoly concentrate before further separation occurs.

The moly flotation circuit has similar groups of flotation cells with chemicals to float the moly concentrate and settle out the copper concentrate. Here, the less dense ore rises in the froth to be collected, while the gangue sinks to be discarded. Flotation separates the metallic minerals from the gangue this way and separates molybdenite from copper sulphide.

High rate thickeners are then used to thicken each of the copper and moly concentrates, and a vacuum drum (or other) filter dewaters the concentrates further before refining or storing until sale.

The gangue (waste) from the rougher and scavenger cells flows to a tailings thickener to recover water for the process. Filters dewater these tailings further, or they are stored in a tailings pond.

• Self-lubricating

• Non-galling

• Survives run dry episodes

• Corrosion resistant

• Dimensionally stable

• Won’t swell

• Improves efficiencies

• -400˚F to 1000˚F (-240˚C to 535˚C)

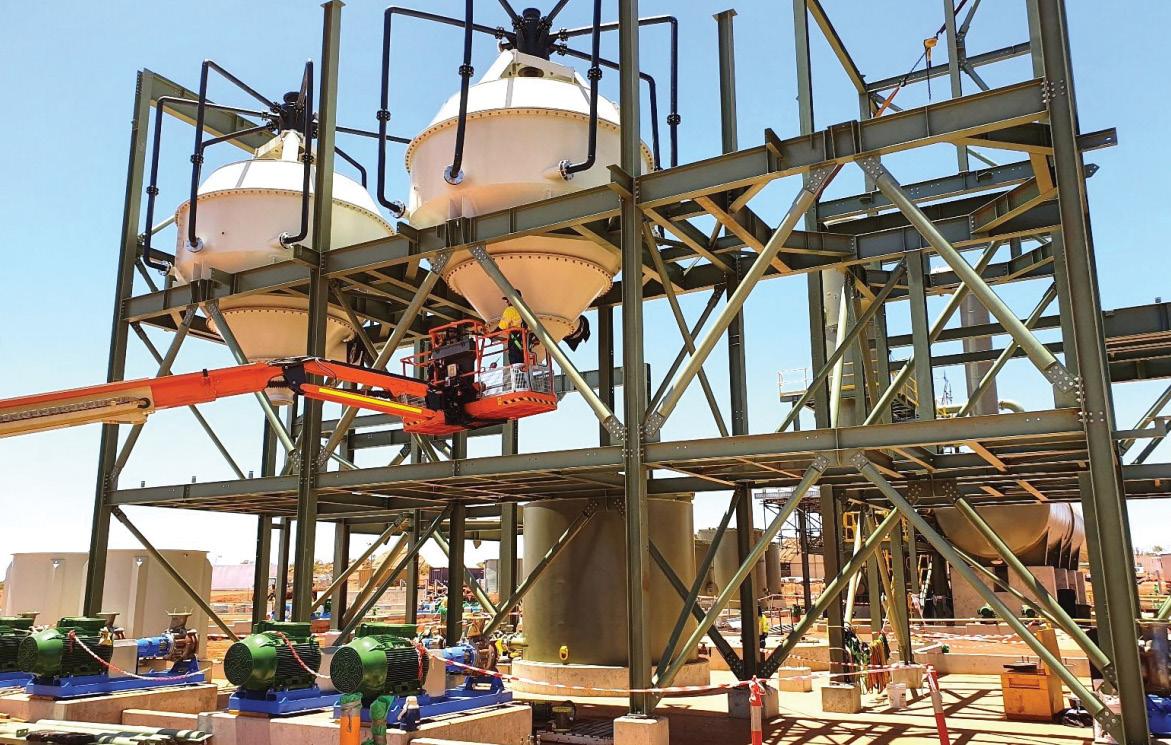

Kalium Lakes’ Beyondie Sulphate of Potash (SOP) project in Western Australia has reached a number of major milestones in recent months, with construction work of major infrastructure completed or entering the commissioning stage, and reaching nameplate capacity at its brine extraction and supply infrastructure. Here, we take a look at these milestones and some of the equipment being used throughout the project.

Since 2019, more than 93,000 tonnes of contained SOP has been pumped from the bore field and trenches into the primary evaporation ponds. Nameplate flow rates were reached in October following the completion of brine extraction and supply infrastructure, including brine production bores and pump stations.

Brine is supplied from two resource locations – Ten Mile and Sunshine –and each of the brine extraction areas includes a series of production bores to extract brine from the paleochannel and sandstone aquifer resources located between 10m and 140m below ground level. Actual flow rates achieved from commissioning and test pumping matched modelling for the bore field within each of the extraction areas.