IRRIGATION KEY to dairy farm’s renewable energy transition

HEAT PUMPS

helping to decarbonise meat industry

Urban Utilities

INVESTS IN MAJOR PUMP INFRASTRUCTURE

ISSUE 44 WINTER 2023

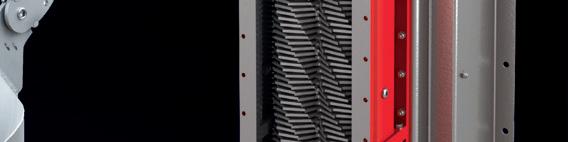

Wrapflex and Omega

Not your average pump drive

• The benchmark in Elastomeric Couplings for Pumps

• Engineered materials and patented designs to increase longevity and reduce reactive load on equipment

• Flexible enough to accommodate moderate misalignment and vibration

• Split elements for ease of in-situ replacement

• Stocked in Australia for quick and stress free access

Orange Peel®

• Coupling and Shaft Guarding

• Configurable to fit most applications

• Powdercoated steel and Polyethylene variants

• Multiple sizes and styles

• Off the shelf availability

Newcastle 02 4962 8000 | Perth 08 94124100 | Sydney 02 4677 6000 | Melbourne 03 9736 6000 | sales.australia@regalrexnord.com INDUSTRIAL POWERTRAIN SOLUTIONS

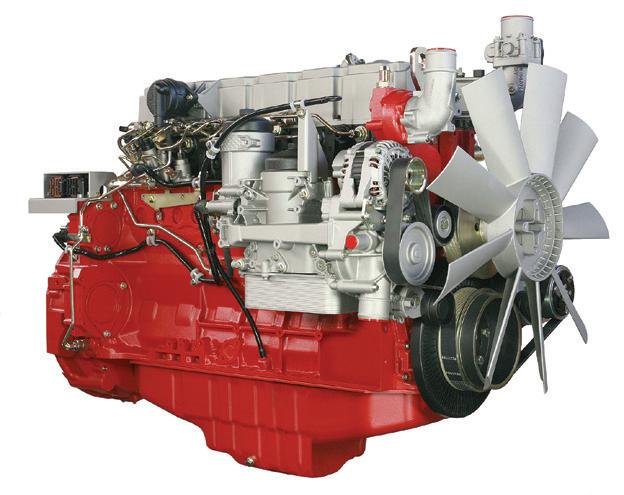

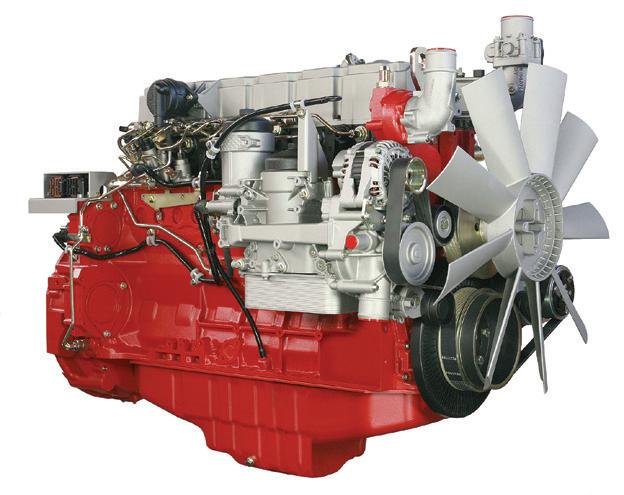

A POWERFUL PARTNERSHIP

Volvo Penta. Robust, fuel efficient industrial diesel engines that keep running even in the toughest conditions. Easy to install, operate and maintain. A powerful partnership you can trust all the way from the drawing board throughout the operational life of your engine. Competitively priced complete power-pack units ready for delivery Australia wide with a local support team on hand 24/7. To find your nearest dealer visit www.volvopenta.com

105-515 KW

Hello all and welcome to the Winter Edition of Pump Industry Magazine for 2023.

As we head into the second half of the year it poses the question of whether we might see a softening in key parts of the economy. A downturn might cause a localised recession in the eastern state capitals, but nationwide mining and agriculture may keep the nation in the black.

In Q1, GDP rose 0.2 per cent marking a 2.3 per cent increase year-over-year in line with expectations with annual growth still expected to be around 1.25 per cent. All eyes will now be on the Q2 GDP results as to where the economy is headed. Unemployment sits at around 3.5 per cent, creating another problem: labour shortages.

remain in place. Not the answer we were hoping for.

So, in essence, a plumber will need to be on hand if you wish to disconnect a domestic pump to take away for repair or simply replace in accordance with the PD Act 2018.

I believe the STC does not want to fragment the PD Act by allowing other practitioners to operate in place of a plumber. It appears they don’t want to introduce grandfather clauses either as a solution.

Clearly the Act relates to plumbing and drainage work that would include anywhere there is a public health risk to the water supply, such as shopping centres, apartments blocks, etc.

Pump Industry Australia Incorporated C/-340, Stuarts Point Road Yarrahapinni NSW 2441 Australia Ph/Fax: (02) 6569 0160 pumpsaustralia@bigpond.com www.pumps.org.au

PIA Executive Council 2023

John Inkster – President Brown Brothers Engineers

James Blannin – Vice President De.mem – Stevco

Kevin Wilson – Treasury/Secretary Executive Officer

Alan Rowan – Councillor Executive Officer – Publications and Training, Life Member

Ken Kugler Executive Officer – Standards, Life Member

Steve Bosnar – Councillor Franklin Electric/Pioneer Pumps

Geoff Harvey – Councillor Irrigation Australia

Joel Neideck – Councillor TDA Pumps

Jamie Oliver – Councillor Grundfos Pumps

Mat Arnett – Councillor Ebara Pumps

Michael Wooley – Councillor Tsurumi Pumps

Billie Tan – Councillor Regent Pumps

Meanwhile the RBA is battling inflation of 6.8 per cent by lifting the cash rate to 4.1 per cent in June, the twelfth rate increase in 13 months, making it the highest it has been in the last decade. The RBA says it believes that inflation has passed its peak but remains too high. On that point I think we can expect more increases before the cycle ends.

When speaking to industry colleagues, I hear of a softening in box product for the retail and domestic markets but it appears that there is still plenty of activity in mining, municipal, infrastructure, energy and industrial markets with most commenting that they still have a reasonable pipeline of work ahead. Fortunately the diversity of our industry provides a degree of immunity to the vagaries of economic highs and lows.

The resources sector shows no sign of slowing, but there are indications that the economy will slow if not this year then maybe in the new year.

In recent editorials I have commented on the continuing dialogue with Queensland Building and Construction Commission (QBCC) and the Services Trade Council (STC) regarding the rules, interpretation and regulations covered by the PD Act 2018. As stated previously, the QBCC petitioned the STC on our behalf to consider allowing pump industry practitioners to lawfully perform work on pumps installed as part of a plumbing or drainage system.

At the time of writing, I was advised that the QBCC received a letter dated 5 June from the STC stating a decision had been made and a report was being prepared to go to the Minister of Energy and Public Works and that PIA will get a formal response in due course.

I did learn that our request, after considerable discussion by the STC, has been denied and that the status quo will

How hard this will be enforced remains to be seen, but PIA is aware of some members being given a written warning for not employing a plumber to disconnect a pump. Once we receive a formal response we can determine the next move, but I think STC will be steadfast in their decision.

On a more positive note, I see book sales of our Pump Technical Handbook and Pipe Friction Handbook have increased 82 per cent in the last 12 months, again confirming both Handbooks remain the industry standard. Our thanks to Alan Rowan for his dedicated work and research in keeping both Handbooks up to date.

Ken Kugler our Standards Officer continues to be busy in reviewing numerous ISO Standards including numerous fire related sprinkler standards. The Building Code of Australia has finally released its latest revision that now formally specifies some pump requirements that our industry has been complying with for some time.

Ken advises that he will be writing an editorial for Pump Industry Magazine as the Standards Committee CE-024 issued for public comment for ISO 5167 seeking direct adoption to become a formal Australian Standard. ISO 5167 is a suite of Flow Measurement Standards and is specified in our Pump Testing Standard AS ISO 9906:2018.

The next PIA activity is planned to be held at Link Pumps in Williamstown July/ August. John Link is a stalwart of the industry with a wealth of knowledge and an interesting pedigree when it comes to pump applications over several decades.

Thank you for your continued support of Pump Industry Australia and all the best in the coming months as we navigate a likely slowdown in the economy.

John Inkster – President

2 pump industry | Winter 2023 | Issue 44 www.pumpindustry.com.au PRESIDENT’S WELCOME

Scan to subscribe to Pump Industry Magazine’s weekly newsletter – delivered to your inbox every Thursday afternoon.

ABN: 36 426 734 954

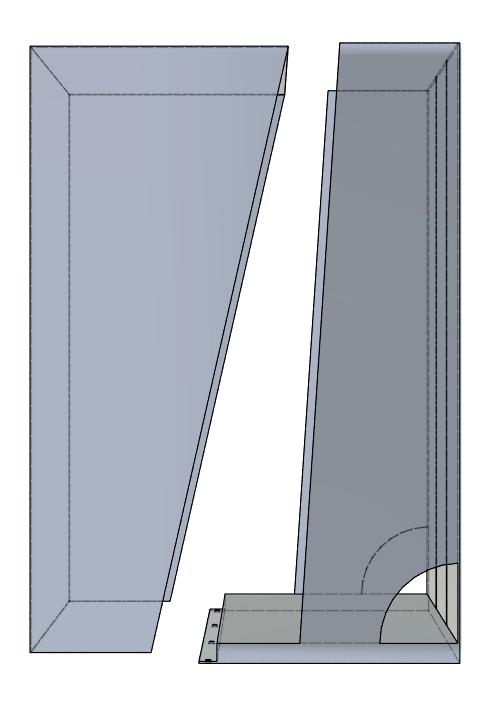

C/- The Commons, 36–38 Gipps St, Collingwood VIC 3066 P: (03) 9988 4950 monkeymedia.com.au info@monkeymedia.com.au pumpindustry.com.au magazine@pumpindustry.com.au

Editor: Katie Livingston

Journalists: Stephanie Nestor, Tess Macallan, Steph Barker, Kody Cook

National Media Executives: Rima Munafo, Brett Thompson, Ryan Sheehan

Design Manager: Alejandro Molano

Senior Designer: Luke Martin

Designers: Danielle Harris, Ozlem Munur

Marketing Manager: Radhika Sud

Marketing Associates: James Holgate, Natalie Ta

Digital Marketing Assistants: Rhys Dawes, Bella Predika

Publisher: Chris Bland

Managing Editor: Laura Harvey

ISSN: 2201-0270

PIA MEMBER

This magazine is published by Monkey Media in cooperation with the Pump Industry Australia Inc. (PIA). The views contained herein are not necessarily the views of either the publisher or the PIA. Neither the publisher nor the PIA takes responsibility for any claims made by advertisers. All communication should be directed to the publisher.

The publisher welcomes contributions to the magazine. All contributions must comply with the publisher’s editorial policy which follows. By providing content to the publisher, you authorise the publisher to reproduce that content either in its original form, or edited, or combined with other content in any of its publications and in any format at the publisher's discretion.

CONTENTS Pumps Industry Magazine acknowledges Aboriginal Traditional Owners of Country throughout Australia and pays respect to their cultures and Elders past, present and emerging. Published by Monkey Media Enterprises NEWS Major contract awarded for Pioneer-Burdekin pumped hydro 6 $116.4M for Paradise Dam ahead of major construction .............................. 8 New Board Chair announced for Hydro Tasmania........................................ 10 Contract awarded for $150M water recycling plant upgrade ...................... 12 New research shows groundwater pumping has shifted Earth’s tilt ........... 14 Electric heat pumps to power hospital’s sustainable expansion 15 Warren Reservoir valve upgrade reveals a piece of local history 16

NEWS New AS ISO fluid flow test standards announced 17 The importance of online asset monitoring 18 Ebara Pumps releases new GSO model process pump 20 This

produced to international environmental management standard ISO14001 by a certified green printing company.

document has been

5 www.pumpindustry.com.au pump industry | Winter 2023 | Issue 44 MINING Carbon capture in the NT 22 Exploring Beetaloo’s fracking frontier ........................ 26 INDUSTRY MARKETING Content marketing 101 for the pump industry 30 IRRIGATION Irrigation overhaul: how pumps helped a dairy farm’s renewable energy transition 34 MANUFACTURING Going electric: the opportunity for heat pumps in industry 42 INSTRUMENTATION AND MONITORING Go with the flow – choosing the right type of flow measurement 46 FOOD Pump the grapes: the careful balance of wine pumps 48 Hot stuff: how heat pumps can help decarbonise the meat processing industry 52 PROJECT Hay Shire’s pumping flood recovery 56 Urban Utilities invests $65M in major pump infrastructure 58 PUMP HANDBOOK Intake design – part 1 60 REGULARS President’s welcome ........................................................2 ASK AN EXPERT Progressive cavity pumps in the mining industry ....... 38 PUMP SCHOOL What are the solutions to pump cavitation? 40 Editorial schedule 64 Advertisers’ index ......................................................... 64

Major contract awarded for PIONEER-BURDEKIN PUMPED HYDRO

The Queensland Government has awarded a major contract on the Pioneer-Burdekin pumped hydro energy storage project to a local family business from the Mackay region.

Twin Hills Engineering and Drilling was announced as the successful tender for the six-month geotechnical shallow drilling program, which will be used to inform the project design and will be a fundamental part of the development of this nation-building project.

Supporting more than 3,000 jobs during the peak of construction, the proposed scheme is expected to provide the world’s biggest pumped hydro energy storage with 5GW of clean, reliable, and affordable power supply and storage to Queenslanders over a 24-hour period.

Pumped Hydro Energy Storage is a proven technology that is a foundational investment in Queensland’s SuperGrid to provide 24/7 clean and reliable power.

The Pioneer-Burdekin project is proposed to generate 5000MW for 24 hours, equivalent to around half of the entire state’s peak usage.

Pumped hydro acts like a giant water battery:

• It uses electricity from the grid or nearby renewables to pump water from a lower reservoir into an upper reservoir when energy prices are low

• When energy is needed, water is released from the upper reservoir into the lower reservoir, generating energy as it passes through a turbine

• Hydroelectricity can be generated almost immediately and at any time, so power can be fed into the grid when it is needed

A Queensland-based joint venture with a strong presence in Mackay, Water2Wire was also announced as the successful proponent for the project’s Front-End Engineering and Design (FEED), as part of the Queensland Energy and Jobs Plan Member for Mackay, Julieanne Gilbert, said this is an exciting major project for the region that will mean business opportunities for local companies and thousands of jobs for

locals – whether it’s electricians and technicians, suppliers of building materials, or drillers and engineers like these two contracts.

“Pumped hydro energy storage and clean energy will provide another lane on Mackay’s industrial superhighway with thousands of locals who stand to benefit from it,” Ms Gilbert said.

Queensland Minister for Energy, Renewables and Hydrogen, Mick de Brenni, said the Pioneer-Burdekin Pumped Hydro Project is the cornerstone of the Queensland Energy and Jobs Plan, and will be the largest pumped hydro scheme in the world.

“This mega pumped hydro project will act like a giant battery, and when connected to our Queensland SuperGrid, will underpin the reliability of our publicly owned grid by storing the energy generated by our renewable energy zones,” Mr de Brenni said

“The project is poised to offer hundreds of supply chain opportunities, and with application of the Palaszczuk Governments’ signature Buy Queensland Procurement Policy, local businesses like Twin Hills and Water2Wire will be the preferred project partners.

“It’s regions like Mackay that are at the centre of Queensland’s renewable energy transformation – which will unleash new industrial jobs in hydrogen, renewables, manufacturing, and critical minerals.”

Queensland Hydro CEO, Kieran Cusack, said with Water2Wire’s recent work on high-profile projects like Borumba and Kidston, and their collective expertise in delivering pumped hydro projects around the world, they will be a great asset to this project.

“We are looking forward to working with them on this worldclass project,” Mr Cusack said.

“We’re also delighted to be working with a local family business employing local workers that has been awarded the first geotech drilling contract for Queensland Hydro’s PioneerBurdekin project.”

6 pump industry | Winter 2023 | Issue 44 www.pumpindustry.com.au

NEWS

Dam

$116.4 million has been allocated to the pre-construction activities of the Paradise Dam Improvement Project, which includes work to replace the dam’s irrigation valves.

These major dam improvement works will deliver long-term water security for the Bundaberg region by restoring the dam’s capacity and will improve the dam’s resilience against major flooding and extreme weather events.

This rebuild will support around 250 jobs during construction and will, once back to full operation, deliver significant flow-on benefits for local businesses and Bundaberg’s regional economy.

Federal Minister for Water, Tanya Plibersek, said water is one of our country’s most precious resources.

“The Albanese Labor Government knows how important rebuilding the Paradise Dam is to provide water security and drive economic growth in Queensland’s food bowl of Bundaberg,” Ms Plibersek said.

“That’s why we are investing $600 million towards the Paradise Dam Improvement Project.

“I look forward to continuing working in partnership with the Queensland Government to build a secure water future for all Queenslanders.”

Sunwater is progressing procurement, design development and approval activities to prepare for site mobilisation ahead of major construction commencing in late 2024.

Outlet works to replace the dam’s irrigation valves are expected to be completed by August 2023.

Queensland Premier, Annastacia Palaszczuk, said this is an investment in long-term water security and local jobs for regional Queensland.

“Rebuilding Paradise Dam will provide future certainty for local growers – as well as ensuring a safe and secure water supply across the region for generations,” Ms Palaszczuk said.

“This is one of the largest construction projects in the history of the Bundaberg region and it will ensure water security for the farmers, industry, and the broader community is safeguarded for decades to come.”

Treasurer and Minister for Trade and Investment, Cameron Dick, said this complex infrastructure project delivered in a live operational environment is a major and vital undertaking.

“When completed the Paradise Dam Improvement Project will return the dam to its full 300,000ML capacity and will provide a safe, reliable and secure water

supply to local agricultural, industrial and urban communities,” Mr Dick said.

“The strength of this year’s Budget gives us the ability to make the investments necessary to ensure Queensland’s continued prosperity.”

Minister for Regional Development and Manufacturing and Minister for Water, Glenn Butcher, said returning Paradise Dam to its original capacity and getting jobs on the ground for the region is a priority for the Queensland Government.

“This is why it is an important item in the Big Build, ensuring water security for the region.

“A rebuilt Paradise Dam is a vote of confidence for the farmers and industry in the Bundaberg and Burnett region – and it will undeniably unlock new economic opportunity,” Mr Butcher said.

Member for Bundaberg Tom Smith, said this is a critical step on the path to fixing Paradise Dam and one that will benefit and support local growers.

“We know that a reliable water supply is a key ingredient for continued growth and prosperity for our region – which is one of the most important food bowls in the country.

“I’m proud that Bundaberg workers will play an important role in delivering this project.”

8 NEWS

52 Woodlands Drive, Braeside Victoria 3195 PO Box 876, Braeside Victoria 3195 Tel: (03) 9588 6900 Fax: (03) 9588 6999 Email: info@lkdiesel.com.au Web: www.lkdiesel.com.au • Petrol engines up to 13 HP • Diesel engines up to 83 HP • Generating sets up to 30 KVA We provide diesel engine solutions to EMPOWER your business WATER PUMPS ALSO AVAILABLE

for

pump industry | Winter 2023 | Issue 44 www.pumpindustry.com.au

$116.4M

Paradise

AHEAD OF MAJOR CONSTRUCTION

Climate

population growth, and water scarcity are creating new challenges, and desalination is becoming an important alternative to traditional freshwater resources.

Are you ready?

MADE IN ITALY SAER ELETTROPOMPE S.p.A. � Via Circonvallazione, 22 42016 Guastalla (RE) - Italy � +39 0522 830941 � info@saer.it � saerelettropompe.com � SAER.Elettropompe � saerelettropompe � Saer Elettropompe DUPLEX SUPER DUPLEX

change,

face these new scenarios with a strong

fast answer: a full range of high efficiency end suction, close coupled, high pressure, split casing

submersible pumps

motors in DUPLEX

SUPER DUPLEX

of

best delivery time

the market, thanks to the italian production.

the water management in civil, industrial, marine

agricultural water services

rest assured with SAER quality.

Use our SAER pump selector to find out your solution

SAER is ready to

and

and

and

and

, available with one

the

on

Let’s improve

and

and

#saerready

New Board Chair announced FOR HYDRO TASMANIA

Hydro Tasmania has appointed Richard Bolt as its new Chair of the Board.

Mr Bolt has worked in both public and private sectors, leading major innovation and reform across industries including energy, resources, agriculture, education, economic development and transport. He was a leading architect of the national energy market’s governance systems.

Hydro Tasmania Chief Executive Officer, Ian Brooksbank, said senior executives look forward to working

closely with Mr Bolt over a period of growth for Hydro Tasmania.

“We have a bold vision for the role of hydro energy in powering the Tasmanian economy and in leading the national transition to renewable energy,” Mr Brooksbank said.

“Mr Bolt’s incredible knowledge and track record in the energy sector will be invaluable in charting that course.”

Mr Brooksbank paid tribute to outgoing Chair, Grant Every-Burns, who has been on the Hydro Tasmania Board since 2012 and in the role of Chair since 2014.

“An electrical engineer by trade, Mr Every-Burns knows every corner of the energy industry,” Mr Brooksbank said.

“He steered the company through an enormous shift in the energy sector and his passion for Tasmania as the battery of the nation has put the state in prime position to capitalise on that transition.”

Mr Brooksbank also acknowledged Mr Every-Burns’ calm and steady leadership throughout 2015 and 2016, when the Basslink outage combined with drought posed significant challenges for energy supply in Tasmania.

10 pump industry | Winter 2023 | Issue 44 www.pumpindustry.com.au NEWS DELIVERING PUMPING SOLUTIONS 05/23 Ph: 1300 4 BBENG www.brownbros.com.au The most comprehensive range of pumps and innovative pumping solutions. Contact us to see how we can deliver your pumping solution.

The missing link in your B2B Marketing Strategy

While traditional trade publications have quality audiences and high levels of trust, they can lack the full range of services to guarantee a return on your investment. And while traditional marketing agencies offer the latest marketing techniques, they don’t have the audience or the industry understanding the B2B sector needs.

Monkey Media is the missing link that brings together a trusted brand and powerful audience, with a complete agency offering.

TO FIND OUT MORE SCAN THE QR CODE NOW

Contract awarded for $150M water recycling plant upgrade

Sydney Water has awarded a contract to deliver $150 million of upgrades to the Richmond Water Recycling Plant (WRP) to improve its wastewater network, which includes the construction of a new pump station.

BMD Constructions will deliver the project, which is expected to double the plant’s capacity. The contract includes upgrades to the 7km main that transfers flows from North Richmond to Richmond, construction of a new wastewater pumping station, and upgrades to the three existing wastewater facilities in the area.

Sydney Water Senior Project Manager, Greg Cable, said the planned works will play a major part in ensuring a more sustainable future, meeting the needs of Richmond’s growing population.

the completed upgrades will help future-proof the region’s rapidly growing population over the next three decades,” Mr Cable said.

“This project will also contribute significantly to circular economy benefits by expanding water recycling capacity at the site and the production of biosolid matter for reuse.”

“Growth is set to increase by 70 per cent, and we estimate

BMD Constructions General Manager, John Vida, said the contract is an exciting opportunity to work with Sydney Water to deliver wastewater upgrades that will benefit the area for decades to come.

“We’re looking forward to maximising our collaborative partnership with Sydney Water and together bolstering outcomes to benefit the people of Sydney,” Mr Vida said.

Construction of the Richmond WRP will commence in September 2023 and is scheduled to be completed by 2026.

Innovative solutions to solve your environmental pollution problems

MAIRS Technology uses traditional technologies and innovative engineered solutions to service a range of industries and customers to help manage their environmental needs and systems, whilst meeting environmental and health safe regulations, and health of nearby communities.

Our capabilities:

• Project Management Services

• Engineering Service Support

• Equipment Spares Supply

• Construction services and supervision

• Sub-contract management

• Commissioning and training

• Asset inspections and reports

• Asset maintenance and management planning

• Optimisation and system improvements

03 9028 8080 sales@mairstech.com www.mairstech.com

NEWS

RAINWATER RE-USE AND WATER BOOSTING SYSTEMS

Built to suit your needs

Custom made rainwater re-use, and water boosting system. Maxijet Australia is committed to manufacturing the best pump systems for water conservation.

Available in many configurations to suit your flow requirements or any project specifications.

All manufactured locally in our Melbourne factory allowing for quicker lead times to meet required delivery dates.

Additional Options

Protective Cover Design

• Full Cover Removal

• Cover is Optional

• Made with ALPOLIC™/fr

• Fire Retardant

• 2 Year Warranty

• Representational Image Only

Address: 32 McGregors Drive, Keilor Park Vic 3042 Email: sales@maxijet.com.au Web: www.maxijet.com.au Phone: 03 9336 1000 Fax: 03 9336 1099

Specifications

Built

Trusted Quality

Domestic,

Agricultural Applications

Trusted Quality and Service Built to Suit

Made Locally,

In-house

Suitable for Commercial,

and

VSD Controller Submersible Option Anti Tamper/ Weather Cover Suction Strainer

NEW RESEARCH SHOWS groundwater pumping has shifted Earth’s tilt

Humans have shifted such a large mass of water that the Earth tilted nearly 80cm east between 1993 and 2010 according to a new study published in Geophysical Research Letters, AGU’s journal for short-format research.

The movement, caused by groundwater pumping, has implications spanning the Earth and space sciences.

Based on climate models, scientists previously estimated humans pumped 2,150Gt of groundwater – equivalent to more than 6mm of sea level rise – from 1993 to 2010. However, validating this estimate is difficult.

One approach lies with the Earth’s rotational pole, which is the point around which the planet rotates. It moves during a process called polar motion, which is when the position of the Earth’s rotational pole varies relative to the crust. The distribution of water on the planet affects how mass is distributed. Like adding a tiny bit of weight to a spinning top, the Earth spins a little differently as water is moved around.

Seoul National University geophysicist Ki-Weon Seo, who led the study, said, “Earth’s rotational pole actually changes a lot. Our study shows that among climate-related causes, the redistribution of groundwater actually has the largest impact on the drift of the rotational pole.”

Water’s ability to change the Earth’s rotation was discovered in 2016, and until now, the specific contribution of groundwater to these rotational changes was unexplored. In the new study, researchers modelled the observed changes in the drift of Earth’s rotational pole and the movement of water – first, with only ice sheets and glaciers considered, and then adding in different scenarios of groundwater redistribution.

The model only matched the observed polar drift once the researchers included 2,150Gtons of groundwater redistribution. Without it, the model was off by 78.5cm, or 4.3cm of drift per year.

Mr Seo said, “I’m very glad to find the unexplained cause of the rotation pole drift. On the other hand, as a resident of Earth and a father, I’m concerned and surprised to see that pumping groundwater is another source of sea-level rise.”

Jet Propulsion Laboratory Research Scientist

Surendra Adhikari said, “This is a nice contribution and an important documentation for sure. They’ve quantified the role of groundwater pumping on polar motion, and it’s pretty significant.”

The location of the groundwater matters so researchers can discover how much it could change polar drift; redistributing water from the midlatitudes has a larger impact on the rotational pole. During the study period, the most water was redistributed in western North America and northwestern India, both at midlatitudes.

Countries’ attempts to slow groundwater depletion rates, especially in those sensitive regions, could theoretically alter the change in drift, but only if such conservation approaches are sustained for decades, Mr Seo explained.

The rotational pole normally changes by several metres within about a year, so changes due to groundwater pumping don’t run the risk of shifting seasons. But on geologic time scales, polar drift can have an impact on climate, Mr Adhikari said.

The next step for this research could be looking to the past.

“Observing changes in Earth’s rotational pole is useful for understanding continent-scale water storage variations. Polar motion data are available from as early as the late 19th century. We can potentially use that data to understand continental water storage variations during the past 100 years. Were there any hydrological regime changes resulting from the warming climate? Polar motion could hold the answer,” Mr Seo said.

14 pump industry | Winter 2023 | Issue 44 www.pumpindustry.com.au

NEWS

Electric heat pumps to power hospital’s sustainable expansion

The first of 21 large heat pumps has been delivered to the Canberra Hospital’s Critical Services Building site, as part of the facility’s new expansion.

The heat pumps are one of the fundamental features of the new all-electrical building, replacing traditional gas boilers as the building’s source of hot water.

The new Critical Services Building showcased its environmentally sustainable credentials for World Environment Day, with the building targeting a five-star Green Star rating.

ACT State Minister for Health, Rachel Stephen-Smith, said the Canberra Hospital expansion project is leading the way nationally in environmentally sustainable health infrastructure design.

“The Critical Services Building will be Australia’s first allelectric major hospital building and when it opens in 2024 it will mitigate the release of an estimated 1,886t of carbon emissions each year, the equivalent of removing 760 cars from Canberra’s roads.

“We are building on that momentum by targeting a five-star Green Star rating for the new Critical Services Building. This incorporates the latest environmentally sustainable design features such as a high performing façade and new technology that automatically monitors and controls heating, ventilation and cooling,” Ms Stephen-Smith said.

Key features of sustainable design in the Critical Services Building to target an enhanced Green Star rating include:

A high-performing façade glazing of thermally-broken double glazed units, which minimises the cooling required in summer and heating required in winter, and other energyefficient façade elements

Energy efficient and intelligent HVAC systems

• A holistic Building Management and Control system, which monitors and controls all systems in the building

• A high indoor environment quality

• Landscaping and irrigation that uses recycled water and open courtyards and green spaces with plants suitable to the local environment

• Environmentally conscious decision-making, which has been at the forefront of the Critical Services Building throughout its construction process

• During demolition of the previous buildings that stood on site, with 96 per cent of the materials salvaged and repurposed for other projects

Concrete for the new building includes locally sourced low carbon concrete, a 40 per cent reduction in carbon content when compared with standard concrete mixes, and has eliminated more than 2,000t of embodied CO² on the project to date – the equivalent of carbon removed by more than 30,000 tree seedlings grown over ten years.

The use of electric cranes has also helped to eliminate pollution and noise during building construction.

Leading fluid path solutions provider expands Australian presence with new Perth office

Watson-Marlow Fluid Technology Solutions (WMFTS) is celebrating the opening of its new Perth office, the company’s second in Australia.

Previously operating solely out of its Sydney office, WMFTS has been a leading provider of fluid path solutions for the past 13 years. This new Perth office brings the Watson-Marlow team closer to its Western Australia-based customers so that it can further enhance its quality of service.

This new Perth base is located in Belmont, and is focused on directly supporting, selling, servicing and repairing WMFTS solutions.

Elie Elazar, Country Manager at Watson-Marlow Australia, said, “We’re delighted to strengthen our presence in the market with the opening of our second office in Perth. We put the customer at the heart of everything we do and with our Perth site, we are making sure that we can truly partner with them on their fluid path challenges.”

15 www.pumpindustry.com.au pump industry | Winter 2023 | Issue 44

For further information please contact us: Watson-Marlow Fluid Technology Solutions +61 8 6156 7555 / +61 2 8787 1400 info.au@wmfts.com NEWS

Warren Reservoir valve upgrade reveals a piece of local history

SA Water’s recent $8 million upgrade of the intake and scour valves at Warren Reservoir’s dam has revealed a piece of local history –the Second South Para Bridge emerged from the water’s depths for the first time since the reservoir was initially filled more than 100 years ago.

Built in 1890, the 20-metre-long bridge provided a shorter crossing over the South Para River within the original family property of the reservoir’s namesake – John Warren.

As part of the upgrade, Warren Reservoir reached zero per cent of its capacity following a five-week drawdown of the water level, to enable safe access for crews to the base of the dam wall.

SA Water’s Senior Manager of Capital Delivery, Peter Seltsikas, said the generally intact 133-year-old bridge was a rare and unexpected sight arising from the valve upgrade.

“The discovery only came to light when the local Williamstown and Districts Historical Society reached out to inform us that one of their members recalled a bridge that had become slightly visible during the 1960s drought,” Mr Seltsikas said.

“After the tip off, we conducted sonar testing while the reservoir was at 16 per cent capacity and detected a structure at the bottom of the water resembling a bridge.

“We have since learned it was originally built on the family property of John Warren – a former councillor and member of the Legislative Council, who the reservoir is named after – with the entire structure fully resurfacing for the first time since it was flooded by the reservoir’s filling.”

Mr Seltsikas said the deck, pylons and substructure appear to be mainly intact, and it’s likely the white sections of the parapet have washed away over time.

“Despite it no longer carrying a horse and cart over the old river, it’s helped provide habitat and shelter for the reservoir’s fish as we’ve caught a large number in and around the bridge during our relocation activities,” Mr Seltsikas said.

As part of the water level’s gradual lowering, around 4.5t of the reservoir’s native fish and turtles have been relocated to the nearby South Para Reservoir, including species like Bony

Mr Seltsikas said with the reservoir now empty, crews were ramping up to start major construction work as part of replacing the dam’s valves.

“Upgrading the intake and scour valves ensures water can be safely transferred from the reservoir and supplied to our customers into the future,” Mr Seltsikas said.

“With the last of the reservoir’s water released early May 2023, crews are set to begin installing a causeway and swing stage scaffolding to safely access the dam wall to decommission the existing valves.

“The valves are connected to a power house near the top of the dam wall and enable water to be transferred from the reservoir to customers for irrigation.

“Two new butterfly valves – which utilise a rotating disc to regulate flow –and a sluice gate scour will be lifted into place with a 220t crane and connected to the existing pipework, and once completed, the valves can be operated automatically from access platforms installed on the dam crest.”

16 pump industry | Winter 2023 | Issue 44 www.pumpindustry.com.au NEWS

Bream, Murray Cod, Golden Perch and Silver Perch.

NEW AS ISO FLUID FLOW test standards announced

The Standards Australia Committee CE-24 recently issued a suite of draft AS ISO Flow Measurement Standards for public comment.

ISO standard 5167 has seven parts and covers the measurement of fluid flow by means of pressure differential devices inserted in circulation crosssection conduits running full. The various pressure differential devices covered include nozzles and venturi nozzles, orifice plates, venturi tubes, cone meters, and wedge meters.

These AS ISO 5167 standards are expected to be published within the next two months and will be direct adoptions of the current ISO standards. For the record, in the past an Australian Standard that was a direct adoption of an ISO standard was known by a separate AS number, the ISO number was secondary. ISO 5167 is included in the bibliography of the pump test standard AS ISO9906:2018 and the fire pump standard AS2941-2013.

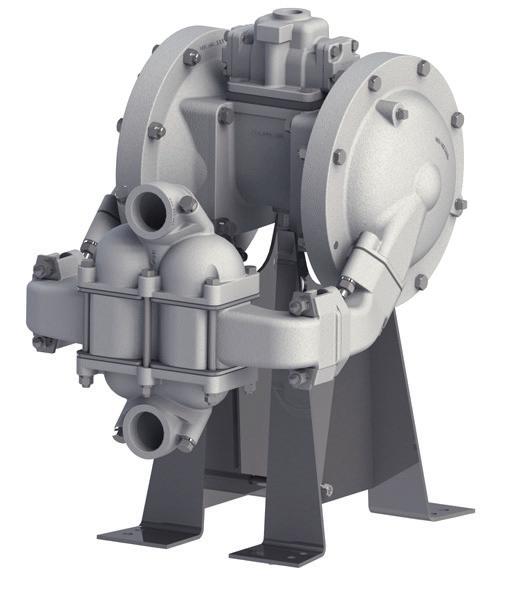

SANDPIPER EVOLUTION and SIGNATURE series

Engineered to deliver industry leading durability and performance, for even the most severe and demanding mining environments.

Durable and portable pumps suitable for: - Dewatering

- Fuels and lubricants

- Refining, smelting and milling process

- Water treatment

We know the importance of choosing the right equipment to match your process. With our extensive range of pumps, first class customer service and ongoing comprehensive support, Kelair Pumps are second to none when it comes to your pumping requirements.

17 www.pumpindustry.com.au pump industry | Winter 2023 | Issue 44 PIA MEMBER NEWS WHEN PUMP KNOWLEDGE MATTERS Rely on Kelair Find out more today 1300 789 466 www.kelairpumps.com.au Heavy Duty Flap Valve Pumps Heavy Duty Ball Valve Pumps Standard Duty Ball Valve Pumps The Beast Heavy Duty, Clog Resistant Flap Valve Pumps

05/23

THE IMPORTANCE OF ONLINE ASSET MONITORING

Unplanned production downtime is one of the key reasons for lost productivity and profitability in a sector. Corrective maintenance events can be avoided by continually monitoring machine parts and equipment online.

With the help of hardware for data collecting, gateways for transmission to the cloud, software for data visualisation and sophisticated analysis, and operational and maintenance staff, the WEG Motion Fleet Management solution is a high-level tool for managing and monitoring industrial fleets. With WEG Motion Fleet Management, a well-planned predictive maintenance methodology can be implemented while keeping an eye on the asset's operational state.

Online asset condition monitoring has a big impact on how well operational and maintenance resources are used, including spare parts management, increased asset availability, and the reduction of both direct and indirect costs.

Since a sudden breakdown typically results in stress and deterioration of the equipment's mechanical and electrical components, methods of this kind also help to extend asset lifetime.

Smart condition monitoring to your fleet

WEG Motion Fleet Management is designed to be the best way to keep track of and improve the availability of the industrial fleet. It was created to bring more practicality and agility to the operation, maintenance, and management of industrial facilities. Asset monitoring is possible at any time and from any location thanks to cloud computing technologies.

The operating status of low and medium voltage motors and drives (inverters and soft-starters), gearboxes, gearmotors, compressors, and other assets used in any industry or installation can be determined with the help of the WEG Motion Fleet Management. Valuable insights are produced by routine data gathering and sophisticated data processing, both at the edge and in the cloud.

By keeping an eye on how the fleet is operating, predictive maintenance plans can be created (conditionbased maintenance).

With this strategy, fewer unplanned stops occur, repair actions are optimised, and the operation and maintenance team's decision-making process is sped up. The drive fleet will eventually have greater availability and lower total cost of ownership (TCO).

Advantages and benefits of the WEG Motion Fleet Management Solution:

• Ability to monitor several assets and plants in a single environment

• Ecosystem in constant development, both hardware and software

• Fleet management view with reports and indicators

• Ready-to-use solution, just register the WEG Scans in the application and use it

• Customised layouts for navigation at various levels (geolocation, site, plant, device)

• Definition of favourite assets for easy tracking of their status

• Daily notifications of assets in alert and/or critical state (via email)

• Customisation of tolerances to generate alerts and notifications

• Enables maintenance management based on the operational condition of the assets

• Dashboards with indicators, graphics, and history of measured data

• Screens for user and subscription management

• Flexible solution available to service providers

• Operational cost reduction (TCO, total cost of ownership)

• Multi-language application

18 pump industry | Winter 2023 | Issue 44 www.pumpindustry.com.au

PIA MEMBER NEWS | SPONSORED EDITORIAL

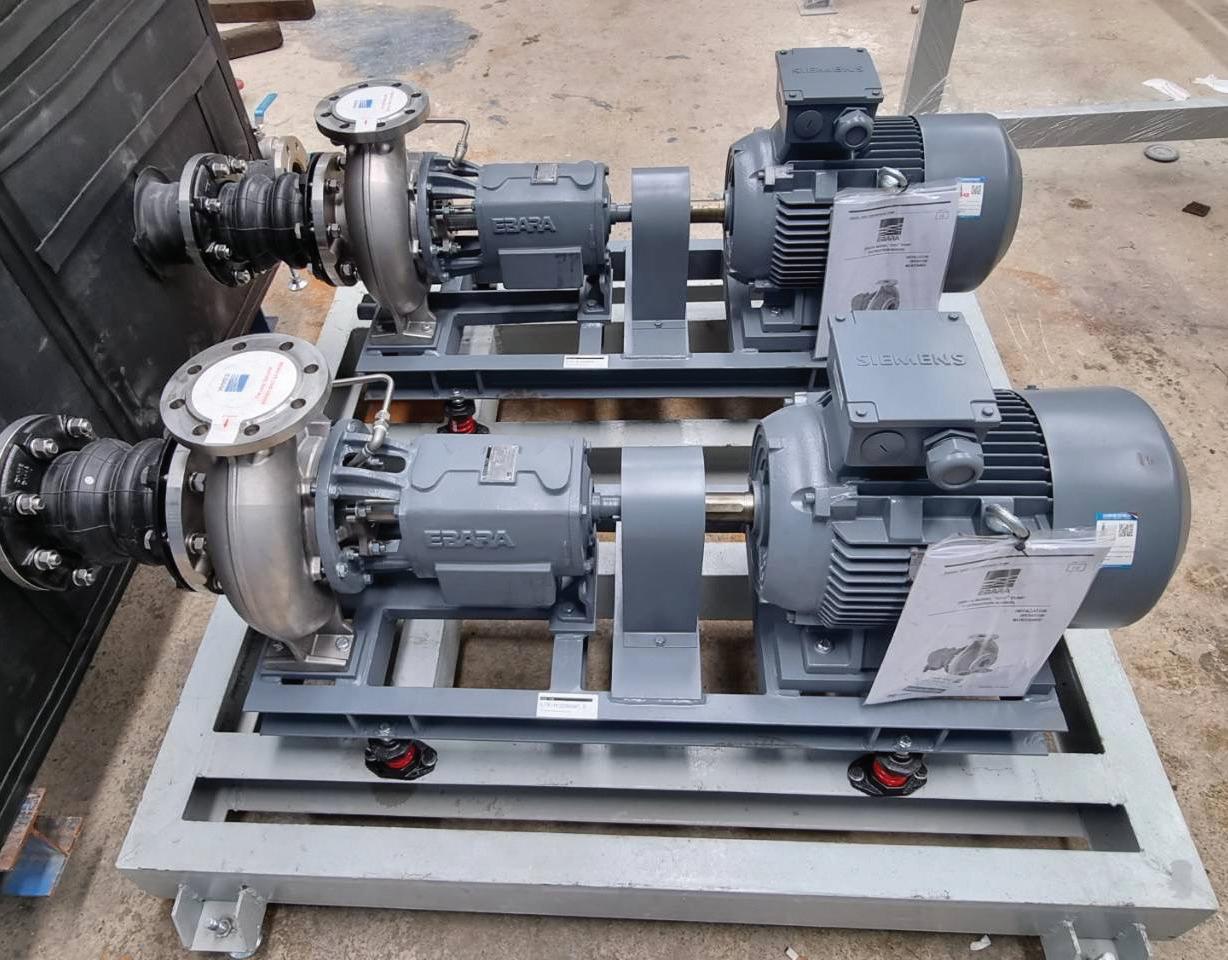

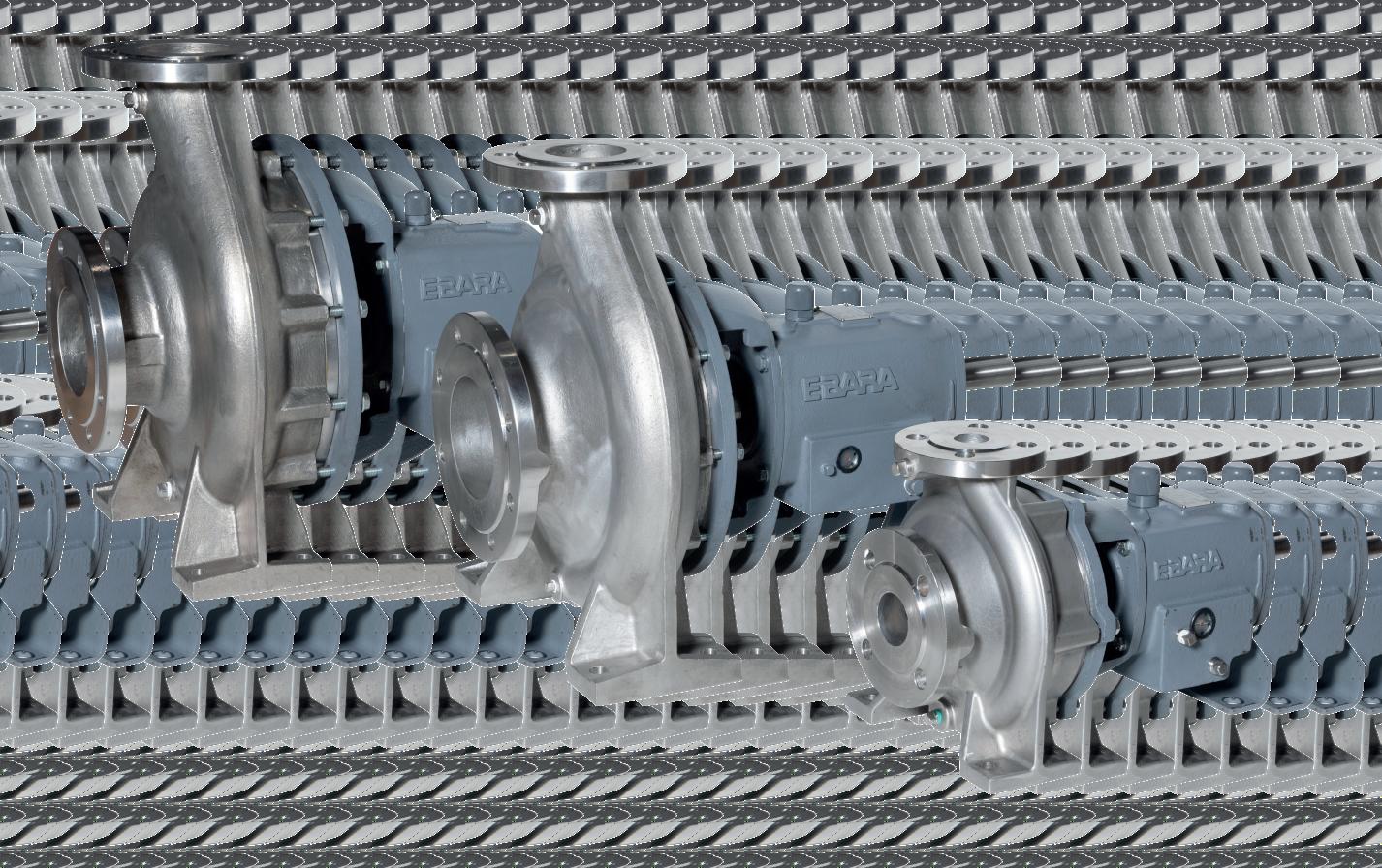

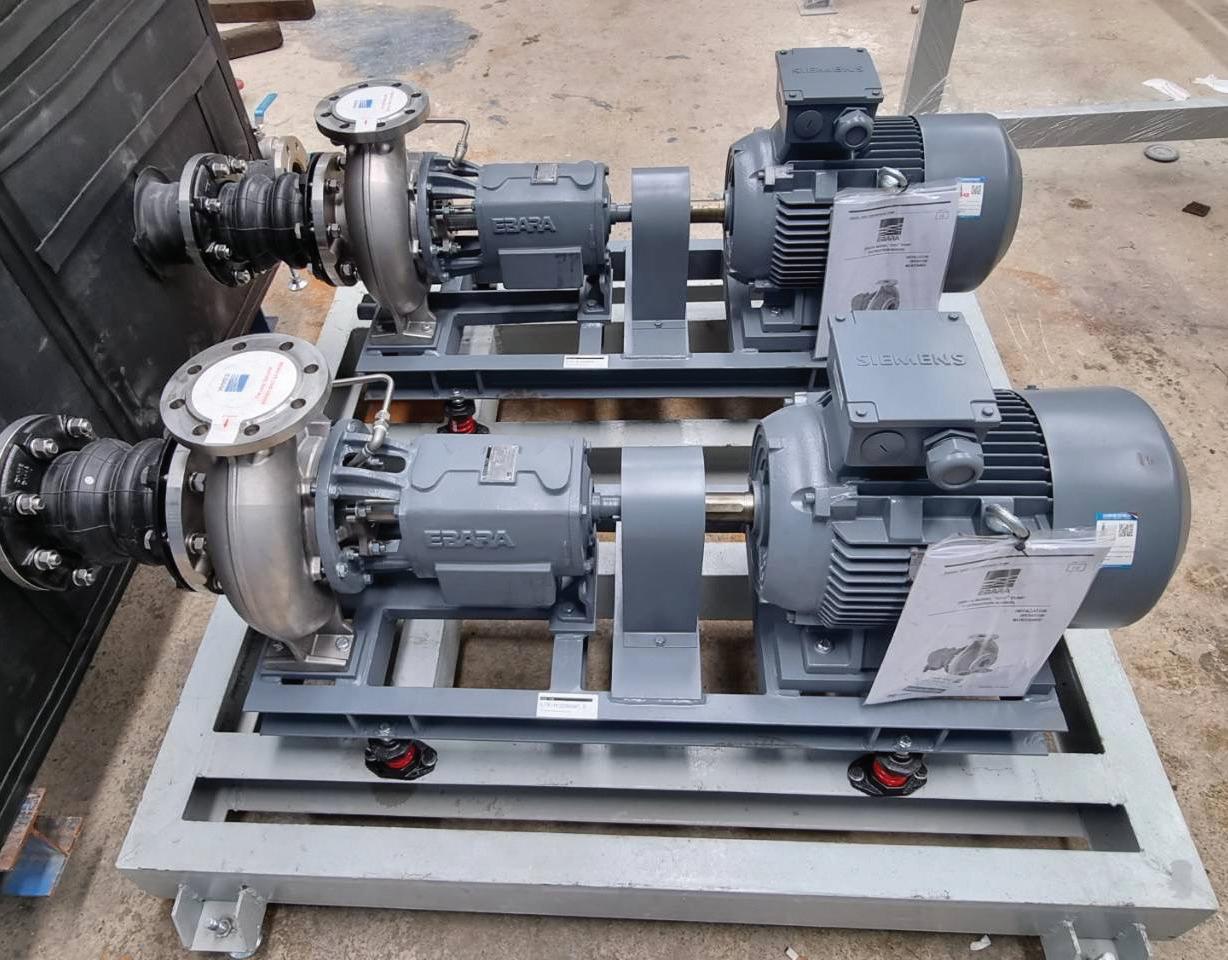

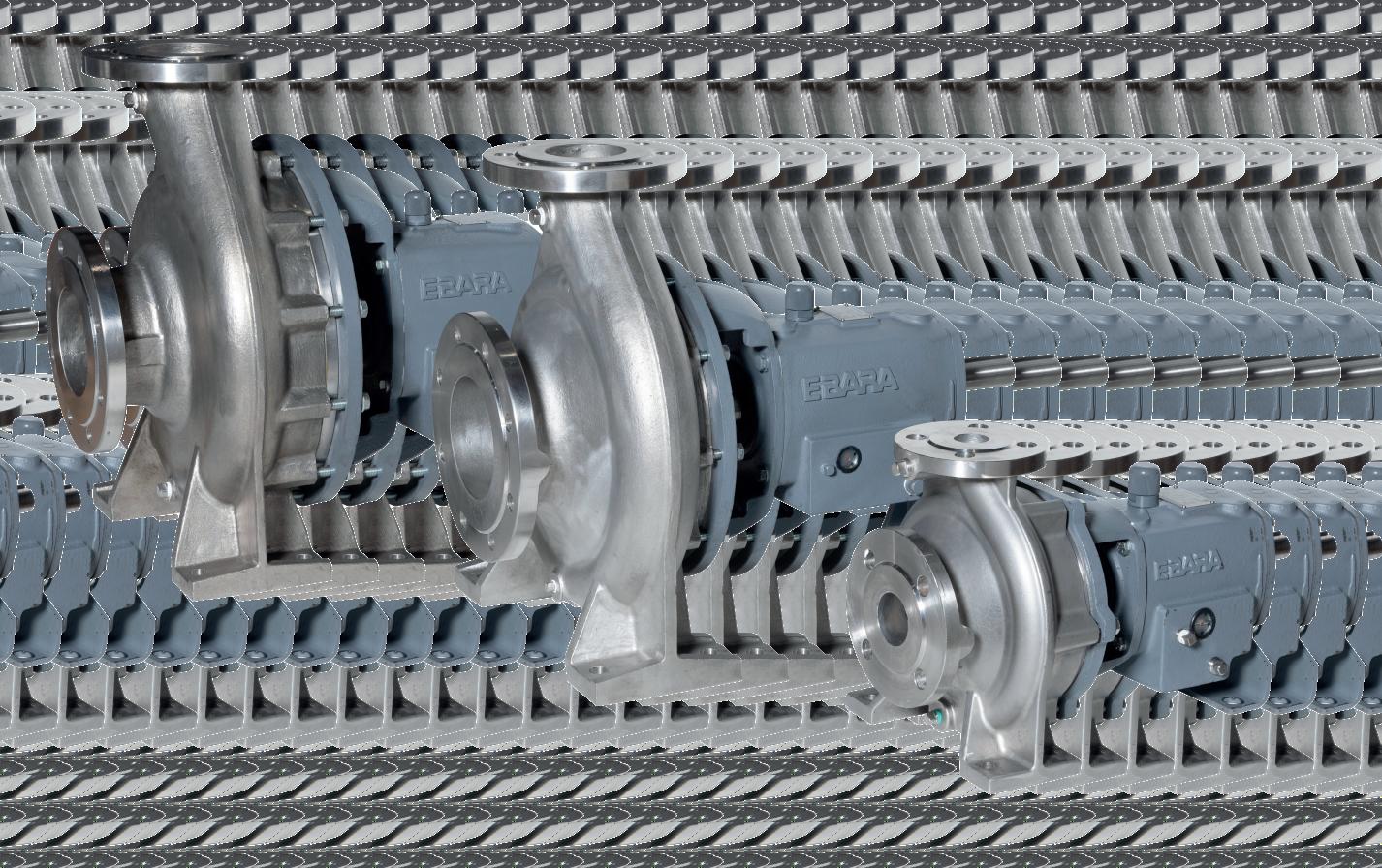

EBARA PUMPS RELEASES NEW GSO MODEL PROCESS PUMP

Ebara Pumps Australia has recently introduced its new range of ISO 2858/5199 end suction process pumps to the Australian market. This new design allows for superior mechanical seal operation and extended life and has a range of material and customisation options to suit specific applications.

The GSO range of semi-open impeller process pumps is available in 304, 316, 316L and duplex stainless steel wetted materials, and has been designed by Ebara (Japan) engineers using the latest computational fluid dynamics (CFD) software.

One of the benefits of this design is that it can produce a low seal chamber pressure thus enabling superior mechanical seal operation and extended life. Also, the unique reverse open type impeller minimises axial thrust but also creates higher efficiencies for a semi open impeller type design.

The Ebara GSO model is a true ISO2858/ISO5199 end suction pump and is manufactured at one of Ebara’s many owned and operated factories located throughout the world, which all operate under the strict Ebara Japanese QA standards and management policies.

Other available options and features of the Ebara GSO include:

• 304,316,316L, duplex stainless steel wetted parts

• Reverse open impeller design as standard

• Grease or oil bath bearings

• Various single and double mechanical seal combinations

• Various mechanical seal piping plans

• PN 16 or ANSI flange drilling

• Sizes up to 200mm (discharge) and 500mm impeller (nominal)

The Ebara GSO is a true global pump and is sold throughout the world via the Ebara network of sales offices. Notable orders include for a water treatment plant in the middle east and various industrial applications in South East Asia.

About Ebara Corporation

Ebara Corporation was founded in Japan in 1912 as a manufacturer of industrial pumps. Today, as a group it consists of more than 100 companies in six continents, with a workforce of more than 19,000 team members and with company-owned and Japanesemanaged factories that cover ten countries and four continents.

The huge scale of production and distribution is matched by a constant commitment to research, development and design of new products and the modern technologies for the manufacturing of them. Ebara products have gained a worldwide reputation for their technology and quality.

Ebara Corporation has developed businesses in the fields of fans and blowers, cooling towers, chillers, environmental plants and the precision machinery industry for computer chips.

20 pump industry | Winter 2023 | Issue 44 www.pumpindustry.com.au

PIA MEMBER NEWS | SPONSORED EDITORIAL

New hydraulic design - World leading performance

Combining over 100 years of experience with the latest computer aided design, EBARA has developed the new GSO series of pumps that offer world leading performance and efficiencies.

ISO2858/ISO5199 centrifugal process pumps

Pump dimensions to ISO2858

Mechanical design to ISO5199

Seal chamber to ISO3069

High efficiencies

Unique reverse open impeller design

Heavy duty shaft & bearing housing

Available in 304, 316, 316L & Duplex stainless steel

37 pump sizes from 50-32-125 to 250-200-500

Unique reverse open impeller design

Low axial thrust

Low seal chamber pressure

High efficiency

Less wear than with front open type

Able to handle light liquid slurries

Unique shaped rear shrouds developed by Ebara utilising Computational Fluid Dynamics.

21 www.pumpindustry.com.au pump industry | Winter 2023 | Issue 44 SPONSORED EDITORIAL | SECTION HEADING

going beyond expectations

Looking ahead,

Available now

www.ebara.com.au ACN 090 963 572 ABN 81 090 963 572 sales@ebara.com.au EBARA PUMPS AUSTRALIA PTY. LTD 7 Holloway Drive Bayswater, Vic. 3153 Ph: 03 9761 3033 2900 rpm 100 20 40 60 80 200 400 600 1000 150 8 10 15 20 30 40 60 80 100 Total Head (m) Capacity (m³/h) 1450 rpm 5 10 15 20 40 60 80 100 2 20 40 80 200 400 600 1000 300 100 60 10 Total Head (m) Capacity (m³/h)

22 pump industry | Winter 2023 | Issue 44 www.pumpindustry.com.au MINING

CARBON CAPTURE IN THE NT

The Northern Territory Government is working to develop a carbon capture, utilisation and storage (CCUS) hub at Middle Arm. Here we discuss the project, how CCUS works and what pumps are used in the process.

As one of the world’s largest carbon emitters per capita, Australia faces the challenge of reducing greenhouse gas emissions while still relying on fossil fuels for its energy needs.

Carbon capture and storage (CCS) is an emissions reduction technology that could have the potential to help mitigate climate change by preventing greenhouse gases from contributing to global warming.

CCS is the process of capturing carbon dioxide (CO2) emissions and storing it deep underground to prevent its release into the atmosphere. Utilisation involves turning that carbon, which would otherwise be waste, into feedstock for another industry or purpose.

Pump technology plays a vital role throughout the CCUS process, and is utilised to facilitate the movement, compression and injection of CO2 during CCS activities.

As CCUS projects continue to develop, the pump industry will play a crucial role in ensuring the safe and efficient operation of CCUS systems.

Middle Arm Sustainable Development Precinct

The proposed CCUS hub at the Middle Arm Sustainable Development Precinct will be one of the largest facilities of its kind in the world.

Once carbon is captured and transported to the hub, it will either be stored or used. Storage at the precinct will entail carbon being sent via a pipeline to geological storage outside of Darwin.

There will also be opportunity for industries to utilise carbon captured at Middle Arm to produce other valuable products.

The Northern Territory Government is working in partnership with the CSIRO, industry and engineering companies to develop a business case to map a pathway for establishing CCUS at Middle Arm.

The State Government said the hub is intended to enable existing liquefied natural gas (LNG) production to expand while creating a lower carbon footprint, as well as establish new lowemission hydrocarbon and hydrogen based industries.

23 www.pumpindustry.com.au pump industry | Winter 2023 | Issue 44

MINING

Northern Territory Chief Minister, Natasha Fyles, said, “The Territory is rapidly emerging as a key player when it comes to the global supply chains, and new technologies needed for energy transition.

“We have always said the core component of the Middle Arm development is sustainability and will include renewable energy. We are creating new jobs for Territorians in existing and emerging sectors, including low-emissions energy, advanced manufacturing, and low-emissions minerals processing.

“The creation of a carbon capture and storage industry in the Territory will allow us to develop more projects as we work towards clean, green energy.”

With CCS gaining momentum, there is a greater need for reliable, energy-efficient pump technologies that can handle the unique challenges of CO2 transportation and injection.

Pumps and CCS

Due to the similarities between fossil fuel extraction and CCS, pumps used to inject natural gas liquids (NGL) into production fields (centrifugal pumps) and inject acid gas liquid back into the fields (high pressure pumps) can be applied to CCS activities.

Multistage pumps and hydraulic power recovery turbines can also be used in CCS processes at refineries, and petrochemical and chemical manufacturing plants.

CCS also encompasses a range of other pump-related equipment such as boilers, compressors, blowers and turbines.

In the capture phase, CO2 is separated and captured in a gas or exhaust stream. This can be achieved through precombustion, post-combustion, or oxyfuel methods. Pumps are employed to handle the movement of gases and facilitate the separation of CO2. Specifically, they help to maintain appropriate flow rates and pressures during processes such as absorption, stripping, and membrane separation. Both single and multistage pumps can be used, depending on the application.

Upon capture, the CO2 must be compressed to higher pressures for transportation and injection. Compression pumps, including centrifugal or reciprocating compressors, are often employed to increase the pressure of CO2. These pumps ensure that the CO2 is efficiently compressed for costeffective transportation via pipelines or other means.

The compressed CO2 is then transported from the capture site to the storage site. Pumps play an important role in this phase, providing the required pressure to overcome friction and transport the CO2 efficiently over long distances. Pump stations are placed strategically along the pipeline route to maintain pressure levels and regulate the flow of CO2

Once the CO2 reaches the storage site, pumps are used for the injection process. Injection pumps provide the pressure necessary to safely inject the CO2 deep underground into suitable geological formations.

The selection and design of pumps in CCS projects are critical to ensuring efficient and reliable operations. Factors such as flow rates, pressure requirements, temperature, and the properties of the CO2 stream must be considered when choosing the right technology. Additionally, pump systems in CCS need to be carefully designed and maintained to minimise leakage and ensure the safe and secure storage of the CO2 underground.

Unlocking the potential

Northern Territory Minister for Mining and Industry, Nicole Manison, said CCS is vital to achieving net zero emissions.

“The State Government is working with CSIRO, INPEX, Santos and other big industry players to establish a carbon capture and storage common-user hub at Middle Arm.

“We are making sure we are creating an industry that will be able to provide crucial energy security to Australia and the region, into the future,” Ms Manison said.

The Northern Territory’s existing LNG industry, export links with the Asia-Pacific region and high renewable electricity potential mean it is well positioned to create valuable CO2-derived products and support industry’s decarbonisation efforts.

A recent report by CSIRO highlights the opportunity for CO2 utilisation to support low-emission manufacturing in the Northern Territory, as part of the Northern Territory Low Emission Hub business case.

According to the report, the Northern Territory could turn waste carbon dioxide into commodity products by integrating CO2 utilisation technologies into local hub developments.

CSIRO Oil and Gas Researcher, Dr Andrew Ross, said, “The potential near and long-term role of carbon capture and utilisation within a Northern Territory Low Emission

24 pump industry | Winter 2023 | Issue 44 www.pumpindustry.com.au MINING

Hub is an important input to understanding the interaction between different industries in the context of a low emissions industrial ecosystem.”

There are opportunities to manufacture methanol, jet fuel, urea, methane and mineral carbonates in the Northern Territory using captured CO2

Urea is a compound with a high nitrogen content and is commonly used in fertilisers, although it is also used for resins and glue, fuel additive Adblue, medical and cosmetic products and fire extinguishers.

While Australia imports the vast majority of the urea it requires, the precinct offers the opportunity to make urea using CO2 waste from other industries.

Another example of carbon utilisation is cement manufacturers developing technologies to inject carbon into their manufacturing process. This improves product performance and offsets emissions.

Development of a hub with shared CCUS and hydrogen production infrastructure can support the deployment and scale-up of CO2 utilisation opportunities.

Limitations of CCS

The large-scale CO2 storage hub could support the development of low emissions industries, benefit manufacturing industries, and have the potential for a significant emissions management hub beyond the Northern Territory, including South-East Asia.

However, the CCS is not a substitute for clean energy sources such as wind, solar and pumped hydro. While CCS can only address emissions from specific sources, clean energy sources provide a long-term solution to reduce emissions across numerous sectors.

In addition, the CCS process is not foolproof. It carries the potential risks of leakage or accidental release, which can have a significant environmental impact.

Successfully mitigating climate change will require a reduction in reliance on fossil fuels and widespread adoption of clean energy sources. CCS should play a complementary role as Australia transitions away from gas and coal.

25 www.pumpindustry.com.au pump industry | Winter 2023 | Issue 44

MINING

Exploring BEETALOO’S FRACKING FRONTIER

Situated roughly 500km south-east of Darwin is the Beetaloo Sub-basin, an enormous shale gas reserve known for its vast energy potential and significant natural resources. Here we take a look at fracking in the Beetaloo and explore how pumps are used in this controversial process.

The role of gas in Australia’s energy transition continues to be the subject of ongoing debate. As the nation gradually increases its renewable capacity, many argue that new gas projects play a vital role in the energy mix. However, this line of argument has also been called into question, as Australia exports a significant amount of the gas it produces.

Gas projects involving hydraulic fracturing (fracking), the method of extracting gas from shale formations, face even more controversy.

In the Northern Territory, many have raised concerns about the impacts of fracking in the Beetaloo Sub-basin – a

significant natural gas reserve. The Territory Government, however, has cited its potential to help meet energy demands and boost the region’s jobs and economic growth.

In May 2023, the Northern Territory Government gave Beetaloo the green light to move into commercial production. Three companies –Tamboran Resources, Empire Energy and Santos – are currently exploring in the Beetaloo.

As the holder of the biggest tenement position across the site, Empire Energy welcomed the announcement.

Empire Energy Managing Director, Alex Underwood, said, “Building on the encouraging results of our exploration activity over the last four years, we look forward to submitting applications for all required approvals to enable us to move into gas production and the delivery of much-needed new gas supply to the Australian domestic market, and subsequently to increase LNG exports, already the NT’s largest source of foreign income and a significant contributor to Federal Government revenues.”

Empire Energy has conducted extensive seismic surveys and exploratory drilling programs in the

MINING

26

Beetaloo. The company has been evaluating the potential gas resources in the basin, assessing gas content and productivity to determine the viability of gas extraction.

In late 2021, Empire announced it had successfully drilled, cased, and suspended Carpentaria-2H (C-2H) – its first horizontal well located within its 100 per cent owned and operated EP187 tenement. Fracking activities in C-2H began in July 2022.

The role of pumps in fracking

There are two primary pumping and pressure applications involved in the upstream production process. The first application is the extraction of water and gas from the wells, while the second is the compression of the gas for transport via high-pressure pipelines.

Fracking involves injecting a fluid mixture into the wellbore to create fractures in the shale rock. Various types of pumps are used to generate the high pressure needed to push fracking fluid into the well, causing the rock to fracture and create pathways for the trapped gas or oil to flow. Pumps must be large and robust to be able to handle the demanding conditions of the process.

Progressive cavity pumping systems are often used to extract water from the wells. These systems utilise progressive cavity pumps, which are lowered into the well casing on steel tubing to a depth of around 800 to 1000 metres. The pumps are driven by a rotating steel shaft connected to the surface, either through a hydraulic power unit driven by

a gas-fired engine or electrically using a gas-fired microturbine combined with a variable frequency drive.

As the progressive cavity pump rotor spins, water is forced up inside the steel tubing. This extraction of water helps reduce pressure in the targeted shale formations, enabling the release of natural gas. The gas flows to the surface between the well casing and tubing due to the lowering of water levels and pressure.

Triplex or quintuplex pumps, a different type of positive displacement pump, are frequently used in fracking. These pumps are capable of generating the high pressures required for fracking activities.

Centrifugal pumps are often used in fracking for specific purposes, such as transferring or circulating fluids within the fracking system. They operate by using an impeller to create centrifugal force that pushes the fluid outward, generating pressure and flow. Centrifugal pumps are typically employed for water transfer, fluid circulation, or blending operations during the fracking process.

Following extraction, at the wellhead, the extracted gas and water are separated and sent through separate low-pressure gathering pipeline systems. The gas is then compressed to sales gas pressure for transportation via high-pressure pipelines. The water is directed to central water treatment facilities for further processing and treatment.

Pumps used in fracking are also closely monitored and controlled to maintain the desired pressure, flow rate, and fluid consistency. Advanced technologies and sensors are often employed to monitor pump performance, ensuring efficient and effective operations.

Frack programs are often designed to meet the unique geological and reservoir conditions of the region. Empire has tested a number of frack fluid mixes to understand which design will achieve the best production results.

One challenge with fracking is that materials pumped underground need to be slowly removed over a matter of weeks, in order to keep the perforations steady and stabilise pressure downhole. Fracking waste materials are transported to a dump on-site or into tanks, depending on cost and logistics. Once fracking materials (including sand abrasive liquids, acids and expanding gels) have been removed, companies are able to commence gas flow testing.

Advancing operations in the Beetaloo

Empire Energy’s C-2H well production test provided the company with an early production-type curve and a better understanding of gas composition in developing a full field development plan, including processing and gas handling facilities.

In May 2023, the company announced it had wound up its latest round of flowtesting at C-2H, pulling up a total of 323 terajoules over 127 days.

MINING 27

As well as monitoring the well’s flow rates, the company also used pump tests to garner important information, examining the benefits of soaking in Beetaloo and understanding the flow characteristics of the Velkerri B shale host.

Soaking refers to when injected fracturing fluid is left to sit in the wellbore and the formation for a certain period of time. During soaking, the fluid interacts with the rock formation, allowing it to penetrate deeper and initiate or enhance the creation of fractures. Pumps are usually shut off during this stage.

Following the completion of flow testing, Empire Energy shut-in C-2H and earmarked the well as a future gas producer.

In early March 2023, the company announced it had put its Carpentaria-H3 (C-3H) well through its paces by testing flow pressure for 27 days straight. It then began the shut-in processes for soaking after fracture simulation. This refers to a series of complex processes to increase the flow pressure of the well.

In late March, Empire announced it had lifted its average 30-day gas flow rate by more than 17 per cent in initial tests held at the Beetaloo Basin, citing the results as validation of its soaking strategy.

The company recently released revised estimates of its EP187 resource, which includes technical results from its 2022 drilling, fracture stimulation and production-testing campaign.

Empire’s management believes that results from its C-2H and C-3H wells demonstrate that it can cost-effectively deliver 3km of hydraulically-stimulated horizontal wells utilising Australia’s existing rig and frack spread fleet. The wells represent the intended design for future development of its Carpentaria project at EP187.

Concerns surrounding fracking

While government support has allowed Empire Energy to increase its portfolio of gas opportunities and move projects in Beetaloo forward, controversy still surrounds the development.

The risks associated with fracking include:

• Air pollution: fracking involves the release of volatile organic compounds and hazardous air pollutants, which can have detrimental effects on human health and contribute to climate change

• Risk to water resources: fracking requires large amounts of water mixed with chemicals that may be harmful and can potentially contaminate groundwater through leaks or improper disposal of wastewater

• Induced seismicity: fracking has triggered small to moderate earthquakes in some regions

• Greenhouse gas emissions: the extraction and burning of fossil fuels obtained through fracking contributes to emissions, exacerbating climate change

Fracking can also have social and economic impacts, such as increased truck traffic, noise pollution, disruptions to local communities and conflicts over land and finite water resources.

The Federal Government has played a major role in supporting the exploration and development of the Beetaloo, with the previous coalition government committing significant amounts of funding. This support has drawn condemnation from some communities, including traditional owners who fiercely oppose the development.

Empire Energy was awarded $21 million from the Federal Government under the Beetaloo Cooperative Drilling Program, sparking a federal court challenge by environmental activists, who argued that the decision to give Empire the money was unlawful because the federal resources minister at the time failed to properly consider the risks to global heating.

However, in October 2021 the company announced it had secured environmental approval from the Northern Territory Government, granting it permission to drill new wells in the basin.

Concerns around fracking led to an almost two-year moratorium on unconventional sale gas developments in the Territory, beginning in 2016. An independent Scientific Inquiry into Hydraulic Fracturing of Onshore Unconventional Reservoirs in the Northern Territory was also initiated.

MINING 28

Findings were handed down to the Territory Government in 2018. It announced it had accepted all of the recommendations and lifted the moratorium. One of the key recommendations was the Strategic Regional Environmental and Baseline Assessment (SREBA), which the government committed to finalising before any production licences were issued.

The three-year SREBA study found no new risks associated with the development of an onshore gas industry and in 2023 the Territory Government announced it had finalised all 135 recommendations of the inquiry, including a new regulatory framework for fracking. This set the stage for approval of gas production in the Beetaloo.

The Territory’s independent regulator has disputed the claim that the government met all of the recommendations of the inquiry before approving fracking.

Regardless of the Northern Territory Government’s decision, the harmful effects of fracking and fossil fuels remain an issue.

Empire is likely to begin construction on its Beetaloo pilot gas production facilities in early 2024.

FOR HIGHER MOBILITY MINE DEWATERING UNIT

The SEEPEX Mine Dewatering Unit, used in both fixed and mobile installations, is engineered for efficient separating of oversized solids and conveying of mine water. The unit consists of a skid baseplate, tank, pipework and pump with drive and controls. The compact design enables easy transport, while the effortless maintenance reduces downtime and costs.

y Maintain in Place design: Quick and easy maintenance and no dismantling of pipework

y Lower operating costs

y Lightweight components

y Robust pumps for small spaces

y Equal wall stators increase pressure capability

SEEPEX Australia Pty. Ltd. T +61 2 43554500 info.au@seepex.com www.seepex.com

29 www.pumpindustry.com.au pump industry | Winter 2023 | Issue 44

MINING

Katie Livingston Editor, Pump Industry Magazine

Katie Livingston Editor, Pump Industry Magazine

It can be challenging to strike the right balance when marketing to the pump industry, where the emphasis is on providing end-users with products and solutions that effectively and efficiently meet their needs. If you’re not familiar with business-to-business (B2B) marketing solutions, it can be difficult to get the best results.

The most successful businesses, particularly in B2B sectors, approach marketing with a multi-pronged strategy. This includes a combination of a great website, effective social media campaigns and a wellresearched, well-executed content marketing plan.

When organisations are choosing who to partner with to help them deliver their marketing strategy, there are marketing experts, and then there are industry marketing experts. In a B2B setting like the pump industry, you should be working with the latter.

30 www.pumpindustry.com.au

INDUSTRY MARKETING

CONTENT MARKETING 101 FOR THE PUMP INDUSTRY

What is content marketing?

Content marketing is a strategic marketing approach focused on creating and distributing valuable, relevant and consistent content. The goal is to attract and retain a clearly defined audience ‒ and ultimately drive action and sales.

Content can be produced in various forms including news articles, blogs, whitepapers, ebooks, newsletters, infographics and social media posts.

Chances are you know your industry better than most, but if creating content is not your main focus, you’re probably not doing it effectively. Pump Industry Magazine Editor, Katie Livingston, explains the unique content marketing challenges faced by companies in the pump industry, and how specialist content teams have an impact.

“The pump industry is unique, complex and includes a variety of different challenges, with high value placed on content that helps members of the industry solve the problems they deal with every day.

“It can be difficult for those working in the industry to find a marketing professional that can comprehend the intricacies of these challenges; and explain pump industry issues clearly without oversimplifying a situation.

“Pump end-users are dealing with complex challenges, and they need their problems solved yesterday. Here at Pump Industry Magazine we know marketing that successfully targets this audience, focuses on solving pain points and demystifying the hidden workings of complex machinery.”

Katie says it’s important to have an editorial team that understands the challenges of the end-user, who in the case of Pump Industry Magazine, is individuals working across a wide variety of verticals, including water and wastewater, oil and gas, chemicals, food and beverage and more.

“We know that when people read industry articles, they are looking to gain something – whether that be new knowledge, expert insight or solutions to certain problems. When a writer already knows who their audience is, and how to write for that audience, they have a much better chance of producing content that is meaningful to the reader,” Katie said.

What content is useful to potential customers?

A good content marketing piece of work solves a problem for potential customers. You know what your customers are asking. You know their pain points. Some of the best content your business can create will address these issues. Great articles are then read, saved, shared and ultimately draw customers to you when they are ready to buy.

Katie said there are many different types of articles that appeal to customers in the pump industry.

“Longer feature articles that explore technical challenges with pumps and pump systems, and explain in detail how to resolve problems and overcome these challenges, are particularly popular with our readers. Creating content like this can position advertisers as industry experts and thought leaders within the industry. In addition, project stories can emphasise a particular area of expertise for a business.”

31 www.pumpindustry.com.au pump industry | Winter 2023 | Issue 44

INDUSTRY MARKETING

Strategy is the key to success

Successful content marketing, and marketing in general, comes from having a clear strategy that is executed flawlessly. The biggest content marketing mistake businesses make is to release content with all guns blazing for a couple of weeks, then leave their customers listening to crickets for the next few months. Perhaps they hit them with another flurry of content a few months down the track, but they lack consistency or a defined strategy.

All companies benefit from having a clear content marketing plan in place, and those in the pump industry are no exception. This plan should include a commitment to release content relating to industry-specific events throughout the year, such as the impact that the Federal or State Budgets may have on customers or others in the industry.

The content marketing plan should be flexible enough to be able to respond to unexpected relevant events, such as the release of a new standard that impacts the industry, or the announcement of a funding grant. Working with content specialists within the industry makes it easier to lay out article plans for the year. Having dedicated writers who know the industry means this content can be produced quickly and while it is still relevant.

Businesses also need content that can be prepared ahead of time to keep customers informed and increase their own brand recognition. In the pump industry, these could be articles around new products that increase the efficiency of pumping systems, or allow manufacturers to create their products more effectively.

Leading businesses will also have some long-form content available – such as whitepapers or ebooks – with comprehensive analysis that help to stamp them as an authority in the market.

Be sure that web content suits the online world

Before great content actually makes an impact, it’s important for a business website to be in good shape. This includes being mobile responsive, since so many people view websites on their phones. It’s also good to produce content for search engine optimisation (SEO), which means making use of a range of keywords, optimising images for the web and successfully building relevant links.

Businesses in the pump industry should also be careful not to disregard social media in their marketing plan. Sticking with the goal of avoiding being obnoxious, there are still ways to interact with potential customers through social media without being too intrusive.

Facebook has a place in business to consumer (B2C) transactions, and to a lesser extent business to business (B2B) interactions. Given many decision-makers are on Facebook, business content can still reach these people and have an impact. The downside is that they are often not in business decision-making mode when using Facebook. Your best bet is to be sharing content of value that people appreciate reading. When they are at work and ready to make a purchase, your business has already made an impression on them.

LinkedIn is a great platform for businesses in the pump industry to foster B2B transactions and nurture relationships.

32 pump industry | Winter 2023 | Issue 44 www.pumpindustry.com.au

INDUSTRY MARKETING

Being a professional network by nature, LinkedIn is a convenient and appropriate way to keep in contact with other industry leaders.

There is often a spike in connections made after networking or industry events such as AIMEX, Irrigation Australia, IMARC and OzWater. Once these relationships are formed, the content-sharing nature of LinkedIn can broaden your reach in the industry.

What’s next for marketing in the pump industry?

The goal will always be to stay relevant to the intended customer base. This is often best achieved through targeted content marketing produced by journalists with industry knowledge as well as general writing experience.

Pure industry experts often lack writing skills to get their message across. Pure marketing experts don’t have the industry knowledge to produce quality content for the intended audience. Find someone in the middle who has both sets of skills.

Want a more in-depth understanding of content marketing?

Scan the QR code below to learn how we can help you achieve your marketing goals.

4 ways B2B marketing is different to consumer marketing

1. Different demographics

When marketers are targeting the consumer market, they often base their campaigns on traditional demographics like age, gender and income level. But B2B demographics are very different, and a scattergun approach simply won’t work and can waste a lot of resources. B2B marketing should be done through platforms where you can directly target these people. This could include meeting them directly at industry events, targeted campaigns through LinkedIn, where you can segment on appropriate demographics, sending newsletters to existing clients or lists you build yourself, advertising in industry journals that the right people actually read, and custom-lead generation campaigns.

2. Long lead times

Many consumer purchases are made once and straight away, possibly in a physical shop or increasingly online. But many B2B deals involve a tender process, or protracted negotiations for high value deals – it’s not a click and forget scenario. As a result, it’s important to set the pace of your marketing to match the length of your sales cycle. This means that it’s ok to drive traffic to your site if that’s what you want to do, but if they’re not ready to buy that day, you should still have options for them to engage with you, such as a newsletter to sign up for or an eBook download or webinar registration for which they provide their details.

3. Dealing with multiple decision makers

When a consumer makes a purchase, they decide and that’s it. In B2B, there’s often a whole chain of people who are involved in some way in the decision making process. If you are dealing with a large organisation, there may be more hands-on employees that use the product and recommend it, senior management that have ultimate sign off, or even external stakeholders like engineering consultants who make recommendations. Good marketing needs to reach all of these people with different variations of your message that are adapted but also consistent.

4. Personal relationships

In B2B, it’s often necessary to have ongoing, long-term relationships with the individuals at the companies you sell to. This means that consistency and reputation are key. This matters in all marketing, but in B2B it’s as much about your personal integrity and reputation as anything else. The best way to deliver on this is by living these values. But the perception can be further enhanced with the right marketing and communications. In B2B there’s often great scope to build up the profile of your key staff as experts or thought leaders. The more they get quoted on a topic, speak at a conference, or be seen in trade media or on social media, the more that trust will be reinforced.

33 www.pumpindustry.com.au pump industry | Winter 2023 | Issue 44

INDUSTRY MARKETING

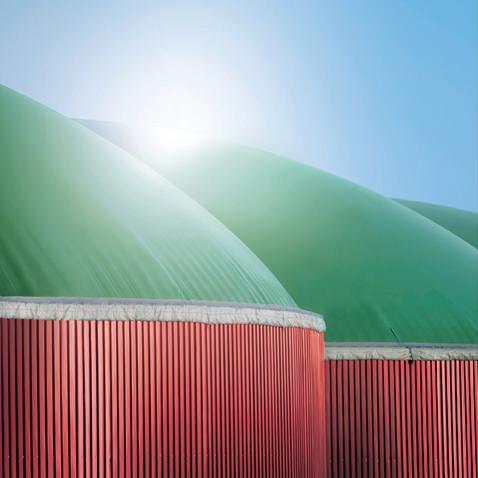

IRRIGATION OVERHAUL: HOW PUMPS HELPED A DAIRY FARM’S RENEWABLE ENERGY TRANSITION