Eltirus

Michael

Quarry

18 Strength in numbers

Phil Agius talks about Delta Rent’s outlook for 2025.

20 Family values

Craig Pedley spoke to Quarry about how differences from state to state can influence the industry.

22 Tried and trusted

Ciaran Lagan shares his insights on what lies ahead in 2025.

24 Thinking ahead

Darren Toth shares his thoughts on the state of the Australian quarrying industry.

26 Ambitious growth planned

Grahame Hopkins is the vice president of sales and service at Multotec Australia.

30 Sand in the hourglass

Bram Smith offers insights into the future of sand and sustainability

32 Investing in the fundamentals

Marcis Pavars is the international business development manager for Superior Industries.

34 Making a mark

David Hunter is the business line director for McLanahan.

36 Half a century of CJD

Grayden Leaver tells Quarry about the company’s goals, milestones, and innovation.

38 Safety, stock and sustainable growth

Andrew Cousins discusses the mechanical power transmission sector and its potential to support quarries in 2025.

40 Top tier training

Dean Olzard is the general manager at a registered training organisation working around Australia.

45 Meet your IQA Ambassadors

Quarry talks to the IQA Ambassadors about their thoughts on the industry.

Welcome to 2025 – we’re halfway through the decade already. A lot has changed, but even more has stayed the same.

It will be hard to talk about the 2020s without mentioning COVID-19. The pandemic caused unthinkable disruption, changing how we live our lives and how we work.

Quarries were highlighted as a critical industry during that time – houses still needed to be built, roads still needed to be paved, and resources were still needed to fuel those efforts.

However, while the pandemic created new disruptions, the industry is still grappling with the same challenges it has for years – particularly when it comes to finding skilled labour.

It’s no secret that it’s becoming harder to find a workforce that has the skills required for such an important industry. The industry is ageing, so it’s important to secure the next generation of quarry workers.

The Institute of Quarrying Australia (IQA) has been working hard to get more young people engaged, working with educators

to teach young people about the quarrying industry.

At last year’s IQA Conference, one of the highlights was seeing just how many students were interested in the industry, and willing to learn more. It also featured keynote addresses that highlighted the challenges and benefits of engaging Generation Z in the workforce.

In addition to this, more original equipment manufacturers are designing their products to be automated, reducing the number of staff required to efficiently operate a quarry.

Innovation will play an important role in the future of quarrying, allowing sites to get more out of less, and remain competitive.

This edition of Quarry highlights several of the challenges the industry is facing, with industry leaders providing their thoughts on the year that was, and what the future might bring.

Read on to learn more about how the industry is responding to economic changes, technological developments, and more.

William Arnott Editor

AT LAST YEAR’S IQA CONFERENCE, ONE OF THE HIGHLIGHTS WAS SEEING JUST HOW MANY STUDENTS WERE INTERESTED IN THE TECHNOLOGY, AND WILLING TO LEARN MORE.

Published by:

379 Docklands Drive

Melbourne VIC 3008

T: 03 9690 8766

www.primecreativemedia.com.au

Chief Executive Officer

John Murphy john.murphy@primecreative.com.au

Managing Editor

Paul Hayes paul.hayes@primecreative.com.au

Editor

William Arnott william.arnott@primecreative.com.au

Assistant Editor

Adam Daunt adam.daunt@primecreative.com.au

Business Development Manager

Les Ilyefalvy les.ilyefalvy@primecreative.com.au

Client Success Co-ordinator

Janine Clements janine.clements@primecreative.com.au

Art Director

Michelle Weston

Subscriptions

T: 03 9690 8766

subscriptions@primecreative.com.au

The Publisher reserves the right to alter or omit any article or advertisement submitted and requires indemnity from the advertisers and contributors against damages or liabilities that may arise from material published. © Copyright – No part of this publication may be reproduced, stored in a retrieval system or transmitted in any means electronic, mechanical, photocopying, recording or otherwise without the permission of the publisher.

As we step into 2025, I am thrilled to share the exciting journey that lies ahead for the Institute of Quarrying Australia (IQA) and our dynamic community. This year promises to be filled with opportunities for growth, learning, and innovation.

Reflecting on 2024, we laid strong foundations, and now we are poised to build on that momentum. Our commitment to education and professional development remains steadfast.

For 2025, our Education and Training team has curated an extensive program incorporating in-person sessions, online courses, on-demand learning, and corporate group training, tailored to address specific company needs.

This comprehensive approach ensures our members have access to the resources they need to excel in their careers.

In response to industry demand, we are expanding our focus on safety and health through a series of state-wide conferences. These events will provide essential insights and facilitate discussions on best practices, ensuring safety remains at the forefront of our industry. Our commitment to safety is ongoing, and these conferences serve as invaluable platforms for sharing knowledge and experiences.

Our calendar of networking events for 2025 is in its final stages of preparation and promises to deliver even more opportunities for collaboration and knowledge sharing. Stay tuned for the detailed schedule coming soon.

Digital transformation is a key priority for us this year. We are excited to announce the development of a new IQA website

and a dedicated member app. These digital tools will enhance user experience and accessibility, serving as valuable resources for our members by providing easy access to information, events, and educational materials.

2025 will also see the IQA launch a national public awareness campaign to ensure communities understand the vital role and benefits of quarrying in infrastructure development, job creation, and community growth. This initiative will highlight our sector’s contribution to Australia’s future and sustainable development.

We are also proud to introduce new diversity and inclusion policies and initiatives aimed at ensuring our sector better reflects the communities we serve. These programs will create more opportunities for underrepresented groups and promote a more inclusive quarrying culture.

2025 is shaping up to be a monumental year for the IQA community. I encourage all members to engage actively with the available opportunities and contribute to our shared mission of promoting innovation, sustainability, and professional excellence. Together, we can drive positive change and set new benchmarks for our sector.

Here’s to a successful and dynamic 2025!

Michael Close President Institute of Quarrying Australia

REFLECTING ON 2024, WE LAID STRONG FOUNDATIONS, AND NOW WE ARE POISED TO BUILD ON THAT MOMENTUM. OUR COMMITMENT TO EDUCATION AND PROFESSIONAL DEVELOPMENT REMAINS STEADFAST.

www.quarry.com.au

The IQA’s Strategic Plan 2023 to 2026 embodies the following vision, values and strategic priorities:

Vision:

Thriving communities supported by a sustainable industry

Operational Priorities:

• Deepen industry participation

• Sustainable revenue streams

• Highly capable team

• Technological innovation

• Effective engagement

• Great governance

Strategic Priorities:

• Support industry participants with compliance and regulation

• Build a diverse and skilled industry workforce

• Foster strong industry connectivity

IQA Contacts:

Phone: 02 9484 0577

Email: admin@quarry.com.au

Chief Executive Officer Jane Schmitt

President Michael Close

Company Secretary David Cowie

For all education, member and branch enquires please email: admin@quarry.com.au.

EDUCATION

Member access to IQA

Education Hub & Learning Management System (LMS)

Discounted fees for ALL courses

Over 100 courses, workshops, tours and events offered annually

1

3

Professional connections

INDUSTRY RECOGNITION

Use of IQA digital member badge

Recognition membership status through post-nominals

IQA Award Nominations

Acknowledgement of industry contributions

2 IQA MEMBER BENEFITS

4

Incentives for Young Members

Contribute to the industry Opportunity to join branch committees

Engagement with quarrying professionals nationally & globally

Initiatives and support for Women in Quarrying

A range of site tours and workshops, events & conferences

PROFESSIONAL DEVELOPMENT NETWORKING

Under the terms of the definitive agreement, Heidelberg Materials

North America will acquire GCHI and its subsidiaries Giant Cement Company, Dragon Products Company, and Giant Resource Recovery from the Fortaleza, Uniland and Trituradora groups.

“Our latest additions are yet another great strategic fit, creating value in the near term through significant synergies with our existing assets

on the East Coast. This move follows a series of key acquisitions this year that have already contributed to our consistently strong financial performance in North America,” Dominik von Achten, chairman of the managing board of Heidelberg Materials said.

“At the same time, we are excited about taking further steps in building a sustainable future and positioning Heidelberg Materials as the front

“OUR LATEST ADDITIONS ARE YET ANOTHER GREAT STRATEGIC FIT, CREATING VALUE IN THE NEAR TERM THROUGH SIGNIFICANT SYNERGIES WITH OUR EXISTING ASSETS.”

DONIMIK VON ACHTEN

CRH has confirmed its appointment of an interim chief financial officer who will take over from Jim Mintern in 2025.

Alan Connolly has been appointed as the interim chief financial officer from January 1, 2025. Connolly will take over from Jim Mintern, who will step up as the chief executive officer of CRH from the start of next year.

Connolly’s appointment comes as CRH continues its process to find a permanent successor to Mintern in the key position. The company confirmed it had engaged an independent recruitment consultant

and is considering internal and external candidates for the role.

“Alan brings extensive and relevant expertise to the Interim Chief Financial Officer role and is deeply familiar with CRH’s business and financials. As our Director of Strategic Finance, Alan and I have worked closely together on key finance initiatives, and I look forward to continuing to partner with him to execute on our strategy and drive value for our shareholders,” Mintern said.

“We are grateful that he is stepping into this interim role while we conduct

runner on the path to net zero and a circular economy in the key North American market.”

This transaction includes an integrated cement plant in South Carolina, four cement distribution terminals in Georgia and South Carolina, a joint venture deepwater import terminal in Georgia. Additionally, it includes assets in New England with cement and slag distribution terminal in New Hampshire and a deep-water import terminal in Boston.

The deal also includes Giant Resource Recovery, an alternative fuel recycling business with four strategically located facilities in the Eastern US.

“The acquisition of the GCHI assets will further strengthen our cementitious footprint in the growing Southeastern US and New England markets,” said Chris Ward, president and chief executive officer of Heidelberg Materials North America and member of the managing board of Heidelberg Materials.

“We are excited to expand our supply network on the East Coast to better serve our broad customer base and we expect strong synergies with the Giant Resource Recovery fuel recycling business.”

The purchase price for the transaction is approximately US$600 million, subject to ordinary post-closing adjustments. The deal is expected to be completed in the first quarter of 2025. •

a search to identify a permanent chief financial officer.”

Connolly is a chartered accountant with more than three decades of experience. He has held several senior finance roles across the CRH’s European and Americas businesses. During his time with the company, Connolly served as director of strategic finance, finance and performance director of Europe Materials, chief financial officer of global building products, and director of group finance. •

Following a successful event in July 2024, the Papua New Guinea Industrial and Mining Resources Exhibition and Conference (PNG Expo) is set to return in 2025.

The event will be held at the Stanley Hotel in Port Moresby from 2–3 July, and offers attendees plenty of networking opportunities, including a gala dinner and welcome drinks.

Rebecca Todesco, marketing manager of mining events at Prime Creative Media, said the team looks forward to welcoming even more exhibitors and attendees to the 2025 event and networking opportunities.

“Creating bespoke networking opportunities for our sponsors is a benefit of the event being located at

a high-quality hotel in PNG,” she said. TriCab, a premium supplier of high-performance flexible cable and accessories and a silver sponsor of the 2024 event, has renewed its sponsorship for 2025.

TriCab Queensland state manager Shane Plumridge said the company is keen to showcase its commitment to supporting and growing the blooming PNG sector.

“At TriCab we pride ourselves on supplying premium, highperformance flexible cable and accessories that reflect our values of innovation and quality,” Plumridge said.

“Providing engineered cable solutions, which save our customers

“CREATING BESPOKE NETWORKING OPPORTUNITIES FOR OUR SPONSORS IS A BENEFIT OF THE EVENT BEING LOCATED AT A HIGH-QUALITY HOTEL IN PNG.”

REBECCA TODESCO

time and cost, is where we make our difference. At TriCab, we listen and respond to a range of customer needs, remaining innovative in our operations to ensure we can meet demands of all markets, existing and emerging.”

Plumridge said the company was proud to be a silver sponsor at the 2024 expo, being able to showcase its products and people to the interested attendees.

“The ability to see people from the local area in the one place all with the same values, who were looking for new and innovative products and services, was a tribute to the organisers,” Plumridge said.

“It gave TriCab the ability to expose our vision of demonstrating our capabilities in the growing demand for the mining market in PNG.”

Plumridge is encouraging all stakeholders involved in the mining and industrial support channel to attend the 2025 event.

“The organisers have created a concentrated group of suppliers in a safe and easy-going atmosphere, where the cream of the mining supply chain providers are showcasing innovative products,” he said.

“Events like the PNG Expo are vital in bringing like-minded consumers and suppliers together in the one space where it is mutually beneficial to all parties, in a relaxed and safe environment.” •

Holcim has confirmed the looming spin-off of its North American business remains on track to be completed during 2025.

The company is undertaking the full capital market separation of its North American business. The 100 per cent spin-off will be listed on the New York Stock Exchange. The initiative is subject to shareholder approval at Holcim’s annual general meeting. If the approval is granted, the spin-off is expected to be completed by the first half of 2025.

It comes after the company first announced its plans for the spin-off earlier this year. Jan Jenisch, the former chief executive officer of Holcim and current chairman of the managing board, is leading the company’s project.

“With a US listing, we will unleash its full potential to be the partner of choice for our customers in one of the world’s most attractive construction markets,” Jenisch said earlier this year.

“This next step of growth and value creation is possible thanks to the outstanding leadership of

our empowered teams around the world delivering record results year after year.”

According to Holcim, the spin-off is planned as a domestic issuer under SEC rules, reporting in US GAAP and seeking inclusion in relevant US equity indices.

An additional listing on the SIX Swiss Exchange is planned to accommodate European investors.

The endeavour is subject to customary approvals. •

Far North Queensland’s bowls evening

Swapping steel caps for bare feet, Far North Queensland sub-branch members took to the greens at West Cairns Bowling Club for a vibrant evening of bowls on 1 November.

Against a backdrop of colourful tropical shirts, industry colleagues shared laughs, barbecue and friendly competition.

Thanks to committee member Keoni Kidner’s organisation, the casual Friday evening proved a perfect way for FNQ members to strengthen industry bonds beyond the quarry gate.

North Queensland’s festive farewell to 2024

Townsville’s historic Heritage Exchange came alive on 15 November as North Queensland branch members gathered for their year-end celebration. The atmospheric venue buzzed with industry conversations, while soloist Ben Bennett from HeartSongs Entertainment provided the perfect soundtrack for the evening.

Under the guidance of branch chair Paul Hooton and deputy chair Lawrie Fahey, and with support from MS Fabrications QLD, the event captured the spirit of regional camaraderie that’s become a hallmark of North Queensland’s industry gatherings, setting an upbeat tone for 2025’s program.

Hunter branch ends year with family flair

The Hunter branch added a fresh twist to their year-end celebration as 53 quarrying professionals and their families gathered at Charlestown Golf Club on 28 November.

Under the guidance of branch chair Greg Dressler, the evening struck a perfect balance between professional networking and family entertainment.

Supported by Westrac and Rimex, the evening saw quarrying professionals involved in a spirited dress-up competition.

The family-friendly format proved a welcome innovation, bringing a new dimension to industry connections as children joined their parents in the celebrations.

Northern NSW branch wraps up 2024

From hard rock to river sand, Northern NSW branch members experienced the region’s quarrying diversity during their November Grafton tour. Thirty participants explored McLennan’s drill and blast quarry operations and CDE wash plant, before heading to Boral’s Grafton site where excavator dredging extracts sand and gravel from the Clarence River. The day wrapped up at Humes’ state-of-the-art precast concrete pipe facility.

A vibrant networking event followed, where 50 industry professionals gathered to hear CDE discuss wash plant technologies and Westrac showcase their VisionLink Equipment Management Software. The successful day showcased the best of the Northern Rivers quarrying sector, with the branch already planning their next regional tour for 2025

Wollongong Golf Club hosts Southern NSW’s year-end celebration

Against the backdrop of Wollongong’s coastal skyline, the Southern NSW branch gathered for its final 2024 celebration on 27 November.

Forty-one quarrying professionals joined an evening that balanced formal insights with relaxed networking.

The evening buzzed with industry conversation as branch chair Michael Holz reflected on the year’s achievements, while Westrac’s presentation sparked engaging discussions over a premium buffet, strengthening the region’s quarrying connections.

The branch’s commitment to professional development shone through with IQA’s Mikayla Stephen sharing valuable updates on education opportunities for individuals and companies, rounding out an engaging evening of industry collaboration.

Queensland branch hosts inspiring fireside chat

The Queensland branch’s November fireside chat brought industry members together at the Hamilton Hotel’s Gus’s Guestroom on 28 November. The evening’s spotlight guest, Awesome Women in Construction (AWIC) Founder and CEO Amanda Bulow, sparked lively discussions among attendees.

Sponsored by Orana Drill & Blast, the event provided an intimate setting for industry networking and knowledge sharing, adding to the branch’s dynamic 2024 program.

SA branch concludes 2024 with critical health and safety focus

The SA branch concluded its 2024 calendar with a comprehensive work health and safety technical breakfast seminar at the Adelaide Pavilion on 22 November. The early-morning session drew significant industry attendance, highlighting the sector’s commitment to safety and regulatory compliance.

Sarah Pennington and Paul Thompson from the Department for Energy and Mining’s regulation and compliance division, delivered important insights into the change to operations process and provided updates on the mining and exploration regulation (MERs) system upgrade. This presentation offered valuable guidance for operators navigating regulatory requirements.

The event’s focus on emerging health and safety challenges continued with Mining and Quarrying Occupational Health and Safety Committee (MAQOHSC) WHS specialist Peter Williams, who detailed the new work health and safety regulations specifically addressing crystalline silica substance management – a topic of increasing importance in the quarrying sector.

A particularly impactful presentation came from Michael Williams, general manager Operations at Adbri, who shared critical learnings from a serious fall from heights incident at their Klein Point mine in 2021. Williams’ candid discussion covered the incident’s impact on the injured operator, the broader workforce, and the subsequent regulatory response through SafeWorkSA’s enforceable undertaking mechanism.

The morning also celebrated professional achievements, with membership certificates presented to John Schulz from AdBri (TMIQ) and Lynton Nitschke from Hallett Group (MIQ), reflecting the industry’s ongoing commitment to professional development.

“The strong attendance at this final event for 2024 demonstrates our industry’s dedication to workplace health and safety,” James Rowe, IQA SA Branch Chairperson siad. “The practical insights shared by our speakers, particularly regarding real incident learnings and regulatory updates, provide valuable takehome messages for all attendees.”

Brews and business mark Tasmania’s year-end gathering

The Tasmanian branch crafted a memorable finale to 2024, blending history with strategy in Launceston on 28 November. The day began with members exploring the craft and culture behind James Boag’s iconic brews during an exclusive brewery tour, before transitioning to The Sports Garden Hotel for branch business and celebration.

The evening proved an ideal platform for both reflection and looking ahead, as members elected their 2024–25 committee while strengthening industry connections over dinner.

The successful format, blending Tasmania’s brewing heritage with branch planning, energised members for the year ahead, with anticipation already building for the branch’s upcoming Bridport IQA technical and social weekend.

Championing sustainability at Victorian spring technical night

Sustainability was front of mind at the IQA’s Victorian branch spring technical night, which featured a site tour of Alex Fraser’s Epping facility and a keynote speech from Kayasand’s Frank Grech.

IQA members from across Australia visited Alex Fraser’s Northern Sustainable Supply Hub, which contains a high-volume construction and demolition recycling facility, a new rock crushing plant, and a Benninghoven asphalt plant. The plant produces recycled content asphalt mixes containing up to 70 per cent recycled materials, including reclaimed asphalt pavement, glass sand, recycled tyre products, and plastics.

Alex Fraser general manager of recycling Murray Butterworth provided an overview of the company’s supply offerings, including its

commitment to compliance, competitiveness, and sustainability.

The company has recovered and recycled more than 58 million tonnes of concrete, brick, rock, asphalt and glass to produce highquality, high-specification, recycled products needed to build greener roads, rail, bridges, pipelines and ports.

Following the site tour, attendees learnt more about how engineered sand can improve supply chain security for Australian construction.

“Victoria, in particular, can see a natural sand shortage on the horizon,” Grech told Quarry at the event.

“It’s getting more difficult to access these sands, so the industry needs to look for alternatives.”

Kayasand’s innovative Kemco V7 technology enables quarries to engineer sand of such high quality, it completely removes the need to use natural sand in concrete. The ability to precisely control the shape, grading, contamination and consistency of the sand enables quarries to play a critical role in the construction industry’s path to net zero carbon emissions by 2050.

Grech said that for concrete plants, engineered sand makes stronger concrete that uses less cement and has lower carbon emissions.

“For quarries it means greater utilisation of crusher dust, lower costs and ‘washing without water’,” he said.

“The result is a profitable and sustainable alternative to natural sand.”

Grech has worked extensively in crushing and screening, contract negotiation and business development, previously holding senior roles at Holcim Australia and Sandvik Mining and Rock Technology. He is also a director and ambassador at the IQA.

“The IQA supports the industry in total – from processing to safety, diversity, resources and more,” he said.

“These networking events are important. They provide us with an opportunity to share our knowledge, learn about new technologies, and rediscover the value of existing ones.”

The event also included a presentation about rockbreaking technology, delivered by Michael Baumann, Breakers and Attachments’ Victorian branch manager.

Victorian branch closes 2024 with Bendigo celebration

The Victorian sub-branch concluded their 2024 calendar with a dynamic end of year networking dinner at Bendigo’s All Seasons Resort Hotel on 28 November. The evening drew 87 industry professionals and featured AFL identity Glenn Manton, who delivered an engaging keynote address, sharing inspiring stories and encouraging active audience participation.

A highlight of the evening was IQA CEO Jane Schmitt’s presentation of the FIQ badge and certificate to John Mawson.

The event, which included a presentation from Komatsu’s Rob Saxby, brought together key industry figures including IQA president Michael Close, branch chairs from Victoria and South Australia, and

six IQA Ambassadors, ending the year on a high note.

IQA WA golf day drives industry connection at Joondalup

The IQA’s Western Australian branch celebrated another successful golf day at the prestigious Joondalup Resort on 22 November, drawing together more than 100 industry professionals for a day of networking, friendly competition, and community building.

The annual event showcased the strong collaborative spirit within Western Australia’s quarrying sector, with Westrac leading as the major sponsor. Teams representing various segments of the industry competed on the picturesque championship course, including dedicated Women in Quarrying (WIQ) and Young Member Network (YMN) teams, highlighting IQA’s commitment to diversity and inclusion.

“The enthusiastic participation from across our industry made this year’s Golf Day particularly memorable,” Johannes Barnard, WA Branch Chairperson said.

“It’s heartening to see the event evolve into more than just a golf tournament – it’s become a vital platform for strengthening industry relationships and fostering collaboration.”

The event featured comprehensive support from industry leaders, with 15 gold sponsors including Liebherr Australia, Orica Australia, and Hitachi Construction Machinery. Special features included a massage tent sponsored by B&F Consolidated, refreshment services by MACA’s drinks cart, and a well-attended post-golf function hosted by Komatsu.

The tournament format encouraged both experienced golfers and newcomers, with team and individual registrations available. Each registration included green fees, golf cart hire, lunch, and post-game refreshments, ensuring a full day of engagement for all participants.

Strong backing came from WA State Sponsors, with CJD Equipment and B&J Catalano as WA major sponsors and Komatsu supporting Women in Quarrying initiatives. Additional support from WA Premium Sponsors and National Partners, including Metso and Astec, reinforced the event’s significance in the industry calendar.

“The success of this year’s Golf Day reflects the robust state of our industry and its commitment to community,” Barnard said. “These events play an essential role in maintaining the strong networks that characterise our sector.”

Kleemann national sales manager Ben Lefroy outlines how global economic outcomes have affected the quarrying industry, and what it means for suppliers.

One of the most important things is to stay in touch with global and local economic trends. Last year was a bit of a tough one, with quite unusual circumstances. I’m not an economist, though I do keep a close eye on FX rates as it has a large effect to our supply chain to include shipping rates.

It’s also important to watch what other economies are doing, especially in Europe, China, and the US. China has slowed down over the past year, and there has been global inflation, which has effects on our industry and market. While global changes lag, when it hits in Australia, it tends to hit very quickly.

This year has highlighted just how important it is to keep your finger on the pulse to navigate the way through the year ahead.

High interest rates have slowed businesses down. Governments are pulling funding or slowing funding to major infrastructure projects. It’s no big secret – the Reserve Bank of Australia and governments are deliberately looking to reduce the inflation rate.

We somewhat expected a slowdown, but didn’t expect it to occur as quickly as it has. It’s led to companies downsizing, reducing their capital fleet, and in the worst cases, going into administration.

The workforce. As the industry slows down, its existing workforce potentially leave to join other industries. There’s also a lack of younger generations coming through the quarrying industry.

When the industry ramps back up again, trying to find skilled personnel will become a real challenge for the quarrying industry. It’s one of the biggest issues the industry is facing, and it’s something the IQA is addressing.

I sat in on a panel at the IQA conference in Adelaide last year for the next generation of students. There was a spread of people with a range of experience, with recent university

graduates, tradespeople, and senior industry figures. There’s definitely a requirement for the next generation to understand what quarrying is. It’s not a dirty word – people don’t understand just how important it is for the community and the economy.

We are continuously putting on apprentices and bringing them through the system to fuel the industry in the future, not right now. We have also engaged our parent companies out of Germany to support us with overseas training and get our people up to a level where they can support our customer base. Its is an ongoing challenge, but it’s something that we’re very mindful of, and we’re actively working towards to try and improve that space.

I’m excited and optimistic about seeing some economic change. I don’t see that in the short term. When we start to see the interest rate cuts, and people start to get a bit more confidence, it’ll be a knock-on effect. We will see the industry releasing the purse

with equipment or people. From our point of view, we’ve always got exciting things going on, whether it’s new products to market, which allows us to play in new industries. It’s exciting times ahead.

WHAT INNOVATIONS ARE YOU MOST EXCITED TO SEE DEVELOP IN 2025?

The digitalisation of data. That’s a driver for us, and something we’re really seeing from all our global brands from the Wirtgen Group, not just Kleemann.

It gives the clients more transparency on job site operations, letting them plan better for maintenance and know when a machine is down. It reduces the operators required to keep plant running, because the machines are talking to each other.

WHAT DOES KLEEMANN HAVE PLANNED FOR 2025?

As a business in Australia, we’re continuing to grow. The global downturn hasn’t ceased our willingness to grow so we are investing in in the future. Now is the time to grow, whether it’s facilities, personnel, or training requirements. •

POWERFUL PERFORMANCE AND RUGGEDNESS, COUPLED WITH INTUITIVE, LOW-MAINTENANCE OPERATION. The MOBICAT MC 120 PRO mobile jaw crusher features an impressively powerful crusher and the largest independent pre-screen in its class – for maximum performance up to 650 t/h! The intuitive SPECTIVE operating concept actively supports the user in finding the ideal setting for every task – quickly and precisely –simply by touchscreen. The MOBICAT MC 120 PRO: The intelligent power pack. www.kleemann.info

Eltirus founder Steve Franklin explains how innovation is being highlighted across quarries, and what it means for the future of the industry.

WHAT WAS THE MOST IMPORTANT LESSON FROM 2024?

Take nothing for granted, always work to find out new ways of doing things and adding value for clients.

WHAT SURPRISED YOU ABOUT 2024?

That both the IOQ conference in Rotorua earlier in the year and the IQA conference in Adelaide both focused on innovation as their theme.

I think that innovation is a greater focus now than it has been in a while. With rising costs and softening sales in some quarters, doing more with less (or using new approaches or technology) makes a lot of sense and is increasingly important to companies large and small.

WHAT DO YOU THINK IS THE BIGGEST ISSUE FACING THE QUARRYING INDUSTRY?

We need to ensure that school leavers know about our industry, know that it is an interesting industry and somewhere they can make a career. We must get beyond the simplistic “turning big rocks into small ones” nullification of what we do and show people that there is

something to know about the industry and that it is essential to the community.

HOW IS YOUR TEAM HELPING TO SOLVE THIS PROBLEM?

Our efforts include outreach to school children (hats off to Siri Schlebaum, one of our senior mining engineers for her work in this area), magazine articles, presentations and posts and working wherever we can to increase the technical understanding of quarry resource extraction.

WHAT ARE YOU LOOKING FORWARD TO IN 2025?

A renewed focus on innovation across the industry – we believe that there is a lot of opportunity to do things differently and improve productivity.

WHAT INNOVATIONS ARE YOU MOST EXCITED BY?

We have been involved with whole of site and stockpile drone survey since 2016 and during that time have seen many platforms come and go, with one in particular rising to become the default across the industry.

More recently we have seen the rise of a competing platform, Strayos which is built for quarries from the ground up and has a wide range of AI based tools that just aren’t found in any other platform. Examples include Haulroad AI that can analyse road width, grade and berm heights automatically. It can also track material from blast to primary crusher to optimise fragmentation and throughout and reduce drill and blast costs.

The second technology we are excited about is resource optimisation. By this I mean, software that can look at the cost and value of each part of the resource and then determine that correct extraction sequence to meet production targets and maximise net present value – this takes much of the guesswork out of longer-term quarry planning and is incredibly valuable.

My personal focus is on giving back to the industry. I am lucky to have travelled extensively and been involved in many different operations and situations and I think it is important to share that knowledge. This includes things like mentoring, speaking at conferences, writing monthly articles for Quarry, LinkedIn posts and the like.

WHAT DOES YOUR COMPANY HAVE PLANNED FOR 2025?

A primary focus for us this year is the rollout of our quarry reporting system, Enable. Having a simple, easy to use system that can show users what their targets are and whether they are meeting them or not is critical to any business that wants to improve productivity and reduce costs.

We are seeing tremendous interest in this solution across Australia and the US and look forward to bringing on several new clients this year.

HOW DO YOU THINK THE INDUSTRY WILL CHANGE OVER 2025?

A focus on innovation, more community outreach and consolidation. •

For more information, visit eltirus.com

Eltirus Exploration, Geological Modelling, and Resource Assessment services.

We work with quarry operators to explore, model, and assess your resource, increasing certainty of operation and reducing risk. Our experienced geological team help identify gaps in understanding, create exploration programs, and manage the program for you. Whether it be field mapping or blast hole, RC, aircore or diamond drilling, we not only help you explore and assess your deposit, but also ensure outputs are accessible through the use of world-class geological modelling software that provides you with interactive models that truly make a difference on the ground and in the field.

Delta Rent general manager Phil Agius spoke to Quarry about the changes the industry faced in 2024, how Delta Rent successfully navigated them, and his outlook for 2025.

Few things remain constant within the quarrying industry, and demand is forever changing.

One of the hallmarks of a great business is adapting to the changing demand and leveraging it for their business or, in the case of dealers, helping their customers.

Delta Rent has a unique insight into this as one of Australia’s largest providers of rental machinery to the quarrying sector.

The main lesson was that we needed to move north up the east coast and get into Brisbane and north of Brisbane. We had to ship a lot of gear north which is just due to the demand. The four sectors have become stronger predominantly in Queensland, from construction to

One of the major trends we noticed is that civil infrastructure and quarrying have slowed in Victoria. Around 30 per cent of our work was coming from those sectors; now it is closer to 10 per cent.

That is mainly due to the projects not being there at this stage. Without the projects coming through the funnel, we had to look elsewhere and see where the demand was.

The biggest concern is within the infrastructure projects or the lack of them at the moment.

Housing is getting going again now and they’re selling and we’re seeing some of the big land developers going well this year.

WHAT ROLE DOES AN EXPERIENCED TEAM PLAY IN HELPING A BUSINESS MANAGE THESE TIMES?

I think it does help because you’ve seen the peaks and troughs before and can see what is coming.

We predicted there would be a dropoff in Victoria about 12 months ago, and we started building up our stock on the east coast in October 2023 to be ready to move into Brisbane. We were already purchasing into Brisbane and looking for machines built in Brisbane.

You need to be able to see the sectors that are dropping and the sectors that are growing and through the Delta brand, which is national, we were able to see those opportunities.

WHAT SECTOR DO YOU THINK WILL BE ONE TO WATCH IN THE COMING YEARS?

I think renewables will be the major growth area in terms of projects.

The wind farms, the solar farms and those battery farms are only going to become more in demand and that’s where companies will have to shift.

That is where our main contracting business in Delta Group has shifted towards. We’ve been looking at that sort of work even though we’ve never played in that sort of space before.

We’re looking to shift into the mining space more next year. We’ve already done some work in that space this year which was relatively new for us.

We have found, in terms of our business, that is where the longerterm rental contract is, to be honest. It probably isn’t anything new, a lot of people in our space are trying to do that and are targeting the likes of BHP, Rio Tinto and Glencore.

But that is the challenge for us as a business is to make our mark there. •

For more information, visit deltarent.com.au

24/7 service Australia wide

Expert advice and analysis

OEM backed support, service and technicians

Purpose built fleets tailored to quarry site requirements

Late model, low hour fleet GPS systems hardwired

Striker Crushing founder Craig Pedley spoke to Quarry about state-to-state how differences can and influence the industry.

Following a set plan for innovation that does not need to be based on new technology. Based on operator and maintenance personal feedback, some of the best innovations come from lessons learned in the past and then using those lessons to make product upgrades. We have also focused heavily on increasing our in-house manufacturing capabilities to ensure we have the resources to be more self-sufficient in our manufacturing processes in Australia and less reliant on external sources.

WHAT DO YOU THINK IS THE BIGGEST ISSUE FACING THE QUARRYING INDUSTRY?

Training and knowledge: Over the last decade, the number of experienced quarry workers has decreased. A new generation of quarry operators is emerging, and they will need a lot of knowledge from the old-timers. Harnessing this knowledge will be critical to the industry’s success over the next couple of decades. Organisations like the Institute of Quarrying Australia (IQA) will and should play a crucial part by setting up initiatives like mentor programs and training programs that

focus on taking the knowledge of existing and past operators and passing it on to the new generation.

HOW IS YOUR TEAM HELPING TO SOLVE THIS PROBLEM?

In-house training sessions for our team and creating training programs alongside some of our long-term existing customers.

WHAT INNOVATIONS FROM YOUR BUSINESS ARE YOU MOST EXCITED BY?

This is not so much an innovation as a change in direction for our manufacturing going forward. We have set up a dedicated manufacturing facility in Western Australia to supplement what we do in Malaysia and Thailand. This will give us greater flexibility to react faster, reduce turnaround times on spare parts, and reduce lead times for projects and customers.

DO YOU SEE THE CRUSHING AND SCREENING SECTOR CHANGING MUCH IN THE YEARS TO COME?

The West Australian market is different to the east coast markets. A lot of what happens in WA is not only based around government roads and infrastructure projects but also around mine site requirements. Things like road base for haul roads and aggregate for stemming all need to be made by “on-site quarries”, and as such, the demand for 24/7 operations requires machines that have a longer life cycle than the traditional 1600 hours a year. We have several quarry customers that

operate seven days a week, 24 hours a day, and have taken advantage of the Striker range. I see this increasing as a new “quarry industry”. The need to increase capacities from existing quarries will also be needed as the West Australian population rises and more sub-divisions are brought online. This has also been the case in Victoria, where the set-up of “satellite quarries” using rock sourced on the housing development site is used to make the road base for the development and, in doing so, is saving development contractors large sums of money not having to purchase from fixed quarries and transport long distances to their sites.

CRUSHING AND SCREENING IS A COMPETITIVE SPACE. HOW HAVE YOU CREATED A UNIQUE IDENTITY WITHIN IT?

We have created a product range that is flexible in configuration. With our Striker, 90 per cent of the Striker range can be either electric or diesel-hydraulic and can be converted from track to modular plant to suit the client’s needs.

We believe in being different and changing the norm, not just following what the big guys are doing. We feel that most of the innovations from Europe and the USA are based on their needs rather than the needs of Australian customers.

We are launching several new products after conducting extensive research and development over the past 18 months. These include the new ECOMIX 610, a pugmillbased machine that can be used for soil stabilisation, making cement from bitumenstabilised road base, and making paste mixes in mining applications.

We will also release the new model track impactor in 2025. This upgraded version of the Striker HQR1112 will now feature an increased crusher capacity, an optional double-deck sizing screen with dual radial stackers, increased power, and increased feed hopper capacities. We will also release the upgraded telescopic stacker range and track stacker range in 2025, so it will be a busy year with lots of further upgrades, research and development.•

For more information, visit strikercrushing.com

SMA (Screenmasters Australia) national sales manager Ciaran Lagan shares his insights into the industry and what lies ahead in 2025.

Having a national presence in the Australian quarrying sector means being ready for anything, especially when the market forces you to adapt.

SMA (Screenmasters Australia) has an Australian-wide coverage in the quarrying and recycling industries. It is a recognised dealer of mobile and fixed crushing and screening brands, including Keestrack, SRHeavy By Metso, GIPO, CMS Cephor, Convir, Rockster and more.

One of our major learnings from the year is that the support we give to our customers is very much welcomed and appreciated. This is evident in our repeat order clients. Communication and presence are key to the success of any relationship, especially when

suits our business profile.

Our continued relationship with our existing clients has helped us. It has allowed us to support them with their needs and offer them some of the new machines we have introduced to the Australian market, including the Keestrack R5h and the K3h.

Because of the slowdown, the support from our existing client base has been essential to getting us through this tricky year. We’ve also learnt to diversify the business.

We’ve recently taken on the SRHeavy by Metso. Offering a genuine alternative original equipment manufacturer range of fixed crushers and screens, exclusively to Australia. SRHeavy offers significantly more competitive market pricing.

Embracing the SRHeavy range allows the business to leverage off its strong mobile

It has been a tricky year in the industry, with a market downturn, but it has also been interesting, as some markets have been slow and others have been thriving.

Queensland has thrived this year, and our yard has been quite busy. Victoria has been quiet when compared to previous years.

As a national dealer, we’ve been exposed to these different markets and as a result, this has seen us work closely with our long-term customers to mitigate the effects and find solutions to best suit their needs in the current climate.

In many cases, the Australian market is isolated from the global geo-political events or, in some cases, the impact is delayed but ultimately our industry is showing signs of

strong European quarry and recycling market

“feel the pinch”.

We’re seeing that now, especially compared to the first few years after COVID, where everything was incredibly busy.

The big stand out issue is clear for everyone to see, there are fewer and fewer younger generations attracted to the industry. This will leave a great void in years to come.

It is not an easy industry to work in, and it is very difficult to find good mechanics and fitters with the right skill sets who want to work in a quarry environment. They’re proving more challenging to find.

We’re lucky enough to have many longstanding employees getting us through, but we are constantly looking for the younger generation to integrate them into our business as we continue to grow.

Experience is invaluable and we see the importance of passing this on to the

younger generation. SMA mentors our younger people by placing them with our experienced staff to support, guide and learn from.

We’re always trying to look after our staff and provide them with the training they need to become the best they can be.

We see the industry looking for electric equipment now and in the future. Therefore, bringing in more mobile “E” equipment to meet these requirements and upskilling our staff in this area so we can best support our customers.

The electric Keestrack equipment has plug-in options that allow you to run the machine straight off the grid if you have power available on the site. This will minimise fuel costs and the impact on the environment.

It is something we’re thrilled to bring to the Australian market.

In 2025, we have a few new models coming out, which we’re excited about.

The Keestrack B7h, a large 70-tonne jaw, and the B5h, a mid-range 49-tonne jaw crusher. We’re also bringing the Keestrack K8, a 20x7 scalping screen, to the market. It is one of the largest scalpers available and capable of producing four products in one pass. We’ll be introducing more electric mobile crushing and screening equipment to Australia, with the Keestrack H6e, an electric cone crusher, and the K5 and K8 electric screens. We’re developing the SRHeavy By Metso brand nationally. As part of that, we’ll be releasing more fixed products, including VSI crushers, cone crushers, and impactors, next year. We’ve extended our exclusive Australian contract with Keestrack to an ongoing period, and we’re looking forward to continuing to develop their products in the Australian market.•

For more information, visit screenmasters.com.au

ToThink Engineering director Darren Toth shares his thoughts on the state of the Australian quarrying industry as a well-regarded supplier.

It does not take a long time to have a lasting impact in the industry and ToThink Engineering is an example of that.

The Melbourne-based company has been providing quality screens and feeders to the Australian quarrying industry for just shy of a decade.

The biggest lesson we took out of the year was the need to streamline the business to focus more on the equipment side of things.

For the last five years we’ve been manufacturing equipment on top of the hardware we’ve been selling since the business started. A lot of the business we did initially was service based including design consulting and problem solving. We added the equipment side of things later on.

This year we decided to really streamline our equipment offering to ensure we were able to support our loyal customers when they needed it, and it proved quite successful.

The value of experienced people with strong technical skills has continued to increase within the industry as whole. I mentioned this last year, the need for local businesses to step up and produce equipment that is designed and built here with as many locally sourced parts as is practicable remains of critical importance. Nothing compares to the real time support and nuanced knowledge of the Australian conditions provided by Australian businesses.

WHAT DO YOU THINK IS AN ISSUE FACING THE QUARRYING INDUSTRY?

Looking broadly across the industry, I think the quarrying industry is struggling for experience and we’ve also seen a slowdown in demand in 2024.

There have been a lot of older workers who have retired and left the industry and there are a lot of young workers who need guidance and support as they start their journey in the industry. I think the younger workers will definitely get there, it will just

take time and having the right programs and support in place to help them. In terms of demand and projects, there is a bit of uncertainty as people wait to see where the government expenditure is at and where it is invested in different states. Once people get a clearer picture on this over the course of next year, it will help demand within the industry.

ToThink’s mission to be the best value equipment supplier by designing locally, building quality machines and pricing competitively remains at the forefront of what we do.

From an equipment and parts and hardware supplier standpoint, I think availability and technical knowhow provides a great amount of support to the industry which in turn promotes growth at a wholistic quarry operation level. Therefore, we are committed to striving to be a provider of these things.

We are wanting to show our support to an organisation who supports us, and we also want to build our brand within the industry as

a trusted equipment supplier.

The opportunities through the events created by the IQA are also valuable to be a part of and we enjoyed our involvement in them this year. We are looking forward to attending more IQA events as well as offering some education through presenting at some of these events.

We are excited to continue to expand ToThink Equipment, providing value through supplying screens and feeders (especially apron feeders) across Australia.

We’re aiming to continue being the best value equipment supplier we can be.

By doing our job in building high-quality equipment, we’ll be able to support our customers in the industry to a high-level in their projects and applications. So, we’ll continue designing and building our machines locally, pricing them reasonably and support our customers.

We have added to our workforce and we plan to continue to do so. There are also several exciting projects on the horizon to be delivered in the new year.•

For more information, visit tothink.com.au

Multotec Australia vice president of sales and service Grahame Hopkins chats to Quarry

Multotec has been a well-recognised name in mining for more than 50 years, but a new era is set to begin as the global business expands into the Australian quarrying industry.

The company is bringing its expertise in metallurgy and process engineering while leveraging its recognisable European brands to shake up the Australian sector.

Quarry sat down with Grahame Hopkins, vice president of sales and service at Multotec Australia, to discuss the company’s plans, diversification in quarrying and what benefits its community engagement program is having after its inaugural year.

For us, we have had to diversify. We’ve typically concentrated supplying screen media and cyclones to the mining industry, whether copper, gold, iron

Organic growth is vitally important to us. In 2024, we saw the need to expand our coverage of the quarry and aggregates markets.

We have really committed to that. We have been attending industry events, including the Institute of Quarrying Australia’s national conference, and supporting our customers. Typically, we went through distributors, but now we deal directly with the customer.

We leverage the capabilities of group companies, Isenmann, Tema Isenmann and Hein Lehmann GmbH businesses, which are traditionally working in aggregates in Europe. We are using their knowledge in Australia and South-East Asia as well.

Quarrying and aggregates will be a huge part of our business moving forward.

We have noticed the urban sprawl around Australia and the need for raw materials and construction materials, and we are positioning ourselves to help customers in this space.

WHAT IS ONE OF THE BIG ISSUES FACING THE QUARRYING INDUSTRY, AND HOW ARE YOU HELPING SOLVE IT?

One of the big issues is community perception. While there can be a negative perception of quarrying and mining, people do not realise that all these technologies, including solar and wind farms and mobile phones, need materials from mining and quarrying.

Given that all these materials are acquired from mining and quarrying, we need to help people understand how we can work together in the community.

We have been running local community engagement programs to help this.

Recently, we had school kids tour our site in Logan, and we coloured one of our vehicles with their artwork.

The important thing is showing these kids what we do and why we do it. This is why we have been working very closely with Marsden State High School, the largest state school in the Southern Hemisphere, near our workplace. We are working with the kids to show them that mining and quarrying are not bad. This is essential to changing the market perception.

This is our first year conducting these initiatives, and they have been a huge investment for the business. They have been a success, and I have signed contracts with these local organisations for the next three years. We are looking to extend that and invest further in them.

Everyone is worried about noise pollution, and our group has technology available that clients can access to reduce their site’s noise. This will allow them to continue operating under stricter compliances.

If you travel to Germany or around Europe, you may see a quarrying site near a hospital or a shopping centre. However, these sites cannot operate if there is dust or noise. Therefore, we decided as a group to invest our research and development in this area to help our customers.

If we can reduce that noise, which we can, it will be much easier for the quarry owners to operate their businesses. The benefits are not singular; they can be extensive.

We have an aggressive growth plan in place, which includes moving into SouthEast Asia, where we need to establish our footprint.

New Zealand is another area we are looking to grow in, and we need to develop that into a larger team. As we grow in these regions and here in Australia, job availability in Berrinba will also increase.

We are also doubling our building in Logan to 10,000m2, which will help double our production and introduction of new advanced manufacturing technologies. It will also support the local community with 50 jobs to come from the project.

We want to grow substantially in revenue, grow significantly in people, and every bit of profit we make, we invest it back into the business for the future. •

For more information, visit multotec.com

For over 50 years, Multotec has helped it’s clients process minerals more efficiently and reliably.

Backed by recognised industry leaders in metallurgy and process engineering, our mineral processing equipment is used to optimise recoveries and reduce cost of ownership in processing plants in 100 countries on six continents.

Multotec screen panels are used in sorting, classifying, dewatering, scalping and desliming applications, across a range of minerals.

With a complete range of modular screen panels, Multotec ensures your screen deck is optimised to achieve your required cut size efficiently, reliably and over an extended service life.

Multotec cyclones are used across the world for applications in mineral processing, quarry and aggregates and manufacturing, food processing, wastewater treatment and other industries.

Our industry proven product range of classification cyclones have been optimised to improve classification efficiency, provide greater lifespan and reduce energy requirements.

Multotec is a global leader in trommels screen design and manufacture, have been supplying the international market for more than 25 years.

Our trommels screens are used across the world’s mining and aggregates industries.

Simone and Brendan O’Dowd discuss how they established a business, how they can help with the sand shortage, and revitalise previously underused resources.

American businessman and writer Philip Crosby once shared this sentiment: slowness to change usually means fear of the new. The sentinment can also be somewhat valid in the quarrying sector. Sometimes, change happens slowly until an innovator disrupts the market.

Simone and Brendan O’Dowd are the two people who started ODE Materials to up-end sand dredging and processing in Australia.

We needed to remove a resource in a profitable way, but there were no contractors who could extract and process the material simultaneously. There was no one dredging and processing at the same time.

So, we designed and built our own plant to do both in a continuous process.

We’re a consortium of two main contractors who have worked jointly in the sand processing industry for more than ten years. Brendan worked in the manufacturing and cement industries for over a decade, and Simone has significant experience in the mining and logistics sector.

We worked jointly for 10 years to develop this continuous process plant equipment. Instead of developing it on an ad hoc basis, we formed ODE Materials to take it to the next level.

After building our plant, we immediately realised there were no contractors because the existing contractors were either dredge operators or sand processors. If they were sand processors, we realised they often used dry-feed plants, which hit us like a tonne of bricks.

By building the plant, we confirmed what we knew: to truly clean sand, you can’t just spray and dewater it; you need a continuous process.

It achieves a far more superior quality washed sand than what can be achieved with a dry-feed plant.

We realised there weren’t many equipment manufacturers doing what we had done, and there was a gap in the market for continuous process equipment

HOW DOES YOUR COMPANY PLAN TO HELP SOLVE SAND SHORTAGES?

True washing cannot be done by rewatering and dewatering the material, but that is currently all that is sold.

Our technology enables abandoned or previously unsuccessful resources to be redeveloped so they can deliver highquality sand at an efficient operating cost. It delivers high-spec material regardless of the resource used.

From the beginning, we have consistently delivered this high-value product on time. Because we supplied some major Australian companies and large regional manufacturers in NSW, the material from our plant sold itself.

WHAT DOES THE BUSINESS HAVE PLANNED FOR 2025?

We’re open to working with clients with a resource that needs to be re-utilised. If they have the capital expenditure to get the equipment in there, then that’s going to be our next project.

We would love to work with resource owners who may have thought their resource

As Australia’s longest running mining show, Asia-Pacific’s International Mining Exhibition (AIMEX) has a long, established history of showcasing and supporting the latest trends and developments in the industry.

AIMEX is relocating and will call South Australia home for the next 10 years, following market feedback and strong support from the local government and key mining players.

The move marks an exciting new chapter for the event and the region’s resource sector, with the state leading the way in future-focused mining.

AIMEX offers unparalleled opportunities to connect with Australia’s largest community of mining suppliers and professionals in an environment that stimulates innovation and collaboration.

Kayasand chief executive officer Bram Smith offers insights into the future of sand, sustainability and Australia’s construction industry.

The growing realisation that quarries can play a big part in lowering emissions from concrete production. By producing high quality concrete aggregates quarries can enable significant reductions in cement usage. Results from trials using engineered sand in Australia and New Zealand have shown that we are well on our way to reducing the amount of cement in concrete by up to 20 per cent.

I recently attended an international concrete conference in Christchurch where sustainability was high on the agenda. Each country has set out a pathway to net zero emissions concrete by 2050. The go-to solution is supplementary cementitious materials (SCMs) such as slag and fly ash to reduce cement. These are already widely used in Australia and the CCAA estimates improved use of SCMs could reduce emissions by 3 per cent in

emissions reductions in construction, downstream of their own operations.

Manufactured sand is such a broad term –people use it to describe everything from washed sand to raw crusher dust. As a result, it gets a bad reputation for highly variable quality.

Kayasand enables quarries to turn crusher dust, often considered a byproduct of quarry operations, into a consistently high-quality sand that offers several benefits for concrete. We call it Engineered Sand because it’s designed to meet specific quality standards around the shape, grading, contamination and consistency of sand required for use in concrete.

The industry is transitioning from headline

products. You get what you measure, and this sort of data helps focus the construction industry on technologies that will have the biggest impact. Particularly as building developers and specifiers are increasingly demanding evidence backed low emissions products to give them a competitive edge.

There are a variety of issues, but the increasing difficulties around regulatory approvals for quarry expansions is a major. The long time and substantial investment required to get consents for quarry expansions was a topic at the IQA conference this year. If you have a long resource life, you can invest in good equipment.

Streamlining the consenting process would mean that same time and money could instead be invested in equipment to produce high-value and sustainable quarry products. For fine aggregates, this means quality sand from quarries that reduces dependence on mined natural sand.

WHAT ARE YOU LOOKING FORWARD TO

people seeing the impact that good quality engineered sand has on concrete.

We see challenges around the sourcing of sand getting more acute, and the demand to demonstrate sustainability rising. Plus, quarries must maximise business efficiencies and utilisation to drive profitability.

We want quarries to see that pile of crusher dust in the corner in a new light. That crusher dust could be the key to more sustainable building materials and increased quarry profitability. For many quarries, the coarse aggregates have been the most profitable products. We want to see the fine aggregates (0.1-7mm) materials become a key profitability driver for quarries. Then we’ll focus on the ultrafine (<0.1mm) materials to achieve true 100 per cent quarry utilisation. •

For more information, visit kayasand.com

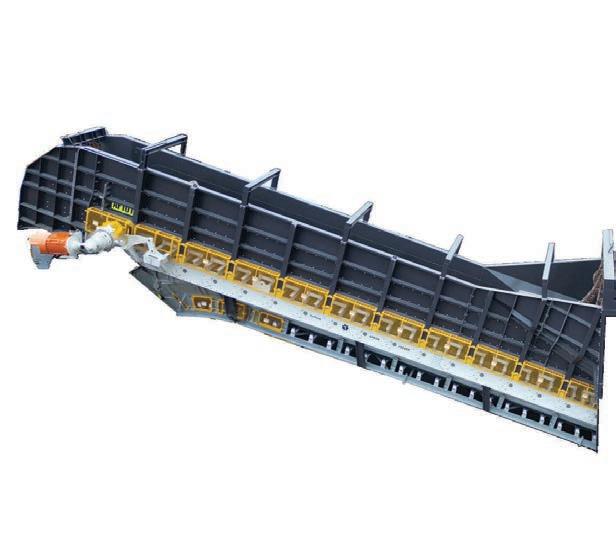

Marcis Pavars is the international business development manager for Superior Industries.

Superior Industries supplies its global clients with solutions to take them from the rock face to load out. The US-based manufacturer is known for quality crushing, screening, washing and conveying equipment.

Marcis Pavars chatted with Quarry about different markets around the world, the impact of artificial intelligence on the industry, and the company’s plans for 2025

One key lesson was the importance of adapting to evolving market preferences. As rising interest rates prompted a shift from equipment purchases to rentals, we adjusted our approach to align with these changes. Additionally, after years of navigating supply chain challenges, manufacturing lead times began to normalise, enabling dealers to maintain robust inventory levels and better meet customer demands. These observations reinforced the importance of agility, supply chain resilience, and strategic market focus. Superior’s ability to navigate these dynamics contributed to its continued growth across its major product segments— crushing, screening, washing, and conveying— while positioning the company for long-term success in the aggregates industry.

One of the most notable trends we identified this year is the growing adoption of digitalisation tools, particularly artificial intelligence (AI) and machine learning, within the aggregates industry. At Superior Industries, this trend has been driven by the need to enhance efficiency, maintain quality, and increase production speed in a competitive market.

Our conveyor components division has seen substantial benefits from robotic technology and automation over the years, but 2024 marked a turning point as we introduced even more into the manufacturing of idlers and pulleys. By leveraging these advanced tools, we have streamlined operations, reduced waste, and ensured consistent quality across our product lines. To support this initiative, we’ve invested in a full-time AI engineer whose expertise is driving further innovation and optimisation in our processes.

This commitment to digitalisation not only helps us stay ahead of the curve but also aligns with our broader goal of delivering superior value to our customers.

One of the quarrying industry’s biggest issues today is the shortage of skilled labour. This challenge is driven by an ageing workforce, with many seasoned professionals nearing retirement, and a decline in younger individuals entering the field. As a result, labour costs are rising. Additionally, the retirement of experienced workers could result in the loss of critical industry knowledge, which is essential for maintaining high operational standards.

At Superior Industries, we recognise this challenge and are actively working to address it. One of our key strategies is supporting knowledge transfer through targeted training initiatives. By enabling seasoned employees to share their expertise with the next generation, we aim to preserve operational excellence and ensure long-term growth for our customers.

Moreover, our commitment to designing user-friendly, equipment helps offset the impact of labour shortages by making processes more efficient and less reliant on manual intervention. These efforts reflect our dedication to supporting our customers and the broader quarrying industry in overcoming this critical issue.

In 2025, Superior Industries is excited to advance our Fusion Modular Platforms to further assist aggregate producers in overcoming permitting delays and accelerating project timelines. These pre-engineered, semistatic structures seamlessly integrate with our crushing, screening, washing, and conveying equipment, offering a streamlined solution for plant construction and expansion. The modular design of the Fusion Platforms facilitates quicker installation, enabling producers to commence operations sooner. This approach not only expedites the permitting process but also provides cost-effective scalability and simplified maintenance, allowing

operations to adapt swiftly to market demands. The growing demand for these platforms, as evidenced by our record backlog, reflects their effectiveness in addressing industry challenges. Looking ahead, we are committed to enhancing the capabilities of our Fusion Modular Platforms, ensuring they continue to meet the evolving needs of our customers and support the efficient development of aggregate processing facilities.

In 2025, Superior Industries is focused on building upon our foundational values while driving innovation and growth across all product segments. Key areas of emphasis include further strengthening our customer intimacy initiative, which prioritises building deep, longlasting customer relationships and tailoring our support to their specific needs.

Operationally, we plan to expand our warehousing and parts strategy to enhance availability and reduce lead times, ensuring our customers have access to the equipment and components they need, when they need them. Investments in automation and supply chain efficiency will continue, enabling us to maintain competitive pricing and high-quality standards across our portfolio.

Our commitment to serving others, fostering a culture of opportunity, and maintaining strong work ethics will guide these initiatives, ensuring that we remain a trusted partner for our dealers and customers while pursuing sustainable, long-term success. •

For more information, visit superior-ind.com

Our expansive lineup offers unmatched flexibility, with models for every crushing stage that deliver precise, efficient results.

From separating fines to sizing rocks, our screens are engineered for durability and precision across all sorting applications.

No two wash sites are the same, which is why we offer a wide range of wash products, each customizable to ensure exact specs every time.

TeleStacker® Conveyors deliver high volume, in-spec stockpiles with reduced segregation and significantly lower operating costs.

David Hunter is the business line director for McLanahan.

For nearly 200 years, McLanahan has supported clients across many industries, including the quarrying and aggregates markets globally.

As the company prepares in 2025 to celebrate 190 years since it was established, David Hunter, business line director for McLanahan, spoke to Quarry about the key trends he saw in 2024 and how the company is set-up for the year ahead.

Don’t stand still, keep moving forward, rise to any challenges you face and continue to improve for both customers and the wider McLanahan business.

WHAT SURPRISED YOU ABOUT 2024?

McLanahan’s visibility as a global leader of aggregate processing equipment has continued to expand, and we’re seeing more people around the world seeking out our knowledge and expertise

WHAT IS A TREND YOU SPOTTED, AND WHAT HAS CAUSED IT?

More the continuation of the trend towards processing construction and demolition waste material for use as secondary products. We are seeing this in more markets across the globe and is driven by the need for a sustainable future although legislation also plays a part in driving this trend.

WHAT DO YOU THINK IS THE BIGGEST ISSUE FACING THE QUARRYING INDUSTRY?

I think some of the biggest challenges facing the quarry industry revolve around environmental issues.

Every thing from site permitting to plans for tailings management takes significant planning and resources to meet the specific local regulations.

HOW IS YOUR TEAM HELPING TO SOLVE THIS PROBLEM?

We can offer the complete package in terms of process equipment, water treatment right through to filter press to help manage the waste and recycle water back into the process. We also work with customers who have existing plants to try and find ways to upgrade and improve their existing installations.

HOW DO YOU THINK THE INDUSTRY WILL CHANGE OVER 2025?

We are in a very competitive industry with more and more competition entering the market.

I believe this trend will continue in 2025, which is good for our customers as healthy competition drives innovation.

WHAT ARE YOU LOOKING FORWARD TO IN 2025?

The continued growth and success of our business.

Among industry leaders in liquid-solid separation for tailings are Diefenbach, who were acquired by McLanahan in 2023. Diefenbach has developed a new patent pending rapid, filter press plate cloth change out system.

This could dramatically reduce filter cloth change times from ten to 15 minutes to as little as two minutes per cloth, offering significant operational savings and well as improved health and safety.

We plan to offer this as an optional extra for customers ordering new Diefenbach and McLanahan presses in 2025.

We continue to invest in our business and our people. In doing so we are offering customers nearly 190 years of knowledge and experience.

When working on a specific project or process, quite often there are multiple solutions available to the customer, however their options may be limited by equipment on offer by one company or another.

With the considerable experience of the McLanahan group and vast array of equipment we have to offer, we are able to select the best solution for each individual customer depending on their requirements.

I believe this approach helps grow the industry in general.

Our business will continue to grow in 2025 so we will continue to invest in our people and grow the team to support this growth. We have invested heavily in raising market awareness in our brand and will continue to do this in 2025.

McLanahan will also be celebrating 190 years of being in business, having been established in 1835•

For more information, visit mclanahan.com

CJD Australia executive general manager of sales and marketing Grayden Leaver tells Quarry about goals, milestones and innovation.

Early this year we introduced to the market Volvo Construction Equipment’s zeroemission electric machines to the market.

The first two models were the electric ECR25 compact excavator and the electric L25 wheel loader and both have been received very well.

These electric machines offer the same performance as their diesel counterparts but with zero emissions, near-silent operation as well as reduced vibrations, all of which provides a fantastic work environment.

These electric compacts can fast-charge, with an off-board solution that allows a full charge in about one hour.