5 minute read

INSIGHT: AN ENHANCED QUARRY MANAGEMENT TOOL

from Quarry February 2022

by Prime Group

INSIGHT: AN ENHANCED

QUARRY MANAGEMENT TOOL

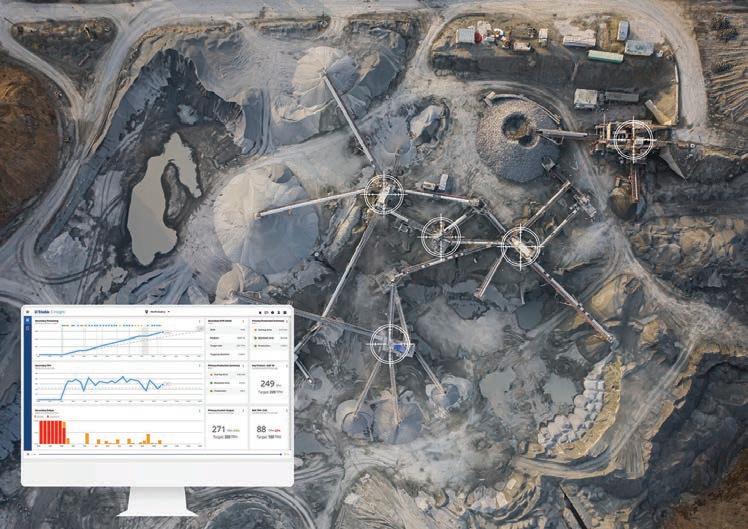

SmartTech Australia has hit the ground running in 2022 by delivering Trimble Insight, an enhanced operations productivity and efficiency tool destined to change the game in quarry management.

SmartTech Australia has successfully provided its aggregate customers with a range of connecting Trimble solutions that are used to improve productivity, reduce waste and re-work, and enable decision-making through better awareness, data flow and collaboration.

Off the back of being awarded the Top APAC LOADRITE Software Sales by Trimble, SmartTech Australia has solidified this recognition in 2022 by launching Trimble Insight (Insight) to the APAC region.

Gone are the days of quarry managers and operators relying on tally sheets, spreadsheets or in-house systems to manage quarry operations. Insight brings new operational dashboards to the table that provide actionable insights to identify, respond to and solve issues, control inventory and increase productivity.

Dan Barry, the general manager for SmartTech Australia, said quarry evolutions starts with the adoption of customisable solutions.

“Quarries continue to evolve their

Insight allows for real-time access which enables quarry managers to make changes during the shift and view the immediate impact on production. operations by adopting customisable solutions which provide a high level of dashboard information so they can benchmark and scorecard their operations,” Barry explained.

“That’s why Trimble Insight will be pivotal. It will be about the data which guides a lot of quarrying businesses’ decisions.”

Insight allows for real-time access which helps management make changes during the shift and see the immediate impact on production. It has the ability to display the target versus. actual production, delays, downtime and more, so informed decisions can be made. It draws data from Trimble LOADRITE excavator, loader, haul truck and conveyor belt scale sensors into centralised cloud storage. All operational data is visible in one place so management can track progress against targets and take action.

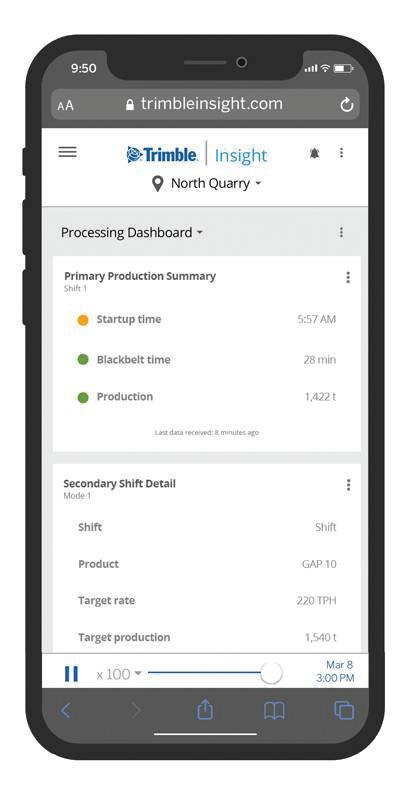

DASHBOARDS Real-time visibility of all your production metrics (load/haul, processing and

A mobile plant summary using Trimble Insight on a cell phone. products) from an operation’s excavators, haul trucks, articulated dump trucks, conveyors, and loaders.

NOTIFICATIONS Proactive customisable alerts keep producers informed of lost productivity opportunities. By raising awareness that the operation has drifted outside the plan, corrective actions are easy and timely.

ACTION REPLAY Using production data – eg payload, cycle times and speed – overlaid with location, an animated replay provides an objective view for alternative haul plans, incident safety reviews and operator training.

SECURE ACCESSIBLE DATA Maintains data integrity from the machine, with validation and caching (in the event of communications downtime) to provide a single source of the truth. Data can be accessed on desktop or mobile devices across one or many operations.

CLEAR REPORTING Insight provides a summary or transaction level historical data. Reports are customizable using the report builder, which allows management to focus on what’s important to the business.

API INTEGRATION Insight is ready to integrate with existing quarry business systems and processes.

TEST DRIVING INSIGHT SmartTech Australia will be exhibiting at Booth 42 at the 63rd IQA National Conference in Newcastle in March. Delegates will experience a live demonstration where SmartTech’s trained group of professionals will show producers how they can improve their quarry operations, focusing on fleet management, production KPIs, and individual assets - all driven by Trimble Insight. •

BIG BUCKET MODEL

JOINS CRAWLER EXCAVATOR SERIES

The R 928 G8 crawler excavator is a completely new model, developed and produced by Liebherr-France SAS.

Positioned between the R 926 G8 and the R 930 G8 crawler excavators, the R 928 G8 complements the current Generation 8 series, which includes seven models with a gross vehicle weight of 22 to 45 tonnes. The modularity of the Generation 8 facilitated the launch of this new model as its design is based on existing, high performance components.

The R 928 G8 has several features in common with the R 926 G8 and R 930 G8, including the same superstructure and equipment as the R 926 G8 and the same long carriage (LC) or narrow long carriage (NLC) undercarriage as the R 930 G8.

The R 928 G8 rounds off the current range of Generation 8 crawler excavators. It is characterised by a high drawbar pull, a heavy load-bearing capacity and a large bucket. Its optimised weight makes it easier to solve the earlier transport problems of many extractive producers. The R 928 G8 can hold its own with machines that are heavier than the R 926 G8 and lighter than the R 930 G8.

The Generation 8 crawler excavators are the result of constant research and improvement work. Their design and architecture has been reworked with the aim of creating optimal ergonomics and performance as well as increased comfort and safety.

The G8 develops higher tear and breakout forces compared to the previous generation. The torque of the superstructure has also been increased, meaning the crawler excavators achieve higher levels of performance under site conditions. In addition, a new equipment concept enables the load curve to be optimised and the inertia in the rotary drive to be improved, reducing fuel consumption. The new, robust X-form undercarriages ensure greater stability. The automatic central lubrication ensures longer service life of parts and improves the productivity of the machines.

The G8 features a spacious, air-conditioned work cab, complete with a fully retractable front window, a pneumatic seat with vertical and longitudinal damping and an easy to use, high resolution touchscreen. The use of LED technology reduces power consumption and improves lighting quality. All-round vision as well as rear and side surveillance cameras maximise safety in the working environment.

The cab is easily accessible thanks to the hoisting control unit and the rear window serves as an emergency exit. To improve safety during maintenance work, access to the superstructure and the maintenance platform has been widened and is located at the side.

Comfort and safety are thus guaranteed over the entire operation cycle of the G8 machines.•

The R 928 G8 has a larger maximum bucket size than the R 926 G8, a high drawbar pull and an excellent lifting capacity.

For more information about the R 928 G8 crawler excavator, visit the Liebherr Australia website: liebherr.com/en/aus/start/start-page.html

Innovation

is our Motivation...